Patents

Literature

57results about How to "Extended oxidation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

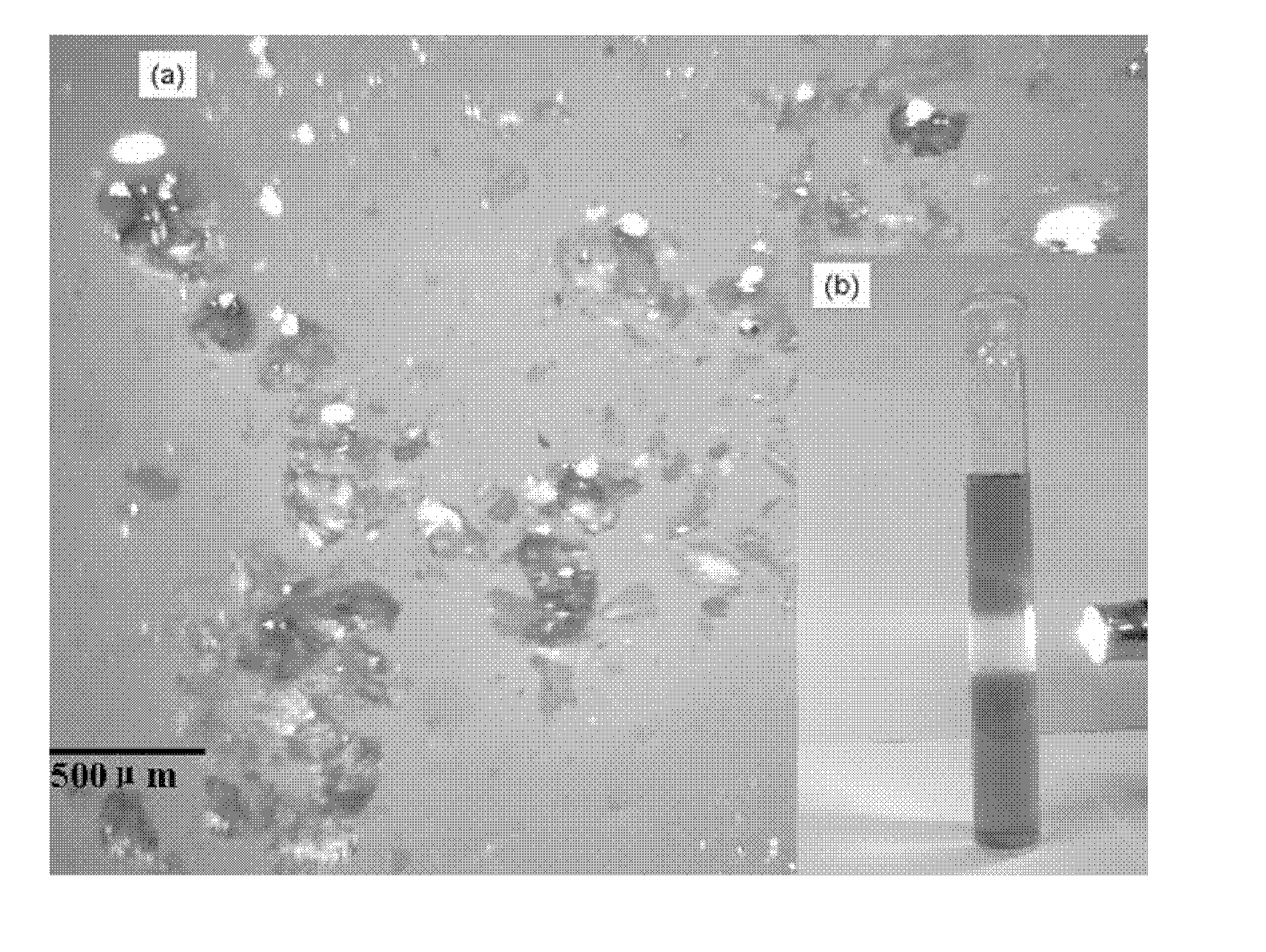

Method for preparing graphene oxide

InactiveCN102491318ACheap and easy to getAvoid it happening againCarbon compoundsToxic gasFiltration

The invention discloses a method for preparing a graphene oxide. The method comprises the following steps of: a) adding concentrated inorganic acid into a sealed reactor, adding graphite powder with stirring, reducing the temperature to the temperature of between 0 and 4 DEG C, and adding potassium permanganate to react for 0.5 to 2 hours; b) heating the obtained reaction system to the temperature of between 60 and 70 DEG C, and standing for 12 to 24 hours; c) adding hydrogen peroxide into distilled water in a volume ratio of 1:10, freezing to obtain ice, transferring the graphite oxide to the distilled water containing the hydrogen peroxide until the ice is completely dissolved, uniformly stirring, performing suction filtration, washing and drying to obtain the graphene oxide. The graphite powder, the concentrated acid and the potassium permanganate serve as raw materials, and the raw materials are low in cost and readily available; NO, NO2 and other toxic gases are prevented from being produced; the reaction temperature is as low as 60-70 DEG C; and the product has high dye adsorption capacity and high industrial application value.

Owner:HEBEI UNIV OF TECH

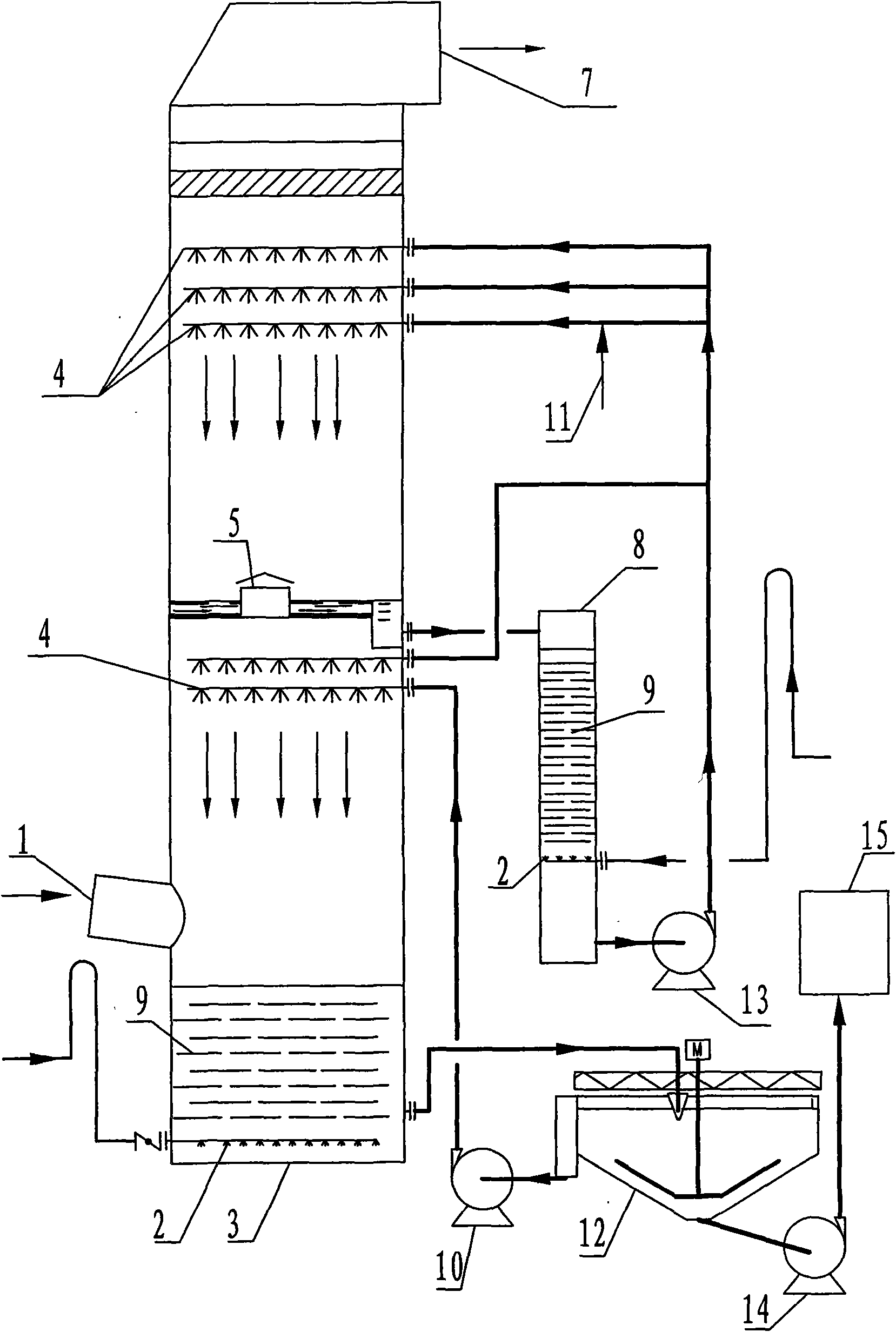

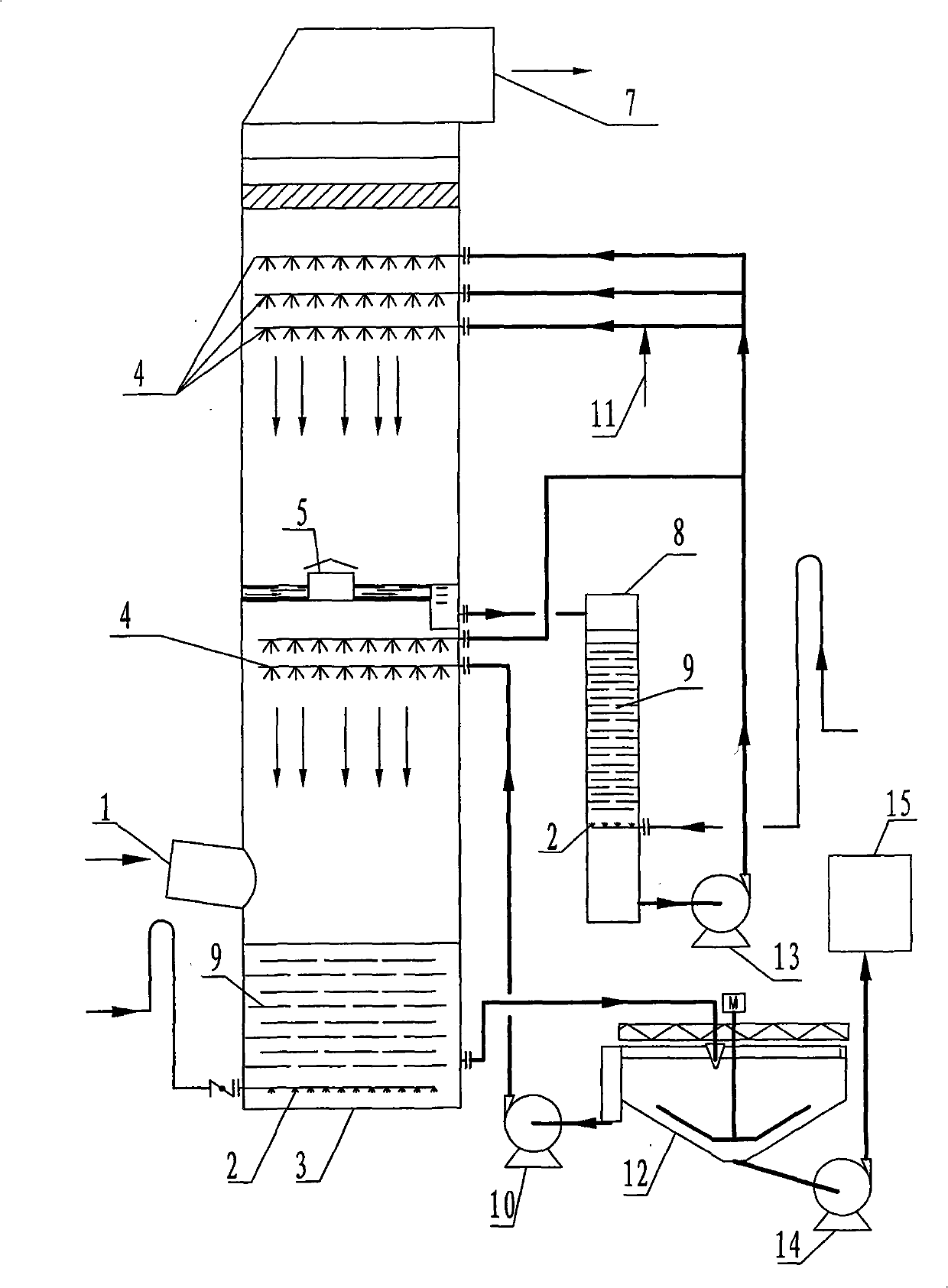

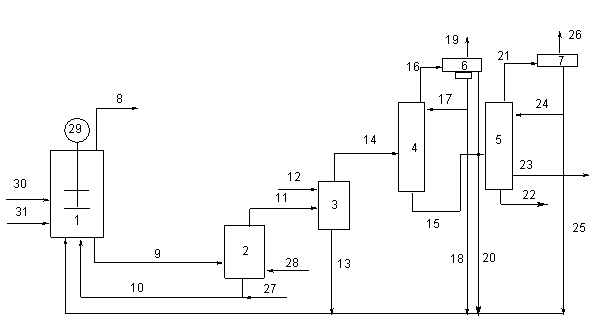

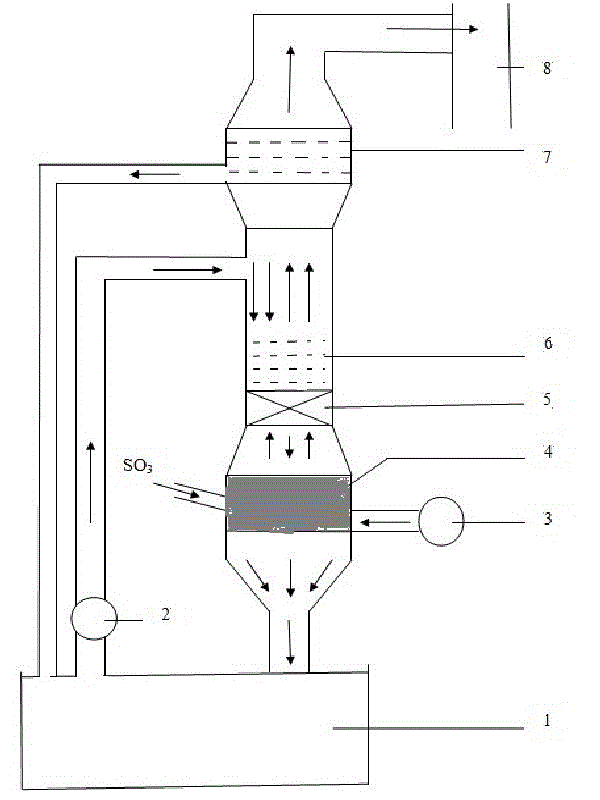

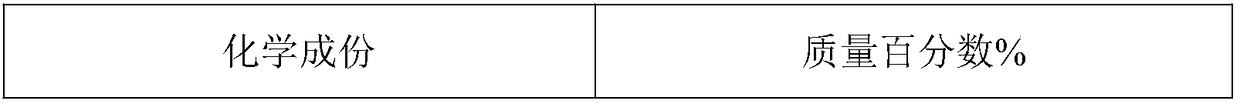

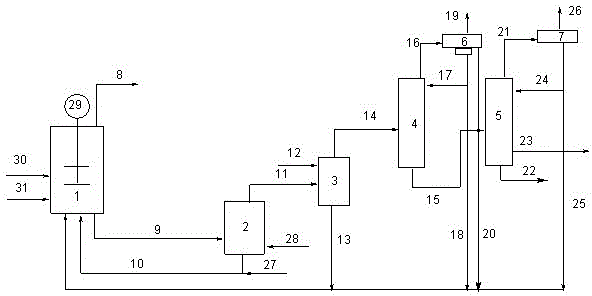

Ammonia desulfurization technology and device utilizing high potential energy

ActiveCN101579600ASolve the problem of large investmentReduce power consumptionDispersed particle separationFlue gasEngineering

The invention belongs to the field of environmental protection equipment, which relates to an ammonia desulfurization technology and a device utilizing high potential energy. The device comprises a desulfurizing tower, a concentrated crystallizing pool, an oxidation communication device, a low-level circulation pump, a high-level circulation pump, a crystal pulp pump and a centrifugal drying system which are positioned outside the tower; the desulfurizing tower is divided into an upper layer section and a lower layer section, and a gas cap through which only flue gas can pass is arranged between the upper layer section and the lower layer section; the lower layer section of the desulfurizing tower and the oxidation communication device are both provided with an oxidation gas distributor and an oxidation gas deflector; and spray heads are 2 to 4 layers. Under the precondition that normal desulfurization efficiency is ensured, the invention not only saves the investment but also reduces the running cost.

