Method for producing ultralow-acid formaldehyde

A production method and ultra-low acid technology, which can be used in the separation/purification of carbonyl compounds, organic chemistry, etc., and can solve problems such as the impact of product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

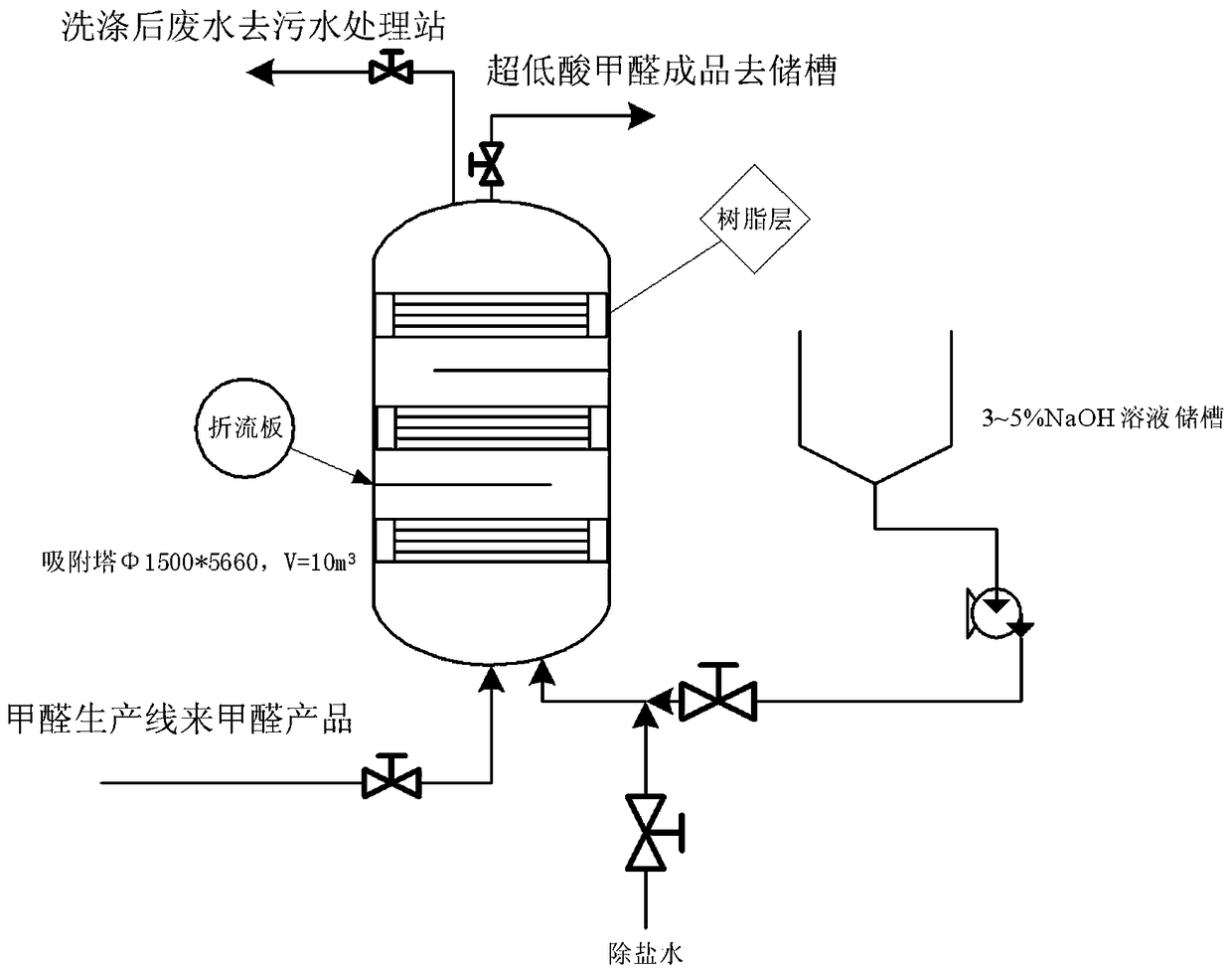

[0019] Such as figure 1 As shown, the 37% formaldehyde solution produced by formaldehyde has an acid content of 0.03% after testing. It is pumped into the first adsorption tower, and the formaldehyde solution enters the tower from bottom to top for adsorption. The flow rate is 20m 3 / h, after being adsorbed by D301 weakly basic macroporous anion exchange resin, the acid content in formaldehyde is detected to be 0.002%; after a period of time, when the acid content in ultra-low acid formaldehyde is detected to be ≧0.005%, switch to the second adsorption tower , immediately regenerate the first adsorption tower, using 3~5% NaOH solution, the flow rate of regeneration lye is 3~5m / s, the regeneration time is 1~2h, and after washing with desalinated water, the pH of the adsorption tank reaches 7.2~8.0, which can be cycle adsorption.

example 2

[0021] The 37% formaldehyde solution produced by formaldehyde has an acid content of 0.04% after testing. It is pumped into the first adsorption tower, and the formaldehyde solution enters the tower from bottom to top for adsorption. The finished product goes to the ultra-low acid formaldehyde product tank, and the pumping flow rate is 20m 3 / h, after being adsorbed by D301 weakly basic macroporous anion exchange resin, the acid content in formaldehyde was detected to be 0.003%. After a period of time, when the acid content in ultra-low-acid formaldehyde is detected to be ≧0.005%, switch to the second adsorption tower, and immediately regenerate the first adsorption tower, using 3~5% NaOH solution, and the flow rate of the regenerated lye is 3~5m / s, the regeneration time is 1~2h, and after washing with desalinated water, the pH of the adsorption tank reaches 7.2~8.0, which can be recycled for adsorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com