Patents

Literature

1003results about How to "Reduce cleaning frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

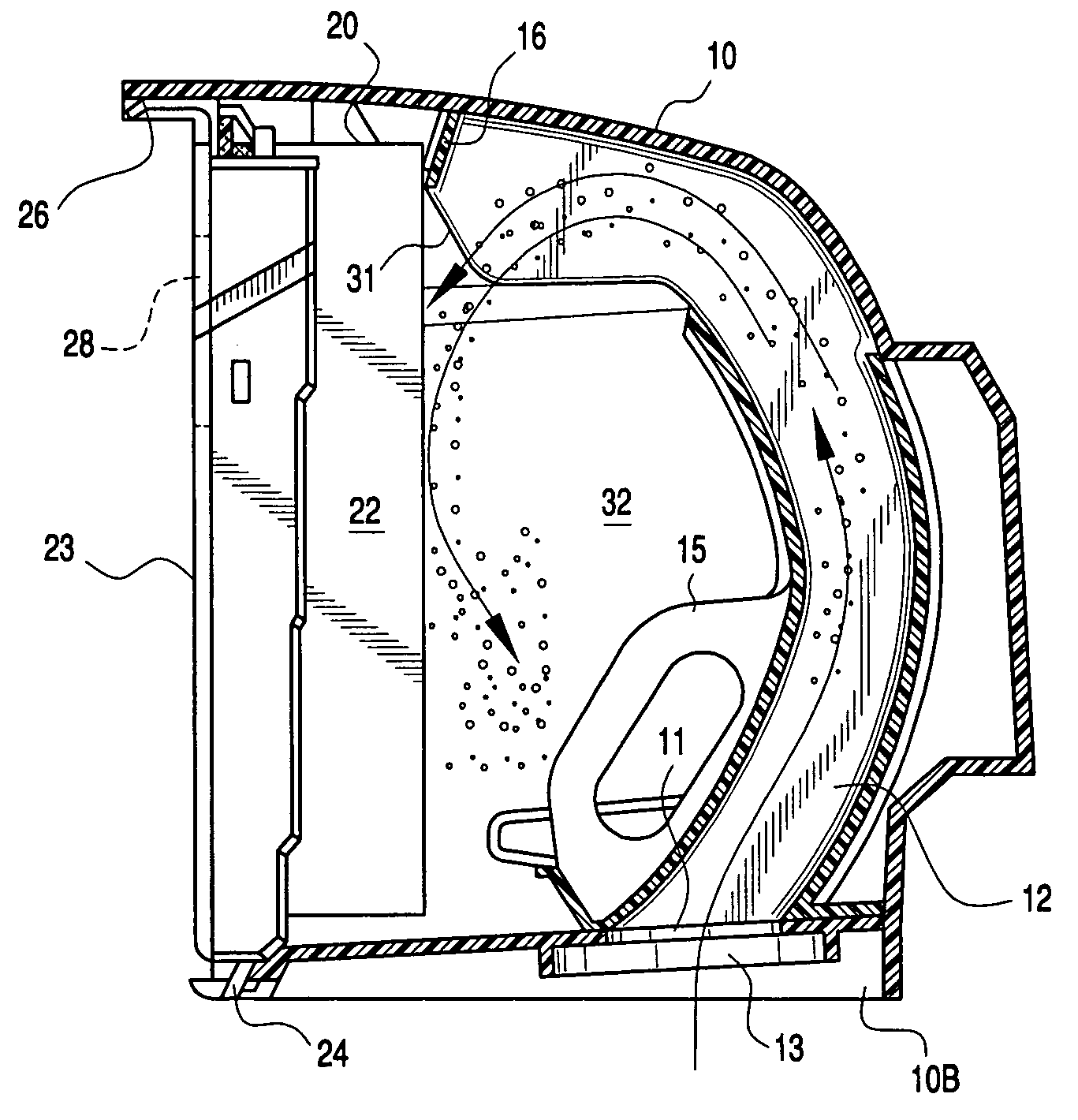

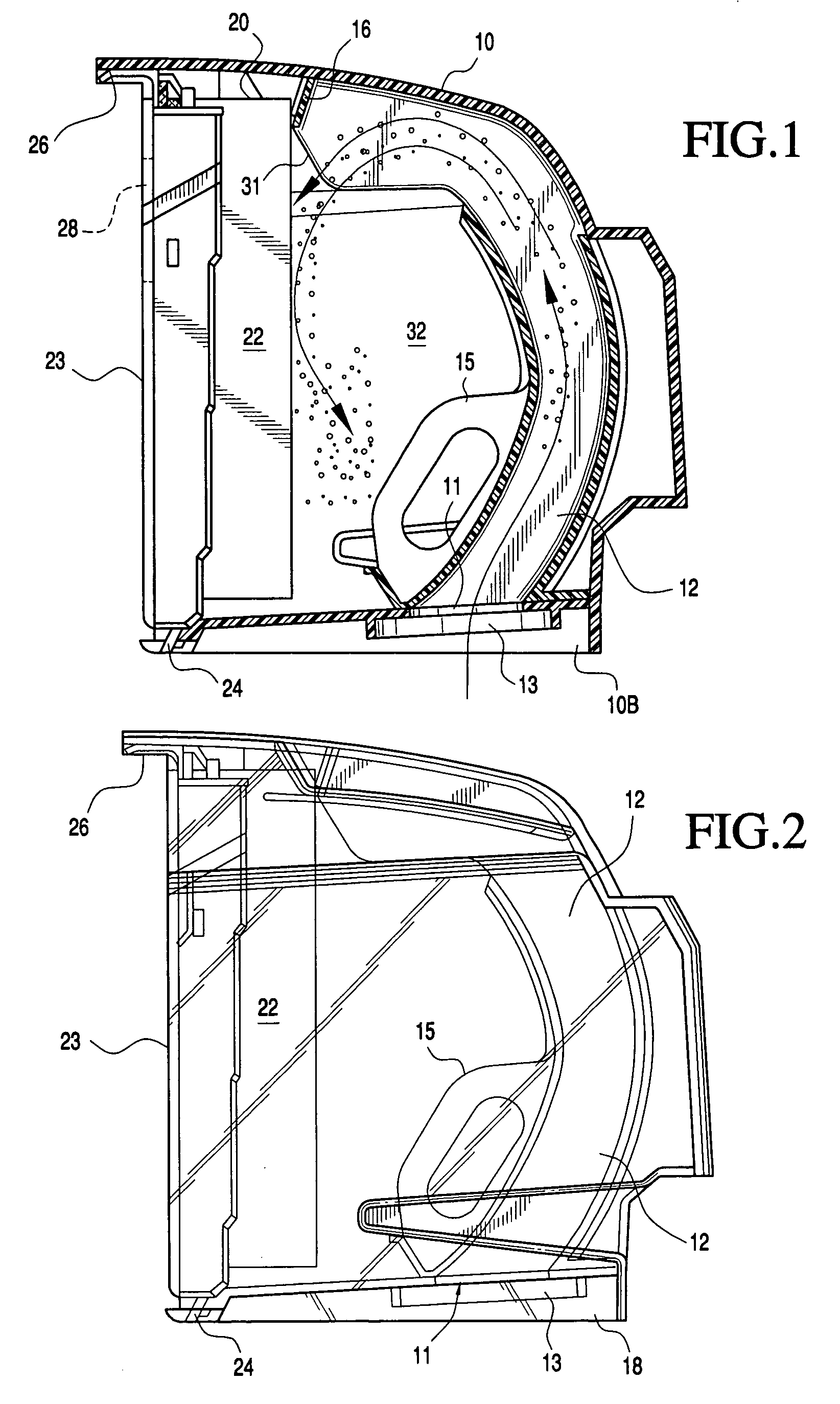

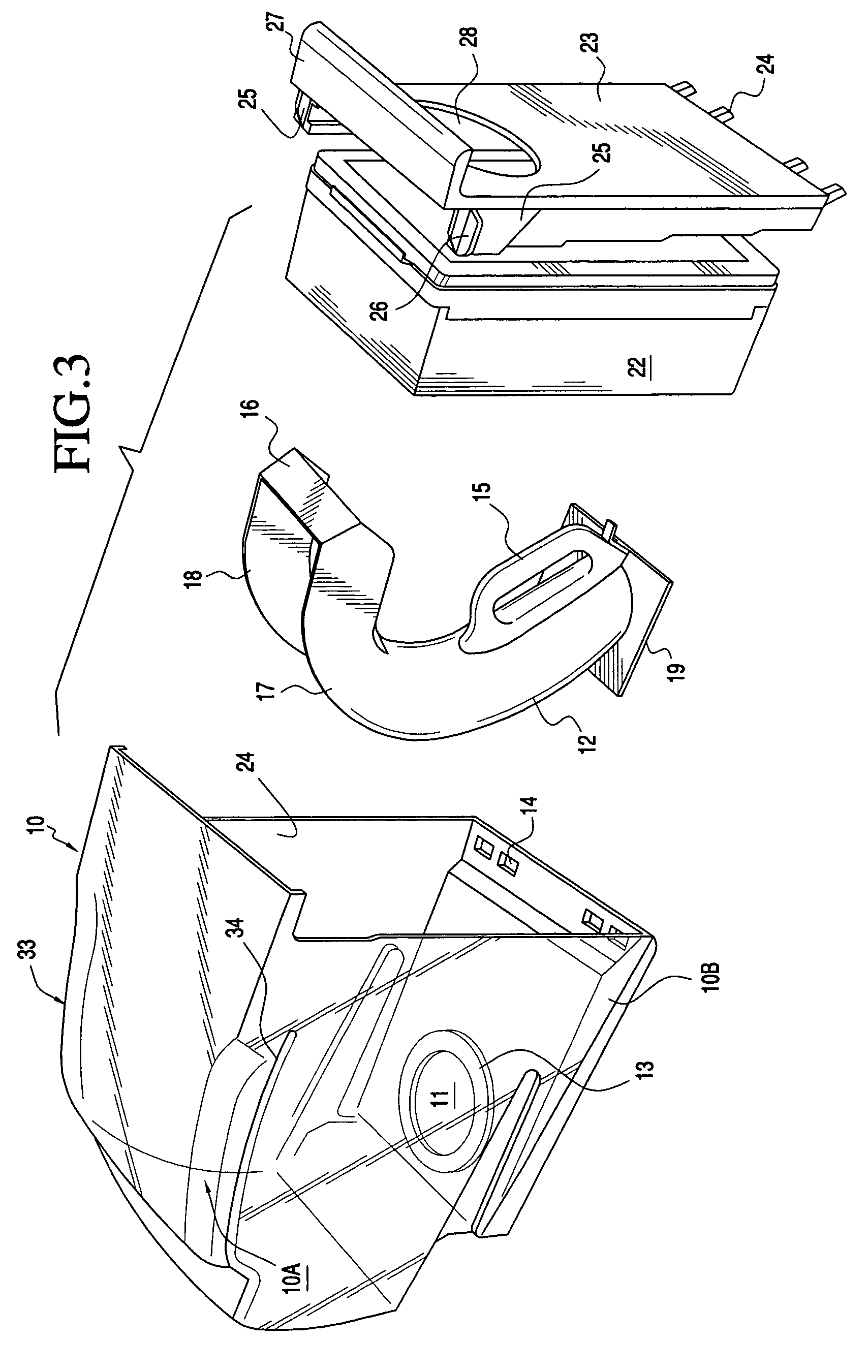

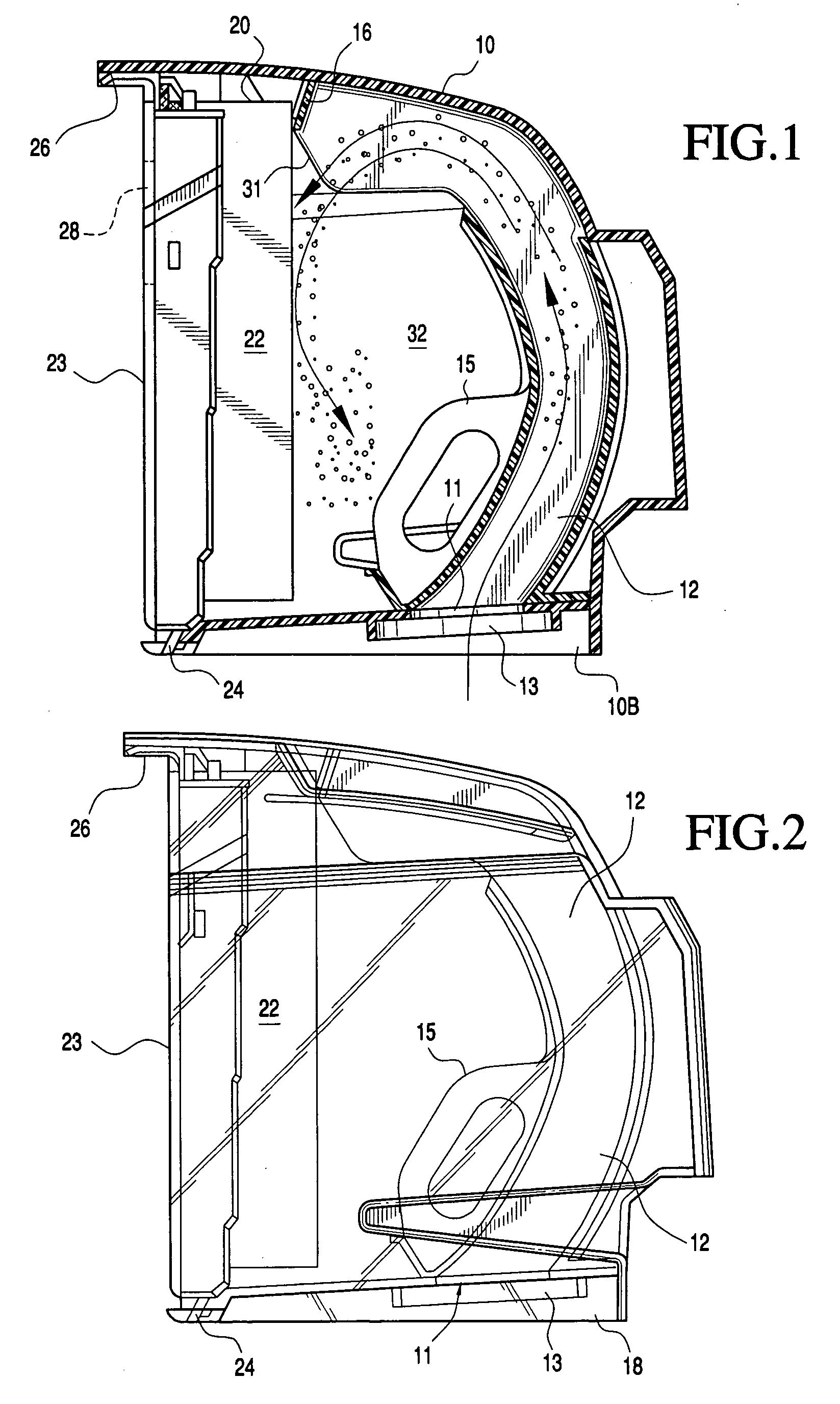

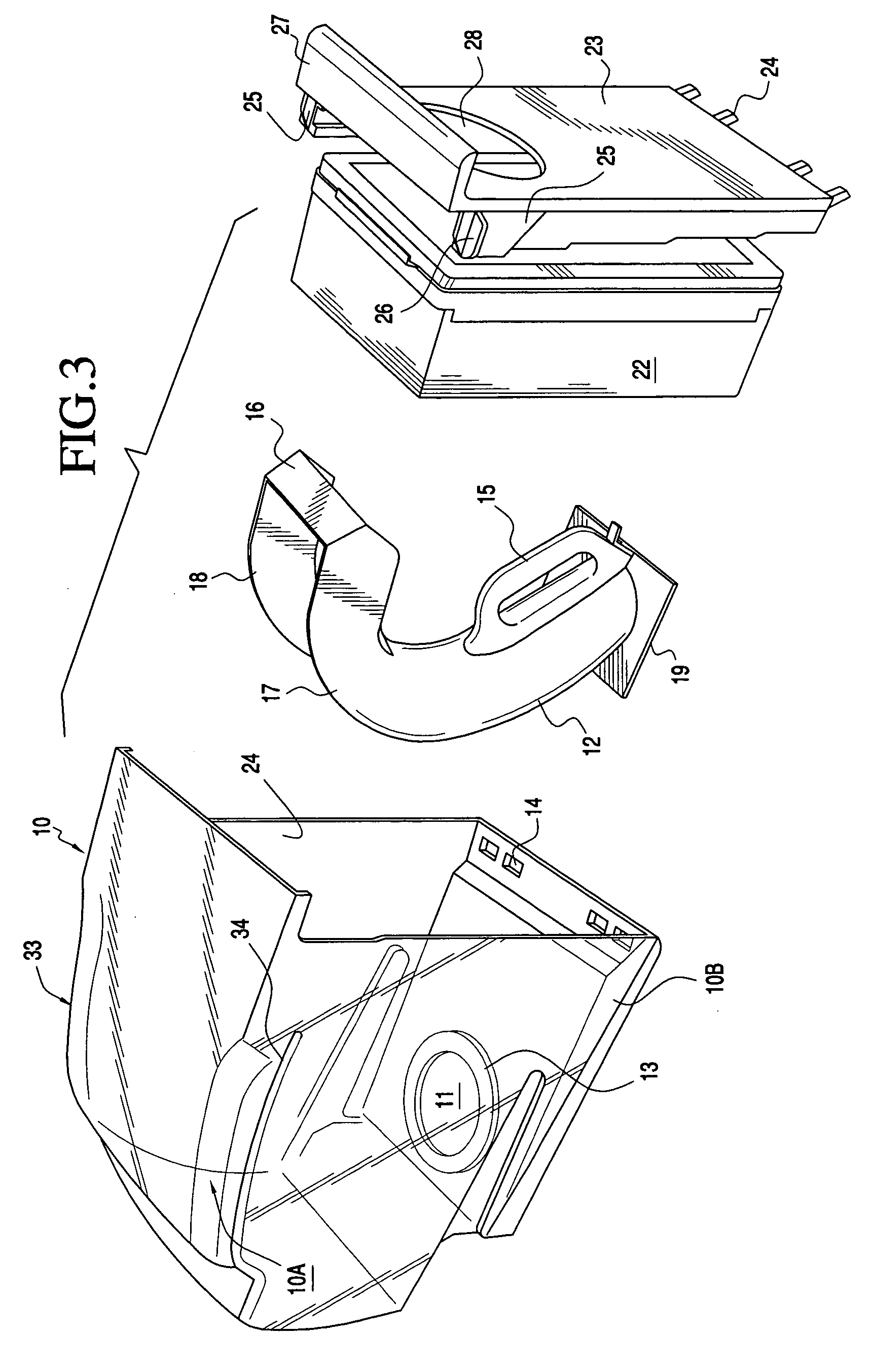

Dust bin and filter for robotic vacuum cleaner

ActiveUS7201786B2No cloggingReduce cleaning frequencyCombination devicesAuxillary pretreatmentEngineeringVacuum cleaner

A detachable dust bin for a vacuum cleaner. A container is provided with a removable sidewall which has an outlet opening which is adapted to be coupled to a source of vacuum. The container includes an inlet for connecting to a passageway which is connected to a vacuum nozzle. A duct extends vertically from the inlet within the container, and then laterally toward the removable sidewall. A filter is supported along the removable sidewall having a front surface facing the outlet of the duct, and a rear surface facing the outlet opening in the removable sidewall. Dirt laden air is drawn through the filter, duct, and vacuum nozzle. Dirt is separated from the air and collected within the container.

