Quenching system and method for box-type workpieces

A cooling system and workpiece technology, applied in the field of quenching cooling system, can solve the problems of poor fluidity of quenching fluid and uneven temperature, and achieve the effects of low cost, improving quenching efficiency and reducing speed loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

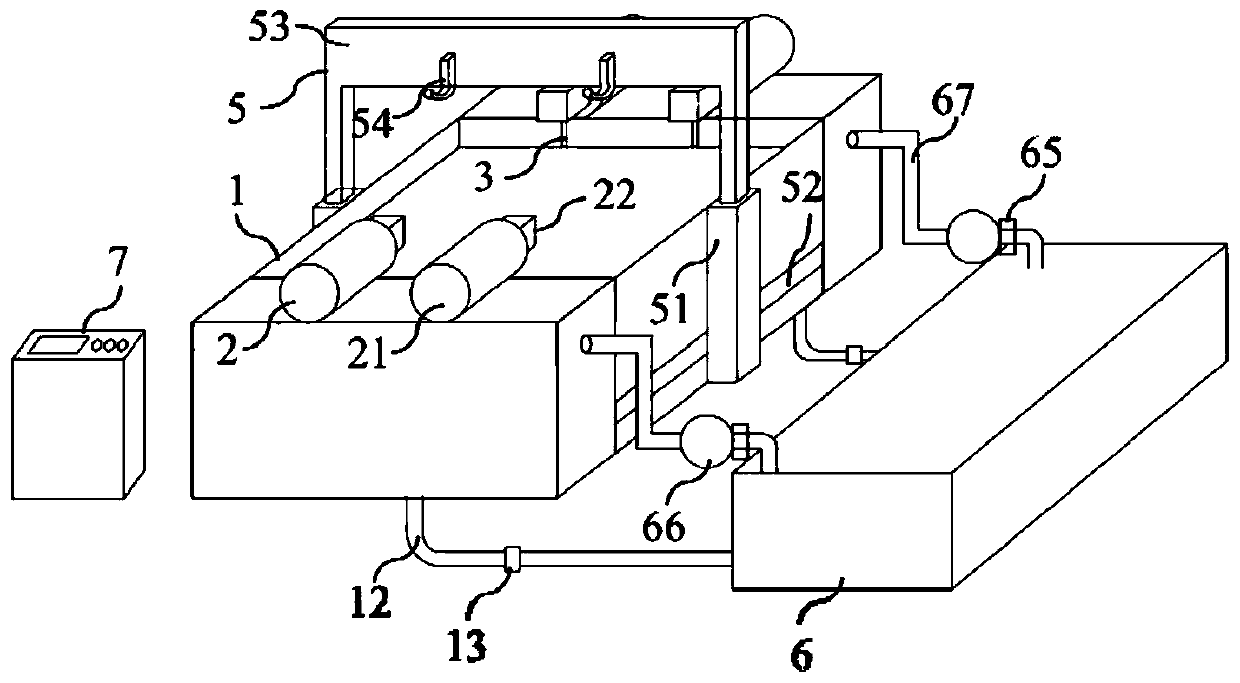

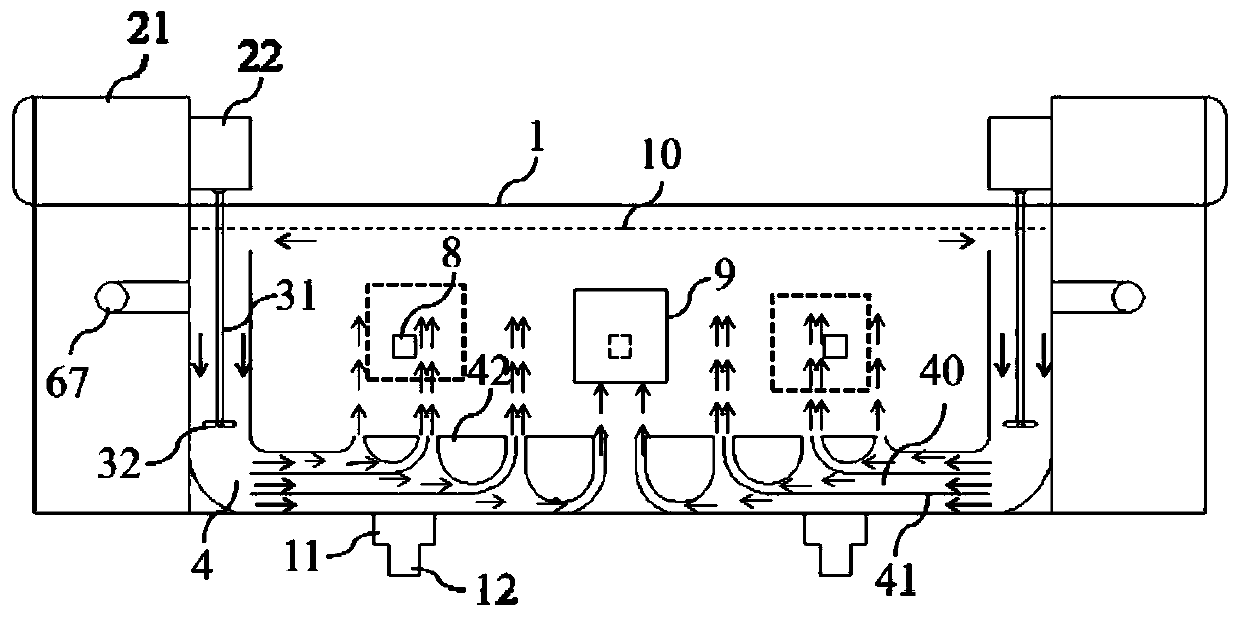

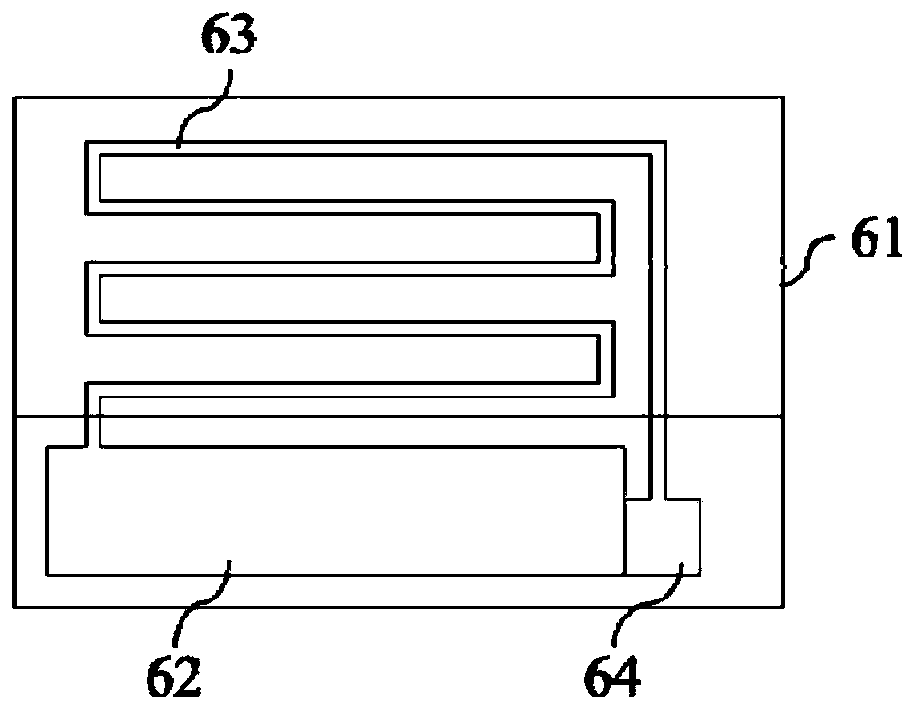

[0041] A kind of quenching cooling system that is used for box type workpiece in this embodiment, such as figure 1 As shown, it includes a quenching pool body 1, and the quenching pool body 1 is a hollow cuboid structure with an open top; as figure 2 As shown, the stirring device 3 is symmetrically installed on both sides inside the quenching pool body 1 from above, and is driven by the driving device 2, and the driving device 2 is installed on both sides of the top of the quenching pool body 1; the stirring device 3 is provided with a deflector 4, and the deflector 4 includes a deflector 41, and the deflector 41 is distributed symmetrically in three layers at the bottom of the quenching pool body 1, and is located at the height of the quenching liquid level 10 In the following positions, the flow guide tube is replaced by a symmetrically distributed multi-layer flow guide plate 41, and the quenching liquid circulation channel 40 is formed between each layer of the flow guide...

Embodiment 2

[0043] A kind of quenching cooling system that is used for box-type workpiece of the present embodiment, basic structure is the same as embodiment 1, difference and improvement are: as figure 2 As shown, the outlet of each deflector 41 is provided with a corresponding height