Calorimeter performance degradation evaluation method, storage medium and equipment

A heat meter and performance technology, applied in the direction of measuring heat, calorimeters, measuring devices, etc., can solve problems such as insufficient rigor of results, insufficient consideration of individual differences in heat meters, lack of actual degradation curves, etc., to solve baseline offset , the effect of a good data foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

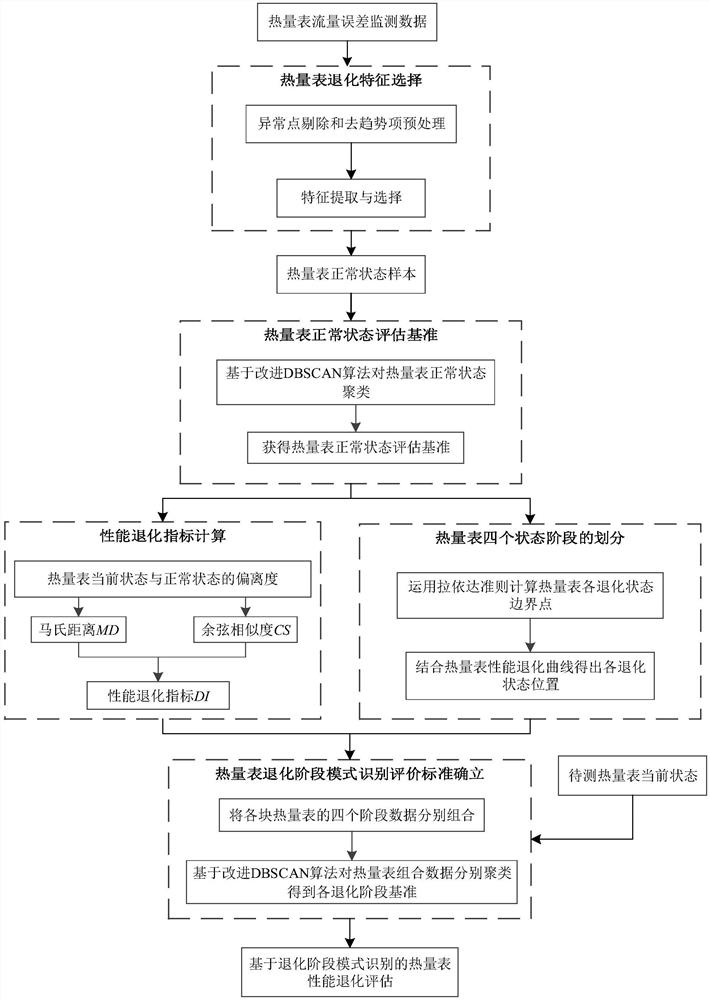

[0066] The invention provides a heat meter performance degradation evaluation method, storage medium and equipment based on the pattern recognition of the degradation stage. First, the original data of the state monitoring of the heat meter is preprocessed by eliminating abnormal points and detrending items; The obtained data is subjected to feature extraction to construct the heat meter performance degradation feature set Ts, and the optimal feature set Tb representing the state of the heat meter is obtained by using the method of multi-index screening;

[0067] Secondly, through the improved DBSCAN algorithm, the normal state characteristic data of the heat meter are clustered to obtain the normal state evaluation benchmark of the heat meter; based on the normal state evaluation benchmark of the heat meter, the performance degradation index is constructed by fusing Mahalanobis distance and cosine similarity To characterize the degree of deviation between the current state of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com