Owner:HEALTHY GAIN INVESTMENTS

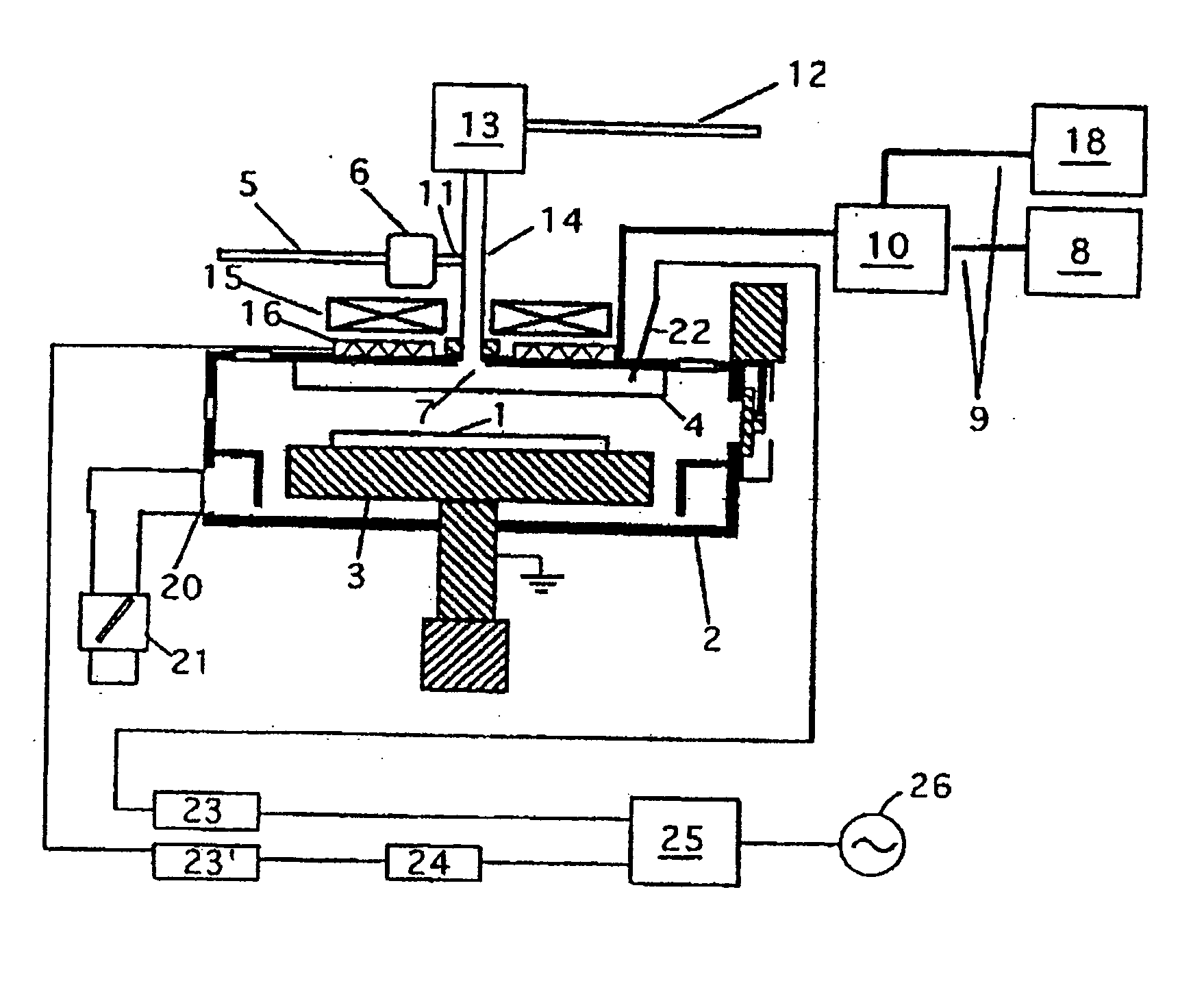

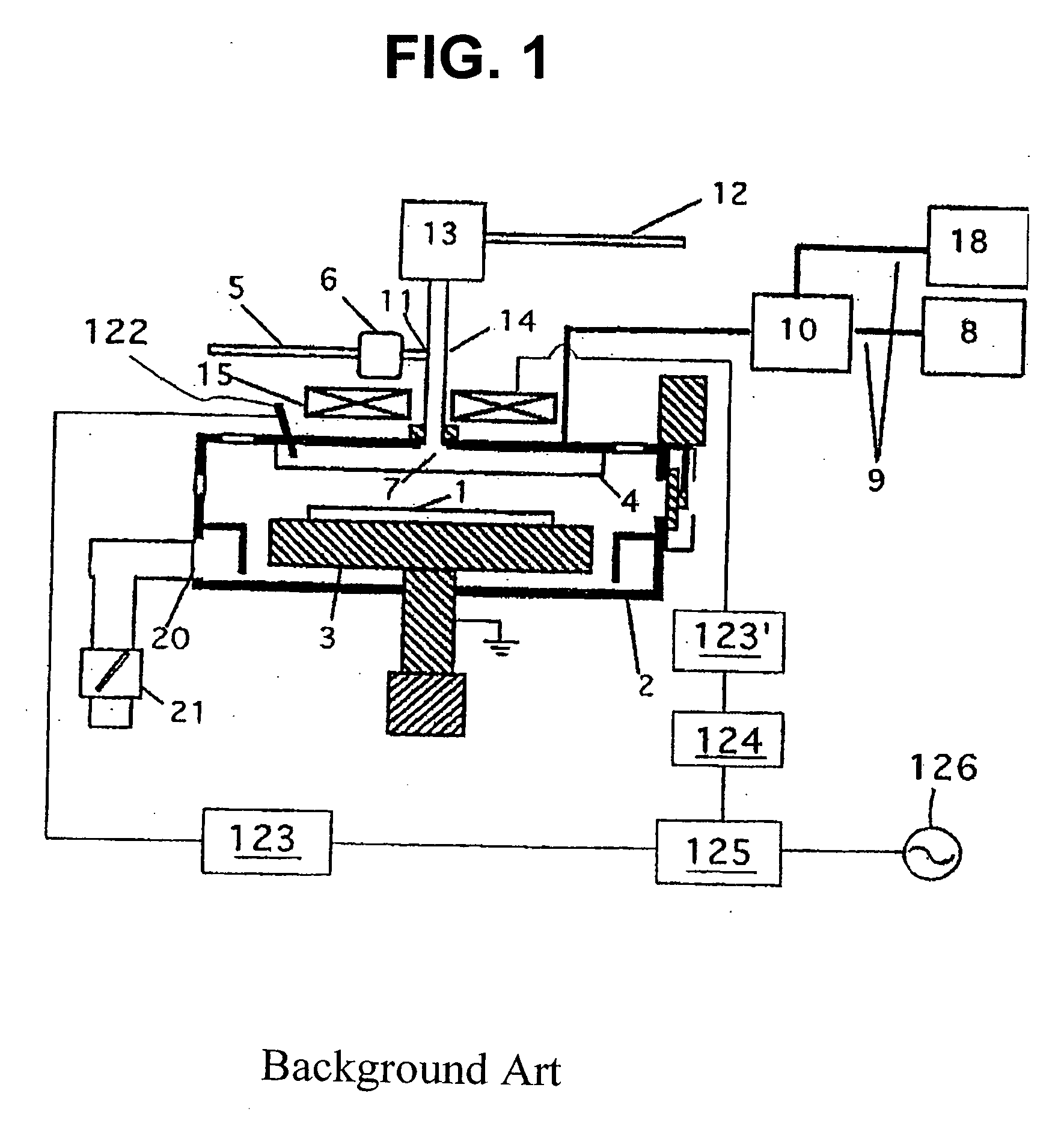

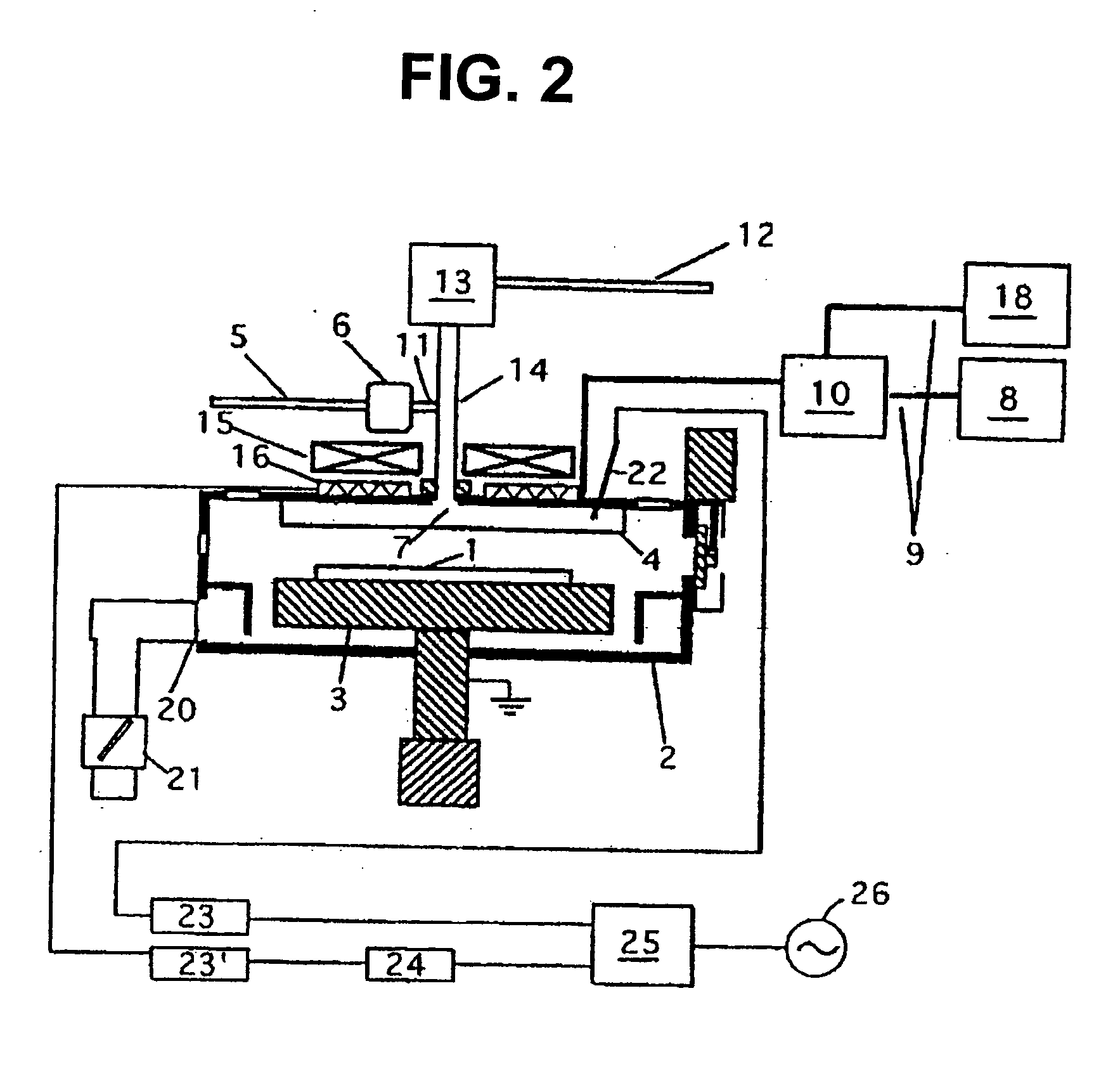

Self-cleaning method for plasma CVD apparatus

InactiveUS20050242061A1Improve cleaning rateReduce cleaning frequencyElectric discharge tubesDecorative surface effectsCleaning methodsPlasma reaction

A self-cleaning method for a plasma CVD apparatus includes: (a) after unloading an object processed in a reaction chamber, heating a showerhead to a temperature of 200° C. to 400° C.; (b) introducing a cleaning gas into the reaction chamber; and (c) cleaning the reaction chamber by plasma reaction using the cleaning gas.

