Sugar cane juice sulfur-free clarification and desalination system and method

A sugarcane juice and desalination technology, applied in the production of sucrose, purification of sugar juice, sugar production, etc., can solve the problems of complex operation, many problems of membrane attenuation, and high requirements on material quality, and achieves quick investment results, less auxiliary equipment, The effect of low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

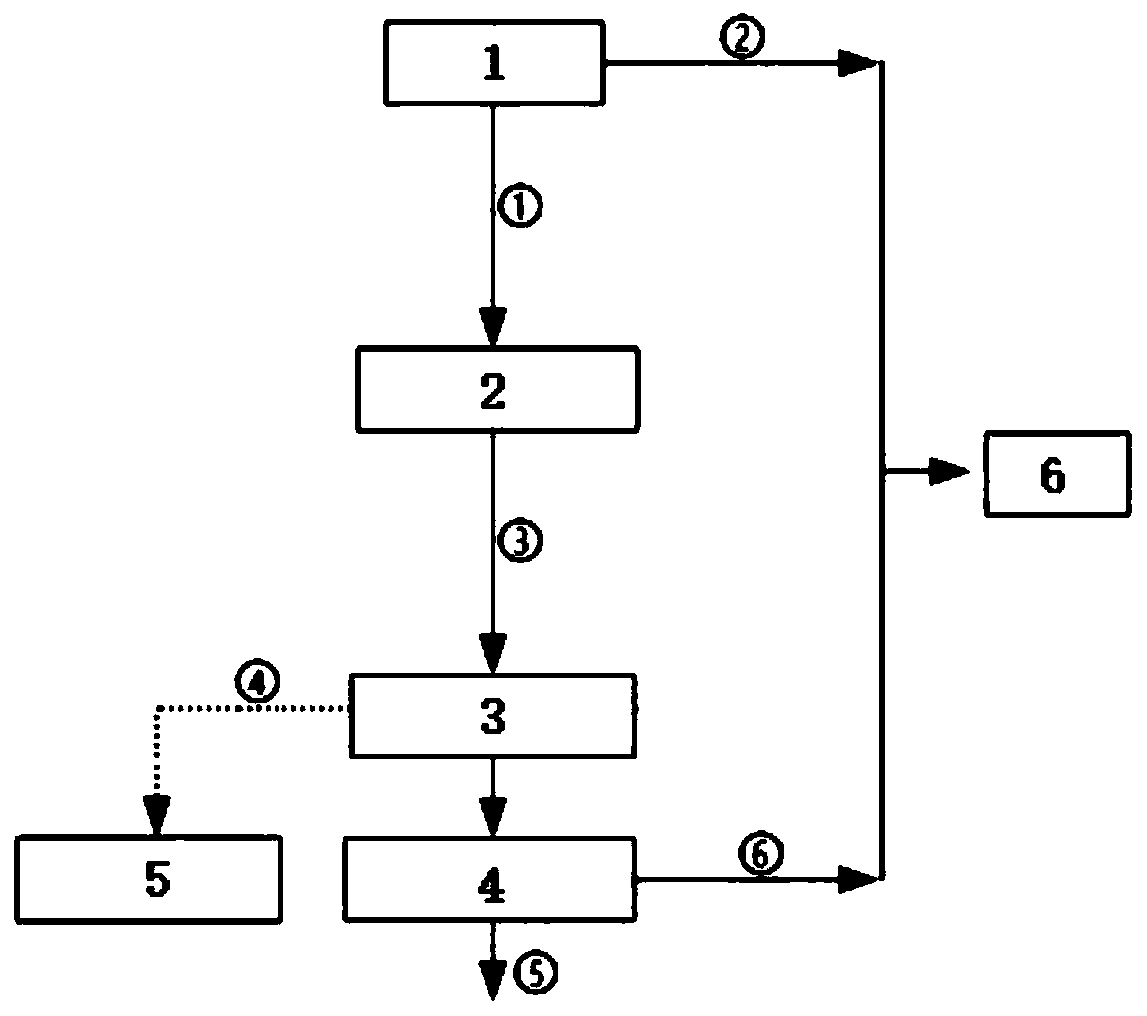

[0030] A kind of sugarcane juice sulfur-free clarification and desalination system of this embodiment, its connection relationship structural diagram is as follows figure 1 As shown, it includes a sugar juice floating device 1, a floating clear juice evaporation device 2, an adsorption device 3, an electrodialysis desalination device 4, an eluent evaporating device 5 and a compound fertilizer preparation device 6; the sugar juice floating device 1 is provided with a floating clear juice outlet ① and the scum outlet ②, the floating clear juice outlet ① is connected to the floating clear juice evaporating device 2, and the scum outlet ② is connected to the compound fertilizer preparation device 6; the floating clear juice evaporating device 2 is provided with a coarse syrup outlet ③ connected to the adsorption device 3; The adsorption device 3 is connected to the electrodialysis desalination device 4, and the eluent outlet ④ is set to be connected to the eluent evaporation device...

