Patents

Literature

335results about How to "Suitable for preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

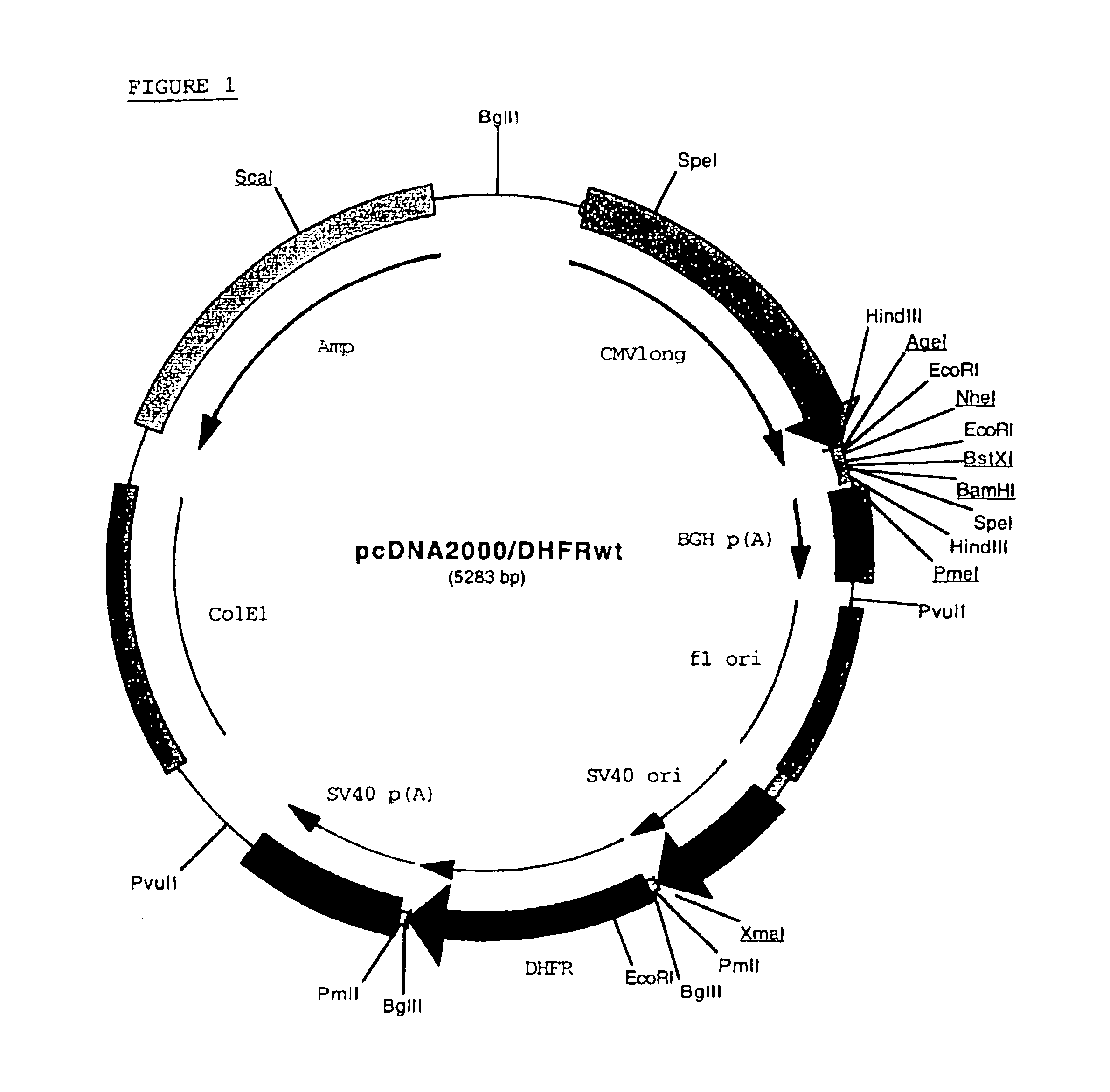

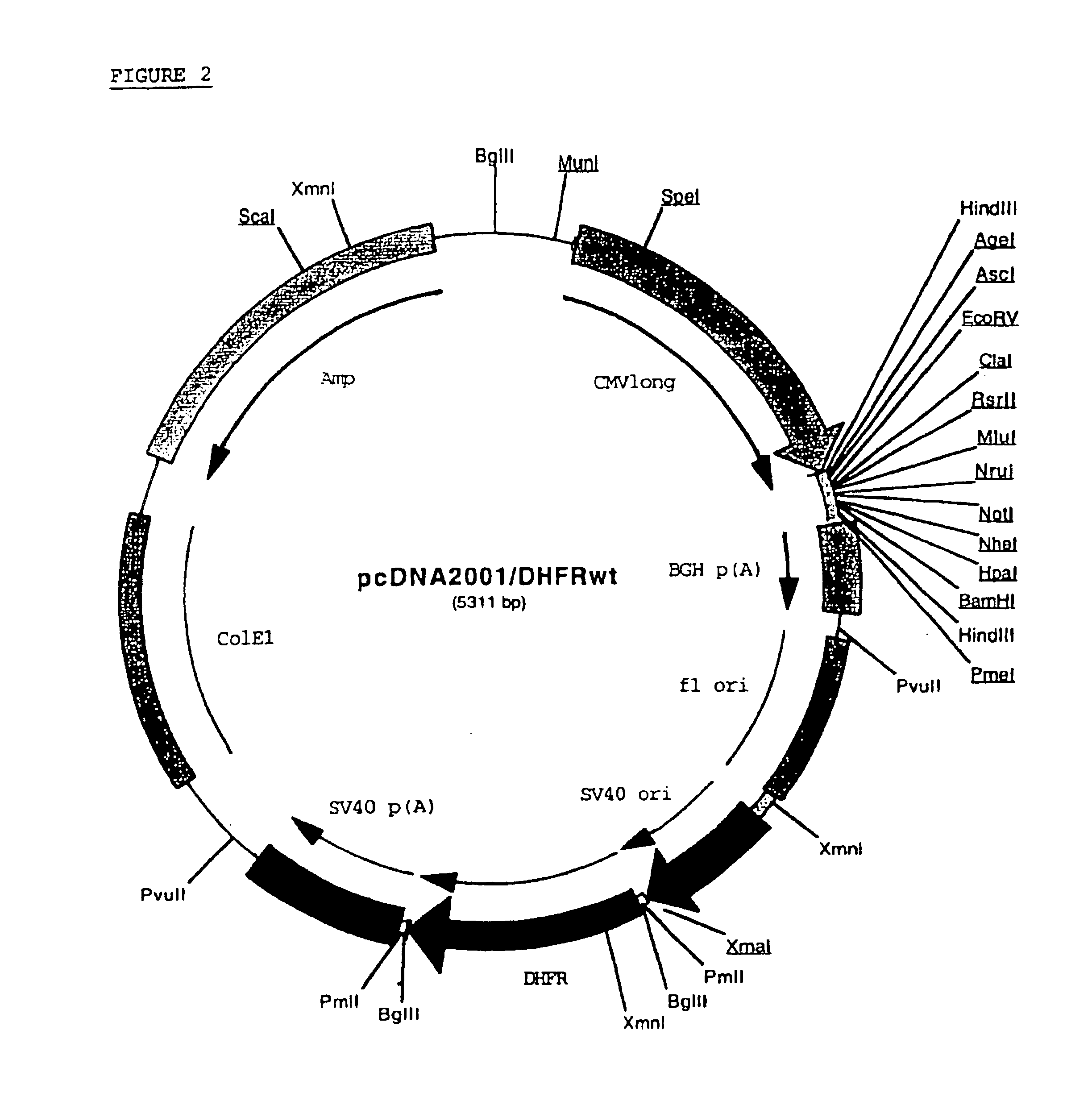

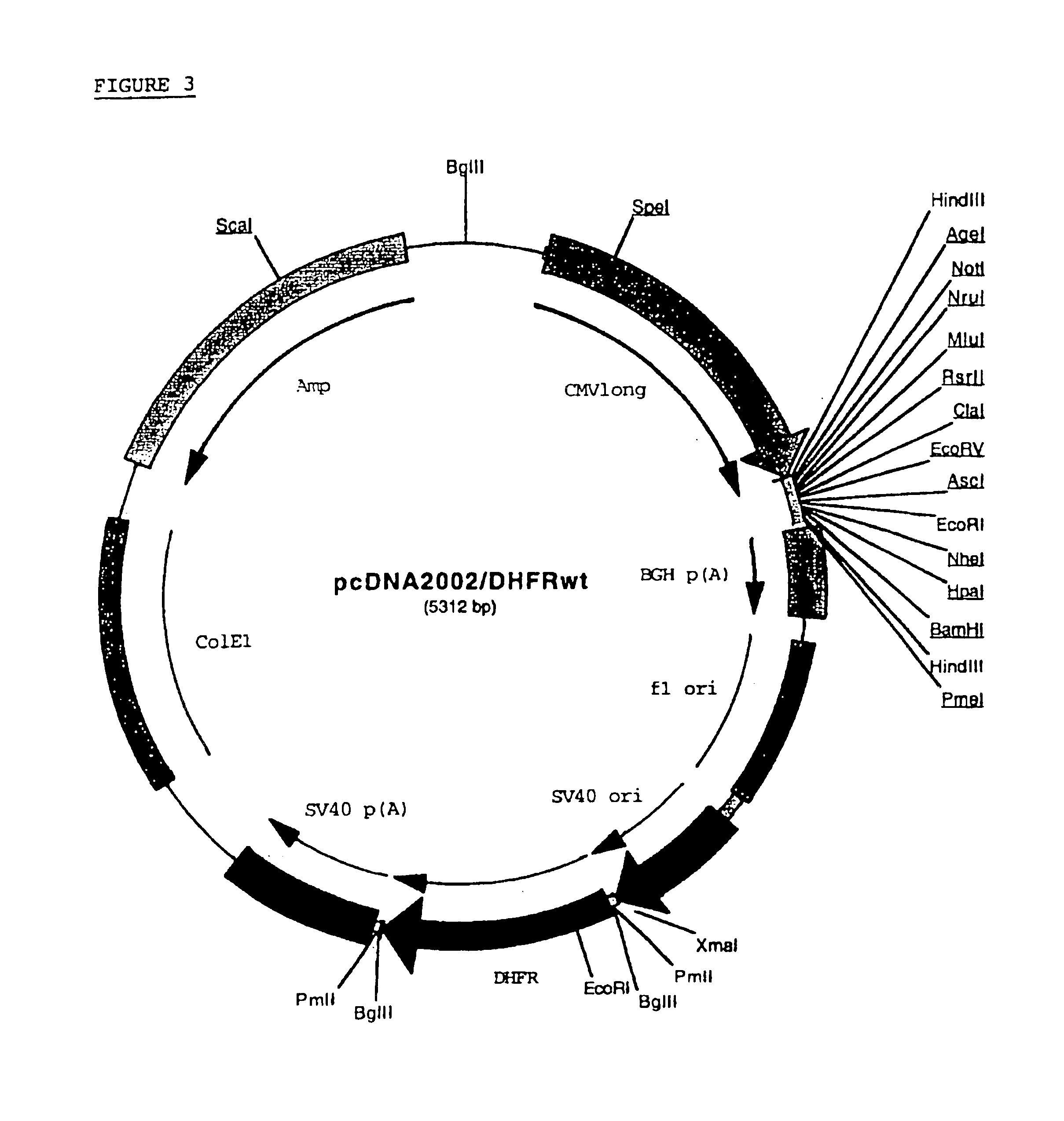

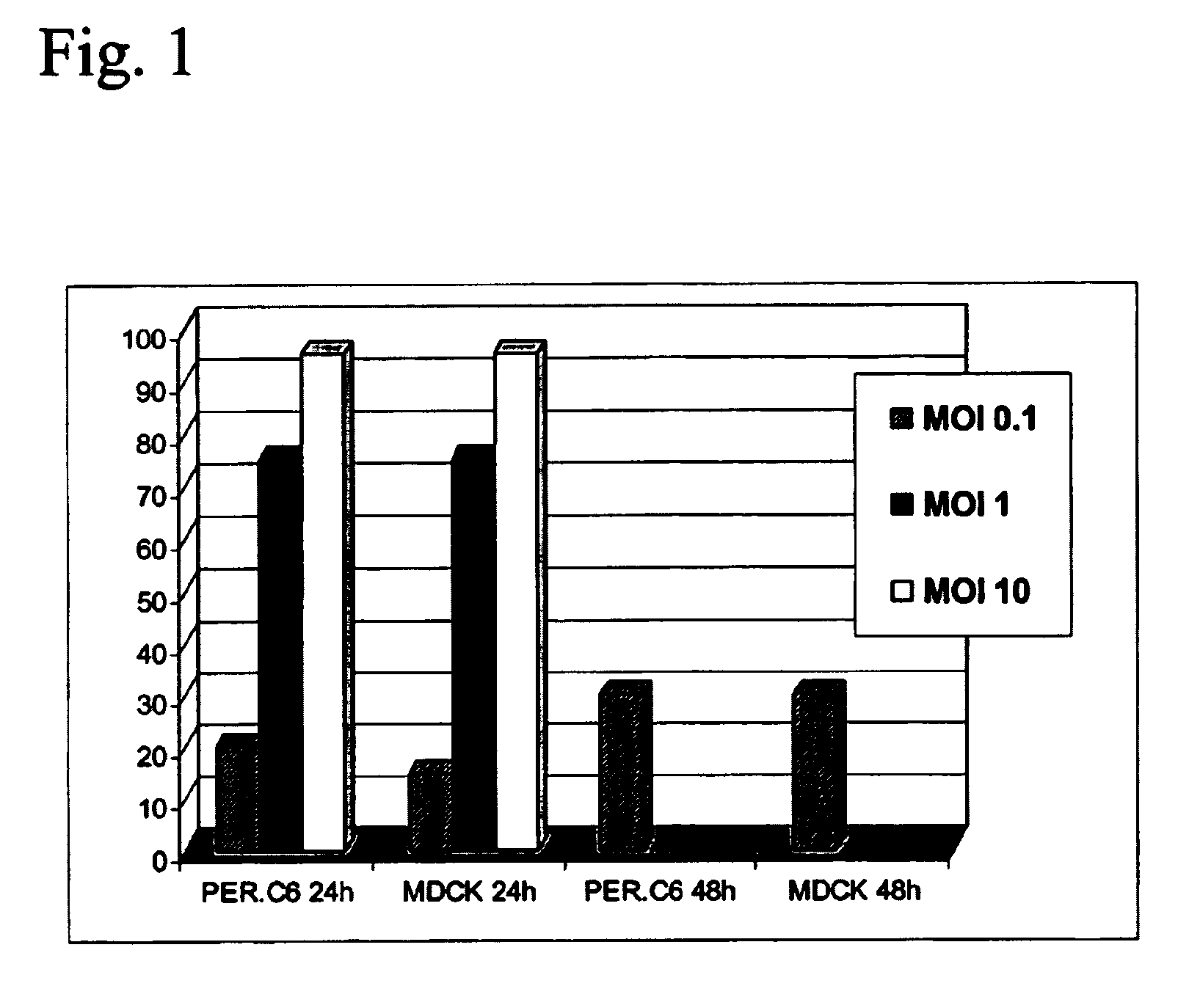

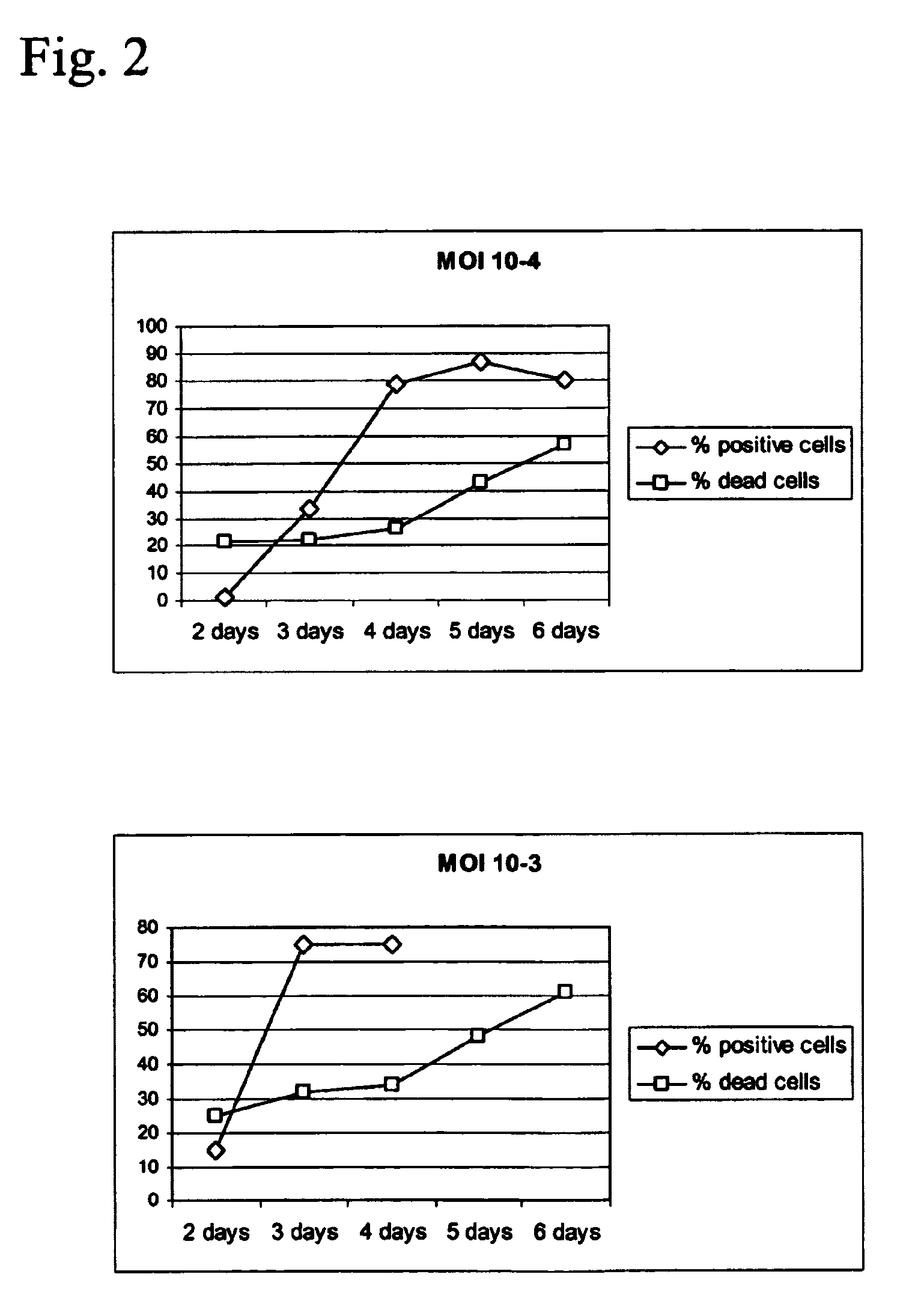

Recombinant protein production in a human cell

InactiveUS6855544B1Easy to handleLarge-scale (continuous) productionSsRNA viruses negative-senseSugar derivativesHamsterHuman cell

Methods and compositions for the production of recombinant proteins in a human cell line. The methods and positions are particularly useful for generating stable expression of human recombinant proteins of interest that are modified post-translationally, for example, by glycosylation. Such proteins may have advantageous properties in comparison with their counterparts produced in non-human systems such as Chinese Hamster Ovary cells.

Owner:JANSSEN VACCINES & PREVENTION BV

Position control apparatus and method of the same, numerical control program preparation apparatus and method of the same, and methods of controlling numerical control machine tool

InactiveUS6097168AEasy to controlPrecise positioningProgramme-controlled manipulatorComputer controlNumerical controlTarget setting

Owner:TOSHIBA MASCH CO LTD

Transparent polymer blends and articles prepared therefrom

ActiveUS20060199919A1Improve claritySuitable for preparationEnvelopes/bags making machinerySynthetic resin layered productsPolyesterPolymer science

Disclosed are polymer compositions having high transparency and low haze comprising immiscible blends of one or more thermoplastic polymers selected from polyesters, polycarbonates, and polyarylates, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend which have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. The blends of the present invention are useful in producing shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce oxygen-scavenging compositions.

Owner:EASTMAN CHEM CO

Transparent, oxygen-scavenging compositions and articles prepared therefrom

ActiveUS20060199904A1Improve claritySuitable for preparationEnvelopes/bags making machineryBottlesPolyesterPolymer science

Disclosed are oxygen-scavenging polymer compositions having high transparency and low haze comprising immiscible blends of one or more thermoplastic polymers selected from polyesters, polycarbonates, and polyarylates, a copolyamide or a transamidized, homogeneous blend of a least two polyamides, and a metal catalyst. The components of the immiscible blend which have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. The blends of the present invention are useful in producing shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties.

Owner:EASTMAN CHEM CO

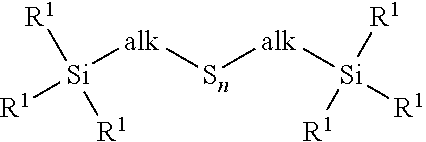

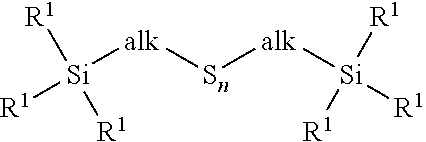

Processes for making silane, hydrophobated silica, silica masterbatch and rubber products

ActiveUS20100022684A1Excellent scorch safetyNo lossPigmenting treatmentSilicon organic compoundsPolymer scienceHydrophobic silica

The present invention provides a process for making silica-filled rubber masterbatch using silica hydrophobated with a trimethoxy silane coupling agent that is soluble in an alcohol-water solution containing at least about 70 wt % water. One embodiment uses a mixture of trimethoxy silanes, one or more of which react with rubber to bond the silica to the rubber, and one or more of which do not react with rubber, but do hydrophobate the silica. Hydrophobated silica is mixed with latex polymer and incorporated into rubber during coagulation of the latex, which is preferably coagulated with calcium chloride. The present invention further provides a process for making the trimethoxy silane coupling agents. Preferred trimethoxy silane coupling agents include bis-(3-trimethoxysilylpropyl)-disulfide and bis-(3-trimethoxysilylpropyl)-tetrasulfide. Rubber products, particularly tires, compounded with the inventive silica masterbatch can be processed for a long time before scorching because the silica masterbatch provides a long scorch time.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

