Perovskite-based thin film solar cell and method for preparing same

A thin-film solar cell and perovskite technology, which is applied in the field of solar cells, can solve the problems of restricting the development of perovskite-based thin-film solar cells, increasing the cost of battery raw materials, and increasing the cost of battery production, so as to reduce the cost of battery preparation and reduce the thickness of the film. Easy-to-control, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Prepare 5 parallel solar cells on a piece of conductive glass, the steps are as follows:

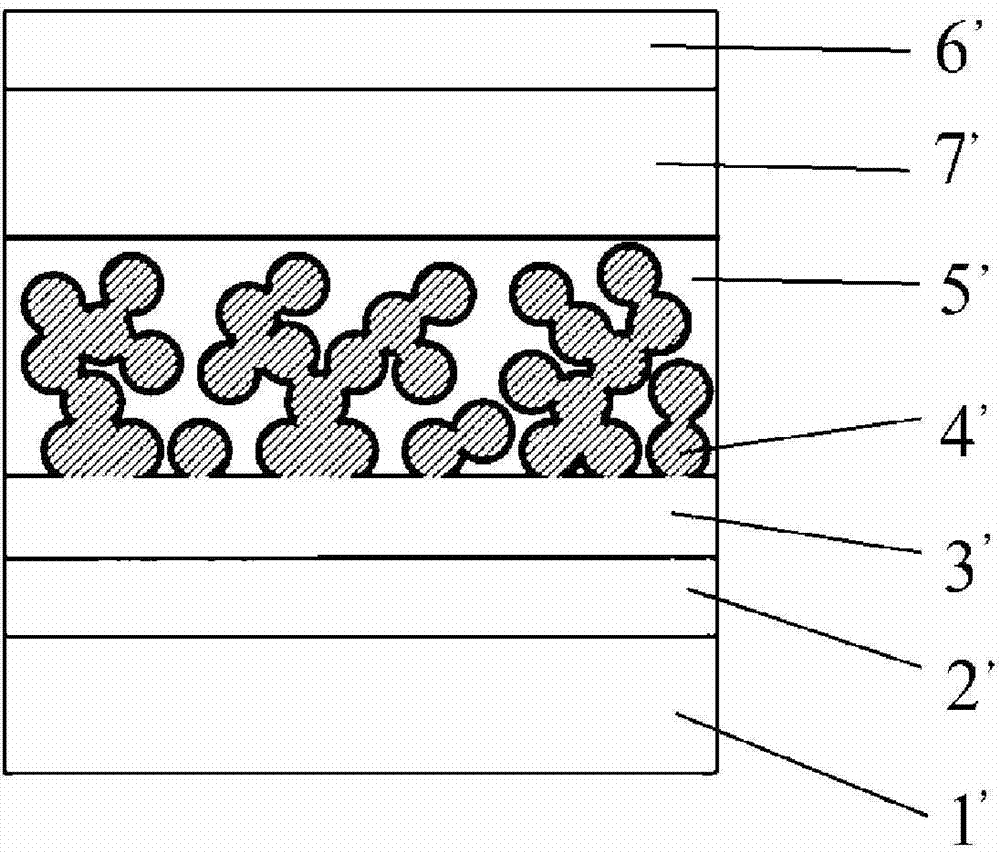

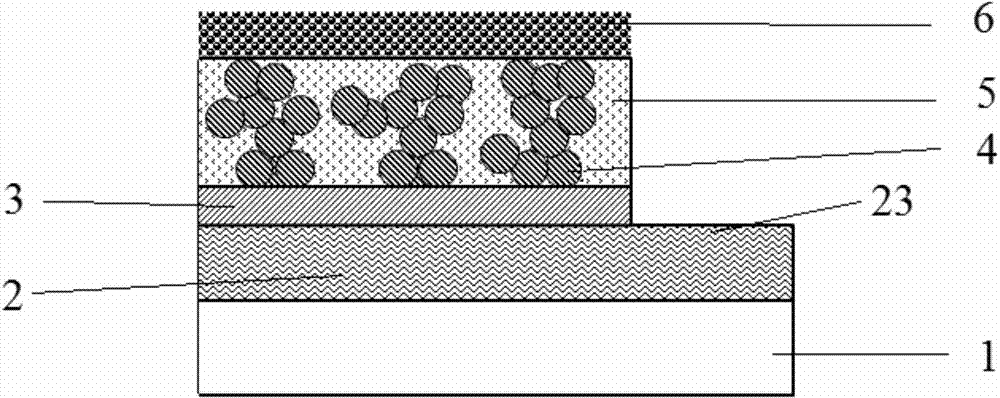

[0076] Conductive glass etching step: cut conductive glass with a size of 20mm (a) × 60mm (b), use a laser cutting machine to etch 4 parallel insulating strips along the direction of the conductive layer b of the conductive glass to divide the conductive glass into 5 sub-areas (each 20mm×12mm). These 5 sub-regions are used to prepare a single solar cell respectively, and the cross-sectional view of each solar cell finally formed is as follows Figure 5 shown. Then on the conductive glass (see Figure 5 ,exist Figure 5 The conductive layer of the middle conductive glass is formed by a transparent substrate 1 and a transparent conductive layer 2) (see Figure 5 On the transparent conductive layer 2), an insulating strip parallel to this side is etched 6mm away from the edge of side b (see Figure 5 Insulating tape 12), divide the conductive glass into the positive electrode ar...

Embodiment 2

[0084] Prepare 5 parallel solar cells on a piece of conductive glass, the steps are as follows:

[0085] Conductive glass etching steps are the same as in Example 1.

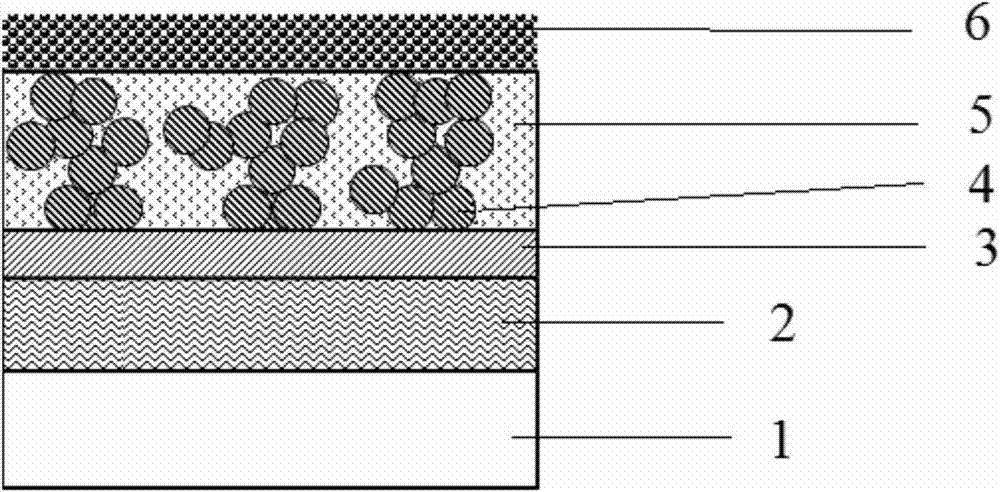

