Method for pre-processing lignocellulose biomass to increase sugar field of lignocellulose biomass

A technology of lignocellulosic and lignocellulose, which is applied in the field of green chemistry and biomass new energy production, and can solve problems such as unfriendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

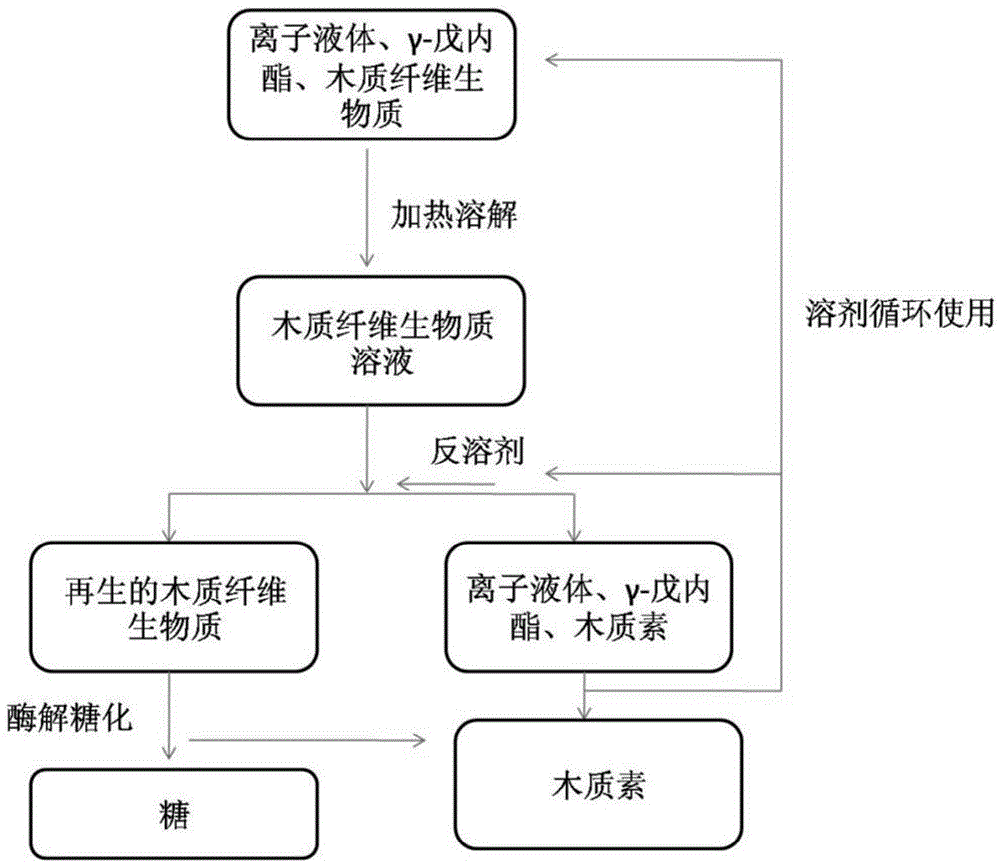

[0061] A method for pretreating lignocellulosic biomass to improve its sugar yield, comprising the steps of:

[0062] 1) mixing ionic liquid, γ-valerolactone, and lignocellulosic biomass to form a pre-dissolution pretreatment system;

[0063] 2) heating and dissolving the pre-dissolved mixture system to form a solution;

[0064] 3) adding an anti-solvent to the solution system to precipitate the dissolved lignocellulosic biomass, and filter and separate;

[0065] 4) Taking a certain amount of regenerated lignocellulosic biomass, adding a buffer solution, cellulase and xylanase to carry out enzymatic hydrolysis to obtain a sugar solution.

[0066] See attached for specific flow chart figure 1 .

