Patents

Literature

160 results about "Sugar yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

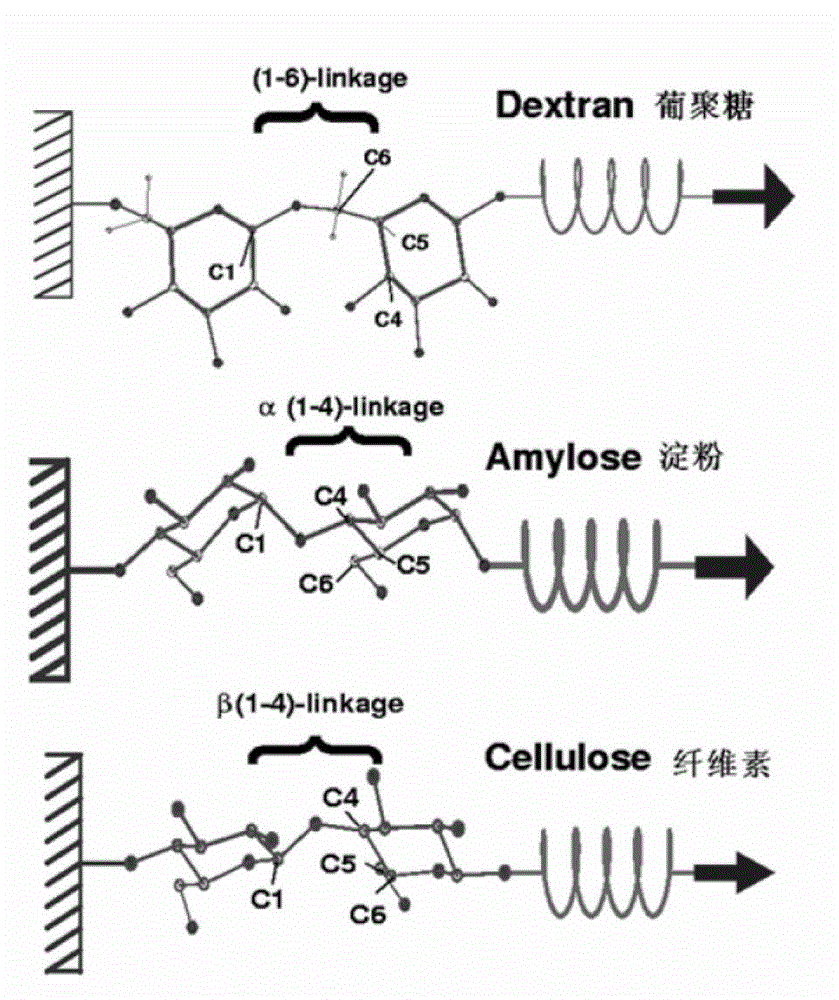

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

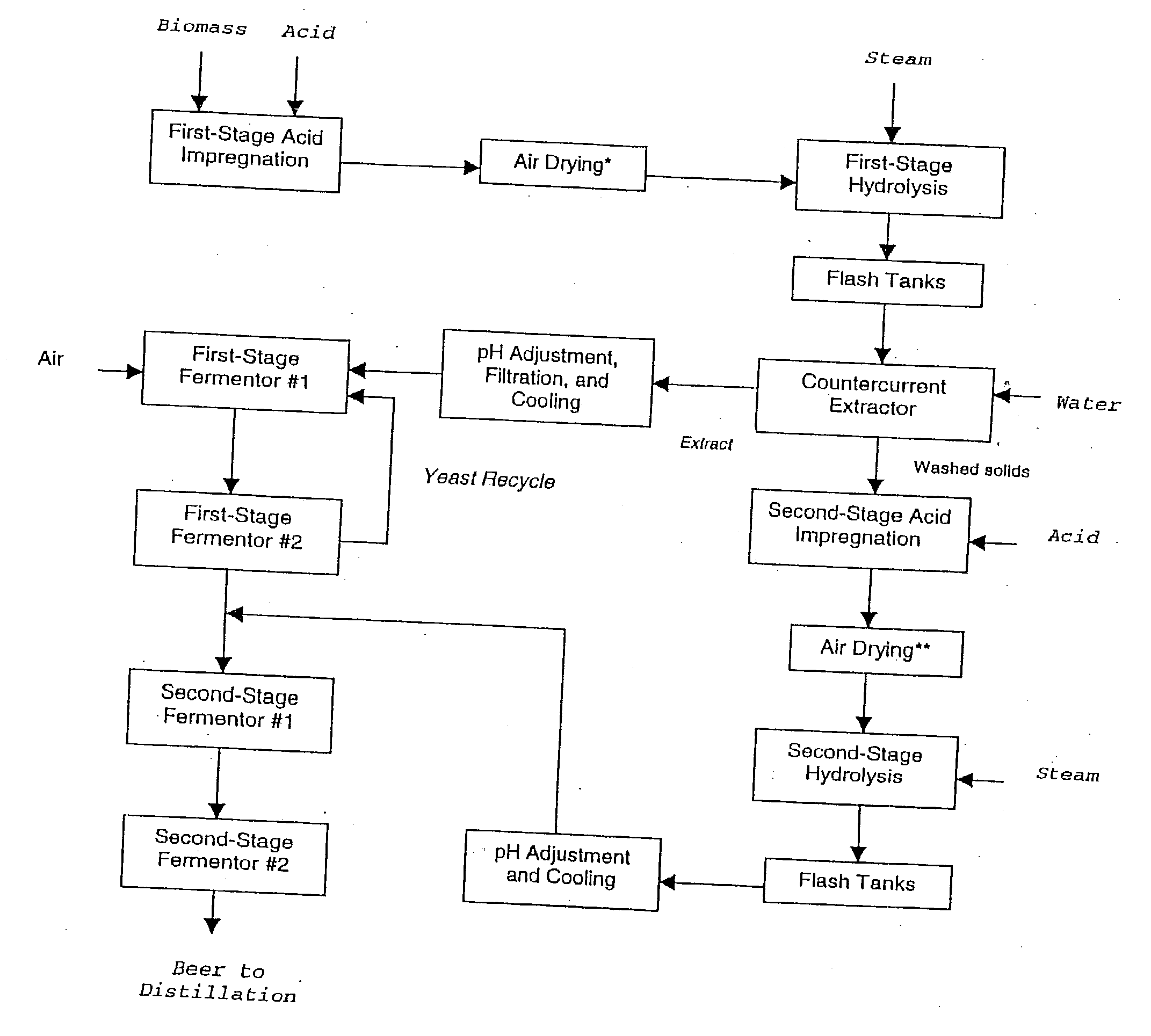

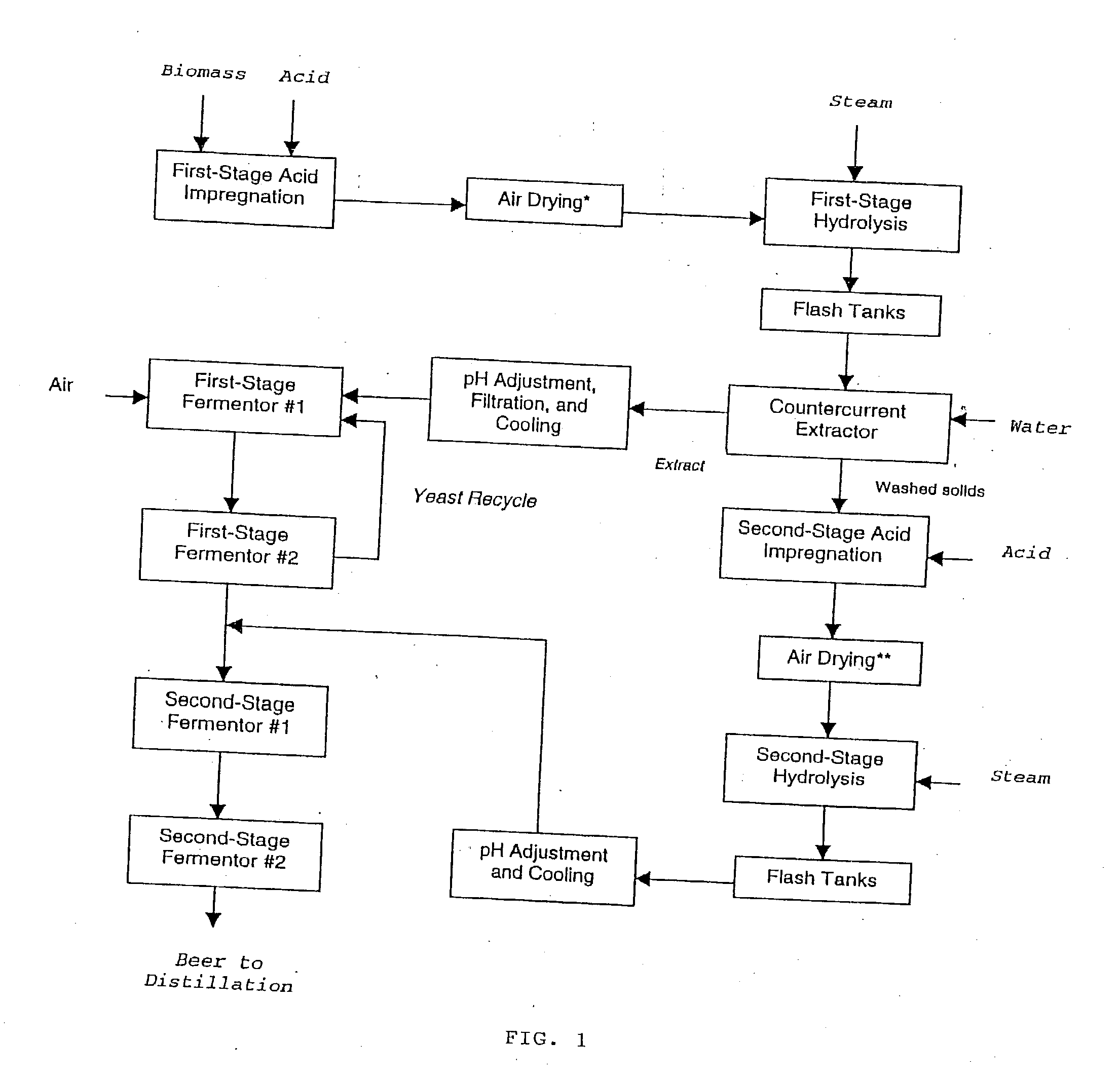

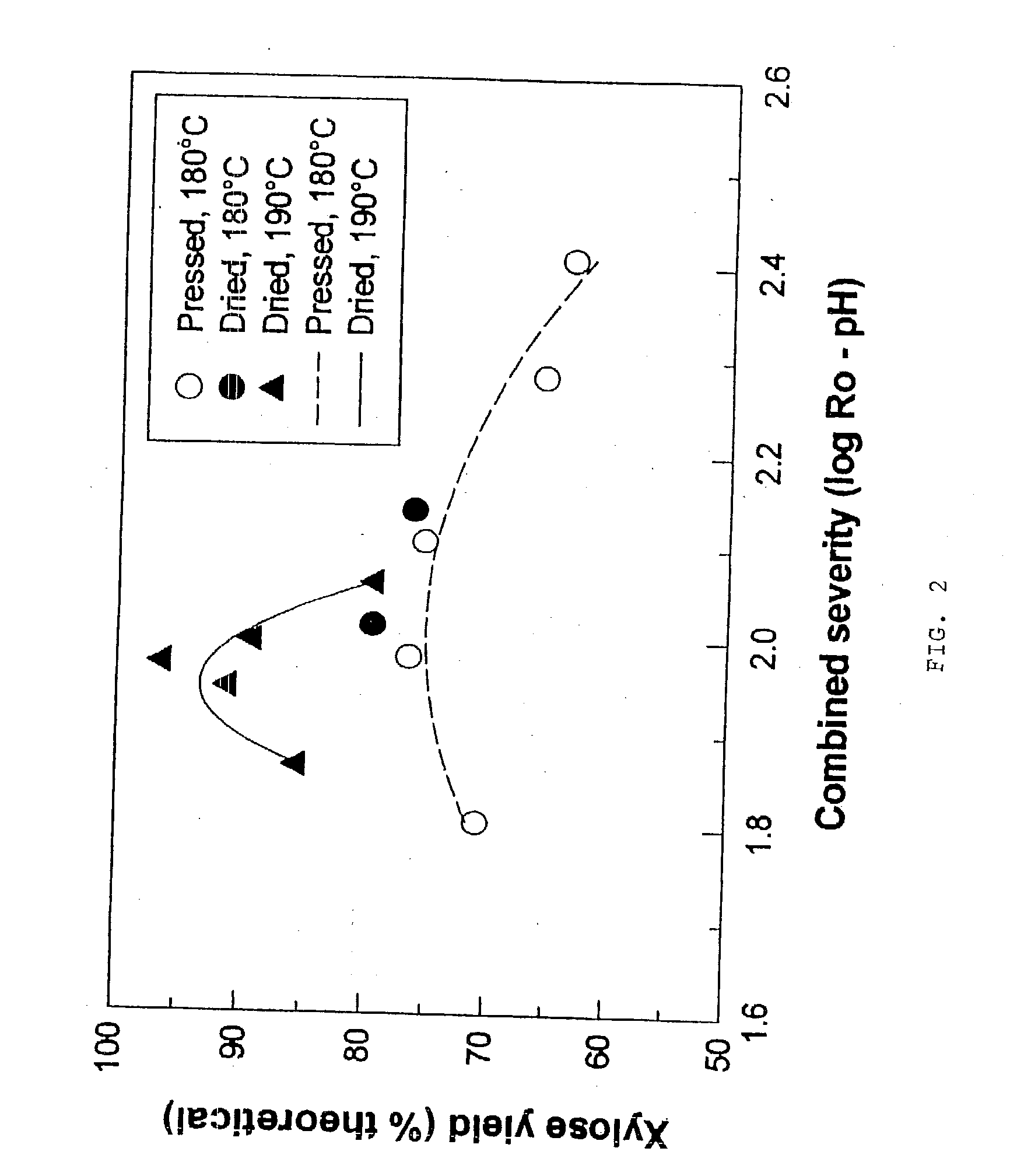

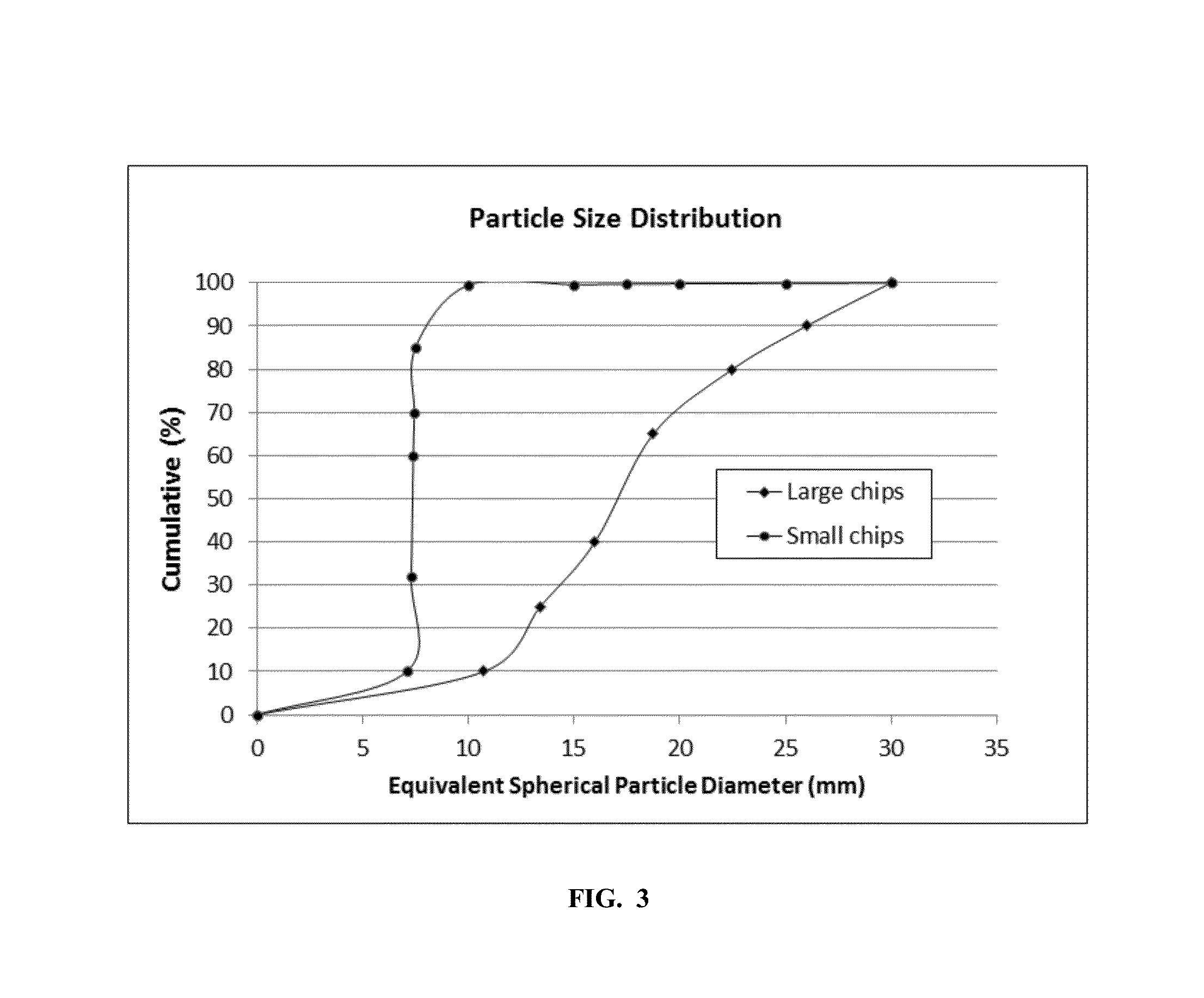

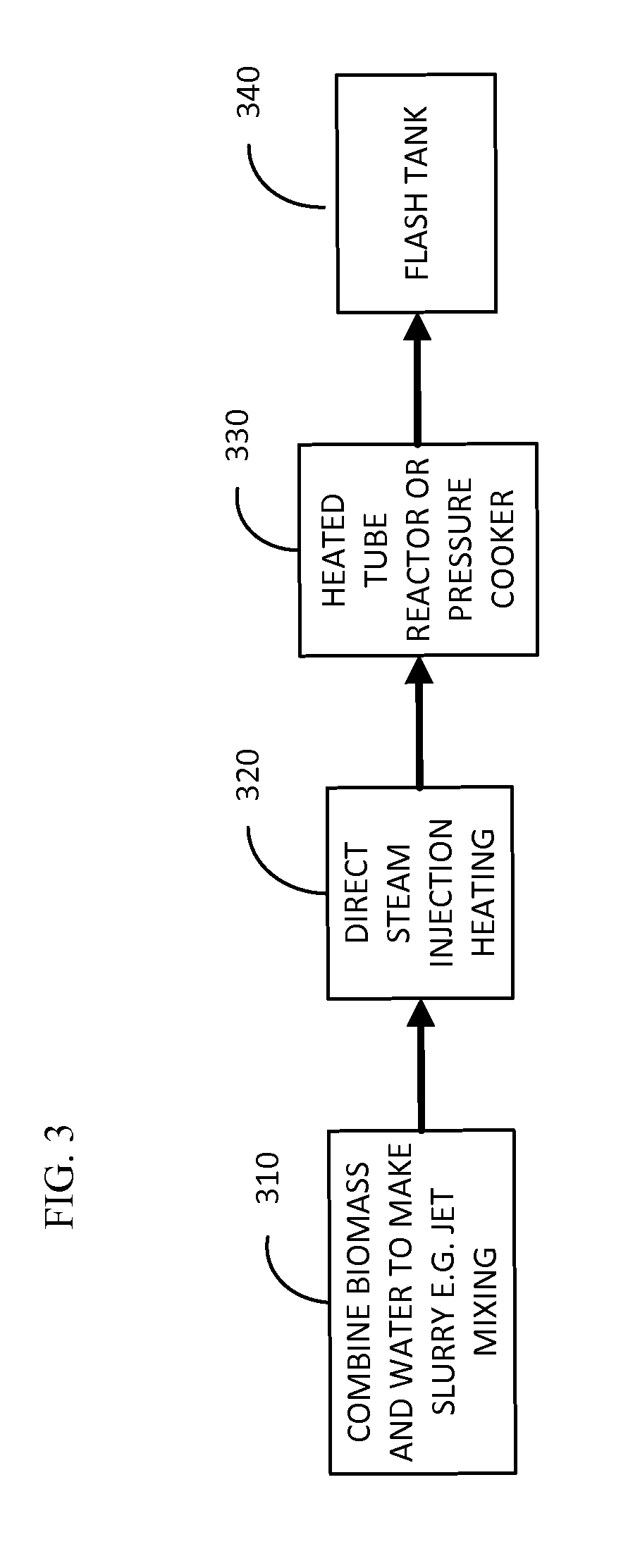

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

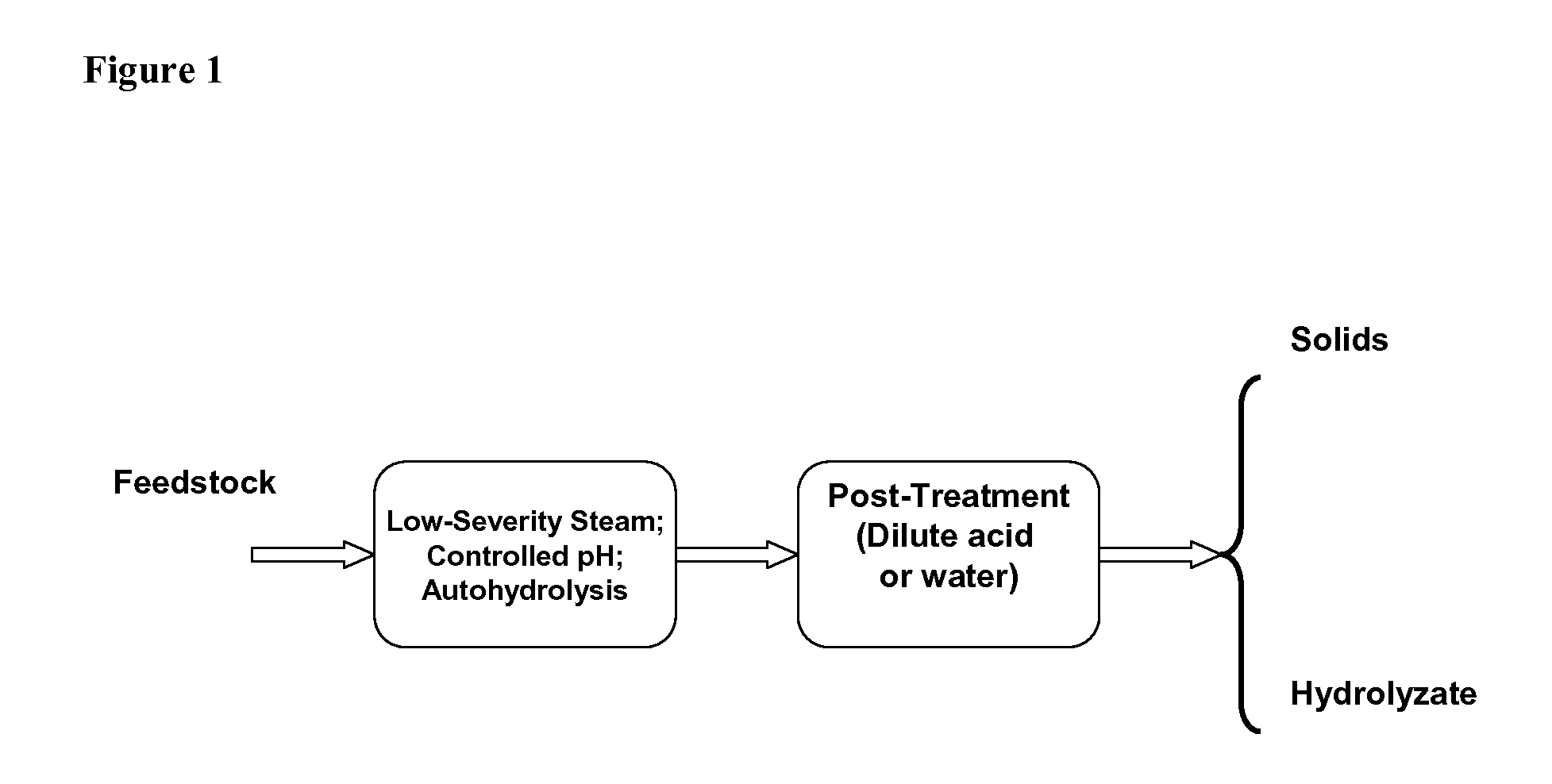

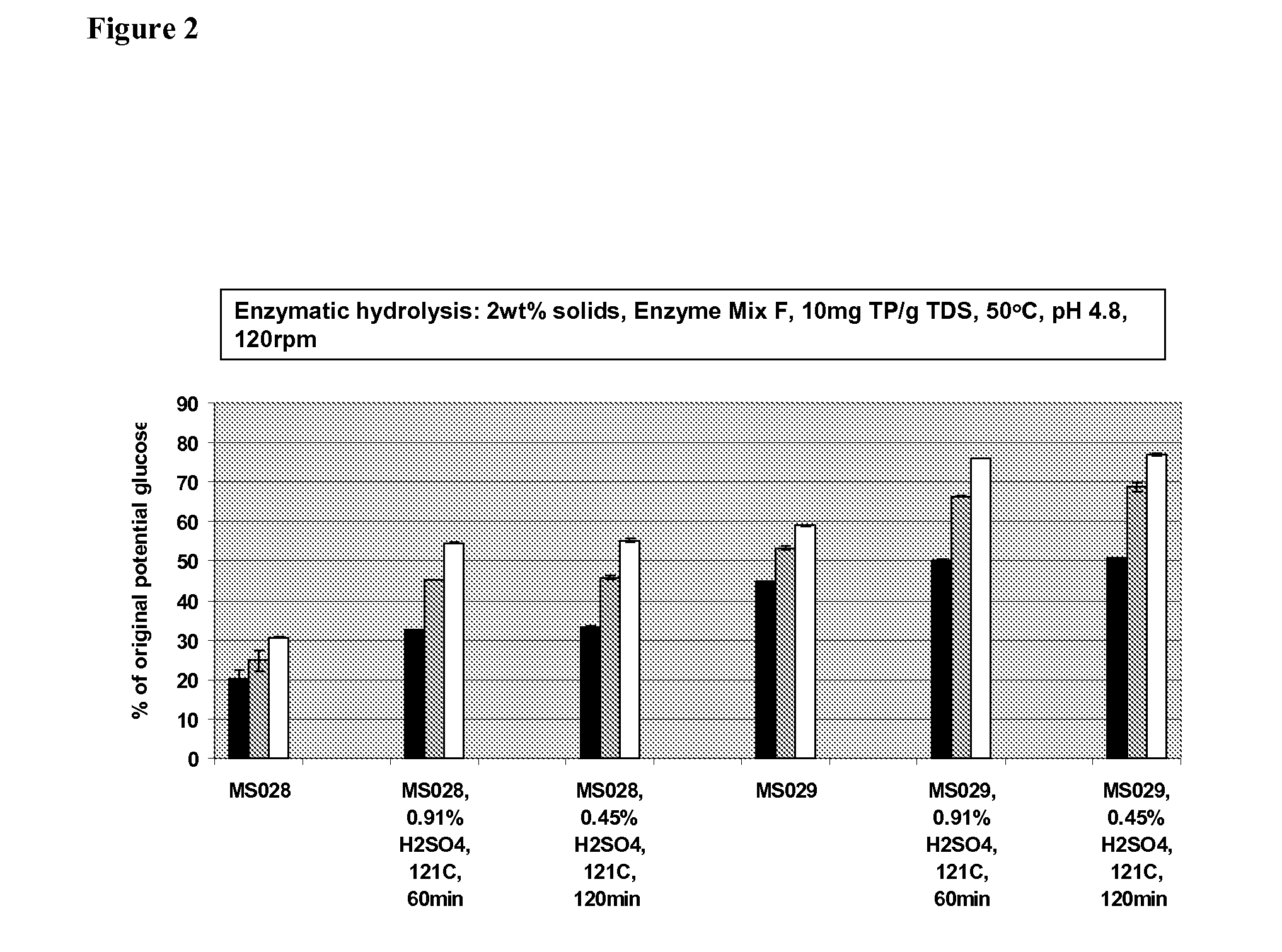

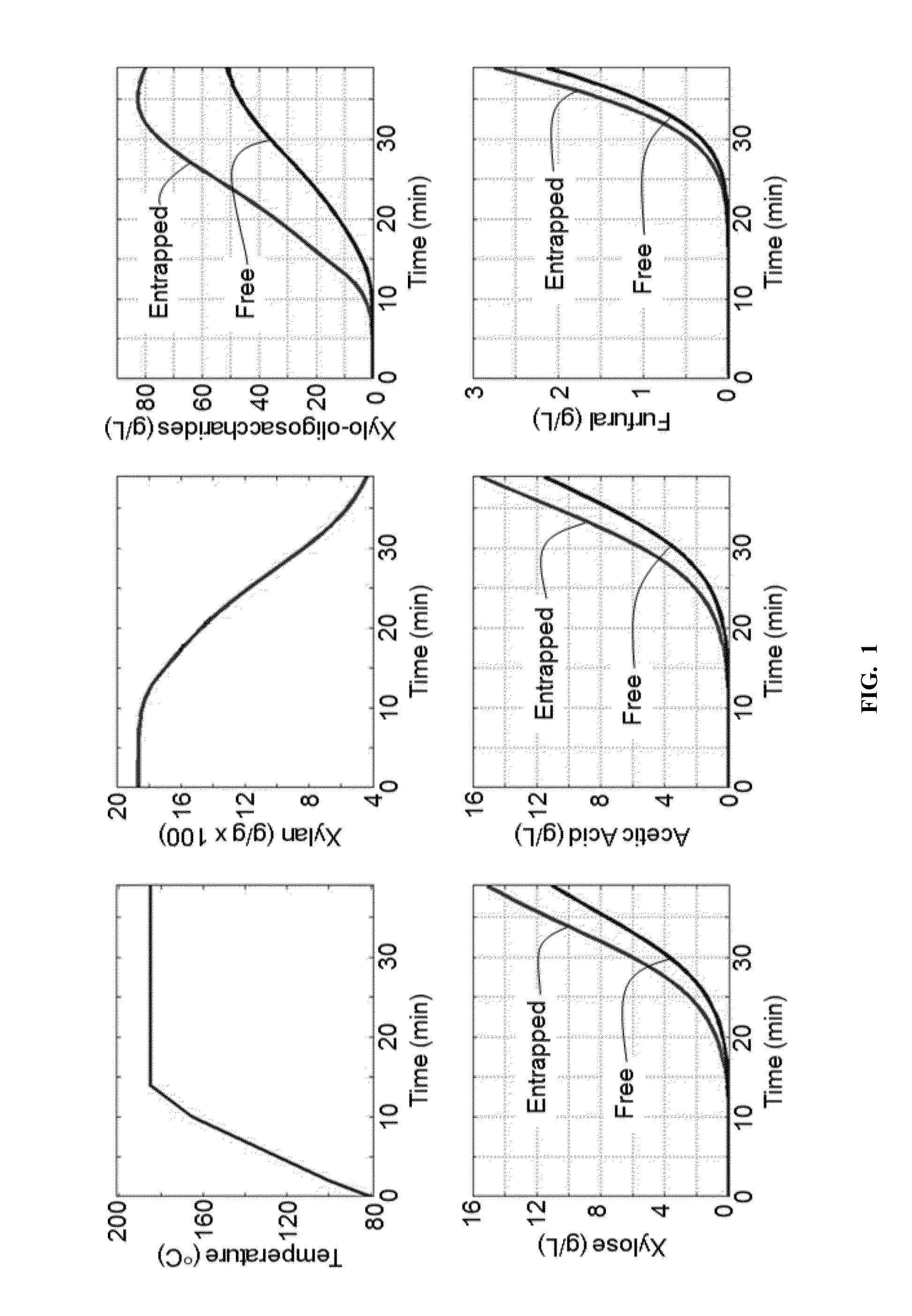

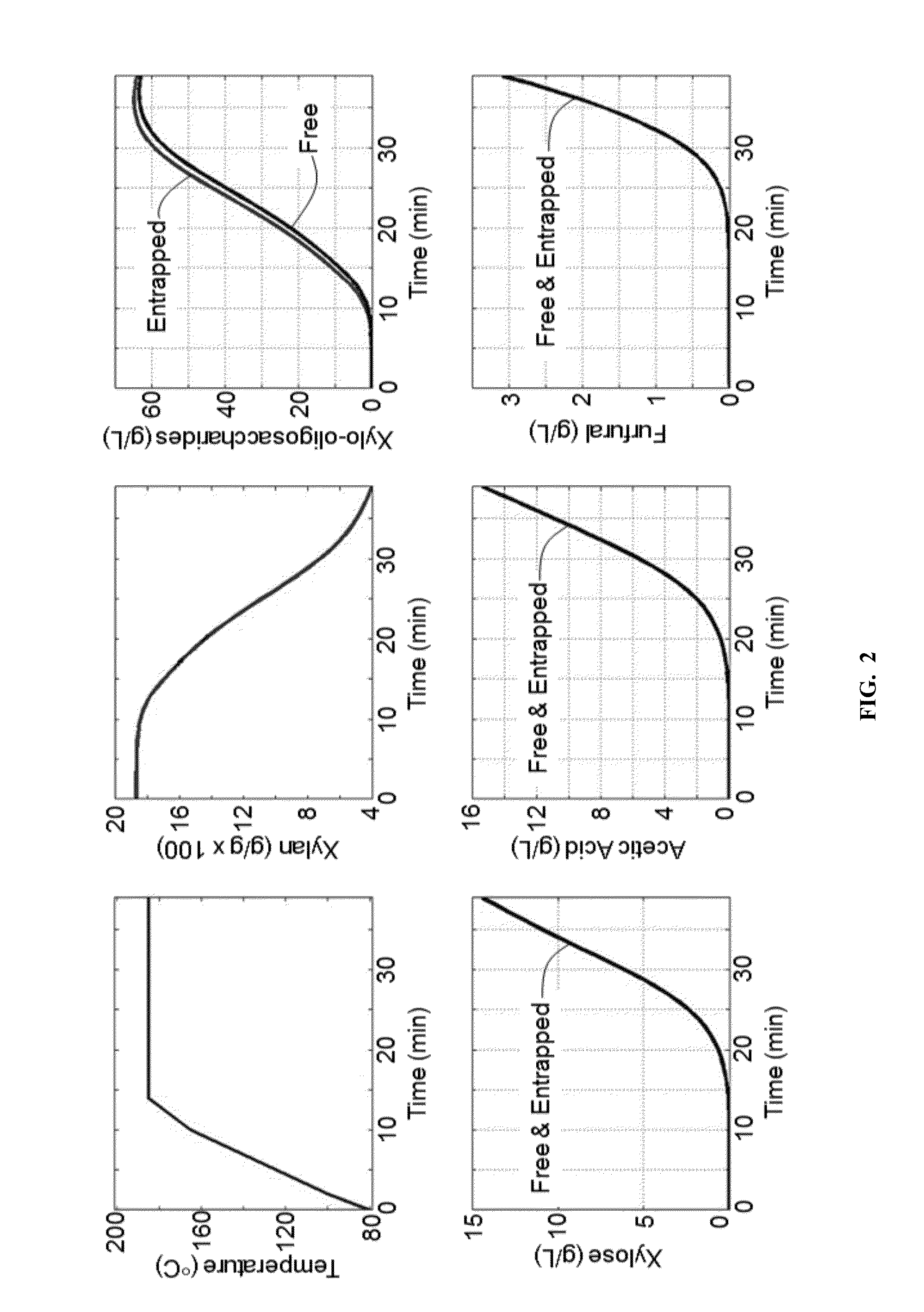

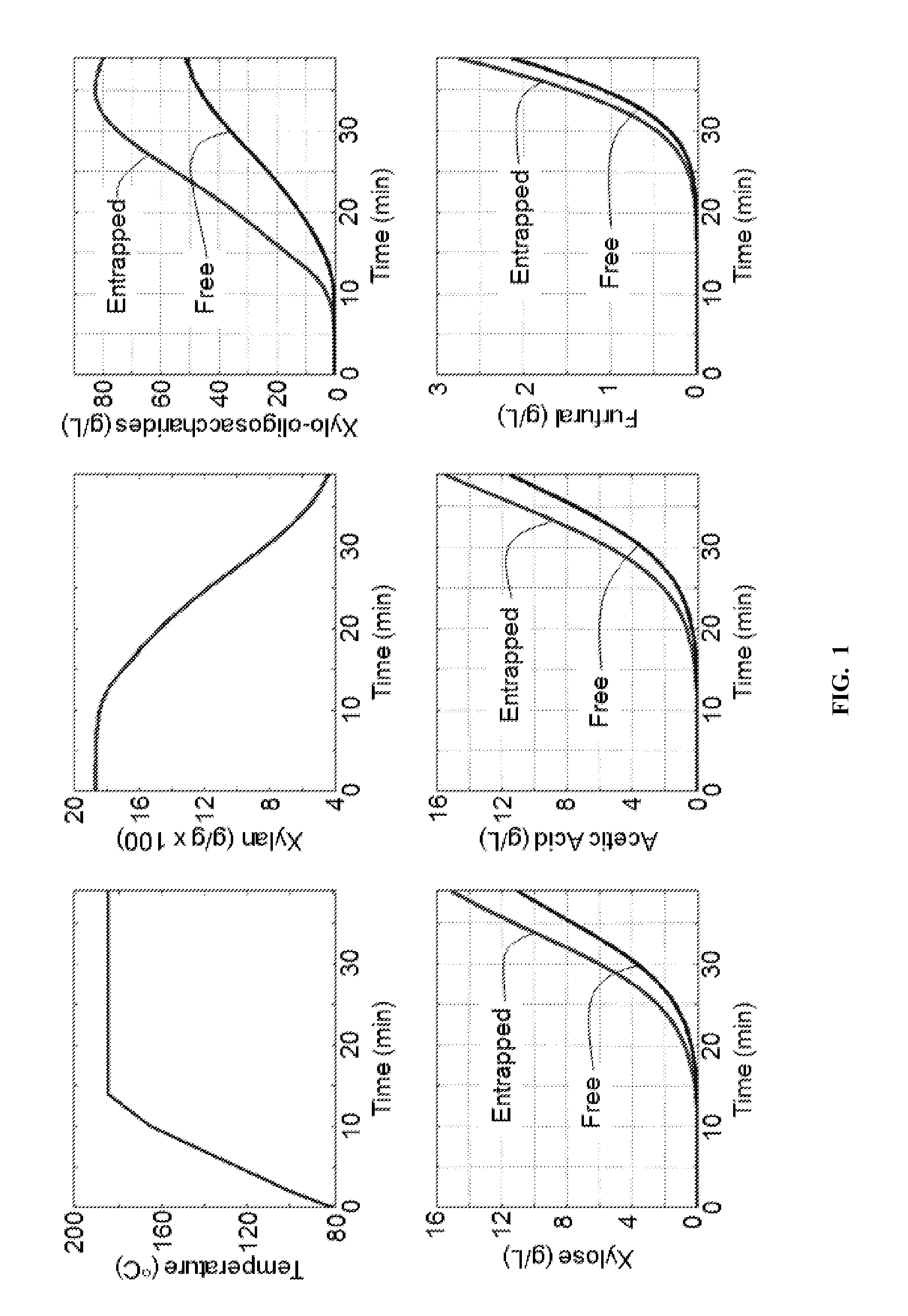

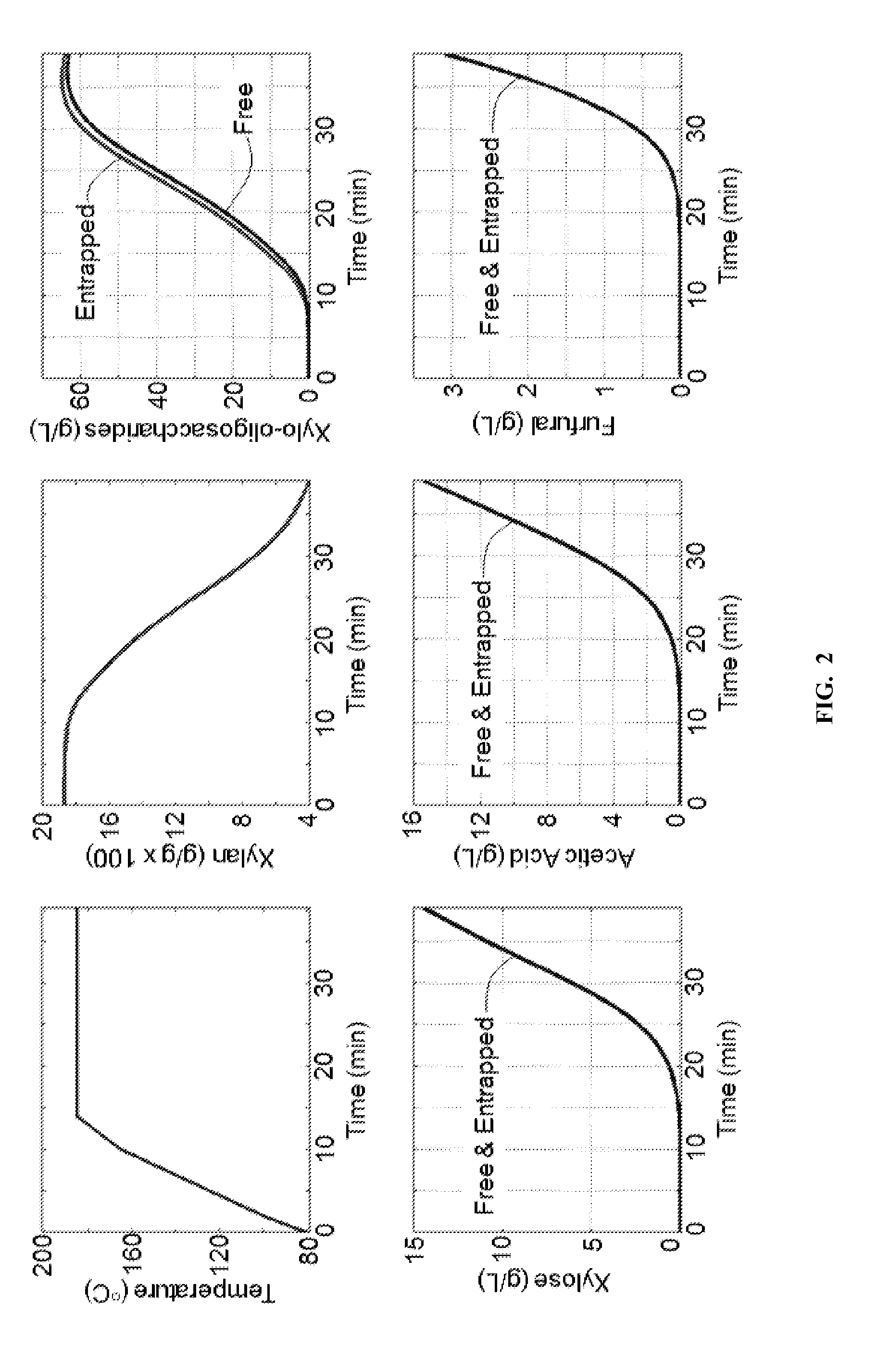

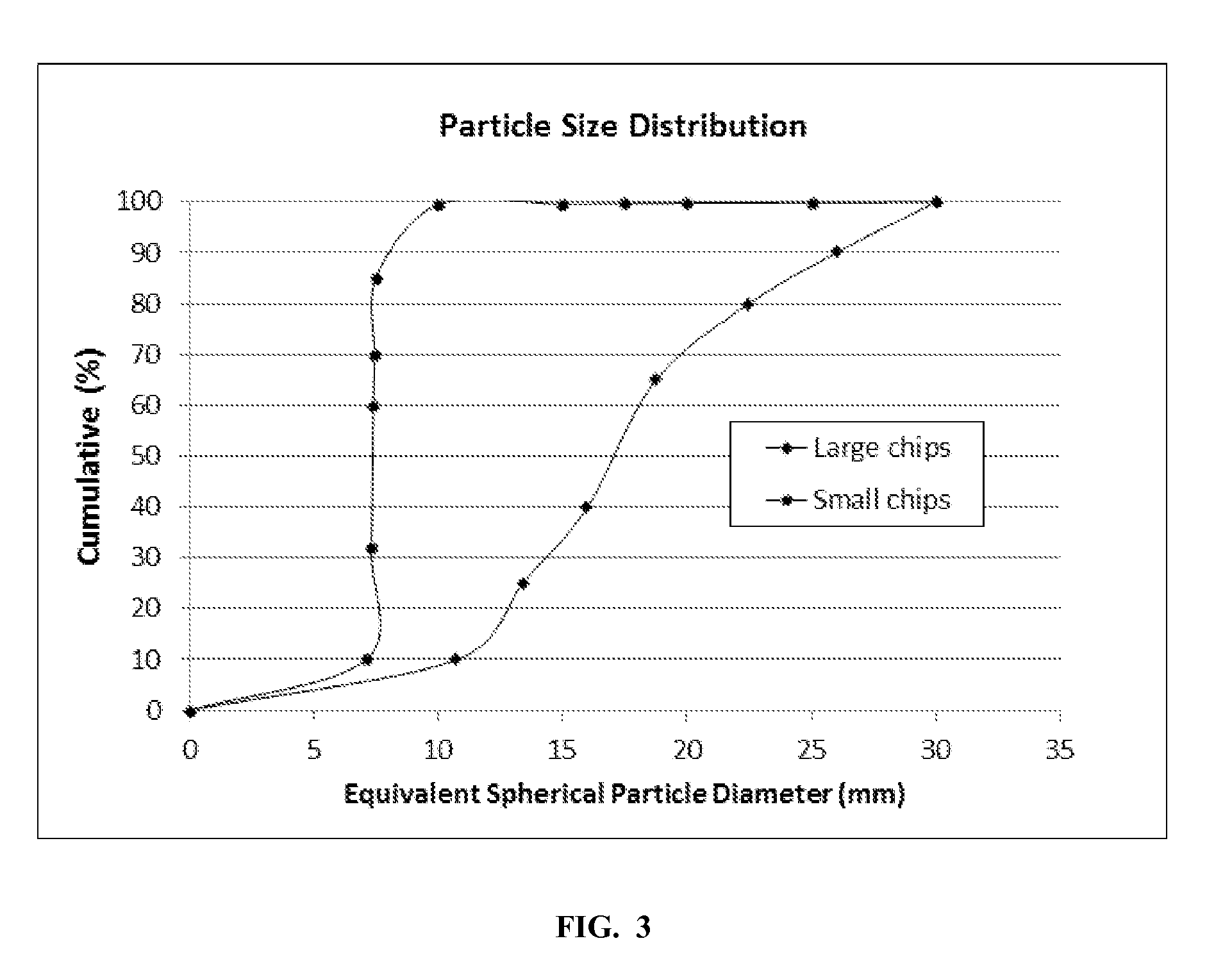

Two-Stage Process for Biomass Pretreatment

InactiveUS20110300586A1Increase rangeImprove digestibilityBiofuelsPulping with acid salts/anhydridesAcid hydrolysisLignocellulosic biomass

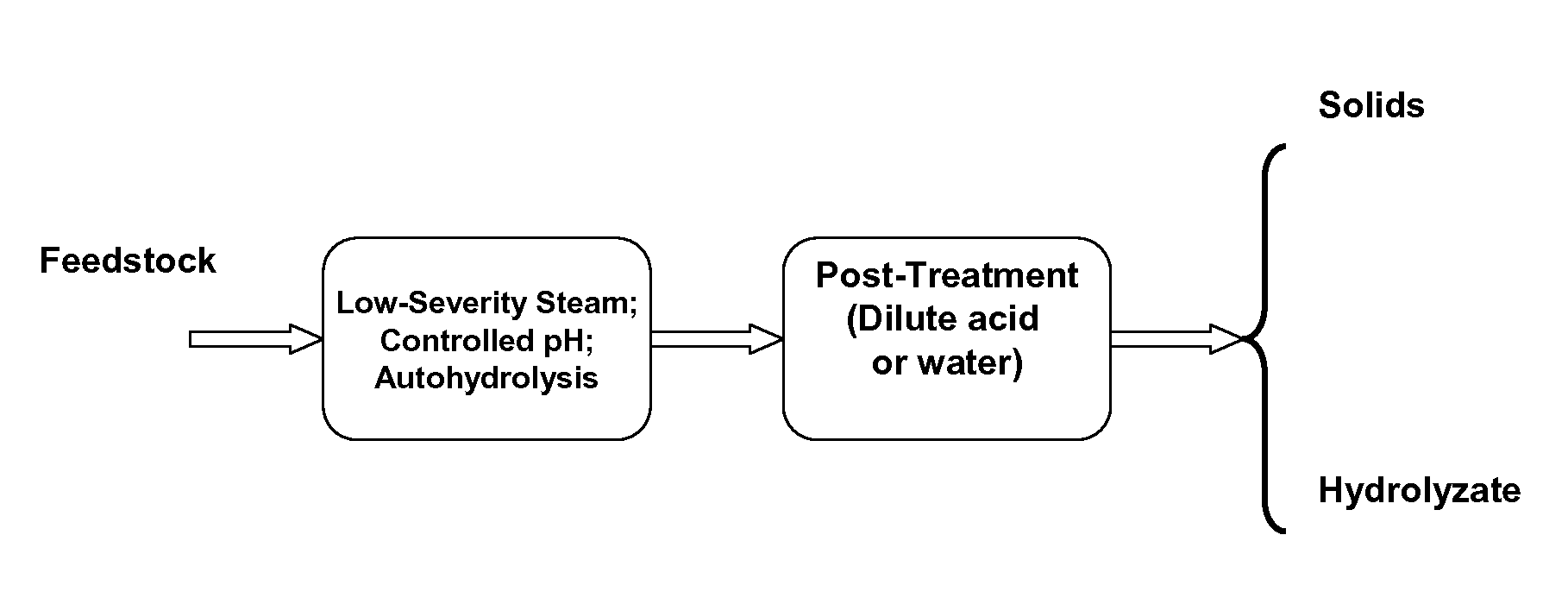

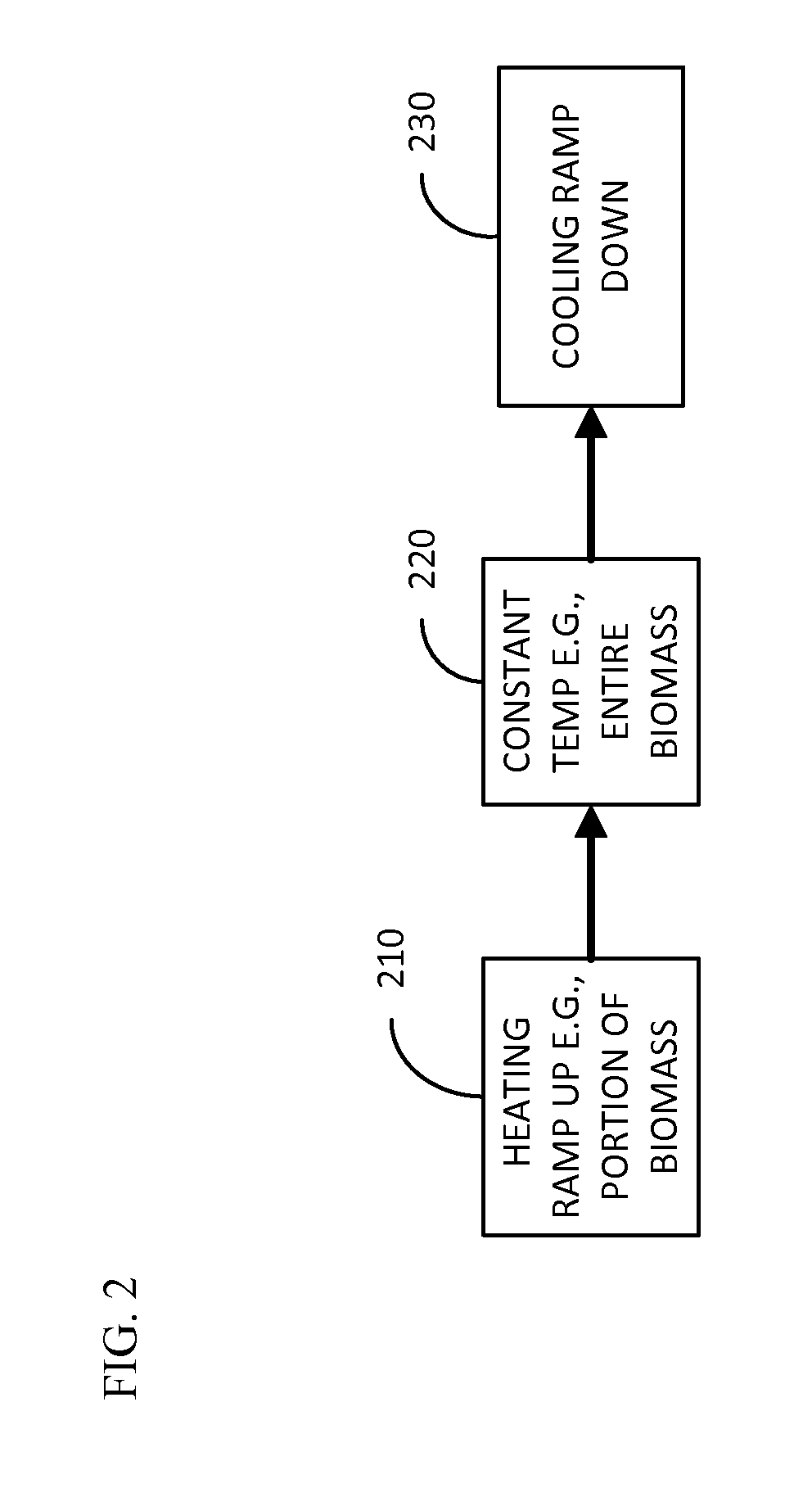

Described herein are improved methods of pretreating lignocellulosic biomass. One aspect of the invention relates to a two-stage pretreatment process comprising a relatively low severity steam treatment, a controlled pH pretreatment, or autohydrolysis, followed by hydrolysis with dilute acid or hot water at a relatively low temperature. In certain embodiments, the methods increase hemicellulose sugar yields, substrate digestibility, and suitability for fermentation as compared to steam explosion or acid hydrolysis alone. The two-stage pretreatment processes also employ few chemicals, minimizing the costs associated with pretreatment of lignocellulosic biomass. Moreover, the two-stage pretreatment process may expand the range of suitable feedstocks for bioethanol production.