[0086] Screen printing film making steps: use a screen printing machine to print a layer of TiO with a size of 8mm×60mm on the negative electrode area of the cleaned conductive glass 2 The dense layer slurry was dried at 80°C and sintered at 450°C for 30 minutes to obtain dense TiO 2 Thin film, the thickness of the film can be selected between 20-150nm; and then print a layer of ZrO with a size of 8mm×60mm on its surface 2 Nanoparticle slurry, after drying at 80°C and sintering at 500°C for 30 minutes, ZrO 2 Porous film, film thickness can be selected between 200-1500nm; in ZrO 2 Print 5 pieces of carbon paste with a size of 6mm×10mm on the porous film, the 5 pieces of carbon paste are respectively located in a sub-region of the conductive glass, and most of the carbon paste covers the prepared ZrO 2 The o...

Embodiment 3

[0092] Prepare 5 parallel solar cells on a piece of conductive glass, the steps are as follows:

[0093] Conductive glass etching steps are the same as in Example 1.

[0094] Screen printing film making steps: use a screen printing machine to print a layer of TiO with a size of 8mm×60mm on the negative electrode area of the cleaned conductive glass 2 The dense layer slurry was dried at 80°C and sintered at 450°C for 30 minutes to obtain dense TiO 2 Thin film, the film thickness can be selected between 20-150nm; then print a layer of SiO with a size of 8mm×60mm on its surface 2 Nanoparticle slurry, dried at 80°C and sintered at 550°C for 30 minutes to obtain SiO 2 Porous film, film thickness can be selected between 200-1500nm; in SiO 2 Print 5 carbon pastes with a size of 6mm×10mm on the porous film, the 5 carbon pastes are respectively located in a sub-region of the conductive glass, and most of the carbon pastes cover the prepared SiO 2 The other part covers the positiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com