Patents

Literature

109results about How to "Protect forest resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

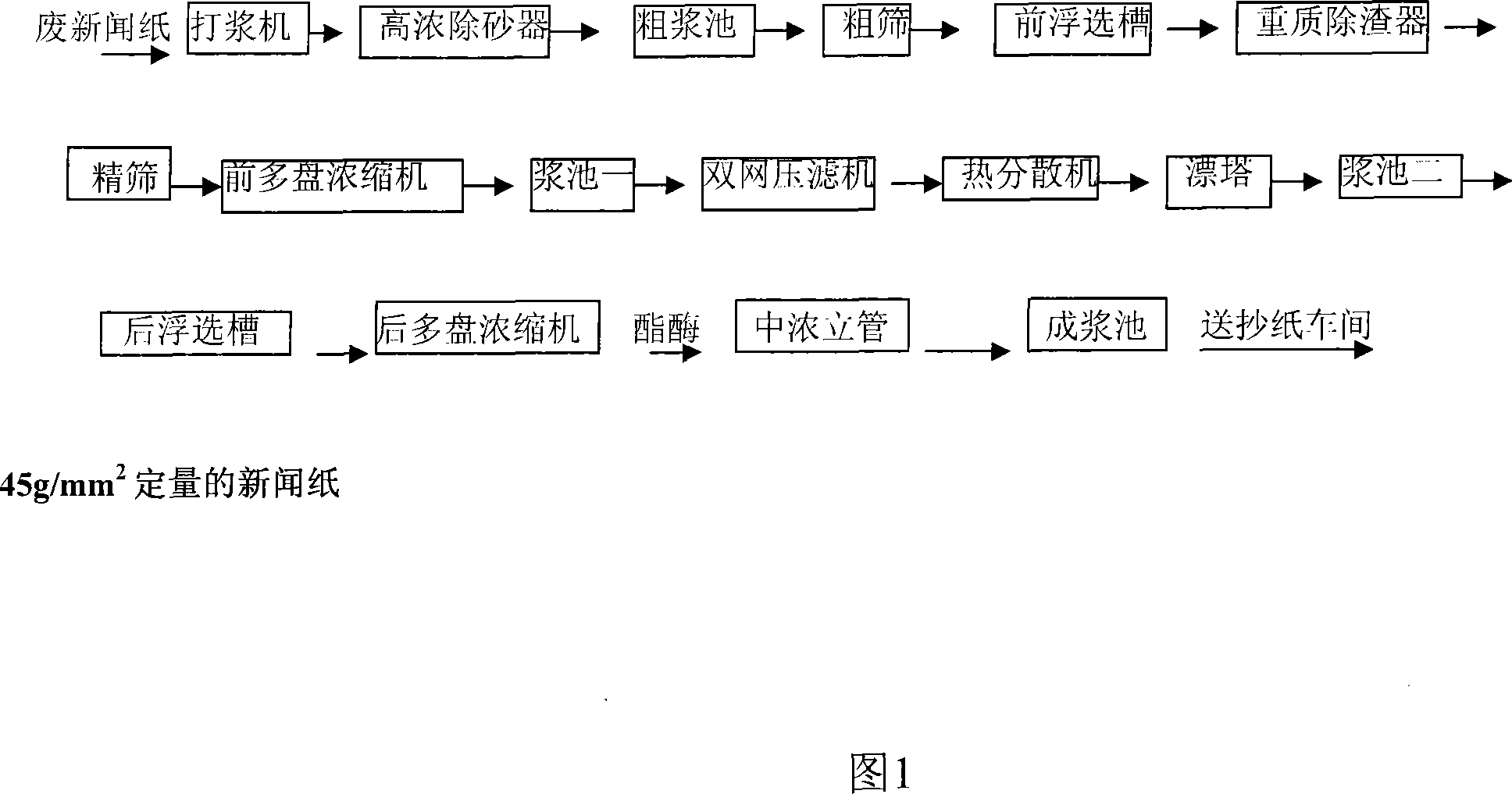

Method for controlling with 100aste newsprint paper deinked pulp esterase

InactiveCN101220567AReduce contentGuaranteed uptimePulp de-wateringPaper recyclingProcessing costPollution

The invention discloses a method that uses esterase obtained by 100 percent deinking and desizing of wasted newspaper controls sticky which mainly aims at producing the low fixed amount newspaper by using the 100 percent deinking and desizing of the wasted newspaper, adopts Optimyze 525 esterase control sticky and produces the newspaper with 45g / mm<2> fixed amount. The invention has the advantages of reducing the dosage of the sticky in the paper pulp, leading the sticky removing rate to be about 20 percent to 40 percent, reinforcing the operating performance of a paper machine, and helping to improve the speed and the output of the paper machine; by adopting deinking and desizing of 100 percent wasted newspaper to make 45g / m<2> lowing amount offset newsprint, the obtained products have good quality, chemical pulp and groundwood pulp which are high in pollution and high consumption are eliminated, the manufactory cost of the pulp material and the processing cost of the water are reduced, and the discharged waste water and the pollutants are reduced.

Owner:GUANGDONG IND TECHN COLLEGE +1

Culture medium and method for culturing ganoderma lucidum by using loquat braches and leaves

InactiveCN102633550AReduce cultivation costSimple technologyHorticultureFertilizer mixturesMicrobiologySugar

The invention relates to a culture medium for culturing ganoderma lucidum by using loquat braches and leaves. The culture medium is characterized by comprising a ganoderma lucidum culture medium, wherein the ganoderma lucidum culture medium is prepared from the following materials in parts by weight: 20 to 80 parts of loquat braches and leaves, 20 to 30 parts of bran, 0 to 50 parts of crop leftover and / or mushroom grass, 1 part of sugar, 0 to 1 part of gypsum, 0.5 to 1 part of lime, and 0 to 0.5 part of calcium superphosphate. A method for culturing the ganoderma lucidum by using the loquat braches and leaves is characterized by comprising the following specific steps of: A, preparation of the ganoderma lucidum culture medium; B, bagging and sterilization; C, inoculation and spreading; and D, emergent management. The invention aims to provide the culture medium and the method for culturing the ganoderma lucidum by using the loquat braches and leaves, so that resources are fully utilized, virtuous circle of the loquat industry is extended, the ganoderma lucidum culture cost is reduced, and the quality and medicinal effect of the ganoderma lucidum are improved.

Owner:福建农业职业技术学院 +2

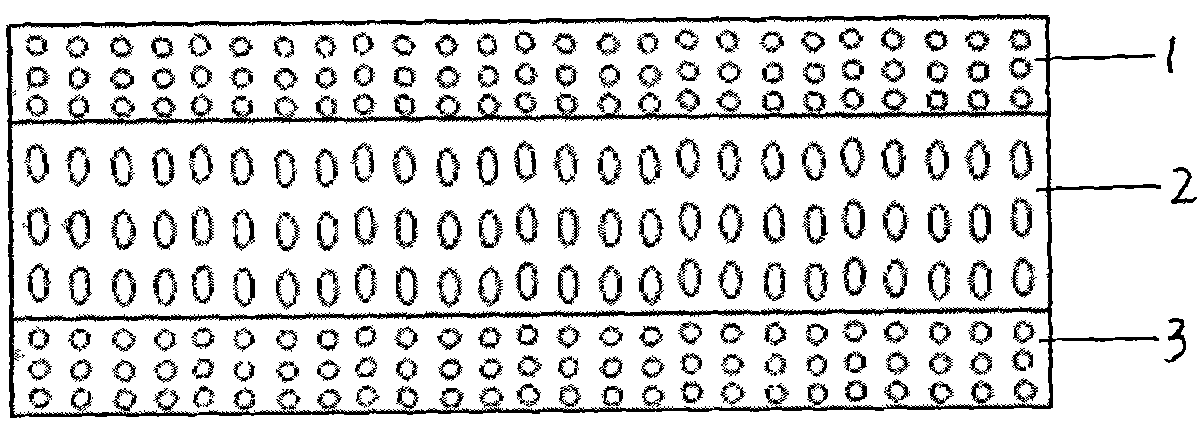

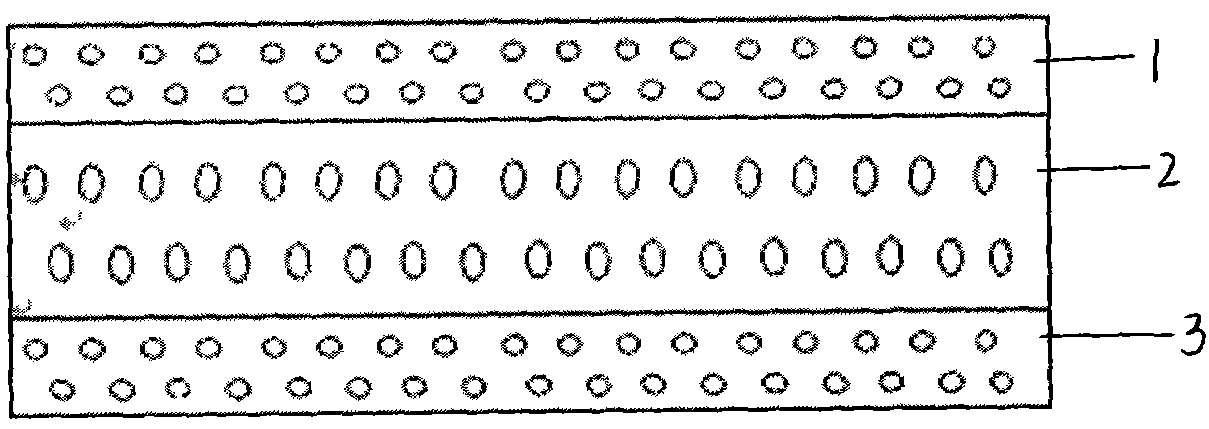

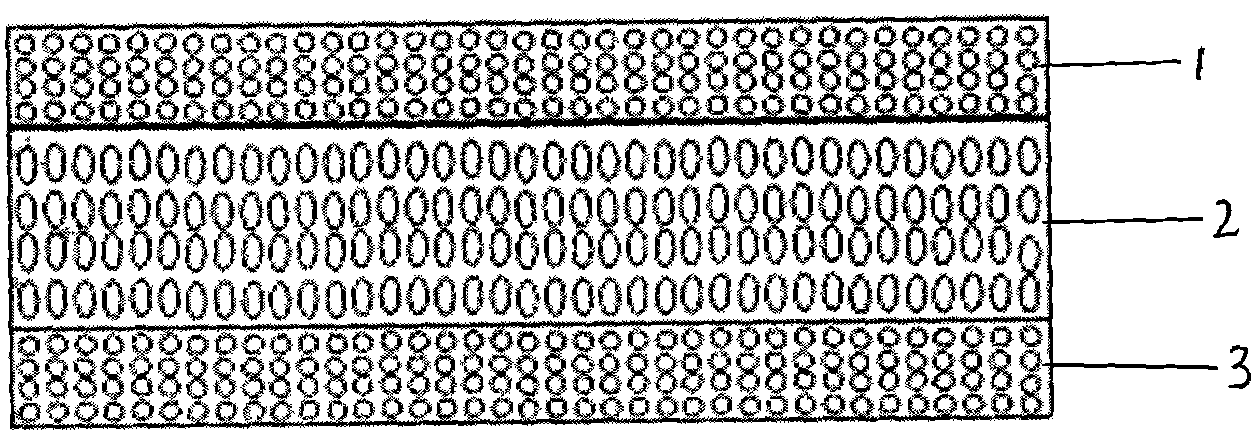

Calcium silicate high-filling polymer modified paper

InactiveCN102011347ALow lateral shrinkageWith whitenessSpecial paperPaper/cardboardLinear low-density polyethyleneCalcium silicate