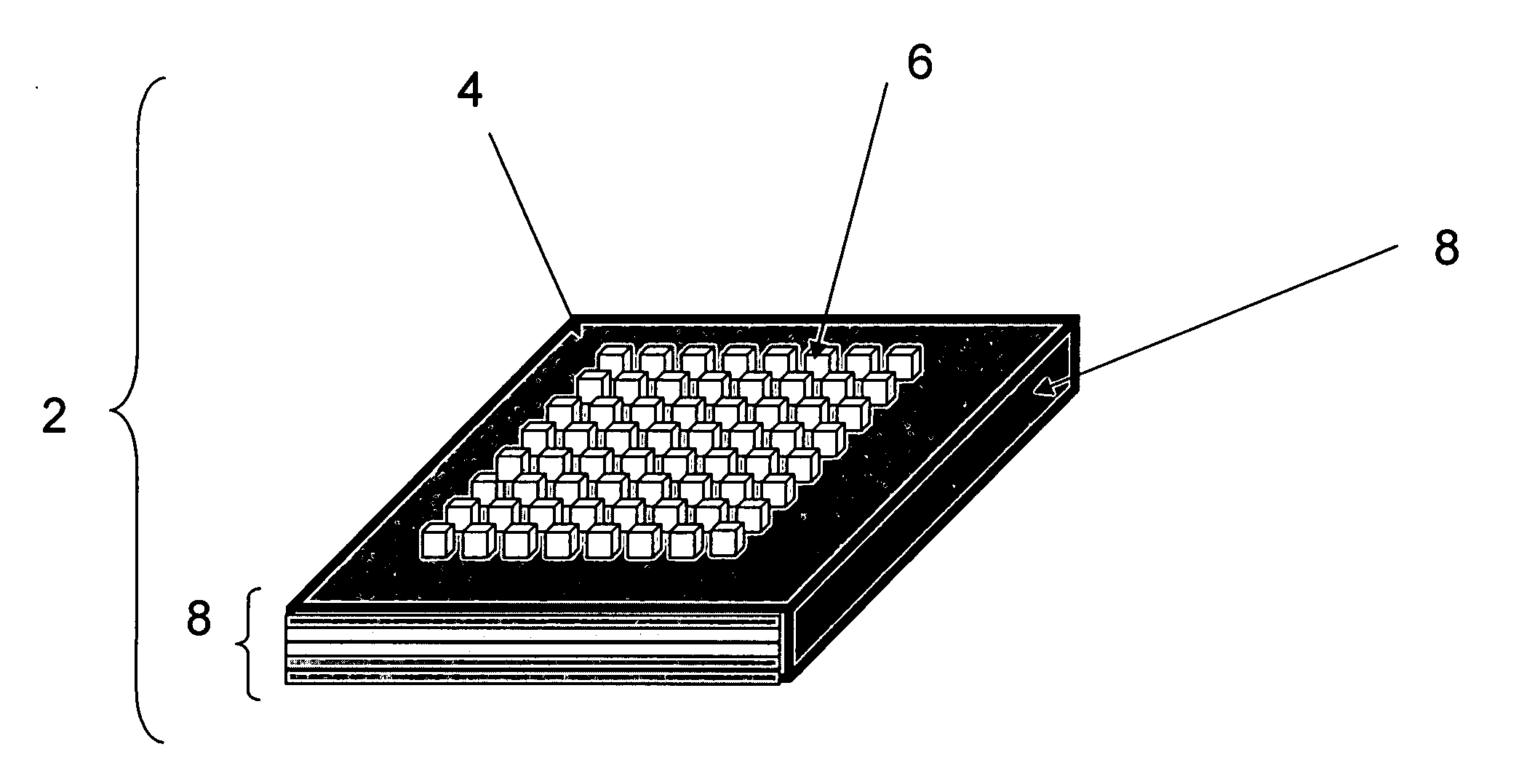

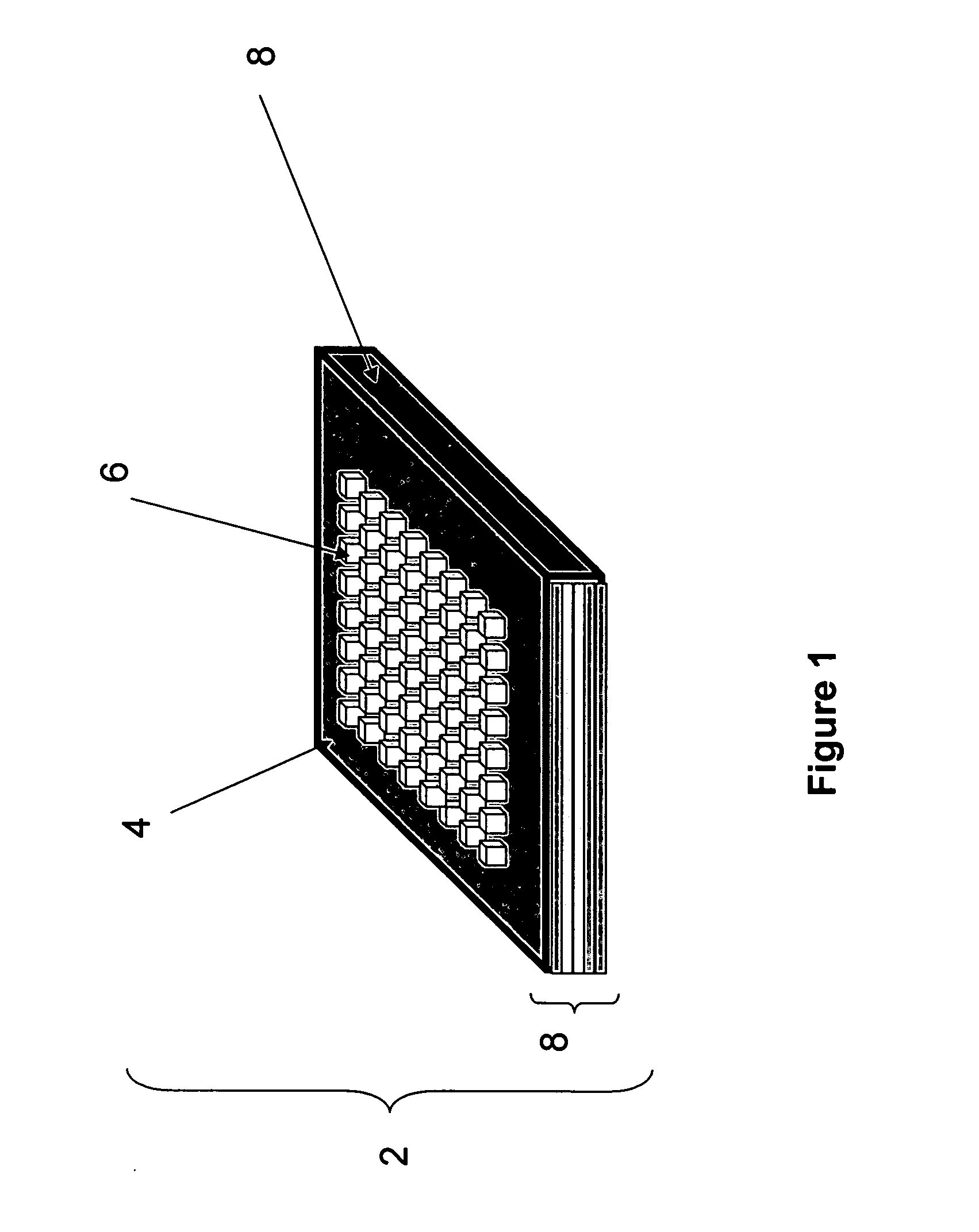

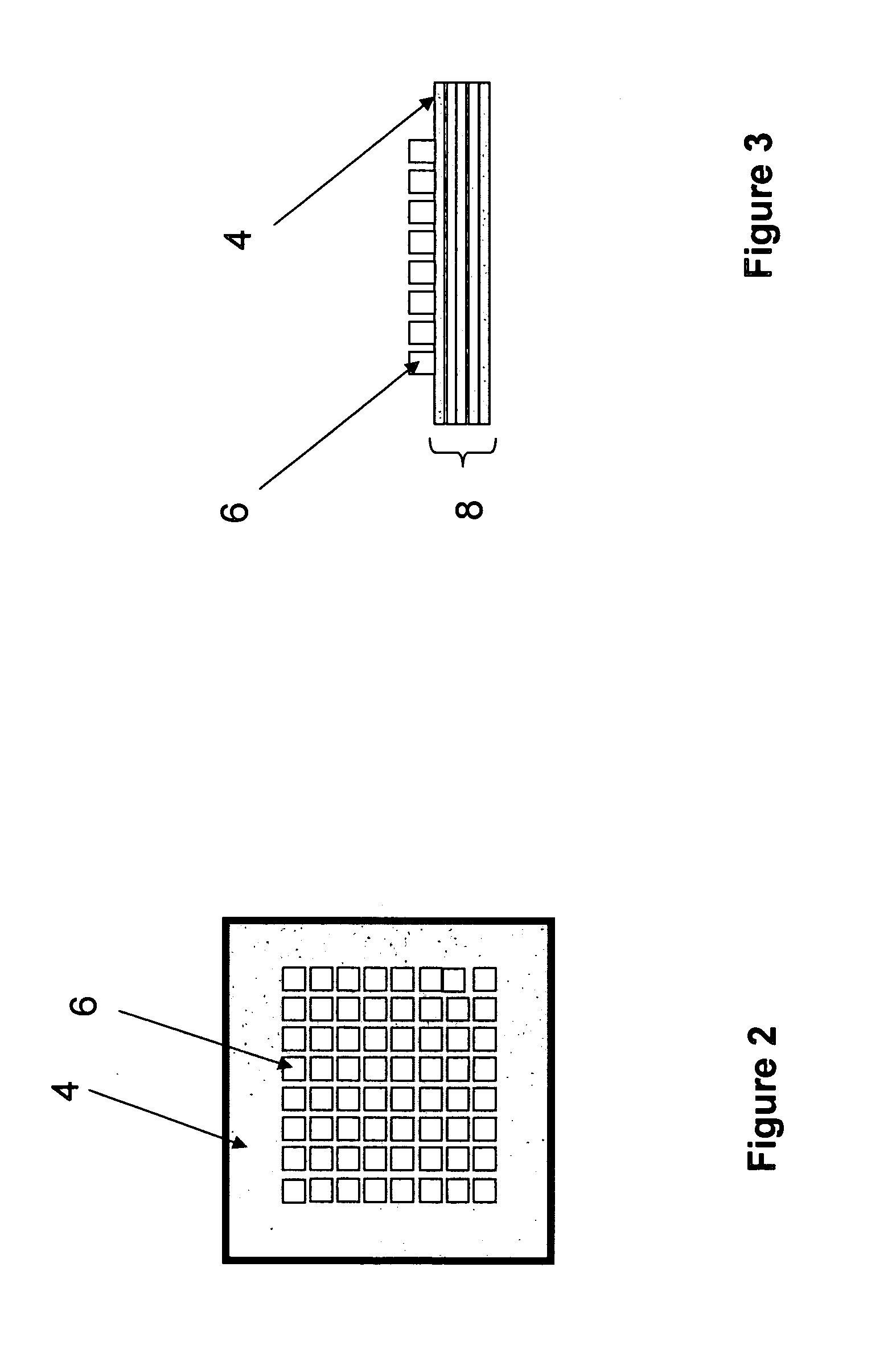

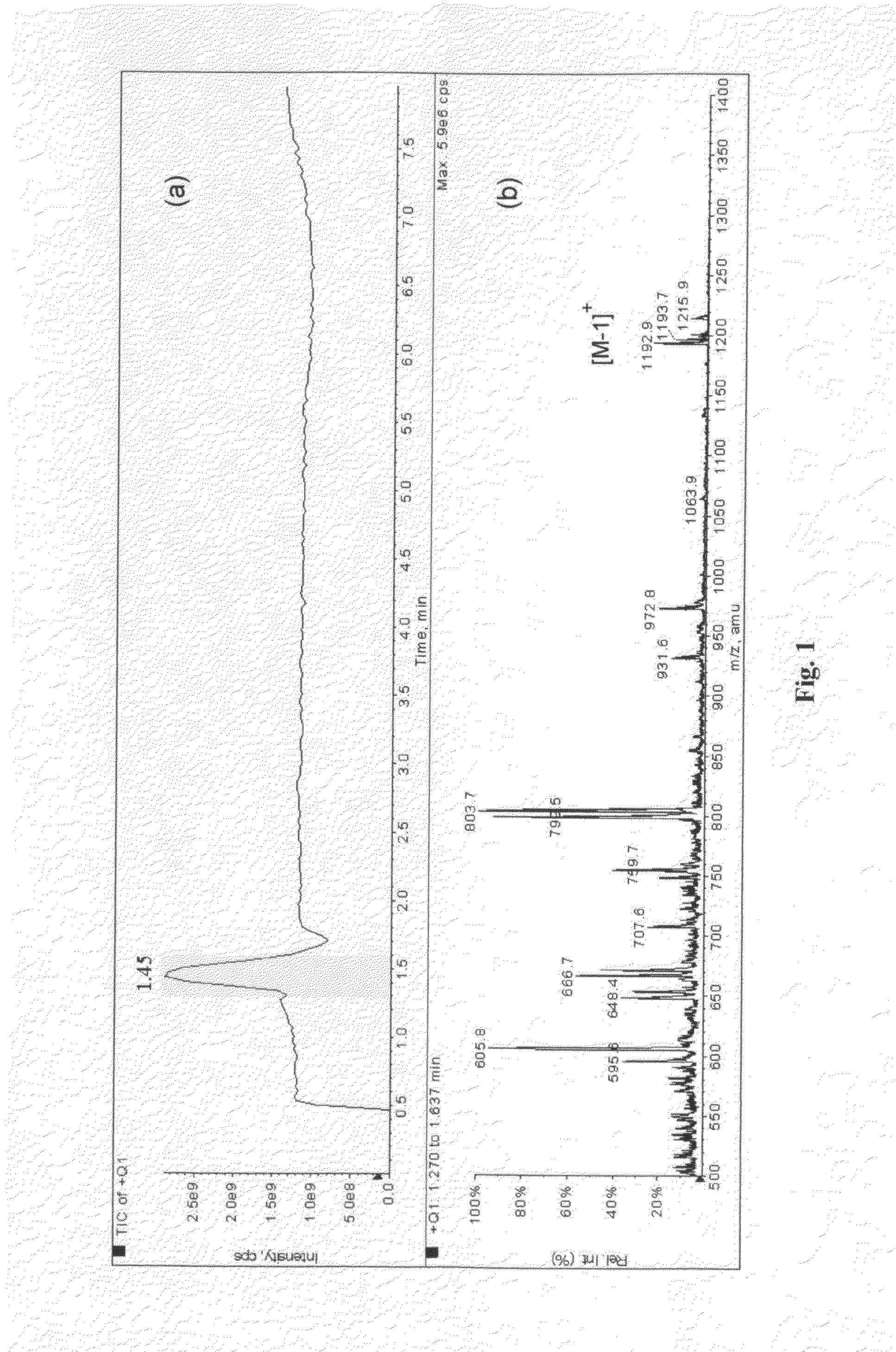

Methods and devices for concentration and purification of analytes for chemical analysis including matrix-assisted laser desorption/ionization (MALDI) mass spectrometry (MS)

InactiveUS20050116161A1High sample throughputReduce analysis costsBioreactor/fermenter combinationsElectrolysis componentsLaser desorption ionization mass spectrometryAnalyte

Owner:PROTEIN DISCOVERY

Processes for making silane, hydrophobated silica, silica masterbatch and rubber products

ActiveUS8357733B2No lossImprove securitySilicon organic compoundsPigmenting treatmentMasterbatchPolymer science

The present invention provides a process for making silica-filled rubber masterbatch using silica hydrophobated with a trimethoxy silane coupling agent that is soluble in an alcohol-water solution containing at least about 70 wt % water. One embodiment uses a mixture of trimethoxy silanes, one or more of which react with rubber to bond the silica to the rubber, and one or more of which do not react with rubber, but do hydrophobate the silica. Hydrophobated silica is mixed with latex polymer and incorporated into rubber during coagulation of the latex, which is preferably coagulated with calcium chloride. The present invention further provides a process for making the trimethoxy silane coupling agents. Preferred trimethoxy silane coupling agents include bis-(3-trimethoxysilylpropyl)-disulfide and bis-(3-trimethoxysilylpropyl)-tetrasulfide. Rubber products, particularly tires, compounded with the inventive silica masterbatch can be processed for a long time before scorching because the silica masterbatch provides a long scorch time.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

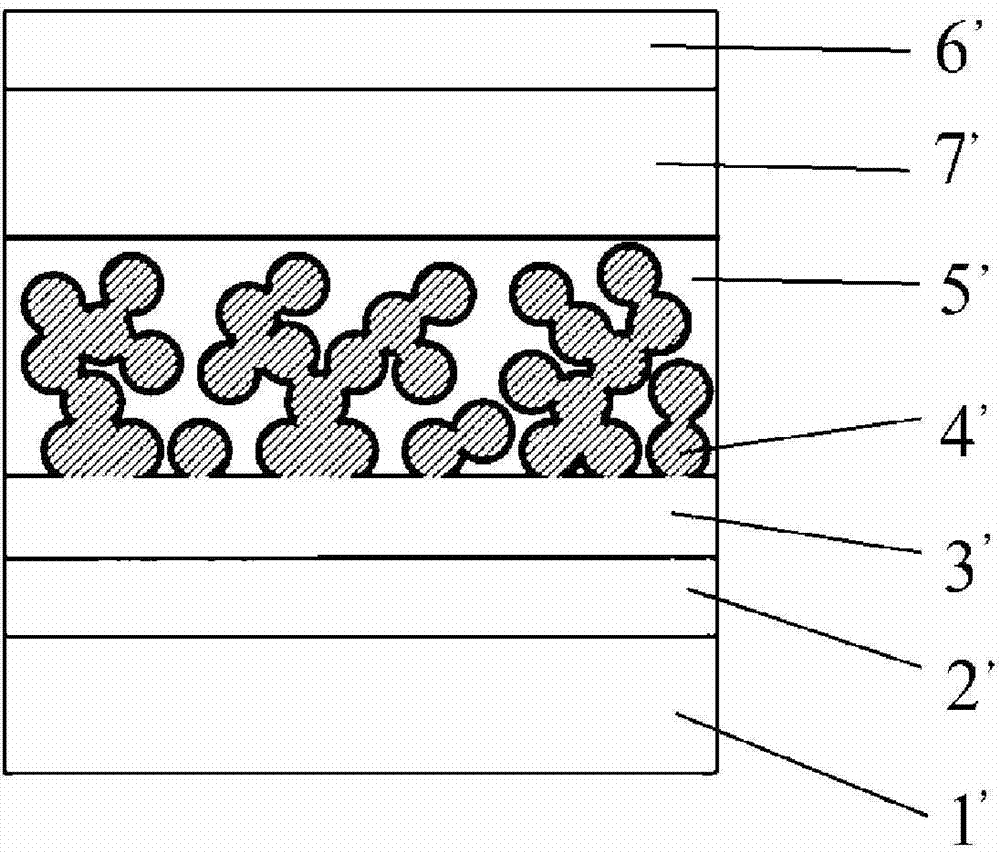

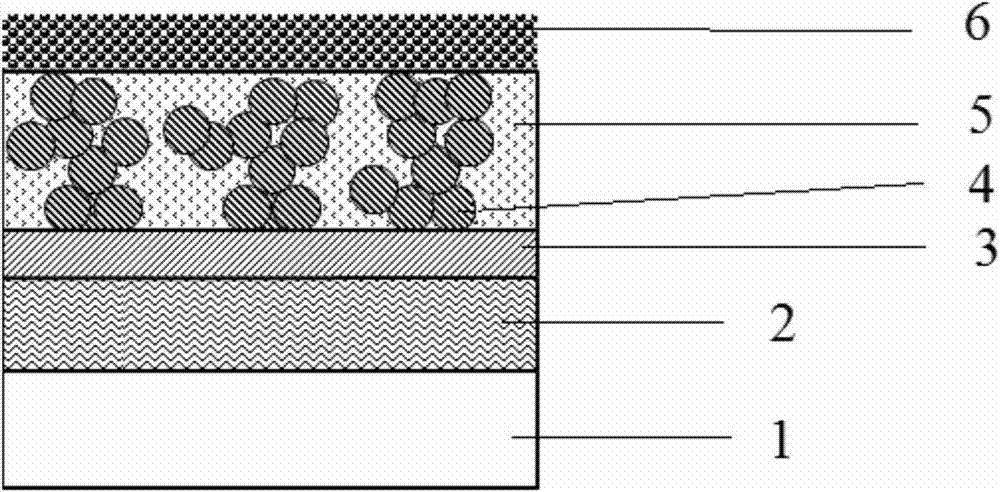

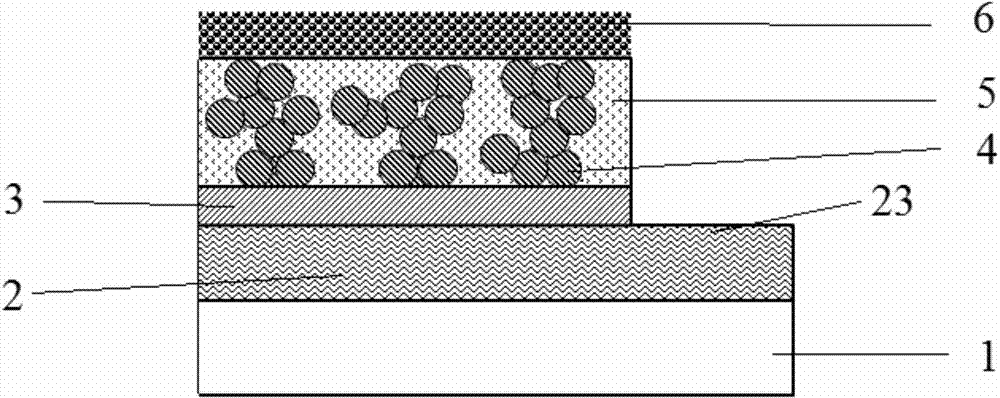

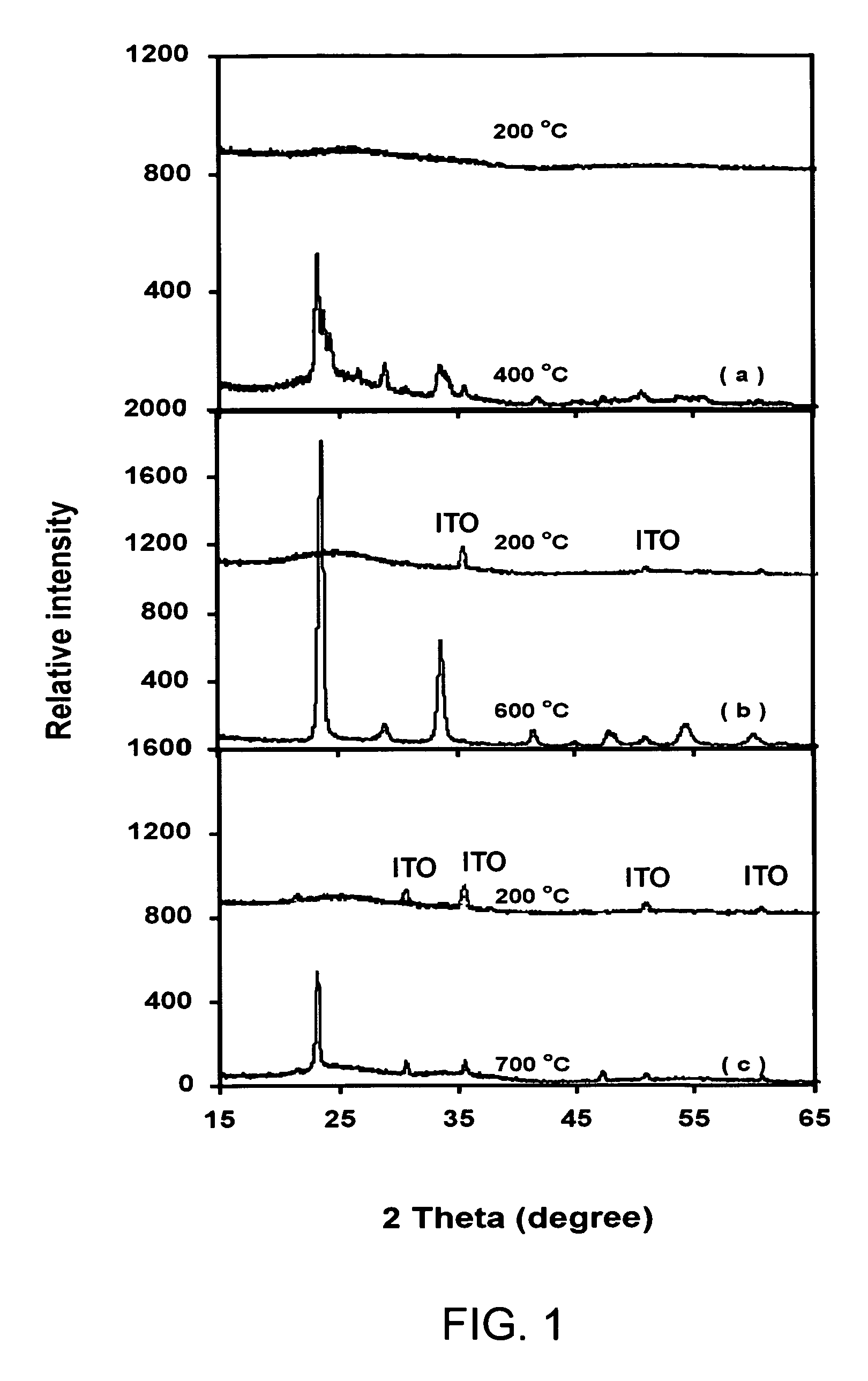

Perovskite-based thin film solar cell and method for preparing same

ActiveCN103490011ASolve problems that are difficult to achieve large-scale productionLow costFinal product manufactureSolid-state devicesSemiconductor materialsPorous carbon

The invention provides a perovskite-based thin film solar cell and a method for preparing the perovskite-based thin film solar cell. The perovskite-based thin film solar cell comprises a transparent substrate, a transparent conducting layer formed on the transparent substrate, a compact layer which is formed on the transparent conducting layer and made of semiconductor materials, a porous insulating layer formed on the compact layer, a porous carbon counter electrode layer formed on the porous insulating layer, and an organic metal semiconductor light absorption material which is filled into pores inside the porous insulating layer and has a perovskite structure. The invention provides application of carbon counter electrodes in the perovskite-based thin film solar cell. Compared with an existing method for preparing the perovskite-based thin film solar cell, the method has the advantages that the counter electrodes are made of carbon materials instead of expensive precious metal materials, and therefore the cost is greatly reduced. The vacuum coating method is replaced by a simple and rapid silk screen print method which allows large-scale production to be achieved, therefore, the cost is further saved, and the achievement of industrial production of the perovskite-based thin film solar cell is facilitated.