Owner:江苏世纪江南投资有限公司

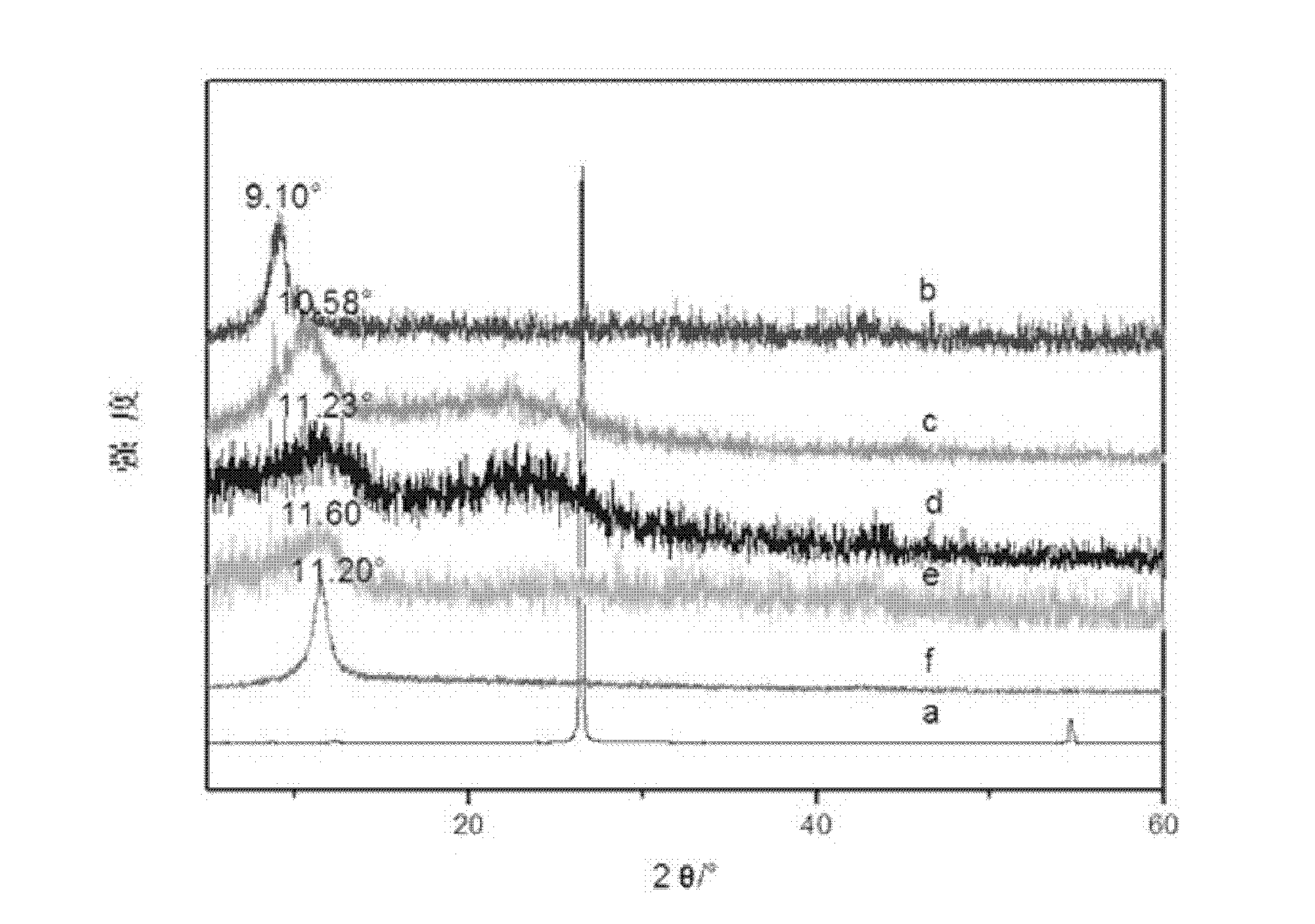

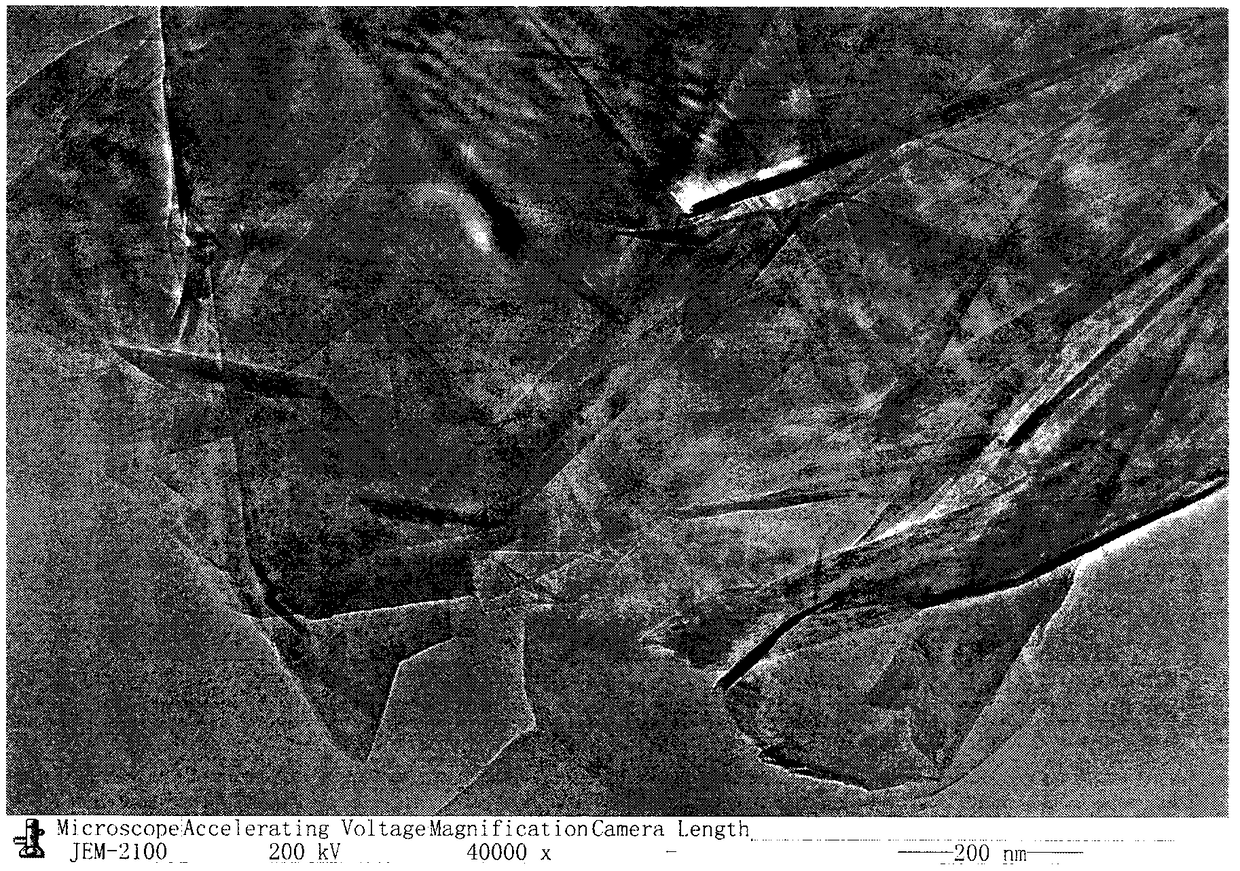

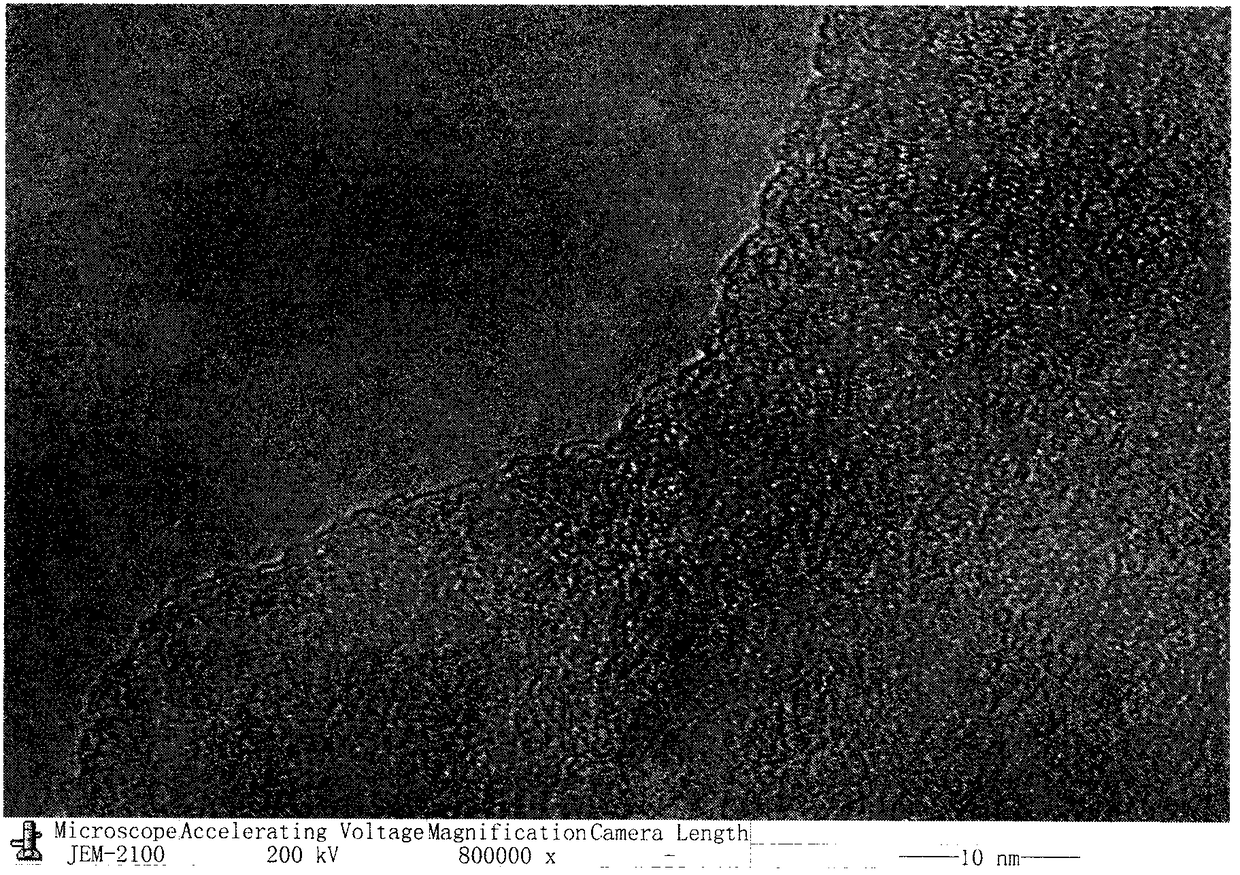

Method for rapidly preparing graphene in large quantities by utilizing graphite oxides

InactiveCN102502611ASimple processExcellent microwave absorbing mediumGrapheneNanotechnologyPotassium dichromatePotassium manganate

The invention aims at providing a preparation method for rapidly obtaining graphene in large quantities. On the basis of obtaining graphite oxides, the molecular thermodynamic movement of groups such as hydroxyl groups (-OH), carboxylic groups (-COOH) and the like which are generated on the surfaces of graphite oxide layers through oxidization can be induced and stimulated through microwave treatment so as to produce a momentary unsteady state, so that Van der Waals binding force between graphite layers is damaged, and graphene can be rapidly obtained in large quantities. The graphite oxides are obtained through the oxidization of metal salt such as potassium permanganate, potassium dichromate and the like as well as strong protonic acid such as concentrated sulphuric acid, concentrated nitric acid and the like, and then microwave irradiation is carried out under the conditions that the power ranges from 2 to 10 kW, the vacuum pressure ranges from 0.01 to 0.06 MPa and so on, so that microwave cleavage of the graphite oxides can be accomplished within 2 to 10 seconds, and graphene with less than ten layers can be obtained rapidly in large quantities. The preparation method can also control the layer number or the thickness of graphene products by controlling the concentration and the oxidation time of oxidizing mediums as well as the power, the degree of vacuum and the like of the microwave irradiation.

Owner:SOUTHEAST UNIV

Replenisher containing complete nutrescin

InactiveCN1463745AImprove food taste qualityExtended oxidation timePeptide/protein ingredientsMetabolism disorderNutrientDietary fibre

The comprehensive nutrient replenishing agent is prepared through mixing casein, taurine, lysine, unsaturated fatty acids, diet fiber, peptide with absorbed metal ions, mineral matter containing Ca, Mg, K, Fe, Zn, Co, Cr, Mn, Se and Cu and trace elements, composite vitamins in certain proportion; water dilution; spray drying to obtain powder; and high temperature sterilization. The product of the present invention can meet the need of children, pregnant women and women in suckling period in replenishing nutrients comprehensively and promoting the absorption of mineral and trace elements.

Owner:丁强

Ammonia desulfurization technology and device utilizing high potential energy

ActiveCN101579600BLower the altitudeLow costDispersed particle separationFlue gasProcess engineering

The invention belongs to the field of environmental protection equipment, which relates to an ammonia desulfurization technology and a device utilizing high potential energy. The device comprises a desulfurizing tower, a concentrated crystallizing pool, an oxidation communication device, a low-level circulation pump, a high-level circulation pump, a crystal pulp pump and a centrifugal drying system which are positioned outside the tower; the desulfurizing tower is divided into an upper layer section and a lower layer section, and a gas cap through which only flue gas can pass is arranged between the upper layer section and the lower layer section; the lower layer section of the desulfurizing tower and the oxidation communication device are both provided with an oxidation gas distributor and an oxidation gas deflector; and spray heads are 2 to 4 layers. Under the precondition that normal desulfurization efficiency is ensured, the invention not only saves the investment but also reducesthe running cost.

Owner:江苏世纪江南投资有限公司

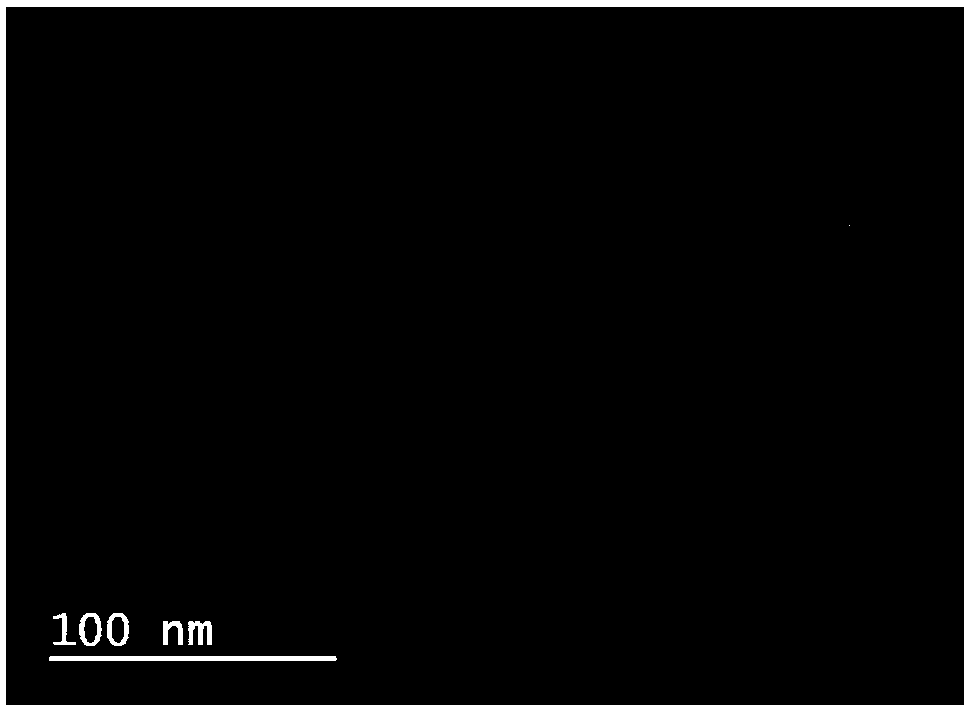

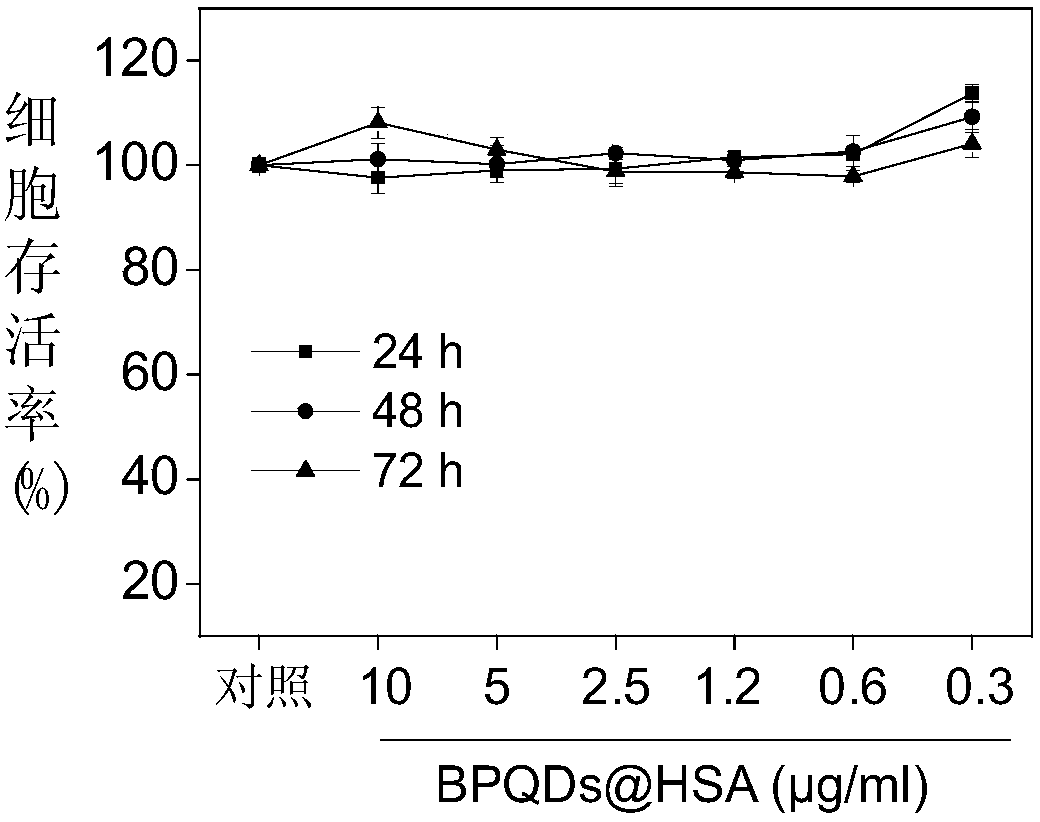

Preparation of human serum albumin modified black phosphorus quantum dots and applications of the quantum dots as a sensitizer

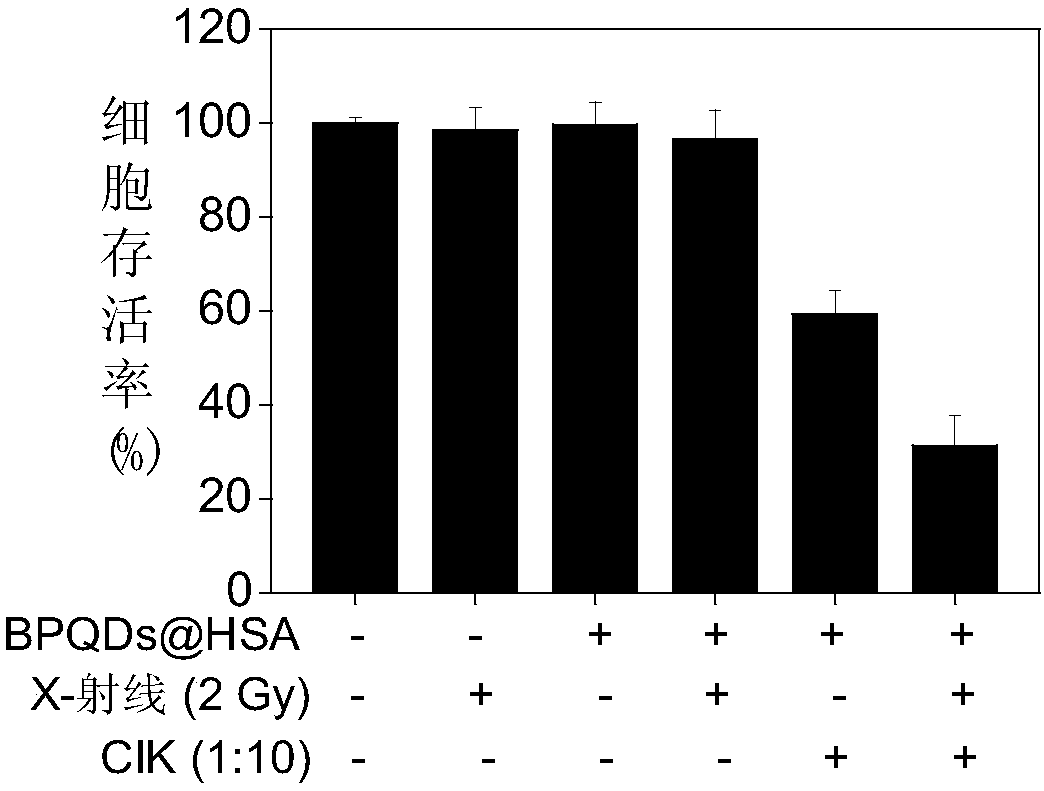

ActiveCN108030919AReduced bioavailabilityGood blood compatibilityInorganic phosphorous active ingredientsNanotechnologyX-rayCell therapy

Preparation of human serum albumin modified black phosphorus quantum dots and applications of the quantum dots as a sensitizer are disclosed. A preparing method of the human serum albumin modified black phosphorus quantum dots includes (1) uniformly dispersing black phosphorus quantum dots into water to obtain an aqueous solution of the black phosphorus quantum dots; and (2) adding an aqueous solution of human serum albumin into the aqueous solution of the black phosphorus quantum dots obtained in the step (1), stirring the mixture, and performing centrifugation to obtain a precipitate that isthe human serum albumin modified black phosphorus quantum dots. The obtained human serum albumin modified black phosphorus quantum dots have a CIK cell therapy sensitizing characteristic, can effectively regulate immune cell cytokine secretion of CIK immune cells, sensitize CIK cells to suppress tumor cell proliferation, have a radioactivity sensitizing characteristic, and cooperate with X rays to inhibit tumor growth. The human serum albumin modified black phosphorus quantum dots can be developed as a novel sensitizer for immunotherapy and radioactive therapy and promote development of novelclinical antitumor medicines.