The invention relates to calcium silicate high-filling polymer modified paper, which is compounded and formed by three layers of non-plant fiber calcium silicate substrates, wherein the first layer and the third layer are prepared from 2 to 6 percent of ethylene bis stearamide, 8 to 23 percent of high-density polyethylene, 3 to 9 percent of metallocene polyethylene, 0 to 1 percent of low-molecular polyethylene, 50 to 60 percent of activated calcium silicate, 10 to 25 percent of calcium silicate inorganic powder and 0 to 3 percent of addition agents, the first layer and the third layer accounts for 25 percent of the weight of the paper, the second layer is prepared from 50 to 60 percent of activated calcium silicate powder, 10 to 25 percent of calcium silicate, 2 to 9 percent of styrene-butadiene block copolymer, 7 to 21 percent of high-intensity polyethylene materials, 4 to 8 percent of linear low-intensity polyethylene and 0 to 3 percent of addition agents, and the second layer accounts for 50 percent of the weight of the paper. The modified paper has the same appearance, whiteness, sizing degree, opacity, strength, toughness and rigidity as plant fiber paper and has simple production processes, no bacteria and poison; and because the product is used for packing paper and can replace the traditional plastic packing paper, a great amount of petroleum can be saved.

Owner:宋旭

Drug controlling plant nematodes

ActiveCN105145633AAvoid harmImprove the effect of prevention and controlBiocideFungicidesPlant nematodeBegonia aptera

The invention discloses a drug controlling plant nematodes. Effective ingredients comprise natural saponin, and the natural saponin is one or more of soapnut saponin, gleditsioside, tea saponin, saikosaponin, esculentoside, ursolic acid, vulgarsaponin and begonia yunnanensis Levl. saponin. Preferably, the drug also comprises lysobacter antibioticus, possseses relatively good killing effect on plant nematodes, nematode host cerambycidae ovum and larva and the like, and additionally, is extremely excellent in controlling effect on fruit tree gummosis. The exploited drug is environment-friendly type, is increased in controlling effect, also avoids environment harm caused by usage of a large amount of severely toxic pesticides, and possesses great reality meaning for protecting our country forest resource and ecological environment and recovering economic loss.

Owner:北京泰克美高新技术有限公司

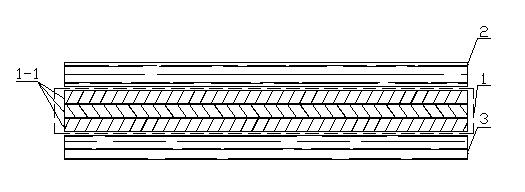

Veneering water-proofing multi-layer solid wood floor

The invention discloses a veneering water-proofing multi-layer solid wood floor, comprising a base material board (2) which is a multi-layer solid wood compound board, the upper part of the base material board (2) is provided with a plastic wear-resisting PVC veneer (1), the surface of the plastic wear-resisting PVC veneer (1) is provided with an aluminium oxide wear-resisting layer. The plastic wear-resisting PVC veneer (1) can adopt various fancies such as wood grains, bamboo grains and various artistic floor surfaces suitable for floors. The wood grains of adjacent solid wood single laminating board of the multi-layer solid wood compound board are intersected vertically and horizontally, and the laminating boards are bonded and heat-pressed into a whole by bonders. The material is stable and is nor easy to expand and deform, the water-proofing effect is good, and the floor can not be foamed and expanded when in water, and is suitable for households or public places; the floor surface has high hardness, the fancy kinds is multiple, and the decorative effect is plentiful; the production speed is rapid, the manufacturing cost is low, and the floor is easy to popularize; the floor not only can meet the using requirements of people, but also can protect forest resource and environment.

Owner:MAC DOUGLAS WOOD FLOORING SUZHOU

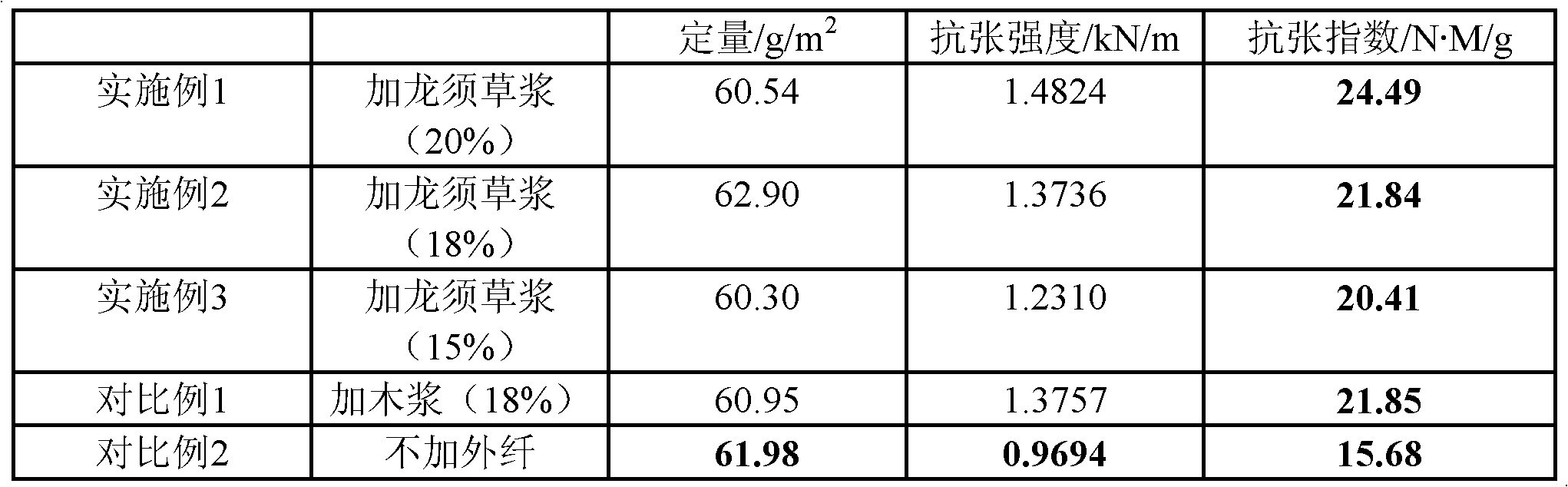

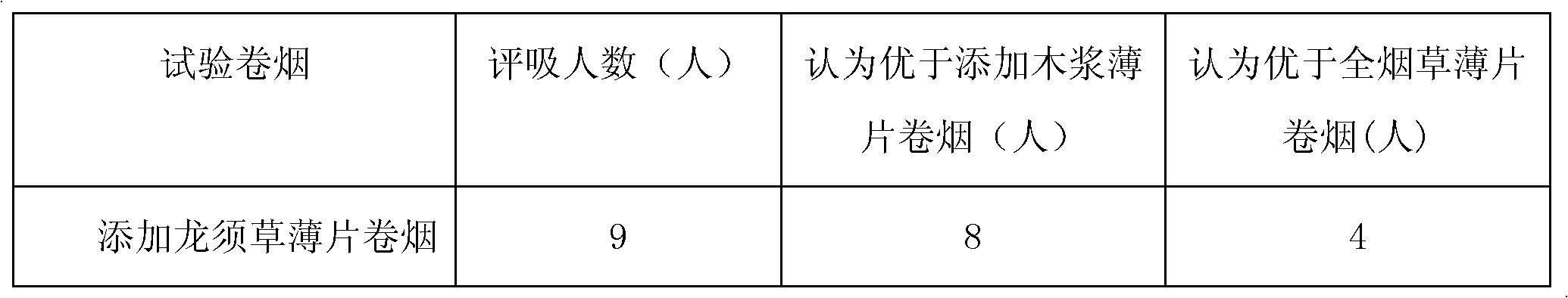

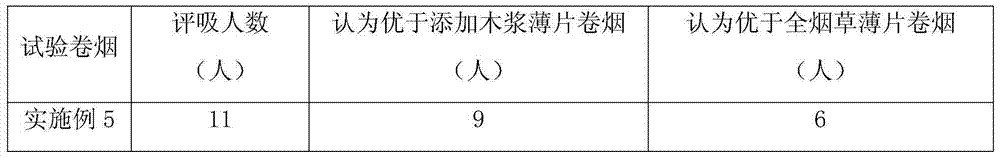

Tobacco additive for improving sensory quality of tobacco sheet and preparation method as well as application thereof

