Patents

Literature

59 results about "Formaldehyde product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formaldehyde is a colorless chemical compound released during the process of chemical combustion. It is also an ingredient widely used in the manufacturing business. There are many formaldehyde products, made for both indoor and outdoor use. One of the most common uses of formaldehyde products is in building materials.

Colour development methyl aldehyde adsorption material and preparation method thereof

ActiveCN101468304AResponsivenessRapid pollutionMaterial analysis by observing effect on chemical indicatorOther chemical processesFormaldehyde productMethyl aldehyde

The invention discloses a chromogenic formaldehyde adsorbing material and a preparation method thereof. The adsorbing material consists of a carrier, a high molecular organic amine polymer, a polylol polymer and a formaldehyde reaction indicator, wherein the high molecular organic amine polymer and the polylol polymer account for 1 to 50 percent of formaldehyde adsorbent, the formaldehyde reaction indicator is little, and the balance being the carrier. The preparation method thereof comprises the following steps: mixing the high molecular organic amine polymer and the polylol polymer according to mass, adding deionized water to dilute the mixture so as to prepare formaldehyde reagent; mixing the formaldehyde reagent and the formaldehyde reaction indicator; and spraying or dipping the mixed solution onto the surface of the carrier, and drying the carrier and so on. The adsorbing material and the preparation method can quickly, thoroughly and continuously remove formaldehyde pollution in indoor air until the content of the formaldehyde is reduced to safe concentration, are nontoxic, pollution-free, safe and environment-friendly to use, and can intuitively show the reaction degree of the formaldehyde.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Collagen polypeptide rich in glycine and formaldehyde scavenger prepared therefrom

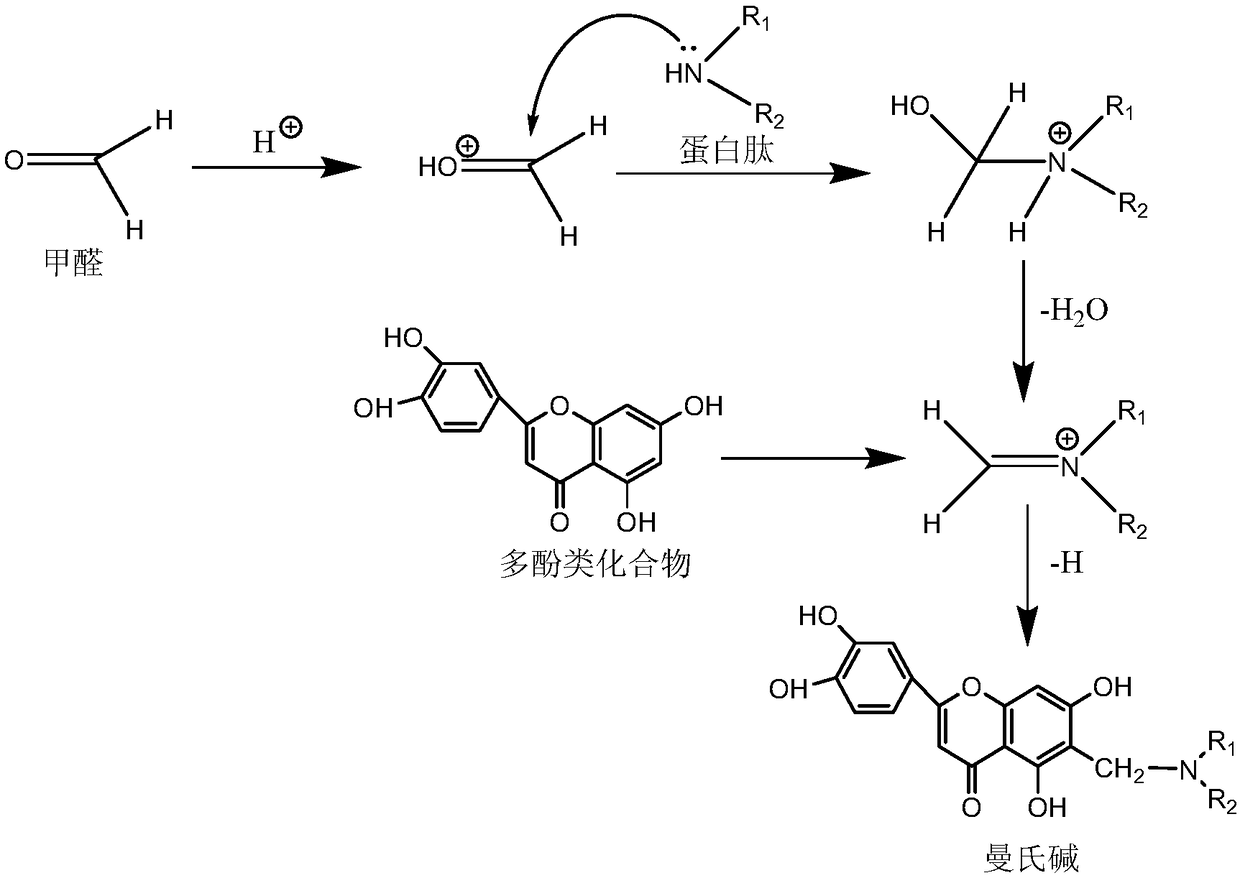

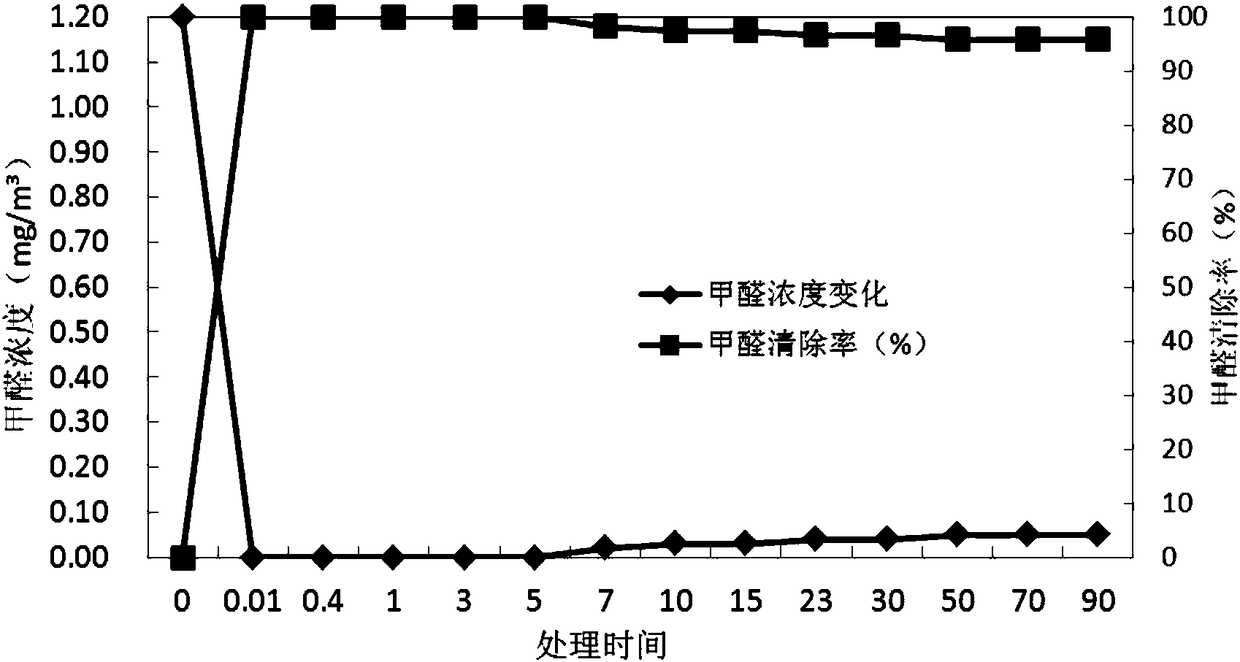

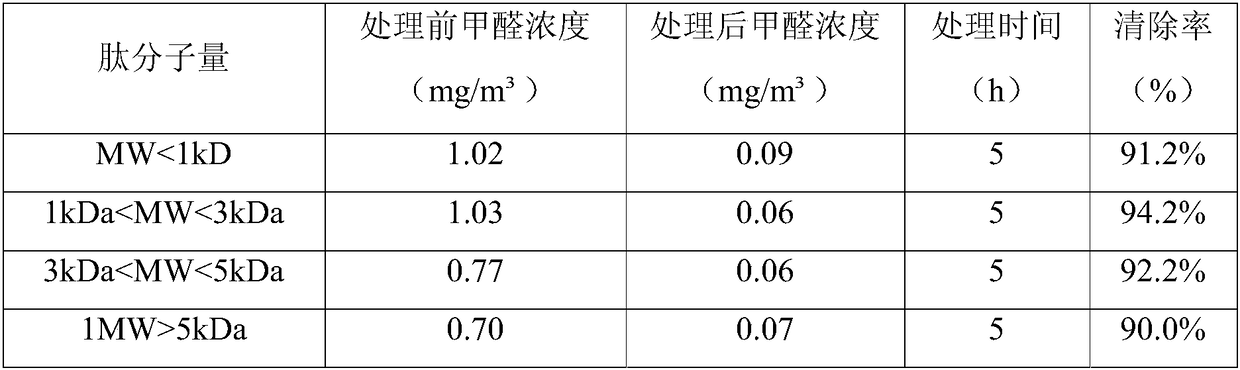

InactiveCN108130355AAchieve high valueHigh viscosityConnective tissue peptidesDispersed particle separationGlycineFormaldehyde product

The invention belongs to the technical field of functional polypeptides and discloses a collagen polypeptide rich in glycine and a formaldehyde scavenger prepared therefrom. The collagen polypeptide is prepared from the following steps: extracting collagens by means of a hot water extraction method; and then preparing the collagen polypeptide rich in glycine by enzymolysis of the collagens by means of protease by taking Tilapia mossambica waste as a raw material. By being combined with plant polyphenol compounds, the quick, long-acting, safe and edible formaldehyde scavenger is prepared. The formaldehyde removal rate of the formaldehyde scavenger can reach 95% or above within 10 min, so that the problem that a single amino acid is not ideal in removing formaldehyde is solved. A colloid film which is 2-10 microns can be formed on the surface of an object such as furniture if being dried to inhibit further release of formaldehyde. The formaldehyde removal rate can be kept at 95% or abovewithin three months, an effect of removing formaldehyde for a long time is achieved, and the problem that existing formaldehyde removal products are rebound in effect and short in effective period issolved.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing low alcohol, high concentration formaldehyde

InactiveCN1473811ALow costLow cost production of alcohol contentCarbonyl compound separation/purificationCyclic processHigh concentration

Owner:洪海玲

Preparation method of pyridine-2-formaldehyde

The invention relates to a preparation method of pyridine-2-formaldehyde. The preparation method comprises the following two steps: preparing an acidity-regulator-containing supported catalyst with titanium dioxide used as a carrier, molybdenum bismuth oxide used as a main body and transition metal oxide used as an auxiliary, carrying out gas-phase oxidation reaction on 2-methyl pyridine, oxygen and water used as raw materials in a fixed bed catalytic reactor at 250-350 DEG C to obtain a crude pyridine-2-formaldehyde product, extracting the crude product with dichloromethane, carrying out pressure-reduced distillation on the extract to remove dichloromethane, and then rectifying to obtain a pure product with a pyridine-2-formaldehyde content more than 98%. The preparation method provided by the invention has the advantages of simple preparation process, high efficiency, low cost, high catalytic reaction activity and selectivity, easy separation of main products and by-products and high purity.

Owner:ZHEJIANG UNIV

Benzaldehyde preparation method

ActiveCN108329196ASimple processSimple and fast operationOrganic compound preparationCarbonyl compound preparationBenzaldehydeDistillation

The invention discloses a natural benzaldehyde preparation method. According to the invention, one oxide or two or three composite oxides from V, Ti, Ag, Ba, and Mg can be taken as a catalyst, O2 or air is introduced as an oxygen source, cinnamaldehyde is atomized through compressed air or oxidation, and then is introduced into a fixed bed reactor, a gas-solid phase catalysis continuous reaction is carried out under normal pressure at the temperature of 120-200 DEG C, a product continuously passes through a molecular distillation apparatus, molecular distillation is carried out at the temperature of 60 DEG C under 100 Pa, and the natural benzaldehyde product is obtained. The natural benzaldehyde preparation method has the advantages of simple and novel process, simple operation, no requirement of solvent, simple separation, and fast reaction rate, excessive oxidation of cinnamaldehyde is prevented, a reaction process is environmentally friendly, the natural degree of benzaldehyde is good, and the product purity is high.

Owner:GUANGXI UNIV

Method for preparing benzaldehyde

ActiveCN107141211ASimple processSimple and fast operationOrganic compound preparationCarbonyl compound preparationReaction rateBenzaldehyde

The invention discloses a method for preparing natural benzaldehyde. The method comprises the steps of gasifying cinnamyl aldehyde at the temperature of 260 DEG C in a manner of taking a composite oxide of two or three of Fe, Mo, W, Mn, Ca, Al, Cu and Zn as a catalyst and introducing O2 or air as an oxygen supply, then, enabling cinnamyl aldehyde gas to enter a fixed-bed reactor, carrying out a gas-solid catalytic continuous reaction, and subjecting a product to molecular distillation continuously through a molecular distillation device at the temperature of 60 DEG C under the pressure of 100Pa, thereby obtaining the natural benzaldehyde product. The method has the advantages that the process is simple and novel, the operation is simple, a solvent is not required to be used, the separation is simple and convenient, the reaction rate is high, the reaction process is environmentally friendly, the natural degree of the benzaldehyde is good, and the obtained product is high in purity.