restriction module 42 according to its depth, and the restriction module 42 is detachably installed at the outlet of the quenching liquid circulation channel 40, and the bottom of the restriction module 42 is arc-shaped And match with the shape of the quenching liquid circulation channel 40, to reduce the speed loss when the liquid flow collides with the limiting module 42, and increase the impact of the liquid flow on the vapor film on the surface of the workpiece; and the upper surface of the limiting module 42 is designed as a plane that can As a support platform that limits the lowest point of the box-type workpiece 9 in the quenching pool, unnecessary losses caused by the box-type workpiece 9 collidin...

Embodiment 3

[0045] A kind of quenching cooling system that is used for box-type workpiece of the present embodiment, basic structure is the same as embodiment 2, difference and improvement are: as figure 2 As shown, the stirring device 3 is controlled and started by the external control box 7. The stirring device 3 includes a connecting rod 31 and a propeller blade 32. The number of blades of the propeller blade 32 is 3 to 4, and the blade helical angle is 25 to 35°, the propeller blade 24 is an airfoil-type propeller, so that the stirring effect is better, thereby increasing the circulation velocity of the quenching liquid; Driven by the motor 21 on the device 2; the multilayer deflector 41 is used in conjunction with the propeller blade 32 facing the surface of the curved deflector 41, and the quenching medium can be transported to various positions in the quenching pool by the propeller blade 32, thereby effectively It solves the problem of circulation dead zone in the quenching pool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com