Method for preparing sulfuric acid from desulfurized gypsum in secondary lead smelting process as raw material

A technology for regenerated lead smelting and desulfurization gypsum, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of unstable operation, poor economic benefits, and high investment costs, and improve absorption efficiency, save energy, and save energy. Effects of Sulfur Resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

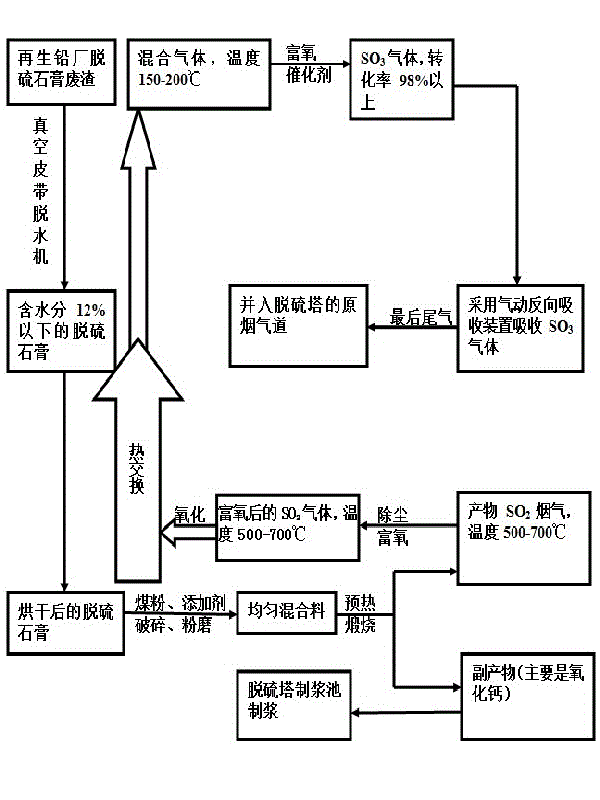

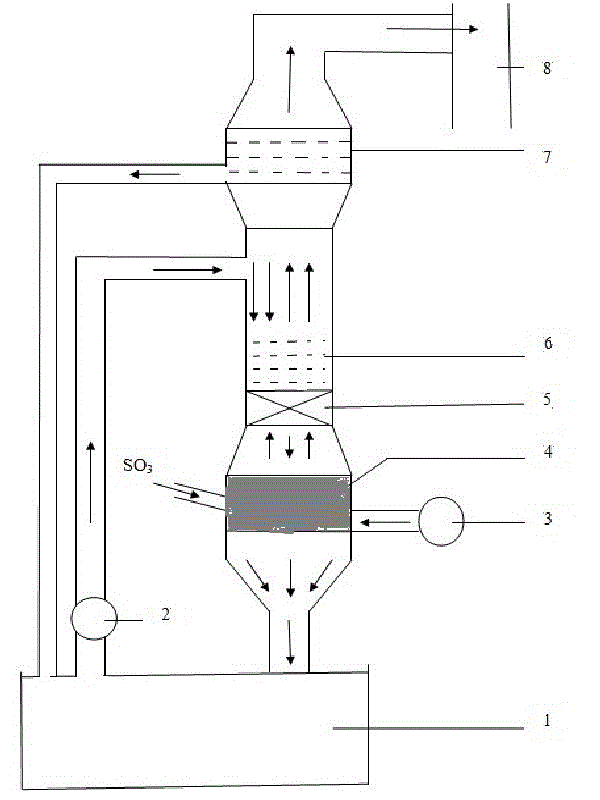

[0044] Take 400kg of desulfurized gypsum residue after being dehydrated by a vacuum belt dehydrator and dried by a quick dryer, and add 80kg of coal powder and 5kg of additive Fe 2 o 3 . After crushing and grinding, it becomes a uniform mixture, and the particle size of the mixture is controlled at 1-3mm. After preheating, it is calcined at 950°C for 15 minutes, and the obtained by-products (mainly calcium oxide) are directly returned to the desulfurization tower pulping tank for pulping. And the product SO at a temperature of 500-700°C 2 After the flue gas dedusting and oxygen enrichment reaction, heat exchange treatment is carried out, which is used for drying of desulfurization gypsum waste residue. After heat exchange, the mixed gas (mainly containing SO 2 , SO 3 , O 2 ) temperature drops to 150~200℃, in the presence of catalyst V 2 o 5 Under the condition of existence, the oxygen-enriched oxidation is performed on the low-temperature mixed gas again, and after the...

Embodiment 2

[0046] Take 400kg of desulfurized gypsum residue after being dehydrated by a vacuum belt dehydrator and dried by a quick dryer, and add 40kg of coal powder and 4kg of additive Fe 3 o 4 . After crushing and grinding, it becomes a uniform mixture, and the particle size of the mixture is controlled at 1-3mm. After preheating, it is calcined at 800°C for 10 minutes, and the obtained by-products (mainly calcium oxide) are directly returned to the desulfurization tower for pulping. And the product SO at a temperature of 500-700°C 2 After the flue gas dedusting and oxygen enrichment reaction, heat exchange treatment is carried out, which is used for drying of desulfurization gypsum waste residue. After heat exchange, the mixed gas (mainly containing SO 2 , SO 3 , O 2 ) temperature drops to 150~200℃, in the presence of catalyst V 2 o 5 Under the condition of existence, the oxygen-enriched oxidation of the low-temperature mixed gas is carried out again, and after the high-low t...

Embodiment 3

[0048] Take 400kg of desulfurized gypsum residue after being dehydrated by a vacuum belt dehydrator and dried by a quick dryer, and add 100kg of coal powder and 10kg of additive Fe 2 o 3 and 10kg additive Fe 3 o 4 . After crushing and grinding, it becomes a uniform mixture, and the particle size of the mixture is controlled at 3-5mm. After preheating, it is calcined at 850°C for 6 minutes, and the obtained by-products (mainly calcium oxide) are directly returned to the desulfurization tower for pulping. And the product SO at a temperature of 500-700°C 2 After the flue gas dedusting and oxygen enrichment reaction, heat exchange treatment is carried out, which is used for drying of desulfurization gypsum waste residue. After heat exchange, the mixed gas (mainly containing SO 2 , SO 3 , O 2 ) temperature drops to 150~200℃, in the presence of catalyst V 2 o 5 Under the condition of existence, the oxygen-enriched oxidation of the low-temperature mixed gas is carried out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com