Owner:GUANGXI UNIV

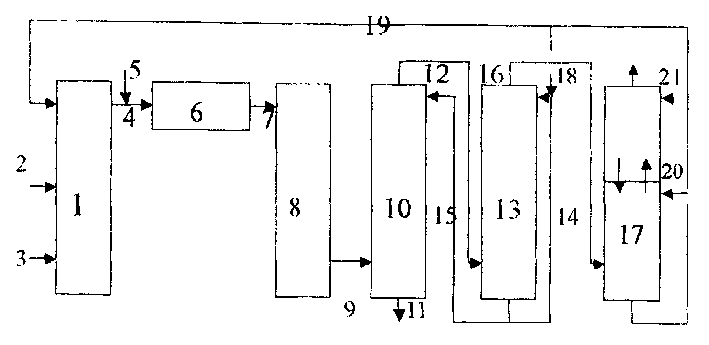

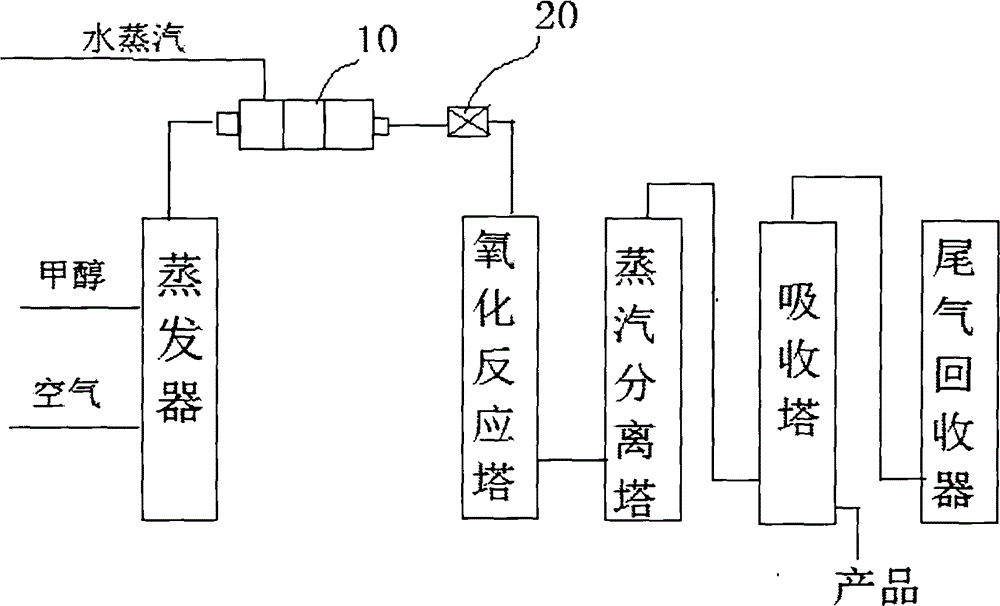

Apparatus and method to co-produce formaldehyde and UFC (urea-formaldehyde concentrate) by iron-molybdenum process

PendingCN108689817AIncrease specificationGood consumption indicatorsOrganic compound preparationCarbonyl compound preparationFormaldehyde productSodium hydroxide

An apparatus to co-produce formaldehyde and UFC (urea-formaldehyde concentrate) by iron-molybdenum process comprises a methanol evaporator, a methanol oxidizer and an absorbing column; fresh air and methanol vapor are mixed in the methanol evaporator, and formaldehyde is generated in the methanol oxidizer; formaldehyde vapor enters the absorbing column via the methanol evaporator; in the absorbingcolumn, the formaldehyde vapor is liquefied, and a liquid formaldehyde product is attained from the bottom; urea and an alkali liquid are added into the absorbing column to react with the formaldehyde to obtain UFC. The apparatus has the advantages that consumption indexes are good, single consumption of formaldehyde is 0.422-0.426 t, byproduct vapor specification is high, up to 22 bar 0.75 t / t,oxidation temperature is controlled to 245-380 DEG C, the methanol oxidizer has designed life up to 20 years and longer, the whole apparatus has designed life of not shorter than 35 years, the apparatus is suitable for flexibly producing formaldehyde products having a concentration of 37-55%, UFC can be produced just by proportionally adding an alkali liquid, and in order to further increase absorbing efficiency of process water, sodium hydroxide solution can be injected into the system to remove the byproduct, formic acid.

Owner:江苏道尔顿石化科技有限公司

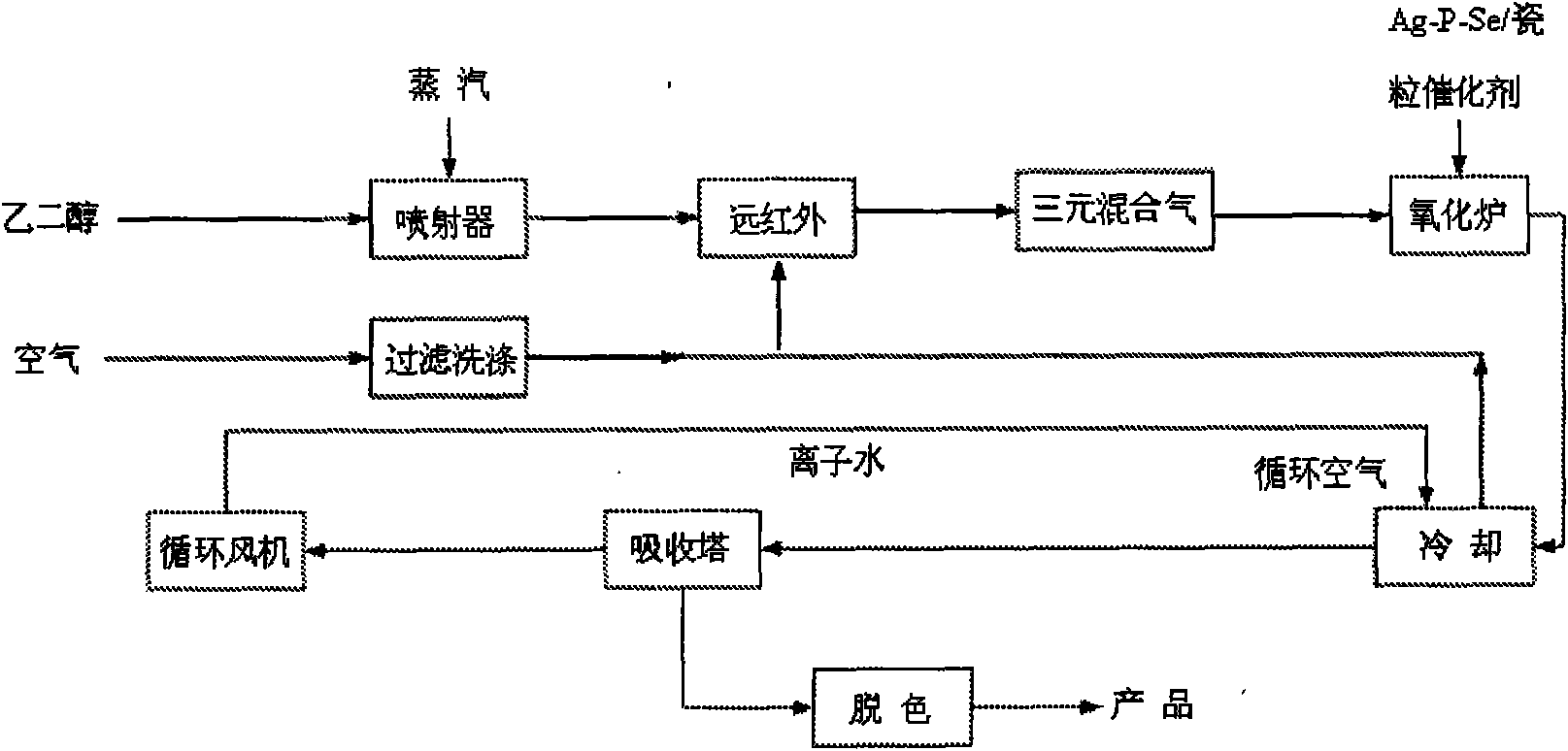

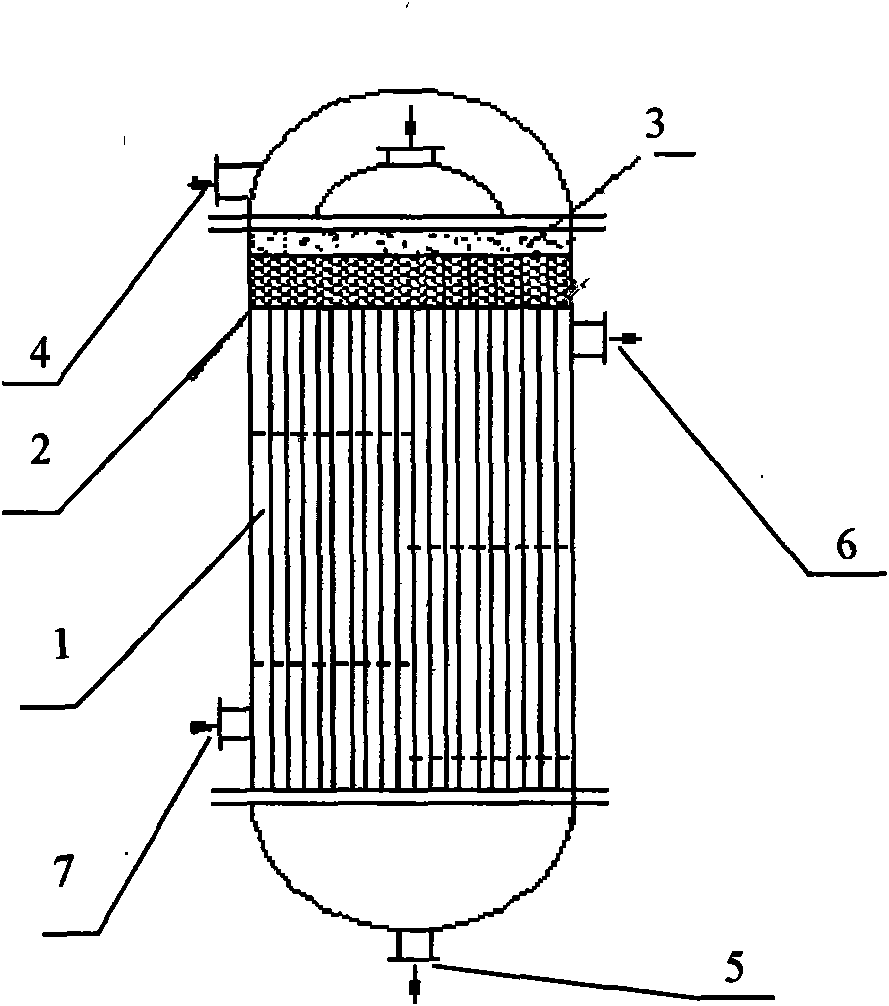

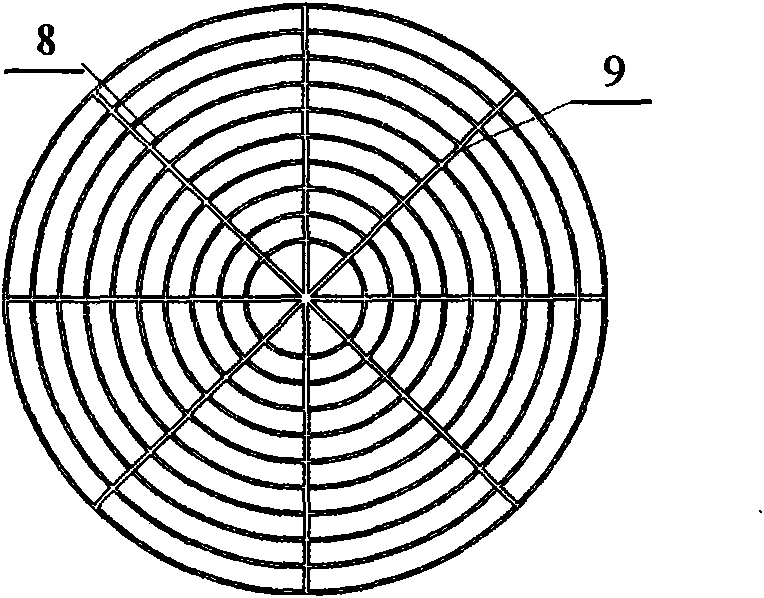

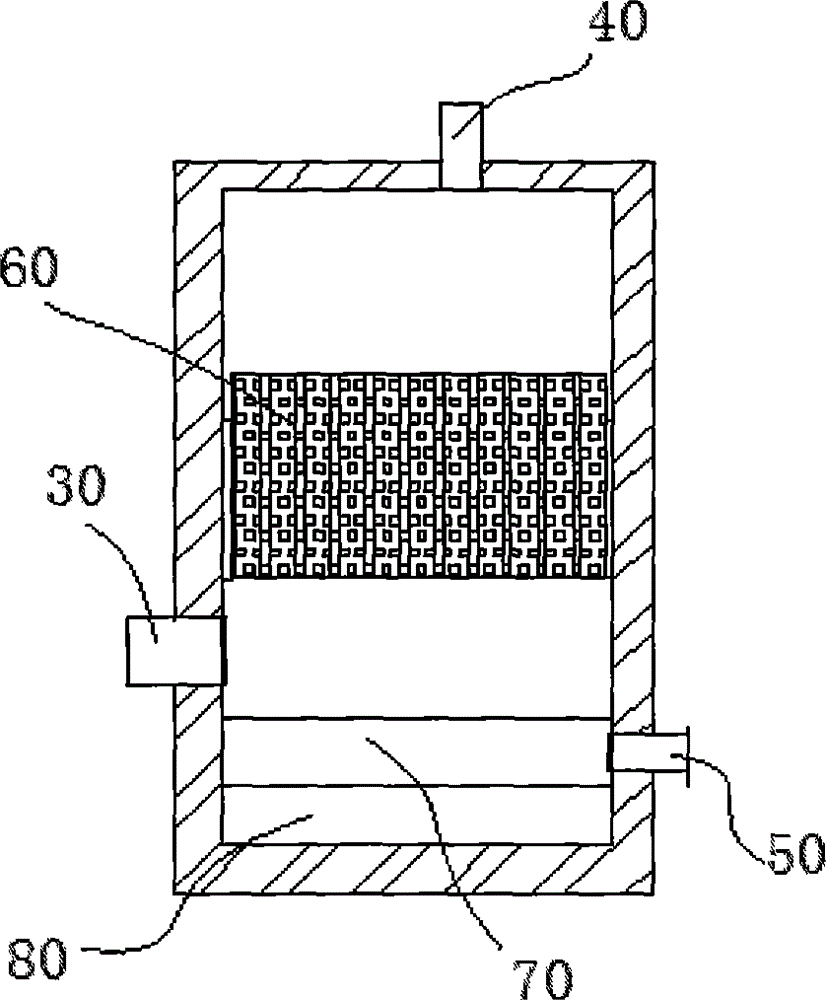

New process for producing glyoxal by using complex silver catalyst to oxidize glycol

