Patents

Literature

86results about How to "Increase sugar yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

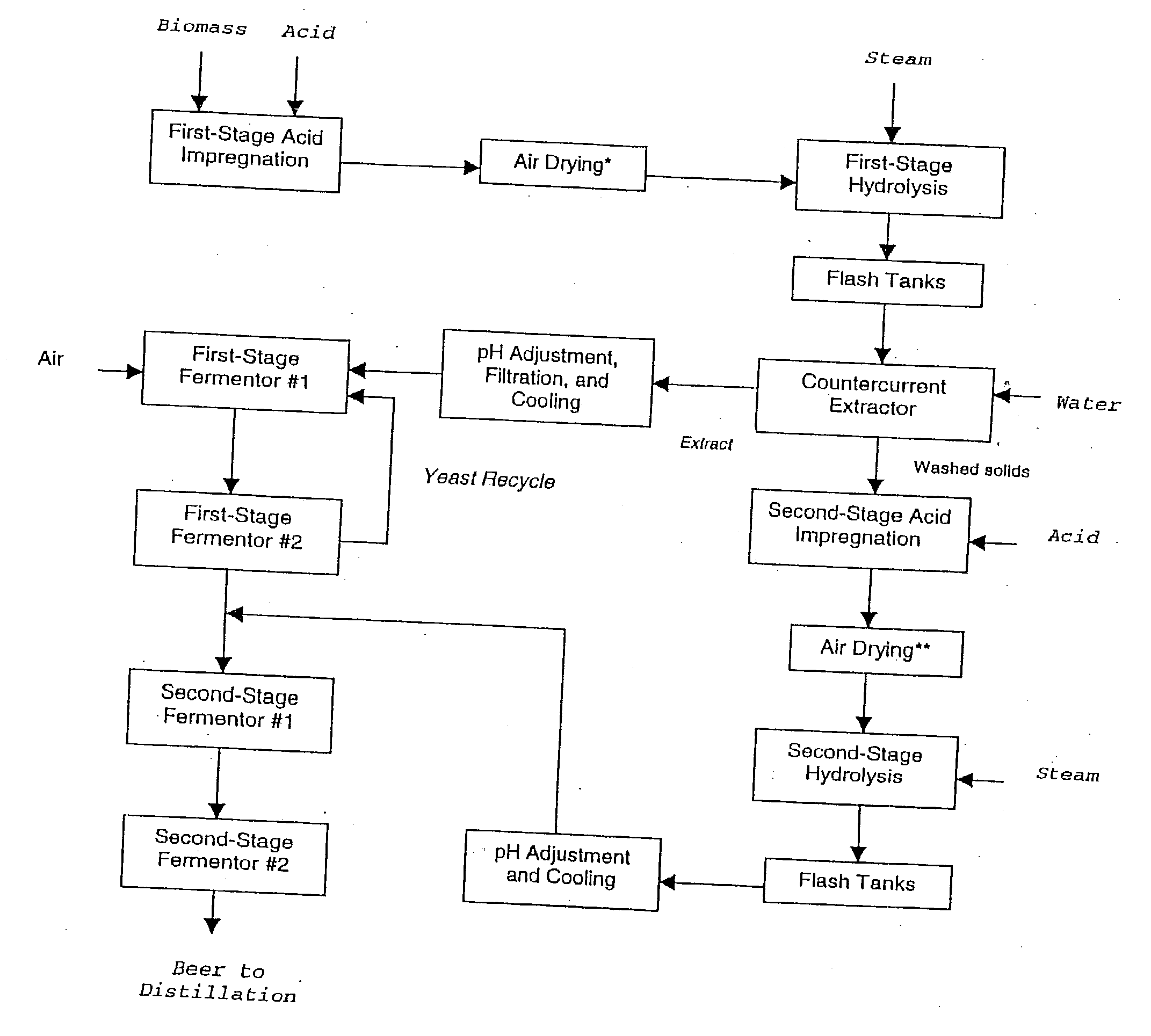

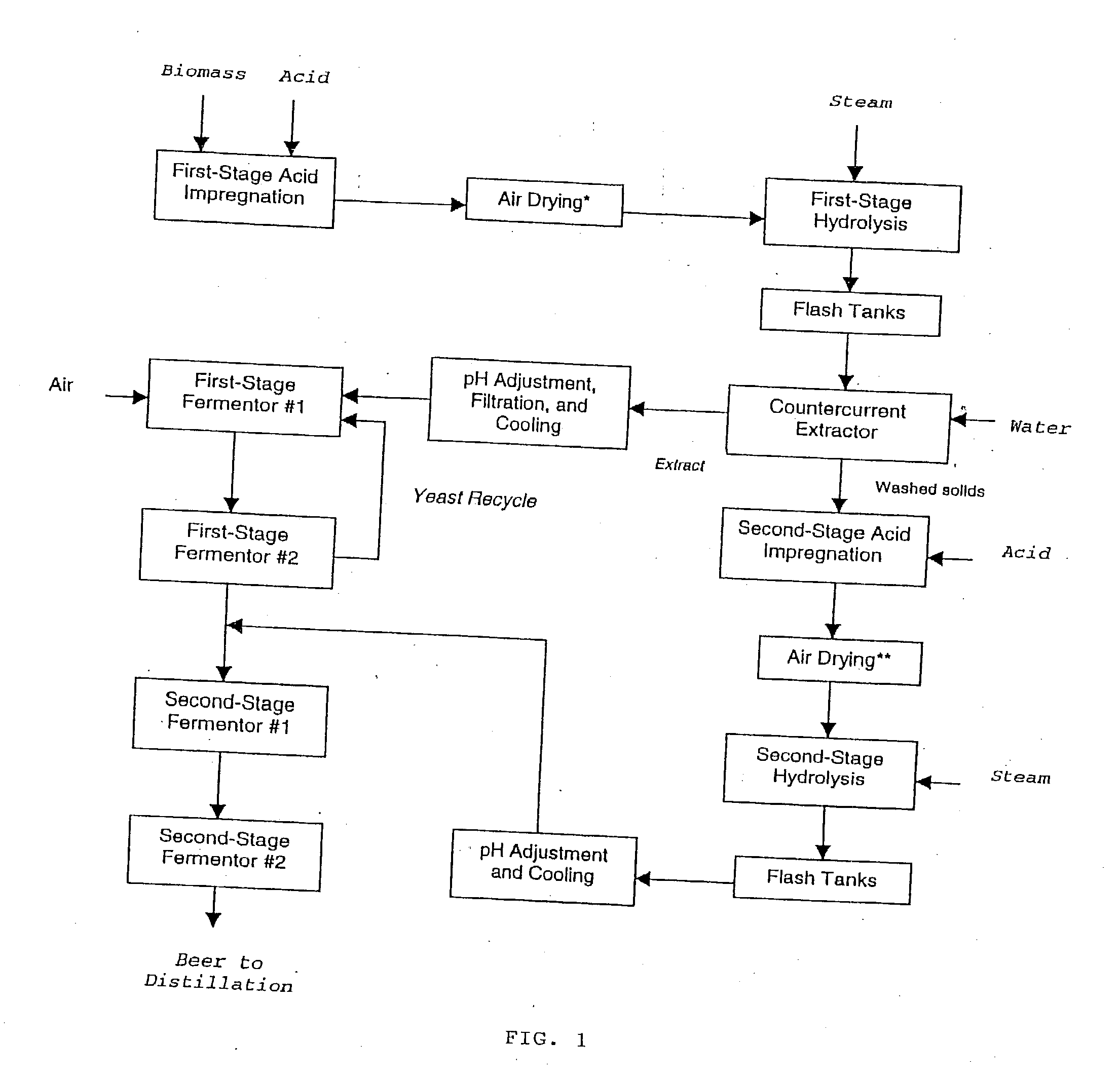

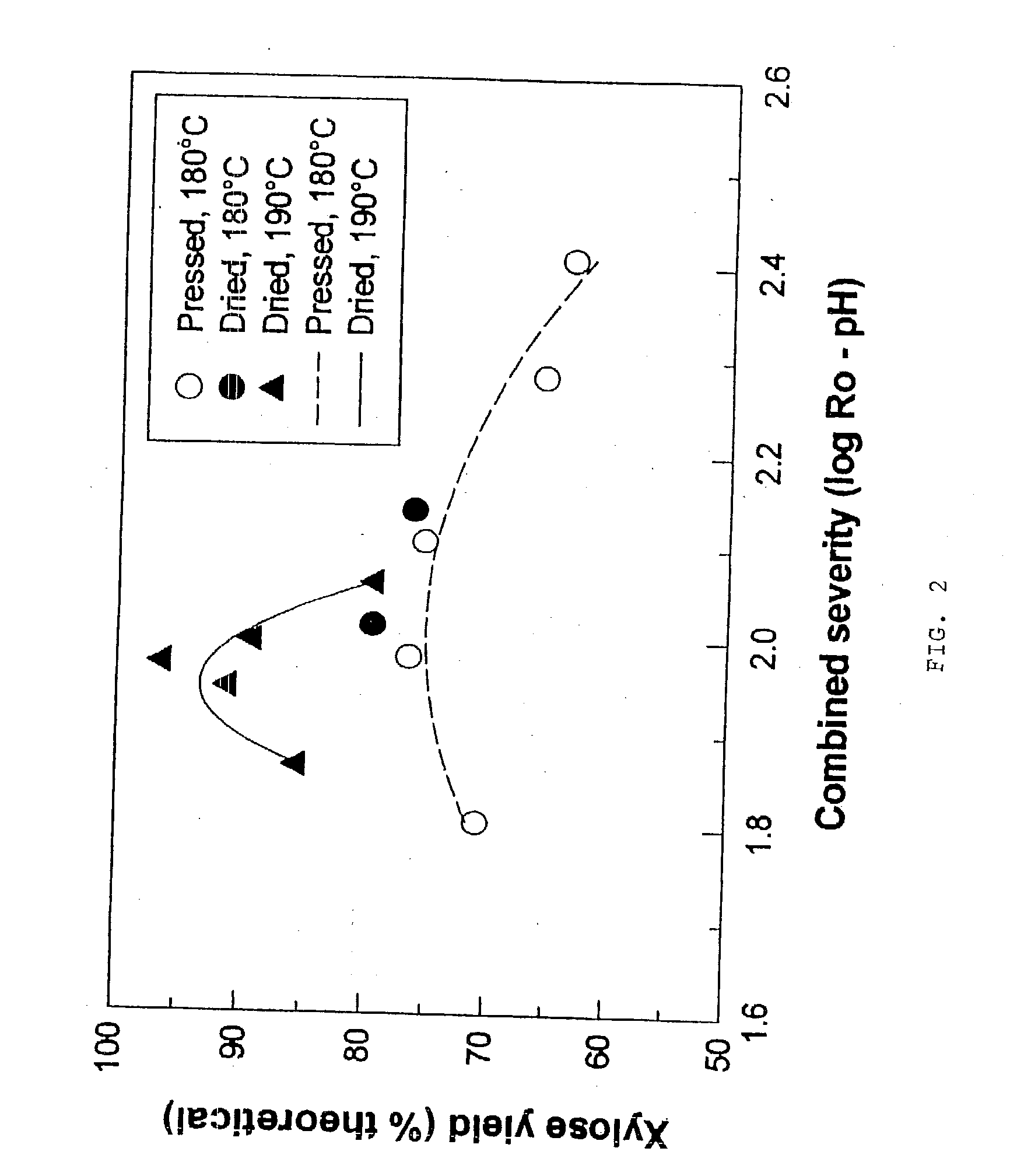

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

Process for effectively hydrolyzing cellulose in ion liquid

InactiveCN101289817ALower catalyst costsReduce acid consumptionCation exchanger materialsOrganic anion exchangersIonSolvent

The invention relates to cellulosic hydrolysis, in particular to a method for high-efficiently hydrolyzing celluloses in ionic liquid. In the method, the ionic liquid in which celluloses are dissolved is used as solvent, and water, the equivalent weight of which is more than or equal to 1 mol, is used as reactant, and inorganic acids, the catalytic amount of which is the stoichiometric amount, are used as catalyst, and celluloses are reacted under the conditions of the normal pressure and the temperature of between 70 to 100 DEG C for 2min to 9hr; after the reaction is over, celluloses undergo the cold water quenching reaction and the alkali neutralization reaction, and the cellulose hydrolysate is obtained; total reducing sugar and glucose in the cellulose hydrolysate are taken with quantitative chemical analysis, and results of which show that the highest yield of reducing sugar is 73 percent, and correspondingly the yield of glucose is 53 percent. Compared with the conventional hydrolysis method, the method of the invention has the advantages of unnecessary pretreatment, mild reaction conditions, high hydrolytic activity, quick reaction speed, little acid consumption, low requirement on corrosion resistance of a reactor and easy tracking and controlling of the extent of reaction; the method opens a new road for resolving the lasting problem of the complete utilization of lignocelluloses.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

