Method for utilizing hydrothermal carbonization for preparing biomass barbecuing charcoal

A technology of hydrothermal carbonization and charcoal grilling, which is applied to biofuels, waste fuels, solid fuels, etc., can solve the problems of loss of cohesive properties of charcoal particles, detrimental to the health of grillers, and increased charcoal production costs, and achieve a simplified process, The effect of good bonding effect and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0024] The biomass raw material in this embodiment is cotton stalks.

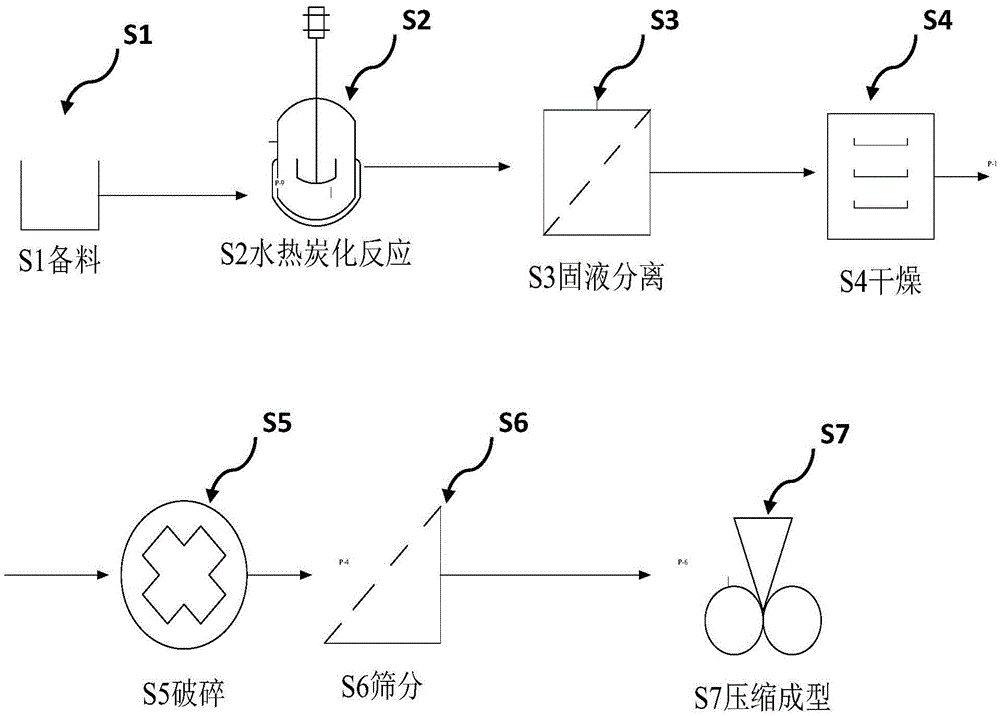

[0025] figure 1 It is a flowchart of the hydrothermal carbonization of biomass barbecue charcoal in this embodiment.

[0026] Such as figure 1 As shown, when cotton stalks are used as biomass raw materials to produce biomass barbecue charcoal through hydrothermal carbonization, the process flow is as follows:

[0027] The first step S1, stock preparation, cotton stalk is 1 kilogram, and water is 10 kilograms.

[0028] The second step S2, hydrothermal carbonization reaction, put the prepared materials into the reaction container for hydrothermal carbonization reaction. The reaction container selected this time is a high-pressure reactor. Oxygen, the temperature of the reaction vessel is raised to 350°C, the pressure of the vessel is increased to 4.5Mpa, and a hydrot...

Embodiment 1

[0034] Function and effect of implementing 1 example

[0035] The product parameters obtained according to this embodiment are as follows: ash content 2.31%, fixed carbon content 61.26%, calorific value 21.85MJ / Kg, ignition point 283°C, compressive strength 7MPa, wherein the ash content is significantly lower than that obtained by the traditional method of preparing barbecue charcoal The ash content and strength of biochar meet the transportation requirements.

Embodiment 2

[0037] The biomass raw material of this embodiment is coconut shell.

[0038] figure 1 It is the flow chart of hydrothermal carbonization system biomass barbecue charcoal in the present embodiment

[0039] Such as figure 1 As shown, when coconut shell is used as biomass raw material to produce biomass barbecue charcoal through hydrothermal carbonization, the process flow is as follows:

[0040] The first step S1 is to prepare materials, the coconut shell is 1 kg, and the water is 4 kg.

[0041] The second step S2, hydrothermal carbonization reaction, put the prepared materials into the reaction container for hydrothermal carbonization reaction. The reaction container selected this time is a high-pressure reactor. Oxygen, the temperature of the reaction vessel was raised to 300°C, the pressure of the vessel was increased to 4.0Mpa, and a hydrothermal carbonization reaction was carried out for 40 minutes to obtain a carbonized substance mixture.

[0042] The third step S3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com