Patents

Literature

176 results about "Sugar industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sugar industry subsumes the production, processing and marketing of sugars (mostly saccharose and fructose). Globally, most sugar is extracted from sugar cane (~80 % predominantly in the tropics) and sugar beet (~ 20%, mostly in temperate climate like in the U.S. or Europe).

A biologic organic fertilizer, and preparation method

InactiveCN1872803APromote growthImprove the ecological environmentBio-organic fraction processingClimate change adaptationOil processingPotassium

This invention relates to a method for manufacturing bioorganic fertilizer. The bioorganic fertilizer is manufactured by: mixing sugar industry waste, breeding industry waste, oil-processing waste, phosphoric fertilizer, trace element fertilizer and silicon fertilizer, and performing aerobic fermentation and post fermentation. The effective components of the bioorganic fertilizer are: organic matters (greater than or equal to 30%), N, P and K (greater than or equal to 8%), beneficial microorganisms (greater than or equal to 200,000,000 / g), active silicone (greater than or equal to 5%), magnetic components (0.25%), and Fe, Zn and Mo (0.5-1%). The bioorganic fertilizer has abundant raw material sources, and is environmentally friendly.

Owner:成官文

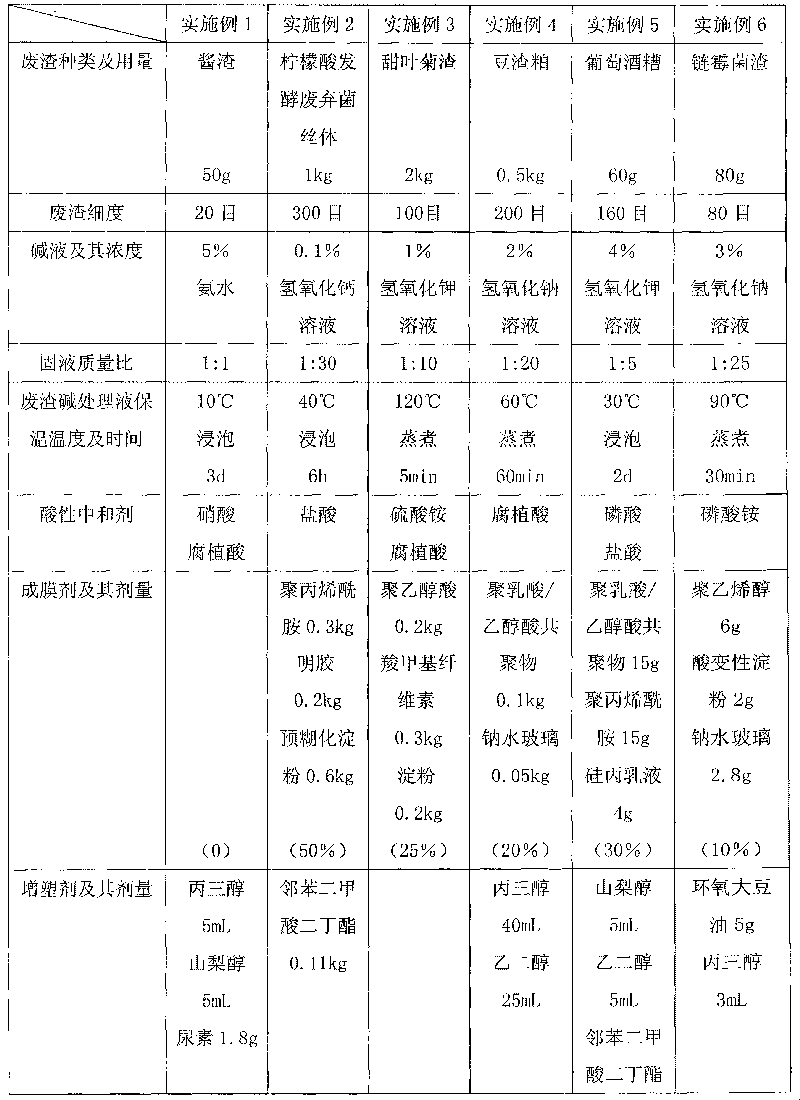

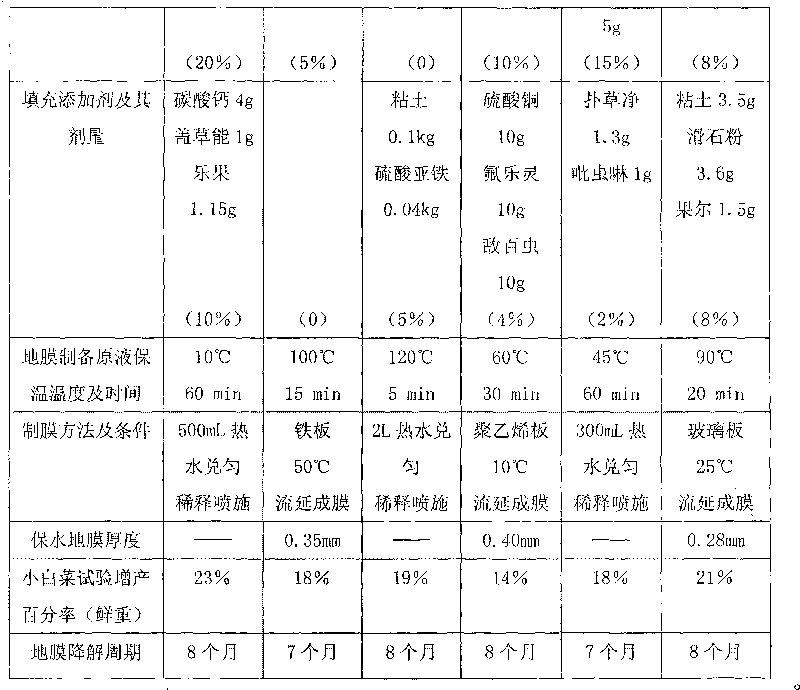

Method for preparing degradable mulch by reusing organic waste residues of biomass

InactiveCN101712805ASolve pollutionAchieve reuseClimate change adaptationOrganic fertilisersPlastic mulchMoisture

The invention discloses a method for preparing degradable agricultural mulches by reusing organic waste residues of biomass, which can be widely used for preparing biodegradable nutritional type water-retention mulches by recycling the by-product residues in the fermentation brewing industry and the sugar industry. In the process, low-concentration alkali liquor is mainly used for processing the waste residues, specified neutralizing agents are used for neutralizing the fertilizers such as N, P, K and the like required for growing the plants which are generated and auxiliary film-forming agents, plasticizers and the like are used for preparing mulch stock solution, or casting or diluting or spraying is carried out. The mulch is low in cost and convenient to operate, such substances as pesticides, weedicides, trace fertilizers and the like can be added to the mulch according to the requirements of different crops, and the mulch not only has the effects of heat preservation, moisture preservation and fertilizer betterment but also has moderate degradation period. The degradation rate of the ground mulch reaches 55-70% after 4 months and almost reaches 100% after about 8 months.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing food hygiene-level active carbon by use of bagasse

ActiveCN103803547ASolve the reuse problemHigh dry matter contentCarbon compoundsActive agentBiological waste

The invention relates to an active carbon material, and particularly relates to a method for preparing food hygiene-level active carbon by use of biological waste resource bagasse. The method comprises the steps of collecting and cleaning the residual bagasse after sugar production; sufficiently fermenting at 10-50 DEG C, drying, grinding and sieving; then performing the operation treatment such as soaking in an active agent solution, charring, activation and the like on the pretreated bagasse; washing, drying and grinding to obtain a high-performance active carbon product which can be applied to decoloration, refining and impurity removal of the sugar industry and the fields of foods and medicines such as medicinal crude drugs and the like. According to the method provided by the invention, by adopting the waste bagasse as a raw material, the comprehensive utilization of resources and environmental protection are facilitated; moreover, the price is low, the product quality is high, and the economic and social benefits are good.

