Patents

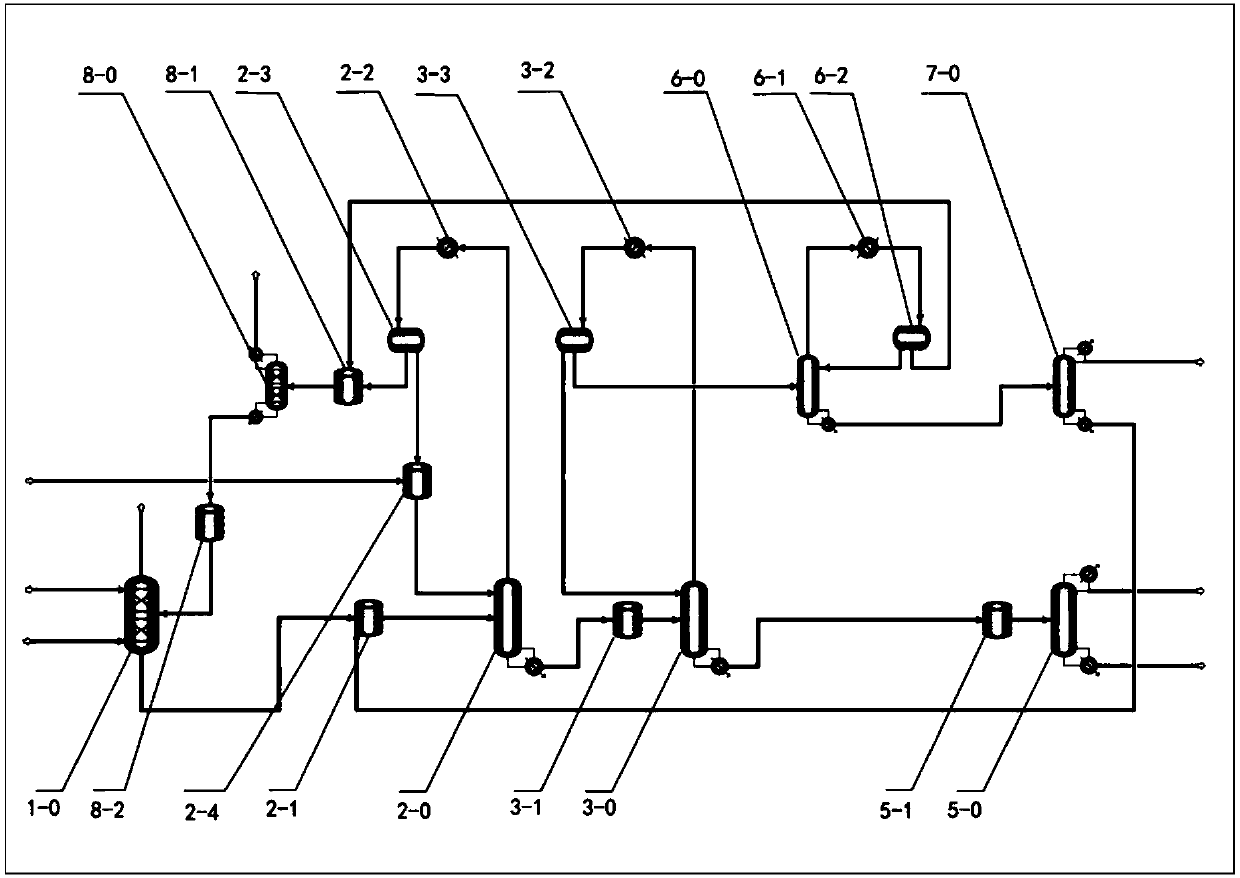

Literature

64results about How to "Long continuous operation period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

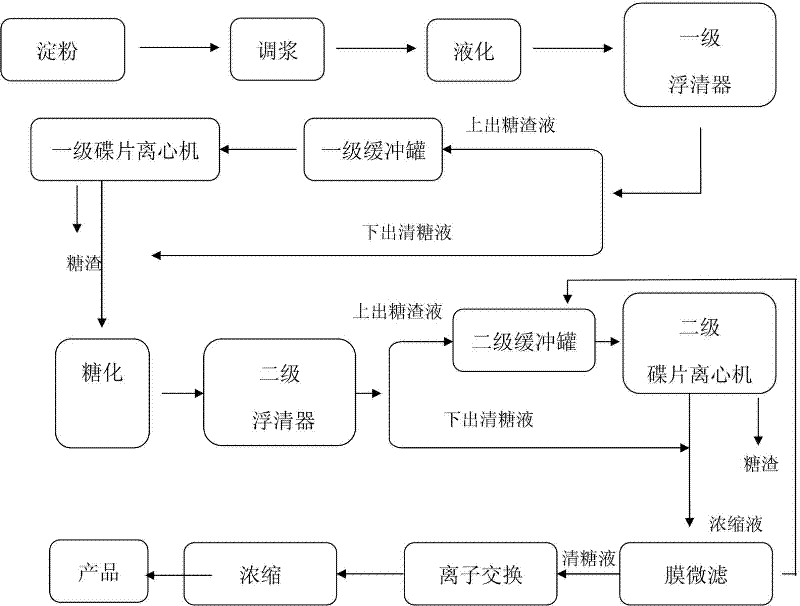

Process for producing starch sugar

ActiveCN102337316AQuality improvementImprove function and effectAnimal feeding stuffAccessory food factorsActivated carbonChaptalization

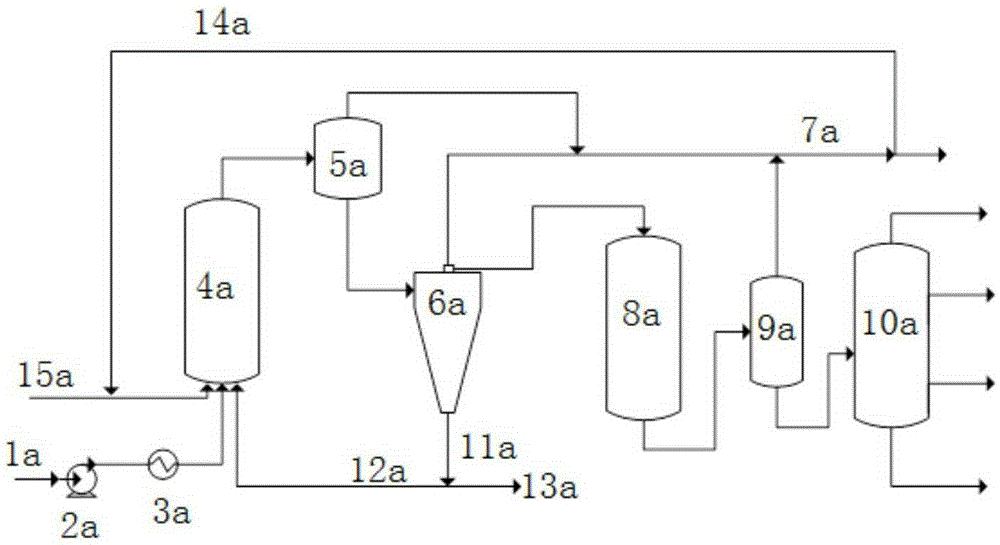

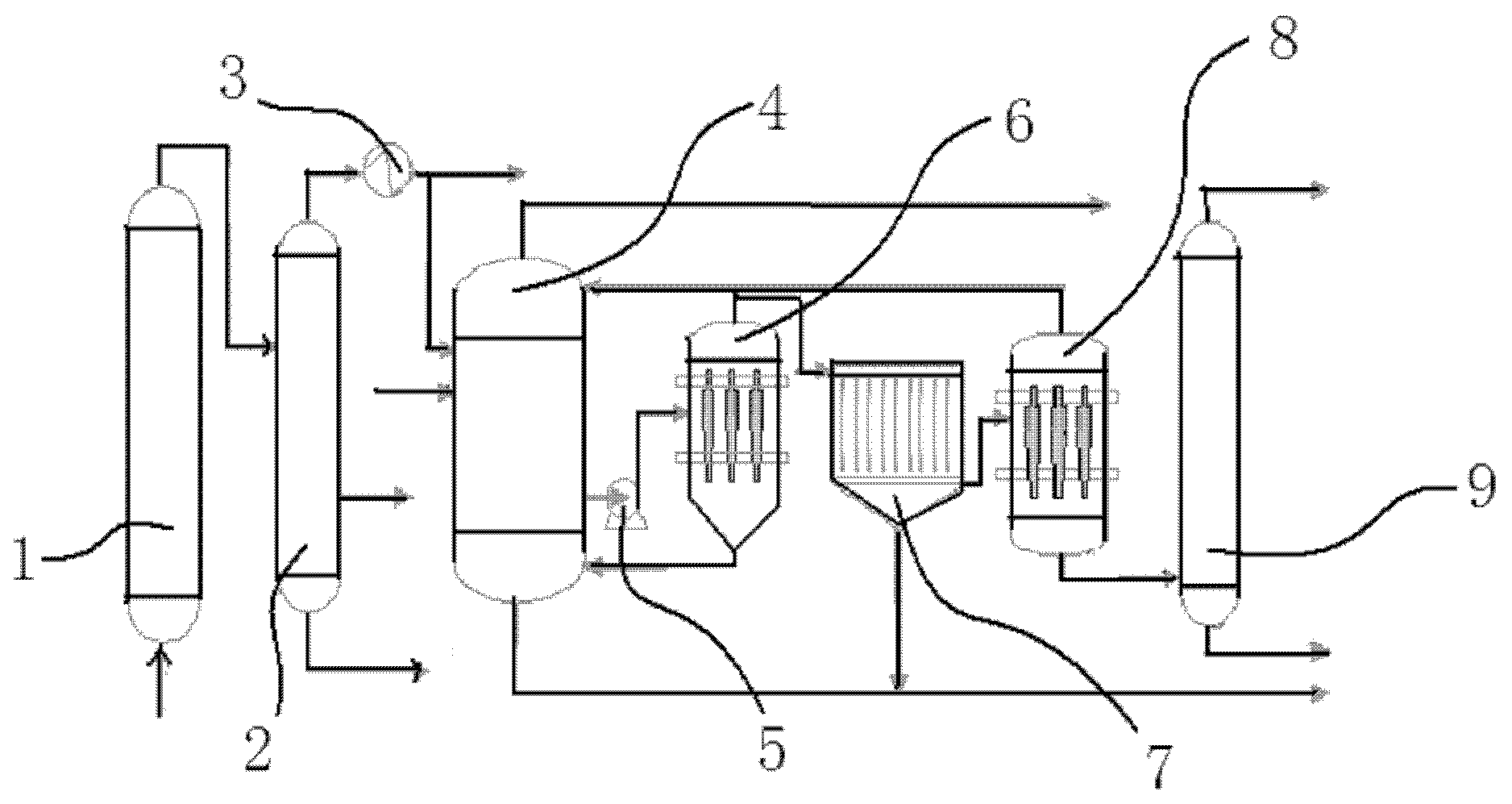

The invention discloses a process for producing starch sugar. The process comprises the following steps of: pulp-conditioning edible starch; liquefying; passing liquefied starch through a primary floating clarifier, guiding an upper floating sugar dreg liquid into a primary buffer tank, and then entering a primary disc-type centrifuge to be centrifugated and separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the primary disc-type centrifuge and a clear sugar liquid flowing out of the primary floating clarifier and flowing into a saccharifying tank to be saccharified into a saccharified liquid; passing the saccharified liquid through a secondary floating clarifier, guiding an upper floating sugar dreg liquid into a secondary buffer tank, and then enteringa secondary disc-type centrifuge to be separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the secondary disc-type centrifuge and a clear sugar liquid flowing out ofthe secondary floating scum clearing device and filtering by passing through a membrane micro-filtration system; and flowing a micro-filtered concentrated liquid containing dregs back to the secondary buffer tank, entering a micro-filtered clear sugar liquid into an ion exchange system to be decolorized and desalted, and then finally concentrating into a product. According to the process for producing the starch sugar disclosed by the invention, filter aids and activated carbon are not required in the clarification and the filtration processes, and high-purity sugar liquid can be obtained through the efficient operation of solid-liquid separation equipment; and meanwhile, sugar dregs without the filter aids and the activated carbon are extracted and can be used as a feedstuff raw materialfor animals, thereby changing waste into valuable, and no discharge of filtered solid wastes during the whole process exists.

