Patents

Literature

94results about "Purification using chemicals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the production of invert liquid sugar

InactiveUS20040255934A1Purification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

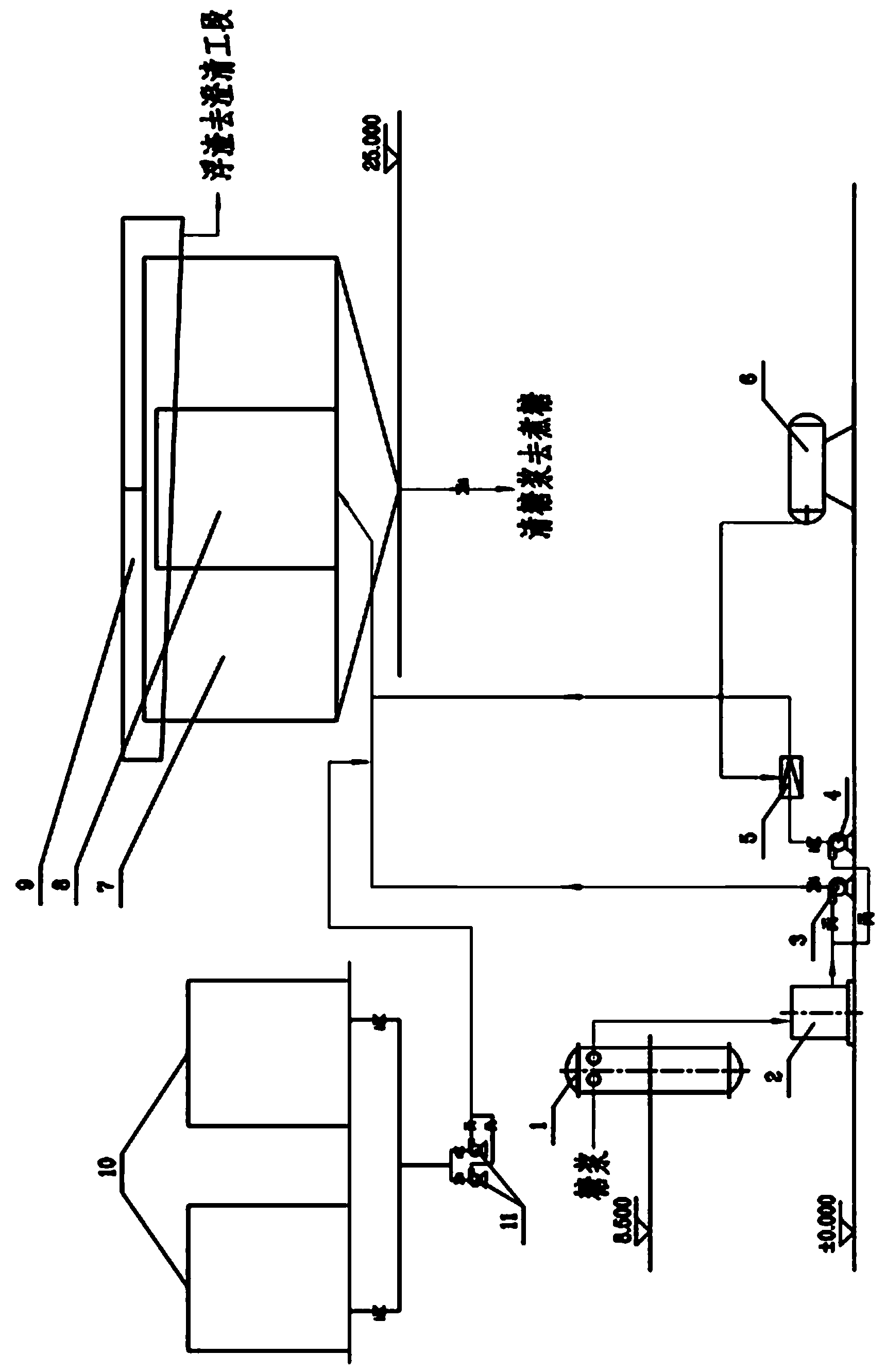

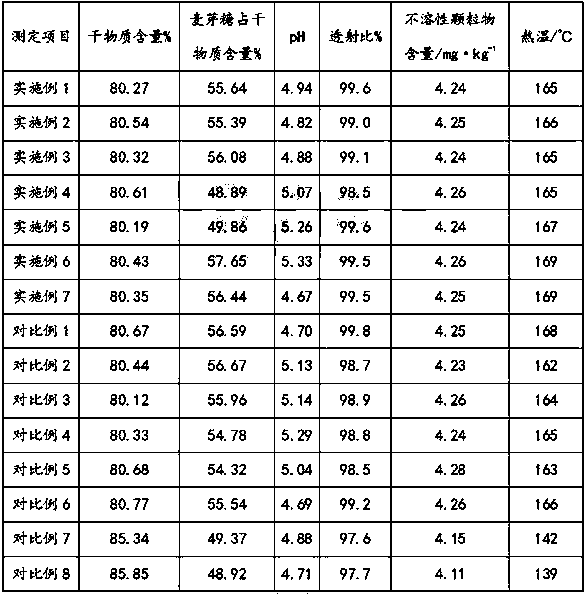

Method for automatically clearing syrup in conveying and storing processes

InactiveCN104313193AAdd cleaning functionReduce sulfur dioxide contentPurification using chemicalsThermodynamicsEconomic benefits

The invention provides a method for automatically clearing syrup in conveying and storing processes. After syrup is discharged from the former procedure, the syrup is firstly heated to a temperature of 80-85 DEG C and then discharged into a syrup box on +_0.000 layer. Then, the syrup is conveyed into a syrup storage box at the top layer of a sugar boiling building through a main and auxiliary pipeline, and a high-molecular flocculant is added before the syrup enters the syrup storage box. On the +_0.000 layer, gas is absorbed and dissolved through an online pipeline air breather and pressure formed by liquid level height difference. After the syrup enters the syrup storage box at the top layer of the sugar boiling building, impurities and air bubbles in the syrup rise to the top of the syrup storage box and are discharged out, and pure syrup is discharged from the bottom of the syrup storage box. The function of automatically clearing the syrup is increased under the condition of storing the syrup by the syrup storage box. The impurities are effectively removed from the syrup, the syrup purity is improved, the syrup conversion losses are reduced, the quality of a white granulated sugar product is effectively improved, and the economical benefit of a sugar making industry is improved.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

Process for the production of invert liquid sugar

InactiveUS6916381B2Reduce amountFew stepsPurification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

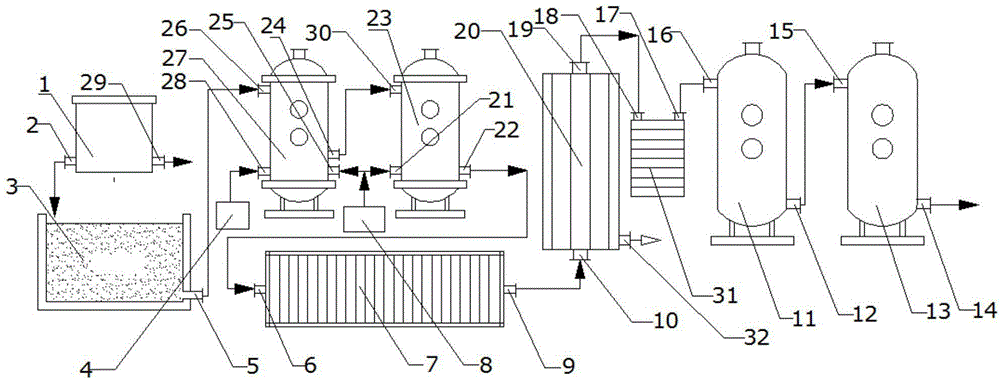

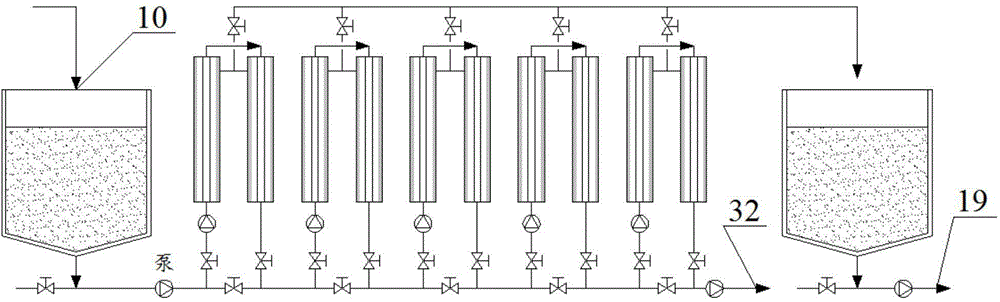

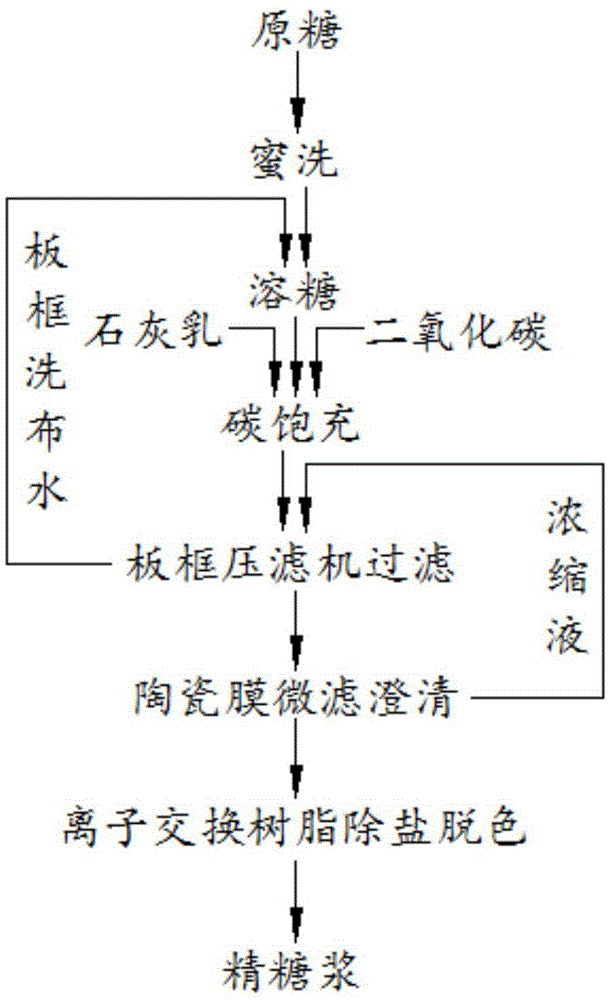

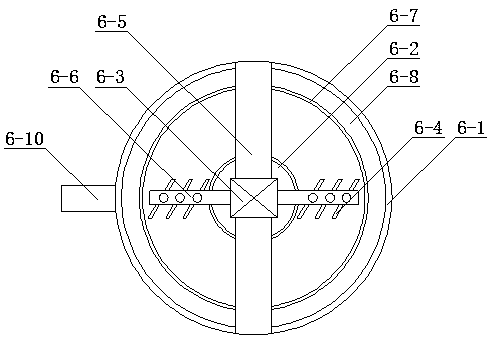

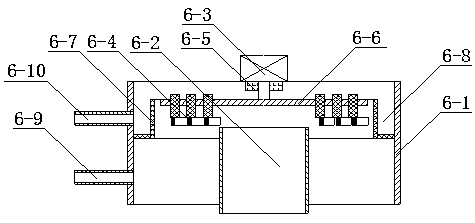

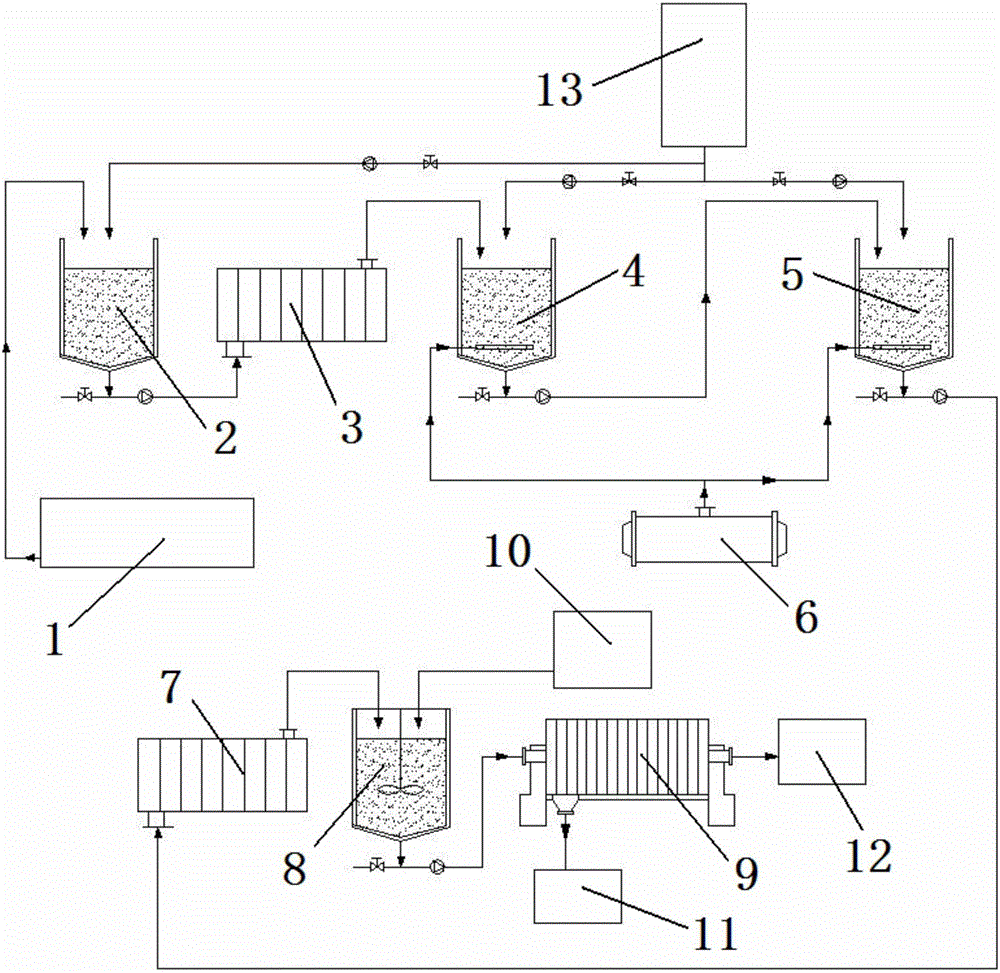

Refined sugar clarification device

ActiveCN104805222AExtended cleaning cycleReduce cleaning frequencySugar productsPurification using chemicalsMicrofiltration membraneTurbidity

The invention discloses a refined sugar clarification device which comprises a device for washing raw molasses, a sugar melting box, a first carbonating tank, a second carbonating tank, a plate-and-frame filter press, a multistage ceramic membrane microfiltration system, a plate heat exchanger, a first ion-exchange resin tower and a second ion-exchange resin tower, which are connected in sequence. Based on the conventional refined sugar clarification technologies and devices, the refined sugar clarification device is additionally provided with the ceramic microfiltration membrane which can clarify remelt syrup carbonated and filtered by the plate-and-frame filter press, so that the turbidity of the remelt syrup before entering the ion-exchange resin is reduced and the service life of the ion-exchange resin is prolonged.

Owner:GUANGXI UNIV

Method for Producing Sugar

InactiveUS20120225455A1Efficient removalReduce color valueSugar derivativesPurification using chemicalsSugarChemistry

Disclosed is a process for producing a sugar, whereby any non-sugar component can be removed from a sugar solution with high efficiency and the color value of the sugar solution can be reduced. Specifically disclosed is a process for producing sugar, which is characterized by comprising: adding ethanol to a sugar solution produced by squeezing a plant; removing precipitates produced by the addition of ethanol from the solution; and crystallizing sugar from the sugar solution from which the precipitates have been removed.

