Patents

Literature

46results about How to "Realize full resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing wastewater denitrification carbon source through lactic acid fermentation of kitchen waste

ActiveCN111333179ASolve the problem of low COD/TNEfficient resource utilizationWater treatment compoundsTreatment with anaerobic digestion processesNutritionWaste oil

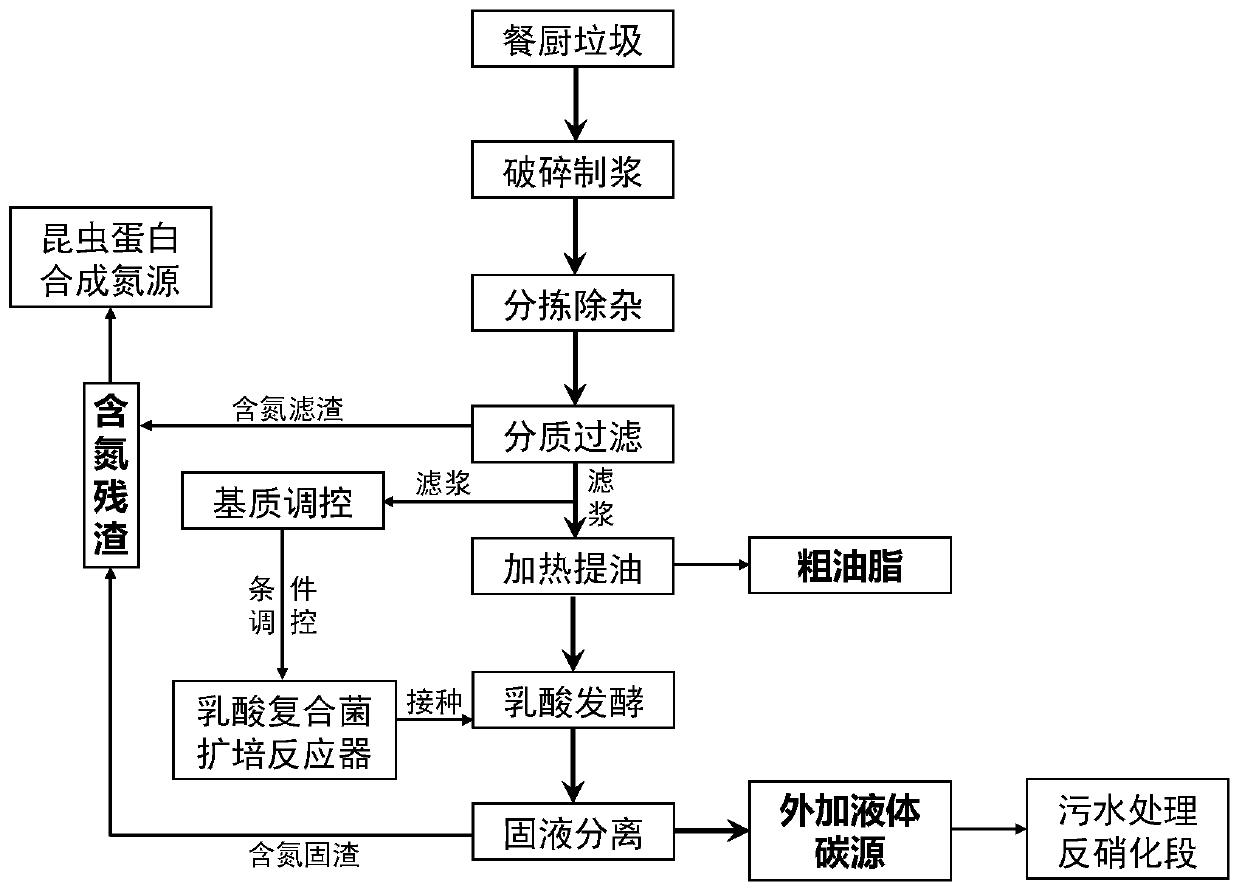

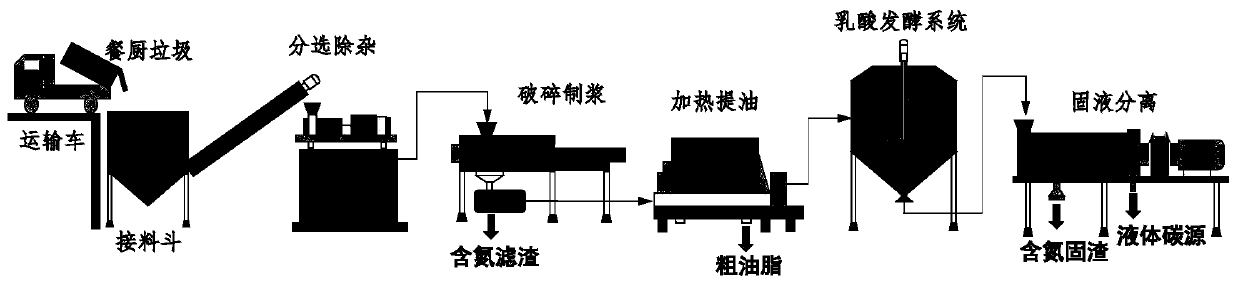

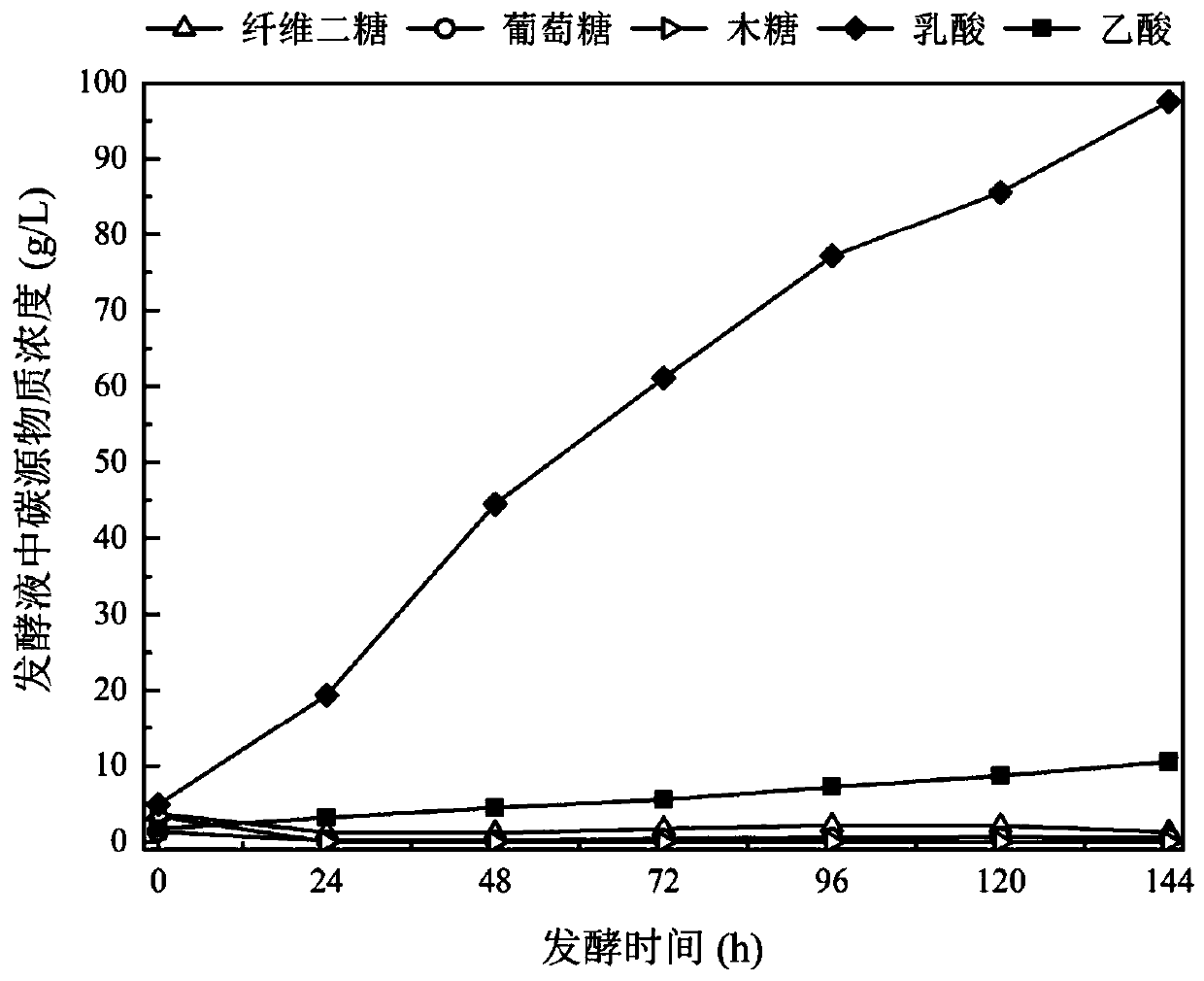

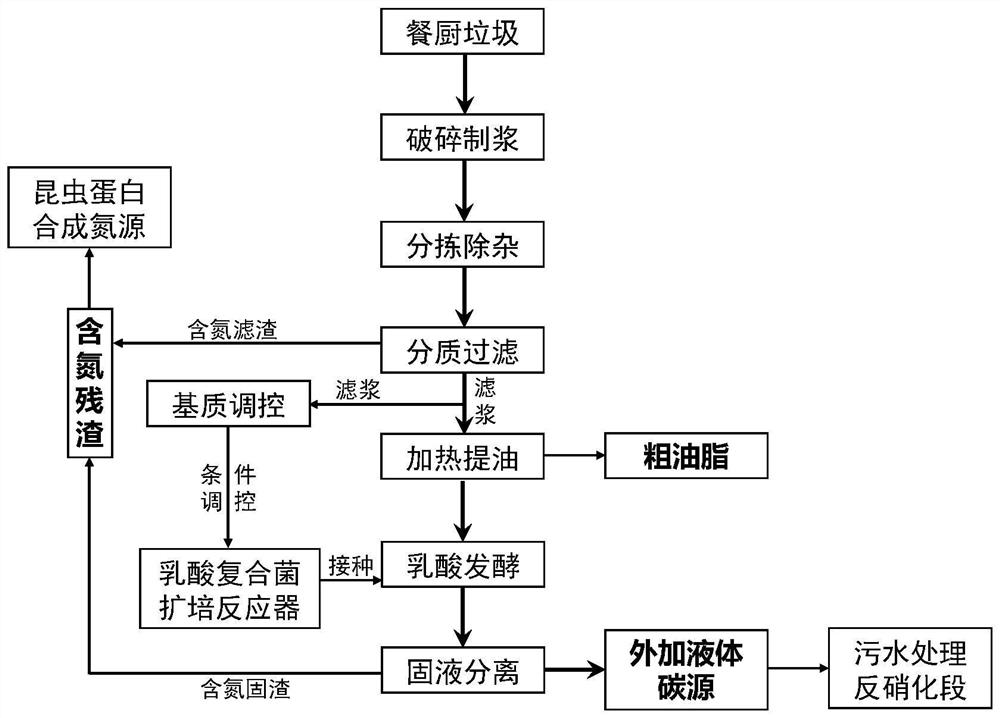

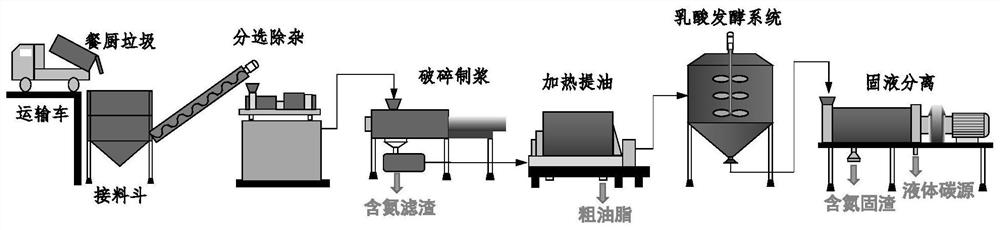

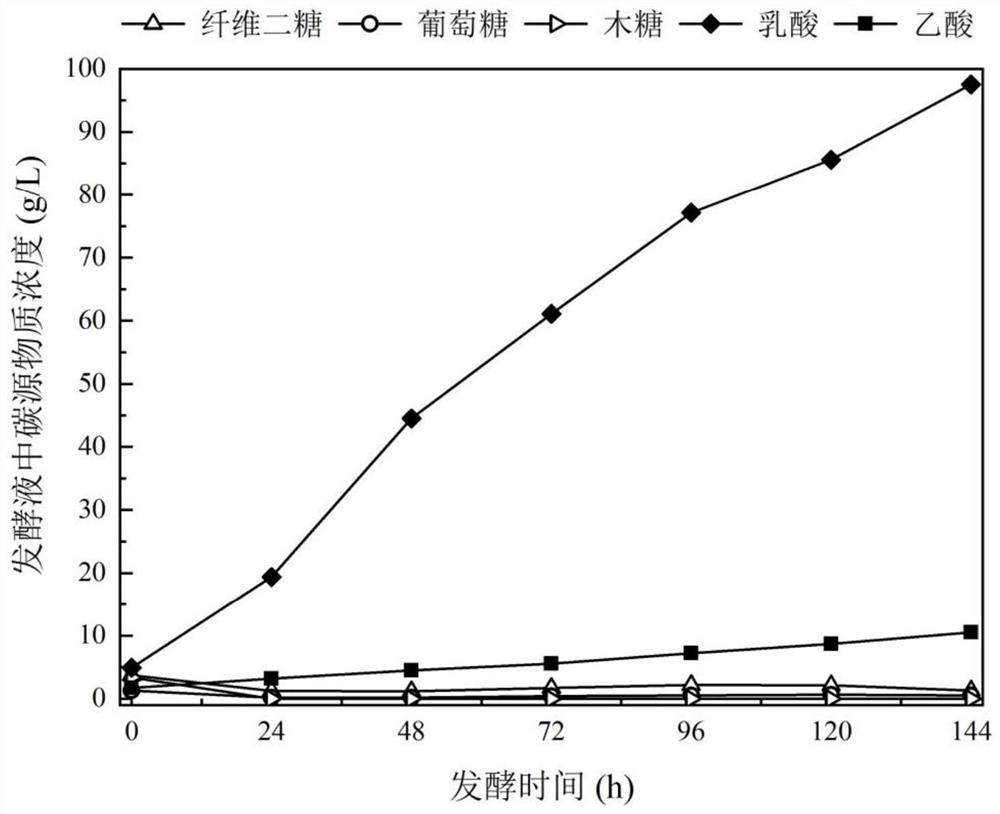

The invention discloses a method for producing a wastewater denitrification carbon source through lactic acid fermentation of kitchen waste, and belongs to the technical field of solid waste resourceful treatment. The method comprises the steps of adopting kitchen waste as a raw material; sorting and impurity removal, controlling the solid-to-liquid ratio, grinding, pulping, and carrying out quality-based and phase-splitting treatment; after the waste oil is heated and recycled, the residual garbage slurry is injected into an anaerobic fermentation tank for batch lactic acid fermentation, after fermentation is finished, solid-liquid separation is carried out, lactic acid-containing supernatant can be directly used as a liquid carbon source in the sewage denitrification stage, a good biological denitrification effect is achieved, nitrogen-containing residues can be collected and recycled, and full recycling is achieved. According to the invention, kitchen waste is directly used for efficient open lactic acid fermentation; according to the method, the indigenous microbial flora in the kitchen waste is fully utilized to hydrolyze the substrate and efficiently and directionally convertthe substrate into lactic acid, exogenous nutrition and industrial enzyme preparations do not need to be added, the process is simple, the production cost is low, a cheap carbon source is provided for a denitrification section of a sewage treatment plant while resource utilization of the kitchen waste is realized, and the biological denitrification efficiency is improved.