Owner:MASCOMA CORPORATION

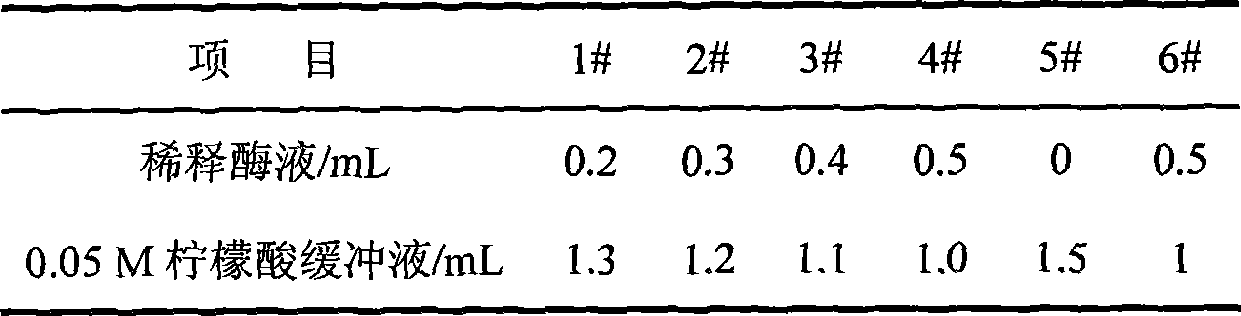

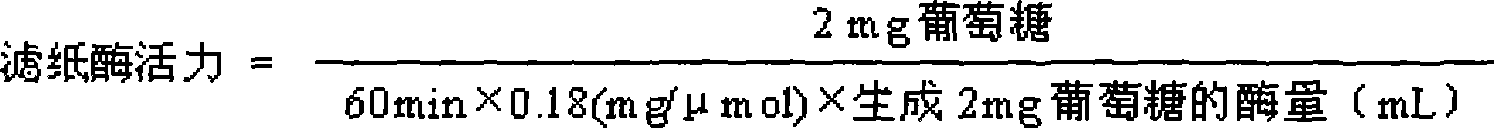

Novel method for saccharification of ligno-cellulose

InactiveCN101434976AAvoid high temperature and pressureSave operating timeBiofuelsFermentationCellulaseXylanase

The invention relates to a new method for processing lignocellulose by saccharification, comprising dilute acid pretreatment, milling and crushing, cellulase compounding and enzymolysis saccharification process. The detail method thereof comprises the following steps: the crushed lignocellulose raw materials are pretreated with dilute acid with the H <+> concentration of 0.01mol / L-0.1mol / L and later milled and crushed, and then acidolysis sugar solution is obtained; at least two types of cellulase are mixed with xylanase for obtaining compound cellulase, and then further enzymolysis saccharification treatment is carried out to the rest solid after enzymolysis and milling for obtaining enzymolysis sugar solution. By using the process that the milling of dilute acid is combined with the one-step enzymolysis of compound enzyme, the hydrolysis sugar yield of the lignocellulose raw materials can be up to more than 90 percent. The method has the advantages of mild reaction condition, simple operation, and high enzymolysis efficiency; moreover, the obtained sugar solution after being processed produces no inhibition to the follow-up fermentation, can be comprehensively utilized, and causes no environmental pollution, etc.

