Device and method for purifying methanol-to-olefin device washing water

A methanol-to-olefin and purification device technology, applied in the field of water treatment, can solve the problems of reducing the cleaning frequency of heat exchangers, air coolers and water-washing tower trays, blockage of equipment and pipelines, etc., and achieves long continuous operation period, easy regeneration, The effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In a 1.8 million tons / year methanol-to-olefins process, according to the method of the present invention, the washing water purification device of the present invention is used to purify the washing water containing solid catalyst and oil wax, so as to purify the washing water The purpose, its specific operation process and effects are described as follows:

[0039] 1. Material properties and related parameters

[0040] The methanol-to-olefin washing water is a multiphase mixture, and the water contains solid catalyst particles and insoluble oil droplets, wherein water is the continuous phase, and oil and solid catalyst are the dispersed phase medium. The washing water treatment capacity is 200t / h, and the density is 915.4 kg / m in the liquid phase operation state 3 , viscosity 0.255 cP, operating temperature 90°C, waste catalyst content 80 mg / L, average particle size 1.5 μm, oil content 85 mg / L;

[0041] 2. Washing water purification device

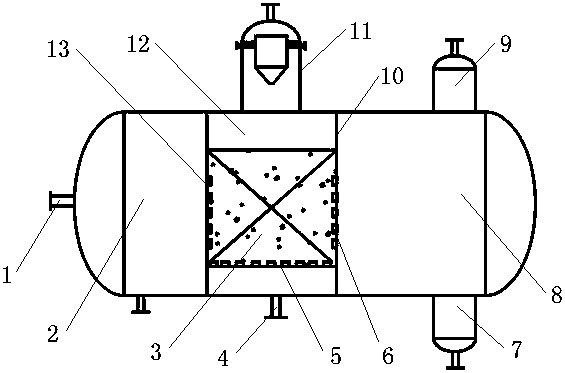

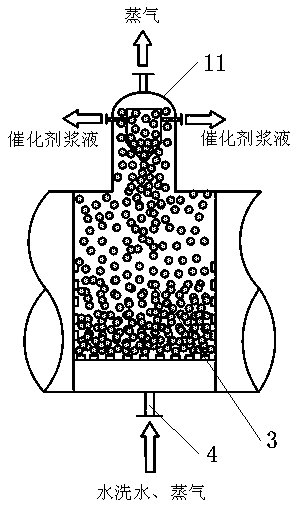

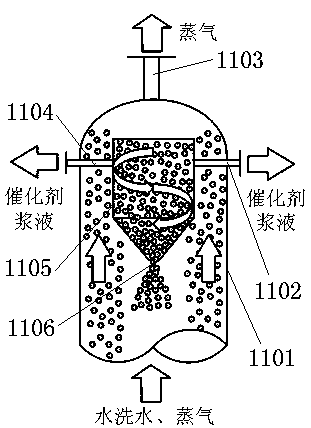

[0042] The device is mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com