The invention provides a tobacco additive, Chinese alpine rush syrup, capable of reducing thrill of a tobacco sheet and reducing poor smell of woody smell and the like for improving intrinsic flavor of smoke and tobacco, and provides a method for preparing the tobacco sheet by taking the Chinese alpine rush syrup in place of wood syrup. The method comprises the following steps of: processing Chinese alpine rush through a beating stage in a sheet production process; and performing full fibrillation on Chinese alpine rush fiber, blending with tobacco syrup and performing papermaking to substitute the wood syrup which plays a role of a frame in the original production process. The use of tobacco stem resource and woody raw material is reduced, so that the tobacco raw material resource which grows increasingly tense throughout the country at present can be easily coped, forest resource can also be protected, and the cigarette cost is reduced; most importantly, the finished tobacco sheet is rolled into cigarette; compared with smoking assessment of the normal wood syrup product, the thrill of the cigarette finished product prepared by the invention is reduced, the poor smell of woody smell and the like is obviously relieved, and the intrinsic flavor of smoke and tobacco is obviously improved.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Energy-saving and environmentally friendly composite floor and manufacturing method thereof

InactiveCN103572940AMoisture-proofWith thermal insulation effectSynthetic resin layered productsLaminationWood veneerEcological environment

The invention discloses an energy-saving and environmentally friendly composite floor and a manufacturing method of the energy-saving and environmentally friendly composite floor. The purpose is to provide the energy-saving and environmentally friendly composite floor which is cheap, convenient to manufacture, few in consumed raw wood, beautiful in appearance, good in quality and high in production efficiency. The energy-saving and environmentally friendly composite floor comprises a panel and a bottom plate, wherein the panel and the bottom plate are made of wood veneers and arranged on the upper surface and the lower surface of the floor respectively. A core plate is arranged between the panel and the bottom plate in a sandwiched mode. The composite floor is characterized in that the core plate is made of polyurethane foaming materials. Tongue-and-grooves or tenons are formed in the side faces around the floor and spliced mutually. The composite floor can effectively block water and moisture and has a moisture-proof effect and effects of heat preservation and heat insulation, when an air conditioner is turned on in summer or in winter, indoor temperature can be effectively kept, heat exchanging is reduced, and energy is saved. Particularly, woods are greatly saved, and the composite floor plays an obvious role in protecting forest resources and the ecological environment. The possibility that formaldehyde is contained in adhesive, and therefore the health is harmed is also avoided. The composite floor is a novel floor which is really green, safe and environmentally friendly and saves the energy.

Owner:JIASHAN JIASHUN PLASTIC

Ginseng cultivation method

The invention discloses a ginseng cultivation method. The method comprises the following steps of (1) land selection; (2) soil preparation; (3) seed selection; (4) sowing; (5) management; (6) pest control; (7) harvesting. According to the ginseng cultivation method, the woodland open spaces are fully utilized, the intensification and three dimension cultivation is realized, the method has the characteristics of little investment, high benefit and the like, and the production of green traditional Chinese medical materials is facilitated.

Owner:DIAOYUTAI MEDICAL GRP JILIN TIANQIANG PHARMA

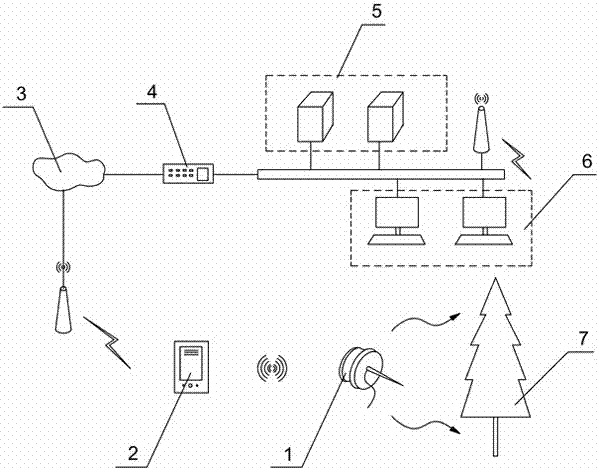

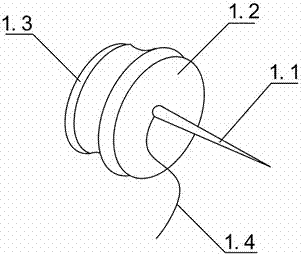

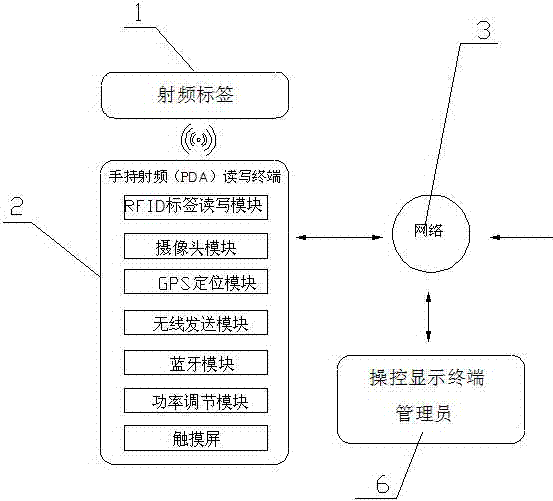

Internet of Things-based forestry pest control monitoring information system and realization method

ActiveCN107067054AEasy to handleImprove management efficiencyCo-operative working arrangementsPaper documentManagement efficiency

The invention provides an Internet of Things-based forestry pest control monitoring information system and a realization method thereof. The system is characterized by comprising RFID labels, a handheld radio frequency read-write terminal, a wireless communication network, a database server and control display terminals, wherein the RFID labels are implanted onto infected woods; by utilizing the uniqueness of physical card numbers of the RFID labels, tracking, prevention and cure are carried out on each infected wood; the handheld radio frequency read-write terminal is used for registering and writing information and situations of the infected woods into the RFID labels, sending the information and situations of the infected woods to the database server through the wireless communication network; the database server is used for carrying out classified registration on the information of the infected woods, establishing infected wood documents and carrying out statistics on the documents; managers monitor the situations of the infected woods through each control display terminal and designate workers to process the infected woods; processing results are synchronously updated to the RFID labels and the database server; and the managers track the processing flows of the infected woods until the situations of the infected woods terminate. According to the system and the realization method, the prevention and cure workers are supervised and instructed to effectively process the infected woods, so that the management efficiency is improved.