Embodiment 2

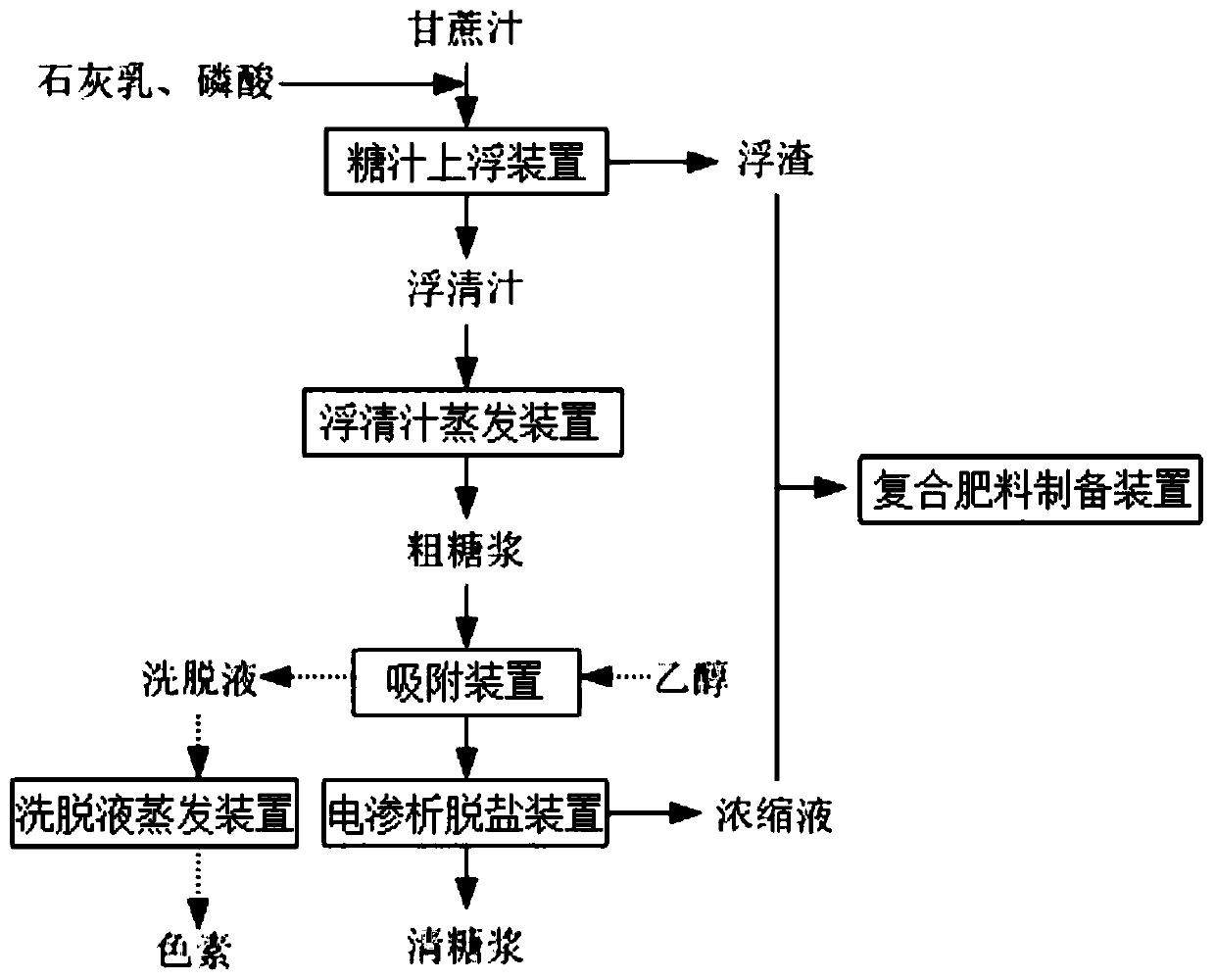

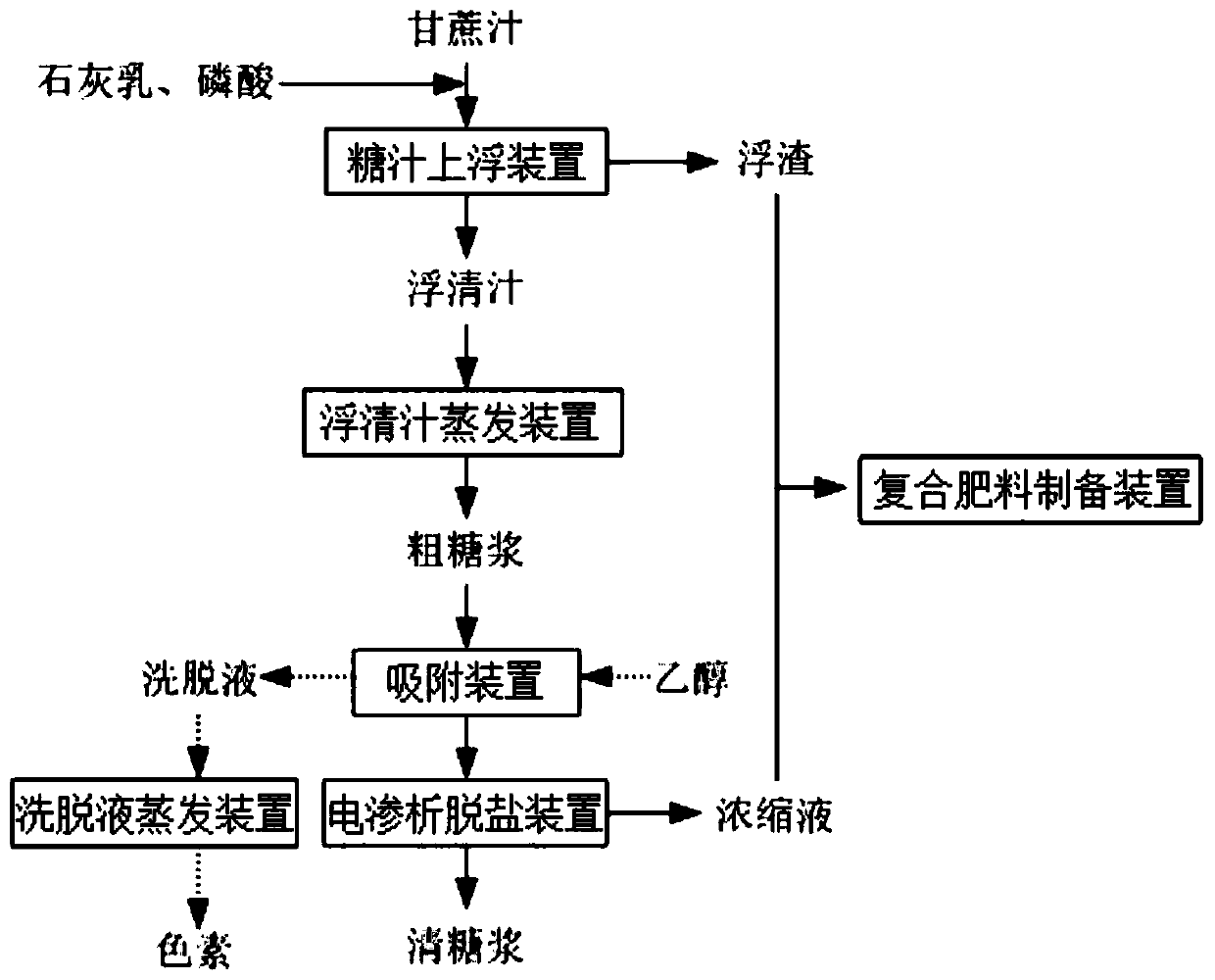

[0039] A kind of sugarcane juice sulfur-free clarification and desalination system of this embodiment, its connection relationship structural diagram is as follows figure 1 As shown, using this system to carry out sulfur-free clarification and desalination of sugarcane juice, the specific process is as follows figure 2 As shown, the steps are as follows:

[0040] (1) After adding milk of lime of 1.5% sugarcane juice quality and 0.1% phosphoric acid respectively in sugarcane juice, separate through sugar juice floating device, obtain floating clear juice and scum;

[0041] (2) Concentrate the floating clear juice obtained in step (1) to 45 ° Bx through a floating clear juice evaporator at a vacuum degree of -0.06 MPa and a temperature of 90 ° C to obtain crude syrup;

[0042] (3) the rough syrup obtained in step (2) is carried out through the D201 type macroporous resin adsorption device for adsorption treatment and the electrodialysis desalination device with a voltage of 10...

Embodiment 3

[0047] A kind of sugarcane juice sulfur-free clarification and desalination system of this embodiment, its connection relationship structural diagram is as follows figure 1 As shown, using this system to carry out sulfur-free clarification and desalination of sugarcane juice, the specific process is as follows figure 2 As shown, the steps are as follows:

[0048] (1) After adding milk of lime of 1.0% sugarcane juice quality and 0.05% phosphoric acid respectively in sugarcane juice, separate through sugar juice floating device, obtain floating clear juice and scum;

[0049] (2) Concentrate the floating clear juice obtained in step (1) to 35 ° Bx through a floating clear juice evaporator at a vacuum degree of -0.1 MPa and a temperature of 50 ° C to obtain a crude syrup;

[0050] (3) The rough syrup obtained in step (2) is carried out through the D101 type macroporous resin adsorption device for adsorption treatment and the electrodialysis desalination device with a voltage of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com