Owner:JIANGSU ZHUHAI ACTIVATED CARBON CO LTD

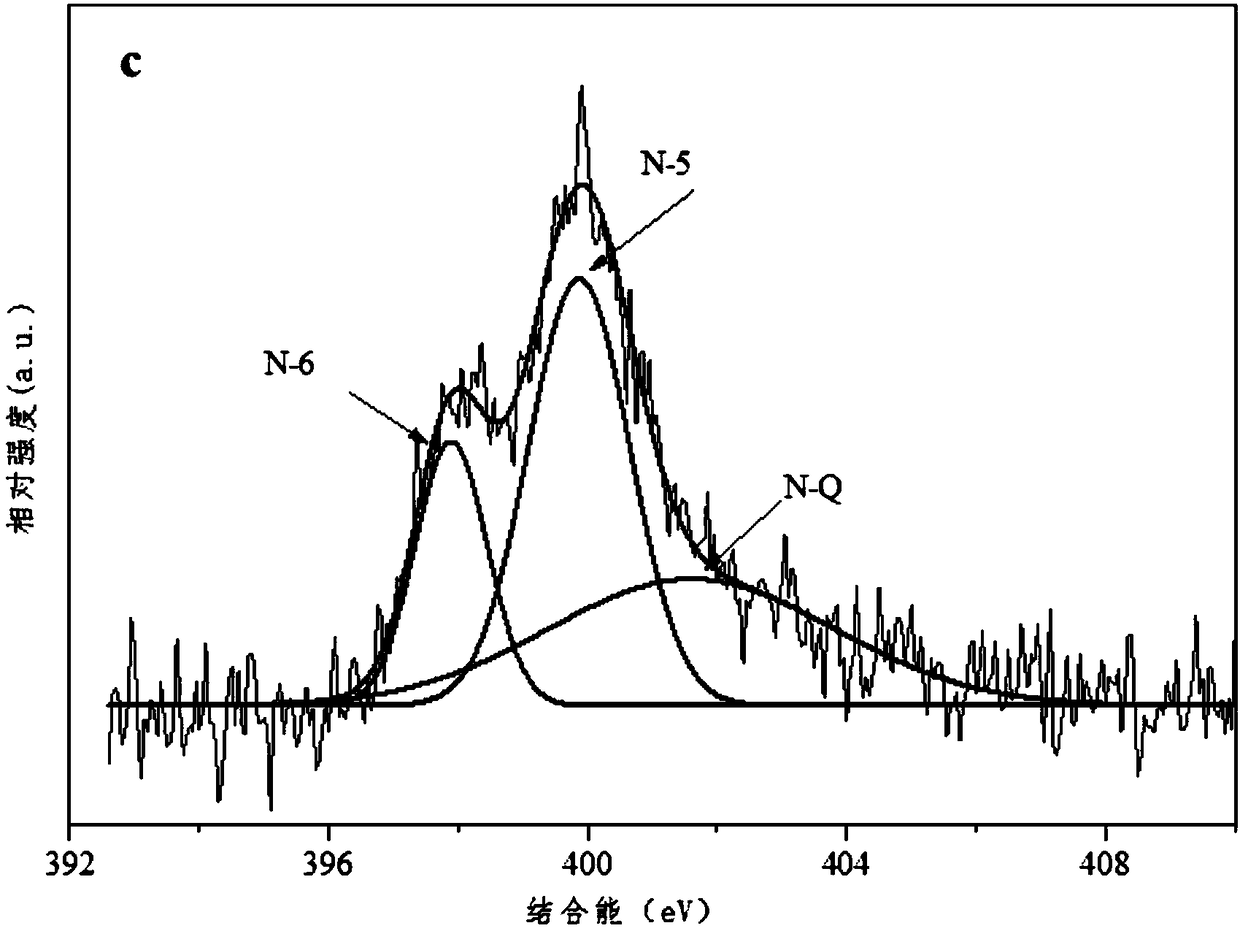

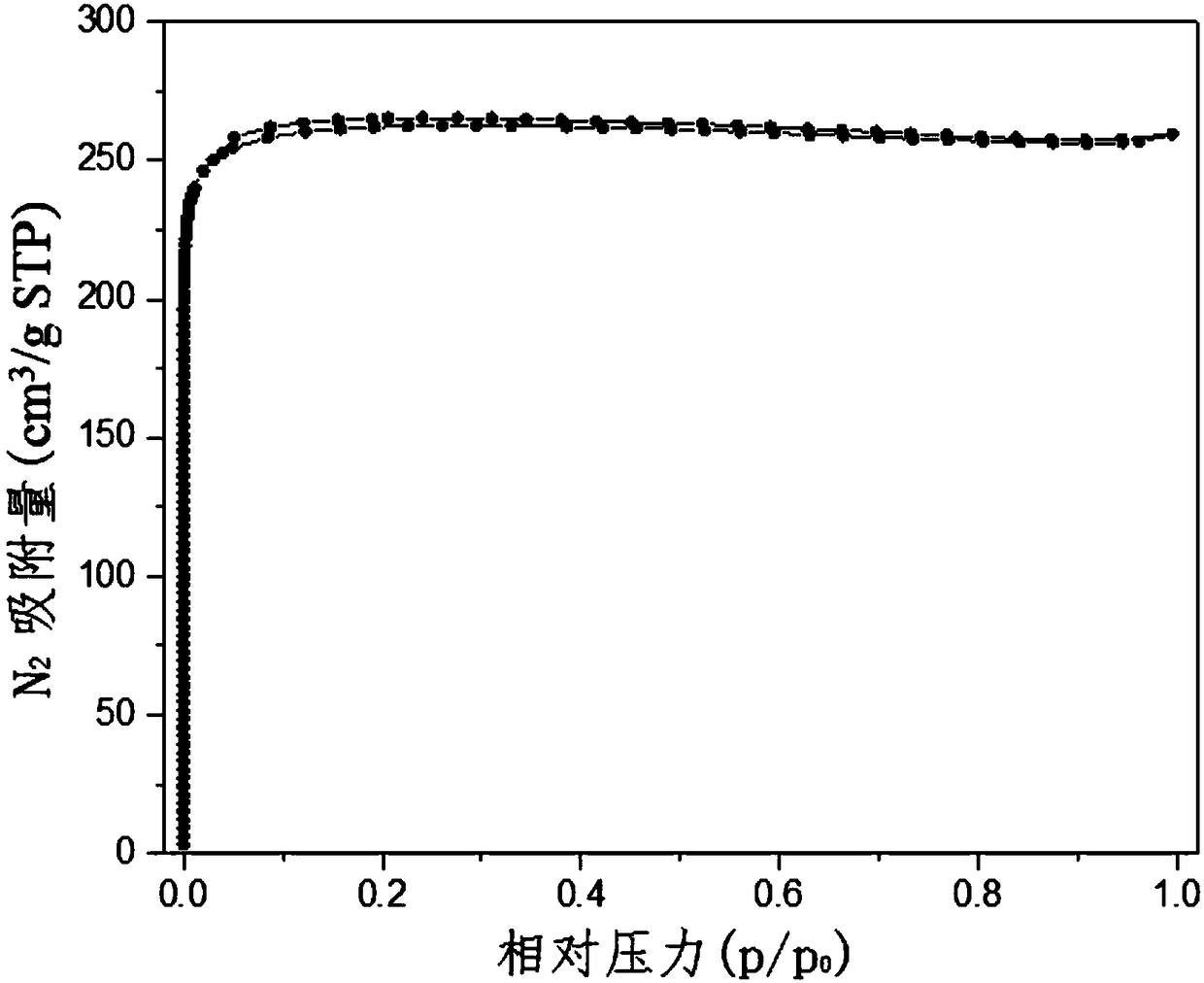

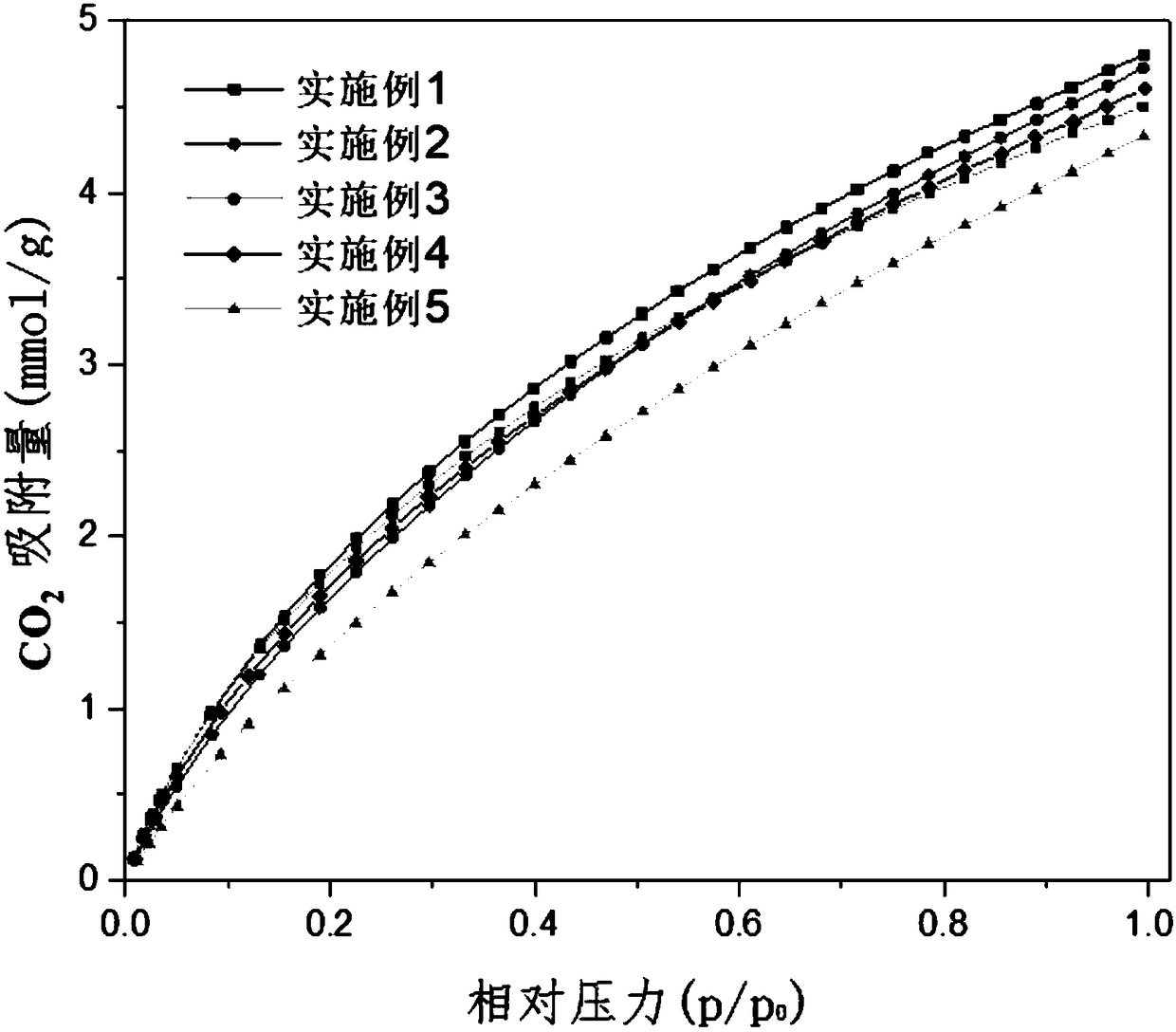

Nitrogen-doped bagasse activated carbon and preparation method thereof

ActiveCN108439400AIncrease added valueEasy to prepareProductsGas treatmentActivated carbonTube furnace

The invention discloses nitrogen-doped bagasse activated carbon and a preparation method thereof. The preparation method comprises the steps of doping nitrogen into urea under the condition of takingwaste bagasse of the sugar industry as a raw material, dipping and drying, then putting the mixture into a tube furnace for carbonizing, and activating the carbonized sample by using an activating agent to obtain the nitrogen-doped bagasse activated carbon. The activated carbon provided by the invention has the advantages of being simple in preparation method, having high specific surface area andpore volume, being developed in micropores, being high in CO2 absorption performance and good in reproducibility, and the like.

Owner:WUHAN UNIV OF SCI & TECH

Method for improving extraction ratio of trehalose

InactiveCN101230407ATotal production cost reductionAchieving a green circular economySaccharides productionChromatographic separationSimulated moving bed

The invention discloses a method of increasing the extraction yield of trehalose, which belongs to sugar industry technical field. Adopting the techniques of hydrogenation and chromatographic resolution, the microorganism or enzyme are used for transforming the starch and the trehalose obtained undergoes the hydrogenation reaction with the mixing solution of the maltose, glucose and maltotriose; therefore the impurity in the mixing solution produces the maltitol, sorbierite and maltotriitol; the trehalose has no reducibility, and is stable in the hydrogenation reaction; and the trehalose is separated from the maltitol, sorbierite and maltotriitol in the mixing solution by the chromatographic resolution technique simulating the moving bed; and the purity and extraction yield of the trehalose are largely increased; the trehalose is crystallized by cooling, and the trehalose product is finally obtained. Compared with the technique of producing the trehalose by adopting the original microorganism or enzyme method, the technique of the invention increases the extraction yield over 80 percent, the sub product maltitol has a comparatively high utilization value; and therefore the production cost for producing the trehalose and the market price are reduced, which makes sense for increasing the market competition of trehalose.

Owner:FUTASTE PHARM CO LTD

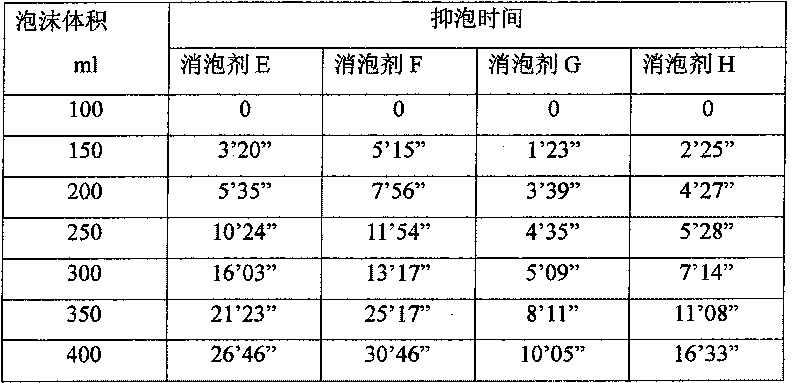

Preparation of antifoaming agent for sugar industry

The present invention relates to a preparation of the antifoaming agent for the sugar industry, belonging to the field of fine chemicals agent. The antifoaming agent is composed of 50 to 90 percents of component A and 20 to 60 percents of component B, wherein the component A is composed of low-viscosity silicone grease, high-viscosity silicone grease, common carbon chain emulsifying agent, polyether modified polysiloxane, thickening agent, preservative and deionized water, and the component B is higher fatty alcohol polyether. The preparation method comprises the steps of: (1) mixing the low-viscosity silicone grease, high-viscosity silicone grease, common carbon chain emulsifying agent and polyether modified polysiloxane in proportion, heating to the temperature of 50 to 80 DEG C and keeping the temperature for 20 to 60 minutes; (2) adding the deionized water slowly, stirring quickly, adding the thickening agent, then adding the deionized water sequentially to the desired concentration and passing a colloid mill; (3) adding the preservative to obtain the component A; and (4) adding the component B into the component A finally, and stirring thoroughly to obtain the emulsion of antifoaming agent for the sugar industry.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Culture medium for straw mushroom

ActiveCN103467187AMeet training requirementsReduce manufacturing costFertilizer mixturesDrug biotransformationMushroom

The invention provides a culture medium for straw mushroom, which comprises the following raw and auxiliary materials in parts by weight: 300-600 parts by weight of cane trash, 100-400 parts by weight of dregs, 0-200 parts by weight of straw, 0-200 parts by weight of corncob, 0-10 parts by weight of peanut bran, 5-10 parts by weight of compound fertilizer, 5-10 parts by weight of plaster, 5-8 parts by weight of lime, and 4-8 parts by weight of urea. According to the invention, cane trash and dregs, two primary by-products of the sugar industry, are used for cultivate the straw mushroom; the recipe is reasonable; the physical and chemical properties are reliable and can meet the cultivation requirement of the straw mushroom; the culture medium has the advantages of increasing comprehensive utilization of sugar refinery by-product, reducing straw mushroom manufacturing cost, reducing environment pollution, and accelerating the development of domestic fungus industry; the biotransformation ratio of straw mushroom cultivated through the culture medium is higher than 40%.

Owner:GUANGXI UNIV

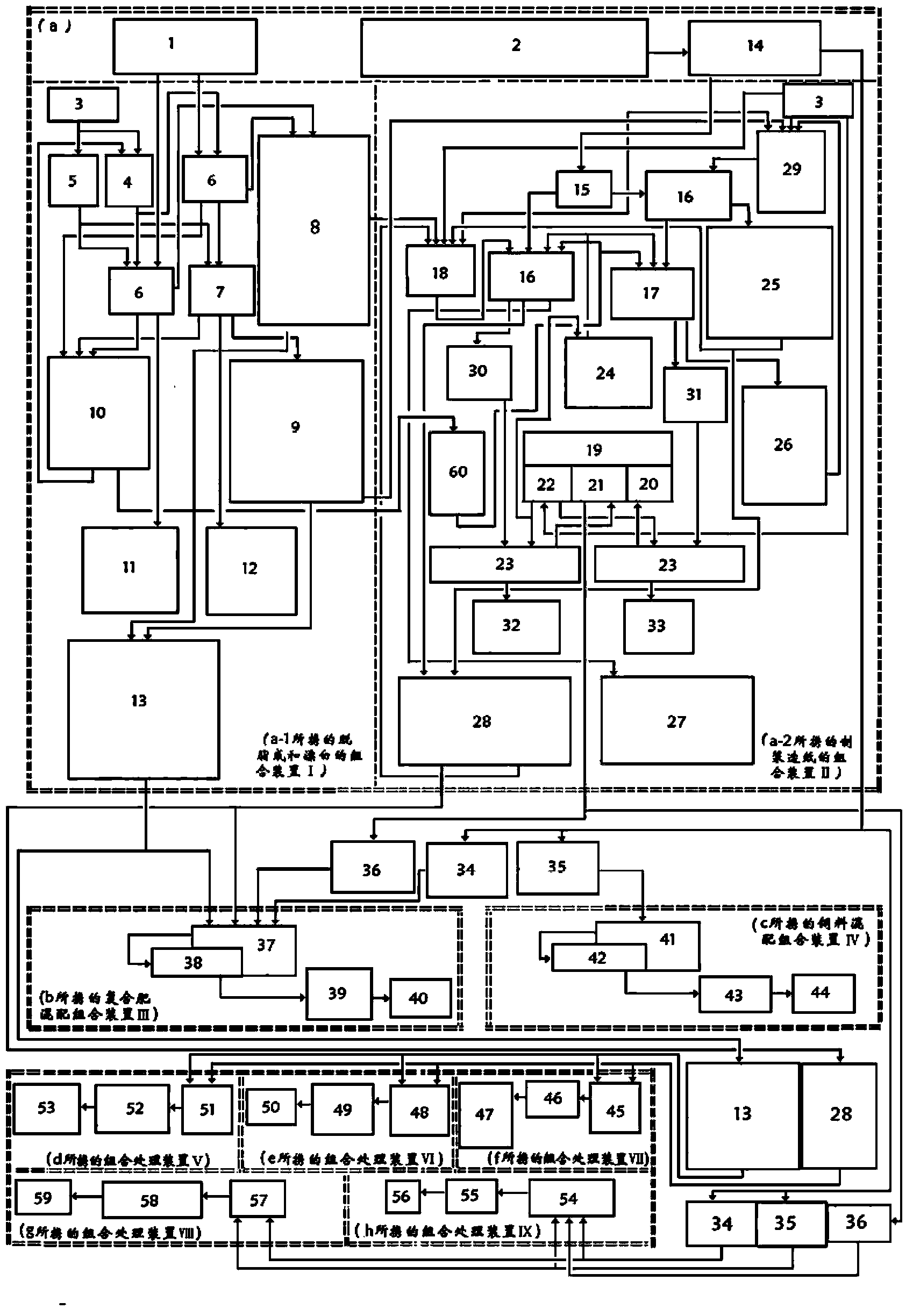

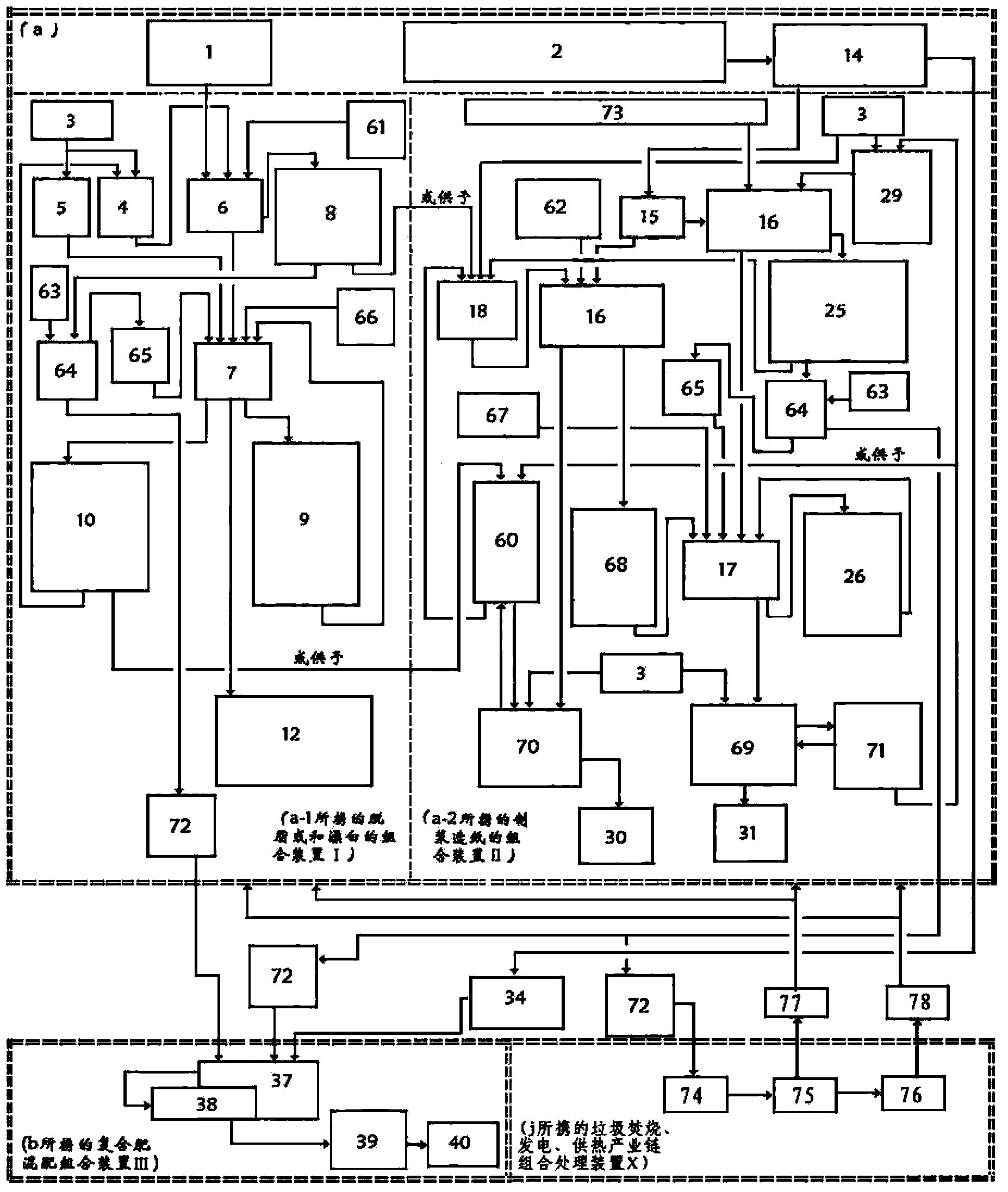

Clean production method of plant fiber product

InactiveCN103523945ARealize cleaner productionReduce processing costsMultistage water/sewage treatmentWaste water treatment from plant processingSludgeSugar industry

The invention discloses a clean production method of a plant fiber product, relating to the regeneration treatment on the black liquid generated by the deinking or degreasing or / and delignification in a production process of the plant fiber product or / and the implementation of interception-type recycling of the black liquid containing sodium ions, relating to the circulating water treatment and application in a production process in the field of different sub-products of the field of plant fiber products, relating to the treatment and utilization of the sludge obtained in black liquid regeneration and circulating water treatment processes, and relating to the blending treatment and utilization of drain water, wherein the plant fiber at least comprises any one of cotton and fibrilia crops, crop straw including any one of cotton straw, rice straw, wheat straw, reed, corn straw and the like, weed including any one of carex meyeriana, solidago decurrens and the like, broadleaf wood and the like including any one of poplar and eucalyptus, bagasse discarded by the sugar industry and any one of waste paper and old cotton or the combination of more than one waste plant fiber product and the like.

