Intelligent control system and control method for cleaning of solar photovoltaic panel

A technology of solar photovoltaic panels and intelligent control systems, applied in the field of solar photovoltaics, can solve problems such as inability to implement discovery and cleaning, reduce cleaning intervals, and low efficiency of manual inspections, so as to achieve power generation efficiency and operating costs, reduce The effect of reducing operating costs and reducing the overall cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

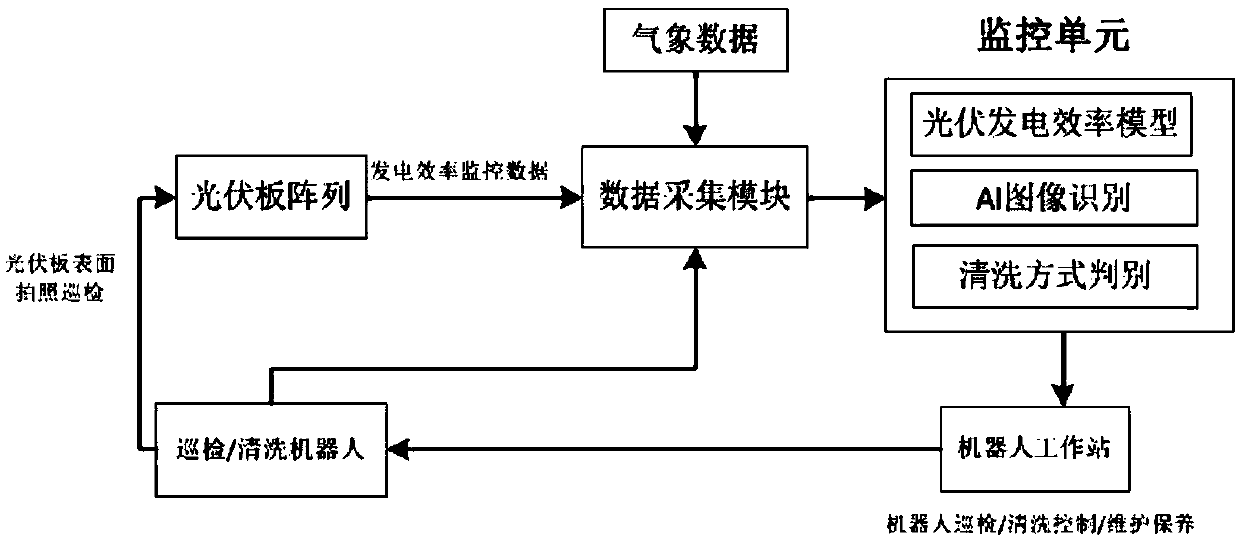

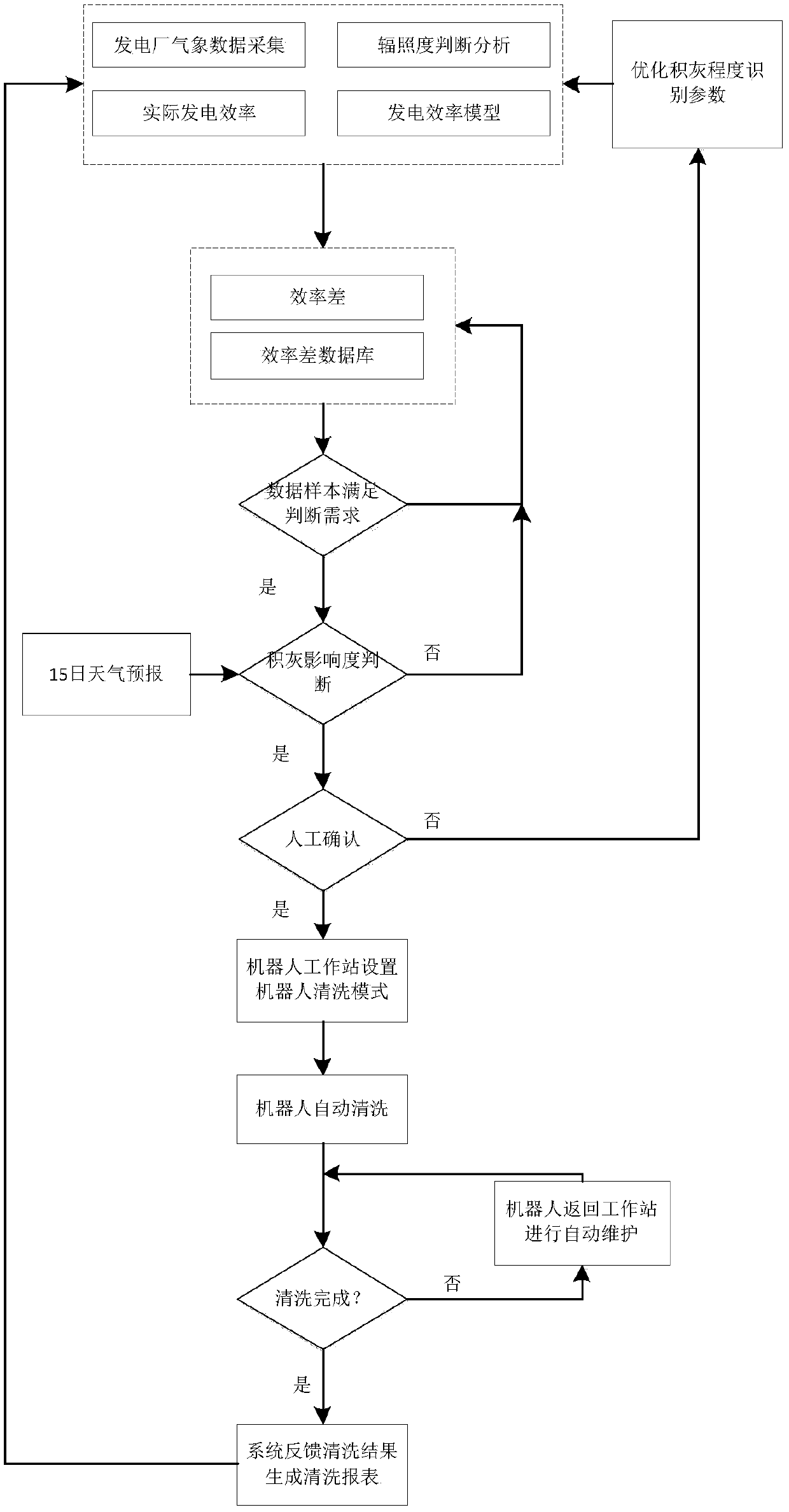

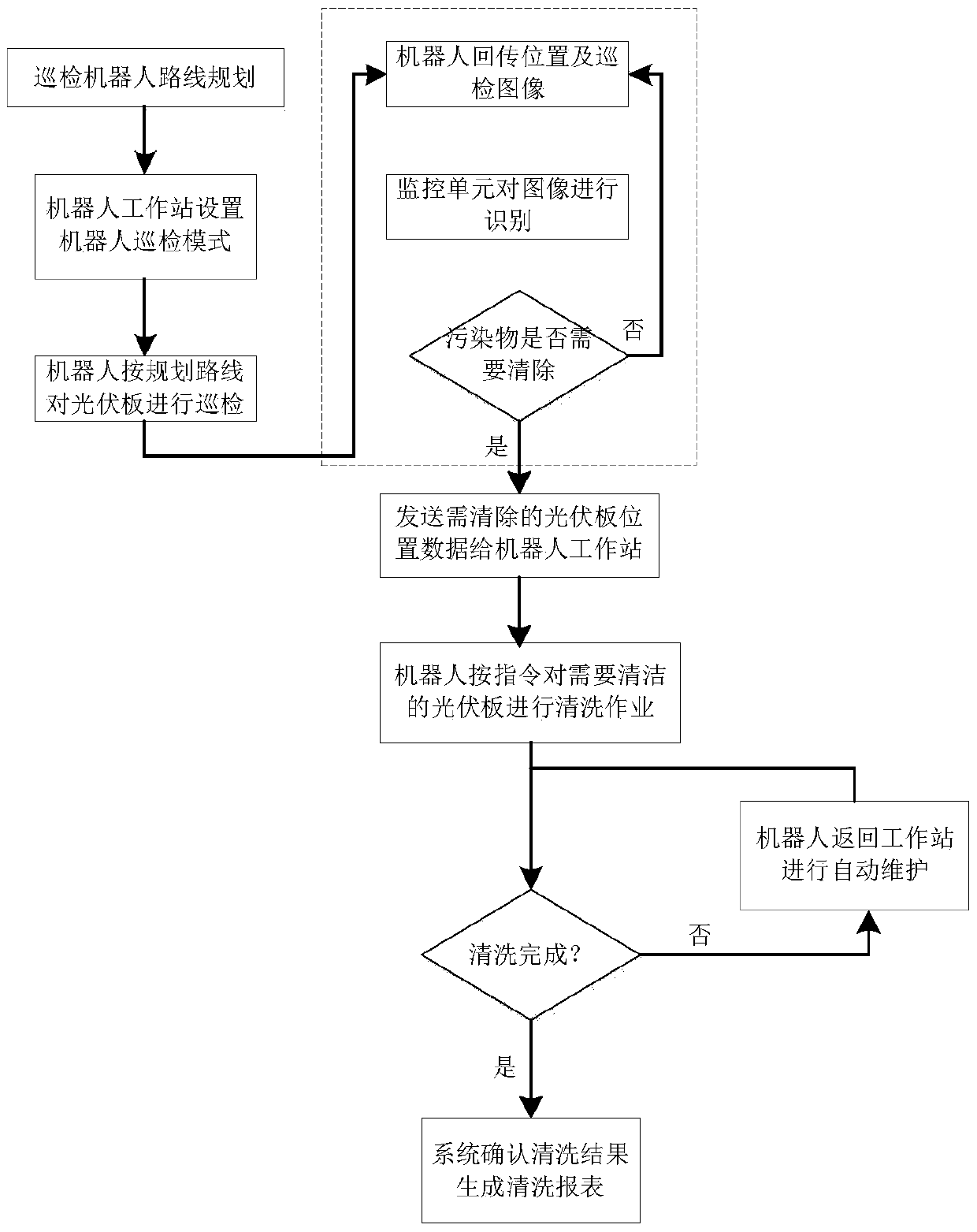

[0035] Refer to attached figure 2 Description of the specific implementation mode 1 Dust accumulation state identification overall cleaning mode

[0036] According to the real-time meteorological data of the power plant provided by the data acquisition module, the monitoring unit obtains the sunlight radiation intensity of the environment where the power plant is located, and inputs the data into the power generation efficiency model for calculation, and obtains the solar radiation intensity that the photovoltaic panel should have under the current irradiance. The power generation efficiency is recorded as efficiency 1. At the same time, the monitoring unit reads the real-time power generation efficiency (efficiency 2) of the power plant provided by the data transmission unit.

[0037] The monitoring unit will compare the theoretical power generation efficiency 1 and the actual power generation efficiency 2 to obtain the efficiency difference (denoted as efficiency 3) and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com