Owner:深圳市华物光能技术有限公司

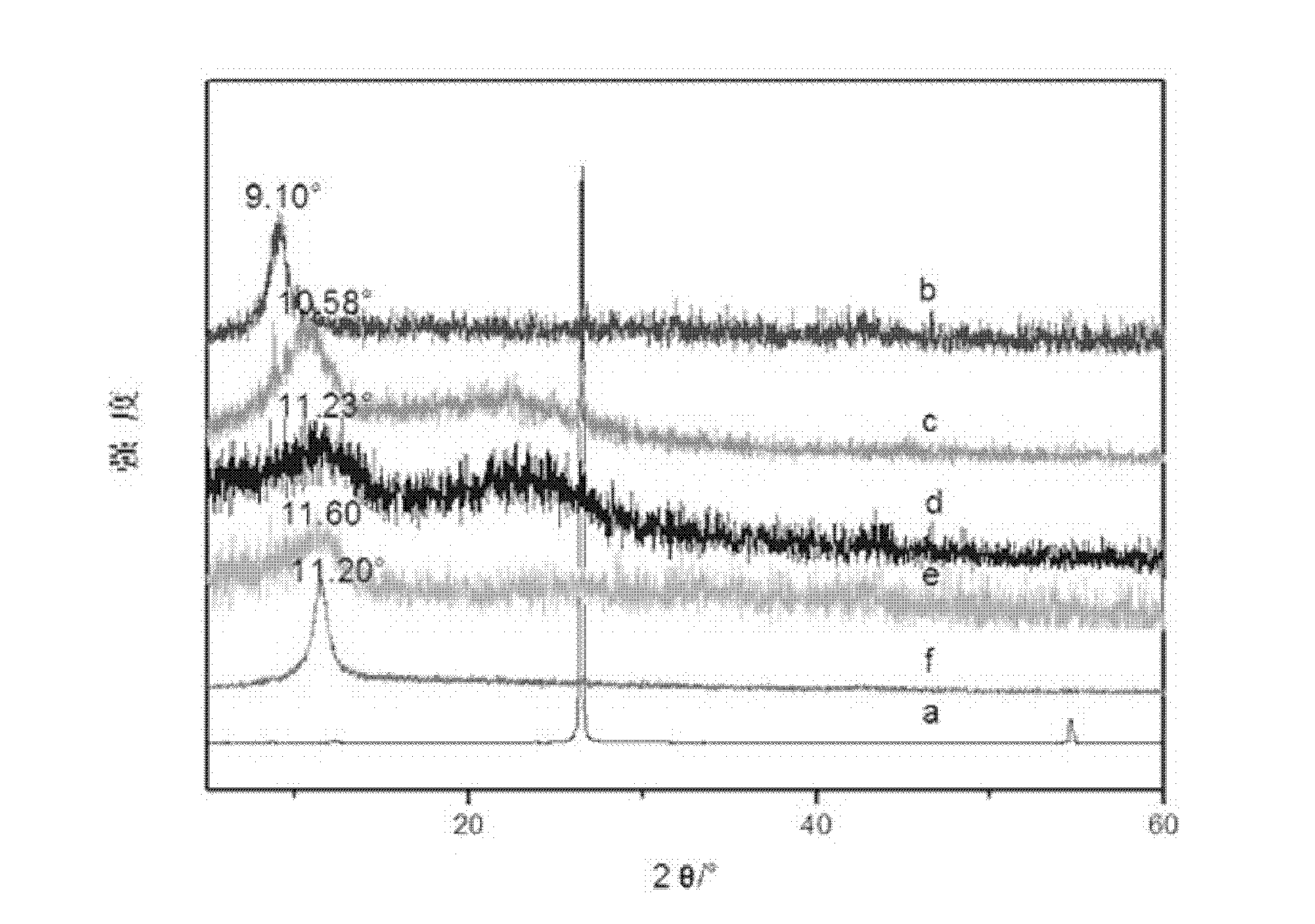

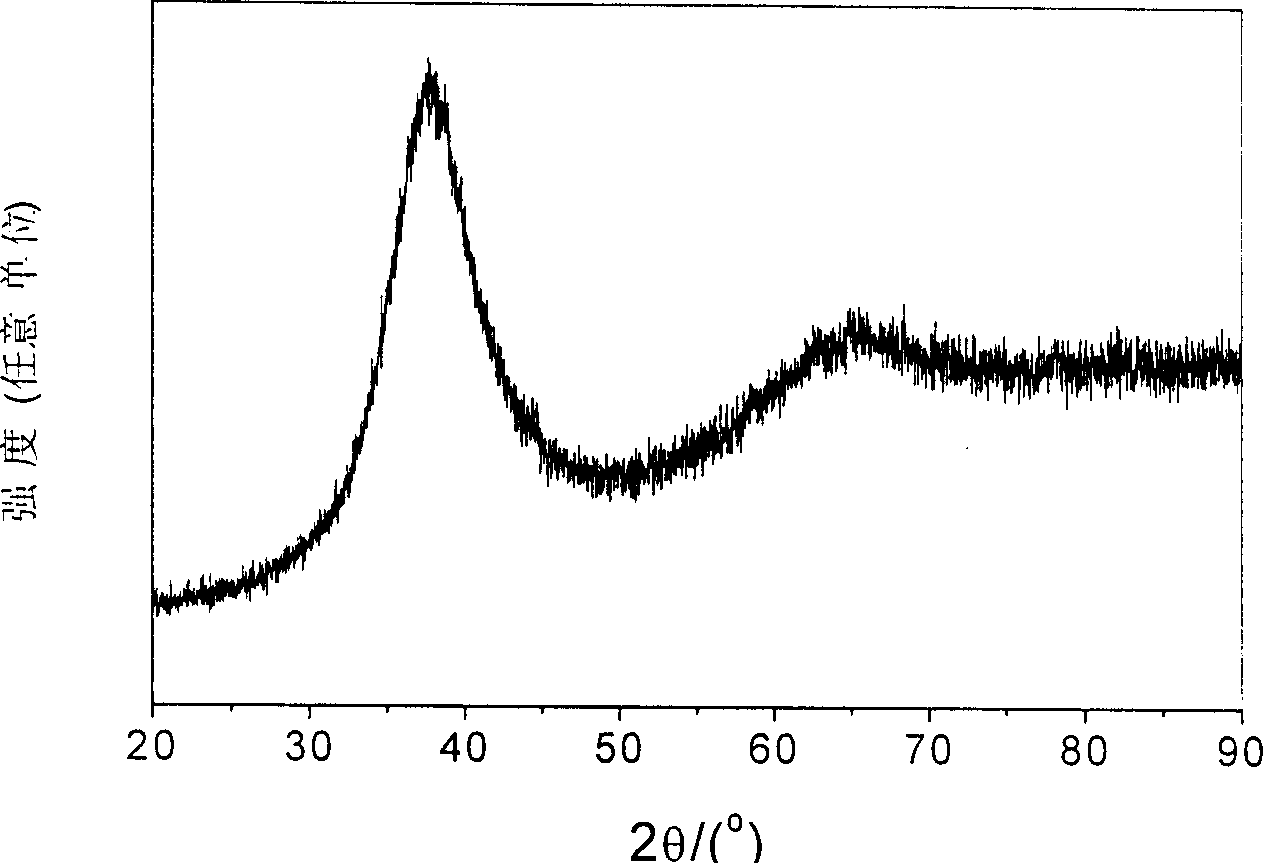

Method for preparing graphene oxide

InactiveCN102491318ACheap and easy to getAvoid it happening againCarbon compoundsToxic gasFiltration

The invention discloses a method for preparing a graphene oxide. The method comprises the following steps of: a) adding concentrated inorganic acid into a sealed reactor, adding graphite powder with stirring, reducing the temperature to the temperature of between 0 and 4 DEG C, and adding potassium permanganate to react for 0.5 to 2 hours; b) heating the obtained reaction system to the temperature of between 60 and 70 DEG C, and standing for 12 to 24 hours; c) adding hydrogen peroxide into distilled water in a volume ratio of 1:10, freezing to obtain ice, transferring the graphite oxide to the distilled water containing the hydrogen peroxide until the ice is completely dissolved, uniformly stirring, performing suction filtration, washing and drying to obtain the graphene oxide. The graphite powder, the concentrated acid and the potassium permanganate serve as raw materials, and the raw materials are low in cost and readily available; NO, NO2 and other toxic gases are prevented from being produced; the reaction temperature is as low as 60-70 DEG C; and the product has high dye adsorption capacity and high industrial application value.

Owner:HEBEI UNIV OF TECH

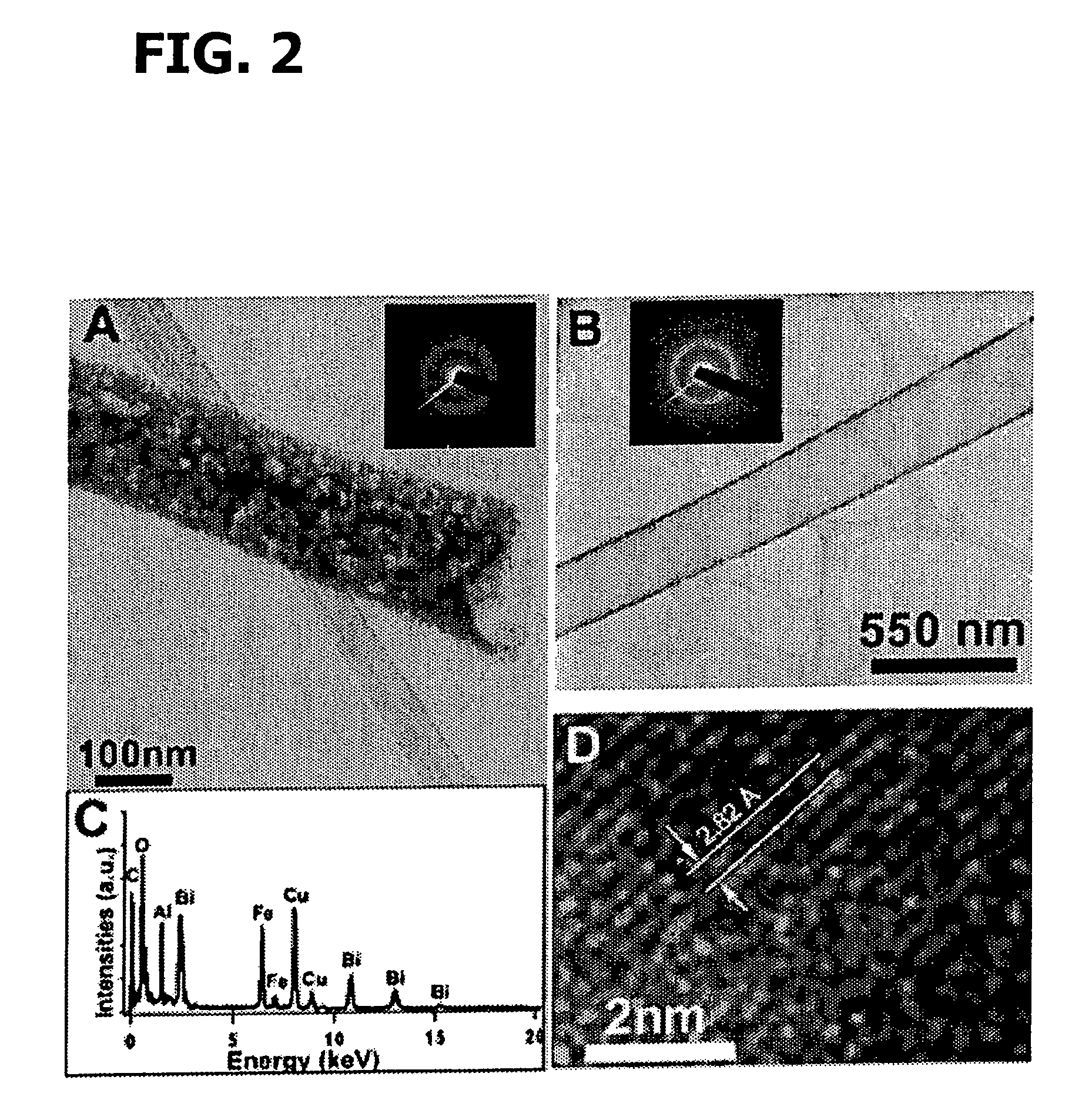

Ternary oxide nanostructures and methods of making same

InactiveUS7585474B2Suitable for preparationFrom gel stateAlkaline earth titanatesSingle crystalNanostructure

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Tl, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

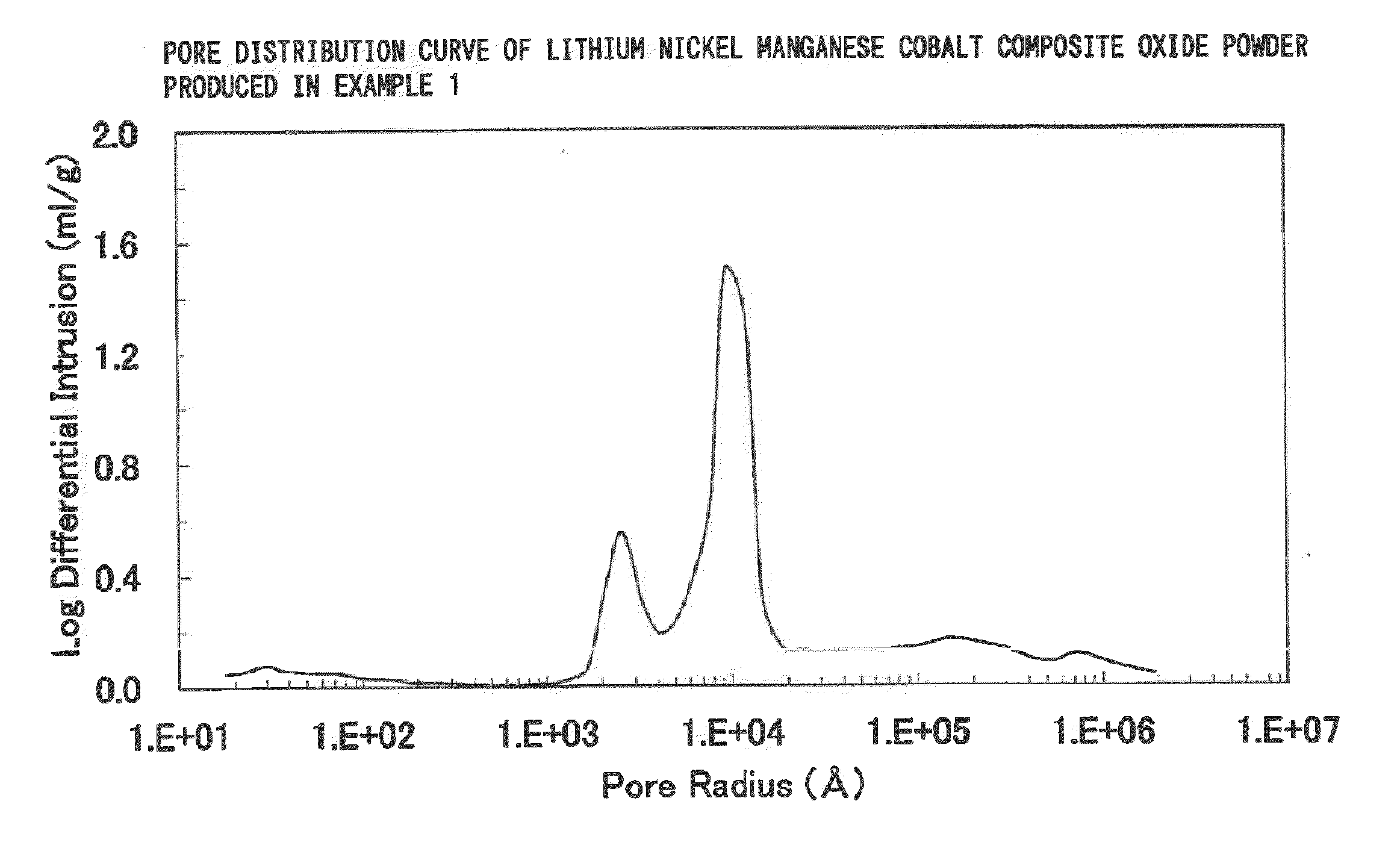

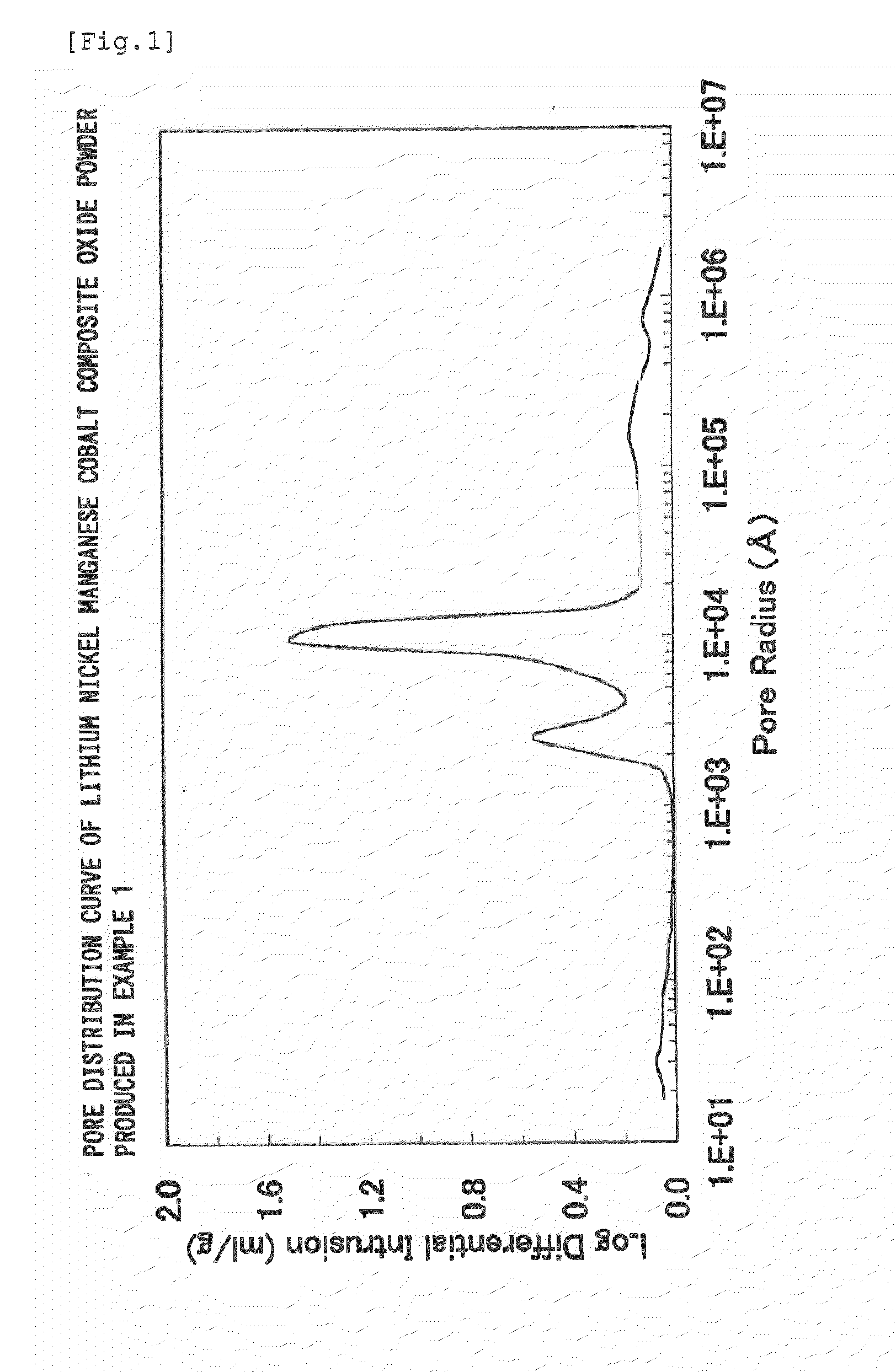

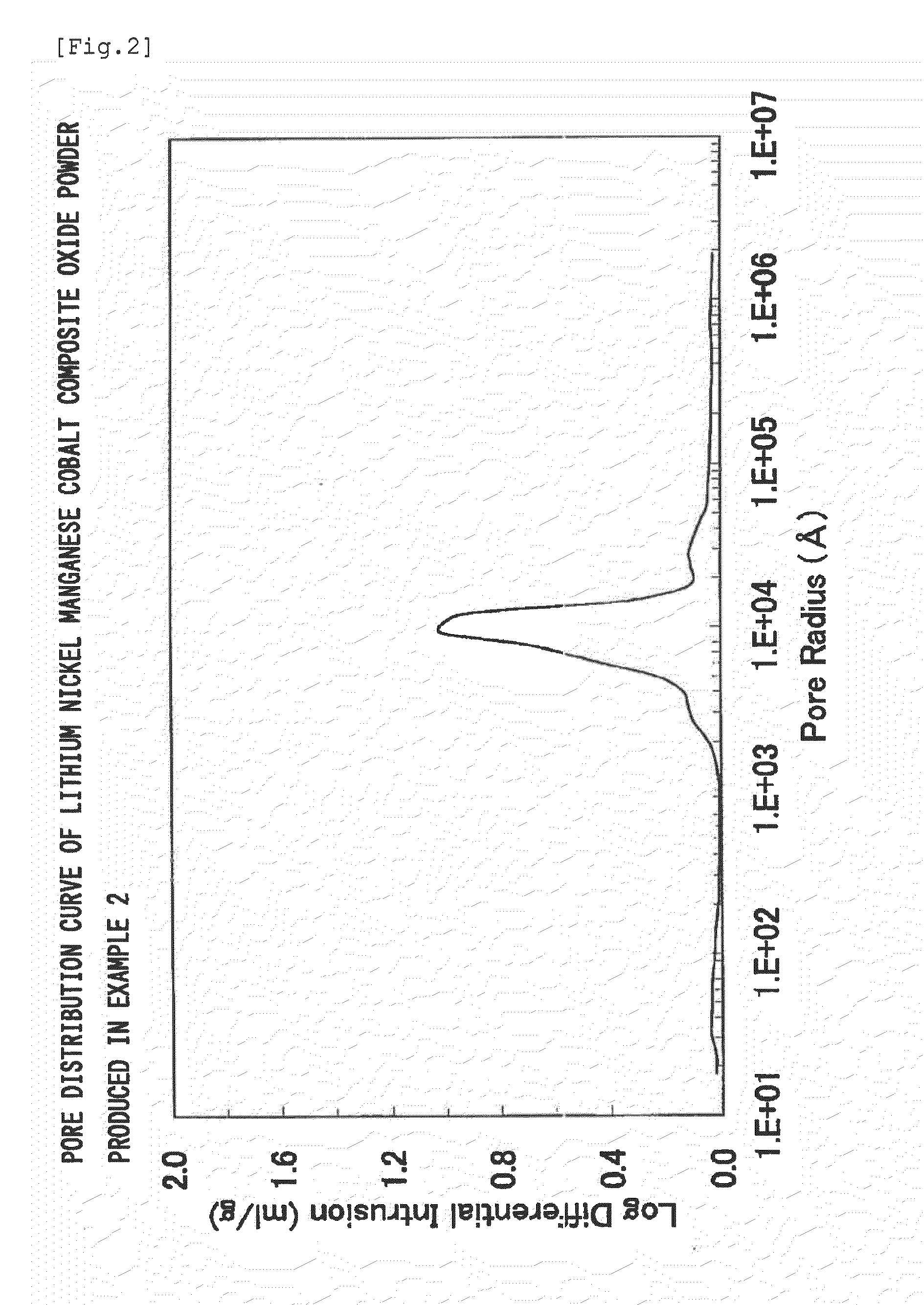

Lithium transition metal based compound powder, method for manufacturing the same, spray-dried substance serving as firing precursor thereof, lithium secondary battery positive electrode by using the same, and lithium secondary battery

InactiveUS20110003200A1Improve securityImprovement in powder handleabilityFinal product manufactureElectrode carriers/collectorsPhysical chemistryLithium-ion battery

A lithium transition metal based compound powder for a lithium secondary battery positive electrode material, characterized by including a lithium transition metal based compound, which has a function of enabling insertion and elimination of lithium ions, as a primary component and being produced by conducting firing after at least one type of compound (hereafter referred to as “Additive 1”) containing at least one type of element (hereafter referred to as “Additive element 1”) selected from B and Bi and at least one type of compound (hereafter referred to as “Additive 2”) containing at least one type of element (hereafter referred to as “Additive element 2”) selected from Mo and W are added in combination to a raw material of the primary component at a ratio of a total of Additive 1 and Additive 2 to a total amount of moles of transition metal elements in the raw material of the primary component of 0.01 percent by mole or more, and less than 2 percent by mole.