Owner:CHINA PETROLEUM & CHEM CORP

Novel method for saccharification of ligno-cellulose

InactiveCN101434977AEliminate individual differencesAvoid wastingBiofuelsFermentationCellulasePre treatment

Owner:CHINA PETROLEUM & CHEM CORP

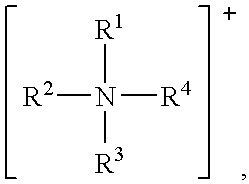

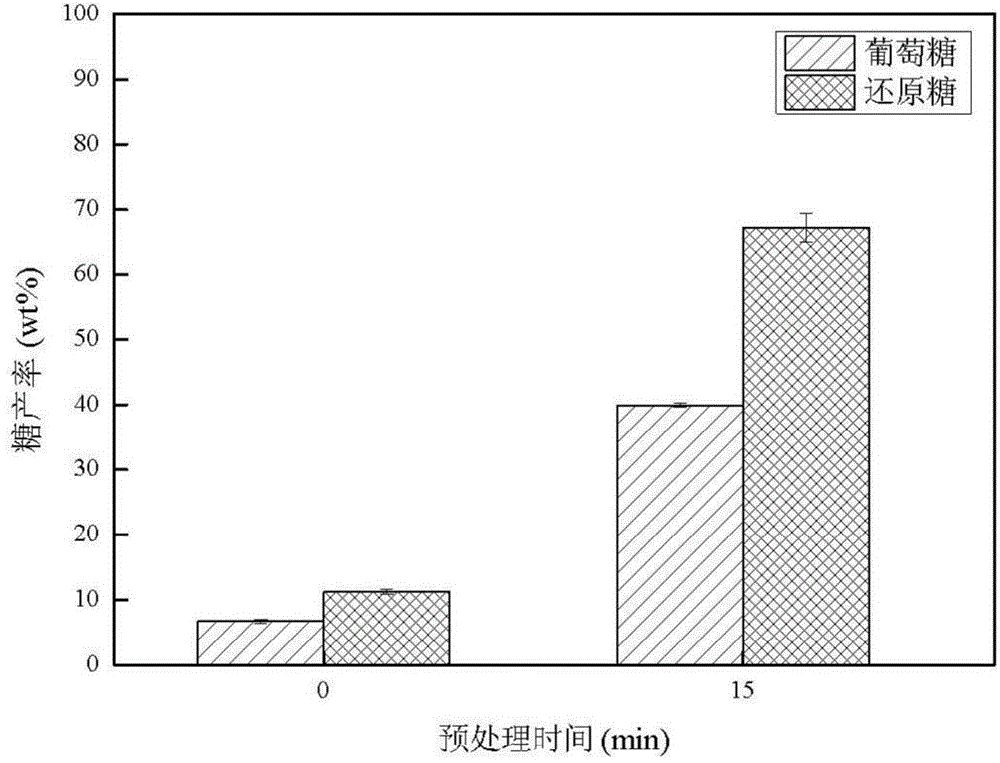

Method for increasing sugar yield of cellulase enzymolysis through pretreatment by using ion liquid

The invention relates to a method for increasing the sugar yield of cellulase enzymolysis through pretreatment by using ion liquid. In the method, natural lignin from different sources is pretreated by using different types of ion liquids to increase the sugar yield of enzymolysis. The method comprises the following steps of: firstly, pretreating natural lignin at certain temperature under fully stirring condition by using an ion liquid; secondly, extracting regenerated cellulose from a mixed liquor and drying; and lastly, adding cellulase which can decompose the regenerated cellulose serving as a substrate into reducing sugar at certain temperature, pH and concentration to generate liquid glucose mainly containing glucose. By adopting the method, the sugar yield of lignin can be remarkably increased, the accessibility and the reaction efficiency of cellulase can be effectively increased, the liquid glucose reaches the fermentation level at the final reaction stage, and the entire technical process is simplified.