Owner:JINAN UNIVERSITY

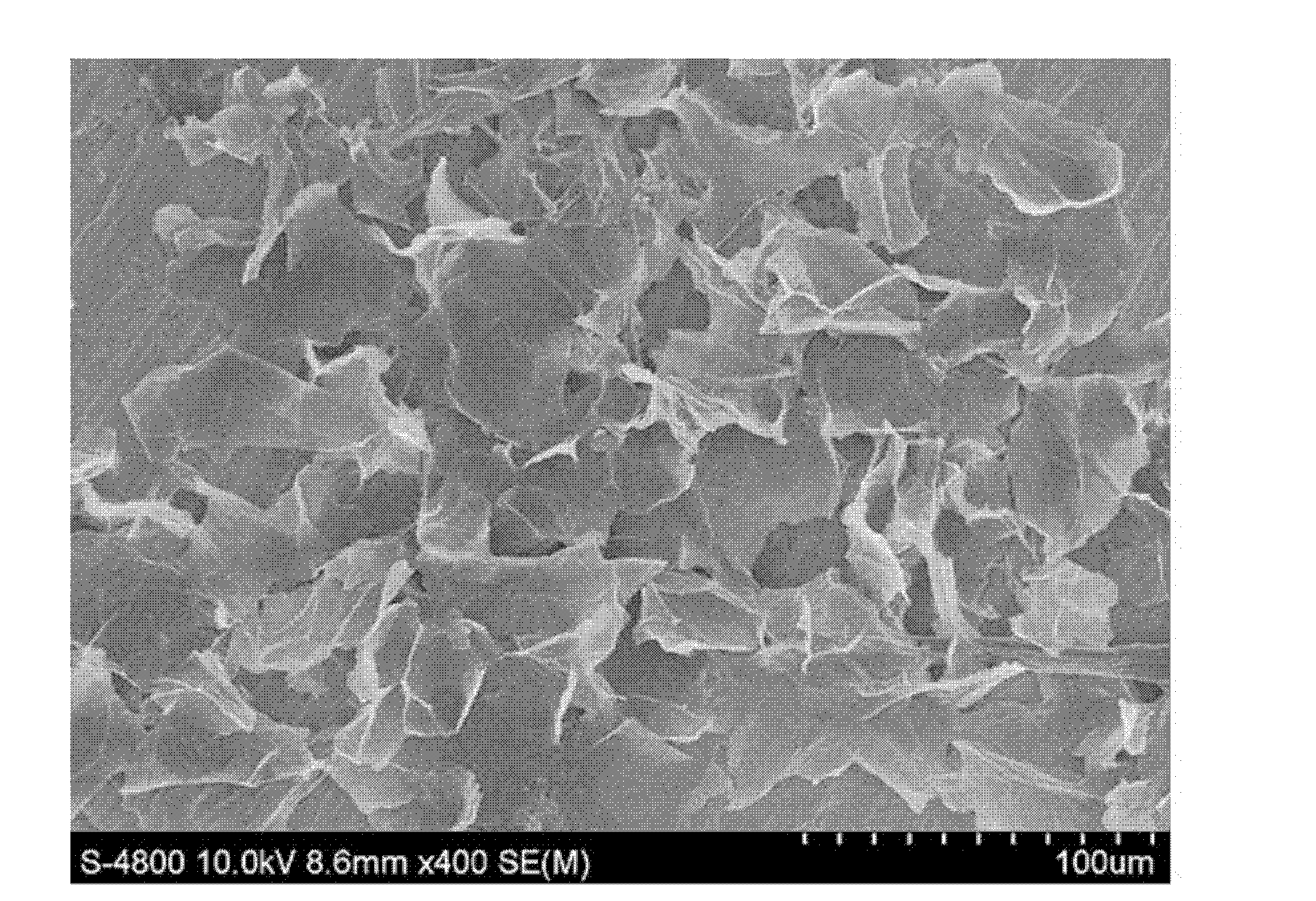

Green efficient electrochemical preparation method of high-quality water-soluble graphene

A green efficient electrochemical preparation method of high-quality water-soluble graphene comprises the following steps: (a) taking the water solution of aromatic carboxylic acid and metal hydroxideas an electrolyte, a graphite material as an anode material and a platinum sheet as a cathode material, and enabling two electrodes to be connected with a DC (direct current) voltage-stabilized powersupply; (b) switching on supply voltage to perform electrolytic reaction to obtain preliminarily dispersed water-soluble dispersion matter; (c) enabling the dispersion matter obtained in step b to besuccessively subjected to ultrasonic treatment and centrifugal washing to obtain high solid content graphene slurry; and (d) enabling the high solid content graphene slurry obtained in step c to be ultrasonically dispersed in water to obtain stable graphene dispersion liquid. The method has the advantages that the raw materials are easy to prepare and obtain, the technological process is simple,the post-treatment is simple and convenient, the cost is low, and the efficiency and yield are high. The prepared graphene has excellent conductive, heat-conducting and mechanical properties, and meanwhile can be stably dispersed in water for 6 months or more under the condition of not adding a dispersing agent.

Owner:青岛烯碳瑞尔新材料科技有限公司

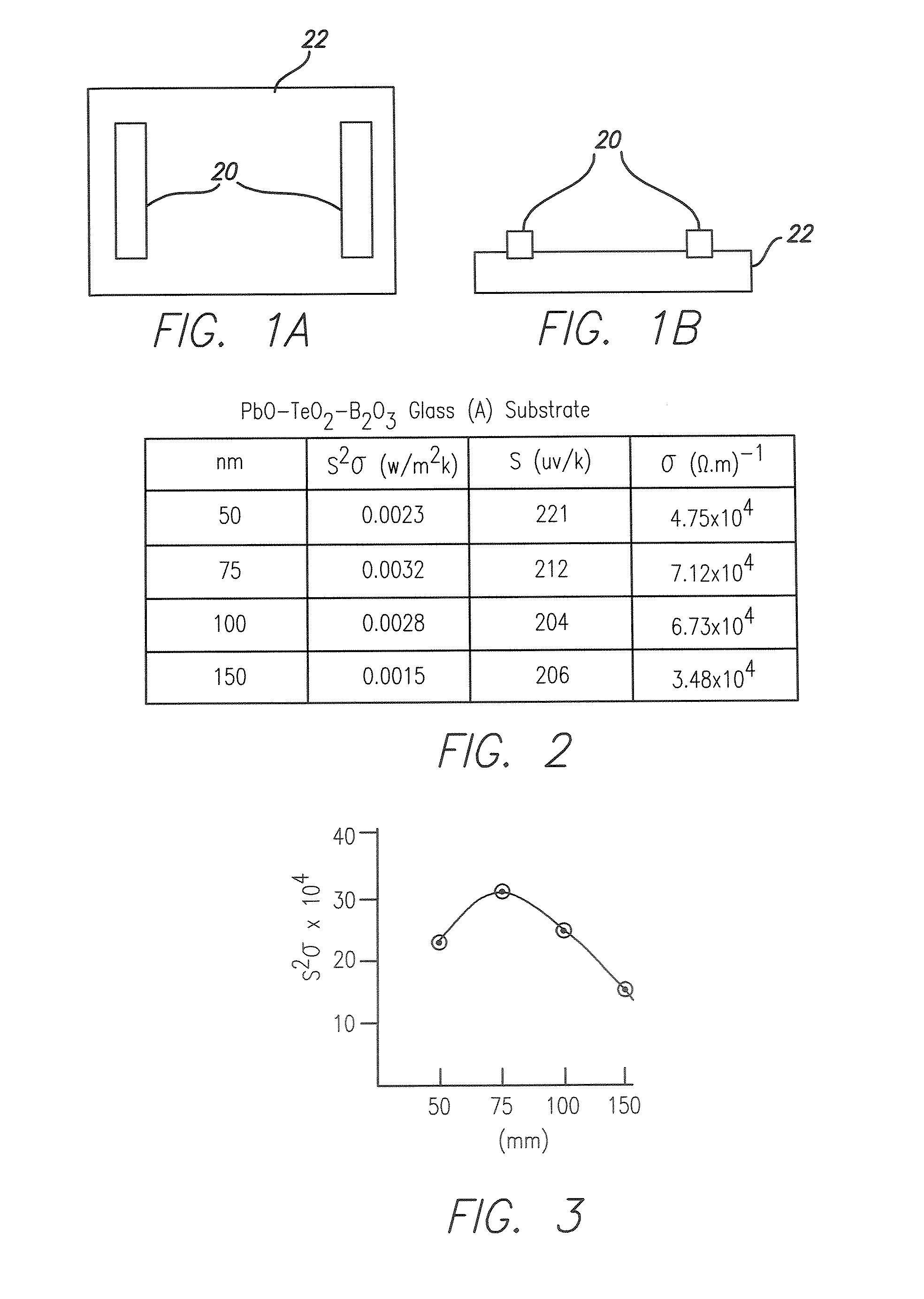

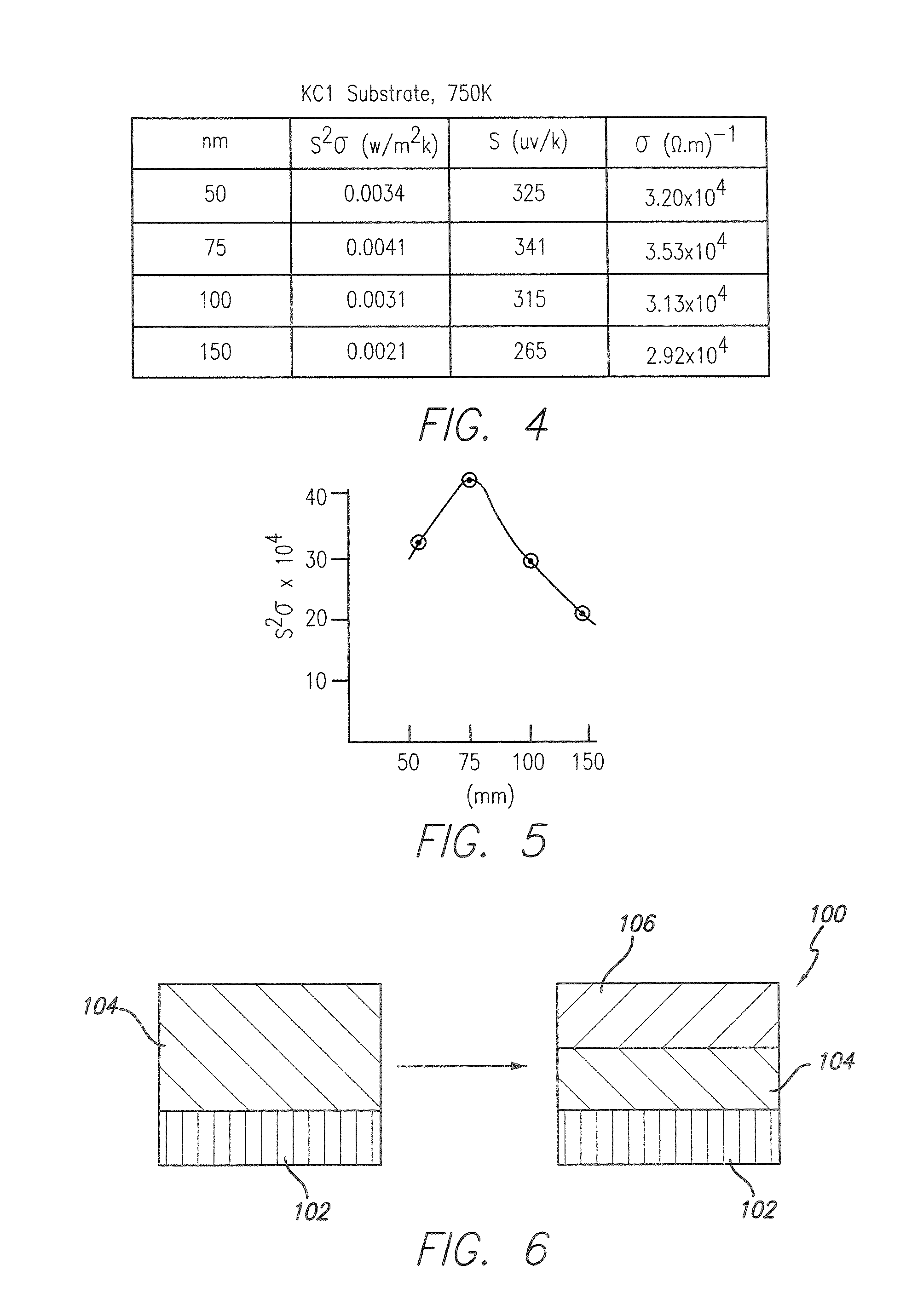

Thermoelectric device produced by quantum confinement in nanostructures

InactiveUS20070084499A1Cost-effectivelySmall footprintThermoelectric device manufacture/treatmentThermoelectric device detailsThermoelectric materialsPartial oxidation

The present invention provides a thermoelectric device comprising a film of thermoelectric material deposited on a substrate, and one or more electrodes located within the thermoelectric film, wherein the thermoelectric film is partially oxidized to form an oxide layer, which is melted to form an electrical insulating and protective barrier on a top surface of the film.

Owner:ZT3 TECH INC

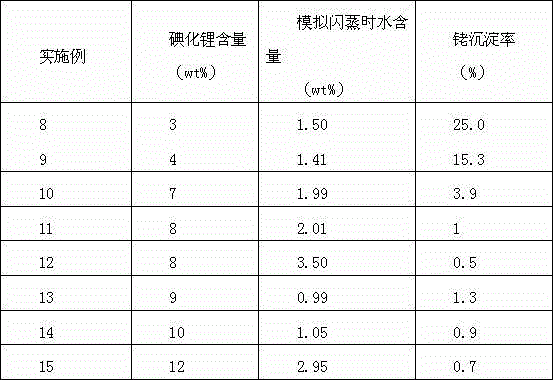

Method for preparing acetic acid through catalytic carbonylation reaction

ActiveCN103012103AGuaranteed stabilityReduce manufacturing costOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reactionHalogenRuthenium

The invention relates to a method for preparing acetic acid through a catalytic carbonylation reaction, and mainly solves the problems of low stability of rhodium catalyst under the low water condition, low reaction activity when producing the acetic acid through low-water carbonylation, and short product oxidization time. Methanol or derivative of the methanol is adopted as a raw material, and is carbonylated with a liquid reaction composition to synthesize acetic acid; the reaction composition comprises the rhodium catalyst, a halogen promoter, methyl acetate, the acetic acid, water, a iodide-salt cocatalyst and a ruthenium complex used as a stabilizing agent, wherein the ruthenium complex is selected from at least one of [Ru(Co)aIb]n, Mn<+>[Ru(CO)aIb]<->n or Mn<+>[RuIb]<->n. The technical scheme solves the problems better, and can be applied in the industrial production of preparing the acetic acid through the catalytic carbonylation reaction.

Owner:SHANGHAI HUAYI GRP CO

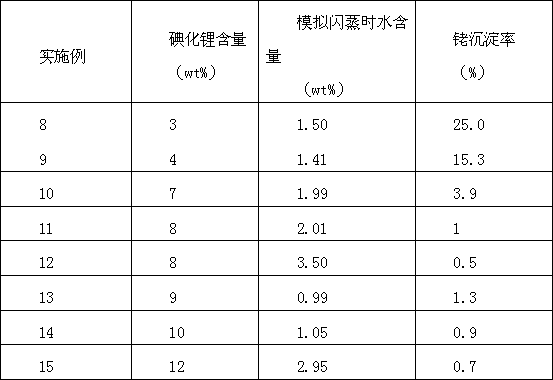

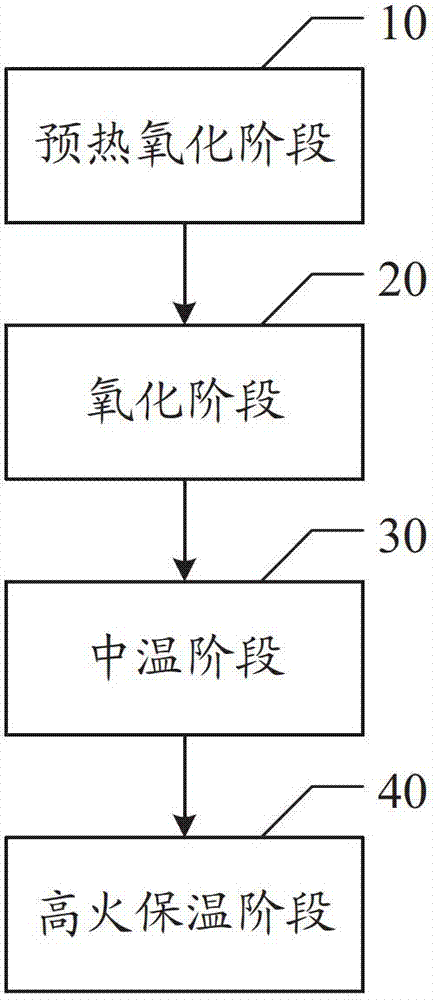

Formulation and sintering method for ultra-flat glaze

The embodiment of the invention discloses a formulation and a sintering method for ultra-flat glaze, applying to the field of industrial production. The formulation comprises potash feldspar, calcite, quartz, kaolin, zinc oxide, barium carbonate and calcined kaolin, wherein the total content of AL2O3 in the formulation is 12-15%, the contents of solvents are 4.3-4.8%, and the solvents include K2O, NA2O, CaO, ZnO and BaO. According to the embodiment disclosed by the invention, the surface of the glaze can be flatted and smoothened, and pores are reduced.