InactiveCN101643394AHigh yieldSolving activityPhysical/chemical process catalystsOrganic compound preparationWater vaporCatalytic oxidation

The invention relates to a new process for producing glyoxal by using a complex silver catalyst to oxidize glycol. The process comprises the following steps: adopting a high-pressure steam-spraying and far-infrared combining heating mode to gasify glycol; uniformly mixing the gasified glycol, steam, preheated filtrated air and circulating air in a tertiary mixer before entering a grid-type oxidation furnace integrated with a feed gas-purifying and refining device and filled with an Ag-P-Se / ceramic catalyst; carrying out a catalytic oxidation reaction; rapidly quenching the reacted gas; sendingthe gas to an absorption tower for repeated absorption; and decoloring the gas to obtain a glyoxal product. The process uses the Ag-P-Se / ceramic catalyst with strong activity and has high glyoxal yield up to 85 percent and small impurity formaldehyde product; a grid-type supporting plate overcomes the defects of easily deformed and crack catalyst bed and decreases the resistance of the bed; and the process integrates the purifying and refining device and the oxidation furnace and adopts the high-pressure steam-spraying and far-infrared combining heating mode to gasify the glycol to save energy and shorten the process flows.

Owner:HUBEI HONGYUAN PHARMA +1

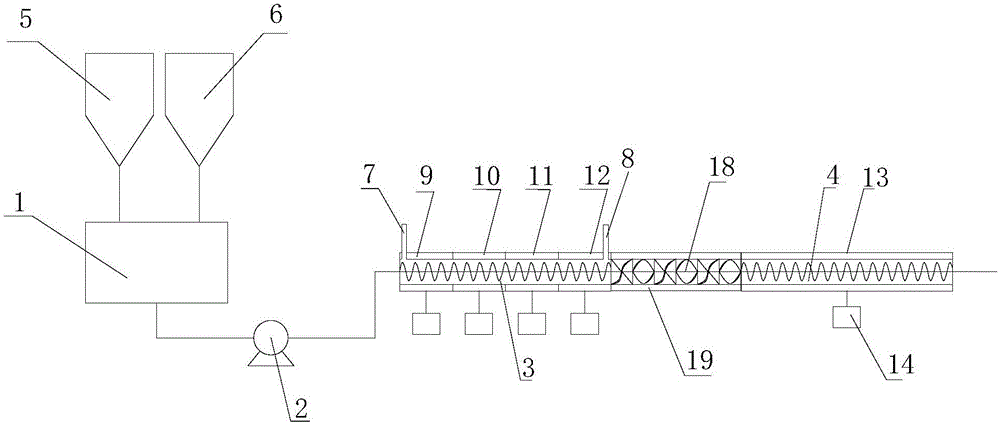

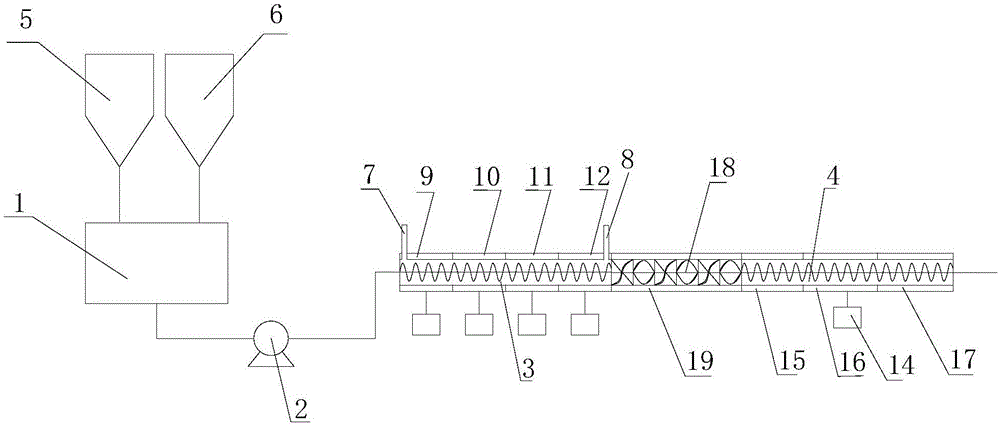

Device for continuous production of melamine-formaldehyde resin

ActiveCN106110987AImprove product qualityIncrease profitTransportation and packagingMixer accessoriesFormaldehyde productPulp and paper industry

The invention discloses a device for continuous production of melamine-formaldehyde resin, and belongs to the technical field of chemical equipments. The device comprises a mixture bin, a material pump, a first screw machine, a static mixer and a second screw machine which are connected in sequence, wherein the mixture bin is connected with a melamine high-order bin and a paraformaldehyde high-order bin respectively, an alkali liquor feed inlet is formed in the feed end of the first screw machine, and auxiliary material feed inlets are formed in the feed end, the middle end or the tail end of the first screw rod. The production device disclosed by the invention is high in utilization rate of raw materials, low in energy consumption, high in yield, free of three wastes (waste gases, waste water and waste residues) in the production process of the melamine-formaldehyde resin, and can continuously produce the melamine-formaldehyde resin with stable quality, and furthermore, melamine-formaldehyde resin products are good in quality.

Owner:郑州峰泰纳米材料有限公司

Novel method for concentration-improving alcohol removing of alcohol-containing thin formaldehyde solution

InactiveCN101139268AIncrease productionImprove distillation efficiencyCarbonyl compound separation/purificationAlcoholFormaldehyde product

The present invention discloses a novel method by concentrating the diluted formaldehyde solution containing alcohol and eliminating the alcohol, belonging to the technological field of the concentration and elimination of the alcohol of the diluted formaldehyde solution containing alcohol; the diluted formaldehyde solution containing alcohol with the alcohol of 0.5 to 15 percent and the aldehyde of 1 to 30 percent is sent into the pressurization and rectification tower for rectification; the product with the formaldehyde concentration of 1.5 to 65 percent can be got on the top of the pressurization and rectification tower; the product on the bottom of the tower is the organic wastewater; the products on the top of the pressurization and rectification tower are sent to the heat exchanger and are cooled to be at the temperature between 80 and 120 DEG C; then the products are sent to the alcohol-doffing tower for the continuous rectification; the methanol solution with the concentration of 40 to 80 percent can be got on the top of the alcohol-doffing tower; the formaldehyde solution with the concentration of 2 to 67 percent can be got on the bottom. The present invention is of the large output and the high rectification efficiency; the formaldehyde can be diluted to have the concentration of the conventional formaldehyde product; at the same time, the separated methanol can be recycled used for the formaldehyde production and so on.

Owner:ZHEJIANG SANPO POLYMER

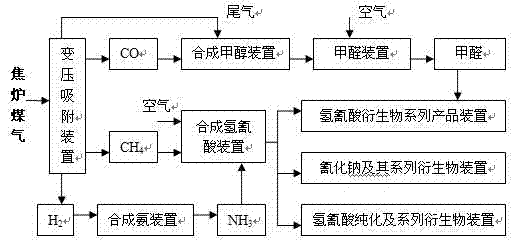

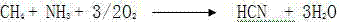

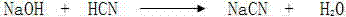

Environmental-protection cleaning technology for producing hydrocyanic acid derivatives by comprehensive utilization of coke oven gas

InactiveCN102897798AGood yieldGood industrial valueHydrogenCarboxylic acid nitrile preparationDehydrogenationSodium cyanide

The invention provides an environmental-protection cleaning technology for producing hydrocyanic acid derivatives by comprehensive utilization of coke oven gas. The environmental-protection cleaning technology is characterized in that 1, through the environmental-protection cleaning technology, coke oven gas is processed into relatively concentrated methane gas having relatively-low quality requirements by separation processes of pressure swing adsorption and the like, and the methane gas as a raw material is used for production of hydrocyanic acid derivatives; and 2, the environmental-protection cleaning technology concretely comprises the following steps that coke oven gas is separated by the separation processes of pressure swing adsorption and the like so that methane gas, hydrogen, carbon monoxide and tail gas are obtained; methane gas is synthesized into hydrocyanic acid mixed gas by ammonium oxidation or ammoniation dehydrogenation, and the hydrocyanic acid mixed gas reacts with a sodium hydroxide aqueous solution to produce sodium cyanide for synthesis of downstream hydrocyanic acid derivatives, or the hydrocyanic acid mixed gas and formaldehyde or other aldehydes are synthesized into hydroxyacetonitrile or other derivatives for synthesis of downstream hydrocyanic acid derivatives, or the hydrocyanic acid mixed gas is absorbed by water or other solvents and the solution is purified into high-purity hydrocyanic acid for synthesis of downstream hydrocyanic acid derivatives; hydrogen is used for synthesis of ammonia; and carbon monoxide and tail gas are used for synthesis of methanol and the synthesized methanol can be further oxidized into a formaldehyde product.

Owner:李宽义

Preparation method of environment-friendly textiles capable of reducing formaldehyde

InactiveCN104562688AReduce formaldehydePlay an environmental roleFibre treatmentFormaldehyde productAlcohol

The invention relates to a preparation method of environment-friendly textiles capable of reducing formaldehyde. The method comprises the following aspects: 1 blocking hydroxymethyl, which is an effective method for reducing formaldehyde emission, and can be divided into the following steps according to different blocking time: (1) blocking in a product production process, and (2) blocking when crosslinking in use; 2 producing a low-formaldehyde product, when hydroxymethyl is etherified with low-level alcohols, the stability of a C-N bond can be improved; and (3) adding polyhydric alcohols to a finishing liquid, so as to reduce the formaldehyde emission to not higher than 400ppm. According to the preparation method, formaldehyde can be effectively reduced, and the environment-friendly textiles are produced.