Owner:双桥(厦门)有限公司

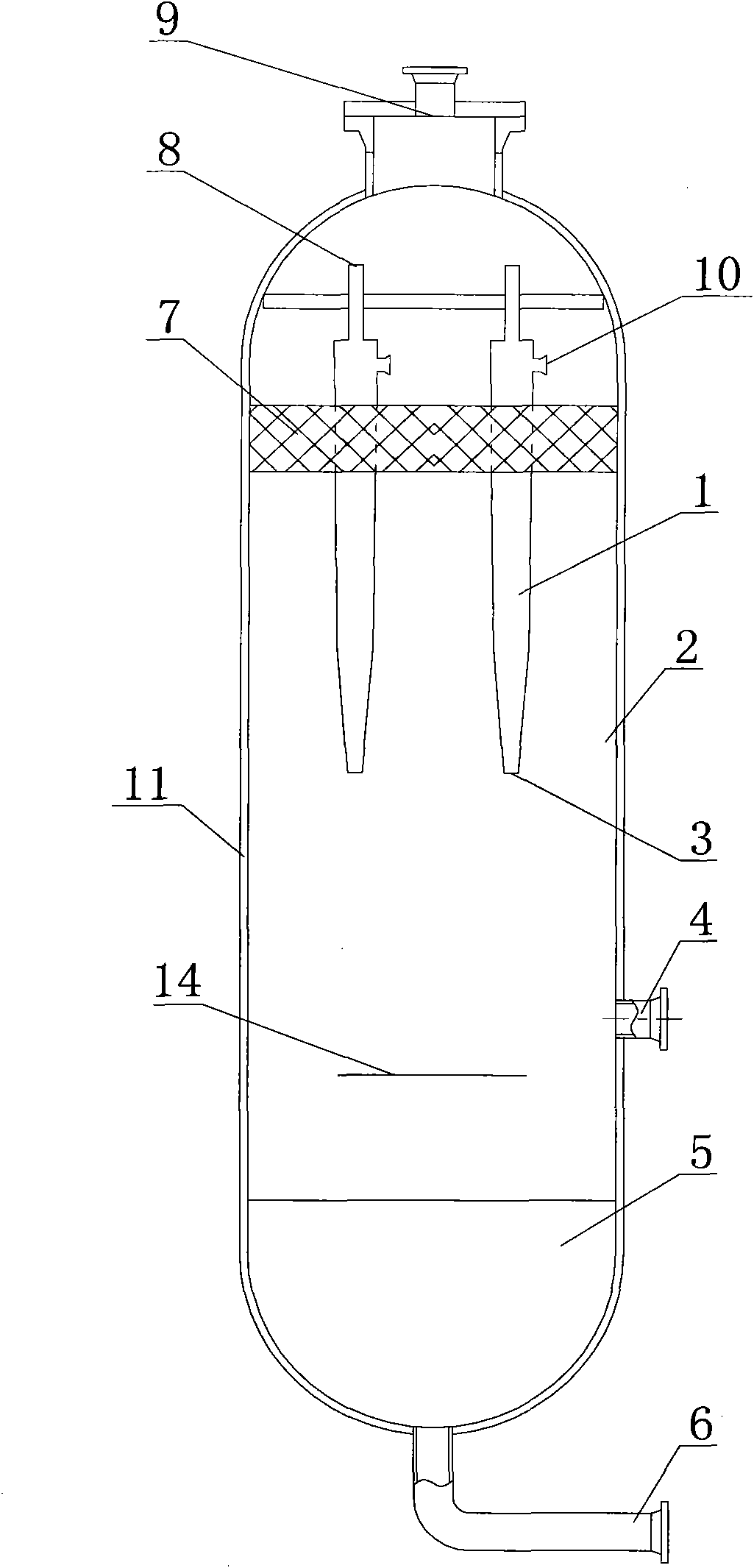

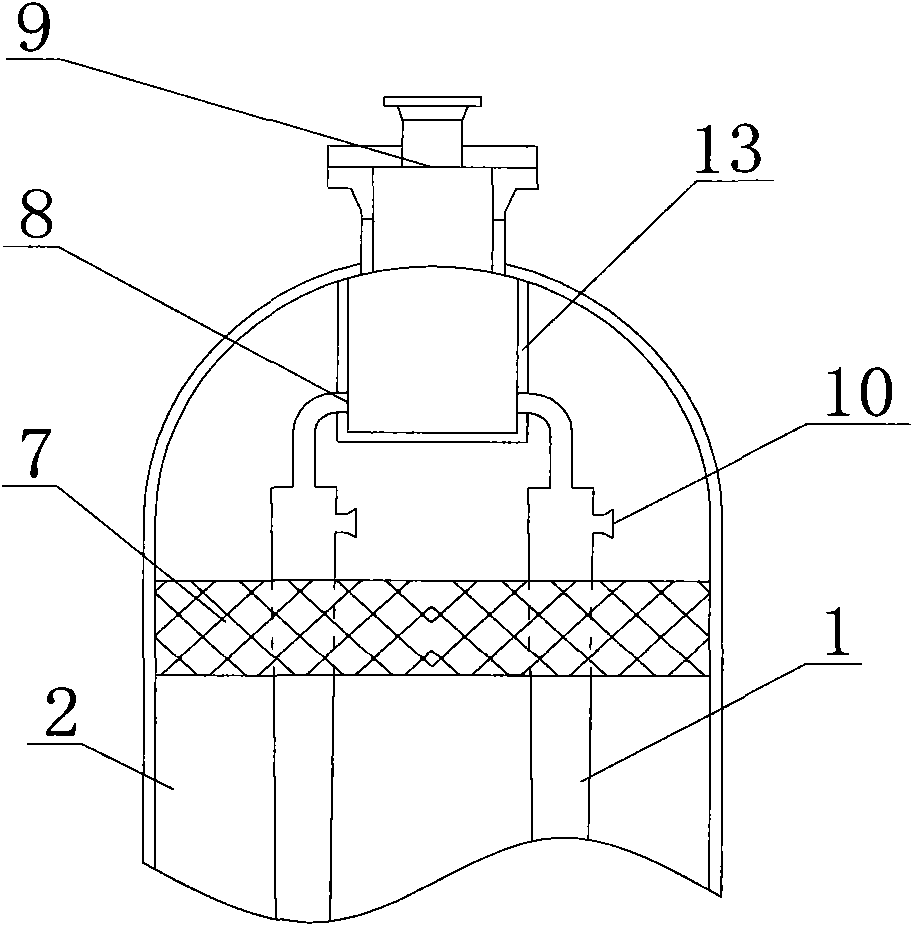

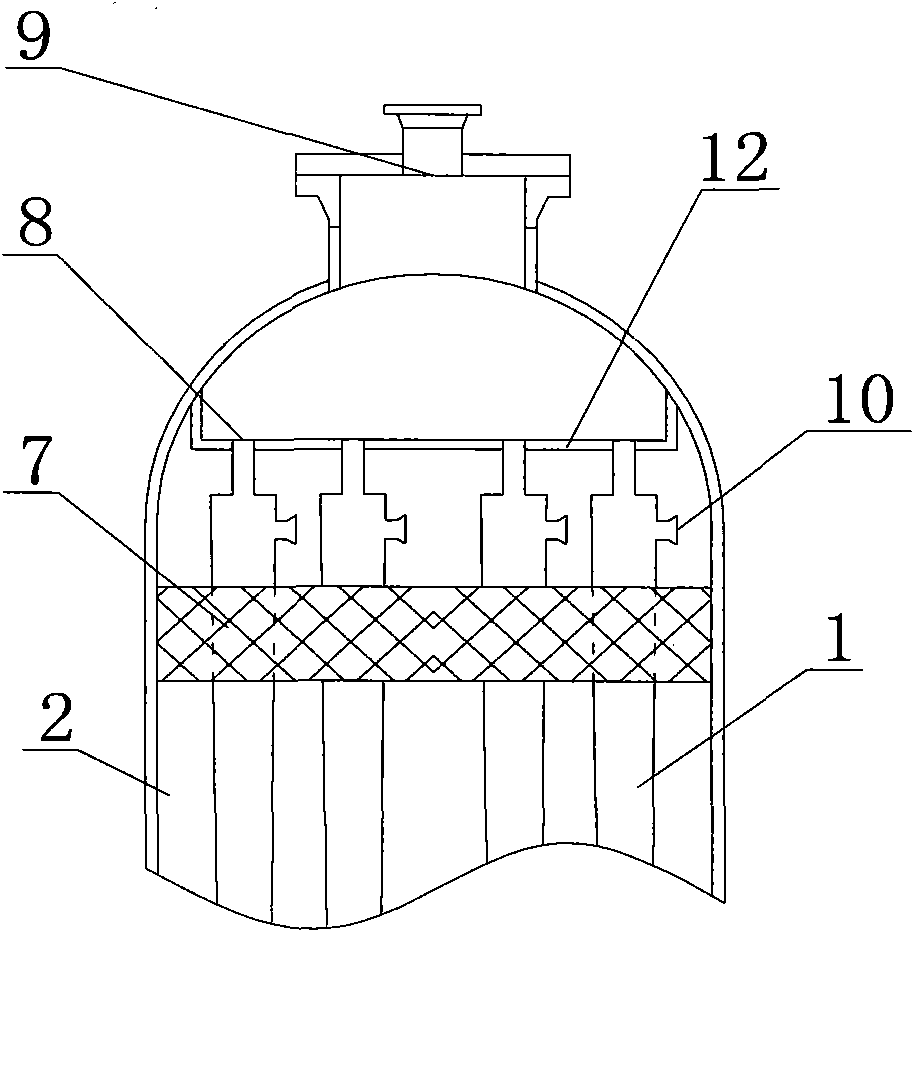

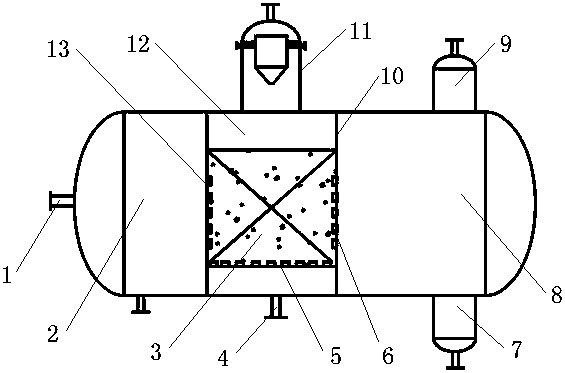

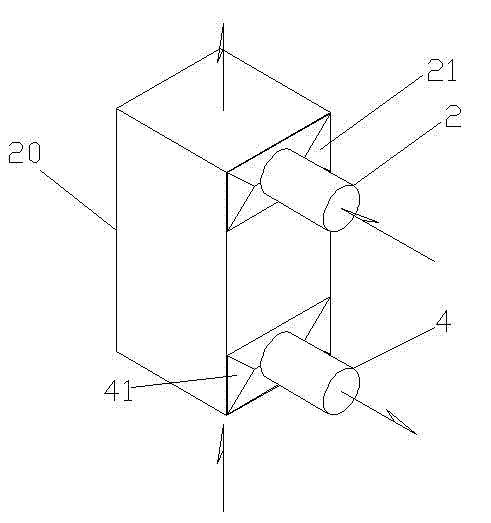

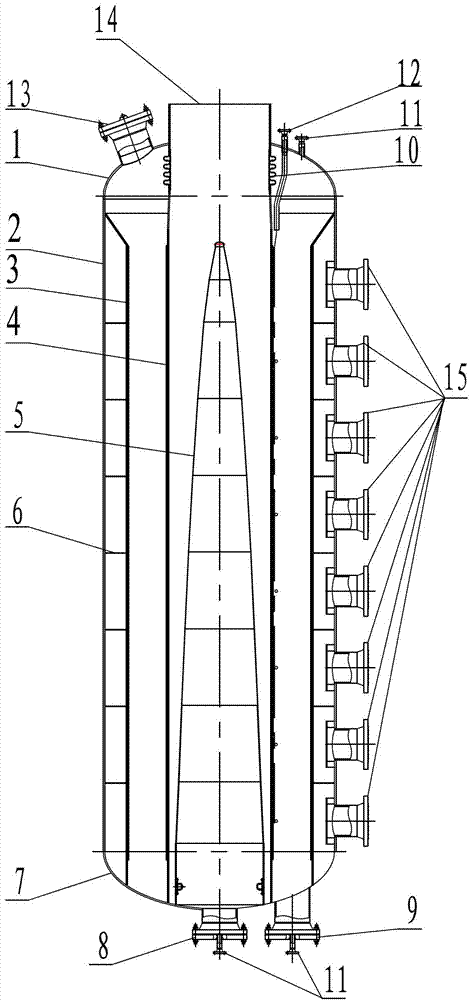

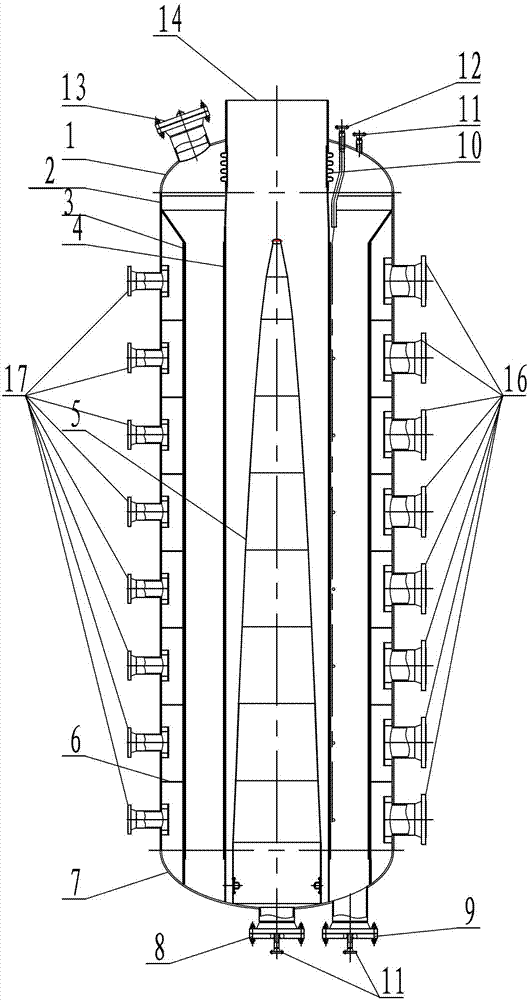

High-pressure separator and method for high-pressure separation

InactiveCN102380262AOvercoming liquid in gas mixtureOvercome the cycleCombination devicesGaseous fuelsCycloneVapor–liquid separator

The invention discloses a high-pressure separator and a method for high-pressure separation, and is characterized in that: a cyclone gas-liquid separator is disposed on the middle-upper part of a housing of the high-pressure separator; the cyclone gas-liquid separator is connected to the housing of the high-pressure separator through a column tray plate or a gas-collecting pipe; mixed gas entering the high-pressure separator is cyclone-separated by the cyclone gas-liquid separator; after oil, water and few solid particles are removed, the gas is discharged from the high-pressure separator. The invention can reduce the gas phase molecular weight of the high-pressure separator, eliminate physical factors which cause foaming of desulfurizers in a desulfurization tower, and prolong the continuous operation period of the whole device.

Owner:CHINA PETROLEUM & CHEM CORP +2

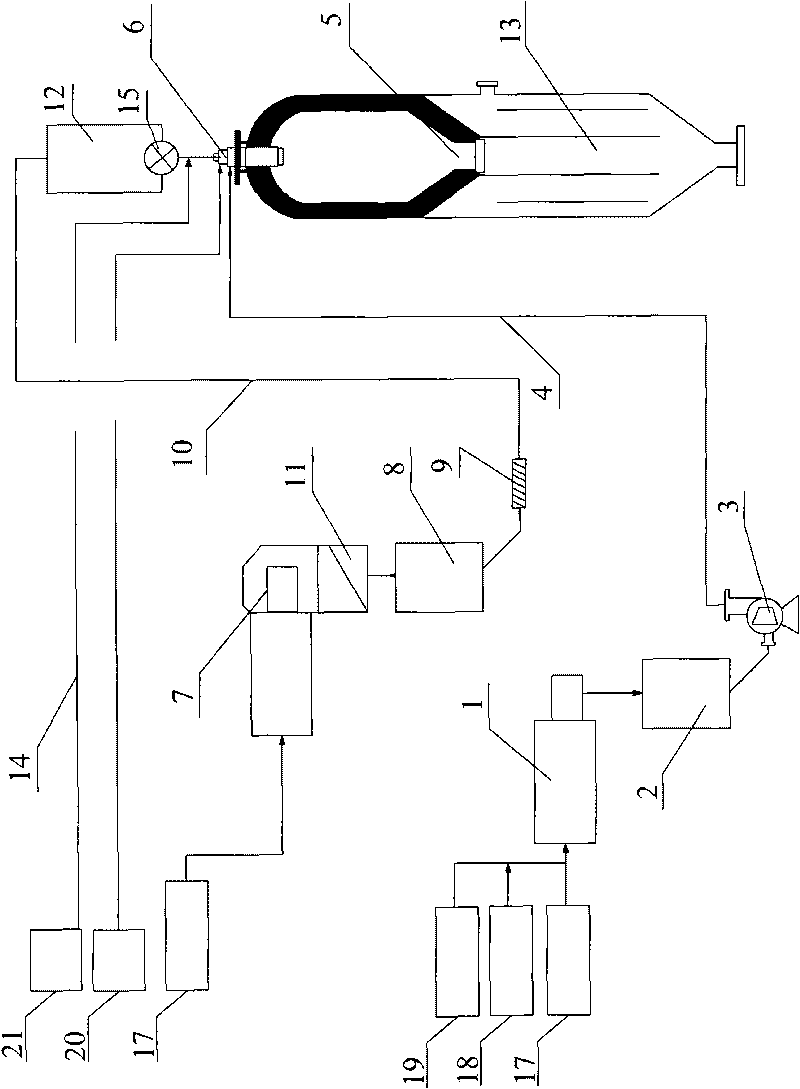

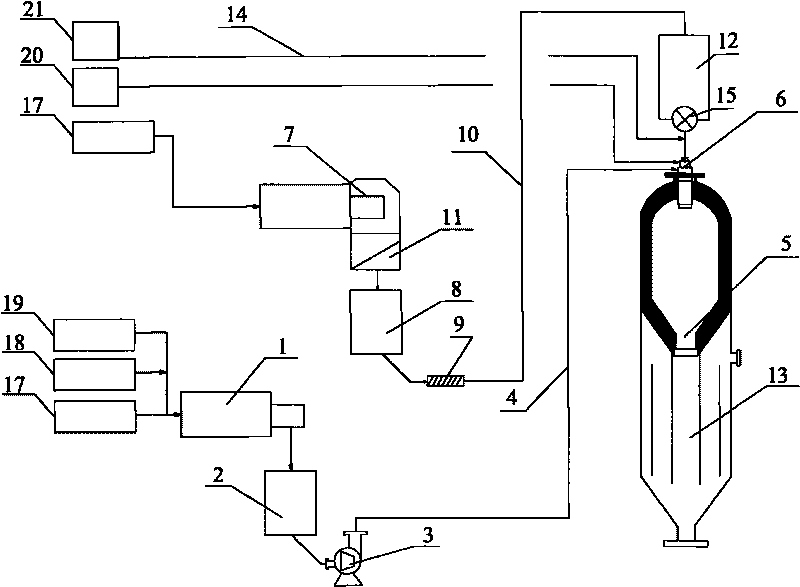

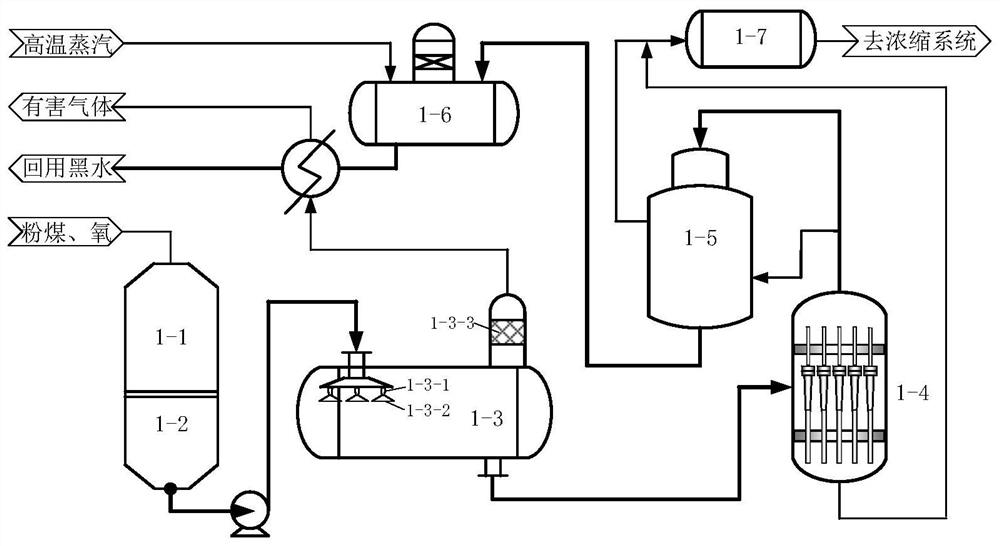

Three-phase multi-raw-material pressurized coal gasification device and process thereof

ActiveCN101760244AIncrease contentReduce contentGranular/pulverulent flues gasificationCombustion chamberEngineering

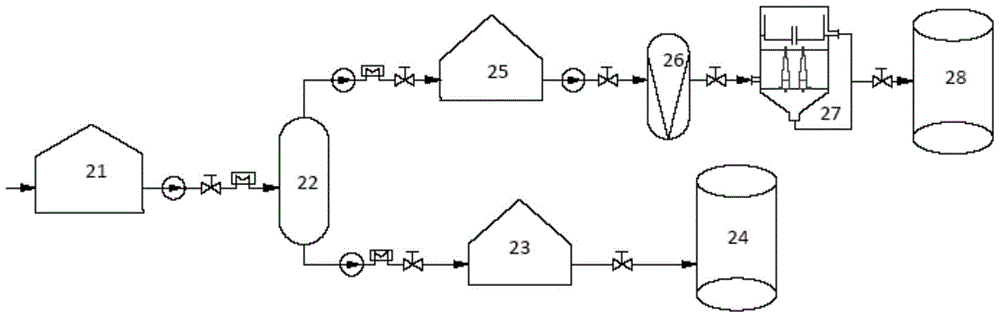

The invention discloses a three-phase multi-raw-material pressurized coal gasification device and a process thereof, which comprises a coal slurry preparing and conveying mechanism, a dry coal powder preparing and conveying mechanism and a pressurized gasification mechanism, wherein the coal slurry preparing and conveying mechanism consists of a coal mill, a coal slurry groove, a high-pressure coal slurry pump, and a high-pressure coal slurry pipeline; the dry coal powder preparing and conveying mechanism consists of a dry powder preparer, a dry powder storage groove, a screw conveyor, a coal powder pipeline and a nozzle feeding bin; and the pressurized gasification mechanism consists of a combustion chamber and a quench chamber. The high-pressure coal slurry pipeline and the nozzle feeding bin are respectively connected with a mixing nozzle which is arranged on the combustion chamber and is communicated with the interior of the combustion chamber. By the combination of multiple phases and multiple raw materials, the pressurized coal gasification device increases the content of carbon in the reactants and increases reacting efficiency and production intensity, and the contents of carbon monoxide and hydrogen in the active ingredients are increased from 80% to 84%-88%, thereby improving the comprehensive utilization ratio of the coal resource and reducing the discharge amount of carbon dioxide.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

Three-phase multi-material three-dimensional pressurized clash coal gasification device and process thereof

ActiveCN101760243AReduce water contentReduce heat lossGranular/pulverulent flues gasificationMulti materialCarbon dioxide

The invention discloses a three-phase multi-material three-dimensional pressurized clash coal gasification device and a process thereof, which comprises a coal slurry preparing and conveying mechanism, a dry coal powder preparing and conveying mechanism and a pressurized gasification mechanism, wherein the coal slurry preparing and conveying mechanism consists of a coal mill, a coal slurry groove, a high-pressure coal slurry pump and a high-pressure coal slurry pipeline; the dry coal powder preparing and conveying mechanism consists of a dry powder preparer, a dry powder storage groove, a screw-rod conveyer, a coal powder pipeline and a nozzle feeding bin; and the pressurized gasification mechanism comprises a combustion chamber and a quench chamber. A water-coal slurry nozzle and a dry coal powder nozzle are arranged on the combustion chamber and are respectively communicated with the interior of the combustion chamber; and the dry coal powder nozzle and the water-coal slurry nozzle are also connected with a high-pressure gas pipeline. The dry coal powder nozzle arranged at the top reduces the damages of the returned air current mixture to the vault and the blind-head firebricks, thereby improving the utilization rate of the equipment. The injection mode of the dry powder and the carbon dioxide at the top increases the content of carbon in the reactants, and the active ingredients in the coal gas are increased to 85% above, thereby improving the utilization ratio of the coal resource and reducing the discharge amount of carbon dioxide.

Owner:SHANDONG HUALU HENGSHENG CHEM IND

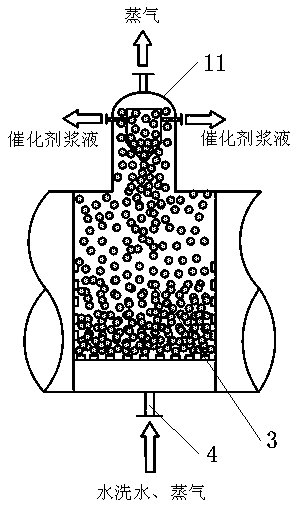

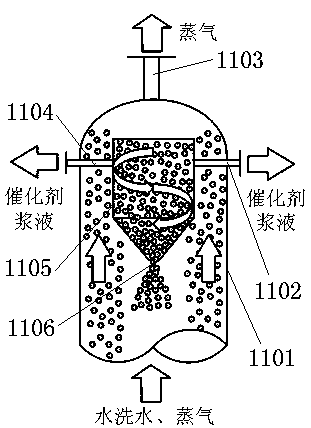

Device and method for purifying methanol-to-olefin device washing water

ActiveCN107720872AAchieve removalGood removal effectFatty/oily/floating substances removal devicesSpecific water treatment objectivesPtru catalystCoal chemical industry

The invention relates to the field of coal chemical wastewater treatment, in particular to a device and a method for purifying methanol-to-olefin device washing water. The method comprises the following steps: pumping out the washing water from the bottom of a washing tower, and sending to a granular-bed separator; enabling the washing water to run through the granular bed in a horizontal direction, intercepting particulate matters in water, and agglomerating microfine oil droplets in the water under the oil substance adsorbing and agglomerating actions of medium particles in the granular bed;performing settling separation on the agglomerated oil droplets under the action of gravity; after the granular bed adsorbs the particulate matters in the water till a saturated state, feeding wastewater from the bottom of the granular bed, mixing with gas, fluidizing the medium particles till a boiling state, releasing solid pollutants between bed layers, and sending the pollutants to a solid concentrating unit along with backwashing liquid. By the method, separation of catalyst particles and the oil substances from the washing water is achieved.

Owner:EAST CHINA UNIV OF SCI & TECH +1

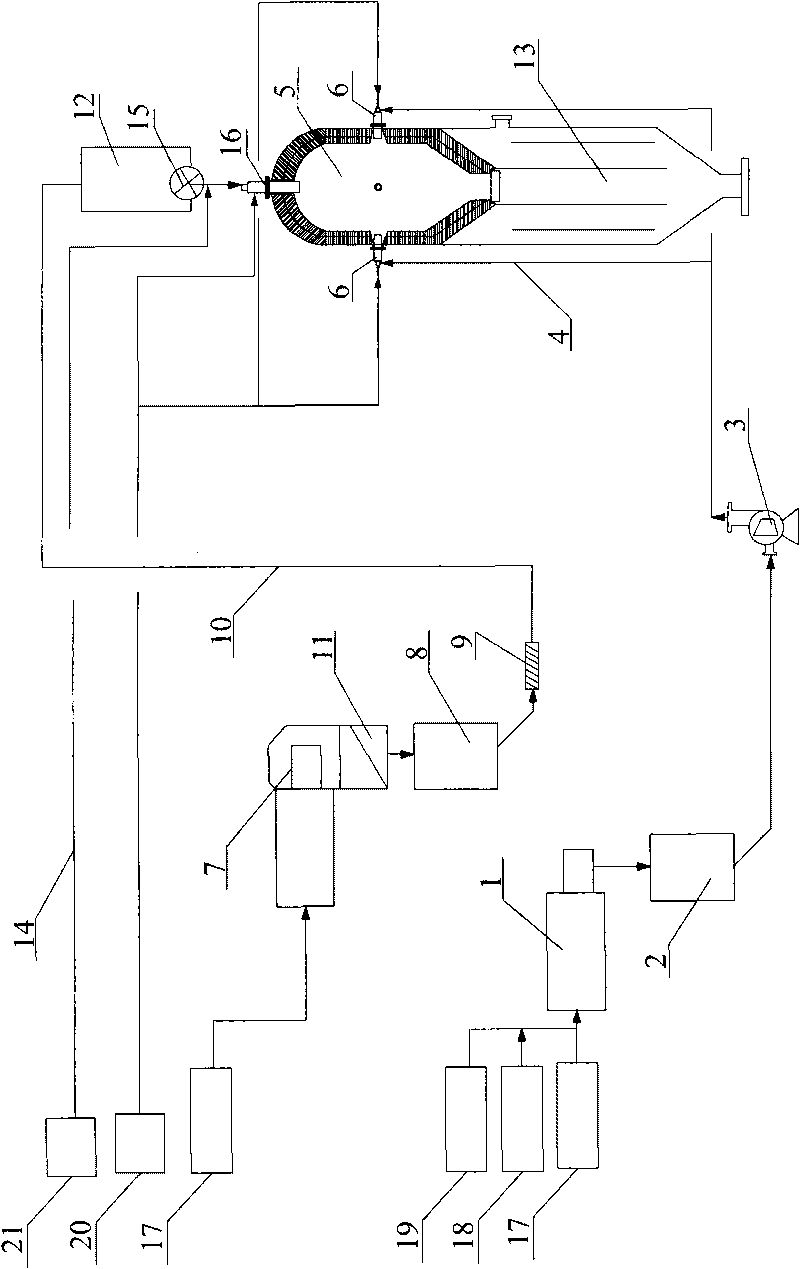

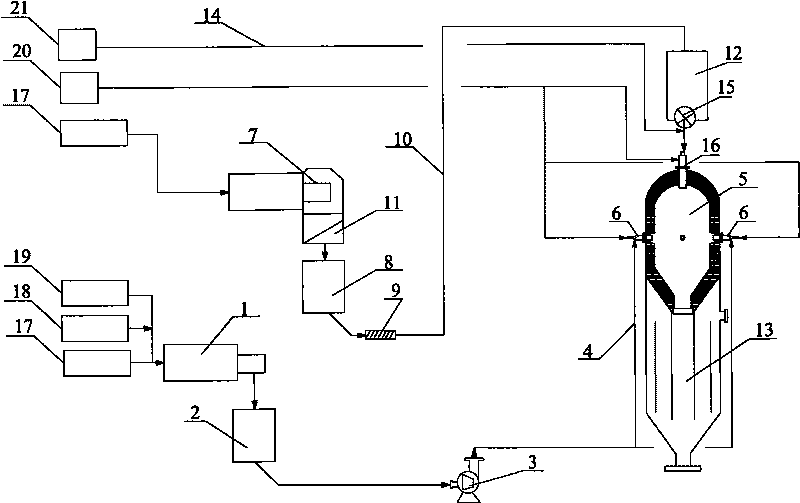

Supergravity hydrate synthesis device

ActiveCN103285781AUniform inflowHigh synthesis efficiencyChemical/physical processesBuffer tankThree-phase

The invention relates to the technical field of hydrate synthesis, storage and transportation and particularly relates to a supergravity hydrate synthesis device. The supergravity hydrate synthesis device comprises a cut-off valve, a one-way liquid valve, a nozzle, a one-way gas valve, a pressure regulating valve, a gas buffer tank, a compressor, a condenser, a turbine flowmeter, an ice maker, a pressure gauge, a pulping machine, a slurry pump, a surfactant storage tank, a Laval spraying valve, a mass flowmeter, a vertical three-phase separator and a supergravity reactor. The supergravity hydrate synthesis device adopts a supergravity technology for enhancing the heat transfer and mass transfer in a hydrate synthesis process, so that the reaction time is shortened, the equipment size decreases, the production cost is reduced, and a tapered outlet is formed so as to be helpful to the outflow of generated hydrates.