Owner:JIANGXI FULIGAO CERAMIC CO LTD

Method for preparing sustained release potassium ferrate clathrate compound for water treatment

InactiveCN104211157AExtended oxidation timeGood decolorization effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationFiltrationWastewater

The invention relates to a method for preparing a sustained release potassium ferrate clathrate compound for water treatment. The method includes the following steps that NaOH and Fe(NO3)3, 9H2O are dissolved in a 10% NaClO solution under the ice-bath condition, stirring is performed for reaction for 1.5 to 2 hours, suction filtration is performed to obtain a sodium ferrate liquid, a 45mL saturated KOH solution is added into the sodium ferrate liquid, then stirring and suction filtration are performed to obtain a potassium ferrate liquid, ethyecellulose and polyethylene are added into cyclohexane, heating is performed to reach 80 DEG C, stirring is performed continuously, heating is stopped to cool to reach 60 DEG C, the potassium ferrate liquid is added, then stirring is performed continuously, after a while, a potassium ferrate clathrate compound and a mixed liquid are subjected to centrifugal separation, and vacuum drying is performed to obtain the dry sustained release potassium ferrate clathrate compound. By means of the method for preparing the sustained release potassium ferrate clathrate compound for water treatment, oxidation time of the potassium ferrate clathrate compound on pollutants can be prolonged, the preparation method is simple, the decolorization effect on dyestuff wastewater is good, and thereby, market prospect is wide.

Owner:JINGDEZHEN CERAMIC INSTITUTE

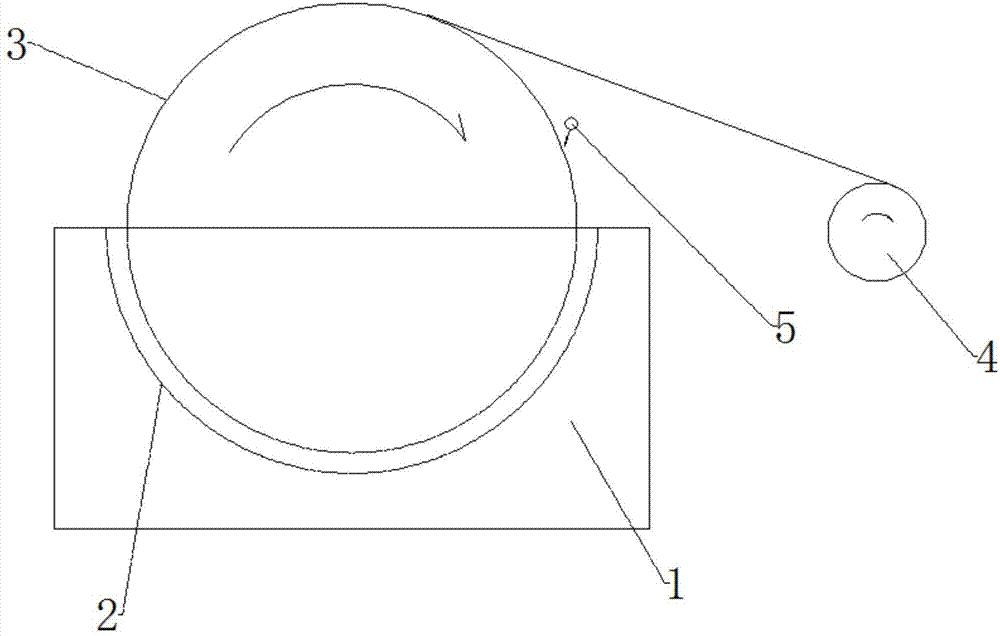

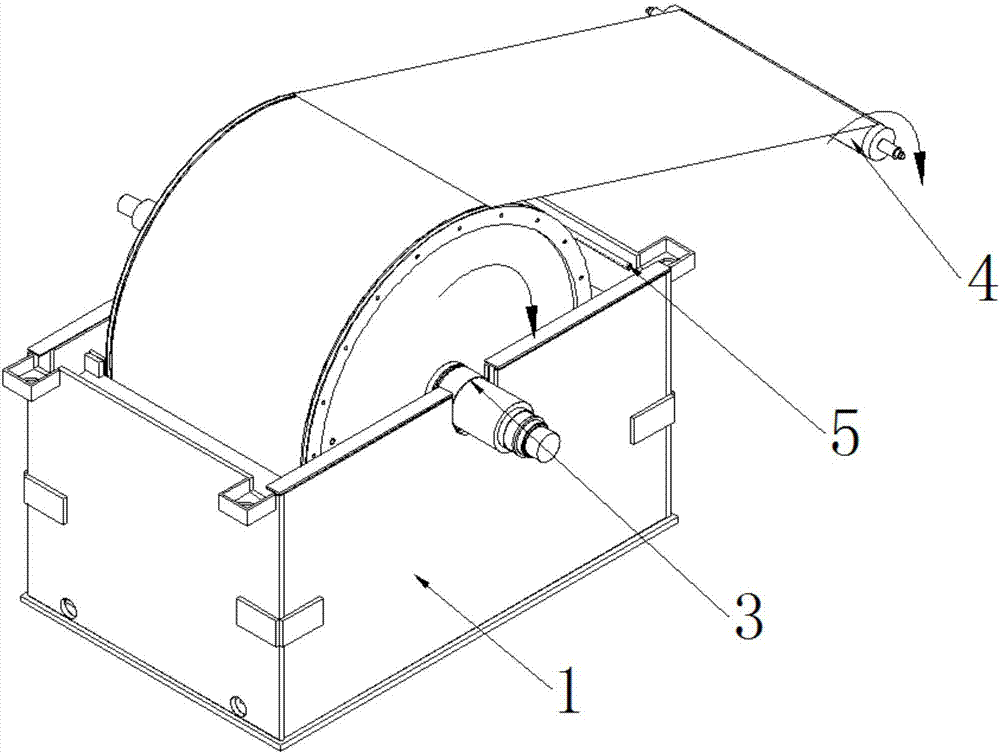

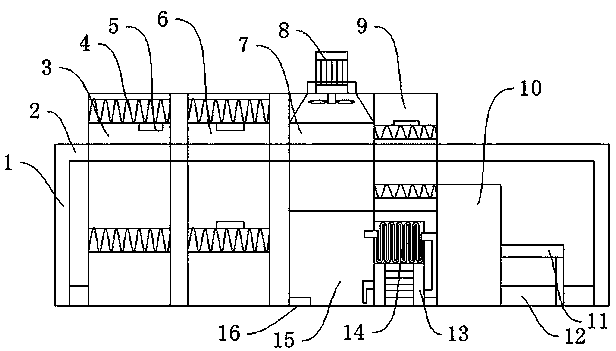

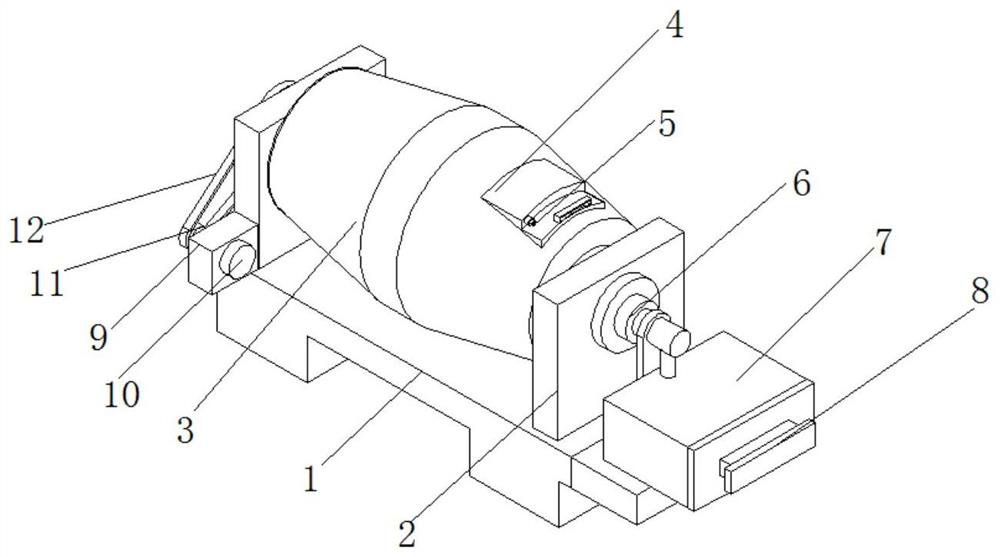

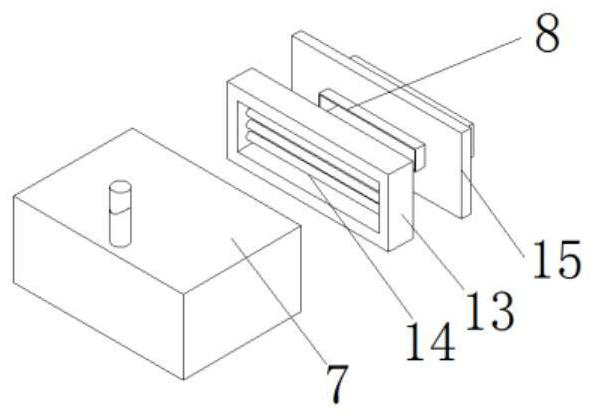

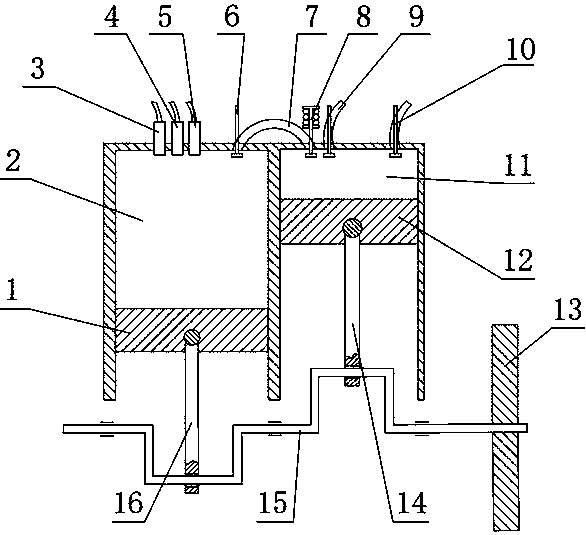

Foil producing machine preventing copper foil white spot forming

PendingCN107419303AEliminate overflow foam contaminationSimple structureElectroforming processesCopper foilEngineering

The invention discloses a foil producing machine preventing copper foil white spot forming. The foil producing machine comprises an electrolytic cell. An anode plate and a cathode roller are arranged in the electrolytic cell. A copper foil winding device is arranged on the right side of the cathode roller. A liquid spraying pipe is arranged on the side face of an inlet of the cathode roller. A plurality of circular holes arranged at equal intervals are formed in the liquid spraying pipe. The foil producing machine has the beneficial effects that the liquid spraying pipe covering the roller face width of the cathode roller is arranged above an ordinary cathode roller, and before the cathode roller enters the electrolyte face, the roller face of the cathode roller is completely covered with an electrolyte solution, and the possibility of overflow liquid foam pollution is eliminated from the source. The structure is simple, generation of electrolysis copper foil white spots can be effectively prevented, the time of oxidization of the roller face of the cathode roller can be prolonged as well, the grinding frequency of the cathode roller is reduced, and the service life of the cathode roller is prolonged.