Owner:ASAHI BREWERIES LTD

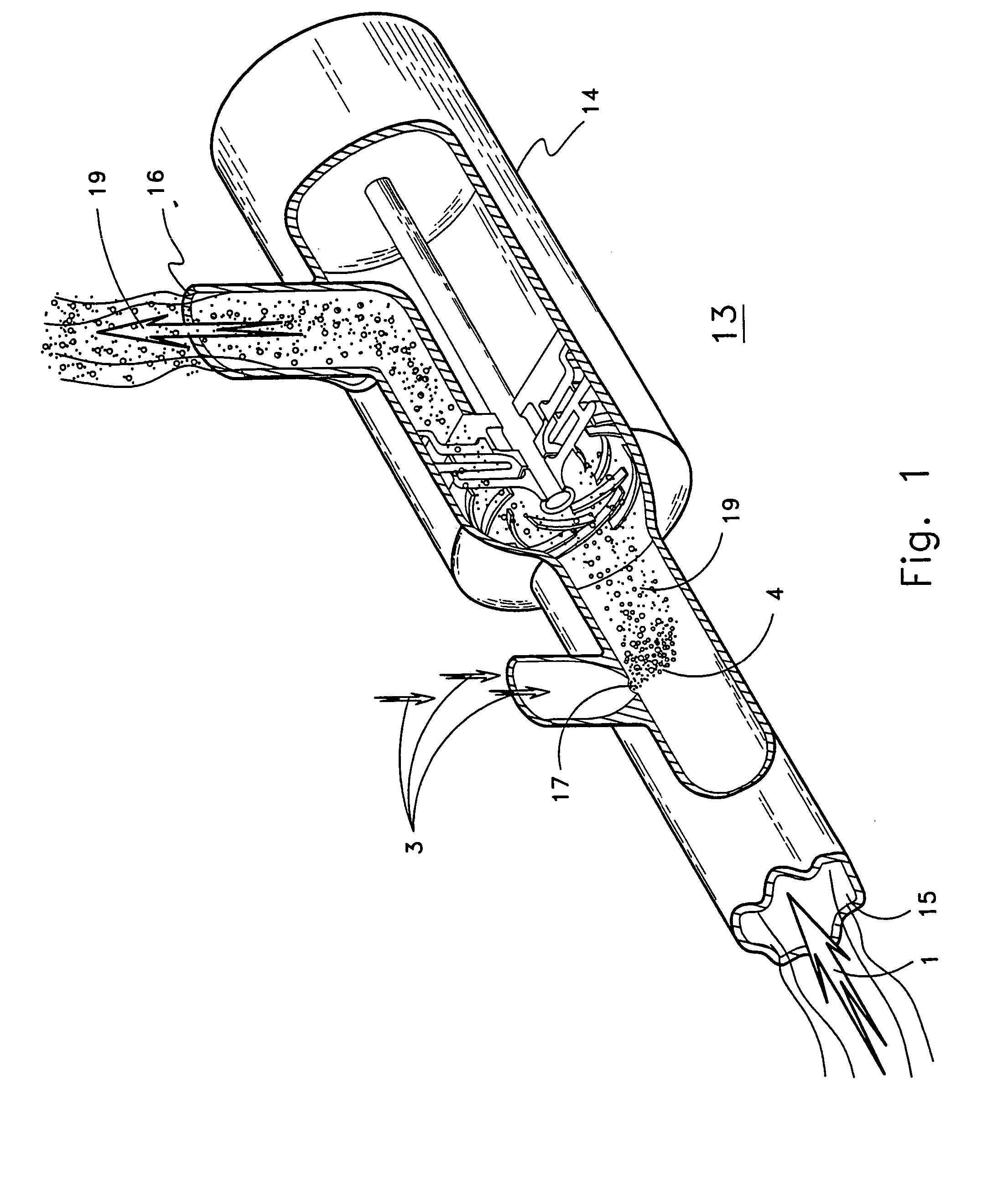

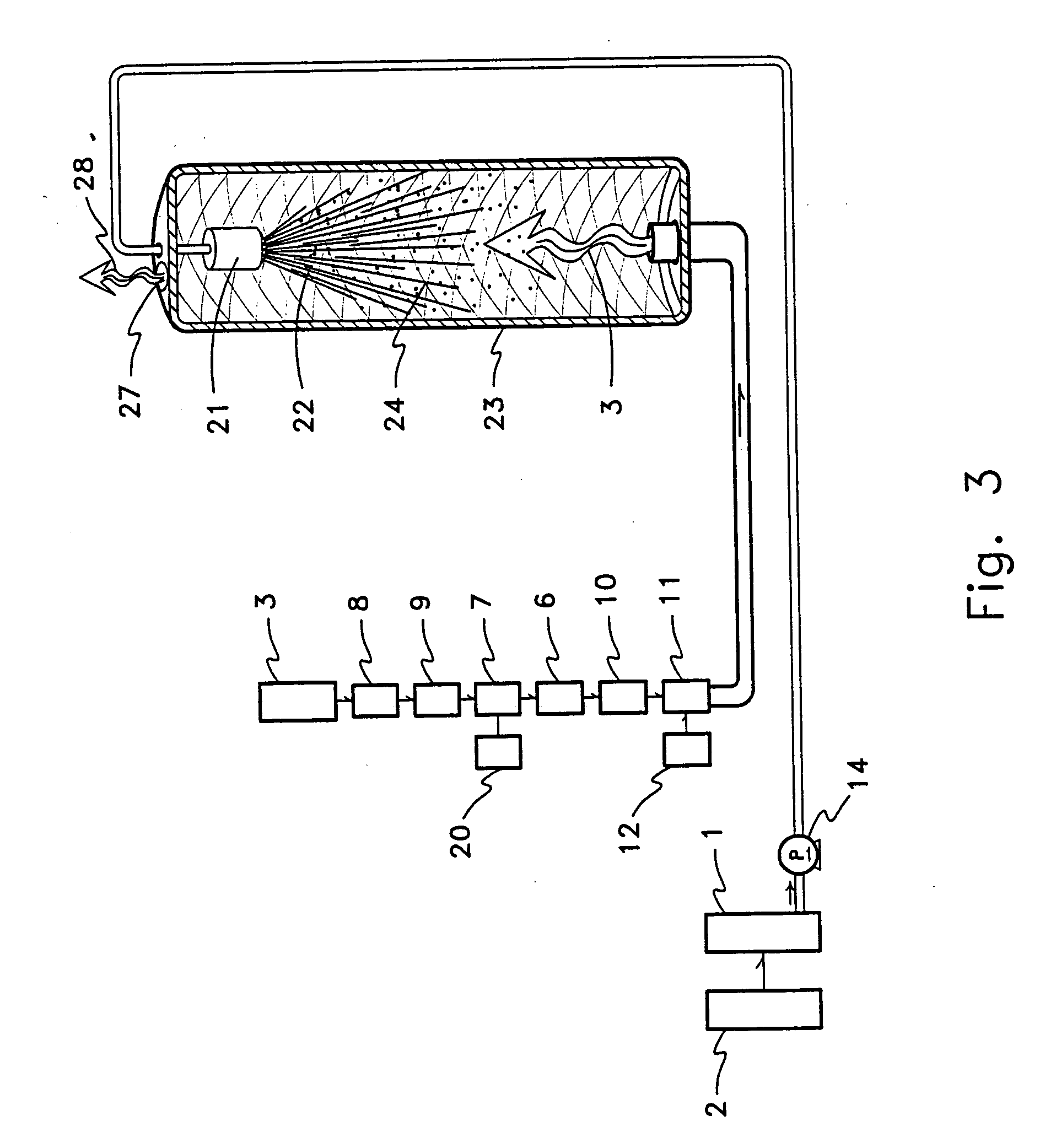

System to produce sugar from plant materials

InactiveUS6656287B2Reduce the amount requiredReduce concentrationPurification by oxidation/reductionPurification using adsorption agentsProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

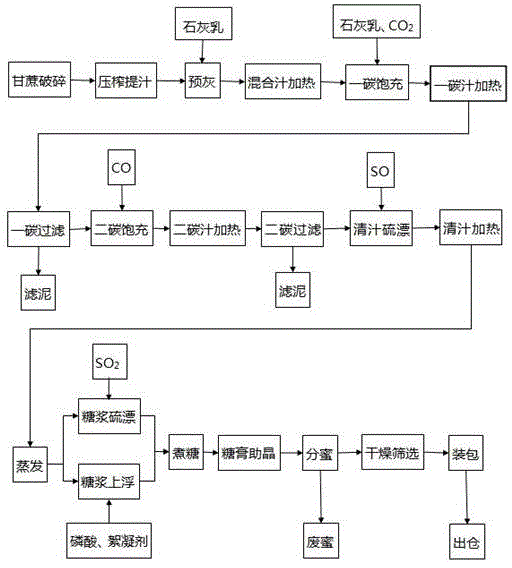

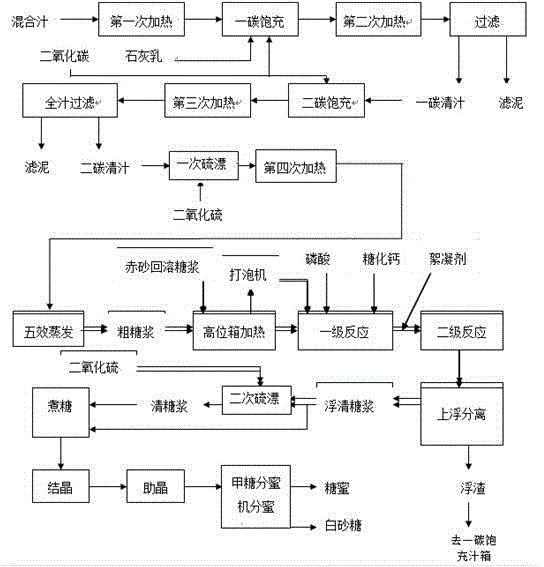

Producing method of pharmaceutic adjuvant cane sugar by carbonic acid method process

InactiveCN104611473ALow equipment requirementsSimple processSugar dryingPurification using chemicalsSucroseImpurity

A producing method of a pharmaceutic adjuvant cane sugar by a carbonic acid method process is disclosed. The producing method directly adopts sugarcane as a raw material and obtains the pharmaceutic cane sugar by steps of smashing, squeezing, clearing, evaporating, sugar boiling, separating molasses and drying. A sulphur bleaching-floating combined step is added between the evaporating step and the sugar boiling step to further remove various impurities in the cane sugar and to improve the cleanliness level of the cane sugar, so that contents of sulfates, residues on ignition, calcium salts, heavy metals, and the like in the cane sugar meet the index requirements in the Chinese Pharmacopoeia of the 2010 edition. The carbonic acid method is low in equipment requirement and simple in process, and therefore the producing method is suitable for large-scale production of cane sugar, and overcomes the problem that cane sugar produced by traditional carbonic acid method processes cannot meet the standards of the pharmaceutic cane sugar and the problem that the pharmaceutic cane sugar is difficult in large-scale production.

Owner:NANNING SUGAR INDUSTRY CO LTD

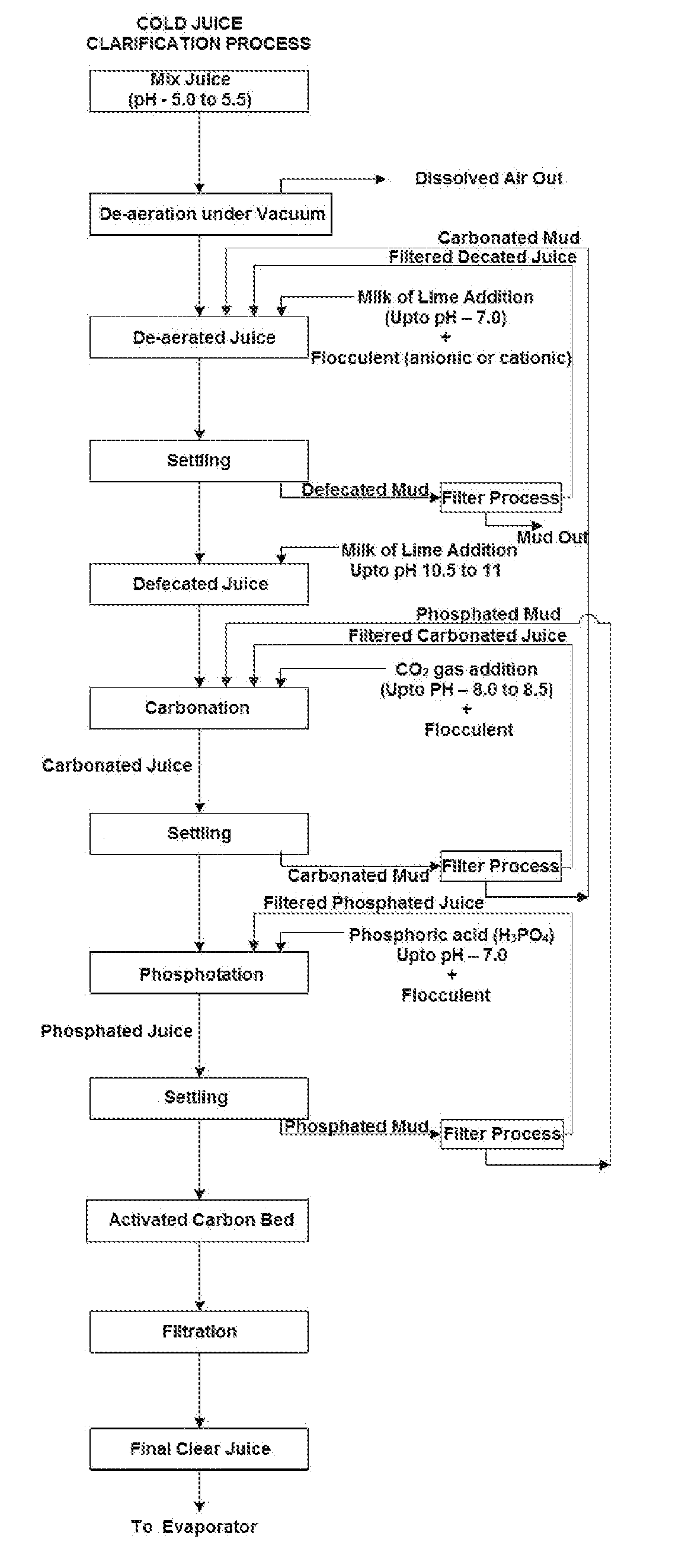

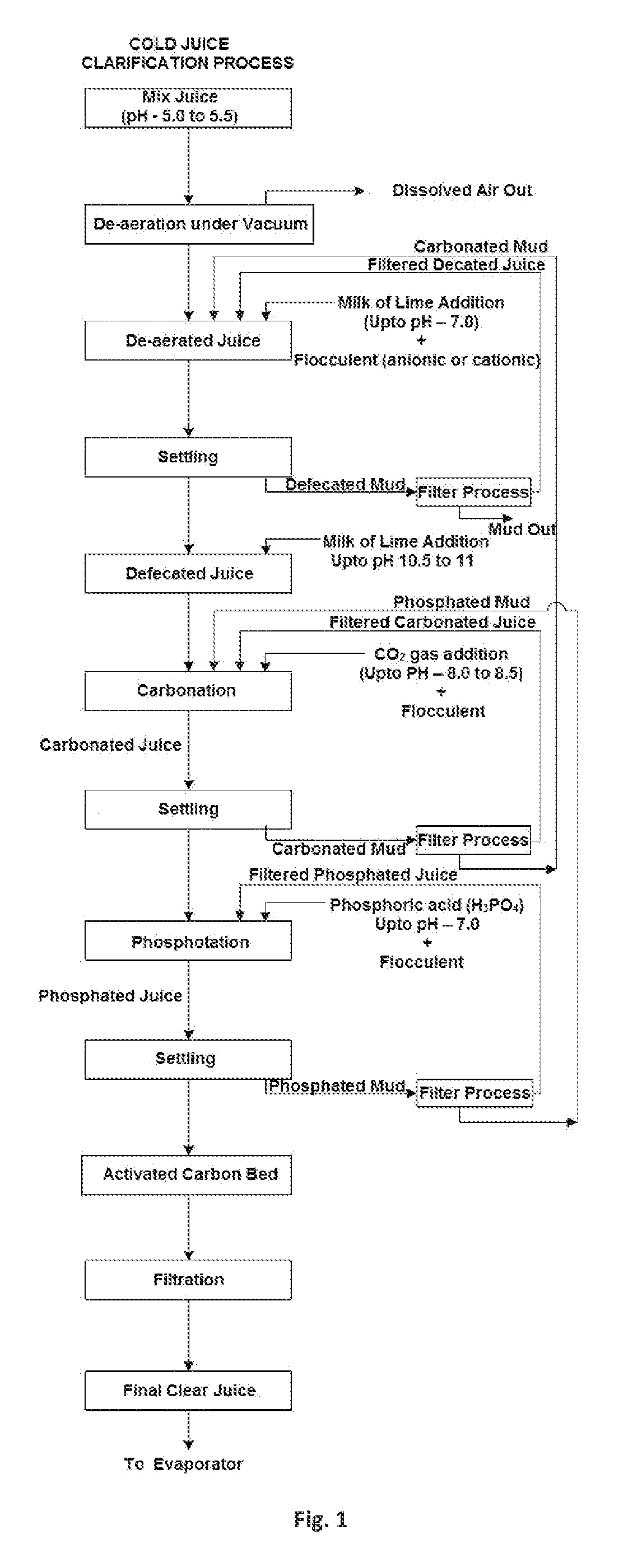

Cold juice clarification process

InactiveUS20150101594A1Increase sugar yieldMore energy efficientPurification using adsorption agentsPurification using chemicalsActivated carbonCost effectiveness

A process for cold clarification of juice is described. A sugar cane or beet juice clarification process to clarify raw juice by means of aeration of fresh raw juice, addition of milk or lime, anionic and / or cationic flocculants, particularly together with a carbonating process, addition of phosphoric acid and then passing the juice through activated carbon bed is described. The process eliminates the need to heat the juice at any stage thus making it more cost effective, energy saving and gives better yield in terms of quality and quantity both. The recycling of defecated, carbonated and phosphated filtered juice and carbonated and phosphated mud that reduces the consumption of lime, CO2 and phosphoric acid up to some extent is described.