Owner:TONGJI UNIV

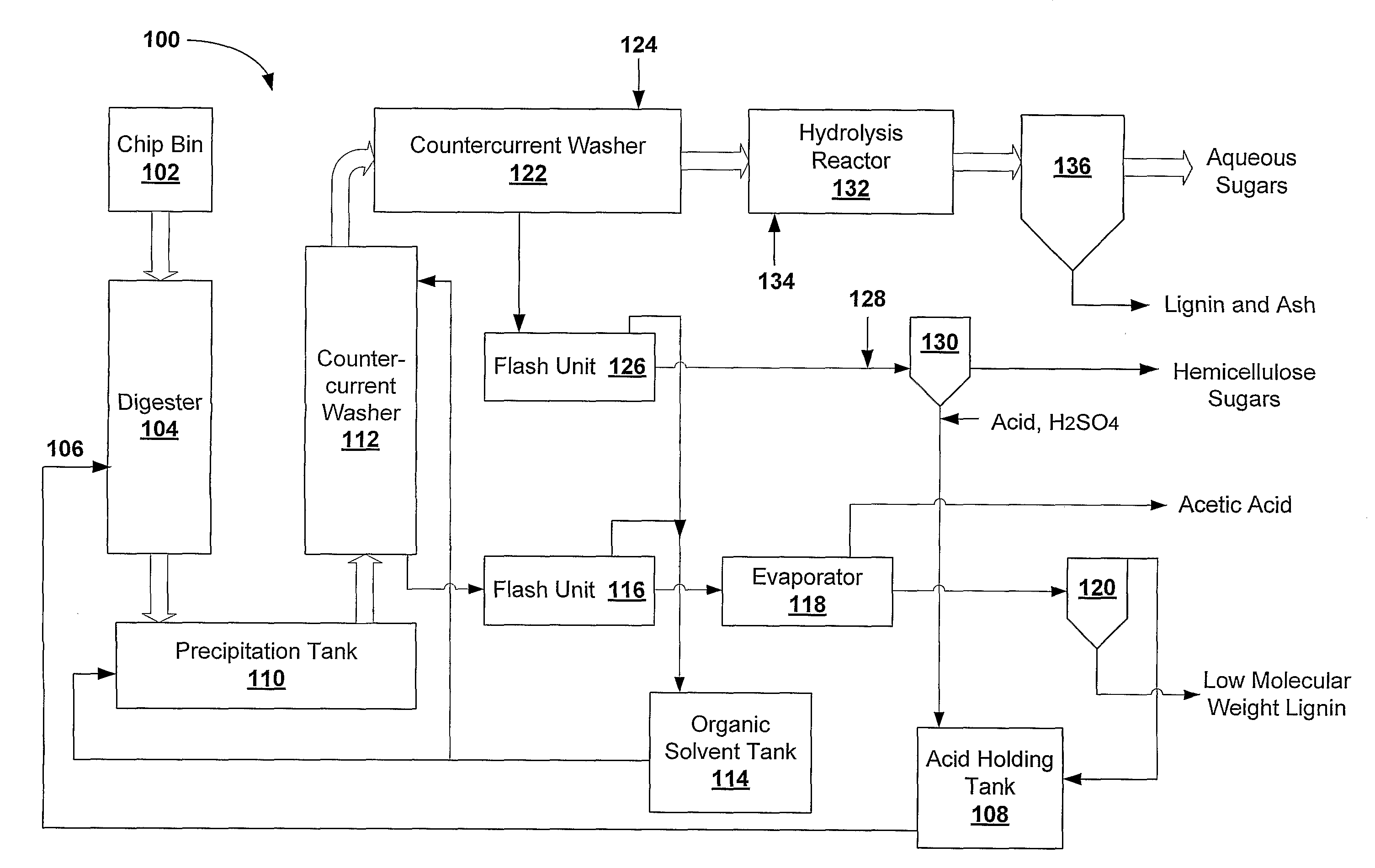

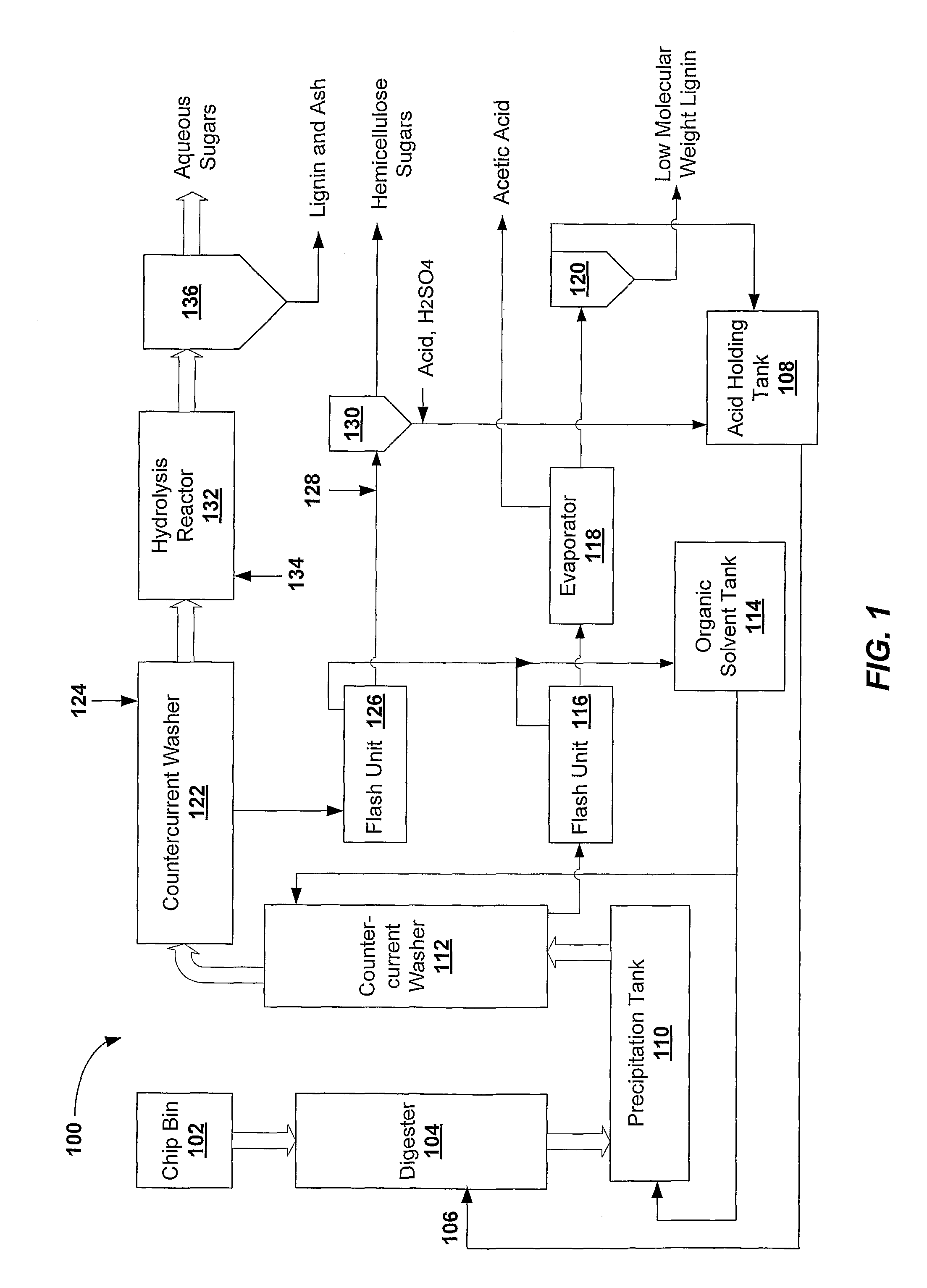

Method and Apparatus for Saccharide Precipitation From Pretreated Lignocellulosic Materials

InactiveUS20090017503A1High saccharide yieldFast hydrolysisSugar derivativesBiofuelsAcetic acidOrganic solvent

A method for separating saccharide components and lignin fractions from a concentrated acid treated lignocellulosic biomass is disclosed. The method involves precipitating the saccharide components by adding an organic solvent to the biomass slurry. The acid may then be recovered, for example, by filtration or by countercurrent washing and the organic solvent may be flashed and recycled. During acid recovery and organic recovery steps, two main lignocellulose components (hemicellulose and lignin) as well as minor components such as acetic acid are separated as well. The method decreases the amount of cellulase required for hydrolysis, increases hydrolysis rates, reduces formation of inhibitor molecules, increase sugar yields, produces high value by-products such as high quality lignin and hemicellulose, and decreases energy and equipment costs.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

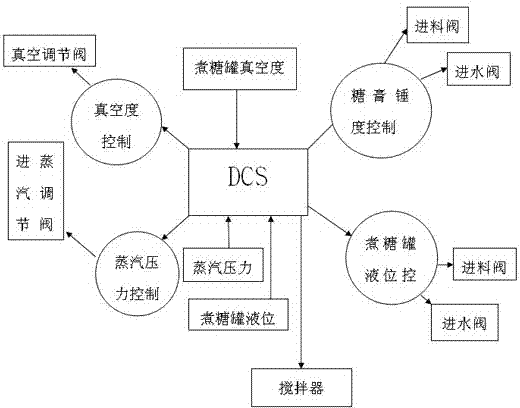

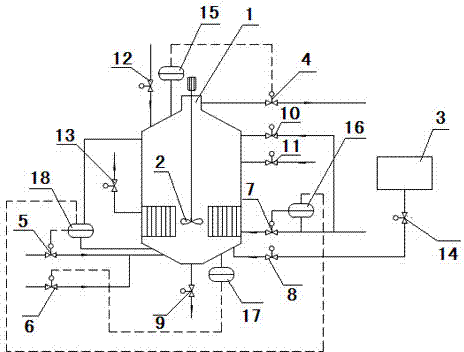

Sugar boiling automatic control device

ActiveCN102925593AImprove reliabilityImprove efficiencySugar juice boiling/evaporationThermodynamicsAutomatic control

The invention provides a sugar boiling automatic control device and relates to a device for controlling several main parameters of a sugar boiling pot automatically. The sugar boiling automatic control device comprises a vacuum control module, a massecuite brix control module, a heating steam pressure control module and a sugar boiling pot liquid level control module. The vacuum control module measures vacuum of the sugar boiling pot through a transmitter and uses a distributed control system (DCS) for regulating a condenser inlet circulating water regulating valve so as to control the vacuum. The massecuite brix control module measures brix of syrupy through a brix meter and controls a feed valve, a water inlet valve and sugar boiling time through the DCS. The heating steam pressure control module measures steam pressure of the sugar boiling pot through a pressure transmitter and uses a DCS for controlling amount of heating steam entering the sugar boiling pot. The sugar boiling pot liquid level control module measures liquid level of the syrupy of the sugar boiling pot through a liquid level transmitter and controls a feed valve and a water inlet valve of the sugar boiling pot through the DCS. The sugar boiling automatic control device achieves full-automatic sugar boiling, effectively improves reliability and economic benefit of sugar boiling control, greatly reduces consumption of water and steam, reduces faulty operation, lowers accident rate, and improves sugar output.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

Method for making dry powder of concentrated molasses alcohol fermentation liquid

ActiveCN102503593ASolve usabilitySolve shipping problemsClimate change adaptationBioloigcal waste fertilisersBranSugar industry

The invention discloses a method for making dry powder of concentrated molasses alcohol fermentation liquid and is characterized in that the method comprises the following steps of: mixing a concentrate of molasses alcohol fermentation liquid having a concentration of 50 to 60 Baume degree with rice bran, wherein the concentrate of molasses alcohol fermentation liquid accounts for 83% to 92% the weight of the mixture and the rich bran accounts for the balance; inoculating yeast 3 to 5 kg per ton of raw materials and allowing fermentation at room temperature for 24 to 36 hours; and heating to dry and grinding to obtain dry powder. The method utilizes the molasses alcohol fermentation liquid which causes serious environmental pollution in cane sugar industry, recycles the molasses alcohol fermentation liquid as complete organic liquid fertilizer for sugarcanes, makes dry powder of molasses alcohol fermentation liquid, not only eliminates inconvenience of use, transport and storage of liquid fertilizers, but also achieves the purposes of turning waste into treasures, improving soil fertility and increasing sugar yield, realizes zero discharge of pollutants and clean production, prevents environmental pollution, and promotes sustainable development of sugar industry.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Novel process for jointly degrading and saccharifying crop straw by means of thermo-chemical treatment, microbial fermentation and enzymatic hydrolysis

InactiveCN105039457APromote degradationIncrease saccharification rateFermentationXylanaseFermentation

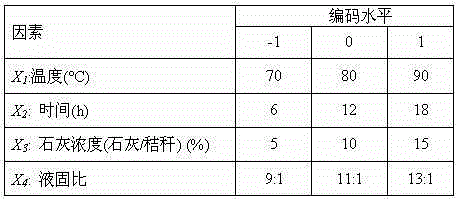

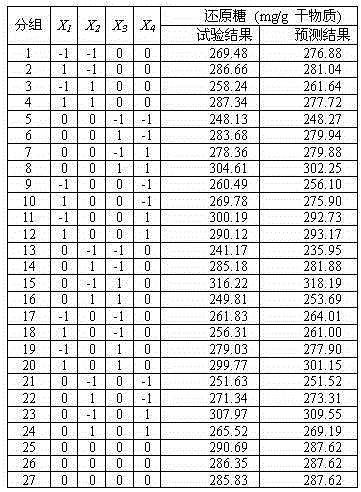

The invention relates to a novel process for jointly degrading and saccharifying crop straw by means of thermo-chemical treatment and enzymatic hydrolysis. The novel process includes steps of 1), mixing the smashed crop straw and soak liquid with each other according to a solid-to-liquid ratio of 1g:9-13ml to obtain mixtures, then carrying out heat-insulation treatment on the mixtures at the temperature of 70-90 DEG C for 6-18h, adding hydrogen peroxide into the mixtures after the heat-insulation treatment is completed, keeping the mixtures at the temperature of 50 DEG C for 6-18h, and fetching and drying the mixtures; 2), transferring the straw obtained in the step 1) into distilled water, adding straw with 20-60 FPU / g of cellulase and straw with 300-600U / g of xylanase into the straw, regulating the pH (potential of hydrogen) of the straw until the pH reaches 4-5, then carrying out enzymatic hydrolysis by the aid of shaking tables at the temperature of 45-50 DEG C for 24-48h, treating the straw at the temperature of 100 DEG C for 30min after enzymatic hydrolysis is completed so as to terminate enzymatic hydrolysis reaction and drying and smashing enzymatic hydrolysis products. The volume of the hydrogen peroxide is 3% of that of the soak liquid. The soak liquid is a lime supernatant with sodium hydroxide, the sodium hydroxide accounts for 2% of the weight of the crop straw, and lime accounts for 5-15% of the weight of the crop straw. The novel process has the advantage that the degradation rate of the straw and the reduced sugar yield (442.85mg / g) of the straw can be obviously increased.

Owner:河南德邻生物制品有限公司 +1

Process for producing high-safety white granulated sugar

InactiveCN103468832AReduce consumptionReduce power consumptionSugar juice boiling/evaporationSugar juice purificationUltrafiltrationPhosphoric acid

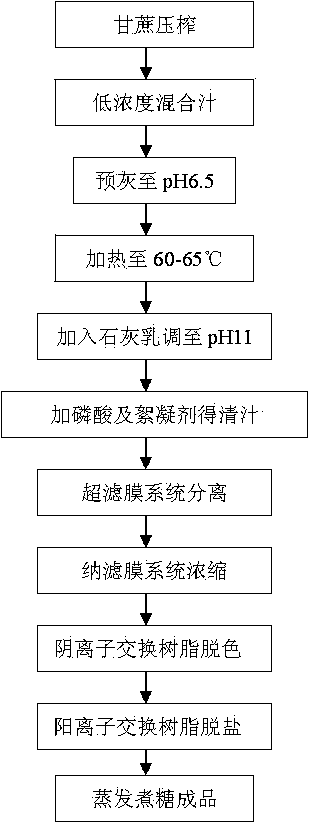

The invention relates to a process for producing high-safety white granulated sugar. The process comprises the following steps of squeezing sugarcane to obtain a mixed juice, pre-liming the mixed juice until the pH value is 6.5, carrying out once heating on the mixed juice until the temperature is 60-65 DEG C, adding lime milk until the pH value is 11, adding phosphoric acid and a polyacrylamide flocculating agent so as to obtain a clear juice, carrying out separation by utilizing an ultrafiltration membrane system, carrying out concentration by using a nanofiltration membrane system, carrying out decoloration by utilizing anion exchange resin, carrying out desalination by utilizing cation exchange resin, and evaporating to obtain a finished product. According to the process, a low-temperature strong-base process is combined with membrane separation, membrane concentration and ion exchange techniques so as to produce sulfur-free organic sugar, so that the problems of existence of sulfur in the product, complex process procedure, low production efficiency, sugar yield and clear juice clarity, serious environmental pollution, low economic benefit and the like in the prior art are solved.

Owner:云南省轻工业科学研究院有限公司

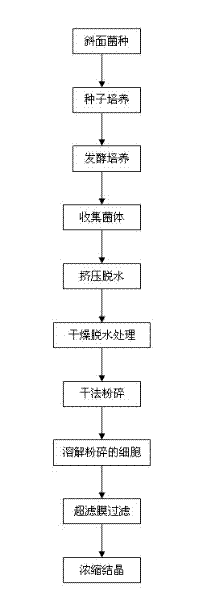

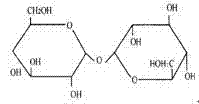

Method for preparing trehalose

The invention belongs to the fields of fermentation and production of microorganisms, and in particular relates to a method for improving the yield of trehalose in a yeast strain by a dry dehydration method. A method for preparing the trehalose comprises the following steps of: fermenting the yeast strain at the temperature of between 30 and 35 DEG C, performing enlargement culture, collecting thalli, performing extrusion dehydration, and performing forced air drying on the dehydrated thalli at the temperature of between 30 and 95 DEG C until the water content of the thalli is 5 to 25 percent; performing ultramicro crushing on the dried thalli to obtain wall breaking thalli powder; and dissolving the thalli powder in water, uniformly mixing, performing ultrafiltration by using an ultrafiltration membrane, and collecting filtration liquor to obtain a solution in which the trehalose is dissolved. By the method, the water content of the yeast thalli is gradually reduced through forced air drying, the yeast thalli is stimulated to synthesize the trehalose in large quantities under a dry environment, the accumulation amount of the trehalose in the yeast thalli is improved, and the content of the trehalose in a yeast cell can be improved by 85 percent.

Owner:SHANDONG TIANLI PHARMA

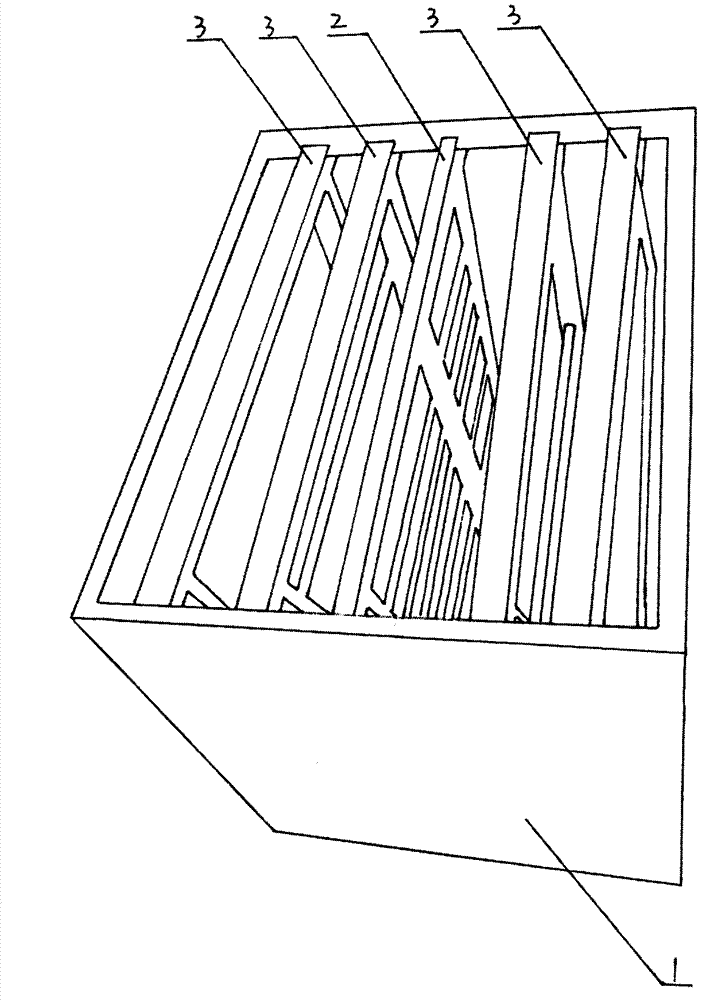

Method for quickly breeding bees

A method for quickly breeding bees specifically comprises the steps that a four-frame-beehive is prepared, the frame beehive is composed of a hive body, a partition plate and frames, wherein the hive body is divided into a left grid and a right grid by the partition plate, the number of the frames is four, the left grid and the right grid of the beehive body are each provided with two frames, and one queen bee is bred in each frame. Through the implementation of the method, four queen bees can be bred in the same beehive simultaneously, the queen bees are increased, and the breeding speed is more than two times higher than that of a traditional method. Meanwhile, swarming of bees in the beehive can not happen easily, the bees can not fly to escape easily, collected honey is more after bee swarms are united, and the sugar yield is more than twice higher than the traditional sugar yield. In addition, though the method is simple and practical, the effect is very obvious, application and popularization are very easy, and the generated economic benefits and social benefits are both very obvious.