Owner:MITSUBISHI CHEM CORP

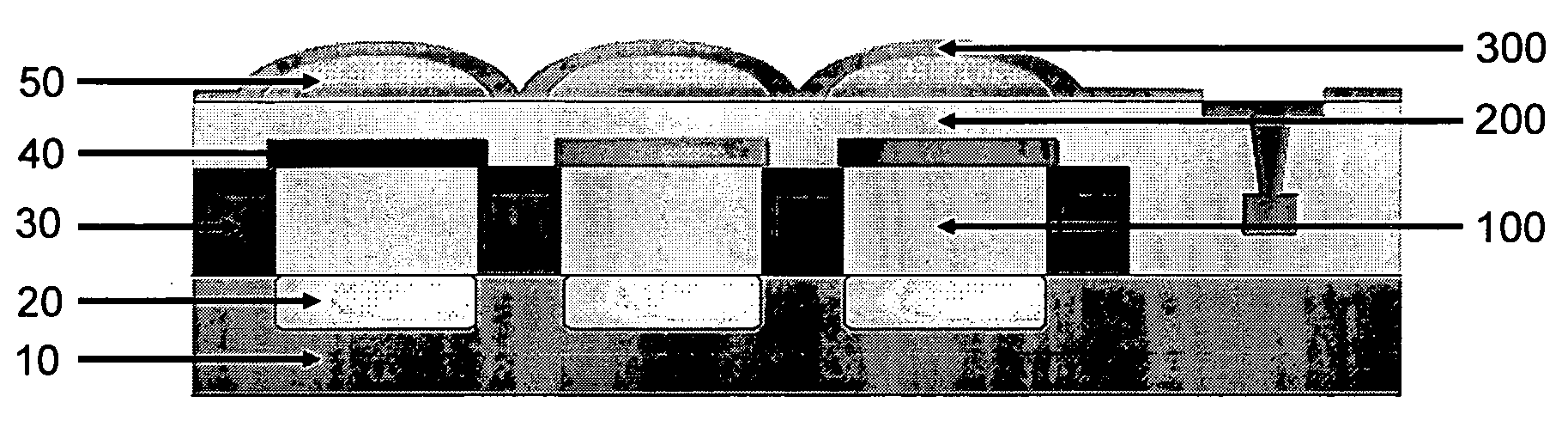

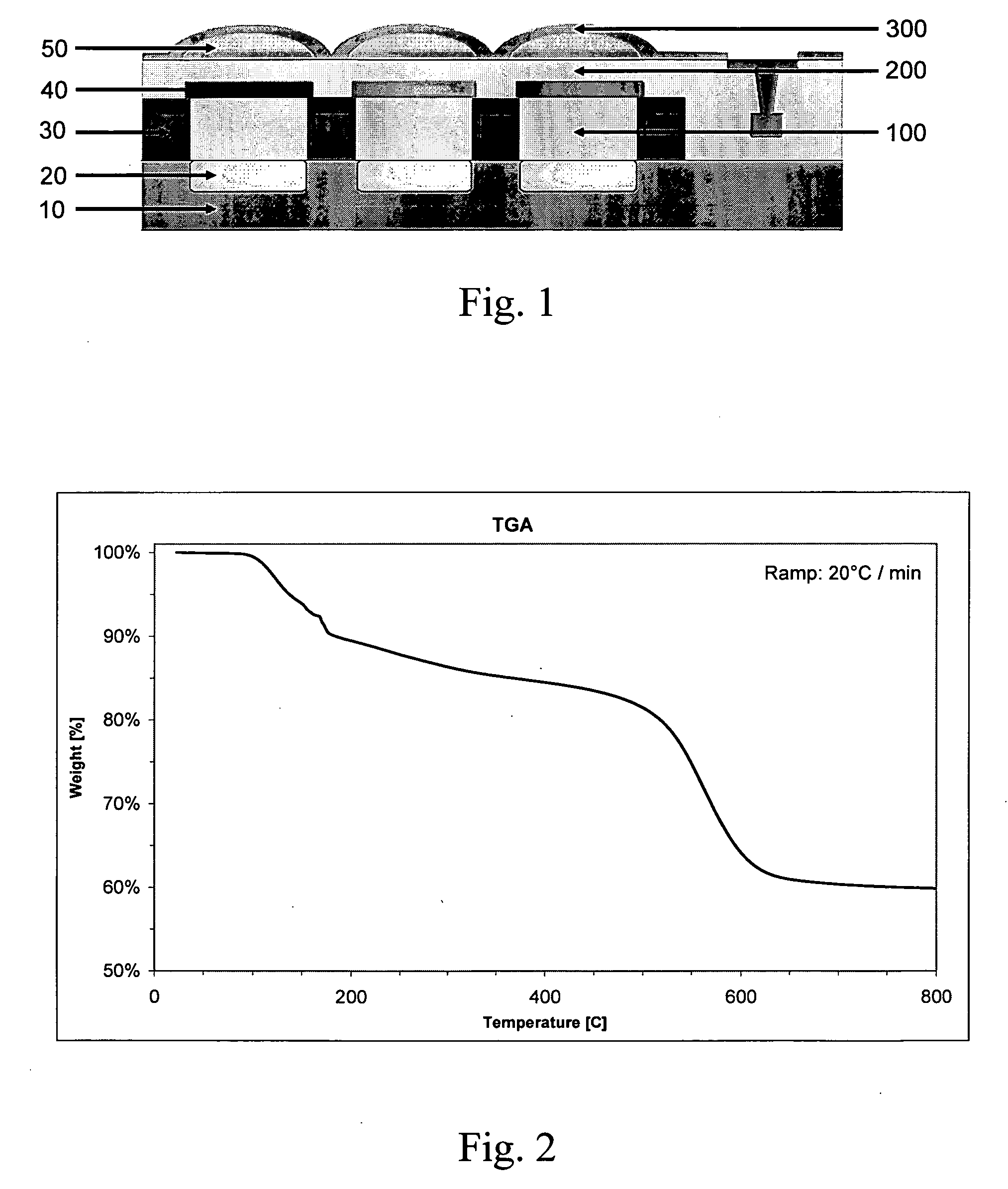

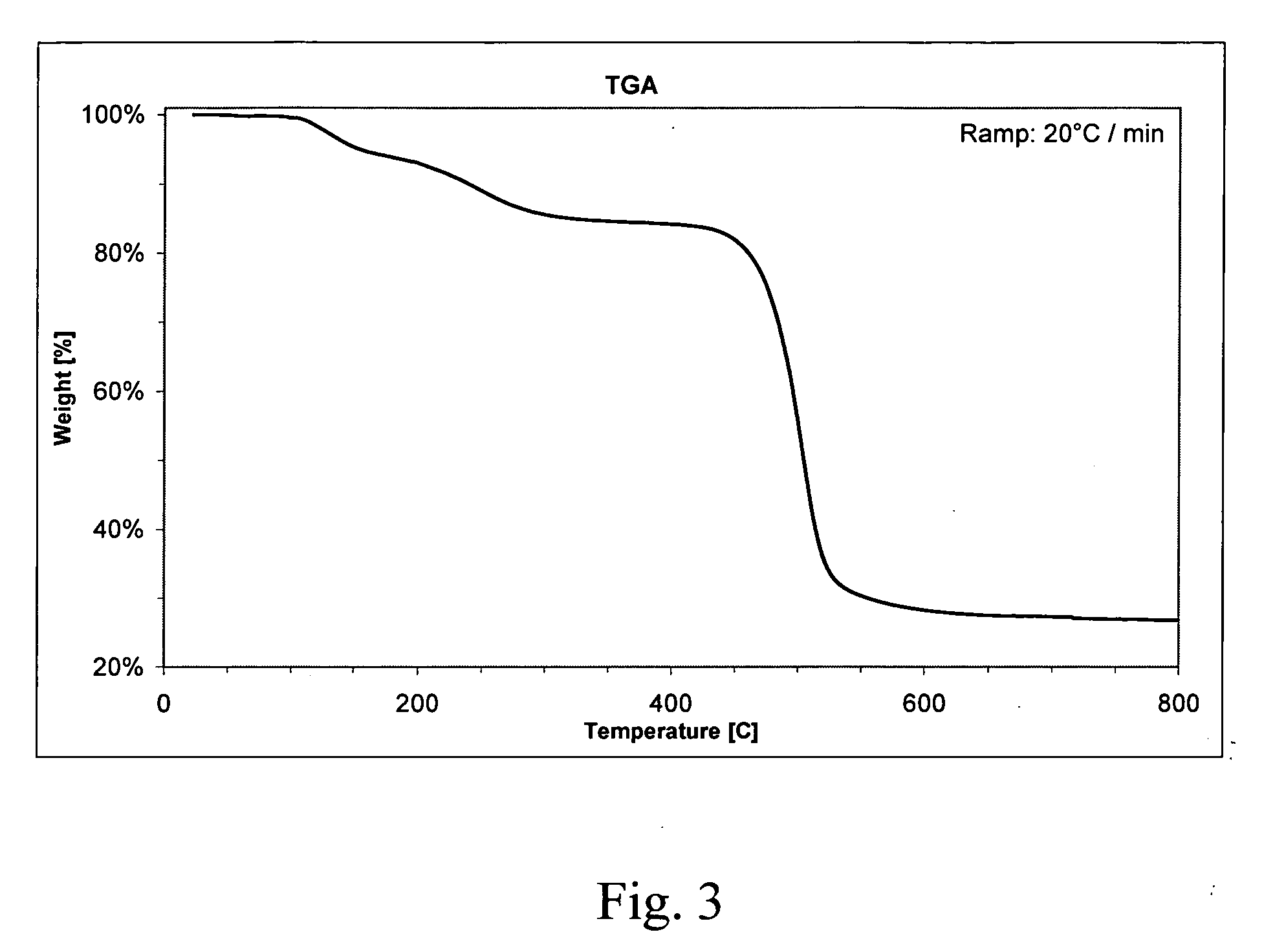

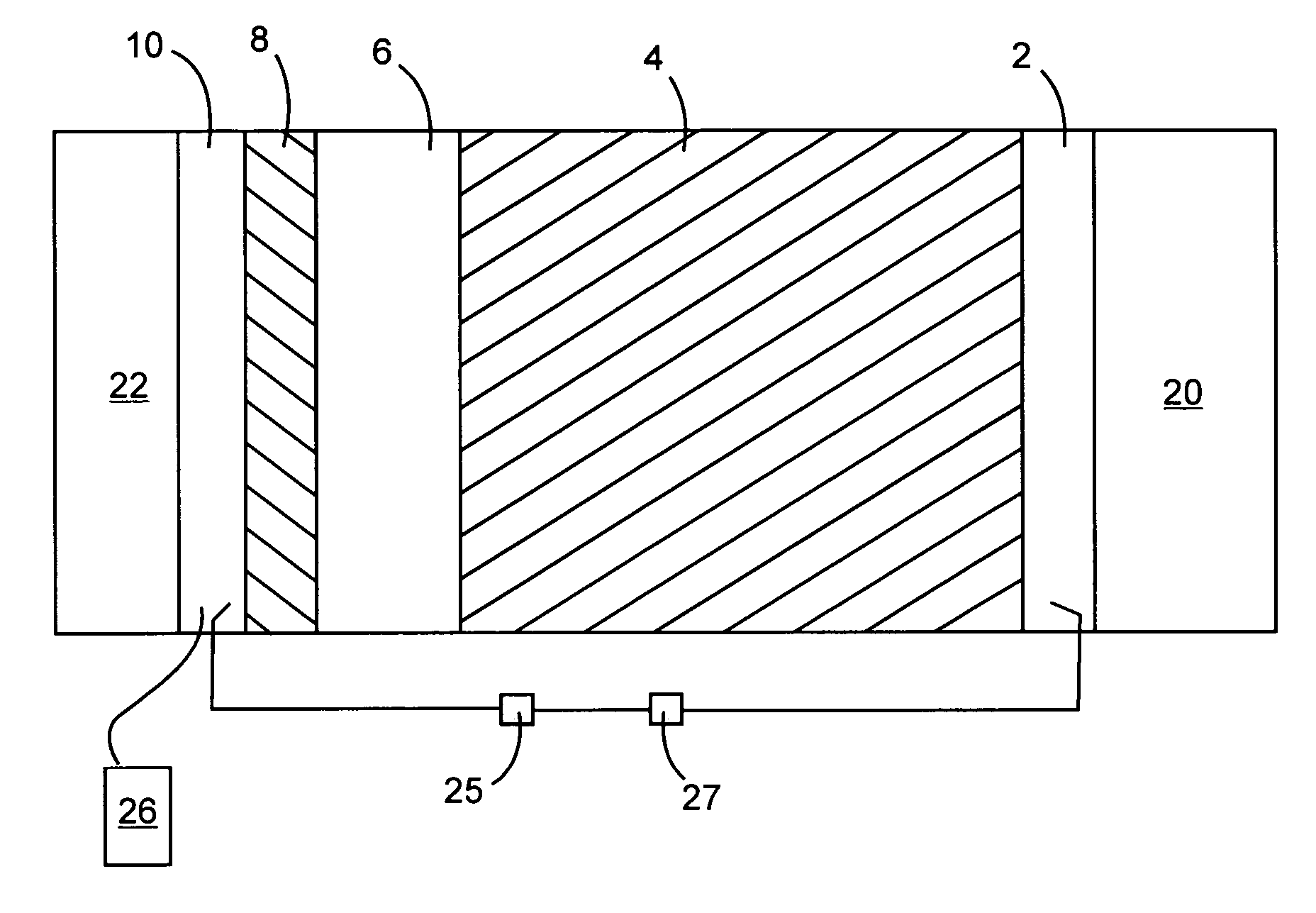

Semiconductor optoelectronics devices

InactiveUS20070284687A1High refractive indexIncrease valueSolid-state devicesSemiconductor/solid-state device manufacturingMicrolensEngineering

A semiconductor device comprising a semiconductor substrate with a plurality of photo-diodes arranged in the semiconductor substrate with interconnect layers defining apertures at the photo-diodes and a first polymer which fills the gaps such as to cover the photo-diode. Further, layers of color filters are arranged on top the gap filling polymer layer opposite to the photo-diodes and a second polymer arranged on the interconnect layers covers and planarizes and passivates the color filter layers. On top of the planarizing polymer there is a plurality of micro-lenses opposite to the color filters, and a third polymer layer is deposited on the micro-lenses for passivating the micro-lenses. According to the invention the polymer materials are comprised of a siloxane polymer which gives thermally and mechanically stable, high index of refraction, dense dielectric films exhibiting high-cracking threshold, low pore volume and pore size.

Owner:SILECS OY

Pure PEG-lipid conjugates

InactiveUS20110040113A1Low costSynthetic is simpleOrganic chemistryOrganic compound preparationOligomerSynthesis methods

Syntheses of polyethyleneglycol (PEG)-lipid conjugates are disclosed. Such syntheses involve stepwise addition of small PEG oligomers to a glycerol backbone until the desired chain size is attained. Polymers resulting from the syntheses are highly monodisperse. The present invention provides several advantages such as simplified synthesis, high product yield and low cost for starting materials. The present synthesis method is suitable for preparing a wide range of conjugates.In another aspect, the invention comprises PEG lipid conjugates having a glycerol backbone covalently attached to one or two monodisperse PEG chains and one or two lipids. These conjugates are especially useful for pharmaceutical formulations.

Owner:UKRAINIAN INDEPENDENT INFORMATION AGENCY +1

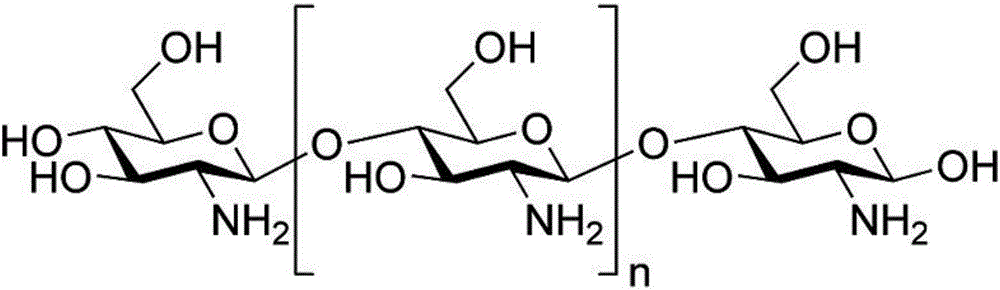

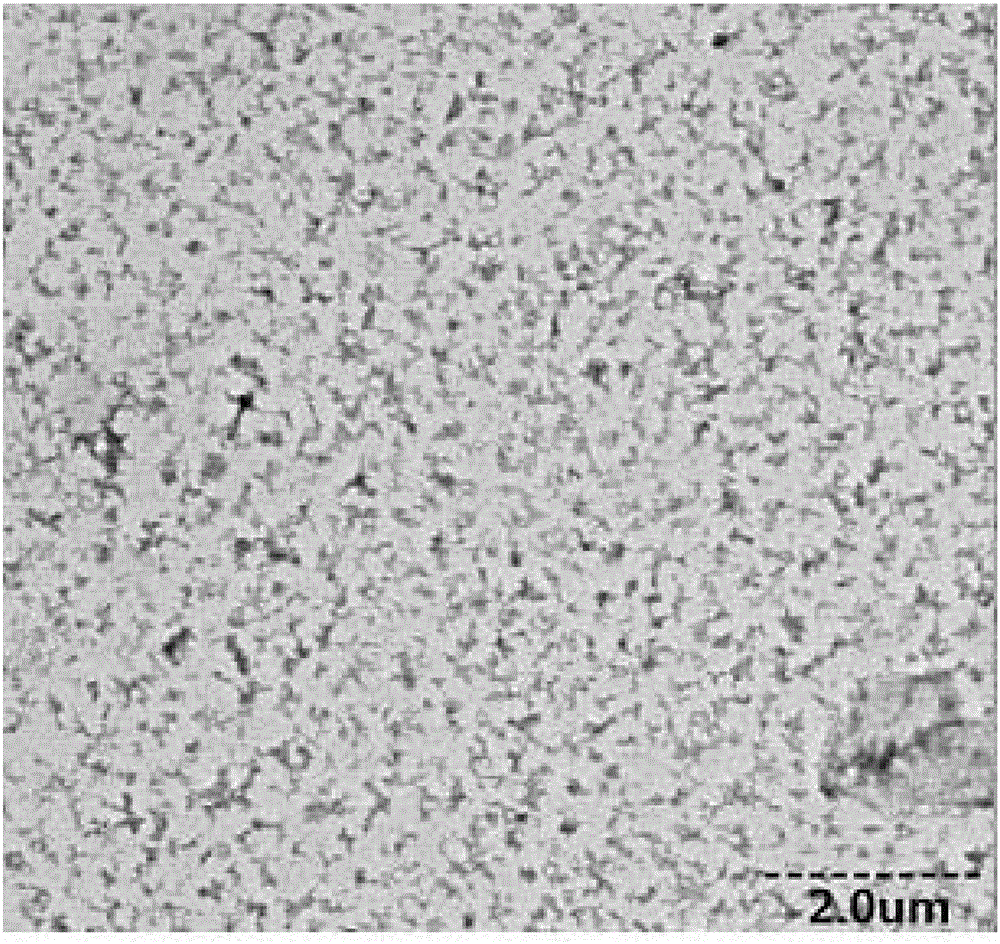

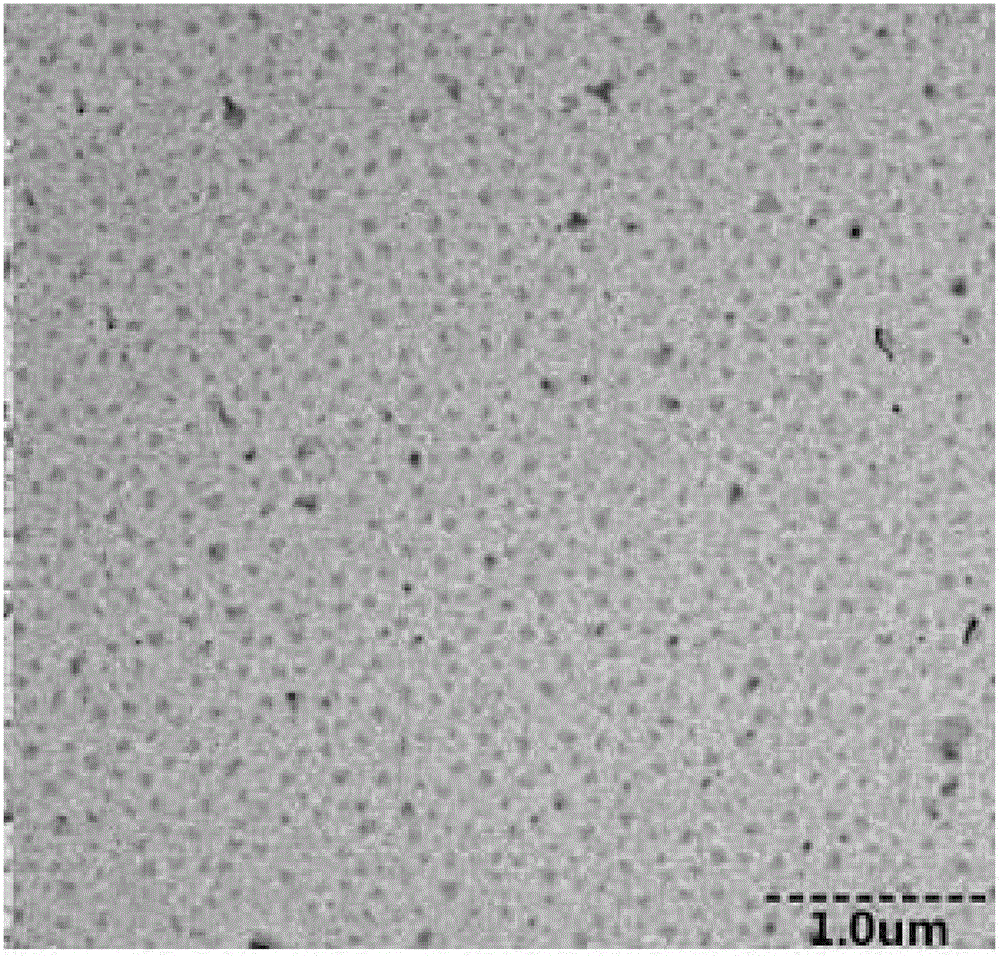

Chitosan nanoparticle suspension preparation method and application thereof

ActiveCN105001433AGood biocompatibilityUniform shapeAntibacterial agentsAerosol deliveryAcetic acidAntibiosis

The present invention discloses a chitosan nanoparticle suspension preparation method and application thereof. The chitosan nanoparticle suspension preparation method comprises the following steps of: (1) dissolving a chitosan into a glacial acetic acid aqueous solution to prepare a chitosan aqueous acetic acid; (2) under stirring, adding a tripolyphosphate sodium aqueous solution dropwise to obtain a coarse chitosan nano suspension; and (3) after filtering the coarse chitosan nano suspension, processing homogeneously the filtered suspension with high pressure to obtain a nano chitosan suspension with a uniform particle size distribution. The invention has the advantages of simple operation, good scale-up preparation reproducibility, and low production cost, and is applicable to industrial production. The prepared nanoparticles are of a uniform morphology, small in particle diameter and applicable to preparing products with functions of antibiosis, hemostasis and promoting tissue repair.

Owner:NANJING XINTONG RUIYI MEDICINE SCI & TECH

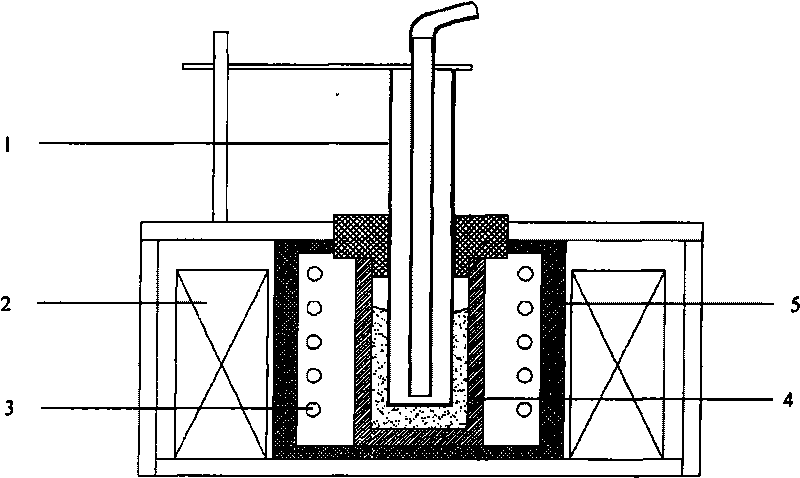

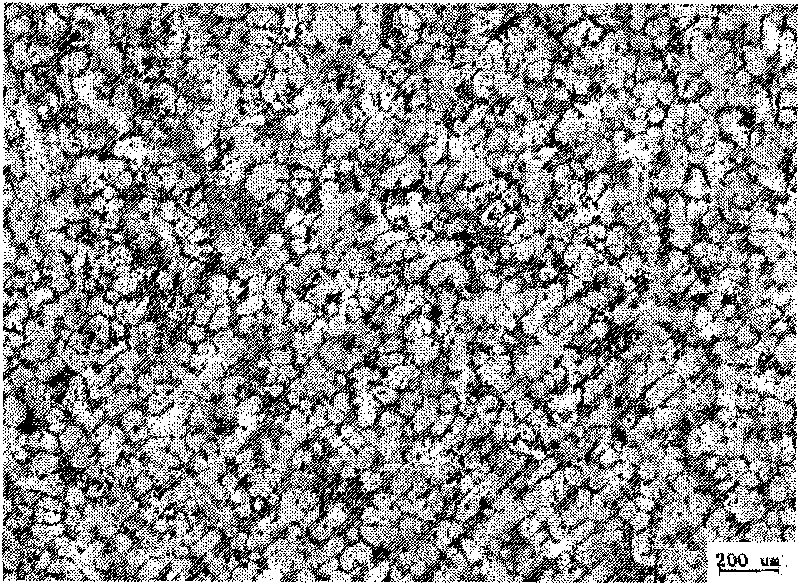

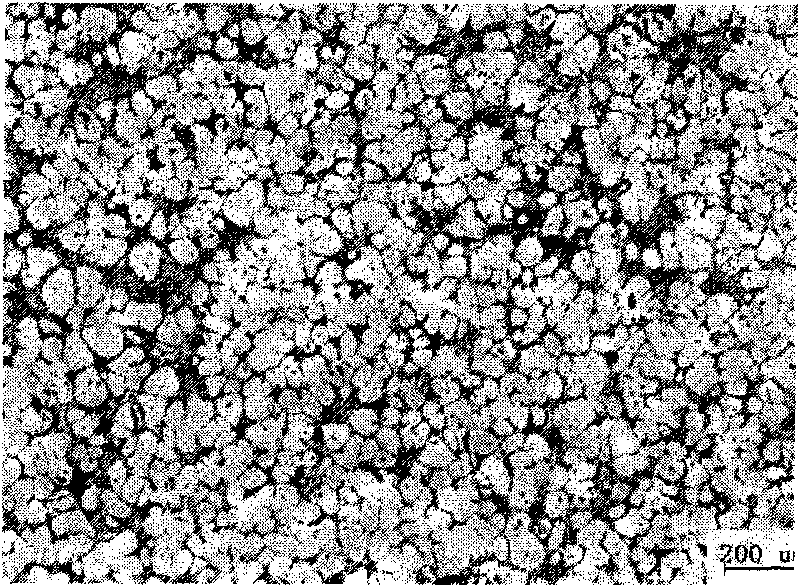

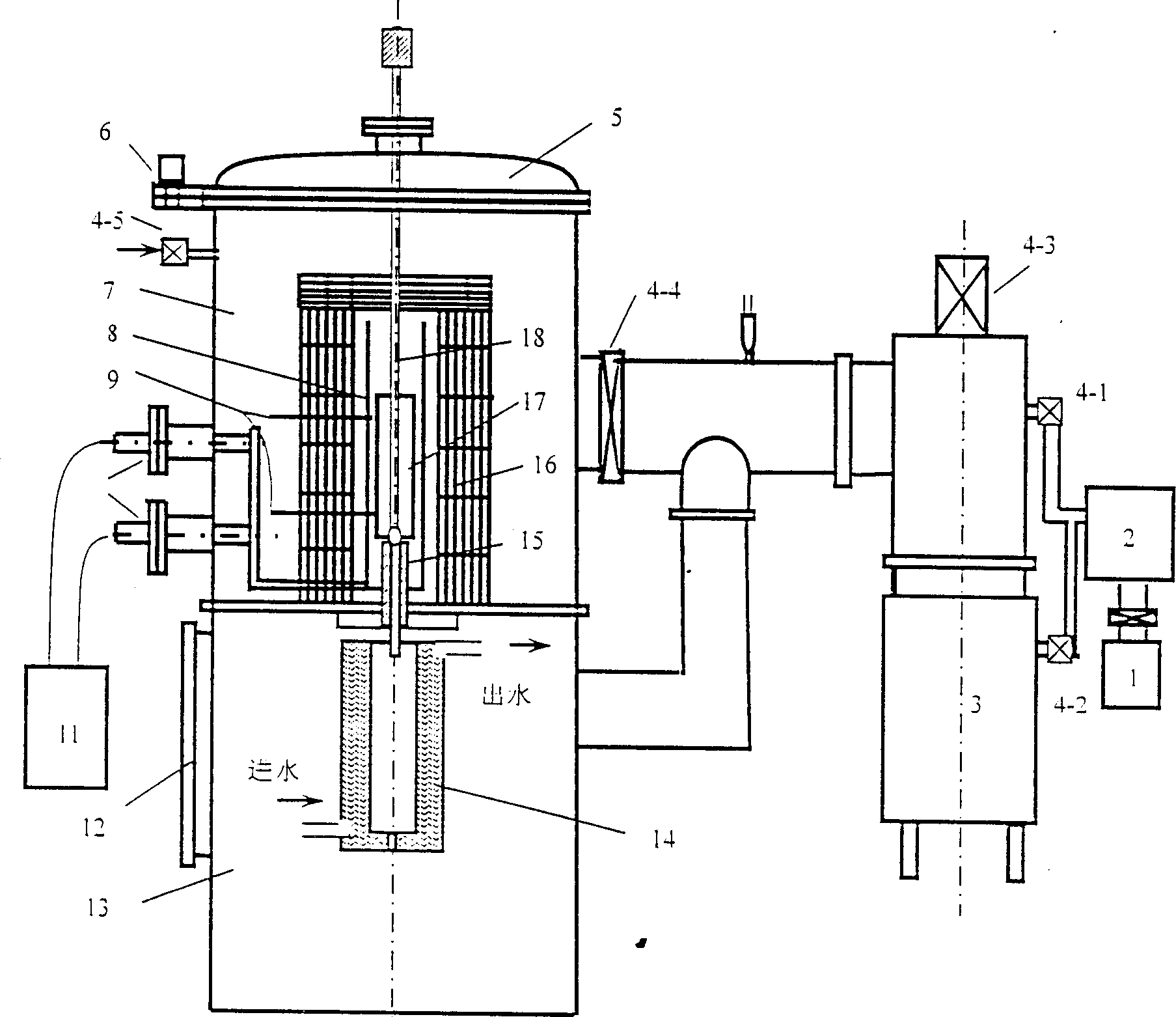

Method for preparing semi-solid alloy rheological slurry or billet through annular-gap type electromagnetic stirring