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD

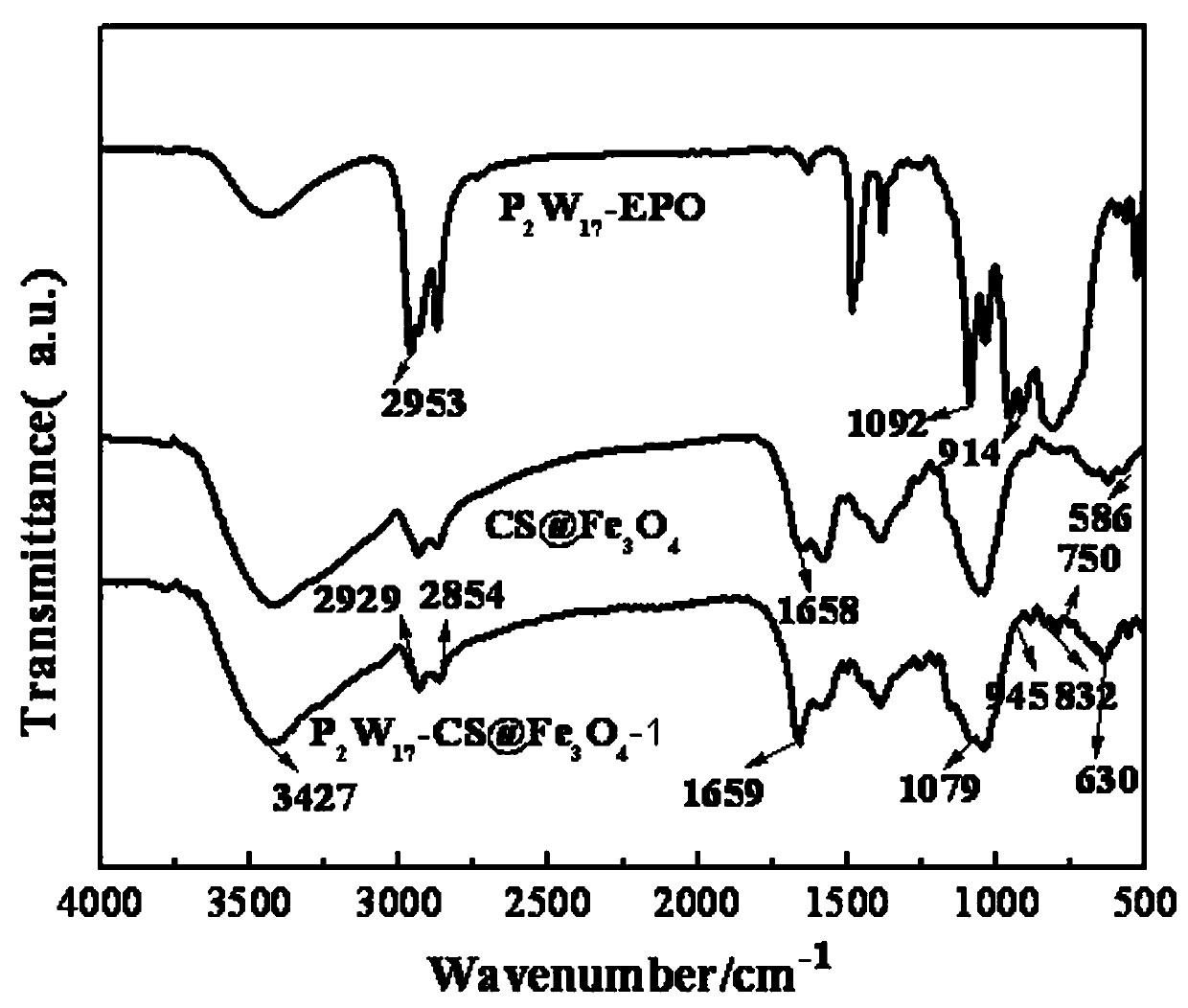

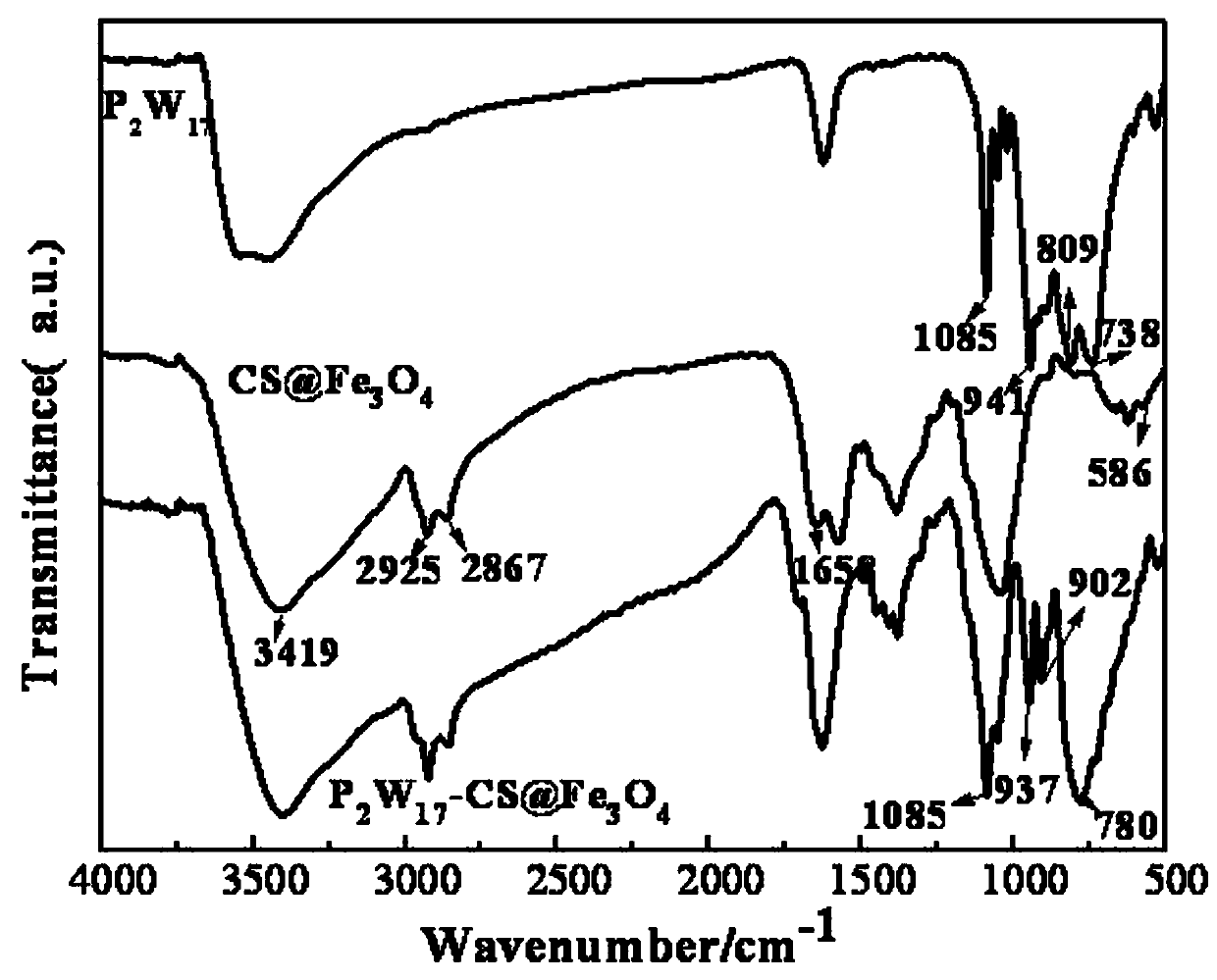

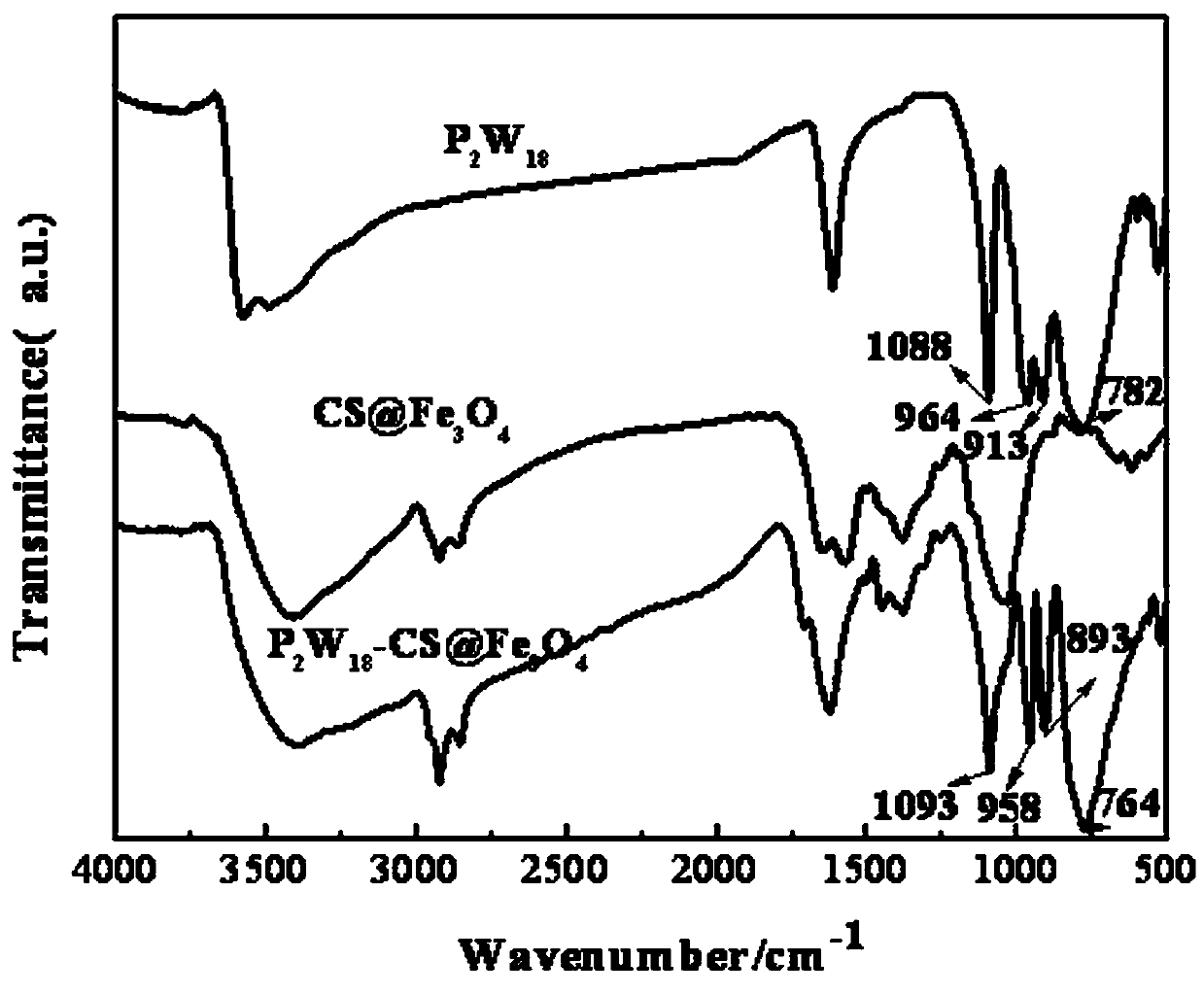

High-dispersion polyoxometallate magnetic microsphere catalyst, and preparation method and application thereof

InactiveCN110586186AGood dispersionReduce dosageOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDispersityMicrosphere

The invention belongs to the technical field of loaded polyoxometallate catalysts, and provides a high-dispersion polyoxometallate magnetic microsphere catalyst, and a preparation method and application thereof so as to overcome the defects that polyoxometallate used as a catalyst is small in specific surface area, few in reaction activity sites, prone to aggregation, soluble in water, difficult to separate and recycle and the like. Dawson type phosphotungstate is loaded onto a CS@Fe3O4 microsphere by a covalent bonding method, and a covalent loaded Dawson type phosphotungstate magnetic microsphere P2W17-CS@Fe3O4-1 is obtained; or, Keggin type phosphotungstate and the Dawson type phosphotungstate are respectively loaded to an organic modified magnetic Fe3O4 microsphere by an electrostaticbonding method, and loaded Keggin type phosphotungstate and loaded Dawson type phosphotungstate are obtained. The dispersity and the specific surface area of the polyoxometallate are improved, the catalytic oxidation activity of the polyoxometallate and the oxidation efficiency of tetrahydrothiophene are improved, and a magnetic carrier provides favorable conditions for catalyst separation and recycling.

Owner:ZHONGBEI UNIV

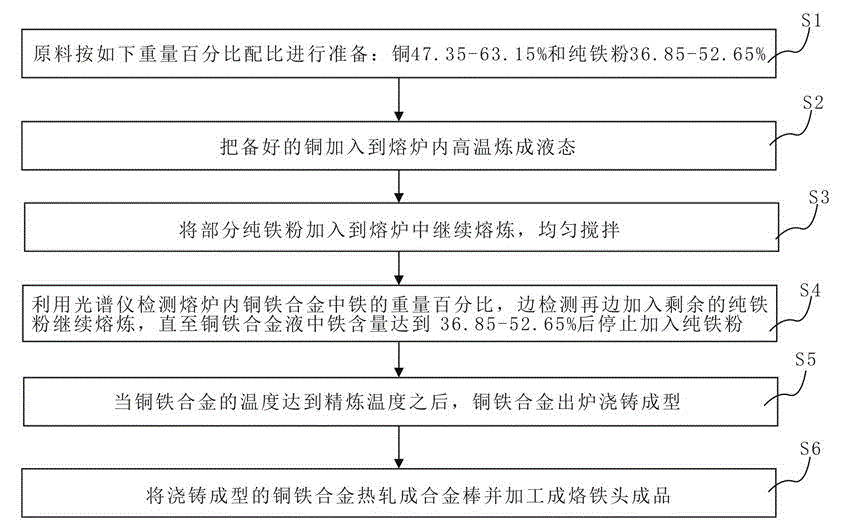

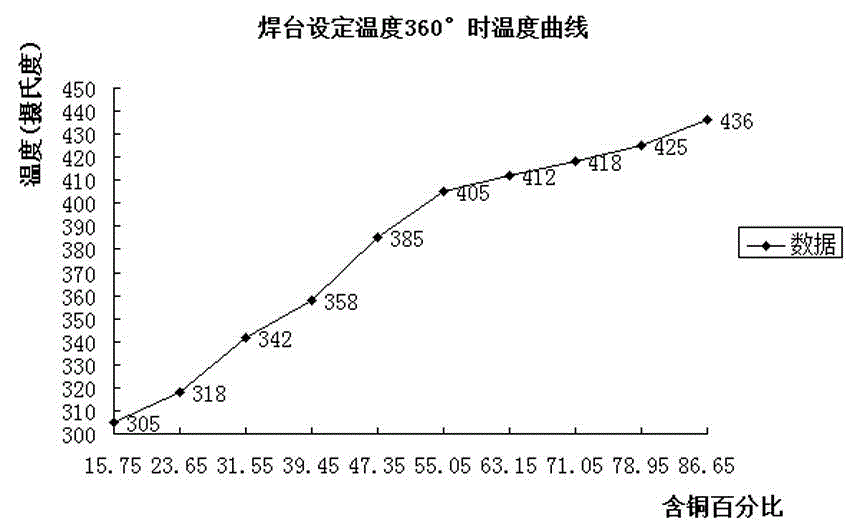

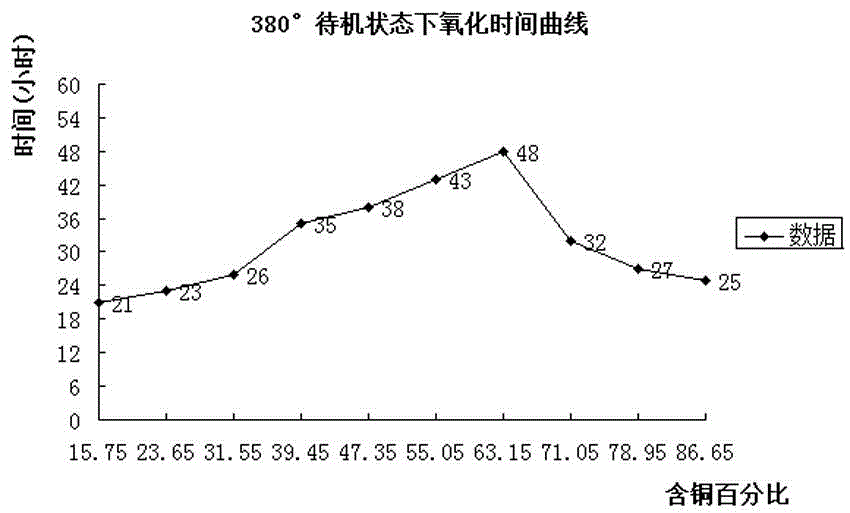

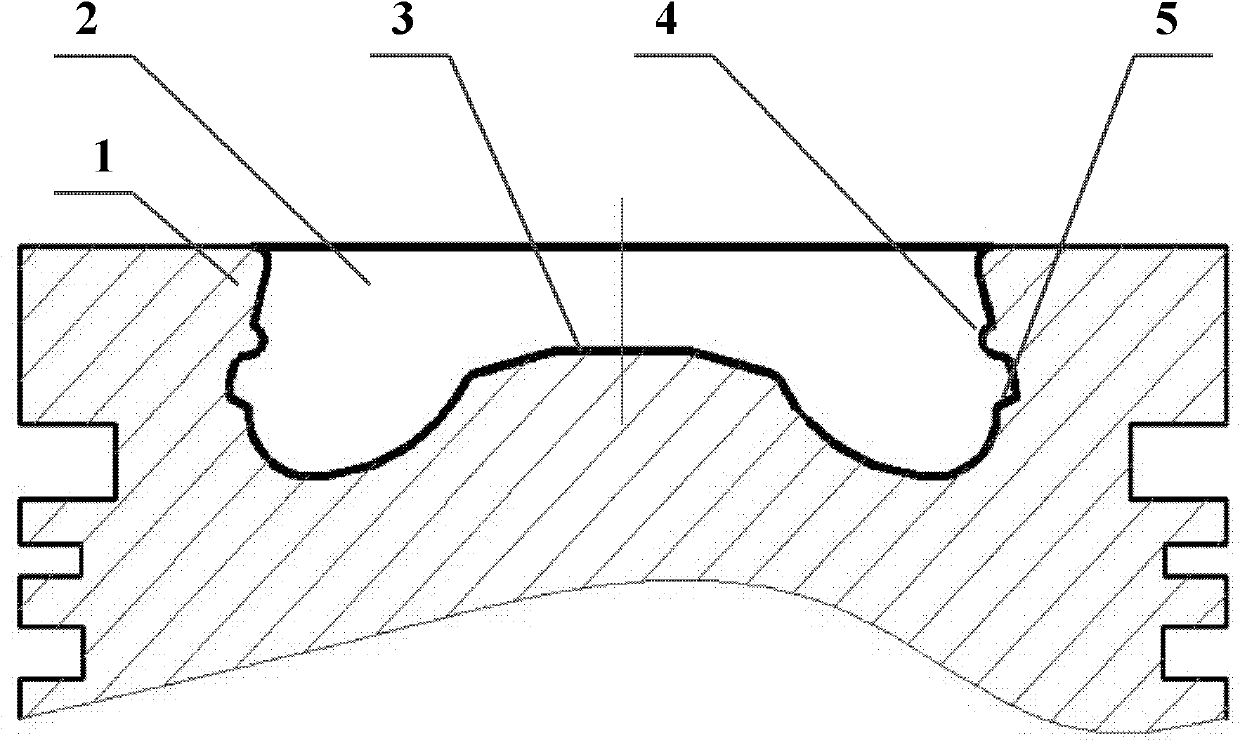

Copper and iron alloy for producing soldering bit and production technology thereof

InactiveCN104152739AReduce pollutionSolve the technical problem that the thickness is difficult to controlIron powderLiquid state

The invention discloses a copper and iron alloy for producing a soldering bit and a production technology thereof. The technology comprises the following steps: preparing the following raw materials in weight percentage: 47.35-63.15% of copper and 36.85-52.65% of pure iron powder; adding prepared copper into a smelting furnace and smelting the copper into a liquid state at a high temperature; adding part of pure iron powder into the smelting furnace, continuously smelting and uniformly agitating the mixture; detecting the weight percentage of the iron in the copper and iron alloy in the smelting furnace by a spectrograph, adding the rest of pure iron powder while detecting, continuously smelting, and stopping adding pure iron powder until the iron content in molten copper and iron alloy reaches 36.85-52.65%; after the temperature of the copper and iron alloy reaches a refining temperature, discharging the copper and iron alloy out of the furnace, and molding through casting; hot-rolling the copper and iron alloy molded through casting into an alloy bar and processing the alloy bar into a soldering bit finished product. The alloy only comprises copper and pure iron powder, electroplating processing is not required, and pollution to the environment is reduced. Meanwhile, the heat conductivity of the soldering bit and the tin loading smoothness are greatly improved, the service life of the soldering bit is prolonged, and the production cost is lowered.

Owner:SHENZHEN GREEN ELECTRONICS

Coal-fired combustion improver with high stability

The invention provides a coal-fired combustion improver with high stability. The coal-fired combustion improver is innovatively characterized by comprising the following components in percentage by weight: 20-30% of an oxidizing agent, 2-8% of a stabilizer, 20-30% of a catalyst, 2-3% of a dispersing agent, 10-20% of an emulsifier and 10-20% of a penetrating agent, wherein the stabilizer comprises 3,5-ditert-butyl-4-hydroxybenzoyl hydrazine, xylogen, silica powder, sodium sulfanilate and zinc stearate, or 3-methyl-5-tert-butyl-4-hydroxybenzoyl hydrazine, xylogen, silica powder, sodium sulfanilate and zinc stearate. According to the coal-fired combustion improver disclosed by the invention, the effect of adding the stabilizer into the coal is to mainly achieve the effects of delaying the decomposition rate after the oxidizing agent is heated and increasing the action time in the combustion system, and then the actual combustion effect is improved.