Owner:FUKUDA HIDEAKI

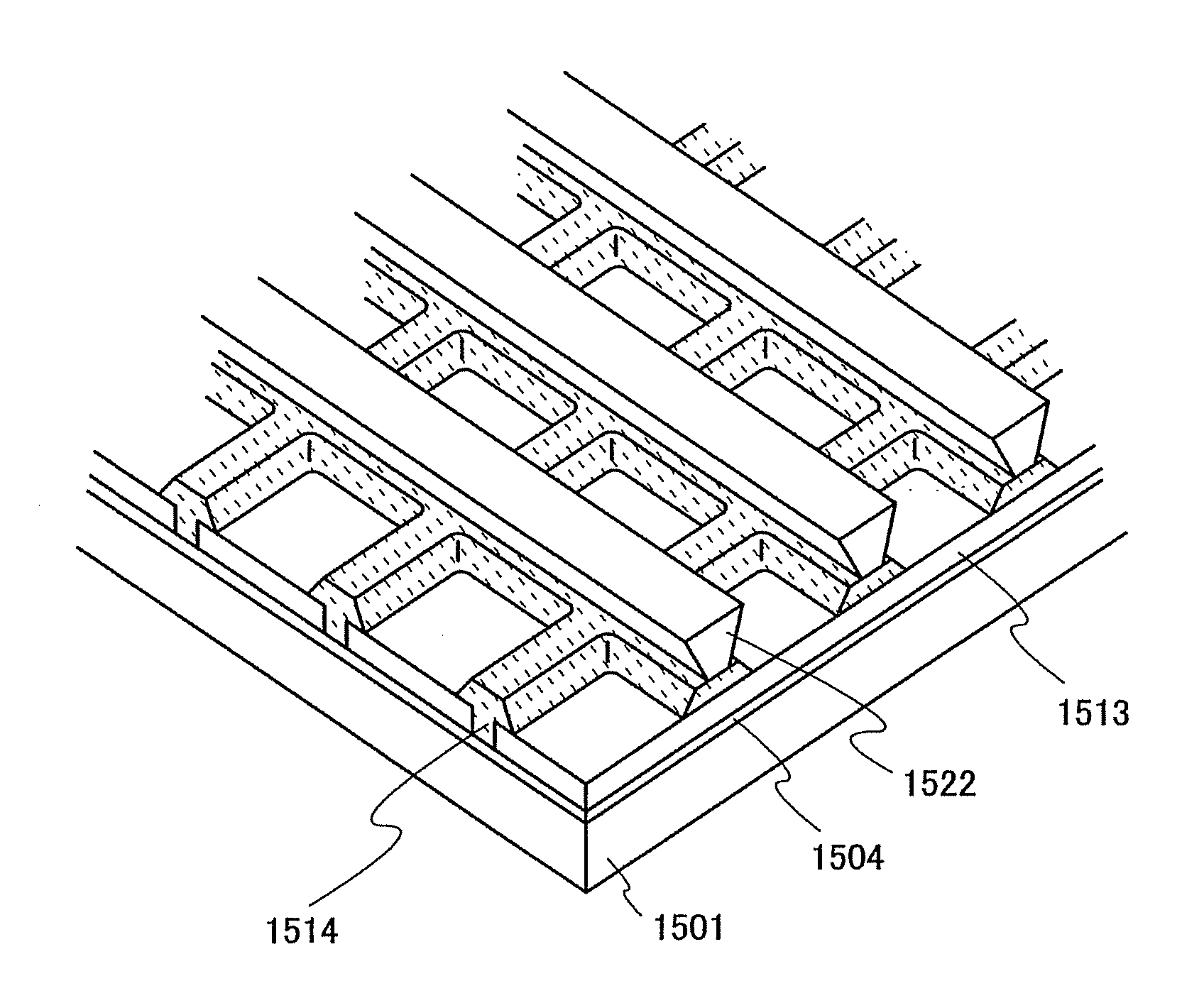

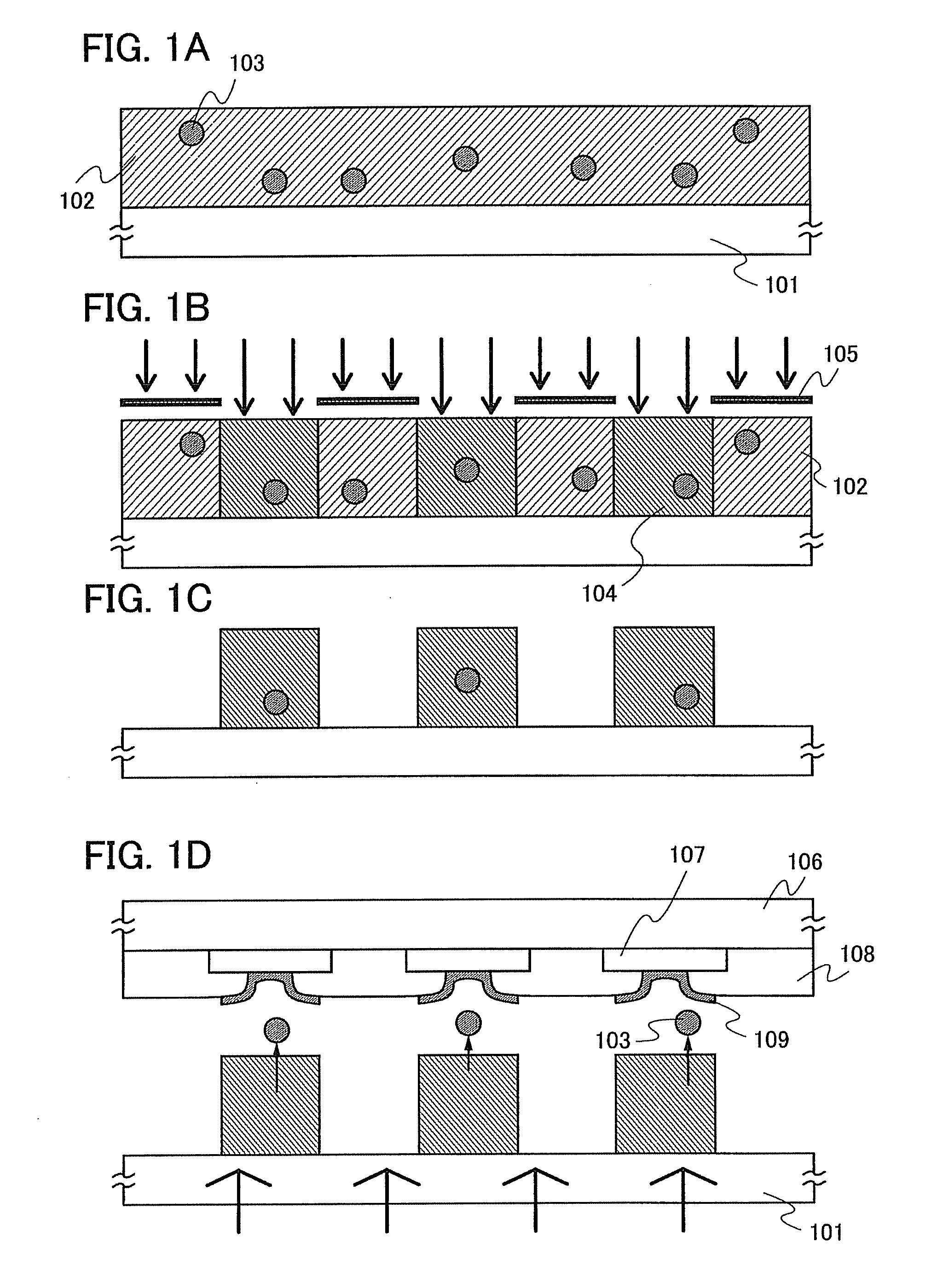

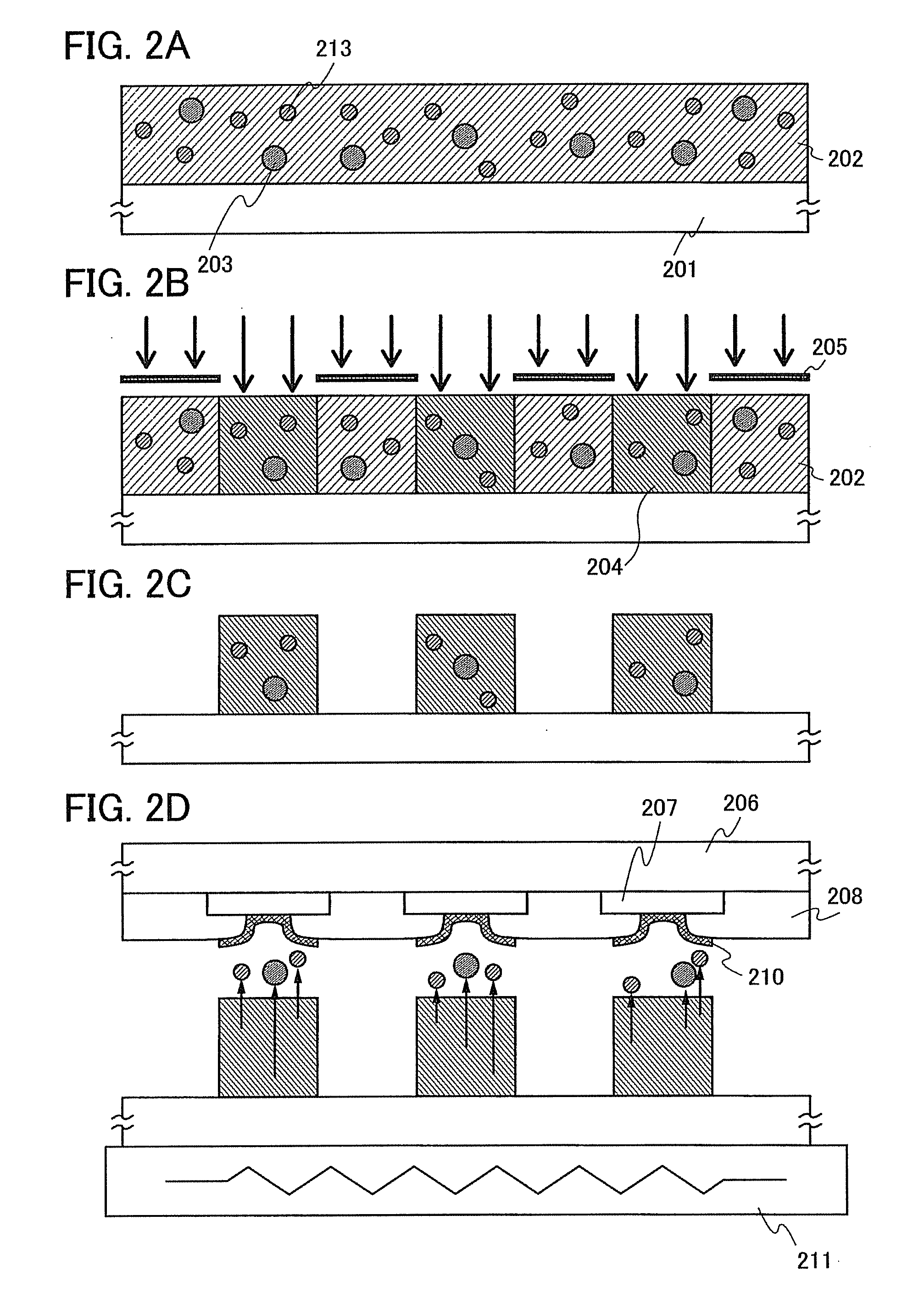

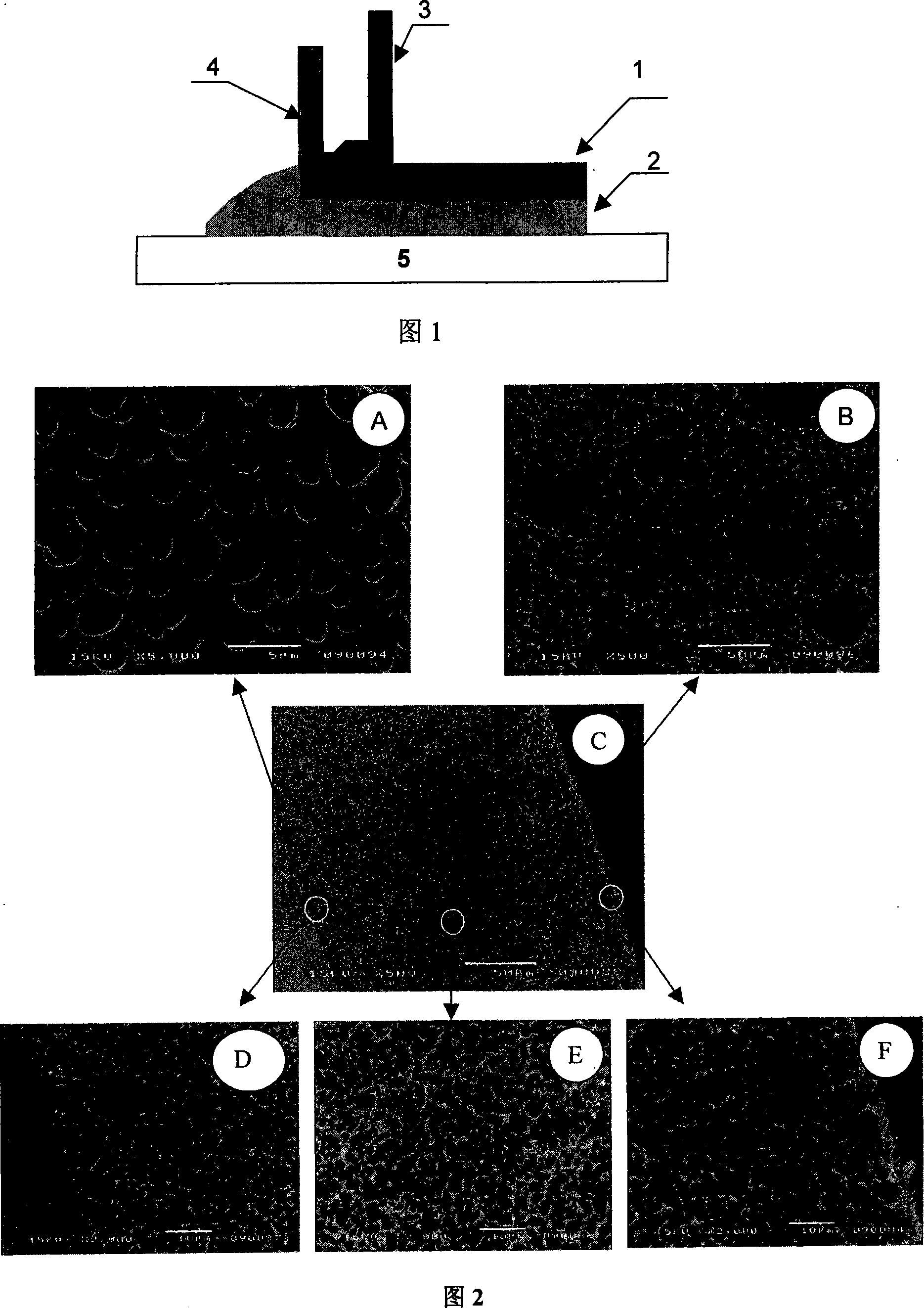

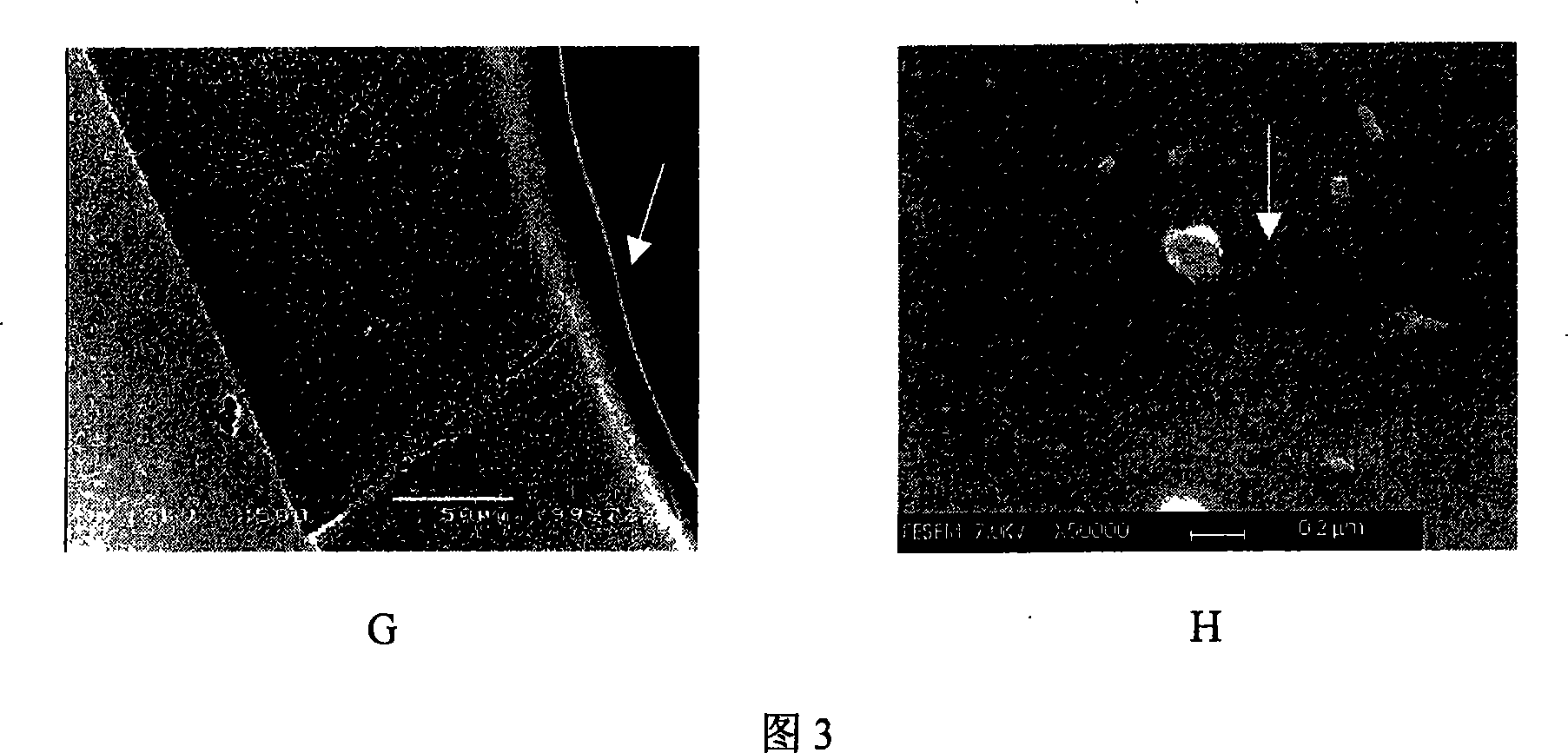

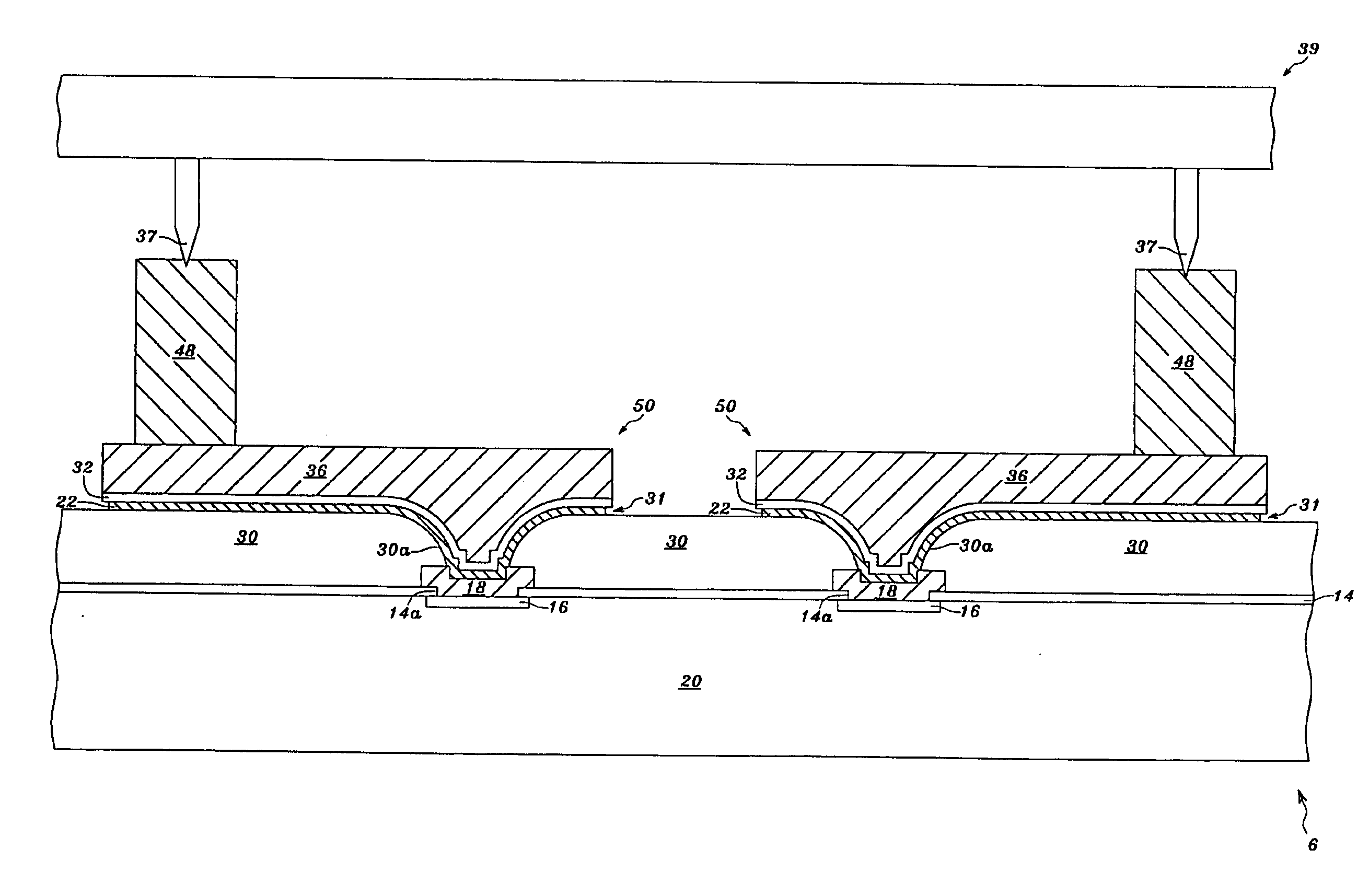

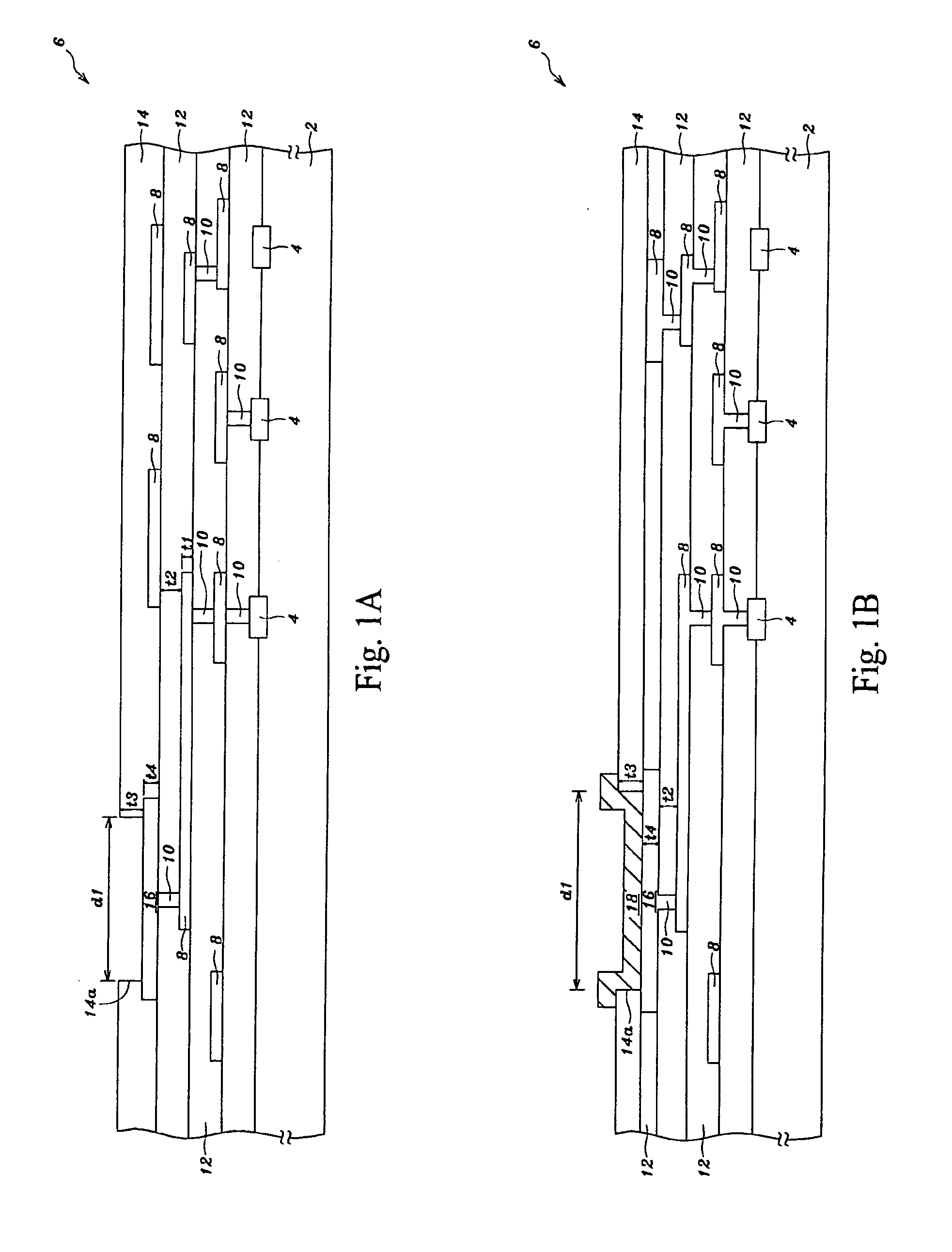

Manufacturing method of light-emitting device

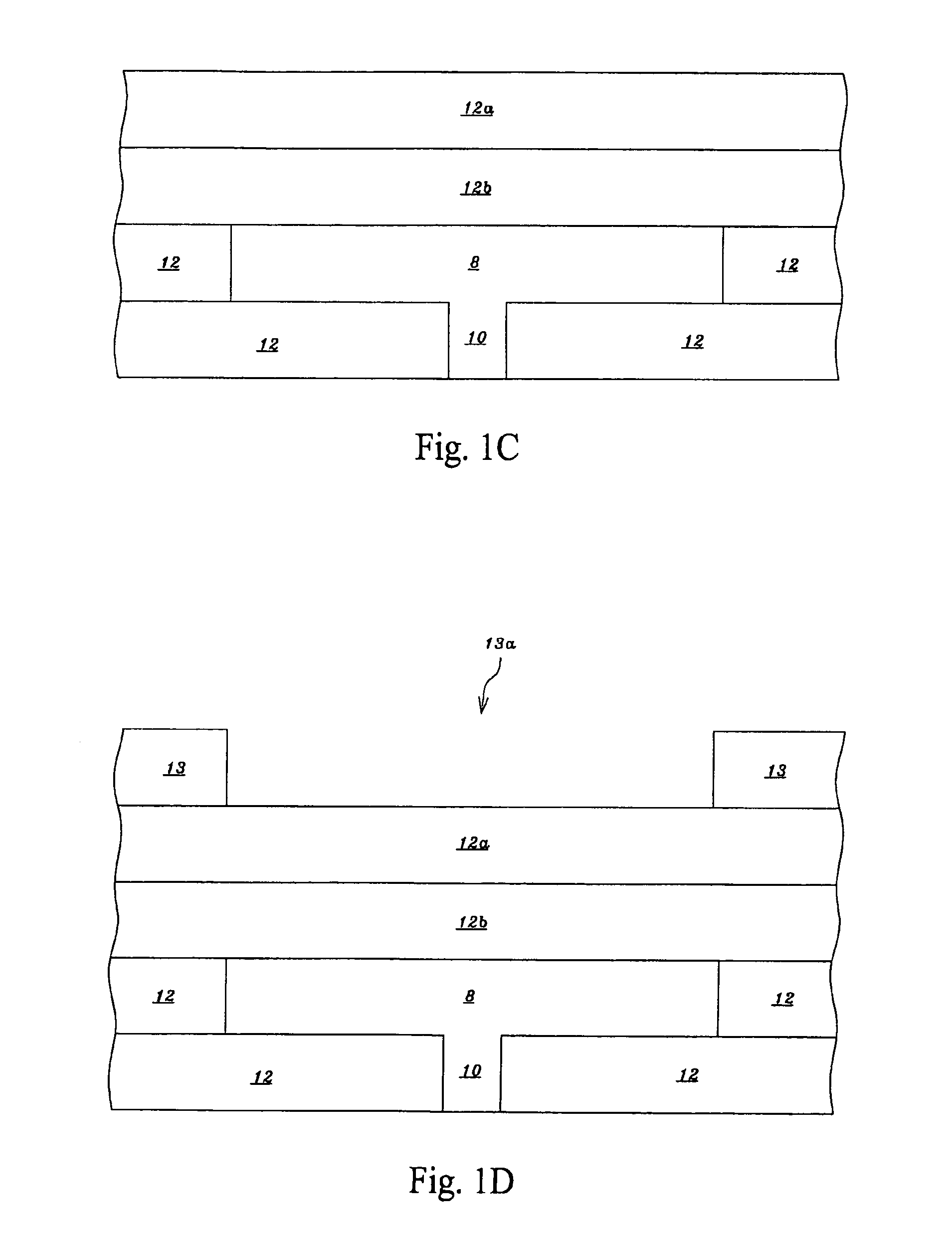

InactiveUS20080268135A1Improve positionHigh definitionSemiconductor/solid-state device detailsSolid-state devicesResistSimple Organic Compounds

For a full-color flat panel display, demands for high definition, high aperture ratio and high reliability have been increasing. Therefore, increasing in the number of pixels and narrowing a pixel pitch have been major issues. According to the present invention, a layer including an organic compound is selectively formed with a light-exposure apparatus used in a photolithography technique without a resist mask. A material layer including a photopolymerization initiator, a material polymerized with the photopolymerization initiator, and an organic compound are formed on a plate, and then are exposed to light and selectively cured. A film-formation substrate is disposed so as to face the plate. The film-formation substrate or the material layer is heated so that the organic compound included in a region exposed to light or a region not exposed to light is evaporated to be selectively deposited on the surface of the film-formation substrate.

Owner:SEMICON ENERGY LAB CO LTD

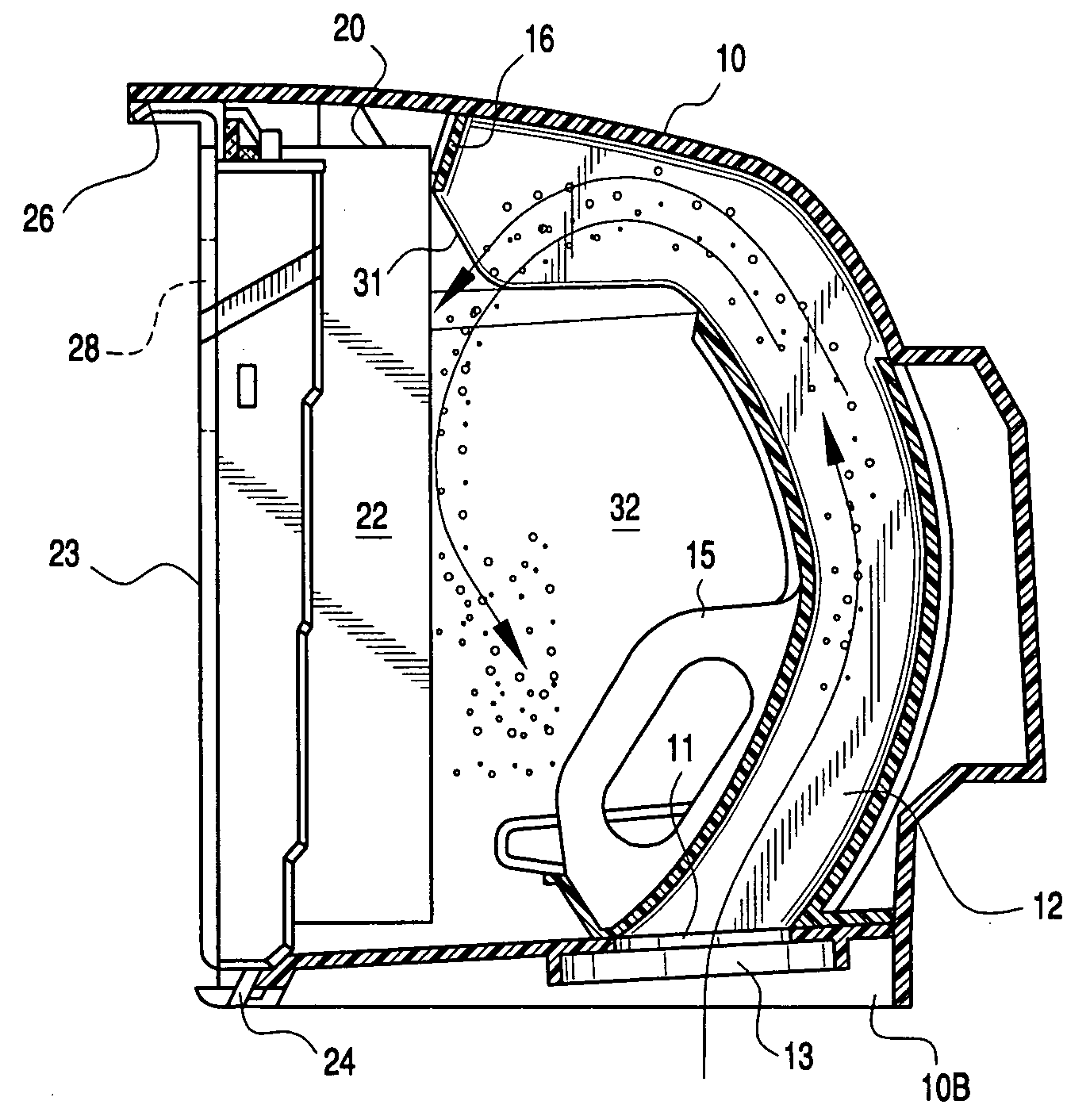

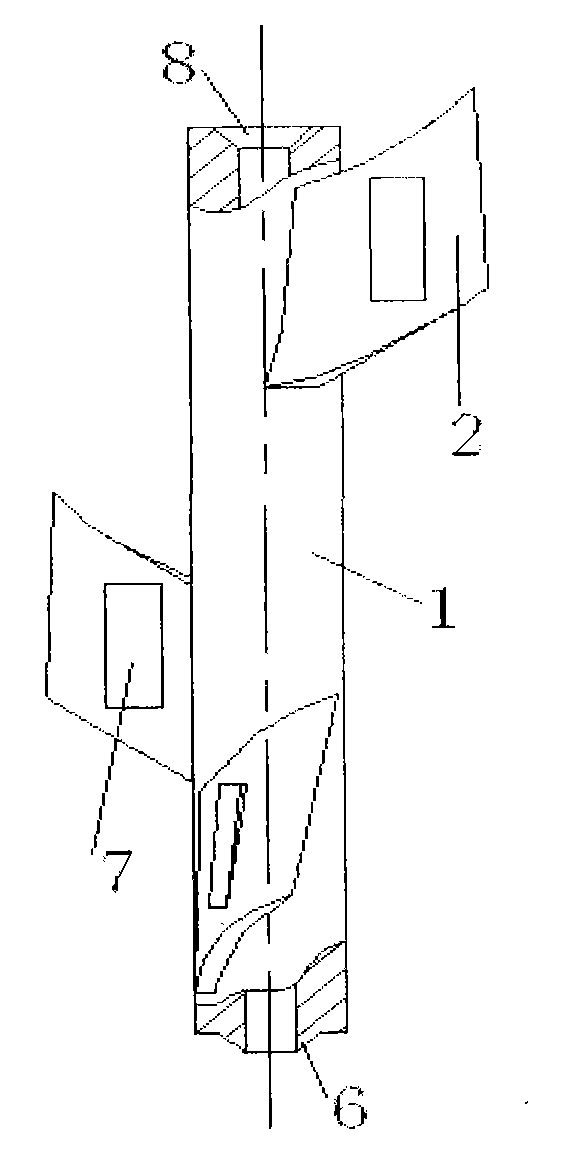

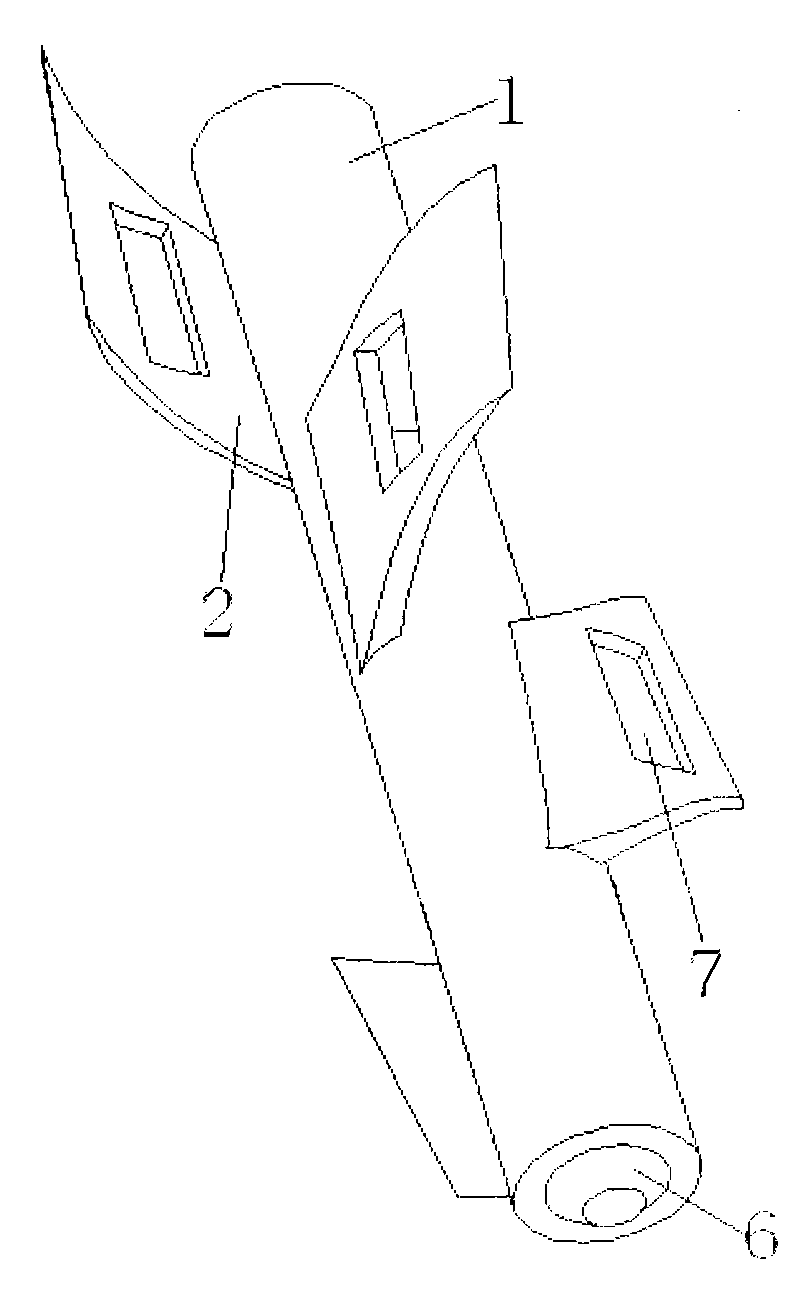

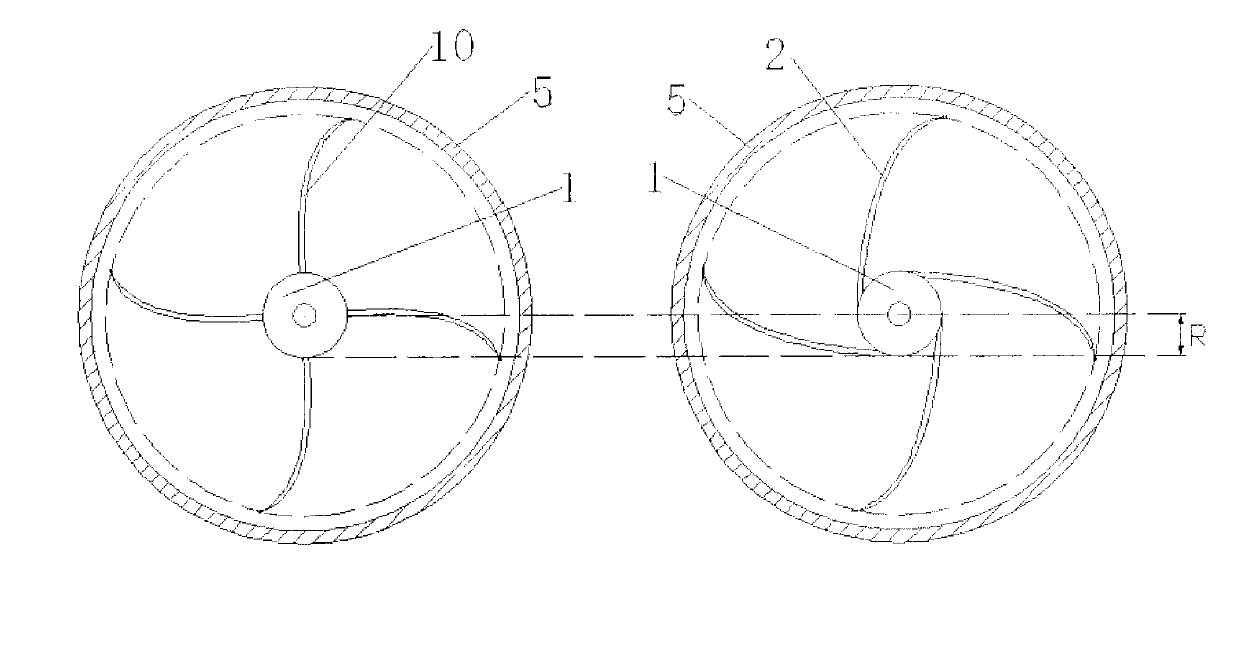

Dust bin and filter for robotic vacuum cleaner

ActiveUS20050132680A1No cloggingReduce cleaning frequencyCombination devicesAuxillary pretreatmentVacuum cleanerDirt

A detachable dust bin for a vacuum cleaner. A container is provided with a removable sidewall which has an outlet opening which is adapted to be coupled to a source of vacuum. The container includes an inlet for connecting to a passageway which is connected to a vacuum nozzle. A duct extends vertically from the inlet within the container, and then laterally toward the removable sidewall. A filter is supported along the removable sidewall having a front surface facing the outlet of the duct, and a rear surface facing the outlet opening in the removable sidewall. Dirt laden air is drawn through the filter, duct, and vacuum nozzle. Dirt is separated from the air and collected within the container.