Owner:南通东湖国际商务服务有限公司

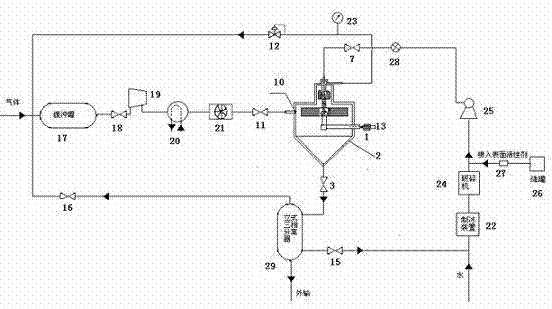

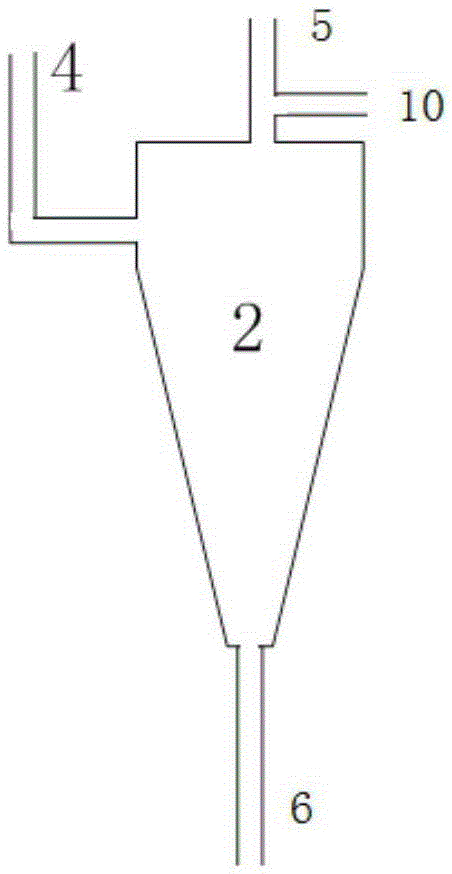

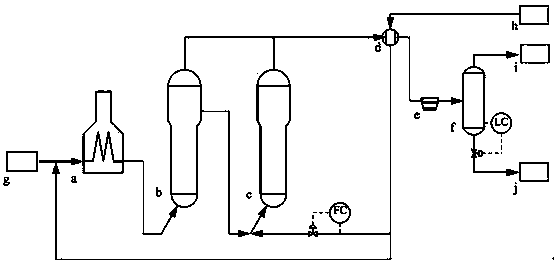

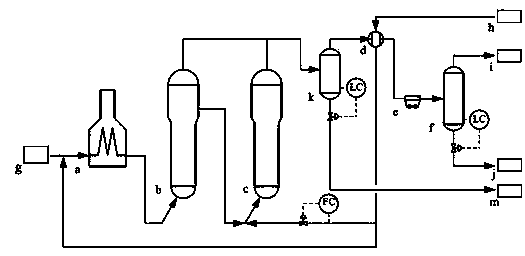

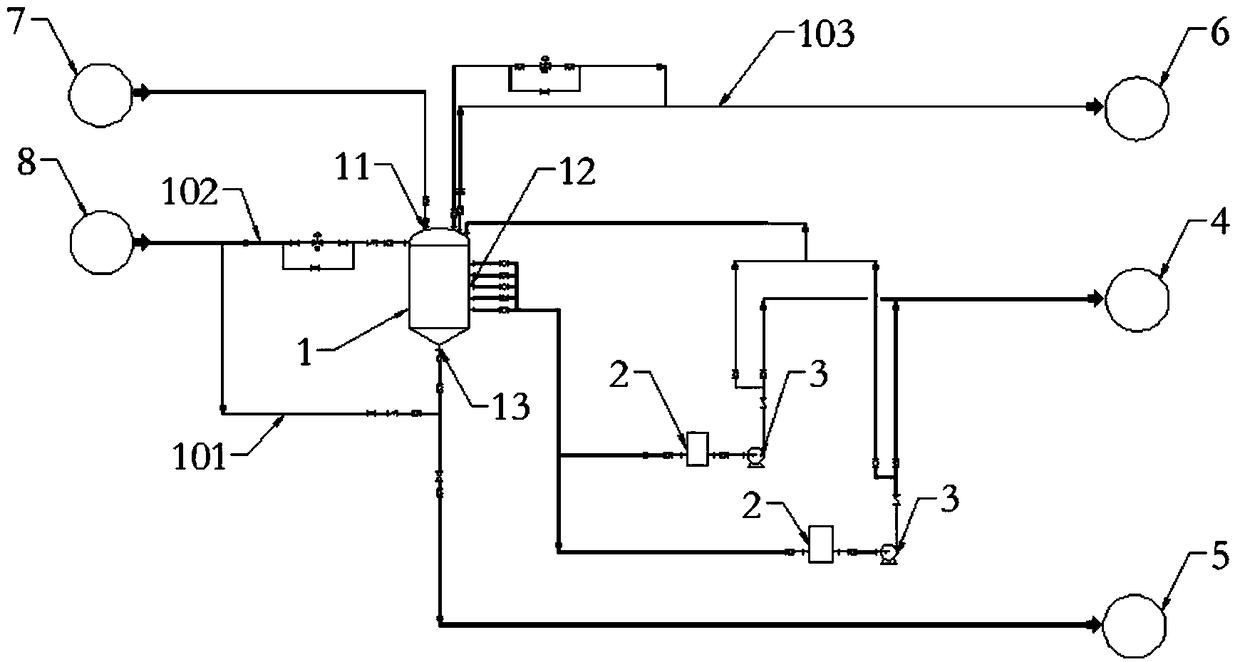

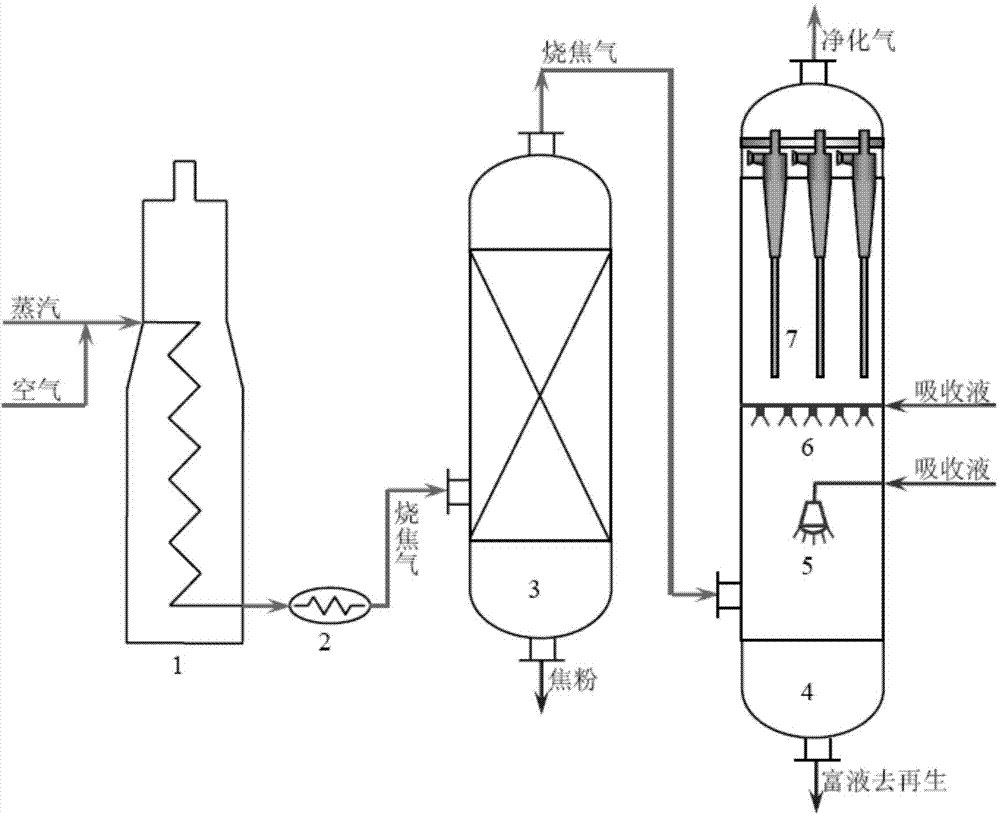

Swirl reinforcing method and device for removing hydrogen sulfide by gas

InactiveCN101564624ALong continuous operation periodImprove separation efficiencyDispersed particle separationMixed gasFuel gas

The invention relates to a swirl reinforcing method and a device for removing hydrogen sulfide by gas, in particular to a swirl reinforcing method for removing hydrogen sulfide by gas. The method comprises the following steps of primarily carrying out a first swirl separation to mixed fuel gas so as to remove the heavy hydrocarbon components mixed wherein; desulfurizing the mixed gas after removing the heavy hydrocarbon components so as to remove the H2S components mixed wherein; carrying out a secondary swirl separation to the mixed gas after removing the H2S components so as to remove the amine-enriched component mixed wherein, thus obtaining a purified gas. The invention also provides a swirl reinforcing device for removing the hydrogen sulfide by gas.