Embodiment 2

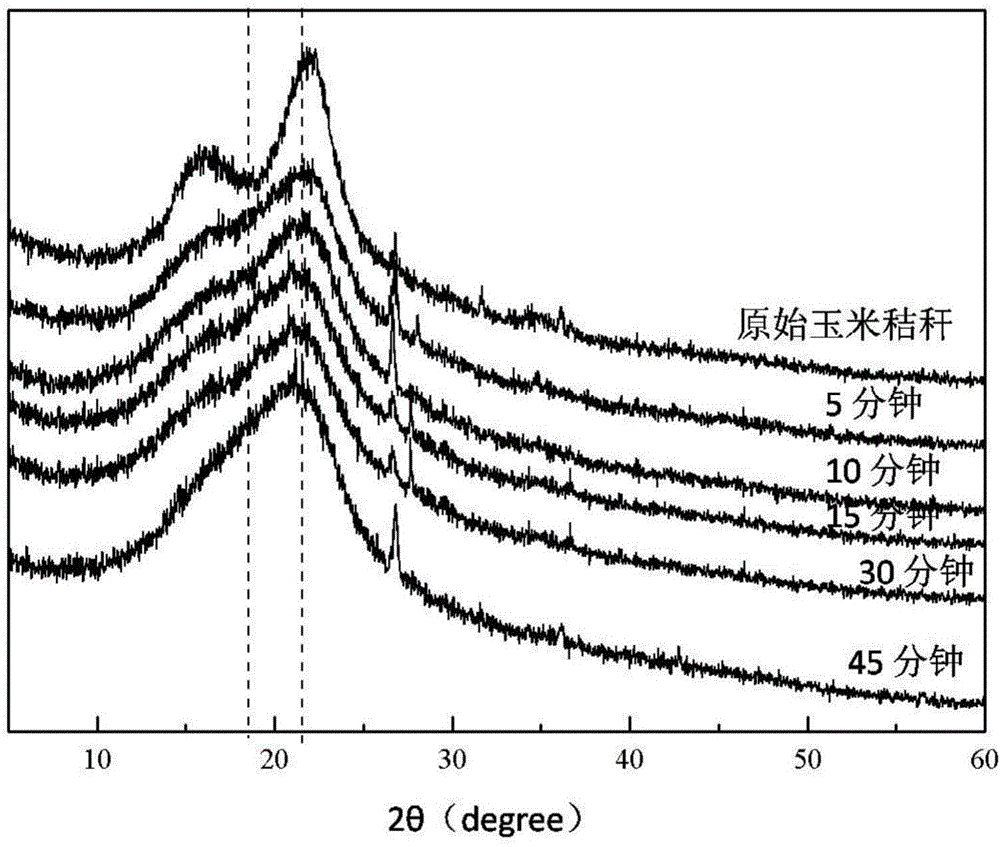

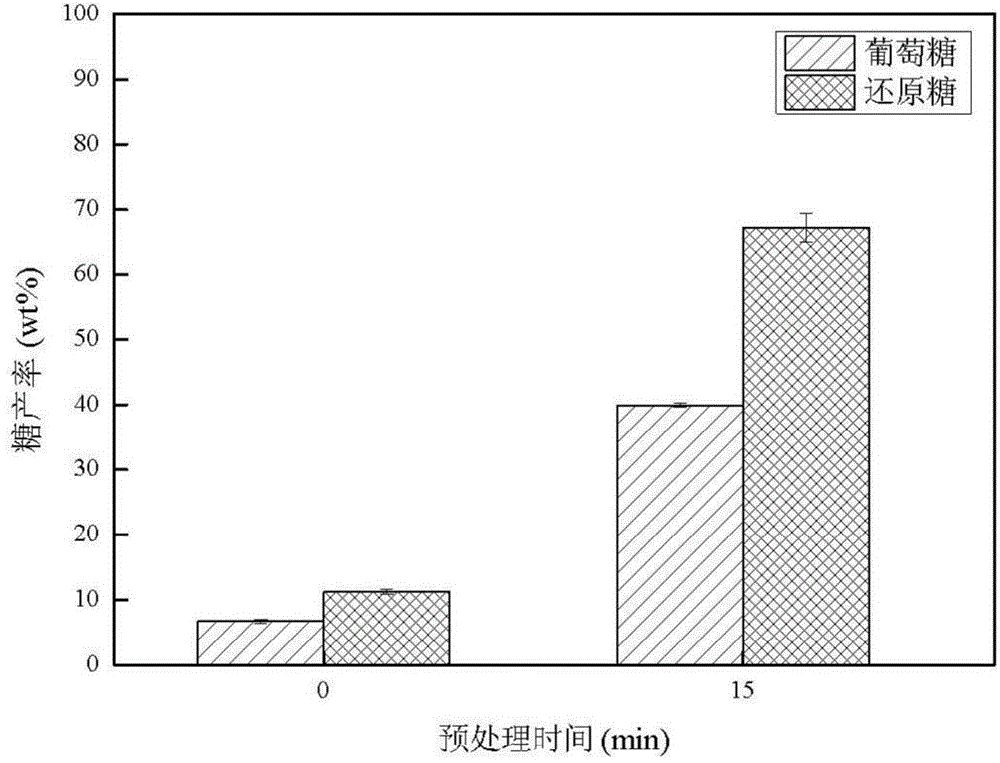

[0068] In a 100 milliliter round bottom flask, add 14.9 grams of 1-ethyl-3-methylimidazole acetate (EmimAc), 35.1 grams of gamma-valerolactone to form a mixed solvent system, wherein the ionic liquid mole percentage is 20%, and then 5 grams of corn stalks (physical size: 1 mm, water content 5%) were added to form a predissolved pretreatment mixed solution. Under mechanical stirring, stir and dissolve at 140°C for 15 minutes. Then cool to room temperature, add 3 times the volume of pretreatment solution of anhydrous methanol to regenerate the pretreated corn stalks, filter and separate, then wash the precipitate twice with 3 times the volume of anhydrous methanol, and freeze-dry the precipitate to obtain Pretreated corn stover. Accurately weigh 0.5 g of regenerated lignocellulosic biomass, place it in a 100 mL Erlenmeyer flask, add 10 mL of citric acid-sodium citrate buffer solution with pH 4.8, stir well, and divide the mixture according to the ratio of 0.02 g / g substrate Ad...

Embodiment 3

[0070] In a 100 milliliter round bottom flask, add 4.1 grams of 1-ethyl-3-methylimidazole acetate (EmimAc), 45.9 grams of gamma-valerolactone to form a mixed solvent system, wherein the ionic liquid molar percentage is 5%, and then 5 grams of corn stalks (physical size: 0.5 mm, water content 8%) were added to form a pre-dissolved pre-treatment mixed solution. Under mechanical stirring, stir and dissolve at 80°C for 180 minutes. Then cool to room temperature, add 3 times the volume of pretreatment solution of dehydrated alcohol to regenerate the lignocellulosic biomass after pretreatment, filter and separate, then wash the precipitate 2 times with 3 times the volume of dehydrated ethanol, and the precipitate will be ready after drying Obtain the pretreated corn stalks. Accurately weigh 0.5g of regenerated lignocellulosic biomass, place it in a 100mL Erlenmeyer flask, then add 10ml of pH4.8 citric acid-sodium citrate buffer solution, stir well, and divide the mixture according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com