Owner:李长娟

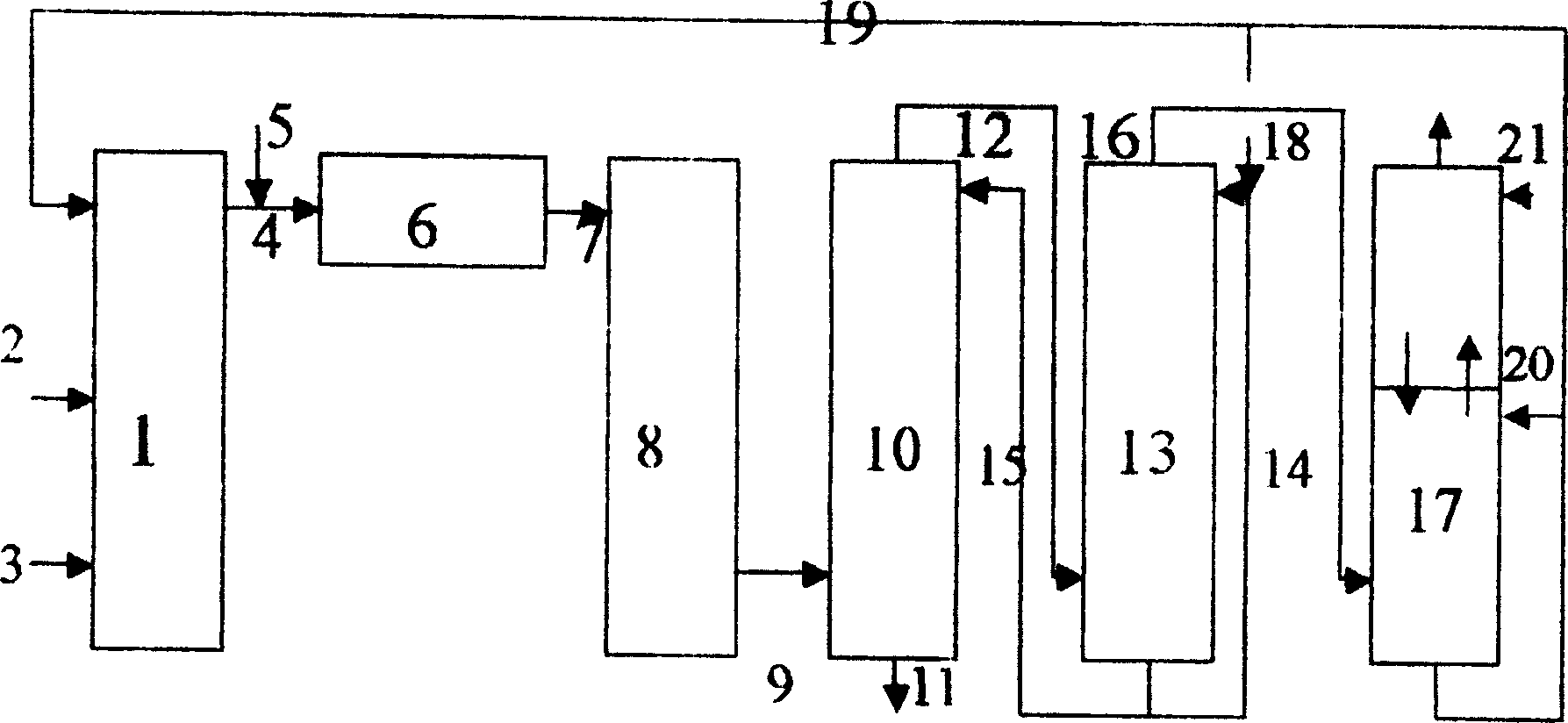

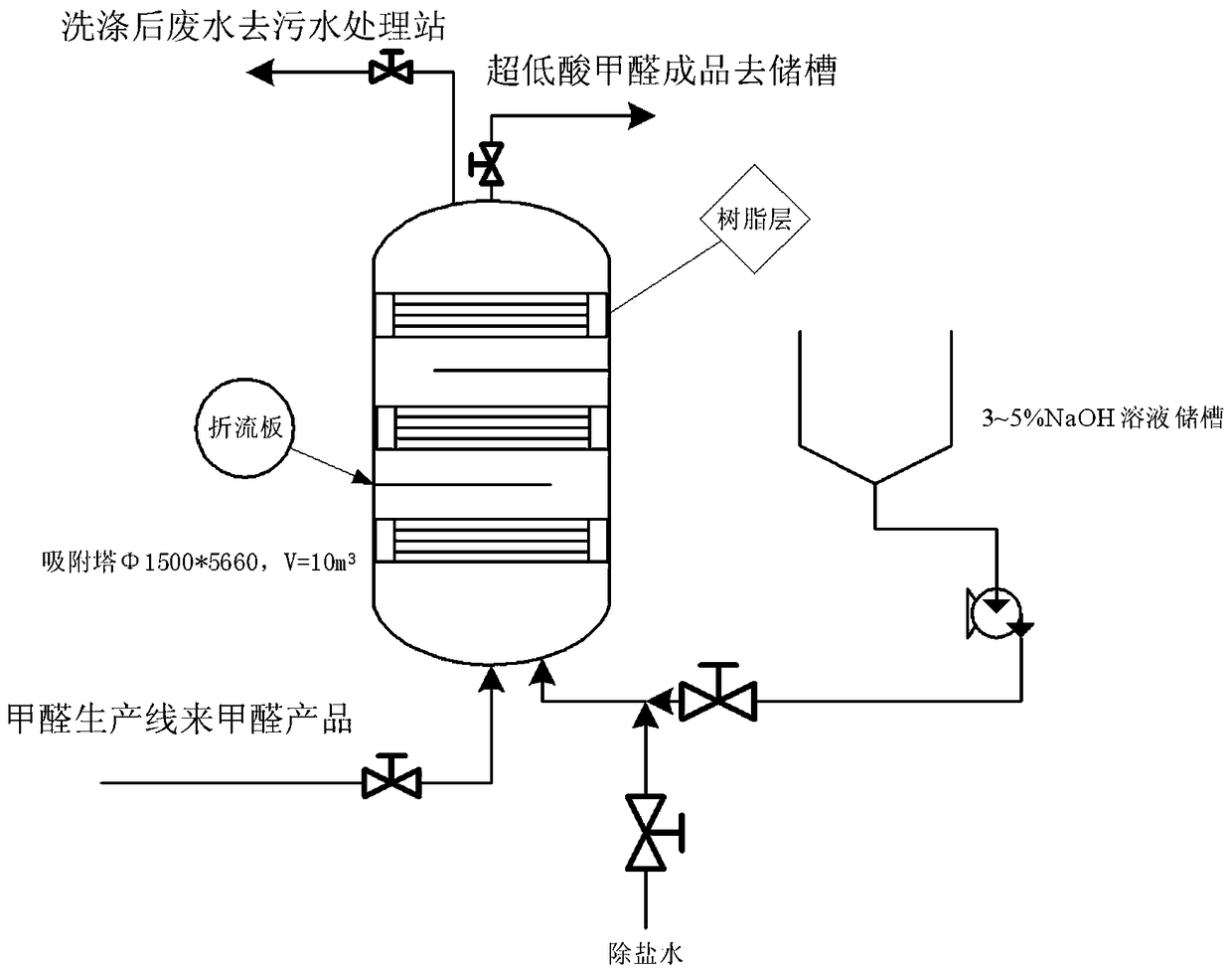

Method for producing ultralow-acid formaldehyde

InactiveCN108358768AMeet market needsCarbonyl compound separation/purificationFormaldehyde productCatalytic oxidation

The invention relates to a method for producing ultralow-acid formaldehyde. The method comprises the following steps: a, pumping 37% formaldehyde obtained by a catalytic oxidation reaction into a first anion exchange resin adsorption tower, adsorbing formic acid in the 37% formaldehyde by using weakly basic anion exchange resin in the first anion exchange resin adsorption tower, and conveying thefinished formaldehyde product obtained after the adsorption into a formaldehyde storage tank; b, timely switching a transfer pump to a second anion exchange resin adsorption tower (2) when the detected acid content of formaldehyde is equal to or more than 0.005%, continuously adsorbing the formic acid in the 37% formaldehyde by the weakly basic anion exchange resin, and conveying the finished formaldehyde product obtained after the adsorption into the formaldehyde storage tank; and c, regenerating the first anion exchange resin adsorption tower by a 3-5% NaOH solution in a forward flow manner,washing the first anion exchange resin adsorption tower with desalinated water, and continuously putting the regenerated first anion exchange resin adsorption tower into production and use. The method has the advantages of continuousness in production of the ultralow-acid formaldehyde, and meeting the needs of the market.

Owner:ANHUI JINGHE IND

Flame-retardant textile and flame-retardant adhesive for flame-retardant textile and preparation method of flame-retardant adhesive

ActiveCN106884317AReduce the temperatureSuppress generationHeat resistant fibresSoftened waterAdhesive

The invention discloses a flame-retardant textile and a flame-retardant adhesive for the flame-retardant textile and a preparation method of the flame-retardant adhesive. The flame-retardant adhesive is prepared from a waterborne white modified emulsion, a water-soluble polymer thickener, a foaming agent, a foam stabilizer, zinc borate, a halogen-free phosphorous nitrogen ammonia-based flame-retardant powder and softened water; the method comprises the steps of weighing a certain amount of softened water and waterborne white modified emulsion in a stirring tank; fully stirring, sequentially adding the foaming agent and the foam stabilizer; weighing the zinc borate, slowly and uniformly adding the halogen-free phosphorous nitrogen ammonia-based flame-retardant powder to a mixture, and stirring while adding; and adding the water-soluble polymer thickener, fully stirring, filtering and discharging to obtain the flame-retardant adhesive. By adopting the halogen-free phosphorous nitrogen ammonia-based flame-retardant powder, the flame-retardant adhesive does not contain halogen and does not cause secondary pollution to the air environment during combustion; since no formaldehyde is added, a product is more environment-friendly; the zinc borate plays a flame-retardant synergistic role as an auxiliary flame retardant; and the flame-retardant adhesive has the advantages of being simple in preparation technology, good in use effect and low in cost.

Owner:青岛博时阻燃织物有限公司

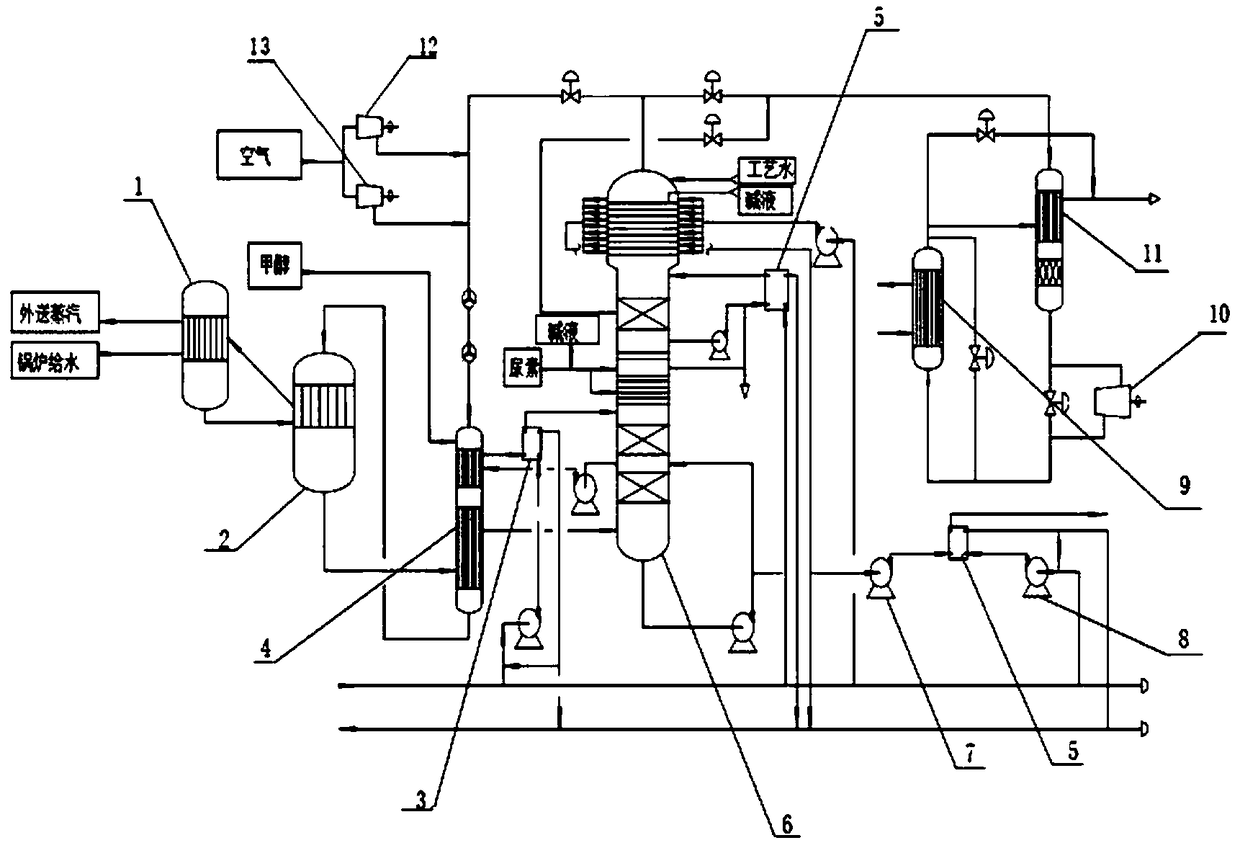

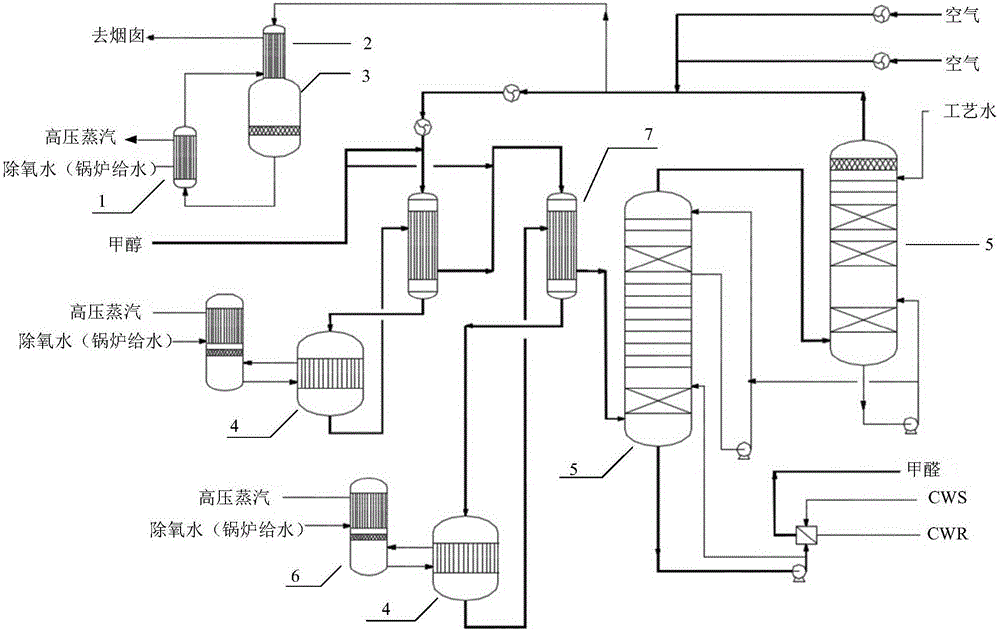

Method for producing formaldehyde and urea formaldehyde pre-concentrated liquid on super-large scale

InactiveCN107522604AImprove conversion rateImprove recyclingOrganic compound preparationCarbonyl compound preparationChemical industryLiquid waste

The invention relates to a method for producing a formaldehyde and urea formaldehyde pre-concentrated liquid. The method comprises steps as follows: S101: methanol is gasified and mixed raw gas is obtained; the mixed raw gas contains methanol with the concentration being 6%-11%, oxygen with the concentration being 9%-13% and the balance of inert gas; S102: the raw gas is sent into a reactor and subjected to a reaction at the temperature of 200-400 DEG C under the action of an iron-molybdenum catalyst; S103: a reaction product is sent into an absorption system to be absorbed by a preset solution, and the formaldehyde or urea formaldehyde pre-concentrated liquid is obtained finally. The provided process for producing oxidation-method (namely, an iron-molybdenum method) formaldehyde on a super-large scale has the outstanding advantages of being high in conversion rate, yield, product concentration and energy recovery degree, excellent in product quality, free of liquid wastes and solid wastes during normal production and the like and is particularly suitable for demands of the large modern chemical industry, the dilemma of extended monopoly of abroad iron-molybdenum method formaldehyde processes is thoroughly broken through, and the blank of the independent intelligent property right of the process in China is filled up.