A method for preparing semi-solid metal or alloy slurry or billet through annular-gap type electromagnetic stirring is hereinafter referred to as an annular-gap type electromagnetic stirring method in which the liquid metal or alloy liquid with 5-100 DEG C higher than the liquidus temperature is cast in an annular gap formed between an inner side wall of a slurrying chamber and an outer wall of an internal cooling controller. The metal or the alloy liquid is strongly stirred under the action of an electromagnetic induction rotary stirrer. Meanwhile, the cooling medium flowing in an external cooling controller and the internal cooling controller lead the temperature field of the slurry to be more uniform, thereby obtaining the fine and uniform semi-solid structure. The method is characterized in that the width of the annular gap formed between the inner side wall of the slurrying chamber and the outer wall of the internal cooling controller is 3-100mm. During preparation, the cooling medium is flowed in the external cooling controller and the internal cooling controller so as to lead the temperature field of the slurry to be uniform. The preparation method leads the stirring force field and the temperature field of the slurry to be more uniform, thereby obtaining the high-quality semi-solid slurry. The method has the advantages of simple preparation process, convenient operation, excellent shape of the semi-solid structure, uniformity and fineness and low preparation cost, and is particularly applicable to preparation of semi-solid aluminum or aluminum alloy, magnesium and magnesium alloy and other metal and alloy or composite material slurry or billet.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

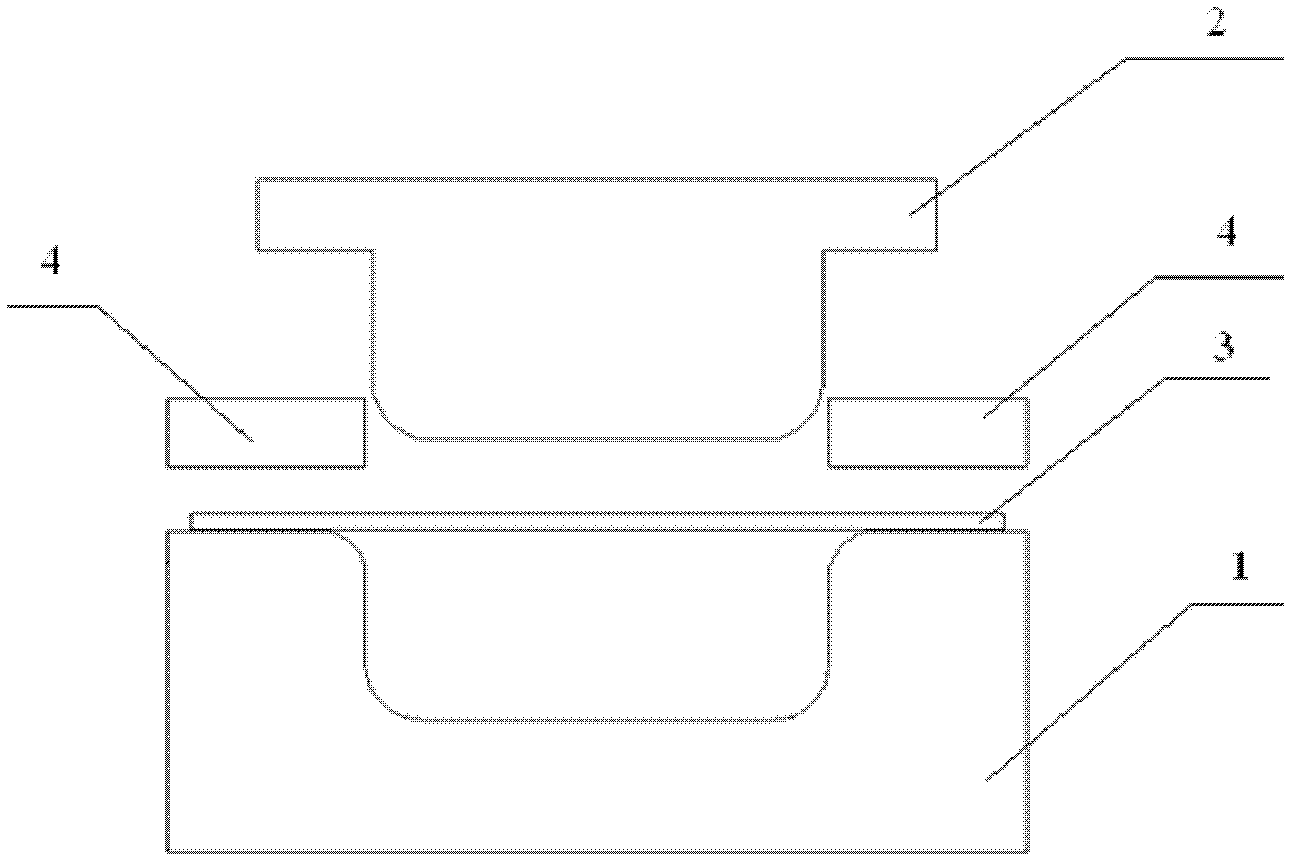

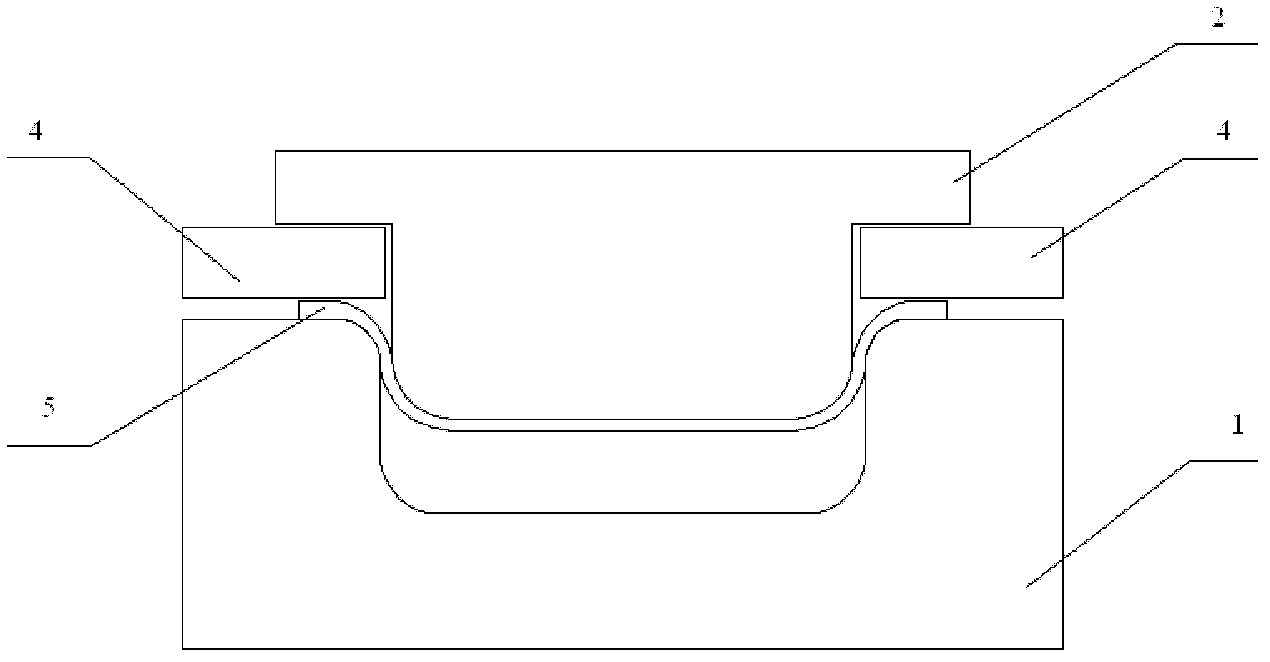

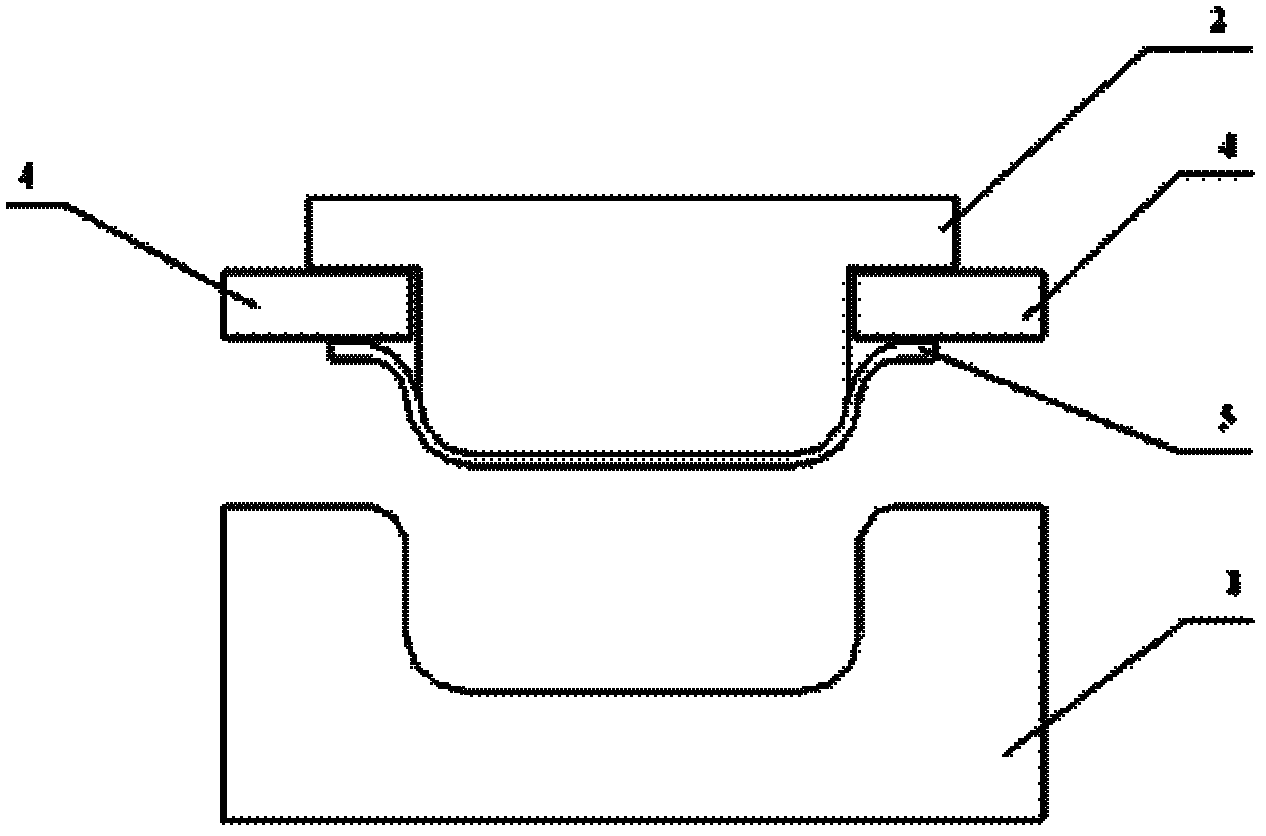

Cold-hot compound die molding method for aluminum alloy sheet metal component

ActiveCN102615201ADimensionally stableDimensional change, shape stability can be obtained directly through one-time formingShaping toolsMetalAluminium alloy

The invention discloses a cold-hot compound die molding method for an aluminum alloy sheet metal component, and relates to a molding method for a sheet metal component. The invention aims to solve the technical problems that the conventional hot-state molding method for the aluminum alloy sheet metal component is low in molding efficiency and can easily cause local crinkles and fractures, and provides the cold-hot compound die molding method for the aluminum alloy sheet metal component. The cold-hot compound die molding method comprises the following steps of: 1, heating a lower die to a temperature of between 200 and 900 DEG C; 2, placing an aluminum alloy plate blank on the lower die and heating the aluminum alloy plate blank to the deformation temperature of the aluminum alloy plate blank; 3, closing the die to press the aluminum alloy plate blank into the aluminum alloy sheet metal component; 4, separating the aluminum alloy sheet metal component, an upper die and a blank holder from the lower die; and 5, cooling the upper die and the blank holder, keeping the temperature for a certain period of time, and taking the aluminum alloy sheet metal component down to finish the cold-hot compound die molding of the aluminum alloy sheet metal component. According to the method, a cold-hot compound die in which the upper die is in a cold state and the lower die is in a hot state is adopted to mold the aluminum alloy sheet metal component. The cold-hot compound die molding method is suitable for making the aluminum alloy sheet metal component.

Owner:天津哈工永兴科技有限公司

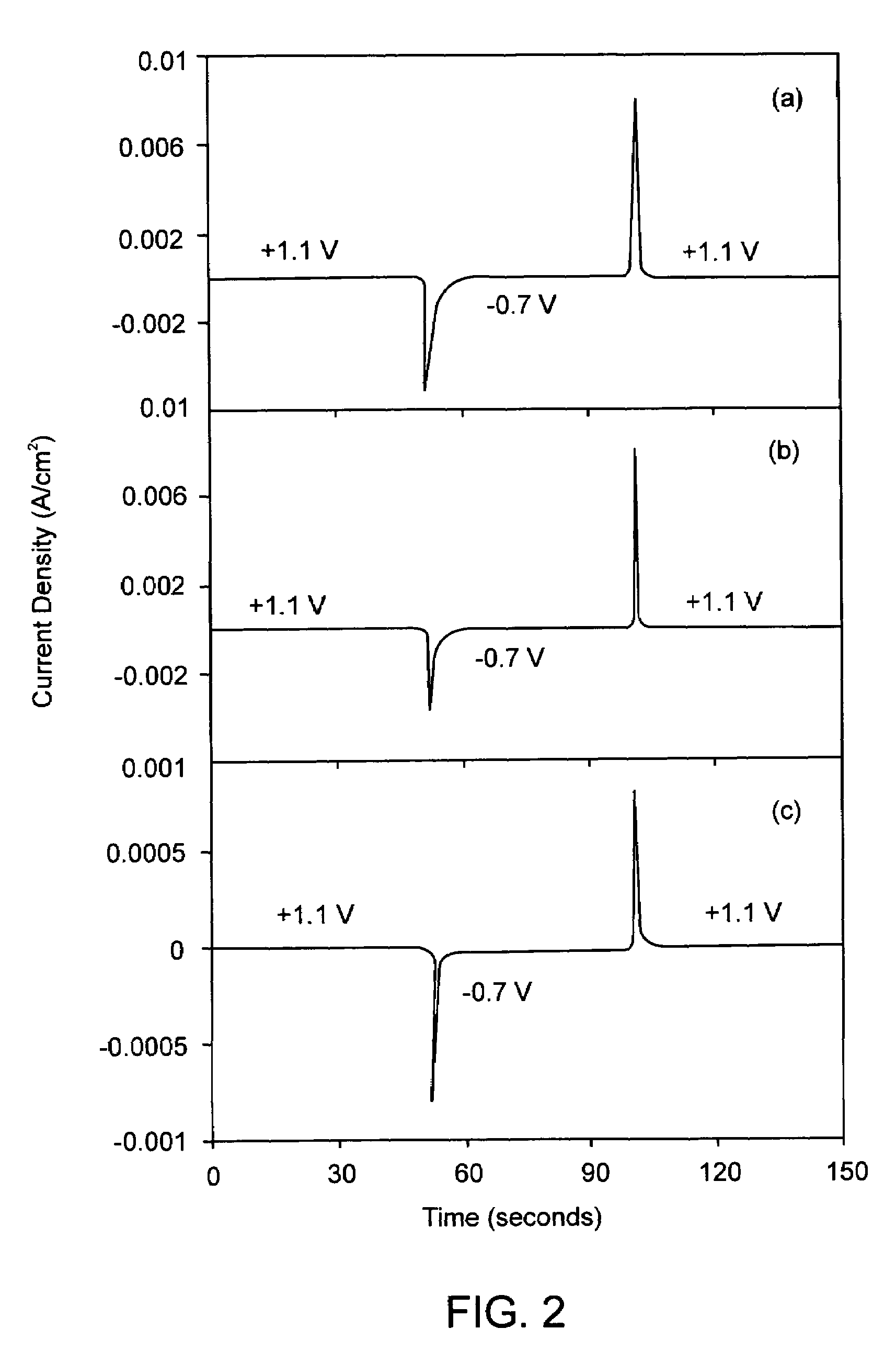

Electrochromic material

InactiveUS7333258B2Increased durabilityImprove stabilityConductive materialMetal/alloy conductorsOptoelectronicsElectrochromism

An electrochromic material having improved durability and more pleasing color characteristics is composed of a single-phase compound of formula W1−xTaxO3−x / 2, x having a value in a range of from about 0.15 to about 0.5. Thin films of the electrochromic material can be manufactured by pulse laser deposition (PLD). Thin films of the electrochromic material are useful in the fabrication of electrochromic devices, such as “smart” windows, mirrors, information displays and variable emittance surfaces.

Owner:NAT RES COUNCIL OF CANADA

Titania supports for fisher-tropsch catalysts

InactiveUS20070123594A1Suitable for preparationMaterial nanotechnologyLiquid hydrocarbon mixture productionTitanium dioxideHydrocarbon

A shaped catalyst carrier containing titania, wherein at least 50 wt % of the titania is present as brookite, and wherein the carrier has between 40 and 100 wt % of crystalline titania based on the total weight of the carrier. Also disclosed are catalyst or catalyst precursors formed from the shaped catalyst carriers described above, and a Group VIII metal or metal compound, and their use in the synthesis of hydrocarbons from carbon monoxide and hydrogen.

Owner:SHELL OIL CO

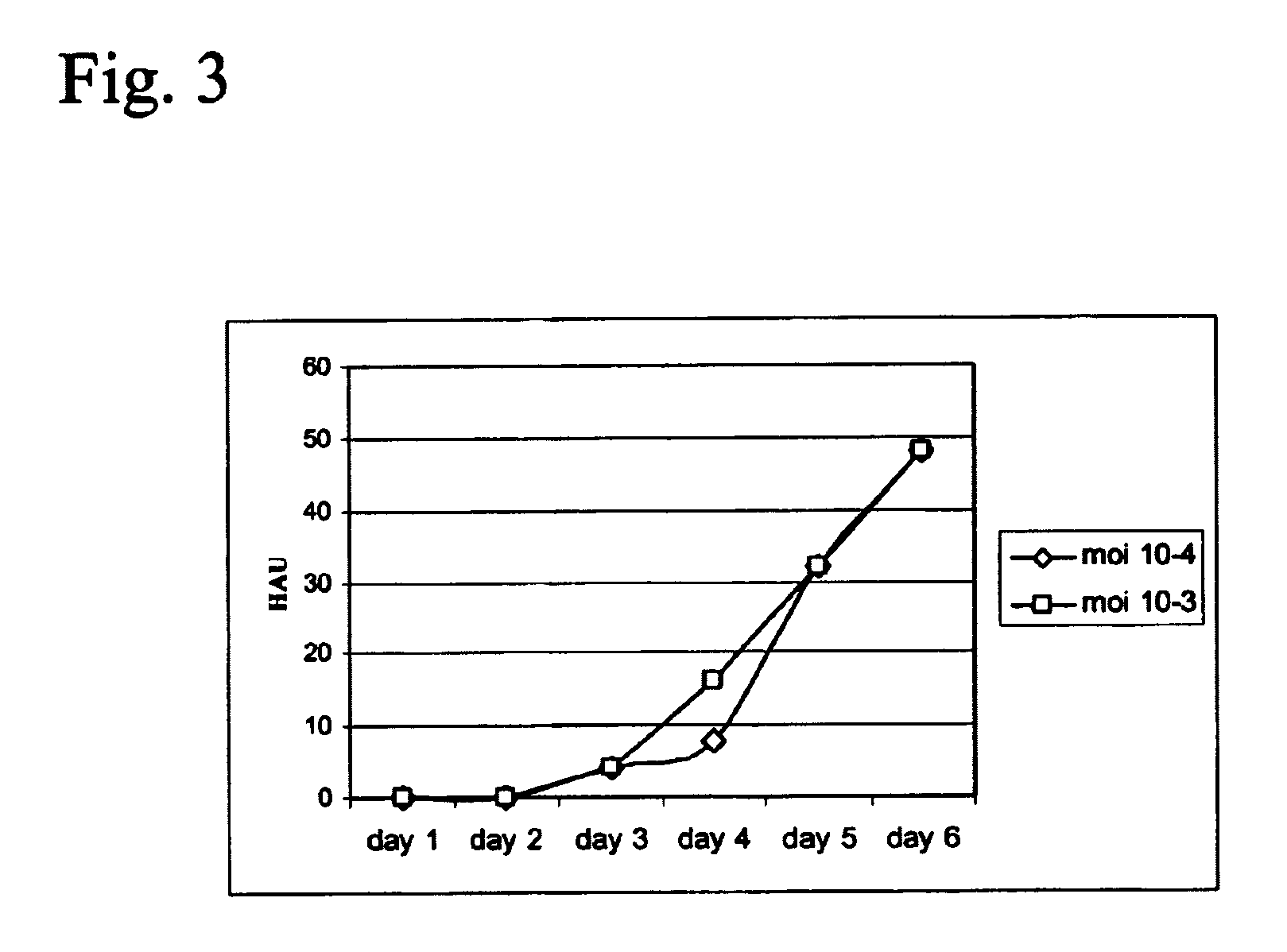

Production of vaccines

InactiveUS7192759B1Improve purification effectHigh yieldSsRNA viruses negative-sensePeptide/protein ingredientsSerum freeHuman cell

Novel means and methods are provided for the production of mammalian viruses comprising, infecting a culture of immortalized human cells with the virus, incubating the culture infected with virus to propagate the virus under conditions that permit growth of the virus, and to form a virus-containing medium, and removing the virus-containing medium. The viruses can be harvested and be used for the production of vaccines. Advantages are that human cells of the present invention can be cultured under defined serum free conditions, and the cells show improved capability for propagating virus. In particular, methods are provided for producing, in cultured human cells, influenza virus and vaccines derived thereof. This method eliminates the necessity to use whole chicken embryos for the production of influenza vaccines. The method provides also for the continuous or batchwise removal of culture media. As such, the present invention allows the large-scale, continuous production of viruses to a high titer.

Owner:JANSSEN VACCINES & PREVENTION BV

Spray casting-suction casting method and equipment for preparing large non crystal alloy

A spray casting-suction casing apparatus for preparing great non-crystal alloy block is composed of upper and lower furnace chambers, water-cooled partition between said chambers, heating body consisting of one Mo sheet layer and 6 reflecting screen layers, mould made of quartz glass or graphite arranged in said heating body and passing through said partition, U-shaped seals, plug pulling unit for the quartz glass (or graphit) plug of the circular hole on the bottom of mould, and water-cooled copper mould made of red copper.