Owner:朱亚东

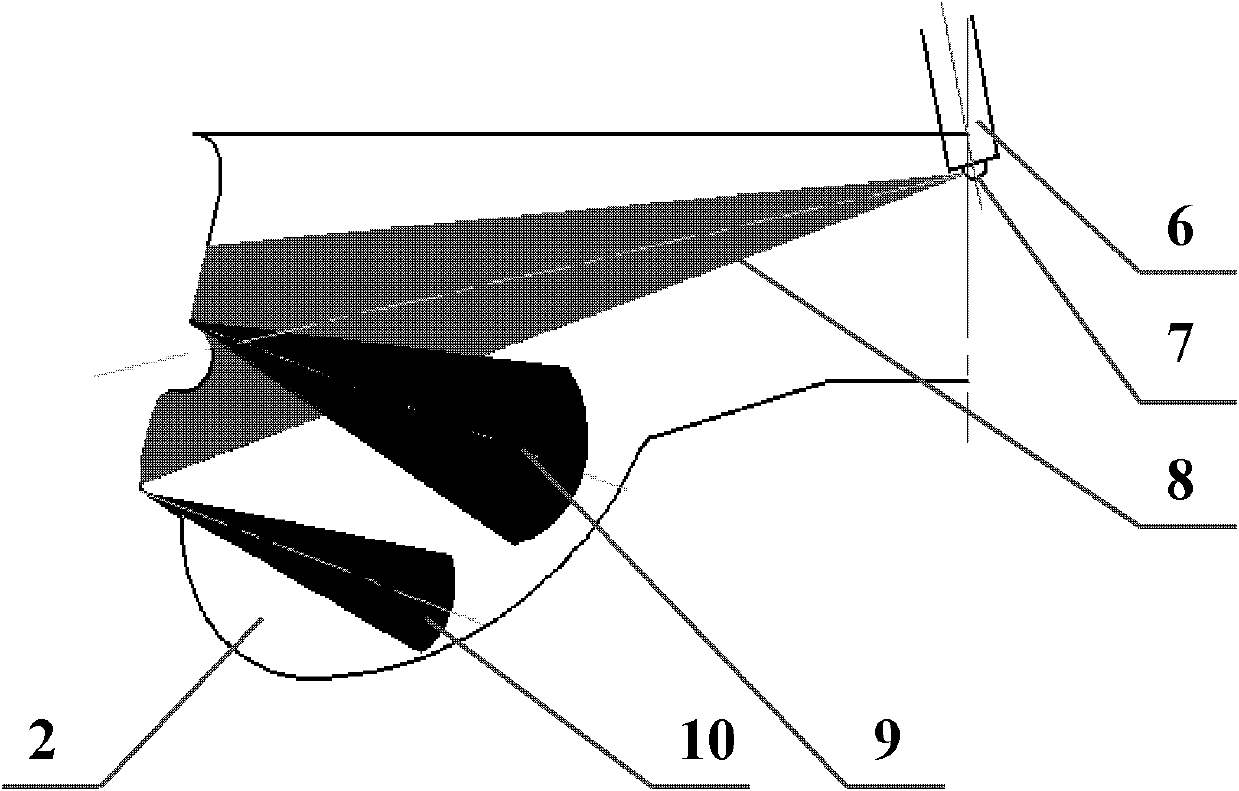

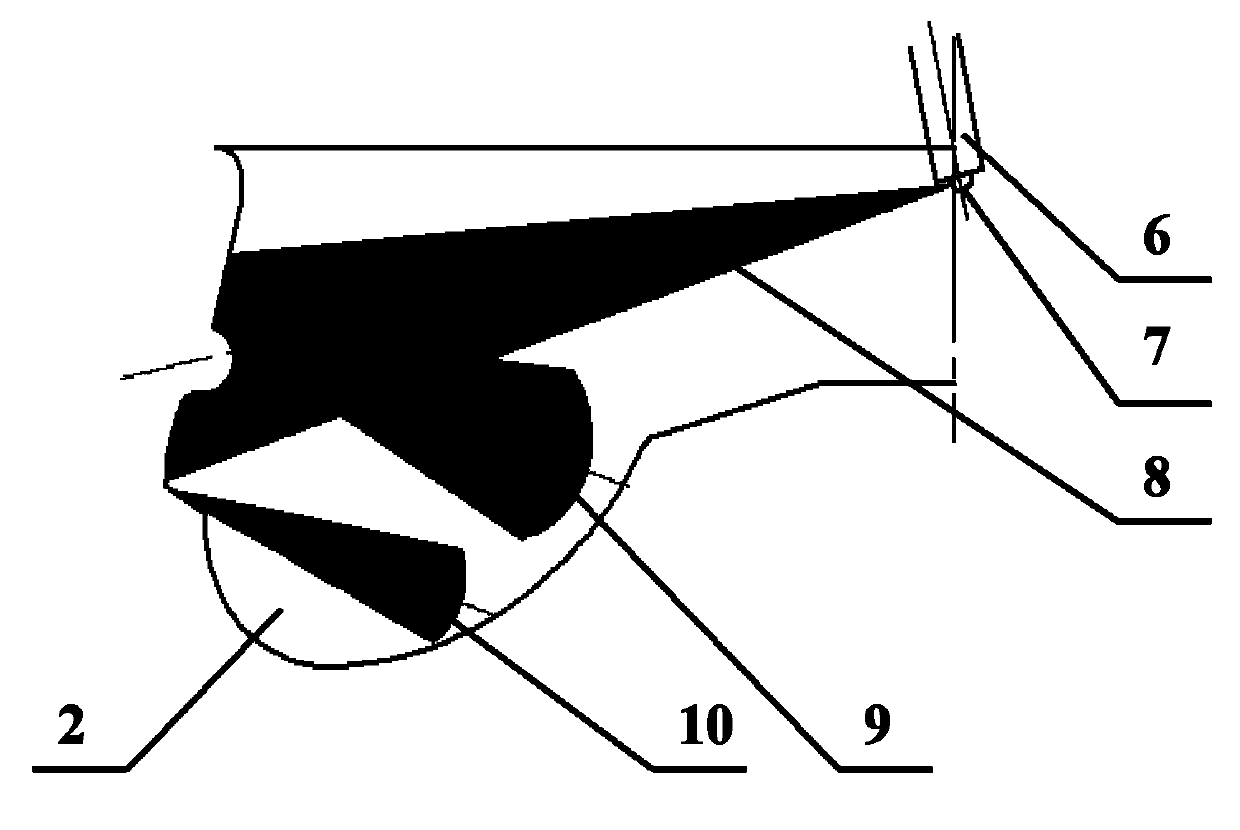

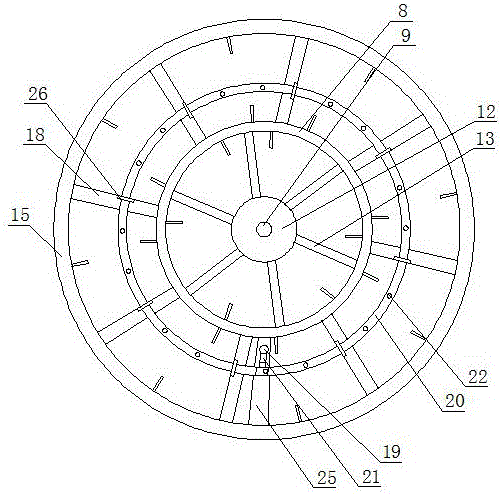

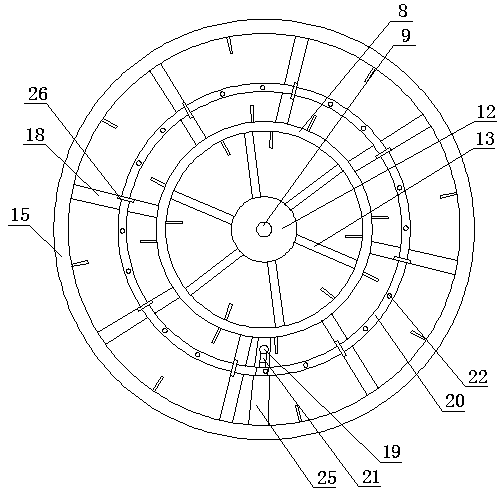

Direction-injection diesel engine combustion chamber

InactiveCN101793206AEmission reductionGood test resultInternal combustion piston enginesPistonsHigh concentrationInjection pressure

The invention discloses a direction-injection diesel engine combustion chamber, belonging to the technical field of internal combustion engine structures and combustion devices. The invention is characterized in that guide convex arcs and small steps are arranged on the wall surface of the combustion chamber. The guide convex arcs and the small steps are arranged fully circumferentially, intermittently or locally. The positions of the guide convex arcs and the small steps on the wall surface are related to the shape of the combustion chamber, the size of injection holes, the angle of the injection holes, oil injection pressure, intake swirl ratio and other parameters. The cross section of each guide convex arc is semicircular, elliptic and the like. The technology adopts the guide bundle spray and stratification theory, adopts 'double wall surface injection' method to inhibit the generation of high-concentration NO at the tips of flames and promotes the mixing of the spray tips. The invention has the advantages that the even mixed gas can be formed at the premixing combustion step, the rapid mixing of oil and gas is realized, the travel time of carbon granules is shortened and thereby the oxidization time of the carbon granules is increased.

Owner:DALIAN UNIV OF TECH

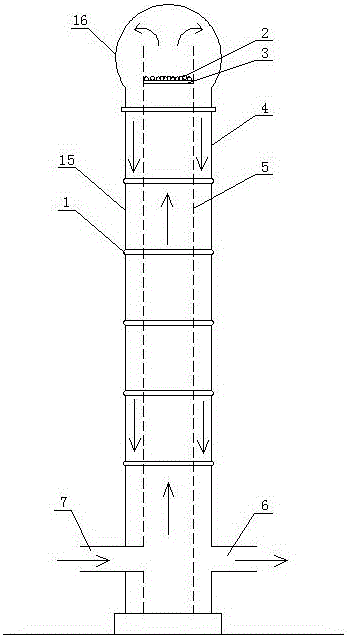

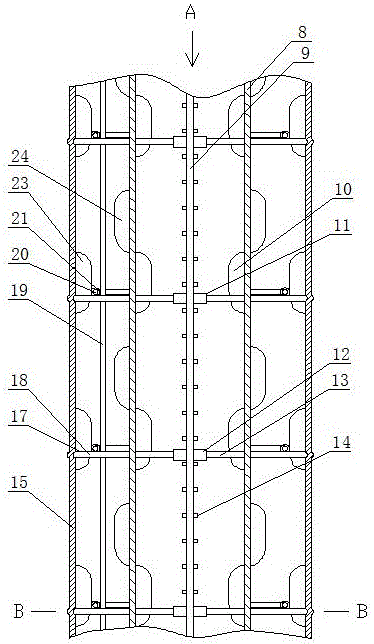

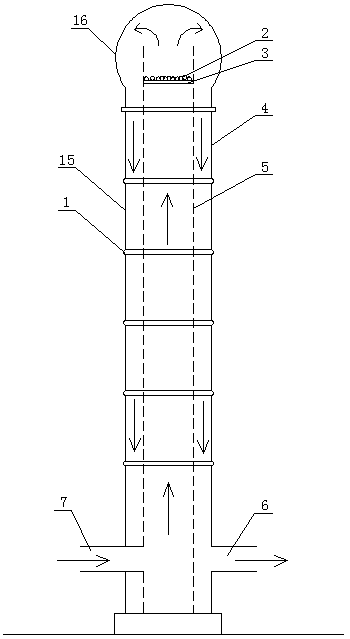

Compound efficient energy-saving desulfurization, denitrification and dedusting integrated purifying column

ActiveCN105797554AHigh temperature resistantCorrosion resistanceCombination devicesGas treatmentGratingFlue gas

The invention discloses a compound efficient energy-saving desulfurization, denitrification and dedusting integrated purifying tower and relates to environmental protection equipment. The compound efficient energy-saving desulfurization, denitrification and dedusting integrated purifying tower comprises a desulfurization device and a denitrification device. The desulfurization device comprises a desulfurization tower and a main desulfurizing agent pipe, the inner upper end of the desulfurization tower is connected with a grating filtering layer, purifying filler is arranged on the grating filtering layer, the main desulfurizing agent pipe is vertically fixed in the desulfurization tower through a supporting component, and a plurality of nozzles are connected to the main desulfurizing agent pipe along the height direction. The denitrification device comprises a denitration tower and a spherical gas surge tower, the gas surge tower is fixedly connected to the upper end of the denitration tower, the denitration tower is fixed in an inner cavity of the denitration tower through a connecting component, and a denitration oxidizing agent pipeline is arranged between the denitration tower and the desulfurization tower and is provided with a plurality of liquid outlet holes. A flue gas inlet and a flue gas outlet are formed in the lower end of the desulfurization tower, the flue gas inlet passes through the denitration tower to be communicated with an inner cavity of the desulfurization tower, and the flue gas outlet is communicated with the inner cavity of the denitration tower. The compound efficient energy-saving desulfurization, denitrification and dedusting integrated purifying tower has the advantages of good purifying effect and low cost.

Owner:江苏绿塔环境工程有限公司

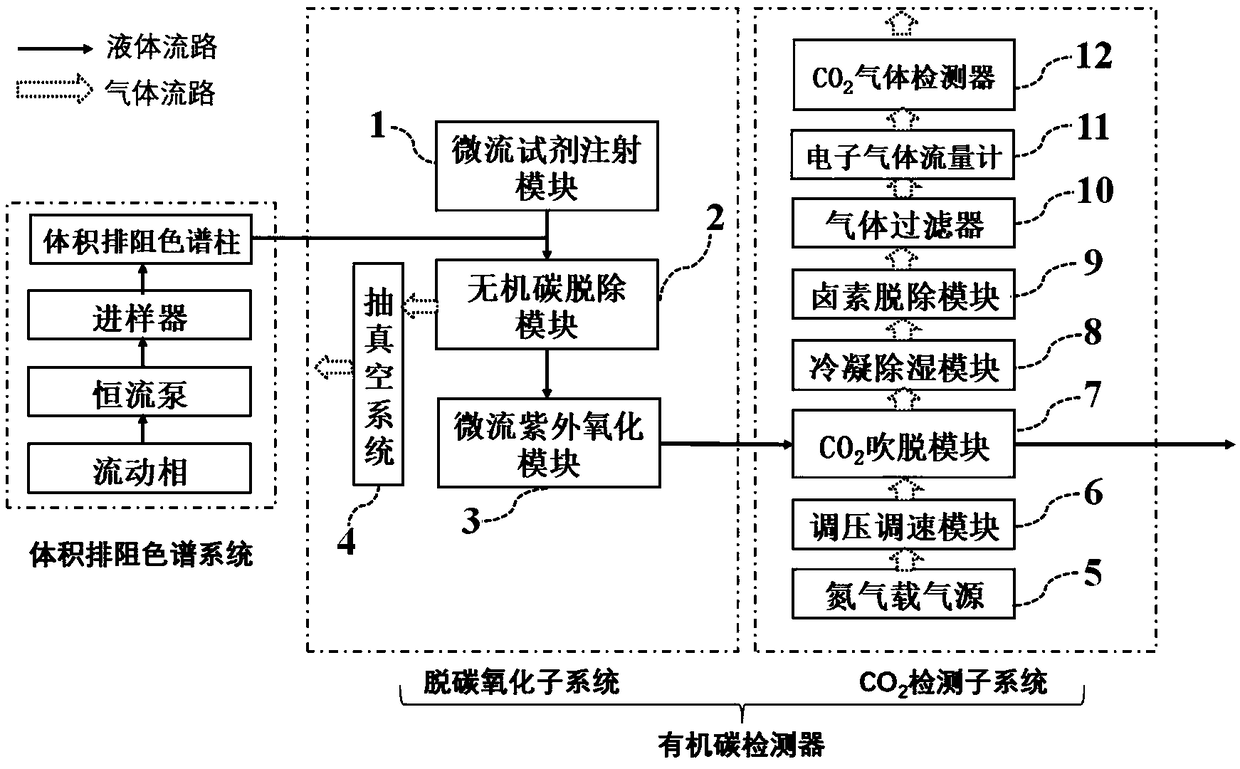

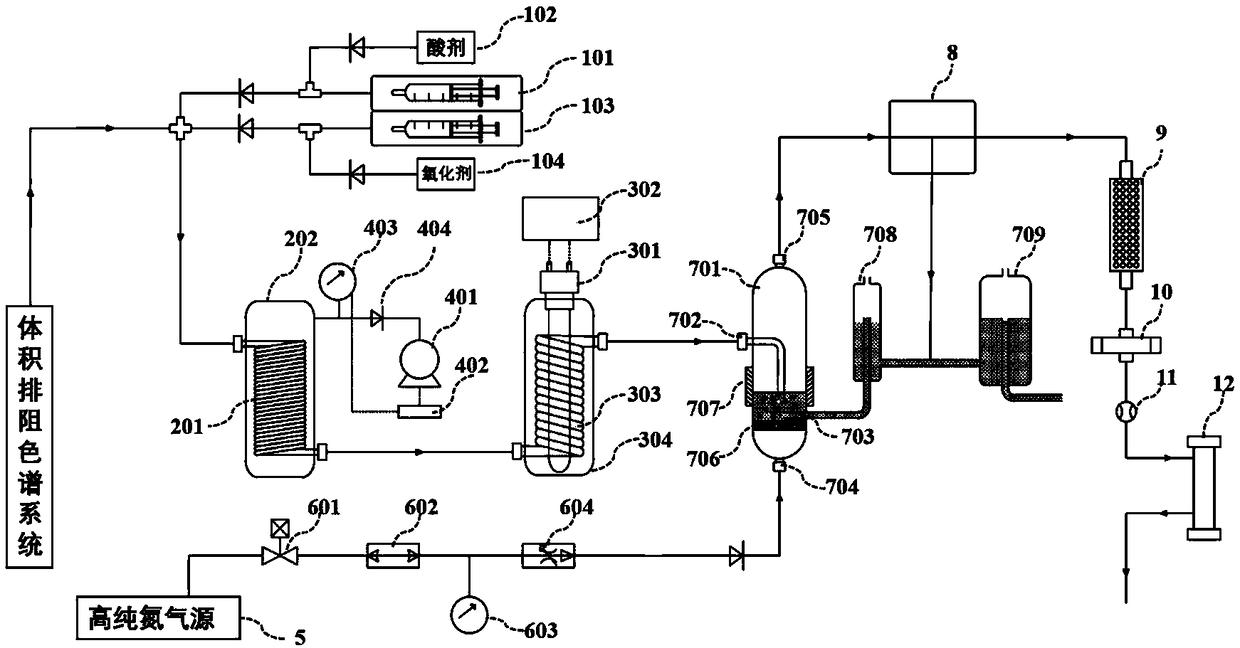

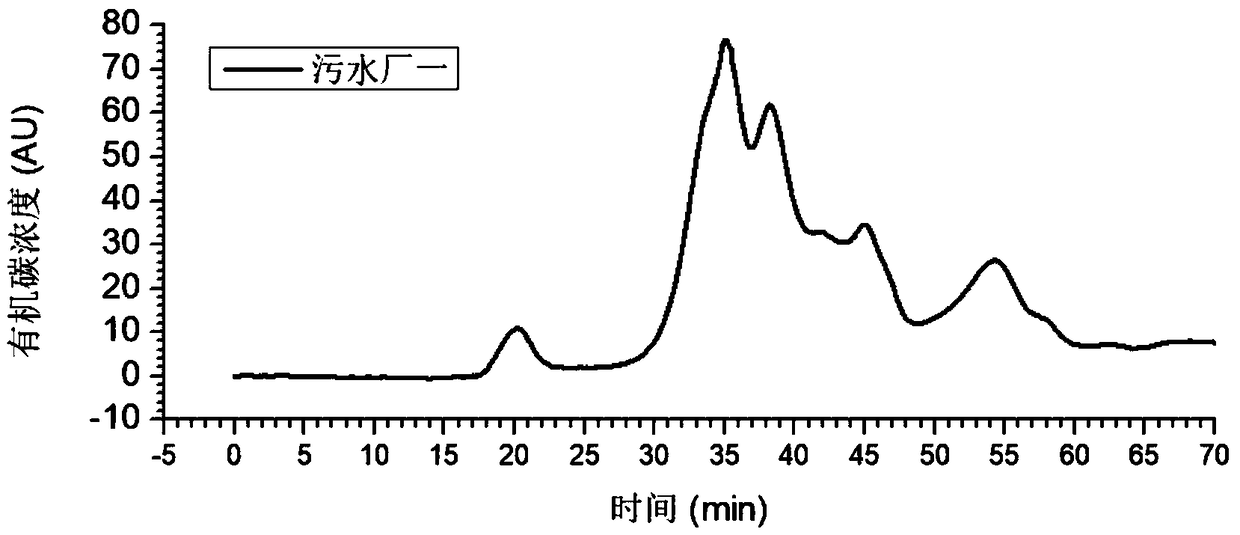

Liquid chromatography combined organic carbon detector and using method thereof

PendingCN109406705ARealize continuous detectionExtended oxidation timeComponent separationTransmissivity measurementsWater qualityNitrogen