Owner:QINGDAO KEEN RUIWANG INTERNET TECH CO LTD

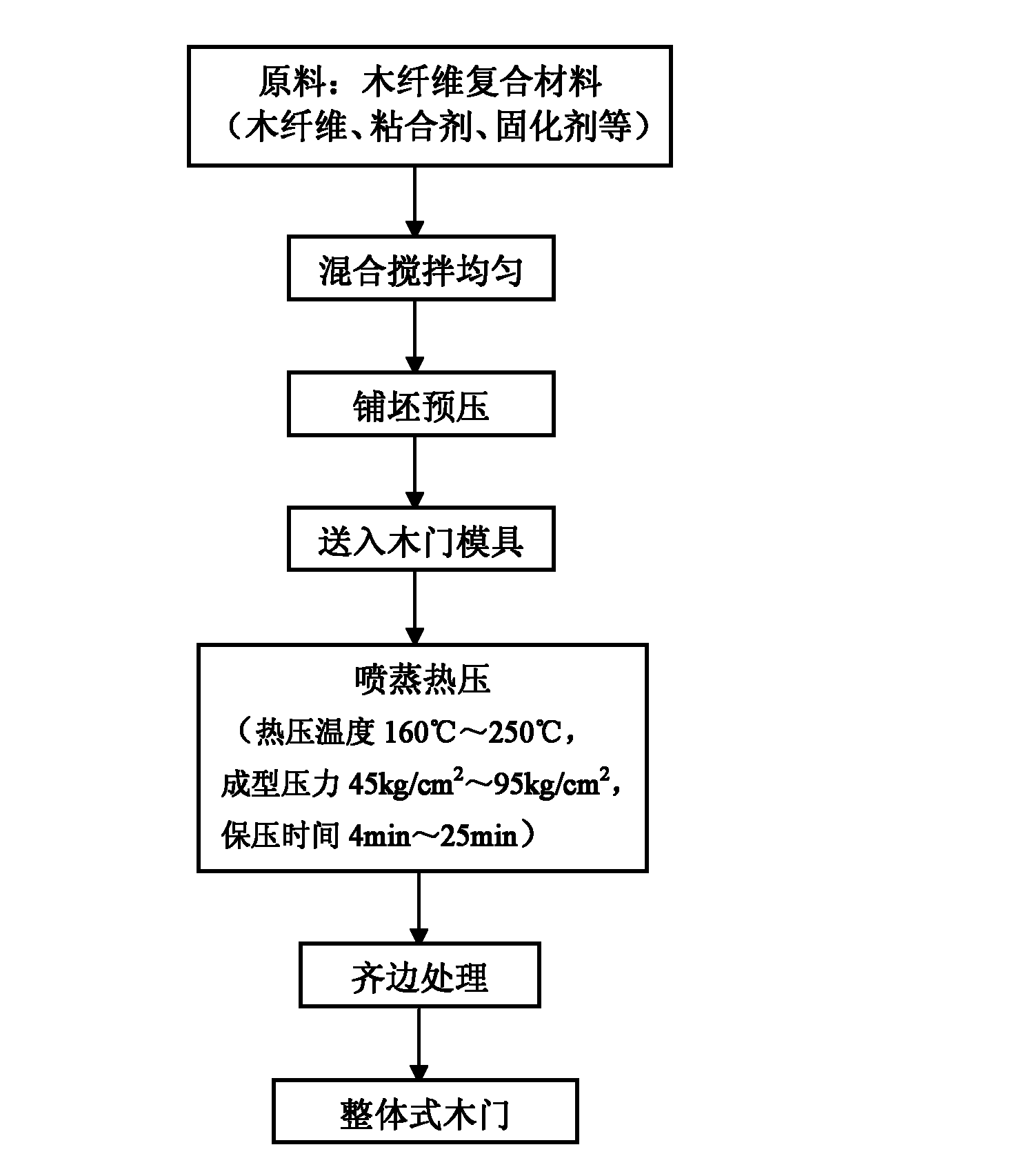

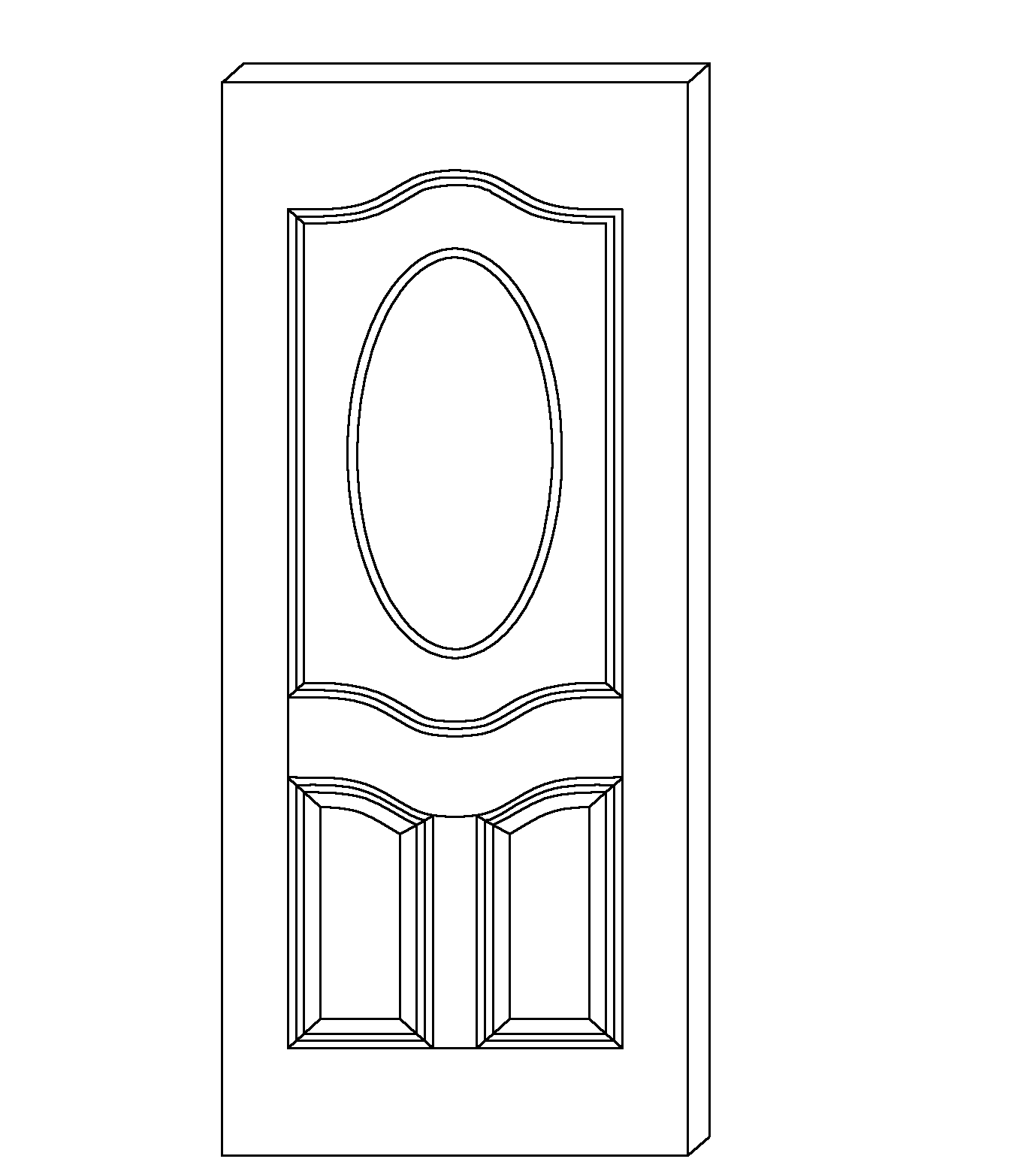

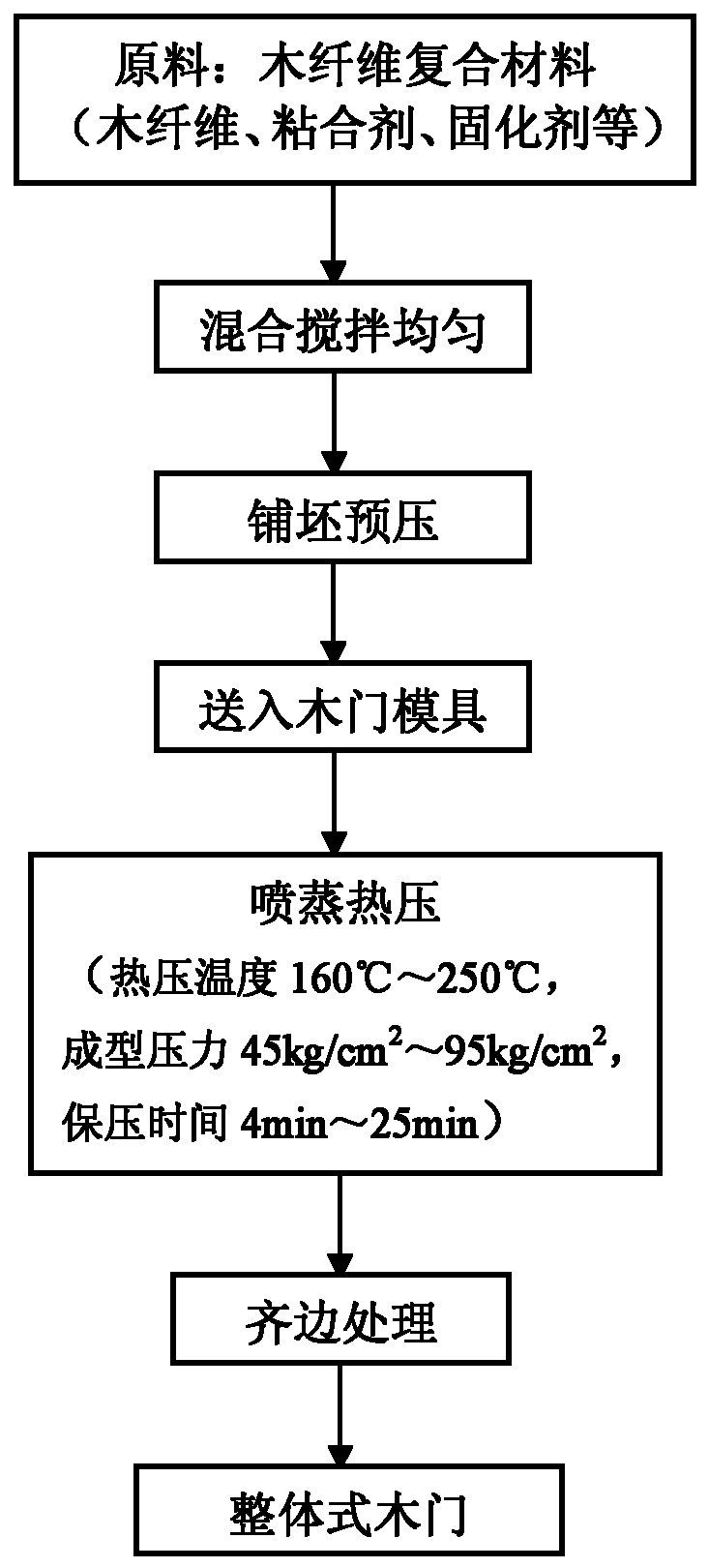

Integral wooden door made of wood fiber composite materials

ActiveCN102555003ASimple process conditionsSimple manufacturing processWood working apparatusFlat articlesEnvironmental resistanceWood fibre

The invention discloses an integral wooden door made of wood fiber composite materials. In the integral wooden door, a traditional wooden door manufacturing process mode is broken through, the wood fiber composite materials which are mainly made of waste wood leftover materials or slash materials are molded at one step by the aid of mould pressing technology, the integral wooden door is successfully manufactured by the aid of optimized hot pressing process, the thickness of the integral wooden door ranges from 30mm to 60mm, and the density of the integral wooden door ranges from 0.65g / cm3 to 1.05g / cm3. Compared with an existing merchant wooden door, the integral wooden door is simple in manufacture, high in efficiency and low in cost, is environment-friendly, and has extremely wide application prospect and economic prospect.

Owner:浙江新木材料科技有限公司

Production process of machine-made charcoal

InactiveCN104629782AHigh densityHigh carbon contentBiofuelsSpecial form destructive distillationCentrifugal forceOxygen deficient

The invention discloses a production process of machine-made charcoal. The process comprises the following steps: preparation of raw material: collecting raw material such as bamboo saw-dust, wood saw-dust, leftover materials and peanut shell and drying until the water content of the raw materials is not more than 5 percent; pulverizing: pulverizing the dried raw material into particles with the particle size of less than 6mm by using a pulverizing machine; drying: drying the pulverized raw material again; bar-making: pressing the dried raw material into a bar with a central hole under the actions of the pressure of a screw rod and high-speed rotation centrifugal force at a high temperature; charcoal-making by utilizing a furnace kiln: carrying out combustion charring the bar at the temperature of 800-1,000 DEG C under an oxygen-deficient condition to ensure that the carbon content reaches up to 85-90 percent. The machine-made charcoal prepared through the production process is high in density, high in carbon content, high is has a heat value, clean and environmental-friendly, long in combustion time and low in cost.

Owner:FENGHUA HONGTAI BIOMASS ENERGY

Method for preparing sanitary scent using with cassava powder

InactiveCN101125059AProtect forest resourcesHigh strengthGaseous substancesReligious equipmentAdditive ingredientEngineering

The present invention relates to a method of making fragrant incense by using cassava flour. The method comprises the steps that: the raw material is crashed, filtered, mixed, stirred, made into stripe, parched or aired, sprayed for spice, and all procedures make out stripe shape or disk shape finished products, wherein, the raw material takes the cassava flour as the agglomerant and the ratio are 15 to 75 percent of cassava flour, 20 to 80 percent of the other bamboo and grass powder, and the other ingredients are fire accelerant and colorant, etc.; the optimized ratio of the raw material are 30 to 60 percent of cassava flour, 35 to 65 percent of the other bamboo and grass powder, and the other ingredients are fire accelerant and colorant, etc. The present invention has the beneficial effects that the ixonanthes chinensis material such as Machilus can be replaced entirely to protect the forest resource; while the product has much higher intensity and is difficult to be broken off and crashed, thus being convenient for transportation; the ash of the product is gray without peculiar smell and the quality is better.

Owner:许景盛

Reducing agents for smelting chemical grade metallic silicon

The invention relates the reducing agent of smelting chemical grade metallic silicon, comprising ganister, oil coke and bituminous coal. The mass ratio of ganister and fixed charcoal content is between 2.7:1.3 and 2.9:1.1. The invention has the advantages of reducing the cost of metallic silicon and good economic benefit and social benefit.