Owner:UNIV OF SCI & TECH BEIJING

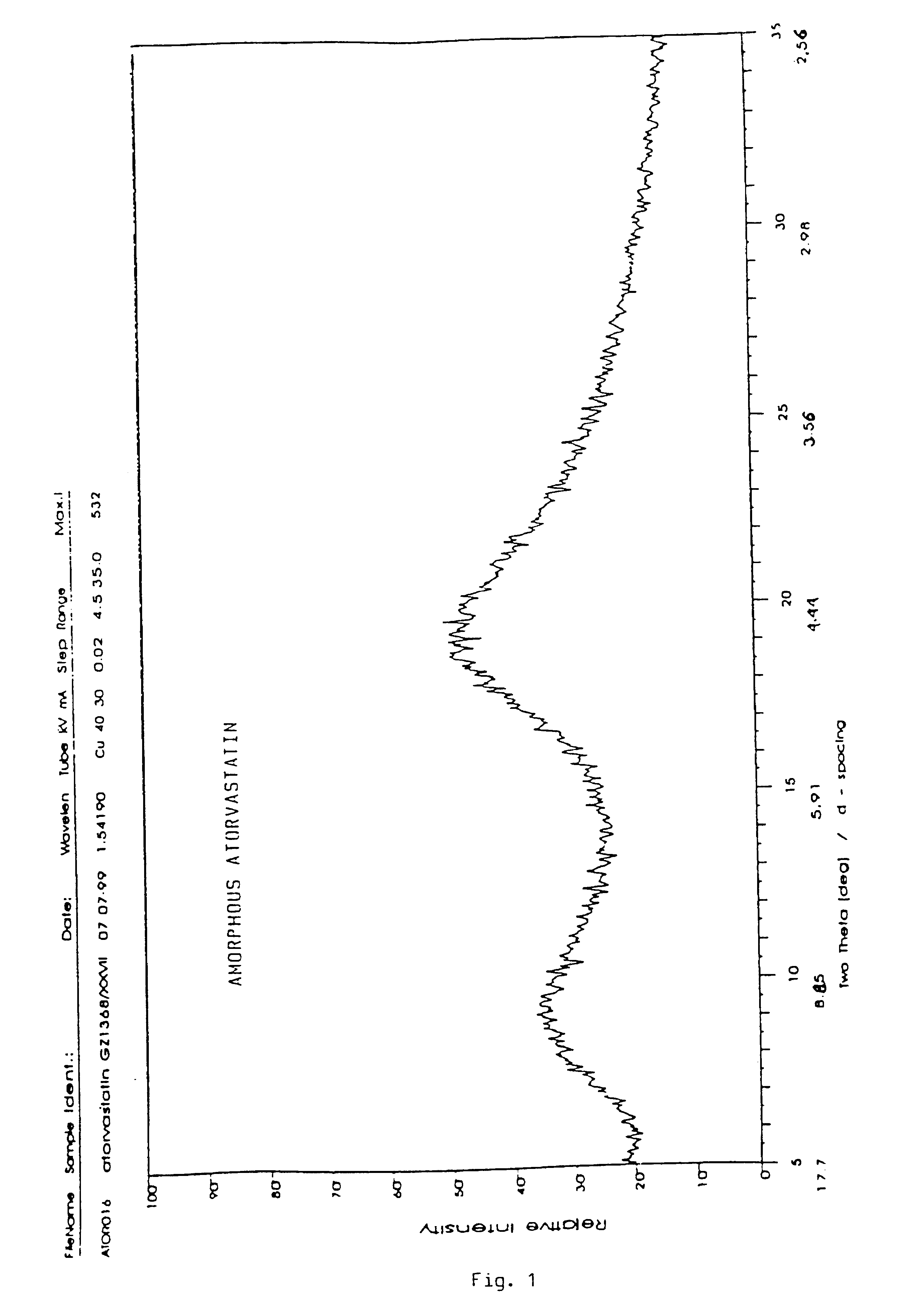

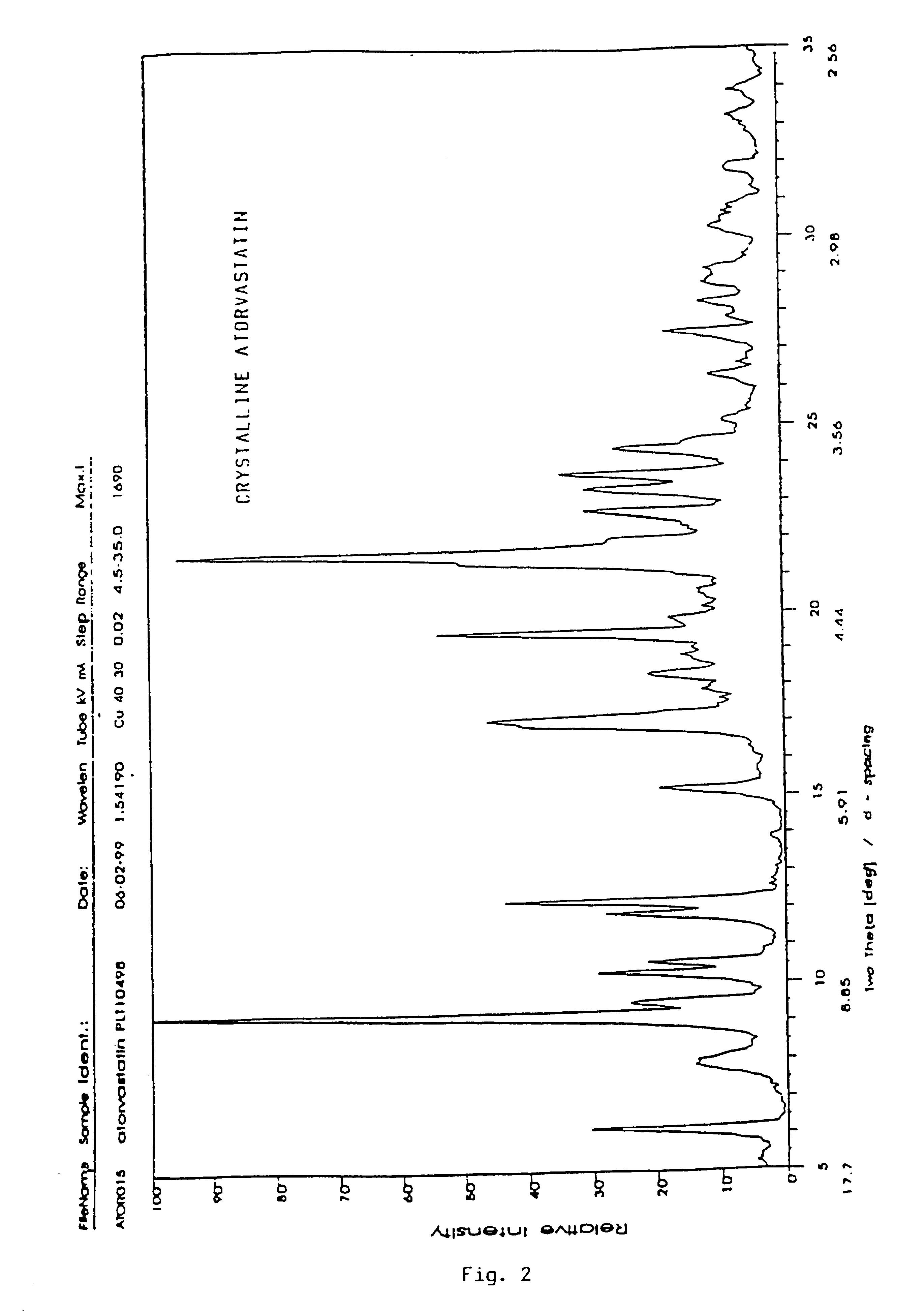

Process for the preparation of amorphous atorvastatin calcium

InactiveUS6646133B1Suitable for preparationShort timeOrganic chemistryOrganic solventSecondary hyperlipidemia

The invention relates to a process for the preparation of amorphous atorvastatin calcium by recrystallization of crude atorvastatin from an organic solvent which comprises dissolving crude amorphous atorvastatin calcium in a lower alkanol containing 2-4 carbon atoms or a mixture of such alkanols under heating and isolating the amorphous atorvastatin calcium precipitated after cooling. The atorvastatin calcium obtained is a known valuable agent useful in treating hyperlipidemia and hypercholestrolemia.

Owner:EGIS GYOGYSZERGYAR NYILVANOSAN MUKODO RESZVENY TARSASAG

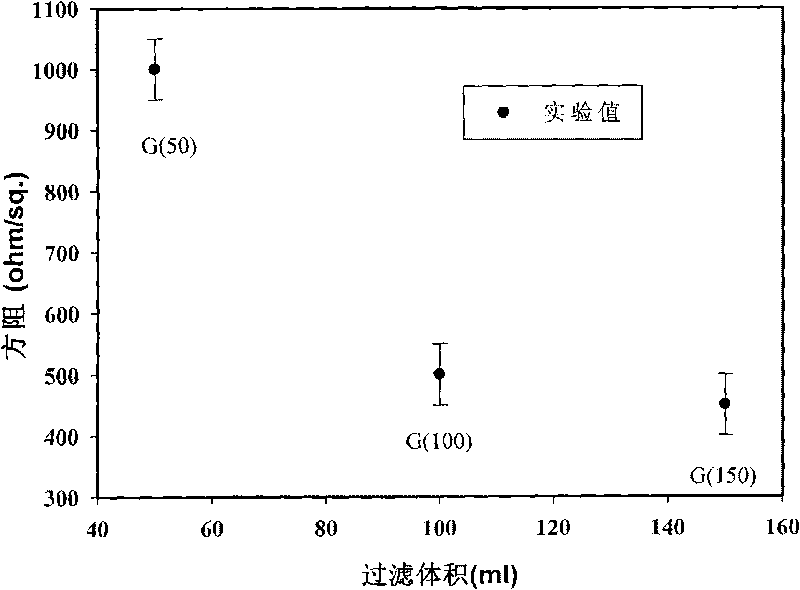

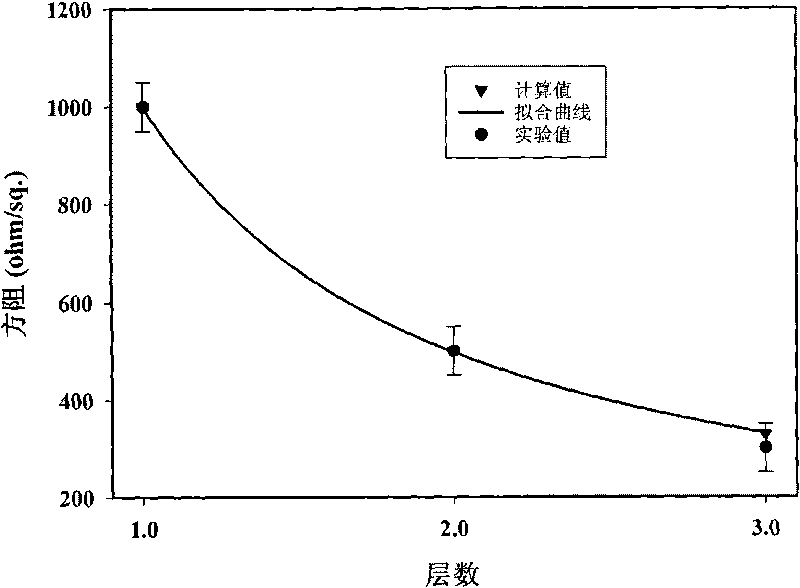

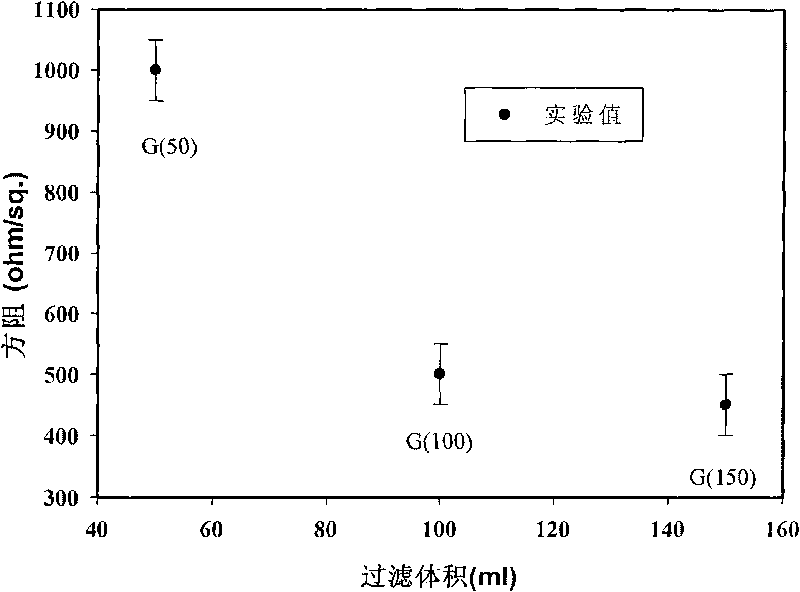

Preparation method for laminated graphene conductive film

InactiveCN101702345AReduce sheet resistanceImprove conductivityConductive layers on insulating-supportsCable/conductor manufactureElectrical resistance and conductanceConductive polymer

A preparation method for laminated graphene conductive film belongs to the technical field of nano-zided photoelectric material. The invention in particular relates to a graphene film with wetting reduction oxidation at the temperature of 60-200 DEG C and a preparation method for forming film through lamination several times. The laminated reduction-oxidation graphene film provided by the invention has the following advantages: (1) the utilization rate of raw material is high; (2) the reduction temperature is moderate; (3) the electric conductivity is high; (4) the square resistance is low and controllable; (5) the cost is low. The invention is widely applied to organic photoelectric functional devices such as organic electroluminescent display, organic electric storage and artificial muscle; and the film is expected to become a novel conductive film in place of the ITO and conductive polymer film applied to flexible device.

Owner:南京南工维明新材料科技有限公司

Multilayered, transparent articles and a process for their preparation

InactiveUS20060199871A1Improve claritySuitable for preparationBottlesSynthetic resin layered productsPolyesterPolymer science

Disclosed is a process for the preparation of multilayered, shaped articles having high transparency and low haze and comprising one or more thermoplastic polymers selected from polyesters, polycarbonates, and polyarylates, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The thermoplastic polymer components and the polyamide components have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into one or more of the layers of the article while maintaining high clarity. These articles can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into one or more layers to impart oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

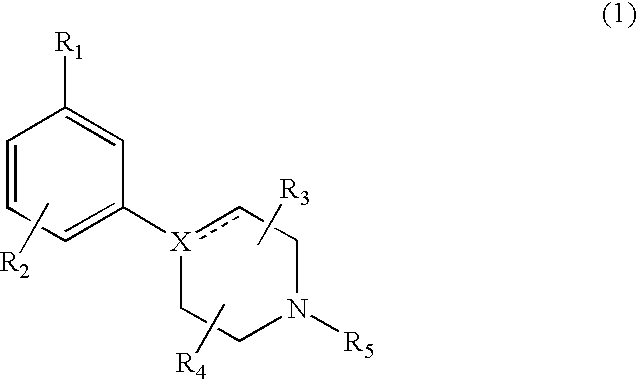

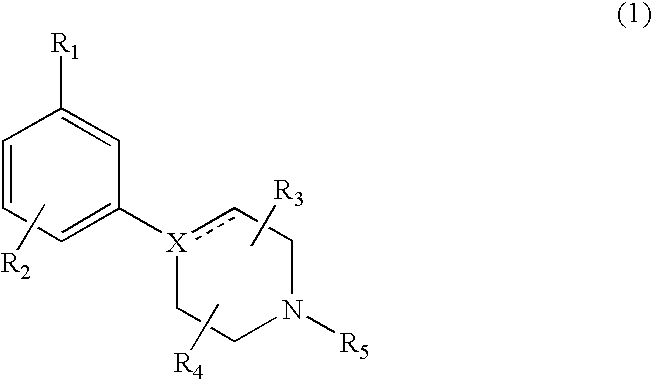

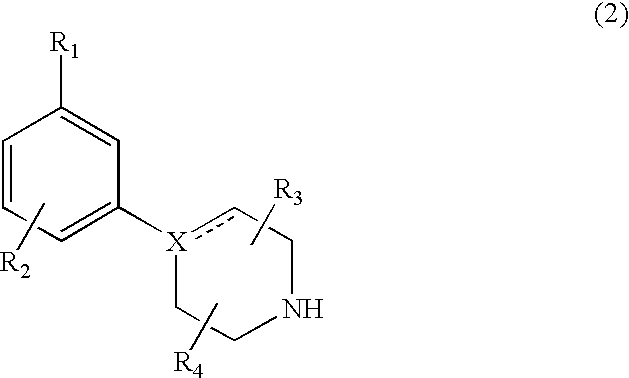

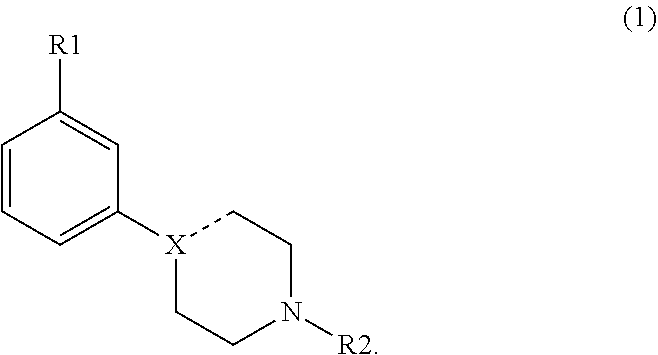

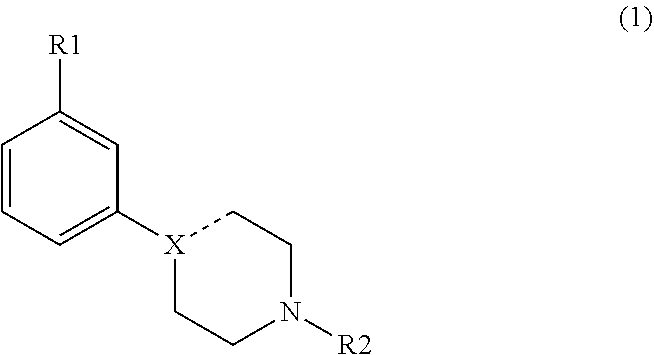

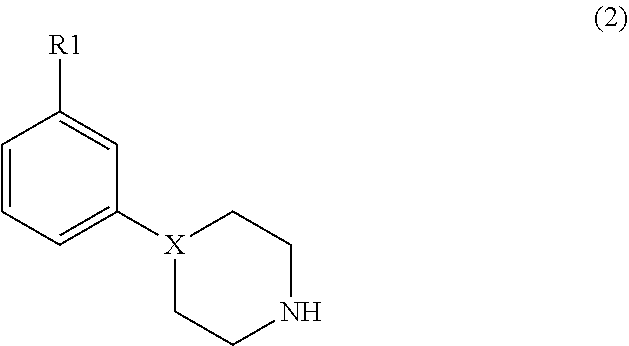

Modulators of dopamine neurotransmission

InactiveUS6924374B2Improve mental and motor functionAmeliorate tremorBiocideNervous disorderCPR - Cardiopulmonary resuscitationCentral nervous system

New 3-substituted 4-(phenyl-N-alkyl)-piperazine and 4-(phenyl-N-alkyl)-piperidine compounds of Formula (1) wherein X is N, CH, or C, however X may only be C when the compound comprises a double bind at the dotted line; R1 is CF3, OSO2CF3, OSO2CH3, SOR7, SO2R7, COR7, CN, OR3, NO2, CONHR3, 3-thiophene, 2-thiophene, 3-furane, 2-furane, F, Cl, Br, or I; R2 is F, Cl, Br, I, CN, CF3, CH3, OCH3, OH, and NH2; R3 and R4 are independently H or a C1-C4 alkyl; R5 is a C1-C4 alkyl, an allyl, CH2SCH3, CH2CH2OCH3, CH2CH2CH2F, CH2CF3, 3,3,3-trifluoropropyl, 4,4,4-trifluorobutyl, or —(CH2)R6; R6 is a C3-C6 cycloalkyl, 2-tetrahydrofurane, or 3-tetra-hydrofurane; R7 is a C1-C3 alkyl, CF3, or N(R4)2, and pharmaceutically acceptable salts thereof are disclosed. Also pharmaceutical compositions comprising the above compounds and methods wherein the above compounds are used for treatment of disorders in the central nervous system are disclosed.

