Method for preparing graphene oxide

A fossil and graphene technology, applied in the field of graphene oxide preparation, can solve problems such as being unsuitable for mass production, unsuitable for industrial production, reducing safety, etc., and achieve the effects of good dye adsorption capacity, convenient operation, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: measure 23ml vitriol oil (massfraction is 98%), join in the polytetrafluoroethylene liner of the stainless steel reactor of 50ml, after mixing under the condition of magnetic sub-stirring, add 1g graphite powder, in Cool down to 0-4°C in an ice-water bath, add 6g of potassium permanganate, control the time within 1h, and stir the sample evenly. After sealing the kettle, put it in a thermostat at 70°C for 24 hours to complete the oxidation of graphite, and the sample turns lavender.

[0025] Add 10ml of 30% hydrogen peroxide by mass to 100ml of distilled water, cool down and freeze to ice cube shape. Transfer the graphite oxide to the distilled water mixture containing hydrogen peroxide frozen into ice cubes. After it is completely dissolved (the sample is bright yellow), stir it evenly and then filter it with a sand core funnel. Wash the graphite oxide with 5% HCl, distilled water, and ethanol in sequence until there is no sulfate group detected by barium...

Embodiment 2

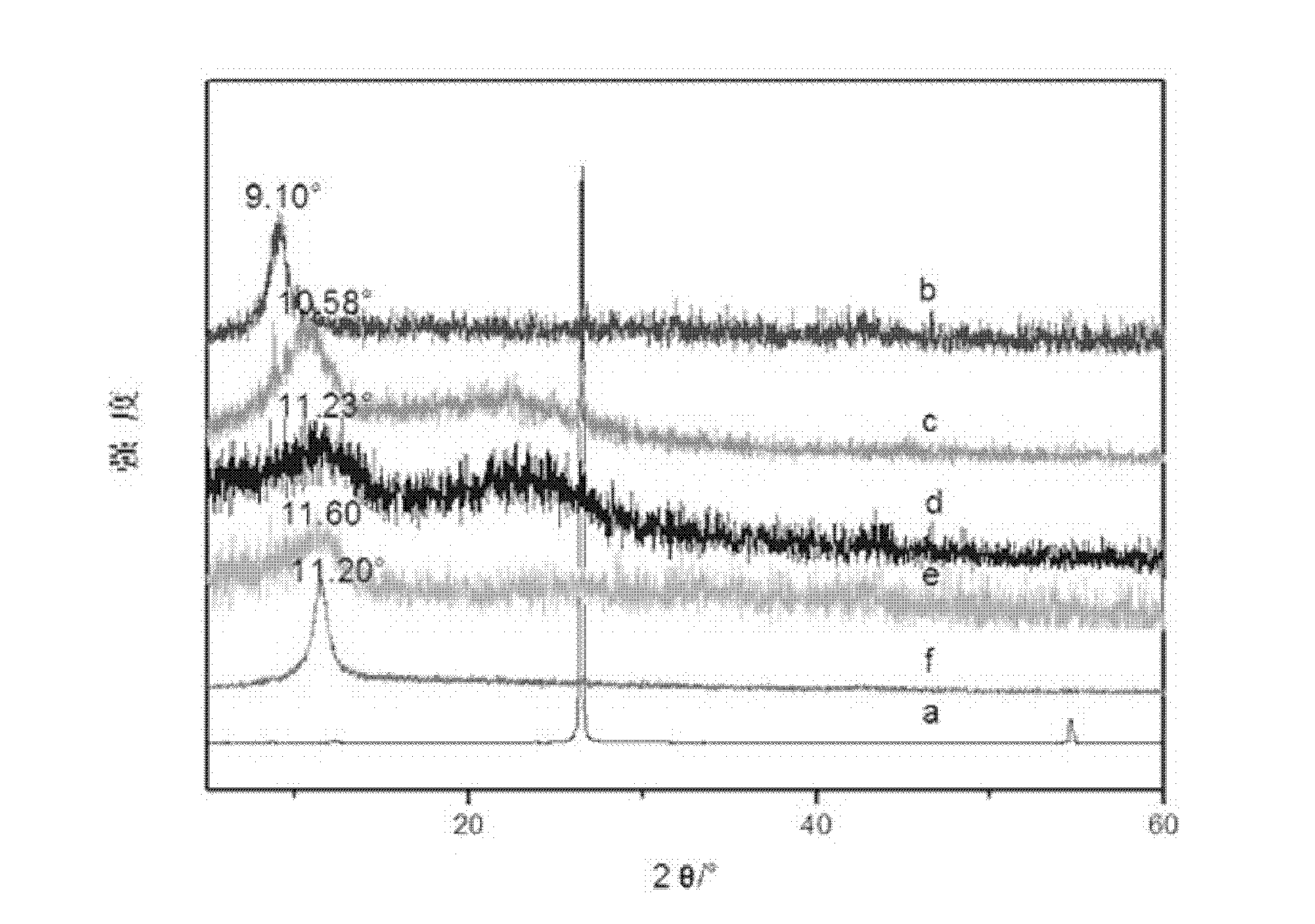

[0027] Embodiment 2: other experimental steps are with embodiment 1, only change the amount of potassium permanganate, the quality that adds potassium permanganate is 5g, and the mass ratio of graphite powder and potassium permanganate is 1: 5, figure 1 The middle curve c is the X-ray diffraction pattern of the sample. It can be seen from the figure that the characteristic diffraction peaks of the graphite powder are no longer obvious, and the calculated layer distance of the sample is It shows that the amount of oxidant decreases, and its force between graphite layers decreases.

Embodiment 3

[0028] Embodiment 3: other experimental steps are with embodiment 1, only by changing the put-in amount of potassium permanganate, the quality of adding potassium permanganate is 4g, and the mass ratio of graphite powder and potassium permanganate is 1: 4, figure 1 The middle curve d is the X-ray diffraction pattern of the sample, and the characteristic diffraction peaks of the graphite powder are not obvious at the beginning, and the interlayer spacing of the calculated sample is It shows that the amount of oxidant is further reduced, and its force between graphite layers is also reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com