Owner:HEALTHY GAIN INVESTMENTS

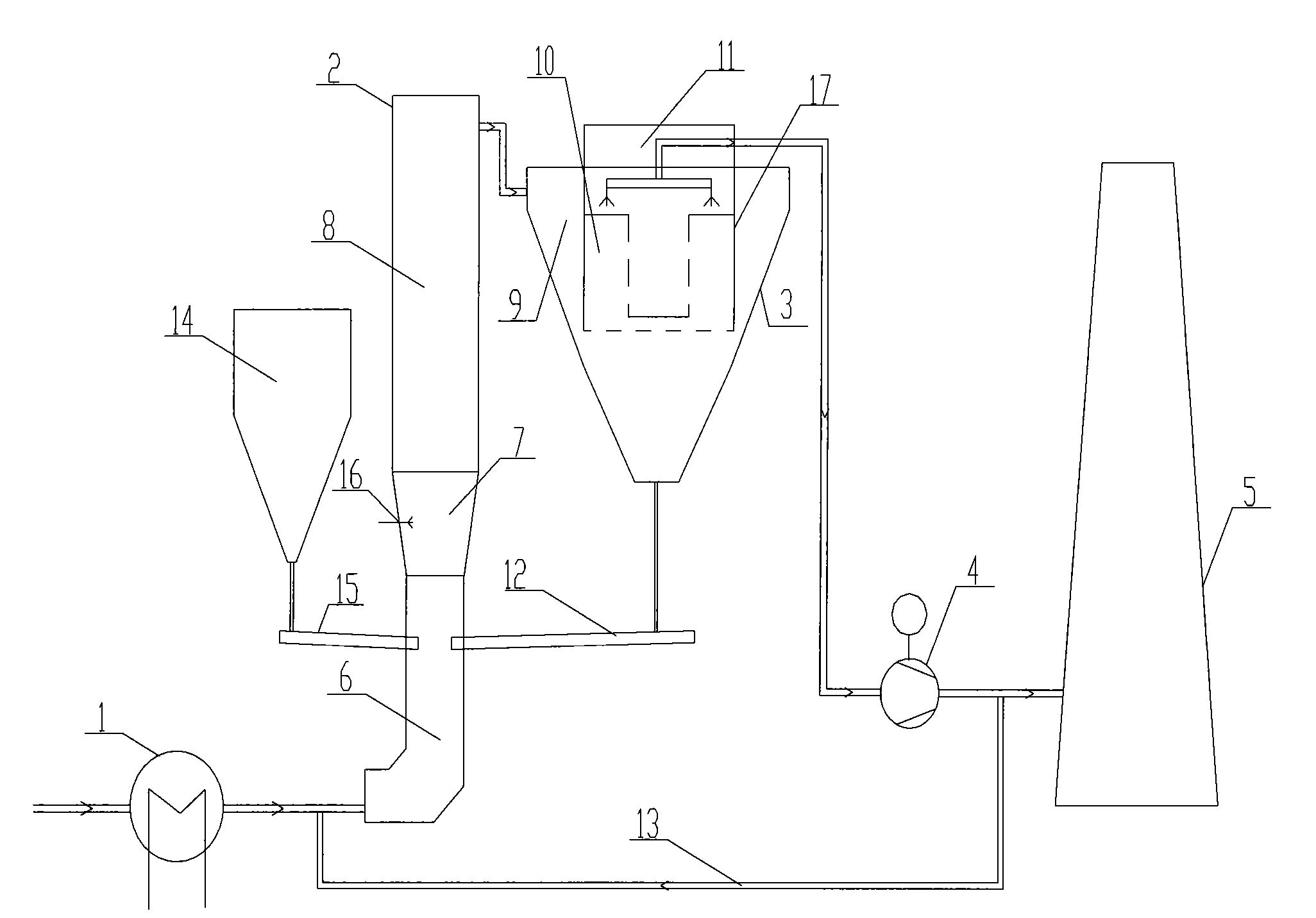

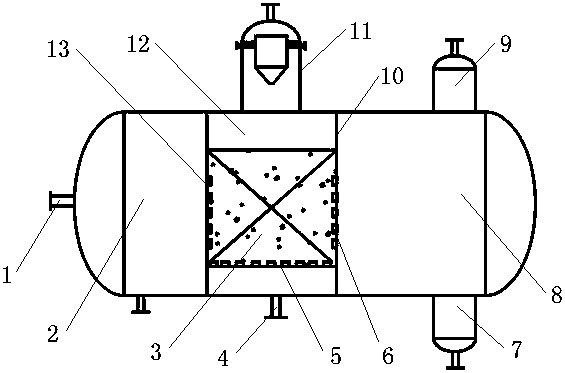

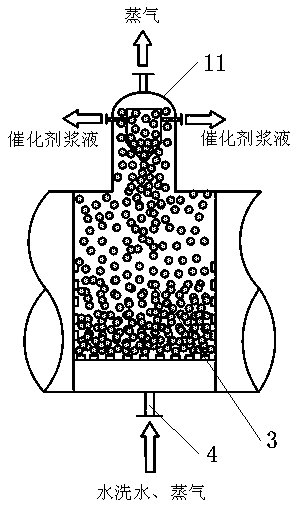

Clearing device for smoke pollutants of glass kiln and clearing method thereof

InactiveCN101628201ASolution to short lifeReduce loadCombination devicesGlass furnace apparatusSmall footprintEngineering

The invention relates to smoke treatment, in particular provides a clearing device for smoke pollutants of a glass kiln and a clearing method thereof. The clearing device is suitable for the glass kiln with high smoke temperature, smaller smoke amount, high clearing efficiency, stable system operation, simple structure and small floor area and is provided with an afterheat recovery boiler, a reaction tower, a bag dust collector, a circulating fluidization flume, a clean smoke recirculating flue, an absorbent bin and a feeding air flume which are sequentially connected. The clearing method comprises the following steps: smoke emitted by the glass kiln enters the afterheat recovery boiler; original smoke emitted by the afterheat recovery boiler enters a high-temperature reaction region of the reaction tower for premixing treatment with an absorbent, is accelerated by a Venturi accelerating region before entering a circulating fluidization reaction region and is cooled and purified before entering the bag dust collector; the purified smoke emitted from the reaction tower firstly enters the bag dust collector to remove particles and is emitted to a chimney by a draft fan in a purification chamber; and reaction dust emitted by the reaction tower is collected by the bag dust collector and is returned to the high-temperature reaction region.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

Method for preparing porous separation membrane

InactiveCN101091880AReduce cleaning frequencyOvercoming many shortcomings of preparation technologySemi-permeable membranesTraffic volumePorous membrane

The invention publishes a method for producing porous separation membrane, especially involves a multi-layer extrusion molding method. Its characteristic is: completing the extrusion molding of different high polymer solution at the same time. Then realizing separation among different high polymer solution through the inversion of phase's method. Lastly, solidifying to become membrane. In the solidification process, the compound level peel support level, the support level becomes the porous separation membrane which needs. This invention uses the multi-layered system membrane technology, and uses compound level to control the membrane structure, which is simple manufacture, overcome many technology insufficient existing in porous membrane material preparation. The pore membrane has the very big percentage open area, when it filters the high suspension liquid, and can hold the massive pollutant, so that it has high current capacity and low clean frequency.

Owner:NANJING UNIV OF TECH

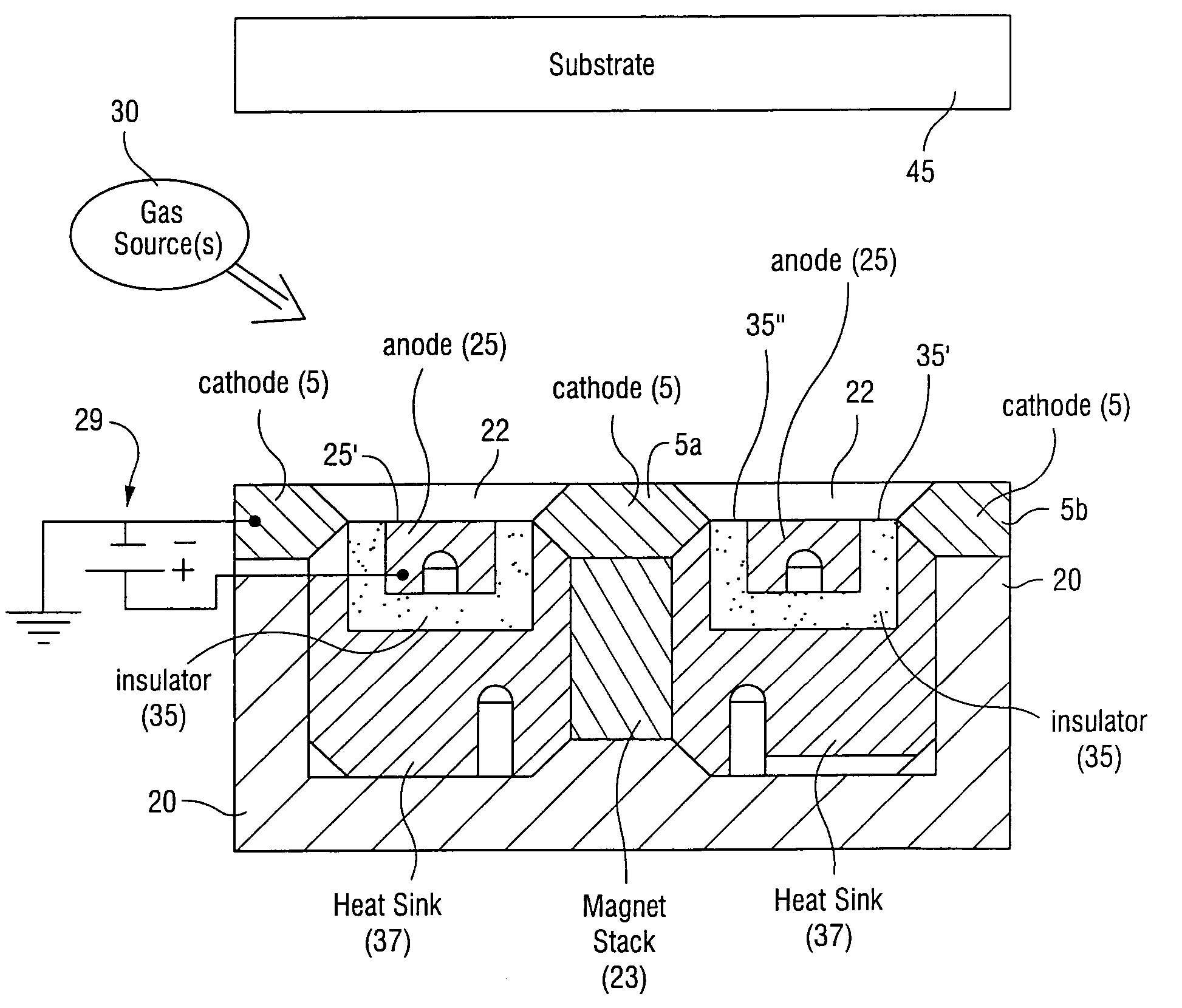

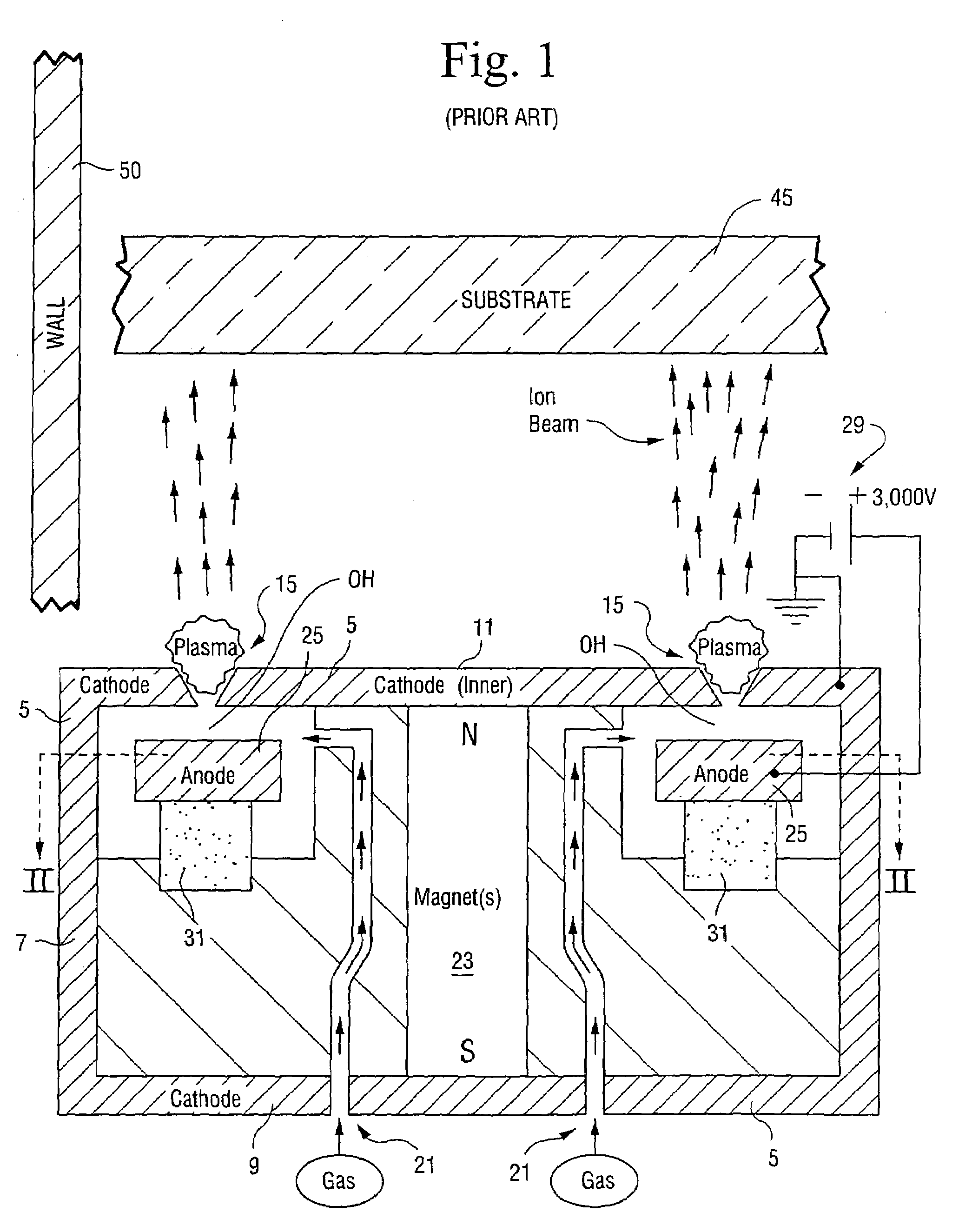

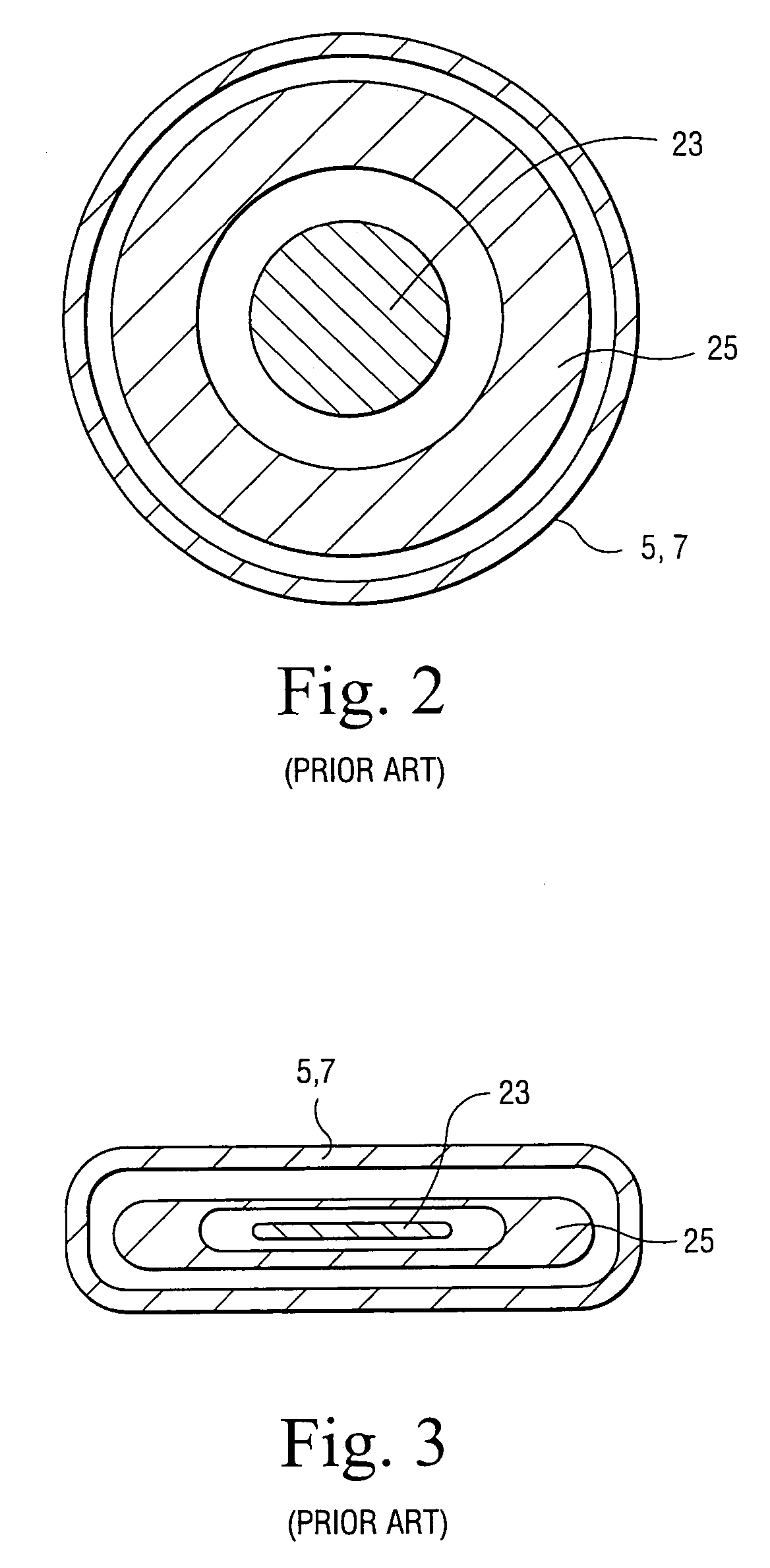

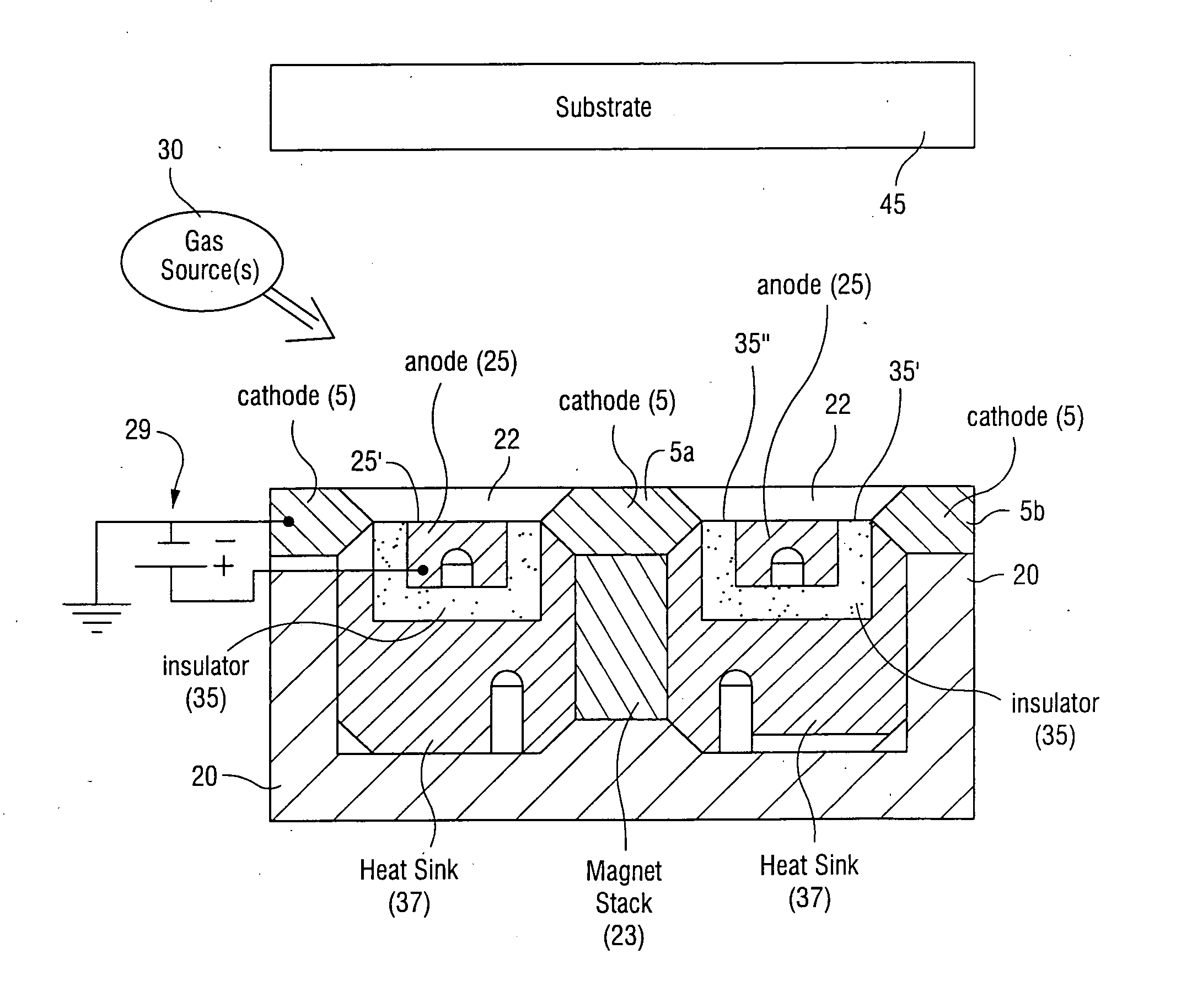

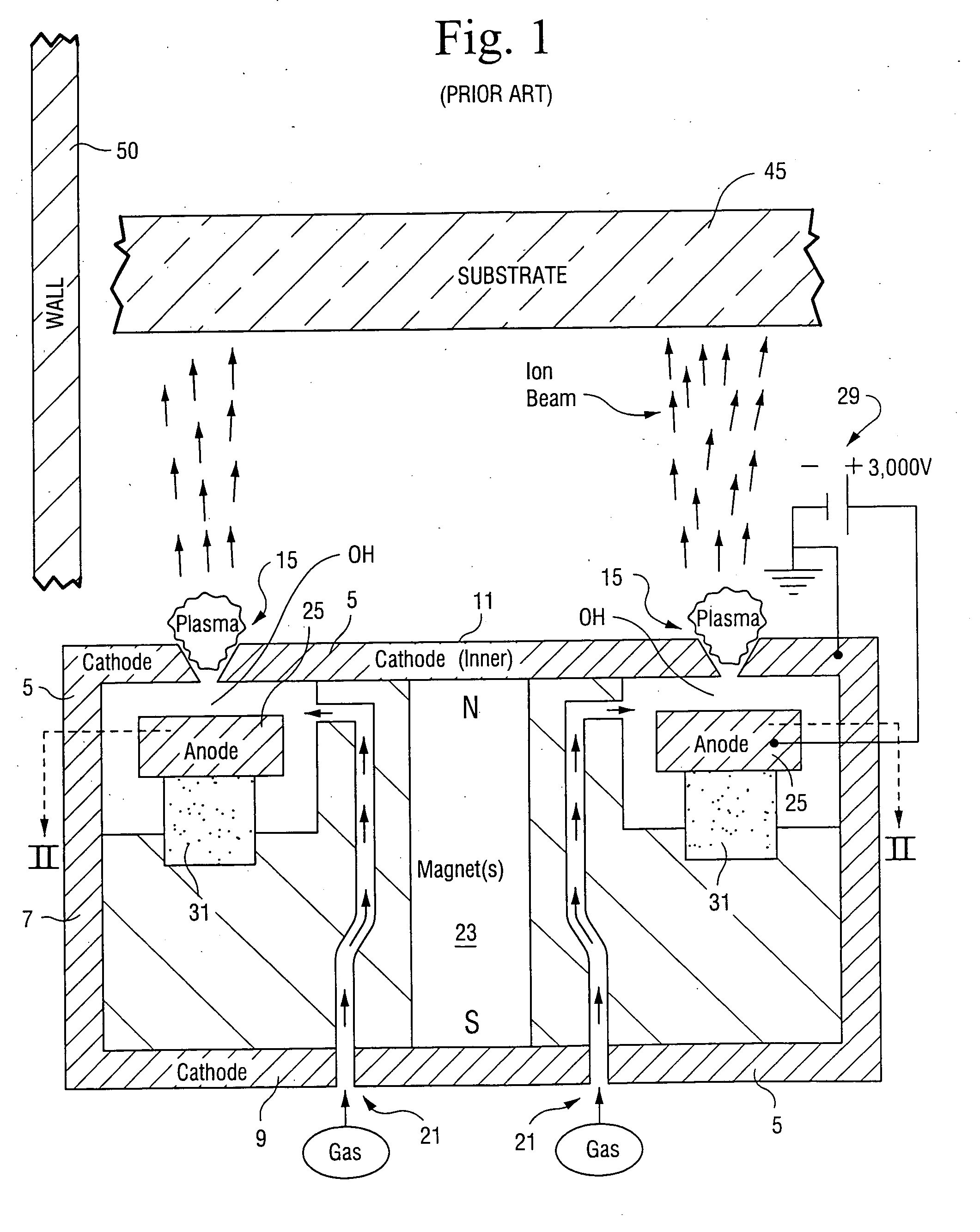

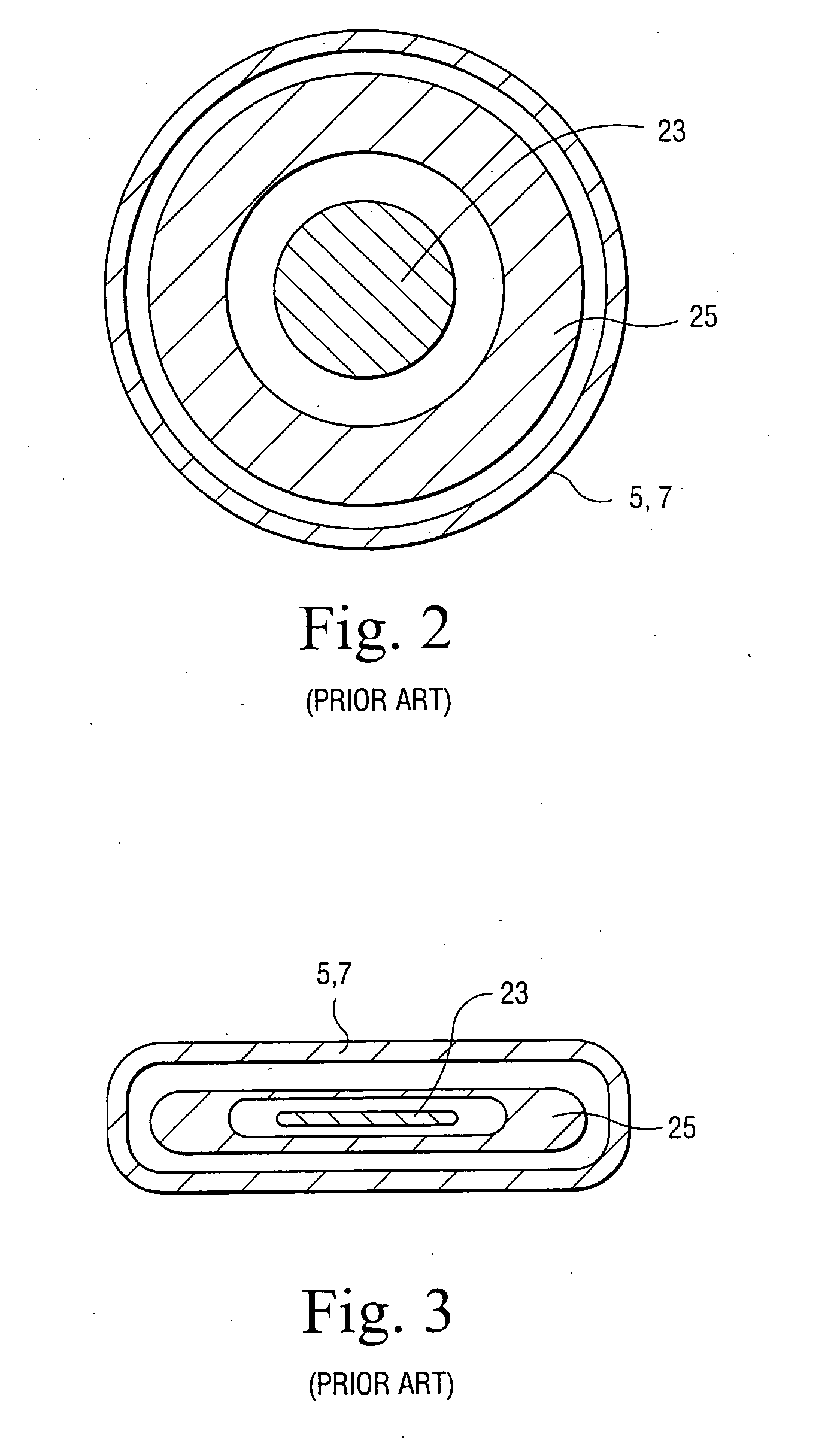

Ion source with substantially planar design

InactiveUS7183559B2Less undesirable build-upSource can run more efficientlyMaterial analysis by optical meansIon beam tubesCeramicAtomic physics