Owner:EAST CHINA UNIV OF SCI & TECH

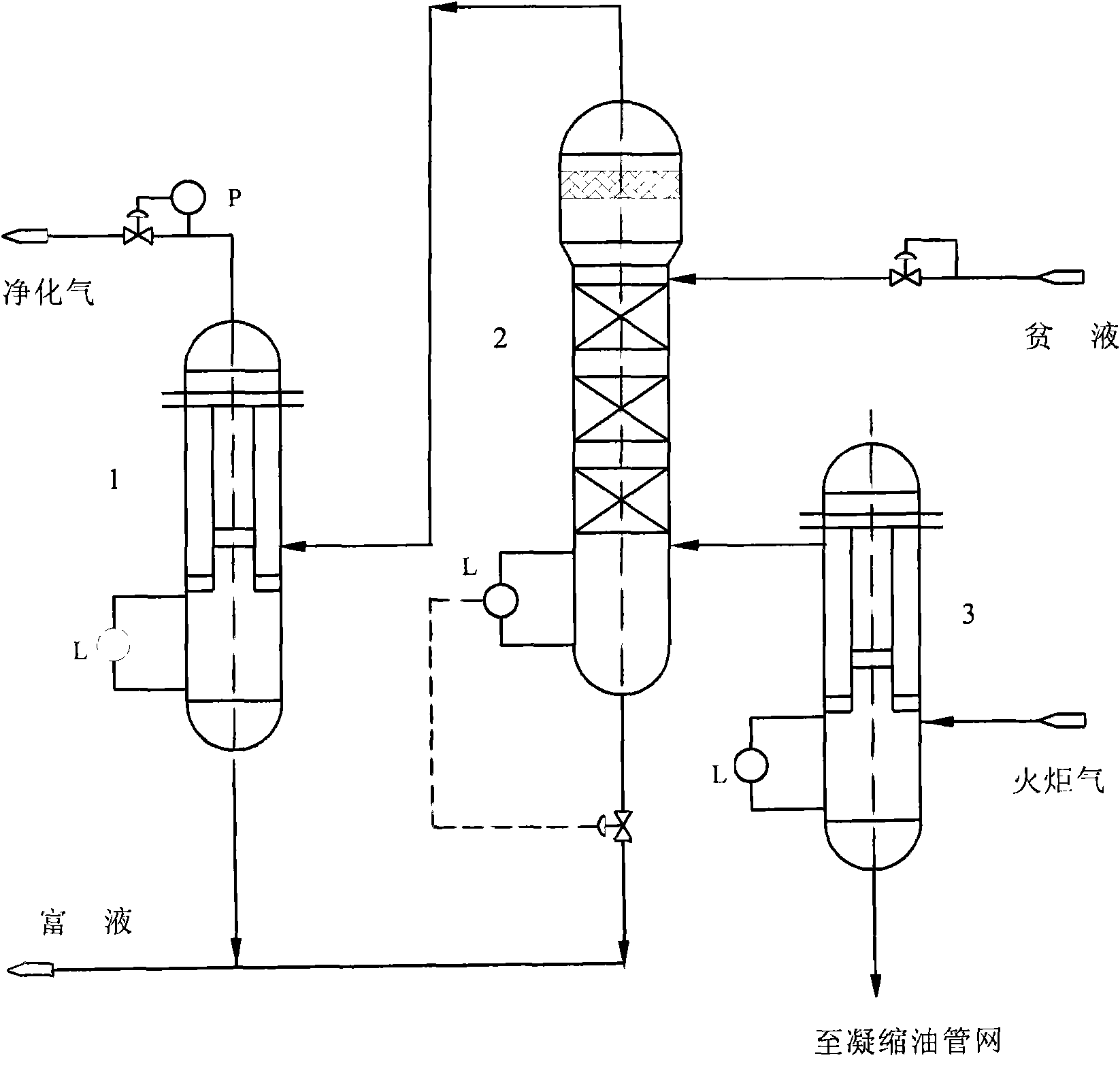

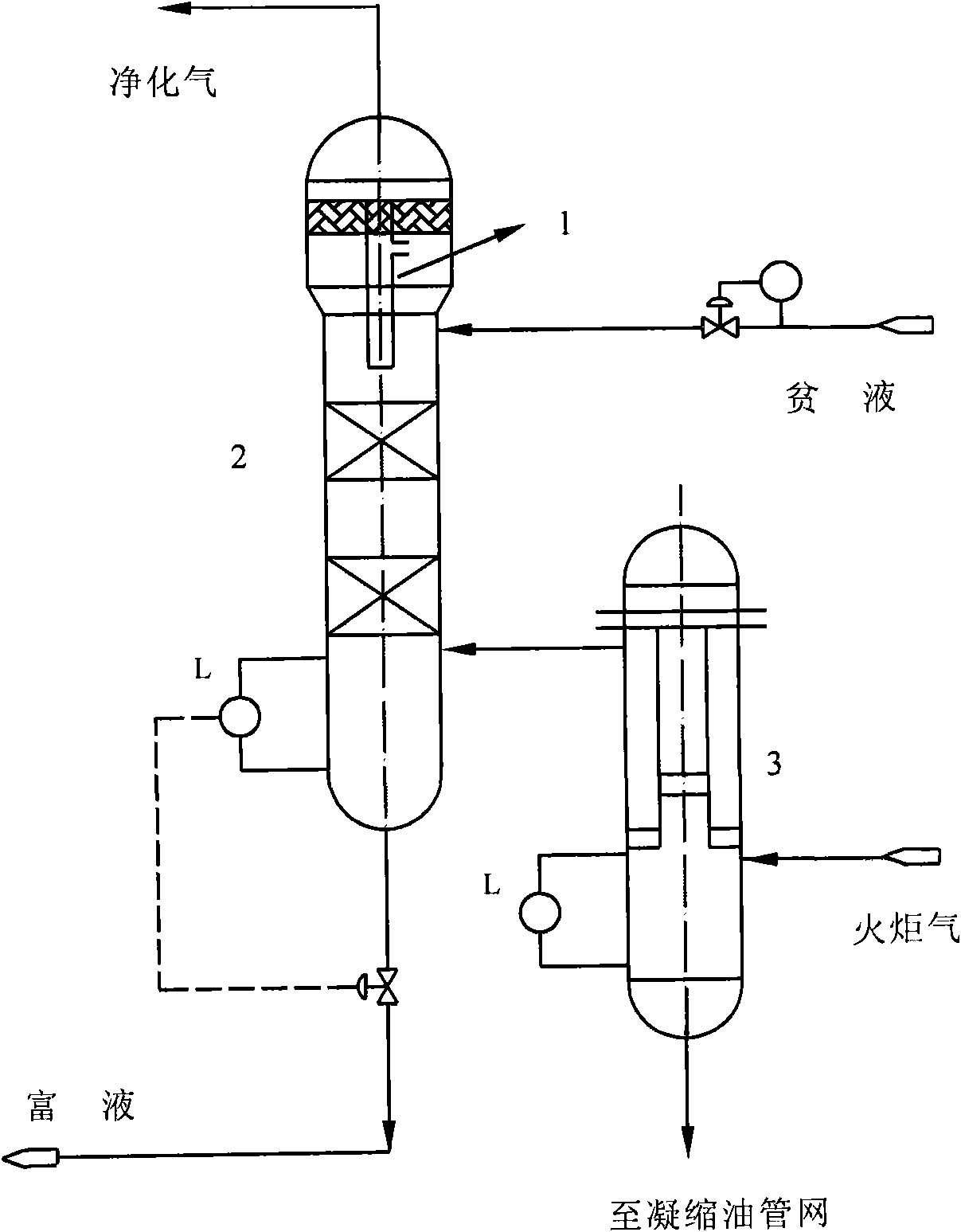

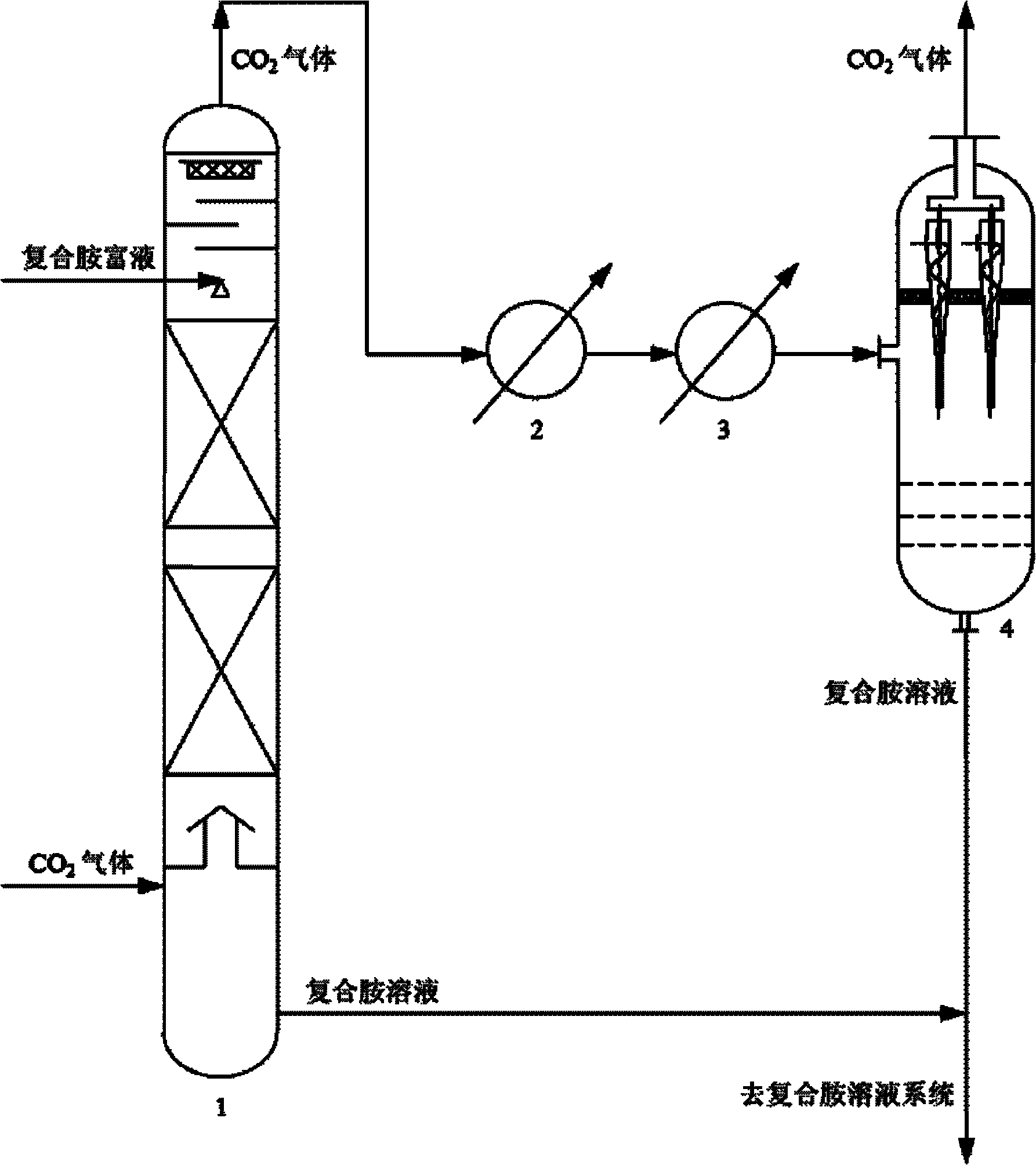

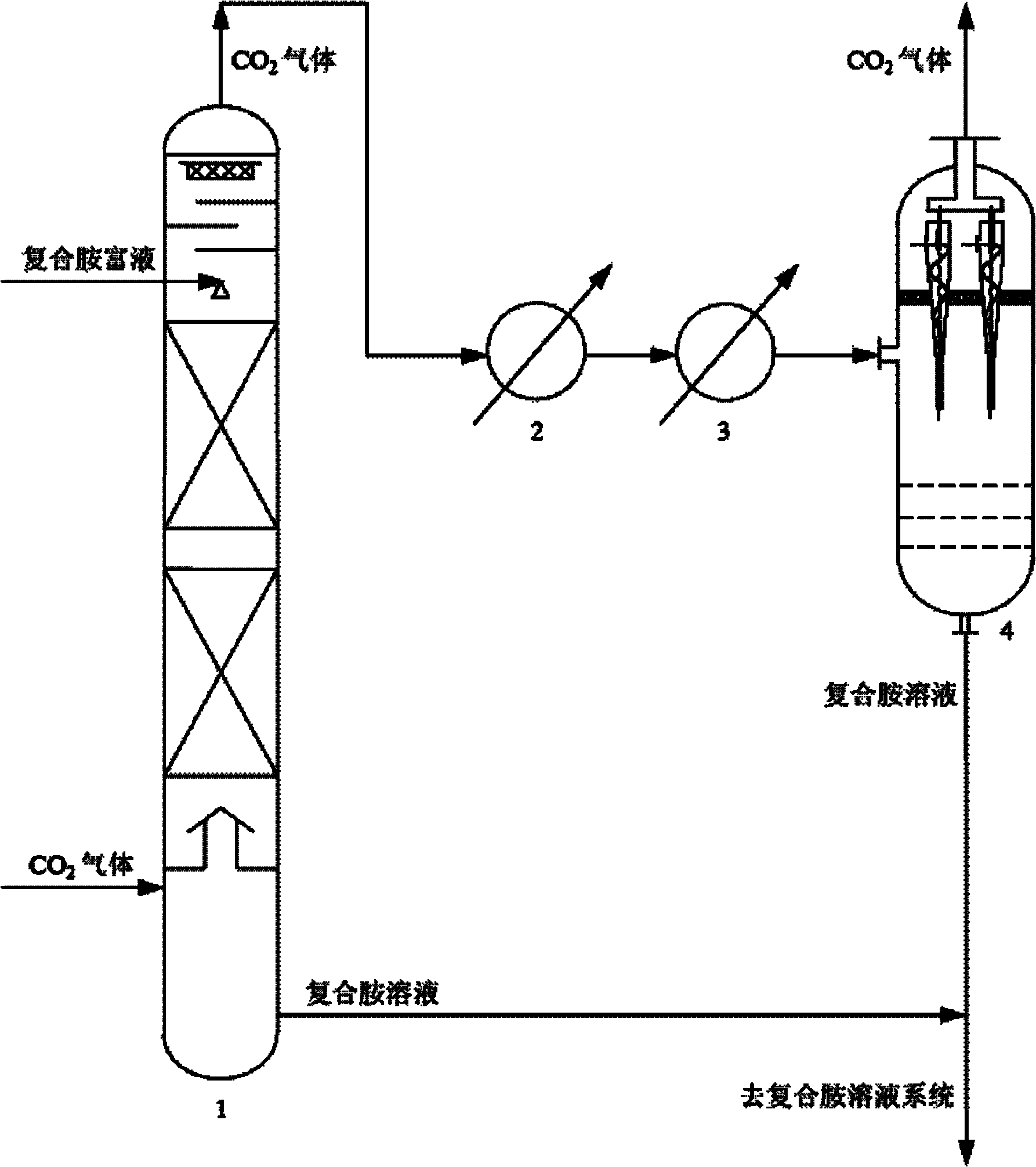

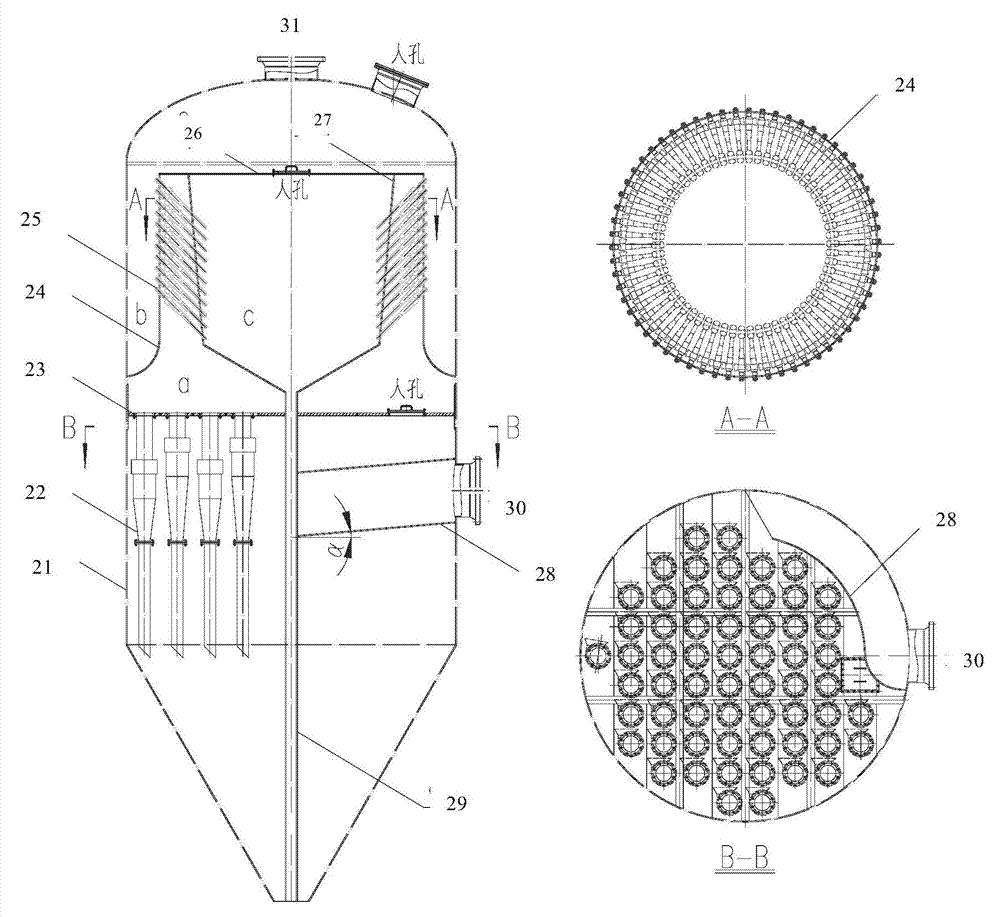

Micro-cyclone liquid collecting method and device for regeneration gas of flue gas and carbon dioxide capture system

InactiveCN102114359AHigh purityReduce consumptionCarbon compoundsDispersed particle separationCycloneFlue gas

The invention relates to a micro-cyclone liquid collecting method and device for regeneration gas of a flue gas and carbon dioxide capture system. The method comprises the following steps: (a) carrying out air cooling and water cooling on the regeneration gas from a regenerating column so as to convert the serotonin solution-containing saturated steam carried in the regeneration gas into fog drops, thus obtaining regeneration gas carrying aerosol particles; (b) performing gas-liquid micro-cyclone separation on the regeneration gas carrying aerosol particles so as to capture the aerosol particles carried in the regeneration gas so as to obtain aerosol particle-removed regeneration gas; and (c) collecting the captured aerosol particles into a liquid, and directly returning the liquid to the serotonin solution system together with the serotonin solution output from the bottom of a regenerating tower.

Owner:EAST CHINA UNIV OF SCI & TECH

Inferior crude oil lightweighting method

ActiveCN106635157AMeet the requirements of hydrogenation feedBroaden sources of raw materialsHydrocarbon oil crackingTreatment with hydrotreatment processesPtru catalystFixed bed

The invention relates to the field of oil refining, and discloses an inferior raw oil lightweighting method. The method comprises the following steps: introducing a reaction material in a slurry bed reactor for a hydrocracking reaction to obtain a hydrocracking mixture; separating the hydrocracking mixture to obtain heavy distillate oil containing a hydrogenation catalyst; introducing the heavy distillate oil in a hydrocyclone separator for separating the heavy distillate oil to obtain the low-density distillate oil of a poor solid content component and high-density tail oil of a rich solid content component; then introducing the low-density distillate oil in a fixed bed hydrotreatment apparatus for a hydrogenation reaction, fractionating the hydrogenation reaction products to obtain hydrogenation tail oil; and circulating the high-density tail oil to the inner space of the slurry bed reactor. The method can efficiently convert the inferior raw oil such as deoiled asphalt and / or high aromatic hydrocarbon component such as ethylene tar, catalytic cracking recycle oil and catalytic cracking slurry to the lightweight distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation technique for low pressure oxygen-enriched air

InactiveCN102213537AReduce energy consumptionLower pressure ratioSolidificationLiquefactionAir filtrationInterference factor

The invention belongs to the field of air separation technology and in particular relates to a separation technique for low pressure oxygen-enriched air, comprising the steps of impurity removal by means of air filtration, compression to 0.33-0.44MPa with an air compressor, purification, heat exchange, rectification, liquid oxygen vaporization and pressurization. The technique has the characteristics of being simple in technological process, convenient in operation, stable and reliable in running, stable in oxygen purity of the product, less in outside interference factors, long in continuous running period, low in power consumption for oxygen generation, low in equipment cost, high in automation degree and convenient in engine start and stop.

Owner:开封黄河空分集团有限公司

Rotational-flow purifying device for gaseous product in fluidized-bed residual oil hydrogenation reactor and method for purifying gaseous product by same

The invention relates to a rotational-flow purifying device for a gaseous product in a fluidized-bed residual oil hydrogenation reactor. The device comprises the fluidized-bed residual oil hydrogenation reactor and a thermal high-pressure gas / hydrogen heat exchanger, wherein a thermal high-pressure flash tank is arranged between the reactor and the heat exchanger, and comprises a thermal high-pressure flash tank shell and an inlet distribution ring arranged in the shell; the inlet distribution ring has a spiral structure and defines a spiral channel together with the thermal high-pressure flash tank shell; a gaseous product inlet is formed in the thermal high-pressure flash tank shell; a tangential inlet guide pipe is mounted on the gaseous product inlet; the thermal high-pressure flash tank also comprises a micro-rotational-flow separator set arranged at the top in the thermal high-pressure flash tank shell. According to the device, the gaseous product in the fluidized-bed residual oil hydrogenation reactor is subjected to stepped rotational-flow separation, so that the entrainment quantity of liquid and catalysts in the gaseous product during a cold high-pressure separation process is reduced, the problem of blockage of the high-pressure heat exchanger is avoided, the energy consumption of a fluidized-bed hydrogenation device is greatly reduced, and the running cycle of the device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +2

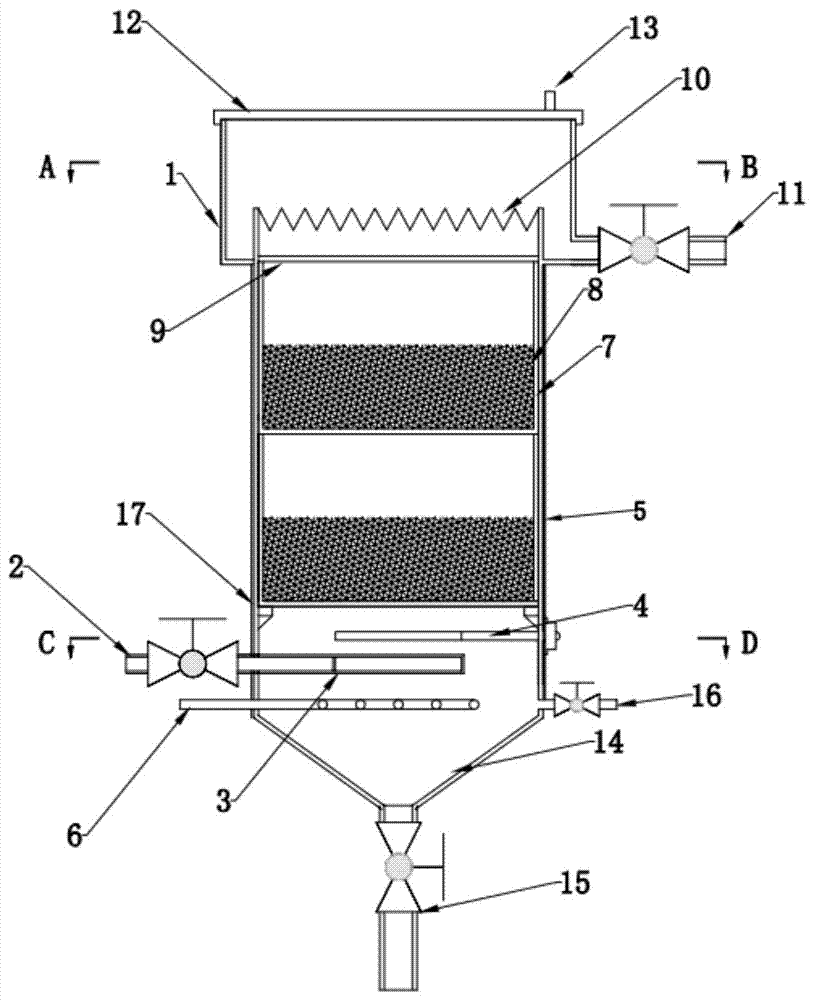

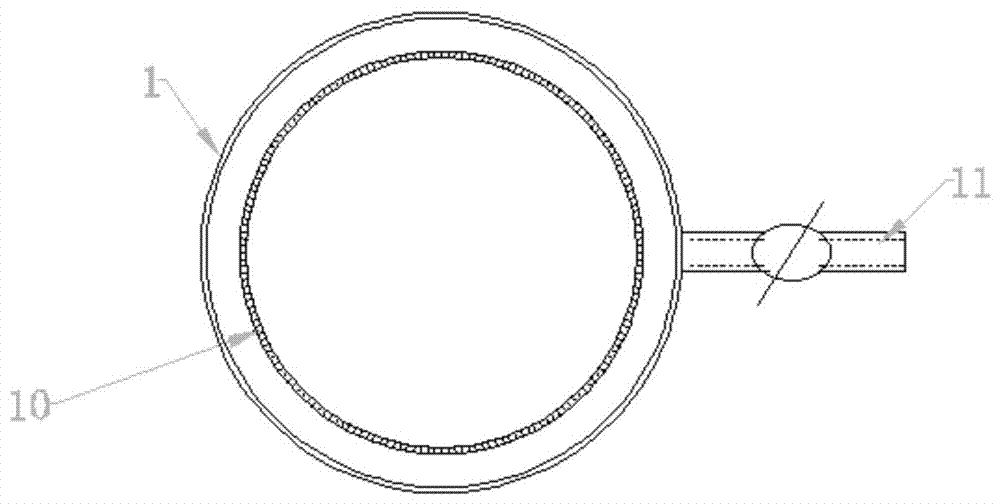

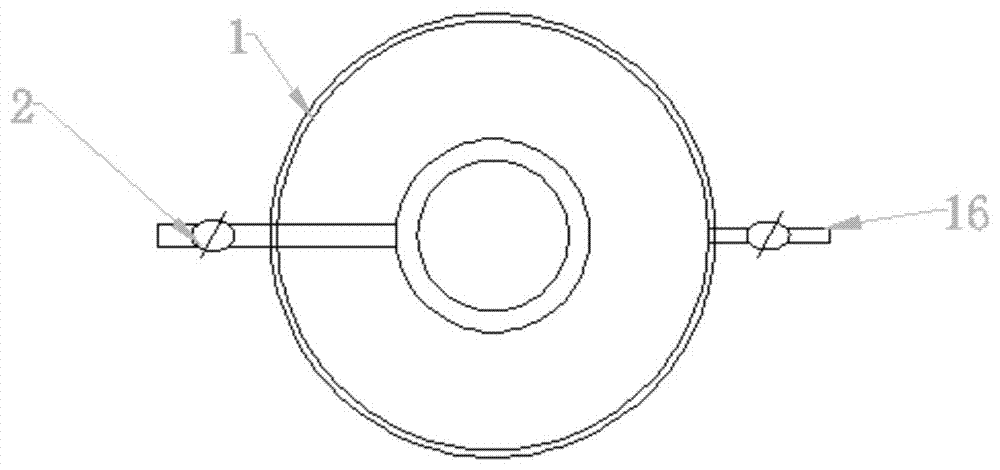

Continuous enlarging cultivation device and method for mineral-bioleaching microorganisms

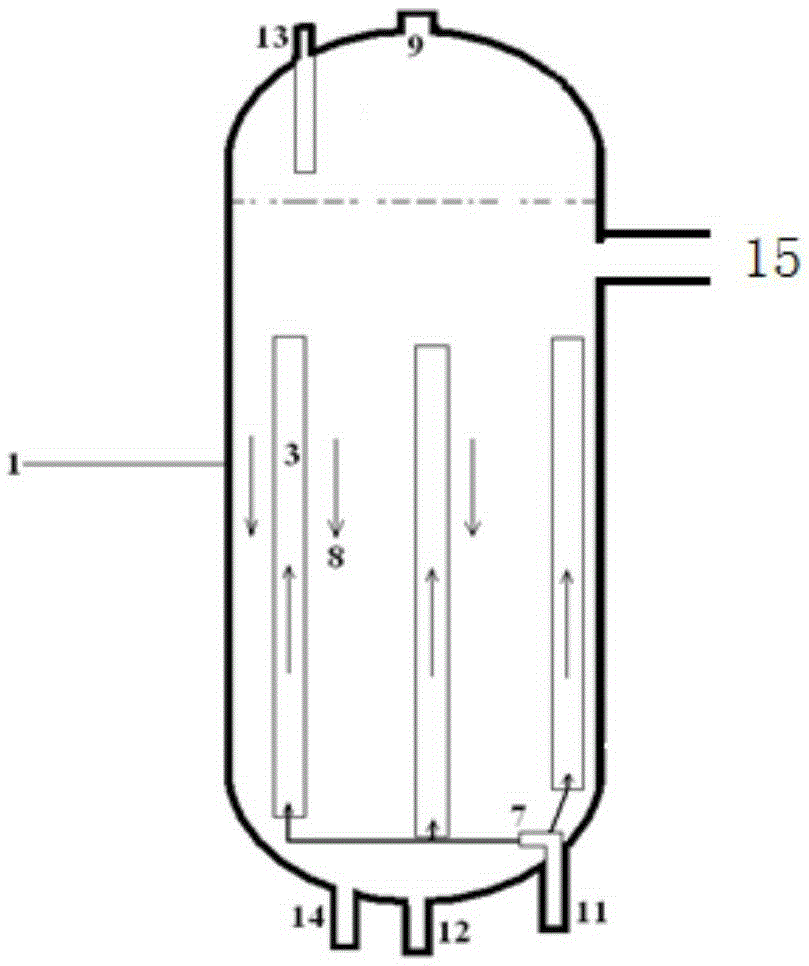

ActiveCN107881081ACompact structureImprove cultivation efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationMicroorganism

The invention discloses a continuous enlarging cultivation device for mineral-bioleaching microorganisms. The cultivation device comprises a cylinder which is formed by sequentially connecting an upper cylinder body, a middle cylinder body and a lower cylinder body, wherein the upper cylinder body can collect feed liquid which is discharged due to overflowing, the middle cylinder body can continuously cultivate the microorganisms in an enlarged mode, and the lower cylinder body can collect discharged precipitates. A detachable multi-layer filler assembly is arranged in the middle cylinder body, the multi-layer filler assembly is composed of a multi-layer filler box and filler which is arranged in the filler box, a heater, a nutrient solution distributing plate and an aeration device are arranged below the multi-layer filler assembly, and the aeration device is arranged below the nutrient solution distributing plate. The cultivation device is simple in design, continuous cultivation canbe achieved, the concentration of the microorganisms in a mature bacteria solution can be improved, and while continuous production of the high-concentration bacteria solution is maintained, the problem about the loss of strains in a reactor is effectively eased. The cultivation efficiency of the mineral-bioleaching microorganisms is improved, and the device has the advantages of being safe, efficient, low in space occupation, low in power consumption, simple and easy in operation and capable of achieving combined cultivation of a plurality of cultivation devices.

Owner:CENT SOUTH UNIV

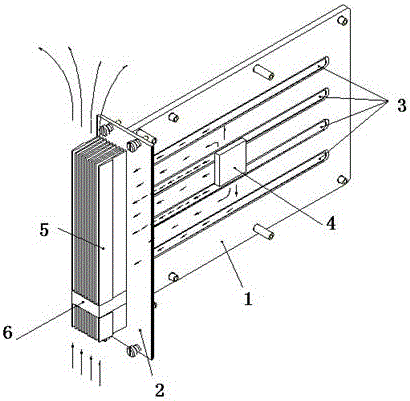

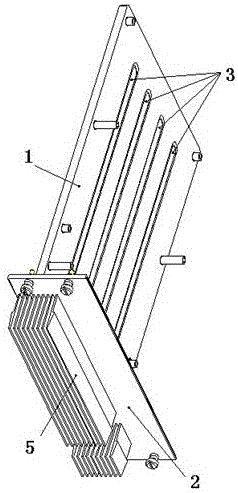

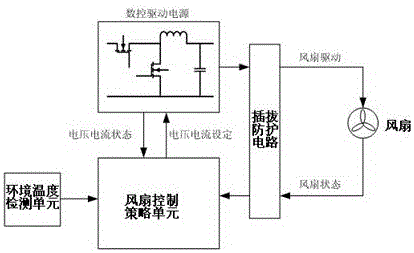

Heat-dissipation assembly suitable for standard 4U cabinet

ActiveCN105979757AExtended service lifeReduce pollutionCooling/ventilation/heating modificationsInterference resistanceHeat conducting

The invention discloses a heat-dissipation assembly suitable for a standard 4U cabinet. The heat-dissipation assembly comprises a heat-conducting plate arranged in the cabinet. The heat-conducting plate is connected with a cabinet plug-in panel; the heat-conducting plate is embedded by a plurality of heat-conducting pipes; the heat-conducting pipes conduct heat to the plug-in panel; a heating element in the cabinet is attached to the heat-conducting plate; the cabinet plug-in panel is externally provided with a heat-dissipation fin; and the heat-dissipation fin is internally embedded by a fan. The heat in the cabinet is conducted to the cabinet plug-in panel through the heat-conducting plate embedded with the heat-conducting pipes, and then, the heat is diffused to the air through the heat-dissipation fin and the fan and through forced air circulation without providing holes in the cabinet, thereby reducing dust pollution of the elements in the cabinet, improving device service life, improving reliability and enhancing anti-interference capability.