Owner:黄秀英

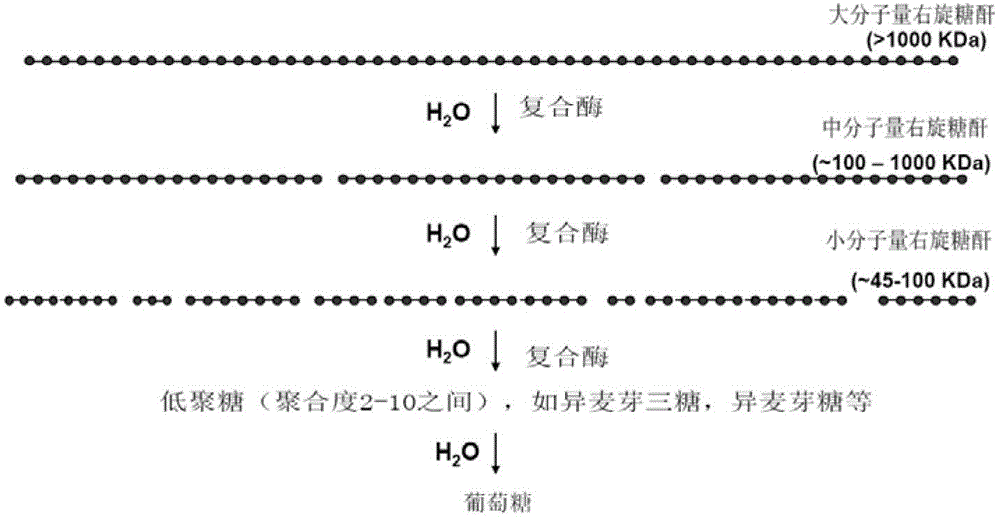

Compound enzymatic clarifying agent for sugar industry and preparation method and application for compound enzymatic clarifying agent

ActiveCN102911924AEasy to joinWithout changing the sugar production processEnzymesSugar juice purificationPectinaseAmylase

The invention discloses a compound enzymatic clarifying agent for the sugar industry and a preparation method and application for the compound enzymatic clarifying agent. The compound enzymatic clarifying agent comprises, by weight, from 35% to 60% of alpha-glucanase, from 20% to 30% of pectinase, from 10% to 35% of amylases, from 5% to 10% of cellulase and from 0% to 15% of water. The preparation method includes proportionally mixing the alpha-glucanase, the pectinase, the amylases and the cellulase which are raw materials to obtain a mixture; and filtering the mixture via a fine filter membrane to obtain the compound enzymatic clarifying agent. The compound enzymatic clarifying agent is added during a working section for extracting juice from sugar crops, the feeding quantity of compound enzymatic clarifying agents added into 1kg of the sugar juice ranges from 10mg to 30mg, the sugar juice clarifying efficiency can be effectively improved, the viscosity of sugar liquor is reduced, the filtering speed and the settling speed are increased, the quality of sugar products is improved, the sugar yield is increased, an original sugar production process is unchanged, and operation is simple and feasible.

Owner:SOUTH CHINA UNIV OF TECH

Artificial nutrient medium for Phellinus linteus fluid culture and method for fermentation of Phellinus linteus polysaccharide

InactiveCN101348803APromote growthIncrease productionMicroorganism based processesFermentationPhellinus igniariusTryptophan

The invention provides a synthetic medium for culturing a phellinus igniarius liquid. The synthetic medium takes glucose as a carbon source and 20 kinds of amino acid as a nitrogen source, and consists of inorganic salt and vitamin. The ratio of carbon to nitrogen is designed as 50 to 1; and the specific concentration g / l is as follows: the glucose: 30 to 80 grams; glutamic acid: 0.1 to 1.5 grams; glutamine: 0.1 to 1.5 grams; aspartic acid: 0.1 to 1.5 grams; asparagines: 0.1 to 1.5 grams; glutamic acid: 0.01 to 0.1 gram; tryptophan: 0.01 to 0.1 gram; valine: 0.01 to 0.1 gram; alanine: 0.01 to 0.1 gram; etc. During the whole culture process of the synthetic medium, phellinus igniarius mycelium is quick in growth; the yield of the phellinus igniarius mycelium can reach 20 grams per liter to the highest degree; simultaneously no agricultural and sideline product is introduced as the carbon source and the nitrogen source; substances such as proteins in the medium, medium compositions and so on are not carried; phellinus igniarius exopolysaccharide produced through fermentation has high purity and stable quality; and the yield of phellinus igniarius polysaccharide can reach 0.198 gram per liter to the highest degree. The synthetic medium has the advantages of clear compositions, stable quality and so on, and can be used for mass culture of the phellinus igniarius liquid and research of the regulation and control rule of polysaccharide anabolism.

Owner:SOUTHWEST UNIVERSITY

Method for mixed biomass hydrolysis

Methods and systems are disclosed for the hydrolysis of mixed biomass. The methods include forming a mixture of at least two modified biomass feedstocks to achieve various benefits, such as maximizing sugar yields and minimizing the formation of degradation products.

Owner:RENMATIX INC

Agent for improving sugarcane brix and method of promoting sugarcane ripening using the same

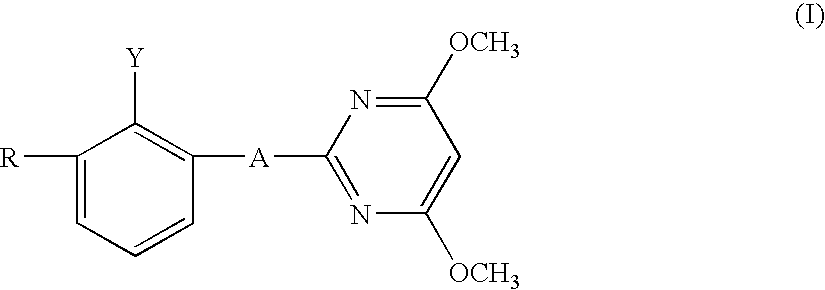

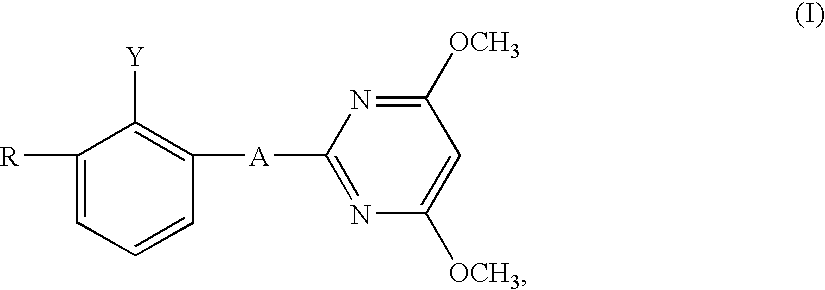

It is intended to provide an agent for improving sugarcane Brix which increases the sugar productivity from pressed juice after harvesting and promotes ripening when applied to sugarcane and, therefore, by which a sugar yield comparable to sugarcane harvested at the best harvest season can be established even from sugarcane before reaching the harvest season, which comprises at least one member of the compounds represented by the following general formula (I)wherein A represents an oxygen atom, a sulfur atom, or a hydroxymethylene group; Y represents a carboxyl group, an alkyloxycarbonyl group, a halogenated methylsulfonylamino group or a diphenylmethylideneiminoxycarbonyl group, either in a free form or forming a salt; and R represents a halogen atom, an alkyl group, a hydroxy-, alkoxy- or alkoxyiminoalkyl group or a 4,6-dimethoxypyrimidin-2-yloxy group, or Y and R may be bonded together to form a group —C(═O)—O—CH(CH3)—.

Owner:KUMIAI CHEM IND CO LTD

Special medium-concentration slow release fertilizer for sugarcanes

InactiveCN102718602AImprove germination rateImprove tillering rateFertilizer mixturesPotassiumNitrogen

The invention relates to a special medium-concentration slow release fertilizer for sugarcanes. The slow release fertilizer contains nitrogen, phosphorus and potassium according to the ratio that nitrogen: phosphorus: potassium equals 20: 10: 5. The special medium-concentration slow release fertilizer disclosed by the invention can effectively improve the emergence rate, tillering rate and plant height of the sugarcanes and significantly improve the agricultural yield and sugar yield of the sugarcanes; tests prove that the yield per unit of the sugarcanes and the sugar yield of the sugarcanes are improved; and the quality of the sugarcanes is obviously improved, and the special medium-concentration slow release fertilizer is more suitable for being applied to soil with medium-concentration fertilizers in sugarcane areas in tropical and sub-tropical regions in southern China.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI +1

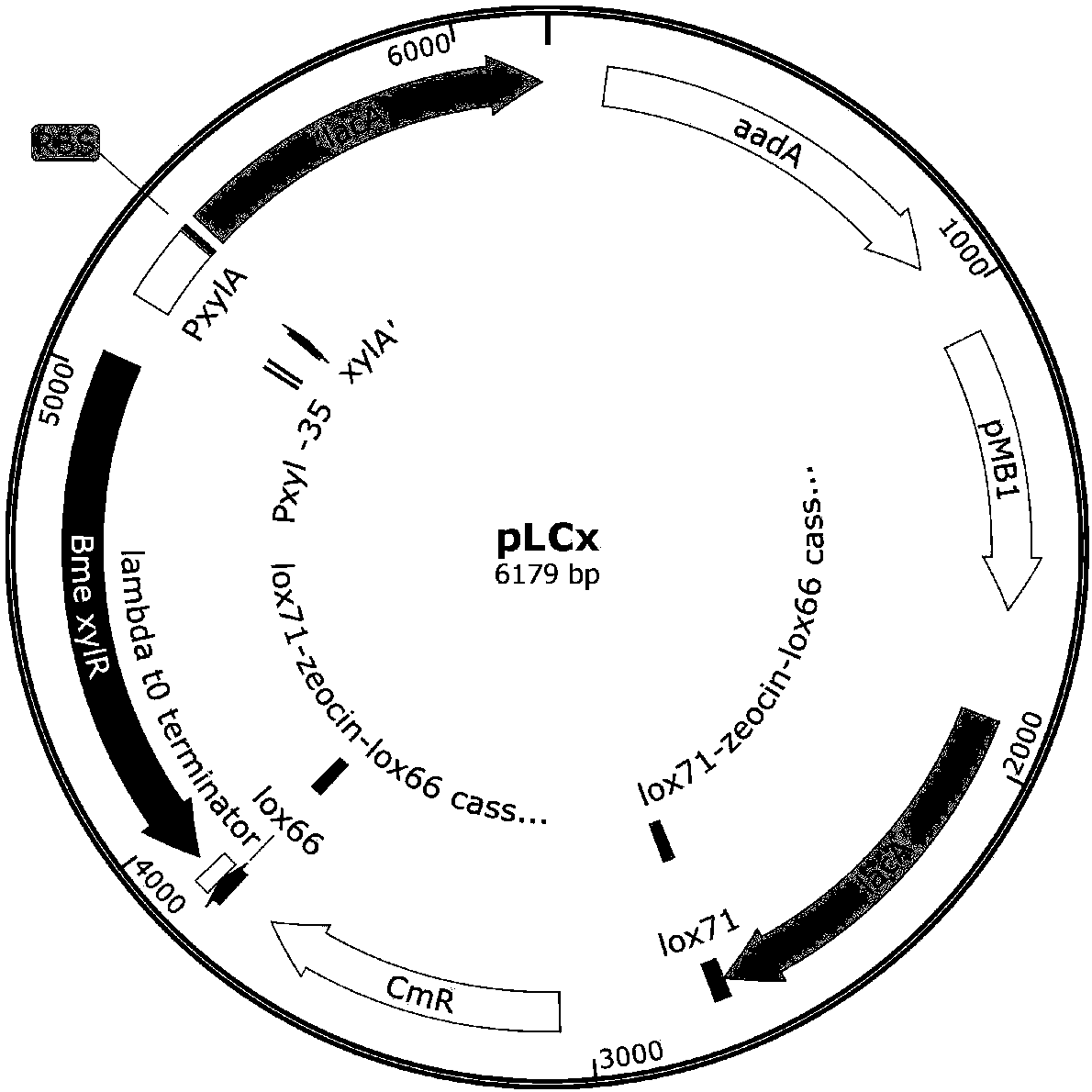

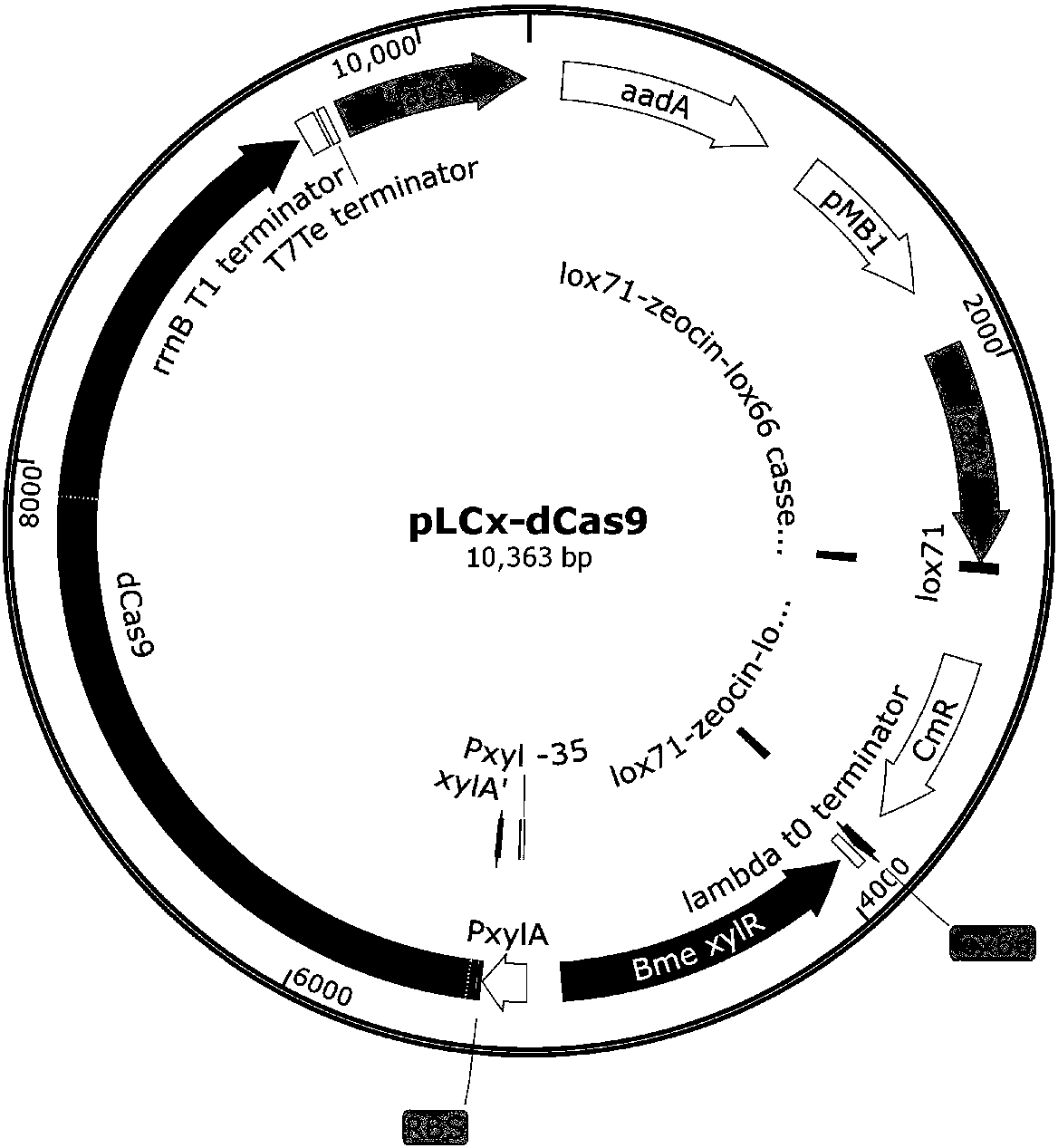

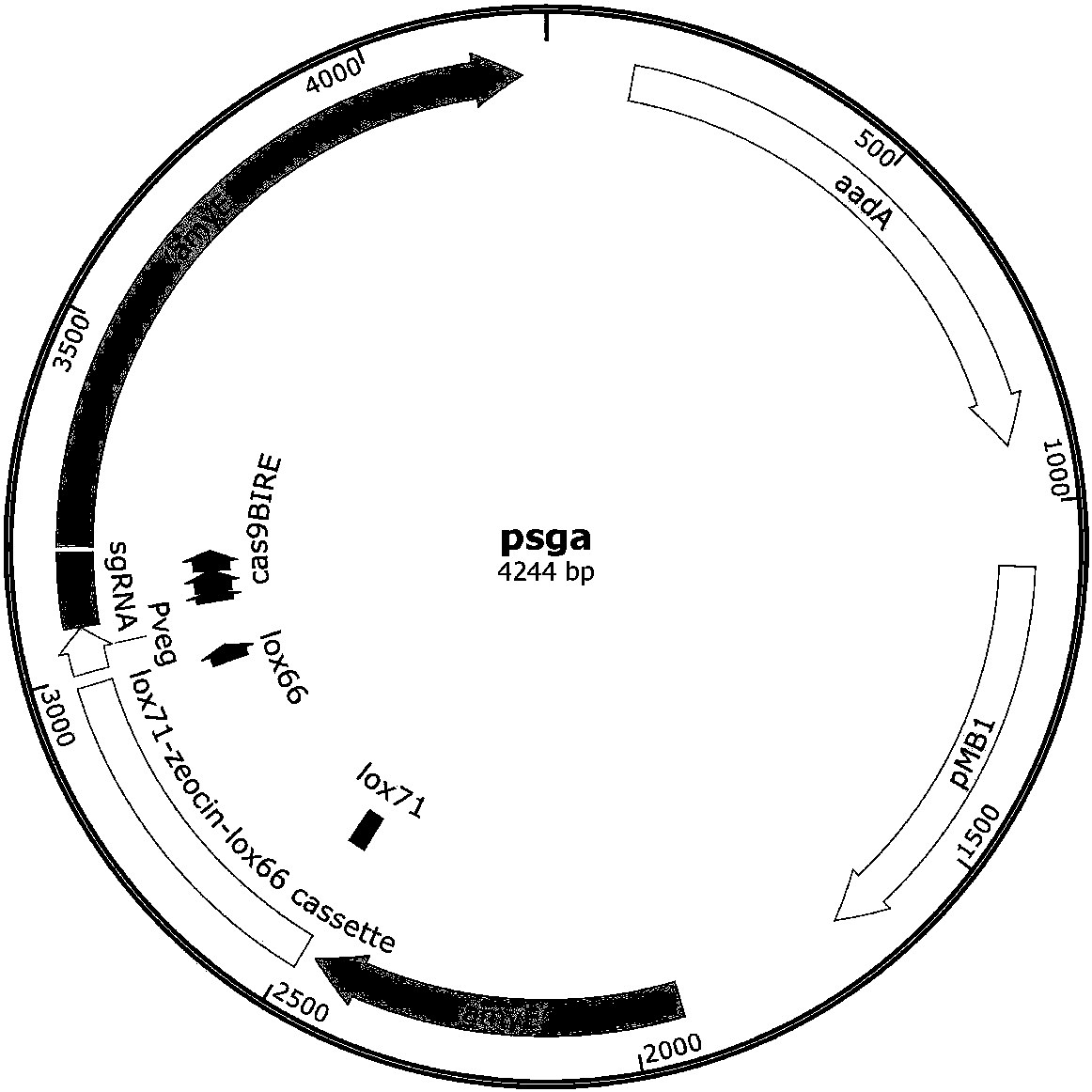

Method for producing N-acetylglucosamine by jointly using glucose and xylose based on CRISPRi

The invention discloses a method for producing N-acetylglucosamine by jointly using glucose and xylose based on CRISPRi and belongs to the field of genetic engineering. Through the method, bacillus subtilis BSGNY-Pveg-g1mS-P[43]-GNA1 is used as a starting strain; dCas9 induced by xylose and three sgRNA expression fragments which respectively act on three genes including zwf, pfkA and g1mM are integrated on a genome; the strain is used for carrying out flask shaking fermentation; the yield of N-acetylglucosamine reaches up to 20.5g / L; and the yield of N-acetylglucosaminein per gram of glucose is 0.612g / g; meanwhile, the recombinant bacillus subtilis is capable of efficiently and jointly using glucose and xylose; the method lays the foundation for production of glucosamine through the modified bacillus subtilis in further metabolic engineering and the industrialization thereof.

