Precision chilled-mirror dew-point hygrometer and method for eliminating drift of measured temperature value

A dew point meter, precise technology, applied in the direction of material moisture content, etc., can solve the problems of temperature measurement drift, affecting the accuracy of temperature measurement, pollution, etc., and achieve the effect of eliminating individual differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

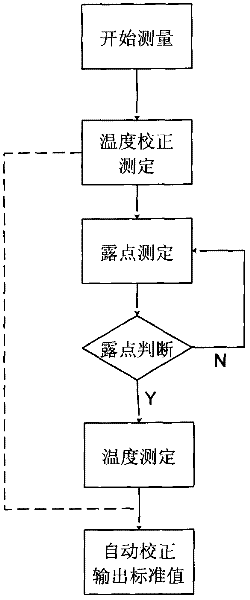

[0019] The precision chilled mirror dew point meter provided by the invention includes a dew point chamber, a photoelectric detection system, a temperature measurement system, a refrigeration system, a single-chip microcomputer control system and an input and output system. Such as figure 1 As shown, after the measurement is started, the control system first corrects the drift of the platinum resistance temperature measurement value. The specific steps are:

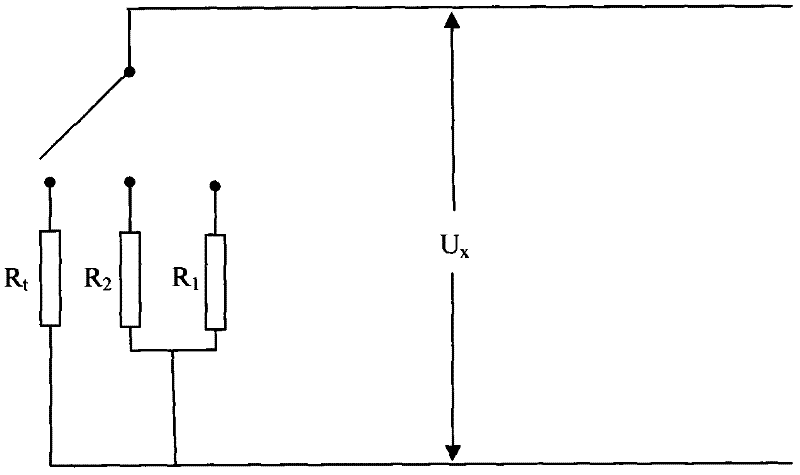

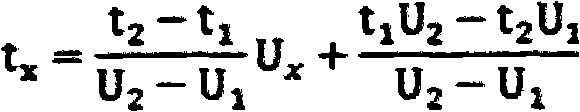

[0020] Such as figure 2 As shown, the single-chip controller controls the multi-way switch to set the precision fixed resistor R 1 Access to the temperature measurement circuit, R 1 The resistance value and the selected upper limit temperature t 1 The resistance values of the platinum resistors are equal, and the controller records R 1 The corresponding output voltage U 1 .

[0021] Disconnect the precision fixed resistor R 1 , the precision fixed resistor R 2 Access to the temperature measurement circuit, R ...

specific example 2

[0025] The precision chilled mirror dew point meter provided by the present invention and the method for eliminating temperature drift can be used for GIS equipment insulating gas SF 6 For dew point measurement, the specific temperature drift correction method is as follows:

[0026] In this example, the precision fixed resistor R 1 The resistance value is 100.0000 ohms, relative to the temperature measured by the platinum resistance sensor is 0 ℃, the precision fixed resistance R 2 The resistance value is 75.0000 ohms, which is equivalent to -63.3°C measured by the platinum resistance sensor. After starting the measurement, first enter the temperature drift correction measurement. The controller controls the multiplexer to place the precision resistor R 1 Connect to the temperature measurement circuit, the controller records R 1 The corresponding output voltage is the output voltage U at 0°C 1 . subsequently disconnect the precision fixed resistor R 1 , the precision f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com