Owner:上海橡本永拓环保科技发展有限公司 +4

Method for making dry powder of concentrated molasses alcohol fermentation liquid

ActiveCN102503593ASolve usabilitySolve shipping problemsClimate change adaptationBioloigcal waste fertilisersBranSugar industry

The invention discloses a method for making dry powder of concentrated molasses alcohol fermentation liquid and is characterized in that the method comprises the following steps of: mixing a concentrate of molasses alcohol fermentation liquid having a concentration of 50 to 60 Baume degree with rice bran, wherein the concentrate of molasses alcohol fermentation liquid accounts for 83% to 92% the weight of the mixture and the rich bran accounts for the balance; inoculating yeast 3 to 5 kg per ton of raw materials and allowing fermentation at room temperature for 24 to 36 hours; and heating to dry and grinding to obtain dry powder. The method utilizes the molasses alcohol fermentation liquid which causes serious environmental pollution in cane sugar industry, recycles the molasses alcohol fermentation liquid as complete organic liquid fertilizer for sugarcanes, makes dry powder of molasses alcohol fermentation liquid, not only eliminates inconvenience of use, transport and storage of liquid fertilizers, but also achieves the purposes of turning waste into treasures, improving soil fertility and increasing sugar yield, realizes zero discharge of pollutants and clean production, prevents environmental pollution, and promotes sustainable development of sugar industry.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Method for producing microbial agent by using filter mud of sugar mills through fermentation

InactiveCN102924133ASimple processLow costBio-organic fraction processingOrganic fertilisersBiosphereMicrobial agent

The invention provides a method for producing a microbial agent by using filter mud of sugar mills through fermentation, belonging to the field of the production technology of the microbial agents. The method can produce the high quality microbial agent and treat the pollutions caused by the industrial waste filter mud of the sugar mills at the same time, and also can achieve the circulating economic benefits for the sugar industries. The method comprises the steps of mixing the filter mud of the sugar mills, weathered coal of the humic acid or grass carbon and dried straw to obtain a mixture, controlling the water content of the mixture to 33%-70%, adding the microbial agent into the mixture at a mass ratio of 2% of the microbial agent to the mixture, rapidly stirring to form a homogeneous mixture, loading into a sealing bag, and carrying out anaerobic fermentation for 10 days at a room temperature of the south of China to obtain the microbial agent with an effective living bacteria number being greater than or equal to 300 million / g (higher than the national standard of 200 million / g). According to the invention, the method has the advantages of low cost, simple operation and high product quality, achieves the effective resource utilization through converting the filter mud of the sugar mill into a treasure, solves the problem of the environmental pollution and saves high environmental protection cost for the sugar industries, and brings good economic benefits at the same time, which can form a closed biosphere of the sugar production; and the biosphere creates circulating economic benefits, and brings rich rewards to the sugar industries and the sugarcane farmers.

Owner:王天喜 +1

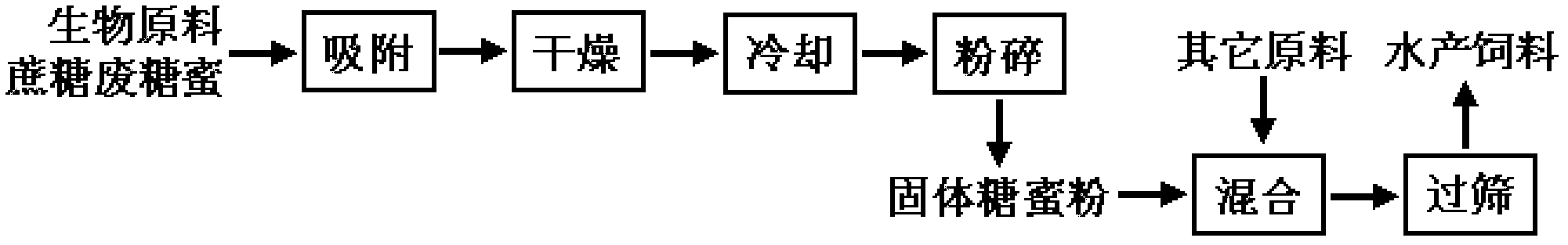

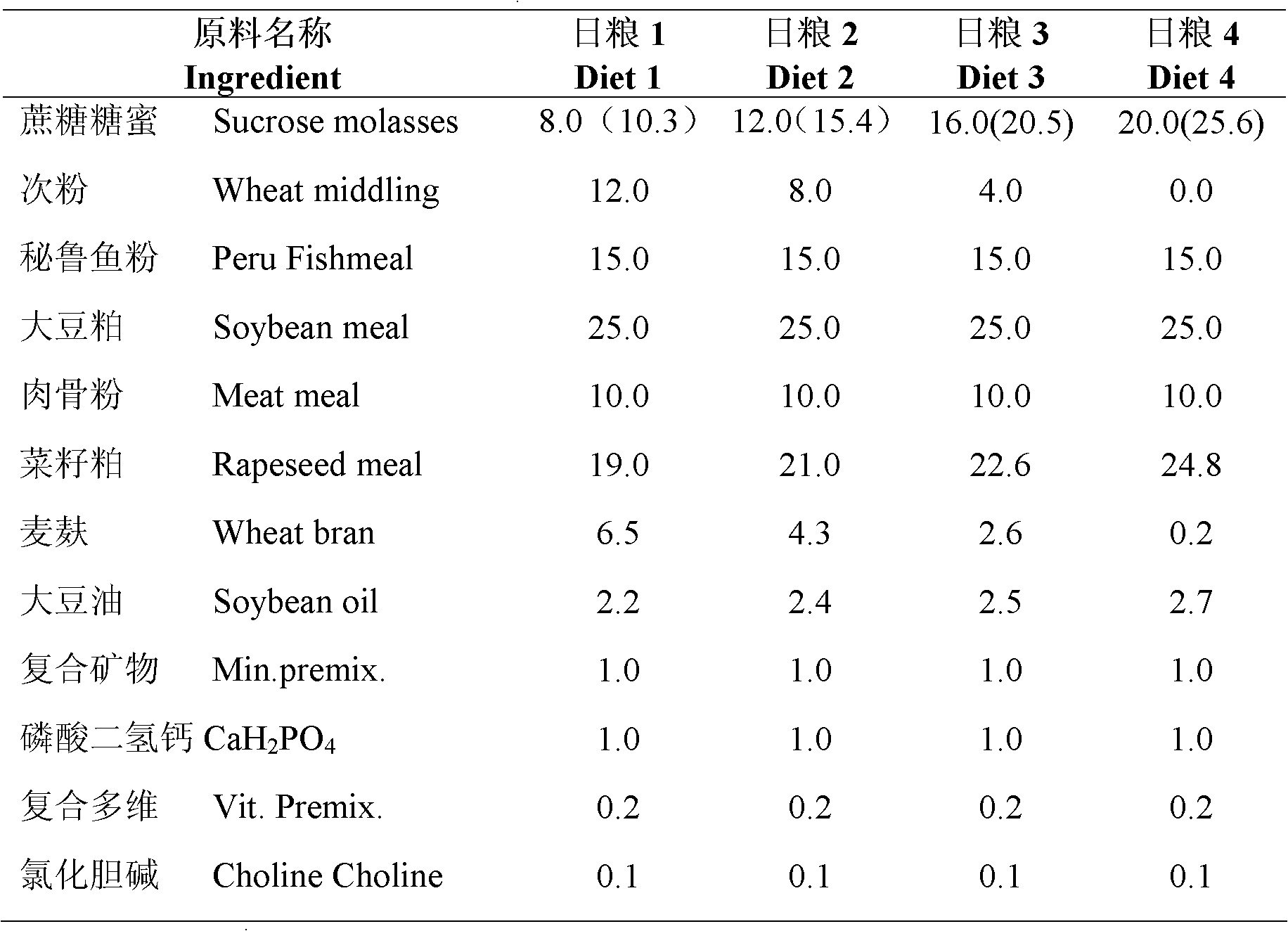

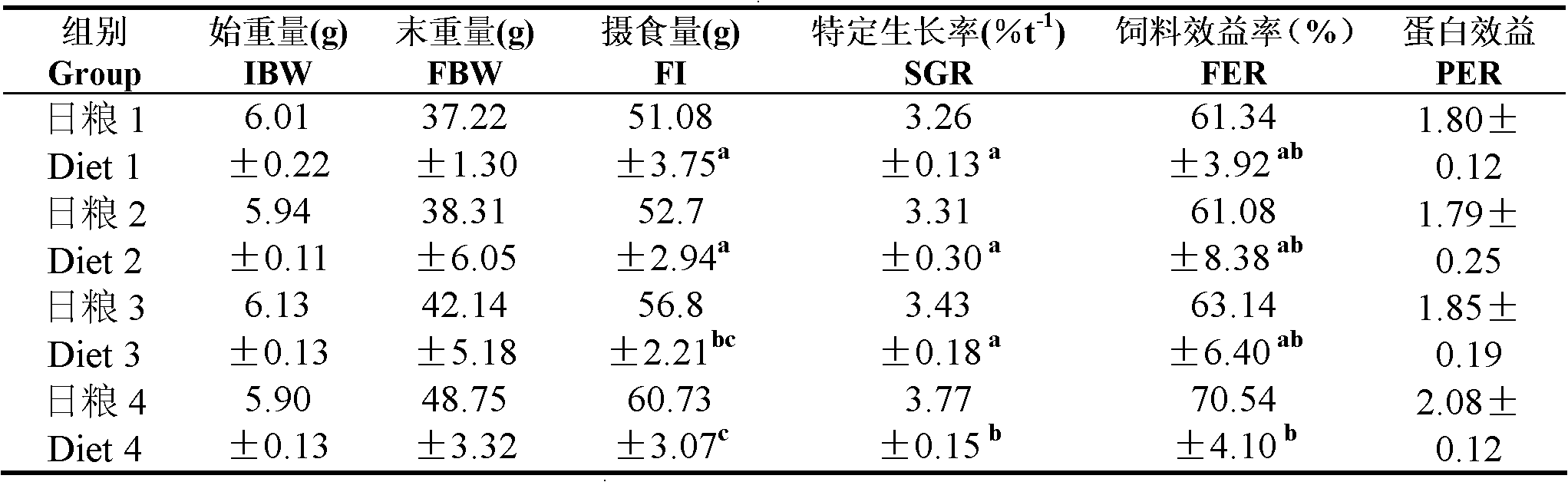

Sucrose waste molasses aquiculture feed and preparation method thereof

The invention discloses sucrose waste molasses aquiculture feed and a preparation method thereof. The sucrose waste molasses aquiculture feed consists of the following components in parts by weight: 4-60 parts of sucrose waste molasses, 4-20 parts of rice bran or wheat bran, 0-16 parts of starch, 24-26 parts of soybean meal, 18-24 parts of rapeseed meal, 13-16 parts of fish meal, 8-12 parts of meat and bone meal, 2-3 parts of soybean oil, 0.8-1.2 parts of calcium dihydrogen phosphate, 0.15-0.20 parts of choline chloride, 0.8-1.2 parts of complex minerals and 0.1-0.3 parts of compound vitamins. The preparation method comprises the steps of using water-absorbing biological raw materials, i.e. the rice bran, bran meal or and / the starch as water absorbing raw materials, making high-viscosity sucrose waste molasses into solid molasses powder, adding other feed raw materials, evenly mixing, adding water, granulating and screening to obtain the aquiculture feed. When the sucrose waste molasses fully replaces the starch, the intake, the specific growth rate and the feed benefit to protein benefit ratio are obviously increased (p is less than 0.05), the cost of the aquiculture feed is reduced, the rich byproduct resources in the sugar industry in China are reasonably used, the economic benefit of the sucrose waste molasses is improved, the grain resources are saved, and the economic benefit, the social benefit and the environmental benefit are better.

Owner:GUANGXI UNIV

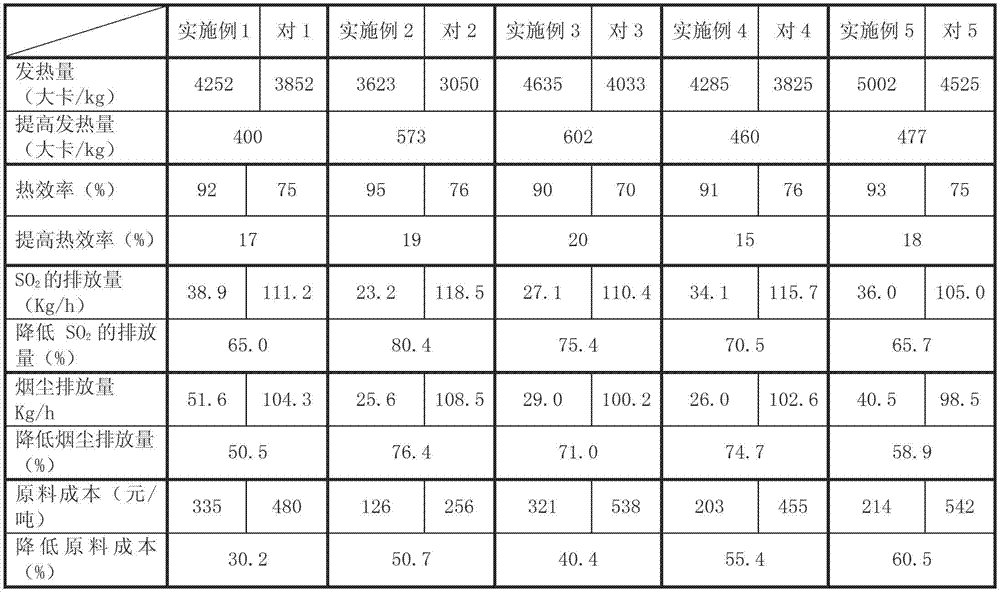

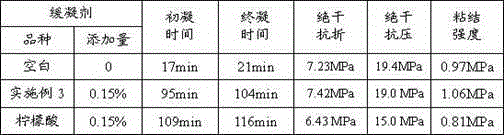

Filter mud containing clean coal and preparation method thereof

The invention discloses filter mud containing clean coal and a preparation method thereof. The filter mud containing clean coal comprises braize, filter mud, a combustion synergist, a composite binder, a sulphur-fixing agent and a deodorant. The filter mud is obtained by a cleaning process in a sulfurous method in the sugar industry. The combustion synergist is potash nitrate and sodium chloride. The composite binder is pregelatinized starch, clay and polyvinyl alcohol. The sulphur-fixing agent is calcium hydroxide and sodium carbonate. The deodorant is ascorbic acid and ferrous sulfate. According to the invention, filter mud of a sugar plant is adequately utilized, so that secondary pollution to the environment is avoided and waste is turned to wealth. The clean coal prepared has the advantages of inflammability, higher thermal efficiency, small discharge of harmful gas, high cold and hot strengths, good waterproof performance, low production cost, environmental-friendliness and the like.