Owner:SPRAY ENG DEVICES

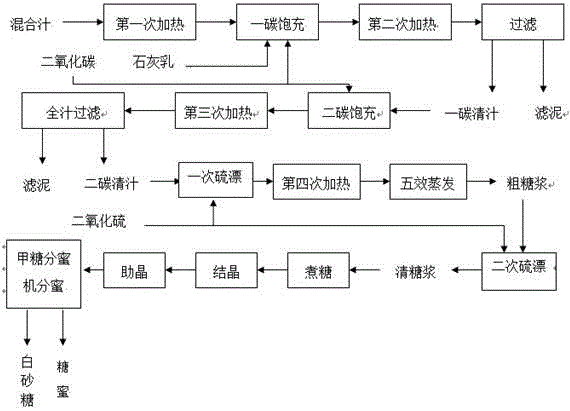

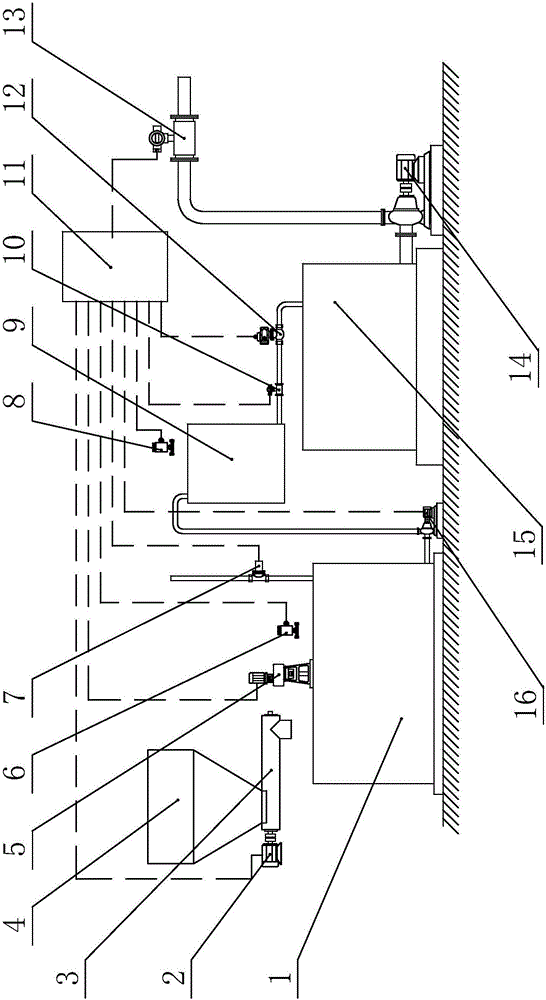

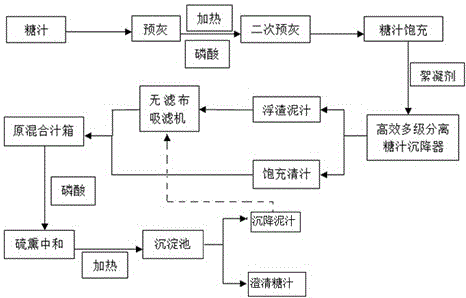

Sugar-juice syrup floating clarification process used in carbonation method

InactiveCN104630390AIncrease the process of floating and removing impuritiesLow viscosityPurification using chemicalsColloidViscosity

The invention discloses sugar-juice syrup floating clarification process used in carbonation method. The sugar-juice syrup floating clarification process comprises two processes, namely, a preparation process of crude syrup and a preparation process of white granulated sugar, wherein the preparation process of crude syrup comprises ten steps, namely, primary heating, first carbonation, secondary heating, filtering and the like and the preparation process of white granulated sugar comprises five steps, namely, secondary sulfitation, sugar boiling, crystallizing, crystallization promoting and honey separation. Since the syrup floating impurity removal process added in the traditional sugar production process by virtue of the carbonation method, high-quality materials are provided for material boiling in each section of the subsequent sugar boiling so that the product quality is improved, brown granulated sugar remelt syrup can be treated at a certain ratio, the colloid and impurities in the remelt syrup can be effectively removed, the honey production factors are decreased and thus the viscosity of the material is reduced and the boiling of various sugar pastes and sugar recovery are facilitated.

Owner:NANNING SUGAR INDUSTRY CO LTD

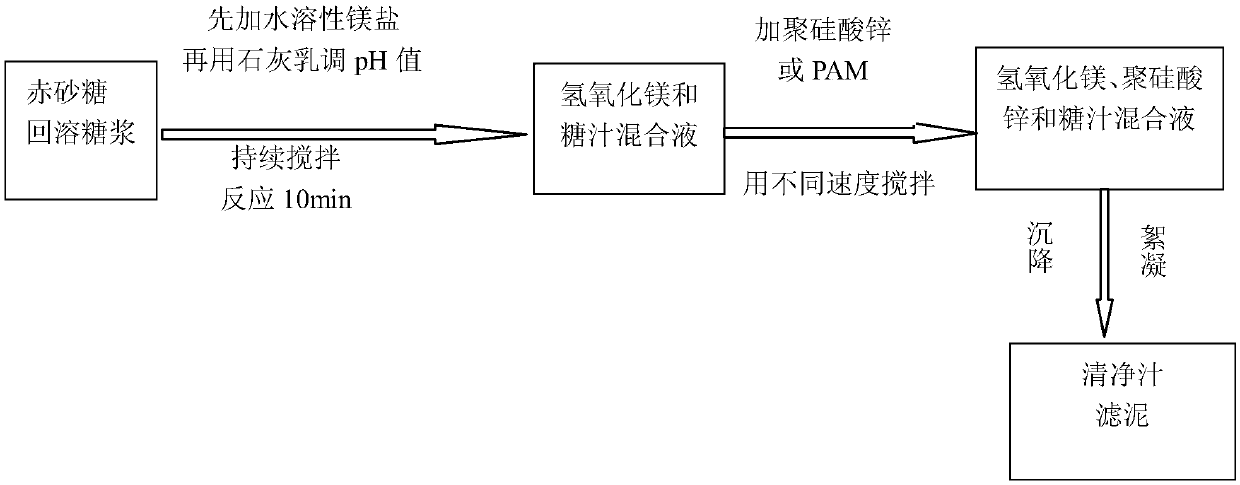

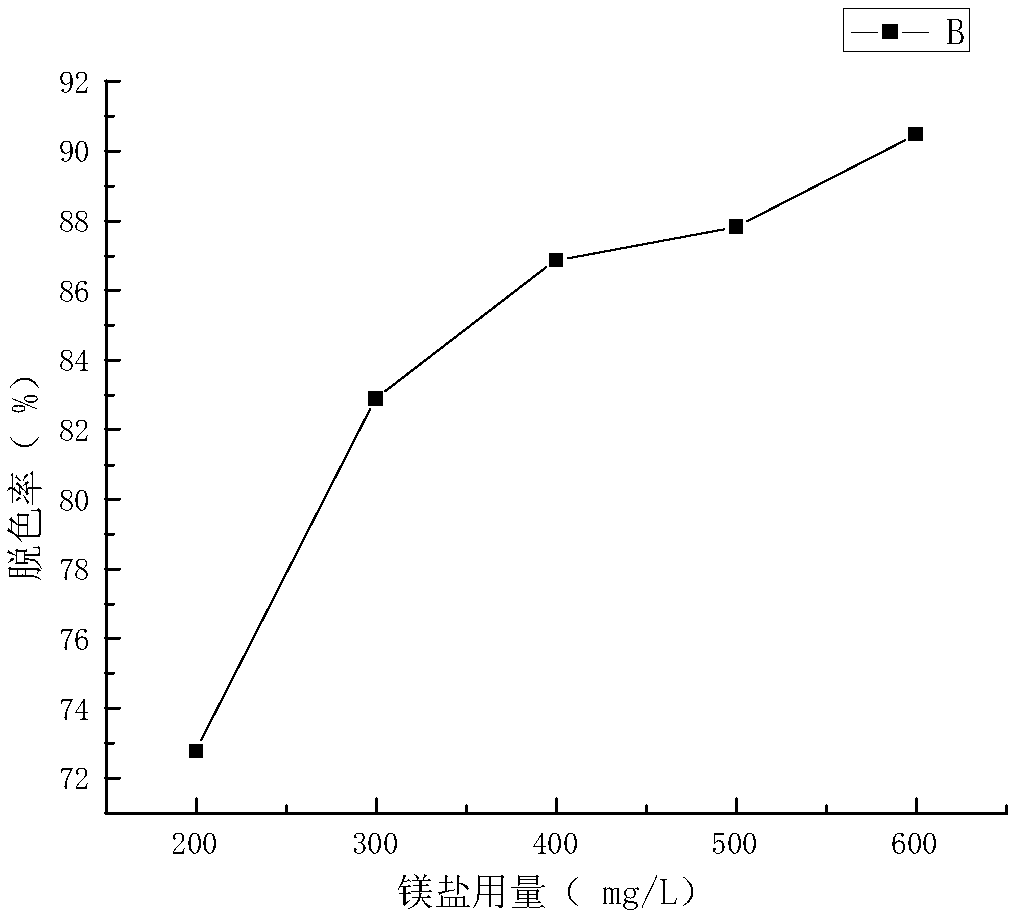

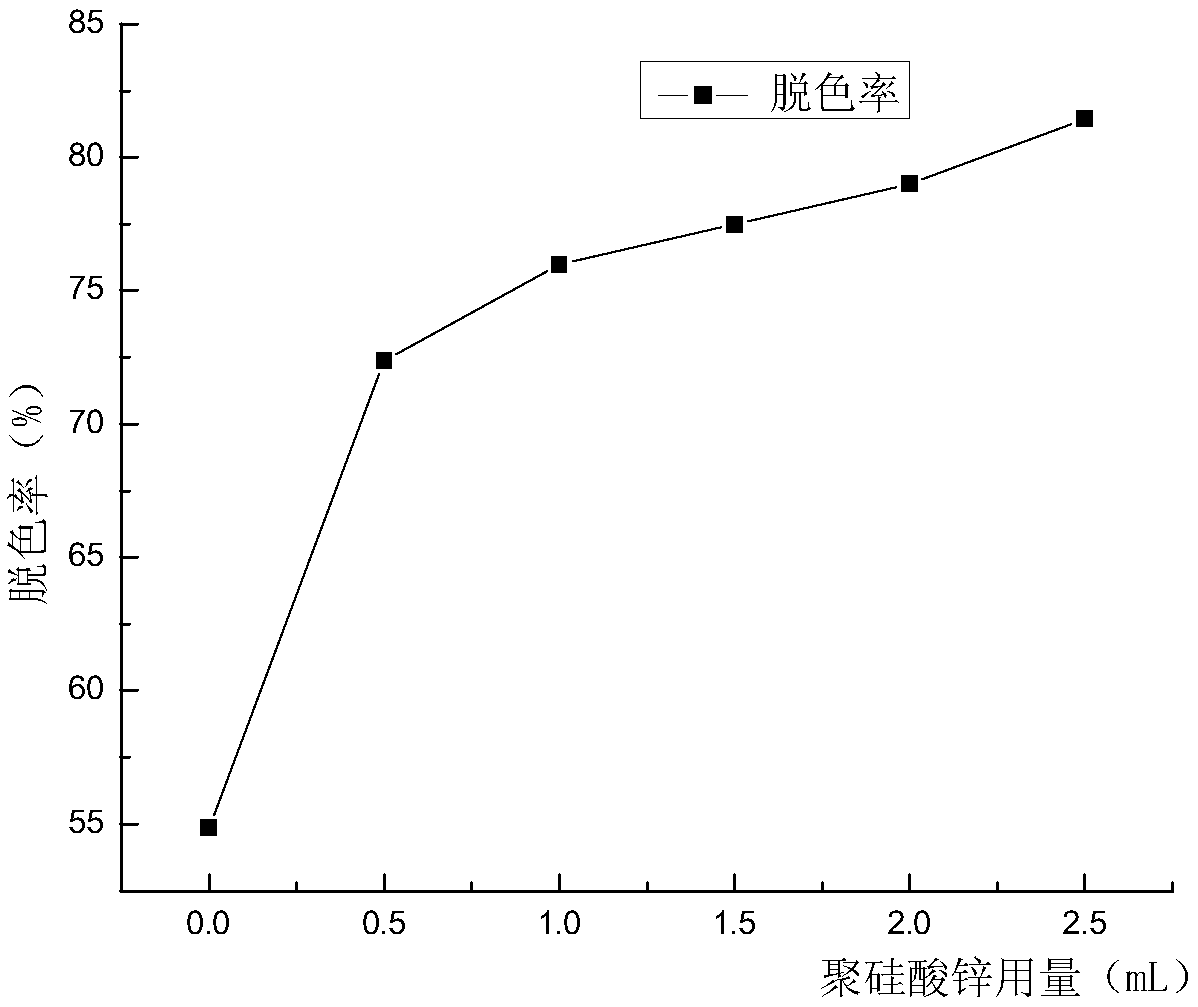

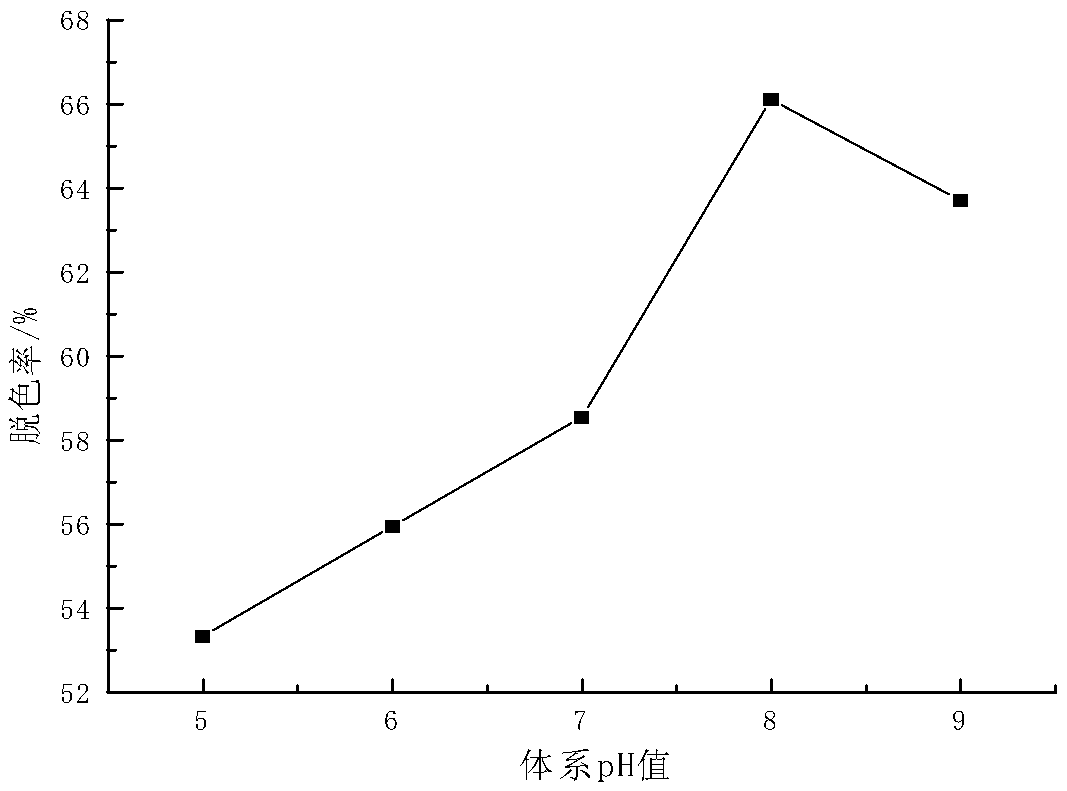

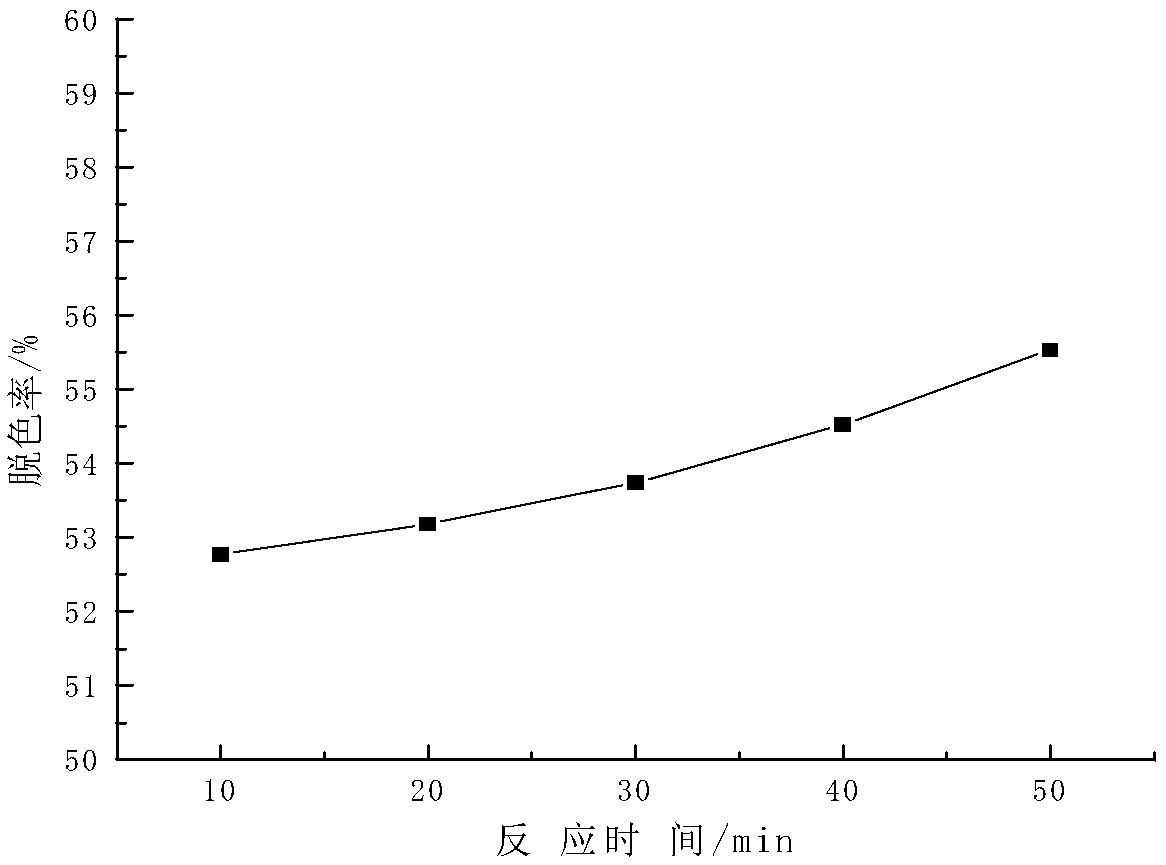

Method for decolorization of sugar juice with water-soluble magnesium salt-lime

InactiveCN110791593AHigh decolorization rateSimple processPurification using chemicalsPurification using alkaline earth metal compoundsFlocculationMagnesium salt

The invention relates to a method for decolorization of sugar juice with water-soluble magnesium salt-lime. The specific steps include: adding a water-soluble magnesium salt into sugar juice, then regulating the pH value with lime milk, performing stirring continuously at certain temperature, then adding zinc polysilicate, conducting stirring at different speeds for certain period of time respectively, and performing flocculation sedimentation to a stable state, thus obtaining clear juice. The invention provides the water-soluble magnesium salt-lime method for clarification and decolorizationof sugar juice, zinc polysilicate is adopted as a flocculant, the decolorization rate is up to 92.21%, also the process is simple and low in cost, does not adopt toxic or harmful substances, belongs to a green clarification and decolorization process, and has important application prospect in the sugar industry. The principle of the method provided by the invention lies in that: a magnesium salt serves as an inorganic decolorizing agent for coagulation reaction under an alkaline condition to generate magnesium hydroxide, non-sugar substances in sugar juice are adsorbed or embedded, then zinc polysilicate is employed as the flocculant for flocculation and clarification, so that a satisfactory result can be achieved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Complex enzyme detergent for high-temperature-resisting cane sugar manufacturing industry as well as preparation and application thereof

InactiveCN109321553AAchieve the effect of removing impurities and clarifyingImprove qualityPurification by oxidation/reductionPurification using chemicalsPectinaseFiltration

The invention discloses a complex enzyme detergent for a high-temperature-resisting cane sugar manufacturing industry as well as preparation and application thereof and belongs to the technical fieldof clarifying technologies of the sugar manufacturing industry. The complex enzyme detergent is prepared from the following components in percentage by weight: 20 to 50 percent of heat-resisting dextranase, 5 to 35 percent of high-temperature-resisting alpha-amylase, 5 to 25 percent of heat-resisting pectinase, 4 to 20 percent of high-temperature-resisting laccase, 3 to 20 percent of heat-resisting horseradish peroxidase, 3 to 20 percent of high-temperature-resisting cellulase and 0 to 10 percent of water. After raw material enzymes are mixed according to a ratio, a mixture is subjected to membrane filtration and is quantitatively filled to obtain a product. In a process from primary heating to secondary heating, the complex enzyme detergent is added into crude sugar juice to carry out clarification treatment. A complex enzyme preparation formed by a proper ratio prevents a condition that only one enzyme usually cannot reach a predicated impurity removal and clarification effect; a buffering stage does not need to be set, adding sites are wide and the limitation caused by temperature is relatively small.

