Refined sugar clarification device

A clarification device and sugar refining technology, which is applied in sugar products, sucrose production, sugar production, etc., can solve the problems of poor clarification effect of back-dissolving syrup and low service life of ion exchange resin, so as to prolong the membrane cleaning cycle and achieve good clarification effect , the effect of slow attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

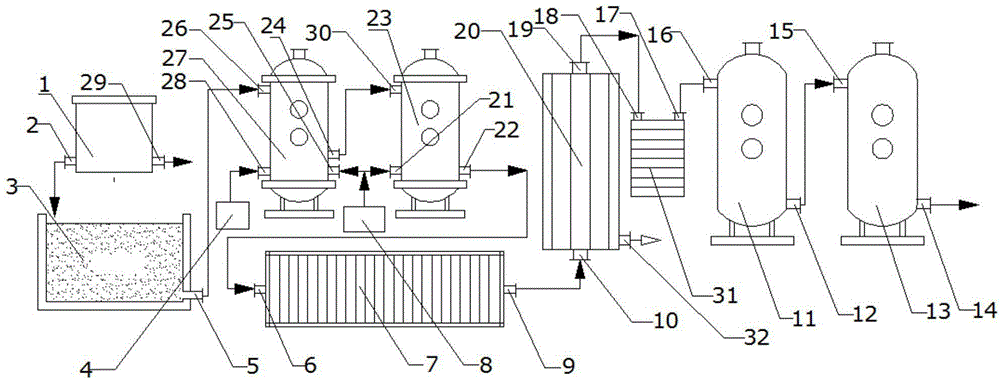

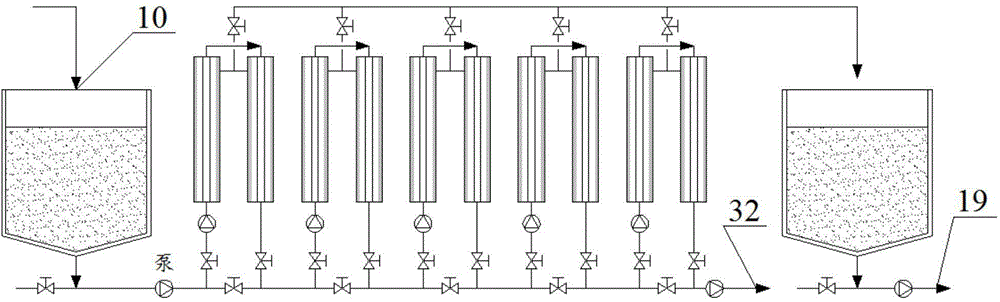

[0026] A refined sugar clarification device, including raw molasses washing equipment 1, sugar dissolving tank 3, No. 1 carbon filling tank 27, No. 2 carbon filling tank 23, plate and frame filter press 7, multi-stage ceramic membrane Microfiltration system 20 , plate heat exchanger 31 , first ion exchange resin tower 11 and second ion exchange resin tower 13 .

[0027] The specific connection method is as follows,

[0028] The honey washing raw sugar outlet 2 of the raw molasses washing equipment is connected to the sugar dissolving tank 3 through a spiral conveying tank, and the remelting syrup outlet 5 of the sugar dissolving tank is connected to the syrup inlet 26 of the No. 1 carbon filling tank, and the No. 1 carbon filling tank The syrup outlet 24 is connected with the syrup inlet 30 of the No. 2 carbon-filled tank, the syrup outlet 22 of the No. 2 carbon-filled tank is connected with the plate-and-frame filter press inlet 6, and the plate-and-frame filter press filtrat...

Embodiment 2

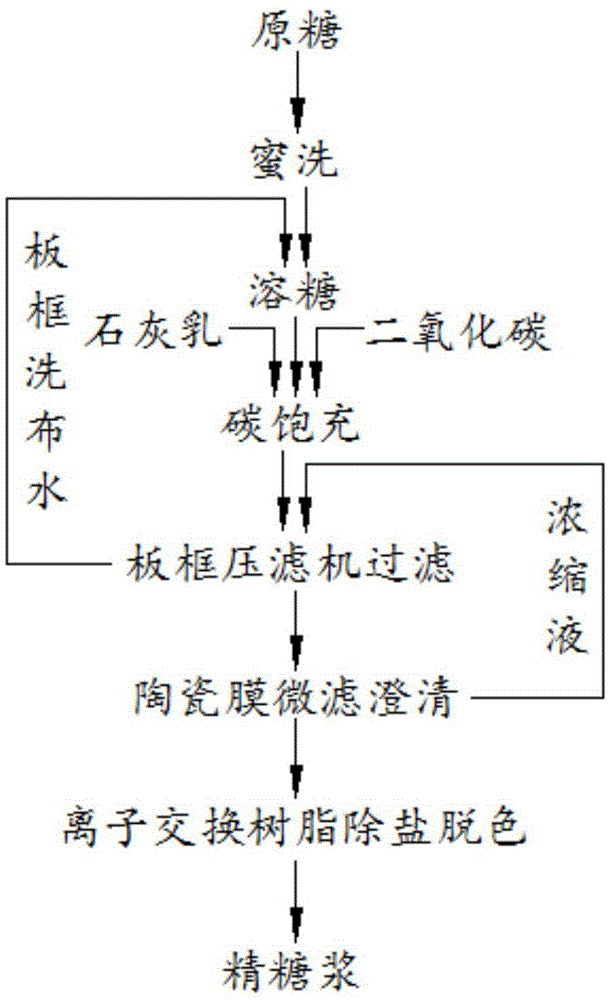

[0038] This embodiment is a specific example of production using the refined sugar clarification device of the present invention, and the specific operation steps are:

[0039] (1) Honey washing: Put the raw sugar into the top-suspension centrifugal honey separator, use R 4 Molasses cleans the pigment on the surface of raw sugar to obtain honey-washed raw sugar;

[0040] (2) Dissolving sugar: dissolving the honey-washed raw sugar with 85°C washing filter cloth water in a sugar-dissolving box to obtain 65.0°Bx back-dissolving syrup for subsequent use;

[0041] (3) Carbon filling: first pump the remelted syrup to the No. 1 carbon filling tank, and add lime milk and carbon dioxide to the No. The carbon-filled syrup is pumped to the No. 2 carbon-filled tank, and carbon dioxide is continued to be filled into the No. 2 carbon-filled tank to obtain the 2-carbon-filled syrup for use. The alkalinity of the 1-carbon-filled syrup is 0.05 and the pH value is 11.0 , the pH value of the c...

Embodiment 3

[0048] This embodiment is another specific example of production using the refined sugar clarification device of the present invention, and the specific operation steps are:

[0049] (1) Honey washing: Put the raw sugar into the top-suspension centrifugal honey separator, use R 4 Molasses cleans the pigment on the surface of raw sugar to obtain honey-washed raw sugar;

[0050] (2) Dissolving sugar: dissolving the honey-washed raw sugar with 80°C washing filter cloth water in a sugar-dissolving box to obtain 60.0°Bx back-dissolving syrup for subsequent use;

[0051] (3) Carbon filling: first pump the remelted syrup to the No. 1 carbon filling tank, and add lime milk and carbon dioxide to the No. The carbon-filled syrup is pumped to the No. 2 carbon-filled tank, and carbon dioxide is continued to be filled into the No. 2 carbon-filled tank to obtain the 2-carbon-filled syrup for use. The alkalinity of the 1-carbon-filled syrup is 0.03 and the pH value is 10.5. , the pH value o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com