Owner:UNIV OF SCI & TECH BEIJING

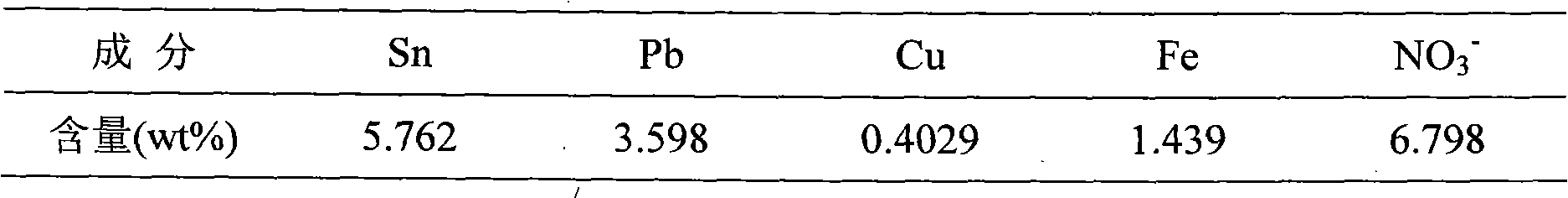

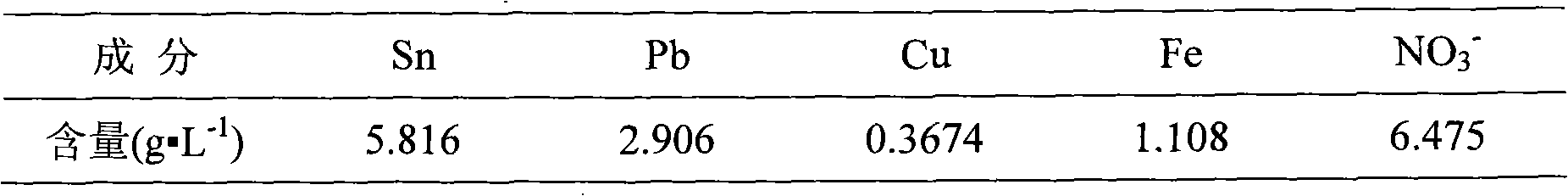

Total recycling method of PCB (printed circuit board) nitric acid type tin-lead stripping waste liquid

InactiveCN102115890AImprove settlement performanceHas a sinking effectWater/sewage treatmentIron sulfatesLiquid wasteFerrous salts

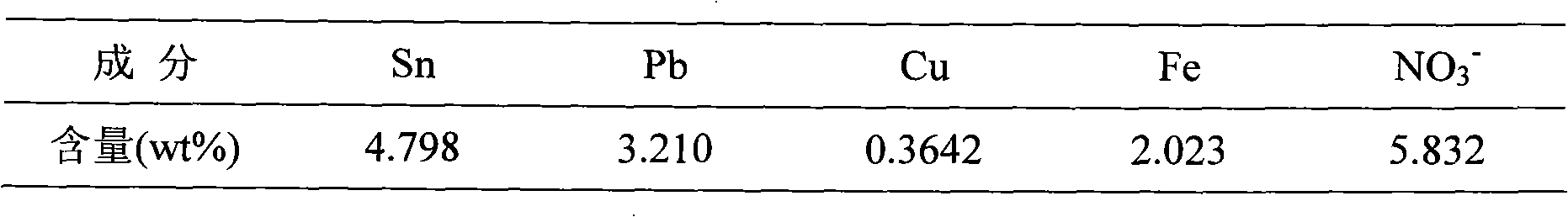

The invention provides a total recycling method of a PCB (printed circuit board) nitric acid type tin-lead stripping waste liquid. Ferrous sulfate is used as a reaction agent and a settling agent to react with the nitric acid type tin-lead stripping waste liquid; a filter cake is acquired from a reaction liquid through filtering separation, and is cleaned for the extraction of solid-phase tin-lead mud; a filter liquid and a cleaning liquid are merged to serve as a mother liquid; then iron is used as a reducing agent and a displacing agent to extract sponge copper from the mother liquid until the residual copper content in the mother liquid is lower than 1mg / L; the sponge copper is rinsed by clear water; after the sponge copper is extracted, the iron content of the residual mother liquid containing a large quantity of ion and acid is regulated through ferric salt or ferrous salt, and the acid content is regulated through acid; and after the residual mother liquid is continuously aerated through air or oxygen gas, ferrous iron is oxidized, hydrolyzed and polymerized, so as to prepare modified polymeric iron which serves as a water purifying agent. Through the method, the nitric acidtype tin-lead stripping waste liquid is totally recycled, the extraction rates of tin, lead and copper respectively exceed 99.3 percent, 99.9 percent and 99.0 percent, the yield of the modified polymeric iron reaches 100 percent, and three wastes and efflux are avoided, so that the environment is protected, and sustainable development of the PCB industry is achieved.

Owner:SOUTH CHINA UNIV OF TECH

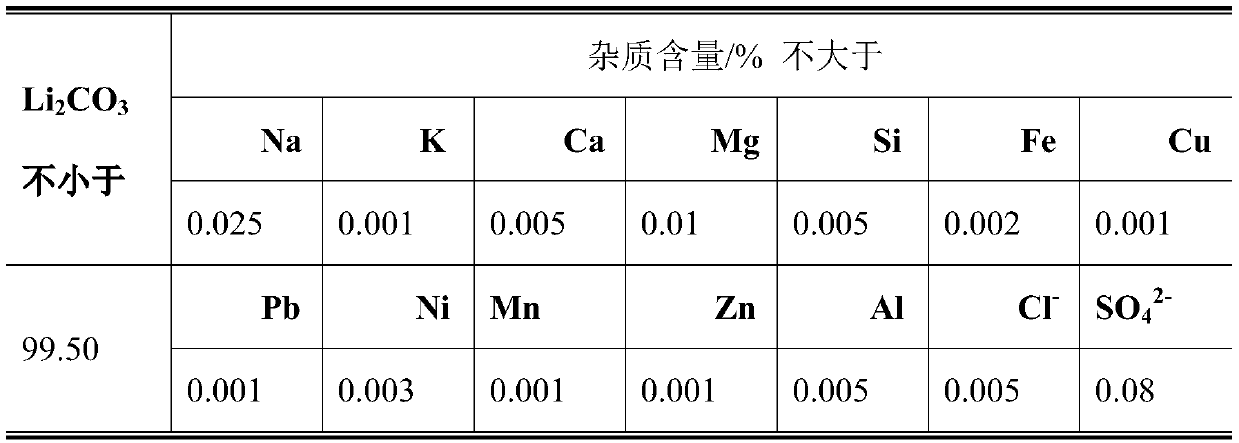

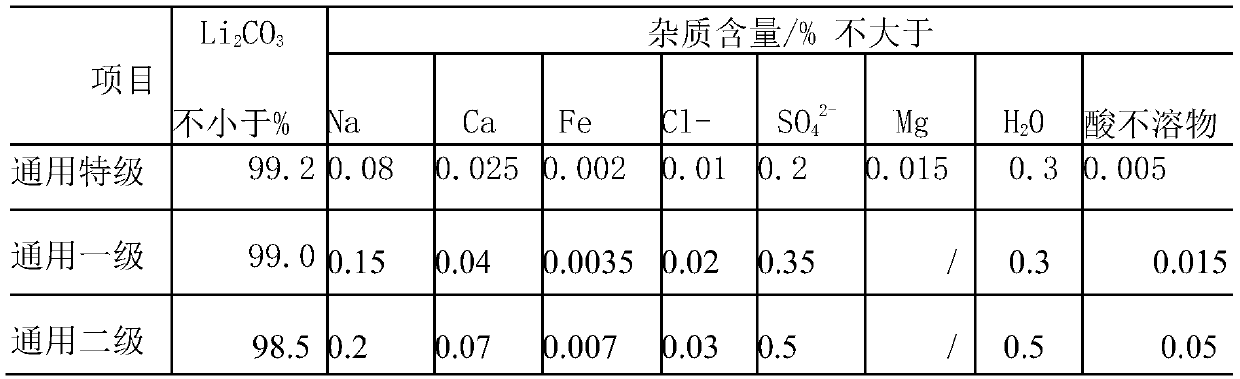

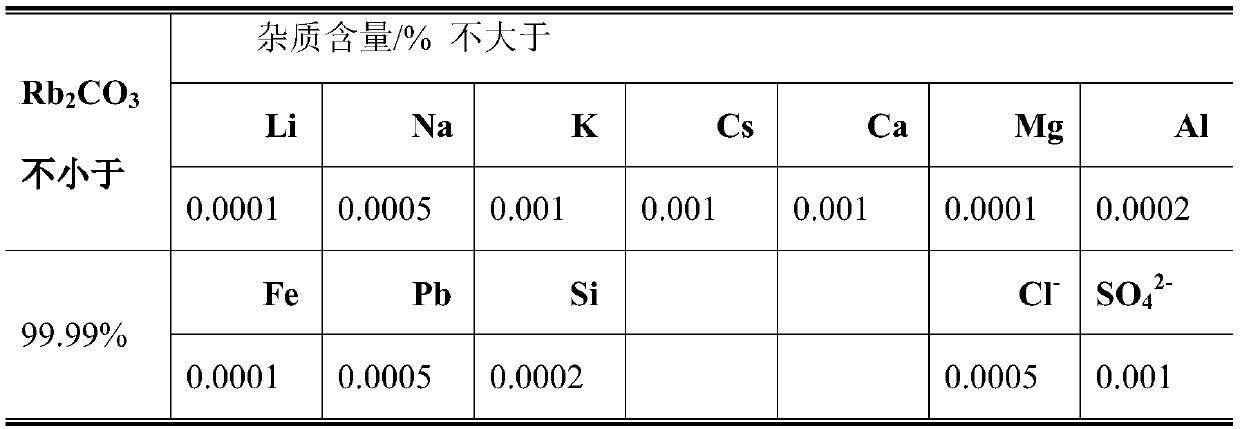

Method for separating and extracting battery-grade lithium carbonate and rubidium and cesium salts from lepidolite

ActiveCN110550644AReduce manufacturing costIncrease contentSulfate/bisulfate preparationRubidium/caesium/francium compoundsLithium carbonateRubidium

The invention discloses a method for separating and extracting battery-grade lithium carbonate and rubidium and cesium salts from lepidolite. Lepidolite is adopted as a raw material, an acidificationroasting method is implemented, and the method comprises steps of crushing, material feeding and pulping, acidification leaching, material mixing, drying, acidification roasting, water leaching reactions, twice cooling crystallization, alkali neutralization, gypsum solid dreg separation, decontamination with a decontamination agent, evaporation concentration, preparation of crude lithium carbonateand rubidium and cesium salts, and the like. The comprehensive cost of lepidolite extraction can be greatly reduced, the comprehensive competitiveness of lepidolite extraction can be greatly improved, and the method is high in equipment utilization rate, environment-friendly and small in waste emission and low in production cost for preparing battery-grade lithium carbonate and rubidium and cesium salts.

Owner:河北铸合集团兴隆县矿业有限公司

Steel slag and red mud reaction resource recycling new technology and application

InactiveCN111850214AReduce oxidationReduce entryCement productionRecycling and recovery technologiesRed mudCarbonization

The invention relates to the field of steel slag and red mud solid waste treatment, in particular to a steel slag and red mud component recycling iron and resource recycling technology and application. The technology mainly includes the following steps that red mud B is added into steel slag A, uniform mixing is conducted, a mixture C is obtained, the mixture C is heated to 1200 DEG C-1600 DEG C,a reducing agent D is added into the mixture C, and after the reducing agent D is sufficiently reacted with the mixture C, molten iron E is separated from molten slag F. The molten slag F is subjectedto subsequent treatment, then petroleum fracture ceramsite sand, cement, glass and the like are prepared. The steel slag A can be steel mill molten steel slag or steel slag smashed after cooling. Thered mud is Bayer process red mud. The main components of the reducing agent are carbon and silicon dioxide and are preferably materials such as carbonized rice husks and gangue comprising carbon andsilicon at the same time. The mass ratio of the steel slag and the red mud is 5:95-95:5. The technology is simple and is a resource modification regeneration green short-process technology, and comprehensive utilization of red mud and steel slag resources is sufficiently achieved.

Owner:BEIJING ZHONGKE JINTENG TECH

Method for treating landscaping solid organic waste by biomass carbonization and two-stage fermentation combined process

InactiveCN109650954AIncrease organic matterIncrease contentExcrement fertilisersBiofuelsLivestock manureResource utilization

The embodiments of the invention disclose a method for treating landscaping solid organic waste by biomass carbonization and a two-stage fermentation combined process. The method includes the following steps: separating branches, trunks and roots from landscaping solid organic waste to obtain a mixed material of the branches, trunks and roots and remaining materials; crushing the mixed material and carbonizing the mixed material to obtain wood tar, pyroligneous liquor containing condensed water, biomass charcoal and combustible gas; crushing the remaining materials and evenly mixing the remaining materials with livestock manure, water, the wood tar and the pyroligneous liquor containing condensed water to obtain a fermentation material; and carrying out the two-stage fermentation combinedprocess treatment on the fermentation material to obtain basic organic fertilizer. The method firstly carries out classification and then carries out treatment by combination of multiple processes, can make good use of complementary advantages of the multiple processes to prepare a variety of resource utilization products, realizes the balance of energy supply and demand, effectively shortens fermentation time, and improves fermentation efficiency and final product quality.

Owner:BEIJING GOLDENWAY BIO TECH +1

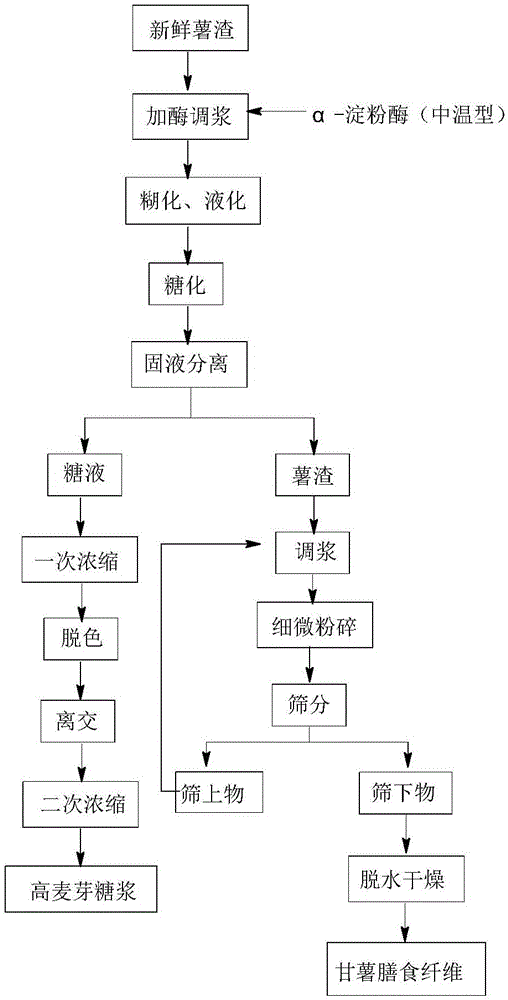

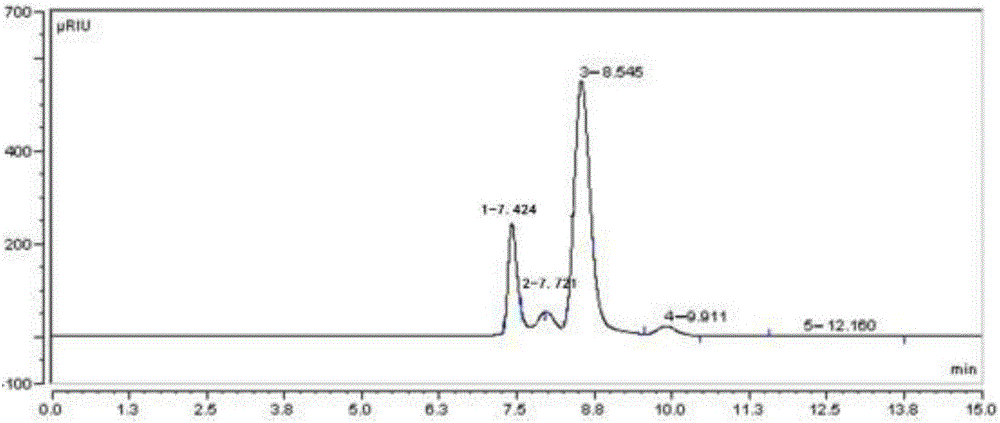

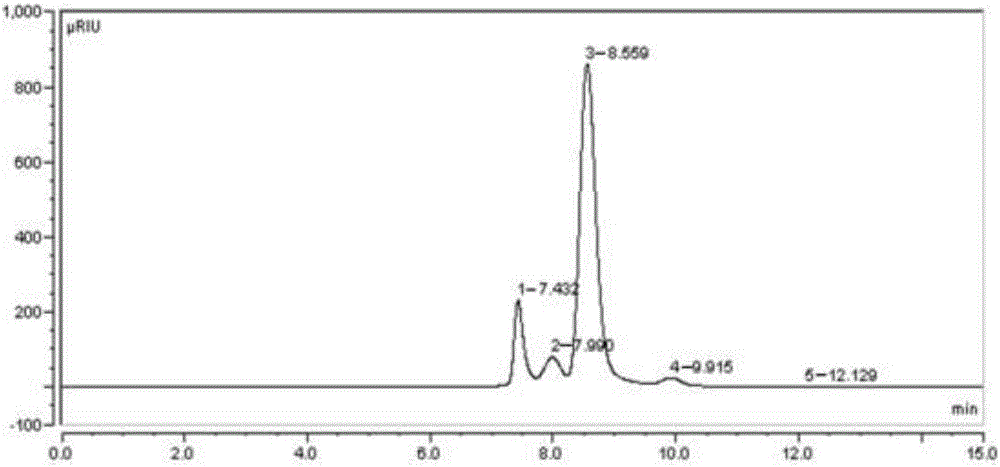

Production method for preparing high maltose syrup and dietary fibers by processing waste residues by means of sweet potato starch