Owner:广西糖业集团金光制糖有限公司

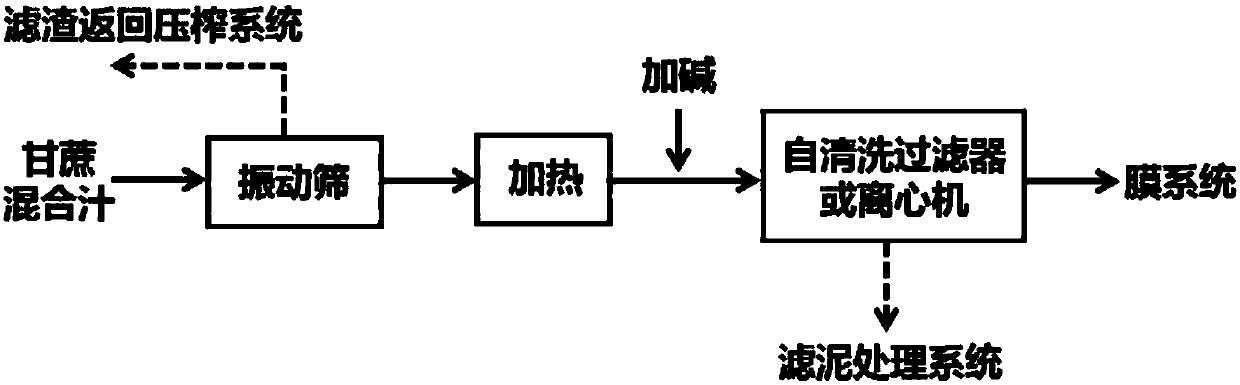

Mechanically harvested sugar cane mixing juice membrane cleaning pretreatment method

InactiveCN107937625AReduce pollutionGuaranteed uptimePurification using chemicalsPurification by physical meansPretreatment methodSlag

The invention relates to the technical field of sugar production. According to the present invention, a sugar cane mixing juice is subjected to residue removing treatment by using a vibration sieve, the pH value of the filtrate of the vibration sieve is adjusted by heating and adding an alkali, the pH value adjusted filtrate enters a self-cleaning filter or a centrifuge system to remove impurities, and the filtrate of the filter or the centrifuge enters a membrane system; the method is suitable for the sugar cane mixing juice cleaning process using mechanically harvested sugar cane as a raw material, and has advantages of simple and safe operation, no chemical additive and easy continuous production; and the sugar cane mixing juice membrane cleaning pretreatment process uses the vibrationsieve-self-cleaning filter or the centrifuge two-stage integrated filtration technology, such that the grading separation of bagasse and soil in the sugar cane mixing juice is achieved, the problems of filtration mud agglomeration and filter clogging during the sugar cane mixing juice pretreatment are avoided, the continuous operation of the sugar cane mixing juice membrane cleaning process is ensured, and the pollution problem of the subsequent membrane system operation is significantly reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing brown sugar

InactiveCN107488753ALess impuritiesLight colorPurification using chemicalsPurification by physical meansImpurityChemistry

The invention discloses a method for producing brown sugar. The method comprises the following steps: 1, squeezing sugarcane, and filtering the squeezed sugarcane to obtain a sugarcane juice; 2, adding sodium carbonate to the sugarcane juice, and heating the sugarcane juice to remove foam; 3, settling the defoamed sugarcane juice to obtain a clear juice; and 4, carrying out evaporative concentration on the clear juice to obtain a massecuite, and cooling the massecuite to obtain the brown sugar. Compared with the prior art, the improved brown sugar production method disclosed in the invention has the advantages of no vacuum or pressure-resistant devices, and less device investment, and makes the produced brown sugar have few impurities and a light color and not agglomerate after being stored for a long time.

Owner:GUANGXI LIUCHENG CHENGLIN AGRI SCI & TECH

Production processing method of refined full-sucrose syrup and production processing equipment thereof

InactiveCN108192998AIncrease concentrationCreate pollutionPurification using adsorption agentsPurification using chemicalsHazardous substancePhosphoric acid

The invention relates to the technical field of sugaring, particularly relates to a production processing method of refined full-sucrose syrup and production processing equipment thereof, and aims toprovide a production processing method of refined full-sucrose syrup, which shortens the processing time, lowers the production cost and can reduce the content of impurities and harmful substances inthe syrup, and production processing equipment thereof. The production processing method comprises the following steps: (I) neutralizing adjustment treatment: conveying primary product of sugar juiceinto an adjusting tank for a neutralizing reaction, namely adding 4-6kg of 10% phosphoric acid and 10-12kg of 8% lime milk into each ton of primary product of sugar juice, and performing neutralizingadjustment for 5-10 minutes, etc. According to the production processing method of refined full-sucrose syrup and production processing equipment thereof provided by the invention, the primary productof sugarcane juice is processed into liquid syrup, thus the production processing flow is shortened, and the production processing cost is greatly lowered.

Owner:浙江同道糖业有限公司

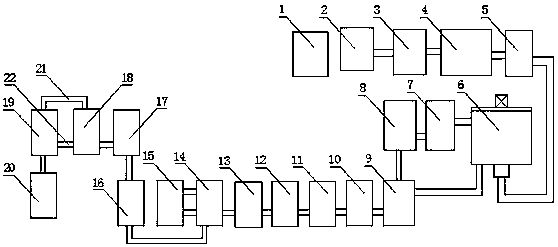

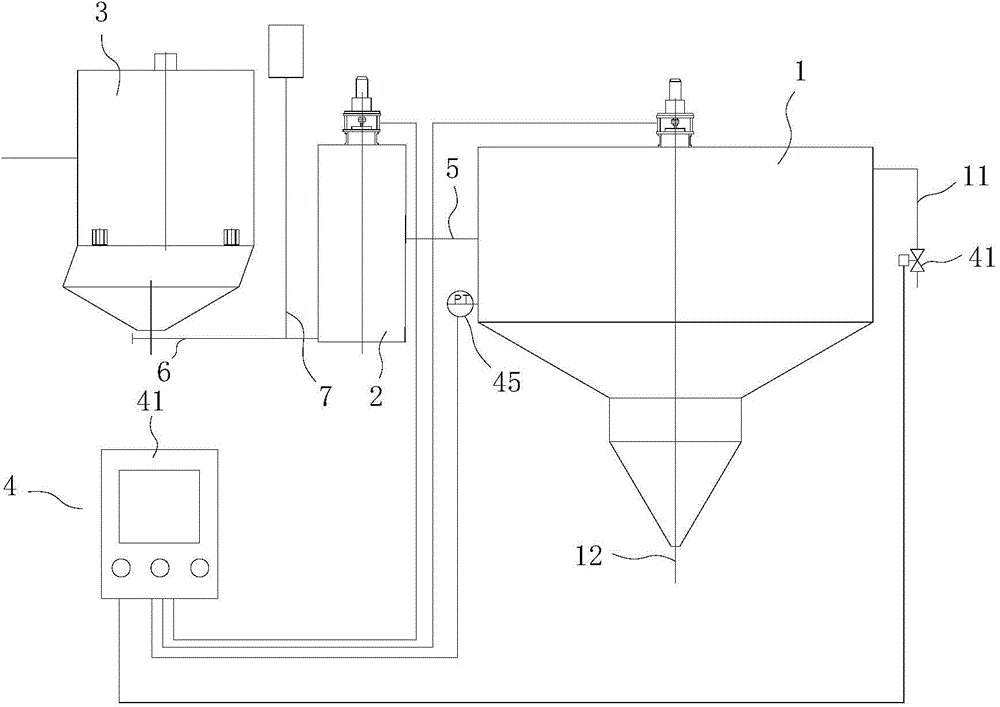

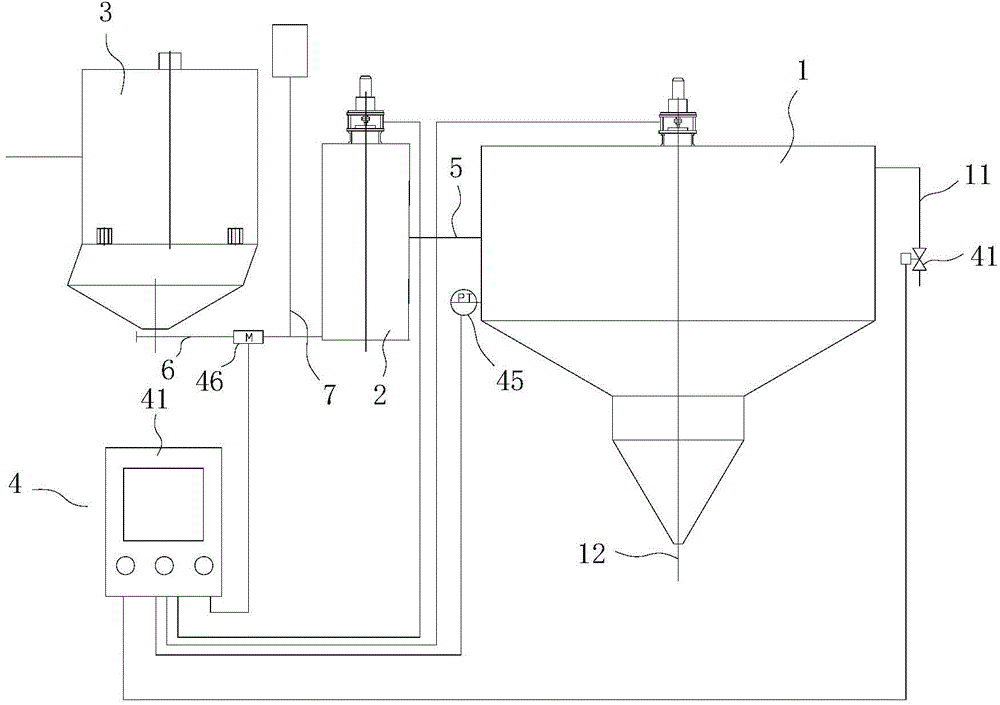

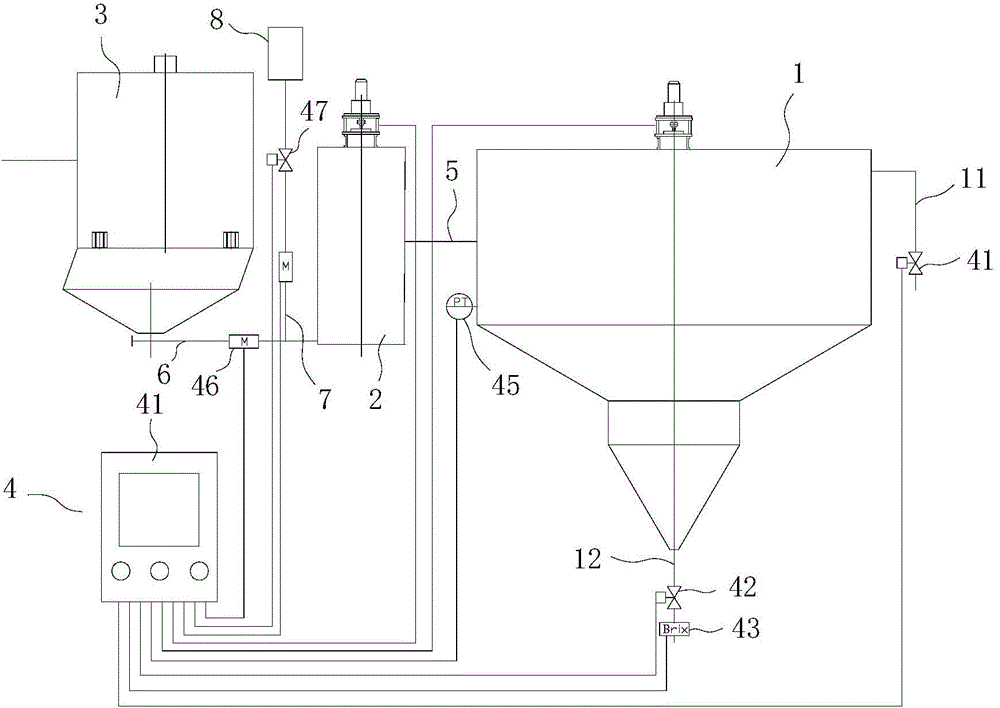

Automatic flocculant solution preparing and quantitative adding system for sugar refinery and operating method thereof

InactiveCN106422879AAdjust the opening in real timeJoin precisionPurification using chemicalsRotary stirring mixersEngineeringSugar refinery

The invention provides an automatic flocculant solution preparing and quantitative adding system for a sugar refinery and an operating method thereof. A storage tank of the system is connected to a flocculant proportioning tank with a stirrer and a liquid level gauge by means of a quantitative feeding device and a water pipe equipped with a proportioning water valve. The flocculant proportioning tank is connected with a temporary flocculant storage tank with a flocculant flow meter and a flocculant flow adjustment valve, and then connected to a temporary sugar juice storage box, and a sugar juice flow meter is installed on a sugar juice delivery and output pipe of the temporary sugar juice storage tank. A main flocculant control unit adds flocculant powder as required by preparation into the proportioning tank, and then adds water to mix. The mixture is pumped into the temporary flocculant storage tank. The main flocculant control unit monitors sugar juice flow in real time and acquires and controls flocculant solution flow entering the temporary sugar juice tank. The automatic flocculant solution preparing and quantitative adding system automatically controls the concentration of the prepared flocculant solution accurately, and the precise flocculant amount is added accurately into the unit volume of the sugar juice to achieve the best flocculating effect and the operation is simple.

Owner:钦州华成自控设备有限公司

Sugar-manufacturing single-layer precipitator control system

InactiveCN104611474AAdjust densityConcentration time shortened or increasedPurification using chemicalsPurification by physical meansControl systemSugar

The invention relates to a sugar-manufacturing single-layer precipitator control system. The sugar-manufacturing single-layer precipitator control system comprises a precipitator and a control system, wherein a clear juice output pipeline is arranged at the upper part of the precipitator, and a mud juice output pipeline is arranged at the bottom of the precipitator; the control system comprises a liquid level sensor capable of testing and sensing the liquid level height of the precipitator, a clear juice regulating valve capable of controlling the flow rate of clear juice, and a controller for regulating the effective flow area of the regulating valve according to the liquid level feedback of the liquid level sensor; the controller realizes the control over liquid level height by regulating the opening of the clear juice regulating valve and then controls the hydraulic retention time of cane juice in the precipitator. The sugar-manufacturing single-layer precipitator control system can realize stepless control of sulphitation and neutralization reaction time, so that the hydraulic retention time is maintained in a certain range value, the clear efficiency of the cane juice is improved, and then the quality of the clear juice is guaranteed.

