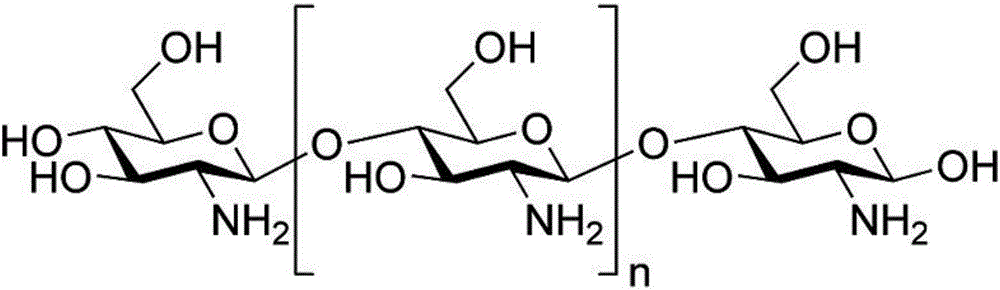

Chitosan nanoparticle suspension preparation method and application thereof

A chitosan nanoparticle and chitosan nanotechnology are applied in the fields of blood diseases, liquid transportation, and pharmaceutical formulations. It can solve the problems of poor stability of nanoparticles, complicated operation steps, and large particle size of nanoparticles to achieve stability. Good, optimized preparation parameters, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a kind of preparation method of chitosan nano particle suspension, comprises the steps:

[0044] (1) dissolving chitosan in an aqueous solution of 0.1% to 2.0% by weight of glacial acetic acid to prepare chitosan acetic acid solution; %; The chitosan is one or a combination of carboxymethyl chitosan or modified chitosan;

[0045] (2) Under the condition of stirring, add dropwise sodium tripolyphosphate aqueous solution with a weight percentage of 0.1-1%, the weight ratio of sodium tripolyphosphate and chitosan is 1:2-8, and the dropping rate is 1-2ml / min, continue stirring for 40-100 min to obtain a coarse suspension of chitosan nanometers;

[0046] (3) Filtrating the chitosan nano coarse suspension, performing high-pressure homogenization treatment, the pressure is 500-800 Mpa, and the number of circulation homogenization is 5-15 times, to obtain the chitosan nano particle suspension.

[0047] Add polymer excipients, the polymer excipients are...

Embodiment 1

[0059] Weigh an appropriate amount of chitosan powder and dissolve it in 1% by weight glacial acetic acid solution to prepare chitosan acetic acid solution. Under stirring, the sodium tripolyphosphate solution that is 0.2% by weight percentage is slowly added dropwise in the chitosan acetic acid solution, and the rate of addition is 1~2ml / min, and the weight ratio of sodium tripolyphosphate and chitosan is 1:5. Stirring was continued for 60 min to obtain a coarse suspension of chitosan nanometers. Take the chitosan nano coarse suspension, put it into a high-pressure homogenizer, the pressure is 500Mpa, repeat the homogenization 10 times, collect and obtain the chitosan nano particle suspension with a weight percent content of 0.5%.