ActiveCN105886577ARealize full resource utilizationIncrease vitalityFood ingredientsFermentationPotato starchFiltration

The invention discloses a production method for preparing high maltose syrup and dietary fibers by processing waste residues by means of sweet potato starch. The method comprises the steps of 1, enzyme supplementation and slurry mixing are conducted, wherein alpha-medium temperature amylase is added to potato residues to be mixed to be uniform according to the starch content of the potato residues; 2, gelatinization liquefaction is conducted, wherein uniformly mixed materials are subjected to heating and heat preservation for gelatinization liquefaction; 3, saccharification is conducted, wherein liquefied materials are cooled rapidly, and saccharification is conducted; 4, solid-liquid separation is conducted, wherein filtration is conducted after saccharification is conducted, and saccharified liquid and the potato residues with the starch removed are obtained; 5, the saccharified liquid is subjected to purification, concentration and refining, and the high maltose syrup is obtained; the potato residues with the starch removed are subjected to smashing, screening and drying, and the dietary fibers are obtained. According to the production method for preparing the high maltose syrup and the dietary fibers by processing the waste residues by means of the sweet potato starch, the fresh potato residues are adopted, saccharification is conducted on the starch in the potato residues by means of beta-amylase of the potato residues to produce the high maltose syrup, and the amount of use of enzymes is reduced; meanwhile, the potato residues with the starch removed are further processed to produce the dietary fibers, the production cost is low, the technological process is simplified, the pertinence is high, and the production method is specially suitable for popularization in sweet potato starch production enterprises.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Full-resource iron tailing utilization method

ActiveCN108585569AHigh precisionHigh strengthCalcareous fertilisersSolid waste managementResource utilizationMaterials science

The invention relates to a full-resource iron tailing utilization method. According to the full-resource iron tailing utilization method, iron tailings are crushed and sieved to obtain aggregates andpowders with different grain sizes, the aggregates and the powders with the different grain sizes are used for preparing various iron tailing resource utilization products so as to achieve full-resource utilization of the iron tailings, and the proportions of the aggregates with the different grain sizes can be controlled according to different needs of the resource utilization products so as to improve the comprehensive performance of the resource utilization products.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

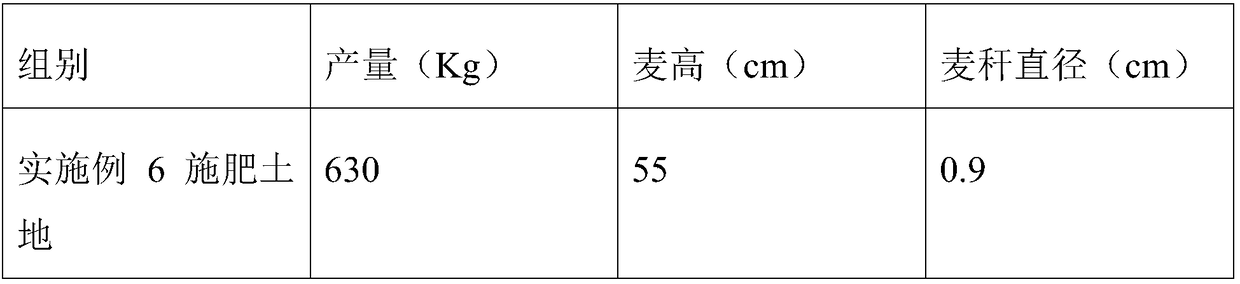

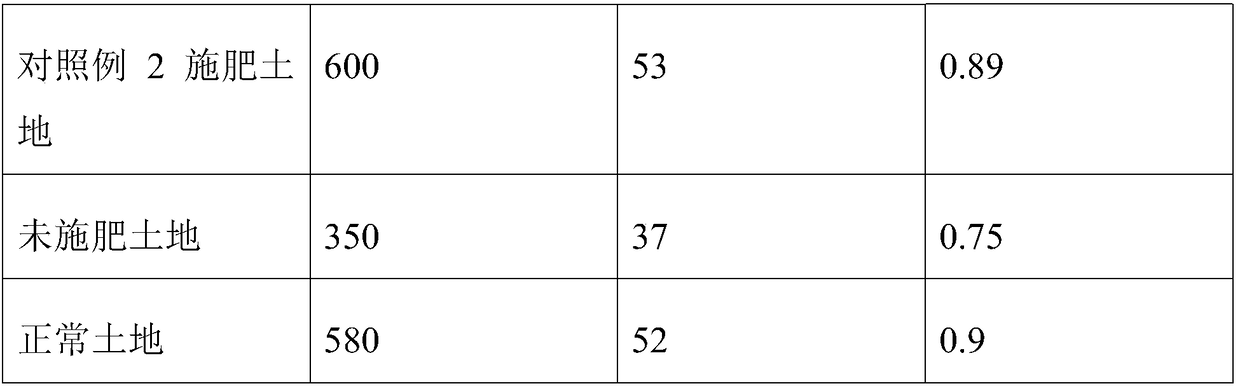

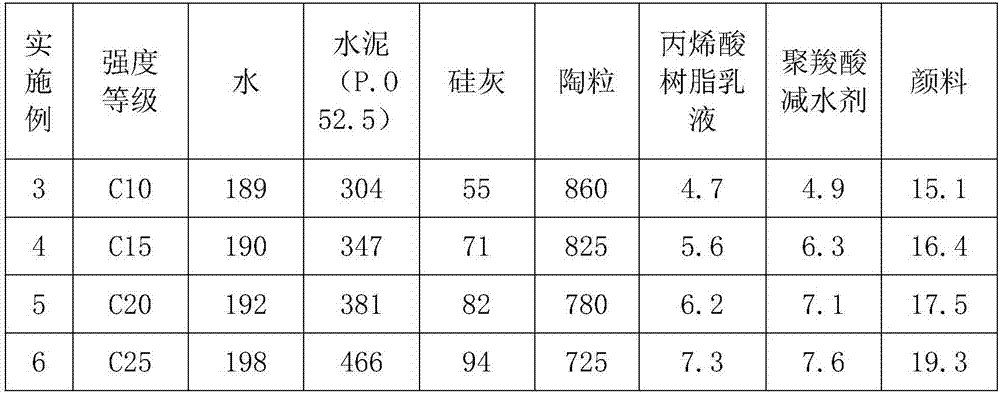

Lightweight permeable concrete of iron tailing sludge ceramsite and preparation method of ceramsite

InactiveCN107010886ARealize full resource utilizationAvoid damageCeramic materials productionCeramicwareSludgeWear resistant

The invention discloses lightweight permeable concrete of iron tailing sludge ceramsite and a preparation method of the ceramsite. The lightweight permeable concrete of the iron tailing sludge ceramsite contains the iron tailing sludge ceramsite, portland cement or ordinary silicon cement, silica fume, an acrylic resin emulsion, a pigment, a polycarboxylate superplasticizer and water; and the ceramsite is prepared from iron tailing sludge, municipal sludge and coal ashes. The permeable concrete has the advantages of being high in permeability, wear-resistant, skid-resistant, ecological, environment-friendly and fast in constriction, and is a novel ground permeable pavement material, the cost of the permeable concrete can be greatly reduced and popularization and application of the permeable concrete in sponge city construction are accelerated; and from the perspective of tailing management, mitigation of environmental pollution is facilitated and great social, economic and ecological benefits are brought.

Owner:CHINA MCC17 GRP

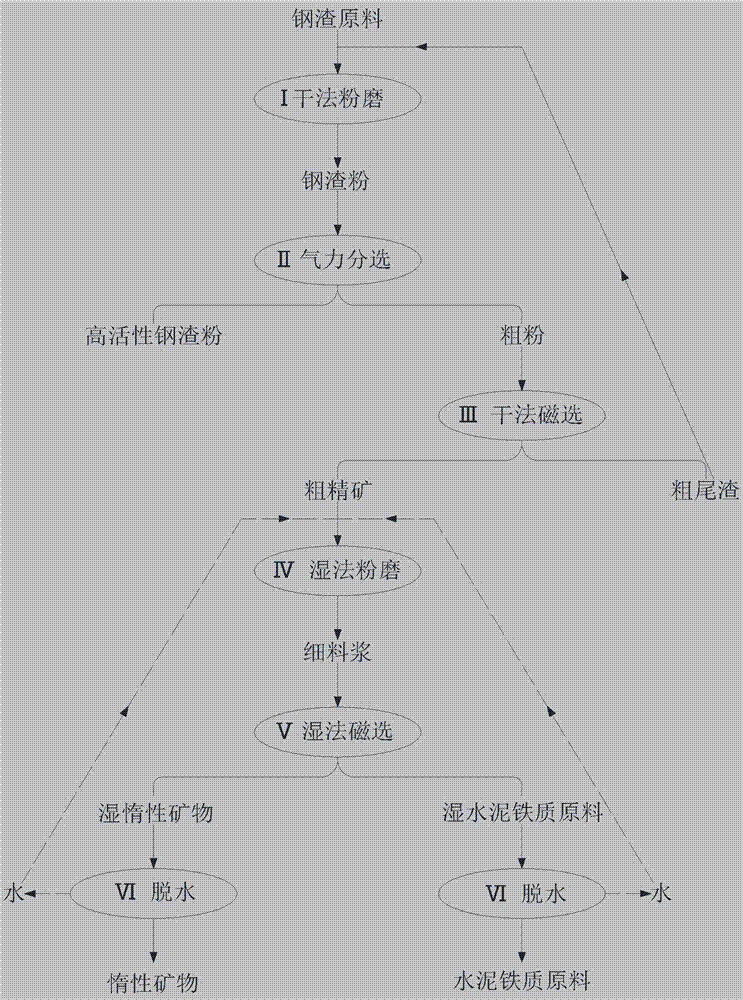

Process for producing highly active steel slag powder and inert mineral products from steel slag

ActiveCN106755650BReduce contentImprove activity indexCement productionRecycling and recovery technologiesSlagResource utilization

The invention discloses a technology of producing high-activity steel slag powder and an inert mineral product by using steel slag. The technology comprises the six steps of dry process grinding, pneumatic separation, dry process magnetic separation, wet process grinding, wet process magnetic separation and dehydration. In the step of the dry process grinding, tailings after slag iron are recovered are ground into steel slag powder, and inert mineral dissociation is realized; in the step of the pneumatic separation, the steel slag powder is subjected to size grading by using a superfine powder concentrator, so that the enrichment of inert minerals in coarse powder is realized, and fine powder is a high-activity steel slag powder product; in the step of the dry process magnetic separation, the coarse powder is purified to be coarse concentrate by employing the magnetism of the inert minerals, and coarse tailings return back to the dry process grinding step; the coarse concentrate is made into fine pulp through the wet process grinding; the fine pulp is separated into a humid inert mineral raw material and a humid cement iron raw material through the wet process magnetic separation; and after the humid inert mineral raw material and the humid cement iron raw material are dehydrated separately, the inert mineral product and a cement iron raw material are obtained, and water returns to the wet process grinding step. According to the technology, the steel slag is processed into the high-activity steel slag powder, the high-iron-grade inert mineral product and the cement iron raw material, so that the full resource utilization of the steel slag is realized.

Owner:西安鼎岩钢渣应用科技有限公司

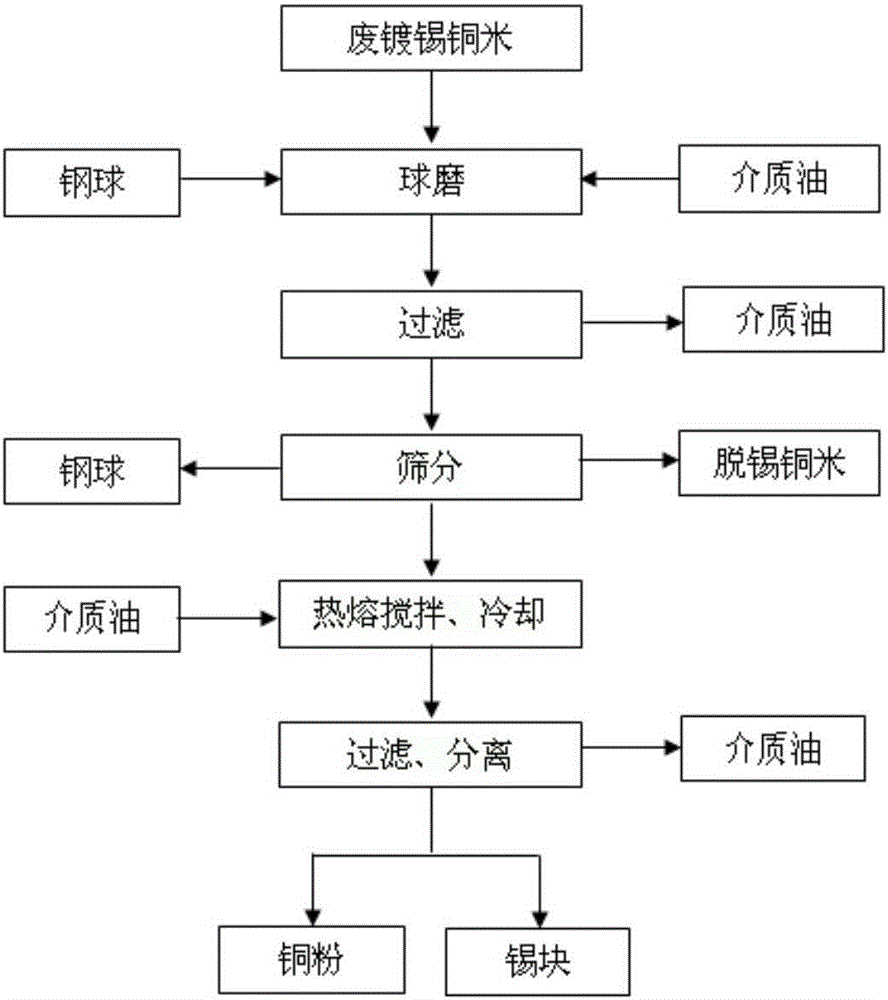

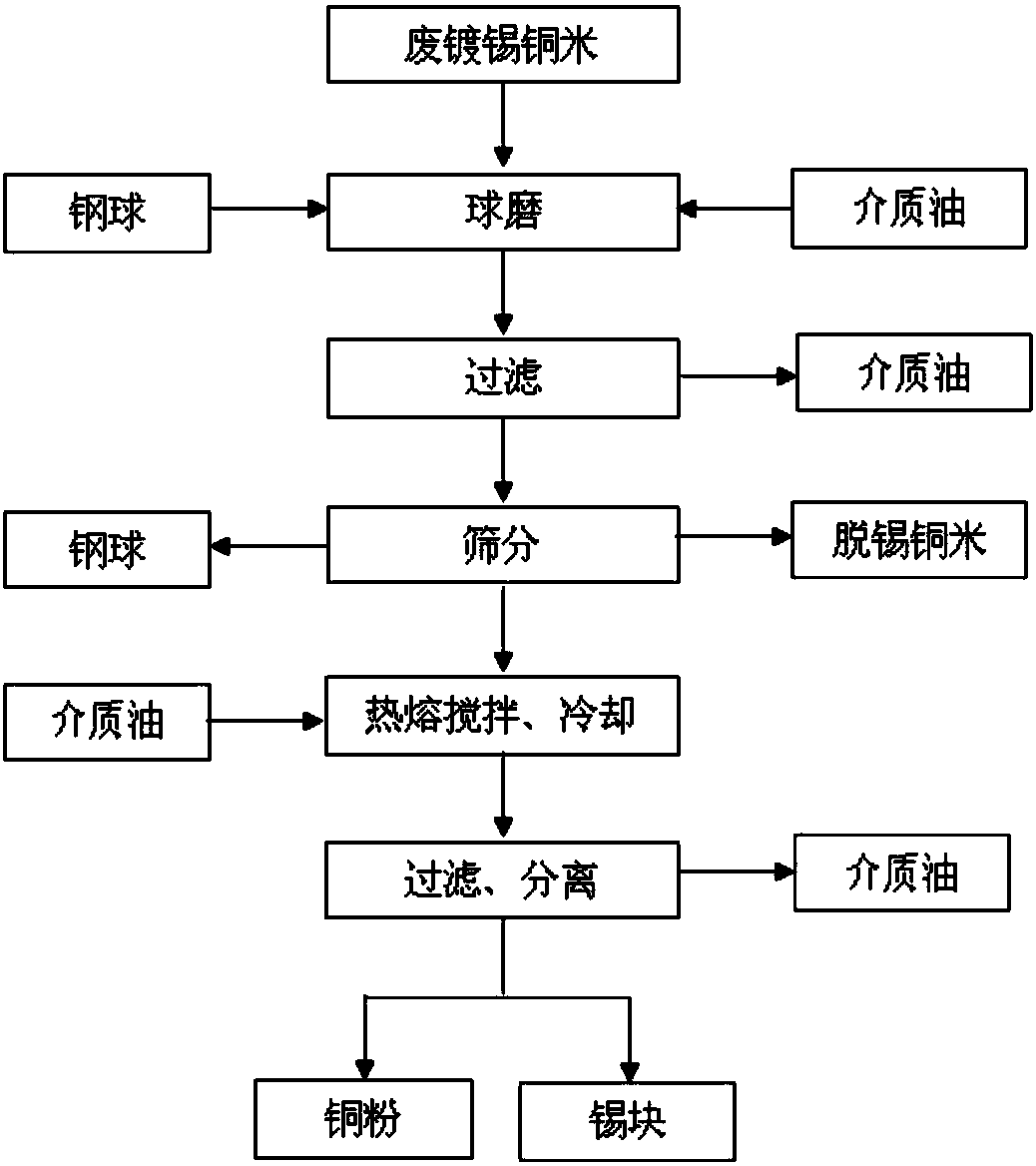

Recycling method of scrap tinned copper rice

ActiveCN106683800ASimple installationLow costBasic electric elementsElectronic waste recyclingVertical mixingScrap

The invention provides a recycling method of scrap tinned copper rice. First, adding a steel ball, waste tinned copper rice, and medium oil into a vertical mixing ball mill in accordance with a certain percentage, wherein the tin and a small amount of copper on the surface of the scrap tinned copper rice are scraped off under a physical friction of the steel ball, and thus a ball mill product is obtained; after filtration and screening, tin-copper mixed powder and tin with removal of copper are got; finally, the tin-copper mixed powder is placed in a vessel with a stirrer, and the medium oil was heated and stirred to separate the tin. The method stripes the tin on the surface of the copper rice by pure physical stripping to realize an efficient separation of a tin plating layer and scrap-copper rice. The invention has the advantages of being simple in method and device, non-pollution for environment, low in cost, and high in efficiency.

