A kind of oil-water separation material and using method thereof

An oil-water separation and matrix technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of increasing system volume, troublesome use, limited absorption and flux, etc., and achieves wide raw material sources, simple preparation process, The effect of controllable coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

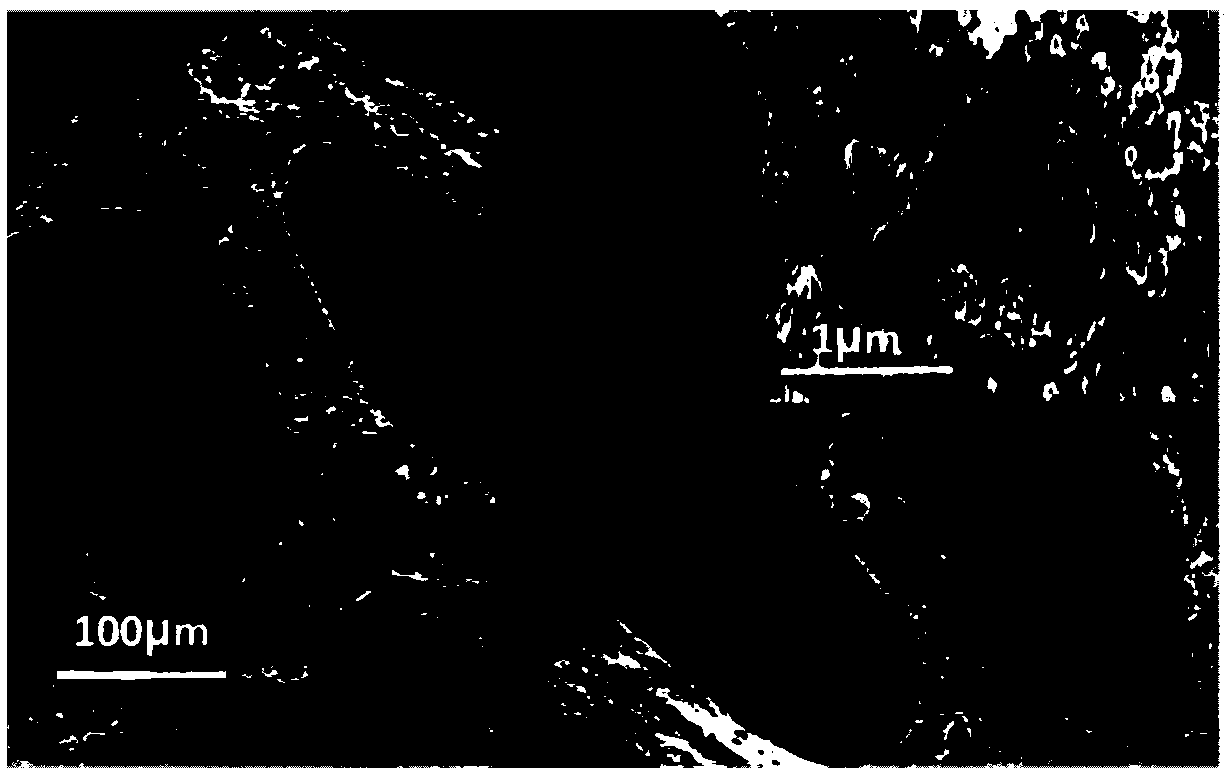

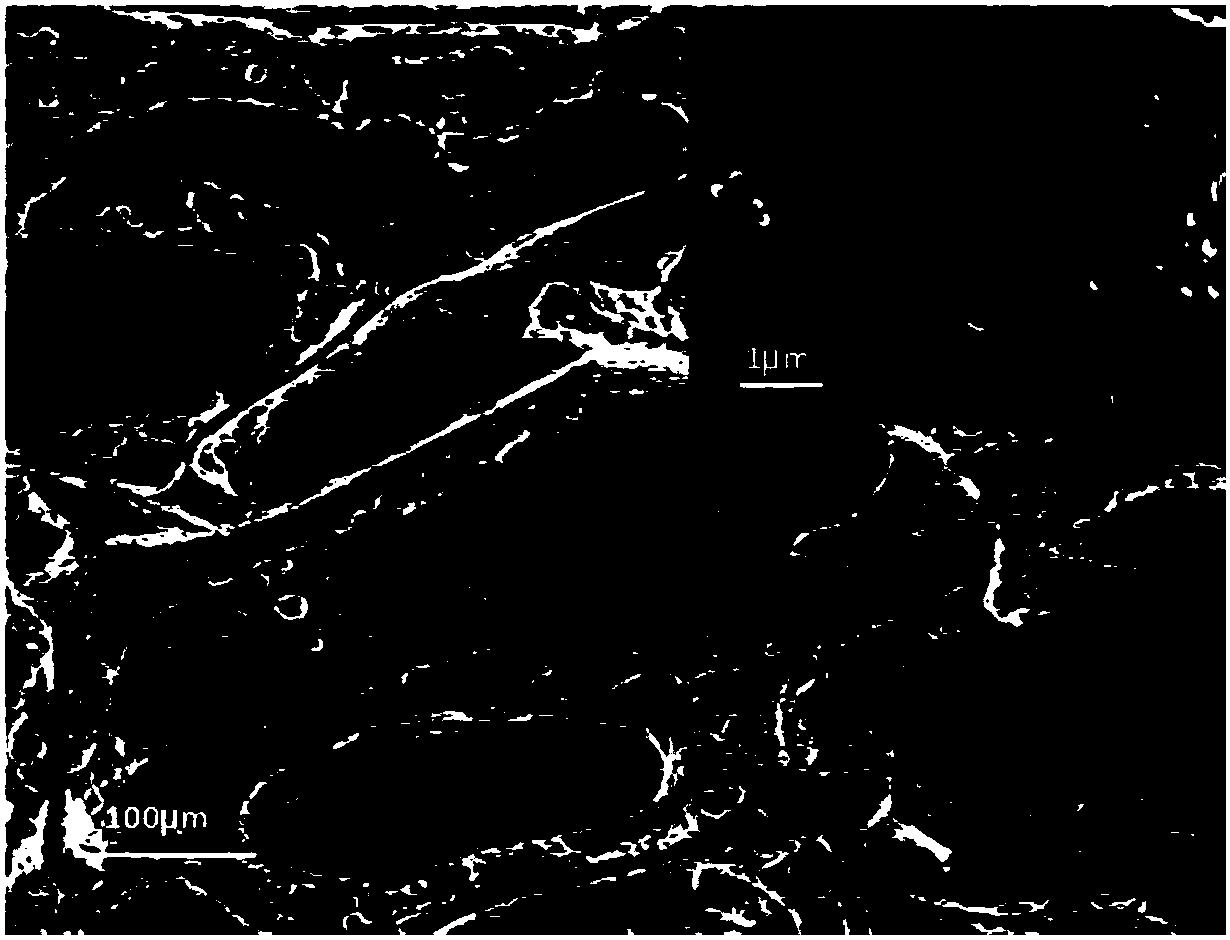

Image

Examples

Embodiment 1

[0033] 1. Material preparation

[0034] (1) Surface pretreatment of foamed nickel:

[0035] After the surface of the foamed nickel container is treated with concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:1, it is placed in an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface. The mass concentration of the ethanol solution is 75%. Take it out and take it out naturally. Dry

[0036] (2) Preparation of the emulsion to form the coating:

[0037] ① 10 parts of PU resin, 20 parts of FEP resin, 30 parts of PTFE, 20 parts of PVDF, 8 parts of talc and 0.8 parts of silane coupling agent are ground by a ball mill for 4 hours;

[0038] ②Add the above 80 parts of modified resin, 2 parts of PDMS, and 18 parts of carbon nanotubes to 100 parts of ethanol solvent and put them in an ultrasonic instrument for ultrasonic treatment until the powder is completely dispersed in the solvent;

[0039] (3) Spray emulsion on the sur...

Embodiment 2

[0063] 1. Material preparation

[0064] (1) Surface pretreatment of foamed copper:

[0065] The surface of the foamed copper is quickly treated by sandblasting and then placed in an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface. The mass concentration of the ethanol solution is 75%, take it out and dry it naturally;