Owner:上海广济硅材料有限公司 +1

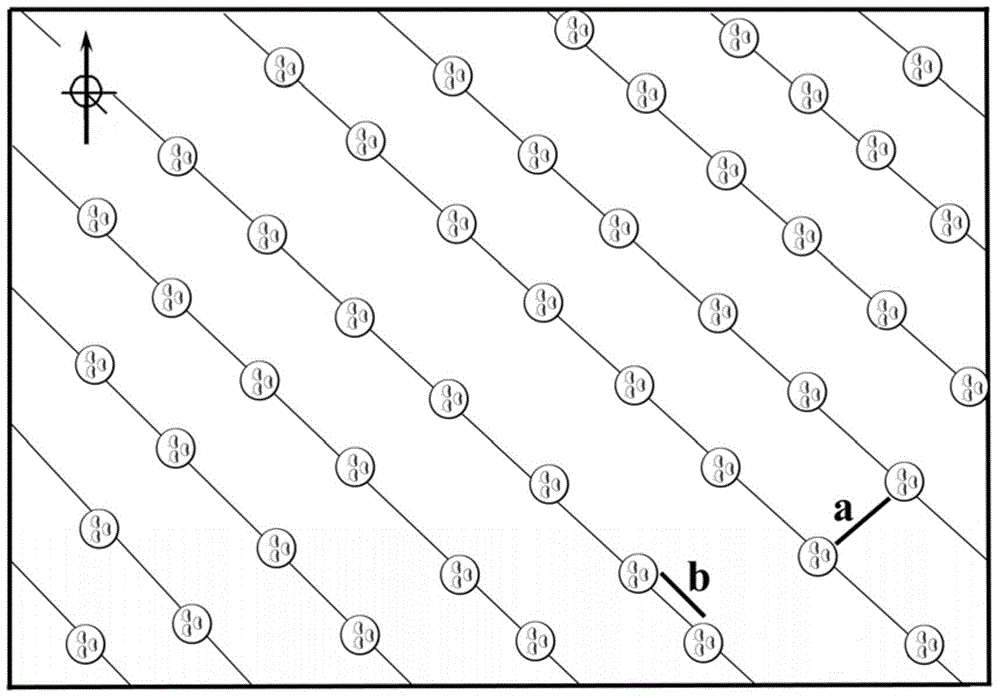

Longitude weft paper and manufacturing method thereof

InactiveCN101235612AImprove qualityImprove performanceSpecial visual effect coatingsSpecial paperYarnFiber

The invention discloses longitude latitude line paper and a method for manufacturing the paper. The method of the invention is realized through the following technical method: firstly, utilizing a rubber coating method to compound paper together or utilizing a papermaking technique to coat paper pulp on yarns or fibrils which are arranged longitudinally, then, turning to any angle to prepare line substrate (latitude line substrate or oblique line substrate), adhering (compounding) the line substrate (latitude line substrate or oblique line substrate) with lines (longitude lines) which are arranged longitudinally, or not adhering (compounding), utilizing the papermaking technique to coat the paper pump on the line or utilizing the rubber coating method to compound with the paper, and obtaining various longitude latitude line paper. The method of the invention has the advantages that the performance of the paper is improved and increased, the use and application field of the paper are improved and enlarged, the material quality of the paper pulp is lowered, paper pulp raw material is saved, and ecological environment of the earth is protected and improved.