Owner:赵达扬 +1

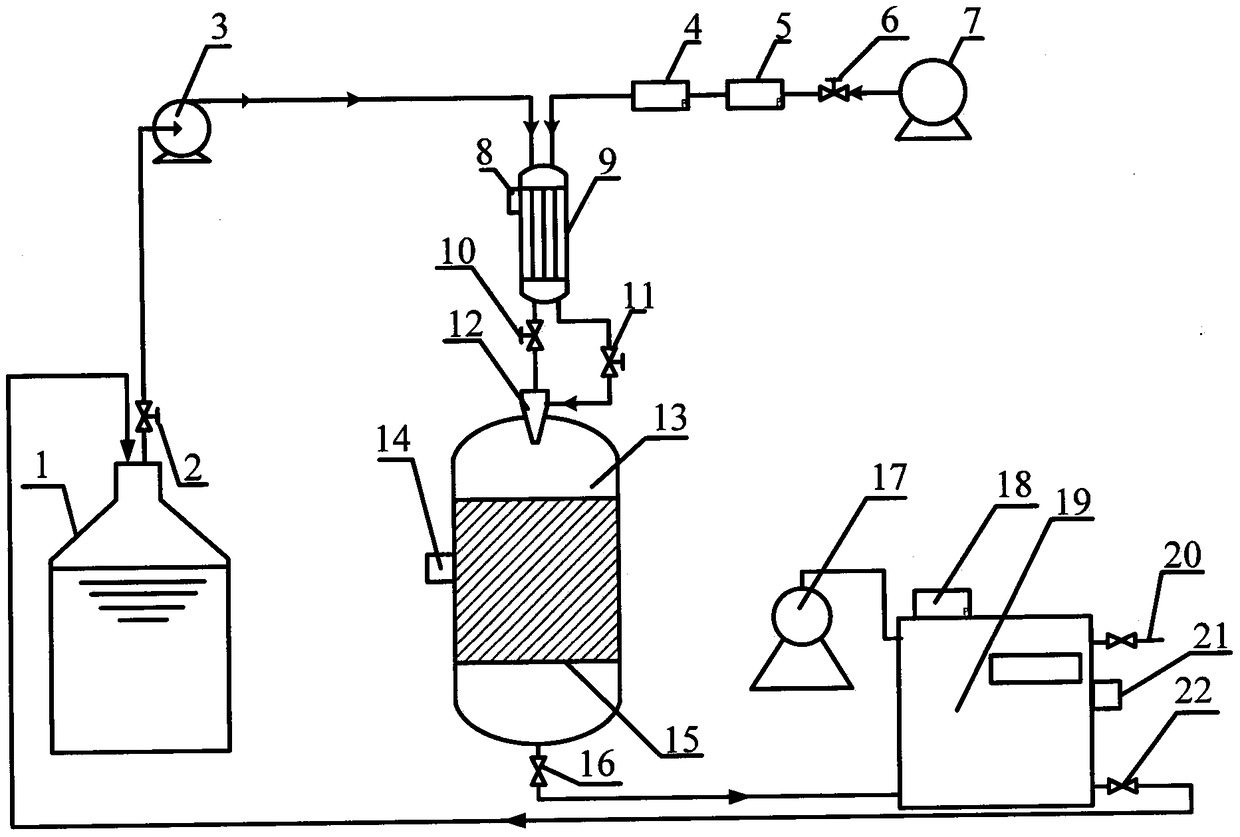

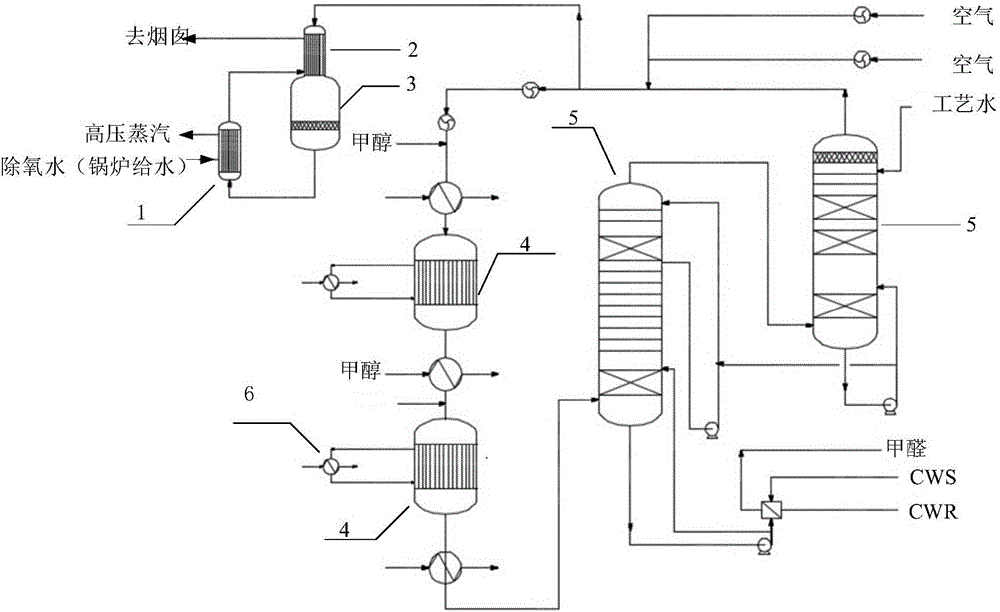

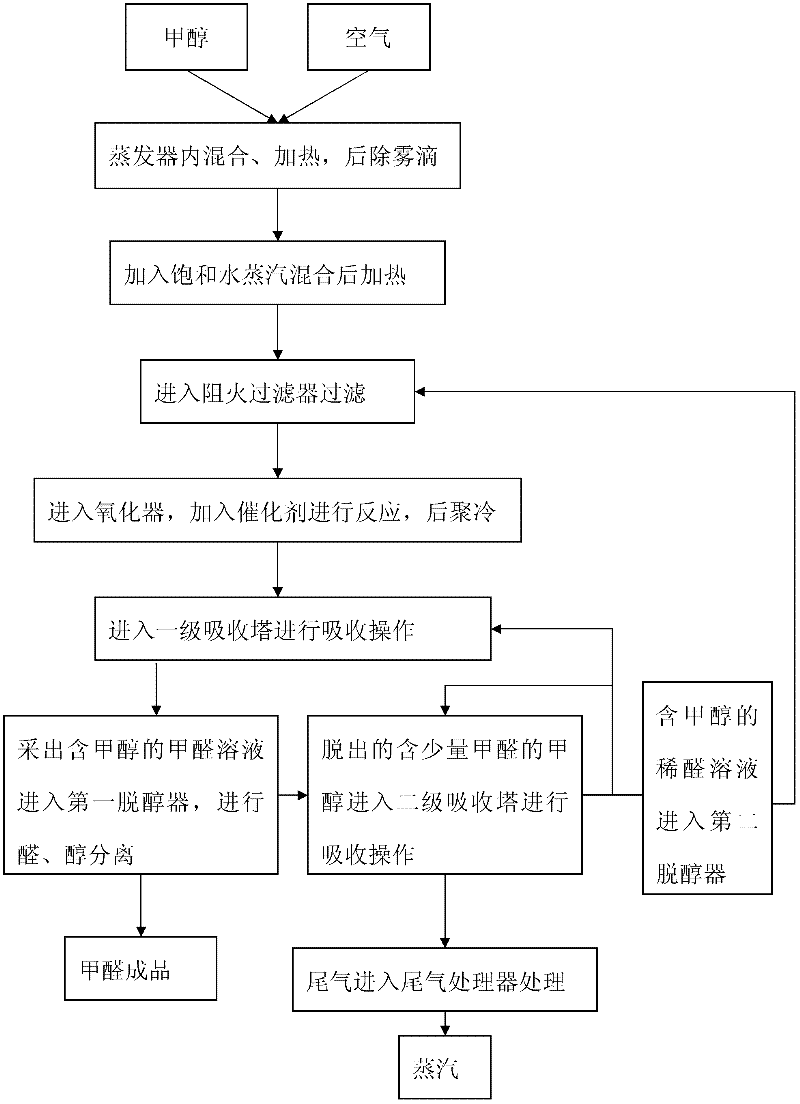

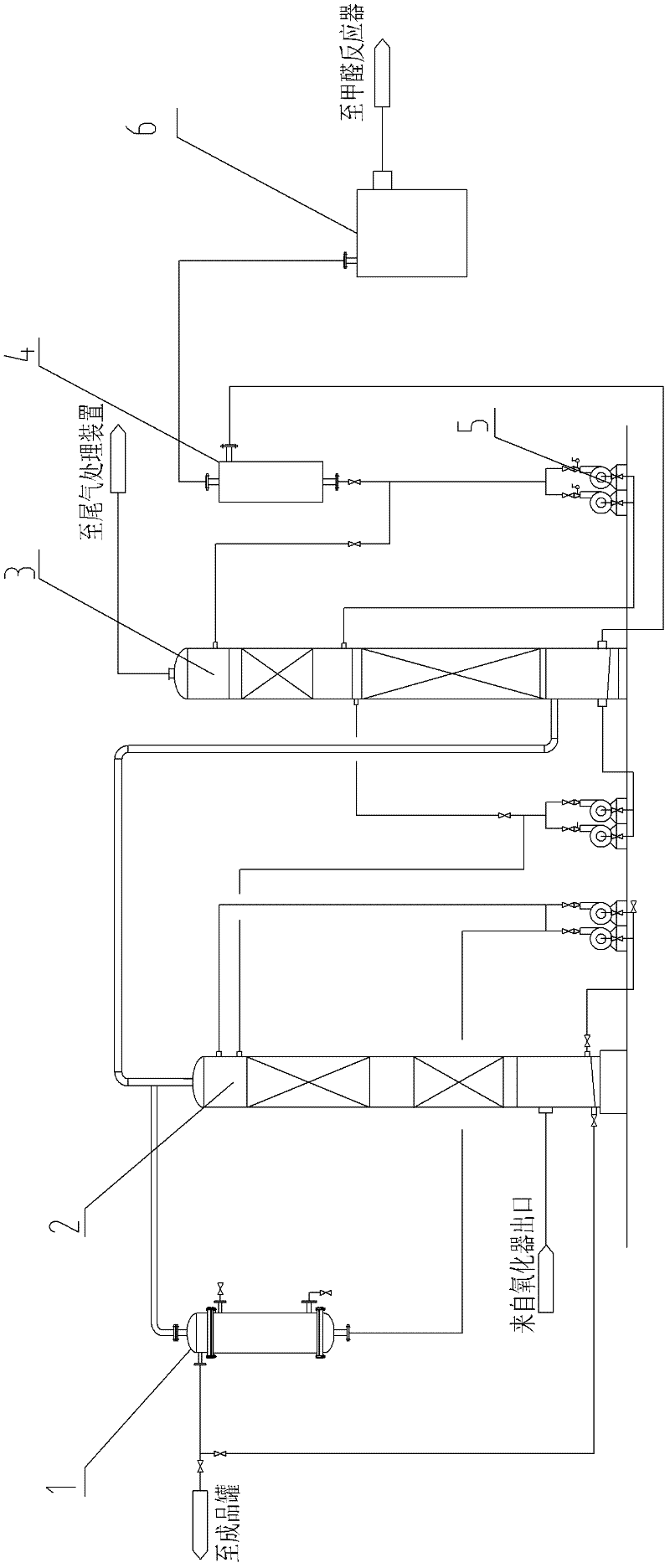

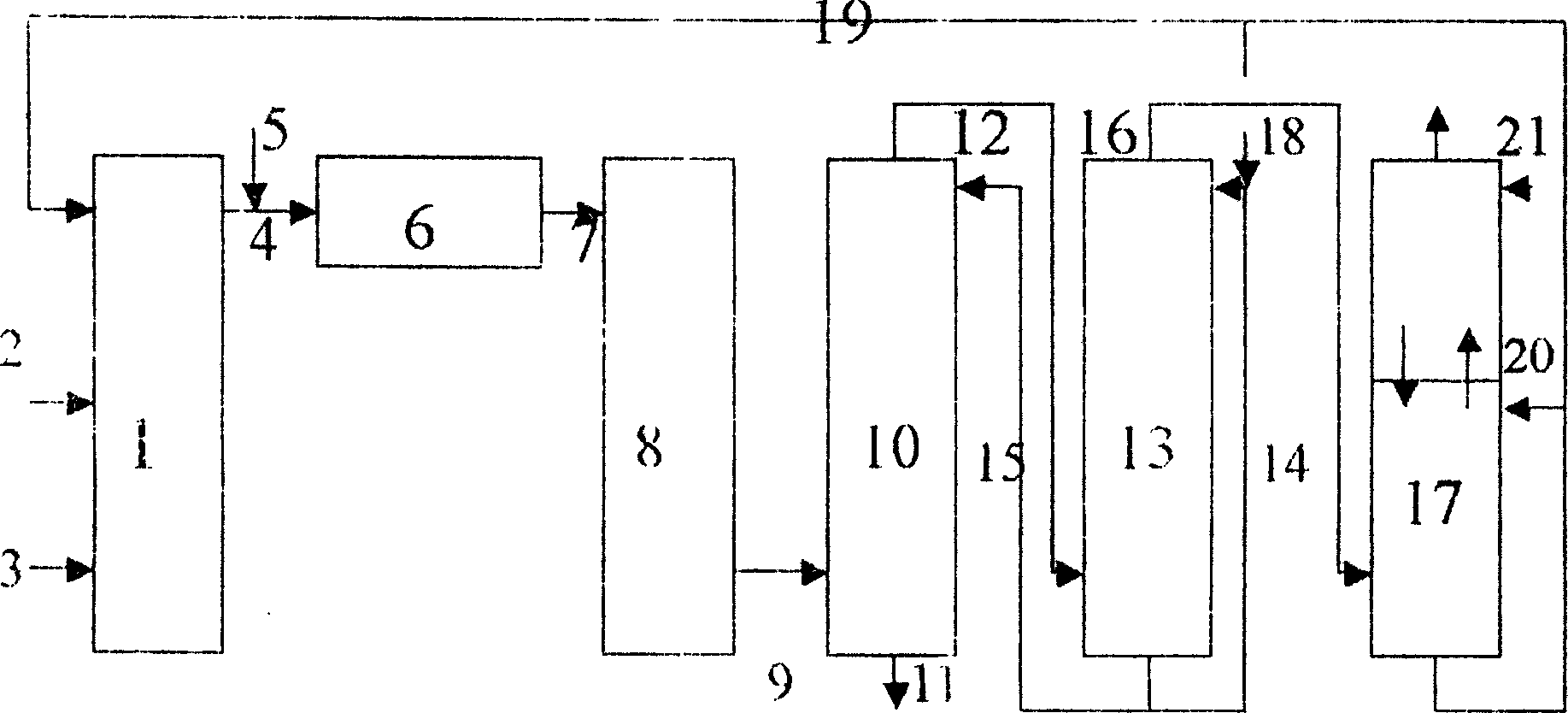

Low-conversion-rate high-yield formaldehyde production technology and device thereof

ActiveCN102381949AHypoxic temperature controlReduce unit consumptionOrganic compound preparationCarbonyl compound separation/purificationTemperature controlFormaldehyde product

The invention relates to the field of formaldehyde production technology, in particular to a low-conversion-rate high-yield formaldehyde production technology and device thereof. Reaction of ternary mixture with excessive methanol under action of catalyst is completed by controlling proportion of methanol in the ternary mixture, generated formaldehyde gas and other gases are cooled suddenly and fed into a primary absorption tower to be absorbed through process water, methanol-contained formaldehyde solution acquired from the primary absorption tower enters a first methanol removing device to be heated, methanol is removed in a gaseous state, the formaldehyde solution with methanol removed is used as finished formaldehyde products to be stored, the gaseous methanol removed by the first methanol removing device still contains formaldehyde in a small quantity so as to be fed into a secondary absorption tower to be absorbed and enter a second methanol removing device for removing methanol again, and the removed gaseous methanol enters a flame-retardant filter to enter a formaldehyde production system again for recycling reaction. The low-conversion-rate high-yield formaldehyde production technology has the advantages of low conversion rate, fewer negative reactions, low oxygen temperature control, long lifetime of catalyst, high yield and low material consumption.

Owner:JIANGSU KAIMAO PETROCHEM TECH

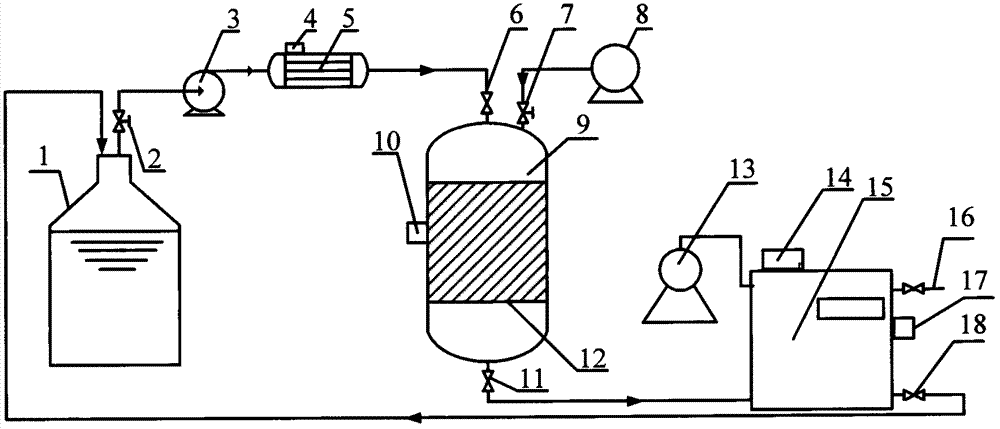

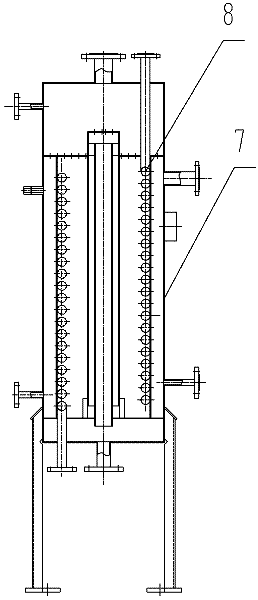

Energy-saving formaldehyde production system

InactiveCN105884593AEfficient removalIncrease mass concentrationOrganic compound preparationCarbonyl compound preparationFormaldehyde productEngineering

The invention relates to an energy-saving formaldehyde production system which comprises an evaporator, a gas mixer, an oxidizing reaction tower, a steam separation tower, an adsorption tower and a tail gas recycling device. The evaporator is connected with the gas mixer, the gas mixer is connected with a steam source, an outlet of the gas mixer is connected with a steam inlet of the oxidizing reaction tower, and a steam outlet of the oxidizing reaction tower is connected with a steam inlet of the steam separation tower. A steam exhaust port of the steam separation tower is connected with an inlet of the adsorption tower, a tail exhaust port of the adsorption tower is connected with a tail gas recycling device, and the steam separation tower comprises a tower body. The upper portion in the tower body is provided with at least one piece of metal regular filler through a frame, a liquid suction disc is arranged on the lower portion of the metal regular filler, and a water circulating cooling pond is arranged on the lower portion of the liquid suction disc. A large amount of steam in a formaldehyde gas mixture can be effectively removed through the steam separation tower, and therefore the mass concentration of produced formaldehyde products can be effectively improved.

