Preparation method for laminated graphene conductive film

A graphene film, laminated graphene technology, applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of low utilization rate of raw materials, high heat treatment temperature, poor reduction effect, etc. High efficiency, mild reduction temperature, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The preparation method of low sheet resistance reduced graphene oxide conductive film.

[0033] Graphene oxide preparation: 2.5g graphite, 1.9g NaNO 3 , 11.5g KMnO 4 and 85ml concentrated H 2 SO 4 After mixing, stir in an ice bath for 1 hour, then stir at room temperature for 2 days, and finally add 250ml of 5wt%-1-concentrated sulfuric acid and 20ml of 30wt% H 2 o 2 Continue to stir for 2 days, centrifuge, and wash with deionized water, repeating this 3 times to obtain graphene oxide.

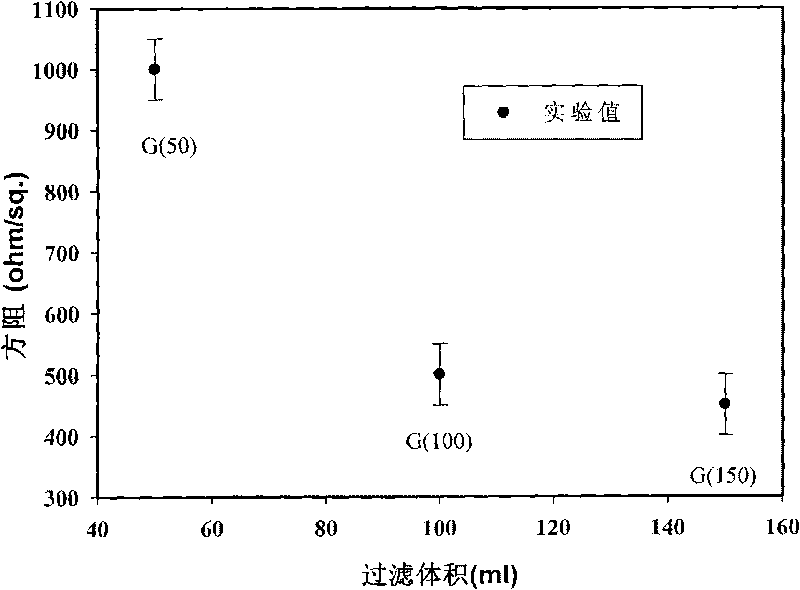

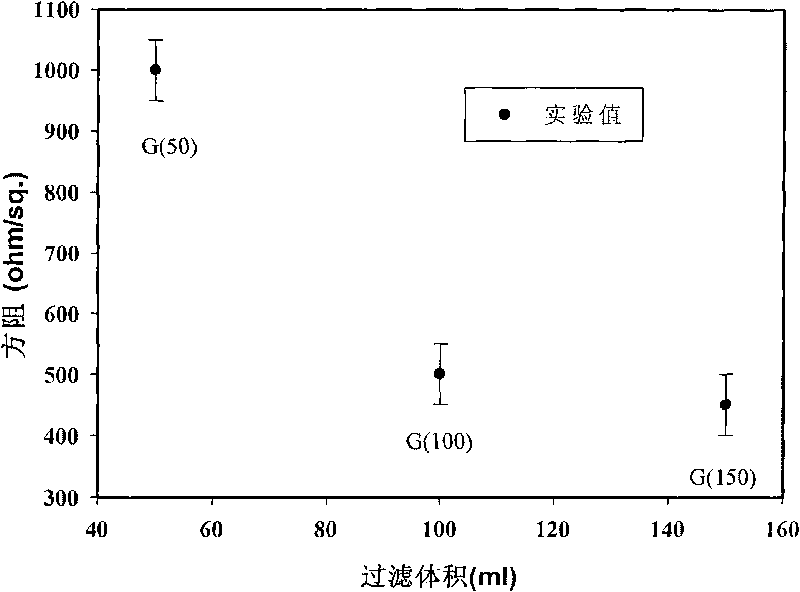

[0034] Preparation and reduction of graphene oxide film: prepare 0.05mg / ml graphene oxide ultrasonic dispersion, and then centrifuge to remove a small amount of large particles. First take 50ml, 100ml, and 150ml of the above solutions to prepare films by vacuum filtration, denoted as G(50), G(100), and G(150), and transfer 4 equal parts of each filter film to a glass substrate. Then select HydraVer 2 hydrazine as a strong reducing agent and wet the surface of the gra...

Embodiment 2

[0035] Embodiment 2: The preparation method of the reduced graphene oxide conductive film with controllable sheet resistance.

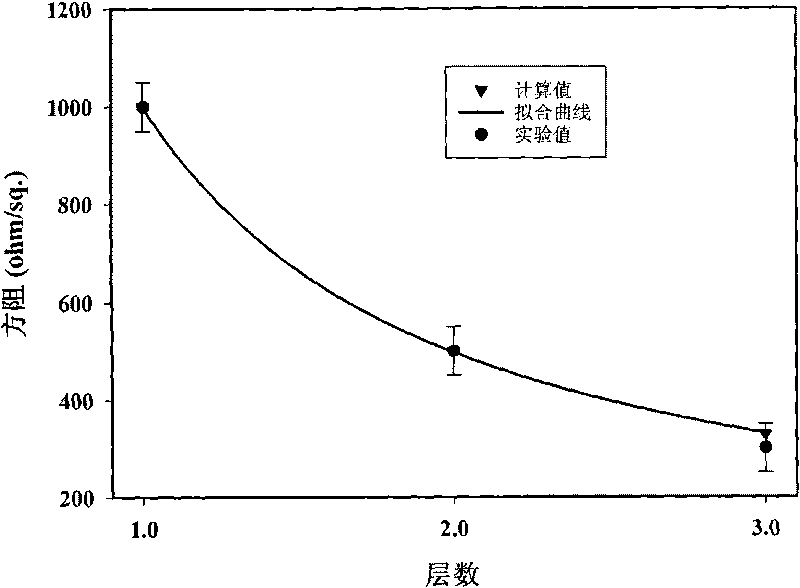

[0036] Here, a graphene oxide film with a filtration volume of 50 ml and a density of 0.05 mg / ml is selected as a single-layer film. On the basis of the reduced graphene oxide film with a filtration volume of 50 ml prepared in Example 1, transfer and superimpose a second layer of graphene oxide film of equal thickness. Then adopt the reduction method in embodiment 1 to reduce the second layer of graphene oxide film. A similar method was used to prepare three-layer stacked reduced graphene oxide conductive films. The four-probe test shows that the sheet resistance of the double-layer stacked reduced film is approximately equal to the sheet resistance of the reduced graphene oxide film with a filtration volume of 100ml in Example 1, indicating that the contact between the stacked films is good and the reduction is uniform and equivalent, theoretically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com