Owner:张玺钧 +2

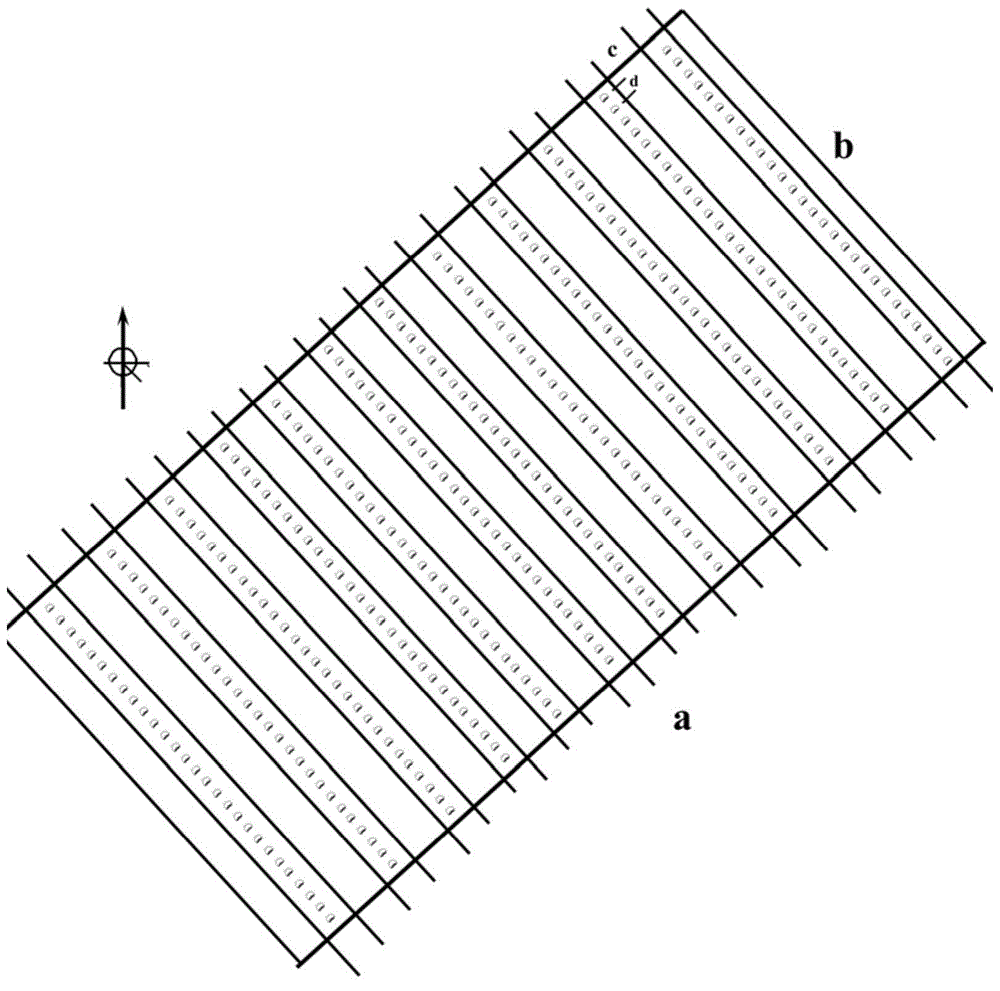

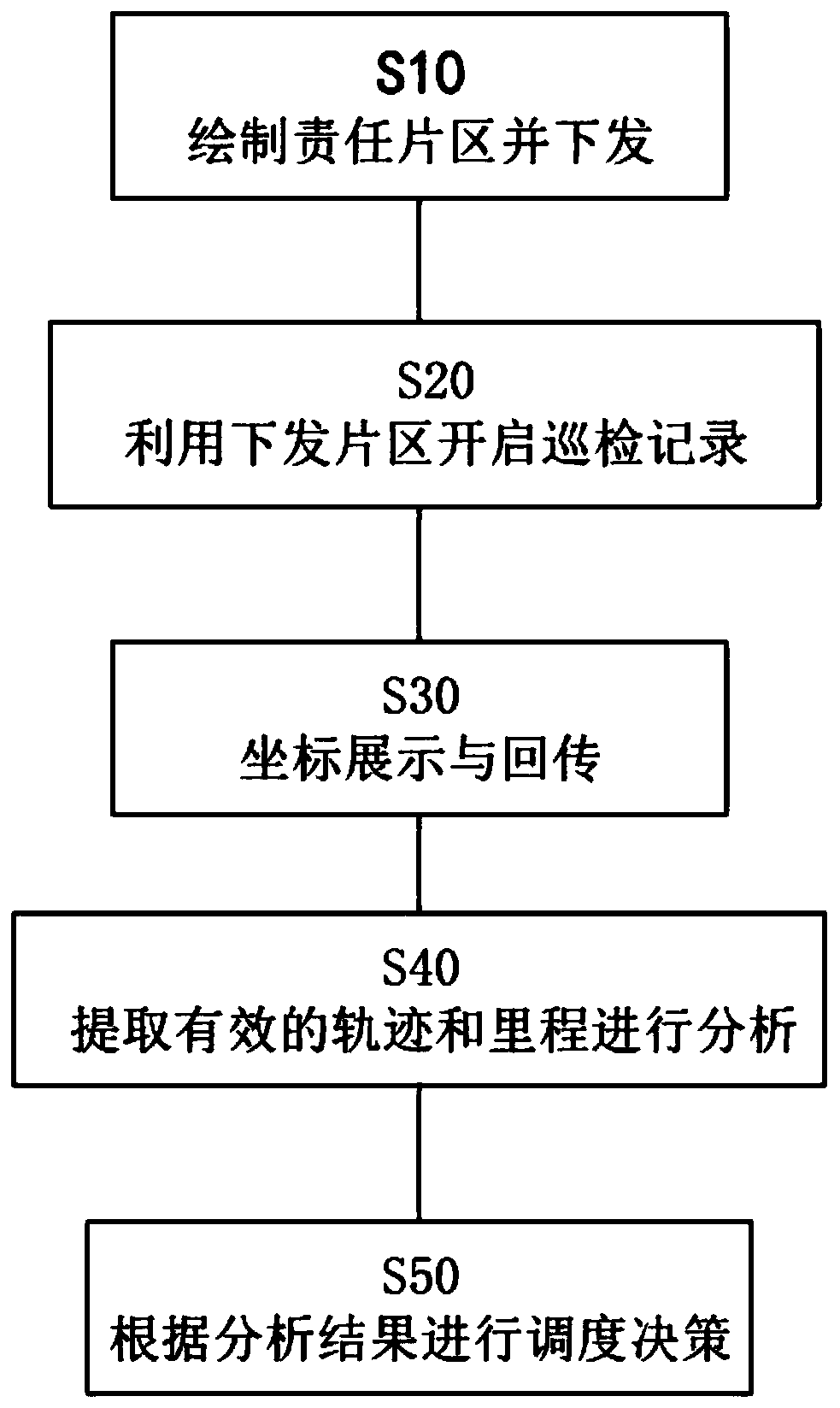

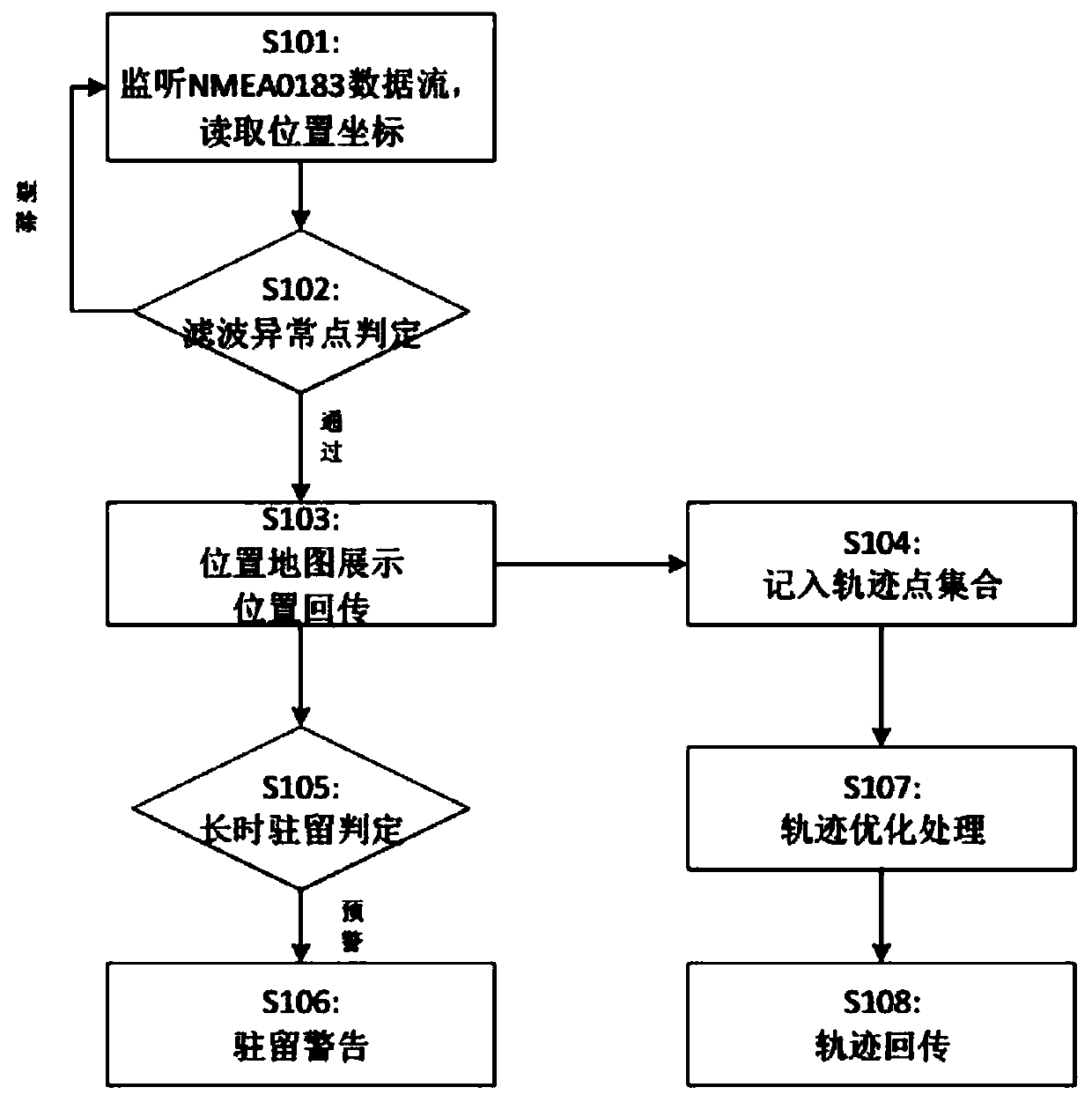

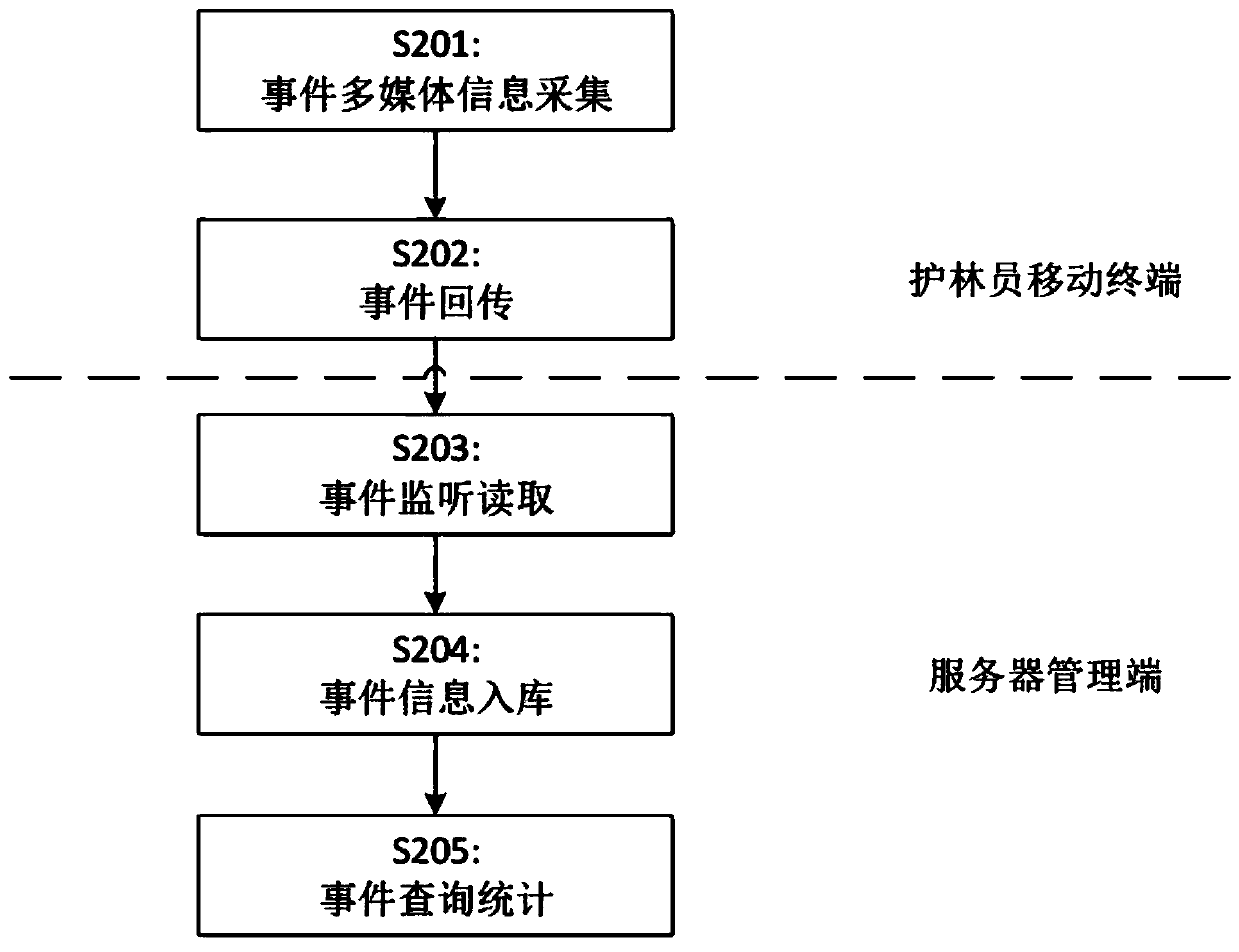

Forest patrol inspection method based on mobile GIS

InactiveCN110796758ASolve the problem of difficult supervision of attendance punch cardImprove work efficiencyChecking time patrolsSatellite radio beaconingTelecommunicationsMobile Web

The invention belongs to the technical field of geographic information systems, and discloses a forest patrol inspection method based on mobile GIS, and the method comprises the following operations based on a mobile terminal and a server management terminal of: locating the ranger in real time and recording the trajectory data by the mobile terminal; recording and collecting multimedia information according to the trajectory data, and the returning the multimedia information; performing attendance calculation and statistics on the trajectory data records returned to the server management terminal. The forest patrol inspection method based on mobile GIS provided by the invention has the beneficial effects that, with the continuous development of mobile GIS, Internet of Things, high-speed mobile communications and other technologies, the problems that the ranger has a weak sense of responsibility, inadequate patrol inspection and untimely supervision can be effectively solved by equipping the ranger with the mobile terminal for positioning and trajectory monitoring, transmitting the patrol inspection information back to the data center in real time for decision analysis by using thehigh-speed mobile network, and carrying out automated participation and attendance analysis based on the trajectory records.