Owner:GUARDIAN GLASS LLC

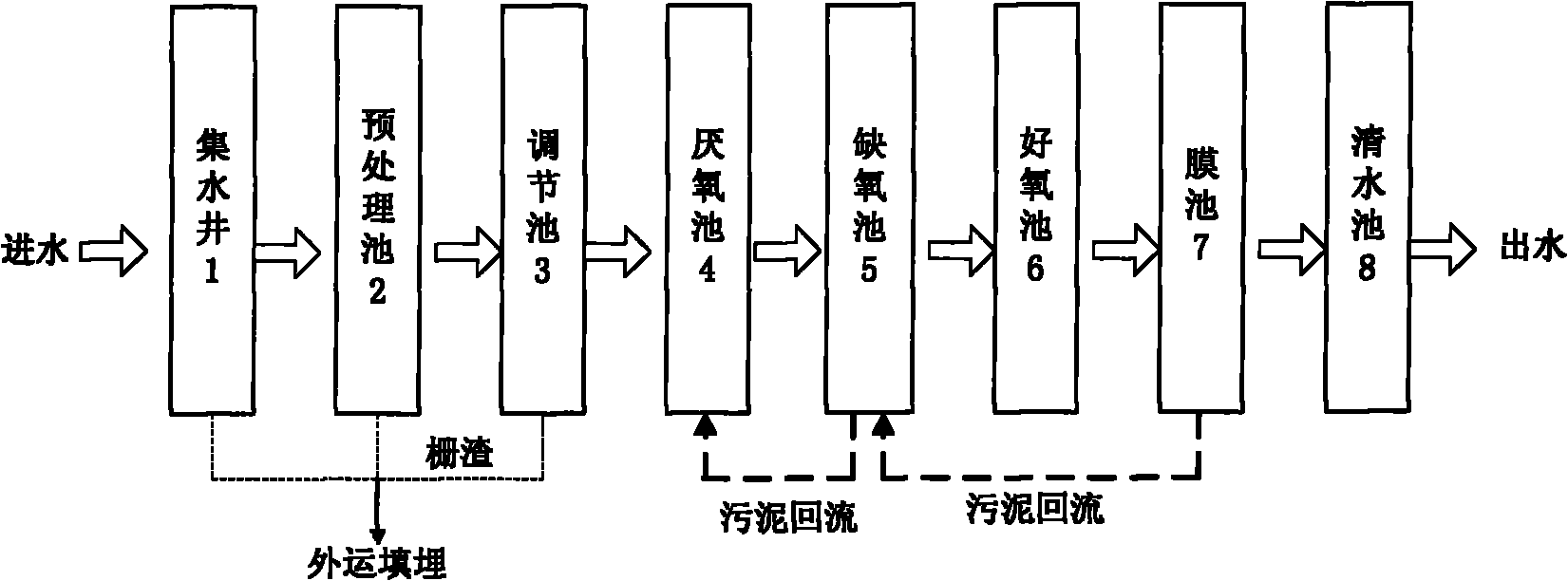

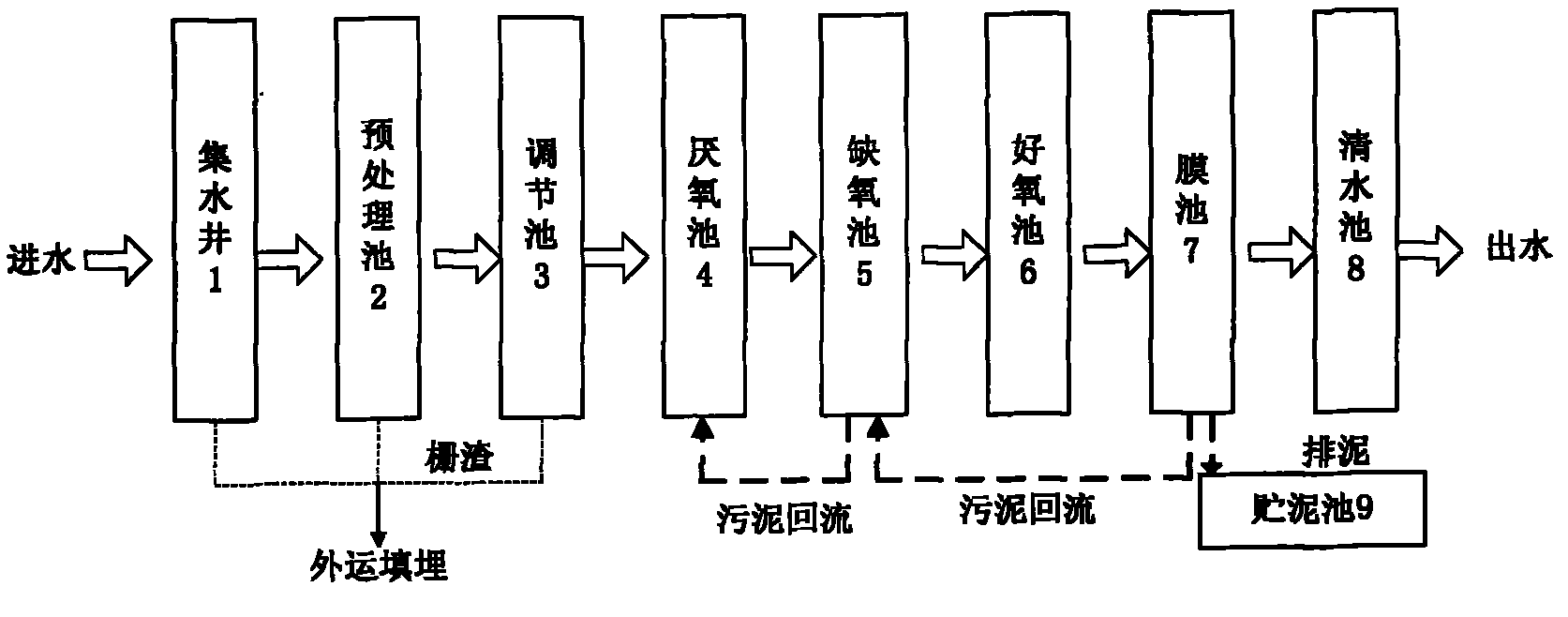

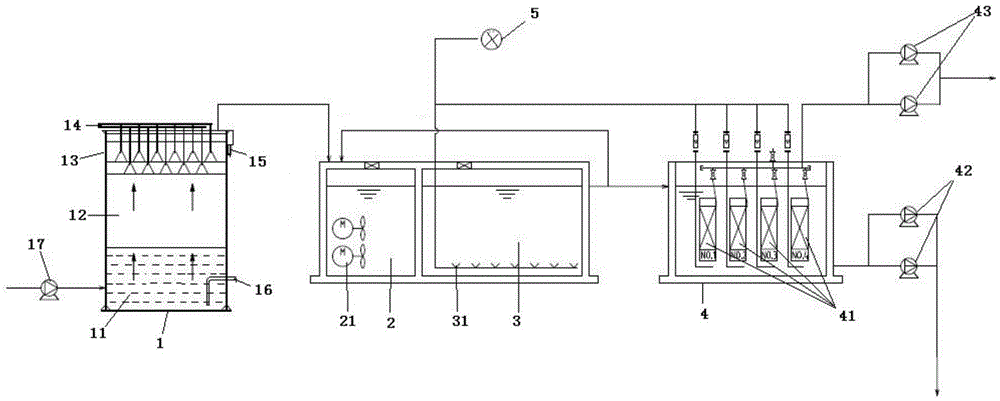

Sewage treatment method and system in ecological sensitive areas

InactiveCN101928096AEfficient removalReach protectionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentVegetable oilWater source

The invention discloses a sewage treatment method and a system in ecological sensitive areas. The method comprises the following steps: larger suspended matters in sewage are removed by using a collecting well the inlet of which is provided with a mechanical coarse screen, the treated sewage enters a pretreatment tank, the suspended matters are further removed by the coarse screen, animal and vegetable oils and mineral oils are removed by an oil separator, and the retreated sewage enters a regulating reservoir to equalize the water quantity and water quality; the pretreated sewage enters an anaerobic tank to be mixed with backflow mixed liquor from an anoxic tank; effluent from the anaerobic tank and the backflow mixed liquor from a membrane pool are mixed to enter the anoxic tank, and effluent from the anoxic tank enters an aerobic tank; effluent from the aerobic tank enters the membrane pool to be biodegraded; and the effluent is filtered by membranes. By adopting an anaerobic-anoxic-aerobic-MBR mode, the invention has higher treatment efficiency and stability and can effectively remove COD, BOD, TN, TP and oils in the sewage; and the effluent meets first grade A emission requirements, and can be used as a reuse water source, thereby protecting the environment and saving the water resources. The invention is especially suitable for treating rural domestic sewage and catering wastewater in the ecological sensitive areas.

Owner:TSINGHUA UNIV

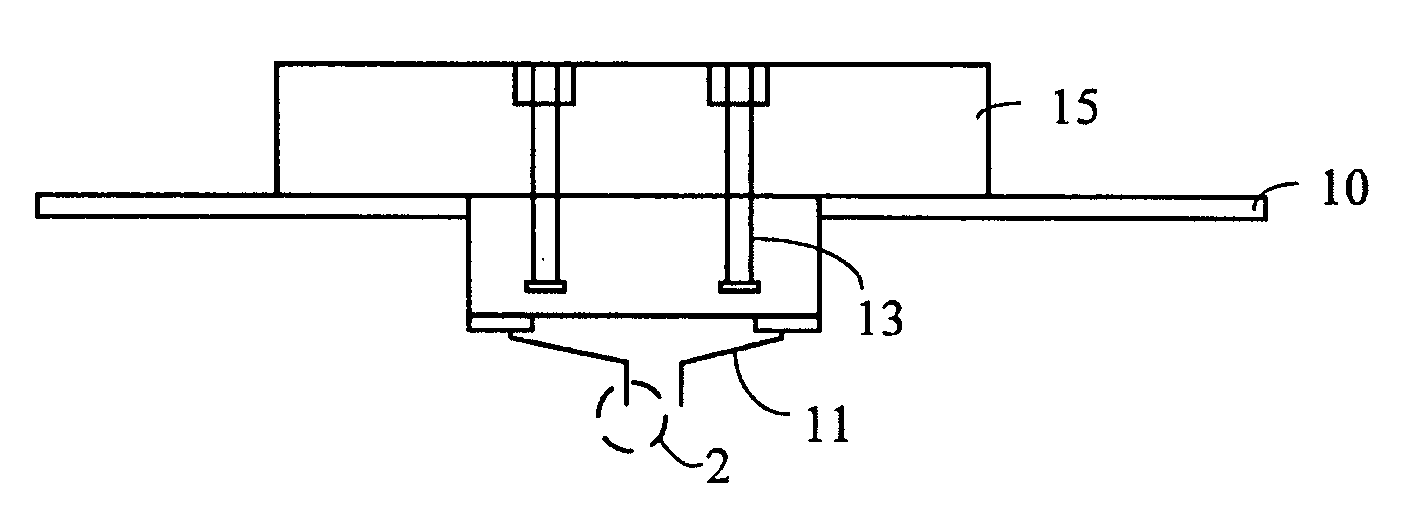

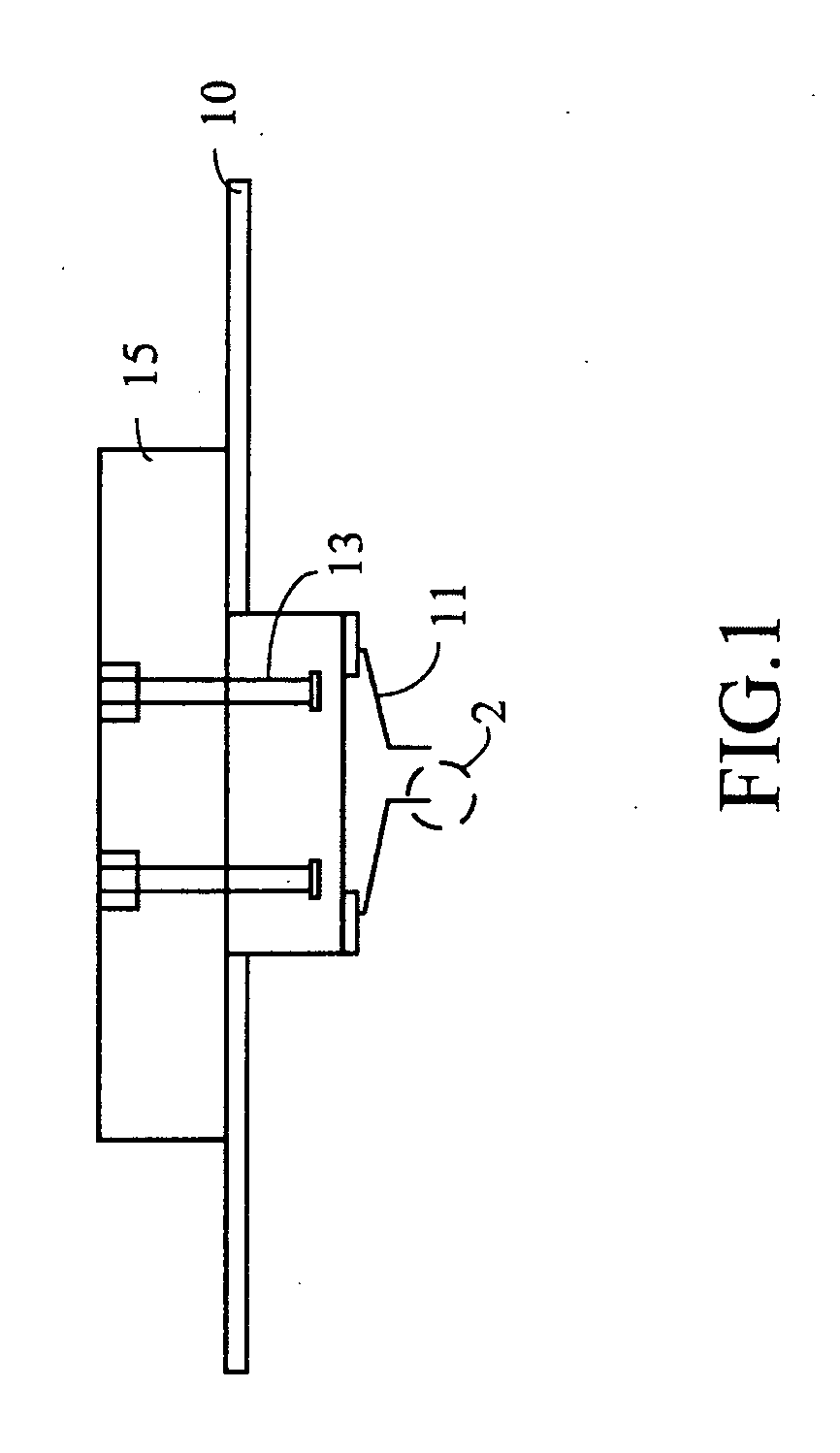

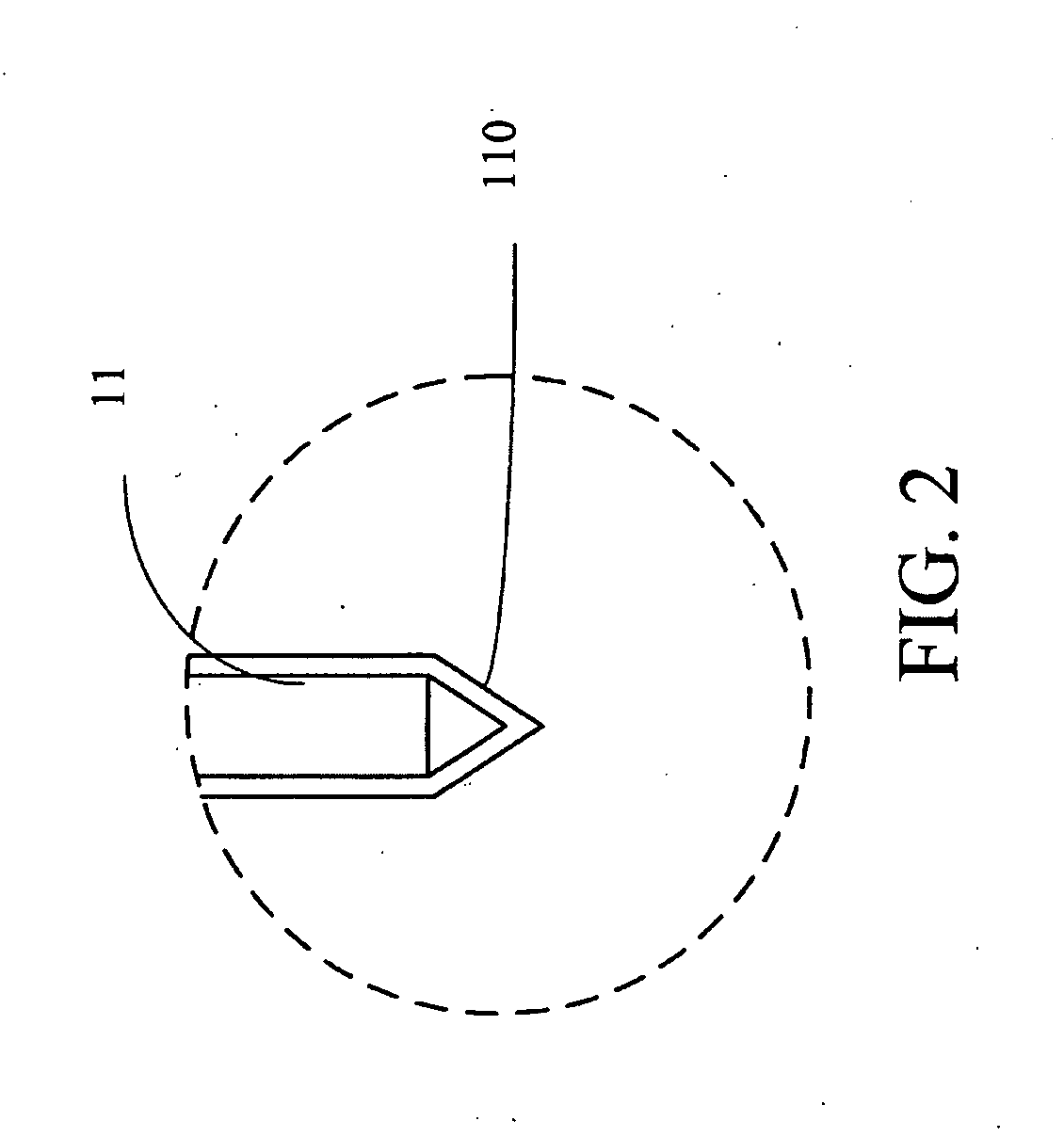

Probe of cantilever probe card

InactiveUS20090212807A1Reduce cleaning frequencyExtended run timeElectrical measurement instrument detailsElectrical testingEpoxyProbe card

A probe of a cantilever probe card (Epoxy probe card) is disclosed. The probe has a tip and a surface region extended from the tip of the probe about 5-10 mil is coated with a nano-film of high electro-conductive nanomaterial. The thickness of the nano-film is about 1-20 nm. Through the coating process, the nano-film coated on the probe of the cantilever probe card can efficiently provide the excellent advantages of no-clean, stable electro-conductivity, minimum overdrive force and longer usage lifetime for the probe of cantilever probe card. Accordingly, the yield of wafer testing can be improved and the frequency of cleaning the probe can be decreased. Furthermore, the total testing cost can be reduced.

Owner:IPWORKS TECH CORP

Livestock and poultry breeding wastewater treating technology

InactiveCN106007201AReduce SS contentEasy to settleSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesPig farmsFeces

The invention discloses a livestock and poultry breeding wastewater treating technology and belongs to the technical field of treatment of livestock and poultry breeding waste. The method comprises the following steps of gravity sedimentation pretreatment, flocculation treatment, special ultrafiltration treatment, nanofiltration treatment, reverse osmosis treatment and aeration biological filter treatment. The membrane technology is used as the core, and a whole set of complete-process technology, which has the good separation and removal effect on organic matter, nitrogen, phosphorus and the like in livestock and poultry breeding wastewater, makes the processed waste water reach the pollution discharge standards in livestock and poultry breeding industry, and is wide in application range and suitable for livestock and poultry breeding wastewater zero discharge of various feces removal, is provided, wherein effluent can be recycled for washing hog houses, pig farm landscape water and toilets and the like.