Owner:TIANJIN FORINT TRANSCENDENTAL TECH DEV CO LTD

Method for producing low alcohol, high concentration formaldehyde

InactiveCN1208298CEnergy utilization is reasonableLow costCarbonyl compound separation/purificationRational useHigh concentration

Owner:洪海玲

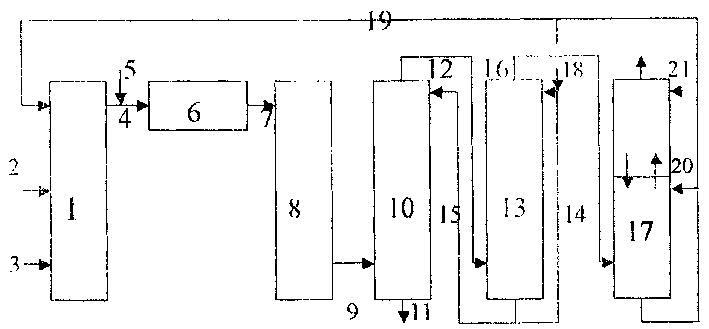

Preparation method of cyclic trimethylolpropane formaldehyde

InactiveCN108383826ASignificant technologySignificant craftsmanshipOrganic chemistryFormaldehyde synthesisFormaldehyde product

The invention relates to a preparation method of cyclic trimethylolpropane formaldehyde (CTF or MCF), mainly aiming at solving the problems in the prior art that synthetic conditions of trimethylolpropane formal are harsh, a process route is complicated, the purity of a product is low and the APHA color number is high. The preparation method comprises the following steps: taking trimethylolpropane(TMP) as a raw material, and mixing TMP, aldehyde, a solvent, a catalyst and an auxiliary agent according to a certain ratio; reacting at 60 to 120 DEG C for 0.1 to 6h; evaporating under low pressure, filtering and rectifying to obtain a cyclic trimethylolpropane formaldehyde product with the quality purity being greater than or equal to 98 percent and the color number APHA being less than or equal to 20. By adopting the preparation method provided by the invention, the problems are solved relatively well; a synthesis technology is simple and conditions are moderate, so that the preparation method can be widely applied to large-scale industrial production.

Owner:天津博奥新材料科技有限公司

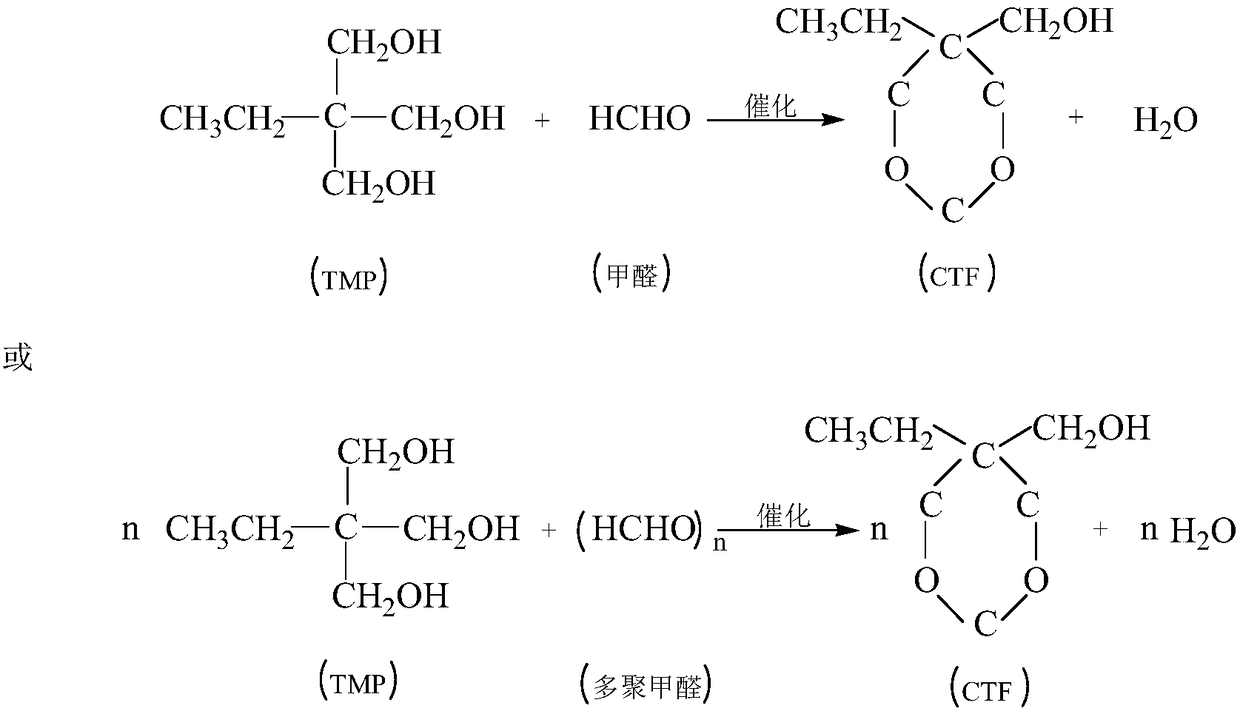

Method for preparing concentrated formaldehyde from low-formaldehyde-content materials

InactiveCN107011135AIncrease loadAppropriate solubilityOrganic compound preparationCarbonyl compound preparationAlcoholFormaldehyde product

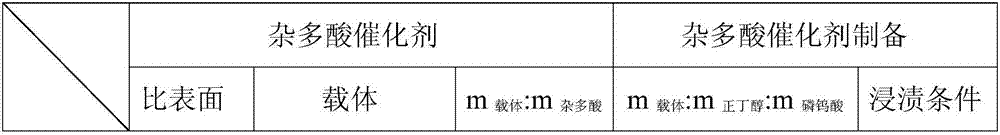

The invention relates to a method for preparing concentrated formaldehyde from low-formaldehyde-content materials. The method includes steps: (1) adding methyl alcohol into the low-formaldehyde-content materials, and performing reaction under the catalysis action of a heteropolyacid catalyst to obtain dimethoxymethane; (2) subjecting dimethoxymethane obtained at the step (1) to catalytic oxidation to obtain products including concentrated formaldehyde, wherein a concentrated formaldehyde product being 65-66wt% in concentration is obtained finally, and the formaldehyde recovery rate in the whole process is 97% or above. The method has advantages that special equipment for concentrating of dilute formaldehyde into concentrated formaldehyde is not needed, so that cost saving and energy consumption reduction are realized; circulation of dilute formaldehyde in a device is realized, independence from production by-products such as dimethoxymethane, urotropin or the like is realized, and COD level of wastewater and wastewater treatment cost are reduced.