Owner:NSAB FILIAL AF NEUROSEARCH SVERIGE

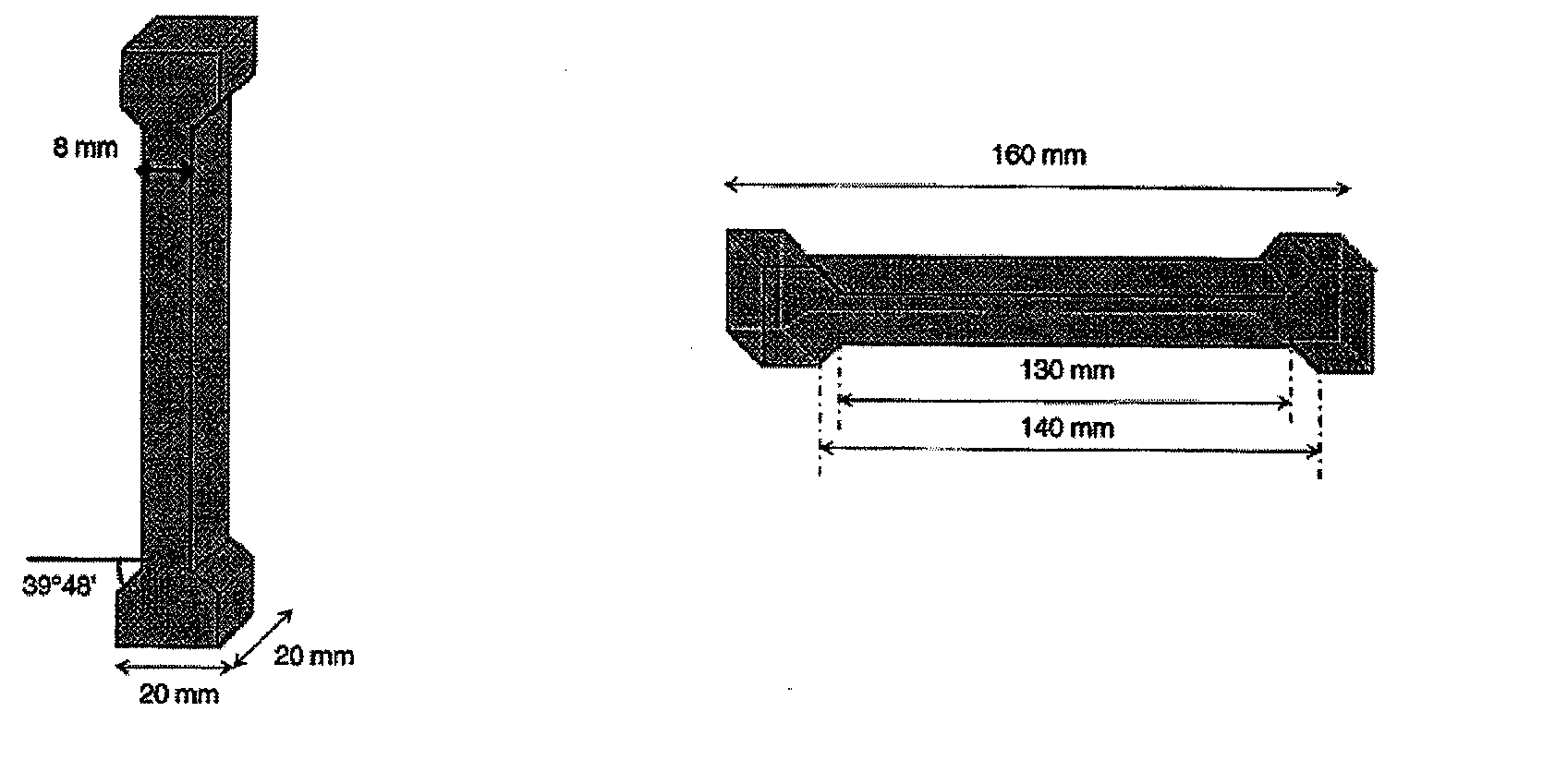

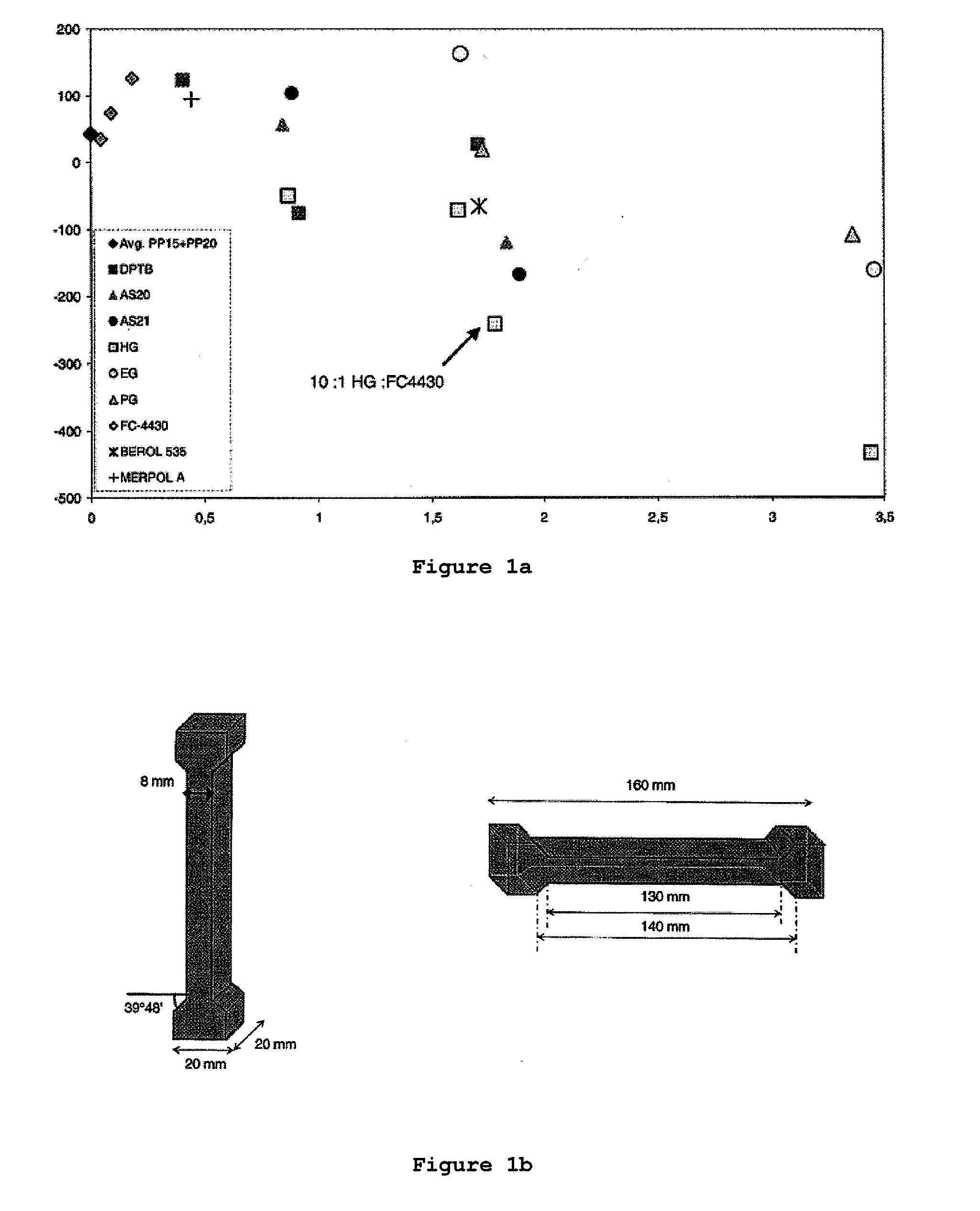

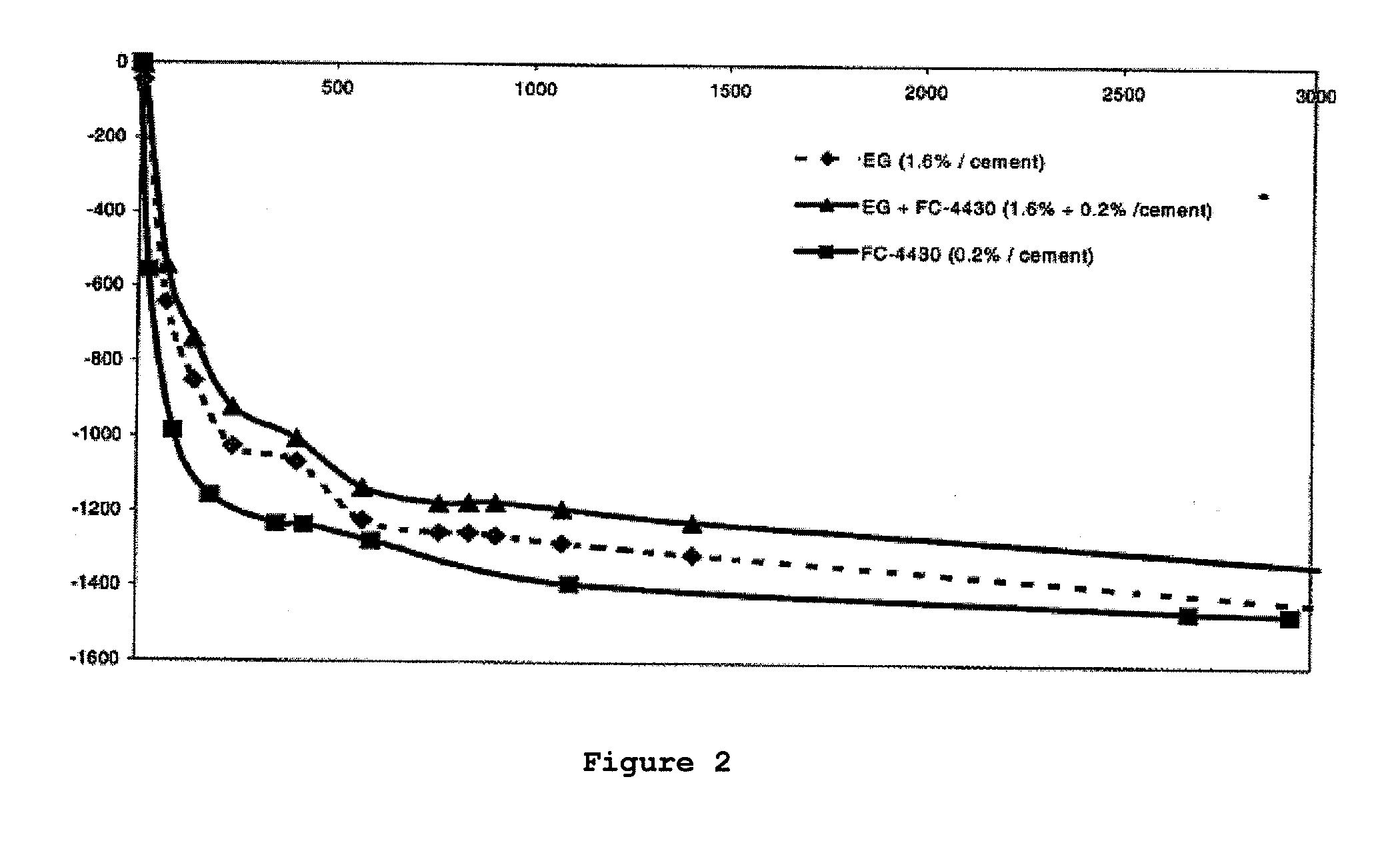

Cement shrinkage reducing agent and method for obtaining cement based articles having reduced shrinkage

InactiveUS20080087199A1Reduce surface tensionReduce Shrinkage ProblemsFluorosurfactantSurface tension

The invention relates to a composition comprising a hydraulic binder, a low molecular weight glycol having the formula CnH2n(OH)2 wherein n is an integer from 2 to 10, preferably 2 to 9, and a fluorinated surfactant capable of reducing the surface tension of pure water to a value below 30 mN / m at a concentration of 1% or less. The invention also relates to a wet mortar or concrete composition comprising a hydraulic binder, a low molecular weight glycol having the formula CnH2n(OH)2 wherein n is an integer from 2 to 10, preferably 2 to 9, and a fluorinated surfactant capable of reducing the surface tension of pure water to a value below 30 mN / m at a dosage of 1% or less, water and sand and / or aggregates and / or fillers. The invention also relates to a method for preparing same.

Owner:LAFARGE SA

Modulators of dopamine neurotransmission

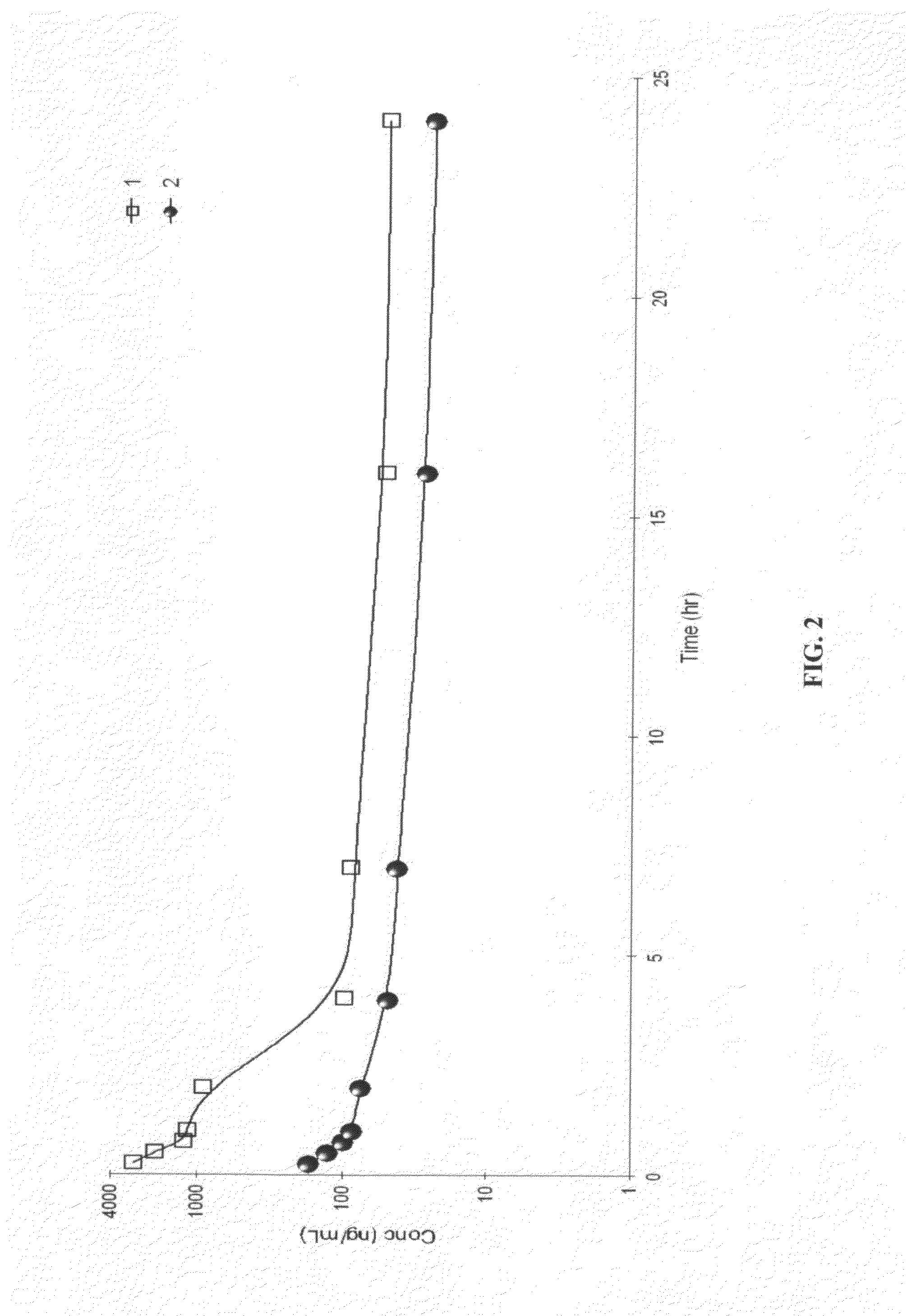

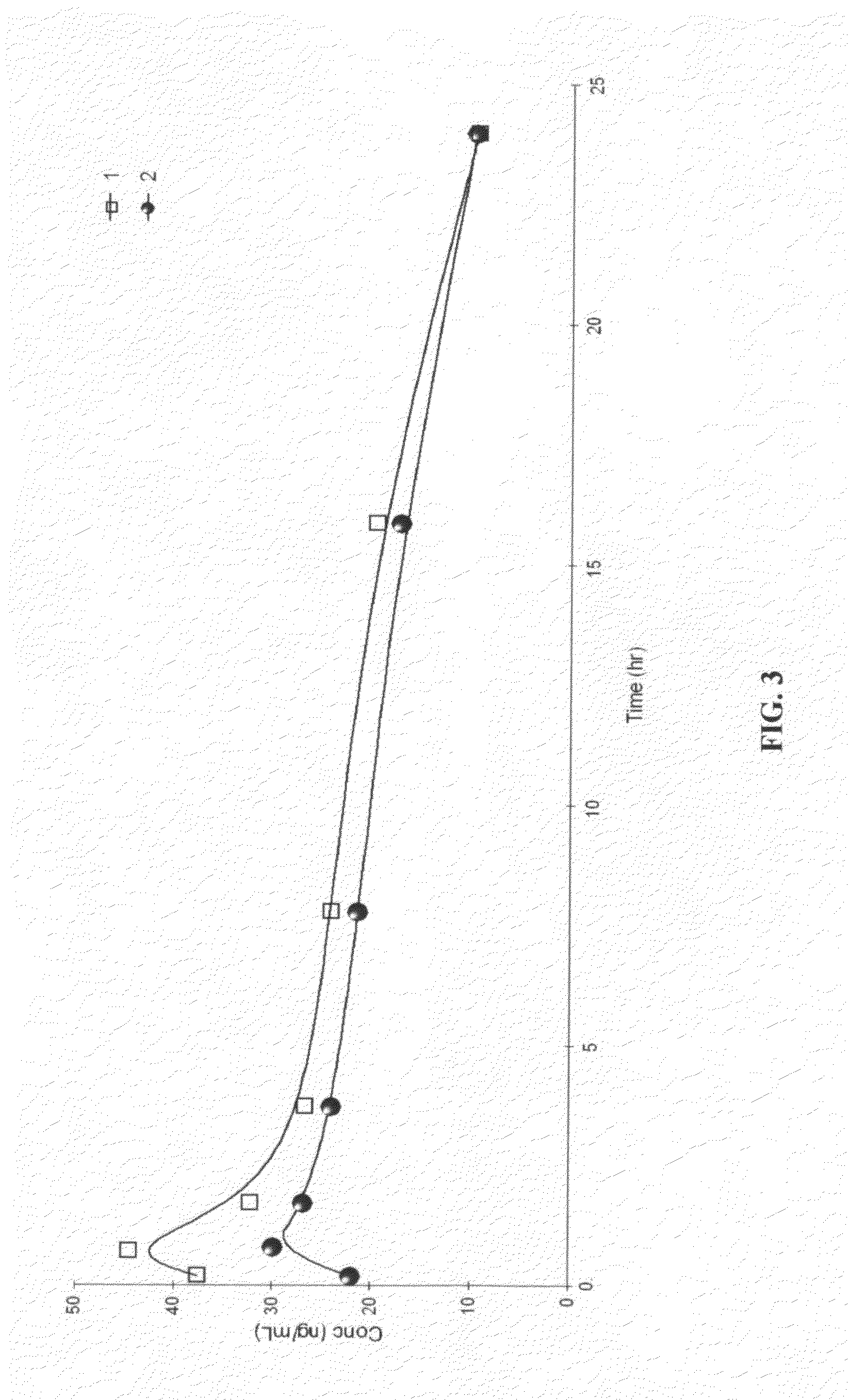

InactiveUSRE46117E1Good effectImproved pharmacokinetic propertiesOrganic chemistryDouble bondDopamine neurotransmission

New 3-substituted 4-(phenyl-N-alkyl)-piperazine and 4-(phenyl-N-alkyl)-piperidine compounds of Formula (1), wherein X N, CH, or C, however X may only be C when the compound comprises a double bond at the dotted line; R1 is OSO2CF3, OSO2CH3, SOR3, SO2R3, COR3, NO2, or CONHR3 and when X is CH or C R1 may also be CF3, CN, F, Cl, Br, or I; R2 is a C1-C4 alkyl, an allyl, CH2SCH3, CH2CH2OCH3, CH2CH2CH2F, CH2CF3, 3,3,3-trifluoropropyl, 4,4,4,-trifluorobutyl, or —(CH2)—R4; R3 is a C1-C3 alkyl CF3, or N(R2)2; R4 is a C3-C6 cycloalkyl, 2-tetrahydrofurane or 3-tetra-hydrofurane, as well as pharmaceutically acceptable salts thereof are disclosed. Also pharmaceutical compositions comprising the above compounds and methods wherein the above compounds are used for treatment of disorders in the central nervous system are disclosed

Owner:PRILENIA NEUROTHERAPEUTICS LTD

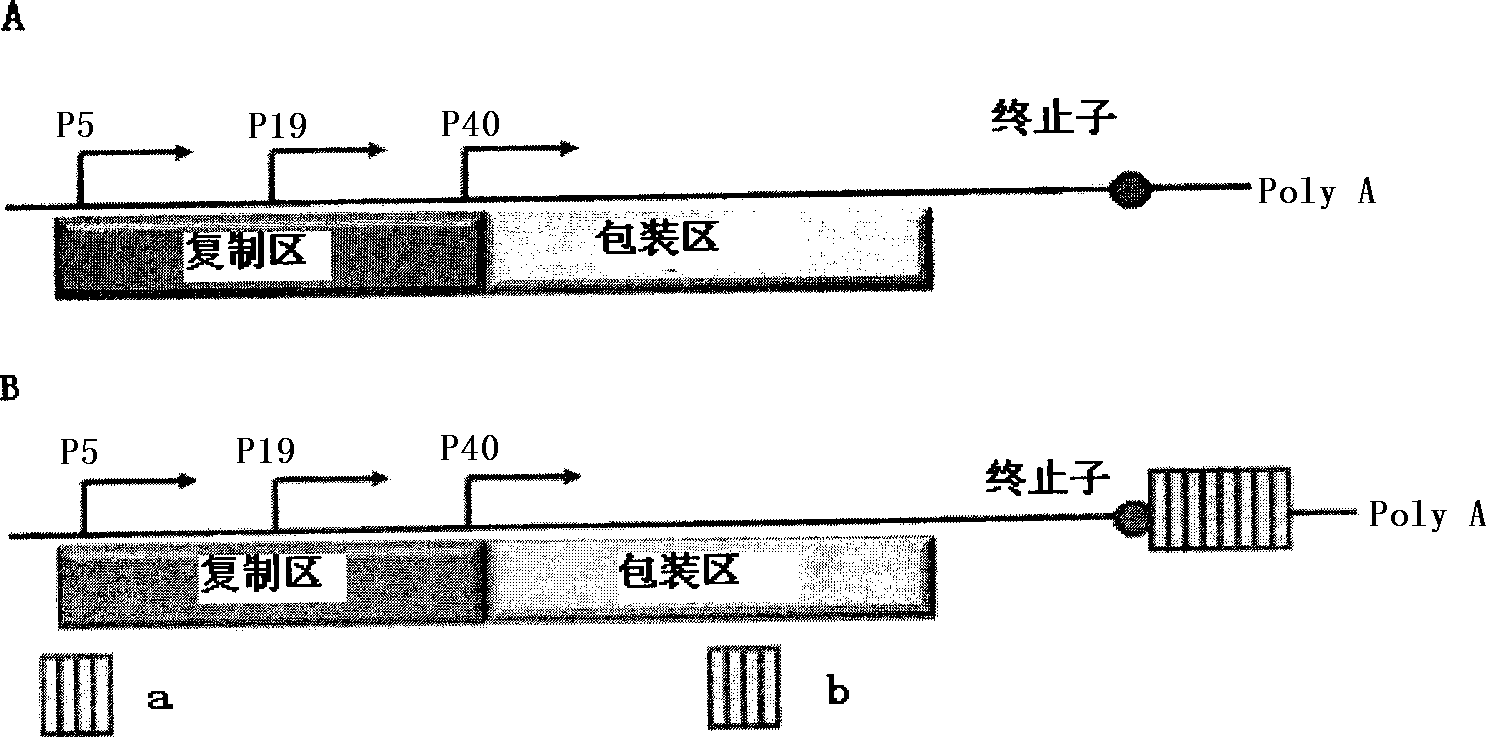

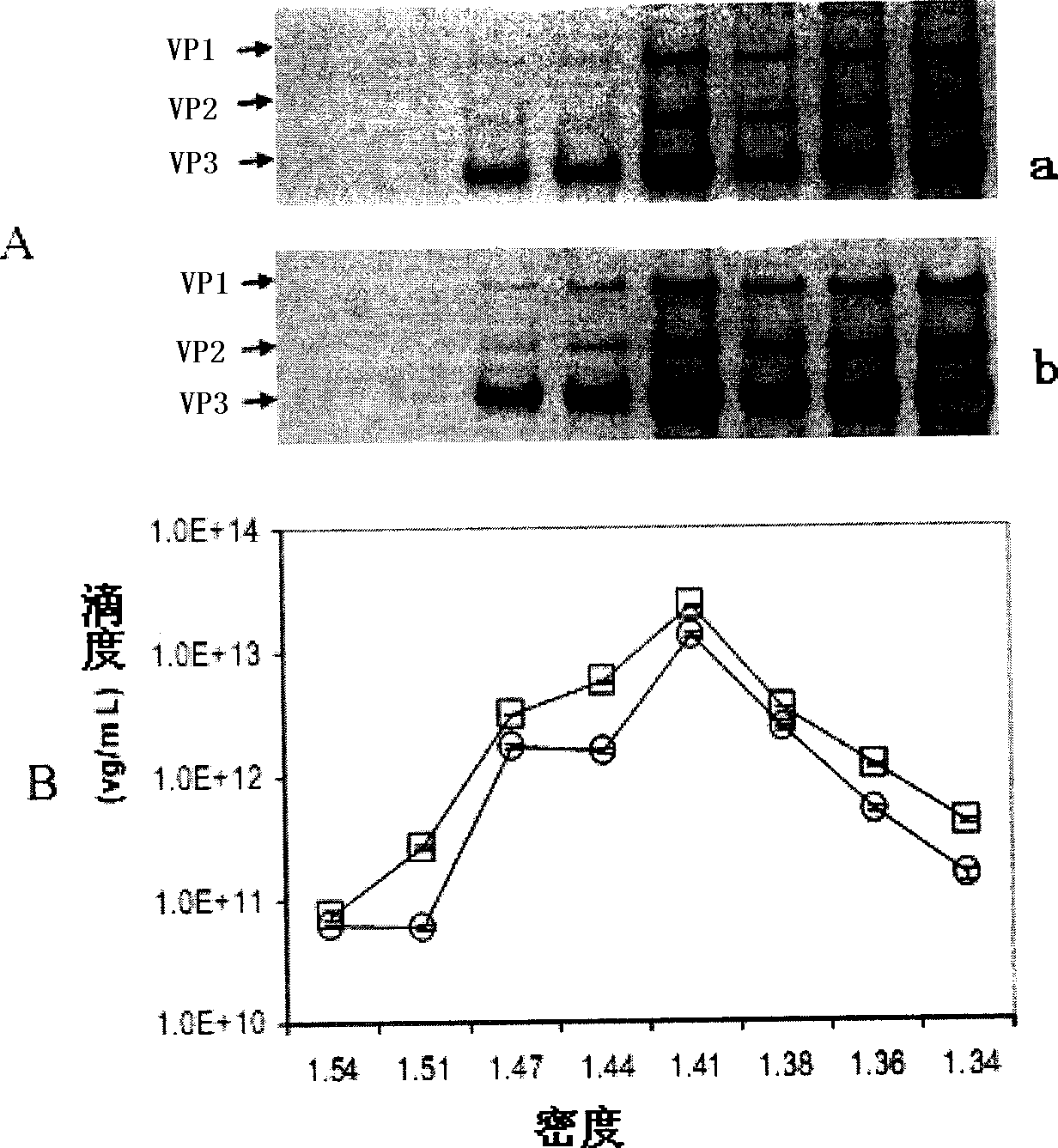

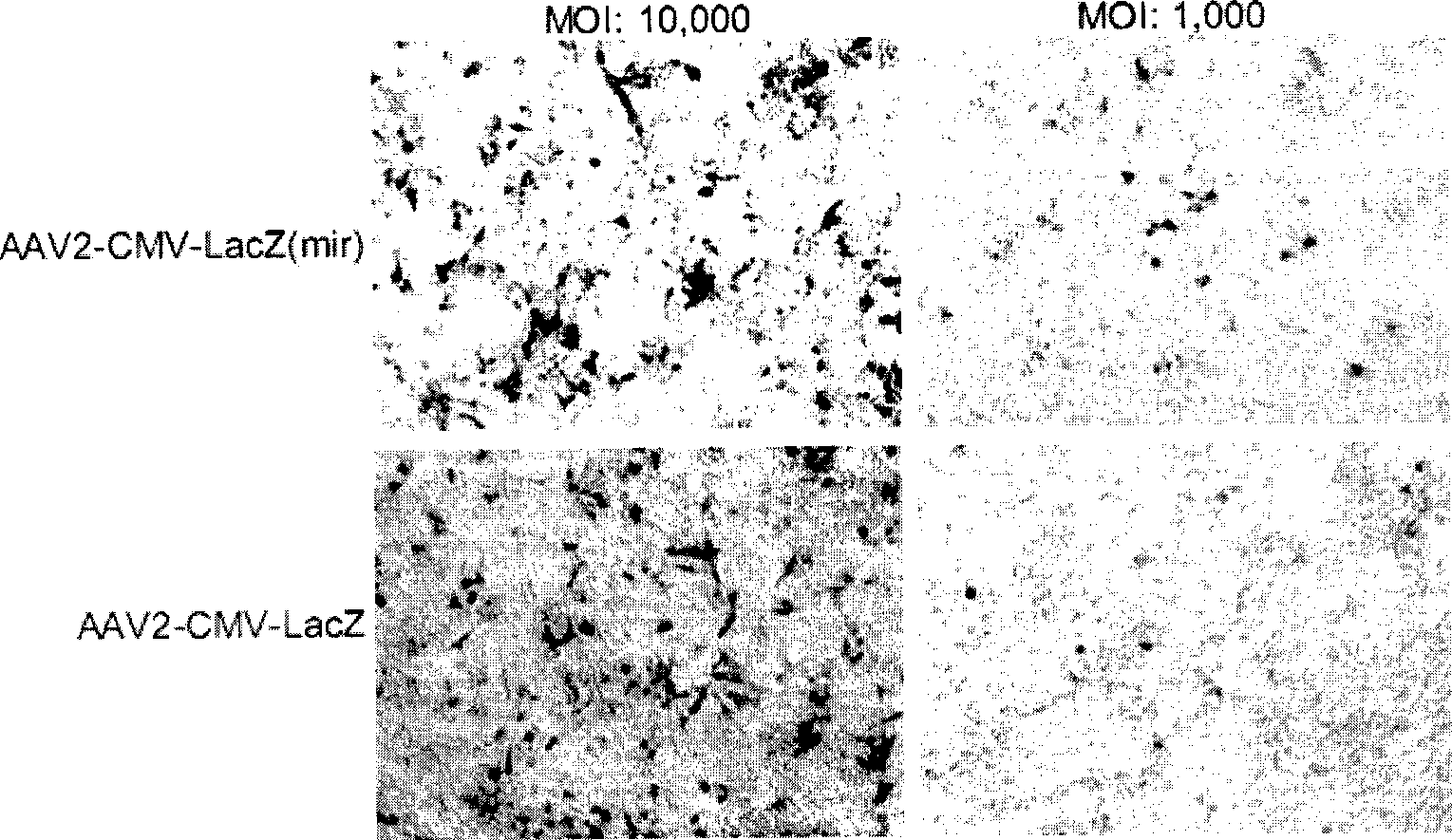

New type cell special gene HAAVmir containing microRNA combined sequence for gene treating