Owner:嘉兴悟净环保科技有限公司

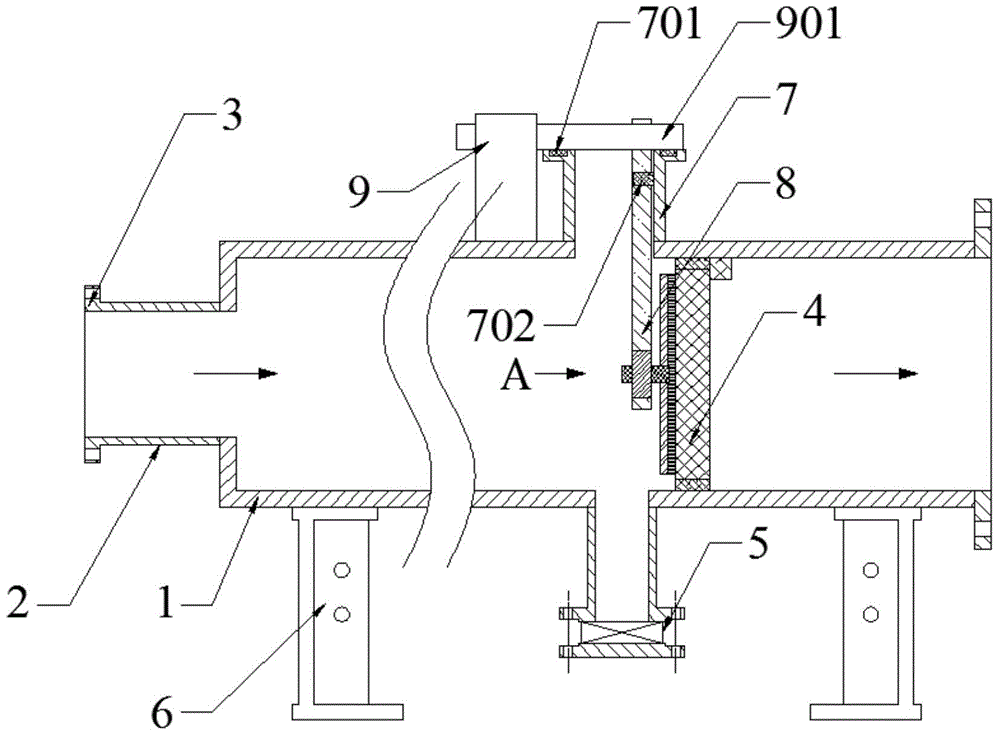

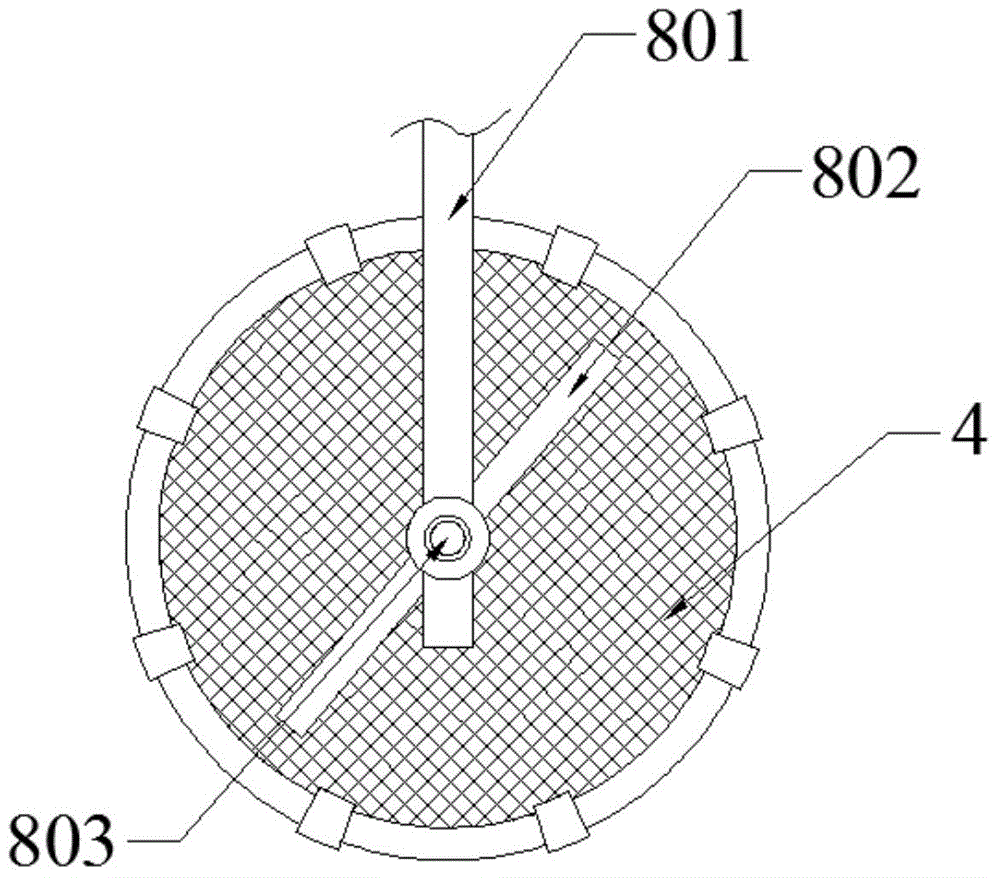

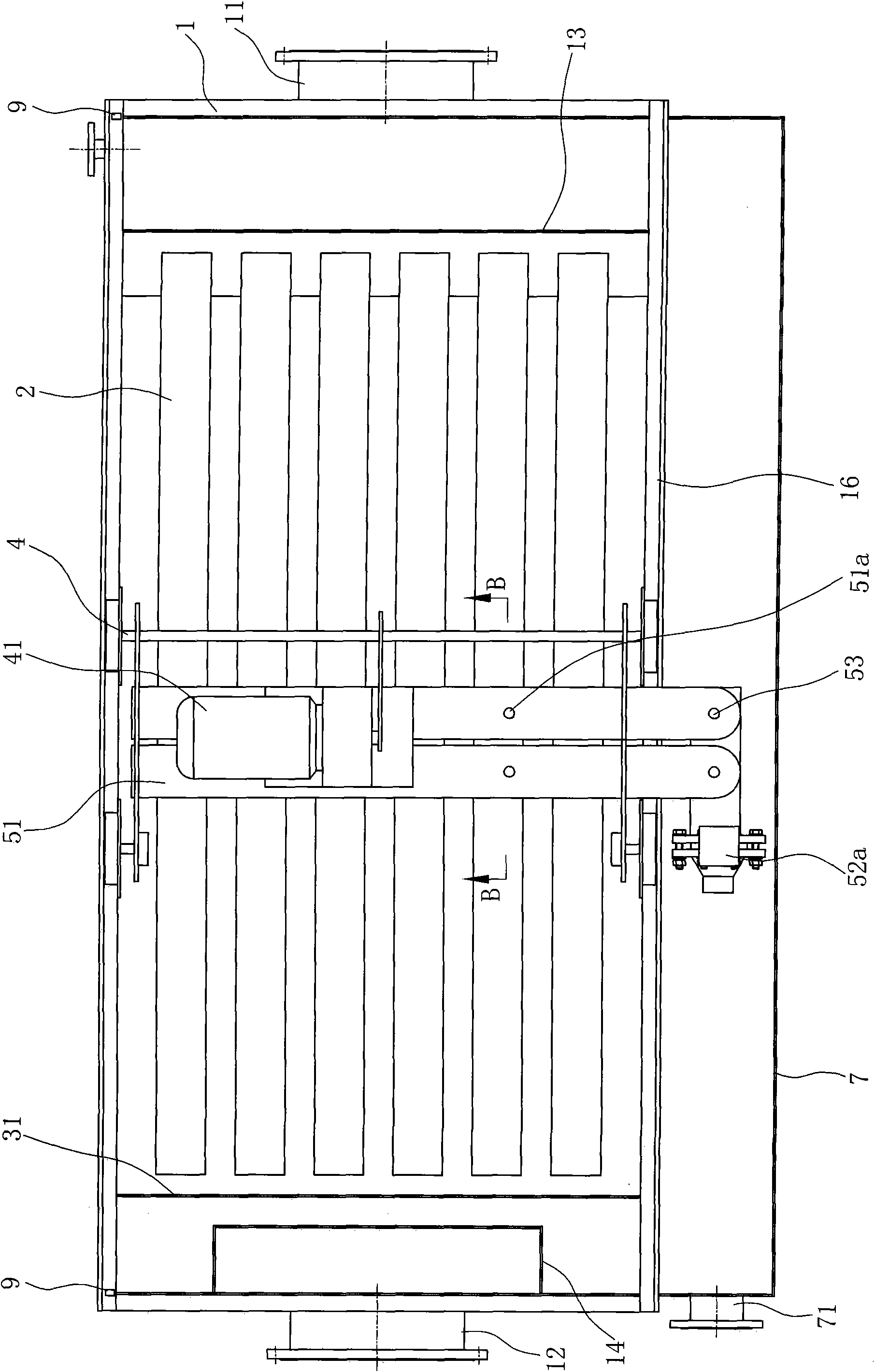

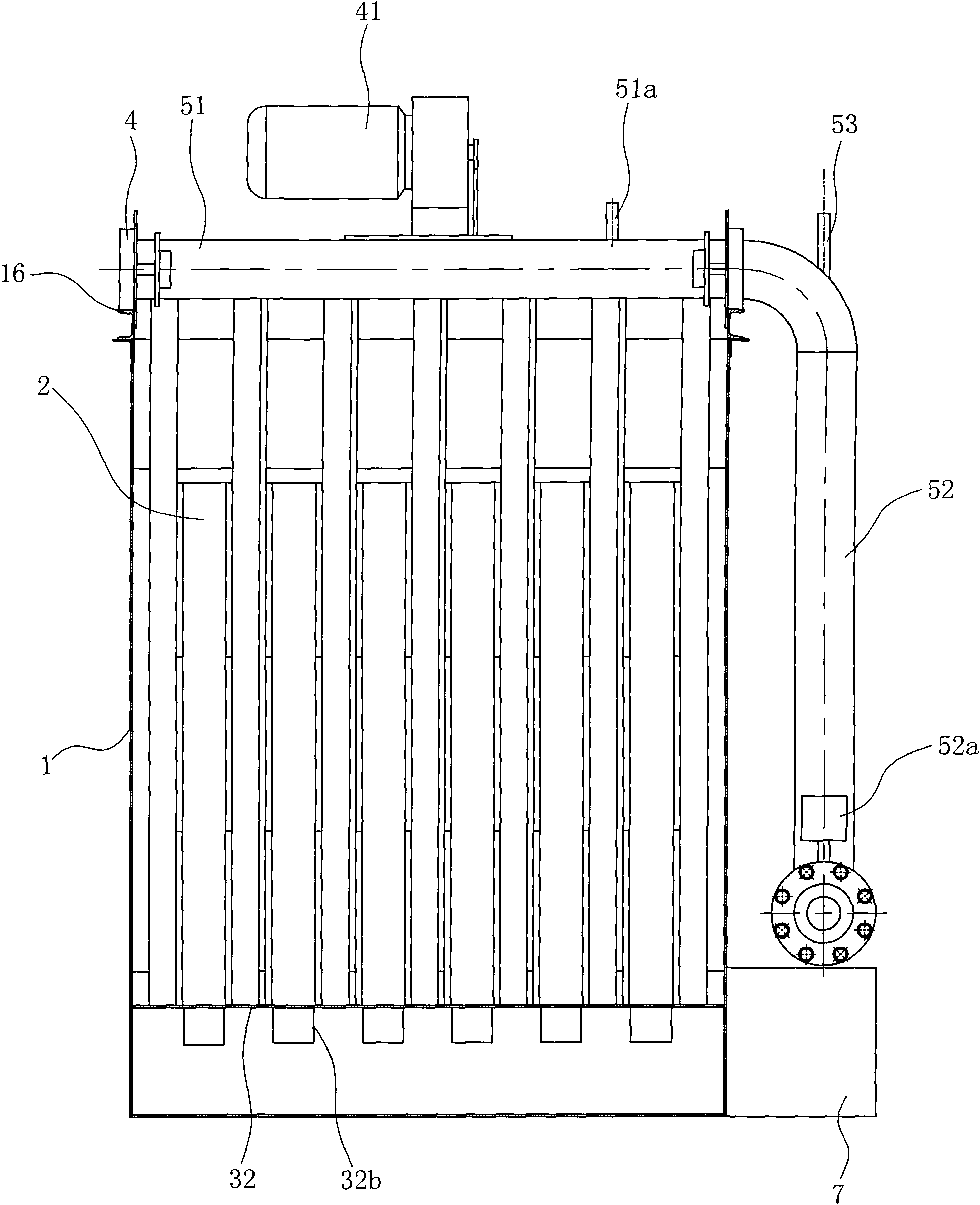

Self-cleaning horizontal type dirt remover

InactiveCN104436822ASimple structureImprove cleaning efficiencyStationary filtering element filtersMotor driveEngineering

The invention provides a self-cleaning horizontal type dirt remover and belongs to the technical field of chemical equipment. The self-cleaning horizontal type dirt remover also comprises a cleaning assembly, wherein the cleaning assembly comprises a cleaning brush, a rotary motor for driving the cleaning brush and a supporting rod for fixing and supporting the rotary motor; the cleaning brush is attached on the side surface of a filtering net towards the inlet end of a body, and is fixedly connected with an output shaft of the rotary motor. The rotary motor drives the cleaning brush to rotate in the vertical surface. The self-cleaning horizontal type dirt remover provided by the invention has the advantages that the structure is simple; due to the arranged cleaning assembly, the filtering net can be cleaned without stoppage, so that the cleaning efficiency is high, no influence on the production process is caused, the frequency of whole maintenance and clearing of the dirt remover is reduced, the production frequency is improved and convenience is brought for use of equipment in the dirt-removing process.

Owner:TIANJIN ZECHANG CHEM EQUIP MFG

Efficient paint mist coagulating agent and preparation thereof

InactiveCN101407353AImprove working environmentExtended service lifeWater/sewage treatment by flocculation/precipitationIron saltsWastewater

The invention relates to a highly-efficient paint mist coagulant and an application method thereof. The paint mist coagulant includes an A reagent and a B reagent, the A reagent is a water solution mainly prepared by a modified macromolecule polymerization metal salt, the macromolecule polymerization metal salt is aluminium salt or iron salt; the B reagent is a water solution mainly prepared by a polymerization amide-type substance with molecular weight of 9 millions to 12 millions. When in application, the paint waste water is blended with the A reagent and the B reagent according to volume ratio of 500:2:1, thus leading the paint in the paint waste water to cake and float, the paint and the water are separated, clear water is obtained to reuse. The usage is firstly adding the A reagent, and adding the B reagent after even blending. The processed paint waste water is fat-soluble paint waster water and water-soluble paint waste water. The highly-efficient paint mist coagulant has a wide reagent source, effectively overcomes the disadvantages of the trivial preparation process, many and complex additional reagents and high price of the traditional paint mist coagulant, can reduce common paint waste water treatment cost to 0.25 yuan / ton and can be widely used in circulating water treatment in a wet-typed paint mist removing system.

Owner:WUHAN UNIV OF TECH

Method for forming post passivation Au layer with clean surface

InactiveUS20080131983A1Residue reductionReduce cleaning frequencyDead plant preservationSemiconductor/solid-state device testing/measurementProbe cardOptoelectronics

A method for fabricating and testing a wafer includes forming metal traces with metal pads, wherein forming the metal traces include forming a TiW layer on a passivation layer and on pads, next forming a seed layer on the TiW layer, next forming a photoresist layer on the seed layer, next forming a metal layer on the seed layer exposed by openings in the photoresist layer, next removing the photoresist layer, next removing the seed layer not under the metal layer, and then etching the TiW layer not under the metal layer with an etchant containing H2O2 at a temperature of between 35 and 50° C., or with an etchant containing H2O2 and with ultrasonic waves applied to the etchant, next contacting probe tips of a probe card with some of the metal pads, next cleaning the probe tips until repeating the step of contacting the probe tips with some of the metal pads at greater than 100 times, and then after cleaning the probe tips, repeating the step of contacting the probe tips with some of the metal pads.

Owner:QUALCOMM INC

A scale inhibitor for reverse osmosis membrane

InactiveCN1864826AReduce cleaning frequencyExtended service lifeSemi-permeable membranesScale removal and water softeningReverse osmosisCarboxylic acid

The invention relates to a water treating technology using reverse osmosis membrane, which is a antisludging agent for reverse osmosis membrane. It is characterized in that it comprises following components with their percentage by weight: organo-phosphines acid compound 5-20%, lignin 0.5-1%, polymaleic anhydride0.5-3%, phosphinic carboxyl acid 5-20% and water with left percentage.

Owner:TIANJIN CHEM RES & DESIGN INST

Method for treating and recycling heavy metal wastewater by double-membrane process

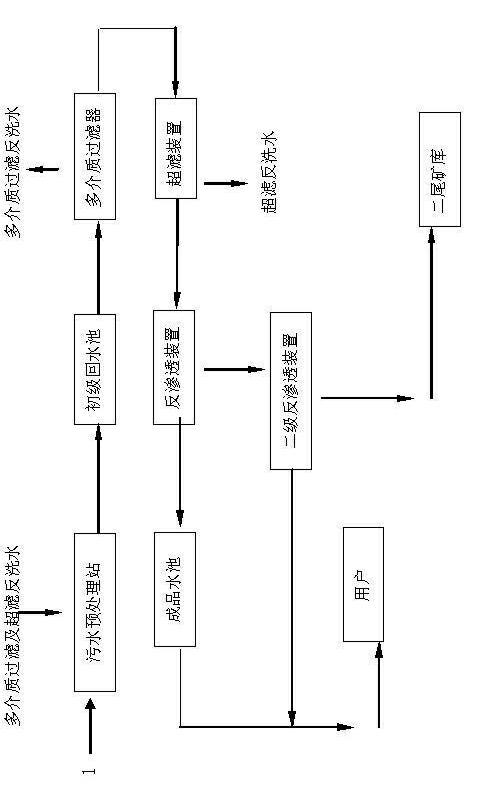

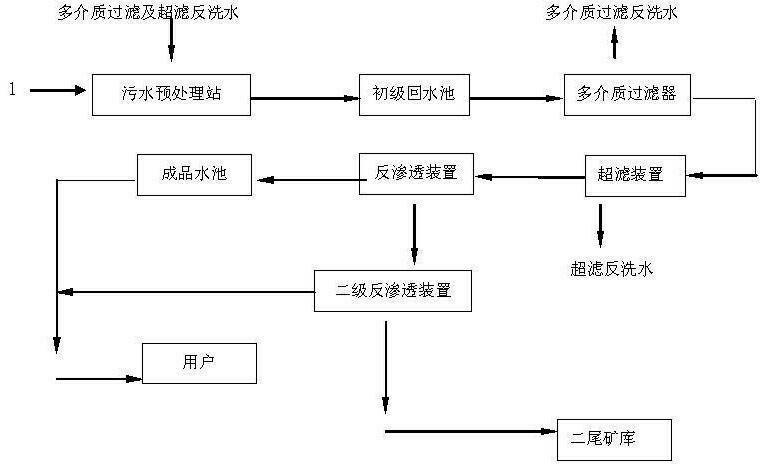

InactiveCN102674590AEnsure water qualityGuarantee the amount of waterWater contaminantsWater/sewage treatment bu osmosis/dialysisReverse osmosisWastewater

The invention discloses a method for treating and recycling heavy metal wastewater by a double-membrane process, comprising the following steps of: treating the heavy metal wastewater by multi-medium pre-treatment, ultrafiltration treatment, first-stage reverse osmosis treatment and second-stage reverse osmosis treatment in sequence, so that the recovery rate of the wastewater is greatly increased, thus saving natural resources and reducing production cost.

Owner:北京诚合盛环境科技有限公司

Processing technology for recovering and utilizing mother solution of glyphosate as resource

ActiveCN101659673AImprove throughputReduce flux decay speedGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisFiltrationCatalytic oxidation

The invention relates to a processing technology for recovering and utilizing the mother solution of glyphosate as a resource, which comprises the following concrete steps: firstly, preprocessing themother solution of glyphosate, and then, separating, concentrating and recovering the glyphosate by a membrane combination technique; returning the concentrated solution to a crystallization working section in the production process of the glyphosate after membrane filtration, thereby effectively recovering and utilizing the glyphosate resource; adsorbing the diluted solution with high efficiency,and further recovering and utilizing the glyphosate; and processing the adsorbed solution by catalytic oxidation with high efficiency to recover the sodium chloride resource with higher purity. The invention achieves the purposes of recovering and utilizing the glyphosate in the mother solution as a resource to the maximum extent and efficiency separating, recovering and utilizing the sodium chloride as a resource, has the advantages of economical technology, high efficiency, good system stability, high safety, easy operation, convenient industrial amplification, and the like, solves the problems of the soil salinization caused by applying water agents with high content of sodium chloride, the processing and disposal of solid wastes of the sodium chloride and the environment pollution, and effectively recovers and utilizes the resources of the glyphosate and the sodium chloride in the mother solution of the glyphosate.

Owner:NANJING UNIV OF TECH

Reverse osmosis membrane scale inhibitor and applications thereof

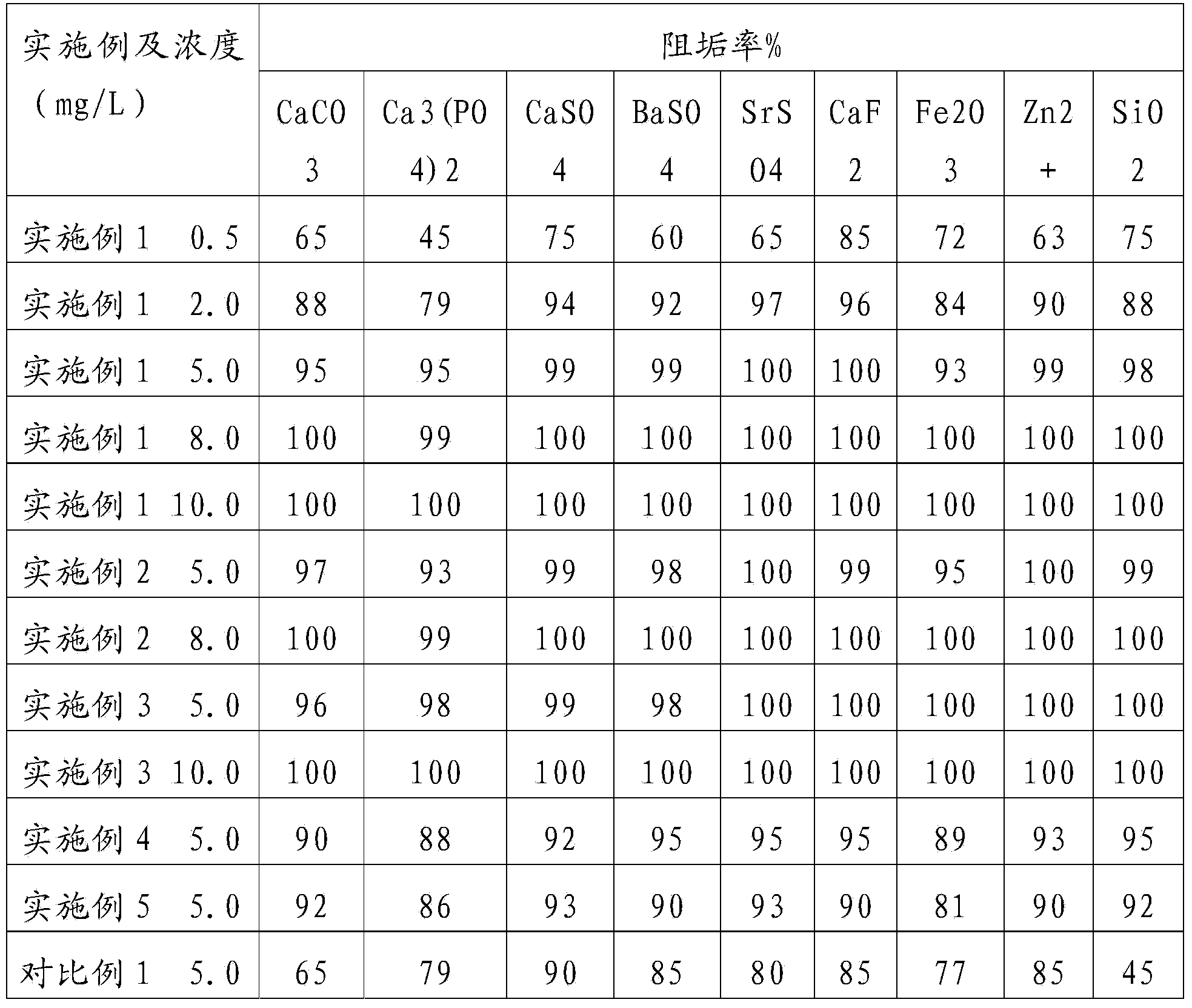

ActiveCN103394289AExtend the life cycleGuaranteed uptimeSemi-permeable membranesSilicic acidCarboxylic acid

The present invention relates to a reverse osmosis membrane scale inhibitor and applications thereof. The scale inhibitor contains an organic phosphonate, an organic carboxylic acid polymer, an organic amine and a surfactant, wherein a weight ratio of the components is 1:0.2-2.0:0.02-0.10:0.02-0.15. With application of the scale inhibitor of the present invention in a reverse osmosis system water treatment, the problem of membrane pollution caused by deposition of CaCO3, Ca3(PO4)2, CaSO4, BaSO4, SrSO4, CaF2, iron oxide and zinc salts on a reverse osmosis membrane can be solved, a reverse osmosis system work efficiency can be increased, a service life of reverse osmosis membrane agents and reverse osmosis equipment can be prolonged, and an operation cost of reverse osmosis can be reduced.

Owner:深圳市爱康泉水处理服务有限公司

Ion source with substantially planar design

InactiveUS20060103319A1Less undesirable build-upGuaranteed uptimeElectric arc lampsMaterial analysis by optical meansCeramicAtomic physics

In certain example embodiments of this invention, there is provide an ion source including an anode and a cathode. In certain example embodiments, the cathode does not overhang over the anode, or vice versa. Since no, or fewer, areas of overhang are provided between the anode and cathode, there is less undesirable build-up on the anode and / or cathode during operation of the ion source so that the source can run more efficiently. Moreover, in certain example embodiments, an insulator such as a ceramic or the like is provided between the anode and cathode.