Owner:广西桂晟新能源科技有限公司

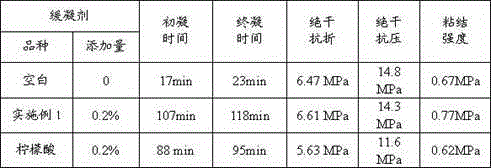

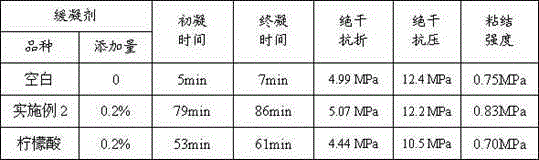

Gypsum retarder capable of improving strength and binding strength of gypsum base material

The invention provides a gypsum retarder capable of prolonging coagulation time of the gypsum base building material and improving strength and binding strength of the gypsum base material. The gypsum retarder comprises following components by weight percent: 20-45% of organic binding agent, 10-25% of animal albumen glue, 7-15% of sugar calcium, 0.5-1% of cellulose ether and 14-64.5% of caking inhibitor, wherein the animal albumen glue is one or more than one of blood albumen glue, fish skin glue, bone glue, lac or jelly glue which have the fineness of 200-300 meshes, and sugar calcium is a product prepared from waste molasses (which is a byproduct of sugar industry) and lime through emulsification. The gypsum retarder has advantages of simple formula, low cost, simple preparation method and strong adaptability to gypsum, and can be used for adjusting coagulation time of gypsum for building, phosphorus gypsum and desulphurized gypsum.

Owner:广东龙湖科技股份有限公司

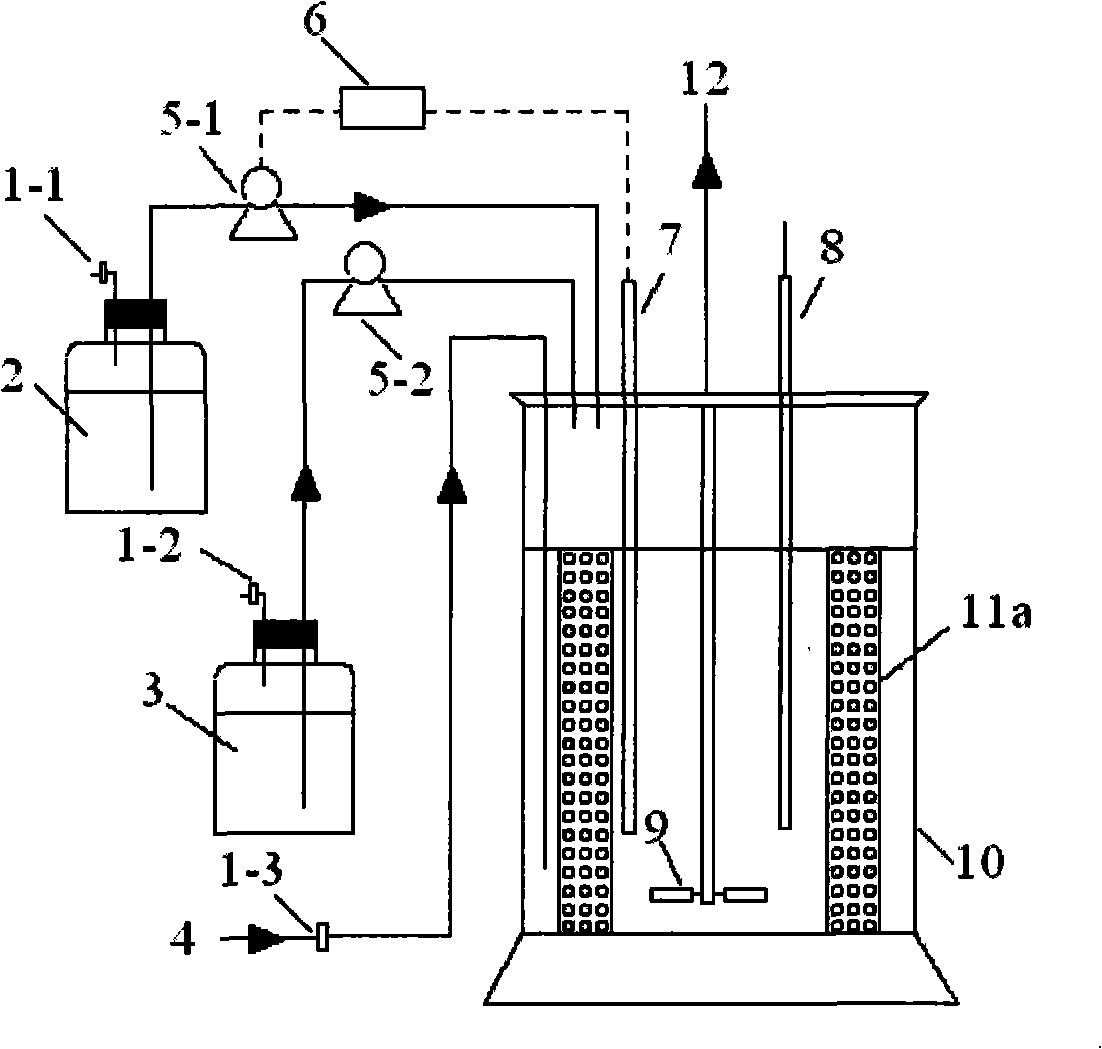

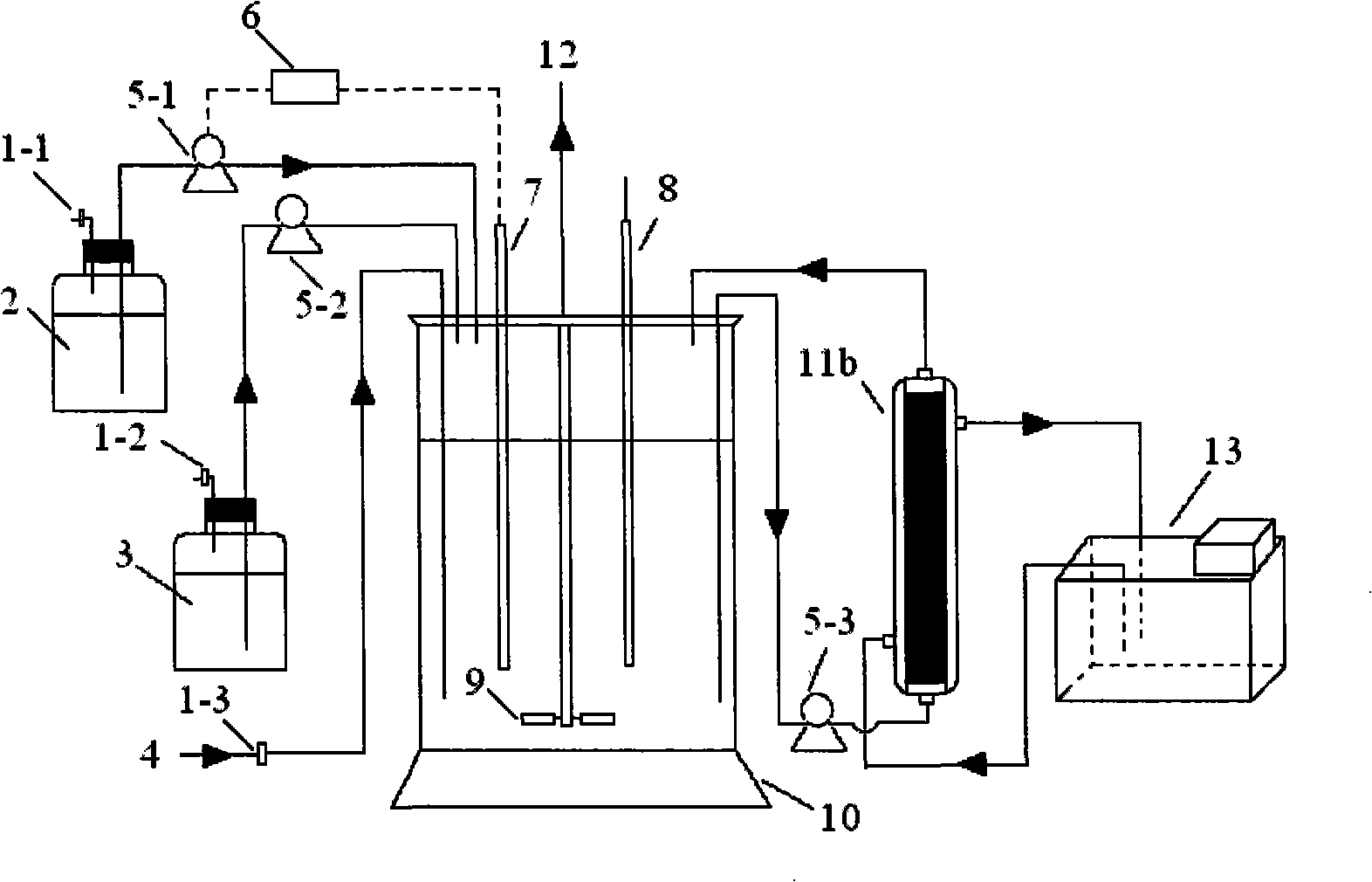

Uses of bagasse in immobilization fibre bed reactor for fermentation production of organic acid as immobilization material

InactiveCN101402914ABioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateOrganic acid

The invention discloses an application of bagasse as an immobilized material in an immobilized fibrous bed reactor applied to fermenting and producing an organic acid. The bagasse as the immobilized material not only can be applied to an internal immobilized fibrous bed reactor but also to an external immobilized fibrous bed reactor. The bagasse applied by immobilized cells is a waste material in sugar industry, therefore the cost as the immobilized material is rather low. After the bagasse is crushed, the specific surface area is increased, cells can be adsorbed on fiber surfaces and in fiber clearance in abundance and can fall off automatically when cells are in degeneration or when cell viability is relatively poor, which guarantees the viability of cells adsorbed at fiber. The production efficiency of the organic acid of the immobilized fibrous bed reactor which takes the bagasse as the immobilized material is far higher than that of a traditional gel entrapment method as well as than other internal and external vegetable fiber bed reactors which are currently reported with the highest production rate.

Owner:NANJING UNIV OF TECH

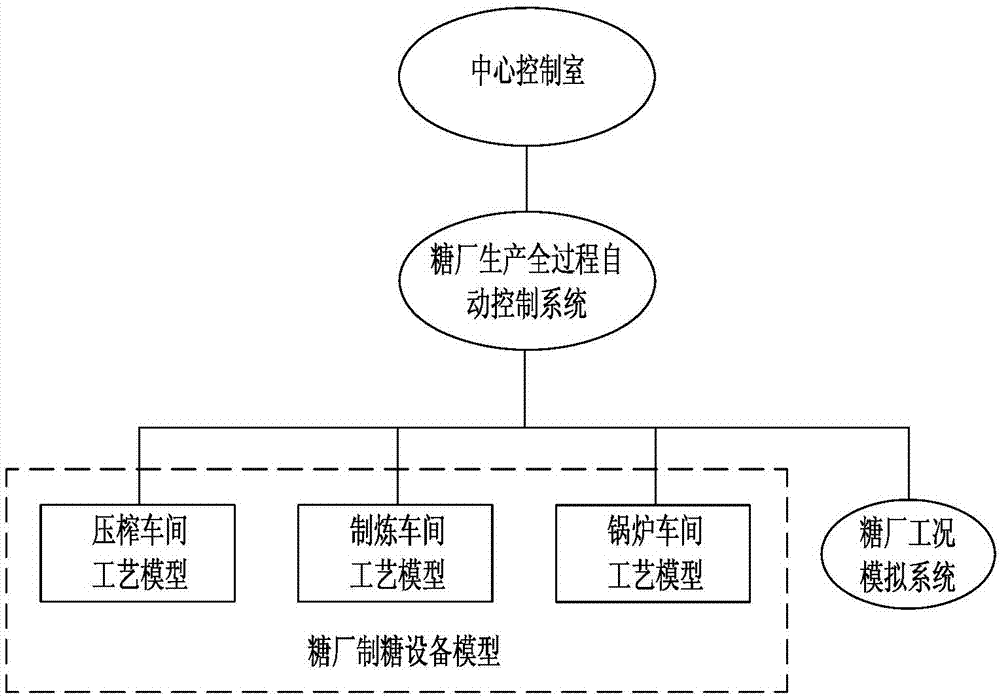

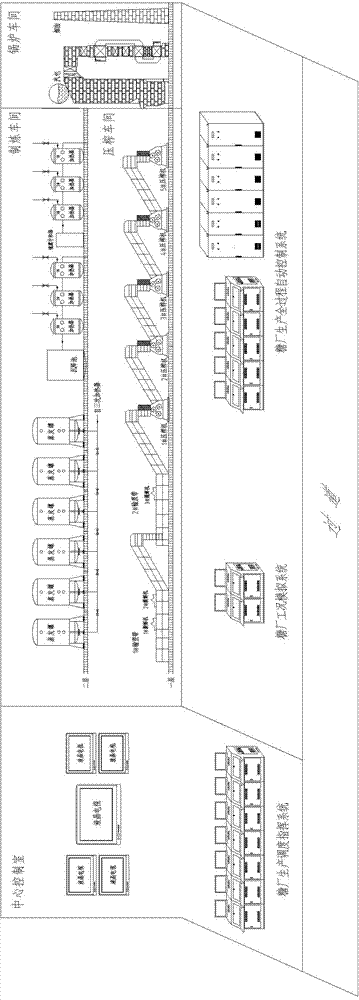

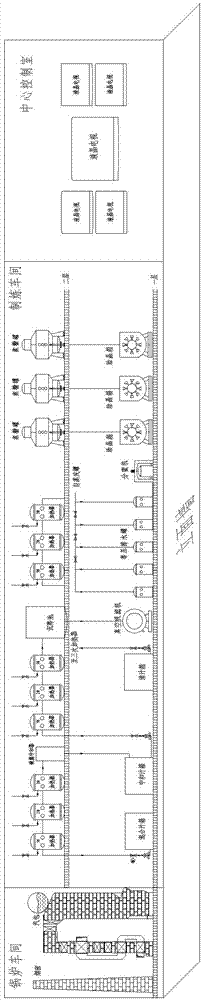

Practical training centre for sugar manufacturing process control technology

ActiveCN104122875AAchieve wiredReal-timeEducational modelsTotal factory controlAutomatic controlAutomated control system

The invention provides a practical training centre for a sugar manufacturing process control technology. The practical training centre comprises a sugar refinery sugar manufacturing equipment model, a sugar refinery working condition simulation system, a sugar refinery production whole-process automatic control system and a central control room, wherein the sugar refinery sugar manufacturing equipment model is produced by scaling down according to the ratio of the appearance and the like of actual production equipment, arranged and connected according to an actual process flow, and further used as a field instrument installation carrier; the sugar refinery working condition simulation system is used for simulating the actual working condition of a sugar refinery; the sugar refinery production whole-process automatic control system is used for implementing automatic control on the whole process of sugar refinery production according to a working condition simulation signal and the signal of a field instrument in each production workshop; the central control room is used for carrying out centralized management and monitoring on the control system data of each working section of each workshop of the sugar refinery, and realizing remote production management and dispatching conduction. The high actual operational abilities of students can be trained through the training of the practical training centre, thus laying a solid foundation for working on the sugar industry or the related work in other automation fields in the future.