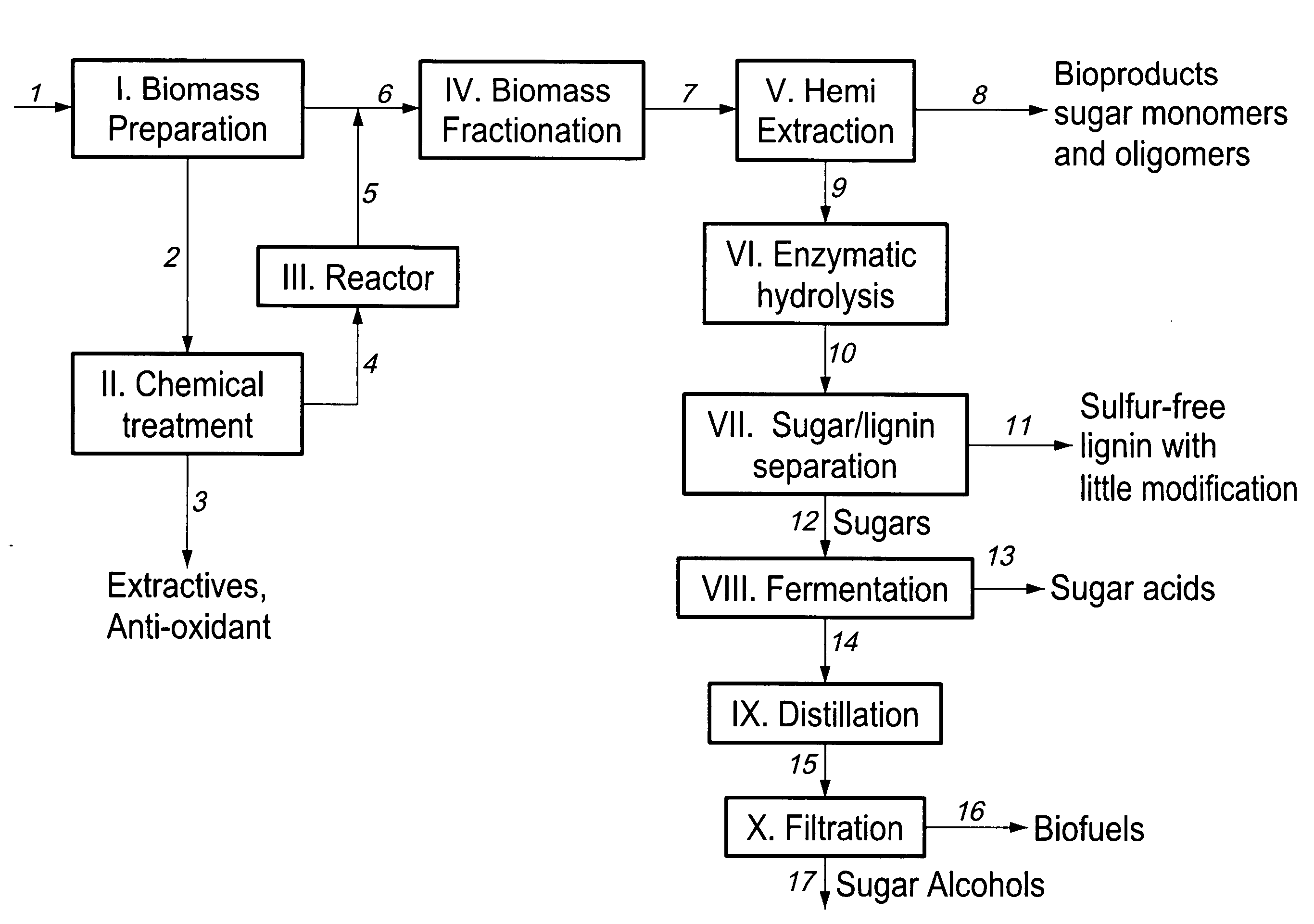

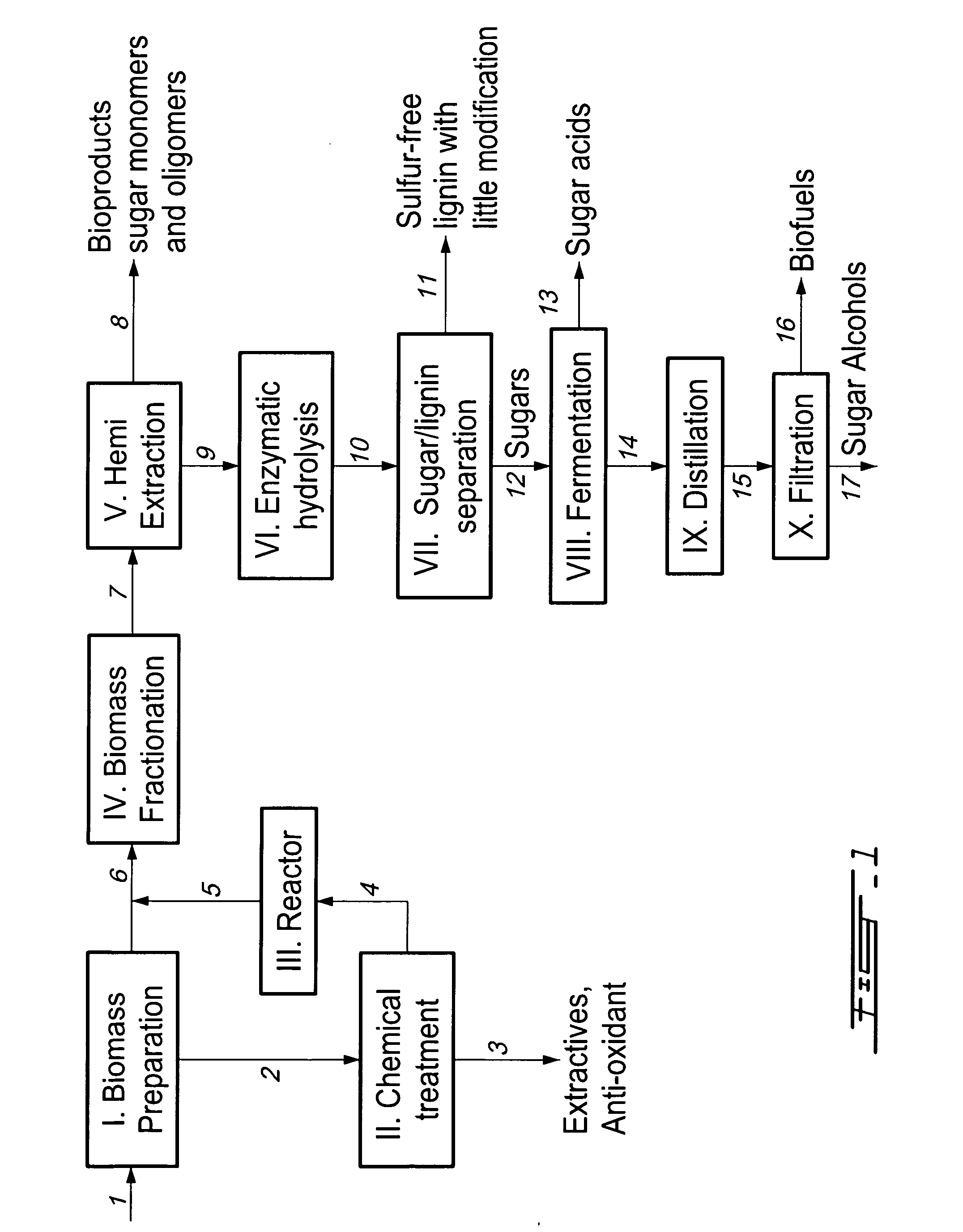

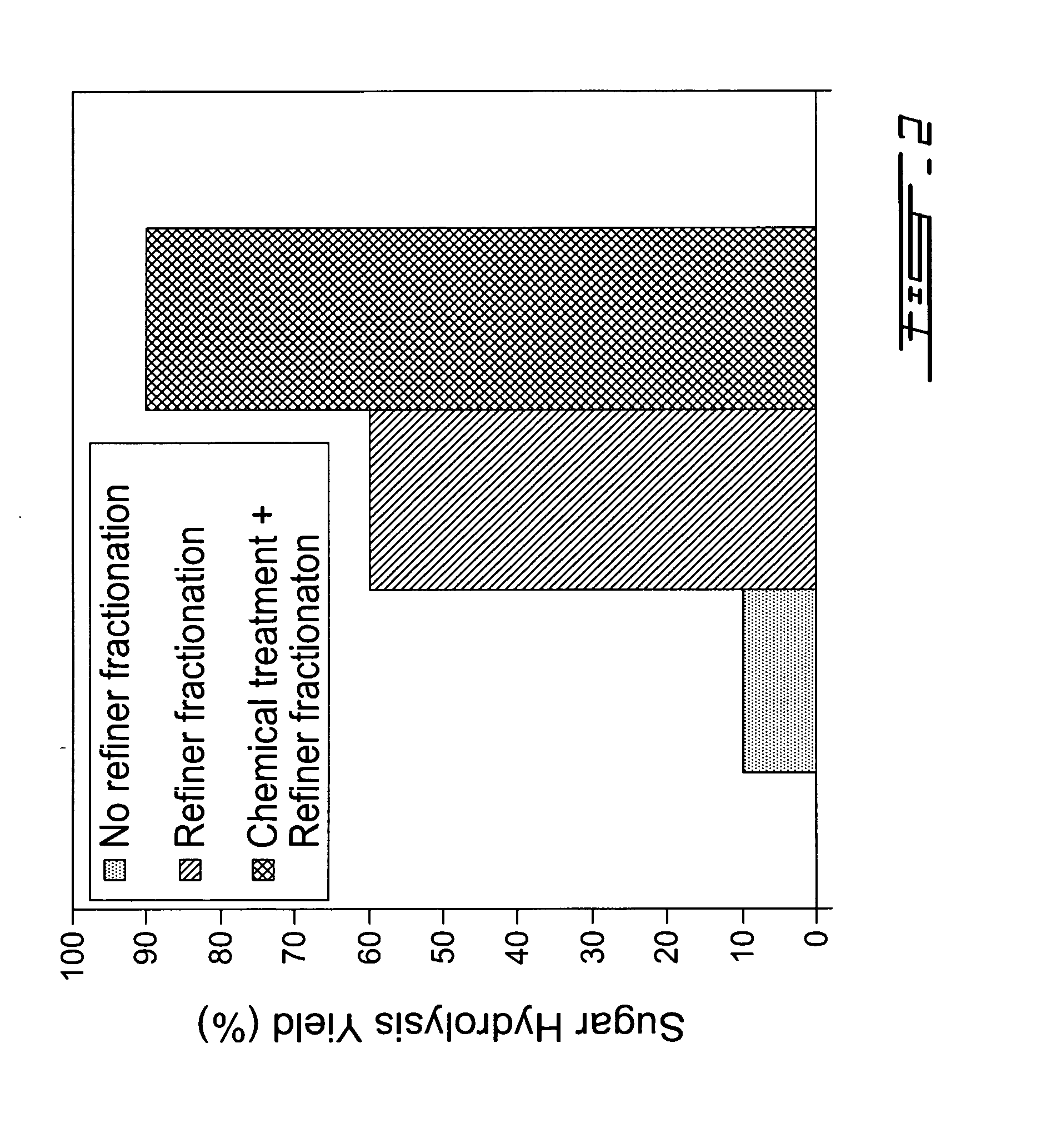

Biomass fractionation process for bioproducts

A fractionation process for producing value-added products from a lignocellulosic biomass, comprises: a) mechanically refining the lignocellulosic biomass under mild refining conditions to form a refined biomass pulp with enhanced susceptibility to separation of hemicellulose, cellulose and lignin, and enhanced digestibility of carbohydrates in hydrolysis b) separating hemicellulose and sulfur-free high-quality lignin from cellulose in the refined biomass, and, optionally c) producing various bioproducts from the above said process.

Owner:FPINNOVATIONS INC

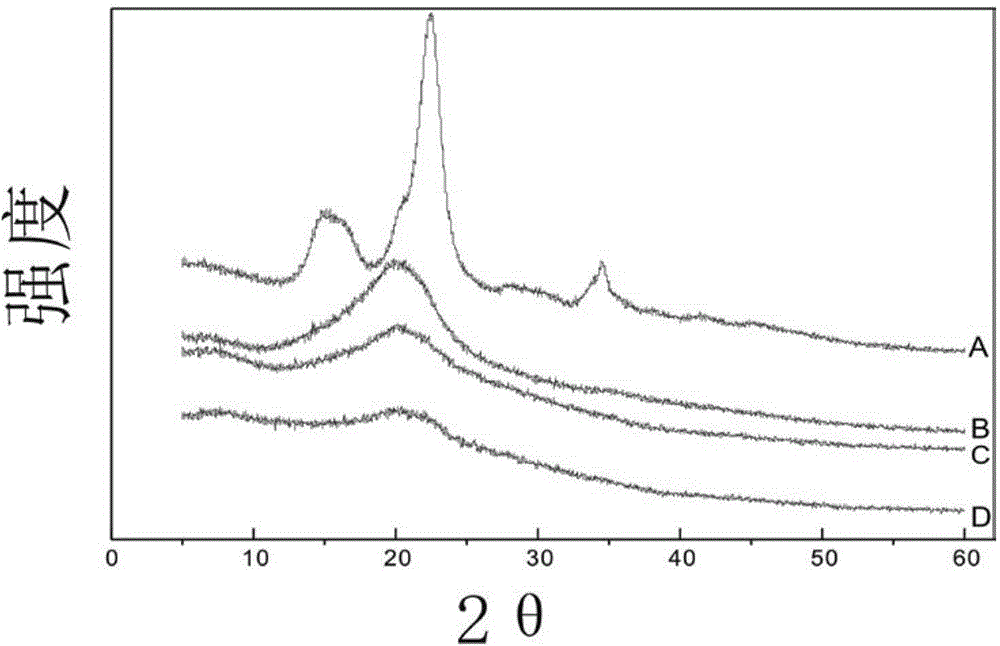

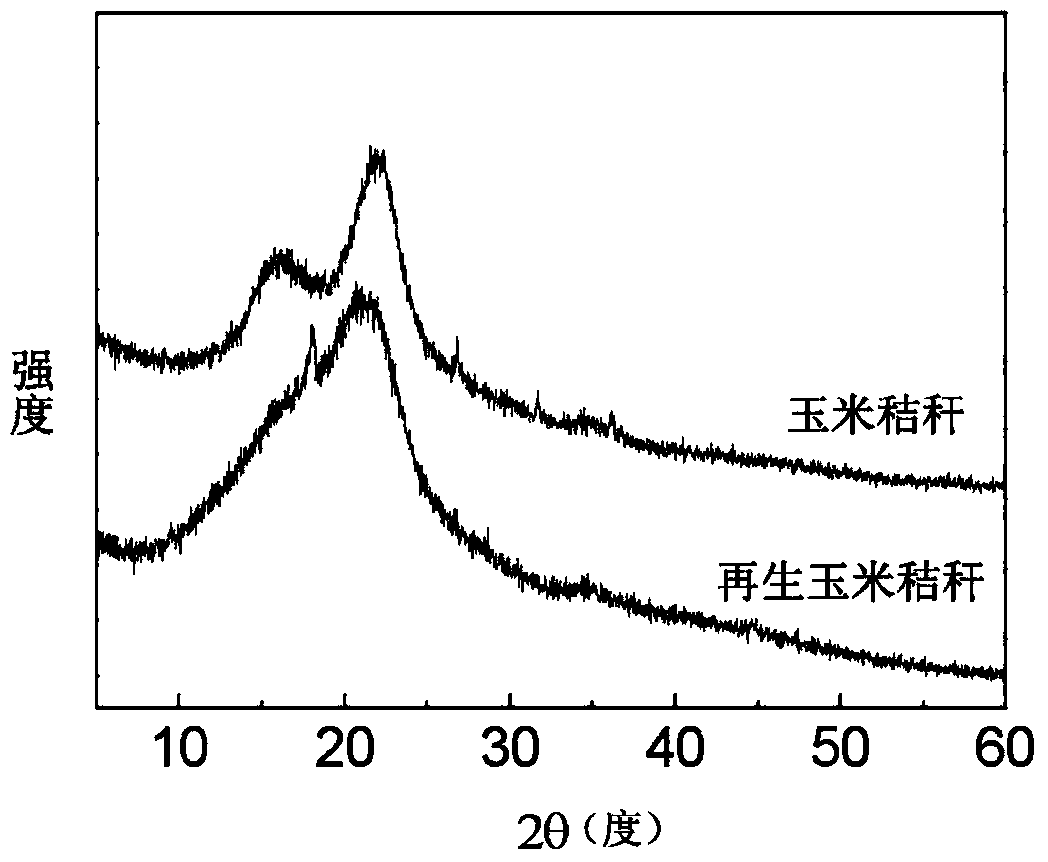

Method for increasing sugar yield of cellulase enzymolysis through pretreatment by using ion liquid

The invention relates to a method for increasing the sugar yield of cellulase enzymolysis through pretreatment by using ion liquid. In the method, natural lignin from different sources is pretreated by using different types of ion liquids to increase the sugar yield of enzymolysis. The method comprises the following steps of: firstly, pretreating natural lignin at certain temperature under fully stirring condition by using an ion liquid; secondly, extracting regenerated cellulose from a mixed liquor and drying; and lastly, adding cellulase which can decompose the regenerated cellulose serving as a substrate into reducing sugar at certain temperature, pH and concentration to generate liquid glucose mainly containing glucose. By adopting the method, the sugar yield of lignin can be remarkably increased, the accessibility and the reaction efficiency of cellulase can be effectively increased, the liquid glucose reaches the fermentation level at the final reaction stage, and the entire technical process is simplified.

Owner:TONGJI UNIV

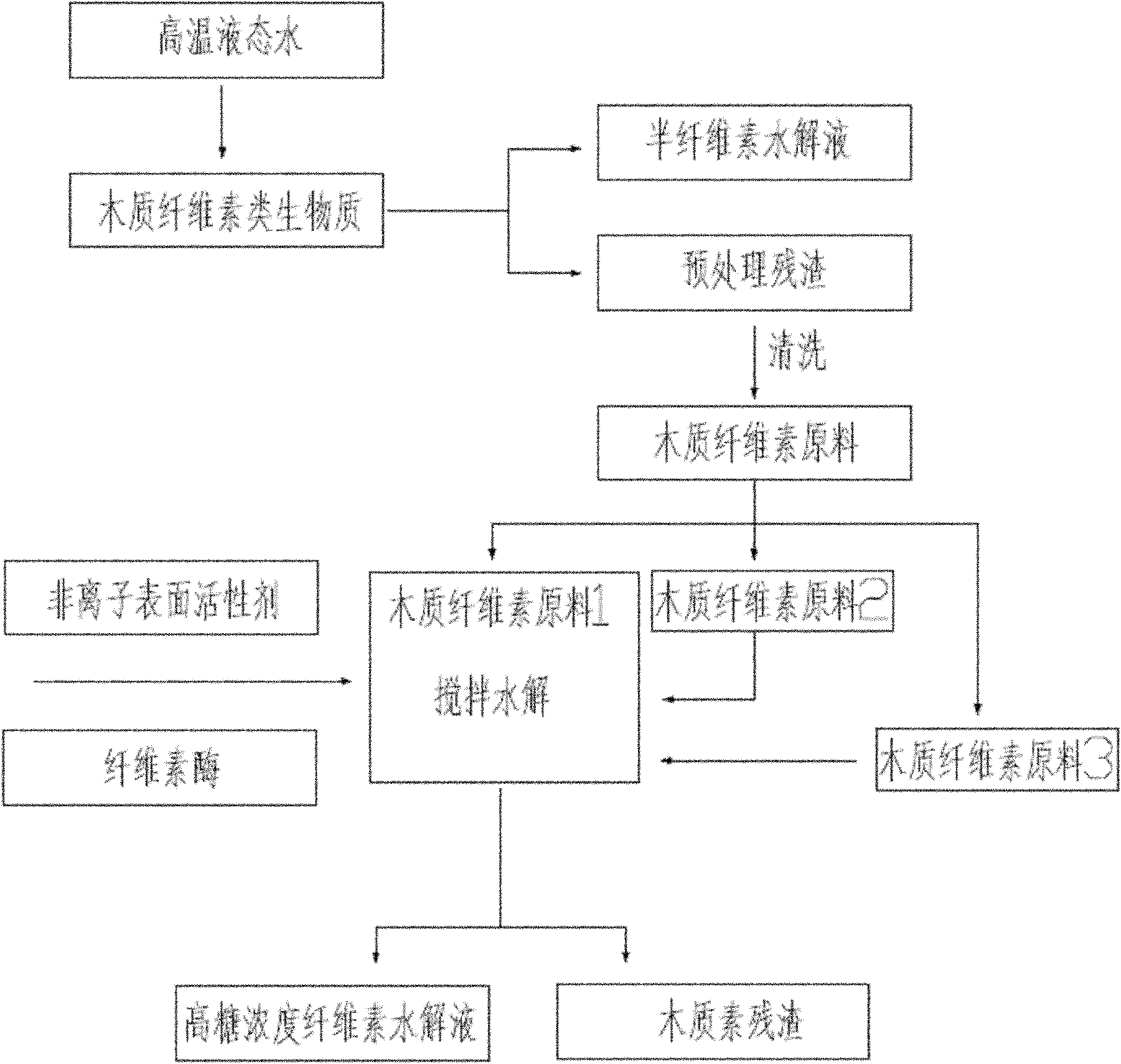

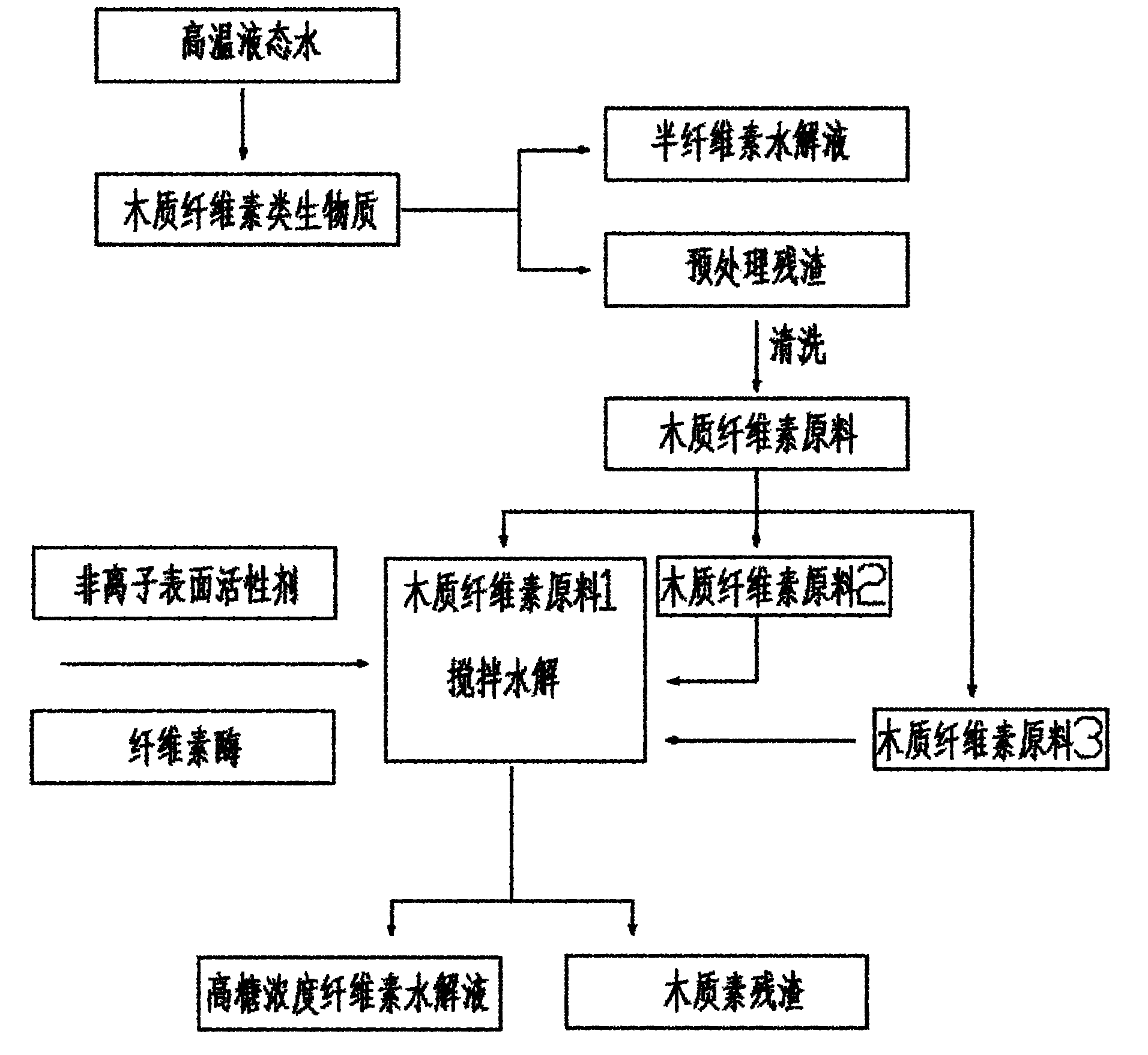

Efficient enzyme hydrolysis method of lignocellulose biomass

InactiveCN102174594AEasy to operatePromote the process of hydrolysis reactionBiofuelsFermentationSodium acetateHigh concentration

