Integral wooden door made of wood fiber composite materials

A composite material and wood fiber technology, applied in the production field of integral wooden doors and wooden doors, can solve the problems that the supply of wood cannot meet people's needs, the production process is complicated, and the processing procedures are many, so as to improve the production efficiency, simplify the production process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

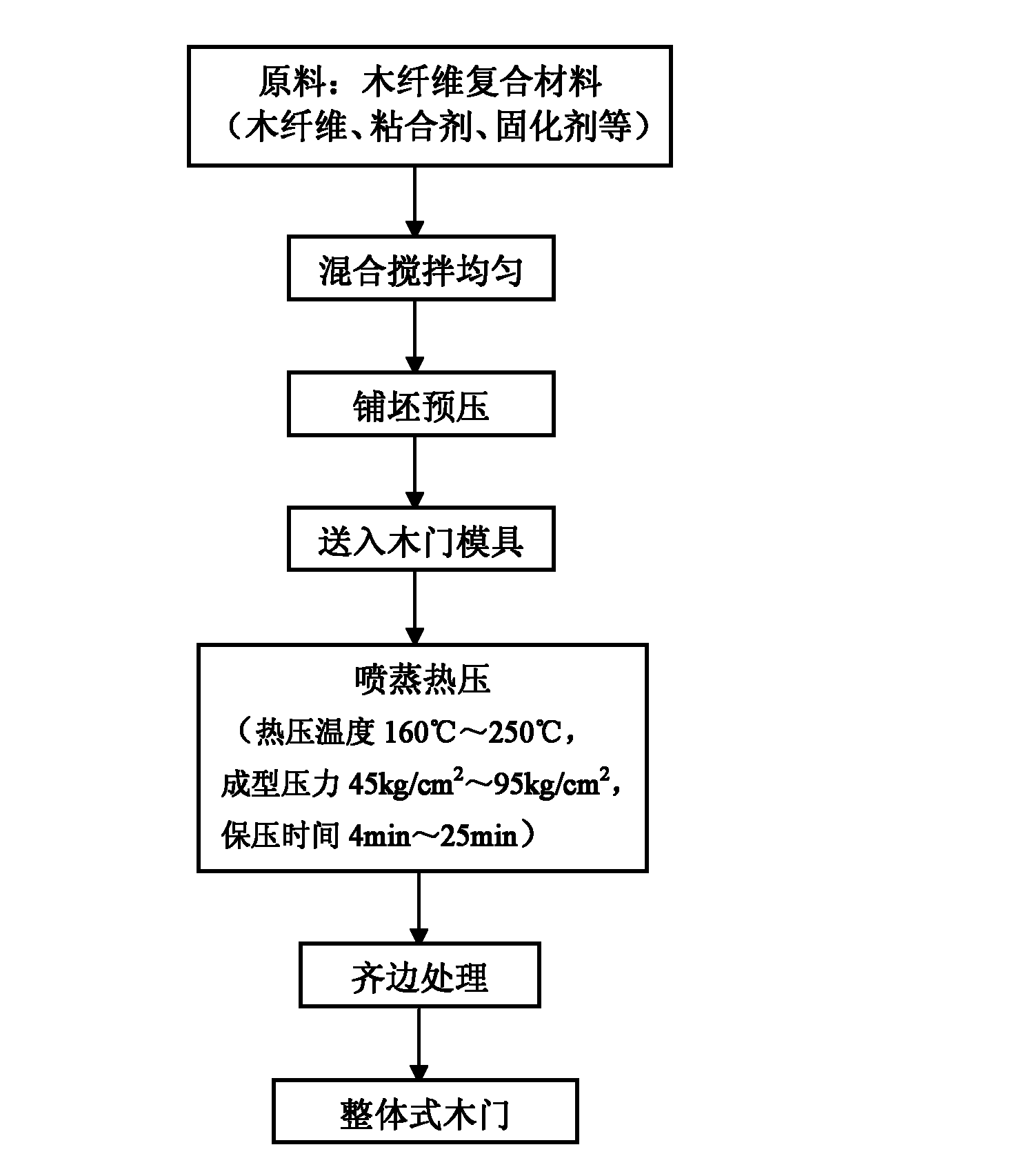

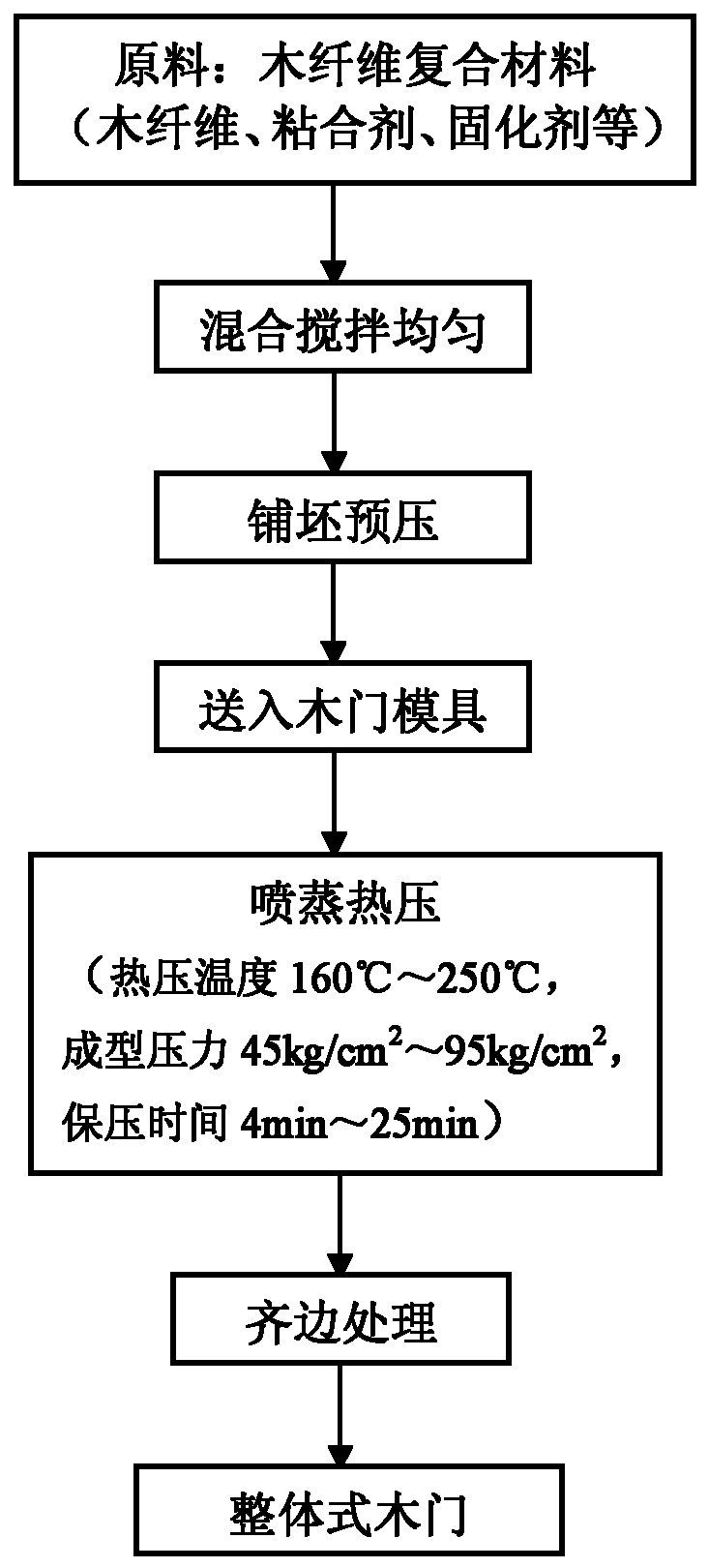

Method used

