Super hydrophobic/super lipophilic filter cloth and preparation method thereof and application thereof in oil-water separation

A super-oleophilic and super-hydrophobic technology, which is applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of cumbersome process, harsh reaction conditions, and low cost, and achieve simple preparation process, mild reaction conditions, and reaction short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] At room temperature, after mixing 10g of toluene and 6g of ethanol in a beaker, add 0.5g of hydroxy silicone oil with a relative molecular mass of 1500 and a hydroxyl content of 6wt%, 0.05g of butyl titanate and 0.01g of dilaurel Acetate dibutyltin, and after magnetic stirring at room temperature for 0.5h, the organosilicon prepolymer was obtained. Add 4g of nano-silica toluene dispersion with a solid content of 35wt% and an average silica particle size of 20nm to the above-mentioned organosilicon prepolymer, and disperse with ultrasonic (400W, 20KHz) for 10min to obtain organosilicon-silica co-polymer mixture. Immerse the polypropylene fiber filter cloth (200 mesh) washed with ethanol aqueous solution and dried in the above silicone-silicon dioxide blend for 30s, then pull it slowly, and finally place the filter at 80°C for 30min to solidify. A superhydrophobic / superoleophilic filter cloth is obtained.

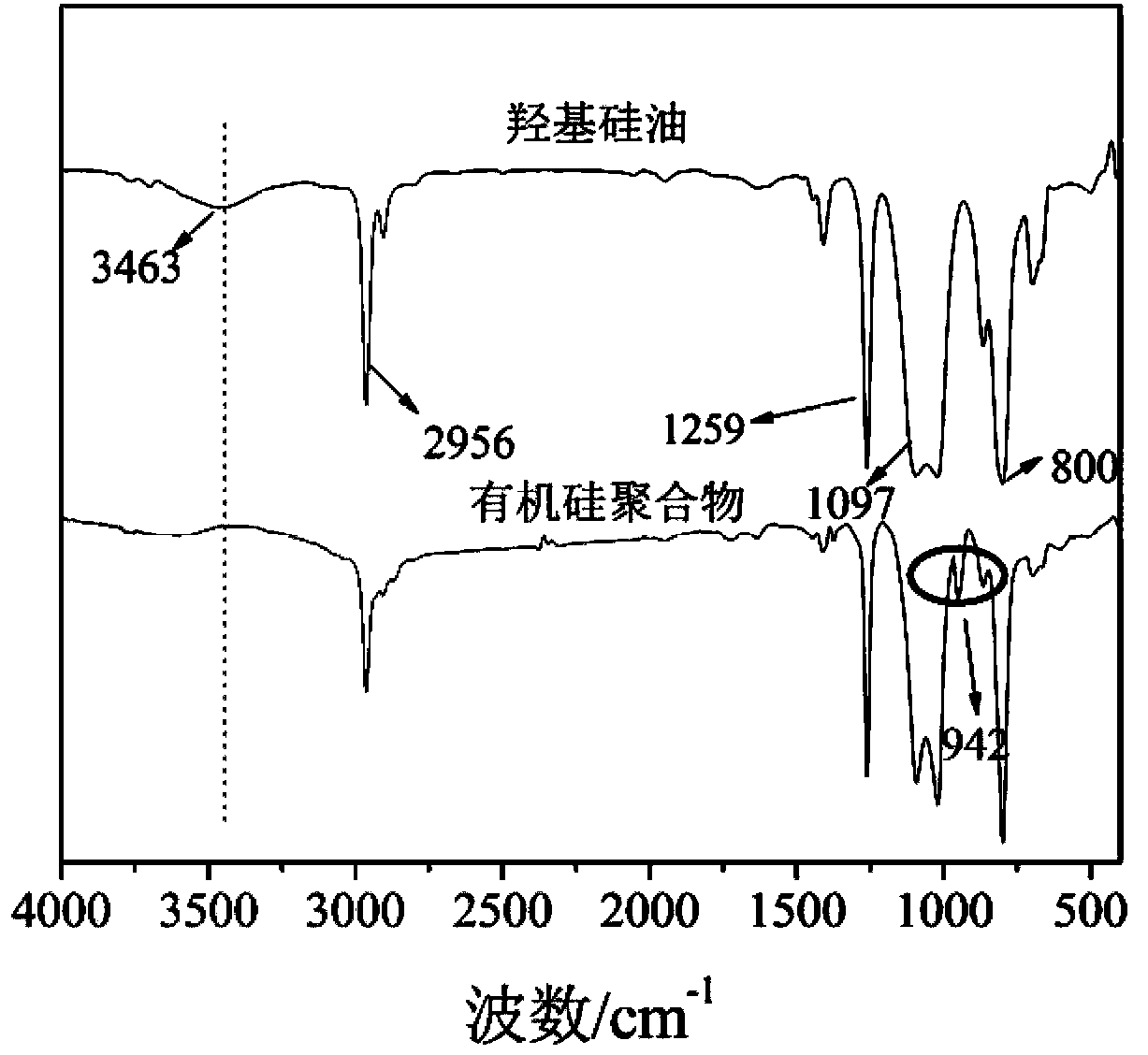

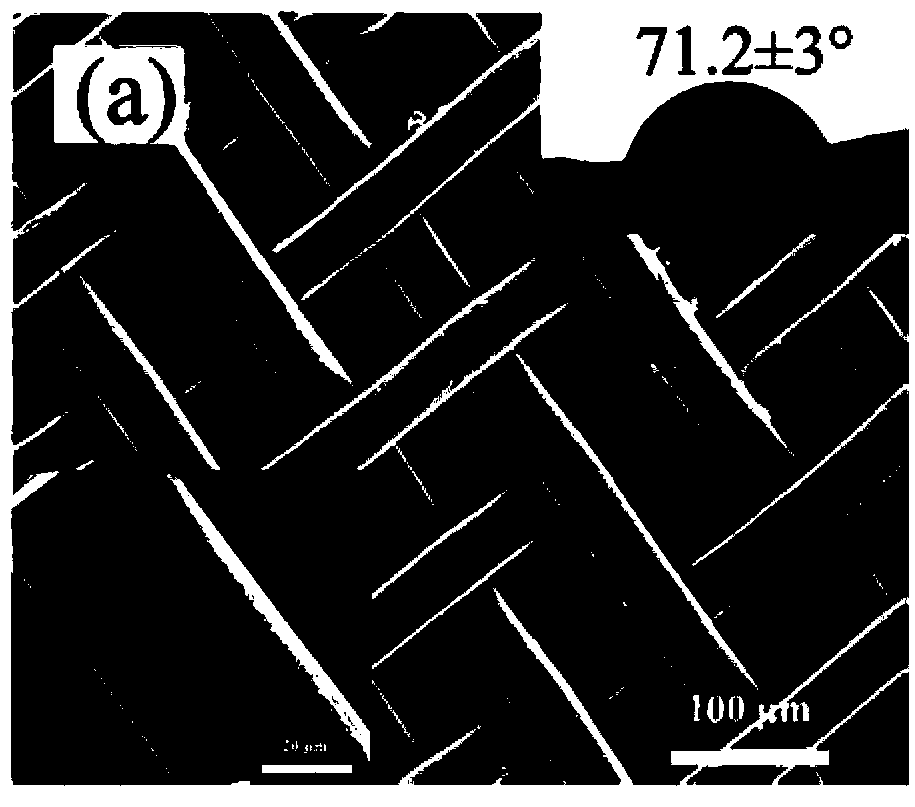

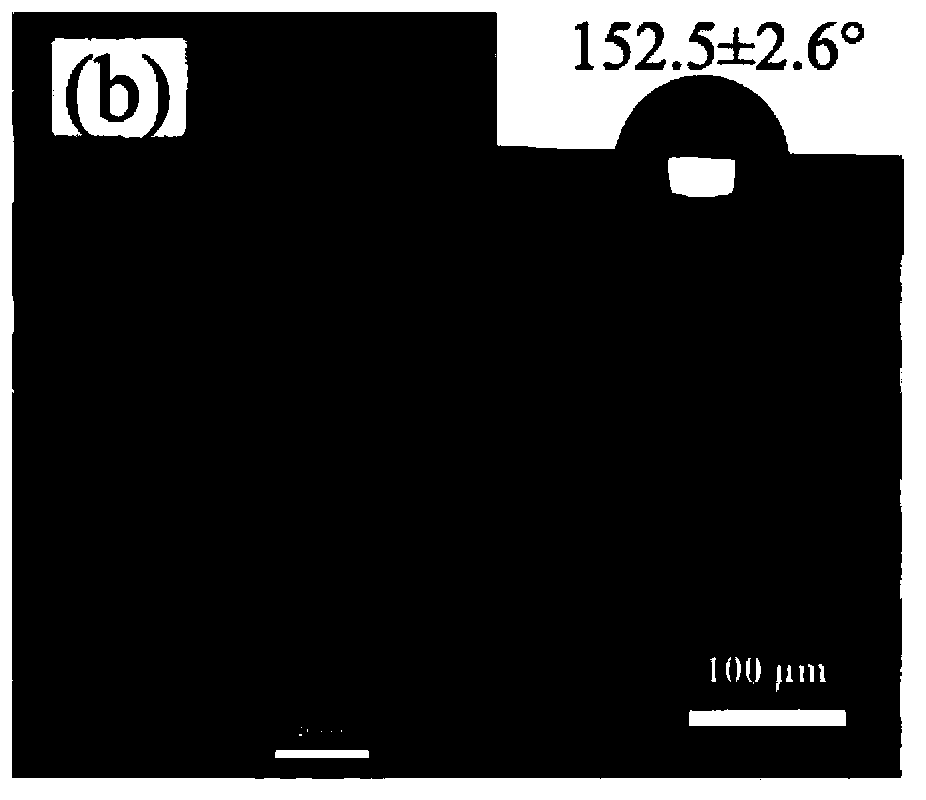

[0025] figure 1 It is the infrared spectrum of the hydroxyl si...

Embodiment 2

[0029] At room temperature, after mixing 10g of toluene and 2g of ethanol in a beaker, add 1.2g of hydroxy silicone oil with a relative molecular mass of 1500 and a hydroxyl content of 6wt%, 0.06g of isopropyl titanate and 0.006g of octanoic acid stannous, and after magnetic stirring at room temperature for 0.5 h, the organosilicon prepolymer was obtained. Add 4g of nano-silica toluene dispersion with a solid content of 25wt% and an average silica particle size of 50nm to the above-mentioned organosilicon prepolymer, and disperse by ultrasonic (400W, 20KHz) for 10min to obtain organosilicon-silica co-polymer mixture. Immerse the polypropylene fiber filter cloth (100 mesh) washed with ethanol aqueous solution and dried into the above-mentioned silicone-silicon dioxide blend for 30s, then pull it slowly, and finally place the filter at 80°C for 30min to solidify. A superhydrophobic / superoleophilic filter cloth is obtained.

[0030] Infrared spectra of cured silicone polymers a...

Embodiment 3

[0032]At room temperature, after mixing 10g of toluene and 10g of ethanol in a beaker, add 0.4g of hydroxyl silicone oil with a relative molecular mass of 3500 and a hydroxyl content of 11.2wt%, 0.08g of butyl titanate and 0.008g of di dibutyltin laurate and magnetically stirred at room temperature for 1 h to obtain a silicone prepolymer. Add 2.5g of nano-silica toluene dispersion with a solid content of 35wt% and an average silica particle size of 30nm to the above-mentioned organosilicon prepolymer, and disperse by ultrasonic (600W, 28KHz) for 10min to obtain organosilicon-silicon dioxide blends. Soak the polypropylene fiber filter cloth (200 mesh) washed with ethanol aqueous solution and dried in the above silicone-silicon dioxide blend for 60s, then pull it slowly, and finally arrange the filter at 100°C for 20min to cure. A superhydrophobic / superoleophilic filter cloth is obtained.

[0033] Infrared spectra of cured silicone polymers and figure 1 Similar; SEM photos an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com