Owner:广西龙河门科技有限公司

Agaricus blazei murill cultivating base stock

ActiveCN103467188AMeet training requirementsReduce manufacturing costFertilizer mixturesSludgeAgaricus blazei

The invention discloses agaricus blazei murill cultivating base stock, which is prepared from the following raw auxiliary materials in part by weight: 300-600 parts of bagasse, 300-500 parts of lime sludge, 0-100 parts of straws, 0-200 parts of corncobs, 0-10 parts of peanut bran, 5-20 parts of compound fertilizer, 10-50 parts of gypsum, 20-50 parts of lime and 0-5 parts of urea. According to the invention, two kinds of main secondary products as bagasse and lime sludge in the sugar industry are adopted to cultivate agaricus blazei murill, the formula is reasonable, the physical and chemical properties are reliable, and the requirement for cultivating agaricus blazei murill is completely met, the base stock has the advantages of improving comprehensive utilization of secondary products of sugar factories, reducing production cost of agaricus blazei murill and environmental pollution and facilitating the development of edible mushroom industry, and the biotransformation efficiency when the cultivating base stock is adopted to cultivate agaricus blazei murill reaches 38% above.

Owner:GUANGXI UNIV

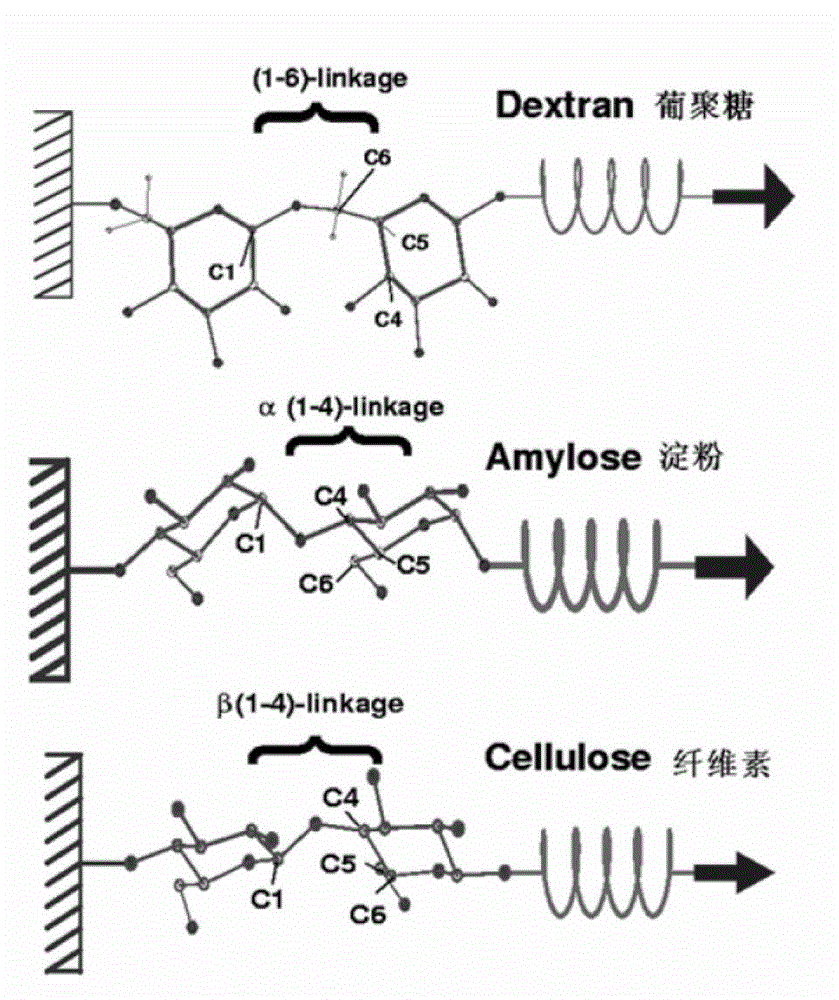

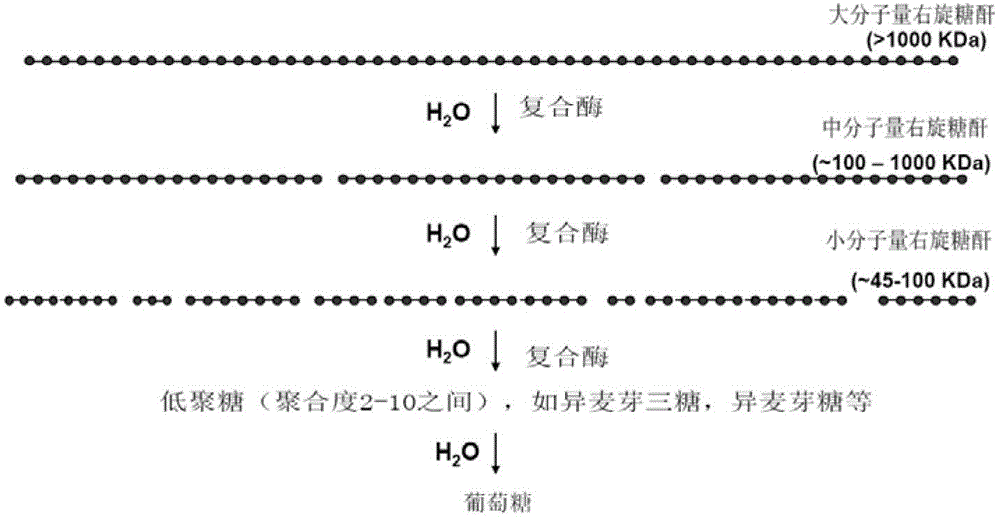

Compound enzymatic clarifying agent for sugar industry and preparation method and application for compound enzymatic clarifying agent

ActiveCN102911924AEasy to joinWithout changing the sugar production processEnzymesSugar juice purificationPectinaseAmylase

The invention discloses a compound enzymatic clarifying agent for the sugar industry and a preparation method and application for the compound enzymatic clarifying agent. The compound enzymatic clarifying agent comprises, by weight, from 35% to 60% of alpha-glucanase, from 20% to 30% of pectinase, from 10% to 35% of amylases, from 5% to 10% of cellulase and from 0% to 15% of water. The preparation method includes proportionally mixing the alpha-glucanase, the pectinase, the amylases and the cellulase which are raw materials to obtain a mixture; and filtering the mixture via a fine filter membrane to obtain the compound enzymatic clarifying agent. The compound enzymatic clarifying agent is added during a working section for extracting juice from sugar crops, the feeding quantity of compound enzymatic clarifying agents added into 1kg of the sugar juice ranges from 10mg to 30mg, the sugar juice clarifying efficiency can be effectively improved, the viscosity of sugar liquor is reduced, the filtering speed and the settling speed are increased, the quality of sugar products is improved, the sugar yield is increased, an original sugar production process is unchanged, and operation is simple and feasible.

Owner:SOUTH CHINA UNIV OF TECH

Carbon-based solid sulfonic acid preparation method using bagasse

InactiveCN103157509AEasy to separateShort reaction timeOrganic-compounds/hydrides/coordination-complexes catalystsAcid catalysisSugar industry

The invention relates to a carbon-based solid sulfonic acid preparation method using bagasse. Carbon-based solid sulfonic acid prepared in the method can be used in reactions which need acid catalysis. The preparation method includes the steps that: concentrated sulfuric acid and the bagasse are mixed, heated, stirred, and partially carbonized, and then filtered to obtain solid powder. The solid powder is washed repeatedly to obtain the bagasse carbon-based solid sulfonic acid. The preparation method has the advantages of being simple and quick in operation, simple in separation, high in product yield, and convenient to complement in an industrial mode, and the like, and providing a novel way for development and utilization of the bagasse, namely a byproduct of the sugar industry.

Owner:TIANJIN POLYTECHNIC UNIV

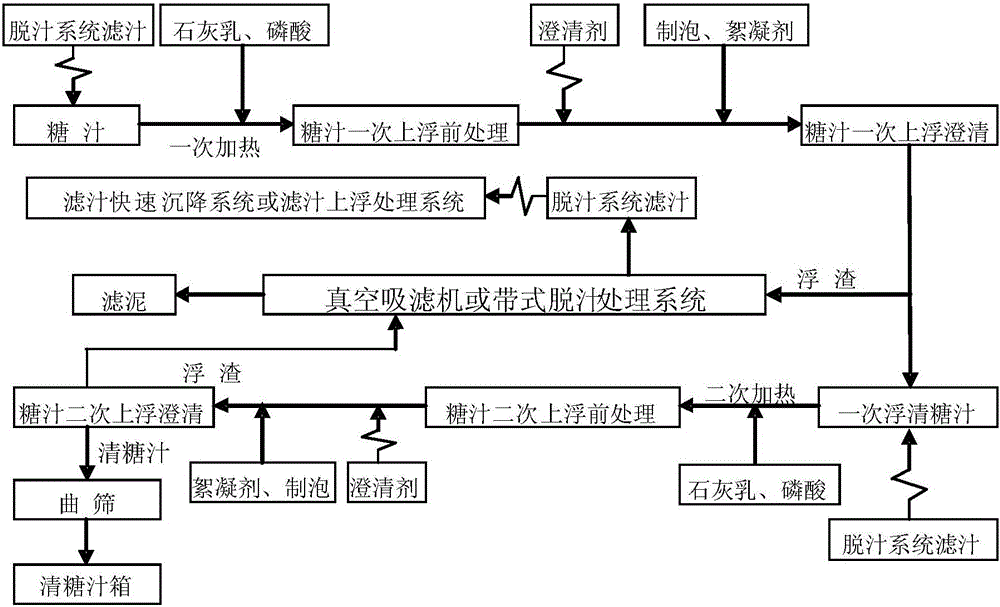

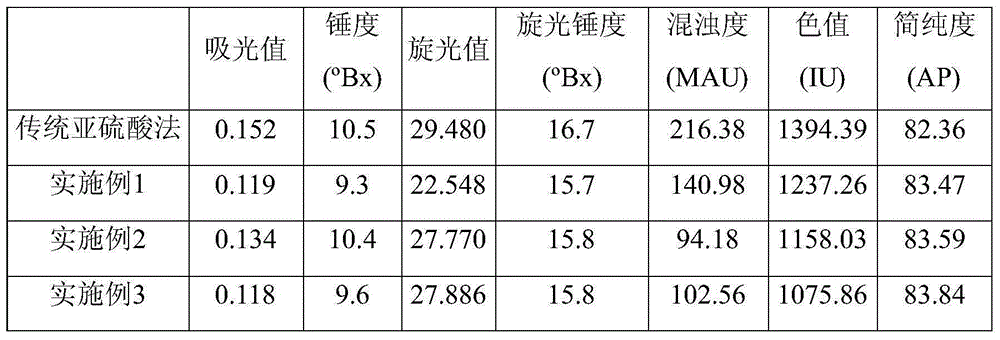

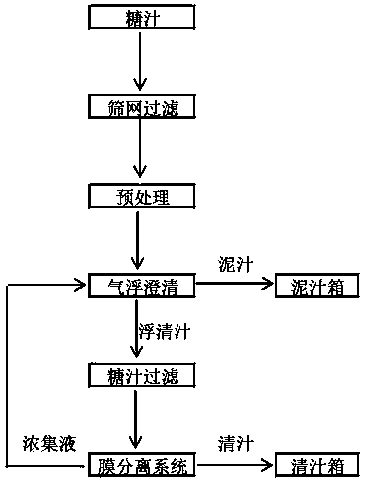

Sugar juice sulfur-free efficient cleaning method

ActiveCN105002306AShort stayReduce lossesPurification using alkaline earth metal compoundsPurification by physical meansSulfurLarge particle

The invention belongs to the technical field of sugar industries and discloses a sugar juice sulfur-free efficient cleaning method. After preliming, heating, foaming and flocculant adding are conducted on sugar juice, one-time floating clarification is conducted, large-particle non-sugar components in the sugar juice are removed; after secondary preliming, heating, foaming and flocculant adding are conducted on the one-time floating clarification sugar juice, secondary floating clarification is conducted; the sulfur-free cleaning process of the sugar juice is completed on the sugar juice obtained through secondary floating clarification through a sugar juice filtering and separating system. According to the sugar juice sulfur-free efficient cleaning method, the cleaning method of two levels of floating of the sugar juice is mainly adopted, and clean and complete sufur-free and carbonic-acid-free processing is achieved on the sugar juice, the equipment technology is simple, automatic continuous production is convenient, and the production efficiency is obviously improved. The obtained clean sugar juice is high in quality and is superior to clean sugar juice obtained through a traditional sulfurous method, and a very good application prospect is achieved.

Owner:广东省科学院生物与医学工程研究所

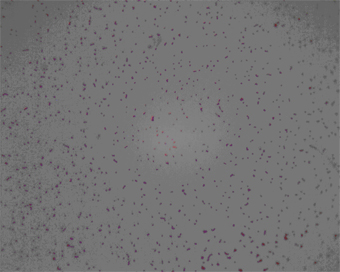

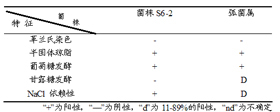

Ocean low-temperature dextranase, enzyme producing method and strain S6-2 produced therefrom

The invention discloses a vibriosp S6-2(Vibriosp S6-2) CGMCCN0.4011. The growth temperaute of the strain ranges from 4 to 37 DEG C, 25 DEG C is the most preferable; the growth pH ranges from 6 to 11, 7.0 is the most preferable; and the concentration of NaCl for growth is 0.5% to 10%, 4% is the most preferable. The invention further discloses a method for producing ocean low-temperature dextranase by vibriosp and a low-temperature dextranase product produced according to the method. The low-temperature dextranase plays an important role in the aspects of prevention and treatment of dental caries, sugar industry, production of pharmaceutical dextran and the like.

Owner:HUAIHAI INST OF TECH

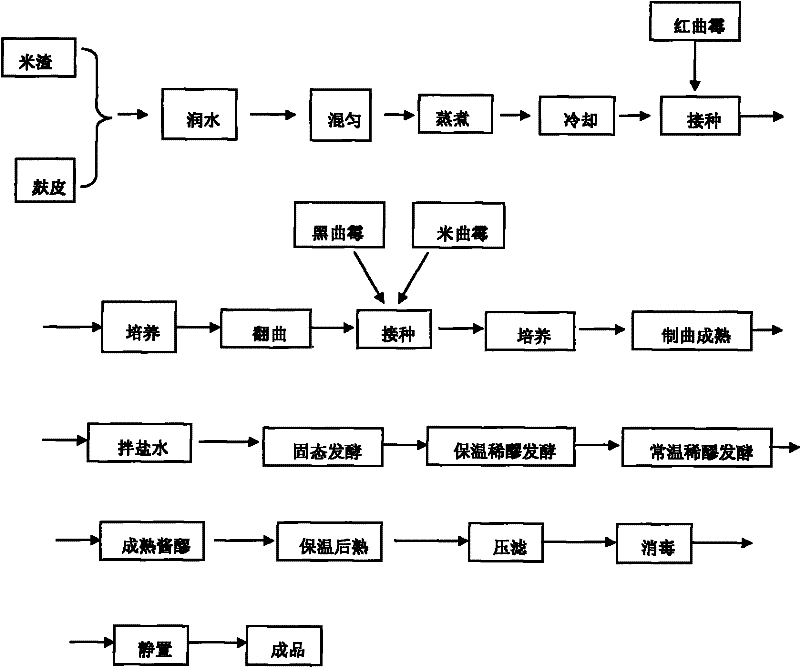

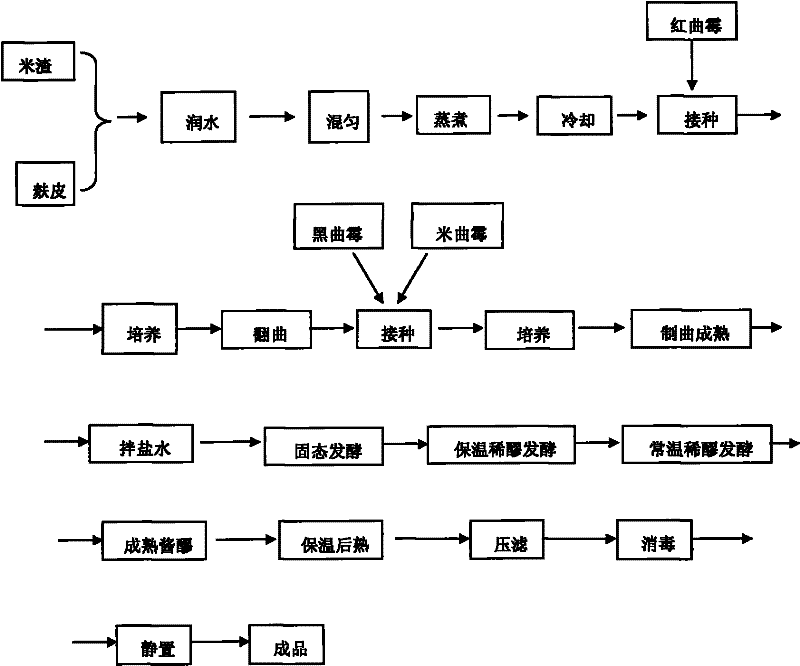

Multi-strain starter propagation process for producing soy sauce by using rice dregs as raw materials