The invention discloses an efficient enzyme hydrolysis method of lignocellulose biomass, comprising the following steps: pretreating the lignocellulose biomass through high-temperature aqueous water to obtain a lignocellulose raw material to be used as a substrate; dispersing the substrate into an acetic acid-sodium acetate buffer solution in a certain concentration; adding a nonionic surfactant and cellulose; stirring the materials; hydrolyzing for some time; adding a certain amount of materials twice; and simultaneously adding the nonionic surfactant and the cellulose; and continuously hydrolyzing to obtain a saccharide compound and lignocellulose residues. In the method provided by the invention, high-temperature aqueous water pretreatment, batch charging, nonionic surfactant adding and stirring and an enzyme hydrolysis process are coupled, thus the hydrolysis efficiency is high, the concentration of the enzymolysized lignocellulose raw material can be greatly improved; the concentration reaches 30%; the sugar generation concentration and the hydrolysis efficiency are high under the condition of high-concentration lignocellulose raw materials; the enzymolysized raw material concentration is improved; and simultaneously the high-concentration sugar is produced, thus improving the hydrolysis efficiency, and realizing the efficient enzyme hydrolysis of the lignocellulose biomass.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

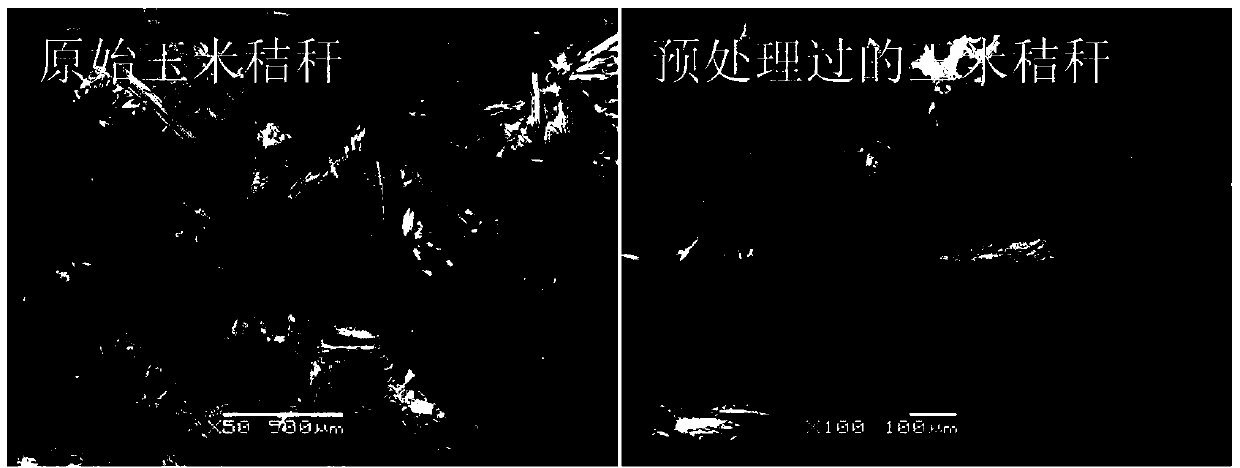

Maize straw pretreatment method

ActiveCN101565725AIncrease sugar yieldRealize regulationFermentationBulk chemical productionSolventChemistry

The invention relates to a maize straw pretreatment method that is a new method for using supercritical or subcritical fluid technology to pretreat the maize straw. The new method improves the enzymolysis efficiency of cellulose in the maize straw, removes lignin that has inhibiting effect on the further fermentation process while improving the sugar yield of the straw, and provides an effective way for further cleanly and highly efficiently producing products such as fuel ethanol and the like. The method is characterized in that the pretreatment temperature is 50-250 DEG C; the operation pressure is 10-20MPa; the reaction time is 0.1-5h; and the solvent is the mixed solvent of CO2, water and one of or more of methanol, ethanol, butanol, pentanol and the like. The sugar yield of the cellulose in the maize straw is 40-95 percent.

Owner:TIANJIN UNIV

Clear-muddy separation settling technology of sugar production

InactiveCN1912143AReduce manufacturing costIncrease sugar yieldPurification using alkaline earth metal compoundsFlocculationPhosphoric acid

The invention relates to cane juice purifying separating technology of sugar making. It includes the following steps: separating the initial extraction liquid and the secondary at sugar cane juicing stage; adding lime cream or other basic compound into the secondary extraction liquid or their mixture to make the pH value equal to 8.0-13; once or many times clarifying of chemical coagulation, flocculation, and solid-liquid separation; mixing the clarified liquid with the initial extraction liquid to do further clarifying by limebase process, phosphoric acid and sulphitation process.

Owner:周少基

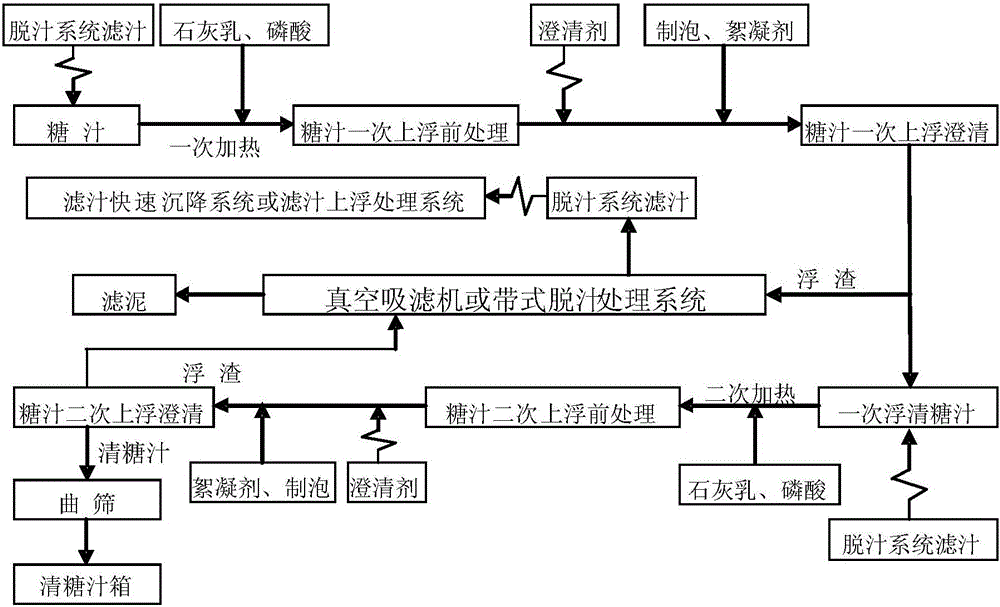

Sugar juice sulfur-free efficient cleaning method

ActiveCN105002306AShort stayReduce lossesPurification using alkaline earth metal compoundsPurification by physical meansSulfurLarge particle

The invention belongs to the technical field of sugar industries and discloses a sugar juice sulfur-free efficient cleaning method. After preliming, heating, foaming and flocculant adding are conducted on sugar juice, one-time floating clarification is conducted, large-particle non-sugar components in the sugar juice are removed; after secondary preliming, heating, foaming and flocculant adding are conducted on the one-time floating clarification sugar juice, secondary floating clarification is conducted; the sulfur-free cleaning process of the sugar juice is completed on the sugar juice obtained through secondary floating clarification through a sugar juice filtering and separating system. According to the sugar juice sulfur-free efficient cleaning method, the cleaning method of two levels of floating of the sugar juice is mainly adopted, and clean and complete sufur-free and carbonic-acid-free processing is achieved on the sugar juice, the equipment technology is simple, automatic continuous production is convenient, and the production efficiency is obviously improved. The obtained clean sugar juice is high in quality and is superior to clean sugar juice obtained through a traditional sulfurous method, and a very good application prospect is achieved.

Owner:广东省科学院生物与医学工程研究所

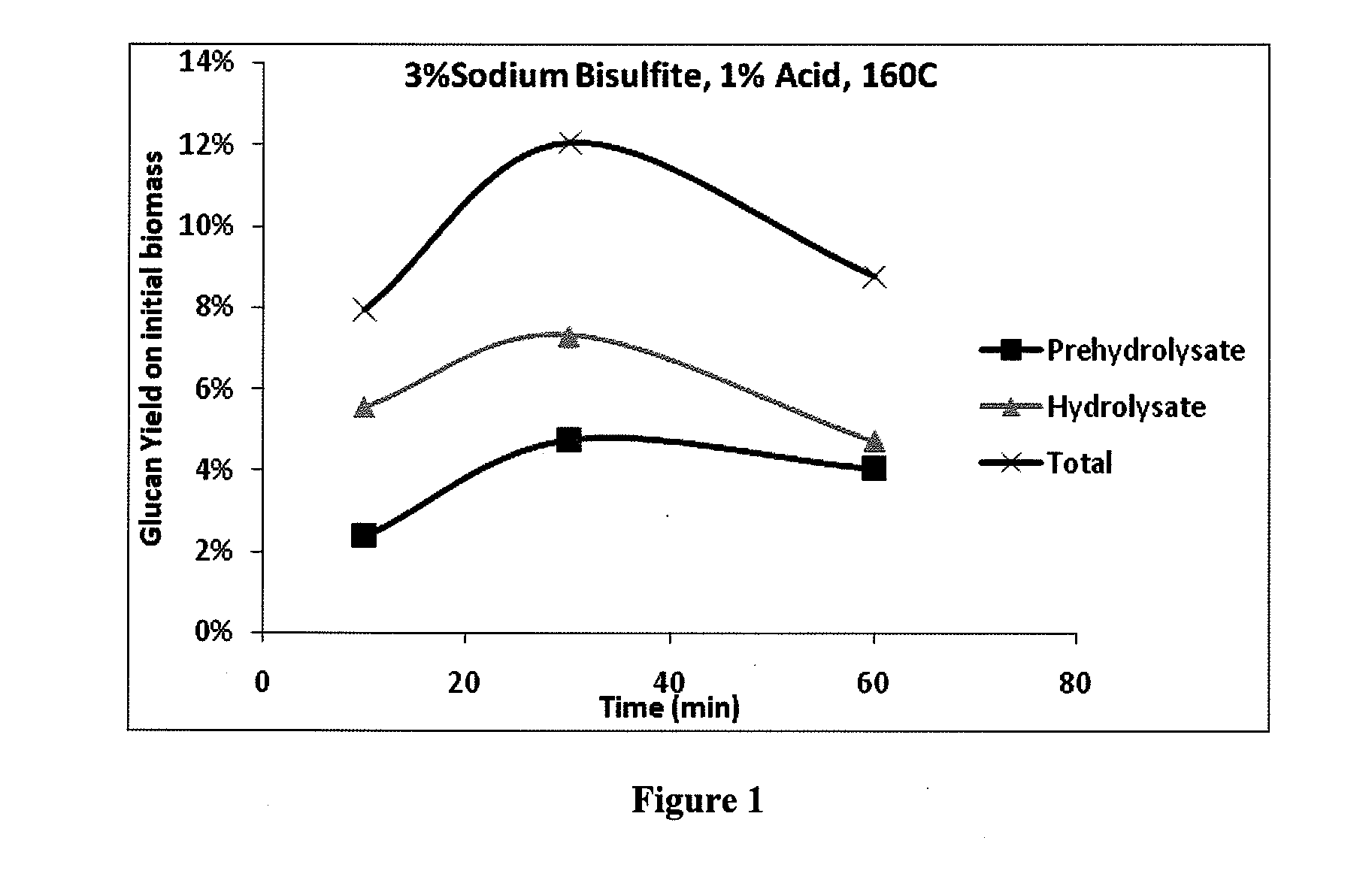

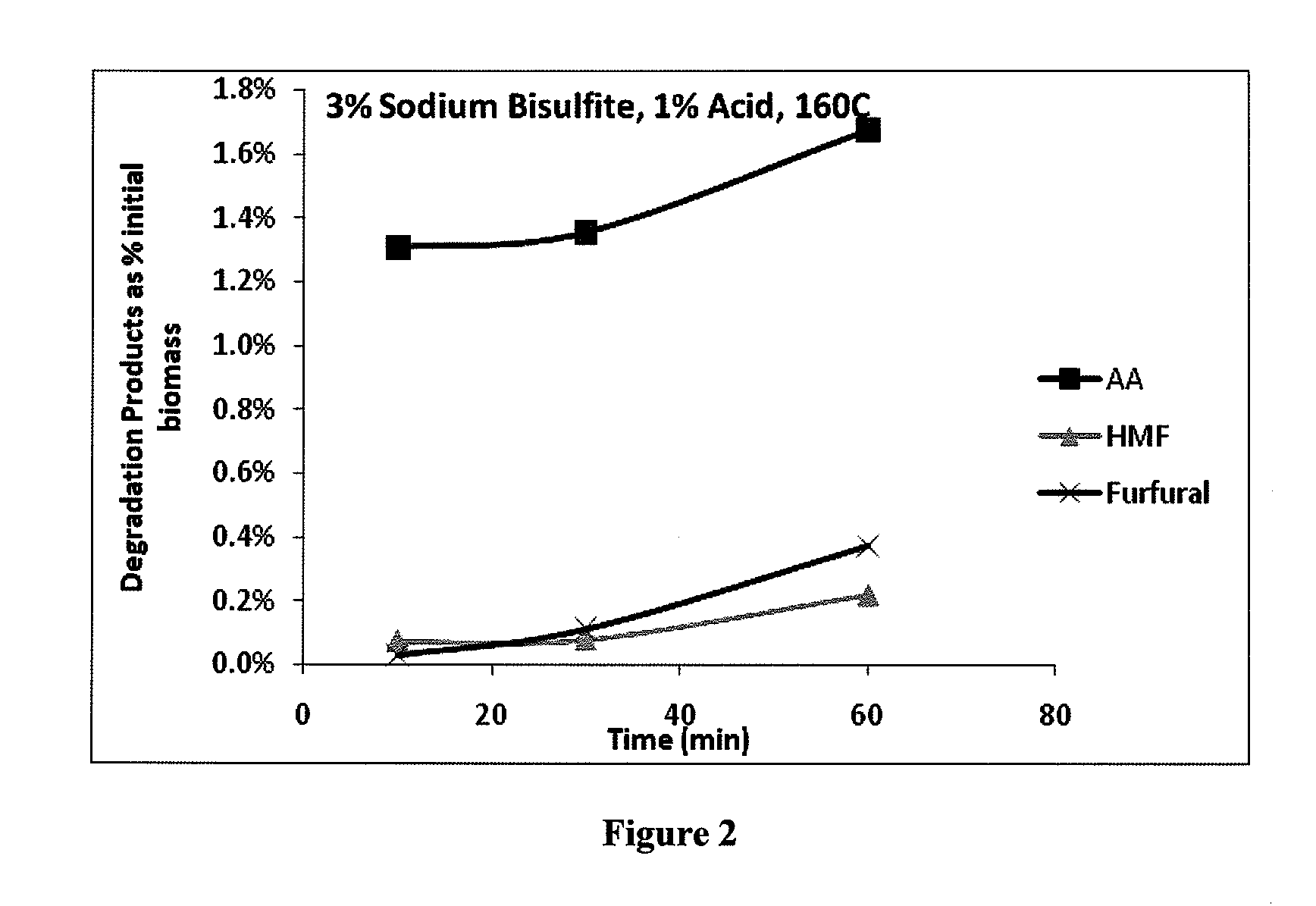

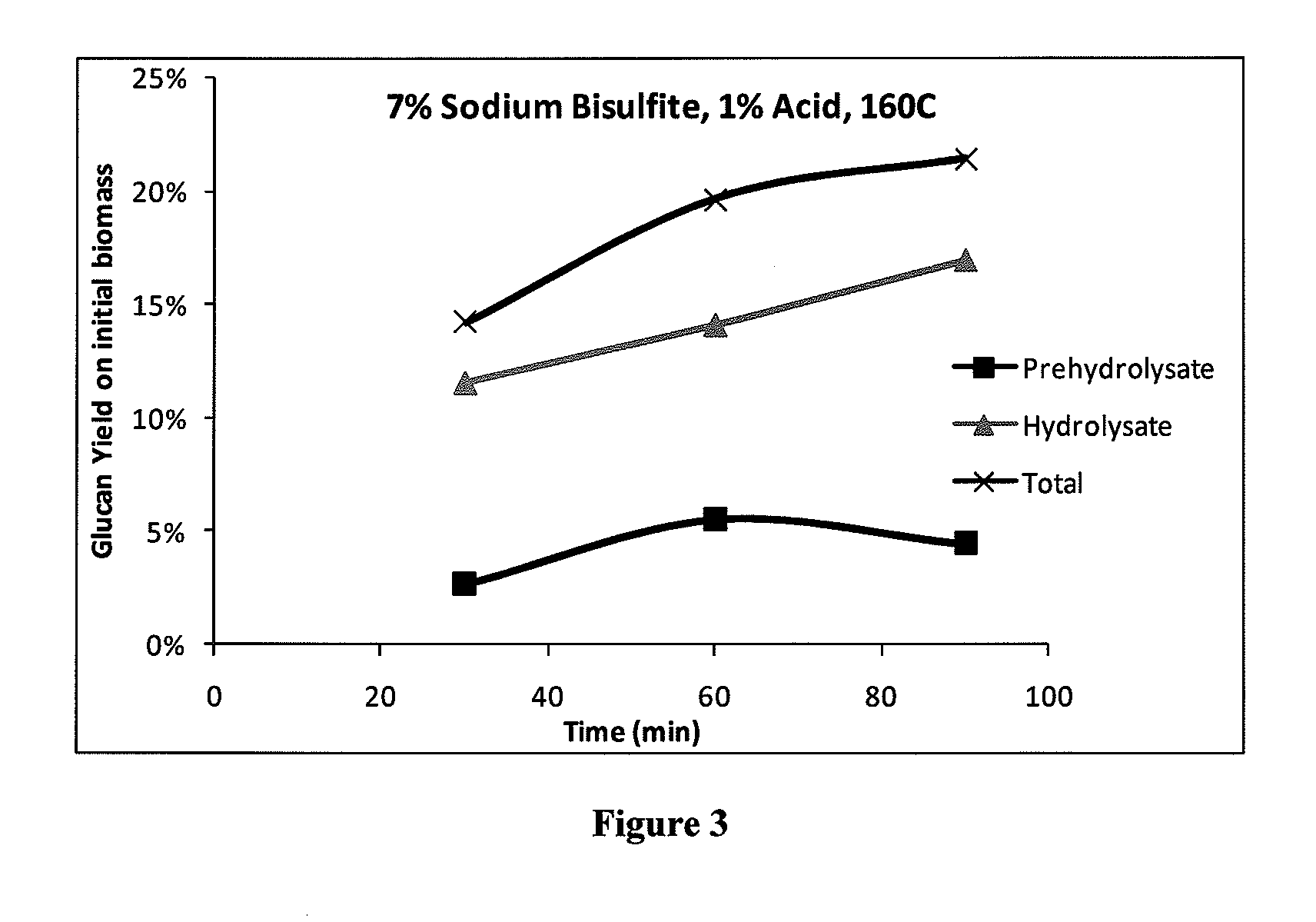

Pretreatment of Ligno-Cellulosic Biomass with Sulfonation

InactiveUS20110124056A1Low costReduce complexityPulping with acid salts/anhydridesPulp by-products recoveryCelluloseDry weight

Provided are methods for the pretreatment of ligno-cellulosic biomass such as softwoods with bisulfite such as ammonium bisulfite without the need for exogenous acid. In one variation, a method of pretreating ligno-cellulosic biomass is provided including the following steps: a) providing ligno-cellulosic biomass; b) contacting the ligno-cellulosic biomass with a solution comprising bisulfite at an amount between 1 and 10% of a dry weight of the ligno-cellulosic biomass to form a slurry; c) heating the slurry to a first temperature of 150-210° C. for a first period of time to form a first mixture; d) cooling the first mixture to a second temperature of 100-200° C. to form a second mixture; and e) maintaining the second mixture at the second temperature for a second period of time to form pretreated ligno-cellulosic biomass; wherein the first temperature is higher than the second temperature.