Owner:JIANGNAN UNIV

Liquor cleaning process for refining sugar from corns

The invention provides a liquor cleaning process for refining sugar from corns, which sequentially comprises steps as follows: (1) mixing: preparing corn powder and then mixing the corn powder to 19-21 baume degrees, (2) pre-liquefying: adding starch containing 0.07-0.08KNU / g amylase in dry basis and having thermal resistance not lower than 100 DEG C, and controlling temperate within 90-100 DEG C, pH value within 5-7, stirring velocity within 35-70rpm for 20-50min, (3), jet liquefying: controlling jetting temperature within 105-108 DEG C and keeping jetting for 4-5min, (4) saccharifying: keeping temperature within 94-100 DEG C, regulating pH to 3.5-5.5 after liquor becomes brownish red through iodine test, cooling the liquor to a temperature within 59-61 DEG C and then adding starch containing 0.5-0.6AGU / g complex diastatic enzyme in dry basis, and retaining the liquor for 22-25h. By utilizing the liquor cleaning process for refining sugar from corns, liquor cleaning can be thorough, thereby greatly increasing sugar yield and being favorable for filtering sugar liquor after being liquefied.

Owner:河南金丹乳酸科技股份有限公司

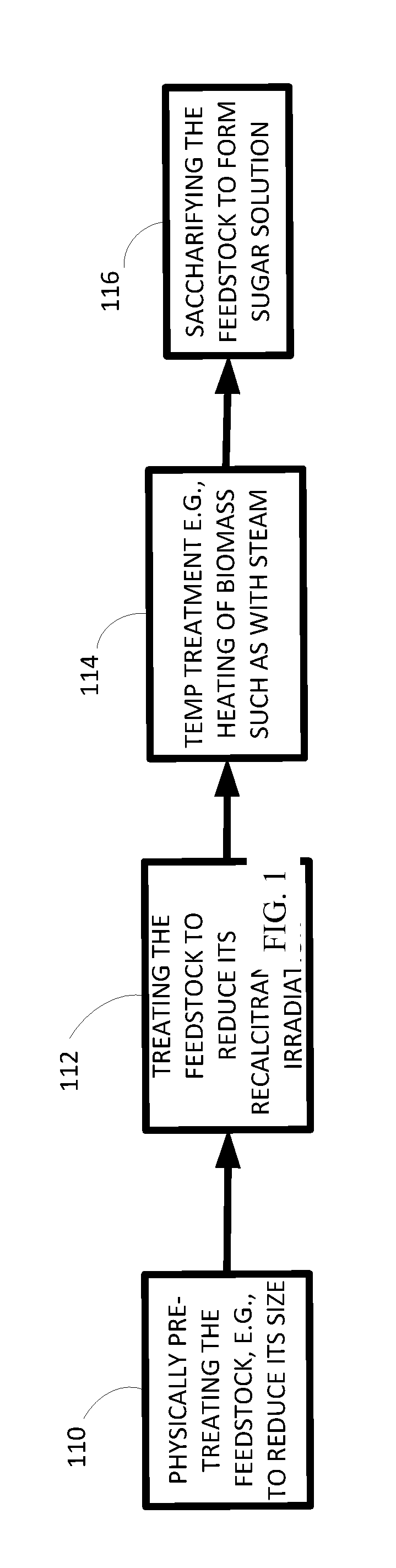

Processing biomass

InactiveUS20160017444A1Increase sugar productionImprove production yieldBiofuelsXylose productionSugar yieldBiomass

Owner:XYLECO INC

Method for improving cellulase hydrolysis sugar field

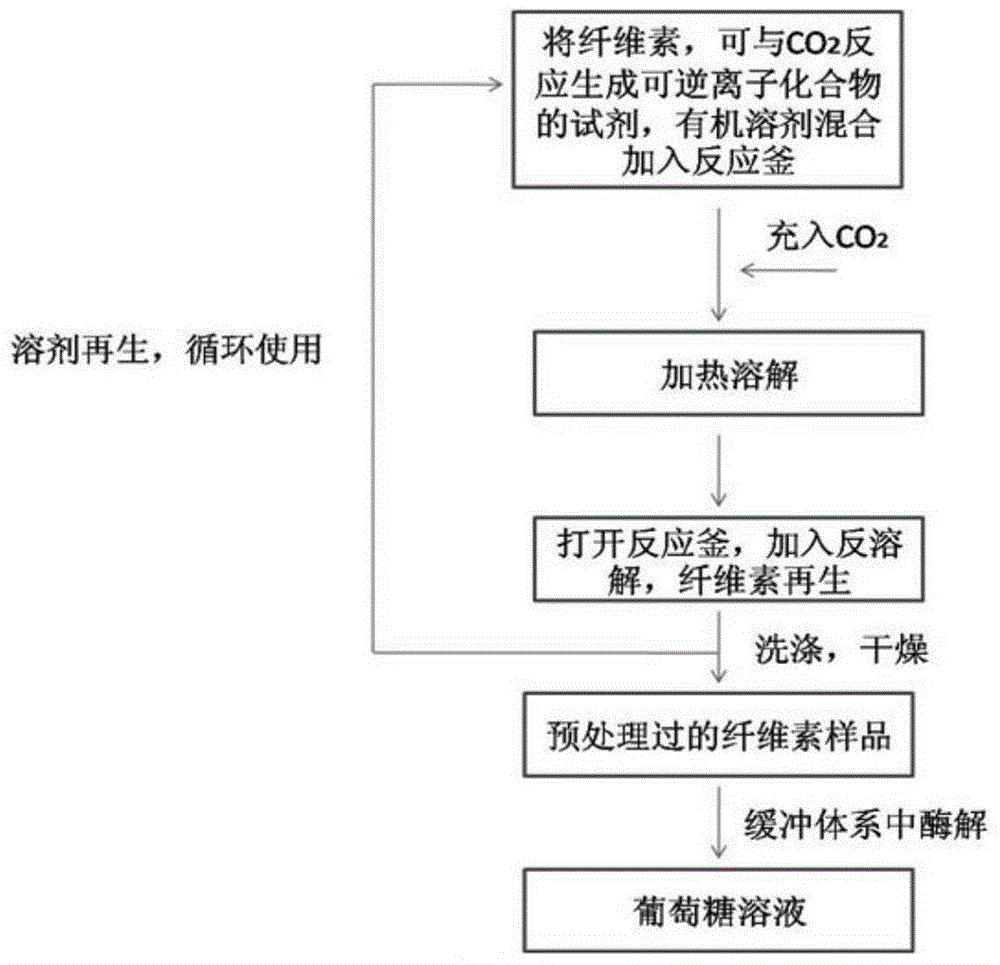

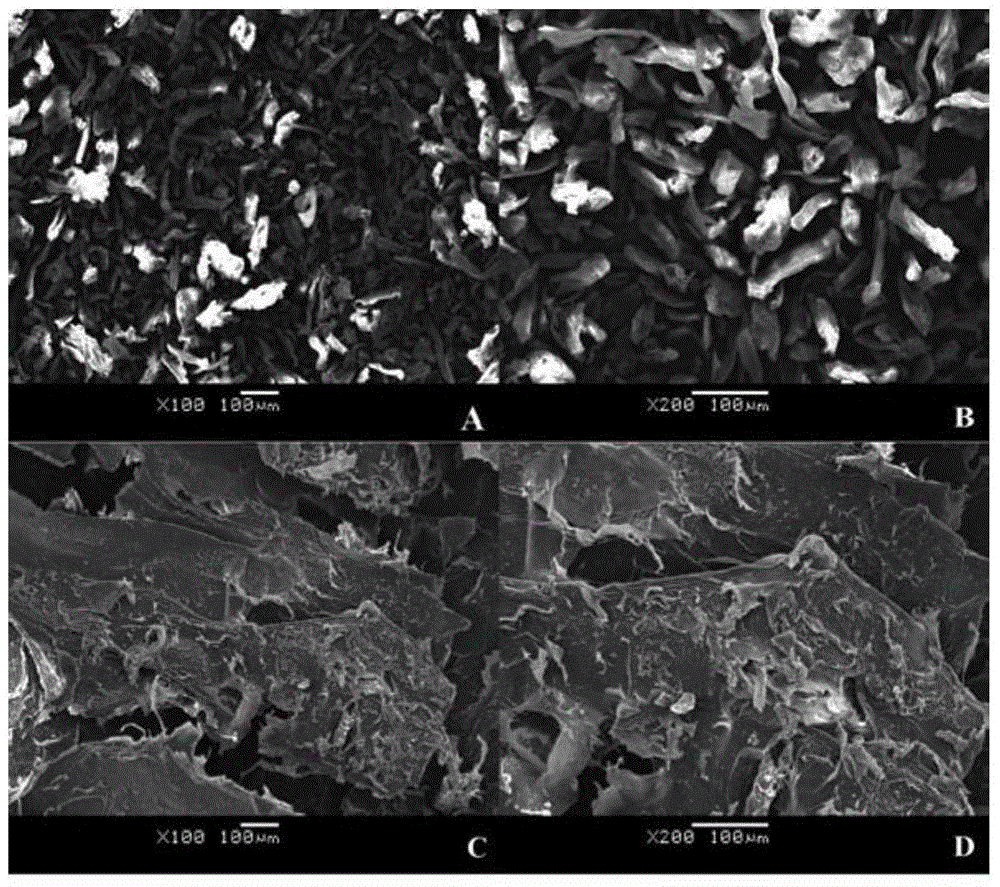

The invention provides a method for improving cellulase hydrolysis sugar field. The method comprises the following steps: (1) taking cellulose as a raw material; (2) dissolving the cellulose in a CO2 switch-type ionic compound or a mixed solvent consisting of the CO2 switch-type ionic compound and an organic solvent, thereby obtaining a cellulose-containing solution; (3) adding an anti-solvent into the cellulose solution, regenerating, filtering and separating the dissolved cellulose, thereby obtaining the pretreated cellulose material; and (4) taking a certain amount of regenerated cellulose, adding a buffer solution and cellulase for performing enzymolysis, thereby obtaining the glucose solution. The CO2 switch-type ionic compound or the mixed solvent consisting of the CO2 switch-type ionic compound and the organic solvent serves as a solvent, the cellulose is subjected to dissolving pretreatment, and the method has the advantages that the process is simple, the solvent cost is low, the operation is convenient, the solvent can be recycled, the cellulase hydrolysis speed is high, the sugar yield is high and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

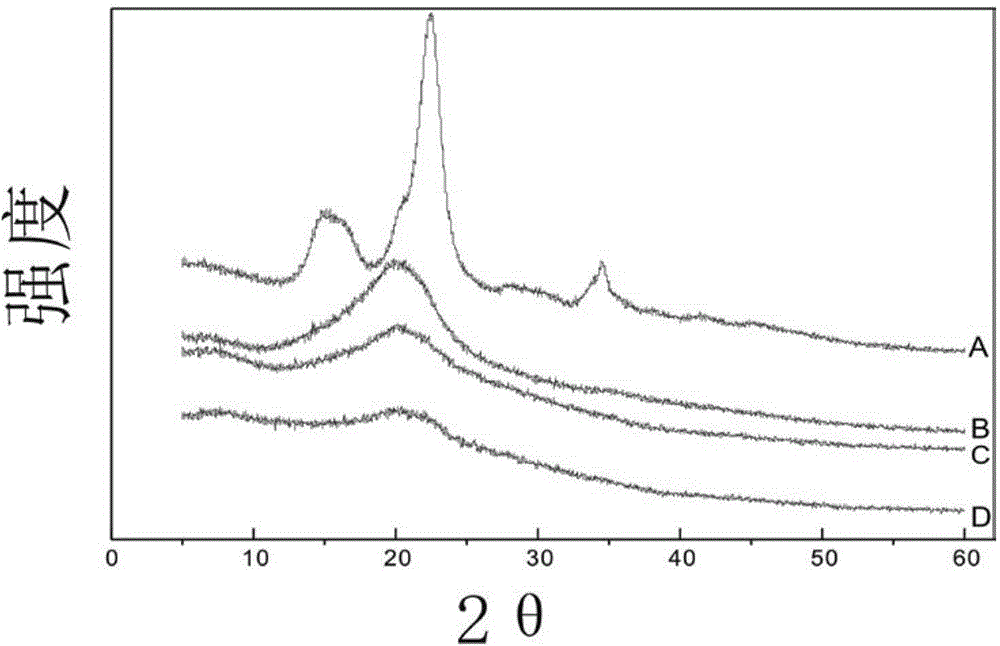

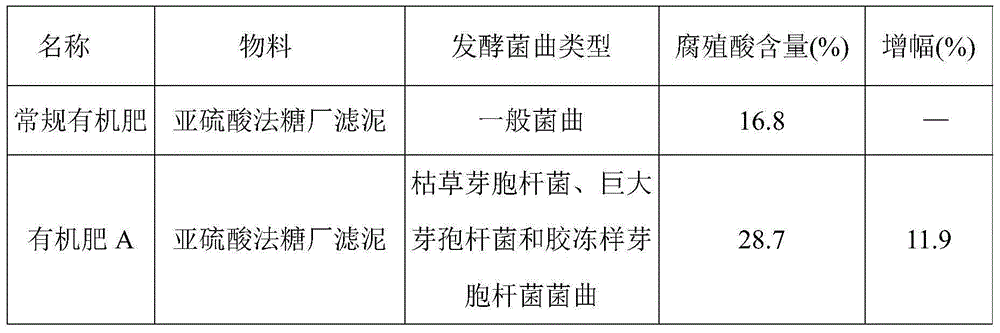

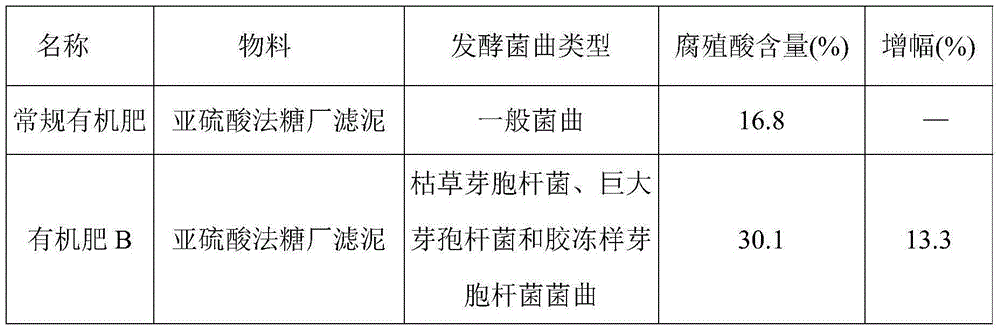

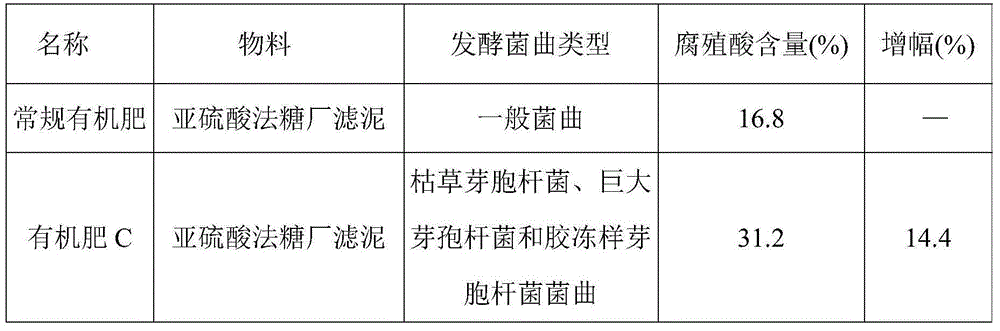

Organic fertilizer with high humic acid content and preparation method thereof

ActiveCN105084948AHigh humic acid conversion rateHigh in humic acidBio-organic fraction processingClimate change adaptationFiltrationMicrobial agent

The invention provides an organic fertilizer with high humic acid content and a preparation method thereof. The preparation method of the organic fertilizer with high humic acid content includes the following steps: preparing fermentative bacteria, wherein the fermentative bacteria include bacillus subtilis, bacillus megaterium and bacillus mucilaginosus; making the fermentative bacteria into fermentation microbial agent; filtering mud in a sugarhouse through a sulfurous method, and mixing with the fermentation microbial agent for fermentation to obtain the organic fertilizer with high humic acid content. Compared with the conventional organic fertilizer, the organic fertilizer obtained through the technical scheme provided by the invention is higher in humic acid conversion rate and humic acid content; the sulfurous method is fully utilized to filter mud in the sugarhouse, and resource utilization is realized in the cane sugar industry, and the problem of environment pollution troubling the sugarhouse, caused by the mud filtration with the sulfurous method in the sugarhouse is solved; wastes are turned to treasures, soil productivity is increased, the sugar yield is increased, cleaner production is realized, the environment is protected, and the sustainable development of the sugar industry is promoted.

Owner:东莞市益田生物科技有限公司

Method for mixed biomass hydrolysis

Methods and systems are disclosed for the hydrolysis of mixed biomass. The methods include forming a mixture of at least two modified biomass feedstocks to achieve various benefits, such as maximizing sugar yields and minimizing the formation of degradation products.