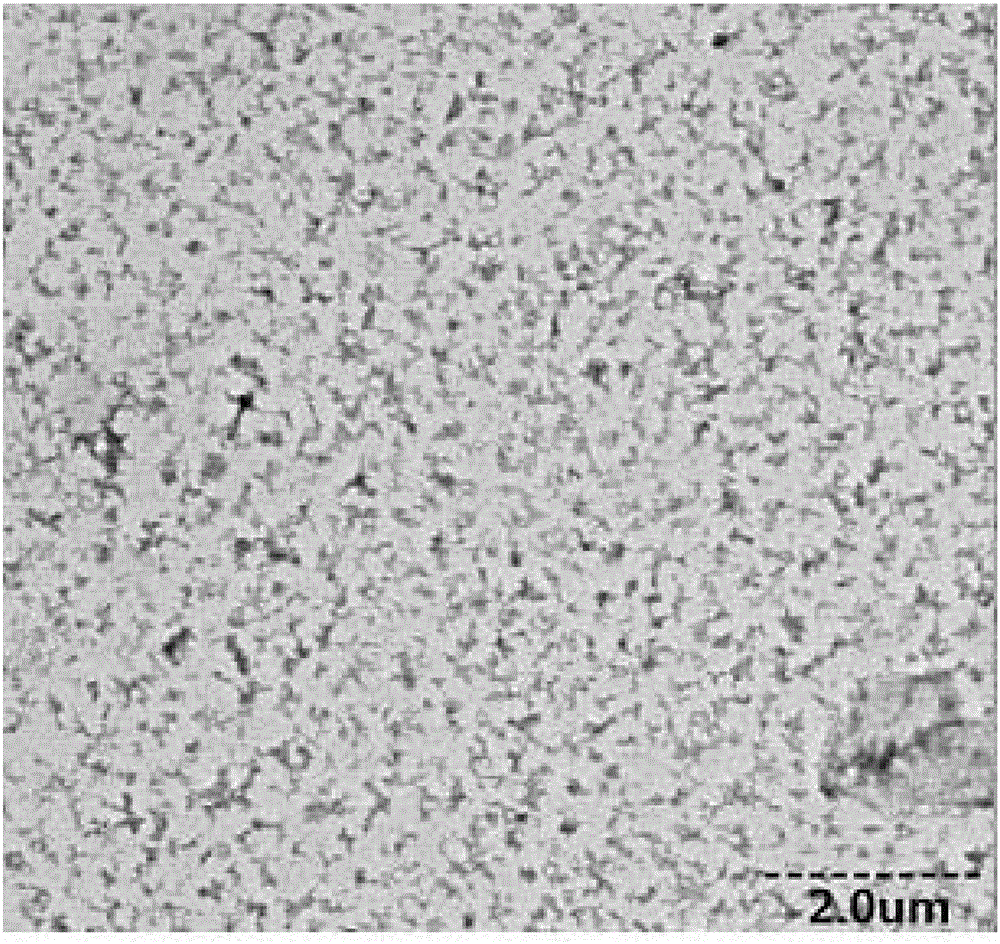

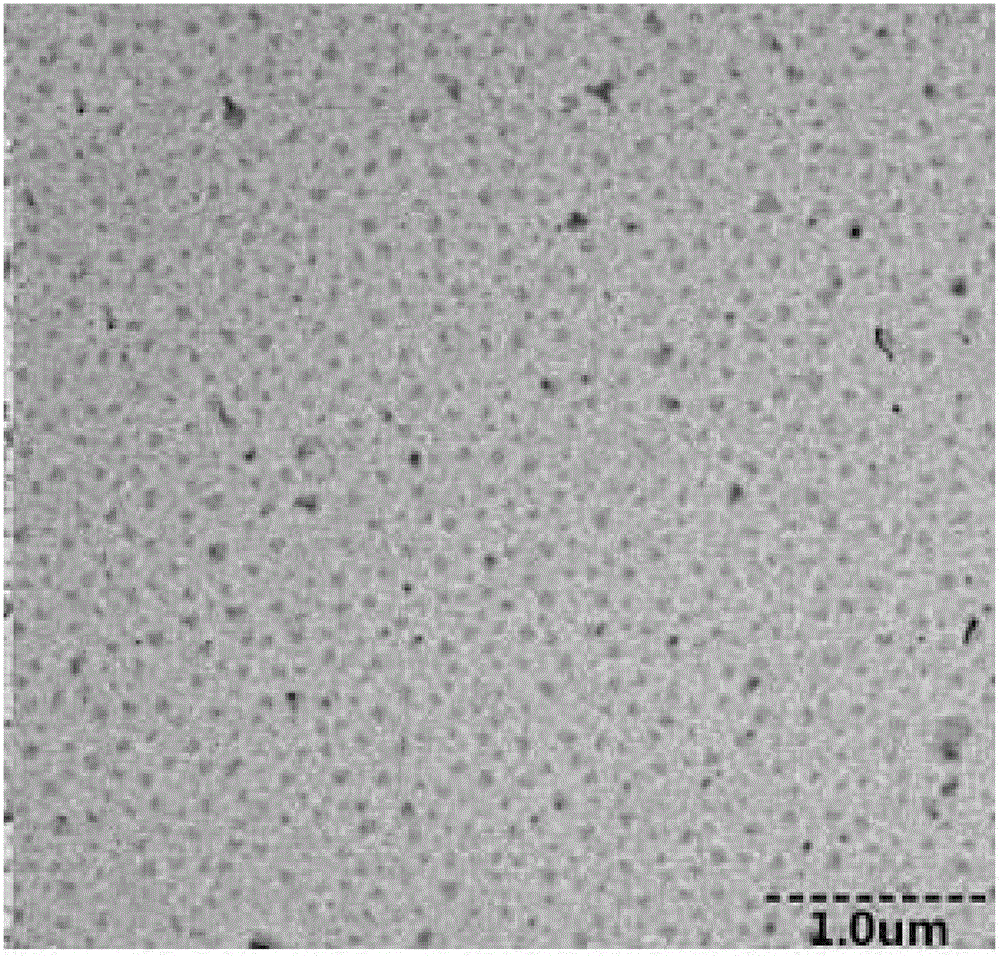

[0060] The electron microscopic picture of the chitosan nanoparticle relevant to the present invention is shown in accompanying drawing. Chitosan nanoparticles prepared by ion gel method IGT method (×2.0k) as figure 2 As shown, the appearance ...

Embodiment 2

[0062] Weigh an appropriate amount of chitosan powder and dissolve it in 0.1% by weight glacial acetic acid solution to prepare chitosan acetic acid solution. Under stirring, the weight percentage is that 1% sodium tripolyphosphate solution is slowly added dropwise in the chitosan acetic acid solution, the dropping speed is 1~2ml / min, the weight ratio of sodium tripolyphosphate and chitosan is 1 :8. Continue to stir for 40min to obtain the chitosan nano coarse suspension. Get chitosan nano coarse suspension, insert in high-pressure homogenizer, pressure is 500Mpa homogenization 5 times, and pressure is 800Mpa homogenization 5 times, the collection obtains the chitosan nano particle suspension that weight percentage content is 1% .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com