InactiveCN102187994AHyperglucoamylaseReduce manufacturing costFood preparationMonosodium glutamateNeutral protease

The invention belongs to the technical field of the recycling of discarded resources, and provides a new multi-strain starter propagation process for producing soy sauce by using rice dregs as raw materials, which comprises the following process steps of: the multi-strain mixed starter propagation of monascus rubber, aspergillus oryzae, aspergillus niger, solid state fermentation, heat-preserving diluted mesh fermentation, normal-temperature diluted mesh fermentation, heat-preserving after-ripening and the like. In the new process, bean pulp serving as a main raw material in the conventional brewing process is replaced by the rice dregs serving as discarded resources in sugar industry, monosodium glutamate industry and rice vinegar industry, so the production cost of the soy sauce is reduced greatly. Simultaneously, the saccharifying enzyme, neutral protease and acid protease of the prepared yeast rice are higher that those of the yeast rice of the conventional starter propagation, so a new process is opened up for the recycling of the rice dregs and the production of the high-quality soy sauce.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

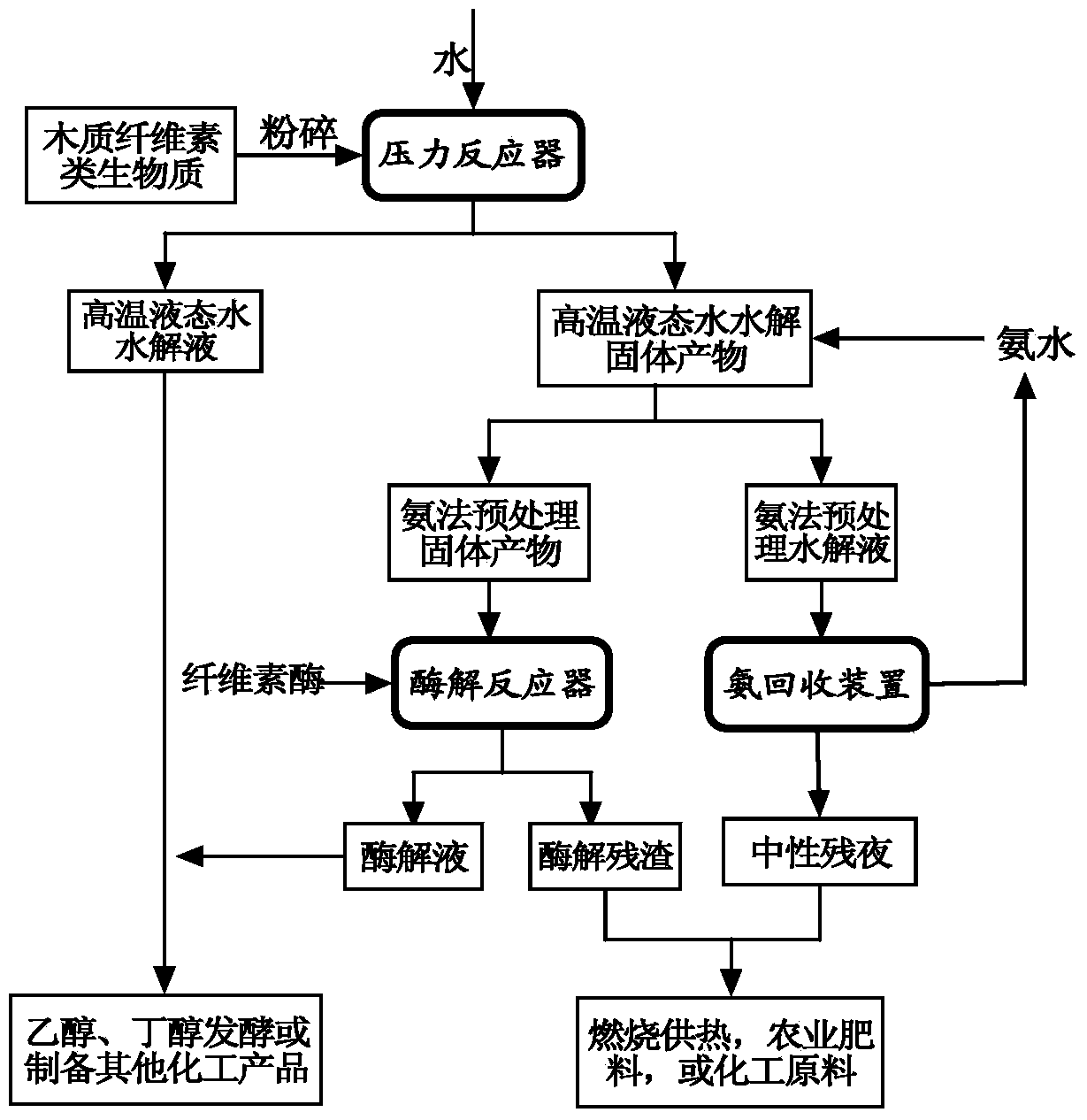

Method for pretreatment of biomass by water-ammonia coupling

The invention provides a method for pretreatment of biomass by water-ammonia coupling. With lignocelluloses biomass as the raw material, the method is characterized by adopting a high temperature liquid water-ammonia process two-step pretreatment technology. The method specifically includes: firstly using high temperature and high pressure liquid water to hydrolyze the biomass so as to obtain a lignin and cellulose dominated solid product, then conducting ammonia hydrolysis on the solid product, further separating lignin, and then performing enzymolysis. With the advantages of environmental protection and high efficiency, the method provided by the invention can realize efficient and complete utilization of lignocelluloses biomass, the sugar loss is small, and the recovery rate is high. Through the process involved in the invention, resource utilization of forestry, agricultural and sugar industry waste can be achieved, and at the same time the environmental problems caused by waste can be solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

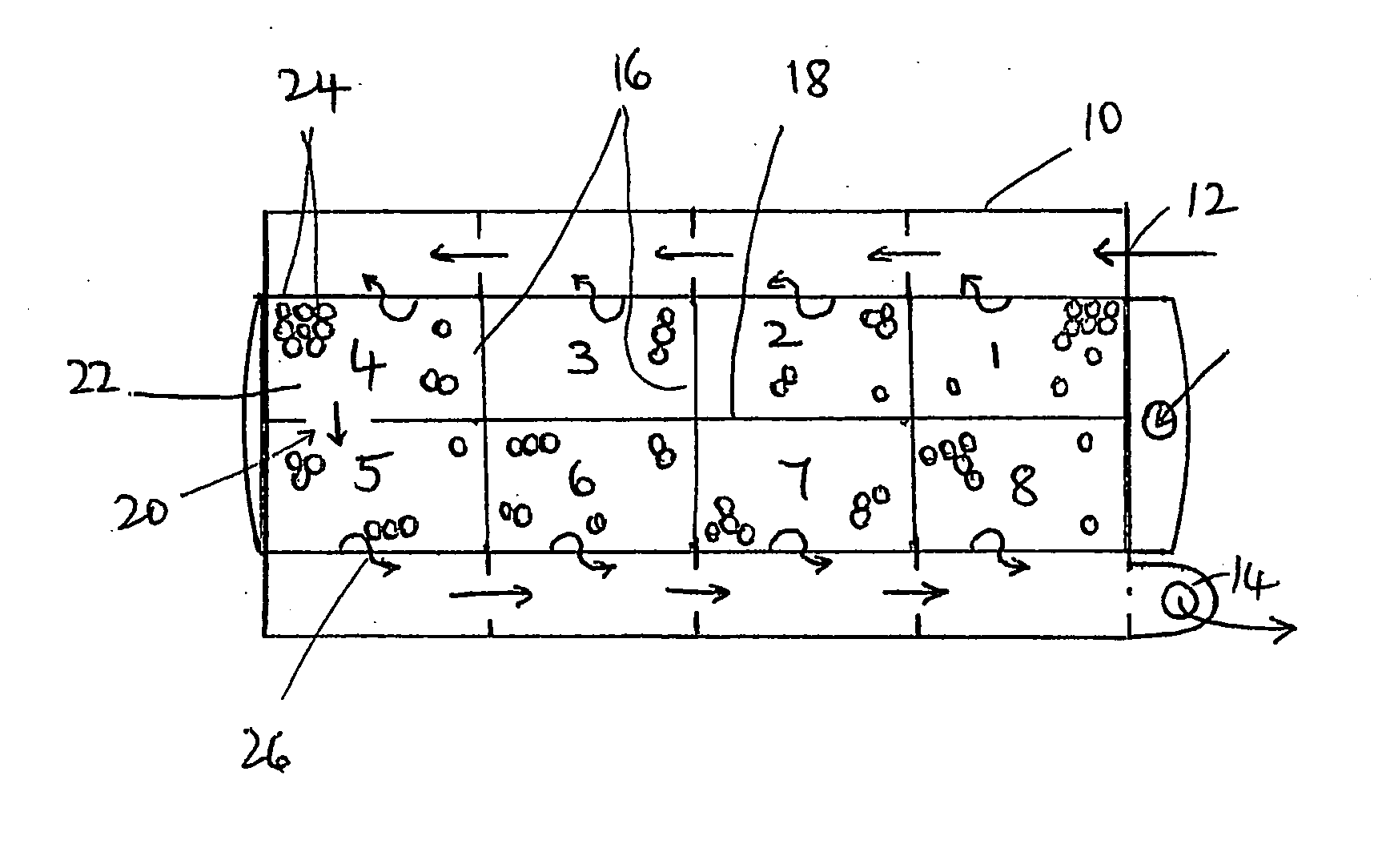

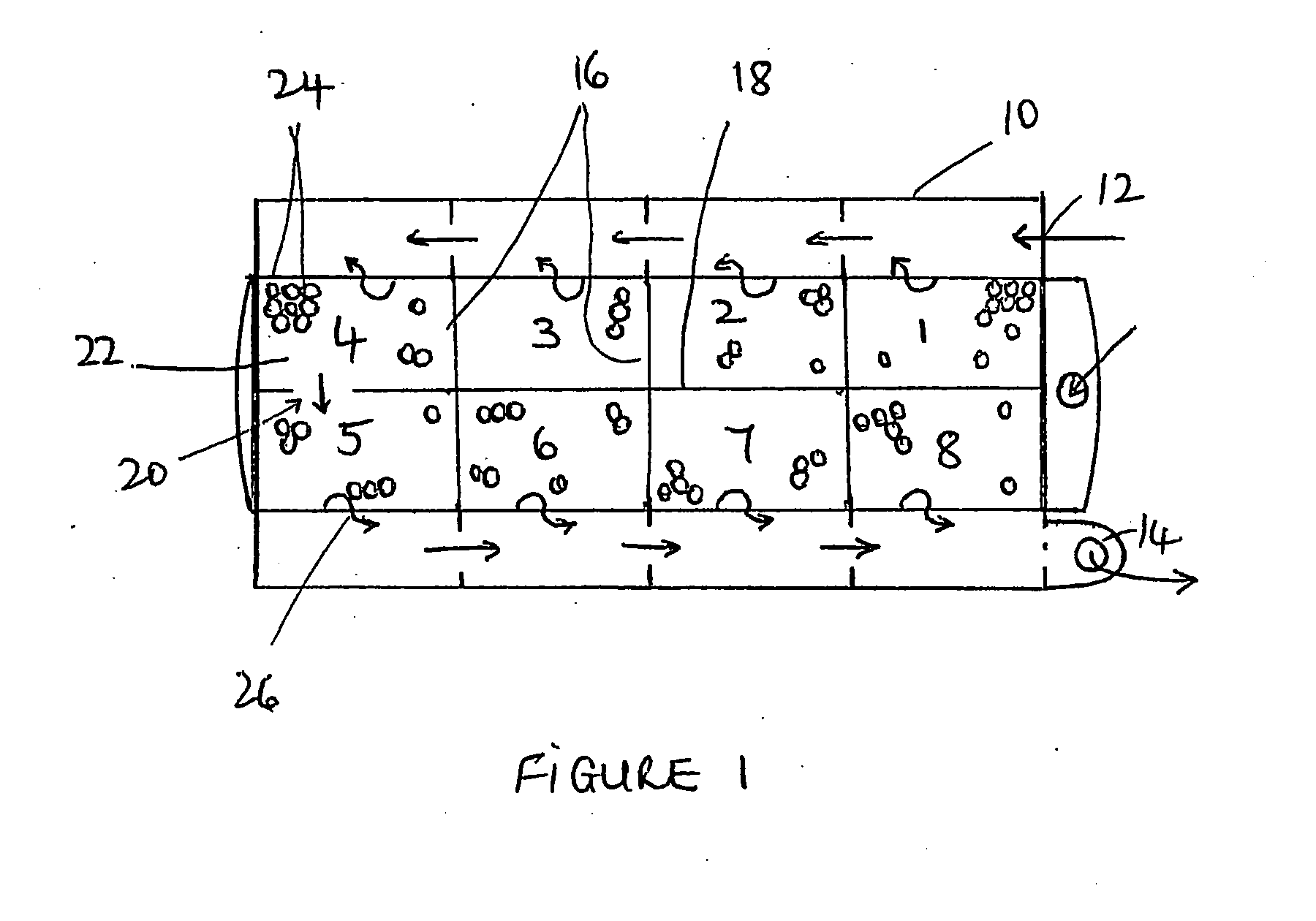

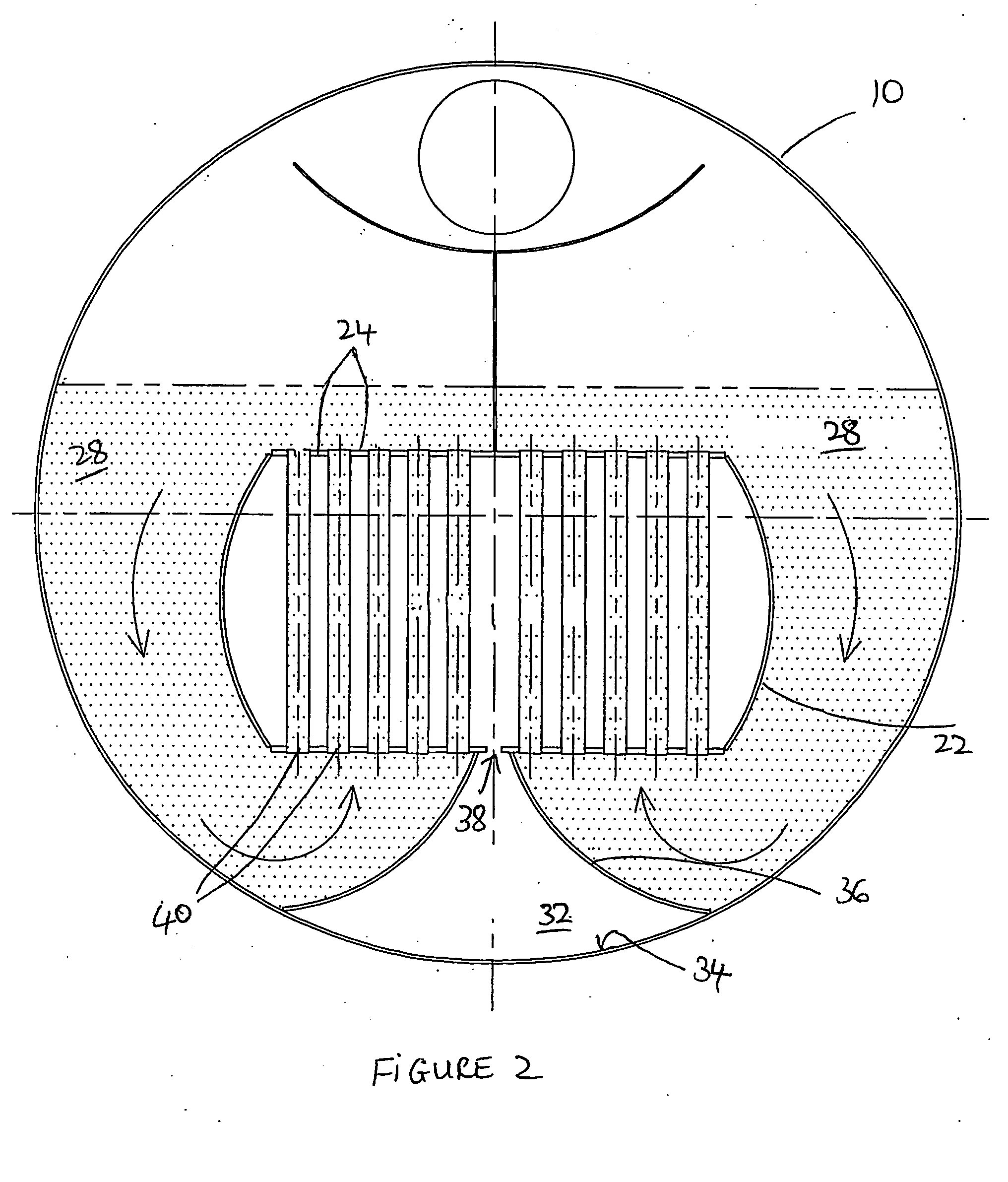

Continuous pan crystalliser

InactiveUS20040177846A1Prevent solidificationLow densitySugar crystallisationSugar juice boiling/evaporationEngineeringVolumetric Mass Density