Owner:CHEVROU USA INC

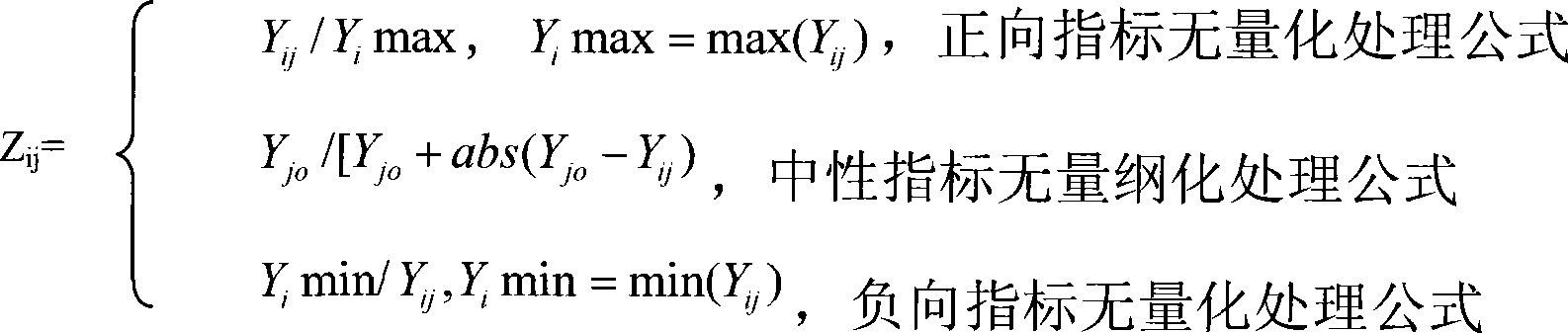

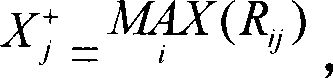

Comprehensive evaluation method for novel stain of sugarcane

InactiveCN101496495AReduce labor inputIncrease sugar yieldPlant genotype modificationAngiosperms/flowering plantsComparative testWeight coefficient

The invention relates to a comprehensive assessment system for a new sugar cane strain. In the sugar material sugar cane variety comparative test stage, 12 character assessment indexes are classified based on a DTOPSIS method and corresponding weight coefficients for the indexes are established after the test data is acquired. The 12 character indexes of the strain to be tested are divided into positive indexes, neutral indexes and negative indexes; and the weight coefficients for the indexes are established.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI

Compound enzyme preparation for sucrose industry

The invention relates to a compound enzyme preparation for cane sugar. The feature is that it contains 14-18wt% amylase, 10-14wt% prectinase, 8-12wt% dextranase, 8-12wt% protease, 16-20wt% cellulose enzyme. It could effectively improve the quality of sugar liquid, lower material viscosity, enhance sedimentation and filtering effect and accelerate absorbance for confection mother liquor sugar. It has the double effect for improving white granulated sugar and the yield.

Owner:唐明

Technique for glycosylated degradation of white spirit waste lees to prepare fermentalbe sugar

InactiveCN101775446AIncrease sugar yieldReduce separation costsGlucose productionSaccharic acidSulfate radicals

The invention relates to a technique for glycosylated degradation of white spirit waste lees to prepare fermentalbe sugar, which includes the procedures of drying and grinding of the white spirit waste lees, glycosylated degradation, the separation of saccharic acid, and the like. The technique is as follows: mixing ground waste lees with hydrogen chloride with mass fraction of 2% according to mass per unit volume of 1:10 for glycosylated degradation and collecting the filtrate; letting the filtrate pass through a chromatographic column which is filled with anionic resin, eluting through distilled water and collecting the eluate by step; and combining the eluates with sugar content equal to or more than 0.5 to be recovered sugar liquid. The recovered sugar liquid can be used as material for alcohol fermentation or other fermentations after being concentrated, and the used anionic exchange resin can be regenerated through NaOH. The concentration of the reducing sugar in the recovered sugar liquid prepared through the technique is equal to or more than 1%, wherein the content of dextrose is 55%, the content of xylose is 35% and the content of others is 10%; and the separation and recovery rate of the saccharic acid is more than 75%. The saccharic acid separation process is low in cost and no harmful impurities such as sulfate radical and the like are left behind, so the fermentalbe sugar has little effect to the subsequent alcohol fermentation or other fermentations. Therefore, the fermentalbe sugar is ideal material for alcohol fermentation and other fermentations.

Owner:SICHUAN UNIV

Method for settling extracted sugarcane juice by using weak base

InactiveCN103114155AShort stayShorten the timePurification using alkaline earth metal compoundsPurification by physical meansSaccharumSucrose

The invention aims to provide a method for settling extracted sugarcane juice by using a weak base. The method comprises the following steps of: filtering the extracted sugarcane juice, adding lime and phosphoric acid to adjust the pH value, heating for the first time, fumigating with sulphur, adding lime to neutralize, heating for the second time, settling the neutralized sugarcane juice, and separating a supernate from a puree. In the step of filtering the extracted sugarcane juice, the content of the absolute-dry sugarcane chaff in the filtered extracted sugarcane juice is controlled below 2.4g / L, and in the steps of fumigating with the sulphur and adding the lime to neutralize, the pH value of the extracted sugarcane juice is controlled at 7.8 to 9. The sucrose prepared by adopting the method has high quality, has a few impurities and is low in color value and high in yield. The scouring and recovering rate of the finally prepared sucrose can be improved by more than 2%, and the improvement is considerable to the enterprises making ten thousand tons of sucrose annually. The whole process dispenses with complex flows, and the cost is kept unchanged. The method has high practical and economic values.

Owner:南宁苏格尔科技有限公司

Method for hydrolysis of corncob under normal pressure

InactiveCN101824494AIncrease sugar yieldHigh light transmittanceSaccharides productionXyloseTransmittance

The invention discloses a method for hydrolysis of corncob under normal pressure, belonging to the field of functional sugar production technology. The method adopts hydrolysis under normal pressure, the hydrolysis temperature is low and the hydrolysis condition is mild. The method includes the steps of: (1) pickling: breaking the corncob to be size of 1-2cm, putting the broken corncob in a hydrolysis kettle, adding sulfuric acid solution with mass concentration of 0.1-1.0% according to solid-to-liquid proportion of 1:5-1:10, heating to 90-100 DEG C, preserving heat for 20-60min, and discharging the waste liquid; (2) rinsing: adding purified water according to proportion of 1-5:1:10 between the pickled dry corncob and the water, heating to 80-100 DEG C, preserving heat for 20-60min and then discharging the waste liquid; and (3) hydrolysis under normal pressure: adding sulfuric acid solution with mass concentration of 1.0-2.0% according to the proportion of 1:8-1:12 between the pretreated corncob and the sulfuric acid solution, heating to 100 DEG C under normal temperature, maintaining the mixture boiling, preserving heat for 2-6h and then discharging the xylose hydrolysate. Detection finds that the dry substance concentration is 5-9%, the transmittance is 20-40% and the content of the xylose is 50-70%.

Owner:FUTASTE PHARM CO LTD

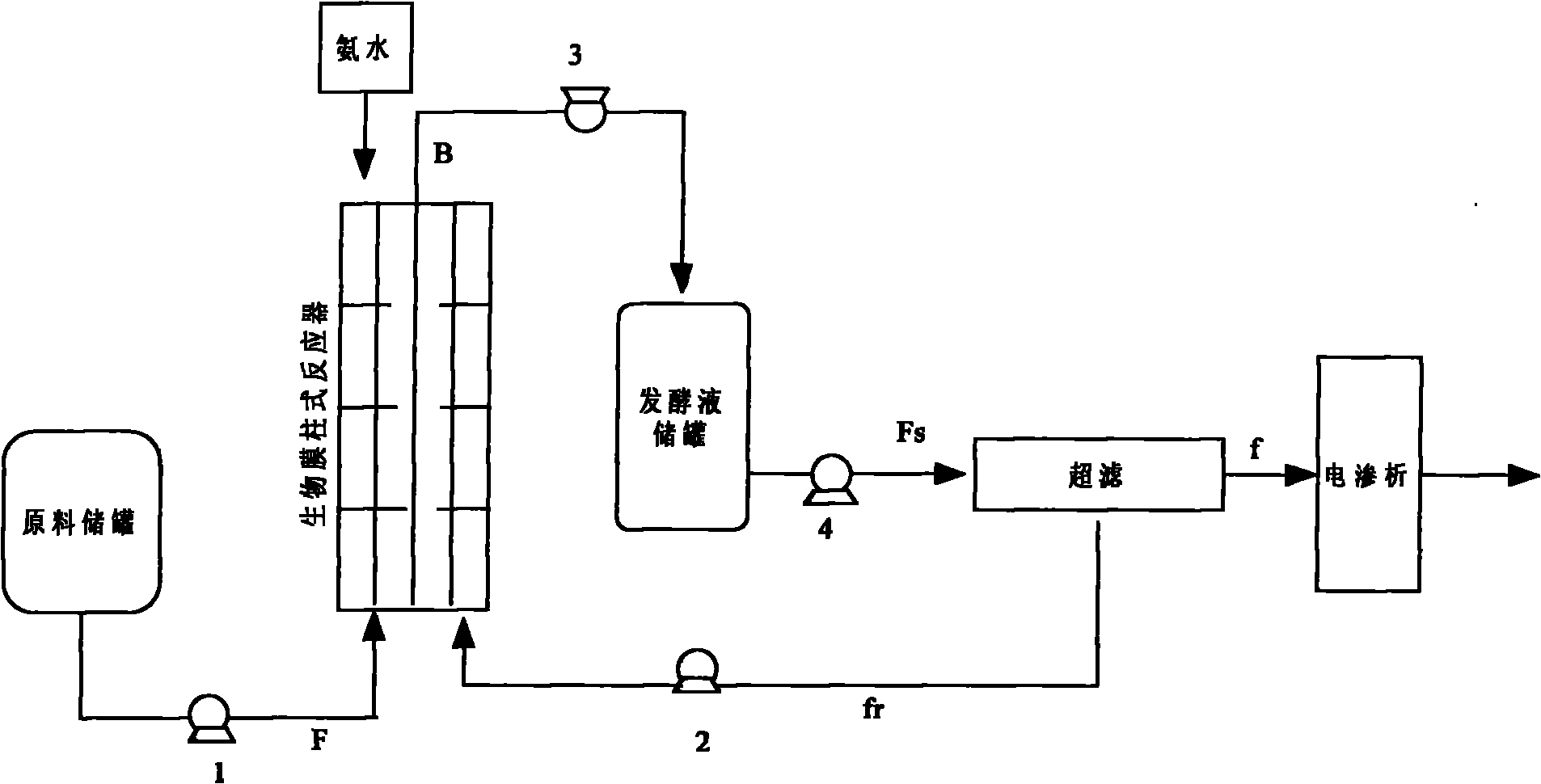

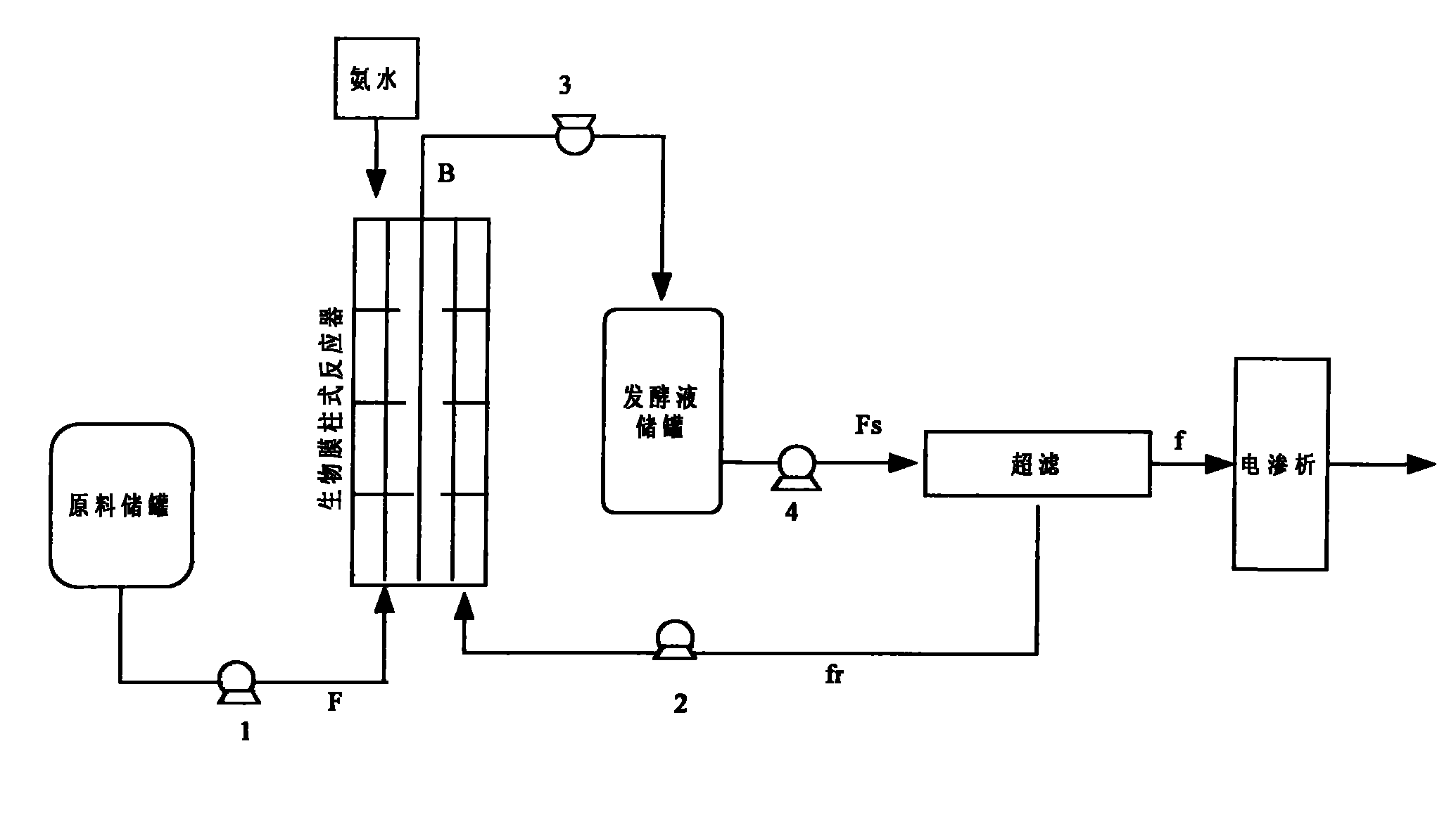

Biomembrane-electrodialysis coupling continuous production technology of L-lactic acid

ActiveCN102041279ATake advantage ofReduce pollutionMicroorganism based processesFermentationUltrafiltrationGlucose polymers

The invention provides a biomembrane-electrodialysis coupling continuous production technology of L-lactic acid. The production technology comprises the following steps: a clear liquid biomembrane column reactor is used to perform continuous anaerobic fermentation, the lactic acid producing strains are adsorbed by combined perforated ring filler, an ultrafiltration membrane is used to filter the fermentation liquor, thalli are blocked by the ultrafiltration membrane, the blocked thalli and liquid are sent back to the biomembrane column reactor, and L-lactic acid is separated through electrodialysis. The method provided by the invention uses the biomembrane column reactor to adsorb lactic acid producing strains on the membrane and uses the ultrafiltration membrane to block lactic acid bacteria, thus the thalli concentration and sugar utilization rate can be effectively increased, and the lactic acid concentration, the acid producing rate and the conversation rate from glucose to lacticacid can be increased greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquor cleaning process for refining sugar from corns

The invention provides a liquor cleaning process for refining sugar from corns, which sequentially comprises steps as follows: (1) mixing: preparing corn powder and then mixing the corn powder to 19-21 baume degrees, (2) pre-liquefying: adding starch containing 0.07-0.08KNU / g amylase in dry basis and having thermal resistance not lower than 100 DEG C, and controlling temperate within 90-100 DEG C, pH value within 5-7, stirring velocity within 35-70rpm for 20-50min, (3), jet liquefying: controlling jetting temperature within 105-108 DEG C and keeping jetting for 4-5min, (4) saccharifying: keeping temperature within 94-100 DEG C, regulating pH to 3.5-5.5 after liquor becomes brownish red through iodine test, cooling the liquor to a temperature within 59-61 DEG C and then adding starch containing 0.5-0.6AGU / g complex diastatic enzyme in dry basis, and retaining the liquor for 22-25h. By utilizing the liquor cleaning process for refining sugar from corns, liquor cleaning can be thorough, thereby greatly increasing sugar yield and being favorable for filtering sugar liquor after being liquefied.