Owner:CHONGQING LONGJIAN METAL MFG

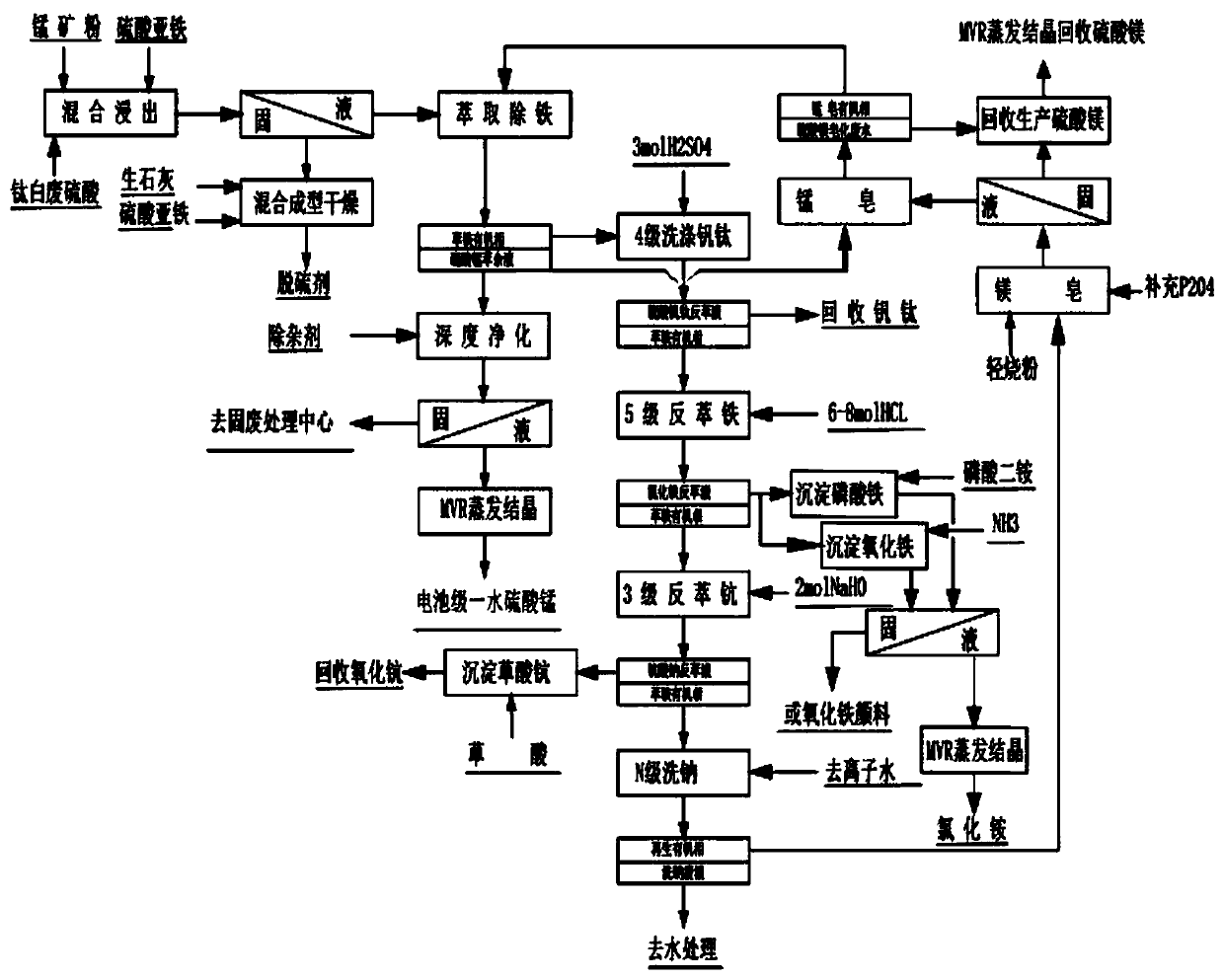

Full resource utilization process of titanium white waste acid

InactiveCN111485102ARealize full resource utilizationIn line with the concept of energy saving and environmental protectionIron oxides/hydroxidesScandium oxides/hydroxidesIron sulfateFerrous sulfate iron

The invention relates to a full resource utilization process of titanium white waste acid. The process specifically comprises the following steps: (1) reducing and leaching manganese oxide ore by using titanium white waste acid and ferrous sulfate to prepare an iron oxide normal-temperature desulfurizer; (2) carrying out magnesium soap extraction on a leached ferric manganese sulfate solution to separate iron and manganese; and (3) treating with an organic phase extractant to respectively recover vanadium, titanium, iron and scandium. The process has the advantages that P204 / 507 is adopted toextract and vanadium, titanium and scandium ions of the enriched titanium white waste acid, full resource utilization of the titanium white waste acid in the real sense is achieved, no new three-wasteproducts are generated, the concepts of energy conservation and environmental protection are met, and the process has a good popularization prospect in the technical field.

Owner:张响

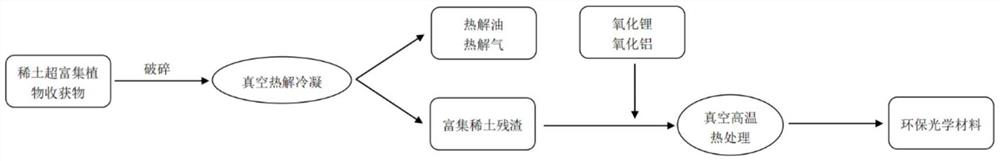

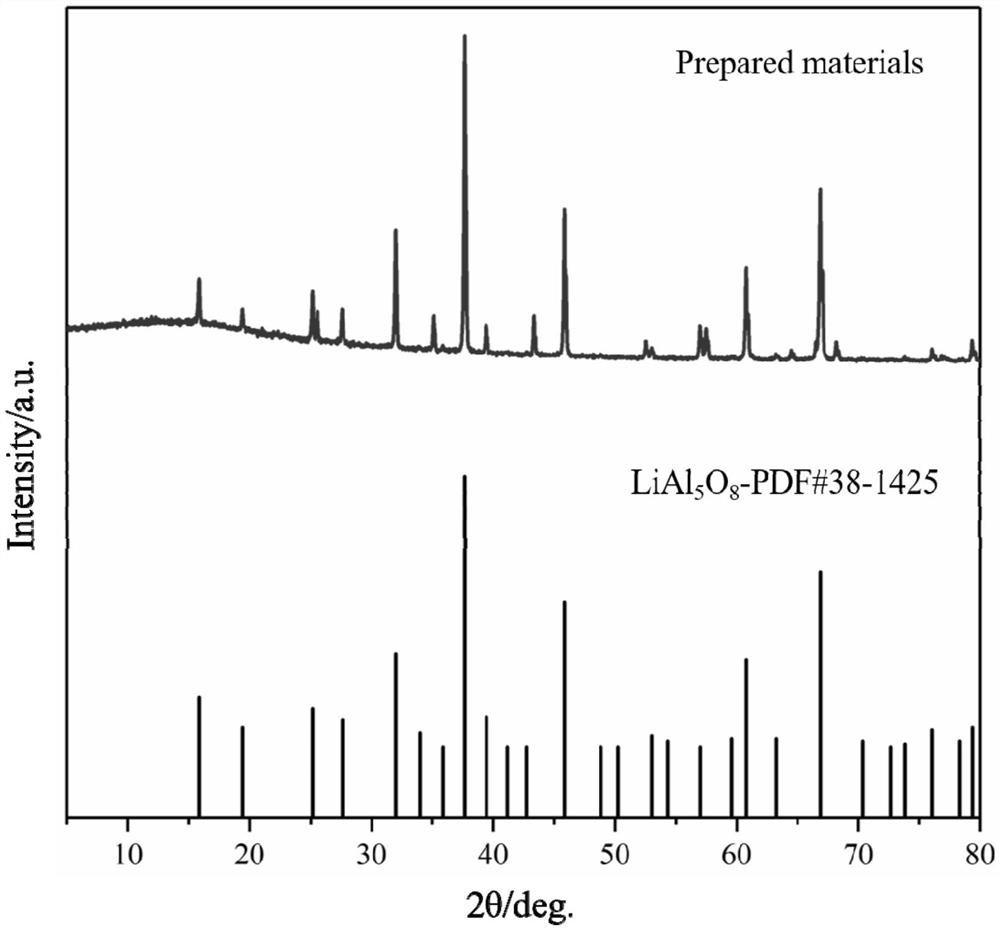

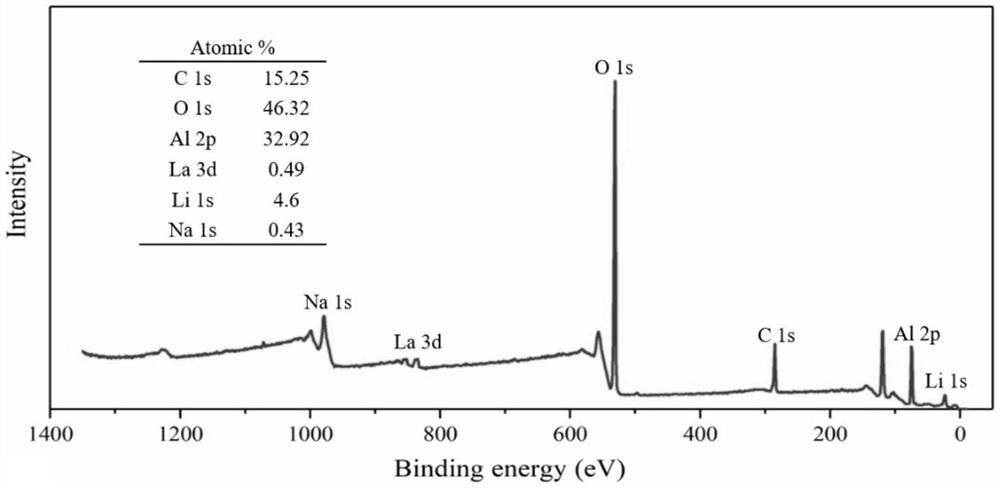

Method for preparing environment-friendly optical material by utilizing rare earth hyperaccumulation plants

ActiveCN112375564AHigh cost of solutionSolve the secondary pollution of the environmentLuminescent compositionsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationWaste recyclingOptical materials

The invention belongs to the technical field of solid waste recycling, and particularly relates to a method for preparing an environment-friendly optical material from rare earth hyperaccumulation plants. The method comprises the following steps: drying and crushing the rare earth hyperaccumulation plant, and sequentially carrying out vacuum thermal decomposition condensation and high-temperaturesolid-phase reaction to obtain the optical material. The full-amount recycling and high-value utilization of the rare earth hyperaccumulation plants are realized, and the problems of high phytoremediation cost and secondary environmental pollution in a rare earth polluted area are solved; compared with a LiAl5O8 matrix optical material, the prepared rare earth doped LiAl5O8 environment-friendly optical material has better optical performance and can be further applied to preparation of light emitting diodes.

Owner:SUN YAT SEN UNIV

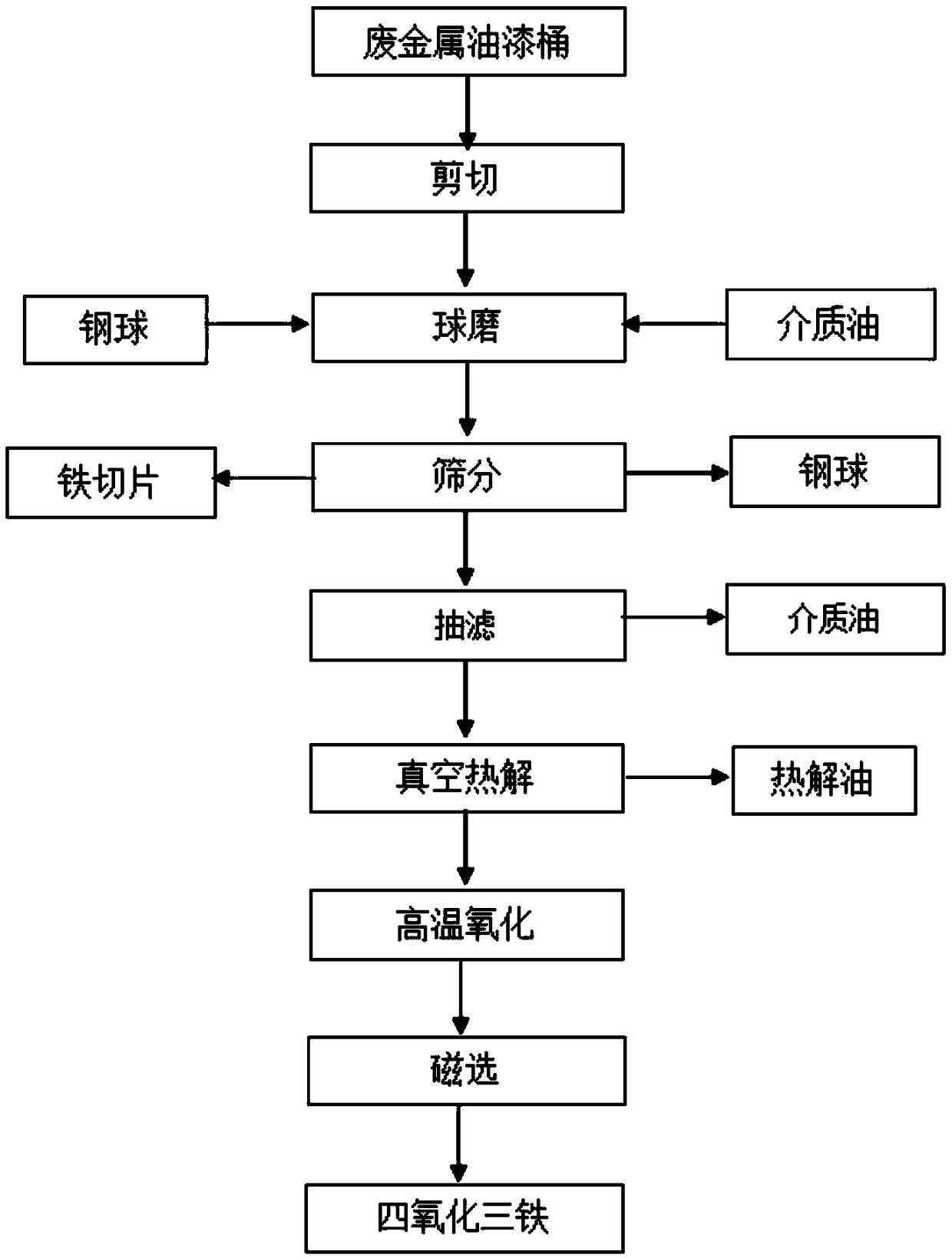

Method for recycling waste metal paint buckets

InactiveCN109337705ARealize full resource utilizationEfficient separationCoke ovensFerroso-ferric oxidesIron powderHigh energy