Owner:GUARDIAN GLASS LLC

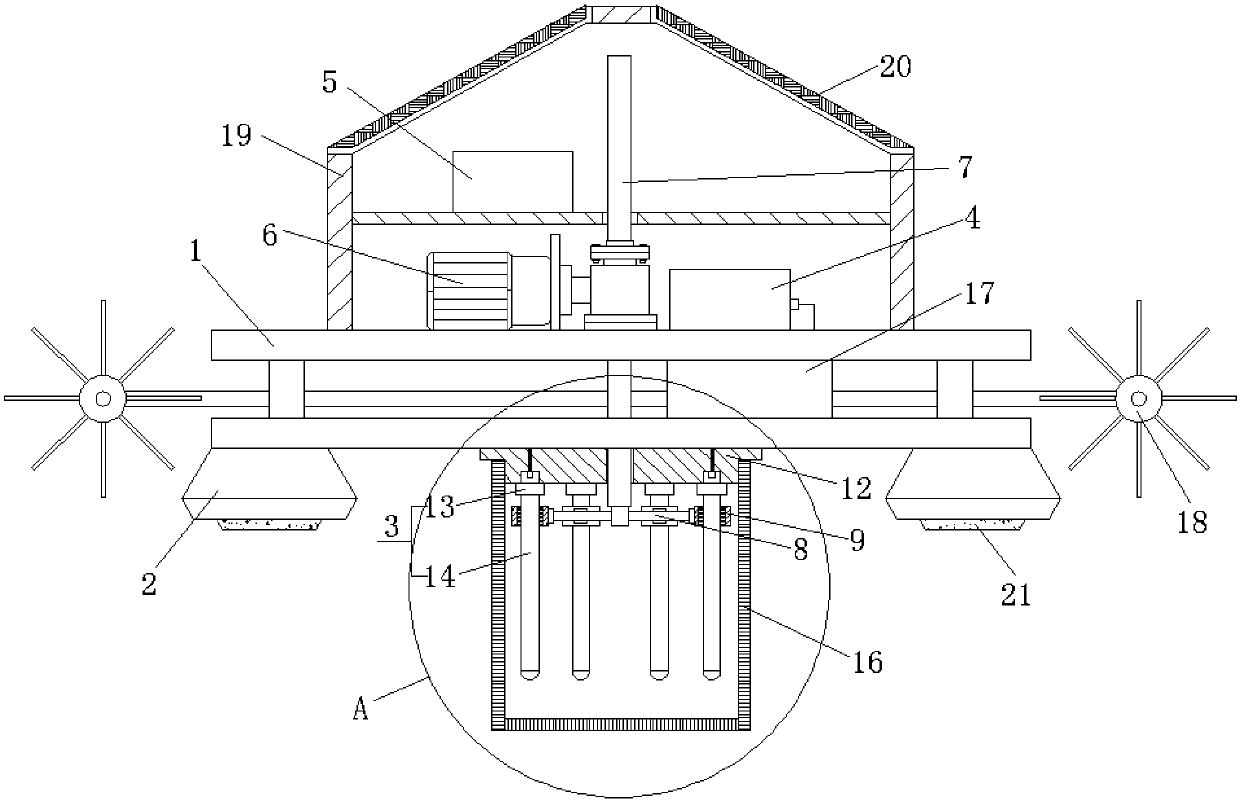

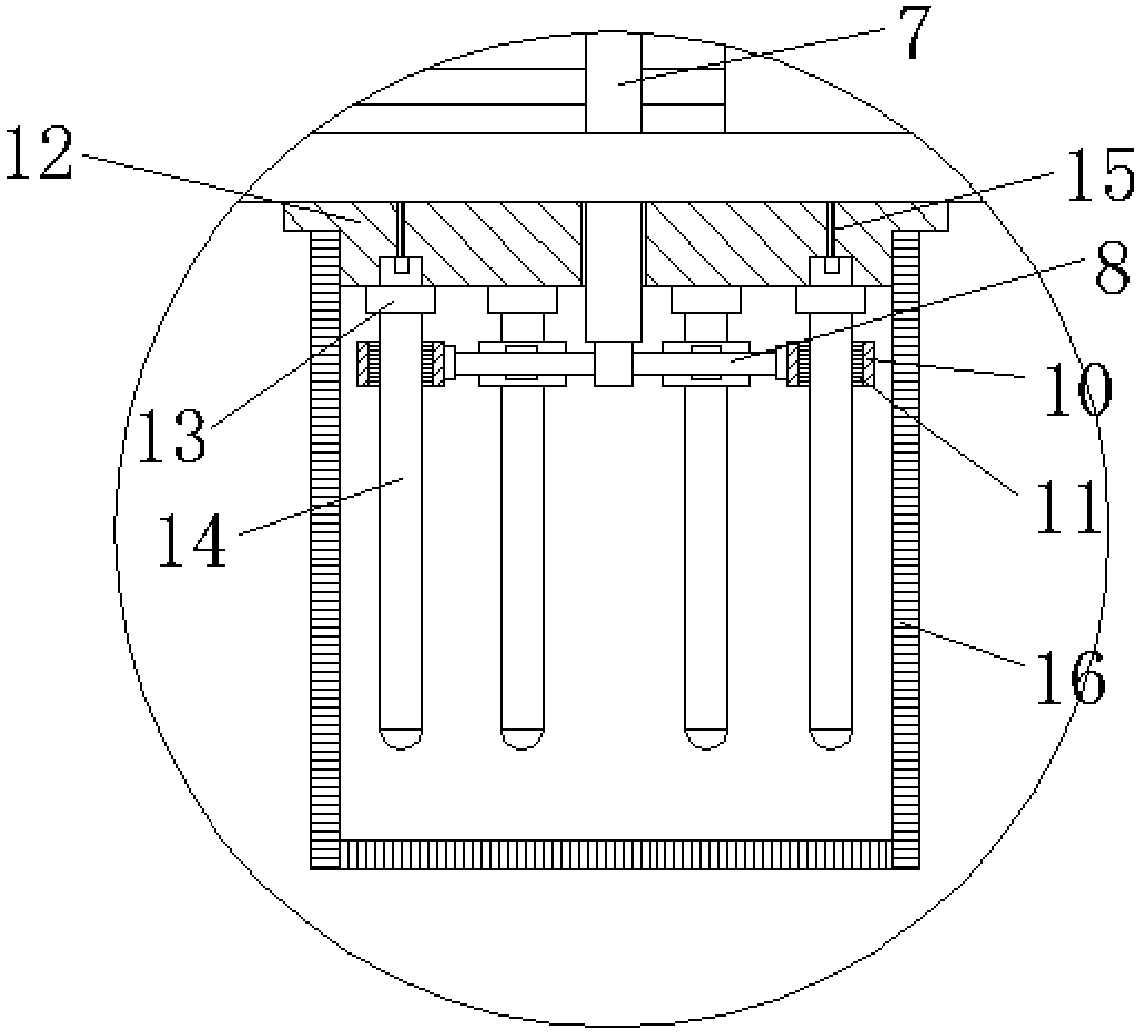

Water quality monitoring equipment for aquaculture

PendingCN107632133AGuaranteed accuracyExtended service lifeBatteries circuit arrangementsTesting waterWater qualityEngineering

The invention provides water quality monitoring equipment for aquaculture. The water quality monitoring equipment comprises a left floating body, a right floating body, a support seat arranged on theleft floating body and the right floating body, a plurality of water quality sensors arranged on the lower end surface of the support seat, a waterproof cover arranged on the support seat as well as alifting motor, a control device and a power supply device which are arranged in the waterproof cover, wherein the lifting motor controls lifting and dropping of a lead screw with the lower end vertically penetrating through the support seat, the bottom end of the lead screw is connected with a plurality of cleaning sleeves, each cleaning sleeve is arranged on the corresponding water quality sensor in a sleeving manner, and the cleaning sleeves can slide on the outer side walls of the water quality sensors with the vertical movement of the lead screw; the water quality sensors and the liftingmotor are connected with the control device, and the power supply device supplies power to the whole equipment. The water quality monitoring equipment for aquaculture has the function of cleaning surfaces of the water quality sensors at fixed period, so that the normal operation of the water quality sensors is guaranteed, and the service life of the equipment is prolonged.

Owner:天津柯基科技有限公司

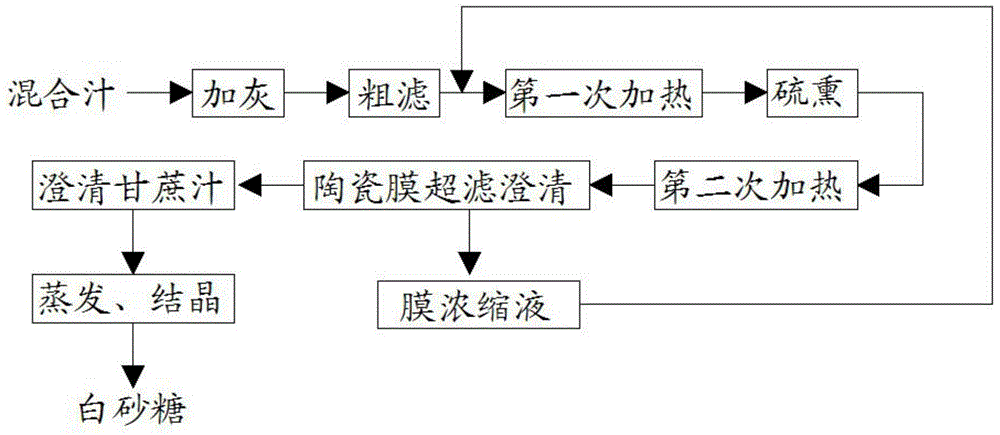

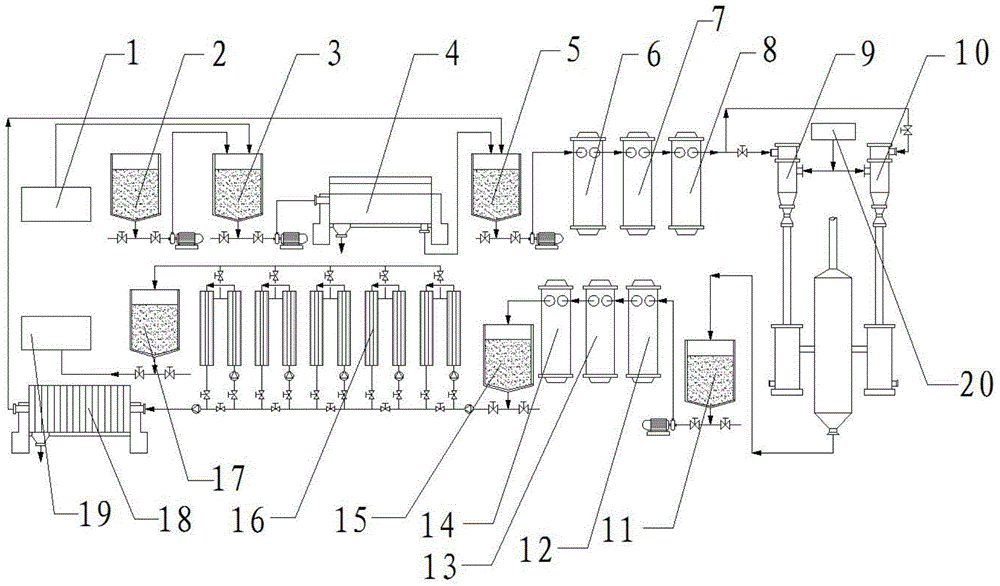

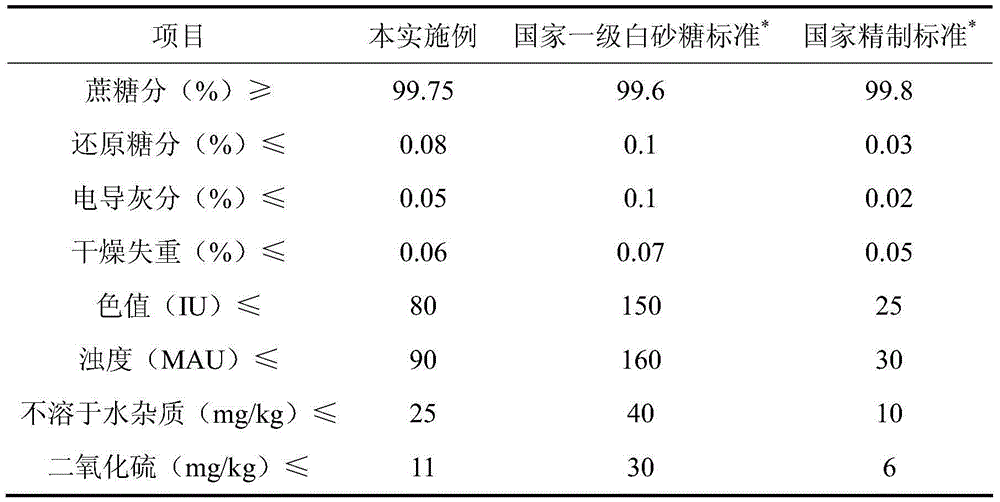

Sugar manufacture clarification process

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

Detergent suitable for cleaning hollow fiber ultrafiltration membrane and method for producing the same

ActiveCN101219341AStrong targetingReduce cleaning frequencySemi-permeable membranesFiberUltrafiltration

The invention provides a cleaning agent that is applicable to clean hollow fiber ultrafiltration membrane, which comprises the compounds (percentage by weight): anhydrous sodium carbonate accounts for 25-45 percent, trisodium phosphate accounts for 5-20 percent, anhydrous sodium sulfate accounts for 2-5 percent, ethylene diamine tetraacetic acid tetrasodium salt (EDTA-4Na) accounts for 5-15 percent, sodium percarbonate accounts for 0-33 percent, emulsifying agent SAS accounts for 8-15 percent, peregal-25 accounts for 0-5 percent and dodecyl sodium sulfate accounts for 4-10 percent. The compounds are added into an enamel reactor with a stirrer and a grinder in sequence to be stirred for 2-3 hours, thus obtaining the cleaning agent through grinding the mixture evenly. The invention has simple preparation and is particularly applicable to clean hollow fiber ultrafiltration membrane such as ultrafiltration oily wastewater, organic wastewater, protein concentration, etc.; the invention has strong decontamination direction, high effect and low cleaning cost.

Owner:OCHEMATE MATERIAL TECH CO LTD

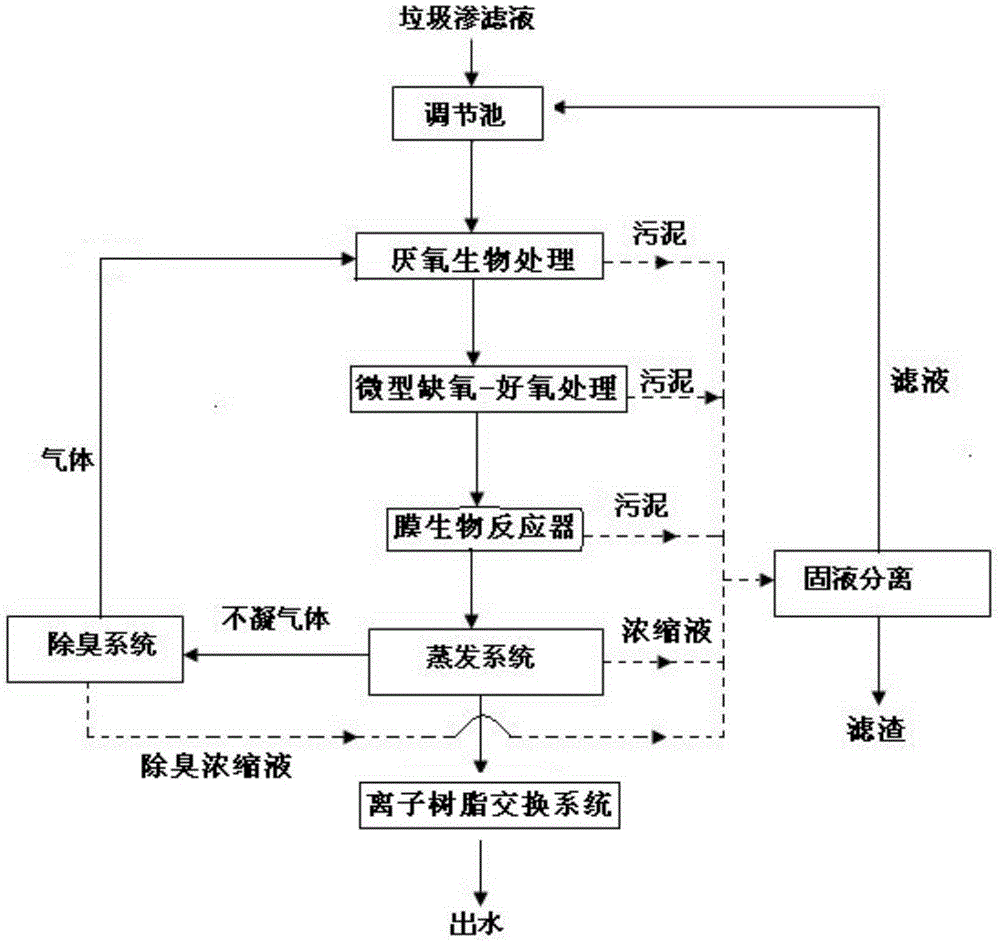

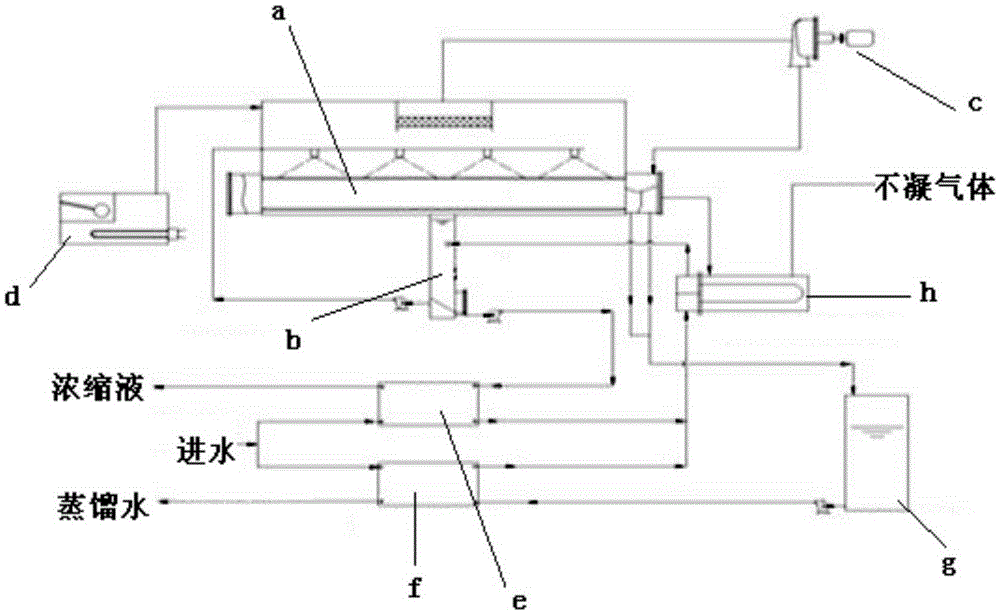

Garbage leachate treatment process

InactiveCN105347615AReduce operating burdenReduce foulingSpecific water treatment objectivesWater contaminantsAnaerobic aerobicEvaporation

The invention discloses a garbage leachate treatment process; a garbage leachate is treated by an adjusting pool, an anaerobic biological treatment unit, a minisize anaerobic-aerobic treatment unit, a membrane bioreactor and an evaporation system (MVC) in turn, and through evaporation, distilled water formed from water and ammonia reaches standards and is discharged after passing through a cation-anion resin exchange system; non-condensable gas reaches standards and is discharged after passing through a deodorization system, and a concentrate is discharged out of the evaporation system; the garbage leachate treatment process is respectively subjected to anaerobic biological treatment, minisize anaerobic-aerobic treatment and membrane bioreactor treatment before evaporation treatment, so as to greatly alleviate the operation burden of the evaporation system (MVC), relieve the fouling problem of the evaporation system (MVC) to a largest extent and reduce the frequency of cleaning; the garbage leachate treatment process is applicable to treatment of conventional high-COD and high-NH3-N garbage leachates, at the same time, is applicable to treatment of leachates with different landfill ages or different types through adjustment of related process parameters, and effectively relieves the burden of process operation.

Owner:江苏金恒环境科技有限公司

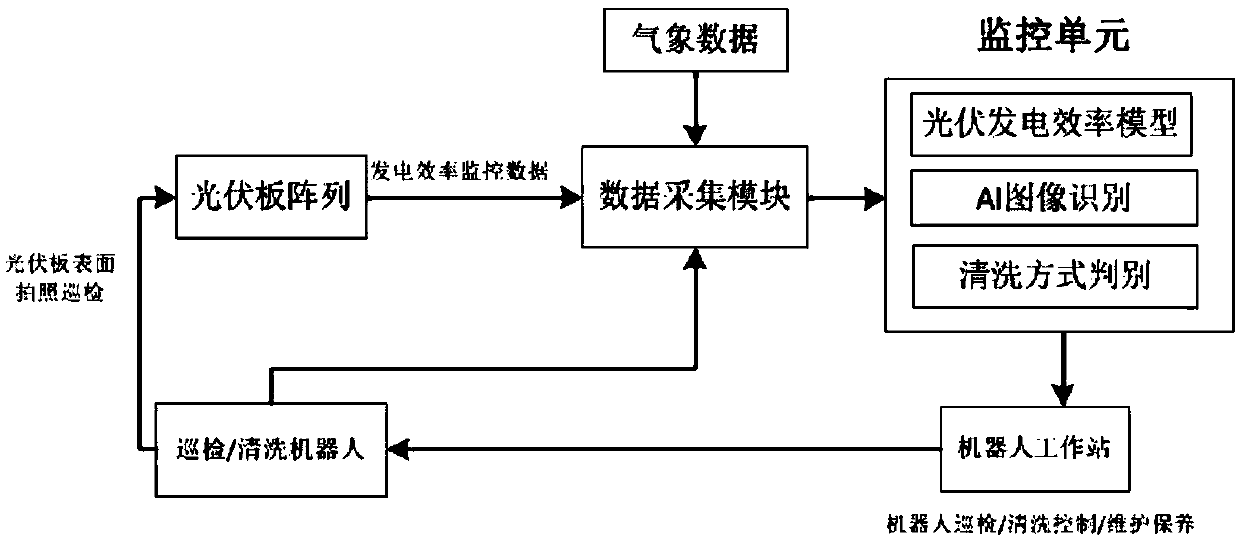

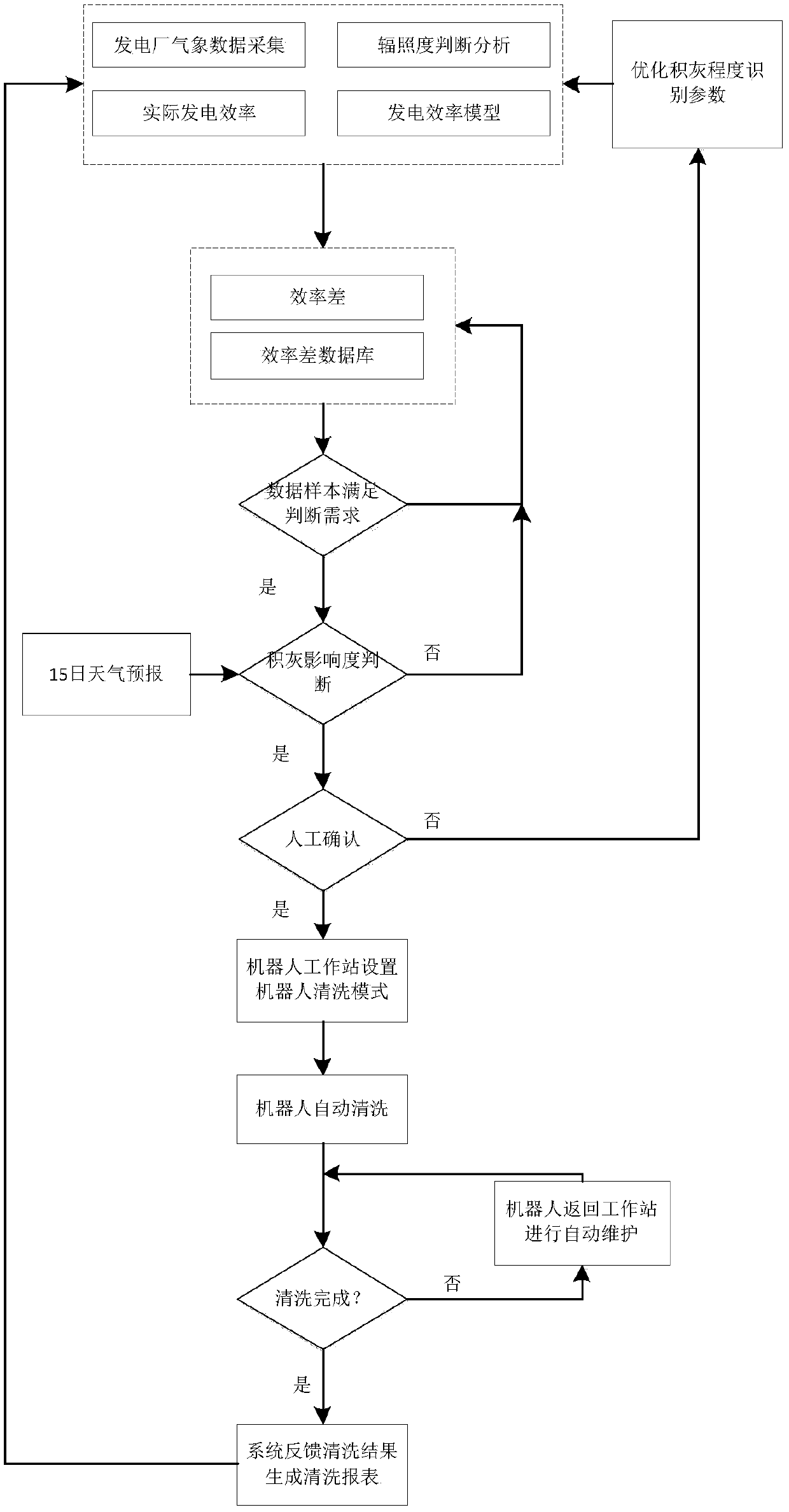

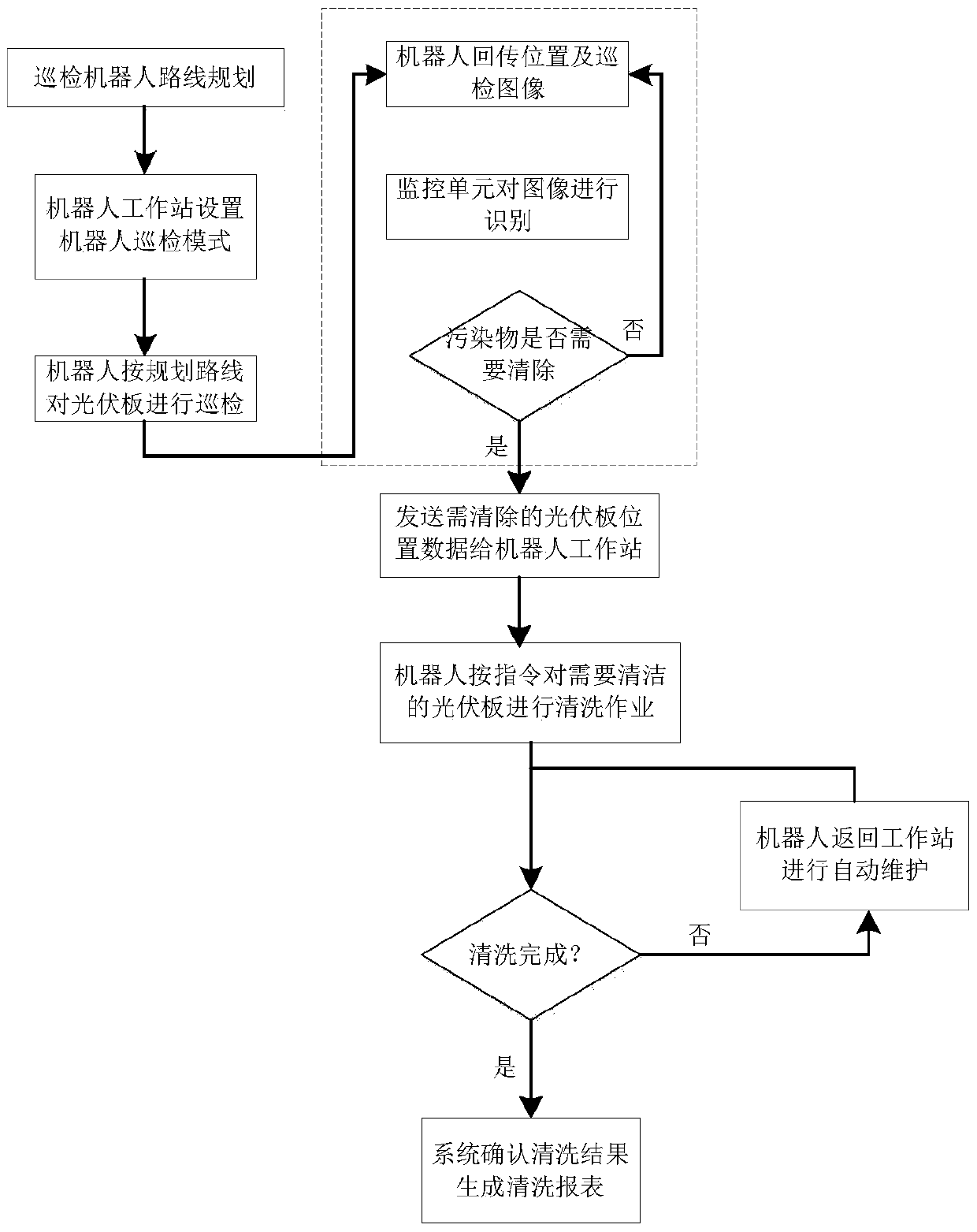

Intelligent control system and control method for cleaning of solar photovoltaic panel

InactiveCN109546954AExtend your lifeExtended cleaning cyclePhotovoltaicsTotal factory controlOperational costsData acquisition

The invention discloses an intelligent control system and control method for the cleaning of a solar photovoltaic panel, and belongs to the technical field of solar photovoltaics. The system is composed of a meteorological data module, a data acquisition module, a monitoring unit, a robot workstation and an inspection cleaning robot. The monitoring unit is used for collecting and recording a powergeneration current and the real-time meteorological data of a power plant and comparing the power generation current and the real-time meteorological data with a normal power generation efficiency attenuation model built in the system to obtain a real state that the accumulated dust affects the power generation efficiency. Through comparing the optimal cost operation data, an optimized scheme forcleaning the photovoltaic array is obtained, and the automatic cleaning robot is controlled to automatically clean the photovoltaic panel. Compared with the prior art, the system can automatically recognize local pollution of the photovoltaic panel and automatically clean he local pollution, can effectively prolong the overall cleaning period of a solar power plant, reduces the overall cleaning frequency, prolongs the service life of the photovoltaic panel, reduces the operation cost, optimizes the cleaning period, and achieves the optimization of the power generation efficiency and the operation cost.