Owner:NARI TECH CO LTD +1

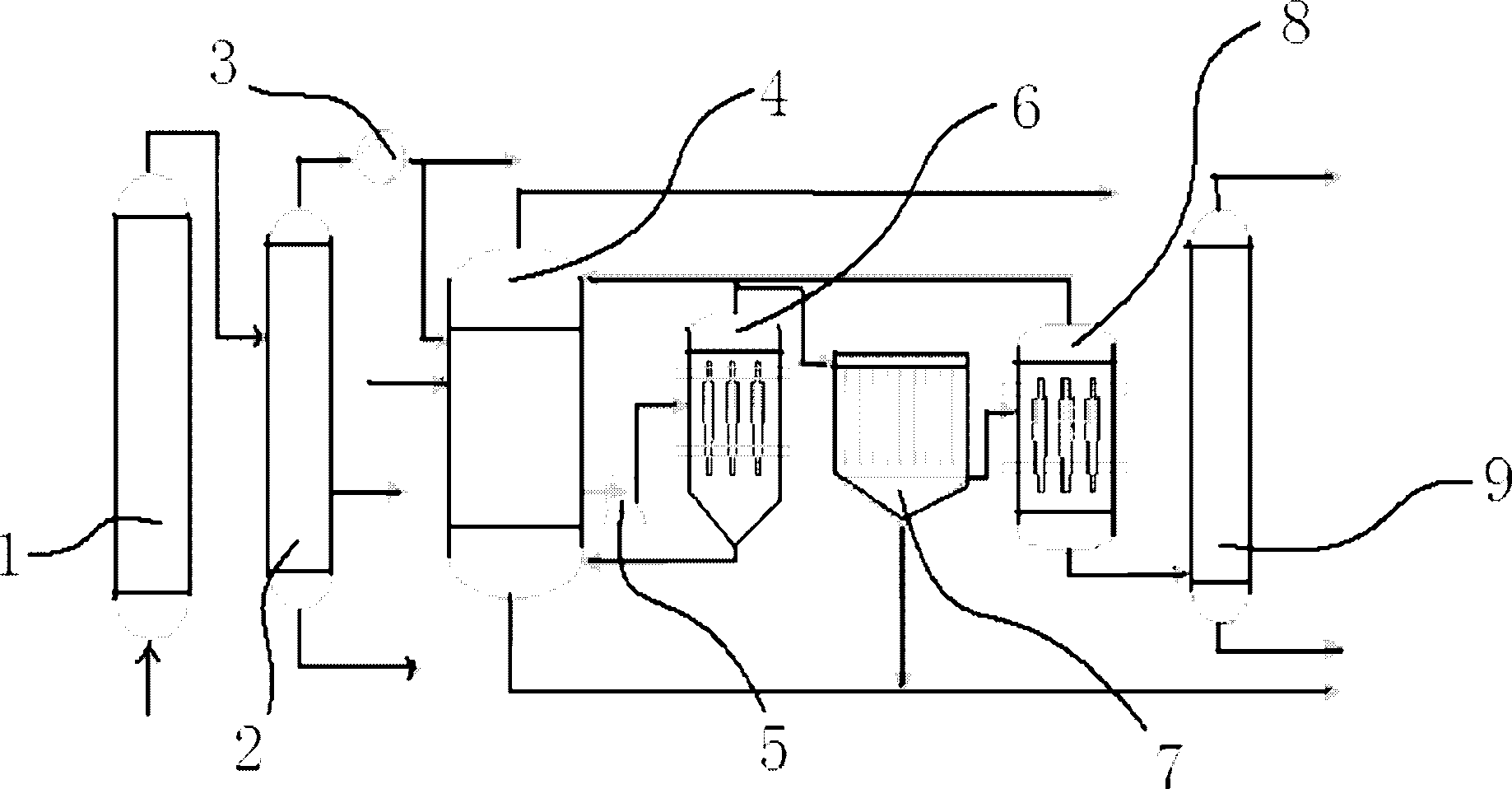

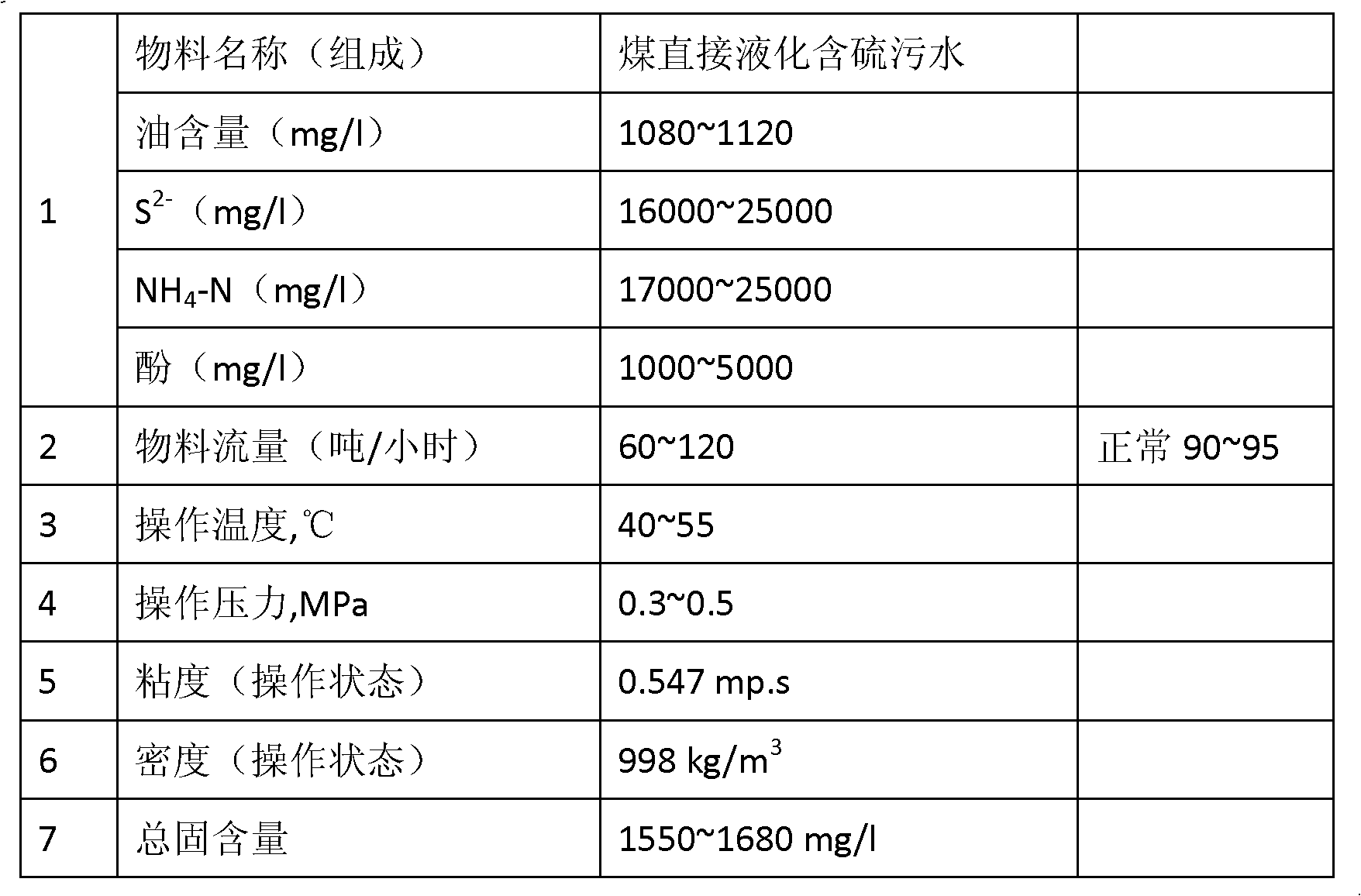

Method and device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water

ActiveCN102583821APrevent sediment cloggingReduce loadWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesCycloneCoal dust

The invention discloses a method and a device for removing coal dust and oil by enabling coal to be directly liquefied and generate sulphur-bearing waste water in the technical field of coal conversion. The method and the device can avoid deposition blocking of the coal dust in a stripping tower, reduce loads of a steam stripping device and improve steam stripping effect, the running cycle of the device is prolonged, simultaneously recycling of dirty oil is facilitated, the processing loss of the device is reduced, and the economic benefit of the device is improved. Besides, a micro cyclone separator and a cyclone deoiler which are adopted in the device are high in separating efficiency, long in continuous running cycle, small in occupied area, high in impact resistance and simple to operate and maintain. The method and the device are characterized in that the device for removing the coal dust and the oil by enabling the coal to be directly liquefied and generate the sulphur-bearing waste water comprises an adjusting tank, a sewage pump, the micro cyclone separator, a precision filter, the cyclone deoiler and the stripping tower; and sewage finally enters into the stripping tower to be treated after the sewage is treated by the adjusting tank, the sewage pump, the micro cyclone separator, the precision filter and the cyclone deoiler.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Chlorosilane-containing slurry treatment method and chlorosilane-containing slurry treatment system

PendingCN108751202AQuality improvementAlleviate problems such as blockingSiliconHalogenated silanesRecovery periodSlurry

The invention belongs to the technical field of polycrystalline silicon production, and relates to a chlorosilane-containing slurry treatment method and a chlorosilane-containing slurry treatment system. The chlorosilane-containing slurry treatment method disclosed by the invention comprises the following steps: chlorosilane-containing slurry gets into a slurry collection tank, and is kept still,and by utilizing the incompatibility and density difference between components in the slurry, the slurry is formed into supernate and bottom turbid liquid in the slurry collection tank; the supernateis discharged out from a plurality of chlorosilane outlets which are arranged at different heights on the slurry collection tank, sequentially passes through a filter and a delivery pump, and gets into a chlorosilane recovery device; and the bottom turbid liquid gets into a washing device from the bottom outlet of the slurry collection tank under the effect of pressure difference and is washed. According to the invention, the chlorosilane recovery rate is high, the quality of recovered chlorosilane is better, and the requirement of electronic-grade polycrystalline silicon production on qualitycan be met. Moreover, the investment of the process is low, safety is good, the continuous operation period is long, later operation and maintenance costs are low, the investment recovery period is short, and risk is low.

Owner:青海黄河上游水电开发有限责任公司新能源分公司 +2

Waste water zero discharge acrylic acid refining device and process

InactiveCN107857701AAchieving zero emissionsAchieve emissionsCarboxylic compound separation/purificationAcetic acidAbsorption column

The invention relates to an acrylic acid refining device with zero discharge of waste water. The device includes an absorption tower, a dehydration tower, an acetic acid removal tower, a weight removal tower, a first circulation system and a second circulation system; the bottom outlet of the absorption tower is connected to the inlet of the dehydration tower through a first storage tank; The top outlet of the dehydration tower is connected with the first circulation system; the bottom outlet of the dehydration tower is connected with the inlet of the deacetic acid tower through the second storage tank; the top outlet of the dehydration tower is connected with the The second circulation system is connected; the bottom outlet of the deacetic acid tower is connected with the weight removal tower through the third storage tank. The invention also relates to a process for refining acrylic acid with zero discharge of waste water. Beneficial effects: the present invention can realize zero discharge of waste water in the true sense.

Owner:张华堂

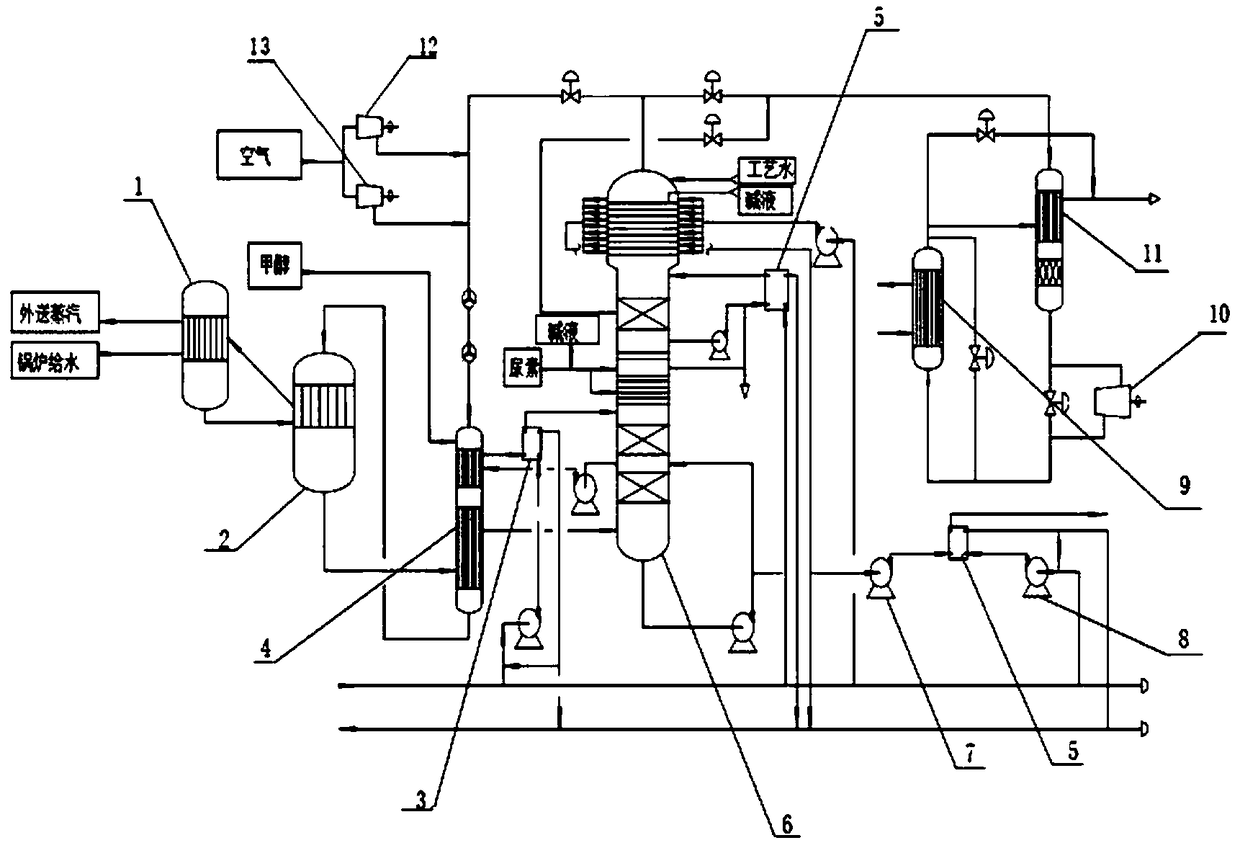

Deep control method and deep control device of pollutant in burning gas of ethane cracking furnace

ActiveCN104117264AEmission reductionReduce pollutionDispersed particle separationCycloneProcess engineering

The invention relates to a deep control method and a deep control device of a pollutant in burning gas of an ethane cracking furnace and provides a deep control method of a pollutant in burning gas of an ethane cracking furnace. The method comprises the following steps: (a) performing micro cyclone separation on the burning gas of the ethane cracking furnace so as to remove solid impurities in gas; (b) washing the gas obtained in the step (a) so as to preliminarily absorb and cool the stinky pollutant in the gas; (c) performing micro cyclone absorption and cooling on the gas obtained in the step (b) so as to deeply absorb and cool the stinky pollutant and absorb enriched liquid and stinky pollutant condensate to separate and recycle; (d) regenerating the absorption enriched liquid obtained in the step (c) for cycle use. The invention further provides the deep control device of pollutant in the burning gas of the ethane cracking furnace.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

Apparatus and method to co-produce formaldehyde and UFC (urea-formaldehyde concentrate) by iron-molybdenum process

PendingCN108689817AIncrease specificationGood consumption indicatorsOrganic compound preparationCarbonyl compound preparationFormaldehyde productSodium hydroxide

An apparatus to co-produce formaldehyde and UFC (urea-formaldehyde concentrate) by iron-molybdenum process comprises a methanol evaporator, a methanol oxidizer and an absorbing column; fresh air and methanol vapor are mixed in the methanol evaporator, and formaldehyde is generated in the methanol oxidizer; formaldehyde vapor enters the absorbing column via the methanol evaporator; in the absorbingcolumn, the formaldehyde vapor is liquefied, and a liquid formaldehyde product is attained from the bottom; urea and an alkali liquid are added into the absorbing column to react with the formaldehyde to obtain UFC. The apparatus has the advantages that consumption indexes are good, single consumption of formaldehyde is 0.422-0.426 t, byproduct vapor specification is high, up to 22 bar 0.75 t / t,oxidation temperature is controlled to 245-380 DEG C, the methanol oxidizer has designed life up to 20 years and longer, the whole apparatus has designed life of not shorter than 35 years, the apparatus is suitable for flexibly producing formaldehyde products having a concentration of 37-55%, UFC can be produced just by proportionally adding an alkali liquid, and in order to further increase absorbing efficiency of process water, sodium hydroxide solution can be injected into the system to remove the byproduct, formic acid.