The invention provides a method for recycling waste metal paint buckets. The method comprises the following steps: firstly cutting the waste metal paint buckets into slices of 50 cm x 50 cm, and charging the slices into a closed container for drying; performing ball milling on the slices, steel balls and medium oil, and sieving; filtering the medium oil mixed with an iron powder and a lacquering material to obtain an oil-containing mixture of the iron powder and the lacquering material; performing vacuum pyrolysis on the mixture of the iron powder and the lacquering material for 30 min at 300to 400 DEG C to obtain pyrolysis oil as a regenerative fuel and pyrolysis residue; then heating the pyrolysis residue in contact with air to 500 DEG C for 30 min, cooling, and delivering the pyrolysisresidue to a magnetic separator to obtain a ferroferric oxide powder as a magnetic raw material. The method fully utilizes the process advantages and the availability of raw materials, avoids the problems of high energy consumption, secondary pollution and the like in the prior art, and facilitates industrialized large-scale recovery.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

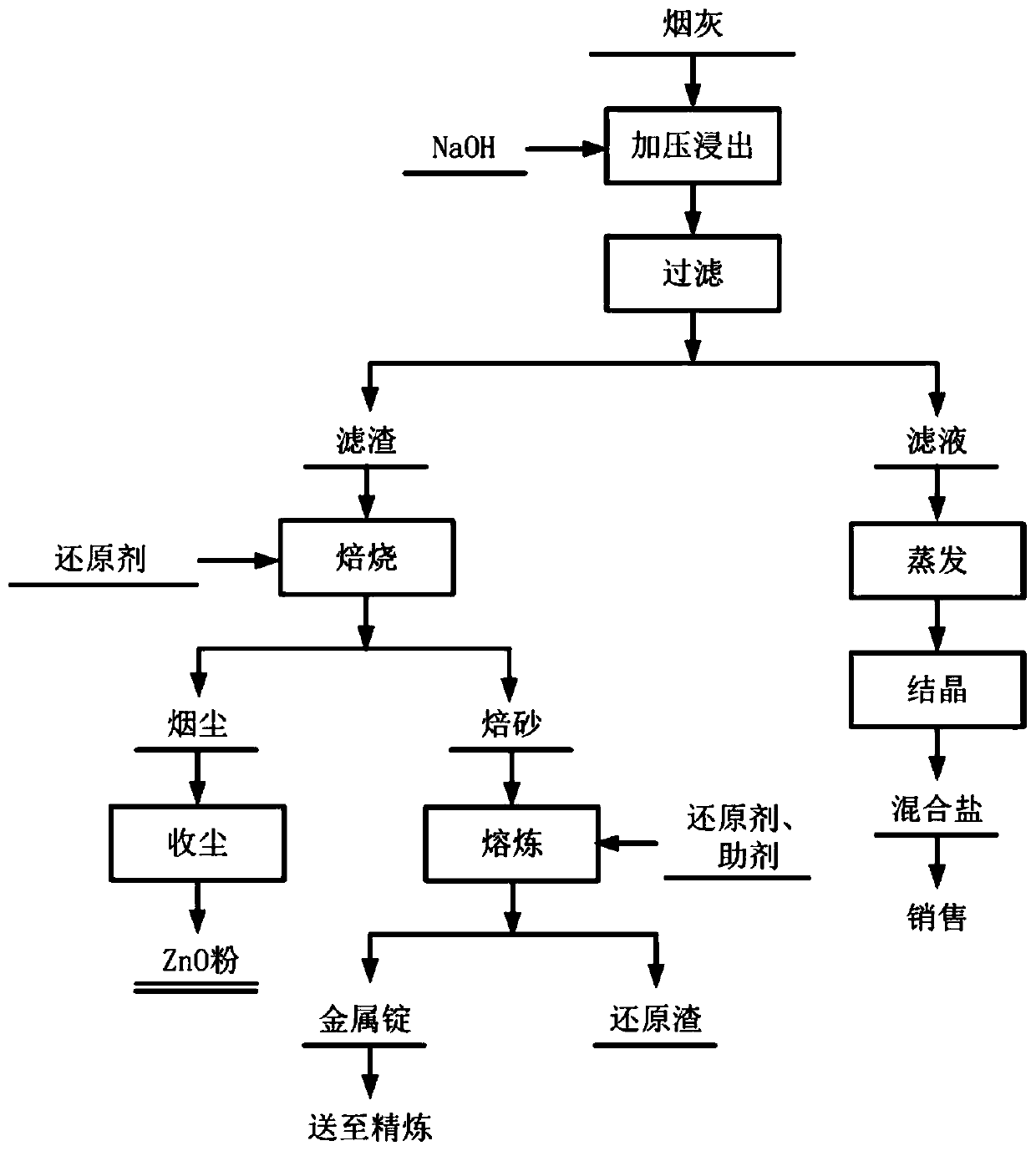

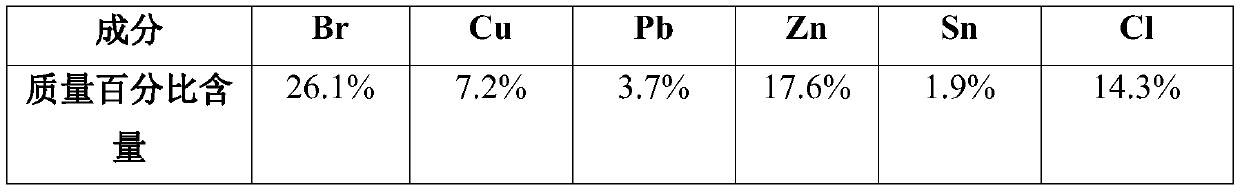

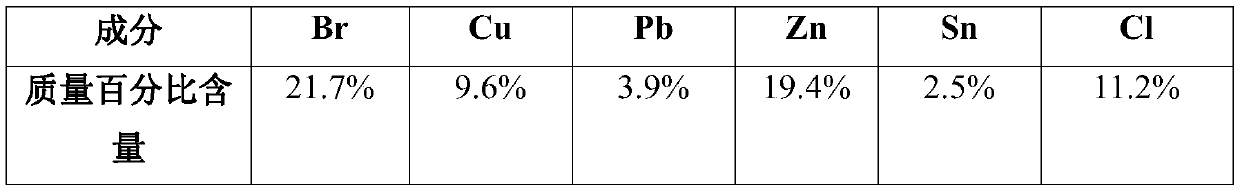

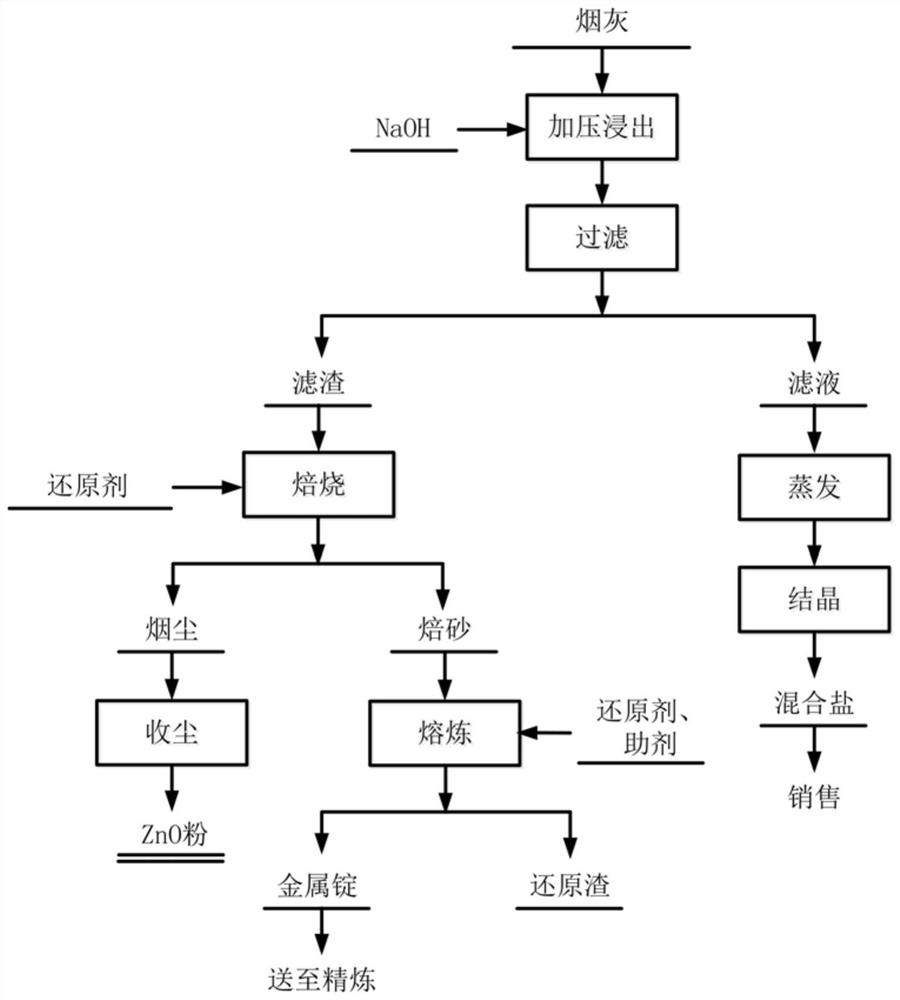

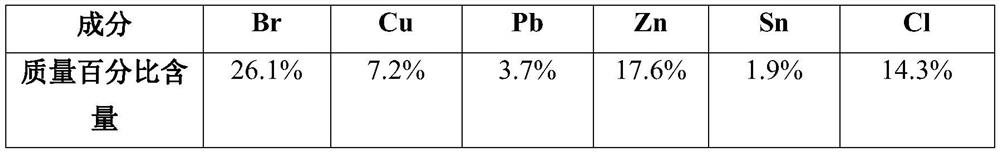

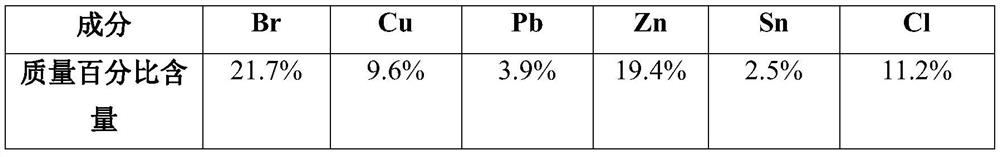

Waste circuit board smelting soot comprehensive recycling method

The invention belongs to the technical field of solid waste treatment, and particularly discloses a waste circuit board smelting soot comprehensive recycling method. According to the recycling method,alkali is added into smelting soot firstly for pressurized leaching, metal bromine and chlorine salt in the soot are converted into hydroxide precipitate, bromine and chlorine are converted into solvable NaBr and NaCl correspondingly, separation of bromine and chlorine from valuable metal can be achieved, filter liquor is evaporated and crystallized to obtain a coarse salt product, filter residueis reduced and roasted, through volatilization, zinc in slag can be recycled, a high-purity zinc oxide product is obtained, then a roasted product is further subjected to temperature rise smelting, and ingot metal and harmless reducing slag can be obtained. The waste circuit board smelting soot comprehensive recycling method effectively recycles bromine, chlorine and valuable metal in the waste circuit board smelting soot.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Novel method for efficiently extractinganthocyanin from black rice

InactiveCN107235951AIncrease added valueRealize full resource utilizationOrganic chemistryUltra high pressureFiltration

The inventiondiscloses a novel method for efficiently extractinganthocyanin from black rice. The method comprises steps of drying ofa black rice raw material, ultra-fine grinding, soaking in a solvent, ultra-high pressure extraction, filtration and centrifugation, ethanol removal, purification by ion exchange resin and freeze drying. The method comprises the following steps: firstly, black rice available in market or broken black rice formed during processing of the black rice is adopted as a raw material, and cells of the black rice are subjected to wall breaking treatment through superfine grinding; then, ultrahigh pressure assisted ethanol extraction is performed, and the ion exchange resin is combined for separation and purification. Extraction efficiency is high, the black rice anthocyanin with higher purity can be prepared, production cost is low, product stability is good, and popularization is facilitated.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

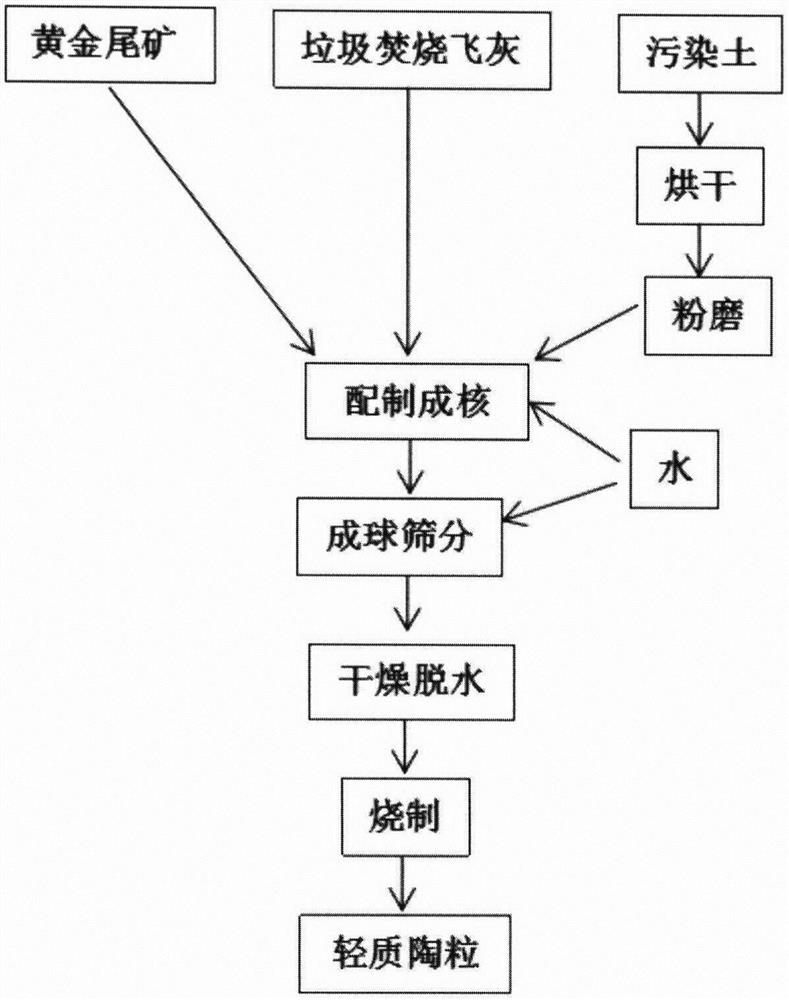

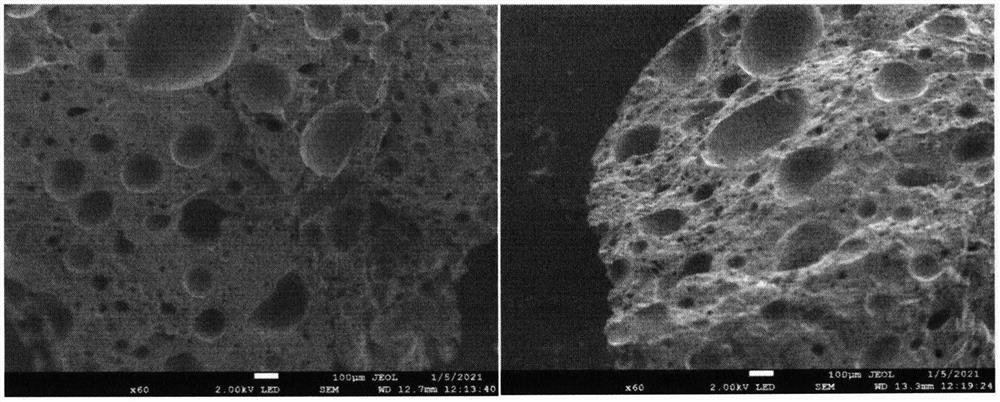

Lightweight ceramsite fired from solid waste and method thereof

PendingCN114751766AHarmlessFully burn and decomposeCeramicwareClaywaresPlastic materialsExpanded clay aggregate