A continuous pan crystalliser for use in the sugar industry includes a heated zone in the form of a steam chamber (32) below a calandria (22). The heated zone heats massecuite in the area below the calandria in the pan and reduces massecuite density and viscosity and promotes the vigorous circulation required for even crystal growth.

Owner:MOOR BRUCE STCLAIR

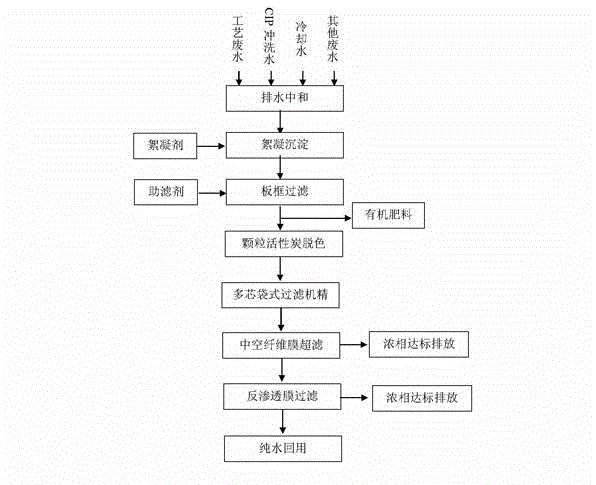

Method for recovering waste water generated in production of starch sugar

ActiveCN102863096AEffective filteringReduce energy consumptionMultistage water/sewage treatmentReverse osmosisWater resources

The invention provides a method for recovering waste water generated in the production of starch sugar. The recovered water can be used repeatedly. The method comprises the following steps of: neutralizing the waste water; performing flocculating sedimentation; filtering and removing residues by using a plate frame; decoloring by using granular active carbon; performing fine filtering by using a bag-type filter; performing ultrafiltration by using a hollow fiber membrane; and filtering by using a reverse osmosis membrane. The method is reasonable and easy to control automatically and is used for treating the waste water generated in the production of the starch sugar; 60 to 70 percent of discharged waste water can be recycled, and on the basis of 40 million tons of discharge of final water every year in the starch sugar industry, at least 24 million tons of water can be recovered every year, so that the economic benefit and social value are obvious while water resources are saved.

Owner:BAOLINGBAO BIOLOGY

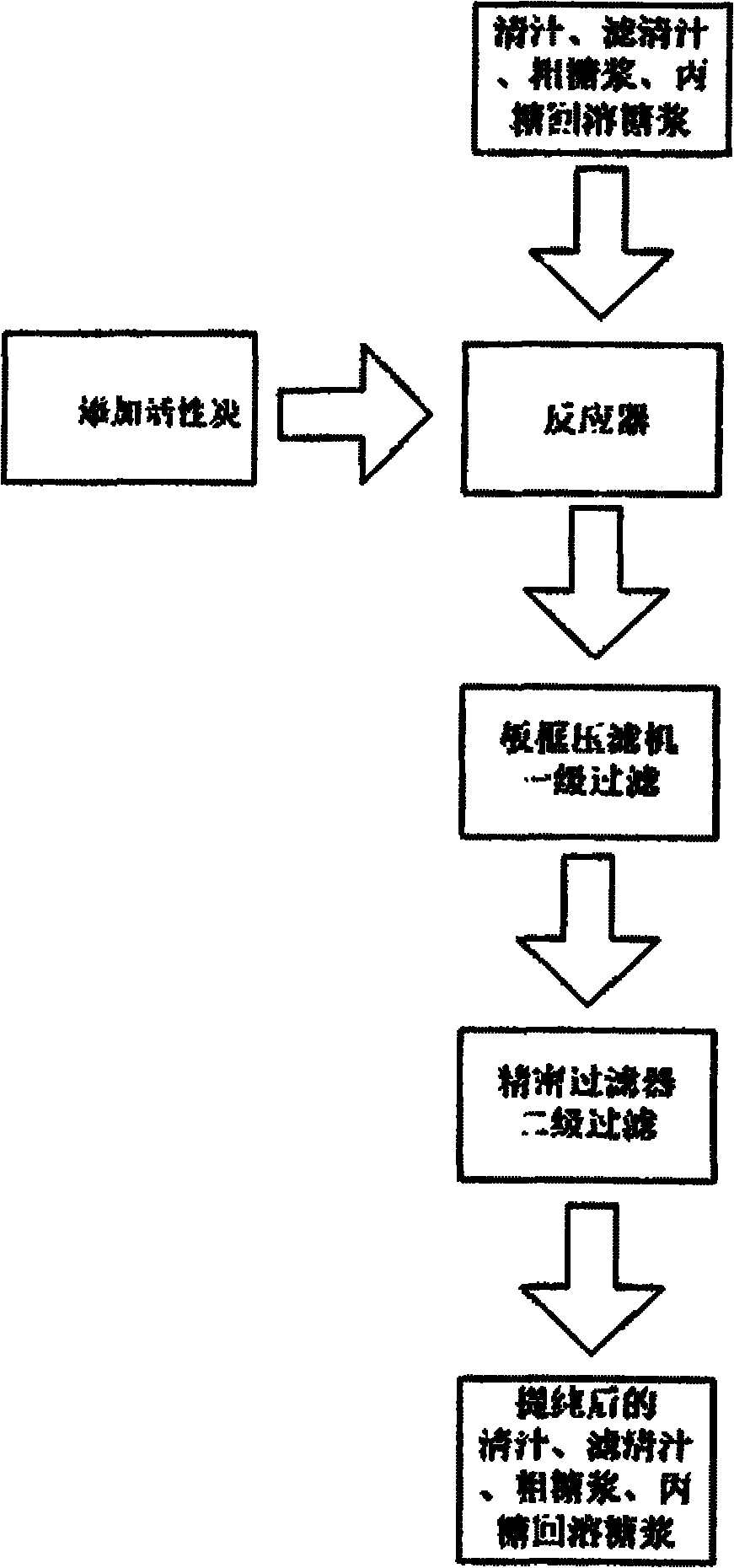

Method for improving sulfurous method production process in cane sugar factory

InactiveCN101818214AMake sure not to filter throughReduce sulfur dioxide contentPurification using adsorption agentsPurification by physical meansFiltrationImpurity

The invention discloses a method for improving a sulfurous method production process in a cane sugar factory. Active carbon is taken as an auxiliary clarifying agent to perform physical impurity removal and decoloration on serum, filtered serum, crude syrup or triose remelt syrup led out from the sulfurous method sugar production flow, and the secondary sulfur smoke process is eliminated further, so the problem of secondary sulfur smoke troubling the sugar industry for a long term is solved, the quality of whiter granulated sugar is improved fundamentally, and the high-quality whiter granulated sugar with low sulfur dioxide and low color number is produced. The method comprises the following steps of: leading the serum, filtered serum, crude syrup or triose remelt syrup out of the conventional production flow into a reactor; adding the active carbon accounting for 0.5 to 3 mass percent of the syrup in the reactor, reacting at the temperature of between 60 and 90 DEG C for 15 to 30 minutes, and performing physical adsorption, impurity removal and decoloration; and discharging sugar liquor after the adsorption from the reactor, and making purified serum, filtered serum, crude syrup or triose remelt syrup subjected to secondary filtration and solid-liquid separation by using a plate-and-frame filter press and a precision filter enter the conventional production flow again.

Owner:云南省轻工业科学研究院有限公司

Syrup clarification method

The invention relates to a syrup clarification method, belonging to the technical field of syrup clarification of the sugar industry. The syrup clarification method is used for clarifying the syrup by use of a syrup air flotation clarification and membrane separation coupling technology and comprises major processes of treating in a syrup air flotation clarification pretreatment system, a syrup air flotation clarification system and a syrup membrane separation system, and specifically comprises the following steps: performing air flotation clarification pretreatment on the syrup first, namely filtering the syrup with a filter screen, adding lime and phosphoric acid to adjust the pH value, and performing primary heating treatment; after the treatment, treating the syrup in the air flotation clarification system, and removing the non-sugar components of the network in the syrup; treating the syrup obtained by the air flotation clarification with a syrup filtering system; and clarifying in the efficient syrup membrane separation system to obtain clear syrup of which the clarification quality is not lower than that of the traditional sugar production technology to finish the syrup clarification process. The process provided by the invention mainly adopts the air flotation clarification and membrane separation coupling technology; the method is simple and advanced, the retention time of the syrup is short, the sucrose loss is little, the clarification is stable and controllable, the clarification efficiency is high, and the method is an effective measure of a sugar refinery for realizing energy-saving and clean production and implementing sustainable development and has a relatively good application prospect.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