Owner:江苏道尔顿石化科技有限公司

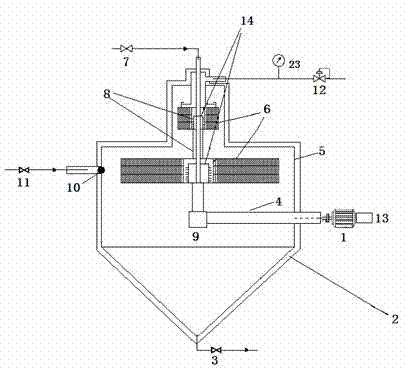

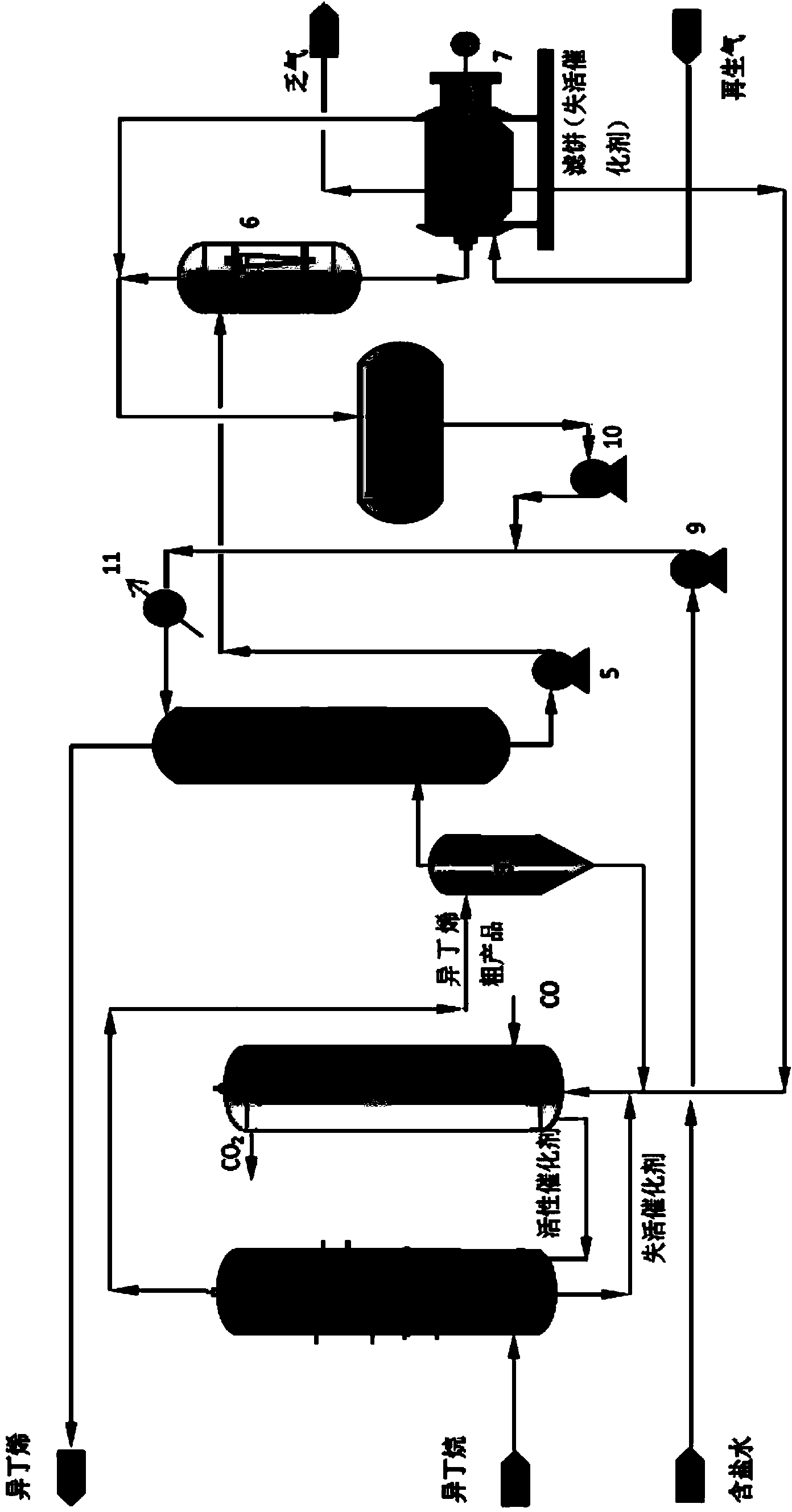

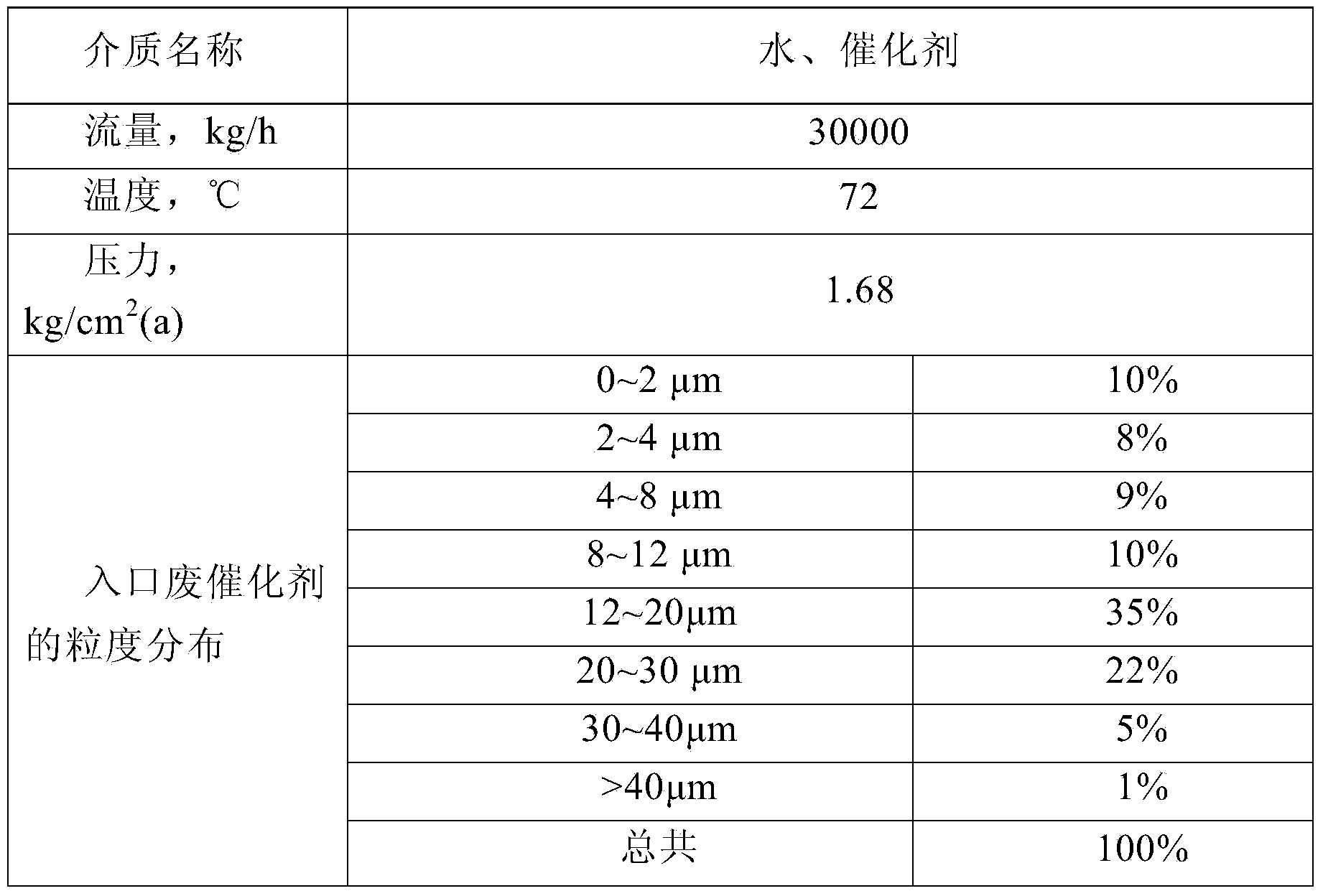

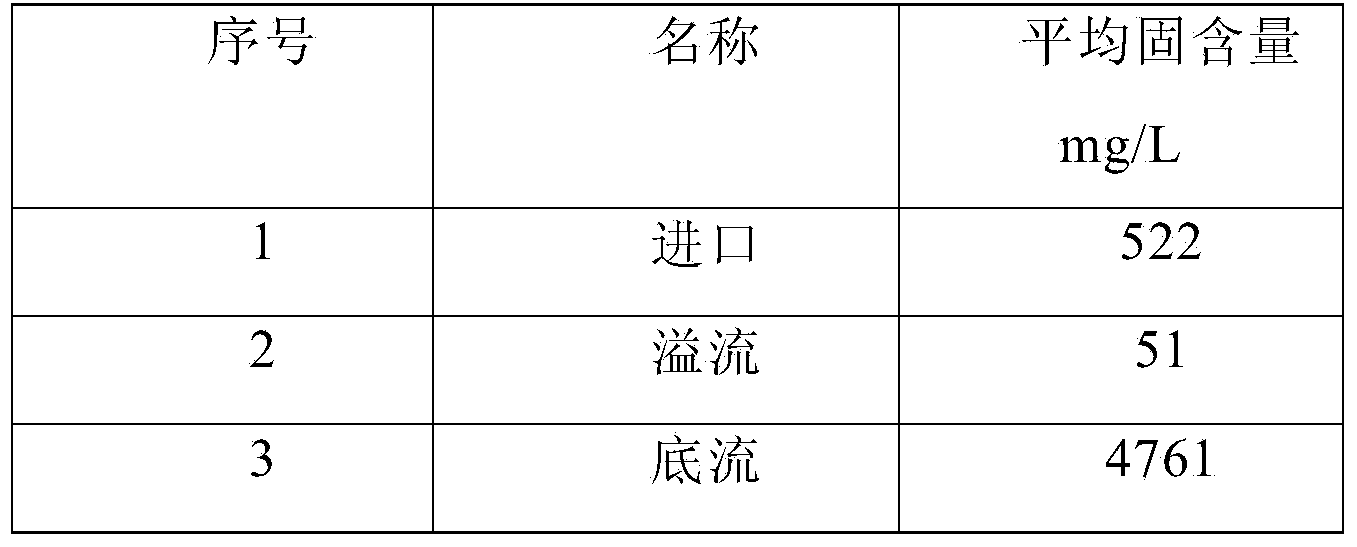

Treatment method and device for concentrating, drying and detoxifying dead catalyst entrained in isobutylene during preparation of isobutylene by isobutane dehydrogenation

ActiveCN103706378ARealize detoxification and recyclingReduce consumptionCatalyst regeneration/reactivationCatalystsWater contentChemistry

The invention relates to a treatment method and device for concentrating, drying and detoxifying a dead catalyst entrained in isobutylene during preparation of the isobutylene by isobutane dehydrogenation. The method comprises the following steps: (a) washing a high-temperature isobutene gas generated by isobutane cracking reaction by using circulating cooling water, so as to obtain a washing wastewater containing the dead catalyst; (b) concentrating dead catalyst particles in the obtained washing wastewater by adopting micro cyclone separation, so as to obtain dead catalyst concentrate; (c) carrying out pressure filtration on the obtained dead catalyst concentrate, so as to further remove free water in the concentrate, thus obtaining a dead catalyst filter cake; (d) baking the obtained dead catalyst filter cake by using a flue gas discharged by a regenerator during preparation of the isobutylene by isobutane dehydrogenation to obtain a wet catalyst filter cake with low moisture content, and simultaneously raising the temperature of the wet catalyst filter cake by using the heat of the regenerated gas; and (e) introducing a CO gas to the regenerator, and carrying out redox reaction to generate a catalyst.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

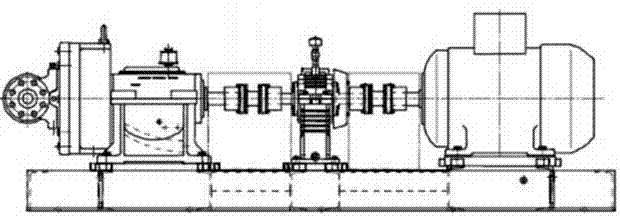

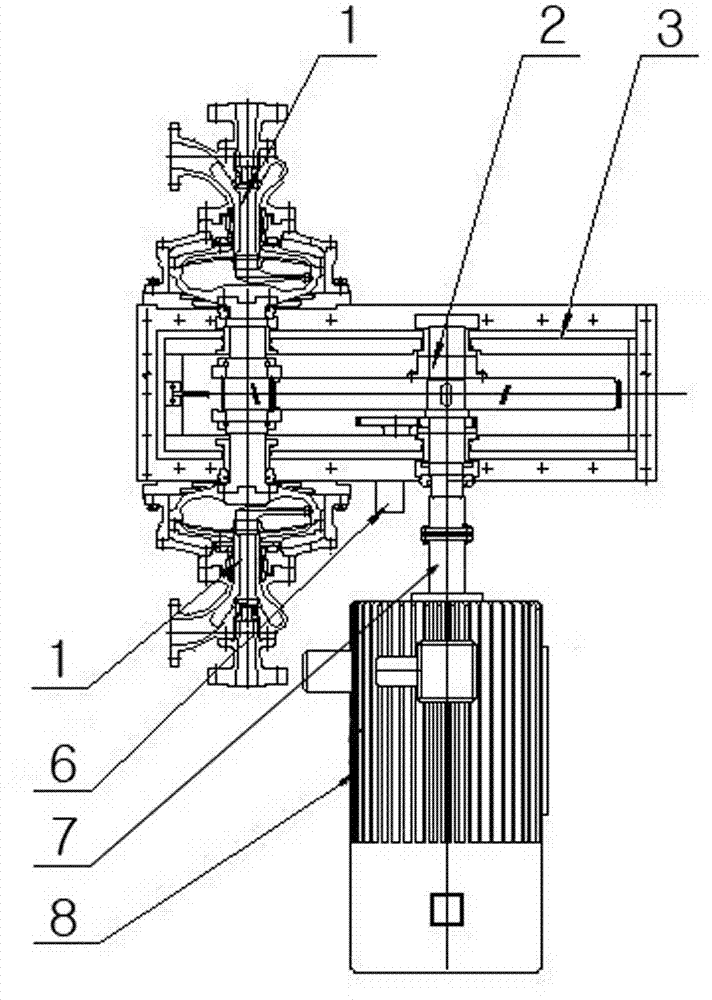

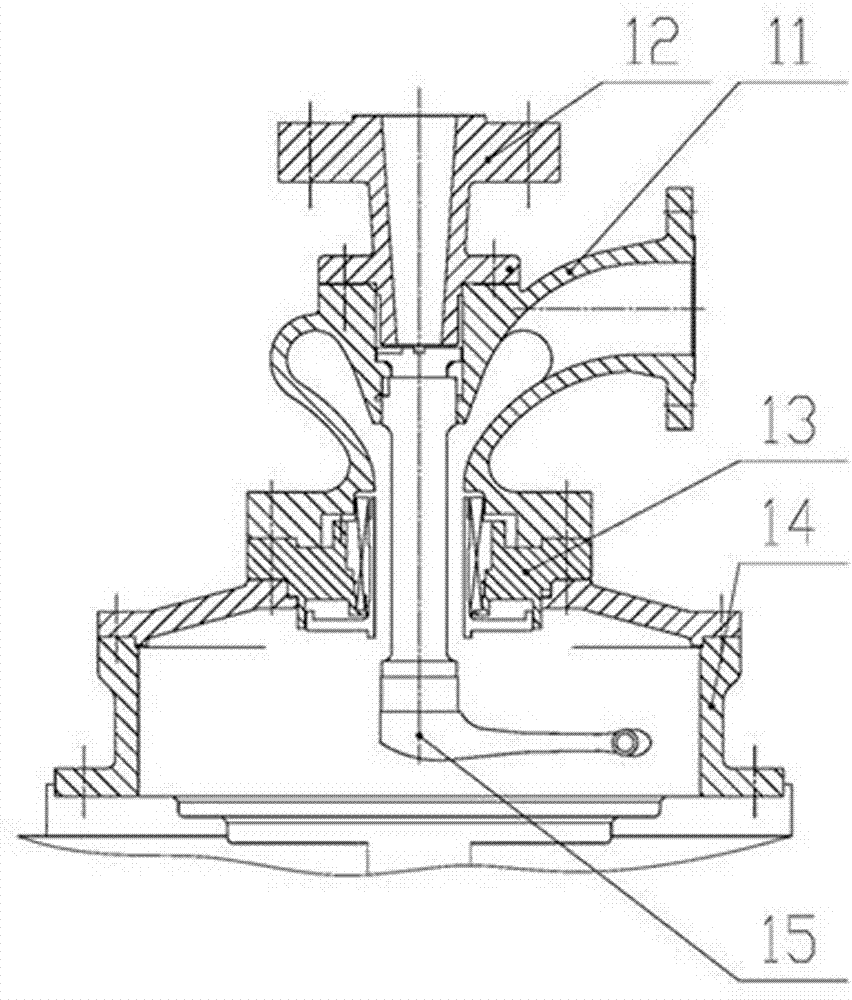

Gear speed increasing assembly type high speed rotating casing pump unit

InactiveCN104265639ASmall form factorImprove anti-cavitation performancePump installationsRadial flow pumpsCavitationLow speed

The invention relates to a high speed rotating casing pump unit, in particular to a rotating casing pump unit composed of a gear speed increasing assembly type high speed rotating casing pump. The pump unit comprises the gear speed increasing assembly type high speed rotating casing pump, an integrated shaft head oil pump, a coupler and a driving motor. The coupler enables the driving motor to be connected with a low speed shaft of the gear speed increasing assembly type high speed rotating casing pump. The gear speed increasing assembly type high speed rotating casing pump is composed of a stator part, a rotor part and a box body part. The stator part is composed of two rotating casing pump suction / discharging parts, a protection casing of the stator part is connected onto a location flange of the box body part, and a shaft seal part is located on the inlet side of each suction part. The rotor part is composed of a high speed shaft system and a low speed shaft system and adopts a single-oblique-tooth gear pair, each rotating casing pump rotor is directly connected with the high speed shaft, and double-side thrust discs for balancing residual axial force are arranged on two sides of the small gear tooth width direction of the high speed shaft to meet the alternating axial load work condition. The high speed rotating casing pump unit is compact in appearance, small in axial force borne by the bearing, large in pump unit flow application range and good in anti-cavitation performance.

Owner:江苏海狮泵业制造有限公司

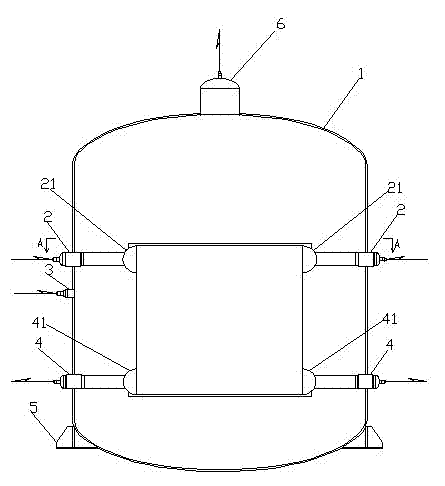

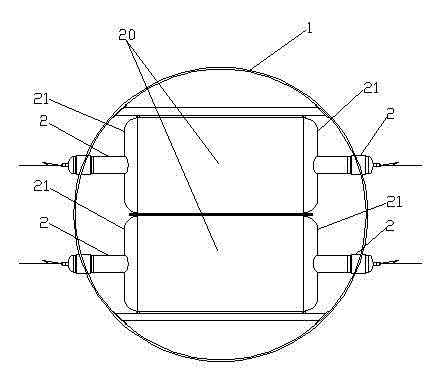

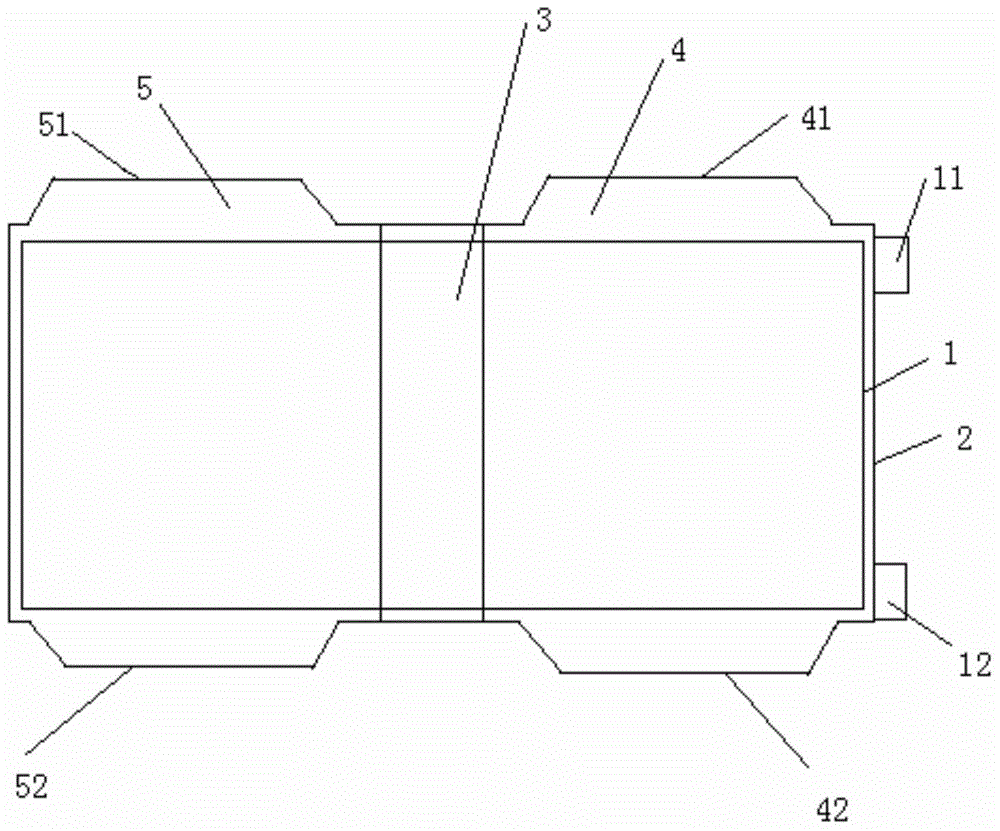

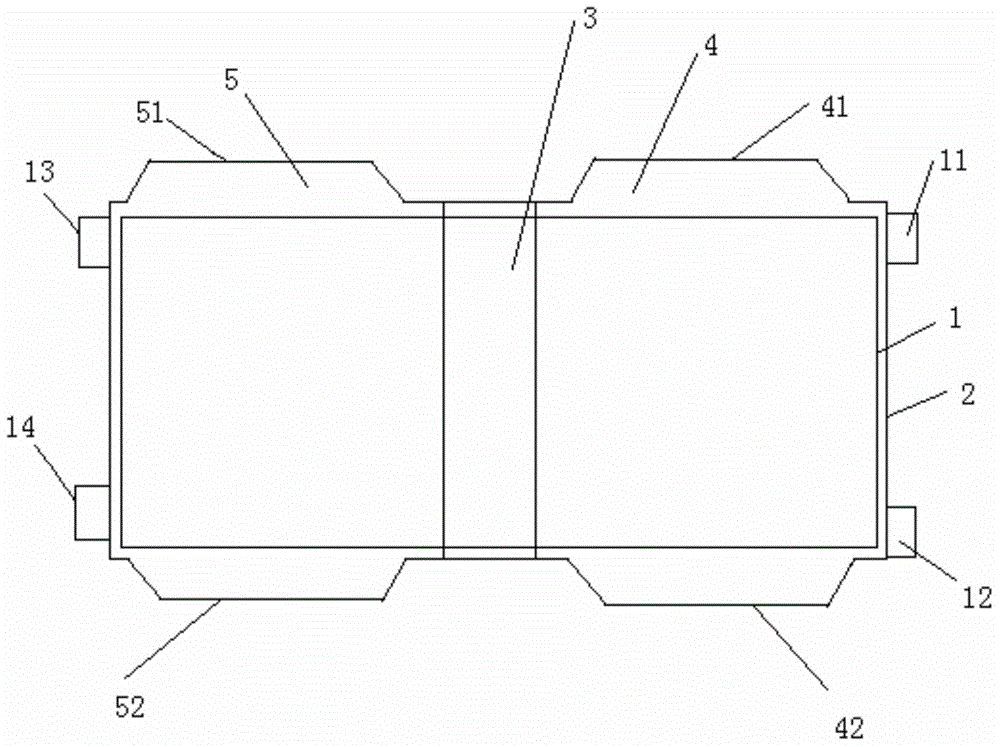

Flue gas heat exchanger and online cleaning method thereof

ActiveCN104315908AOvercome the defect of easy scaling and cloggingExtended service lifeFlush cleaningSolid removalFlue gasProcess engineering

The invention discloses a flue gas heat exchanger and an online cleaning method thereof. The flue gas heat exchanger comprises a rotor (1), a sealing region (3), an original flue pipe (4) and a pure flue pipe (5), wherein the original flue pipe (4) and the pure flue pipe (5) are separated through the sealing region (3); a heat exchanger element is arranged on the rotor (1); the original flue pipe (4) and the pure flue pipe (5) realize heat exchange through the heat exchanger element on the rotor (1); at least one ash blower (11, 12) is respectively arranged at the hot end and the cold end of the original flue pipe (4). Through the application of the flue gas heat exchanger and the online cleaning method thereof provided by the invention, the safety of desulfurization system equipment can be obviously improved, the economical efficiency of desulfurization system operation is improved, and the flue gas heat exchanger has wide application and promotion values.

