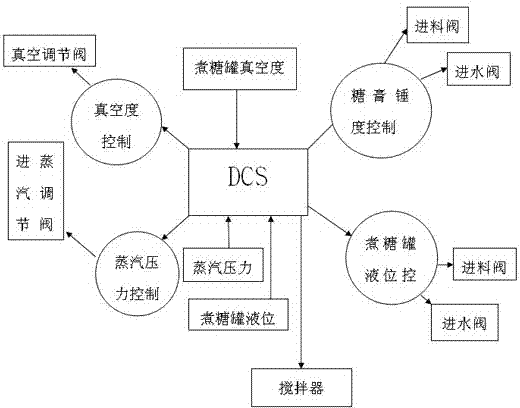

Sugar boiling automatic control device

An automatic control device and sugar cooking technology, which is applied in sucrose production, sugar production, sugar solution boiling/evaporation, etc., can solve the problems of limited investment in automation, poor controllability, and low reliability, and reduce the accident rate. Effects of increasing sugar yield and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

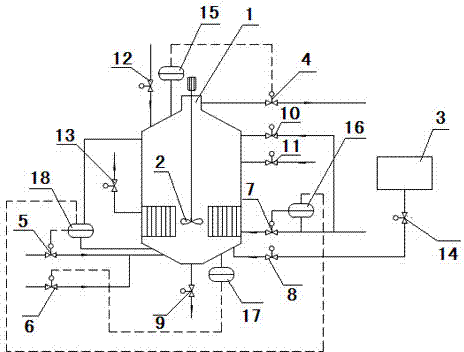

[0030] Such as figure 2 As shown, the present invention is responsible for the automatic operation of the whole sugar boiling process with the time sequence control subsystem. According to the process, the sugar cooking sequence is divided into several sections, and the standard program is set in advance in each section, and the analog control subsystems are called according to the program, or the corresponding on-off valves are controlled according to the set time sequence. The sequence control subsystem controls the opening and closing of the seed valve 8, sugar discharge valve 9, steam washing valve 10, water washing valve 11, vacuum relief valve 12, non-condensable steam discharge valve 13 and seed box bottom valve 14 according to different working hours. Realize the automatic control of cleaning, vacuuming, feeding and discharging of the sugar pot. The application of the sequence control subsystem not only reduces the labor intensity of the operator, but also greatly im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com