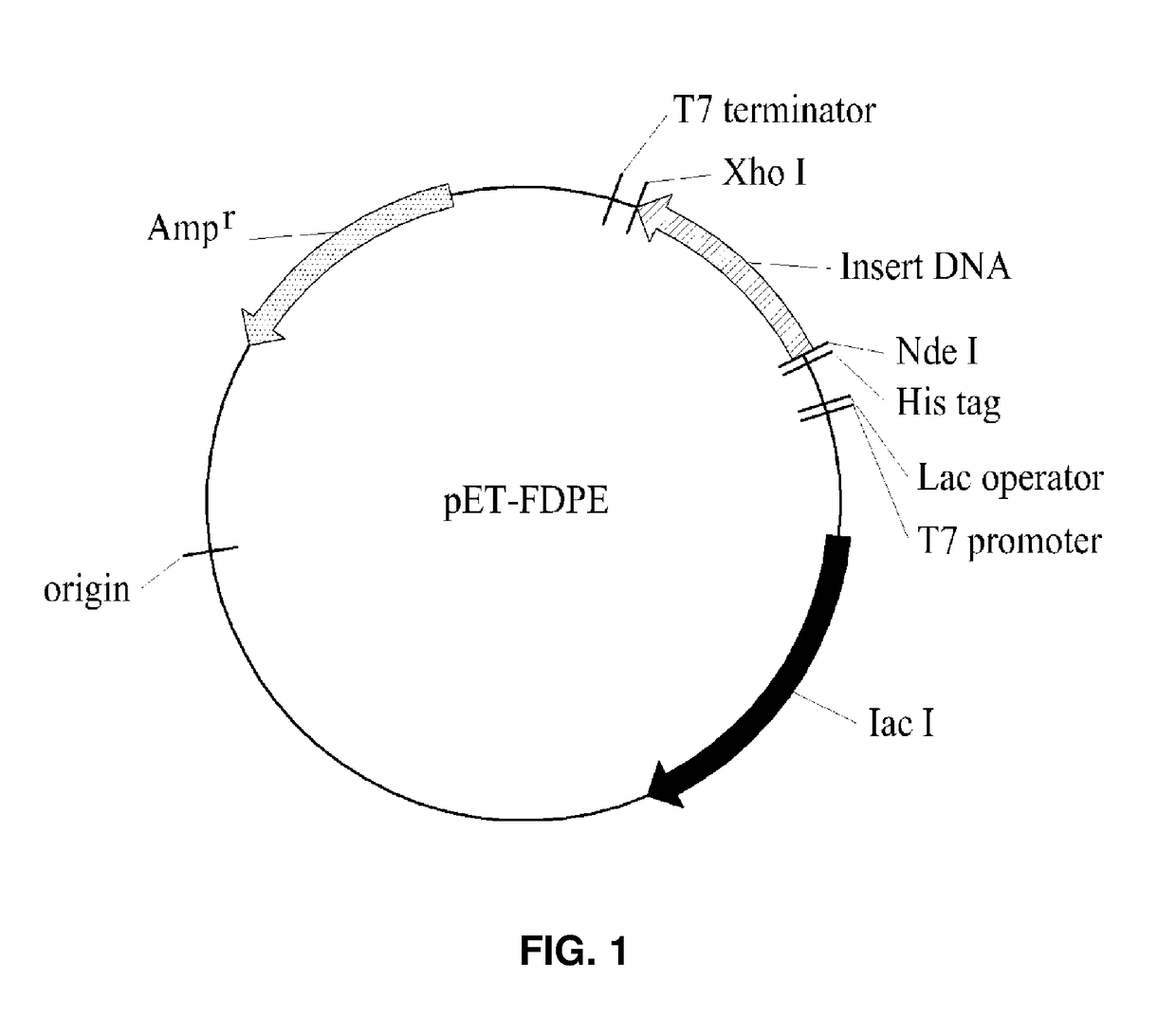

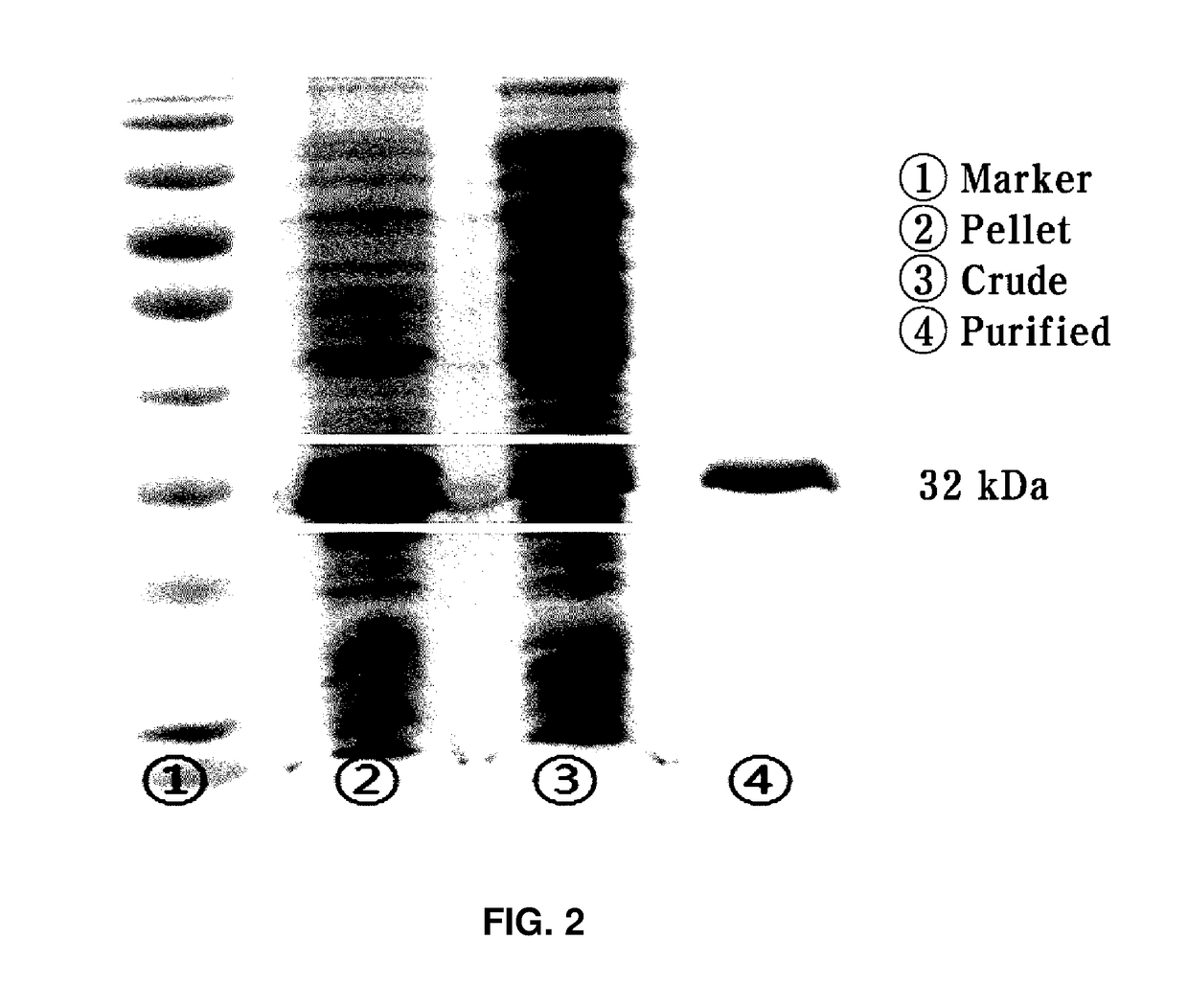

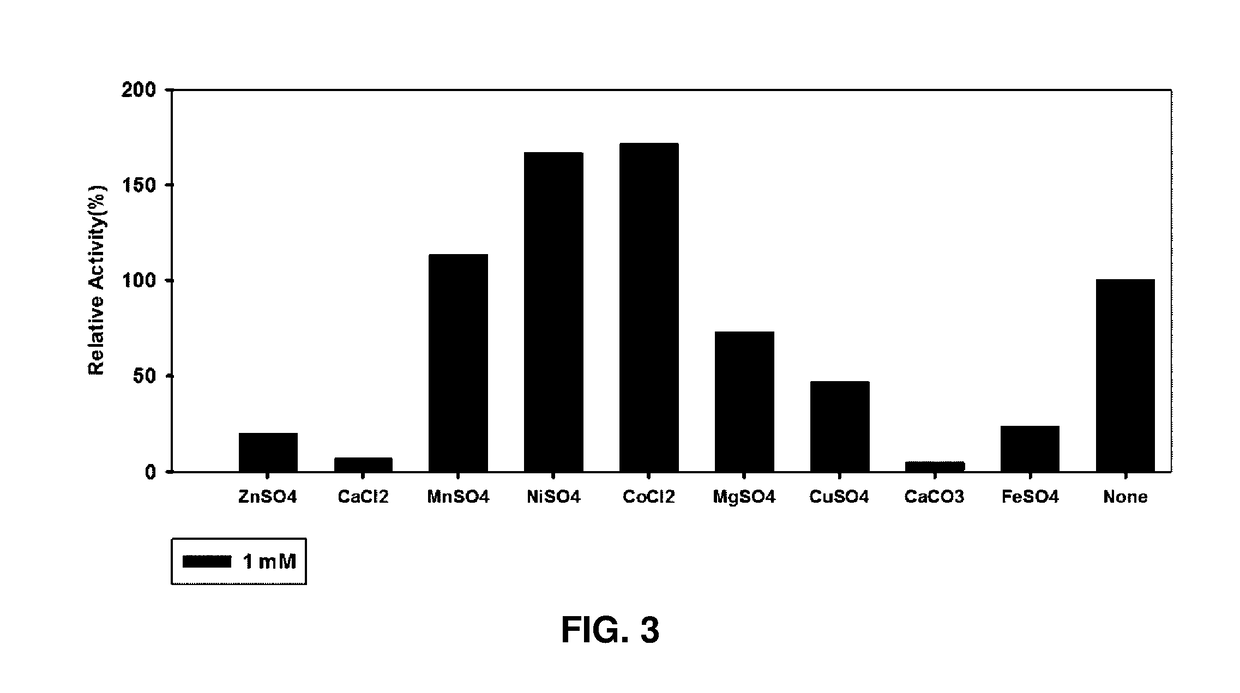

Psicose Epimerase and Psicose Production Method Using Same

ActiveUS20170101637A1Little or no activityImprove thermal stabilityRacemaces/epimerasesIsomerasesFructosePsicose

The present invention provides a novel psicose epimerase derived from Flavonifractor plautii and capable of converting fructose to psicose. The novel psicose epimerase according to the present invention possesses an activity producing psicose by epimerizing the carbon-3 position of fructose, and has maximal activity for the conversion of fructose to psicose at a relatively high temperature and a pH less than or equal to neutral, has excellent thermal stability, and can mass-produce psicose from fructose in a high yield for a short amount of time. Therefore, the psicose epimerase according to the present invention is advantageous in the industrial production of psicose, and it is expected that the psicose produced thereby can be usefully utilized in the functional sugar industry and also as materials for health food, medicine, cosmetics, and the like using the psicose.

Owner:DAESANG

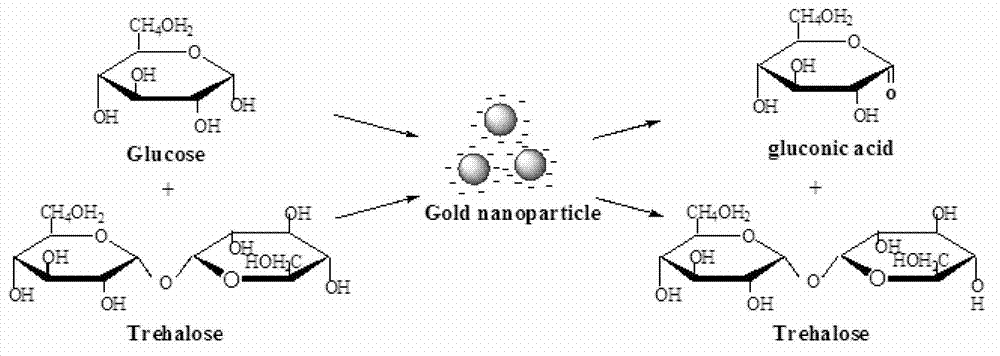

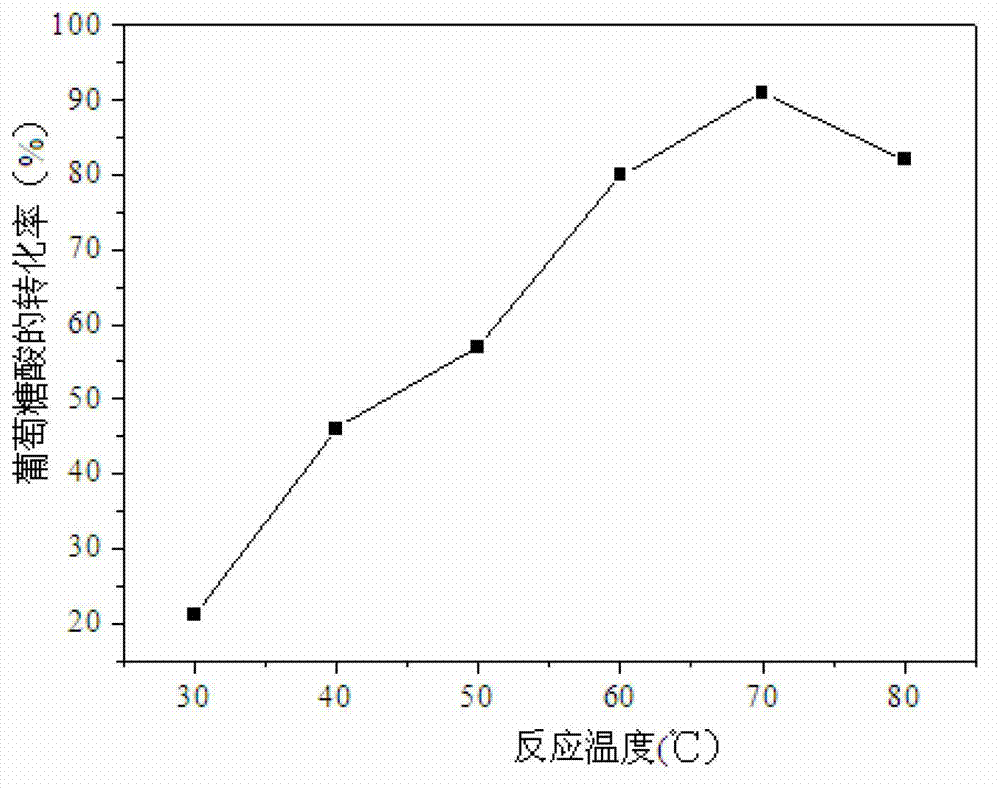

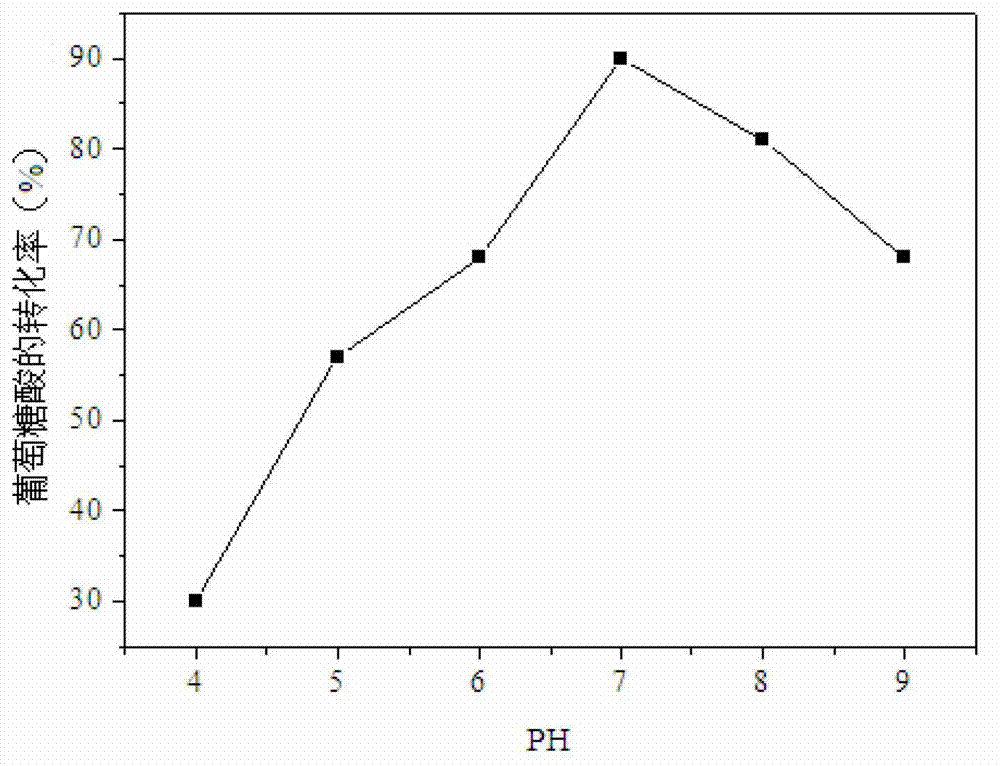

Method for separating mycose from glucose

InactiveCN103113425AThe preparation method is simple and quickLow costSugar derivativesDisaccharidesD-GlucoseGluconic acid

The invention belongs to the technical field of the sugar industry and discloses a method for separating mycose from glucose. According to the method, nano-gold is as a catalyst and the mixed liquid of mycose and glucose is as a substrate, wherein the nano-gold catalyzes glucose in the mixed liquid to generate gluconic acid; and then the gluconic acid is separated from the mycose through a chromatographic process. The glucose is catalyzed by the nano-gold to generate the gluconic acid, and the sugar-to-sugar separation applied to mycose and glucose is transformed into sugar-to-acid separation, so that the separation efficiency is greatly improved; besides, the method is simple and quick, wide in raw material source and low in cost; therefore, the method is an efficient new process for separating mycose from glucose.

Owner:NANJING UNIV OF TECH

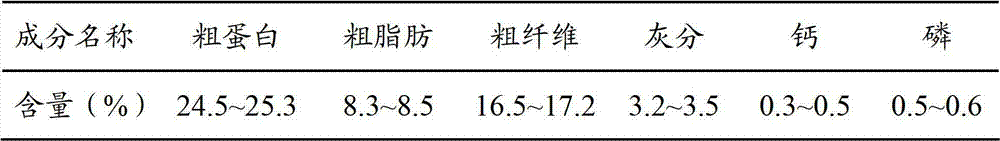

Nutritive feed and preparation method thereof

InactiveCN102860413ASimple design processLess capital to buildFood processingAnimal feeding stuffRoom temperatureSterile water

The invention relates to a nutritive feed prepared by mixing bagasse and brewer's grain and a preparation method of the nutritive feed. The preparation method comprises the following steps of: taking sawdust, sterilizing, adding sterile water, inoculating irpex lacteus according to the weight part proportion of the sawdust to the irpex lacteus of 1:1*10<-5>-3*10<-5>, culturing for 15h-18h under room temperature to obtain a strain; mixing the bagasse with the brewer's grain according to the weight part proportion of 1:(1.5-1.8), adding the strain, fermenting for 15h-18h at room temperature, then adding a bacterium liquid containing nitrobacteria, continuously fermenting for 9h-10h; and after the fermenting is ended, freezing and drying to obtain the nutritive feed. The preparation method is simple in designed process, is little in construction cost, is easy to operate, and is suitable for small farms and retail farmers; meanwhile, the waste of the sugar industry and the brewing industry is recycled without polluting the environment; and the prepared feed is rich in nutrition and can better improve the intestinal tract digestive system of livestocks.

Owner:GUANGZHOU YOURUI BIOSCI

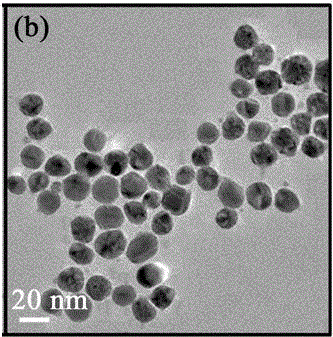

Green quick method for preparing nano-silver sol using bagasse extract

The invention discloses a green quick method for preparing nano-silver sol using a bagasse extract. The method is that, in a water phase system, a bagasse extract and a silver-ammonia solution are added in a microwave reactor to be subjected to a redox reaction, and then nano-silver particles uniformly dispersed and being good in stability can be obtained. The method totally accords with the idea of "green chemistry", so the method is a green, environmental friendly, and quick method for preparing nano-metal. Bagass is a by-product in the sugar industry and also a renewable biomass resource, the method provides a new idea for synthesis of nano-metal, and technological guidance on bagasse utilization with a high value. The nano-silver sol prepared by the green method has a great application prospect in fields of medical treatment, biology and foodstuff.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com