Owner:CHINA SHENHUA ENERGY CO LTD +2

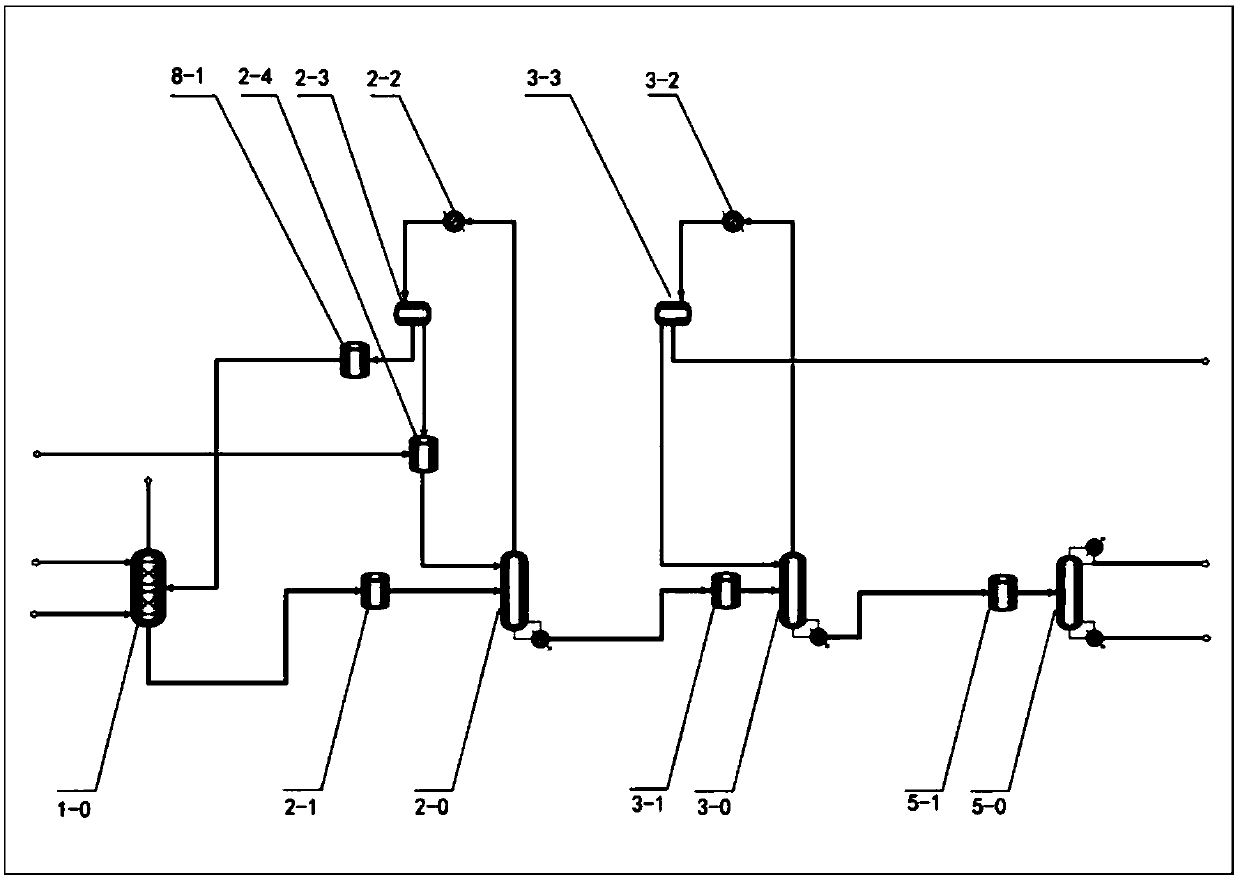

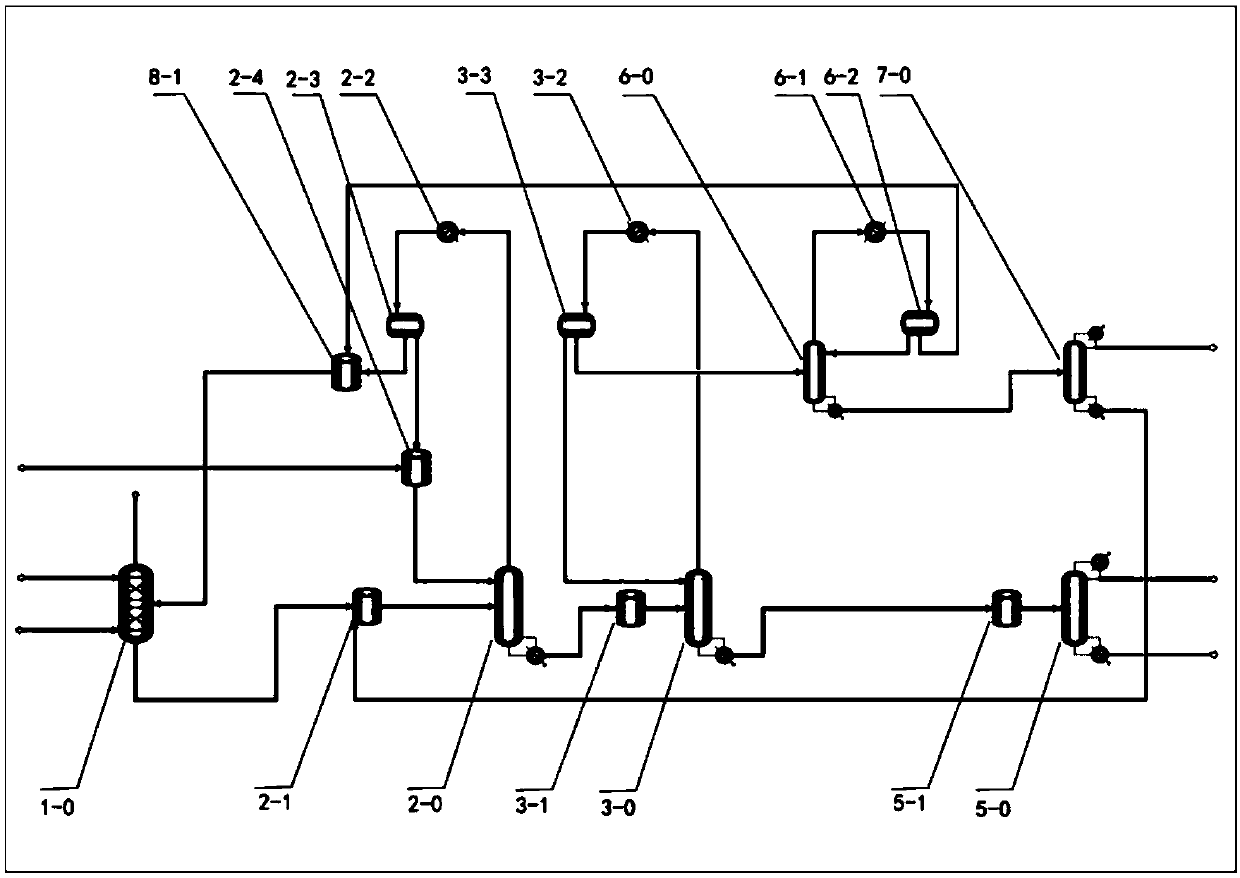

Radial fixed bed oxidative dehydrogenation reactor for regenerating catalyst by sections

ActiveCN102814150BHigh activityImprove conversion rateHydrocarbonsChemical recyclingDehydrogenationFixed bed

The invention relates to a radial fixed bed oxidative dehydrogenation reactor for regenerating a catalyst by sections and belongs to the field of chemical manufacturing equipment. A reaction gas outlet of a 1# reactor is connected with a reaction gas inlet of a 2# reactor through a pipeline. The radial fixed bed oxidative dehydrogenation reactor is characterized in that each one of the 1# reactor and the 2# reactor is a bearing shell formed by a cylindrical body, an upper end socket and a lower end socket; each bearing shell is internally provided with a catalyst inner cylinder and a catalyst outer cylinder, which are concentric and are formed by an opening cylinder and a Johnson net; the catalyst is filled into an annular space between the catalyst inner cylinder and the catalyst outer cylinder; and the part of the Johnson net is filled with an inert magnetic ball. A plurality of annular plates are arranged between the catalyst outer cylinder and the catalyst inner cylinder and a space between the catalyst outer cylinder and the catalyst inner cylinder is divided into a plurality of sections; and each section of the 1# reactor is provided with a material inlet and each section of the 2# reactor is provided with a reaction gas inlet and a regenerated gas inlet. The radial fixed bed oxidative dehydrogenation reactor for regenerating the catalyst by sections disclosed by the invention realizes the aim of carrying out an oxidative dehydrogenation reaction and catalyst regeneration at the same time in an online manner.

Owner:SHANDONG QILU PETROCHEM ENG

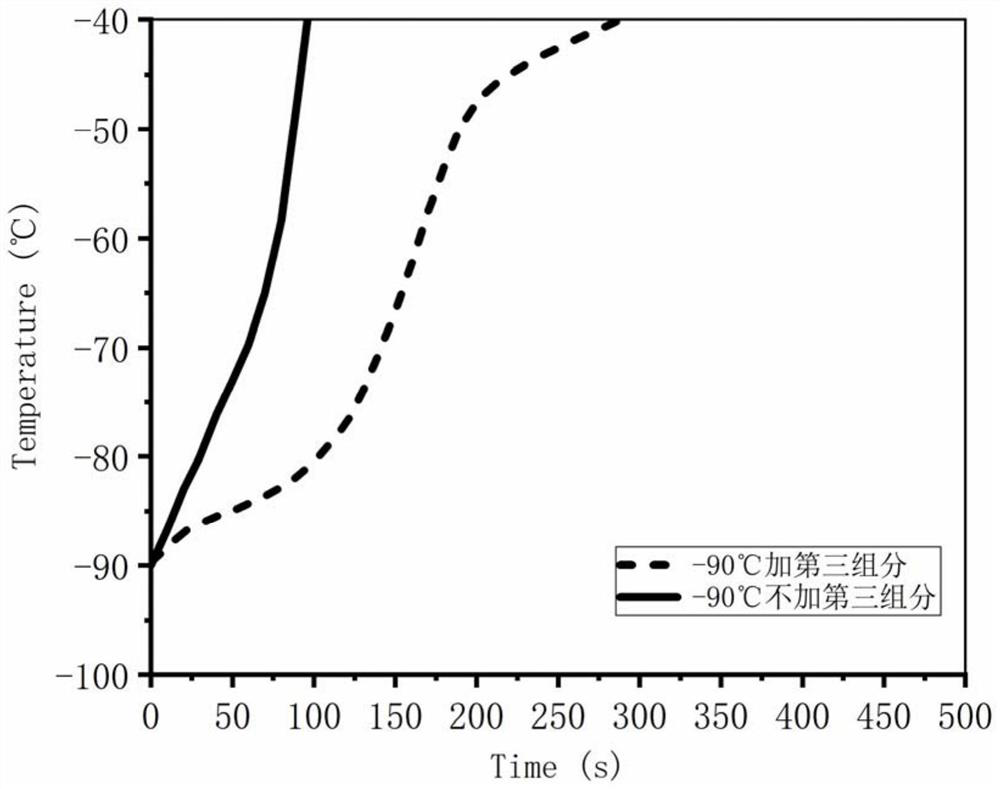

Preparation method for improving polymerization temperature of polyisomonoolefin-based elastomer or molecular weight of elastomer

The invention discloses a series of synthesis methods for increasing the polymerization reaction temperature or molecular weight of a polyisobutylene-based elastomer by adding a third component in a cationic polymerization process. In the traditional production process technology for synthesizing the polyisobutylene-based elastomer, in order to reduce many uncontrollable factors brought to polymerization reaction due to the fact that reaction heat is not discharged in time, extremely low reaction temperature is usually needed. Aromatic ketone, aromatic ether or aromatic ester or a mixture of the aromatic ketone, the aromatic ether or the aromatic ester is added as a third component, so that the active center of carbon cations is stabilized, and the polymerization rate is slowed down. Through exploration, when products with the same molecular weight are prepared, the polymerization temperature can be increased by 5-40 DEG C, the volatilization consumption of a coolant is reduced, the energy consumption is reduced, and the continuous operation period of the polymerization kettle is prolonged. And under the conditions of the same heat transfer area and reaction temperature, the prepared product can obtain higher molecular weight.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Feed method for coal tar hydrogenating unit

The invention relates to a feed method for coal tar. After the pressure of a coal tar raw material is boosted by a hydrogenation reaction raw material booster pump, the coal tar raw material enters a hydrogenation reactor without any indirect heat exchange; and before the pressure of the coal tar raw material is boosted, the coal tar raw material can be hot stream from a fractionating tower. The method can avoid a high-pressure heat-exchange temperature-rise process of the coal tar, eliminate the problem of fouling of high-pressure coal tar heat exchangers, reduce the hydrogenation catalyst bed pressure drop, slow down the coking, and prolong the operation cycle.

Owner:何巨堂

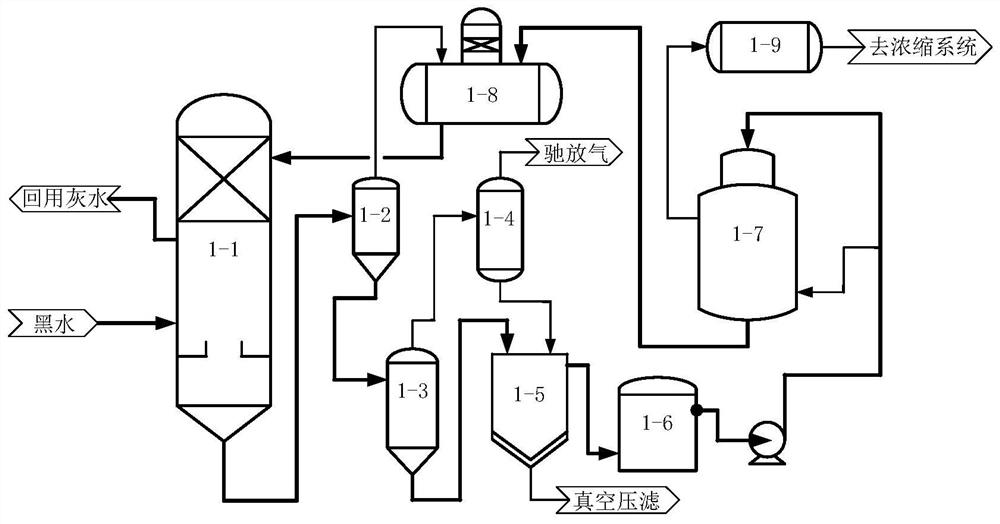

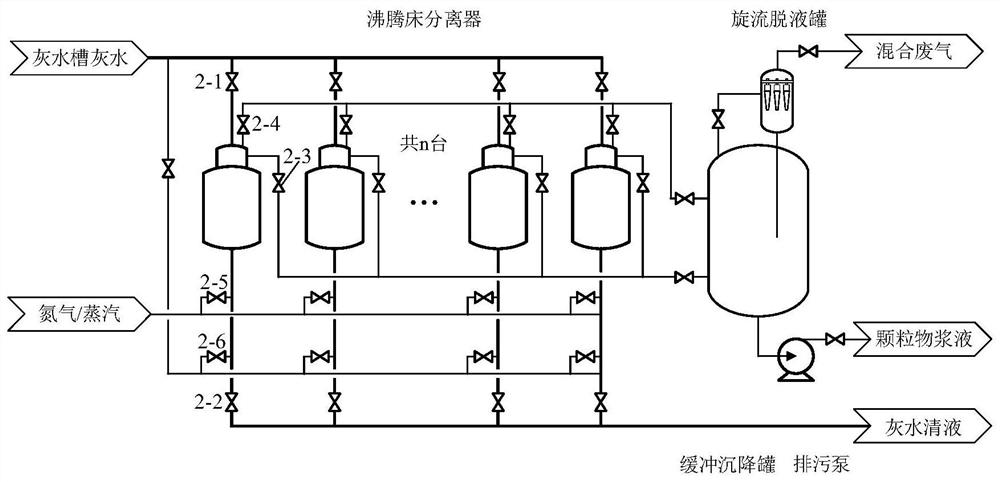

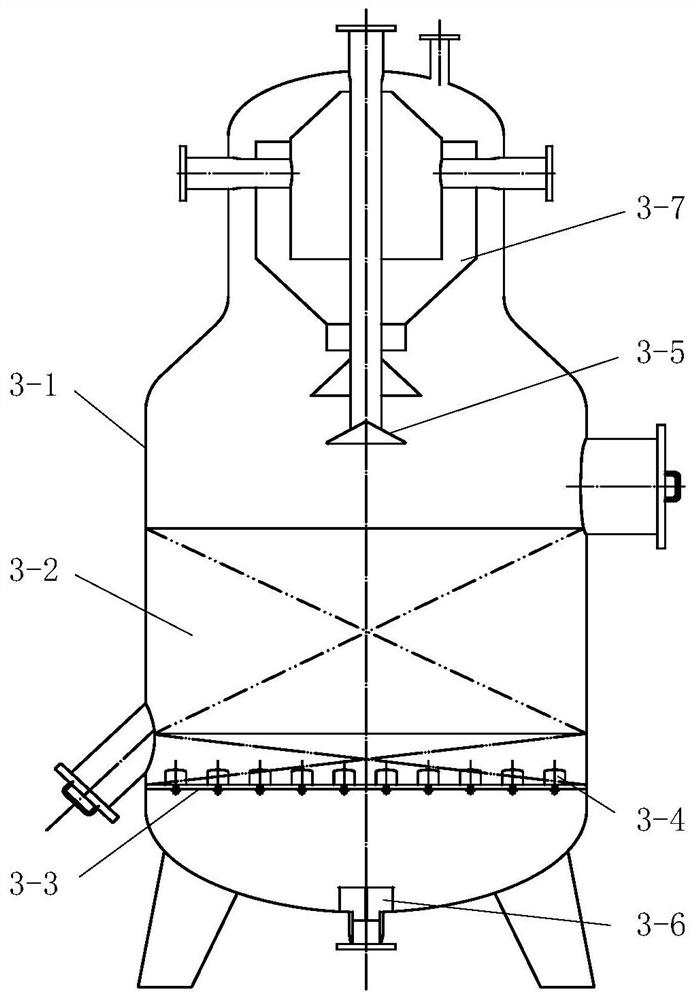

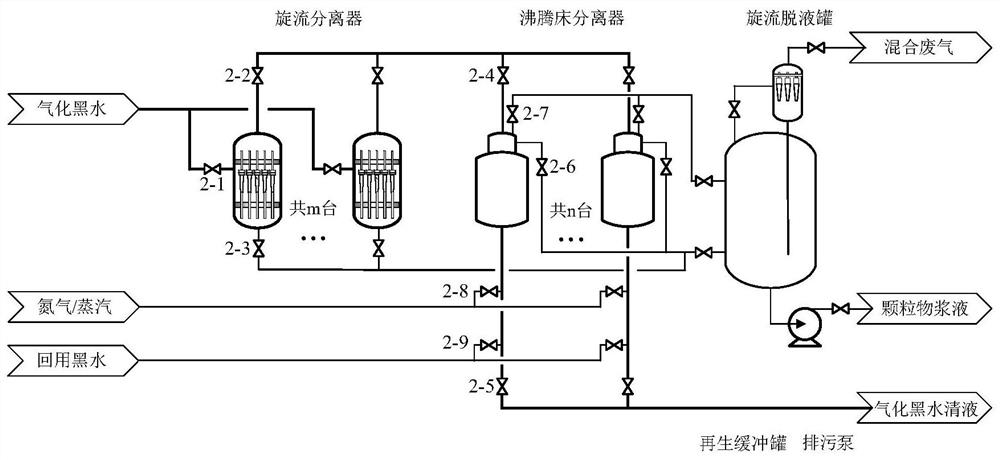

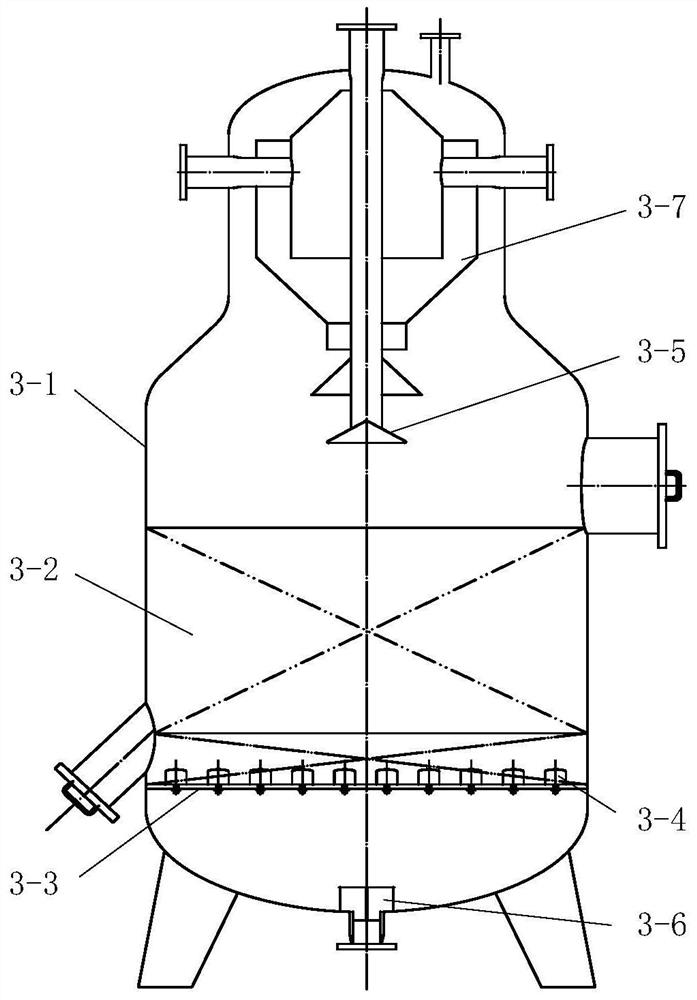

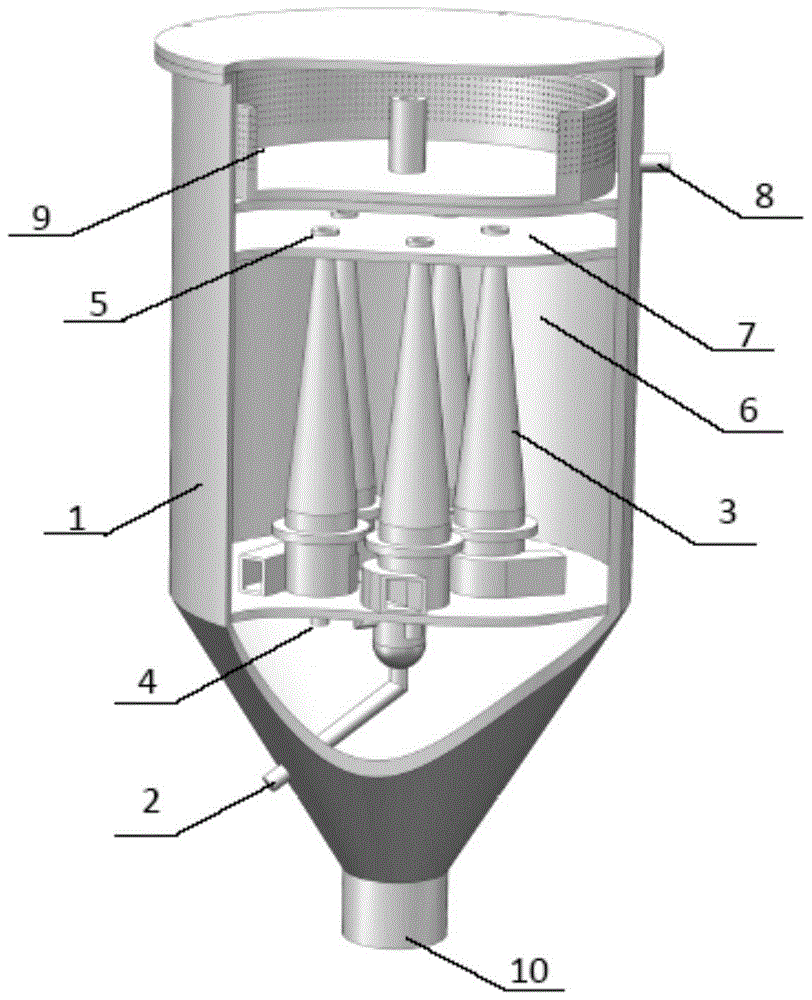

Flash evaporation-sedimentation-fluidized bed separation combined purification method and device for coal gasification black water

PendingCN112624472AMake up for the problem of insufficient separation efficiencySolve the problem of deep purificationTreatment involving filtrationMultistage water/sewage treatmentFine particulateDeaerator

The invention relates to a flash evaporation-sedimentation-fluidized bed separation combined purification method and device for coal gasification black water. The flash evaporation-sedimentation-fluidized bed separation combined purification method for the coal gasification black water comprises the following steps: (i) carrying out flash evaporation treatment on the coal gasification black water; (ii) feeding the coal gasification black water having been subjected to flash evaporation treatment into a sedimentation tank, conducting sedimentation and separating, feeding bottom concentrated suspended matters into a vacuum filter pressing system, and feeding a supernatant of the sedimentation tank, namely coal gasification ash water, into an ash water tank; (iii) pumping the coal gasification ash water out of the ash water tank, and sending the coal gasification ash water to a fluidized bed separator to deeply remove fine particles in the coal gasification ash water; (iv) sending the coal gasification ash water purified by the fluidized bed separator to a deaerator for deoxygenation; and (v) after the fluidized bed separator is operated for a period of time and a pressure difference is 0.3 MPa, mixing the coal gasification ash water and nitrogen, and reversely feeding the obtained mixture to regenerate a separation medium of the fluidized bed separator. The invention further provides the flash evaporation-sedimentation-fluidized bed separation combined purification device for coal gasification black water.