Owner:河南金丹乳酸科技股份有限公司

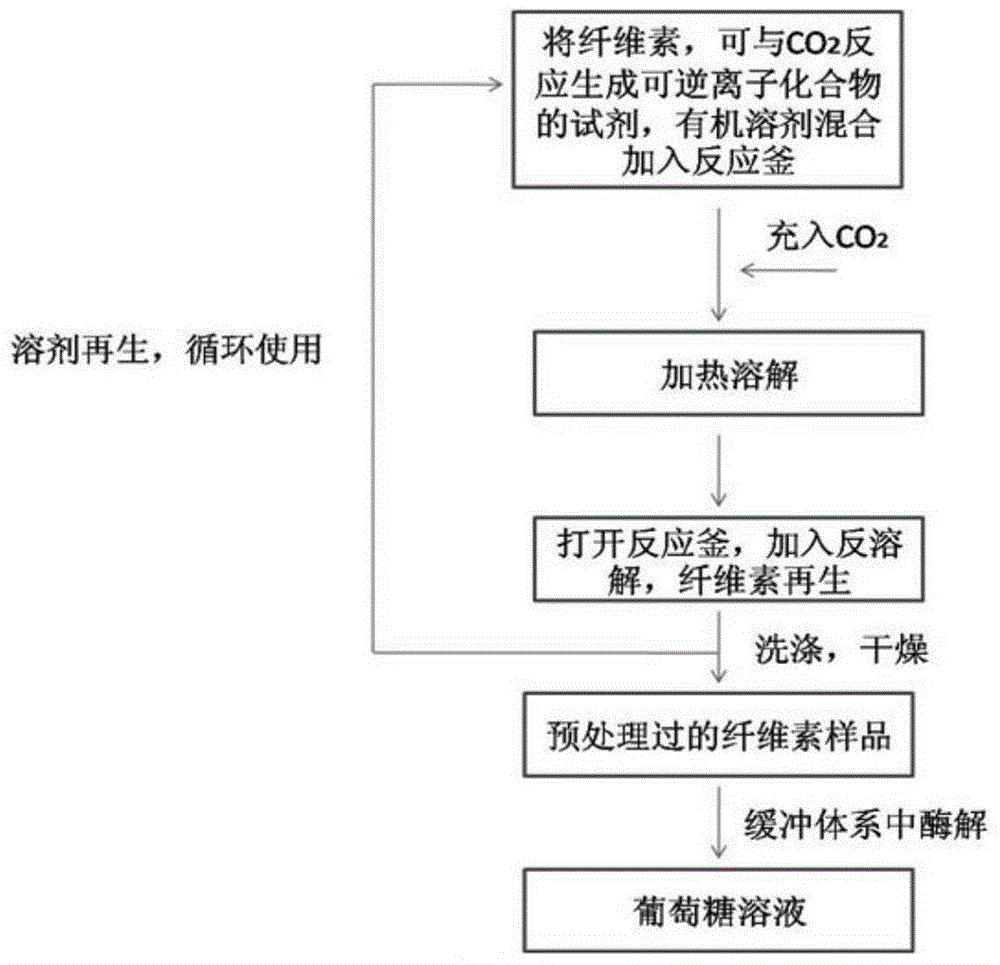

Method for improving cellulase hydrolysis sugar field

The invention provides a method for improving cellulase hydrolysis sugar field. The method comprises the following steps: (1) taking cellulose as a raw material; (2) dissolving the cellulose in a CO2 switch-type ionic compound or a mixed solvent consisting of the CO2 switch-type ionic compound and an organic solvent, thereby obtaining a cellulose-containing solution; (3) adding an anti-solvent into the cellulose solution, regenerating, filtering and separating the dissolved cellulose, thereby obtaining the pretreated cellulose material; and (4) taking a certain amount of regenerated cellulose, adding a buffer solution and cellulase for performing enzymolysis, thereby obtaining the glucose solution. The CO2 switch-type ionic compound or the mixed solvent consisting of the CO2 switch-type ionic compound and the organic solvent serves as a solvent, the cellulose is subjected to dissolving pretreatment, and the method has the advantages that the process is simple, the solvent cost is low, the operation is convenient, the solvent can be recycled, the cellulase hydrolysis speed is high, the sugar yield is high and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparing method for malt sugar

InactiveCN105695532AImprove appearance qualityIncrease sugar yieldFermentationHordeum vulgareHydrolysis

The invention provides a preparing method for malt sugar. The preparing method comprises the following steps that barley is added with water to be steeped and then sprouted; the barley is ground when growing two leaves wrapping the core, the ground barley malt is obtained, part of the ground barley malt is mixed with cooked sticky rice and subjected to primary fermentation, and the rest of the barley malt is added after primary fermentation for secondary fermentation; after secondary fermentation is finished, filtering is carried out to obtain juice, the juice is boiled out, and malt sugar is obtained. According to the preparing method, barley and sticky rice are selected for preparation, and two times of fermentation are carried out in the fermentation process when barley malt and sticky rice are mixed. By means of the two-section type fermentation method, the fermentation time is prolonged so that an amylolytic enzyme in the barley malt can fully perform the hydrolysis action, starch in sticky rice can be hydrolyzed into malt sugar as much as possible, and thus the sugar yield can be increased.

Owner:尹仲荣

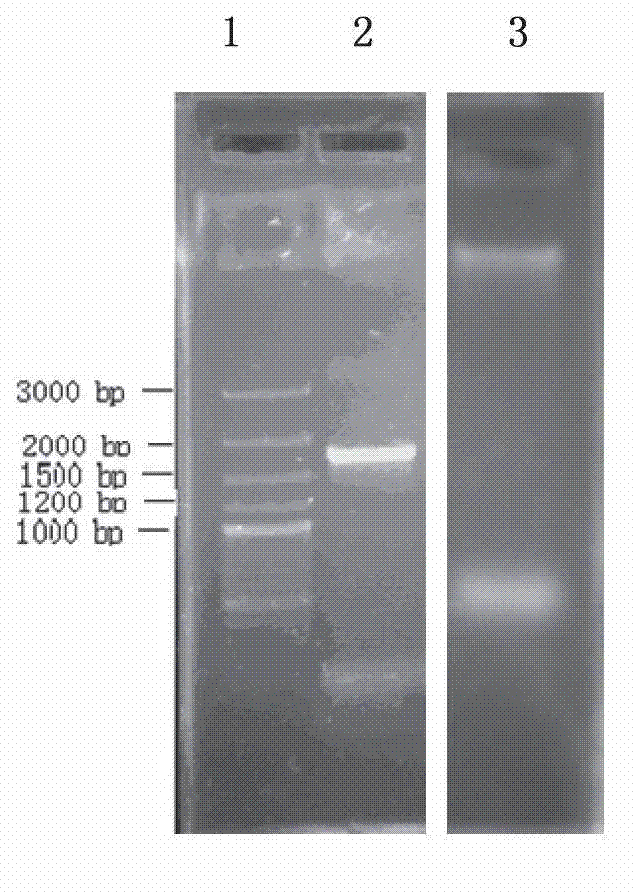

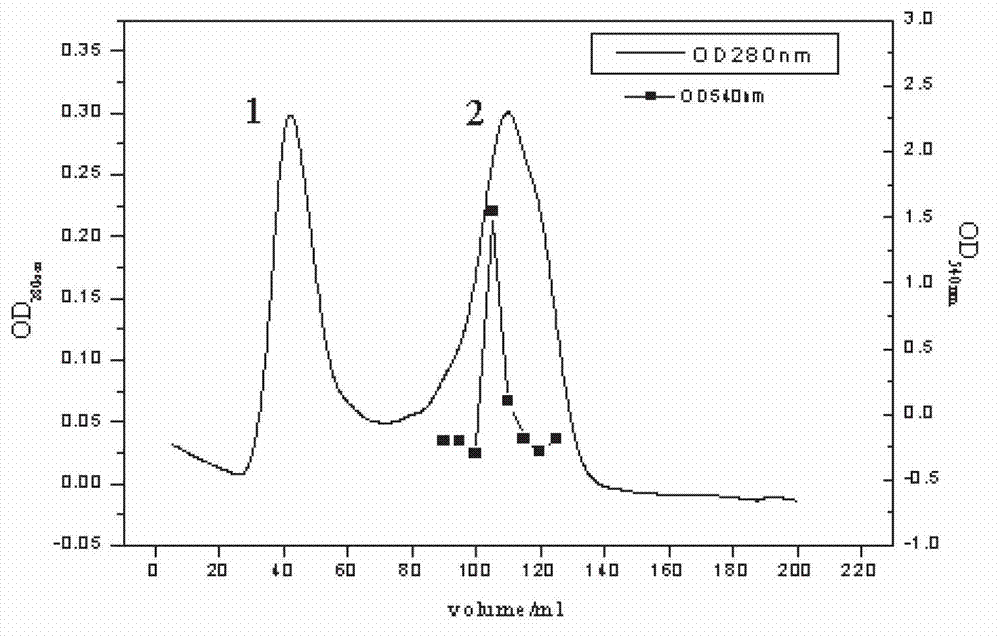

Bacterial strain capable of secreting cellulase as well as cellulase extraction method and application thereof

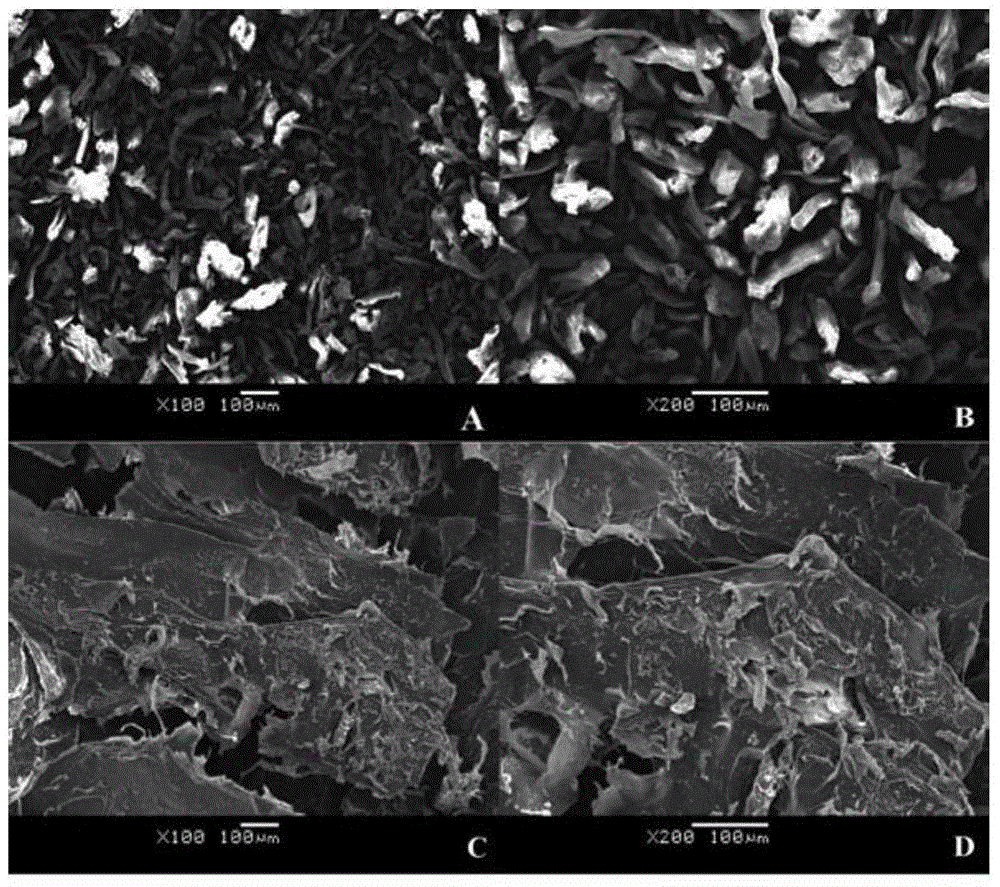

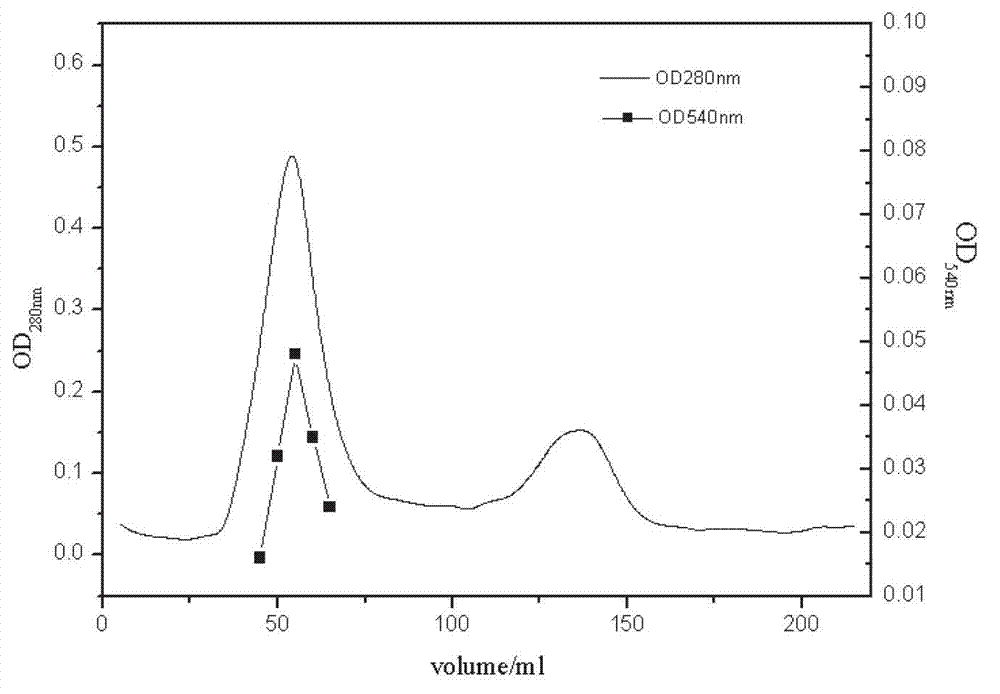

InactiveCN102807958AThe separation method is simpleWide variety of sourcesFungiMicrobiological testing/measurementMicrobiologyCellulose degradation

The invention discloses a bacterial strain capable of secreting cellulase as well as the cellulase extraction method and application thereof, and solves the problems of low enzyme activity and yield in the conventional cellulase producing bacterial strain. The bacterial strain has a collection name of trichoderma virens ZY-01, is collected in China Center For Type Culture Collection (CCTCC), has a collection number of CCTCC No: M 2012205 and has an 18s rDNA sequence as shown in SEQ ID NO.1. A method for separating the bacterial strain, a method for producing, purifying and extracting the cellulase and an application method for efficient degradation of bagasses and straws are described. The bacterial strain has the advantages of high enzyme activity, wide range of adapted reaction condition and simplification of preparation; and the secreted cellulase is high in cellulose degradation activity.

Owner:WUHAN UNIV OF SCI & TECH

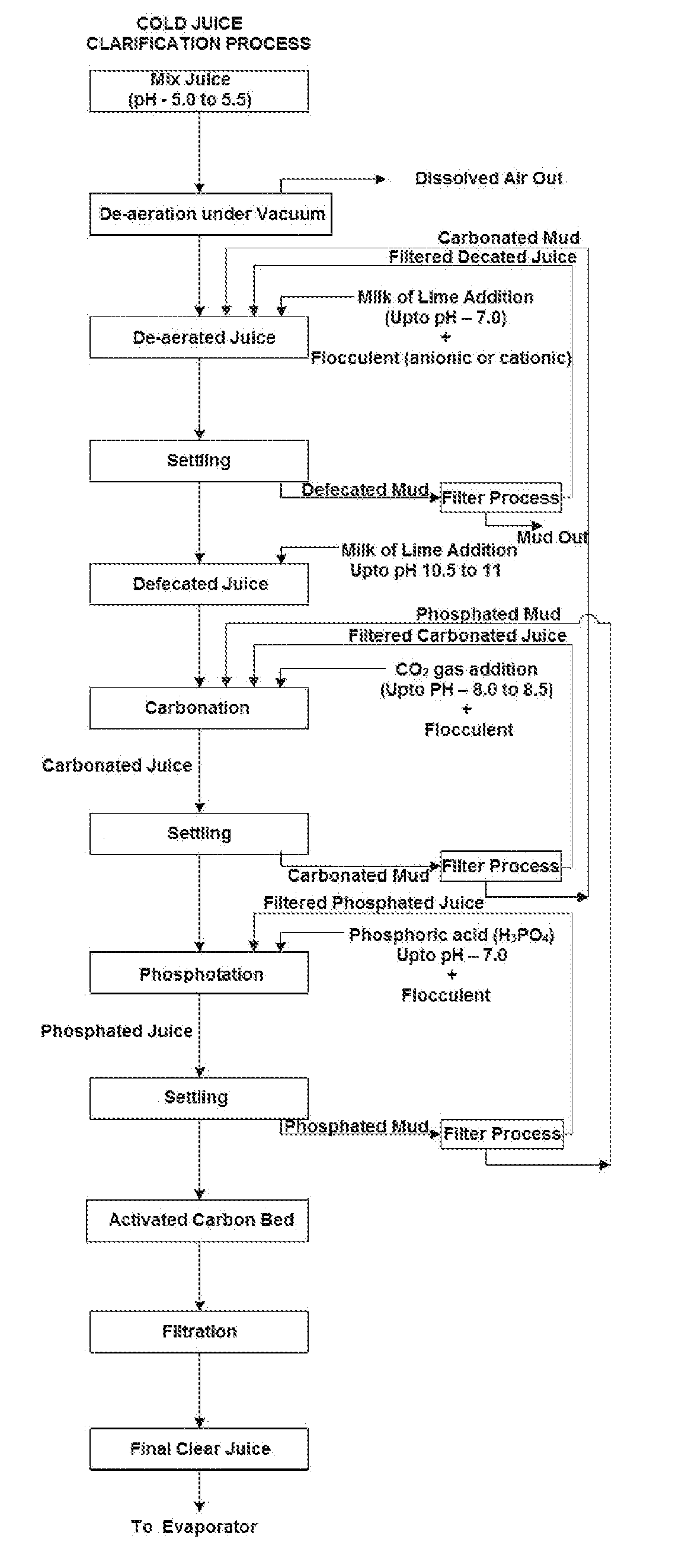

Cold juice clarification process

InactiveUS20150101594A1Increase sugar yieldMore energy efficientPurification using adsorption agentsPurification using chemicalsActivated carbonCost effectiveness

A process for cold clarification of juice is described. A sugar cane or beet juice clarification process to clarify raw juice by means of aeration of fresh raw juice, addition of milk or lime, anionic and / or cationic flocculants, particularly together with a carbonating process, addition of phosphoric acid and then passing the juice through activated carbon bed is described. The process eliminates the need to heat the juice at any stage thus making it more cost effective, energy saving and gives better yield in terms of quality and quantity both. The recycling of defecated, carbonated and phosphated filtered juice and carbonated and phosphated mud that reduces the consumption of lime, CO2 and phosphoric acid up to some extent is described.

Owner:SPRAY ENG DEVICES

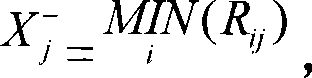

Method for obtaining xylose hydrolysate by corncob hydrolysis

ActiveCN102994655AIncrease sugar yieldSave water washSaccharides productionHydrolysateAqueous solution

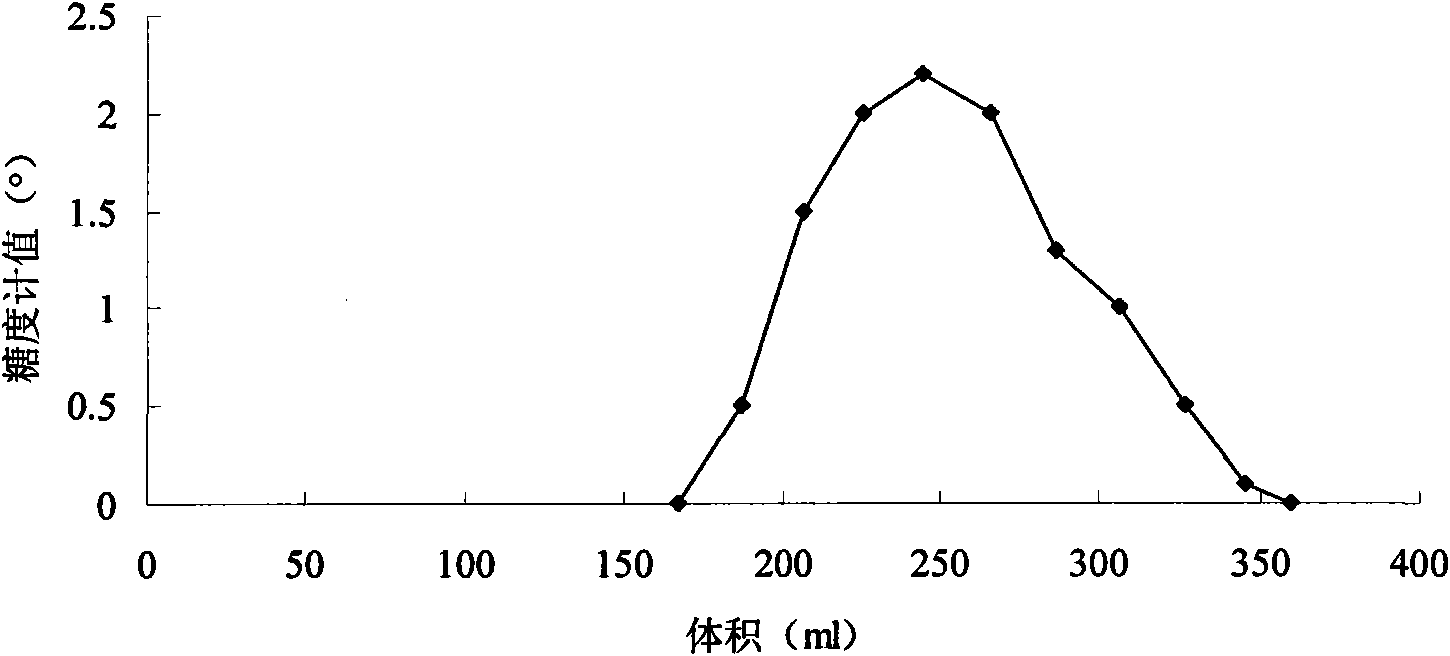

The invention discloses a method for obtaining xylose hydrolysate by corncob hydrolysis, comprising the following steps of: (1) dedusting and crushing corncobs into grains having a grain diameter of 3-5 mm; (2) adding the crushed corncob grains into a 1.5-0.5wt% sulphuric acid aqueous solution or hydrochloric acid aqueous solution, and soaking; (3) heating the solid materials after the soaking is finished to 120-150 DEG C, and performing a gaseous-phase hydrolysis reaction; and (4) after the hydrolysis is finished, washing the materials by a washing liquid to obtain the 12-15wt% xylose hydrolysate. According to the invention, gaseous-phase hydrolysis is adopted, the corncobs are dedusted, crushed and mixed with acid, and then filled in a pot to be directly hydrolysed, and then subjected to affination by adding water to obtain the hydrolysate, and the sugar degree Bx of the hydrolysate is 12-15%, thus greatly increasing the sugar productivity of the corncob hydrolysis; the processes of water washing and acid pre-treatment are omitted during the technical process; the production of the hydrolysis working procedure realizes sewage zero-discharge, and the production cost is reduced simultaneously.