Image

Examples

Embodiment 1

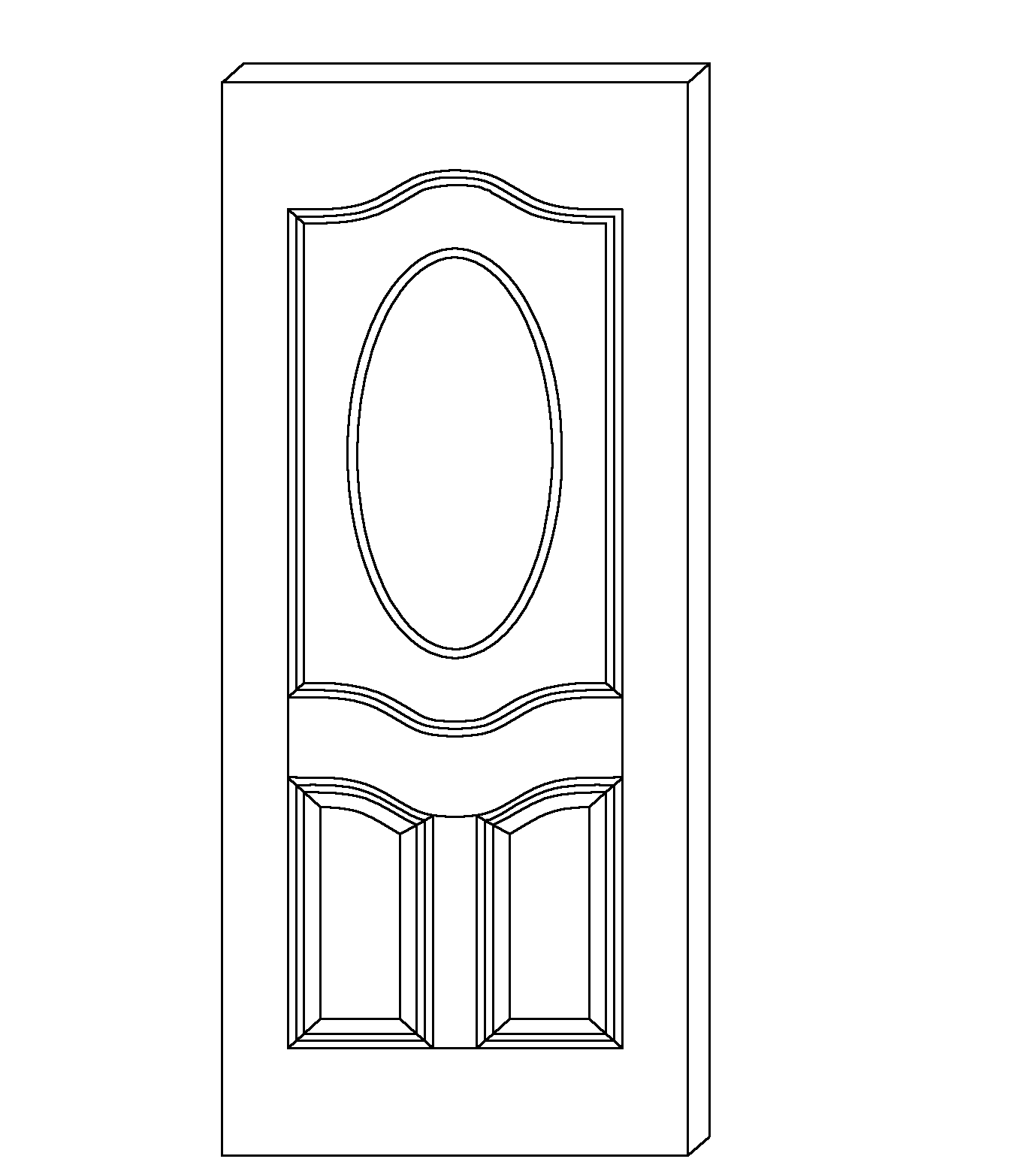

[0024] In this embodiment 1, the front structural schematic diagram of the integral wooden door made of wood fiber composite material is as follows figure 2 As shown, its size is 2000mm×850mm×40mm, and the surface has concave and convex three-dimensional exquisite decorative patterns. The integral wooden door is obtained by one-time molding of wood fiber composite material through molding technology; wherein, in terms of parts by mass, the wood fiber composite material includes 100 parts of wood fiber, 15 parts of adhesive, 2 parts of curing agent, and an appropriate amount of waterproofing agent and The release agent, the adhesive is made of urea-formaldehyde resin, the curing agent is made of ammonium phosphate, the waterproofing agent is made of liquid paraffin, and the release agent is made of sodium silicate; the production process is as follows:

[0025] (1) Drying: The wood fiber is dried, and the moisture content of the fiber is controlled to be about 10-12% according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com