Owner:江苏道尔顿石化科技有限公司

Manufacturing method of controlled natural biological odor-removal formaldehyde-removal product

The present invention relates to a manufacturing method of a controlled natural biological odor-removal formaldehyde-removal product, a plant is put in ice, added with a solvent, put in a mortar for grinding with liquid nitrogen, and after grinding, the plant is put into an extracting liquid for standing in the ice for 3 ~ 4h, and centrifuged at a low temperature of 4 DEG C with a centrifuge in the rate of 11100rpm / 20min to extract a supernatant to obtain plant protein enzyme. The protein enzyme and water are mixed for preparation, and added into a plastic bottle, by use of a cylinder7mm *70mm porous enamel rod for suction floating and use of a top heater for continuous controlled evaporation at a certain temperature, the purpose of removal of indoor formaldehyde and odor can be achieved, and 95% of carbon monoxide, 99 % of formaldehyde, 95% of nitrogen peroxide, 90% of benzene and 92% of trichloro ethylene can be removed.

Owner:江苏微特克纳米科技有限公司

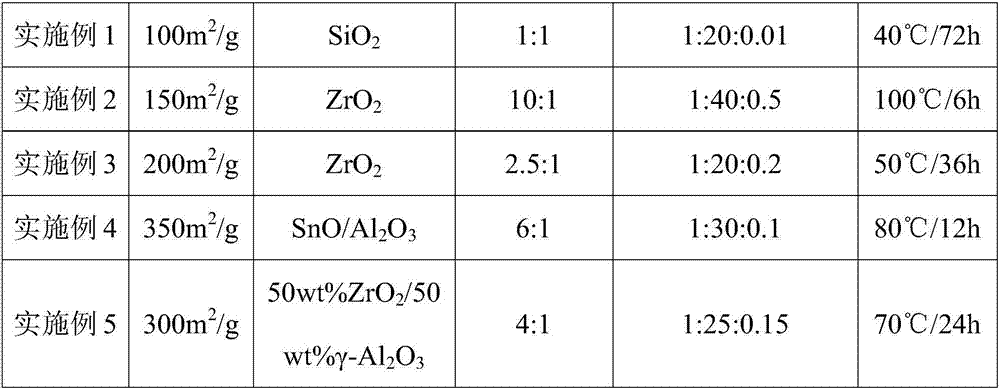

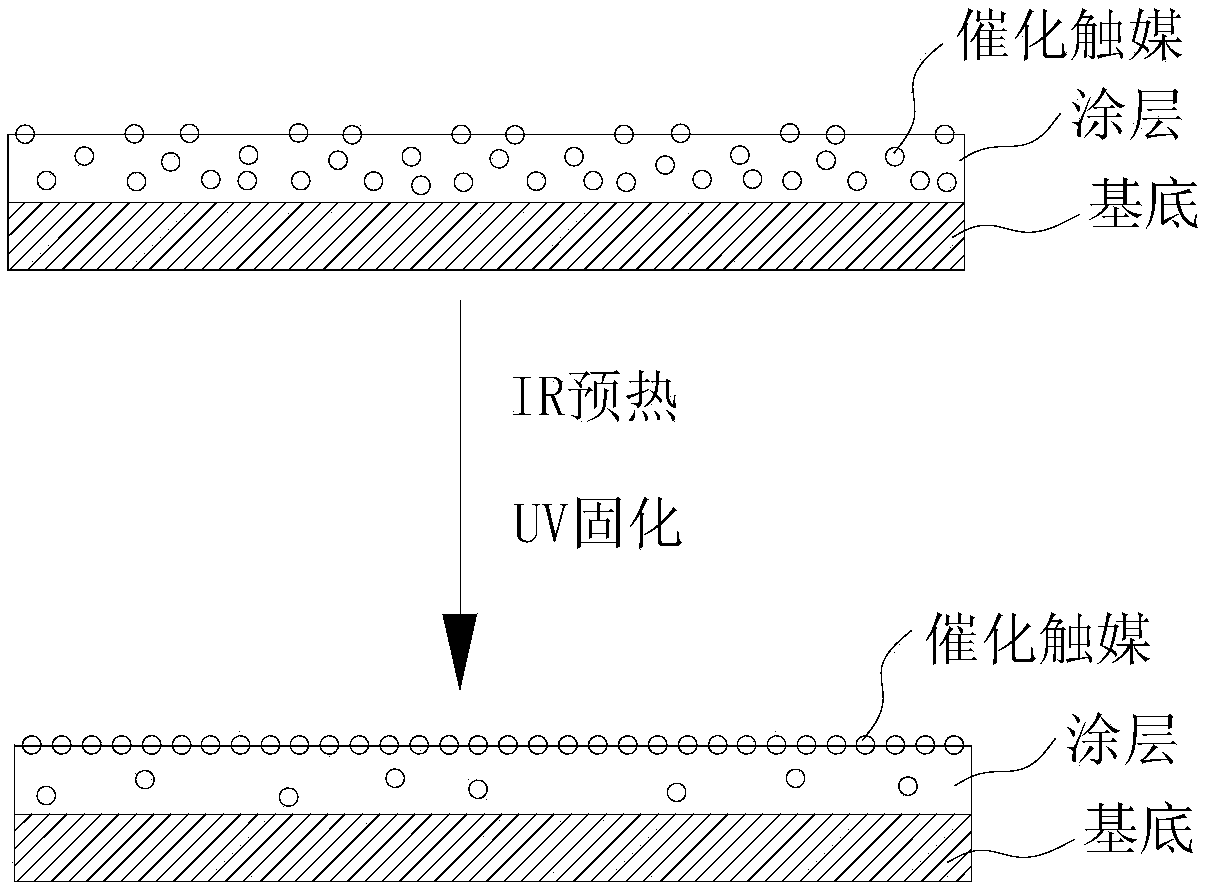

UV-curing coating with formaldehyde-removing function, and formaldehyde-removing product and method for producing the same

ActiveCN108559370AHas the function of removing formaldehydeLow viscosityPolyester coatingsUltraviolet lightsPhotosensitive polymer

The invention discloses a UV-curing coating with formaldehyde-removing function. The UV-curable coating with formaldehyde-removing function is prepared from the following raw materials in parts by mass: the total mass is 100 parts, 15-35 parts of light-sensitive polymer; 10-25 parts of thermoplastic resin; 35-65 parts of photoactive monomer; 1-5 parts of photosensitizer; 1-8 parts of catalytic catalyst; 5-10 parts of filler; 0.1-5 parts of dispersing agent; 0-1 part of defoaming agent. The invention also discloses a method for producing formaldehyde-removing product by using the UV-curing coating, which comprises the following steps of: (1) coating a UV-curing coating on a substrate, and preheating the coating by using infrared light, wherein the preheating temperature is 50-130 DEG C, andthe preheating time is 5 seconds-5 minutes; (2) after the preheating, curing with the ultraviolet light. The invention also discloses a formaldehyde removal product produced by above-mentioned method. The UV-curing coating has the advantages of low viscosity, high light-curing speed and no volatile organic solvent.

Owner:HANGZHOU KEWANG SPECIAL INK CO LTD

Zero-aldehyde adhesive for plywood and preparation method of zero-aldehyde adhesive

InactiveCN107805468AGood viscosity performanceNo emissionsNon-macromolecular adhesive additivesProtein adhesivesFormaldehyde productAdhesive

The invention relates to the technical field of plywood, in particular to a zero-aldehyde adhesive for plywood and a preparation method of the zero-aldehyde adhesive. The zero-aldehyde adhesive for plywood comprises the following components in parts by weight: 10-20 parts of water glass, 5-15 parts of a promoter, 20-30 parts of sodium alginate, 10-20 parts of gelatin, 3-5 parts of sodium fluosilicate, 5-10 parts of a halogen-free flame retardant and 20-30 parts of cationic water. The adhesive is good in viscosity, does not contain formaldehydes products, does not release formaldehyde, methylbenzene, xylene or the like, and can reach fireproof A2 level; and poisonous gas or smoke is not discharged.

Owner:临沂绿醛胶业有限公司

Preparation method of furan resin

The invention discloses a preparation method of furan resin. The preparation method comprises the following steps: (1) preparing raw materials; (2) preparing modified lignin; (3) preparing a graphene dispersant; (4) putting solid formaldehyde and urea into a reaction kettle, and adding boric acid; (5) adding a graphene dispersing agent and furfuryl ketone, and carrying out a catalytic reaction; (6) adding a sodium hydroxide solution to adjust the pH value to 7-9, adding modified lignin, and reacting for 1 hour; (7) adding a coupling agent, and stirring; and (8) adding metal salt, and stirring to finally obtain a finished product. The solid formaldehyde and furfuryl ketone are adopted for reaction, formaldehyde generated in the generation process can be consumed, the free formaldehyde content of the product can be reduced to 0.09%, boric acid is added, the graphitization degree of furan resin is improved, the wear resistance and thermal shock resistance of the furan resin are improved, the brittleness of the furan resin is reduced, and the furan resin has good toughness and bonding strength.

Owner:山东永创材料科技有限公司

Controllable natural biological odour removing and formaldehyde removing product as well as preparation method and application thereof

InactiveCN106178928ASolve the problem of not reaching the temperature and not evaporatingLasting effectDispersed particle separationDeodrantsBenzeneFormaldehyde product

The invention relates to a controllable natural biological odour removing and formaldehyde removing product, as well as a preparation method and application thereof. A plant protein enzyme is obtained by placing a plant on ice, adding a solvent into the plant, grinding the plant in a mortar by using liquid nitrogen, adding the plant into an extracting solution after the plant is ground, standing the mixture on the ice for three to four hours, centrifuging the mixture at 11,100 rpm / 20 minutes / 4 DEG C at a low temperature, and extracting to obtain supernate. The protein enzyme and water are prepared, are added into a plastic bottle, are adsorbed through a cylindrical 7mm*70mm porous enamel rod, and are continuously evaporated at a certain controllable temperature through a top heater, so that the effects of removing the odour and removing the formaldehyde indoors are achieved; 95 percent of carbon monoxide, 99 percent of the formaldehyde, 95 percent of nitrogen peroxide, 90 percent of benzene and 92 percent of trichloroethylene are removed.

Owner:江苏微特克纳米科技有限公司

Modified nanosilica, preparation method and application in preparation of formaldehyde-free products

InactiveCN108640121APlay a role in decompositionLong-acting decompositionSilicaDispersed particle separationFormaldehyde productArtemisinin G

The invention discloses modified nanosilica, a preparation method and an application in preparation of a formaldehyde-free product. The preparation method of the modified nanosilica comprises the following steps: adding 5-15 g of nanosilica to 90-120 ml of ethanol for ultrasonic dispersion for 1-3 h, adding 0.5-1.2 g of [3-(2-aminoethyl)aminopropyl]trimethoxysilane, 0.2-0.6 g of artemisinin and / orliquiritigenin, performing stirring for a reaction for 4-6 h, and performing drying. The modified nanosilica can realize effects of long-term sterilization, antibacterial performance and decomposition of harmful formaldehyde gas. The modified nanosilica has huge market space in preparation of the formaldehyde-free product.

Owner:李兵峰

Colorful urea-formaldehyde material and manufacturing method of urea-formaldehyde product

The invention discloses a colorful urea-formaldehyde material. The colorful urea-formaldehyde material comprises urea-formaldehyde powder and also comprises pearl powder or glitter powder; and the urea-formaldehyde powder consists of urea-formaldehyde resin, filler, a lubricating agent, a stabilizer and a plasticizer. The invention also relates to a manufacturing method of a urea-formaldehyde product. The pearl powder or the glitter powder and an antibacterial material are added into the urea-formaldehyde powder, or the pearl powder or the glitter powder is added in the synthesis process of the urea-formaldehyde powder, so that the outer surface of the urea-formaldehyde product manufactured by the material has colorful effect, and the beautiful degree and the identification degree of the product are increased.