Owner:ZHEJIANG HUAKANG PHARMA +1

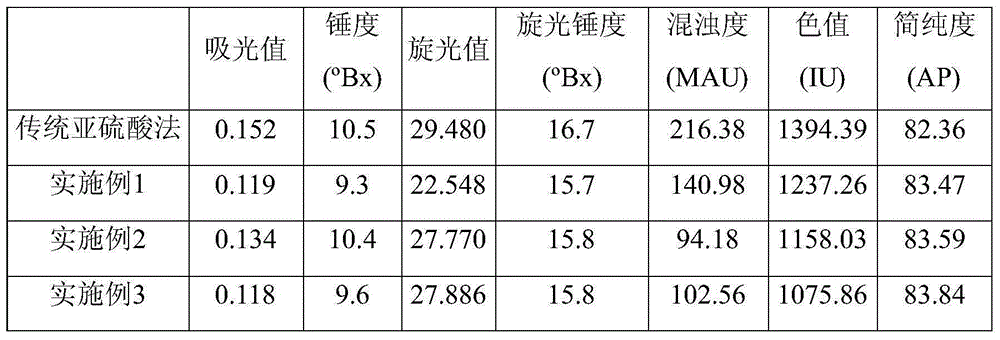

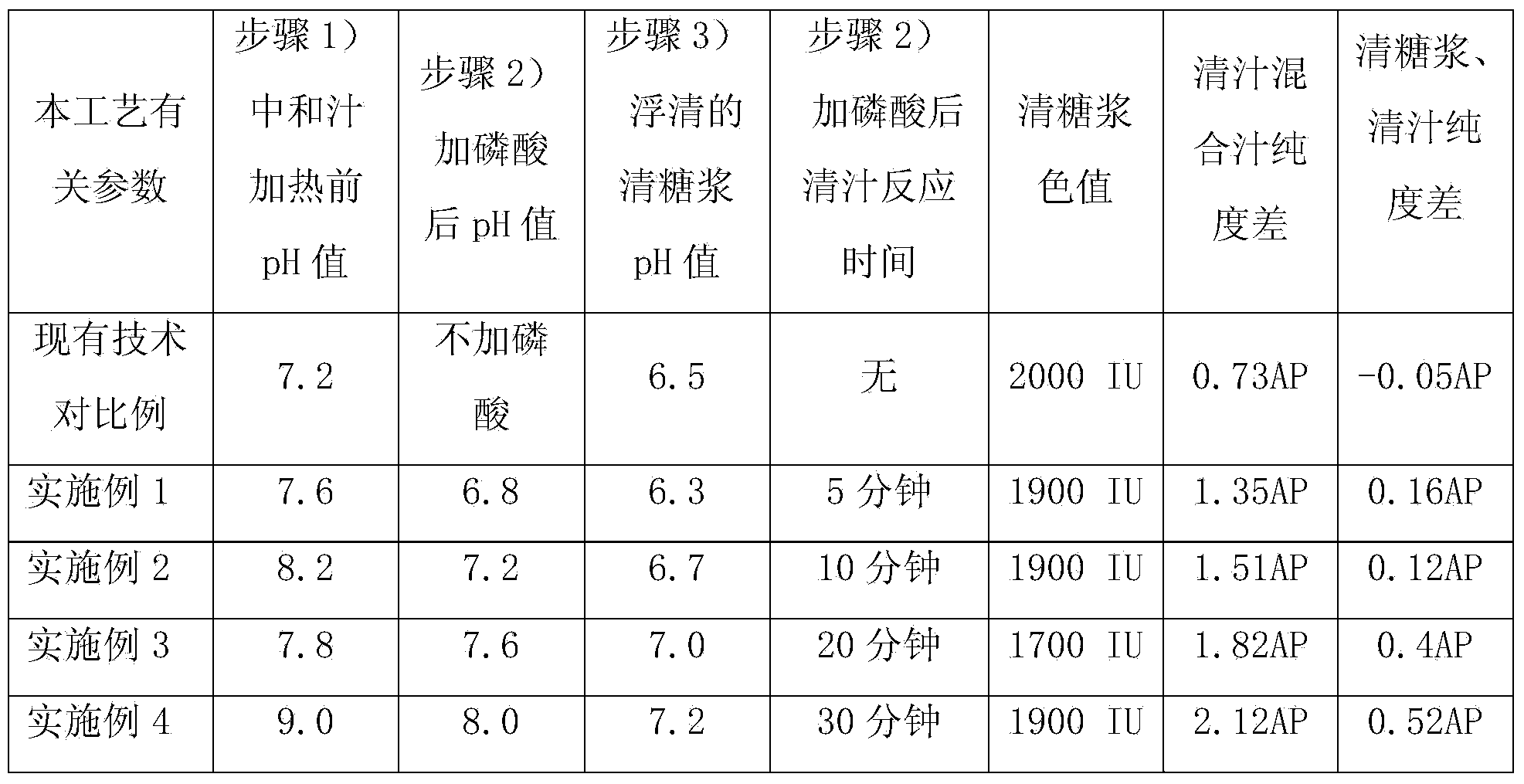

Sugar manufacturing technique for improving yield and reducing color value of white sugar

ActiveCN104388600AImprove clarification efficiencyPrevent pigmentationPurification using alkaline earth metal compoundsPurification by physical meansPhosphoric acidSugar

The invention relates to an improved sugar manufacturing technique adopting the alkaline sulfite method, and particularly relates to a sugar manufacturing technique for improving the yield and reducing the color value of white sugar. According to the sugar manufacturing technique, the appropriate pH value is controlled at three technique points, and the timing of adding phosphoric acid in the conventional method is changed; the reaction time is increased in the step of the phosphoric acid reaction, so that phosphoric acid can completely react with calcium salt in clear syrup; the color value of clear syrup obtained by adopting the sugar manufacturing technique can be reduced from 2000 IU to 1700-1900 IU, and the yield is improved.

Owner:南宁苏格尔科技有限公司

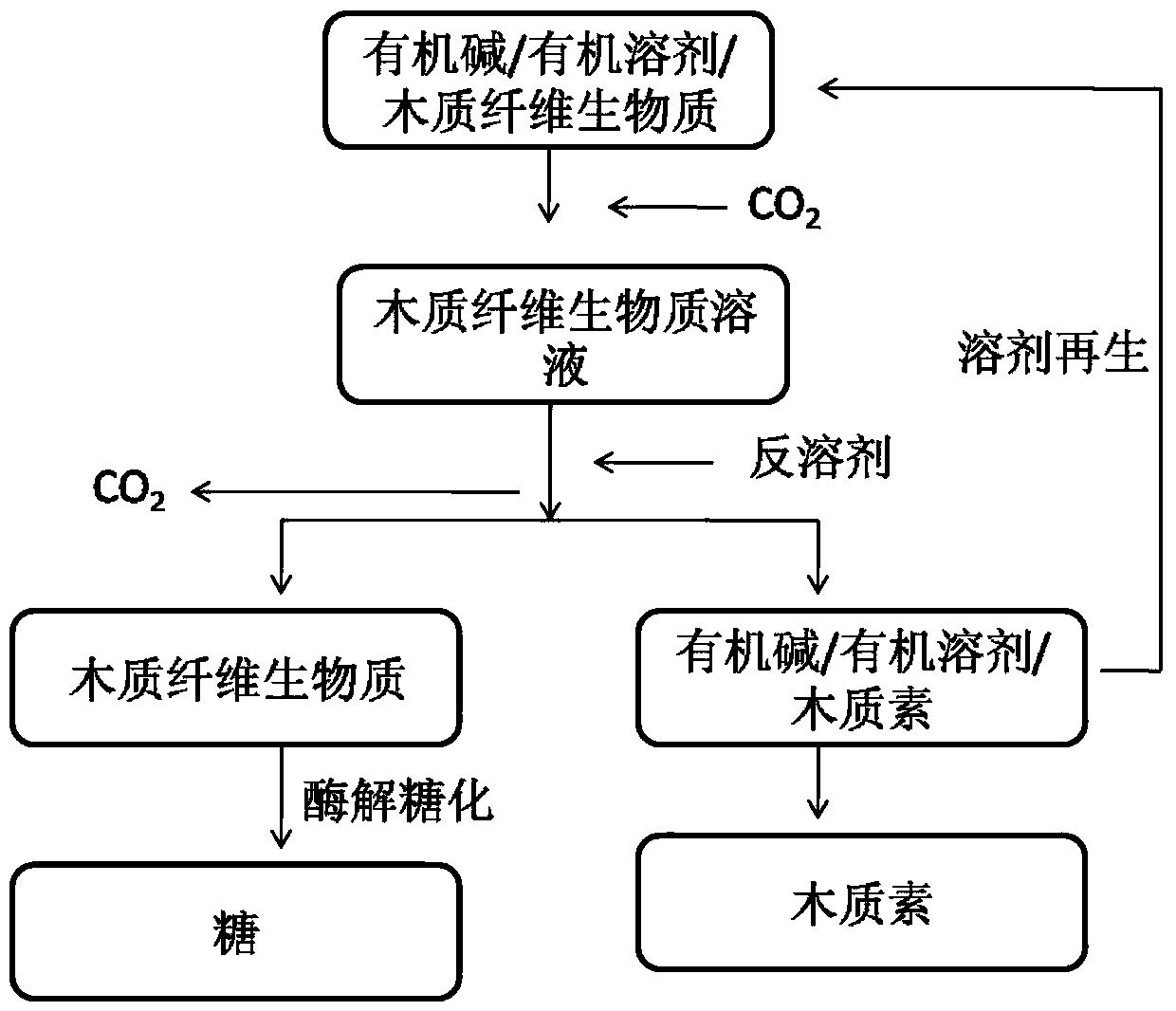

Method for improving sugar yield of lignocellulosic biomass after enzymolysis

The invention provides a method for improving sugar yield of lignocellulosic biomass after enzymolysis. The method comprises the following steps: (1) taking lignocellulosic biomass as a raw material; (2) mixing the lignocellulosic biomass, organic alkali and an organic solvent; (3) filling the mixed system with CO2 with certain pressure, and reacting for certain time; (4) releasing CO2, recycling the biomass by adopting an anti-solvent of cellulose; and (5) taking a certain amount of recycled lignocellulosic biomass, and adding a buffer solution and cellulase as well as xylanase for carrying out enzymolysis, thus obtaining a sugar solution. According to the method, under the existence of the organic alkali, hydroxide radicals in the lignocellulosic biomass and CO2 are subjected to reversible reaction, so that a crystal texture of the cellulose in the lignocellulosic biomass is damaged, and along with the conduction of the reaction, the lignocellulosic biomass is dissolved or subjected to swelling under the effect of the organic solvent, and the lignocellulosic biomass is subjected to the dissolving pretreatment; and the method has the advantages that the technology is simple, the cost of the solvent is low, the operation is convenient, the solvent can be recycled, the hydrolysis speed of the cellulose and the hemicellulase in the lignocellulose is high, and the sugar yield is high.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

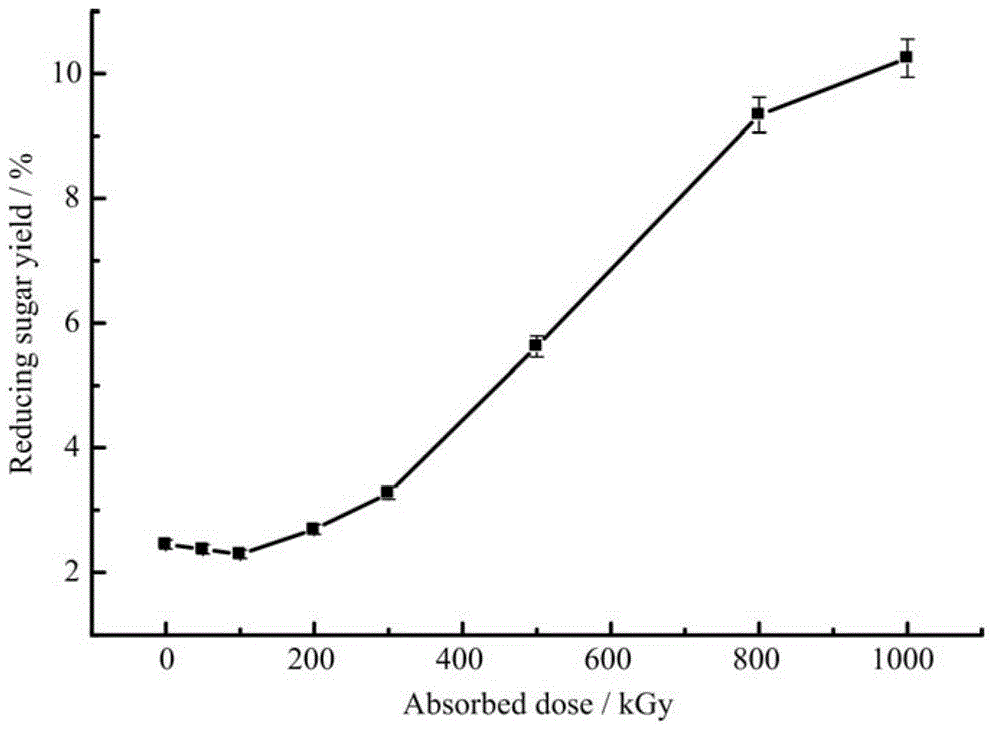

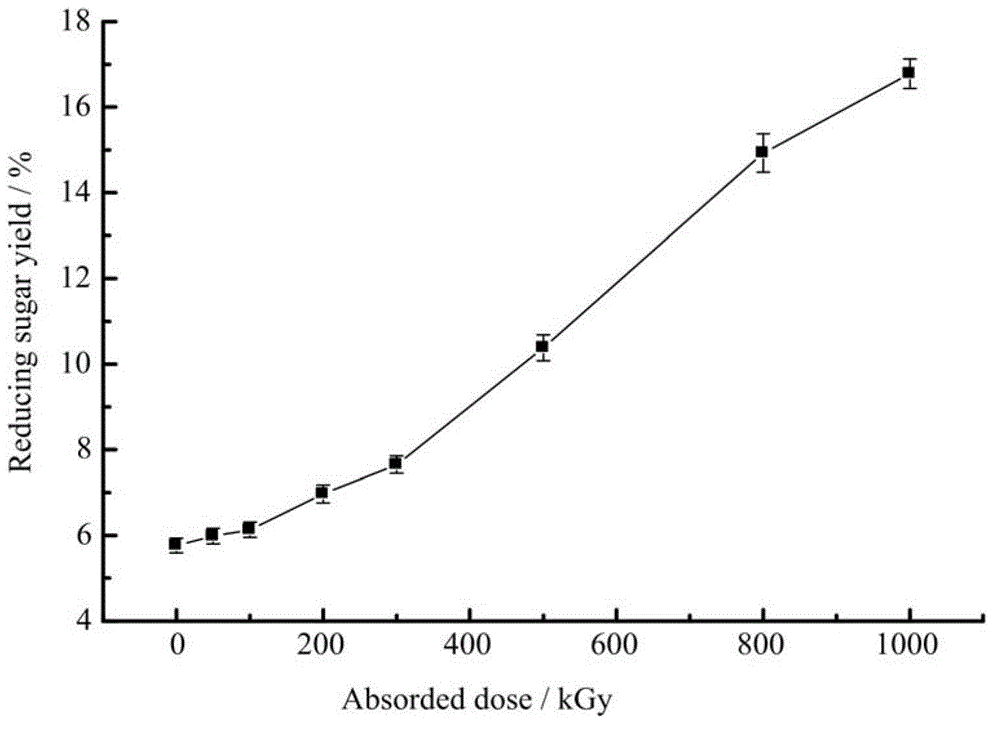

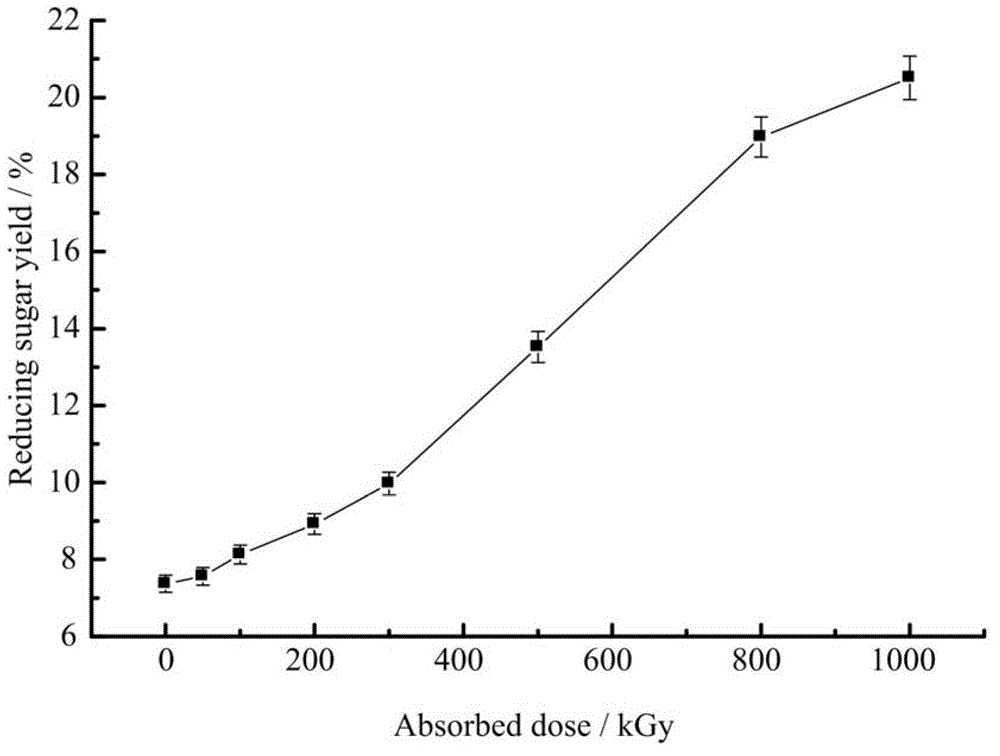

Method for improving reducing sugar content of straws

InactiveCN102978259AChange structural propertiesDestroy the cross-linked structureFermentationGranularityRoom temperature