Owner:XIAN REMOTE SENSING SCI & TECH OF INFORMATION CO LTD

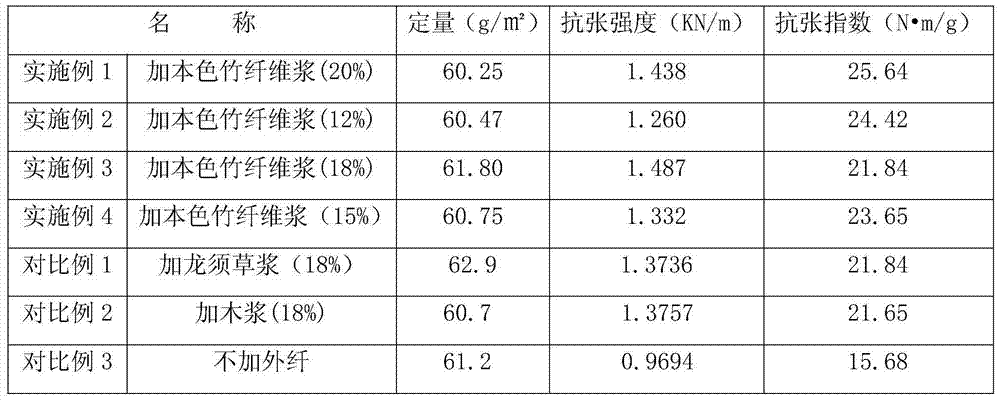

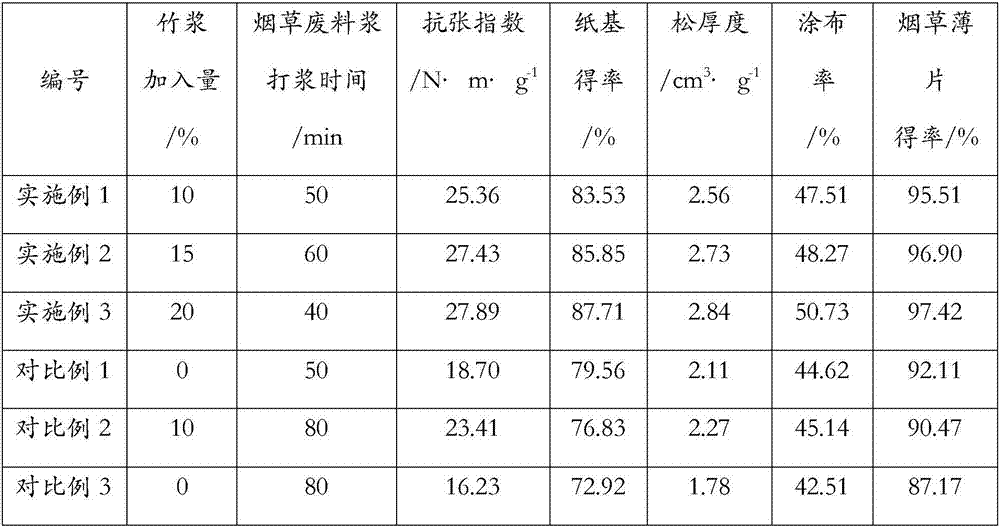

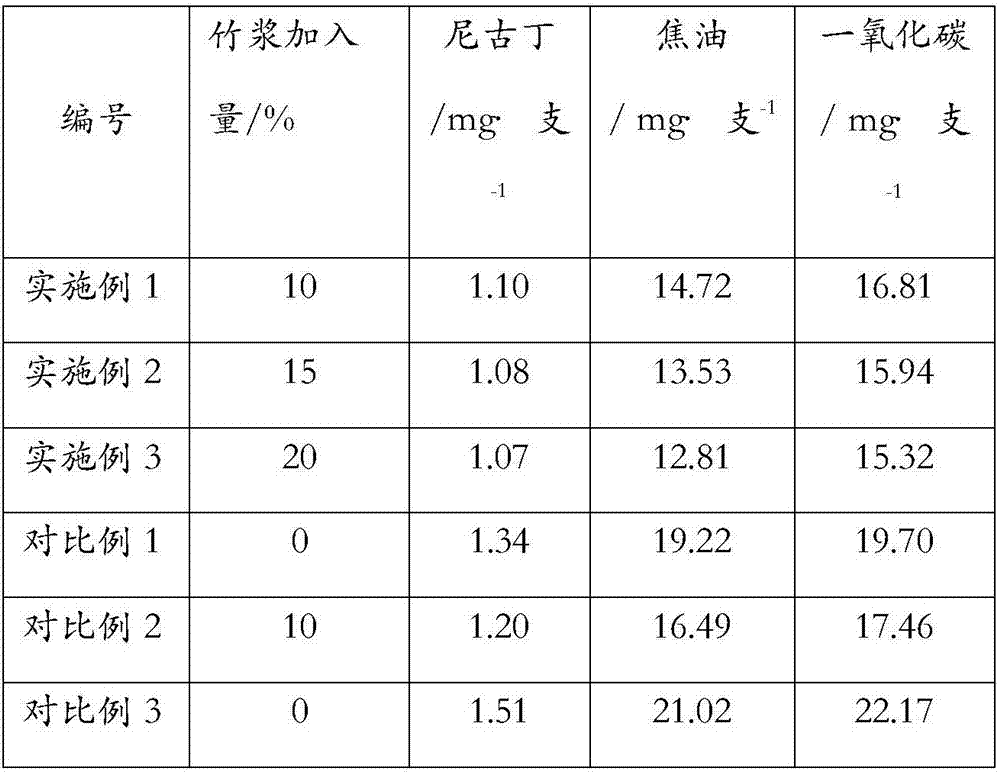

Original-color bamboo fiber pulp, preparation method thereof and an application of the bamboo fiber pulp as tobacco additive

ActiveCN104213458AReduce usageAvoid residual contaminationTobacco preparationWashing/displacing pulp-treating liquorsFiberBoiling process

The invention discloses an original-color bamboo fiber pulp, a preparation method thereof and an application of the bamboo fiber pulp as a tobacco additive. The original-color bamboo fiber pulp is 20-32 degree SR in a pulping degree and is 5-8g in wet weight. The preparation method includes following steps: S1: crush of raw materials: crushing bamboo fiber raw materials into fiber powder through a dry crushing method; S2: a steaming and boiling process: performing the steaming and boiling process to the fiber powder and a steaming and boiling liquid to obtain a low-hardness bamboo pulp; S3: a washing process: performing a crude selection process through a vibrating screen, a black solution extraction process through a vacuum pulp washing machine, a fine selection process through a pressure sieve, a dust removing process through a residue removing device and a pulp washing process through the vacuum pulp washing machine to obtain a screened pulp; S4: a drying process: performing a dewatering and drying process to the screened pulp to obtain an original-color bamboo fiber plate; and S5: a pulping process: performing a pulp crushing process and a pulping process to the original-color bamboo fiber plate with the pulping degree and the wet weight being controlled to prepare the original-color bamboo fiber pulp. The method is simple in operation, is convenient to carry out, is low in cost, and is green and environmental-protective. The original-color bamboo fiber pulp can be used as the tobacco additive, can reduce irritation of a tobacco sheet, can reduce bad smell of wood and the like, and can improve an original smell of tobacco.

Owner:SICHUAN HUANLONG NEW MATERIAL

Method for preparing lophatherum gracile reconstituted sheet and application of lophatherum gracile reconstituted sheet in tobacco product

ActiveCN101919581AReduce usageTake advantage ofTobacco preparationTobacco treatmentNicotiana tabacumTar

The invention discloses a method for preparing a lophatherum gracile reconstituted sheet and application of the lophatherum gracile reconstituted sheet in a tobacco product. The method comprises the following steps of: performing water extraction and catalytic degradation on lophatherum gracile or mixture of lophatherum gracile and tobacco serving as a raw material, mixing the material to preparepulp and making a substrate with the pulp; coating concentrated lophatherum gracile extract on the substrate; and curling, cutting and drying the substrate to prepare the lophatherum gracile reconstituted sheet. The lophatherum gracile reconstituted sheet can be independently prepared into the tobacco product or mixed with tobacco shred to prepare the tobacco product, can completely or partially replace the tobacco leaf, change the style characteristic of the tobacco product, achieve fine, soft and smooth smoke, prolong the incense, reduce the uncomfortable feels such as spiking, biting, coarseness, choking and the like of throat and obviously improve the consistency and the stability of the incense of smoking. Meanwhile, the content of the tar, nicotine and carbon oxide released by the smoke of cigarettes can be obviously reduced.

Owner:CHINA TOBACCO FUJIAN IND

Method for planting ganoderma lucidum by using mulberry twig scraps

InactiveCN107721620AImprove overall economic efficiencyProtect forest resourcesCalcareous fertilisersAnimal corpse fertilisersGanoderma pseudoferreumWater content

The invention discloses a method for planting ganoderma lucidum by using mulberry twig scraps and belongs to the technical field of cultivation of edible fungi. The method comprises the cultivation steps of culture medium preparing, bagging, spawn running stage management and ganoderma lucidum emergence stage management, wherein the culture medium preparing comprises the steps of chopping the mulberry twig scraps, luffa cylindrica, euphorbia thymifolia, peanut shells, wheat bran and corn stalks, then, carrying out uniform mixing and stirring, carrying out water-separated steaming with water vapor, adding water until the moisture content reaches 20% to 40%, carrying out sealed fermentation for 10 to 15 days, then, adding gypsum and a nutrient solution, carrying out uniform mixing and stirring, then, regulating the moisture content of a culture medium to 60% to 65%, and regulating the pH to 5.5 to 6.5, so as to obtain a culture material; then, bagging is carried out; in the spawn runningstage management and the ganoderma lucidum emergence stage management, moisture preserving is achieved through sprinkling bitter melon juice containing moisture. The method for planting the ganodermalucidum, provided by the invention, has the advantages that the invested cost is relatively low, the produced ganoderma lucidum is relatively high in medicinal value and is safe and pollution-free, the popularization and application prospects are good, and the like.

Owner:唐鸿旺

Method for utilizing mulberry branch powder to cultivate lucid ganoderma

InactiveCN104663248AHigh in nutrientsPromote growthSuperphosphatesCultivating equipmentsCaladiumAnimal science

The invention disclosesa method for utilizing mulberry branch powder to cultivate lucid ganoderma. The method comprises the following steps of processing mulberry branches, preparing culture medium, bagging, sterilizing and inoculating, spawn running management, fruiting managing and harvesting in time, and is characterized in that the matching ratio of raw material components for cultivating the lucid ganoderma is: 75-80 percent of mulberry branch powder, 5-10 percent of bran, 5-10 percent of wood flour, 5-8 percent of corncob, 0.1-1 percent of monopotassium phosphate, 0.1-1 percent of magnesium sulfate, 0.1-1 percent of calcium superphosphate, 1-2 percent of sugar, and 1-2 percent of lime. According to the method for utilizing the mulberry branch powder to cultivate the lucid ganoderma, not only are the functions of recycling silkworm industry wastes, improving the whole economic benefit of silkworm and mulberry production, and protecting the forest resources realized, but also the lucid ganoderma cultivated by the mulberry branches is higher in medicinal value, less in investment, low in cost and good in economic benefit.

