Heat treatment device for crankshaft processing device

A heat treatment device and crankshaft processing technology, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of difficult installation, complex structure, inability to effectively recover oil and secondary quenching, etc., to improve efficiency and shorten time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

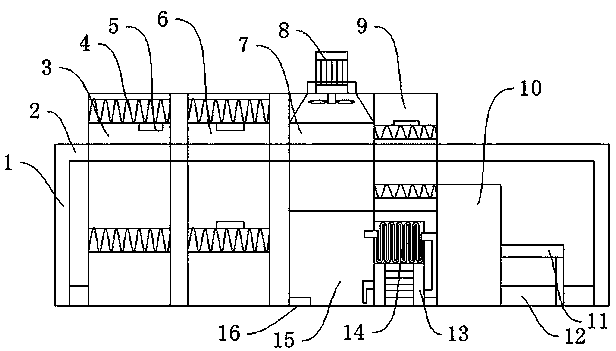

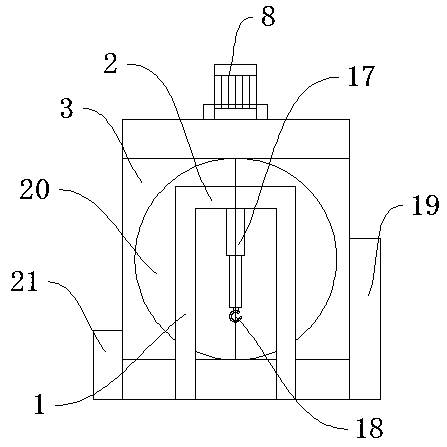

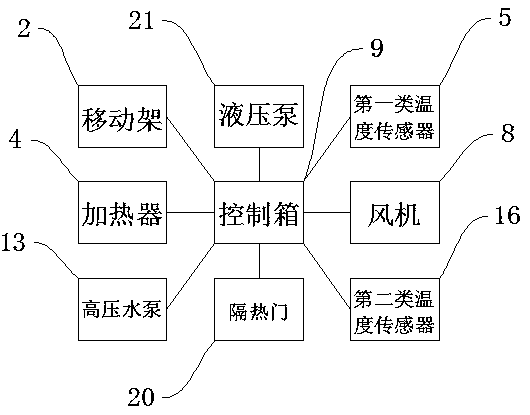

[0027] Such as Figure 1-Figure 3 As shown, a heat treatment device for crankshaft processing includes a normalizing chamber 3, an annealing chamber 6, and a quenching chamber 7. A support frame 1 is provided on one side of the normalizing chamber 3, and an insulating door 20 is provided on one side of the normalizing chamber 3. , a movable frame 2 is arranged above the support frame 1, a heater 4 is arranged above the inside of the normalizing chamber 3, a telescopic cylinder 17 is arranged below the movable frame 2, a hook 18 is arranged below the telescopic cylinder 17, and a same setting is arranged below the inside of the normalizing chamber 3 There is a heater 4, a first-type temperature sensor 5 is arranged under the heater 4, the model of the first-type temperature sensor 5 is TR / 02010, an annealing chamber 6 is arranged on the other side of the normalizing chamber 3, and an annealing chamber 6 is arranged on one side There is a quenching chamber 7, a fan 8 is arranged...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that in this embodiment, the quenching chamber 15 and the high-pressure water pump 13 are connected together through threads, the high-pressure water pump 13 and the radiator 14 are connected together through threads, and the radiator 14 and the quenching chamber 15 are connected together through threaded together.

[0030] Specifically, such setting can lower the temperature of the medium in the quenching chamber 15 and shorten the heat treatment time.

[0031]The working principle of the present invention is: after the crankshaft is hung on the hook 18 during use, the normalizing temperature, annealing temperature and tempering temperature are set by operating the control box 19. After setting, the control box 19 controls the moving frame 2 to move Drive the crankshaft to enter the normalizing chamber 3 for normalizing. After normalizing, the crankshaft enters the annealing chamber 6 for annealing. The first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com