Owner:EAST CHINA UNIV OF SCI & TECH

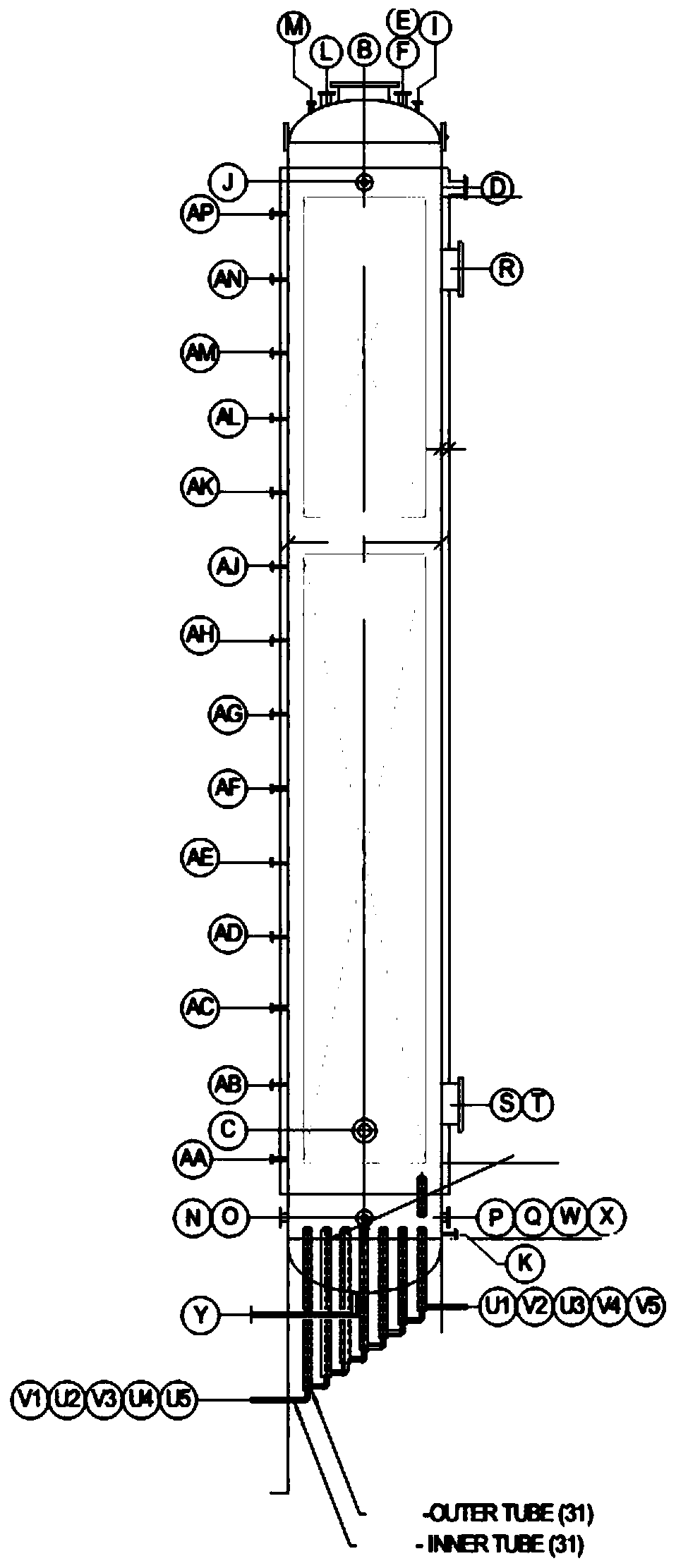

Hydrogen purification equipment carbon adsorption tower in electronic-grade polycrystalline silicon production process

InactiveCN110877898AHigh purityLess impuritiesGas treatmentHydrogen separation using solid contactHydrogen purityMetallurgy

The invention discloses a hydrogen purification equipment carbon adsorption tower in electronic-grade polycrystalline silicon production process. The hydrogen purification equipment carbon adsorptiontower comprises a tower body which is of a cylindrical structure, and five groups of oil input pipes, five groups of oil output pipes and 31 heat exchange pipes which are arranged in the tower body; ajacket form is adopted by the outer wall of the tower body, the oil output pipes and the oil input pipes are connected with the heat exchange pipes in the tower body, and the jacket, and the rest space in the tower body is filled with activated carbon. The hydrogen purity is improved, impurities in hydrogen are reduced, the safety of the system is improved, and the continuous operation period ofthe system is prolonged.

Owner:青海黄河上游水电开发有限责任公司新能源分公司 +2

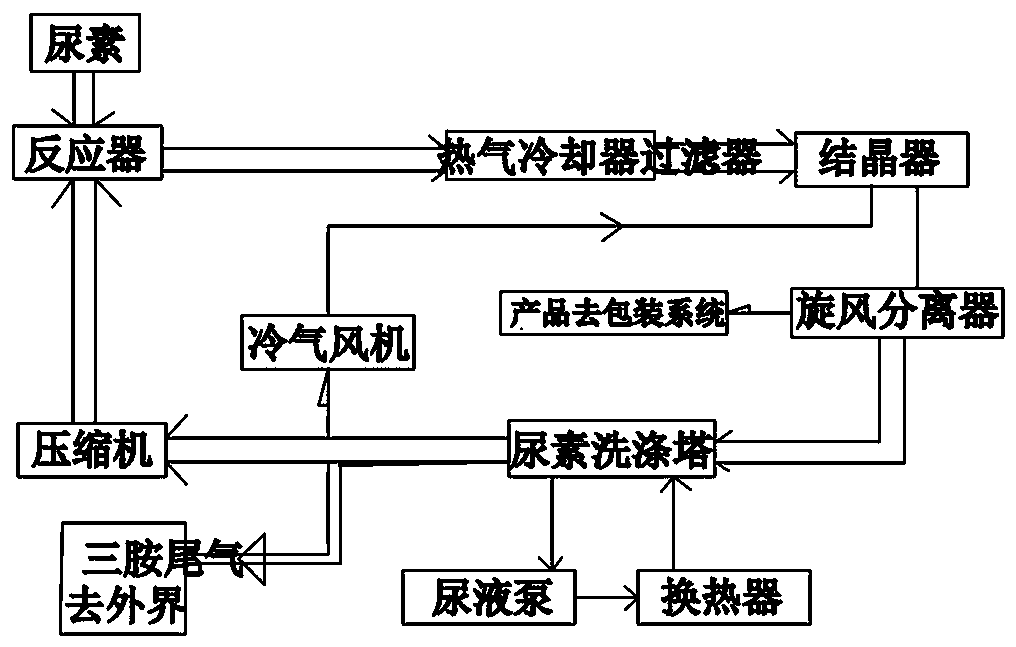

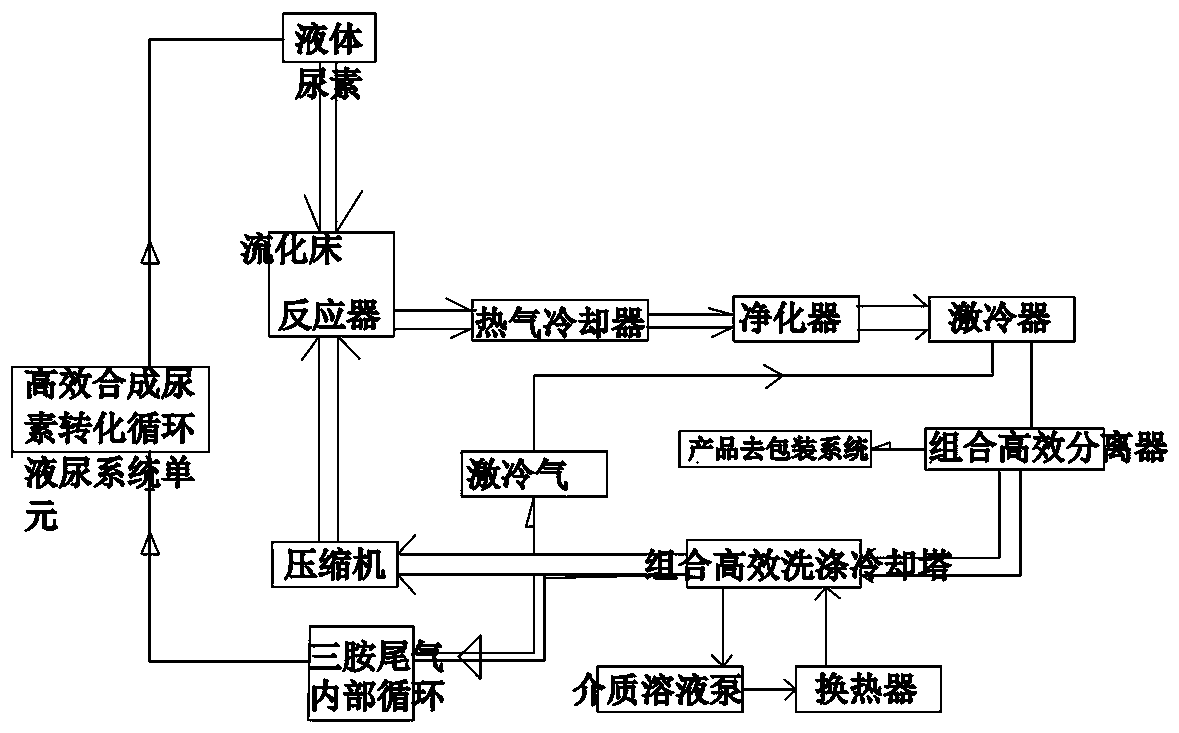

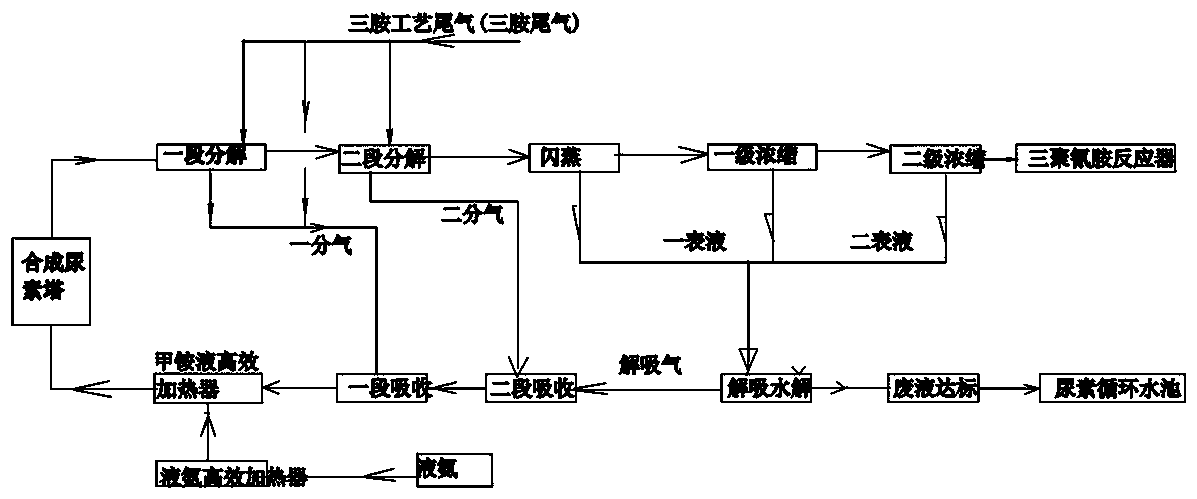

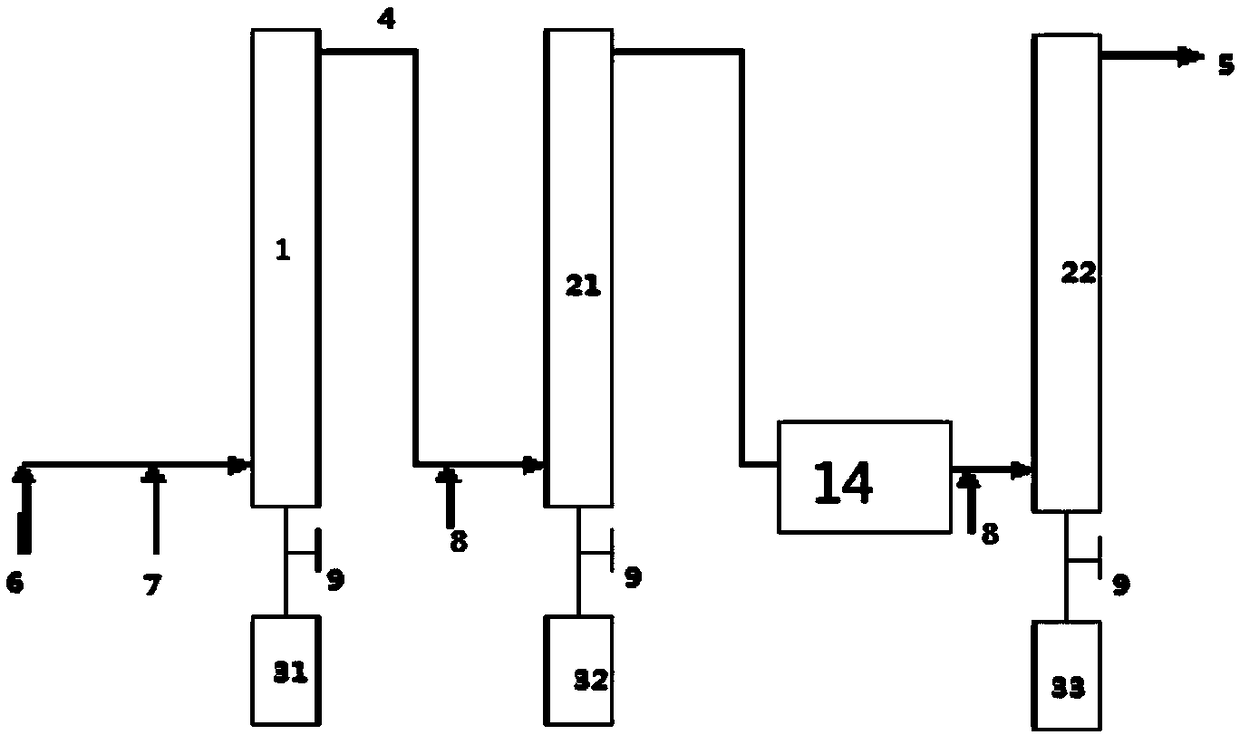

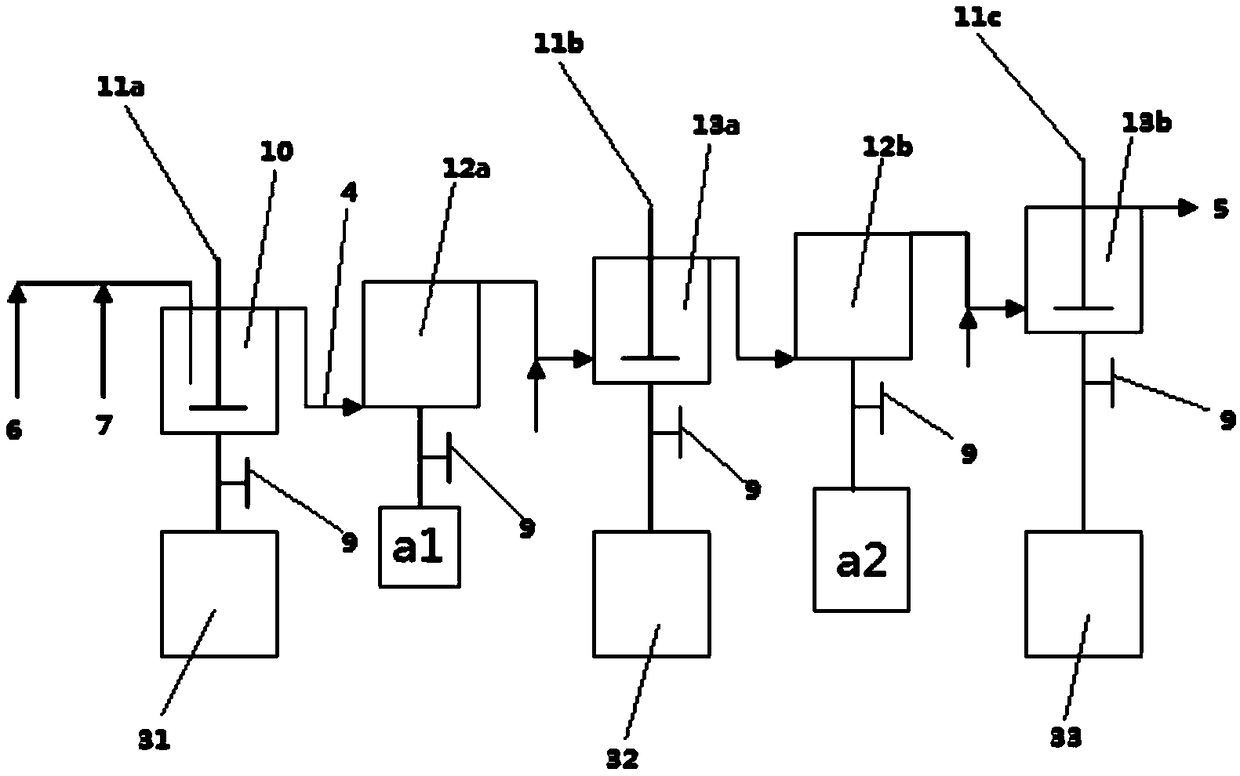

Tripolycyanamide whole circulation production process and device

PendingCN108558783AExtended operating cycleReduce manufacturing costOrganic chemistryChemical/physical/physico-chemical stationary reactorsExhaust gasSolid phases

The invention provides a tripolycyanamide whole circulation production process and device. Liquid urea is used as a raw material to be fed into a tripolycyanamide reactor; tripolycyanamide, ammonia and carbon dioxide gas mixture material gas is generated; after the cooling and purification separation, the tripolycyanamide is subjected to desublimation to form a solid phase in a chiller to realizethe gas-solid separation in an efficient separator; the tripolycyanamide is fed into a packaging system; gas containing ammonia and carbon dioxide and separated from the efficient separator enters a combined efficient washing cooling tower; one path of gas subjected to washing, cooling and temperature lowering is pressurized to enter the tripolycyanamide reactor; one path is subjected to liquid urea synthesis through an efficient synthesis urea conversion system and then enters the tripolycyanamide reactor for repeated production of the tripolycyanamide product. The tripolycyanamide productionprocess has the advantages that tripolycyanamide process tail gas cannot be discharged to a position outside a tripolycyanamide production device boundary region; the tripolycyanamide process tail gas realizes the self circulation utilization inside the tripolycyanamide process production device boundary region; the device belongs to a clean environmental-friendly device; the total efficient circulation utilization of the tripolycyanamide process tail gas in the tripolycyanamide process production device can be realized.

Owner:程克信

Method and system of utilizing temperature variable-pressure variable continuous method to prepare biodiesel

The invention relates to the field of biodiesel preparation, and discloses a method and system of utilizing a temperature variable-pressure variable continuous method to prepare biodiesel. According to the method, raw materials containing grease and alcohols are directly introduced into a first reactor to carry out reactions, a first material is obtained from the upper part of the first reactor; then the first material is introduced into at least two serially connected second reactors to carry out reactions, and a second material is obtained from the upper part of the last second reactor. According to the provided temperature variable-pressure variable continuous method, raw materials containing grease and alcohols are directly introduced into the first reactor to carry out reactions and do not go through a conventional preheating reactor, thus precipitates will not be accumulated in a high pressure heater during the preheating process, and the defect that the system cannot run stablyfor a long term is overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Purification method and device for short-process coal gasification black water

PendingCN112624471AEasy to separateExtended operating cycleWater/sewage treatment by centrifugal separationTreatment involving filtrationPurification methodsProcess engineering

The invention relates to a purification method and device for short-process coal gasification black water. The purification method for the short-process coal gasification black water comprises the following steps: (i) allowing the short-process coal gasification black water to enter a jet flash separator for flash evaporation treatment; (ii) feeding the short-process coal gasification black water having been subjected to jet flash evaporation treatment to a micro-cyclone separator for preliminary centrifugal separation; (iii) sending the short-process coal gasification black water primarily purified by the micro-cyclone separator to a fluidized-bed separator for secondary purification; (iv) sending the short-process coal gasification black water deeply purified by the fluidized-bed separator to a deaerator for deoxygenation; and (v) after the fluidized-bed separator operates for a period of time and a pressure difference is 0.3 MPa, mixing the recycled short-process coal gasification black water and nitrogen and reversely feeding the obtained mixture to regenerate the separation medium of the fluidized-bed separator. The invention further provides the purification device for the short-process coal gasification black water .

Owner:EAST CHINA UNIV OF SCI & TECH

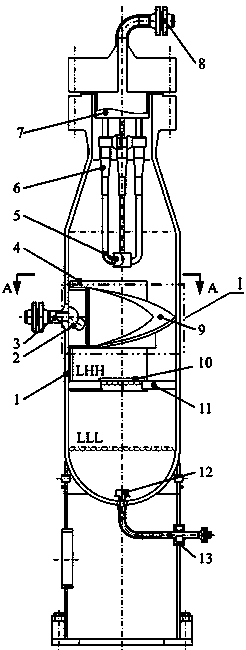

Method and device for cyclone purification of coolant in boron removal section of boron recovery system

ActiveCN104200860BReduce Radiation RiskLong continuous operation periodCentrifugal force sediment separationRadioactive decontaminationCyclonePurification methods

The invention relates to coolant rotational-flow purification methods and devices for boron removal sections of boron recycle systems and provides a coolant rotational-flow purification method for a boron removal section of a boron recycle system. The method comprises the following steps that (i) a micro-rotational-flow separation complete device is provided, wherein the device comprises a shell (1), a micro-cyclone core tube (3) and a dust hopper (9); the shell (1) comprises an upper cavity, a middle cavity (6) and a lower cavity; the micro-cyclone core tube (3) is arranged in the middle cavity (6); the dust hopper (9) is arranged in the upper cavity; (ii) in the boron removal section, reactor coolant distillate is fed into the middle cavity of the micro-rotational-flow separation complete device after boron removal is performed, and rotational-flow separation is performed on the distillate through the micro-cyclone core tube to separate solid impurity particles from the distillate to obtain concentrate containing the solid impurity particles and clear liquid; (iii) the obtained concentrate is fed into the upper cavity to be settled in the dust hopper, so that filtrate is obtained; (iv) the obtained filtrate and the obtained clear liquid converge and then flow to downstream equipment.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com