The invention discloses a method for improving the reducing sugar content of straws. The method comprises the following steps of: crushing the straws, wherein the granularity of the crushed straws is 20-180 meshes; irradiating the straws, wherein the accelerative irradiation dose is 50-1000kGy and is 200-800kGy preferably, the radiation dose rate is 0.5kGy / h, and an irradiation source is a 60Co-gamma ray irradiation source; and carrying out enzymolysis on the straws, then soaking the straws subjected to enzymolysis in a water solution of alkali to obtain a mixed solution and placing the mixed solution at room temperature. The method disclosed by the invention has the unique advantages of being simple to operate and short in required processing time, remarkably increasing the sugar yield and being environmentally-friendly.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

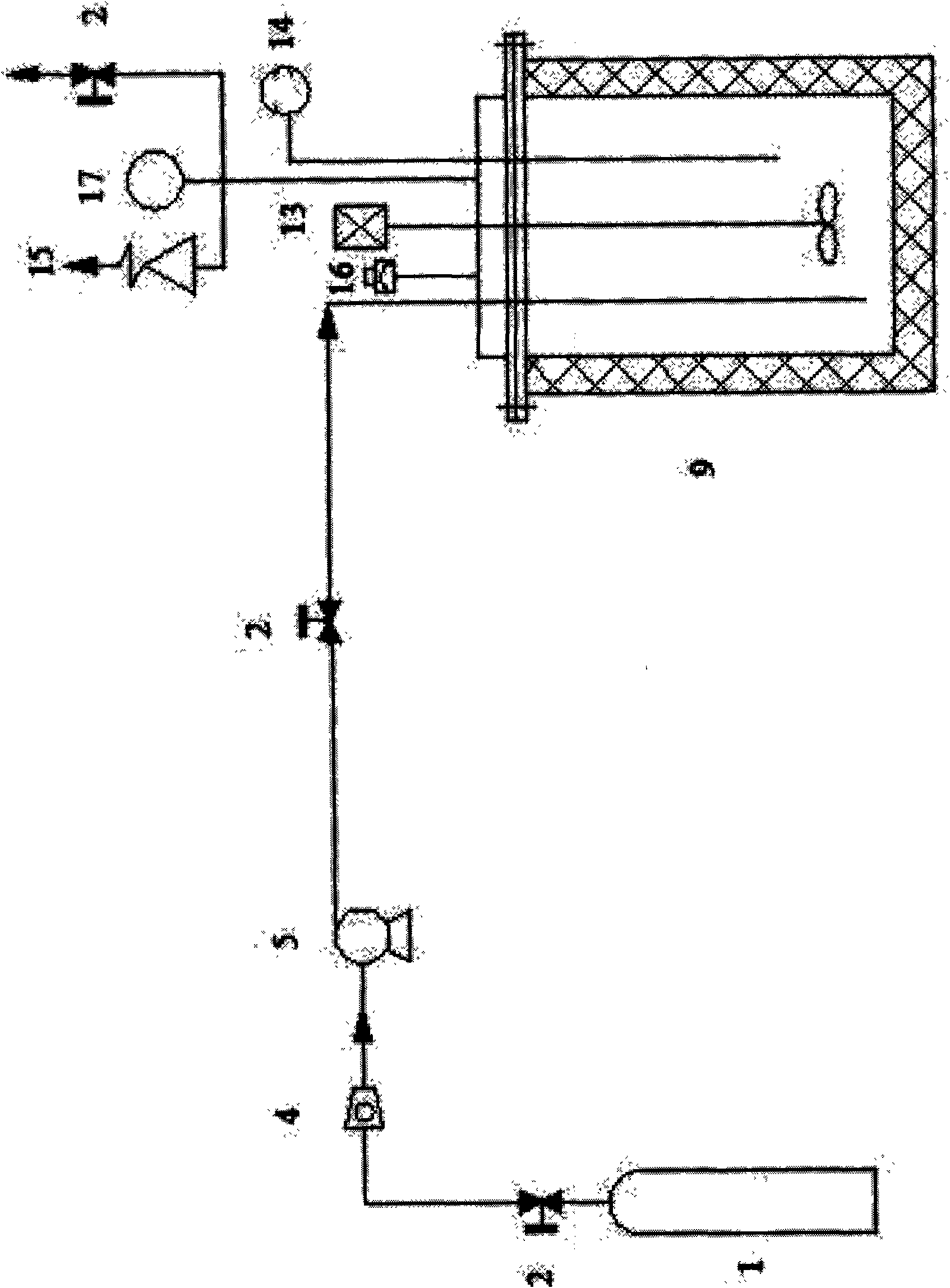

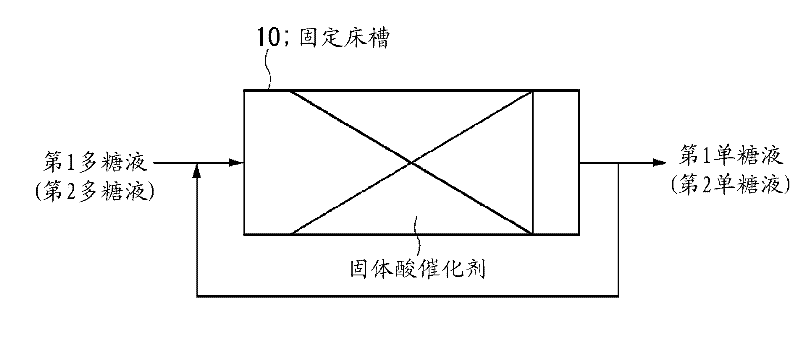

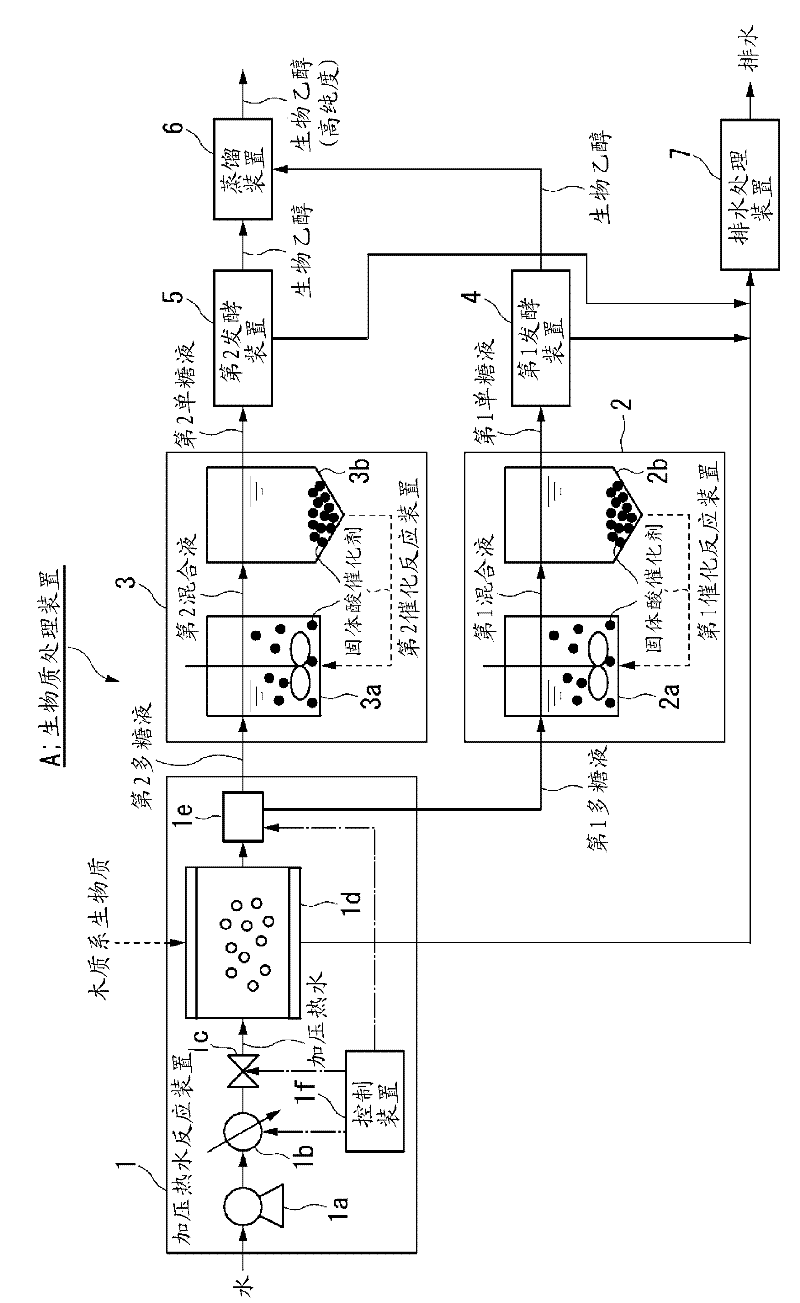

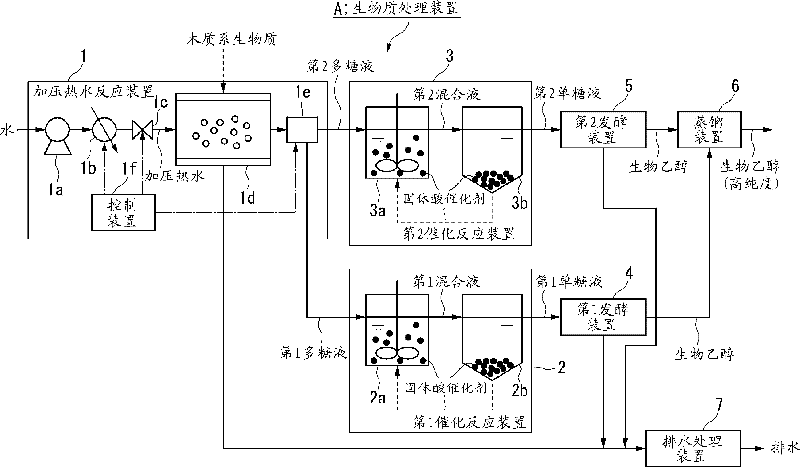

System and method for treating biomass

InactiveCN102597273AAvoid smallIncrease sugar yieldBioreactor/fermenter combinationsPressurized chemical processPtru catalystSolid acid

A system (A) for treating a biomass, comprising: a pressurized hot water reaction unit (1) whereby, using pressurized hot water, the biomass is hydrolyzed under first reaction conditions for degrading hemicellulose to give a first polysaccharide solution containing xylooligosaccharides, and then said biomass is hydrolyzed under second reaction conditions for degrading cellulose to give a second polysaccharide solution containing cellooligosaccharides; a first catalytic reaction unit (2) whereby the first polysaccharide solution flowing out from the pressurized hot water reaction unit (1) is hydrolyzed using a solid acid catalyst to give a first monosaccharide solution containing xylose; and a second catalytic reaction unit (3) whereby the second polysaccharide solution flowing out from the pressurized hot water reaction unit (1) is hydrolyzed using a solid acid catalyst to give a second monosaccharide solution containing glucose

Owner:IHI CORP +1

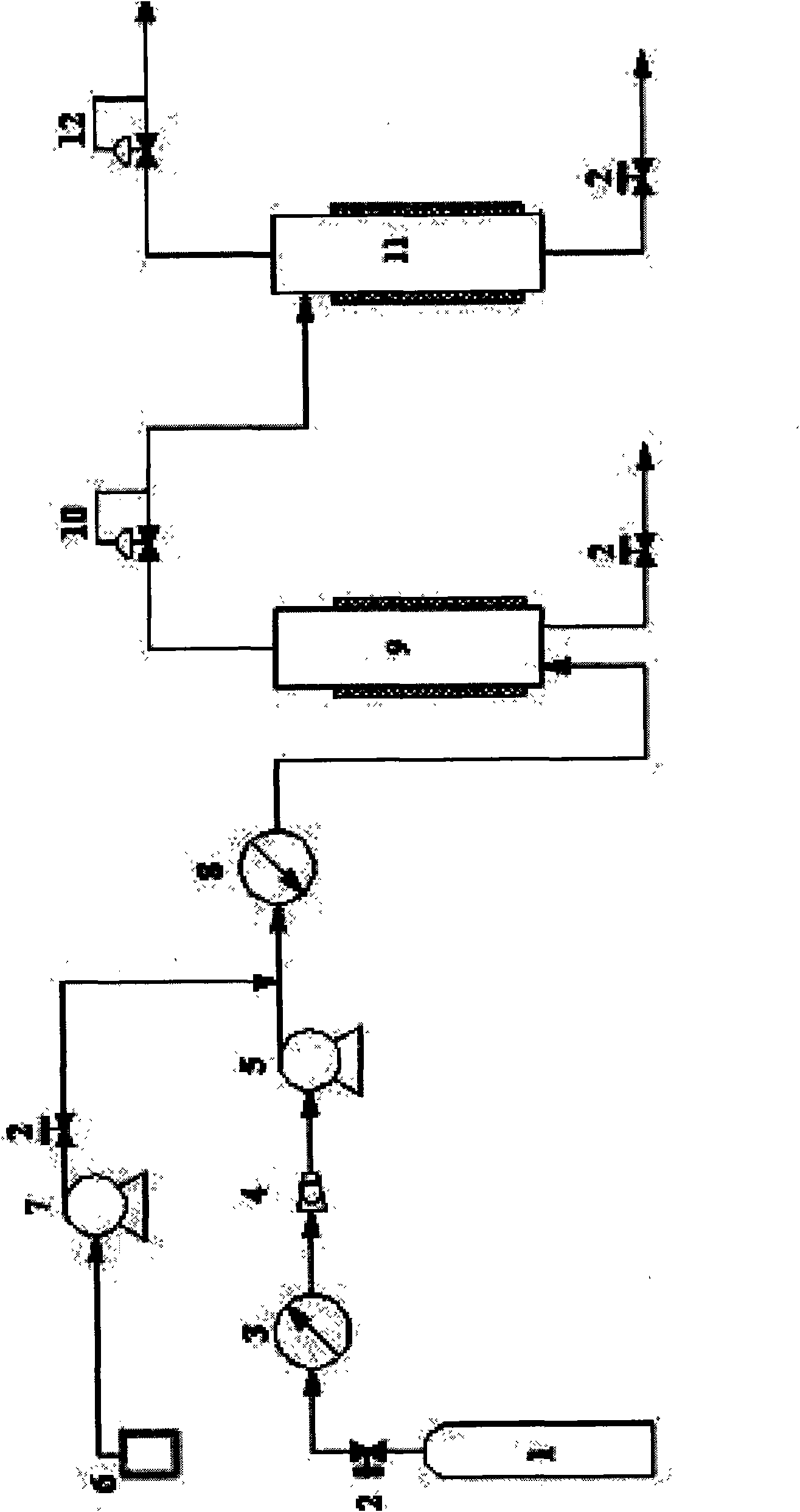

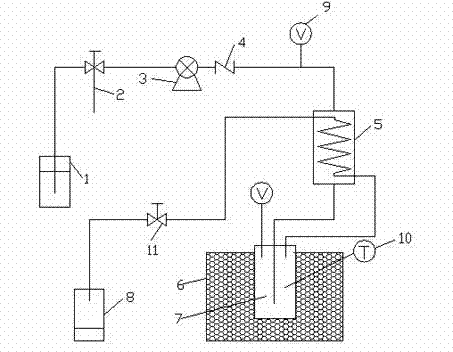

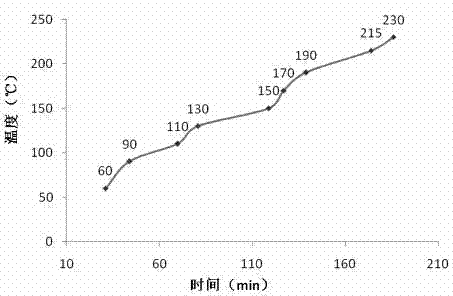

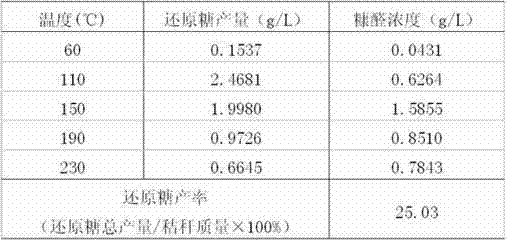

Hydrothermal saccharification method and device for cellulose biomass

InactiveCN102816877AThe source process is fastBreak down completelySaccharides productionCelluloseHydrolysate

The invention discloses a hydrothermal saccharification method for cellulose biomass, which comprises the following steps: pulverizing cellulose biomass; mixing the pulverized cellulose biomass and 0.05-1.00 wt% dilute acid solution in a reactor in a solid-to-liquid ratio of 1:(6-20); and heating the cellulose biomass and dilute acid mixture in the reactor while stirring to carry out reaction at 60-230 DEG C under the reaction pressure of 1-4MPa under sealed conditions, wherein the heating adopts a gradient heating mode, i.e. the temperature is divided into multiple temperature nodes of which the temperature intervals are 15-50 DEG C, the hydrolysate obtained by reaction is discharged and collected and new dilute acid solution is injected every time coming to a temperature node, and the hydrolysates at different temperature nodes are collected respectively. The saccharides obtained by decomposing cellulose biomass by using the method and device disclosed by the invention can be separated immediately after being generated, thereby effectively enhancing the saccharine yield, greatly lowering the toxic components in the saccharides and making a great step forward for industrialized production of saccharides from biomass.