Owner:RENMATIX INC

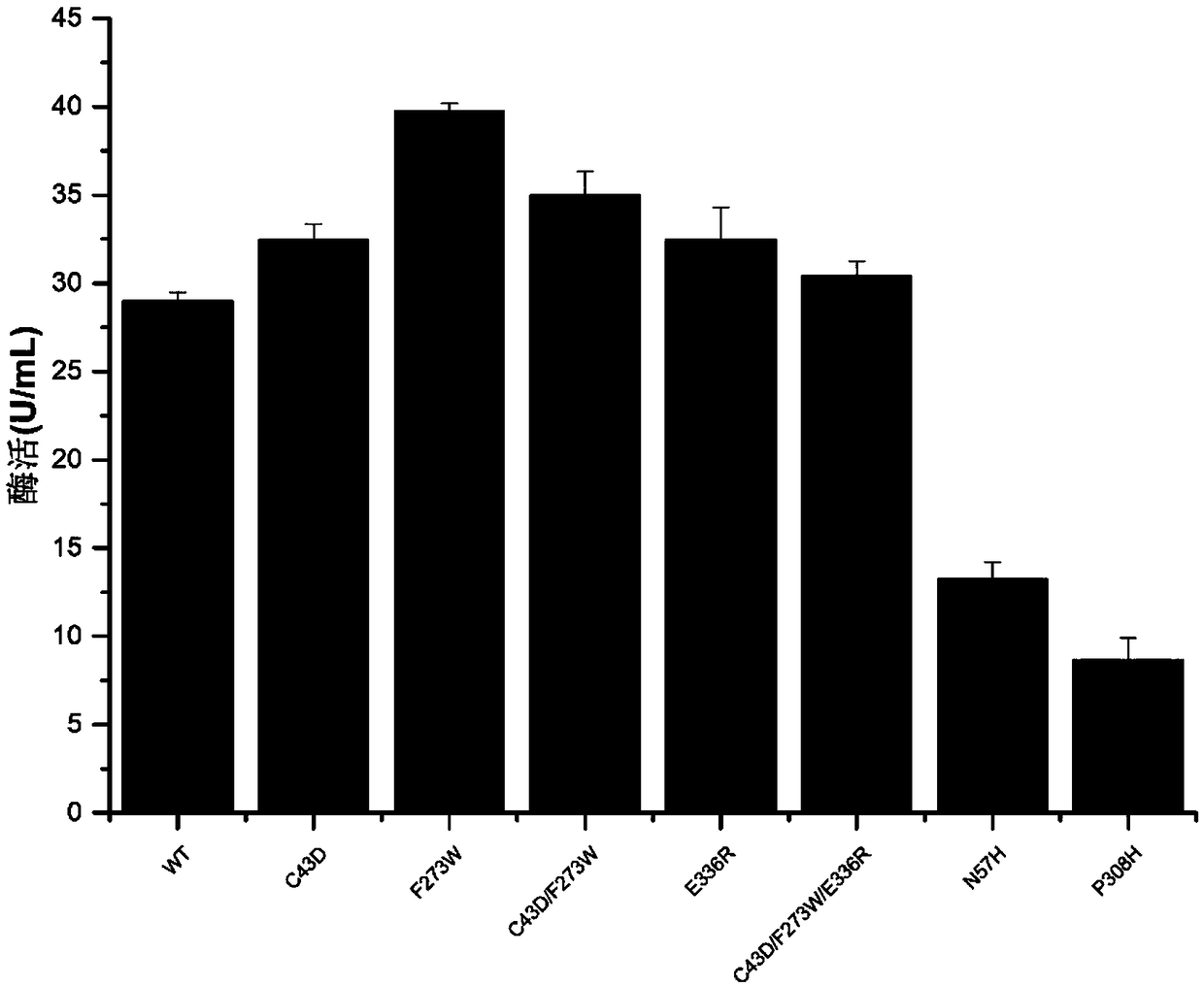

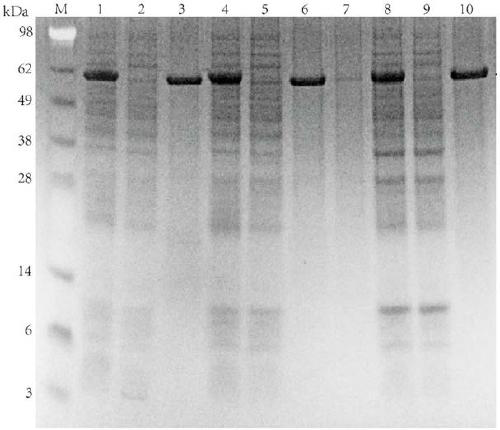

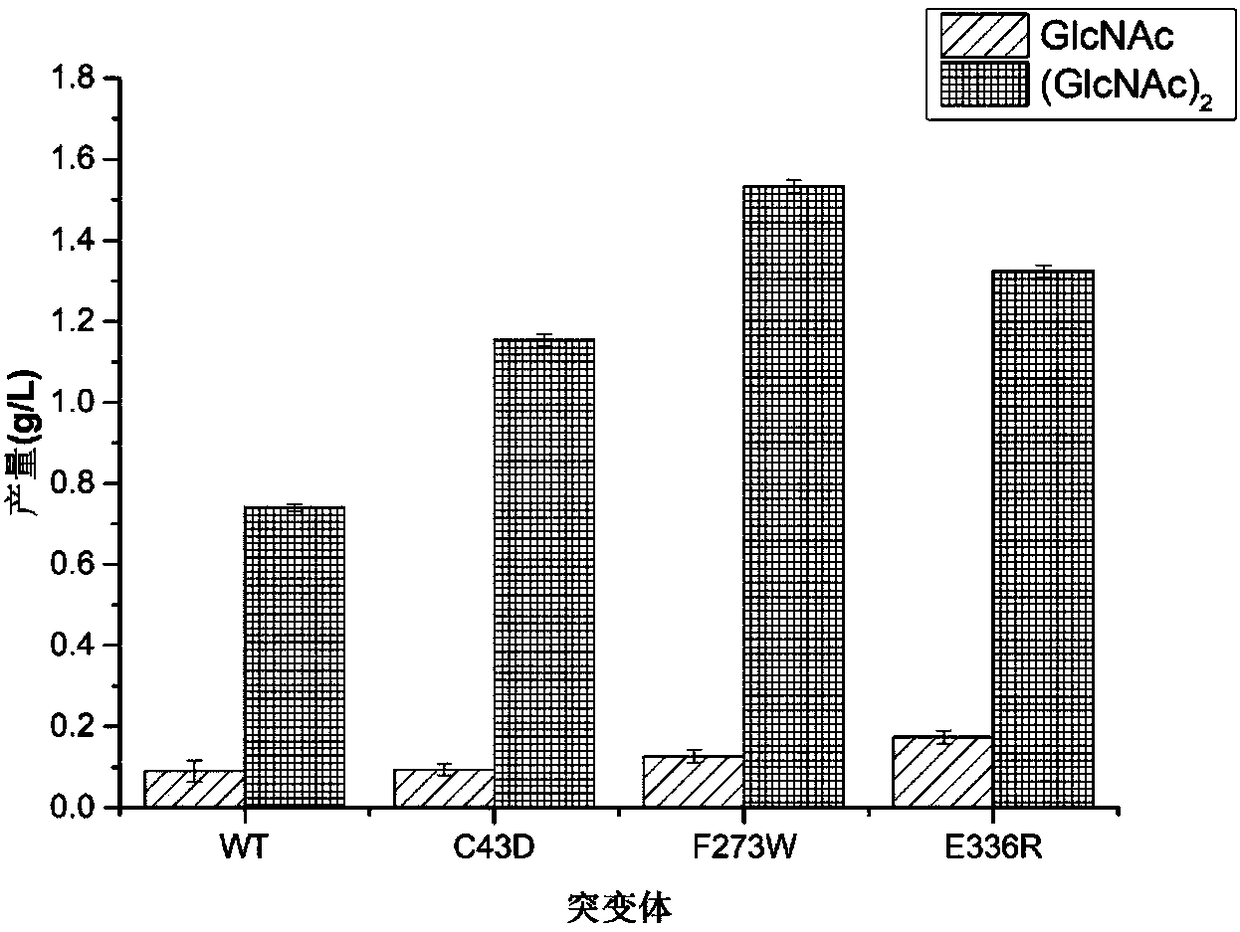

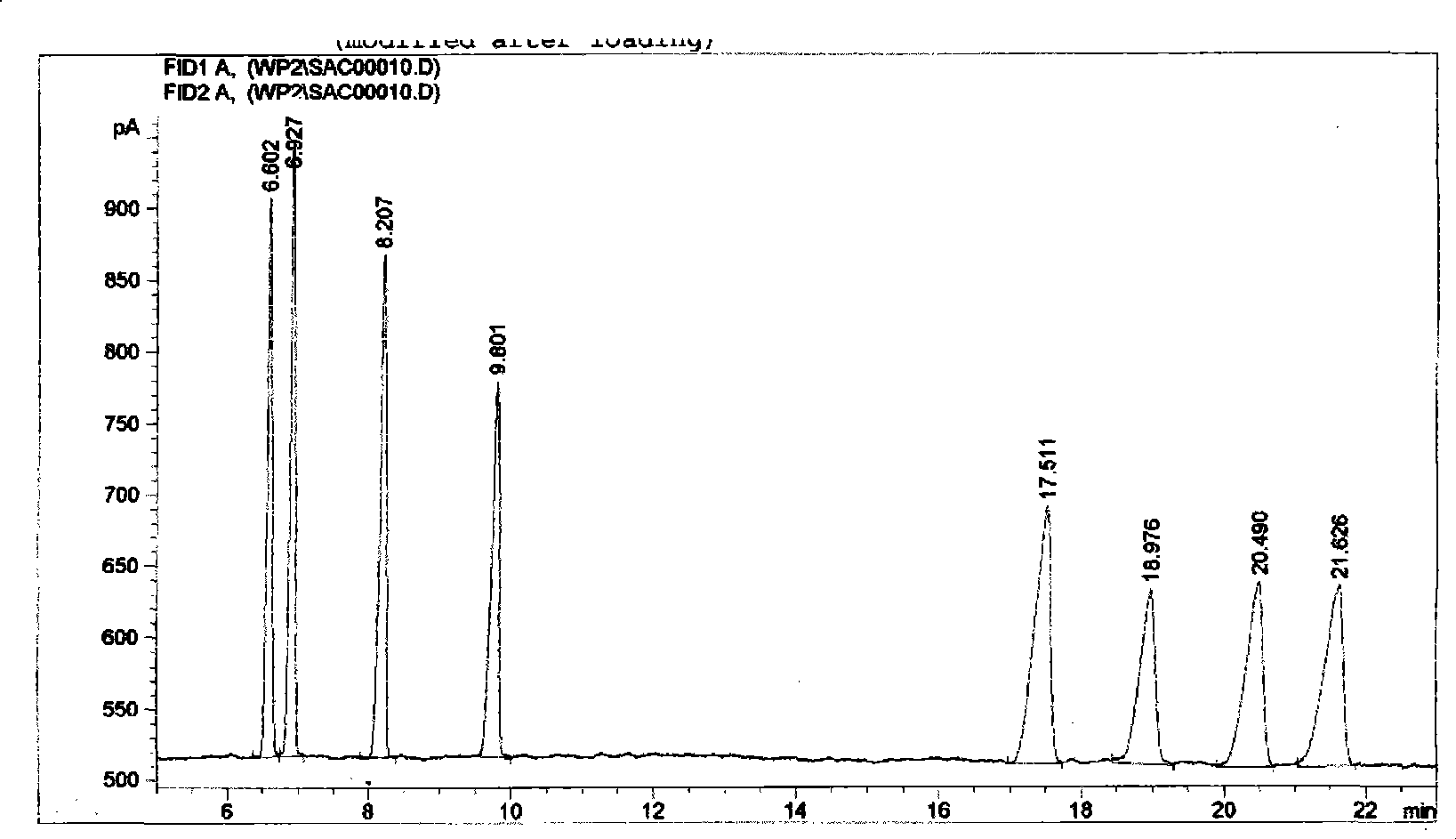

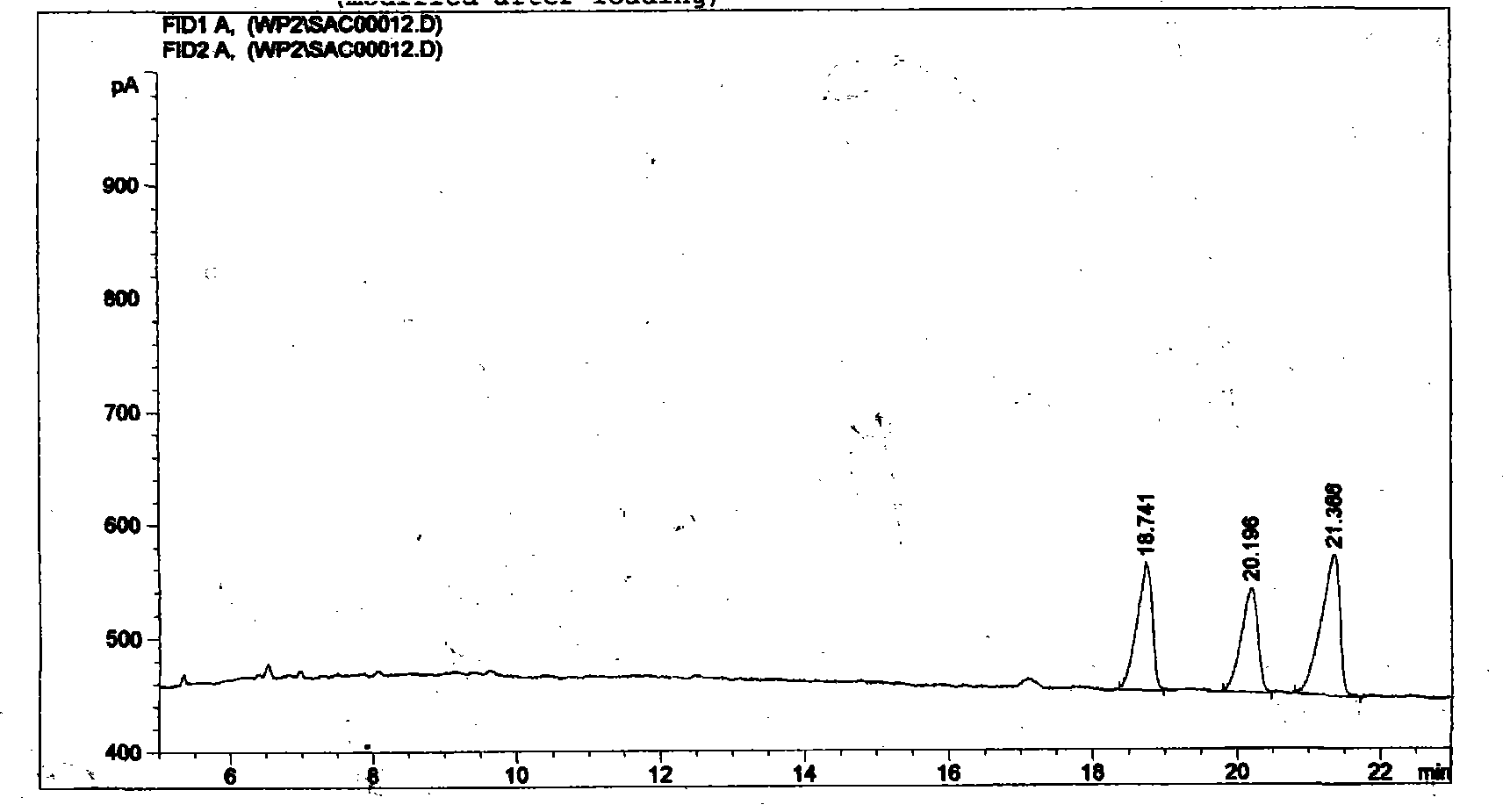

Chitin enzyme mutant capable of improving enzyme activity

ActiveCN109486794AIncrease enzyme activityHigh catalytic efficiencyBacteriaMicroorganism based processesArginineTryptophan

The invention discloses a chitin enzyme mutant capable of improving enzyme activity and belongs to the technical field of genetic engineering and enzyme engineering. By virtue of a site-specific mutagenesis manner, the cysteine at the site 43 nearby a chitin enzyme molecular catalysis structural domain is mutated into aspartic acid, the phenylalanine at the site 273 is mutated into tryptophan, andthe glutamic acid at the site 336 is mutated into arginine, so that the enzyme activity of the chitin enzyme expressed by the strain is obviously improved. Compared with an original strain, single mutant strains F274W and E336R have the advantages that the enzyme activity is respectively improved by 1.37 times and 1.22 times. The enzyme production ability and catalytic efficiency of the modifiedstrain are improved, and after HPLC (High Performance Liquid Chromatography) detection and purification, the content of chitin oligose in the mutant discovers that the sugar yield of the mutant F273wis 1.65g / L when catalyzed for 3 hours, the content of GlcNAc is 0.12g / L, and the content of (GlcNAc)2 is 1.53g / L. Compared with a wild strain, the chitin enzyme mutant disclosed by the invention has the advantage that the enzyme activity is improved by 49.7%.

Owner:JIANGNAN UNIV

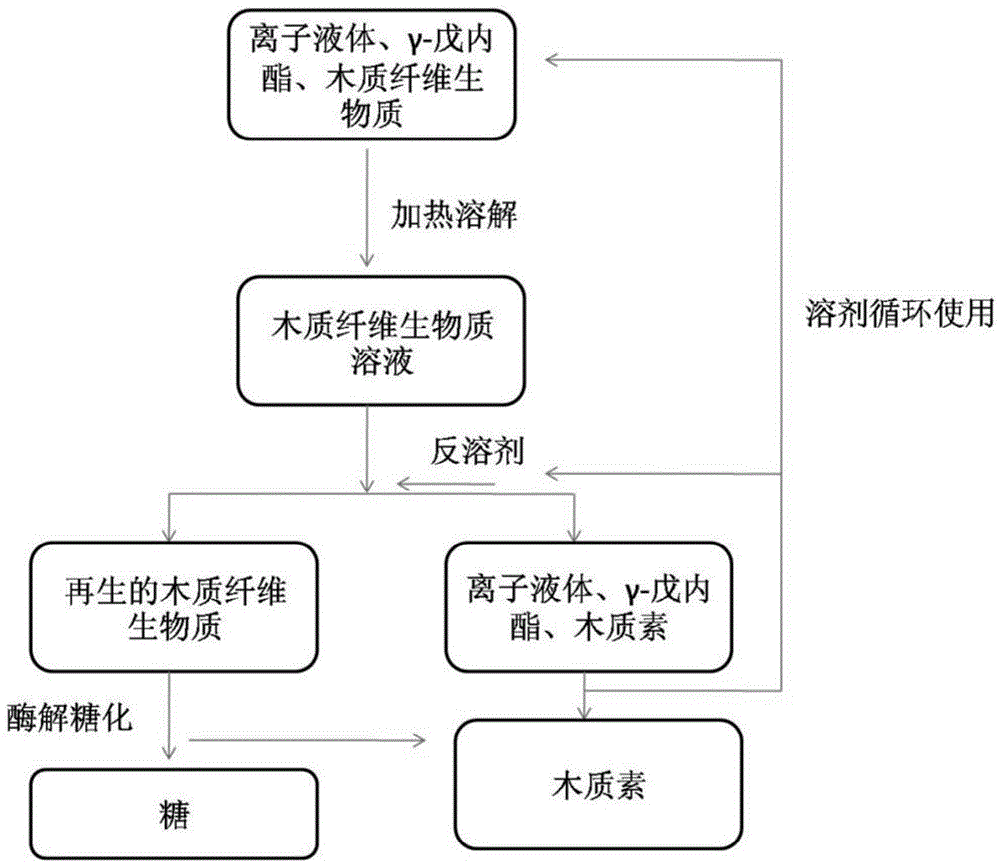

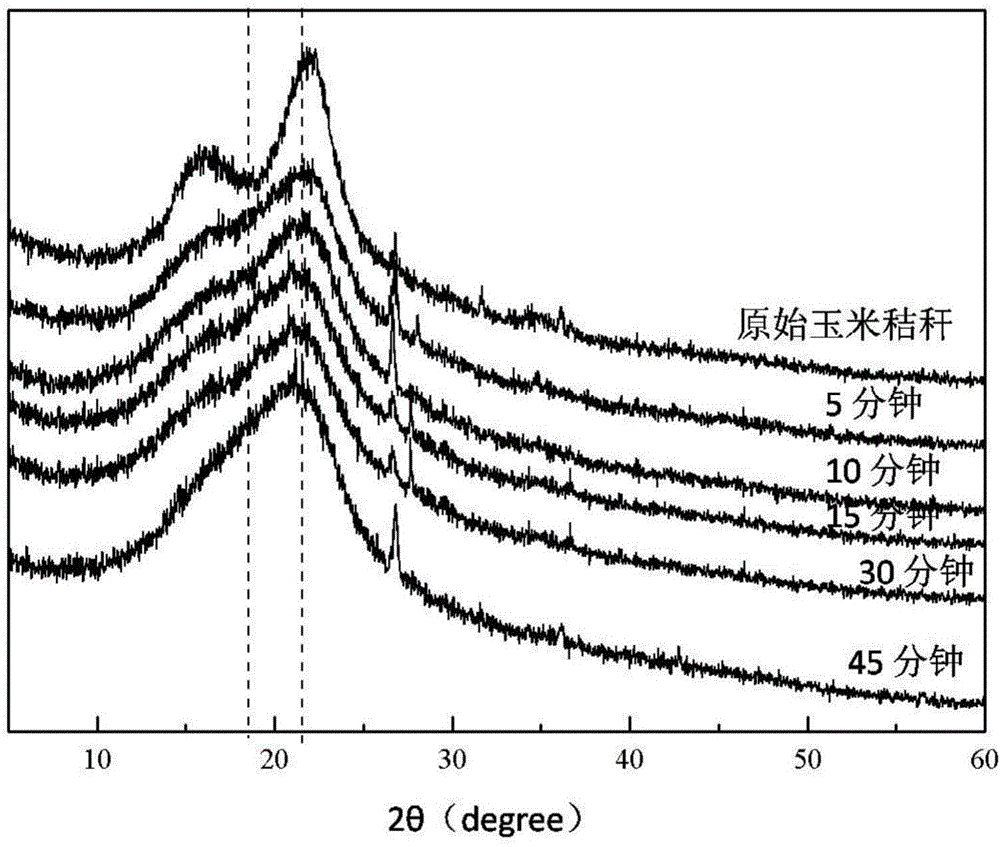

Method for pre-processing lignocellulose biomass to increase sugar field of lignocellulose biomass

The invention provides a method for dissolving and pre-processing lignocellulose biomass through a mixed solvent formed by ionic liquid and gamma-valerolactone to increase the sugar field of lignocellulose biomass. The method includes the following steps that firstly, ionic liquid, gamma-valerolactone and lignocellulose biomass are mixed to form a pre-dissolving and pre-processing system; secondly, a pre-dissolving mixture system is heated and dissolved, and a solution is formed; thirdly, an anti-solvent is added into the solution system, and the dissolved lignocellulose biomass precipitates and regenerates; fourthly, the regenerative lignocellulose biomass is taken, a buffering solution, cellulase and xylanase are added for enzymolysis, and a sugar solution is obtained. Part of the ionic liquid is replaced by biology-base gamma-valerolactone, and the mixed system is formed. The method has the advantages that the technology is simple, solvent cost is low, operation is convenient, the solvent can be recycled, and cellulose and hemicellulose in the processed lignocellulose biomass have the advantages that the enzyme hydrolysis speed is high and the sugar yield is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