Owner:NANJING UNIV

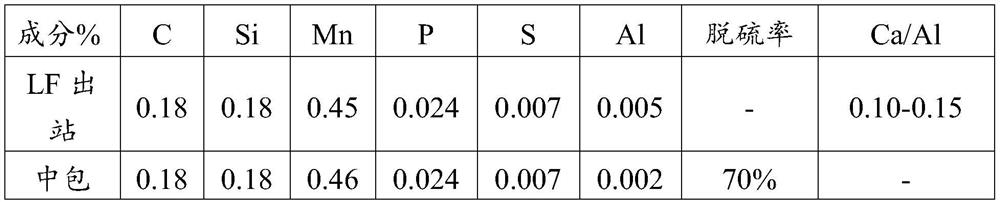

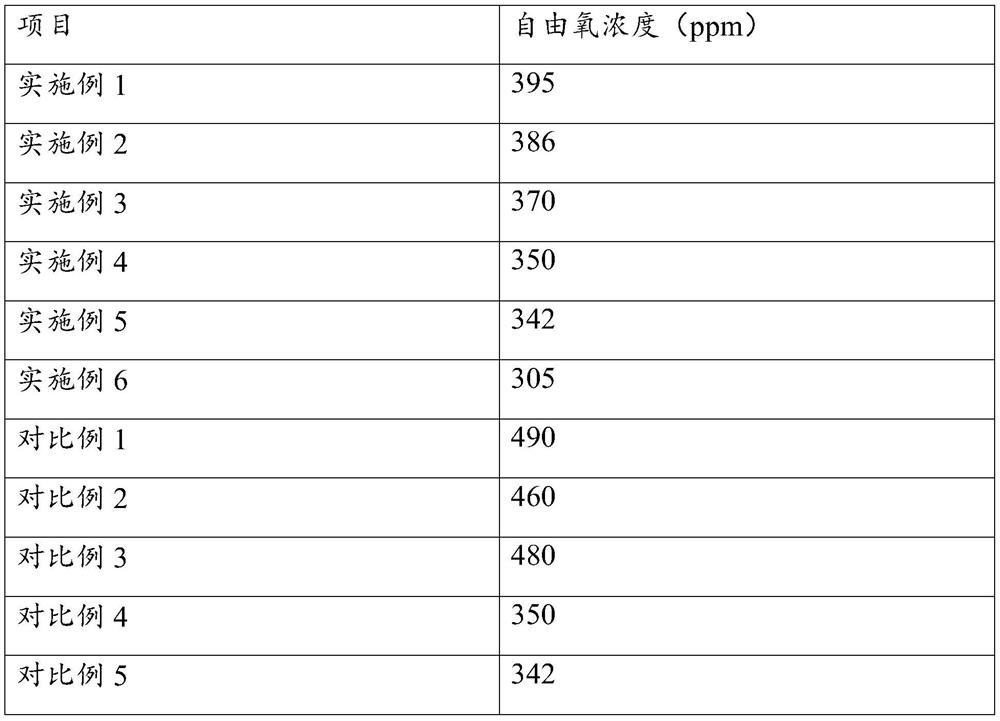

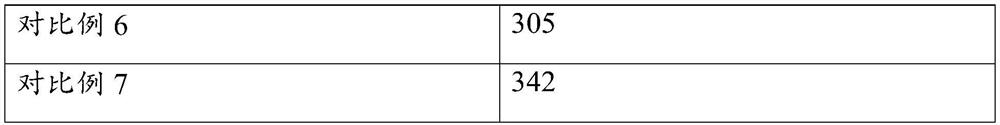

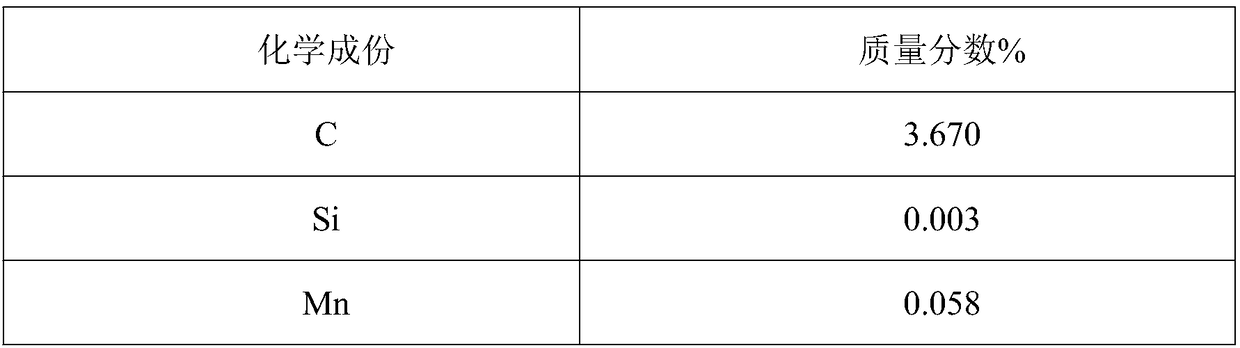

Deoxidation smelting method of slab Q235 steel and slab Q235 steel

The invention discloses a deoxidation smelting method of slab Q235 steel and the slab Q235 steel, and relates to the technical field of smelting. The smelting method comprises the steps that molten iron and scrap steel are loaded, the top-bottom combined blowing converter blowing process is adopted, and argon is blown from the bottom in the whole process; slag charge is loaded, the loading amount of the slag charge at the beginning of blowing is 30%, and the rest 70% of the slag charge is completely added within 10 min after blowing is started; the flow of the oxygen lance is controlled to be 33000-35000 m < 3 > / h The lance position of the oxygen lance during blowing is 1.8-2 m; manganese and silicon are added for tapping deoxidation alloying operation; after tapping, aluminum wire feeding operation is carried out in an argon station; transferring into an LF furnace for refining; and performing continuous casting. The smelting method can ensure good deoxidation of the molten steel, reduce subsurface bubbles generated by the molten steel, reduce the cost, ensure the castability of the molten steel and reduce the occurrence rate of edge cracks.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

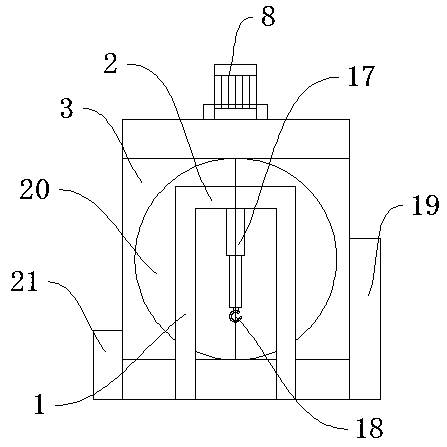

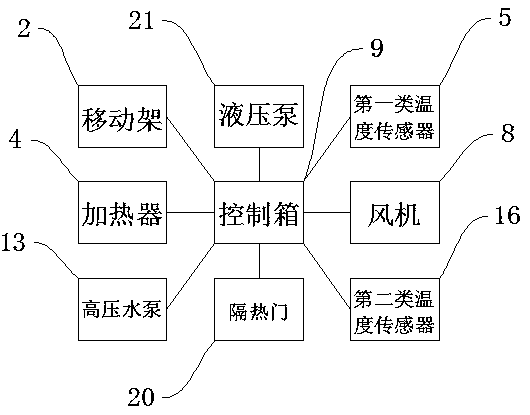

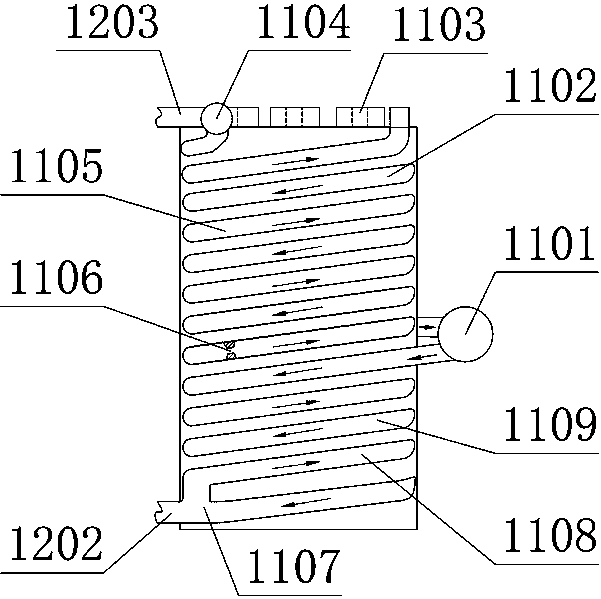

Heat treatment device for crankshaft processing device

InactiveCN108913866AImprove quenching efficiencyShorten the timeFurnace typesHeat treatment furnacesEngineeringMoving frame

The invention discloses a heat treatment device for a crankshaft processing device. The heat treatment device for the crankshaft processing device comprises a normalizing chamber, an annealing chamberand a quenching chamber, wherein a support frame is arranged on one side of the normalizing chamber; a heat insulation door is arranged on one side of the inner part of the normalizing chamber; a moving frame is arranged above the support frame; a heater is arranged on the upper part of the inner part of the normalizing chamber; a telescopic cylinder is arranged under the moving frame; a pothookis arranged under the telescopic cylinder; a heater is arranged on the lower part of the inner part of the normalizing chamber as well; a first class of temperature sensor is arranged under the heater; the annealing chamber is arranged on the other side of the normalizing chamber; and the quenching chamber is arranged on one side of the annealing chamber. The heat treatment device for the crankshaft processing device has the beneficial effects that (1) a heat dissipation tank is arranged on one side of the quenching chamber, so that a medium in the quenching chamber can be cooled, the quenching efficiency is improved, and the heat treatment time is shortened; and (2) an oil quenching chamber is arranged at the tail end of the equipment, and a layer of oil is coated on the outer surface ofa crankshaft while secondary quenching is carried out at the same time, so that the crankshaft oxidizing time is prolonged.

Owner:江苏太宝龙实业有限公司

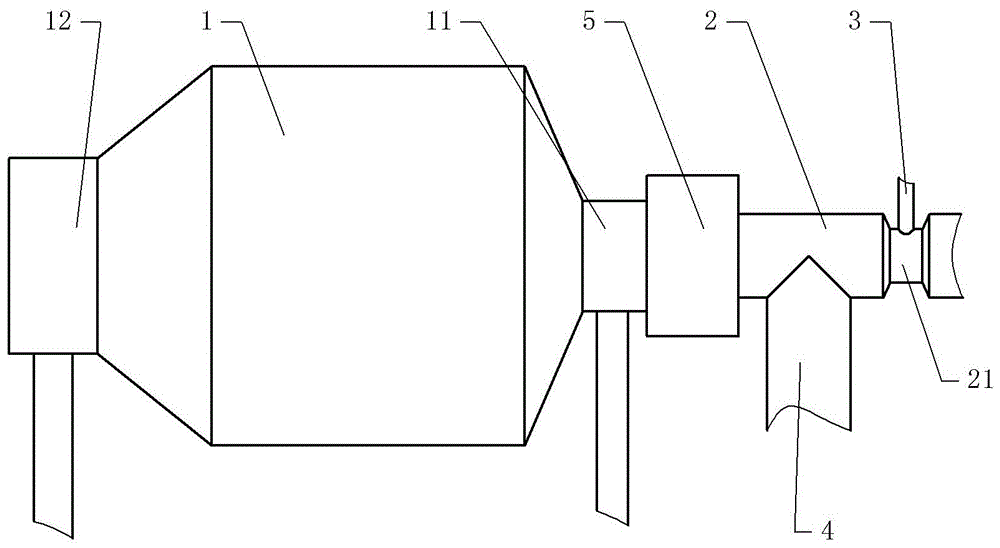

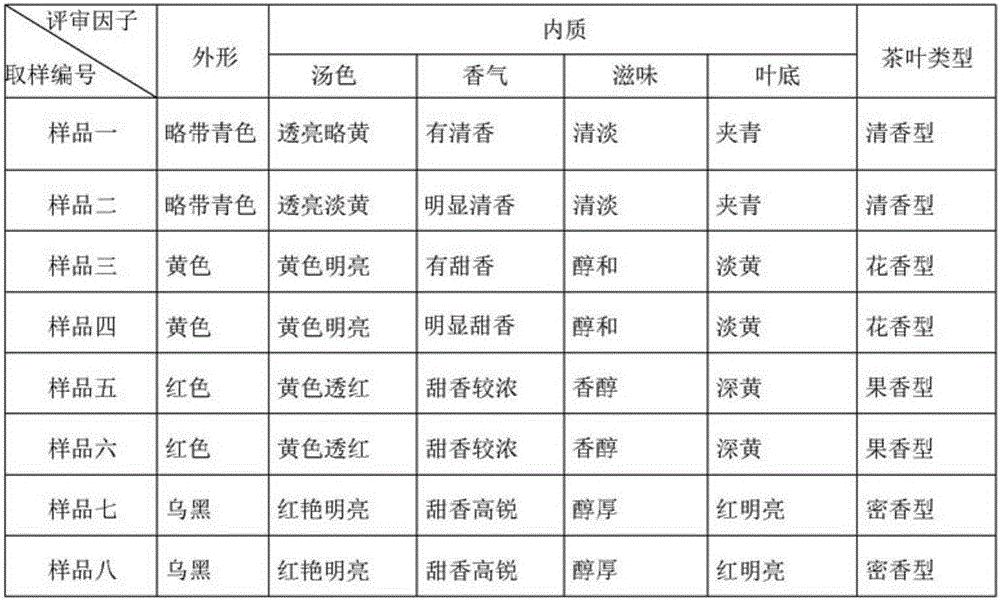

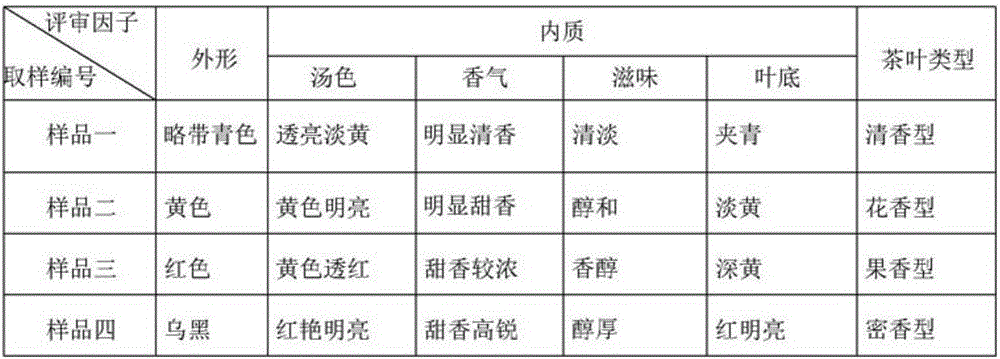

Nitrogen-charging black tea fermenting method

InactiveCN106417723AUniform fermentationHelps control oxygen contentPre-extraction tea treatmentNitrogenBlack tea

The invention discloses a nitrogen-charging black tea fermenting method and relates to a tea production method. The method comprises five steps including a preparation stage, a green tea adding state, a fermentation stage, a nitrogen charging state and a fermentation stopping stage, wherein at the nitrogen charging stage, nitrogen is charged into a fermentation tank, so that the nitrogen content of the fermentation tank is gradually increased from 70% to 90%; at the fermentation stopping stage, tea in the fermentation tank is sampled once every 2-5 minutes, the color and the aroma of the tea are compared, and air introduction is stopped after the tea aroma meets the requirements. The content of nitrogen in the air can be increased and the oxygen content can be reduced through nitrogen charging, so that the fermentation time can be prolonged, and sampling analysis is facilitated.

Owner:贵州黔茗茶业销售有限公司

Method for improving stable wear resistance of automobile metal casting part

PendingCN114570887AImprove wear resistanceExtended oxidation timeFoundry mouldsMetallic material coating processesPolishingIngot

The invention discloses a method for improving the stability and wear resistance of an automobile metal casting part, which comprises the following steps: die manufacturing: designing a die according to the actual size of the metal casting part, then printing a drawing, and manufacturing two dies which are matched with each other; the preparation method comprises the following steps: preparing raw materials, preparing and cleaning proper iron ingot raw materials, polishing and cleaning rust on the surfaces of iron ingots, heating and smelting the iron ingots to obtain molten iron, putting the molten iron into a smelting furnace, and adding a proper amount of metal powder into the smelting furnace to obtain mixed molten liquid. The wear-resistant coating is coated in the casting process of the metal casting part, the surface of the casting part is protected through the wear-resistant coating, so that the wear resistance of the casting part is improved, meanwhile, the wear-resistant coating can isolate direct contact between the casting part and air, and the oxidation time of the casting part is prolonged.