Owner:SHANGHAI JIAO TONG UNIV

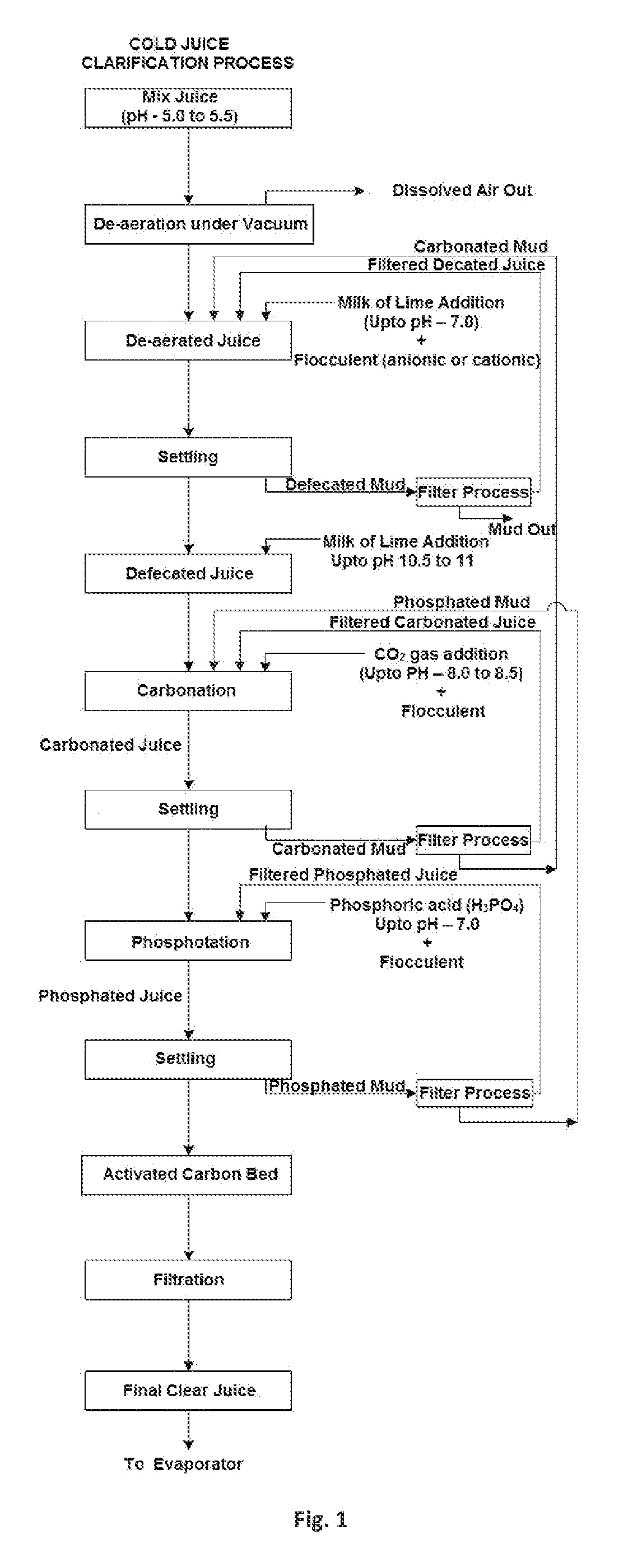

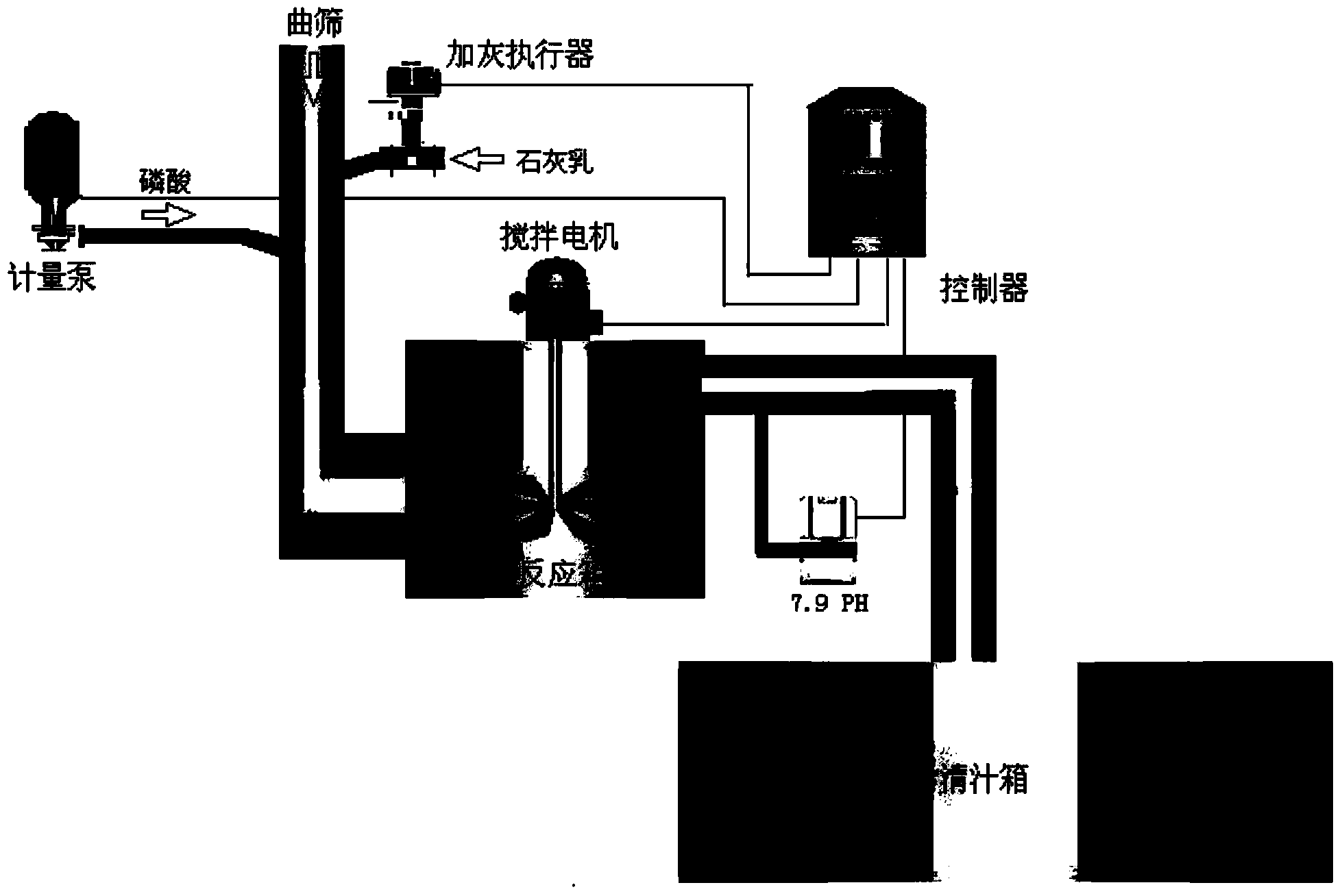

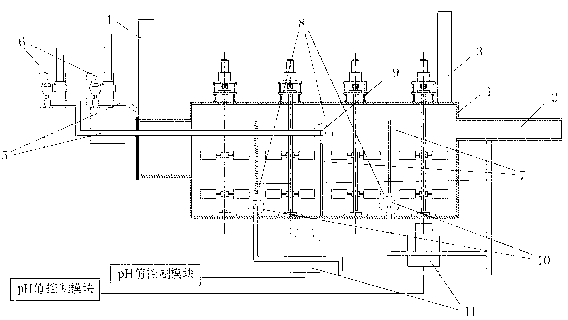

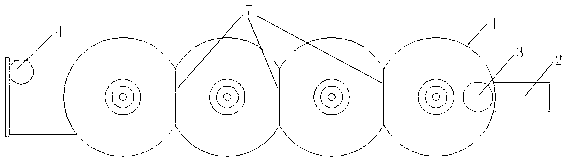

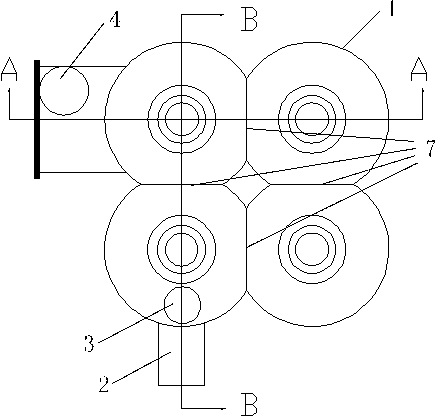

Progressive stoving neutralization reaction device and method

InactiveCN103266184AIncrease flow itineraryImprove uniformityPurification by oxidation/reductionPurification using alkaline earth metal compoundsReaction layerPh control

The invention aims to provide a progressive stoving neutralization reaction device, comprising a box body, an exhaust port, a tube diffuser, a stove tail tube, a lime milk adding tube, an ash adding actuator, more than one separator and a pH control device, wherein the box body is internally divided into more than two reaction layers by the separator in the horizontal direction; and the pH control device is used for detecting the pH of mixed sugarcane juice in the box body and controlling the dosage of the lime milk according to pH information, thus keeping the pH value of the mixed sugarcane juice stable. The invention also provides a stoving neutralization reaction method, wherein pH detection and control are performed on the sugarcane juice in reaction through the pH control device, so that the pH of the sugarcane juice after reaction is kept in a predetermined range. The progressive stoving neutralization reaction device and method provided by the invention have the characteristics that the pH of the sugarcane juice is regulated and controlled in sections and the reaction efficiency of the neutralization reaction is enhanced through a stirring device, so that the pH of the sugar juice is stabilized, the cleaning efficiency is improved and the reaction time is prolonged; and therefore, the device and the method play an important role in improving the product quality and the sugar yield of a sugar refinery.

Owner:南宁苏格尔科技有限公司

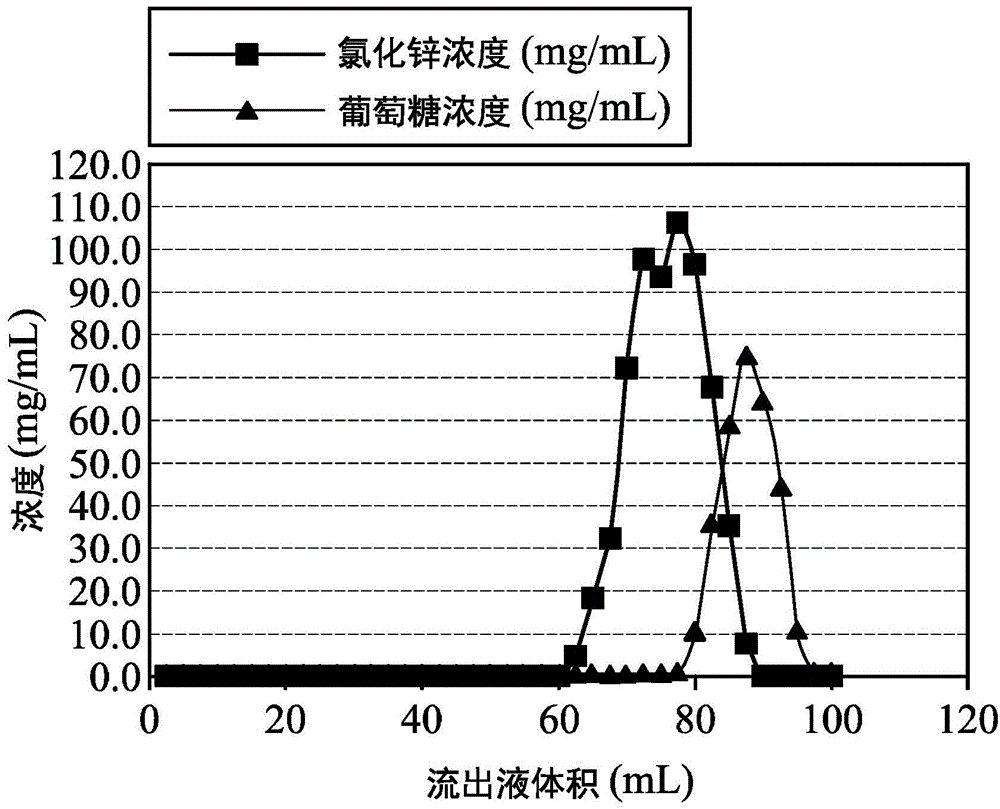

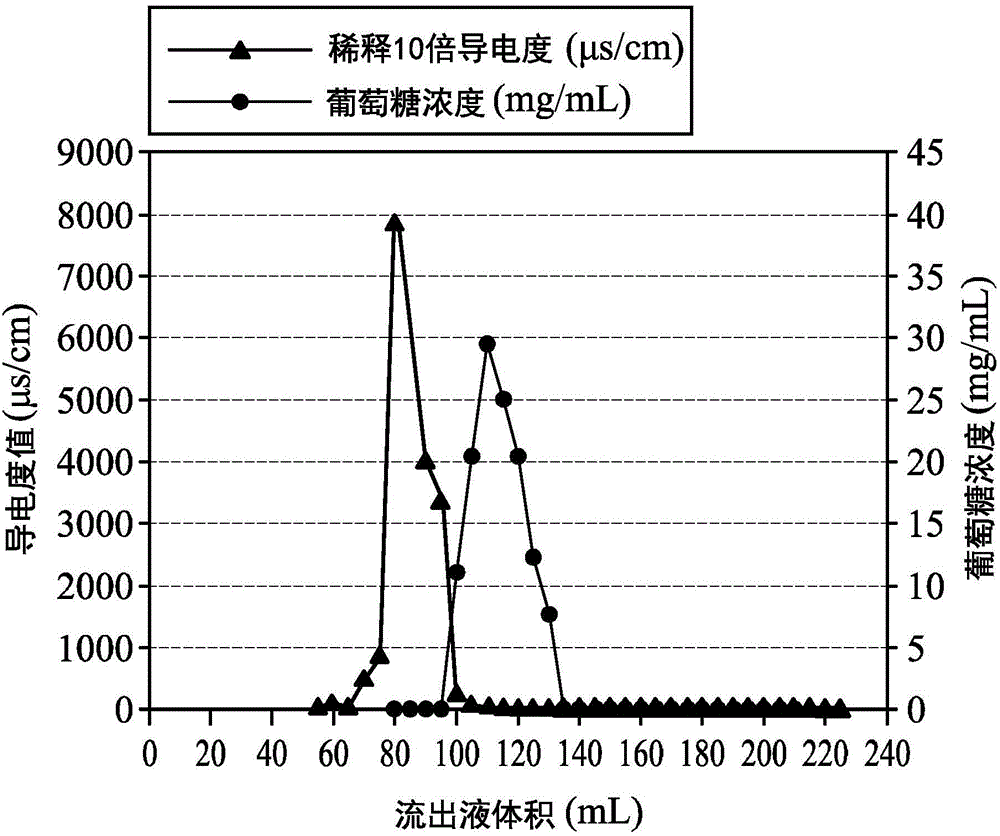

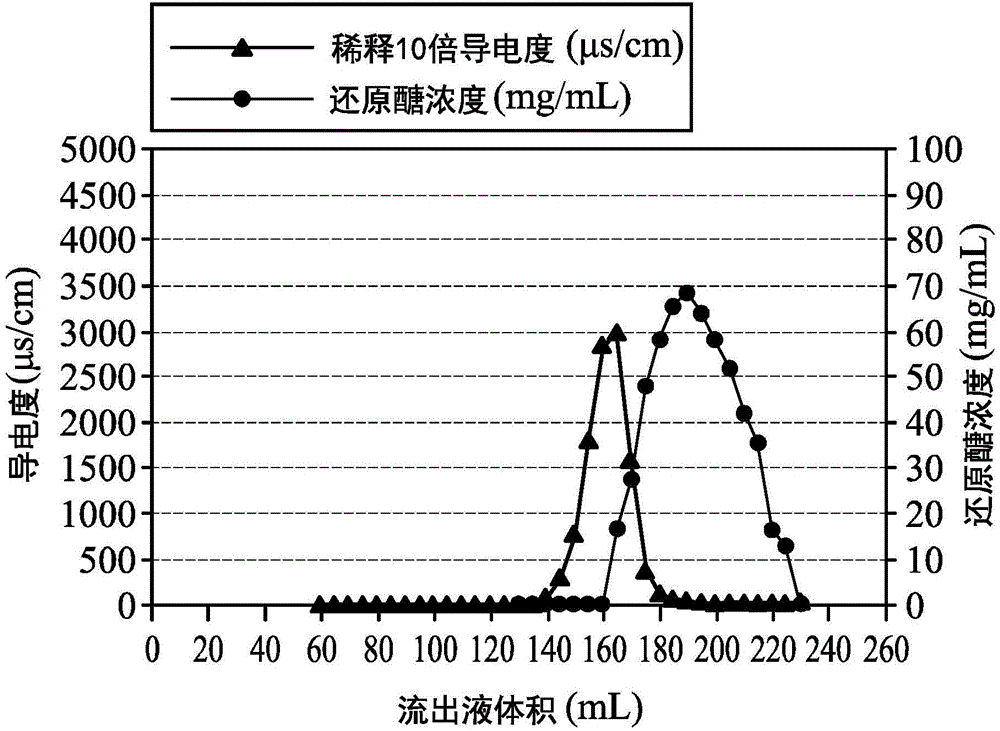

Method Of Separating Carbohydrate

Disclosed is a method of separating carbohydrate, including: mixing formic acid with heteropoly acid, chloride or bromide of lithium, magnesium, calcium, zinc, or iron, or combinations thereof to form a mixing liquid, dissolving a cellulose biomass by the mixing liquid to form a solution, mixing water and the solution to hydrolyze the cellulose biomass for forming a carbohydrate solution, and mixing an extractant and the carbohydrate solution to extract the formic acid out of the carbohydrate solution. The heteropoly acid, the chloride or bromide of lithium, magnesium, calcium, zinc, or iron, or combinations thereof in the carbohydrate solution is separated out of the carbohydrate solution by ion exclusion chromatography separation to obtain a carbohydrate. The method for separating the carbohydrate has the advantages of low temperature, the high speed, the high carbohydrate yield and the like, and does not need to use a reactor made of a material resistant to strong acid corrosion.

Owner:IND TECH RES INST

Preparation method of brown sugar

An embodiment of the invention discloses a preparation method of brown sugar. The preparation method of the brown sugar comprises the following steps of carrying out squeezing, namely thoroughly washing sugarcanes, cutting the washed sugarcanes into sections of which the length is 10-15 centimeters, and pulping the sugarcane sections in a juicer so as to obtain sugarcane juice; carrying out screen filtering, namely filtrating the pulped sugarcane juice for three times, wherein a screen mesh of which the diameter is 2-5 centimeters is utilized in the first filtration, a screen mesh of which the diameter is 1-1.5 centimeters is utilized in the second filtration, and a gauze is utilized in the third filtration; carrying out evaporation, namely adopting four-effect or five-effect evaporation so as to increase concentration of syrup, and thus, sugar cooking time is beneficially reduced; cooking sugar, namely heating and stirring the purified sugarcane juice until syrup is formed and completely changed into brown sugar; and then, carrying out granulation, namely cooling the brown sugar, crushing the cooled brown sugar in a granulating machine so as to obtain granulated brown sugar.

Owner:雷燕梅

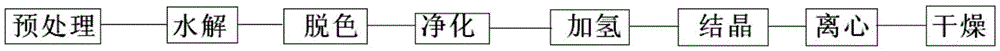

Xylitol extraction process

InactiveCN105622339ASolve the problem of serious pollution of the environmentIncrease economic growthOrganic compound preparationHydroxy compound separation/purificationHydrolysisImpurity

The invention discloses a xylitol extraction process. The process comprises the following steps: A. pretreatment: carrying out coarse crushing on fresh corn straws by a coarse crusher to obtain particles; B. hydrolysis: adding the corn straw particles subjected to coarse crushing into a hydrolyzer, and carrying out hydrolysis to obtain a liquid which is a sugar solution; C. decolorization: removing impurities from the sugar solution with powdery activated carbon; D. purification: removing anions and cations from the sugar solution by using an anion exchange resin and a cation exchange resin; E. hydrogenation: adding the xylose solution into a reaction kettle, and converting the xylose solution into a xylitol solution; F. crystallization: enabling the hypersaturated-state xylitol crystal to grow, form and precipitate by controlling the cooling rate; G. centrifugation: separating the xylitol from the mother solution by controlling the centrifugating speed of the centrifuge; and H. evaporating water in the xylitol by controlling the temperature of the drying machine and the ambient humidity, thereby obtaining the xylitol product. The xylitol extraction process has the advantages of high yield and low water consumption.

Owner:张喜强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com