Owner:GUOSEN COMMODITY

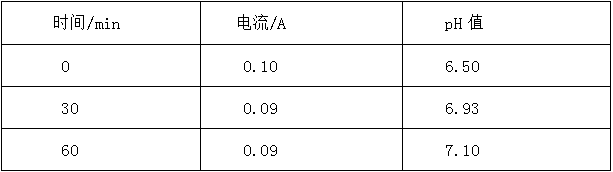

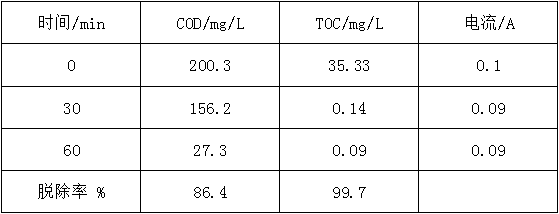

Method for treating methanol and formaldehyde industrial wastewater by electrocatalytic oxidation

InactiveCN105217743BMass transfer speedIncrease the effective reaction areaWater contaminantsWater/sewage treatment using germicide/oligodynamic-processChemical industryAutomatic control

The invention discloses a method for electrocatalytic oxidation treatment of industrial wastewater containing methanol and formaldehyde. An active oxide coating electrode with electrocatalytic function is used for electrocatalytic oxidation treatment of industrial wastewater containing methanol and formaldehyde. Operating process conditions: the operating voltage is 3~100V, current 0.01A / cm2~2.60A / cm2. The invention has the advantages of simple treatment process, convenient operation, stable performance, high efficiency, low power consumption, less investment and low cost. The coating electrode has stable properties and has a good application prospect in the field of treating such industrial wastewater and recycling. The COD content in the water after wastewater treatment in the production of methanol and formaldehyde series products can be reduced to less than 30 mg / L, and the pH value after treatment is neutral, which can make the wastewater treatment in the production of methanol and formaldehyde series products reach recycling recycling The quality requirements stipulated by the national and chemical industry standards used.

Owner:南京桐纳新材料科技有限公司 +1

3,4-dihydroxybenzaldehyde purification and decolorization method

ActiveCN104926632AEasy post-processingSecondary pollutionCarbonyl compound separation/purificationDisodium EdetateCobalt

The invention discloses a 3,4-dihydroxybenzaldehyde purification and decolorization method, comprising the steps of: taking industrial 3,4-dihydroxybenzaldehyde as a raw material; taking a combined reducing agent as a decolorant, wherein the combined reducing agent is formed by proportionately combining solid chemicals such as magnesium powder, iodine-potassium iodide, polyacrylamide and disodium edetate; performing stirring and filtering to obtain filtrate; and cooling and crystallizing the filtrate, so that purified and decolorized 3,4-dihydroxybenzaldehyde is obtained. According to tests, a measured value of product purity of the 3,4-dihydroxybenzaldehyde obtained by using the method of the invention is greater than 99.5 wt%, and chromaticity of an aqueous solution with 20 wt% of 3,4-dihydroxybenzaldehyde is less than 100 (the platinum-cobalt method). The method of the invention has characteristics of having a good effect of purification and decolorization, being simple in post-processing, being stable and non-toxic and causing no secondary pollution. The method is low in decolorant consumption, low in cost, stable in product quality, environmentally friendly and suitable for industrial production.

Owner:SINOPHARM CHEM REAGENT

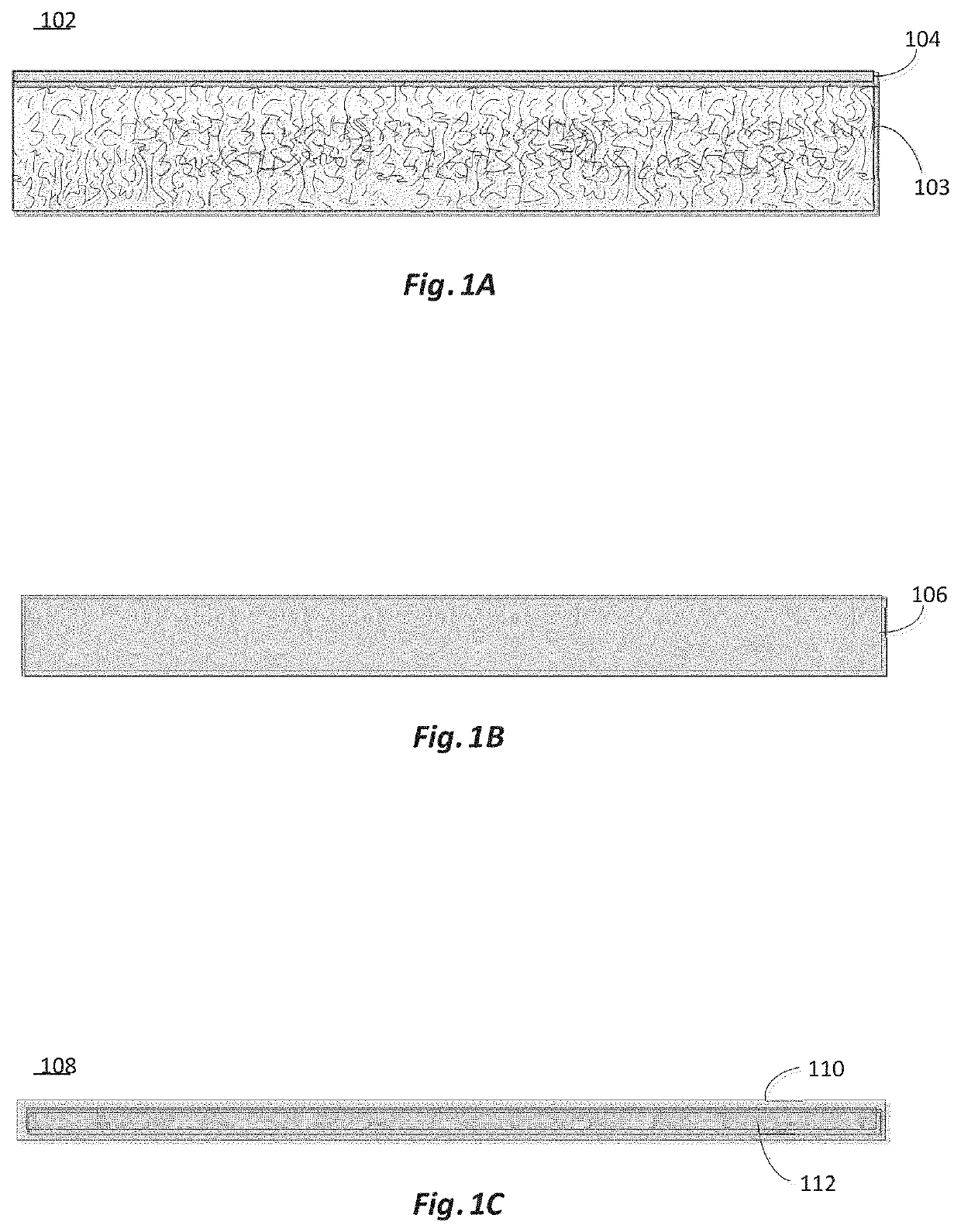

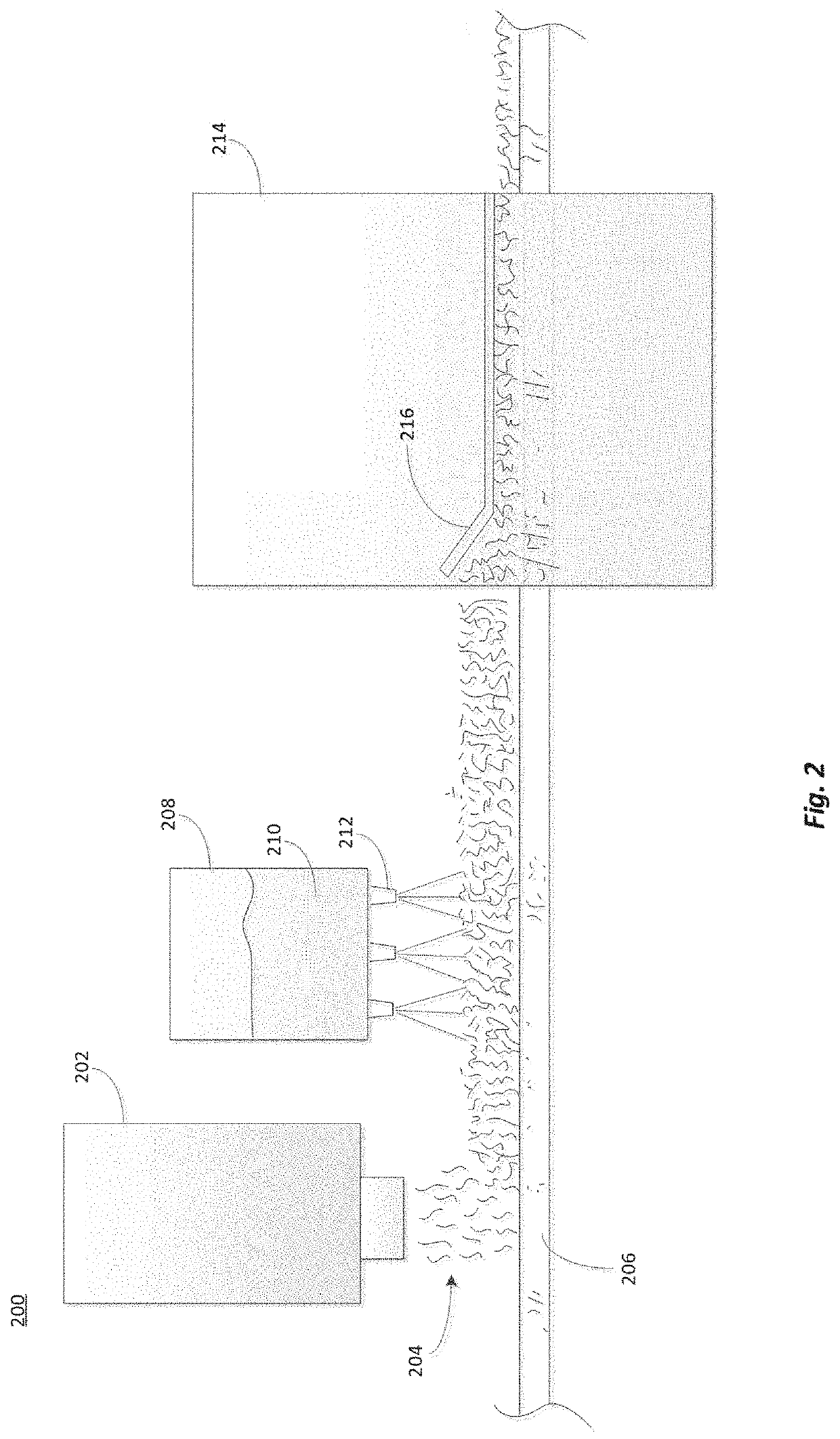

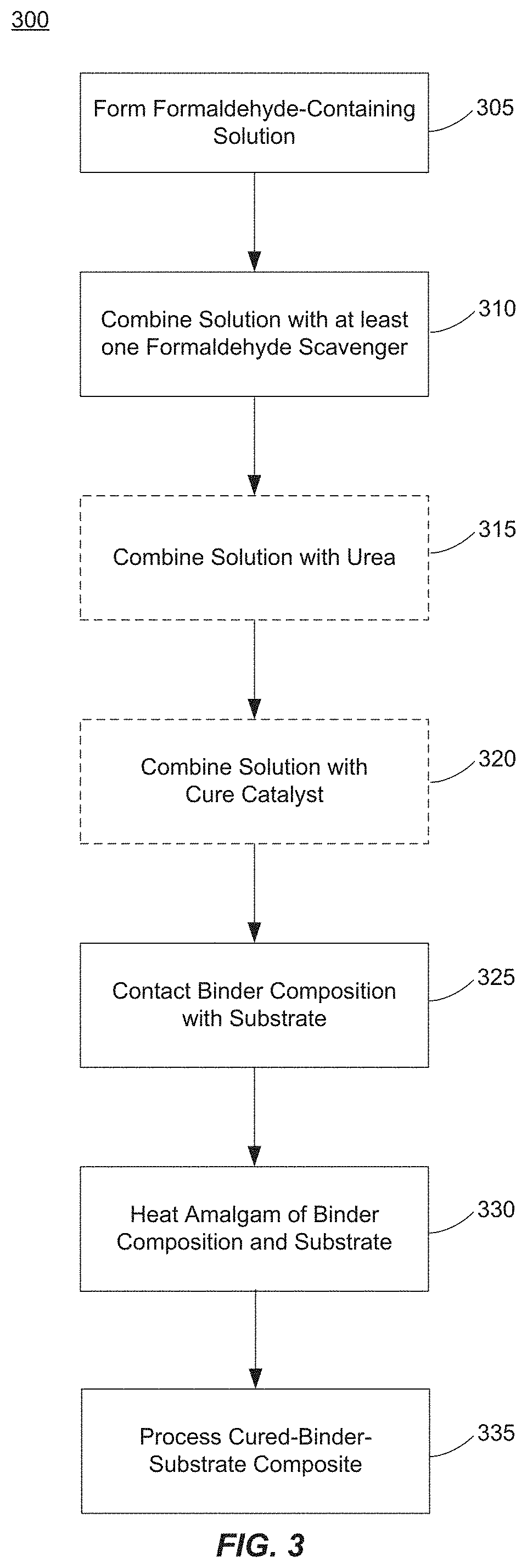

Formaldehyde-containing products with reduced formaldehyde emissions

PendingUS20220364283A1Reduce formaldehyde emissionImprove cure kineticsNon-woven fabricsPolyamine CompoundGlass fiber

Binder compositions are described that include at least one formaldehyde-containing compound, a cyclic urea-dialdehyde compound, and a polyamine compound. The polyamine compound may be selected from melamine and dicyandiamide. The weight ratio of the at least one formaldehyde-containing compound to the combined weight of the cyclic urea-dialdehyde compound and the polyamine compound may be greater than or about 1:1. As described are binder-containing fiberglass products that include glass fibers and a binder. The binder may include a formaldehyde polymer characterized by crosslinking with a cyclic urea-dialdehyde and a polyamine. The binder-containing fiberglass products have reduced formaldehyde emissions.

Owner:JOHNS MANVILLE CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com