Owner:江陵同创机械有限公司

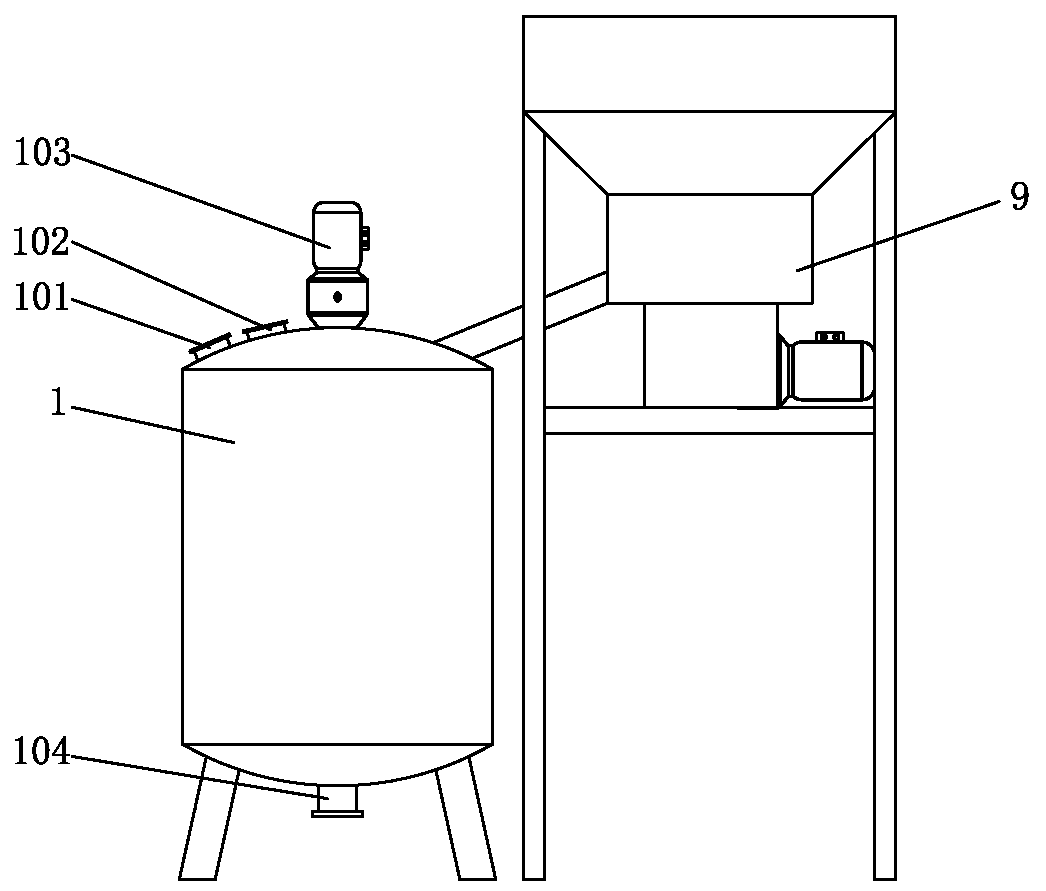

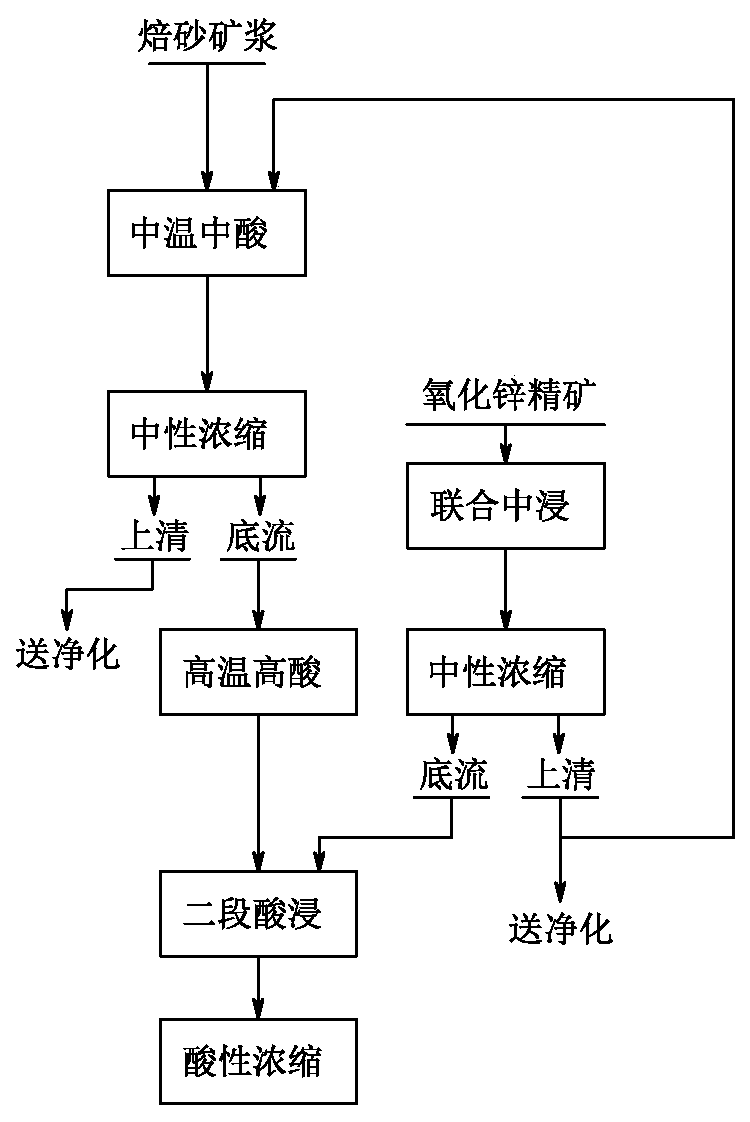

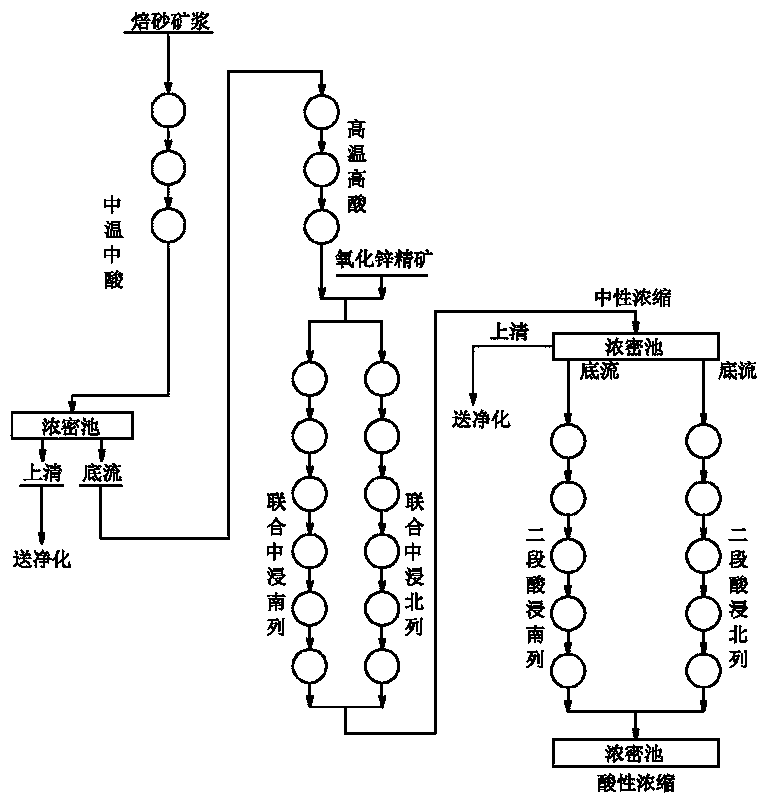

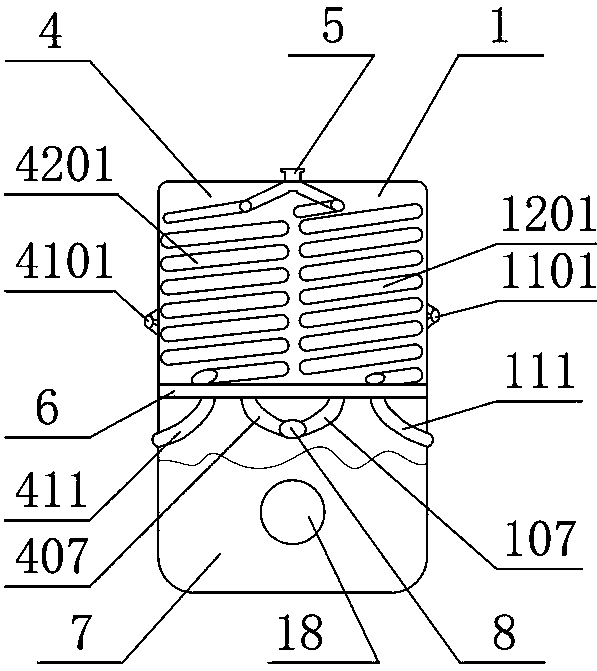

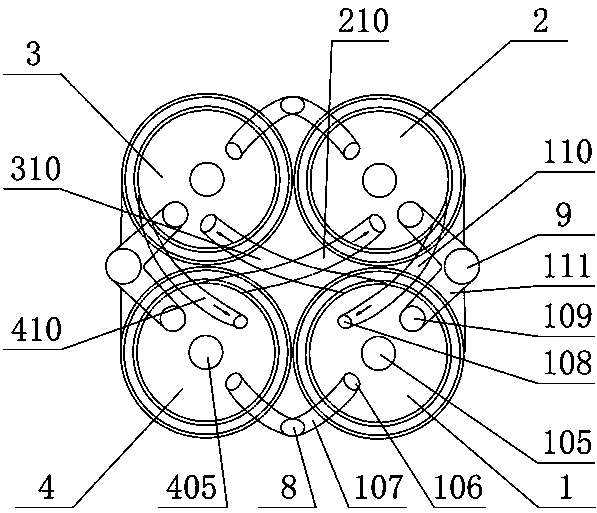

Zinc oxide concentrate leaching equipment and leaching manner thereof

The invention discloses zinc oxide concentrate leaching equipment and a leaching manner thereof, and relates to the technical field of zinc hydrometallurgy. The leaching equipment comprises combined medium-leaching leaching tanks, a second dense pond, a second-section acid-leaching leaching tank, a third dense pond, a high-temperature and high-acid leaching tank, a first dense pond and a medium-temperature and medium-acid leaching tank. A south row of combined medium-leaching leaching tanks and a north row of combined medium-leaching leaching tanks are included. Six combined medium-leaching leaching tanks are distributed at equal interval in each row of combined medium-leaching leaching tanks. According to the zinc oxide concentrate leaching equipment and the leaching manner thereof, zincoxide concentrates are independently subjected to combined medium leaching, then high-temperature and high-acid leaching after liquid is centralized at a second-section acid leaching section to be subjected to combined acid leaching with the zinc oxide concentrates. Through the technology design, a high-iron solution can be treated in a centralized manner, supernatant quality control is not influenced, slag following path opening is achieved for a large amount of iron during second-section pressing filtration, the iron content of supernatant after liquid is within 100 mg / L, and the produced supernatant after liquid quality meets the purification operation requirement; and the manganese powder consumption is reduced, single consumption of leached manganese powder is greatly reduced and is 56 kg / T.Zn for average, and economic benefits are greatly improved.

Owner:云南金鼎锌业有限公司

Novel engine without crankshaft and control method thereof

InactiveCN109139245AHigh thermal efficiencyIncrease the compression ratioLiquid coolingElectrical controlBase functionEngineering

The invention provides a novel engine without a crankshaft. The novel engine is composed of not less than two power cylinders, and includes the power cylinders, secondary expansion gas passages between the power cylinders, an impulse type lubrication system, a fuel injection system, a cylinder body temperature control system, an oxygen injection system, a ventilation system, a starting system, anECU and a power output system. A power cylinder using outputting reciprocating linear motion performed by pistons in the cylinders as a basic function is used as a unit, through the secondary expansion gas passages, exhaust gas in the power cylinder near the end of doing work by combustion expansion is introduced into another power cylinder piston under the compression stroke for secondary expansion work, and the combination of oil cooling and air cooling is adopted, the heat at the tops of the power cylinders is brought to the bottoms of the power cylinders through a double-layer spiral cooling liquid pipe to improve the secondary expansion work capability of the gas to improve the thermal efficiency of the engine, and finally, power output adopts a planetary gear mechanism to convert thereciprocating linear motion into a continuous rotary motion.

Owner:ANYANG INST OF TECH

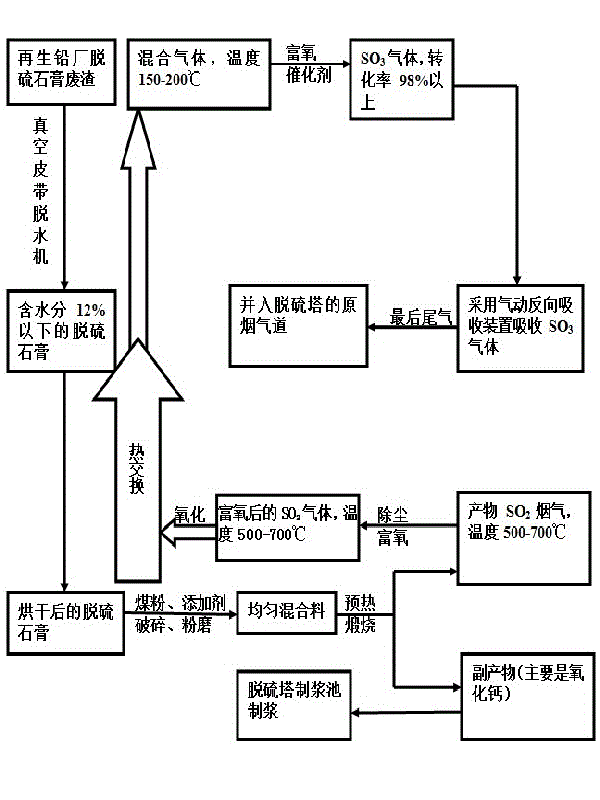

Method for preparing sulfuric acid from desulfurized gypsum in secondary lead smelting process as raw material

The invention discloses a method for preparing sulfuric acid from desulfurized gypsum in a secondary lead smelting process as a raw material. The method comprises the following steps of: (a) taking desulfurized gypsum waste residue in the secondary lead smelting process, dewatering and then baking the desulfurized gypsum waste residue; (b) adding pulverized coal and an additive to the baked desulfurized gypsum, crushing and grinding to form an even mixture, burning and decomposing the desulfurized gypsum after pre-heating, carrying out high-temperature oxidation reaction on product high-temperature SO2 smoke after dust removal and oxygen enrichment, and carrying out heat exchange on the mixed gas to dry the desulfurized gypsum waste residue; (c) reducing the temperature of the heat-exchanged mixed gas, carrying out oxygen-enriched oxidation on the mixed gas again under the condition that a catalyst V2O5 exists; and (e) absorbing the obtained SO3 gas by concentrated sulfuric acid. The sulfuric acid is prepared from the desulfurized gypsum waste residue in the secondary lead smelting process; and the problem of difficulty in processing the desulfurized gypsum is solved, and rubbish is reused, and meanwhile, domestic sulfur resources are saved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

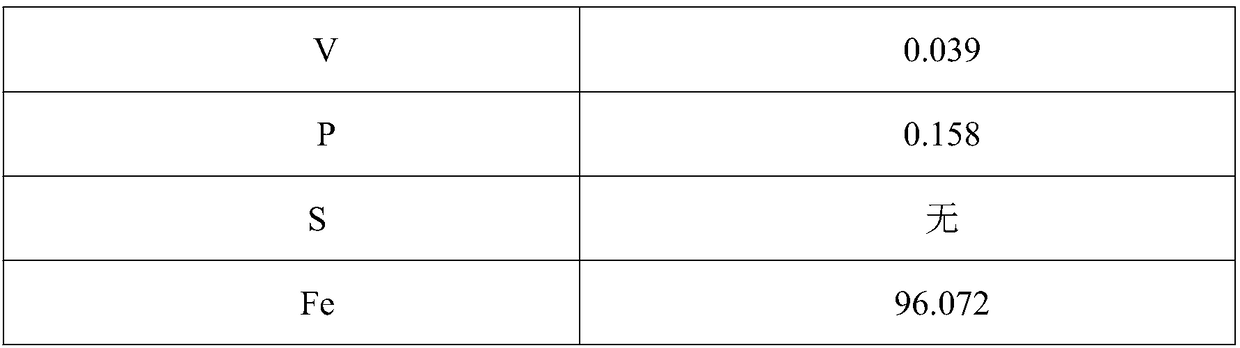

Technology for processing vanadium extraction semi-steel

InactiveCN109136445AGood slag effectSignificant comprehensive benefitsManufacturing convertersCoolantSemi-steel

The invention discloses a technology for processing vanadium extraction semi-steel. The technology includes technological processes of (1), feeding pig iron; (2), carrying out iron charging; (3), carrying out blowing; (4), adding coolants; (5), terminating blowing. Molten pig iron added during production according to the technology comprises chemical components including, by weight, 4%-5% of C, 0.08%-0.3% of Si, 0.2%-0.5% of Mn, 0.25%-0.3% of V, less then or equal to 0.25% of P, less than or equal to 0.07% of S and 93.58%-95.47% of Fe. The technology has the advantages that the original double-slag vanadium extraction smelting is replaced with semi-steel vanadium extraction, the yield of double-slag vanadium slag is approximately 30 Kg / t steel, the comprehensive grade is higher than 13%, and good benefits can be created for companies; slag splashing effects of semi-steel smelting converters can be obviously improved after semi-steel vanadium extraction is adopted, the fettling frequencies can be lowered, the operation rate of the converters can be increased, accordingly, the production efficiency can be improved, and the enterprise benefits can be increased.

Owner:YUNNAN DESHENG STEEL CO LTD

Crack sealing material prepared from crack sealing tape for road crack repairing and net crack sticker

InactiveCN111286305AImprove wear resistanceImprove thermal conductivityNon-macromolecular adhesive additivesBituminous material adhesivesElastomerSynthetic Polymeric Macromolecules

The invention relates to a crack sealing material prepared from a crack sealing tape for road crack repairing and a net crack sticker. The sum of the content of petroleum asphalt, the content of SBS styrene thermoplastic elastomer and the content of rubber powder is 85-90%. The road petroleum asphalt is used as a main material, the SBS styrene thermoplastic elastomer has the advantages of both rubber and plastic and has tensile property, good low-temperature resistance, air permeability, solubility, flexibility, elasticity, heat resistance and unique skid resistance, and the rubber powder is waste heavy-load diagonal tire tread processing powder, is beneficial to improving the wear resistance, fatigue resistance, tear strength and other properties, and greatly relieves the pressure of waste tires on environmental protection. By means of the high-molecular structure and the polymerization capacity of an environment-friendly synthetic high-molecular polymer, all the components of the crack sealing material prepared from a crack sealing tape for road crack repairing and a net crack sticker can be kept in a uniform mixed state for a long time, precipitation and separation are not likely to happen, and long-term stability of the performance of the crack sealing material prepared from a crack sealing tape for road crack repairing and a net crack sticker is guaranteed.

Owner:北京嘉格伟业筑路科技有限公司

A complex energy-saving and high-efficiency desulfurization, denitrification and dust removal integrated purification tower

ActiveCN105797554BHigh temperature resistantCorrosion resistanceCombination devicesGas treatmentFlue gasEngineering

A compound energy-saving and high-efficiency desulfurization, denitrification and dust removal integrated purification tower, which relates to an environmental protection equipment, including a desulfurization device and a denitrification device. The desulfurization device includes a desulfurization tower and a desulfurization agent main pipe. Purification packing is set on the filter layer; the main pipe of desulfurization agent is vertically fixed in the desulfurization tower through the support assembly, and several nozzles are connected along the height direction on the main pipe of desulfurization agent; the denitrification device includes a denitrification tower and a spherical gas buffer tower, and the gas buffer tower is fixed It is connected to the upper end of the denitration tower; the desulfurization tower is fixed in the inner cavity of the denitration tower through a connecting component, and a denitration oxidant pipeline is set between the denitration tower and the desulfurization tower, and multiple liquid outlets are set on the denitration oxidant pipeline; at the lower end of the denitration tower A flue gas inlet and a flue gas outlet are set, the flue gas inlet is connected to the inner chamber of the desulfurization tower after passing through the denitrification tower, and the flue gas outlet is connected to the inner chamber of the denitrification tower. The invention has good purification effect and low cost.

Owner:江苏绿塔环境工程有限公司

Method for preparing acetic acid through catalytic carbonylation reaction

ActiveCN103012103BGuaranteed stabilityReduce manufacturing costOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic preparation from carbon monoxide reactionHalogenRuthenium

Owner:SHANGHAI HUAYI GRP CO

Methanol-high-pressure-oxygen compound two-stroke engine and control method thereof

ActiveCN111287847ARealize work cycleReduce power consumptionElectrical controlInternal combustion piston enginesExhaust valveInlet valve

The invention discloses a methanol-high-pressure-oxygen compound two-stroke engine. The methanol-high-pressure-oxygen compound two-stroke engine is composed of one or more air cylinder groups, each air cylinder group comprises a main air cylinder and a corresponding auxiliary air cylinder, and the main air cylinders are provided with starting fuel nozzles, methanol nozzles, oxygen nozzles and mainair cylinder exhaust valves and are not provided with air inlet valves; and connection channels are arranged between main air cylinder exhaust ports and the auxiliary air cylinders, the connection channels are provided with one-way valves at auxiliary air cylinder inlets, air in the main air cylinders only flows into the auxiliary air cylinders through the one-way valves, the auxiliary air cylinders are not provided with fuel nozzles and are provided with auxiliary air cylinder air inlet valves and auxiliary air cylinder exhaust valves, and the auxiliary air cylinder air inlet valves communicate with an engine air inlet pipe. Methanol is injected into the main air cylinders, the amount of oxygen injected in the main air cylinders is controlled, the degree of fuel combustion is controlled,high-temperature active air which is not completely burned in the main air cylinders is introduced into the auxiliary air cylinders to continue combustion, the cylinder-dividing circulation is achieved, the emission of harmful air is reduced, and the full combustion of fuel is achieved.

Owner:ANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com