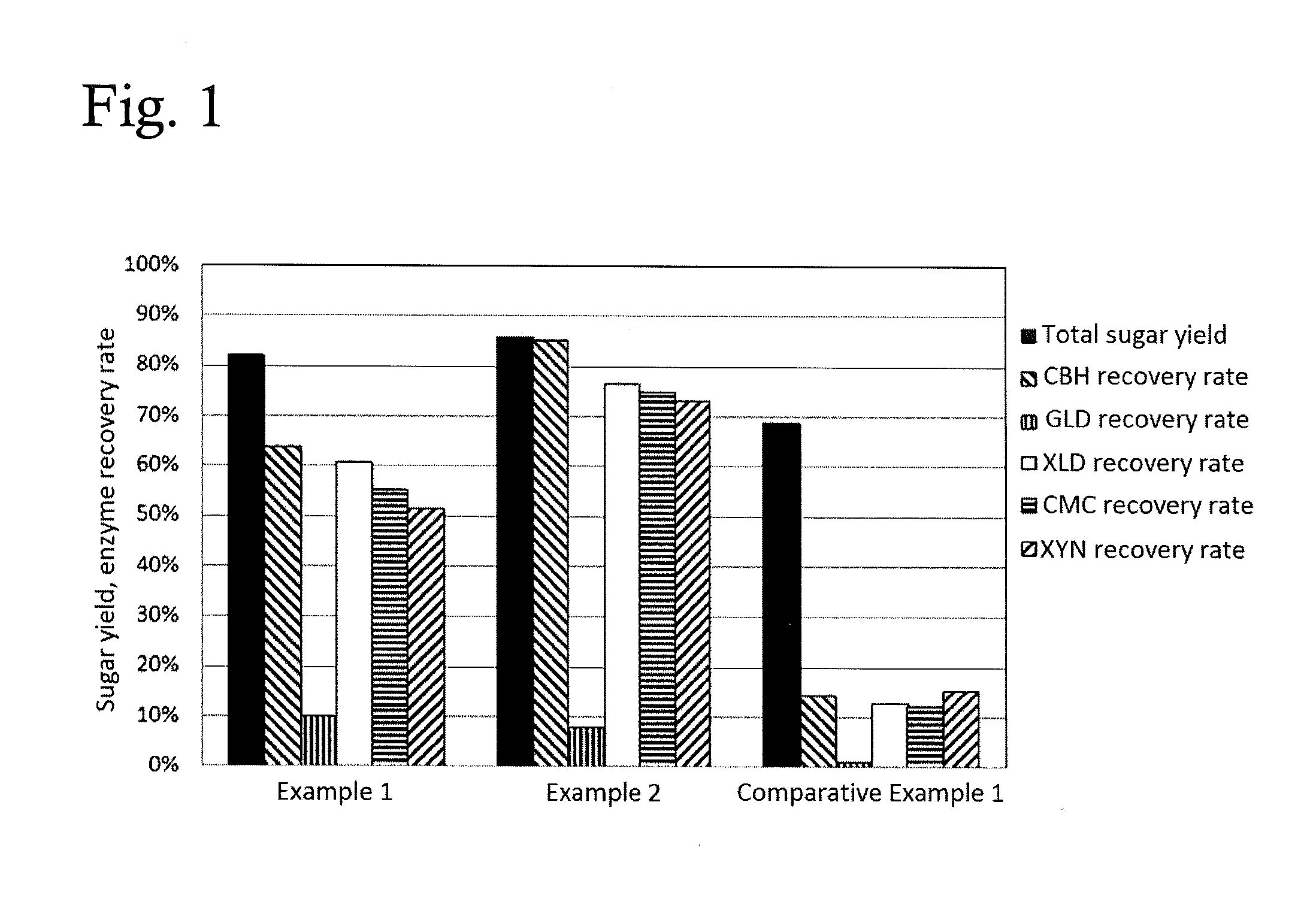

Method for saccharification of biomass

InactiveUS20150005484A1Improve fermentation effectReduce loadSugar derivativesBiofuelsCellulosePulp and paper industry

A method for saccharification of lignocellulosic biomass, the method comprising (1) a pretreatment step of impregnating lignocellulosic biomass with an aqueous alkali solution, subjecting the resultant mixture to solid-liquid separation to remove part of the aqueous alkali solution, and then performing heat treatment, and (2) a saccharification step of enzymatically degrading the lignocellulosic biomass resulting from the pretreatment step to obtain a saccharified liquid can be applied to high-lignin lignocellulosic biomass, reduce the usage of alkali and water in the pretreatment step, increase the sugar yield in the saccharification step, decrease the reaction time, reduce enzyme adsorption on a biomass residue, and improve the enzyme recovery rate.

Owner:NIPPON SHOKUBAI CO LTD

Preparing method for malt sugar

InactiveCN105695532AImprove appearance qualityIncrease sugar yieldFermentationHordeum vulgareHydrolysis

The invention provides a preparing method for malt sugar. The preparing method comprises the following steps that barley is added with water to be steeped and then sprouted; the barley is ground when growing two leaves wrapping the core, the ground barley malt is obtained, part of the ground barley malt is mixed with cooked sticky rice and subjected to primary fermentation, and the rest of the barley malt is added after primary fermentation for secondary fermentation; after secondary fermentation is finished, filtering is carried out to obtain juice, the juice is boiled out, and malt sugar is obtained. According to the preparing method, barley and sticky rice are selected for preparation, and two times of fermentation are carried out in the fermentation process when barley malt and sticky rice are mixed. By means of the two-section type fermentation method, the fermentation time is prolonged so that an amylolytic enzyme in the barley malt can fully perform the hydrolysis action, starch in sticky rice can be hydrolyzed into malt sugar as much as possible, and thus the sugar yield can be increased.

Owner:尹仲荣

Special long-acting slow release fertilizer for sugarcane

InactiveCN103214309AMeet the nutrient needs of the growth periodReduce manufacturing costFertilizer mixturesSludgeTropics

The invention discloses a special long-acting slow release fertilizer for sugarcane. The slow release fertilizer contains nitrogen, phosphorus and potassium according to a ratio of 20:12:5. The slow release fertilizer comprises the following raw materials by mass ratio: 96-190 of ammonium dihydrogen phosphate containing 49% of P2O5 and 9% of N, 149-405 of a calcium magnesium phosphate fertilizer containing 18% of P2O5, 398-416 of urea containing 46% of N, 83 of potassium chloride containing 60% of K2O and 0-180 of a packing material. The packing material is a mixture of clay and dry lime sludge in a mass ratio of (3-7):(7-3); and the water content of the dry lime sludge is controlled to be 5%-10%. By utilizing the fertilizer, the emergence rate, tillering rate and plant height of the sugarcane can be effectively increased, the agricultural yield and sugar yield of the sugarcane are obviously improved, and tests prove that the yield per unit and the sugar yield of the sugarcane are improved; and the quality of the sugarcane is obviously improved, and the fertilizer is applicable to soil with the medium fertility in the sugarcane areas of southern tropics and subtropics in China.

Owner:云南中蔗农业科技有限责任公司 +1

Production of novel bacterial exopolysaccharides by using Phyllobacterium sp.nov.921F bacterial strain

The invention relates to a bacterium capable of producing bacterial exopolysaccharide, and provides a method for producing the bacterial exopolysaccharide by using the strain. The strain has the characteristics of simple nutritional requirement, easy culture, and high yield of the exopolysaccharide. In particular, a semisynthetic medium in the invention is used for to ferment the strain to obtain higher sugar yield. The strain is cultured in a gravy liquid medium containing 3 percent of sucrose for 72 hours, and the yield of a strain exopolysaccharide reaches 1.5 grams per 100 millimeters. The bacterial exopolysaccharide is white powder and is soluble in water, and the weight-average molecular weight thereof is 736 kD, wherein the apparent viscosity of 1.0 percent sugar solution at room temperature is 655 mps. A study on the property of the bacterial exopolysaccharide shows that the polysaccharide consists of glucose, galactose, and repetitive units formed by pyruvic acid substituents, and the mol ratio of the three components is 1 to 1 to 1. The polysaccharide is different from that produced from any industrial production strains in the past; at the same time, as the strain for producing the bacterial exopolysaccharide, the strain of the invention has the characteristics of high product yield, good stability, short production cycle and low cost, and can realize industrial application and production.

Owner:OCEAN UNIV OF CHINA

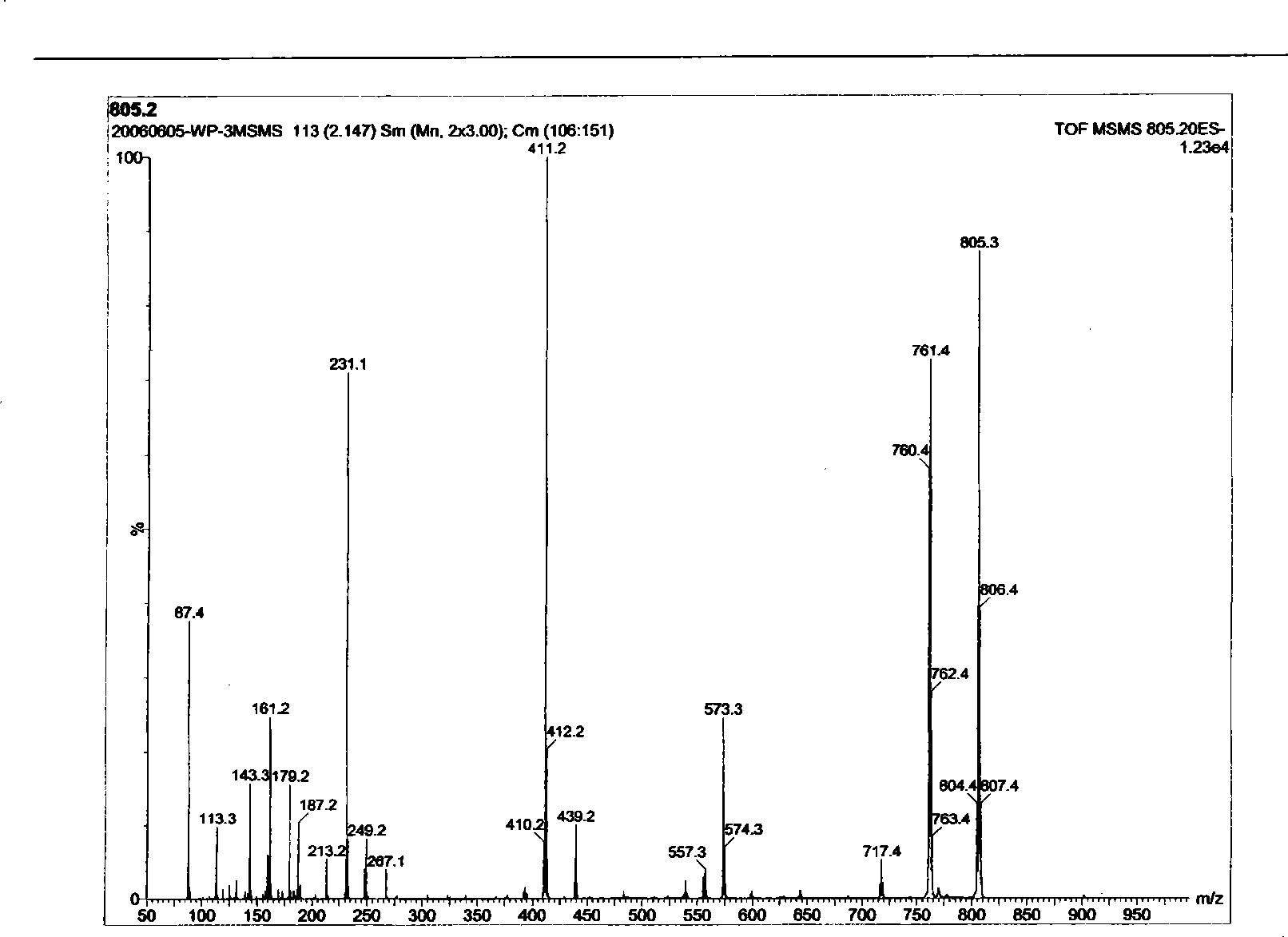

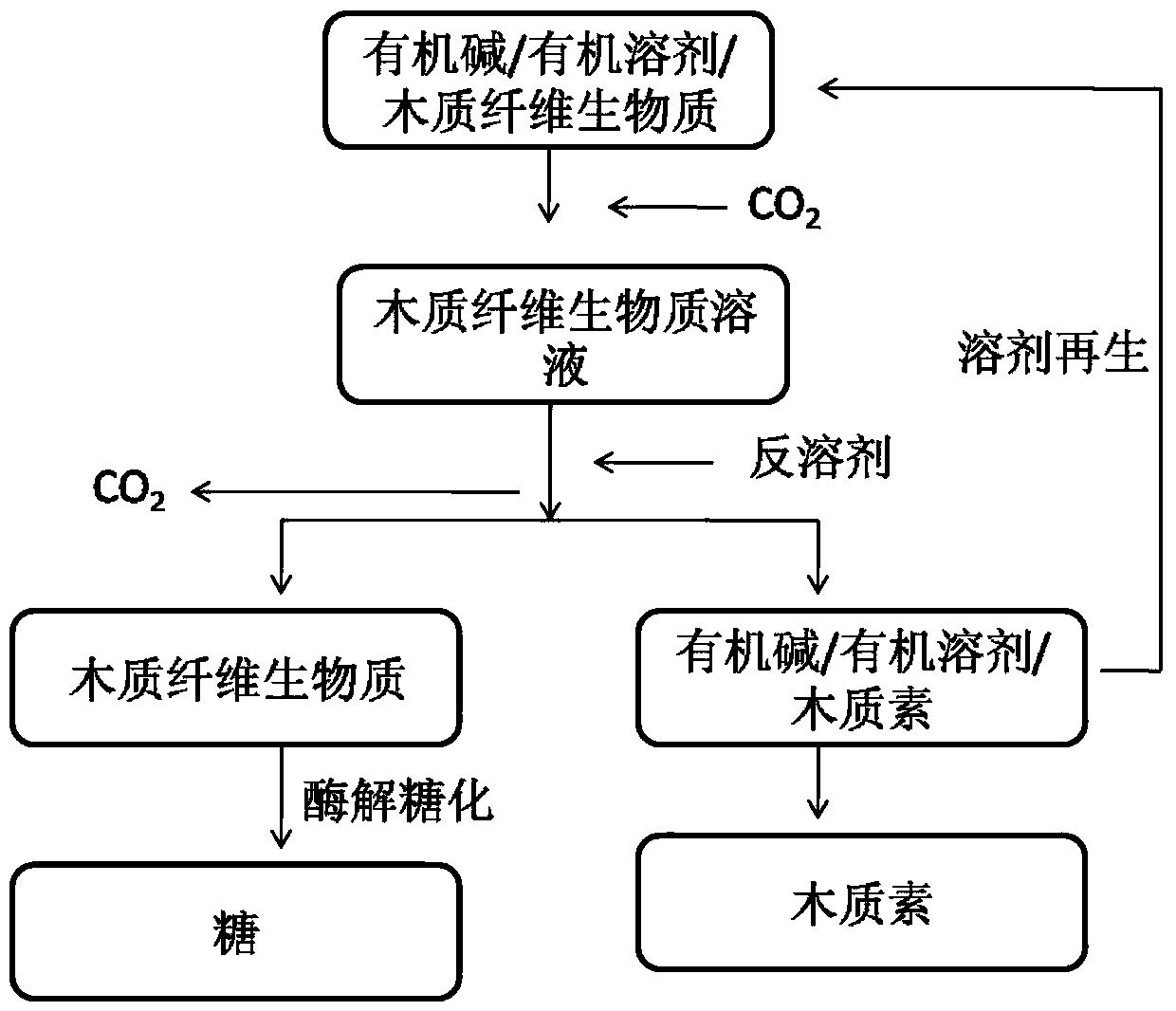

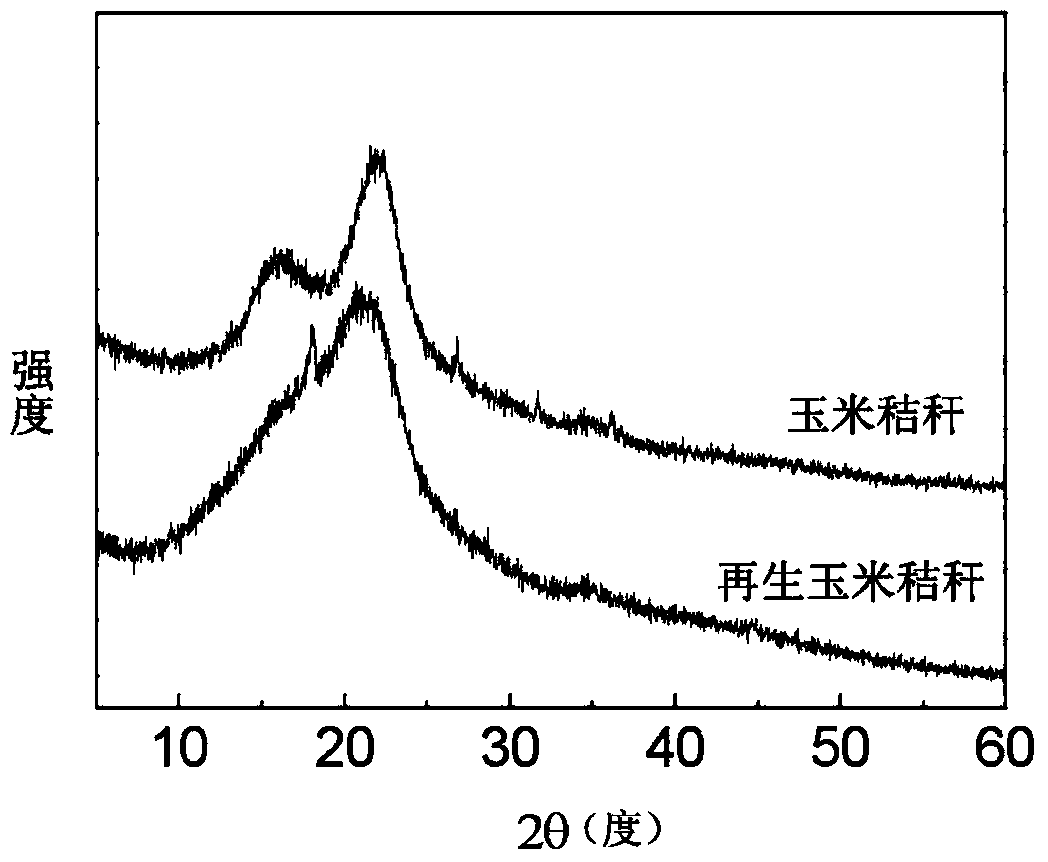

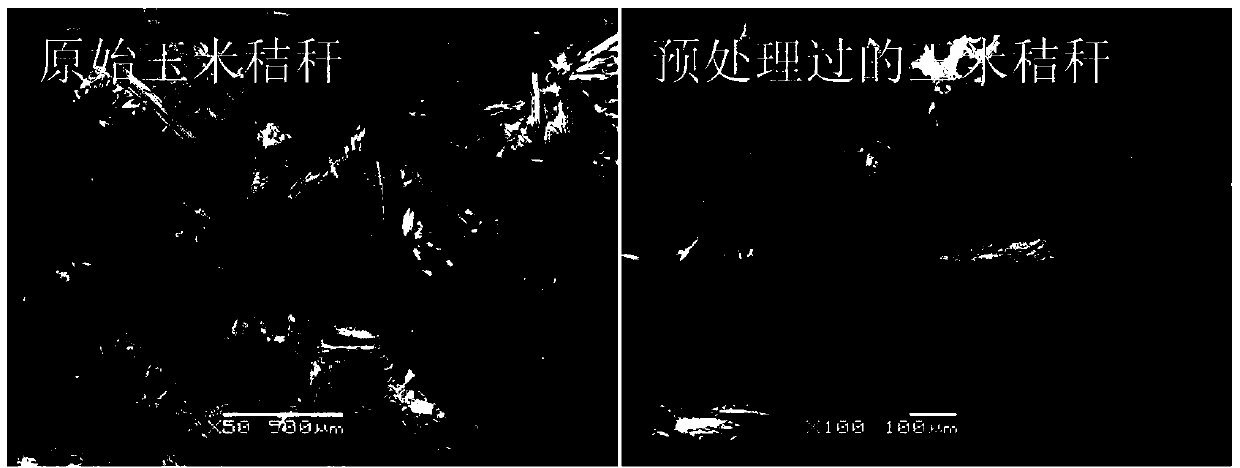

Method for improving sugar yield of lignocellulosic biomass after enzymolysis

The invention provides a method for improving sugar yield of lignocellulosic biomass after enzymolysis. The method comprises the following steps: (1) taking lignocellulosic biomass as a raw material; (2) mixing the lignocellulosic biomass, organic alkali and an organic solvent; (3) filling the mixed system with CO2 with certain pressure, and reacting for certain time; (4) releasing CO2, recycling the biomass by adopting an anti-solvent of cellulose; and (5) taking a certain amount of recycled lignocellulosic biomass, and adding a buffer solution and cellulase as well as xylanase for carrying out enzymolysis, thus obtaining a sugar solution. According to the method, under the existence of the organic alkali, hydroxide radicals in the lignocellulosic biomass and CO2 are subjected to reversible reaction, so that a crystal texture of the cellulose in the lignocellulosic biomass is damaged, and along with the conduction of the reaction, the lignocellulosic biomass is dissolved or subjected to swelling under the effect of the organic solvent, and the lignocellulosic biomass is subjected to the dissolving pretreatment; and the method has the advantages that the technology is simple, the cost of the solvent is low, the operation is convenient, the solvent can be recycled, the hydrolysis speed of the cellulose and the hemicellulase in the lignocellulose is high, and the sugar yield is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com