Owner:南宁苏格尔科技有限公司

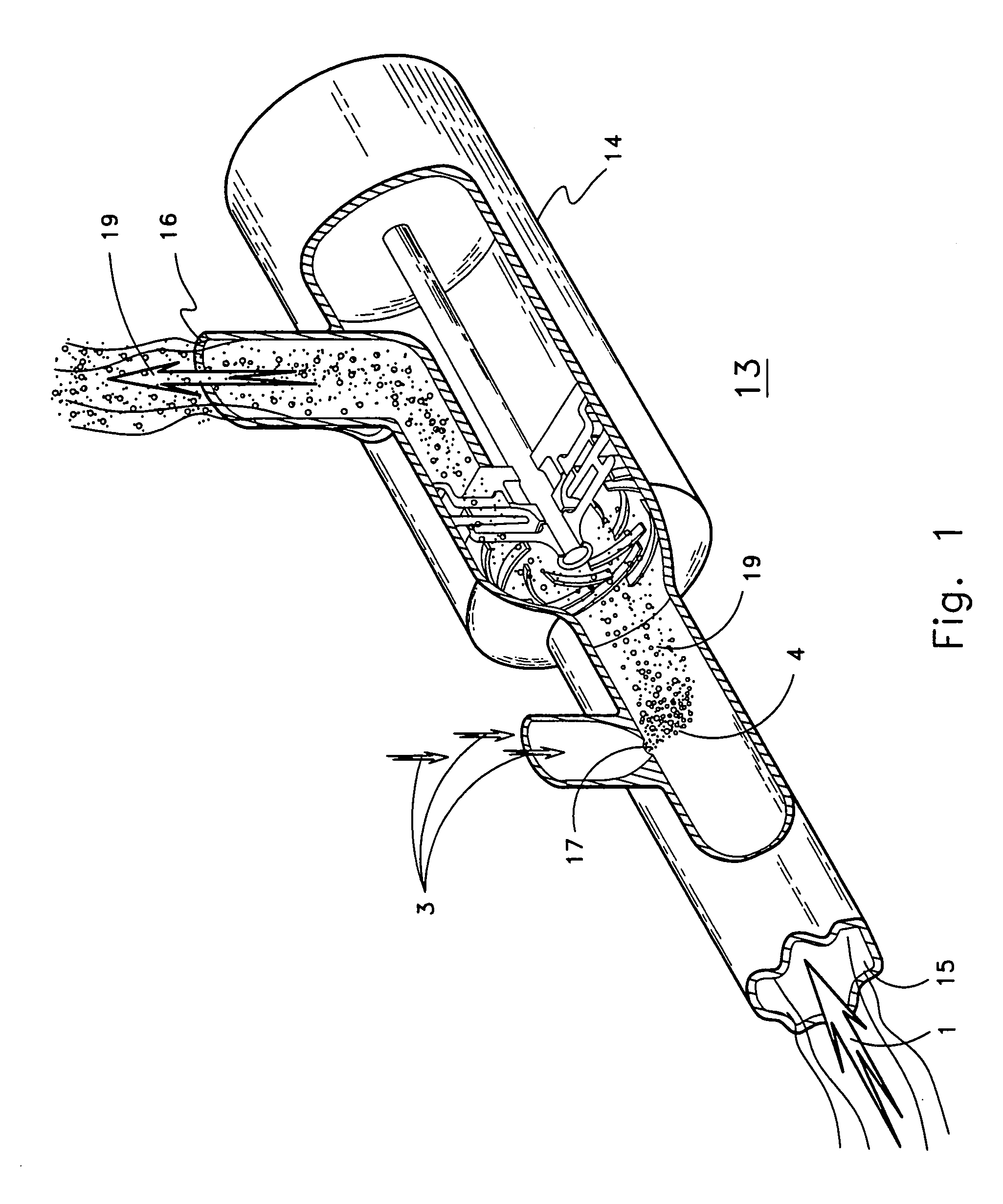

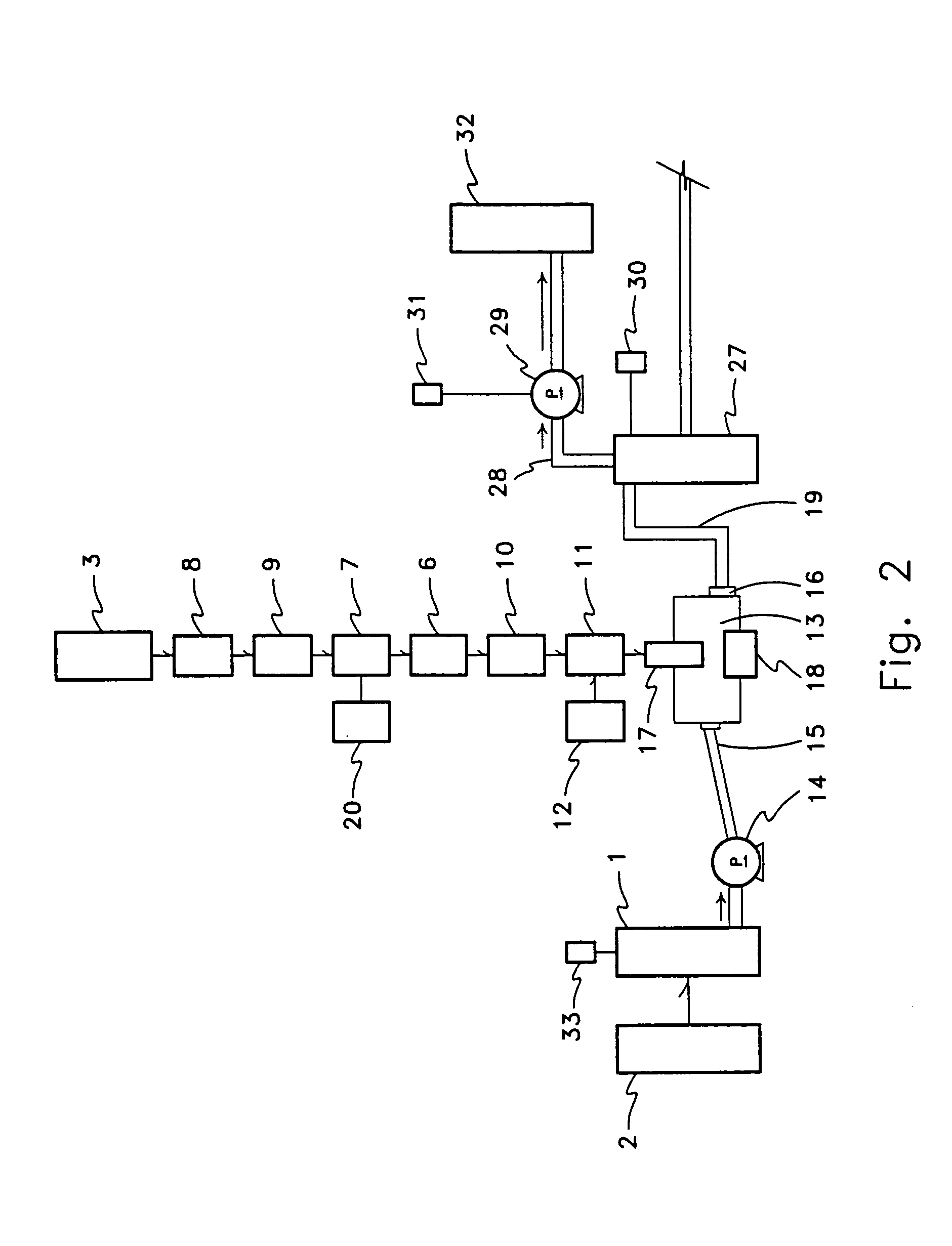

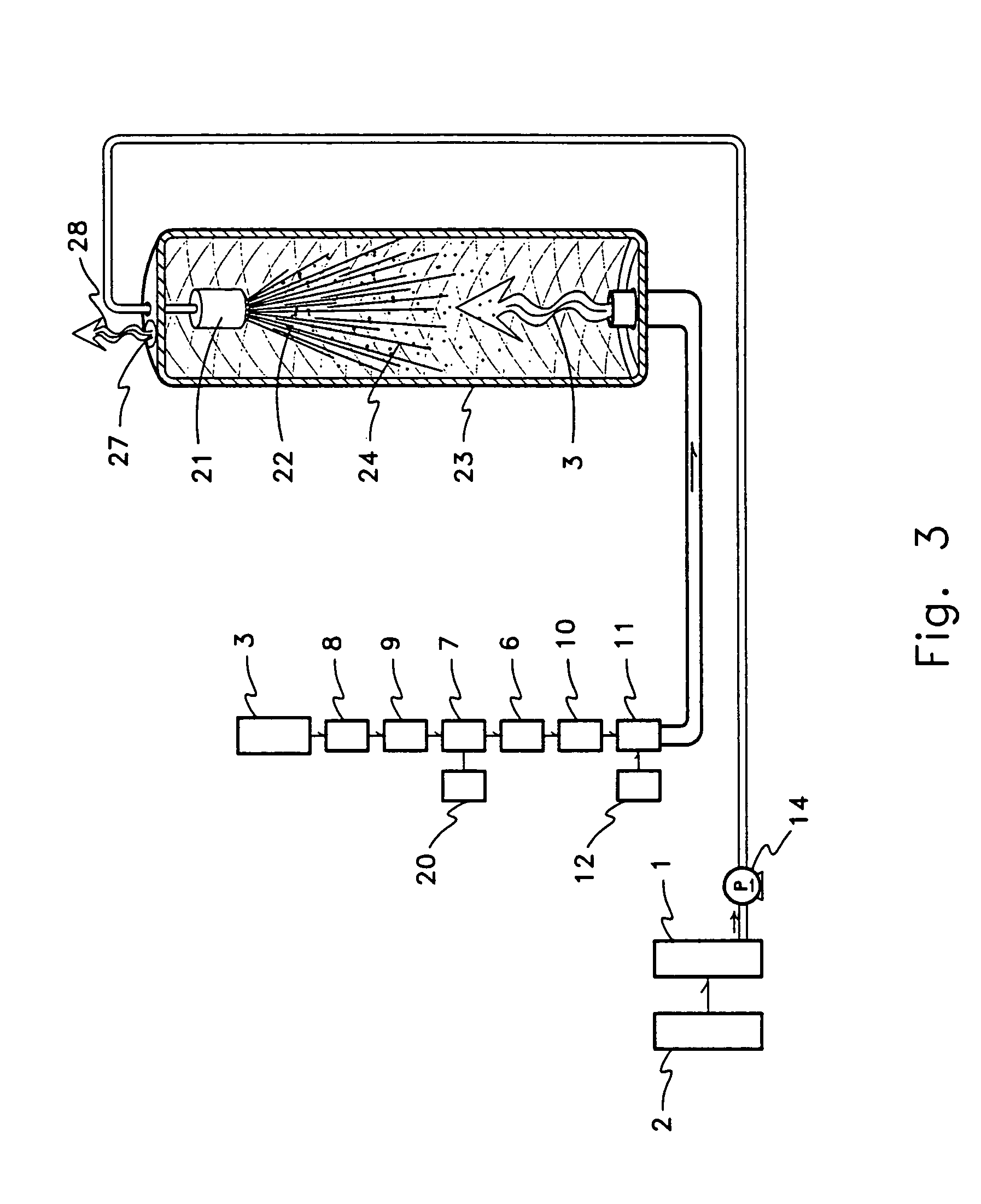

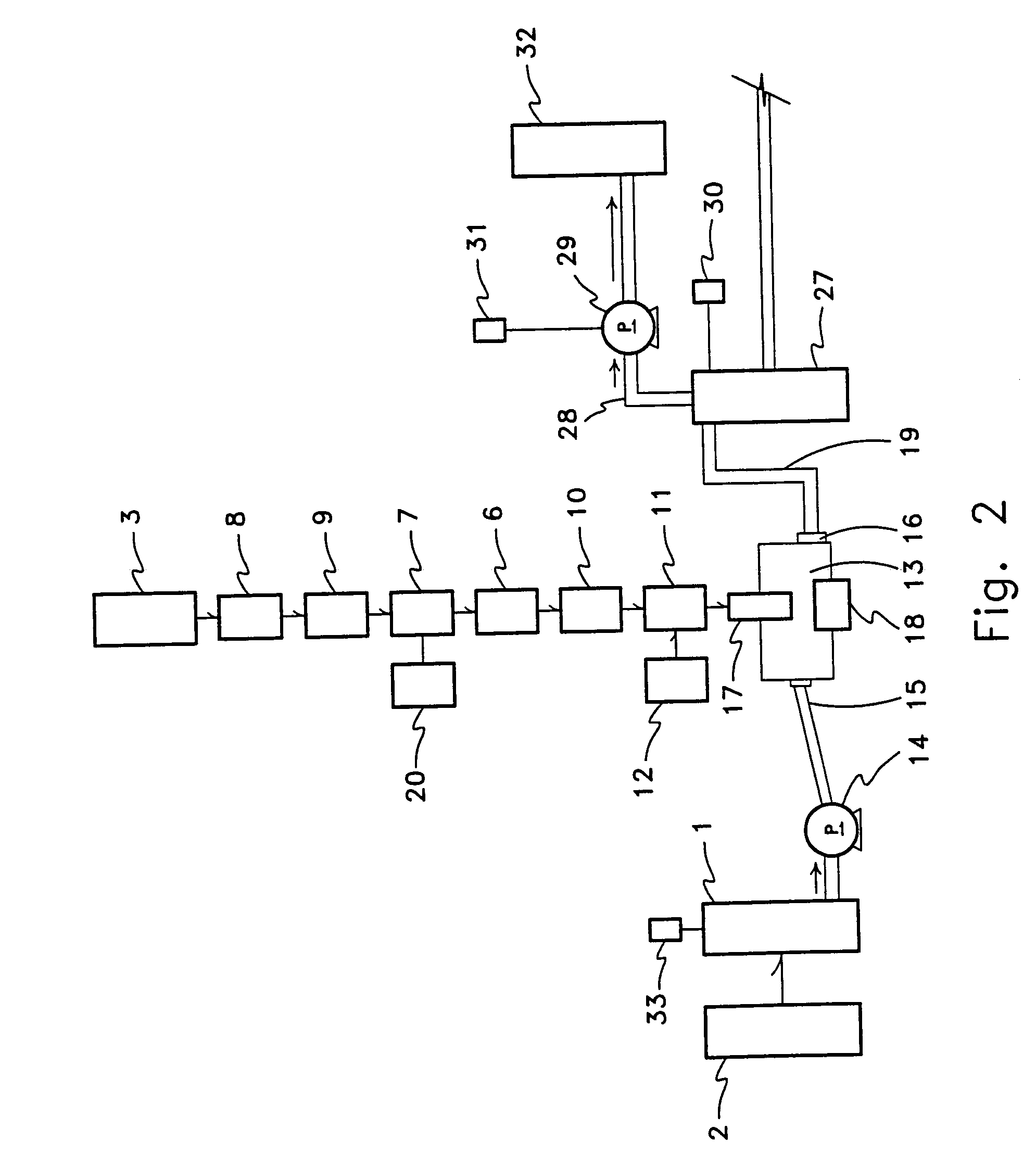

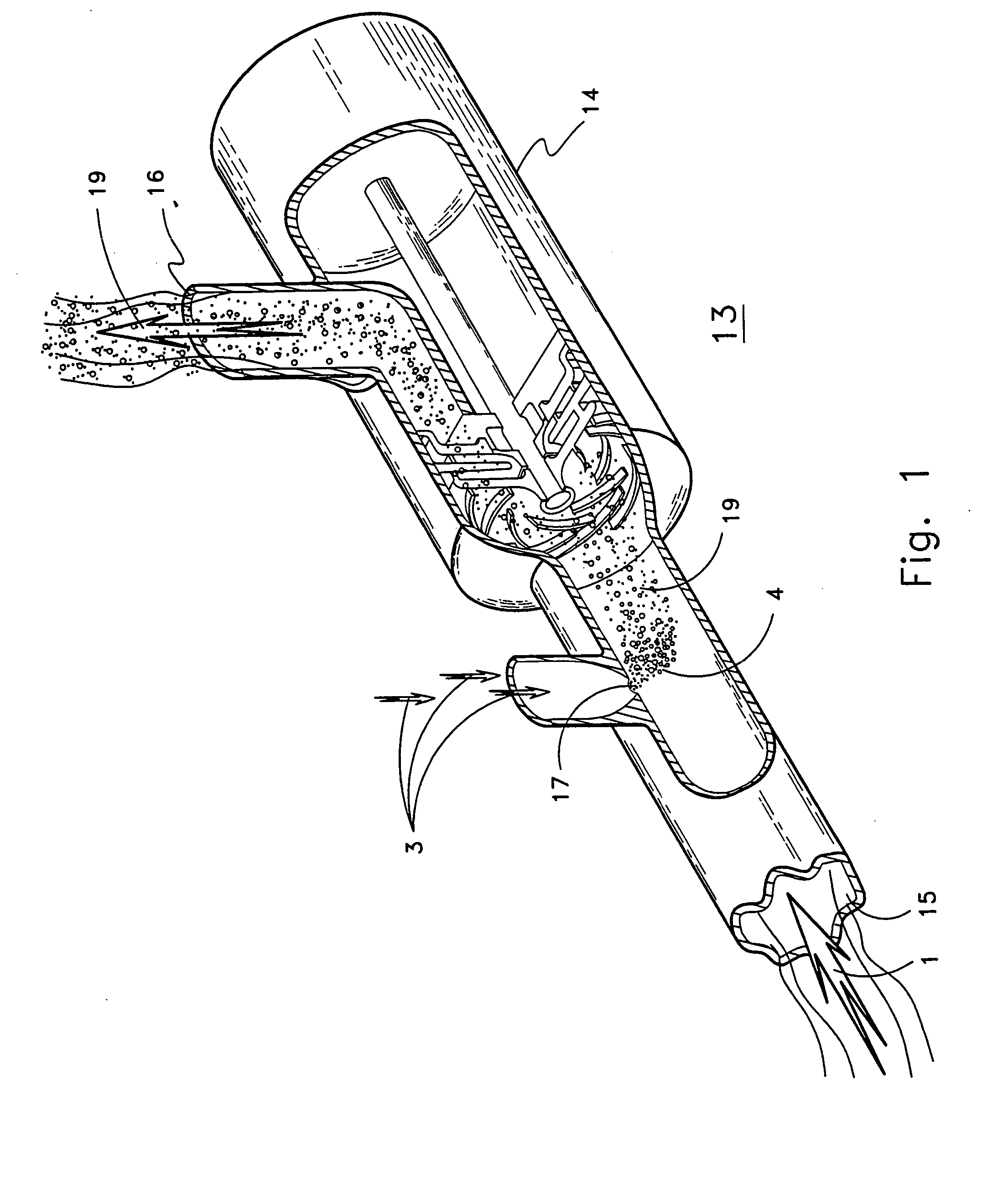

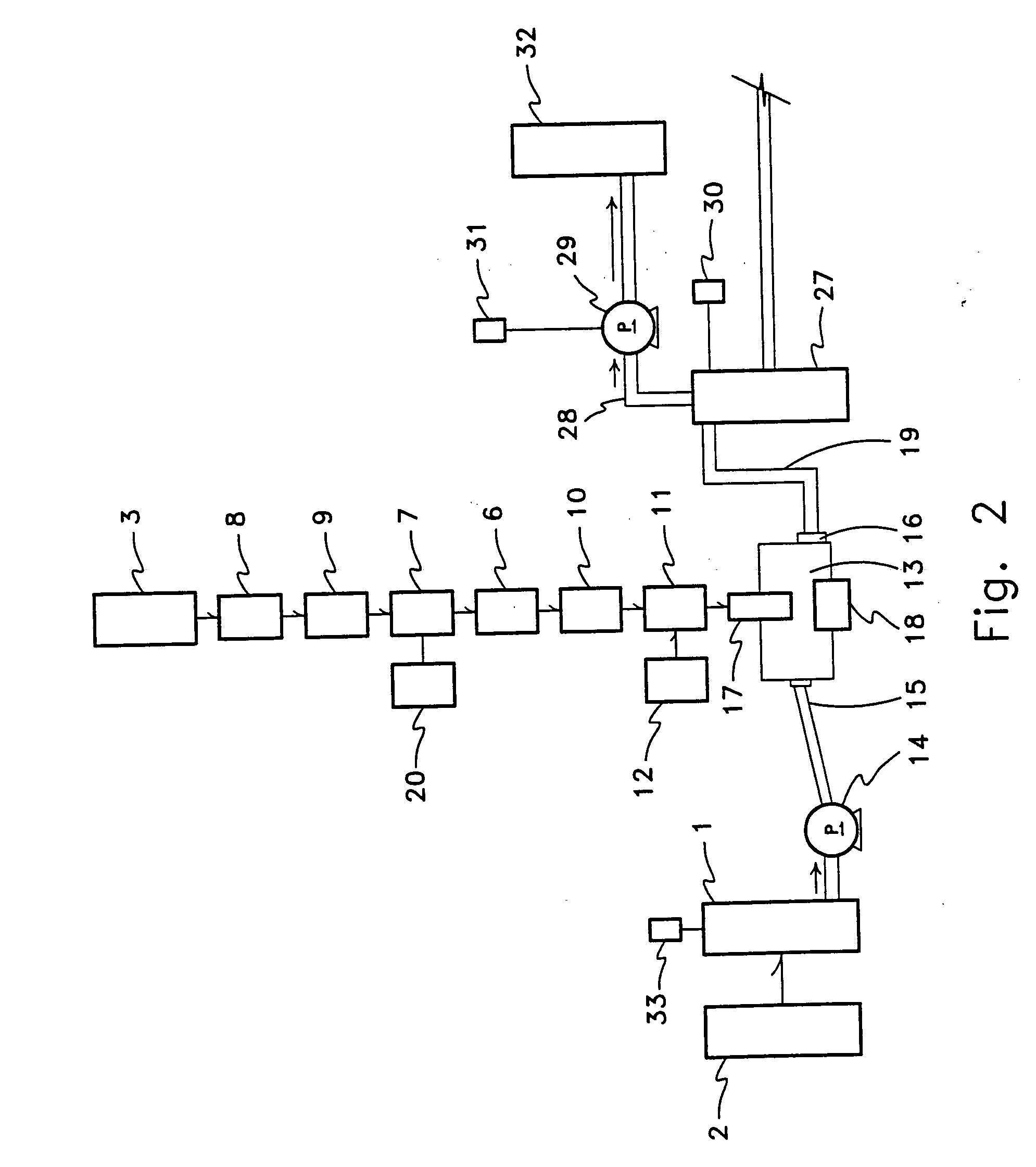

System to produce sugar from plant materials

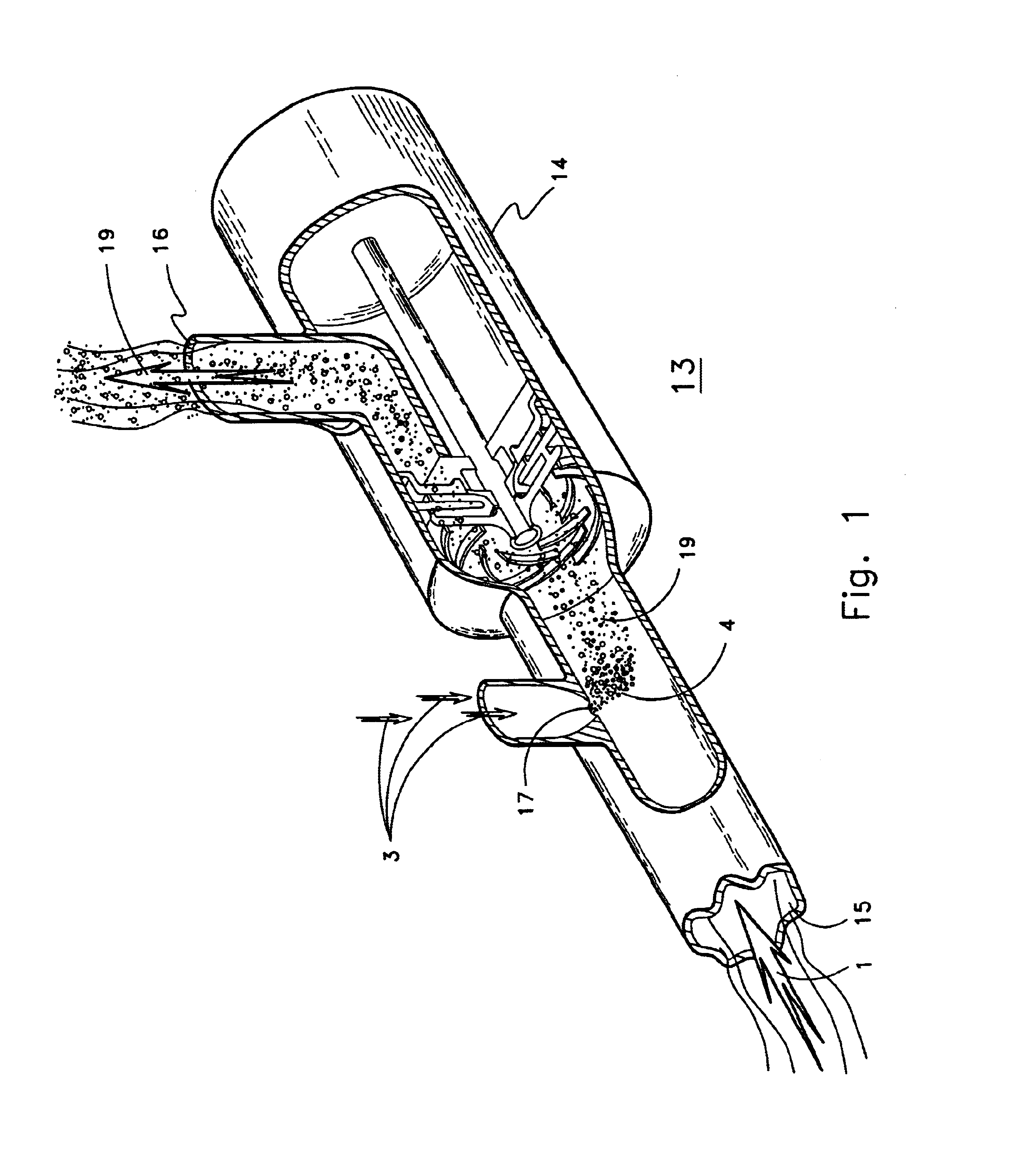

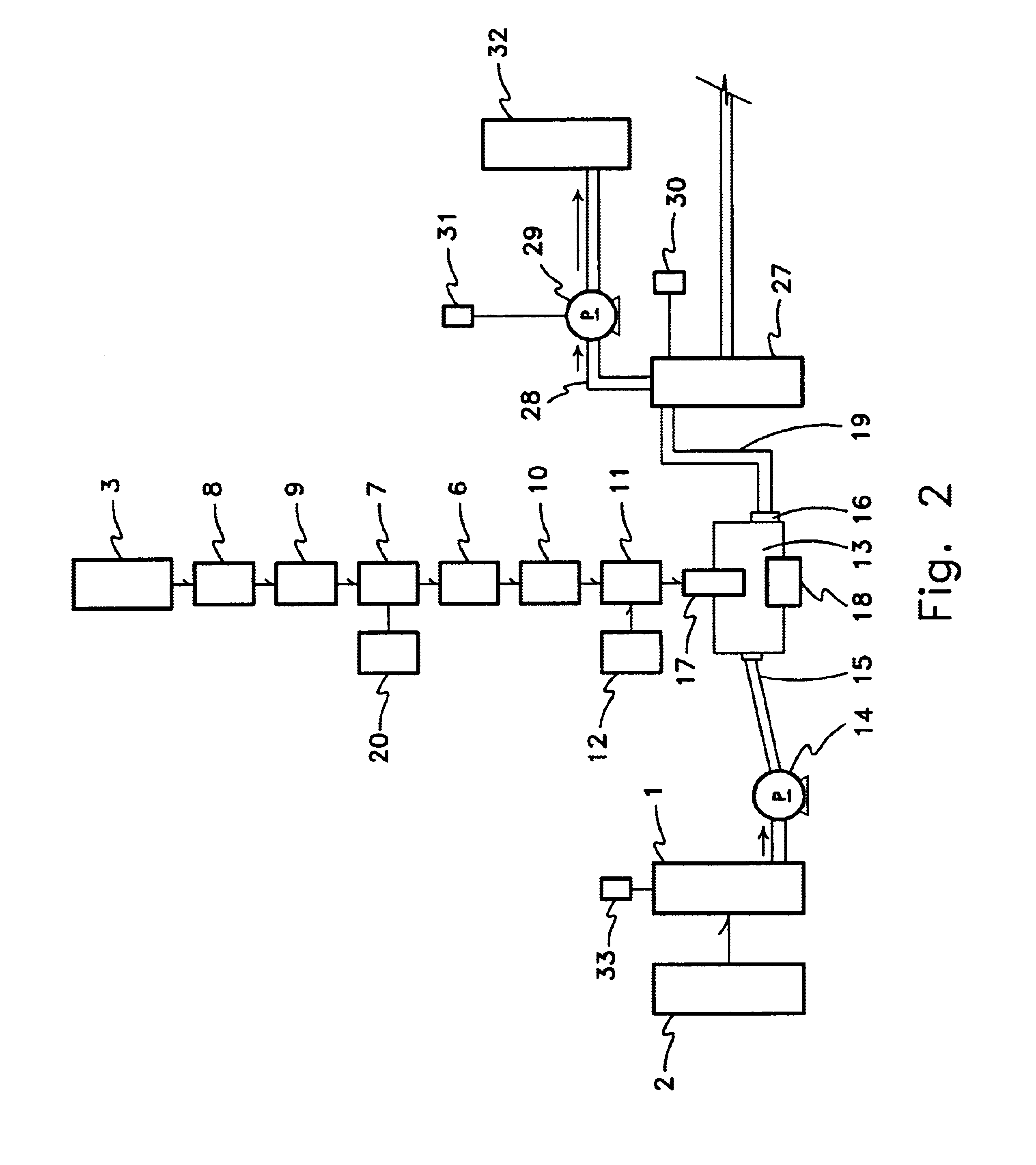

InactiveUS7182818B2Low costReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsBiotechnologyFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice or other process liquid (1) obtained from plant material (2) such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice or other process liquid (1) to increase pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification in subsequent steps, such as preliming (33).