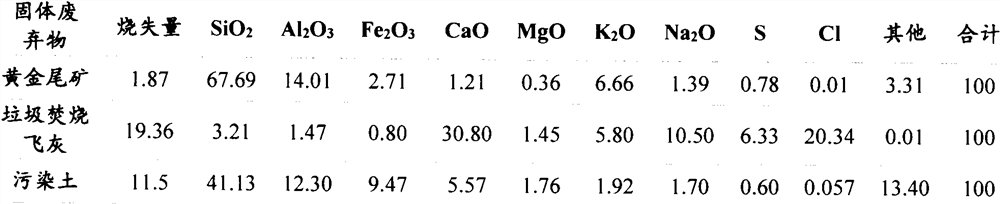

The invention provides a lightweight ceramsite fired from solid wastes and a method thereof. The invention relates to a method for firing light ceramsite by using solid wastes. The method comprises the following steps: S1, preparing materials: selecting an undisturbed raw material of gold tailings, an undisturbed raw material of waste incineration fly ash and polluted soil for later use; s2, preparing a core: adding water into the raw materials in the S1, and mixing to prepare a mixture containing the core; s3, balling and screening: adjusting and preparing water quantity for balling, and selecting wet raw material balling; s4, drying and dehydrating: drying and dehydrating the wet raw material nodules to obtain dry raw material nodules; and S5, firing: transferring the dry raw material pellets into a roasting furnace, preheating, roasting and cooling to obtain the lightweight ceramsite. According to the light ceramsite fired by utilizing the solid waste and the method thereof, the gold tailings are used as the main raw material, the waste incineration fly ash is matched as the fluxing agent and the binder, then the polluted soil is added as the plastic material, and the light ceramsite fired by utilizing the solid waste has excellent performance through the processes of granulation, drying, preheating, roasting and the like; the method for firing the light ceramsite by using the solid wastes has the advantages of high preparation efficiency, low energy consumption and low cost, realizes full resource utilization of the gold tailings, the waste incineration fly ash and the polluted soil, and has good economic benefits, environmental protection benefits and social benefits.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH +1

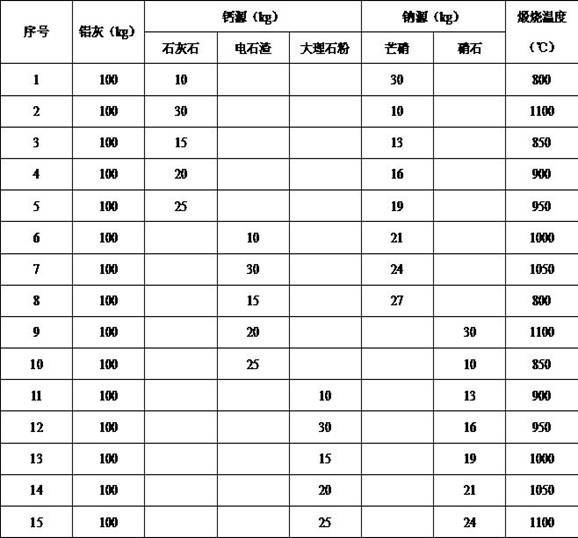

Method for preparing flue gas purifying agent from aluminum ash

InactiveCN112295384APromote generationImprove thermal efficiencyDispersed particle separationCement productionFlue gasPhysical chemistry

The invention discloses a method for preparing a flue gas purifying agent from aluminum ash. The method comprises the following steps: adding a calcium source and a sodium source into the aluminum ash, conducing uniform mixing, and performing calcining in a nitriding device to obtain the flue gas purifying agent. The method is low in production cost and high in efficiency, and high-quality cyclicutilization of resources is achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A method for producing waste water denitrification carbon source by lactic acid fermentation of kitchen waste

ActiveCN111333179BSolve the problem of low COD/TNEfficient resource utilizationWater treatment compoundsTreatment with anaerobic digestion processesLactic acid fermentationLiquid carbon

The invention discloses a method for producing waste water denitrification carbon source by lactic acid fermentation of kitchen waste, which belongs to the technical field of solid waste resource treatment. The invention uses kitchen waste as raw material, after sorting and removing impurities, controls the solid-liquid ratio, grinds, pulps, separates substances and phases, and heats and recovers waste oil, the remaining waste slurry is injected into an anaerobic fermentation tank for batch lactic acid Fermentation, after the fermentation is completed, the solid-liquid separation, the supernatant containing lactic acid can be directly used as a liquid carbon source in the denitrification stage of sewage, to achieve a good biological denitrification effect, and the nitrogen-containing residue can be collected and reused to realize full resource utilization. The invention directly utilizes kitchen waste to carry out efficient open-type lactic acid fermentation, fully utilizes the indigenous microbial flora in the kitchen waste to realize substrate hydrolysis and efficient directional conversion into lactic acid, without adding exogenous nutrients and industrial enzyme preparations, and the process is simple and the production cost Low, while realizing the resource utilization of food waste, it also provides cheap carbon sources for the denitrification section of sewage treatment plants and improves the efficiency of biological denitrification.

Owner:UNIV OF SCI & TECH BEIJING

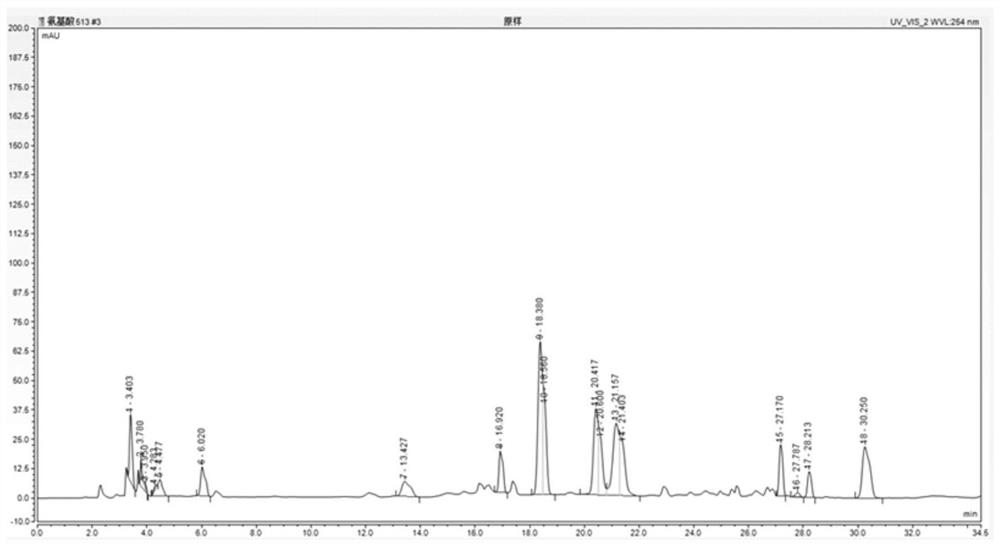

Seafood characteristic food seasoning, preparation method and application

InactiveCN113812598ARealize full resource utilizationImprove product added valueSugar food ingredientsAnimal feeding stuffBiotechnologyMaillard reaction

The invention relates to a seafood characteristic food seasoning, a preparation method and application. Microalgae residues obtained after DHA grease extraction can only serve as a feed processing raw material at present, and an additional value is low. The microalgae residues obtained after DHA extraction still contain more residual DHA grease, protein and other nutrient ingredients, and have a certain seafood characteristic flavor. The invention provides the seafood characteristic food seasoning taking the microalgae which produces DHA grease or cell residues obtained after the DHA grease is extracted as a raw material, a food seasoning which has a good seafood flavor and is rich in DHA is obtained through enzymolysis and Maillard reaction, the seafood characteristic food seasoning is expected to be used as a seasoning for vegetable protein meat, pet food and meal replacement food. and the economic value of the product is obviously improved.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

A kind of resource processing method of waste tinned copper rice

ActiveCN106683800BRealize full resource utilizationEfficient separationBasic electric elementsElectronic waste recyclingTinningFiltration

The invention provides a recycling method of scrap tinned copper rice. First, adding a steel ball, waste tinned copper rice, and medium oil into a vertical mixing ball mill in accordance with a certain percentage, wherein the tin and a small amount of copper on the surface of the scrap tinned copper rice are scraped off under a physical friction of the steel ball, and thus a ball mill product is obtained; after filtration and screening, tin-copper mixed powder and tin with removal of copper are got; finally, the tin-copper mixed powder is placed in a vessel with a stirrer, and the medium oil was heated and stirred to separate the tin. The method stripes the tin on the surface of the copper rice by pure physical stripping to realize an efficient separation of a tin plating layer and scrap-copper rice. The invention has the advantages of being simple in method and device, non-pollution for environment, low in cost, and high in efficiency.

Owner:CHONGQING LONGJIAN METAL MFG

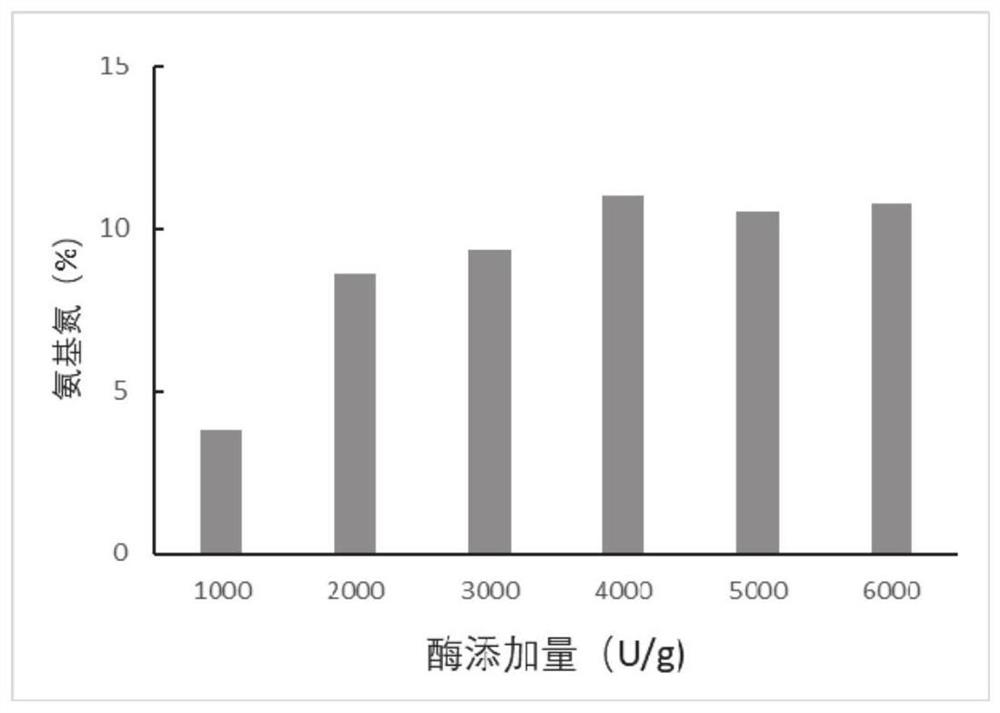

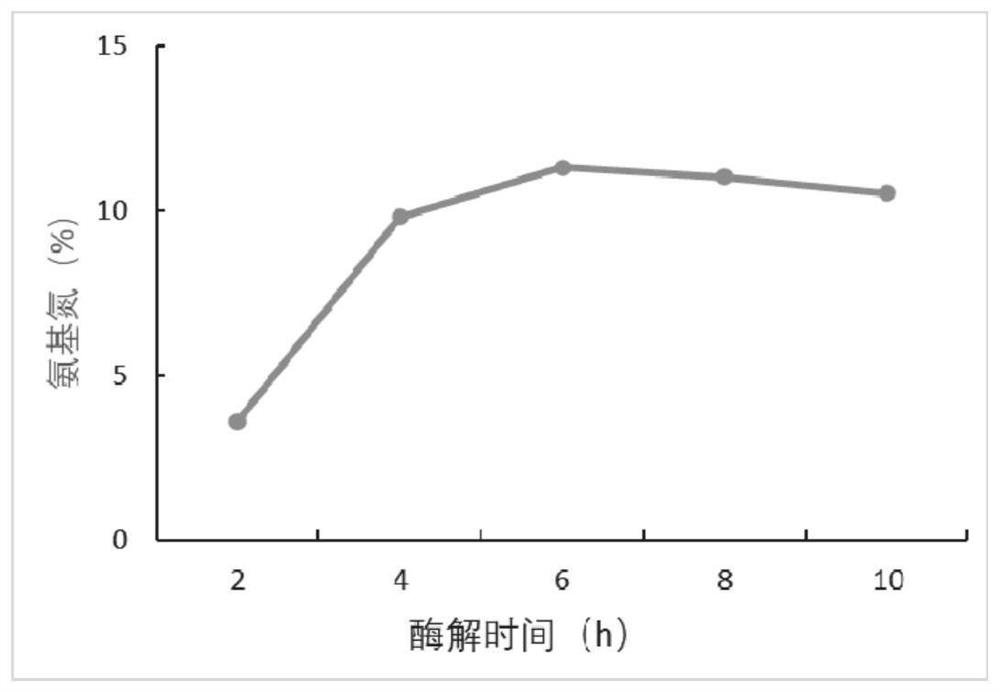

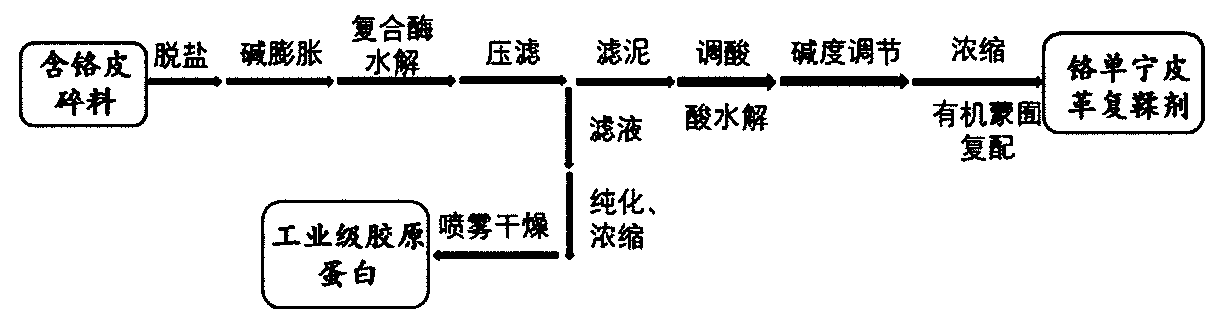

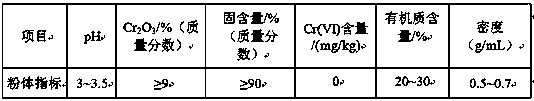

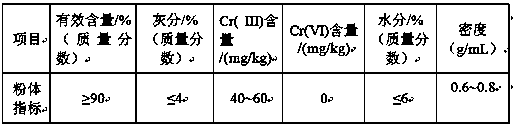

Method for preparing industrial-grade collagen and chromium tannin retanning agent from chromium-containing leather crushed materials and application

ActiveCN110904287ARealize "Zero Emissions"Realize full resource utilizationTanning treatmentRecycling and recovery technologiesAmylaseAlkaline protease

The invention provides a method for preparing an industrial-grade collagen and chromium tannin retanning agent by using chromium-containing leather crushed materials and application of the industrial-grade collagen and chromium tannin retanning agent. The method comprises the following steps: water washing desalination, alkali expansion and enzyme hydrolysis reaction to prepare the industrial-grade collagen and chromium tannin retanning agent, wherein the mass ratio of the chromium-containing leather crushed materials to water is 1: 2, and the moisture content of the obtained leather scraps is60% or above. And in the alkali expansion step, water and the chromium-containing leather crushed materials subjected to water washing and desalination are added into a reaction kettle, and a sodiumhydroxide solution is added for alkali expansion, wherein the enzyme hydrolysis reaction comprises the following steps: reducing the temperature of a reaction system to 40-50 DEG C, and adding compound alkaline protease, lipase and alpha-amylase to carry out the enzyme hydrolysis reaction under the condition of medium-speed stirring. Zero-emission and full-resource utilization of the chromium-containing leather crushed materials are achieved, and the method has important social, economic and environment-friendly significance.

