Novel method for saccharification of ligno-cellulose

A technology of lignocellulose and a new method, which is applied in the field of cellulose hydrolysis and lignocellulose processing to make sugar, can solve the problems of increased energy consumption and production cost, increased maintenance and maintenance costs, high requirements on corrosion resistance, etc. Accessibility and site of action, saving operating costs and time, eliminating individual differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] dry corn stover with OH - The NaOH solution with a concentration of 0.01mol / L is mixed and soaked according to the ratio of material to liquid 1:5 (kg:L) for 8 hours, and then added to a large twin-screw extruder (Jinan Dayi Extrusion Machinery Co., Ltd.) for extrusion treatment. The operating parameters are: Sleeve temperature 90°C, screw speed 20(r min -1 ), with a moisture content of 20%, steamed and exploded once.

[0070] Selection of cellulase and xylosidase for compounding:

[0071] A, cellulase Accellerase 1000 (purchased from Genencor International Company)

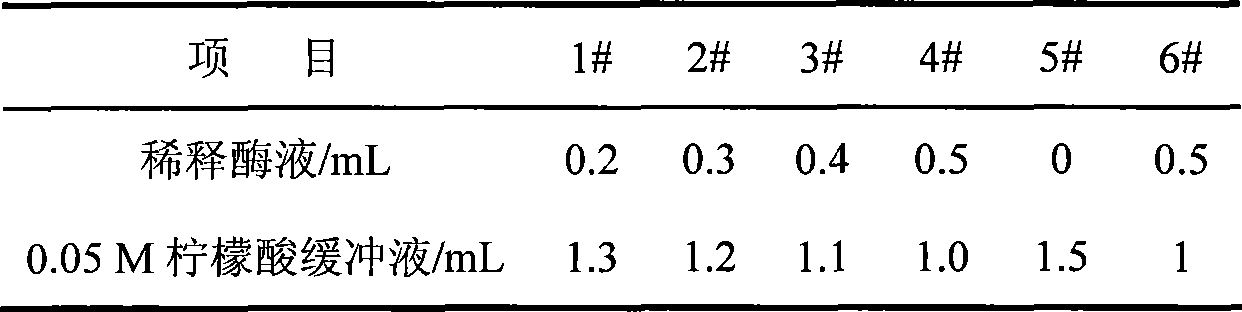

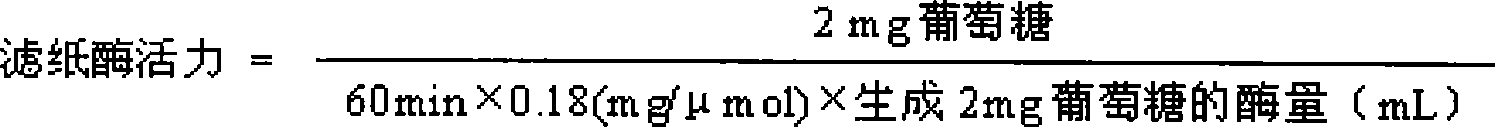

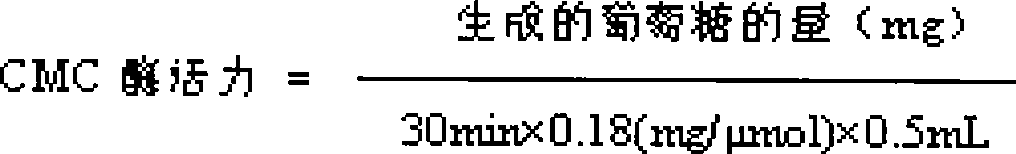

[0072] The results of enzyme activity determination ( / mL cellulase): filter paper enzyme activity 93FPIU, CMC enzyme activity 7.38IU, β-glucosidase 1632.9IU;

[0073] B. Cellulase ZSL-1300 (Shandong Zesheng Biotechnology Company)

[0074] The results of enzyme activity determination ( / mL cellulase): filter paper enzyme activity 77 FPIU, CMC enzyme activity 17.35 IU, β-glucosidase 1356.5 IU;

[0075] C, ...

Embodiment 2

[0080] The bagasse and the HCl solution with a H+ concentration of 0.01mol / L were mixed and soaked for 10 hours according to the ratio of material to liquid 1:15 (kg:L), and then added to a DS322 II single-screw extruder (Jinan Saixin Extrusion Machinery Co., Ltd.) Extrusion puffing treatment, the operating parameters are: screw speed 180 (r min -1 ), moisture content 70%, steamed and exploded 3 times.

[0081] Select cellulase and xylase for compounding:

[0082] A, cellulase Accellerase 1000 (purchased from Genencor International Company)

[0083] The results of enzyme activity determination ( / mL cellulase): filter paper enzyme activity 93 FPIU, CMC enzyme activity 7.38 IU, β-glucosidase 1632.9 IU;

[0084] B, cellulase (purchased from Wuxi Gaorunjie Biological Engineering Co., Ltd.)

[0085] The results of enzyme activity determination ( / g cellulase): filter paper enzyme activity 22 FPIU, CMC enzyme activity 7.8 IU, β-glucosidase 919.5 IU;

[0086] C, cellulase EN0029 (...

Embodiment 3

[0093] Add the dry material of corn stalks directly into the DS322 II single-screw extruder (Jinan Saixin Extrusion Machinery Co., Ltd.), add water for extruding and extruding, operating parameters: screw speed 180 (r min -1 ), moisture content 70%, steamed and exploded 3 times.

[0094] Select cellulase and xylase for compounding:

[0095] A, cellulase Accellerase 1000 (purchased from Genencor International Corporation)

[0096] The results of enzyme activity determination ( / mL cellulase): filter paper enzyme activity 93FPIU, CMC enzyme activity 7.38 IU, β-glucosidase 1632.9 IU;

[0097] B, Cellulase EN0029 (purchased from Shanghai Sculler Biotechnology Co., Ltd.)

[0098] The results of enzyme activity determination ( / g cellulase): filter paper enzyme activity 52 FPIU, CMC enzyme activity 105 IU, β-glucosidase 910.5 IU;

[0099] C, xylanase (purchased from Shandong Zesheng Biotechnology Company), the enzyme activity is 964IU / mL.

[0100] Above-mentioned three kinds of en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com