A kind of superhydrophobic composite carbon airgel oil-absorbing material and preparation method thereof

A technology of carbon airgel and oil-absorbing materials, applied in chemical instruments and methods, seawater treatment, other chemical processes, etc., can solve the problem of oil-absorbing materials not achieving superhydrophobic oil-water separation effect, insufficient stability and recycling rate, graphite To solve the problems of high price of ethylene, to achieve the effect of improving reusability, good oil-water separation effect, and fast adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation steps of carbon airgel:

[0039] At room temperature, resorcinol and formaldehyde solution are configured into a mixed solution with a molar ratio of 1:5, and 10g of basic catalyst Na 2 CO 3 , deionized water as the reaction solvent, stirred evenly on a magnetic stirrer until a completely clear light yellow mixed sol, then poured the sol into the gel mold prepared in advance, sealed it with plastic wrap and placed it at room temperature to continue the reaction until After coagulation and gelation, take out the sample and put it into an oven for further gel aging. Set the temperature program at 40-70°C to gradually increase the temperature, and finally obtain an organic resorcinol-formaldehyde (RF) wet gel.

[0040] Soak the organic resorcinol-formaldehyde (RF) wet gel sample in an ethanol solvent and put it in an oven at a certain temperature. The oven temperature is 60°C. Replace it every 24 hours for 3 times to fully replace the gel. Moisture in the...

Embodiment 2

[0047] (1) Preparation steps of carbon airgel:

[0048] Under room temperature conditions, the catechol and formaldehyde solution are configured into a mixed solution with a molar ratio of 1:3, and 10g of basic catalyst Na 2 CO 3 , deionized water as the reaction solvent, stirred evenly on a magnetic stirrer until a completely clear light yellow mixed sol, then poured the sol into the gel mold prepared in advance, sealed it with plastic wrap and placed it at room temperature to continue the reaction until After coagulation and gelation, take out the sample and put it into an oven for further gel aging. Set the temperature program at 40-70°C to gradually increase the temperature, and finally obtain an organic resorcinol-formaldehyde (RF) wet gel.

[0049] Soak the organic resorcinol-formaldehyde (RF) wet gel sample in ethanol solvent and put it in an oven at a certain temperature. Moisture in the pores, the gel filled with ethanol in the pores can be obtained, using CO 2 Sup...

Embodiment 3

[0056] (1) Preparation steps of carbon airgel:

[0057] At room temperature, resorcinol and formaldehyde solution are configured into a mixed solution with a molar ratio of 1:5, and 10g of basic catalyst Na 2 CO 3 , deionized water as the reaction solvent, stirred evenly on a magnetic stirrer until a completely clear light yellow mixed sol, then poured the sol into the gel mold prepared in advance, sealed it with plastic wrap and placed it at room temperature to continue the reaction until After coagulation and gelation, take out the sample and put it into an oven for further gel aging. Set the temperature program at 40-70°C to gradually increase the temperature, and finally obtain an organic resorcinol-formaldehyde (RF) wet gel.

[0058] Soak the organic resorcinol-formaldehyde (RF) wet gel sample in an ethanol solvent and put it in an oven at a certain temperature. The oven temperature is 70°C. Replace it every 24 hours for 5 times to fully replace the gel. Moisture in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

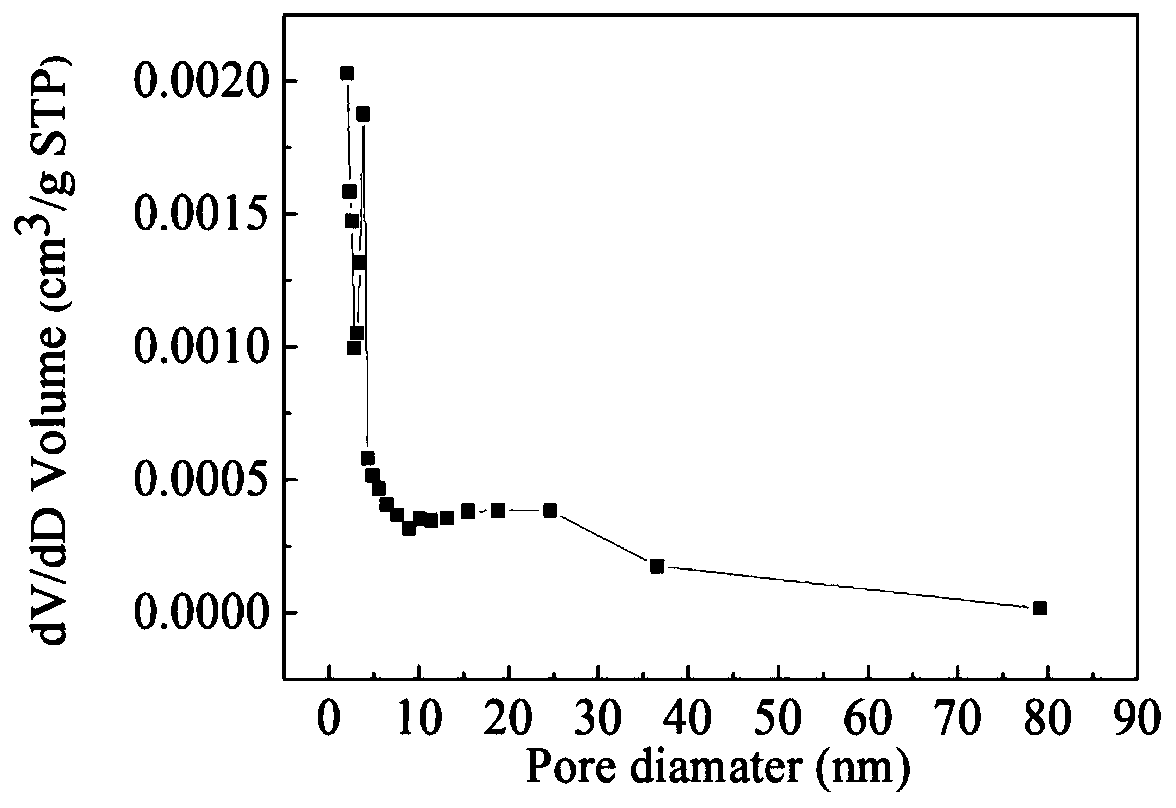

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com