Owner:ECOLAB USA INC

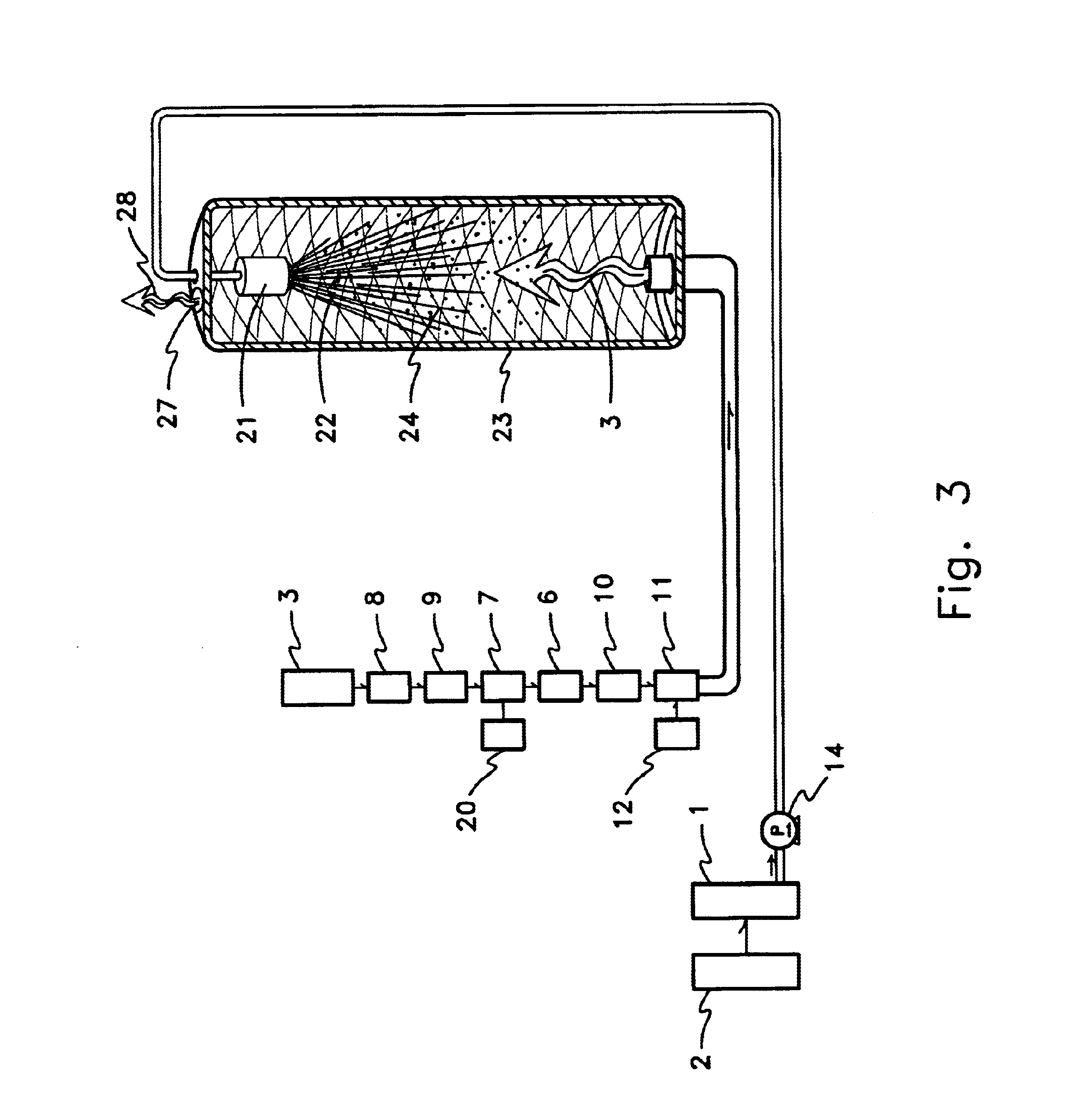

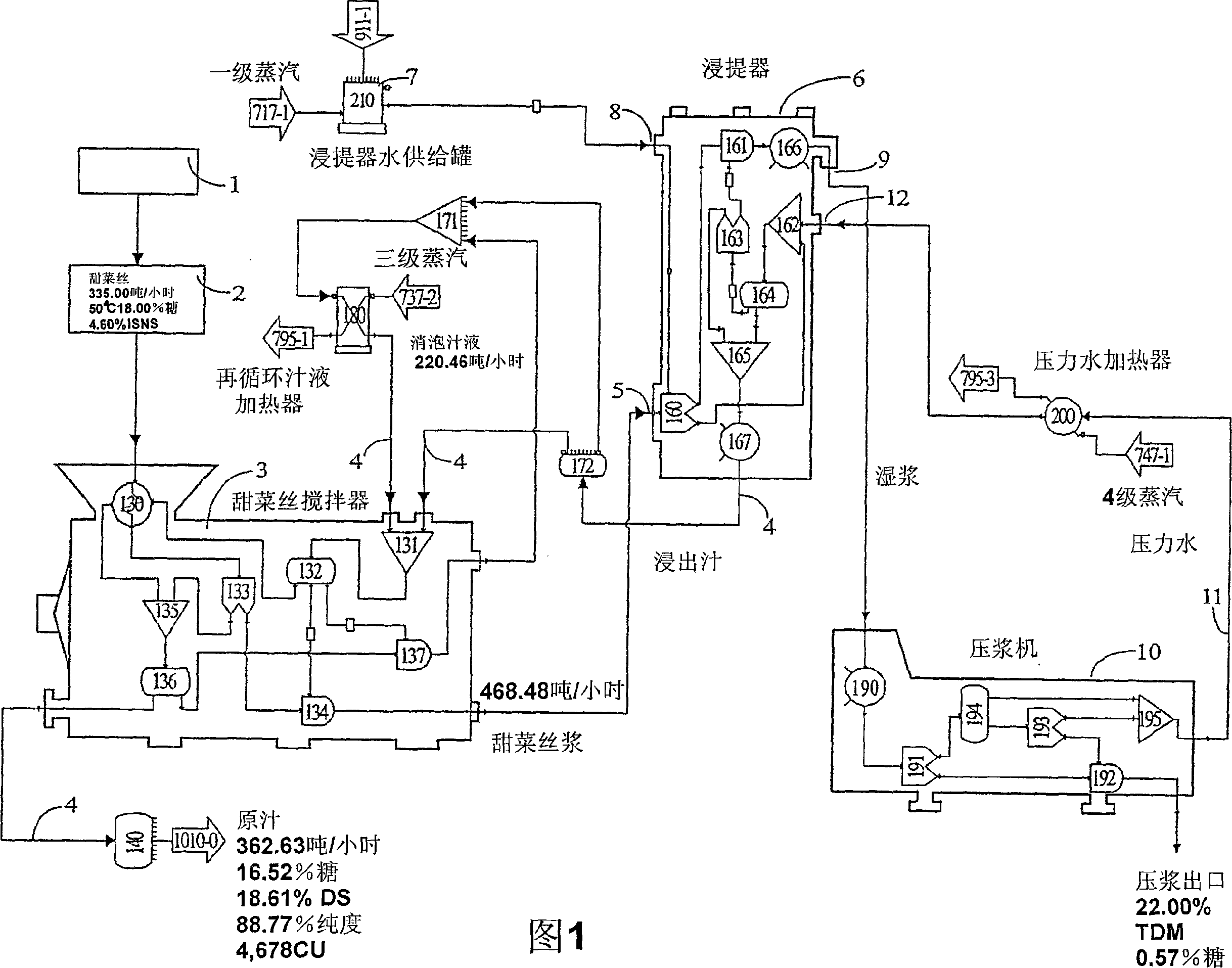

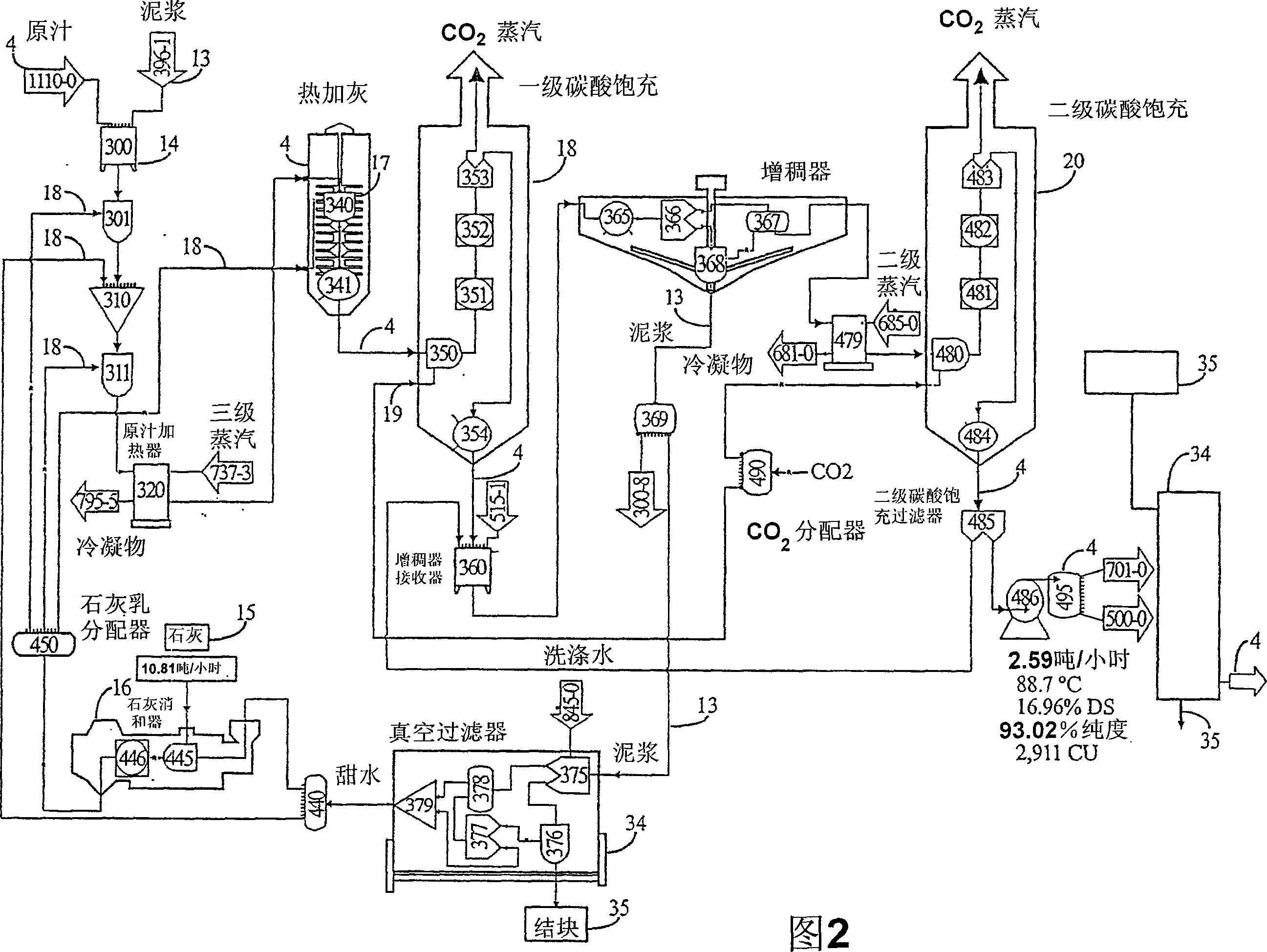

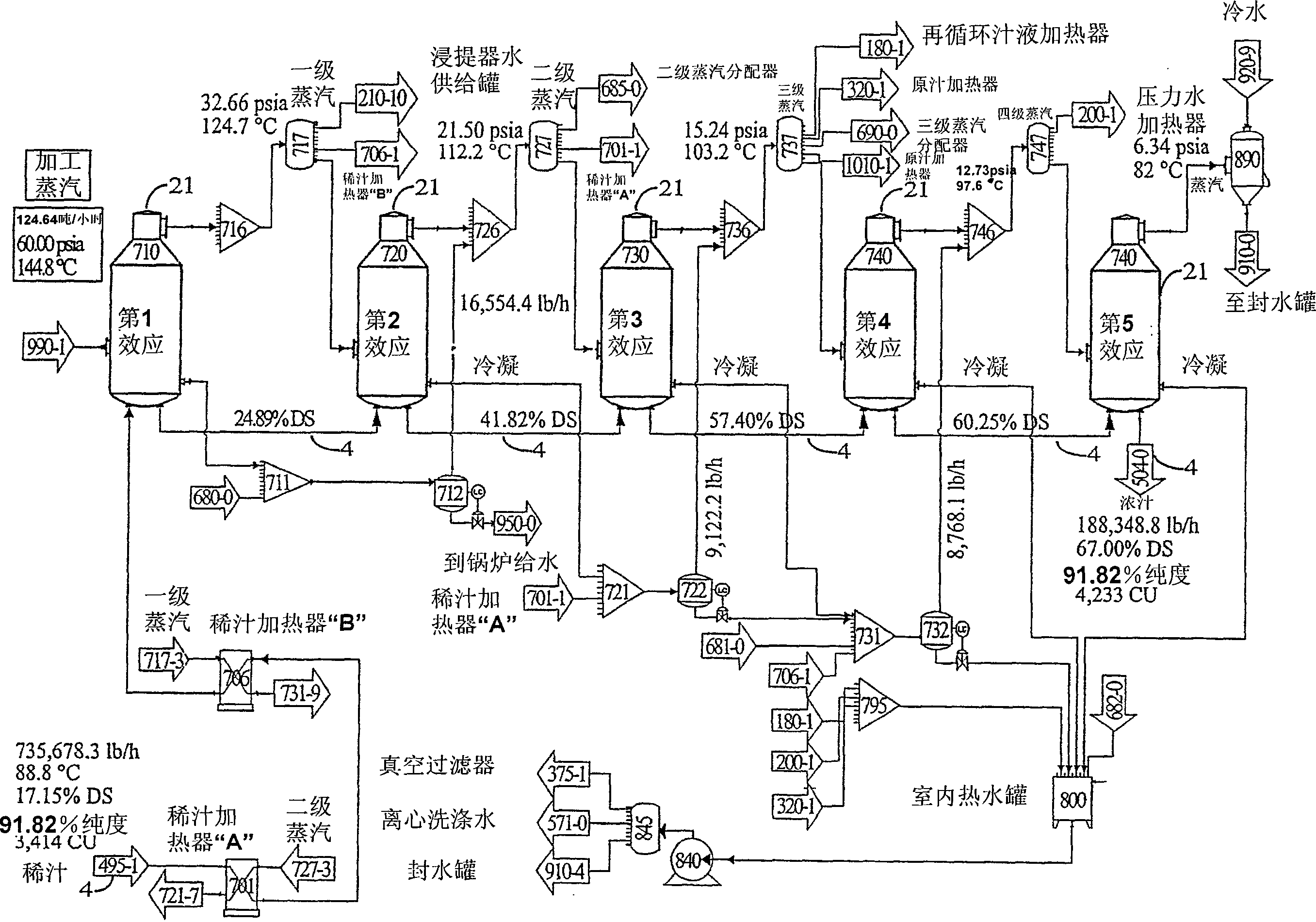

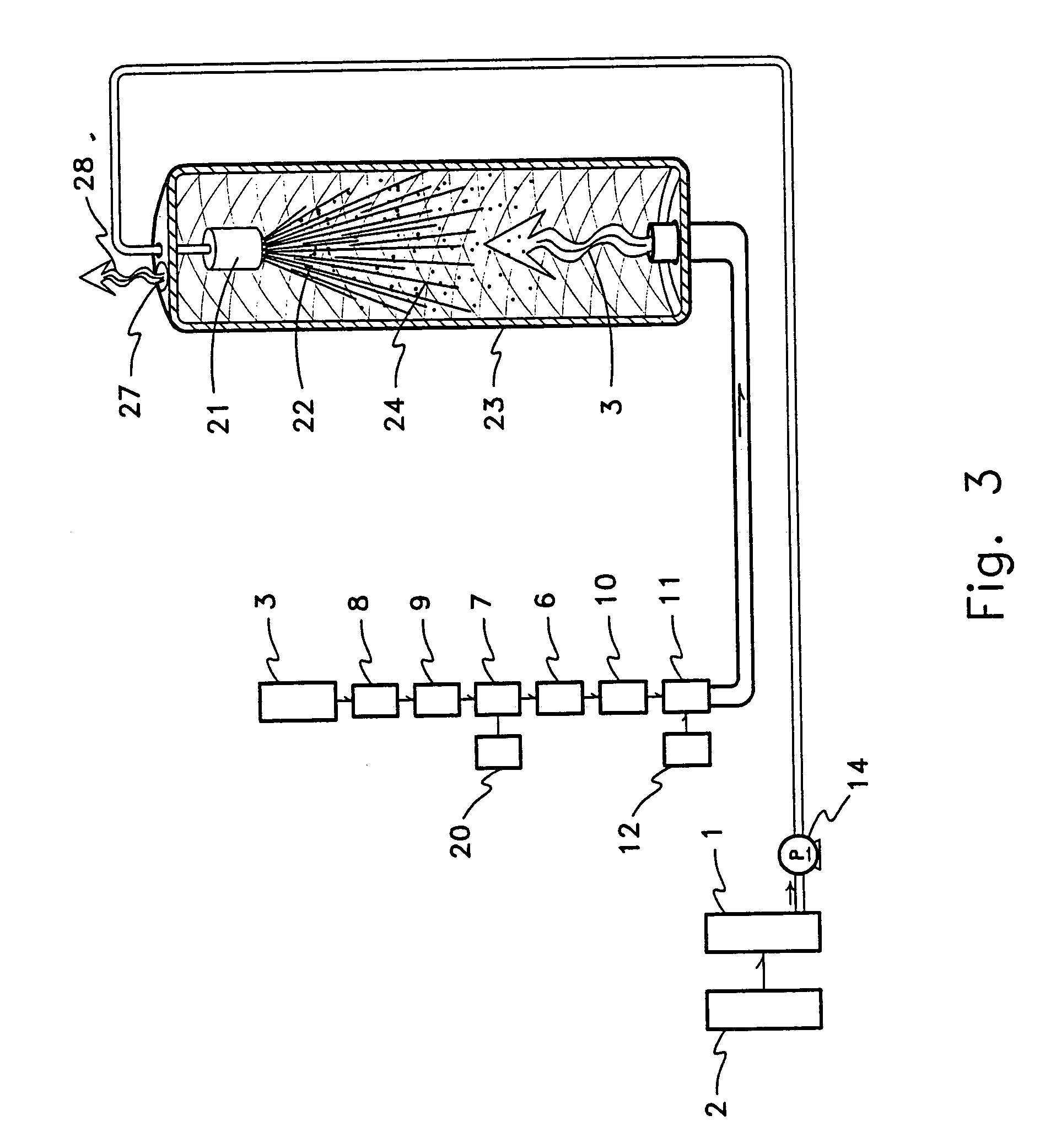

Sugar production system

ActiveCN1791684AReduce concentrationDecrease in amount or concentrationPurification by oxidation/reductionPurification using chemicalsVacuum chamberChemistry

The present invention provides a sugar processing system for conditioning a sugar processing liquid obtained from plant material, the sugar processing system comprising an aeration chamber (37) and / or a vacuum chamber (42).

Owner:NALCO CO

Compound viscosity reducer and application of compound viscosity reducer in molasses viscosity reduction

ActiveCN105420418AReduce viscosityReduce production energy consumptionPurification using chemicalsAlkaneMonoglyceride

The invention discloses compound viscosity reducer and application of the compound viscosity reducer in molasses viscosity reduction. The compound viscosity reducer is prepared from, by mass, 88-95% of ammonia water and 5-12% of compound surface active agent. The compound surface active agent is formed by compounding negative ion surface active agent and non-ion surface active agent according to the mass ratio of (0.5-3):1. The negative ion surface active agent is at least one of fatty acid methyl ester sulfonate and seconary alkane sulphonate sodium. The non-ion surface active agent is at least one of methyl glucoside ester, sucrose fatty acid ester and fatty acid monoglyceride. The compound viscosity reducer can effectively reduce molasses viscosity without molasses dilution and heating and acid-base addition. Operation is conducted under the normal-temperature condition, temperature parameters do not need to be strictly controlled, the production energy consumption can be greatly reduced, the viscosity reduction process can be conducted under the normal-temperature condition, and the process is green and causes no pollution to the environment.

Owner:NANJING TECH UNIV

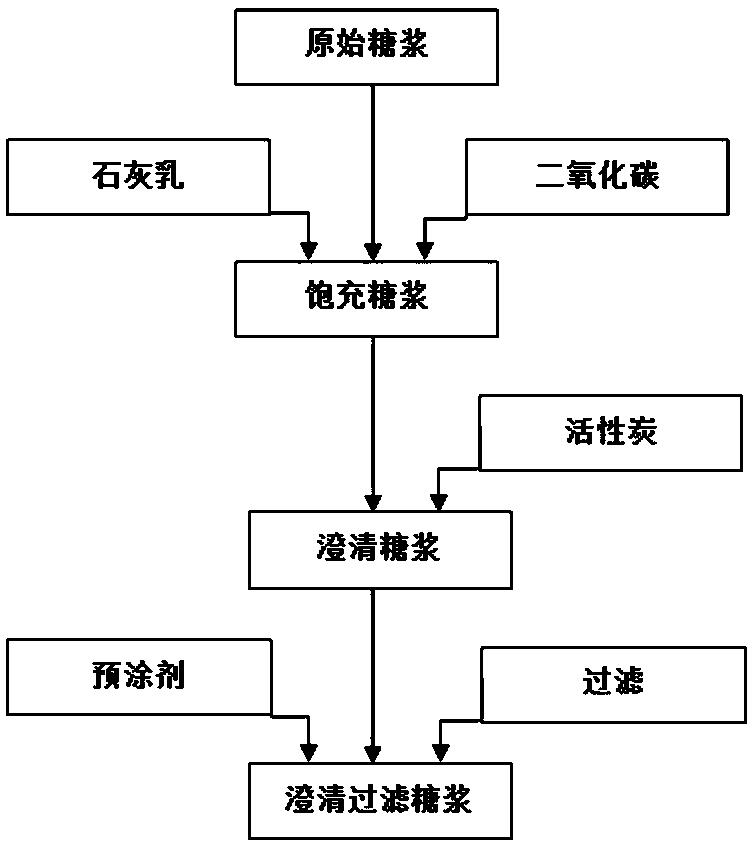

Method for sulfur-free clarification of clear juice

InactiveCN107267672APromote hydrolysis reactionFacilitate segmental softeningPurification using chemicalsPurification by physical meansHydrolysateUltrafiltration

The invention discloses a method for sulfur-free clarification of clear juice. The method comprises the following steps: step 1, subjecting sugarcane to squeezing and filtering so as to obtain bagasse and sugarcane juice, continuously adding phosphoric acid into the sugarcane juice under stirring, adding lime milk at the same time, carrying out heating to a boiling state and then carrying out settlement and separation so as to obtain clarified juice; step 2, carrying out steam explosion on the bagasse and collecting bagasse having undergone steam explosion; step 3, sprinkling a compound enzyme solution onto the surface of the bagasse having undergone steam explosion so as to obtain enzymatic hydrolysate; step 4, heating the enzymatic hydrolysate to 65 DEG D, providing a first clear juice container and carrying out settlement and separation so as to obtain first clear liquid; step 5, heating the first clear liquid to 95 DEG C, providing a second clear juice container and carrying out settlement and separation so as to obtain second clear liquid; and step 6, heating the second clear liquid to a boiling state, removing impurities through filtering, carrying out cooling to room temperature and then successively carrying out ultrafiltration, evaporative concentration, crystallization and purging. Sugar prepared in the invention does not contain SO2, so the chromatic value and turbidity value of the prepared sugar are effectively reduced, and the purity and concentration of the prepared sugar are improved.

Owner:陆丽英

Method for removing calcium and magnesium ions in cane molasses

InactiveCN105779661AReduce dosageLow costSugar productsPurification using chemicalsFluorideAqueous solution

The invention discloses a method for removing calcium and magnesium ions in cane molasses. The method comprises the following steps of firstly, diluting the cane molasses with purified water into an aqueous solution of the cane molasses; weighing fluoride and slowly adding the fluoride into hot water of which the temperature is 80 to 90DEG C to obtain fluoride suspension or solution; slowly adding the fluoride suspension or solution into cane molasses water, simultaneously adding and stirring, and removing precipitate to obtain the cane molasses without the calcium and magnesium ions. According to the method disclosed by the invention, an effect of removing the calcium and magnesium ions in the cane molasses by adopting the fluoride is good, and the removal rate can reach 100 percent; the method needs lower consumption of fluoride, and is low in cost and suitable for industrial production.

