Method for preparing trehalose

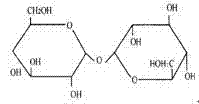

A technology of trehalose and thalline, which is applied in the field of microbial fermentation production, can solve the problems of difficulty in breaking yeast walls and low trehalose, and achieves the effects of simple process, convenient operation, and easy realization of large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

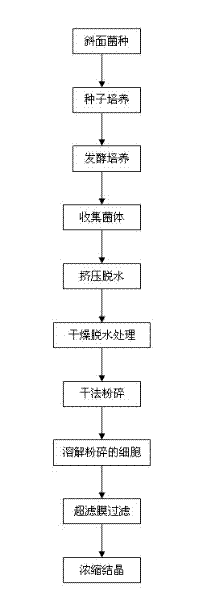

Method used

Image

Examples

Embodiment 1

[0042]The seed medium and fermentation medium selected in this example are: corn steep liquor (25% solid content) 10%, peptone 7.0%, glucose 15%, MgSO 4 0.01%, NaH 2 PO 4 0.1%, the rest is distilled water, the above are mass percentages, and the initial pH is 6.0.

[0043] The method for preparing trehalose comprises:

[0044] (1) Scrape the amphicylic bacteria from the slant of the strain obtained after the activation of the preserved active dry yeast, inoculate it into a 1 L shake flask containing 100 ml of the above seed medium, and cultivate it at 33°C and 220 rpm for 20 h, as Spare strains. After the 7.5 L fermenter with 4.5 L of fermentation medium was sterilized at 121 °C for 20 min, the above strains were inoculated into the 4.5 L fermenter at an inoculation amount of 10% for fermentation. During the fermentation process, the pH was controlled at 5.0±0.1 by automatic feeding of 5 mol / L NaOH and HCI, the rotation speed was 300 rpm, the volume ratio of aeration rat...

Embodiment 2

[0051] The seed medium and fermentation medium selected in this example are: 15% corn steep liquor (containing 20% solids), 2% peptone, 8% glucose, MgSO 4 0.035%, NaH 2 PO 4 0.25%, the rest is distilled water, the above are mass percentages, and the initial pH is 7.2.

[0052] The method for preparing trehalose comprises:

[0053] (1) Scrape the dicyclic bacteria from the slant of the strain obtained after the activation of the preserved active dry yeast, inoculate it into a 1 L shaker flask containing 100 ml of seed medium, and culture it at 30°C and 150 rpm for 15 h, as the strain kind. After the 7.5 L fermenter with 4.5 L of fermentation medium was sterilized at 121 °C for 20 min, the strains were inoculated into the fermenter at an inoculation volume of 15%. During the fermentation process, the pH was controlled at 6.5 by automatic feeding of 5 mol / L NaOH and HCI, the rotation speed was 250 rpm, the volume ratio of the aeration rate to the fermentation broth was 1....

Embodiment 3

[0060] The seed medium and fermentation medium selected in this example are: corn steep liquor (23% solid content) 5%, peptone 5.0%, glucose 11%, MgSO 4 0.02%, NaH 2 PO 4 0.2%, the rest is distilled water, the above are mass percentages, and the initial pH is 6.5.

[0061] The method for preparing trehalose comprises:

[0062] (1) Scrape the bicyclic bacteria from the slant of the strain obtained after the activation of the preserved active dry yeast, inoculate it into a 1 L shaker flask containing 100 ml of seed medium, and cultivate it at 35°C and 180 rpm for 25 h, as a bacterial strain A spare. A 7.5 L fermenter with 4.5 L of fermentation medium was sterilized at 121°C for 20 min, and then the strain was inoculated into the fermenter at an inoculum of 8%. During the fermentation process, the pH was controlled at 6.0 by automatic feeding of 5 mol / L NaOH and HCI, the rotation speed was 250 rpm, the volume ratio of the aeration rate to the fermentation broth was 1.0:1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com