Owner:QILU UNIV OF TECH

A kind of iron tailings full resource utilization method

ActiveCN108585569BHigh precisionHigh strengthCalcareous fertilisersSolid waste managementEnvironmental engineeringTailings

The invention relates to a full-resource iron tailing utilization method. According to the full-resource iron tailing utilization method, iron tailings are crushed and sieved to obtain aggregates andpowders with different grain sizes, the aggregates and the powders with the different grain sizes are used for preparing various iron tailing resource utilization products so as to achieve full-resource utilization of the iron tailings, and the proportions of the aggregates with the different grain sizes can be controlled according to different needs of the resource utilization products so as to improve the comprehensive performance of the resource utilization products.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

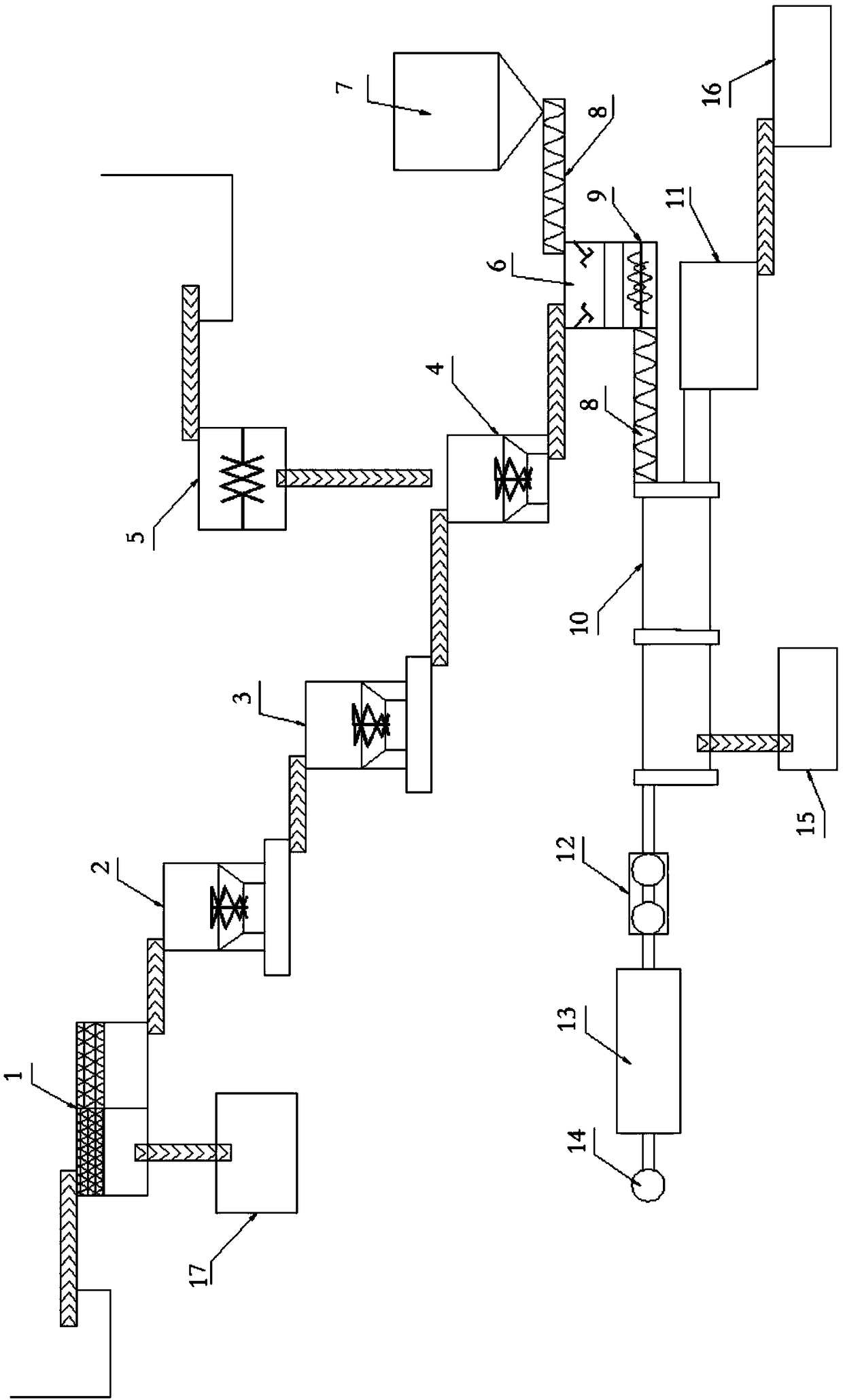

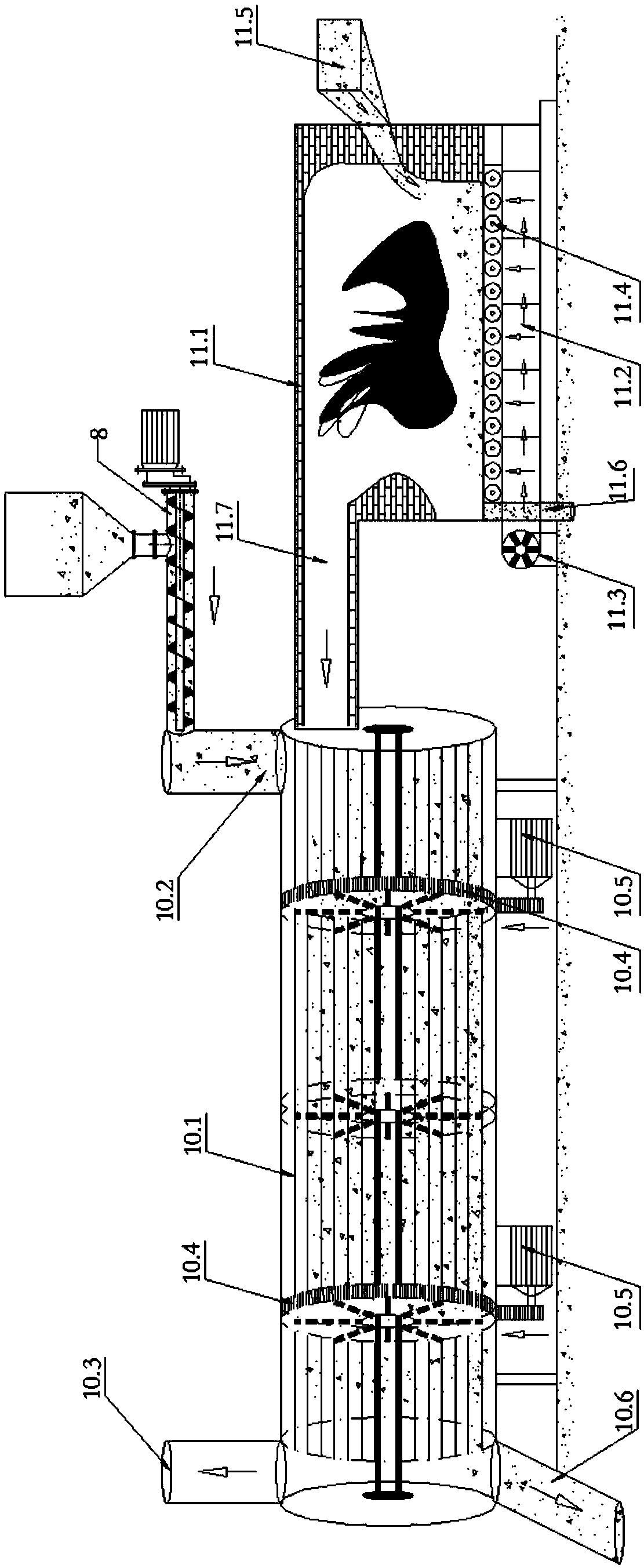

Domestic garbage undersize and sludge mixed carbonization treatment system

InactiveCN106186627BRealize full resource utilizationRealize harmless disposalGas treatmentSludge treatment by pyrolysisCombustionSludge

The invention discloses a domestic refuse screen underflow-sludge mixed carbonization treatment system which comprises a refuse refined sorting mechanism, wherein discharge ports of the refuse refined sorting mechanism and a straw granule feed mechanism are respectively connected to a feed port of a three-stage crushing mechanism through a belt conveyer; a discharge port of the three-stage crushing mechanism is connected with a first feed port of a stirring mixer through a belt conveyer; a discharge port of a sludge tank is connected with a second feed port of the stirring mixer through a screw conveyer; a discharge port of the stirring mixer is connected with a press granulator; a discharge port of the press granulator is connected to a feed port of a carbonization furnace through a screw conveyer; a discharge port of the carbonization furnace is connected with a biomass charcoal finished product storage bin through a belt conveyer; and high-temperature hotblast of the carbonization furnace is supplied by a combustion furnace. The system overcomes various defects in the domestic refuse treatment mode in the traditional technique, and implements complete recycling and harmless treatment on domestic refuse.

Owner:重庆以法莲实业有限公司

Grifola frondosa total-component drink and production method thereof

InactiveCN108013288AEfficient use ofHigh dissolution rateFood ingredient functionsFood extractionNatural productHazardous substance

The invention relates to grifolafrondosa total-component drink and a production method thereof, which belong to the technology of health care food processing. The method comprises the steps of wet micro-granulating cleaned grifola frondosa, fusing at high pressure, regulating tissues, separating, blending, filling, sterilizing and the like, and producing the grifola frondosa total-component drinkwith high active component content, high digestion absorptivity and remarkable effect. The grifola frondosa total-component drink can be directly taken orally, and has all health care functions of natural grifola frondosa. During a production process, no waste is produced, and grifola frondosa resources are fully utilized. The production process is friendly to the environment without producing anywaste residues, waste gas and harmful substances; without using any chemical agent, the product is safe to eat and stable in property and belongs to a high-quality high-efficient natural product.

Owner:吉林省双胜丰药业有限责任公司

Resource treatment method for storage and transportation oil sludge

InactiveCN111977929ARealize full resource utilizationSimple processSludge treatment by de-watering/drying/thickeningPreparation from carboxylic acid halidesSolid carbonDemulsifier

The invention discloses a resource treatment method for storage and transportation oil sludge. The resource treatment method includes the steps that (1) a demulsifier is added into the oil sludge accumulated at the bottom of a petroleum tank, and after heating and fully stirring are carried out, solid-liquid separation is carried out; (2) liquid obtained in the step (1) is separated after standing, oil is recovered for reuse in an oil refining unit; (3) a catalyst and an oxidant are uniformly mixed with solid obtained by solid-liquid separation in the step (1) according to a mass ratio, and anactivator is added to extract soluble small molecular organic matter in a solid-liquid mixture; and (4) the solid-liquid mixture obtained in the step (3) is subjected to solid-liquid separation, obtained filtrate is an organic fertilizer solution, the remaining solid is powdered solid carbon, then the organic fertilizer solution is distilled, the solid is dried to obtain a solid organic fertilizer, separated water is reused to the step (2) to prepare the activator after being condensed, then the powdered solid carbon is oxidized-roasted in a muffle furnace to obtain pyrolysis carbon, and thepyrolysis carbon can be recycled to a catalytic oxidation process in the step (3). The resource treatment method is simple in process, low in cost, quick in effect, and large in processing capacity, and can realize full resource utilization of the storage and transportation oil sludge.

Owner:纽博恩(佛山)科技有限公司

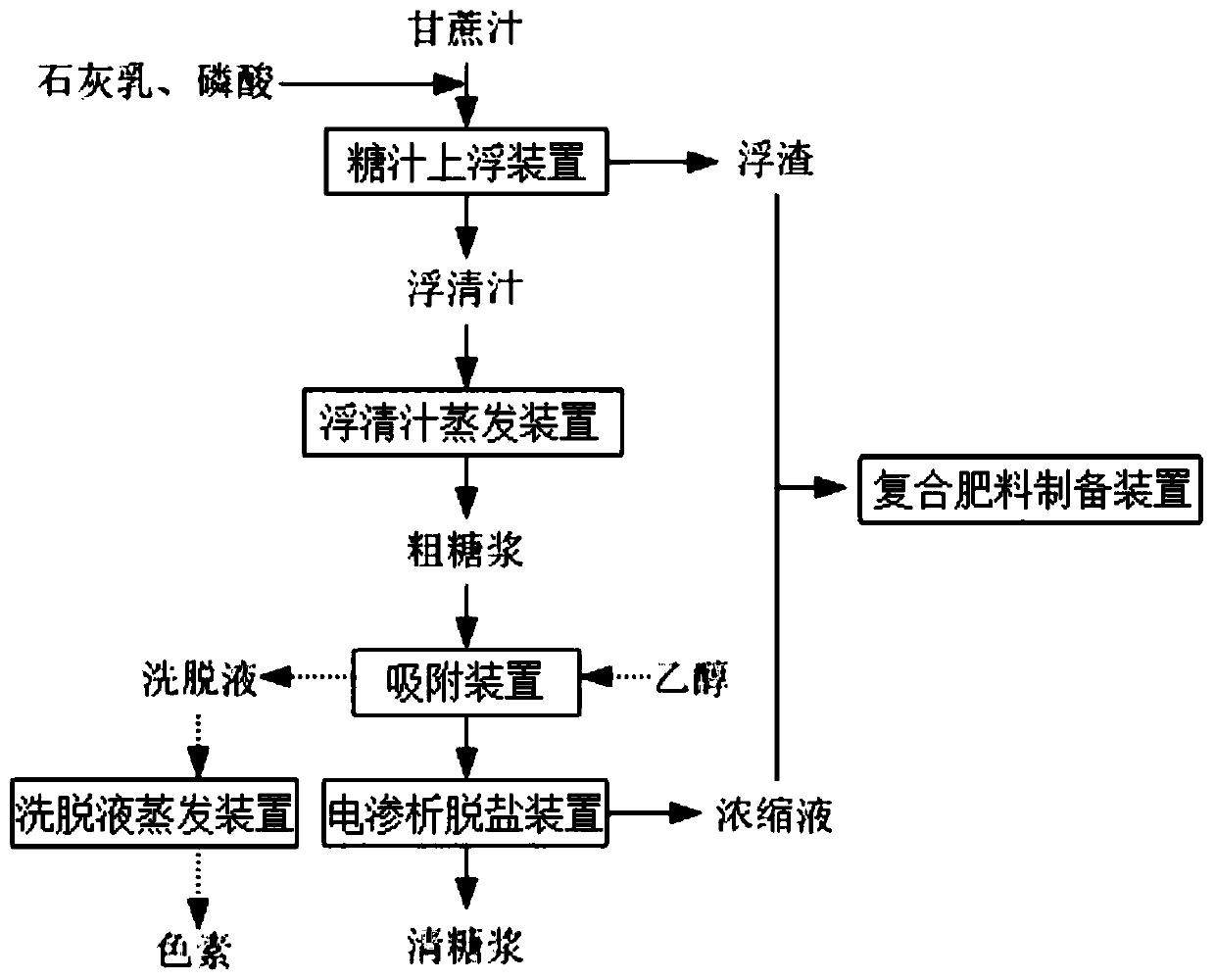

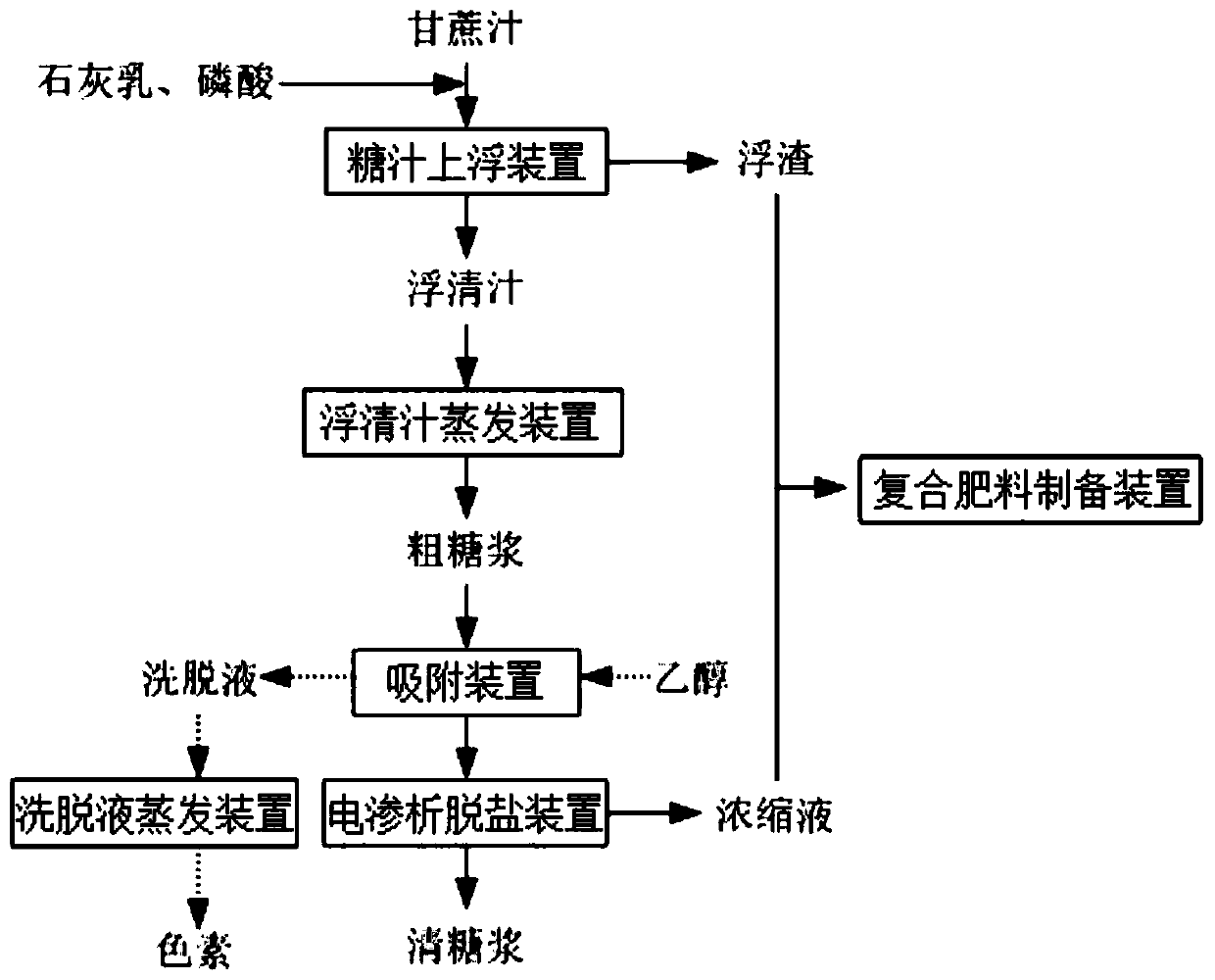

Sugar cane juice sulfur-free clarification and desalination system and method

PendingCN109971892ALow ash contentGuaranteed uptimeSugar juice purificationResource utilizationPhosphoric acid