Owner:邹传军

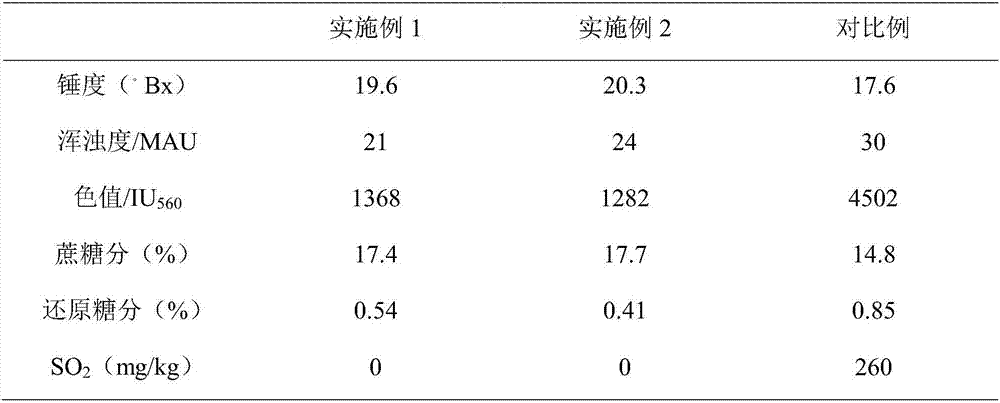

Syrup clarification method using combination of active carbon and carbonic acid method

InactiveCN110358870AImprove the effect of decolorization and clarificationImprove filtration efficiencyPurification using adsorption agentsPurification using chemicalsActivated carbonFiltration

The invention relates to the technical field of sugar manufacturing and discloses a syrup clarification method using a combination of active carbon and a carbonic acid method. The syrup clarificationmethod using the combination of active carbon and the carbonic acid method comprises the following steps: step I, adding lime milk and carbon dioxide into original syrup for saturation by the carbonicacid method to form saturated syrup, step II, adding 0.03-0.05% of active carbon into the saturated syrup for a clarification reaction to form clarified syrup, and step III, performing filtration onthe clarified syrup to form clarified and filtered syrup. The method integrates active carbon and the carbonic acid method to exert a synergistic effect; a decoloration and clarification effect of thesyrup is improved; synchronous separation of active carbon and filtrated mud is achieved through original pressure filtration due to a filtration aiding effect of calcium carbonate in the saturated syrup on active carbon; additional filtration equipment is not required; the equipment investment cost is lowered; pressure filtration equipment is additionally coated with a precoating agent, so thatcarbon leakage is effectively avoided; the filtration efficiency and filtration precision are improved; a clarification effect is good; and the method is short in technical process and high in safety.

Owner:中粮崇左糖业有限公司 +2

Sachima syrup purification method based on polysaccharide fiber carbon degumming technology

InactiveCN110835656AImprove transmittanceLower protein contentPurification using adsorption agentsPurification using chemicalsActivated carbonIon exchange

The invention discloses a Sachima syrup purification method based on a polysaccharide fiber carbon degumming technology, and relates to the technical field of syrup purification. The method comprisesthe following steps: 1, primarily filtering: adding a filter aid into syrup to carry out primary filtration; 2, secondarily filtering: continuously adding activated carbon into the filtered syrup to carry out secondary filtration; 3, carrying out ion exchange: introducing the filtered syrup into a plurality of groups of ion exchange devices to remove impurity ions in the syrup; and 4, adding the syrup subjected to ion exchange into a security filter for primary filtration, adding the collected filtrate into a membrane stack device for filtration, adding the obtained filtrate into an evaporator, and evaporating the filtrate to finally obtain the syrup. The problems of bag sticking, hardening and sand returning of Sachima are solved, and the effect of prolonging the shelf life of the Sachimaby reducing the protein content in the Sachima syrup is achieved.

Owner:双桥(厦门)有限公司

Carbon-sulfur combining sugar juice carbonation and clarifying method through CO2 generated from alcohol in production of sugar from sugarcane

InactiveCN104357587AAchieve emissionsAvoid wastingPurification using chemicalsPurification using alkaline earth metal compoundsAlcohol productionProcess engineering

The invention relates to a carbon-sulfur combining sugar juice carbonation and clarifying method, and belongs to the technical field of a sugar producing process. The method, on the basis of a sulfurous method, makes use of di-carbonation process control point of a carbonic acid method process and takes CO2 generated from molasses alcohol production as a sugar juice clarifying agent to replace SO2 of the sulfurous method, so as to reduce SO2 consumption of the sulfurous method. The method disclosed by the invention, by taking the CO2 generated from molasses alcohol production as a bubble producing air source and in combination of the sulfurous method, the carbonic acid method and an air floatation clarifying technology, can significantly improve clarifying efficiency and effect and reduce consumption of sulfur; and meanwhile, quality of white sugar is improved and pollution of CO2 emission on air is relieved.

Owner:LINCANG NANHUA SUGAR IND +1

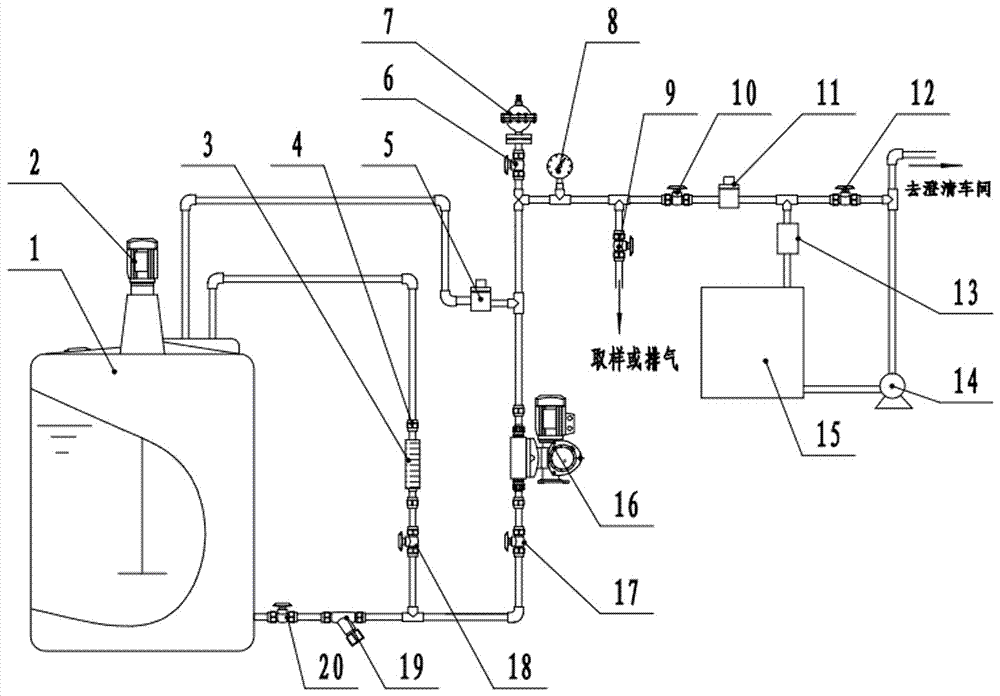

Phosphoric acid adding system in sugarcane sugar manufacturing process

PendingCN106943939AAdd precision and stabilityLow costPurification using chemicalsTransportation and packagingPhosphoric acidPulp and paper industry

The invention discloses a phosphoric acid adding system in sugarcane sugar manufacturing process. The phosphoric acid adding system comprises a solution tank, a mixer, a mixed juice tank, and a metering pump; the solution tank is provided with a stirrer; the lower part of the solution tank is connected with the metering pump via a pipeline; the metering pump is connected with the mixer arranged on the upper part of the mixed juice tank via a pipeline; the lower part of the mixed juice tank is connected with a clarification workshop via a pipeline provided with a mixed juice pump; the pipeline between the solution tank and the metering pump is provided with a No.7 ball valve, a Y-shaped filter valve, and a No.5 ball valve successively; the pipeline between the metering pump and the mixer is provided with a pressure meter, a No.3 ball valve, and a back pressure valve; the pipeline between the mixed juice pump and the clarification workshop is connected with the pipeline between the back pressure valve and the mixer via the pipeline provided with a No.4 ball valve; the pipeline between the pressure meter and the No.3 ball valve is connected with a sampling or exhausting pipe; the sampling or exhausting pipe is provided with a No.2 ball valve. The phosphoric acid adding system is capable of realizing accurate and stable adding of phosphoric acid in sugar manufacturing process, increasing white granulated sugar product quality, and reducing production cost.

Owner:广西糖业集团良圻制糖有限公司

Method for Purification of Lactose

InactiveUS20110034685A1Simple and economical processHigh purityBiocideOrganic active ingredientsAlcoholDivalent metal

The present invention relates to improved methods of purification of sugars and in particular to a method of preparing lactose. A low purity lactose source such as whey is subjected to a first demineralization step involving either ion-exchange or the addition of divalent metal cations, followed by a second demineralization step where alcohol is added. The invention also relates to lactose produced by this method and products comprising lactose produced by this method.

Owner:DAIRY AUSTRALIA

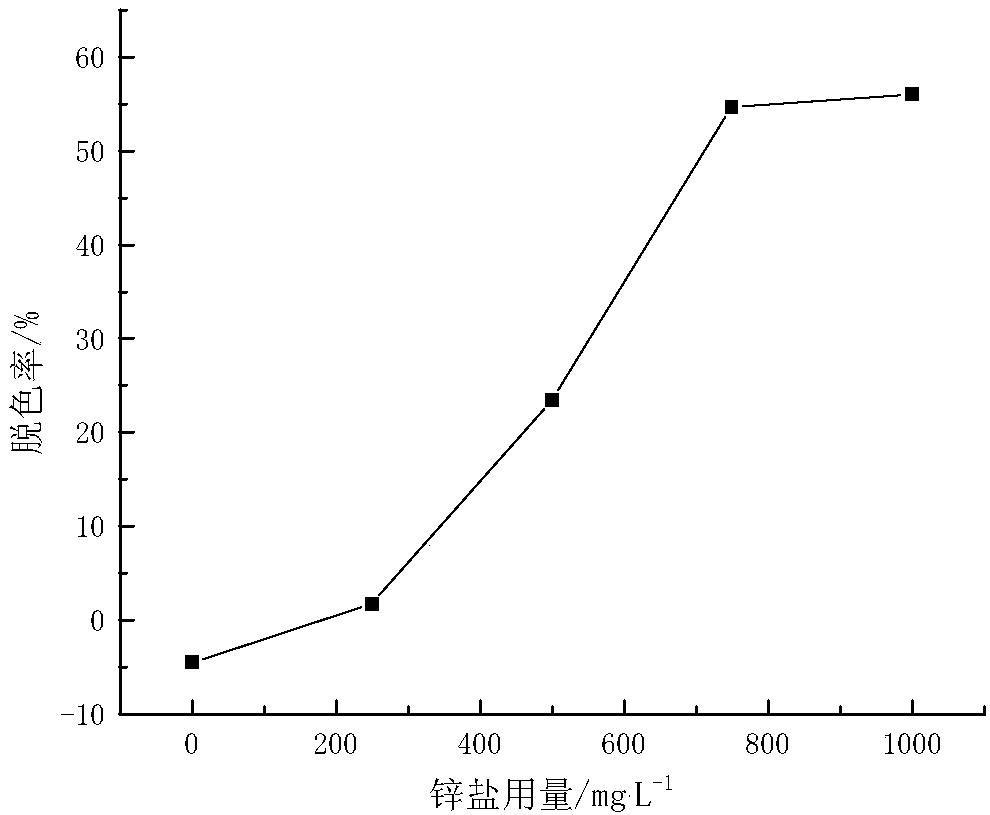

Method for decolorizing sugar juice by using water-soluble zinc salt-lime

PendingCN110904280AHigh decolorization rateSimple processPurification using chemicalsZinc hydroxideSulfate zinc

The invention relates to a method for decolorizing sugar juice by using water-soluble zinc salt-lime. The specifically steps comprise: adding a water-soluble zinc salt into sugar juice, regulating thepH value by using lime milk, continuously stirring at 65-80 DEG C for 10-30 minutes, adding PAM, carrying out standing separation, and obtaining a clean juice after flocculation sedimentation is stable. According to the method, zinc sulfate (zinc sulfate, zinc chloride or zinc nitrate) is used as an inorganic decolorizing agent, and is subjected to a coagulation reaction under an alkaline condition to generate zinc hydroxide and a calcium salt (calcium sulfate, calcium oxide or calcium nitrate) so as to adsorb or embed the pigment and other non-sugar substances in the sugar juice, wherein thedecolorization rate reaches 81.75%; the process is simple, does not use toxic and harmful substances, and belongs to an environmentally friendly clarification decolorization process; and the principle is that a zinc salt is used as an inorganic decolorizing agent, and is subjected to a coagulation reaction under an alkaline condition to generate zinc hydroxide and a calcium salt so as to adsorb or embed non-sugar substances such as pigments and the like in sugar juice.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

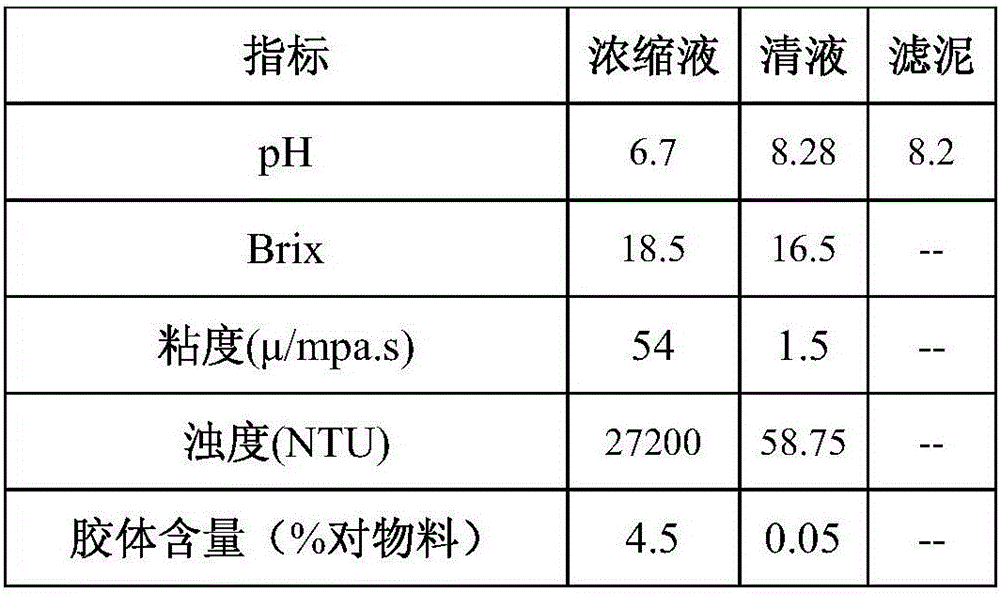

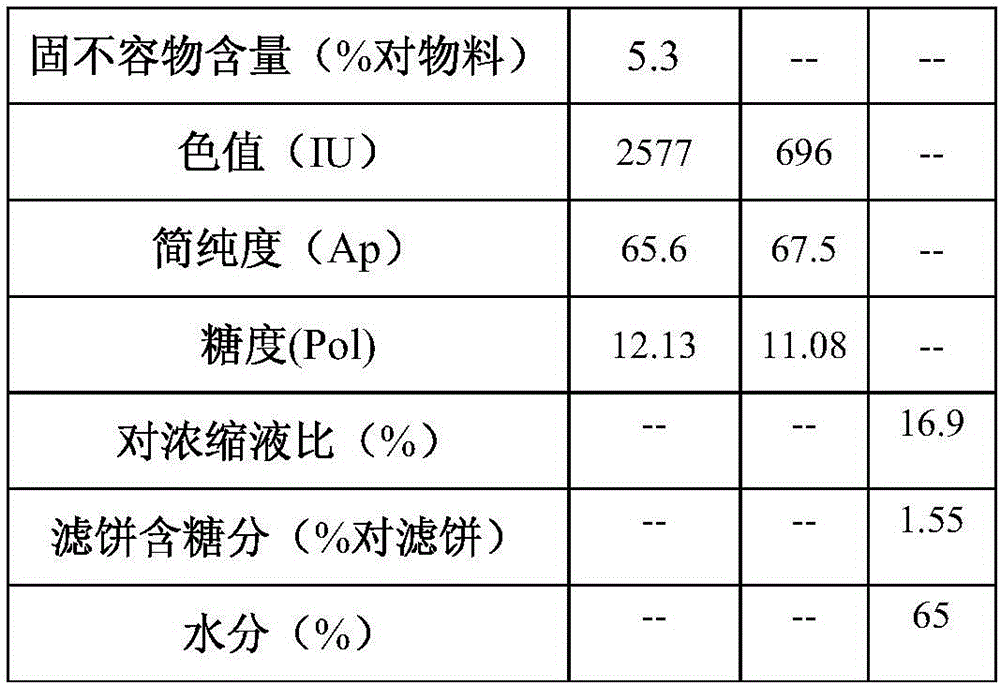

Device and process for treating membrane filtration concentrated liquor generated in membrane based sugar production

PendingCN105886669AHigh recovery rateLow costPurification using chemicalsPurification using alkaline earth metal compoundsEconomic benefitsFilter press

A method for treating membrane filtration concentrated liquor generated in membrane based sugar production includes steps: adding lime milk into the membrane filtration concentrated liquor for the first time to adjust pH to 7.0-7.5, heating for the first time to 45-55DEG C, and adding the lime milk for the second time to adjust pH to 10.5-11.4; feeding carbon dioxide gas for the first time until pH reaches 8.2-8.4; adding the lime milk for the third time to adjust pH to 10.5-11.4; feeding the carbon dioxide gas for the second time until pH reaches 8.2-8.4; heating for the second time to 70-80DEG C, adding a filter aid, well stirring, sending to a filter press, and filtering to obtain filtrate and filter cakes. The method has advantages of simple process, easiness in operation, low equipment input, low energy consumption, low filter aid cost, freeness of environment pollution and the like. The filtrate can be directly used for sugar production, so that the economic benefit in membrane clarification based sugar production is increased; the filter cakes are rich in organic content and can serve as a raw material of organic fertilizers.

Owner:广西尚唐高科技有限公司

Method of reducing materials contained in juice

InactiveUS7150793B2Low costReduce the amount requiredSolid sorbent liquid separationSucrose extraction by chemical meansProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

Method of reducing materials contained in juice

InactiveUS20040105924A1Low costReduce the amount requiredSolid sorbent liquid separationCocoaProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com