[0066] (2) Preparation of the emulsion to form the coating:

[0067] ① Grind 10 parts of PU resin, 20 parts of FEP resin, 30 parts of PTFE, 20 parts of PVDF, 8 parts of talc and 2.4 parts of silane coupling agent through a ball mill for 4 hours;

[0068] ②The above-mentioned 80 parts of modified resin, 2 parts of PDMS, 18 parts of carbon nanotubes are added with 100 parts of ethanol solvent and then placed in an ultrasonic instrument for ultrasonic treatment until the powder is completely dispersed in the solvent;

[0069] (3) Spray emulsion on the surface of foamed copper:

[0070] Use a spray gun with a nozzle diameter...

Embodiment 3

[0080] 1. Material preparation

[0081] (1) Surface pretreatment of foamed titanium:

[0082] Use 7mol / L nitric acid to treat the surface of the foamed nickel and put it in an ethanol solution for ultrasonic cleaning to remove impurities such as grease and dust on the surface. The mass concentration of the ethanol solution is 75%, take it out and dry it naturally;

[0083] (2) Preparation of the emulsion to form the coating:

[0084] ① Grind 28 parts of PU resin, 20 parts of PPS resin, 25 parts of PTFE, 25 parts of PVDF resin, 9.8 parts of molecular sieve and 1 part of silane coupling agent through a ball mill for 6 hours, and then make them uniformly dispersed in the emulsion;

[0085] ②The above-mentioned 98 parts of modified resin, 0.01 part of PDMS, 1.99 parts of carbon nanotubes are added with 80 parts of n-hexane solvent and put into an ultrasonic instrument for ultrasonic treatment until the powder is completely dispersed in the solvent;

[0086] (3) Spray emulsion on the foamed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com