The invention belongs to the field of sugar industry, and discloses a sugar cane juicesulfur-free clarification and desalination system and method. The system includes a sugar canejuice floating device, a floating juice evaporation device, an adsorption device, an electrodialysis desalination device, an eluent evaporation deviceand a compound fertilizer preparation device. After adding lime milk and phosphoric acid to the sugar cane juice, the juice is separated by the sugar cane juice floating device to obtain a floating clear juice and a scum; the obtained floating clear juice is concentrated by evaporation to 25-45 degree Bx to obtain a crude syrupwhich is then subjected to macroporous resin absorption treatment and electrodialysis desalination treatment to obtain the clear syrup and aconcentrate; the obtained scum and concentrate are mixed to prepare a compound fertilizer;macroporous resin is eluted with the ethanol to obtain an eluate, and the eluate is concentrated by evaporation to obtain a pigment. The system has no carbonation saturation and sulfuric acid neutralization device, does not produce calcium carbonate alkaline filter mud, does not use SO2,can achieve full resource utilization of wasteand has remarkable environmental protection benefits, economic benefits and social benefits.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

A kind of comprehensive recovery method of waste circuit board smelting soot

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

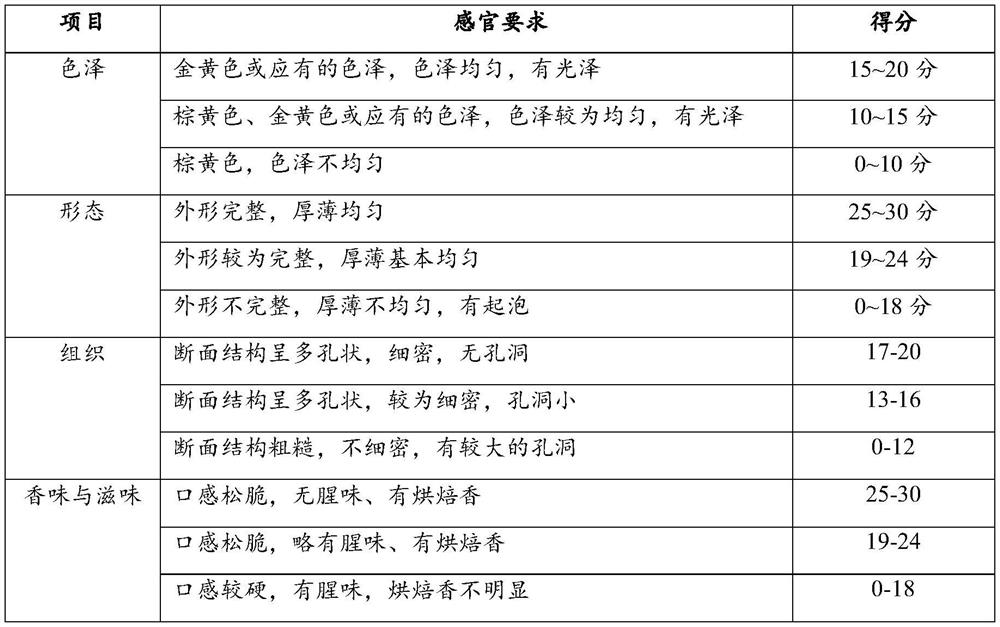

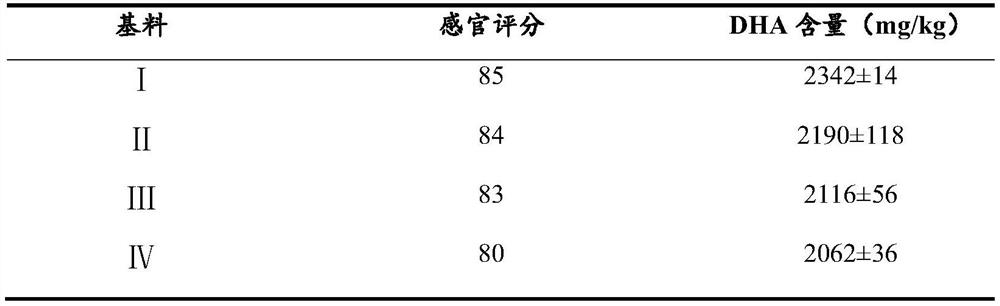

DHA functional biscuit and preparation method thereof

PendingCN113812439ARealize full resource utilizationLow costDough treatmentModified nutritive productsBiotechnologySnack food

The invention belongs to the field of food processing, and particularly relates to a DHA functional biscuit and a preparation method thereof. The DHA functional biscuit is prepared from the following components: 5-15 parts of microalgae thalli containing DHA or microalgae cell residues obtained after part of DHA grease is extracted, 20-30 parts of weak strength flour, 0.1-0.2 part of baking powder, 3-5 parts of butter and 0.3-0.5 part of leavening yeast. The microalgae thalli producing DHA or microalgae cell residues obtained after part of DHA grease is extracted are used for preparing the biscuit, on the one hand, full resource utilization of microalgae is achieved, and compared with current feed application, the added value is increased; and on the other hand, the microalgae thalli or cell residues obtained after part of DHA grease is separated are adopted as raw materials and used for strengthening DHA in the diet of people, the DHA algae oil raw material cost can be greatly reduced, and the price is friendly to people. In addition, the biscuit is the most common leisure snack food in the life of people, and is more acceptable to consumers.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

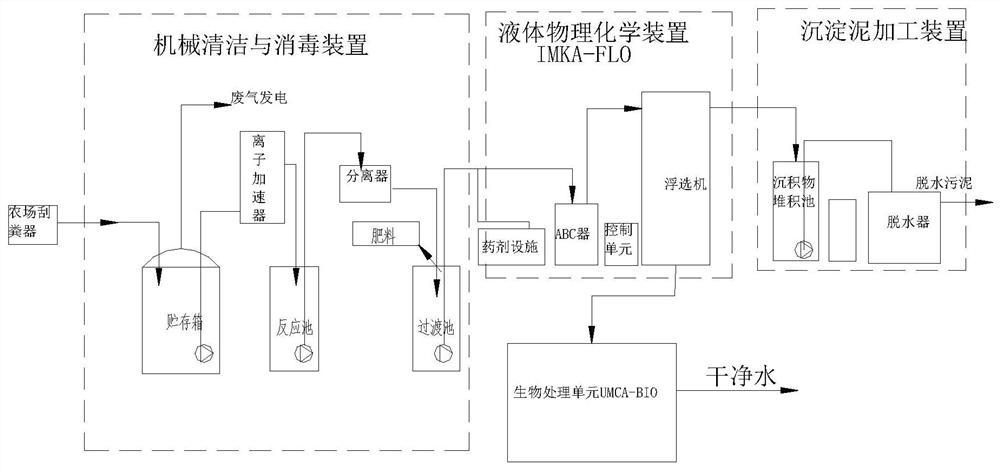

Farm excrement treatment process

PendingCN113880355AStable technical performanceDisposal volume is controllableSludge treatmentWaste water treatment from animal husbandryExhaust fumesCrop livestock

The invention discloses a farm excrement treatment process. The process comprises the following steps: uniformly feeding excrement sewage discharged from livestock raising in a farm into a screening and collecting tank, mixing the excrement sewage and calcium oxide according to a ratio by the collecting tank through a sludge lifting pump, and adding the mixture into a vortex ion accelerator (strong magnetic physical and chemical treatment reactor), performing full treatment, feeding excrement into a static reaction tank for 20-40 minutes, pumping excrement sewage into a solid-liquid separator by using a sludge pump after the reaction is completed, carrying out solid-liquid separation, carrying out air floatation on the separated sewage, carrying out biochemical treatment on supernatant without most suspended solids / eggs / escherichia coli / COD / NH3, enabling concentrated excrement subjected to air floatation to flow into the reaction tank again, and performing secondary solid-liquid separation; making the separated solid excrement into organic fertilizer through an air energy-saving drying machine, and enabling the organic fertilizer to enter the market for selling; treating the liquid into a liquid organic fertilizer, extracting urine protein feed or up-to-standard discharge, collecting waste gas, and preparing or decomposing and discharging a liquid fertilizer through efficient gas-liquid mass transfer technical equipment. Secondary pollution is avoided.

Owner:深圳市旺竹环保有限公司

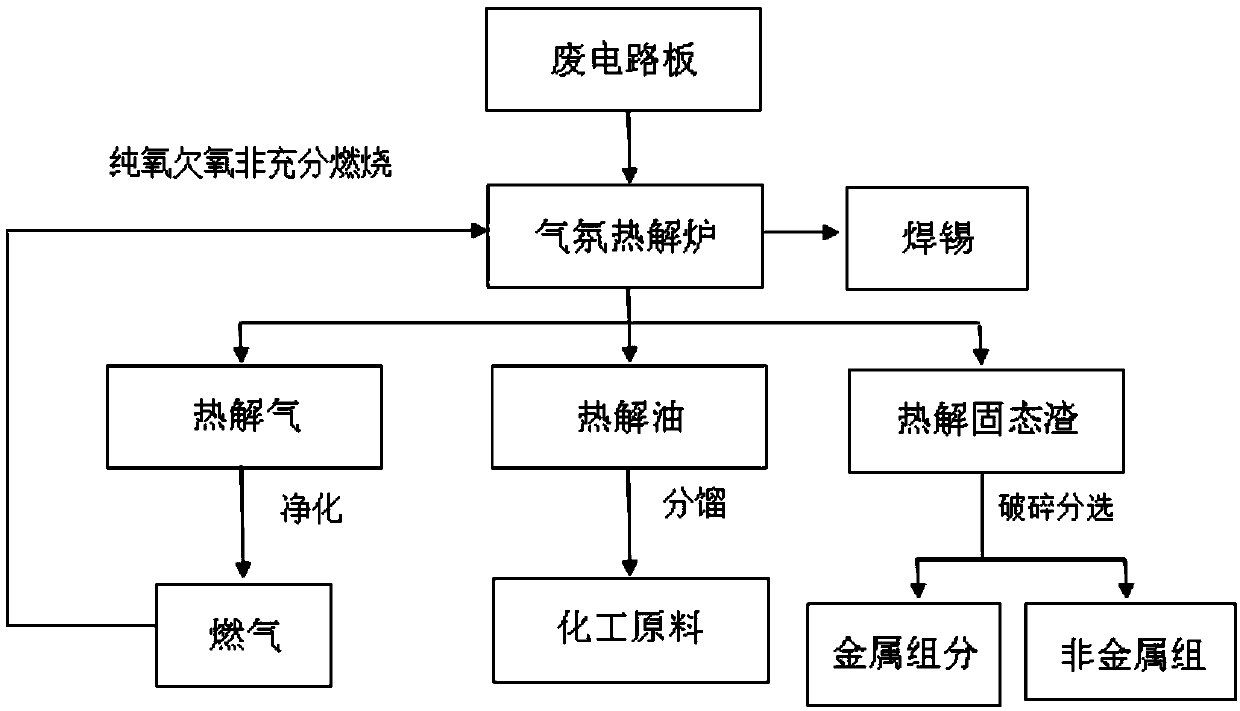

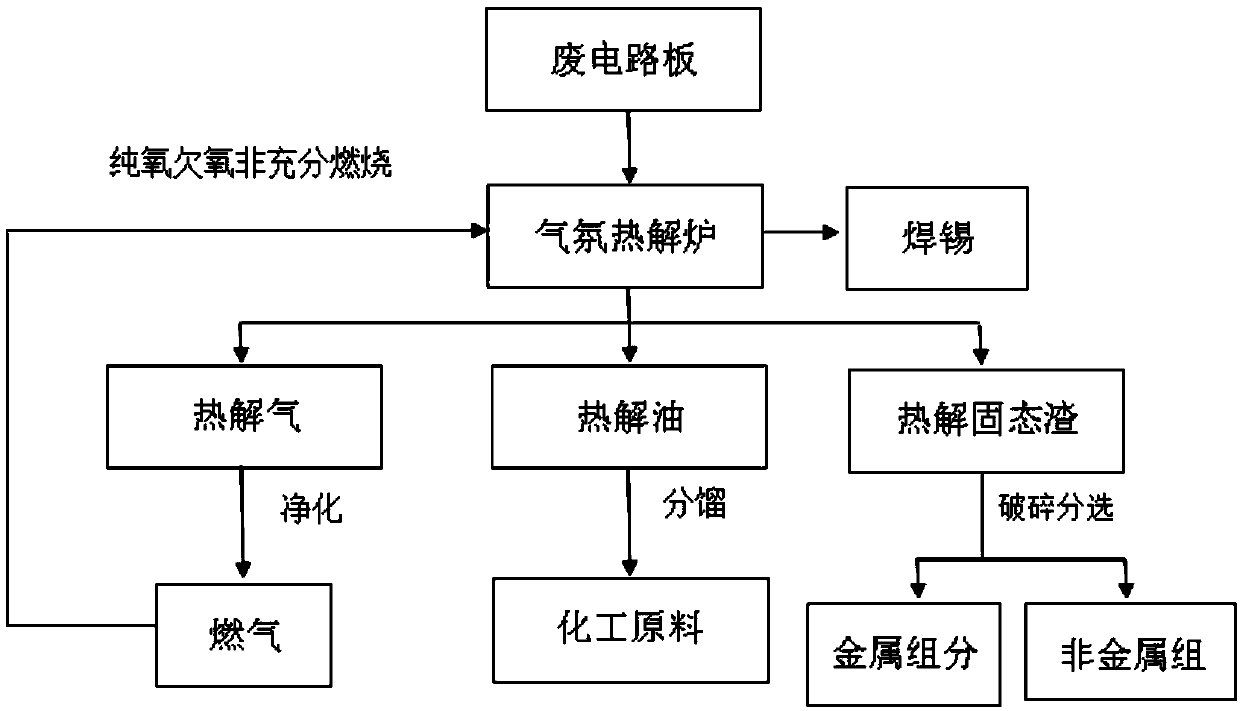

A low-carbon and high-efficiency clean recycling method for full resource recycling of waste circuit boards

ActiveCN106734067BStrong raw material toleranceReduce energy consumptionTransportation and packagingSolid waste disposalLiquid stateOxygen

The invention discloses a low-carbon and high-efficiency full-resource clean recovery method of waste circuit boards. The method is to place the waste circuit boards in a pyrolysis furnace, and feed oxygen and gas into the pyrolysis furnace to perform insufficient oxygen deficiency. Combustion provides a heat source and atmosphere for the pyrolysis of waste circuit boards, controls the temperature in the pyrolysis furnace to continue to rise, the solder is recovered in liquid form, the pyrolysis slag is enriched at the bottom of the furnace, the pyrolysis gas is recovered from the top of the furnace, and the pyrolysis gas is recovered through condensation After the oil is pyrolyzed, the condensed residual gas is washed with lye and returned to the pyrolysis furnace as gas. This method is simple to operate, low in energy consumption, and can realize low-carbon, high-efficiency, and full-resource clean recycling of waste circuit boards.

Owner:广西锐异环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com