Owner:YANGZHOU POLYTECHNIC INST

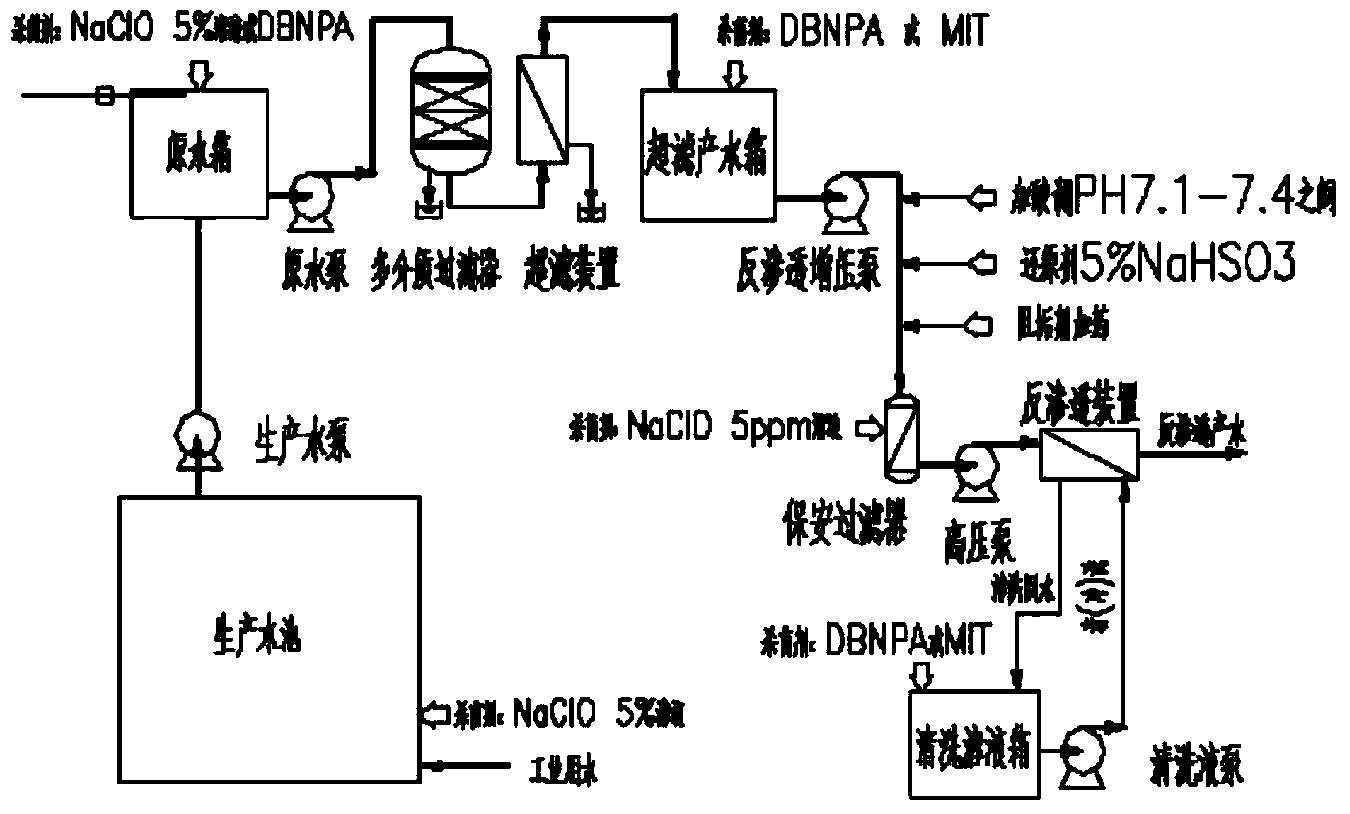

Sterilization method capable of preventing reverse osmosis membrane from being polluted and plugged by microbe

ActiveCN104014247ABeneficial technical effectControl drug resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisControlled drugsUltrafiltration

The invention relates to a sterilization method capable of preventing a reverse osmosis membrane from being polluted and plugged by microbe. The sterilization method mainly comprises the steps of adding an oxidizing sterilizing agent NaClO (5%) solution to a raw water tank continuously; adding a reducing agent NaHSO3 (35% W / V) solution continuously after ultra-filtration; removing residual chlorine thoroughly; controlling a pH value of inlet water at a reverse osmosis inlet between 7.1 and 7.4; monitoring and controlling ORP before a security filter between 200 mv and 300 mv; and sterilizing by carrying out preventative addition of a non-oxidizing sterilizing agent DBNPA solution with a concentration of 50 ppm continuously for one hour once every week in the above flow according to the quick killing characteristic of the non-oxidizing sterilizing agent DBNPA. Meanwhile, NaClO addition to the raw water tank is stopped. The sterilization method mainly takes use of the oxidizing sterilizing agent accompanied by two non-oxidizing sterilizing agents to carry out preventative sterilization alternatively, controls drug tolerance and resistance of the microbe, can effectively prevent and control propagation and excessive multiplication of the microbe on the surface of the reverse osmosis membrane, thereby preventing the reverse osmosis membrane from being polluted and plugged by the microbe.

Owner:INNER MONGOLIA YITAI CTO

Cleaning agent for ceramic membrane for oilfield produced water and cleaning method thereof

InactiveCN102716674AStrong targetingEfficient removalSemi-permeable membranesCleaning methodsCleansing Agents

The invention discloses a cleaning agent for a ceramic membrane for oilfield produced water, and overcomes the deficiency that the ceramic membrane for the oilfield produced water does not have an effective cleaning method and an effective cleaning formula. The cleaning agent comprises a component A, a component B and a component C, wherein effective constituents of the component A are sodium hydroxide and sodium alkyl benzene sulfonate; effective constituents of the component B are sodium hydroxide, sodium alkyl benzene sulfonate, ethylene diamine tetraacetic acid sodium salt, triethanol amine and sodium tripolyphosphate; and effective constituents of the component C are sodium hydroxide, sodium alkyl benzene sulfonate and hydrogen peroxide. The cleaning agent aiming at characteristics of the oilfield produced water has the advantages that dirt on the surface of the membrane and in membrane holes can be removed rapidly and efficiently, the cleaning frequency of the membrane is reduced, the cleaning temperature and the cleaning time are greatly reduced, the permeation flux of the ceramic membrane is recovered rapidly and efficiently, and the regeneration of a system is accelerated.

Owner:PETROCHINA CO LTD +1

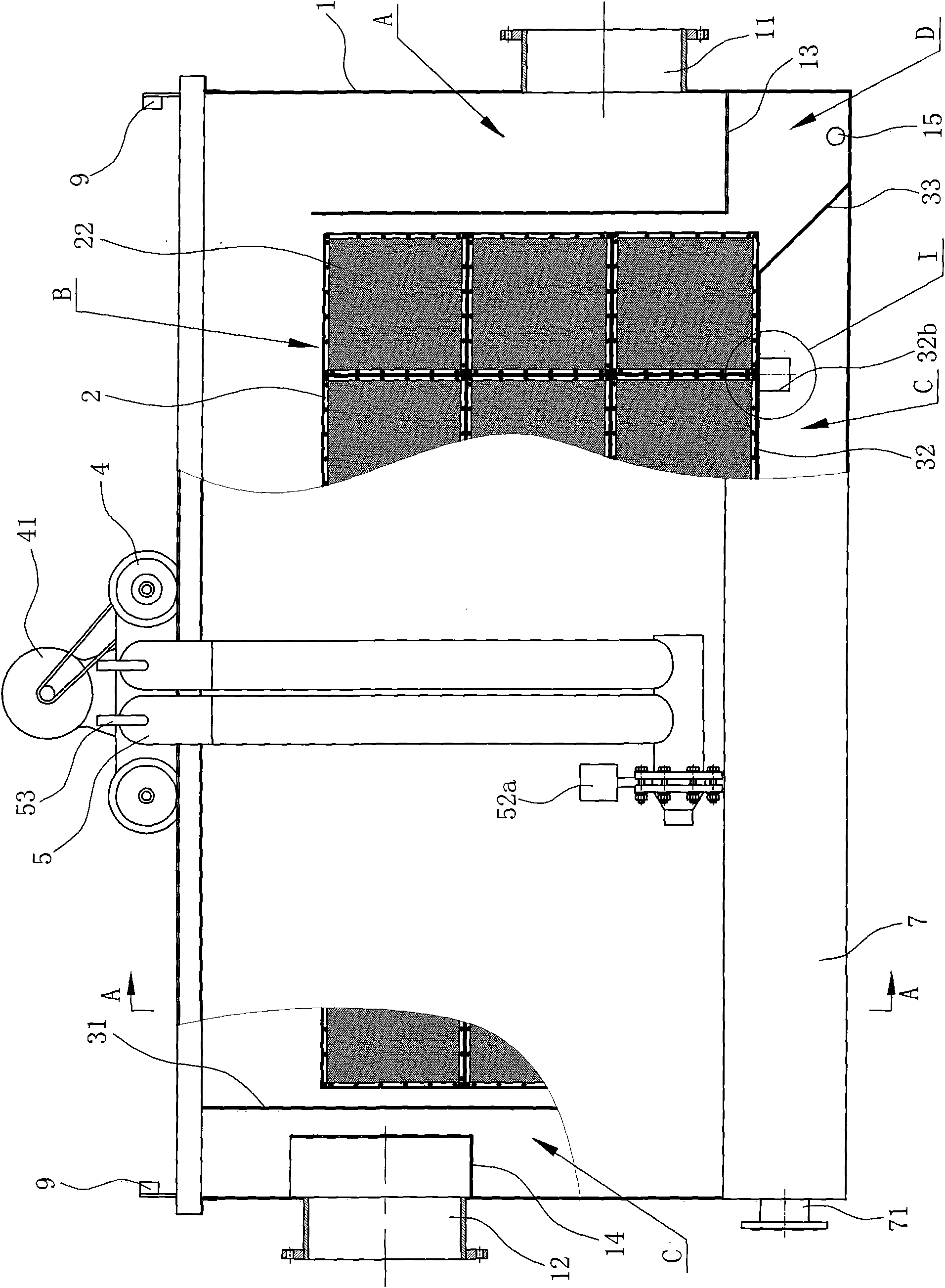

Low driving force self-cleaning and heat transfer enhancement rotor in heat exchange tube

ActiveCN102128559AEffective diffusionIncreased turbulenceHeat transfer modificationRotary device cleaningEngineeringViscosity

The invention provides a low driving force self-cleaning and heat transfer enhancement rotor in a heat exchange tube, which is particularly suitable for the heat transfer enhancement of a viscous fluid of the tube side. The rotor comprises a hollow cylinder and blades, wherein each blade is of a spiral structure; the root part of the outer surface of the blade is tangential with the edge of the hollow cylinder; and when a fluid axially enters from the heat exchange pipe, the acting force of the fluid vertical to the radial direction of the blade enables the rotor to rotate around a rotary shaft. According to the invention, as the root part of the blade is tangential with the edge of the hollow cylinder, the acting area of the fluid on the blade is increased. The larger the radius of the hollow cylinder is, the more obvious the effect becomes. Consequently, if the rotation driving force applied to the rotor is increased, the rotor is more favorable for the heat transfer enhancement in the case of relatively large viscosity of a medium in the heat exchange pipe or low kinetic energy of the fluid. As the outer surface of the root part of the rotor is tangential with the edge of the hollow cylinder to form a smooth curve, the outer surface of the blade does not scale easily, thereby prolonging the using period of the entire device and reducing the cleaning frequency.

Owner:BEIJING UNIV OF CHEM TECH

Filtering pool

ActiveCN101549222AFilter mesh with small pore sizeHigh porosityStationary filtering element filtersPore diameterEnergy consumption

The invention relates to an filtering pool, includes a square pool, multichip unit filters arranged in the pool, a first clapboard, a second clapboard, a third clapboard connected in turns in the pool, the first clapboard is erected in between a water outlet end and end of the multichip unit filters, the second clapboard is supported on bottom of the multichip unit filters and kept space from bottom of the pool, filter bracket of each unit filter includes a substrate and a frame-type lateral plate, filtration medium is lied on external surface of the frame-type lateral plate and the substrate on the bottom is provided with at least one purified water outlet, and position on the second clapboard corresponding to each purified water outlet is provided with purified water outlet. Comparing with the prior art, the invention applies combination of unit filter processing units, capable of setting processing units flexibly according to processing capacity. The invention provides advantages of low energy consumption, filter screen with small pore diameter, abrasion-resistance, high fltering speed, good water quality, high processing efficiency, easy replacement and low cost.

Owner:ZHEJIANG DEAN TECH

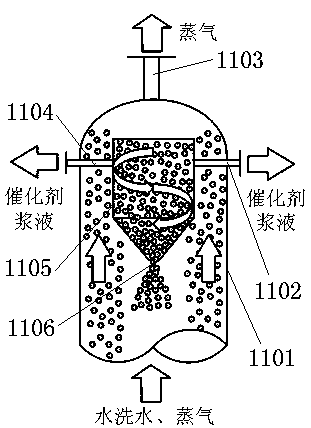

Device and method for purifying methanol-to-olefin device washing water

ActiveCN107720872AAchieve removalGood removal effectFatty/oily/floating substances removal devicesSpecific water treatment objectivesPtru catalystCoal chemical industry

The invention relates to the field of coal chemical wastewater treatment, in particular to a device and a method for purifying methanol-to-olefin device washing water. The method comprises the following steps: pumping out the washing water from the bottom of a washing tower, and sending to a granular-bed separator; enabling the washing water to run through the granular bed in a horizontal direction, intercepting particulate matters in water, and agglomerating microfine oil droplets in the water under the oil substance adsorbing and agglomerating actions of medium particles in the granular bed;performing settling separation on the agglomerated oil droplets under the action of gravity; after the granular bed adsorbs the particulate matters in the water till a saturated state, feeding wastewater from the bottom of the granular bed, mixing with gas, fluidizing the medium particles till a boiling state, releasing solid pollutants between bed layers, and sending the pollutants to a solid concentrating unit along with backwashing liquid. By the method, separation of catalyst particles and the oil substances from the washing water is achieved.

Owner:EAST CHINA UNIV OF SCI & TECH +1

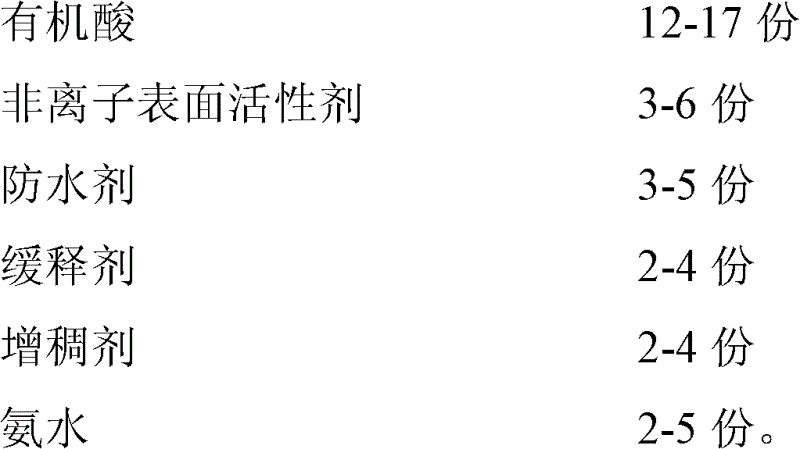

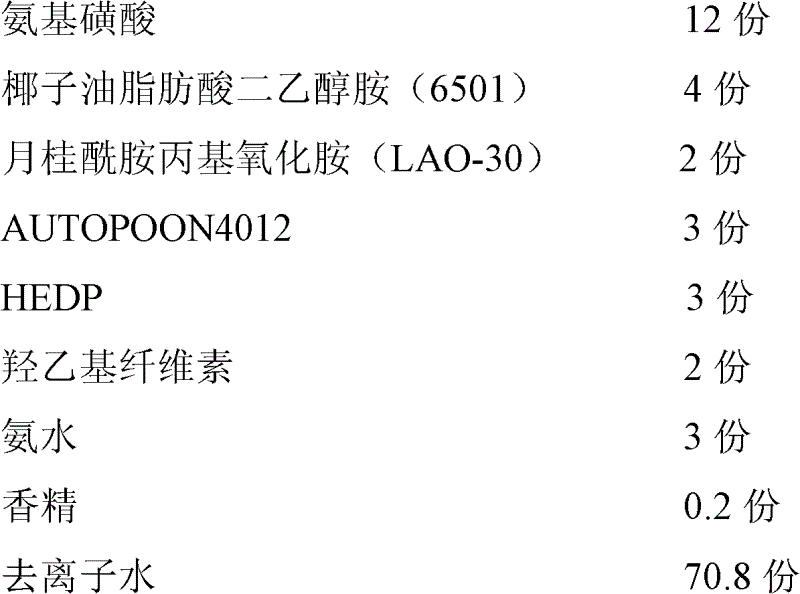

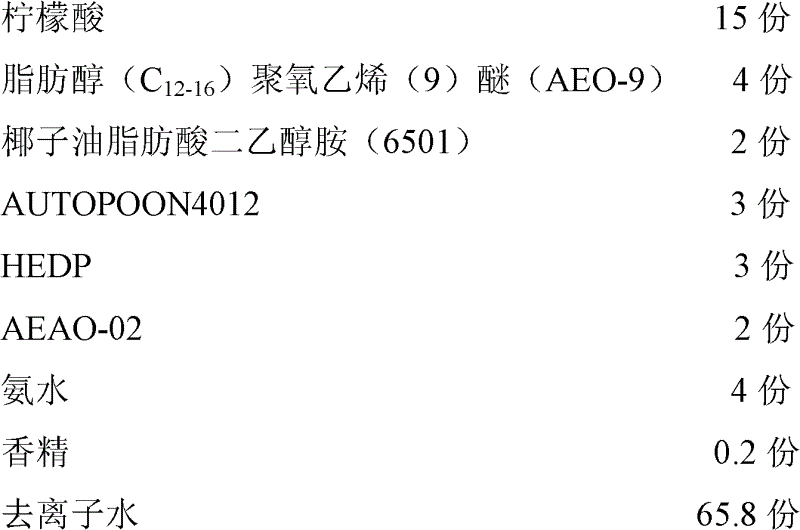

Water-proof ceramic tile cleaning agent

ActiveCN102618395AAvoid recontaminationReduce cleaning frequencyNon-ionic surface-active compoundsDetergent compounding agentsIonOrganic acid

The invention relates to a water-proof ceramic tile cleaning agent. Components and mass part of the components are organic acid 12-17 parts, a non-ion surface active agent 3-6 parts, a water-proof agent 3-5 parts, a slow release agent 2-4 parts, a thickening agent 2-4 parts and ammonia water 2-5 parts. The water-proof ceramic tile cleaning agent has a water-resistant function, can prevent a ceramic tile from being polluted again, reduces cleaning frequency, and is safe and environment-friendly.

Owner:BEIJING REWARD HOME CARE CHEM

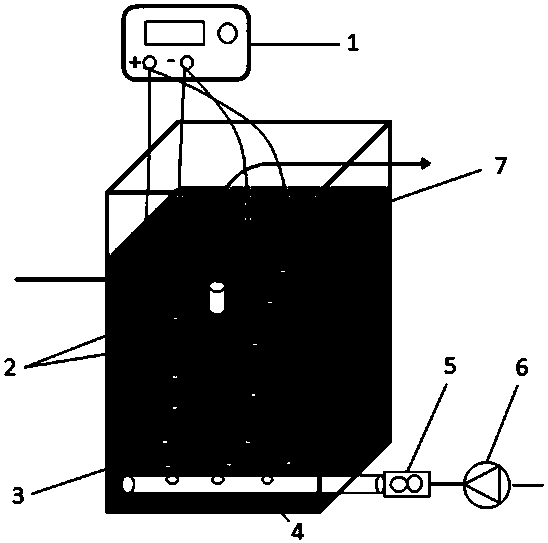

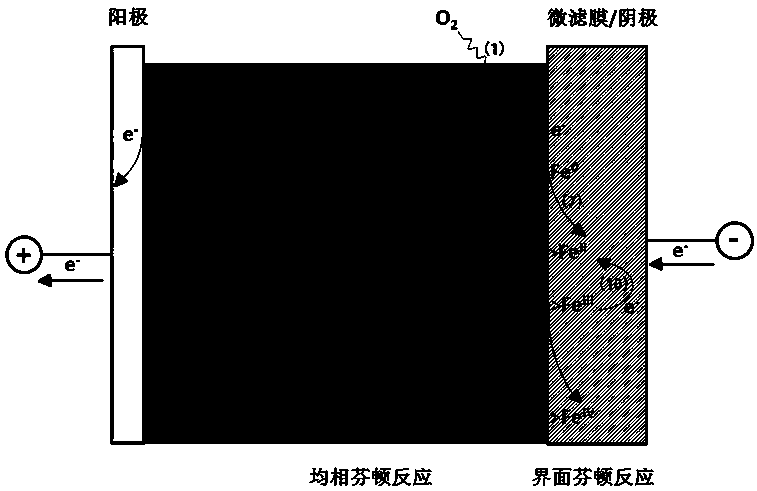

Cathode electrochemical microfiltration membrane coupled reactor suitable for removal of source water pollutants

ActiveCN108394960AReduce processing costsEasy to makeWater treatment compoundsWater contaminantsWater sourceDecomposition

The invention relates to a cathode electrochemical microfiltration membrane coupled reactor suitable for removal of source water pollutants. The reactor provided by the invention adopts graphite as ananode and a flat plate microfiltration membrane module with an internally-embedded steel wire mesh as a cathode, an external electric field is applied by a regulated direct current power supply, thereactor is operated in a continuous flow mode, so that physical interception removal of particles, colloids and macromolecular pollutants in source water can be realized, and degradation removal of refractory organic matter can be realized by utilizing strong oxidizing substances generated by electrocatalysis; in the reactor, in addition to HO free radicals formed by a water decomposition reactionon the surface of the anode, a Fenton reaction is performed on H2O2 generated on the surface of the cathode in situ under the external electric field and aeration conditions and Fe(II) dissolved fromthe steel wire mesh in a cathode interface and a homogeneous solution to form strong oxidants such as HO free radicals and Fe(IV)O<2+>, and therefore oxidative degradation removal of small-molecule refractory organic matter in the source water is realized; and the reactor couples electrochemical oxidation and microfiltration membrane separation technologies, can realize high-efficiency removal ofthe refractory organic matter in a lower external voltage and shorter hydraulic retention time, and reduces operating energy consumption.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com