InactiveCN101532024ADoes not affect appearanceDoes not affect productivityGenetic material ingredientsMicroorganism based processesMicroRNACell strain

Owner:许瑞安 +2

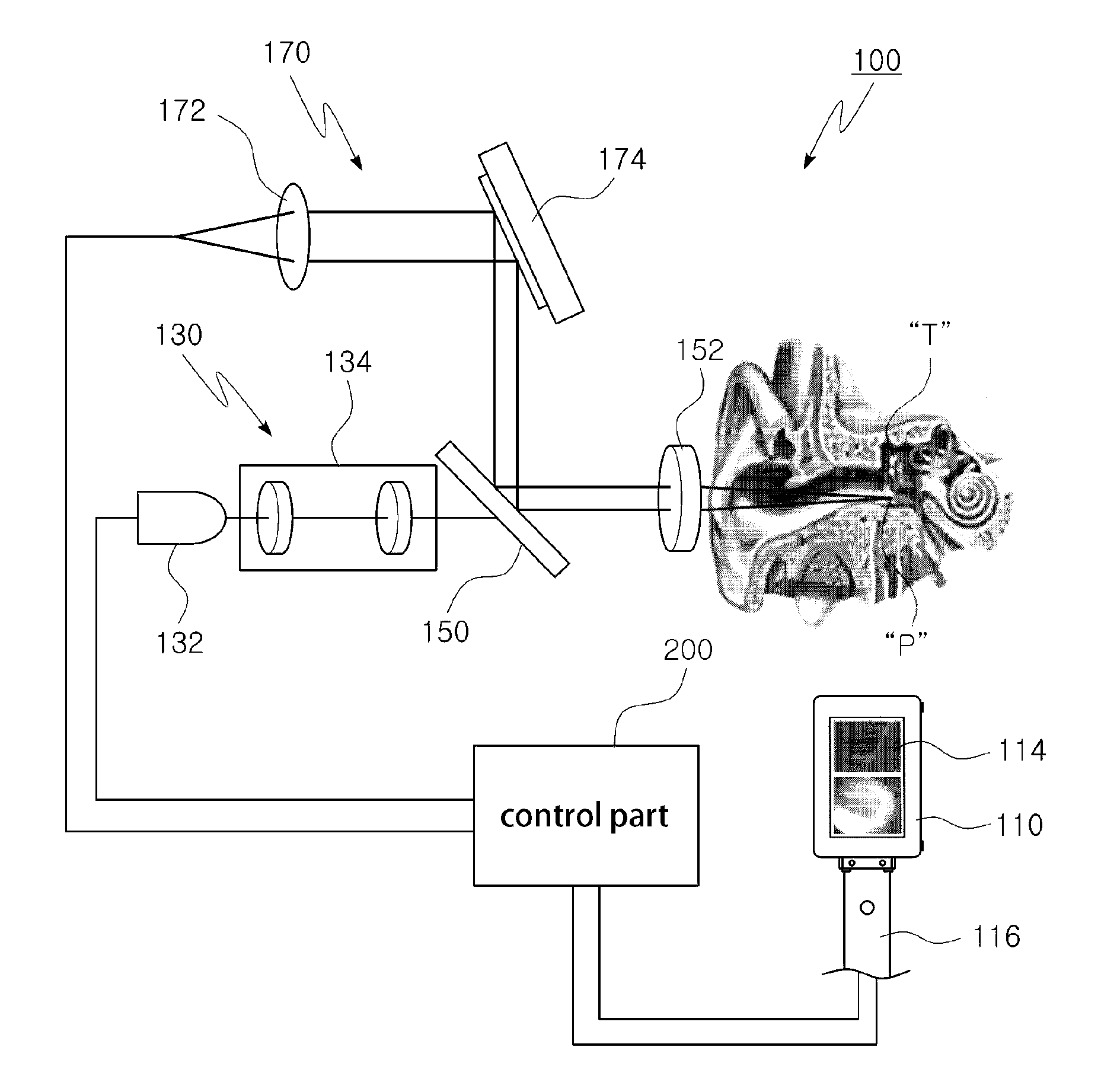

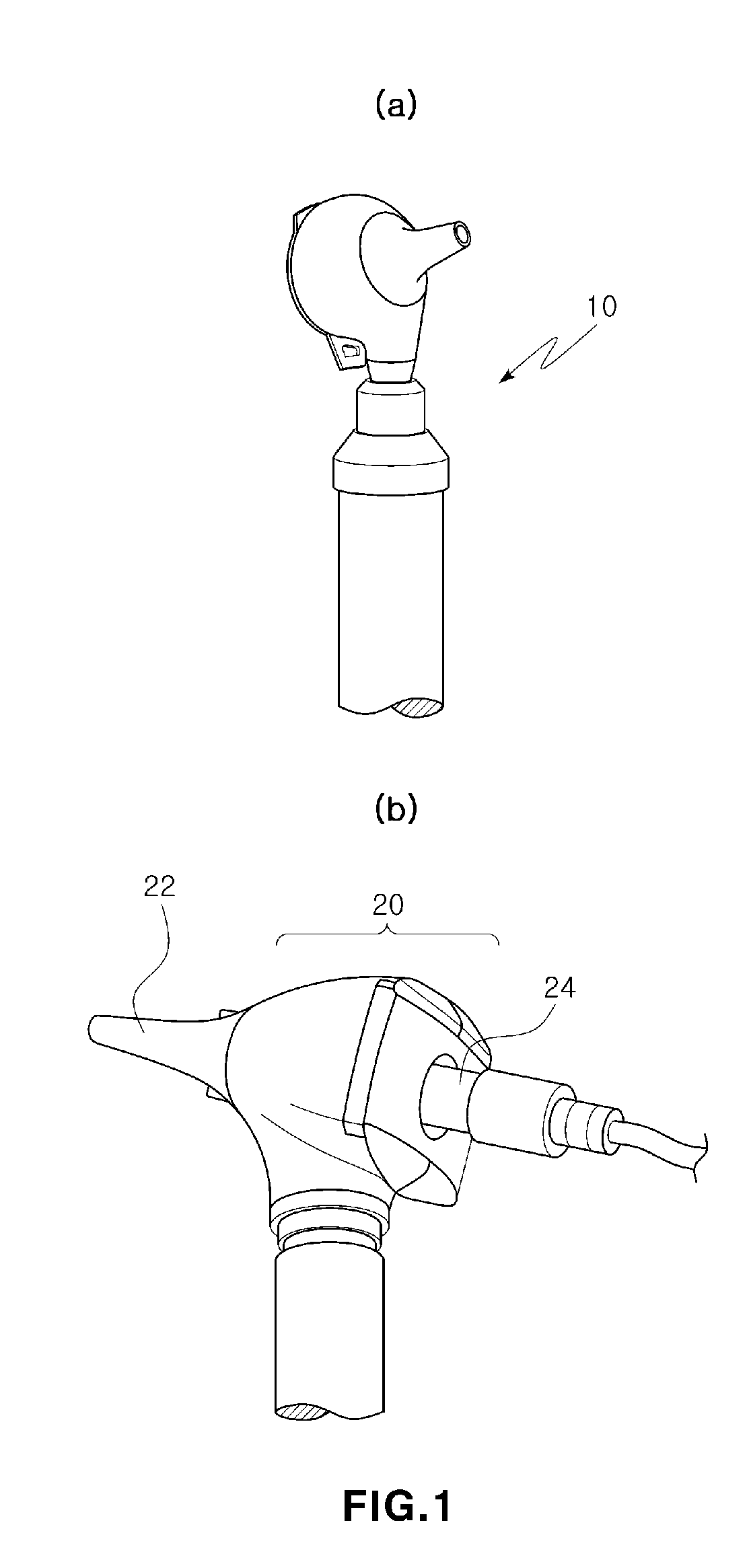

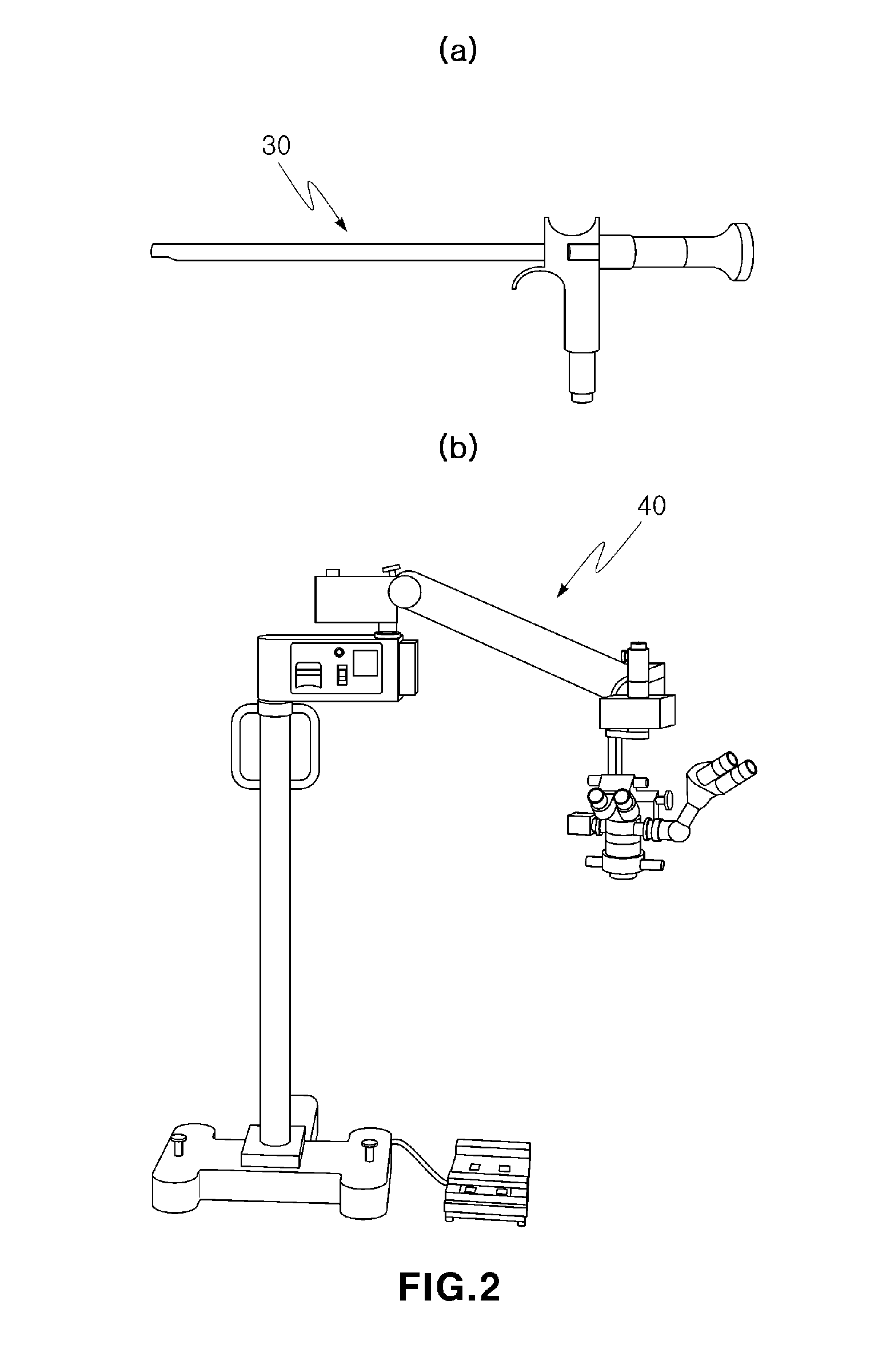

Optical tomographic imaging otoscope with integrated display and diagnosis

InactiveUS20140012141A1High resolutionSimplify disease-diagnosing procedureOtoscopesEndoscopesOtoscopeDisplay device

A diagnosis-and-display integrated optical tomographic imaging otoscope for examining otitis media. A hollow casing includes an ear specular disposed on a front surface, a display including an LCD disposed on a rear surface, and a manipulating handle on a lower part. An image-photographing part includes a CCD camera inside the casing, and photographs an ear drum image of a patient through the ear specular. A section-photographing part includes a collimator and a galvanometer mirror inside the casing, and photographs section images of the ear drum and a middle ear of the patient. The ear drum image obtained by the image-photographing part and the section images of the ear drum and the middle ear are obtained in a non-incision method by the section-photographing part, and are displayed in real time on the LCD such that desirable images can be stored.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

Crosslinkable substances based on organosilicon compounds

InactiveUS20070244230A1Simplify preparationSimple handlingSilicon organic compoundsGroup 5/15 element organic compoundsHydrogen atomHeteroatom

The present invention relates to substances, crosslinkable by attachment of an Si-bonded hydrogen atom to an aliphatic multiple bond, which comprise at least one compound of the formulaR3P(O)(OH)2 (III)and / or the derivatives thereof,R3 being an optionally substituted hydrocarbon radical which can be interrupted by heteroatoms.

Owner:WACKER CHEM GMBH

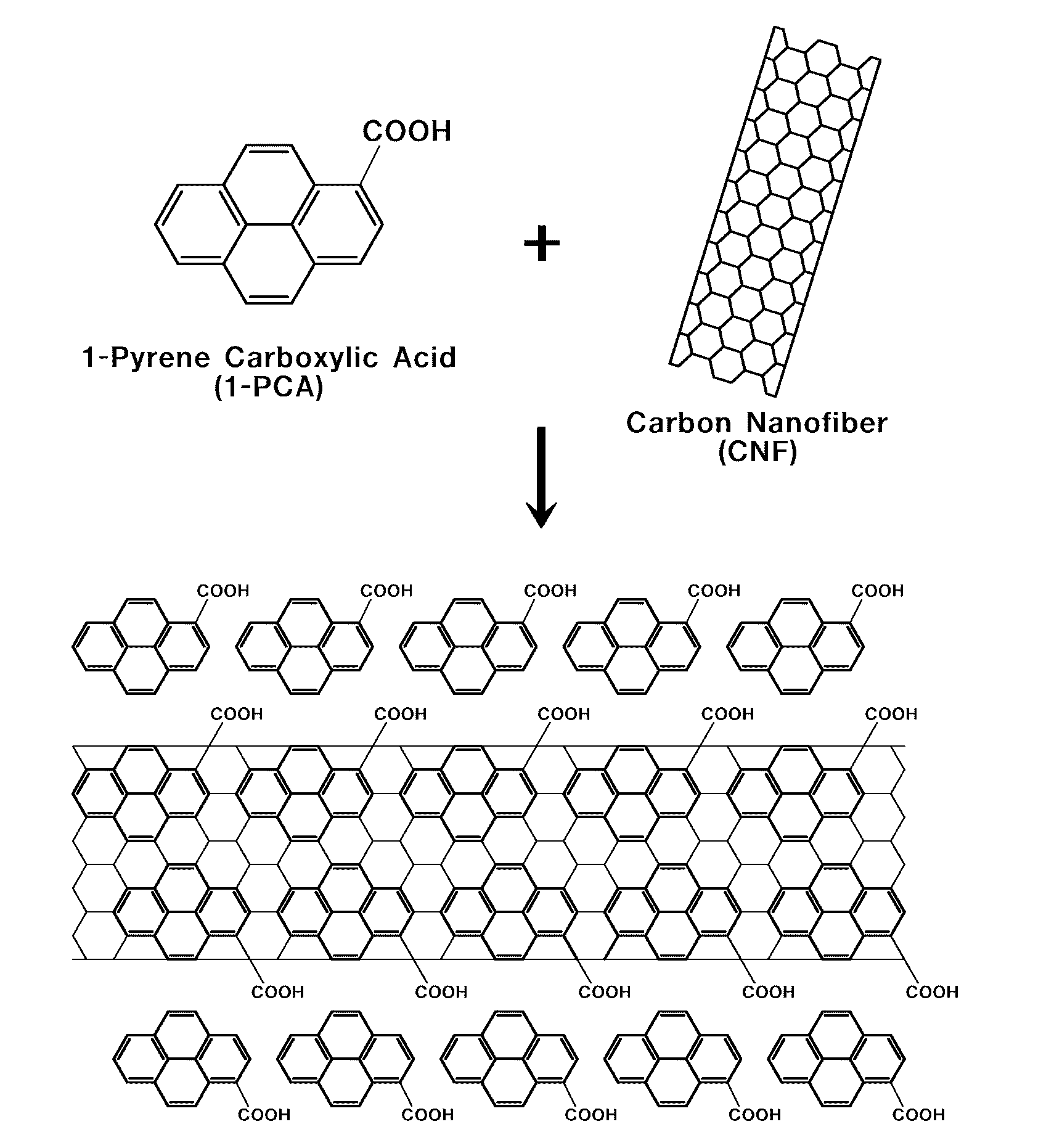

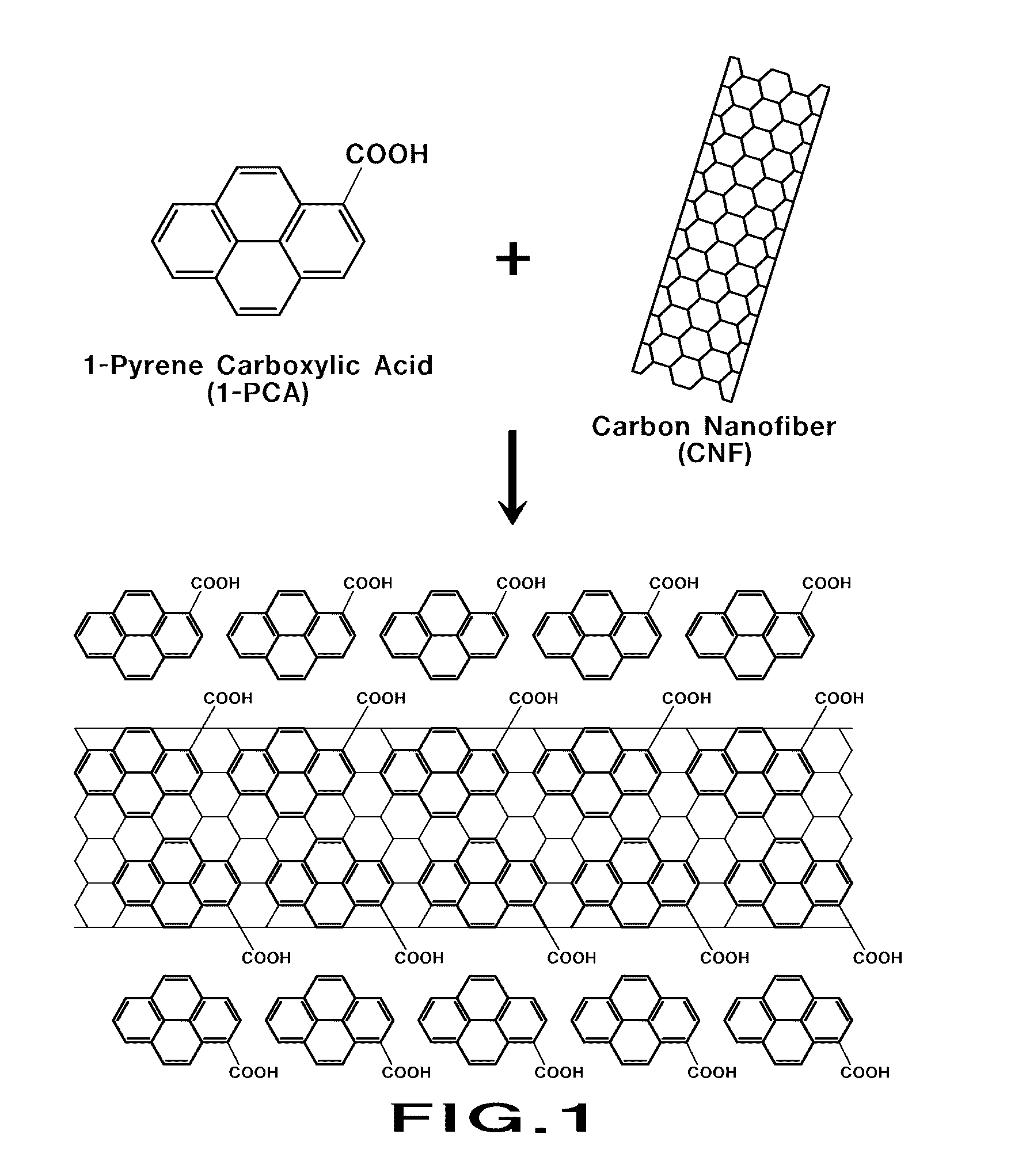

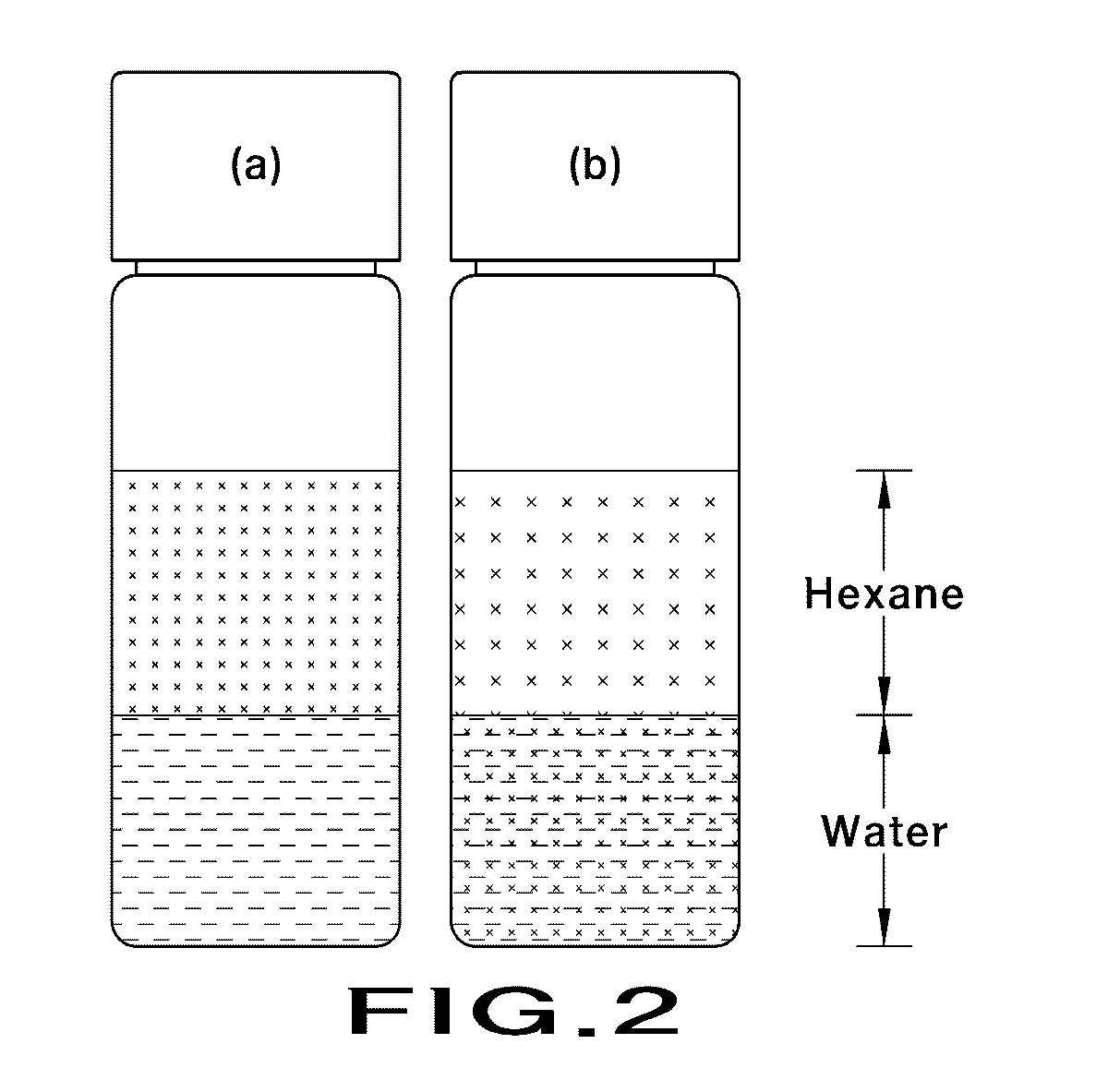

Method of increasing hydrophilic property of crystalline carbon using surface modifier and method of preparing platinum catalyst using the same

InactiveUS20110129762A1Improve hydrophilicitySuitable for preparationMaterial nanotechnologyOrganic chemistryChemistryElectrode material

The present invention features a method for increasing hydrophilic properties of crystalline carbon using a surface modifier and a method for preparing a Pt / C catalyst using the same. In certain preferred embodiments, the present invention features a method for increasing hydrophilic properties of crystalline carbon having water repellency by forming π-π interaction between the surface of the crystalline carbon and a surface modifier and a method for preparing a catalyst by supporting platinum (Pt) on the crystalline carbon having increased hydrophilic property. The Pt / C catalyst prepared by the methods of the present invention is useful for the preparation of electrode materials for fuel cells.

Owner:HYUNDAI MOTOR CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com