Owner:象州县科学技术局

Natural-color bamboo pulp for reconstituted tobacco additive and preparation method thereof

The invention belongs to the technical field of reconstituted tobacco, and specifically relates to natural-color bamboo pulp for a reconstituted tobacco additive and a preparation method thereof. The method is characterized in that bamboo is used as the raw material and subjected to preparing, stewing, squeezing extrusion, dipping, pulping and papermaking to obtain a high-purity product. The physical performance indexes of the natural-color bamboo pulp are that the tensile index is 35-45N-m / g; the burst index is 2.5-3.5kPa-m<2> / g; the tearing index is 6.5-9.5mN-m<2> / g; the intrinsic viscosity is 800-1000mL / g; the whiteness is 30-40% ISO; the pentosane is less than 8%; the ash content is less than 1.0%; the bulk is 5.0-8.5cm<3> / g. The prepared tobacco slices are added to finished cut tobacco based on ratio; the prepared cigarette is capable of supplying more air intake quantity while smoking, so that the cigarette can be promoted to completely burn, and the quantity of pyrolysis products under oxygen-poor condition can be effectively decreased, and as a result, the releasing quantity of harmful components such as tar and nicotine can be decreased.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Method for preparing fire-proof paint of trees during growth period

InactiveCN101117537ADoes not affect normal growthPlay the role of fire preventionFireproof paintsWax coatingsWater basedAcrylic resin

The invention provides a preparation method of a fireproof coating for growth period tree. Ammonium polyphosphate 20, melamine 9, pentaerythritol 6, chlorinated paraffin 5, titanium dioxide 5, talcum powder 4, ethyl cellulose 0.6 solution and tap water 20 are mixed, dispersed and stirred for 60 minutes by a high-speed stirrer. The dispersed slurry is ground by a grinder, mixed with a water-based acrylic resin 30, stirred, filtered and tested. The invention has the following advantages that the invention does not influence normal growth of trees, prevents fire and protects forest resources when the woods catch fire.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Hazel rod, hazel rind regeneration machine-made charcoal

InactiveCN1485403AReduce manufacturing costProtect forest resourcesBiofuelsSpecial form destructive distillationMaterials scienceLarge Calorie

A process of producing charcoal from branches and barks of hazelnut. It comprises, screening and cracking disposed branches, barks of hazelnut, drying the mixed material of branches and barks of hazelnut in a dehydrator, and sending it into a coal-making machine to produce carbon pencils, sending carbon pencils into a charring oven to produce charcoal, the coal content is above 85%, the calorie value is above 8500 kcal, recycling combustible gases produced in making coal to be fuel for burning ceramic products. The invention saves cost and protects resources, and prevent new environment pollution.

Owner:杨铁军

Method to send E-namecard information by mobile SMS

InactiveCN101742443AGo paperlessRealize sendingMessaging/mailboxes/announcementsData informationMaterial consumption

The invention discloses a method to send E-namecard information by mobile SMS. The method is realized by configuring the software in the mobile, which is characterized in the following steps: set the primary data information in the E-namecard information as the indentifying information, categorize the other contents of E-namecards according to the names, addresses, and phone numbers. When sending a message, if you choose the E-namecard information sending function, then the beforehand edited or impromptu edited E-namecards are sent as a short message. When the mobile is receiving short messages, first check if the primary data information is the indentifying information, if not, then receive it as a normal piece of short message, and if yes, then store the content of the E-namecard into the directory to form a independent E-namecard. The mobile returns to the state before receiving the short message. The invention can be used to replace the traditional paper namecards. The method of the invention is also easy to operate and convenient and fast, low-cost and easy to store. What is more, the invention also saves material consumption and is friendly to the environment.

Owner:CHENGDU LVYA TECH DEV

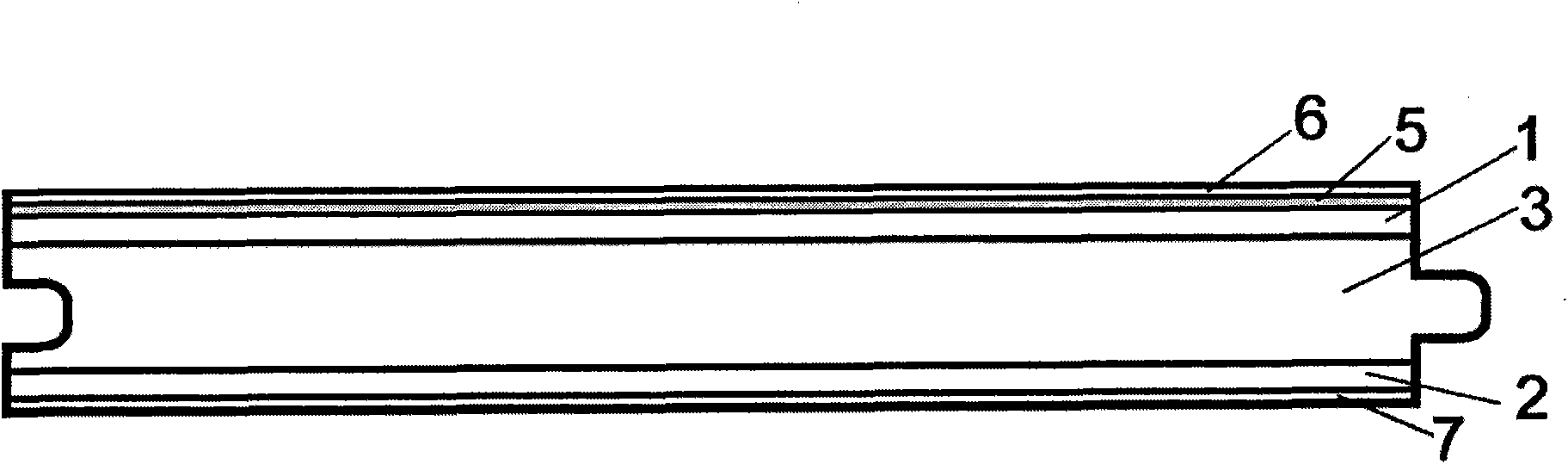

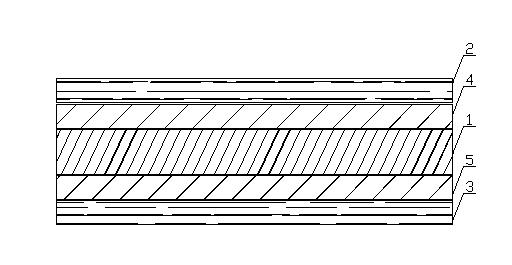

Composite floor

InactiveCN101851997AStable materialNot easy to shrinkWood layered productsFlooringSolid woodWear resistant

The invention discloses a composite floor which comprises a first density board (1), a multi-layer solid wood composite board (3) and a second density board (2), wherein the first density board (1), the multi-layer solid wood composite board (3) and the second density board (2) are sequentially bonded through bonding agents layer by layer and are formed into a whole by hot pressing; a decorative finishing layer (5) is arranged at the upper part of the first density board (1), and an aluminum oxide wear resistant layer (6) is arranged on the surface of the decorative finishing layer (5); the wood grains of adjacent solid wood single laminated boards of the multi-layer solid wood composite board (3) are staggered longitudinally and transversely, and layers are bonded through bonding agents and are formed into a whole by hot pressing; and balance paper (7) is arranged on the lower bottom surface of the second density board (2). The composite floor has the advantages of stable material quality, high surface hardness, high wear resistance, multiple patterned varieties, colorful decorative effects, high production speed and low manufacturing cost, can not expand and deform easily, is beneficial to popularization, and not only can meet the using requirements of people but also can protect forest resources and environment.

Owner:MAC DOUGLAS WOOD FLOORING SUZHOU

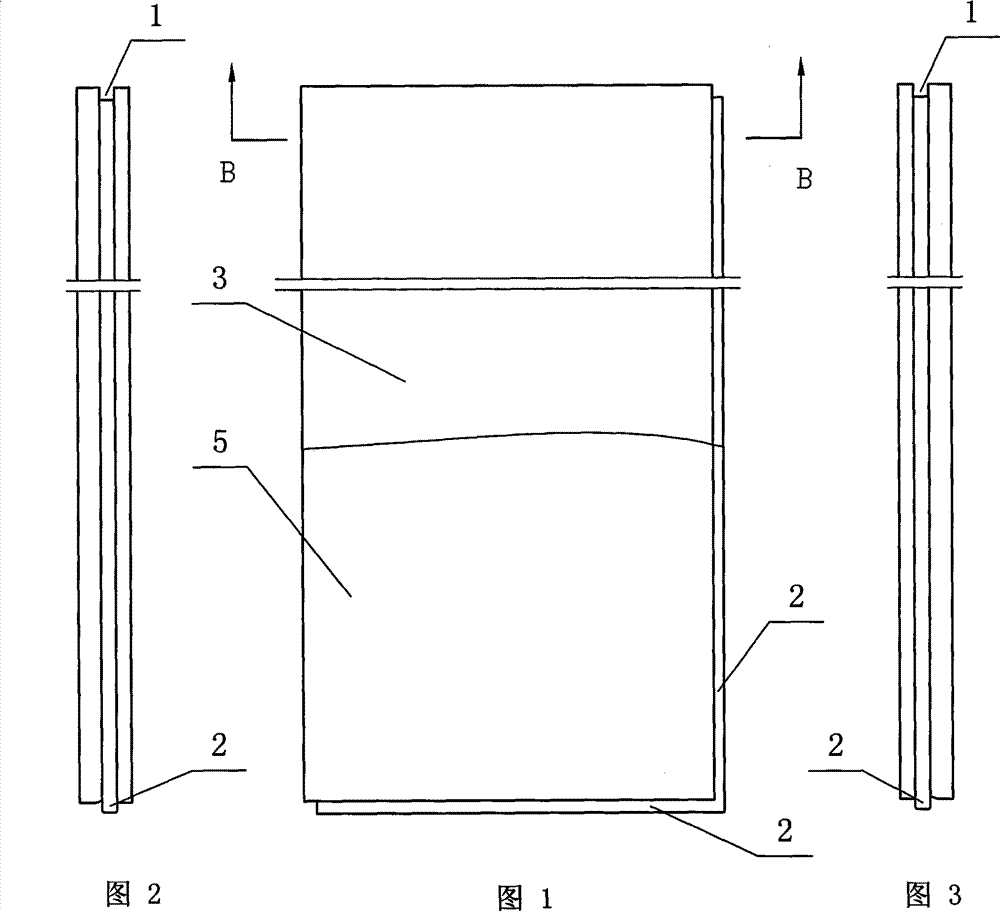

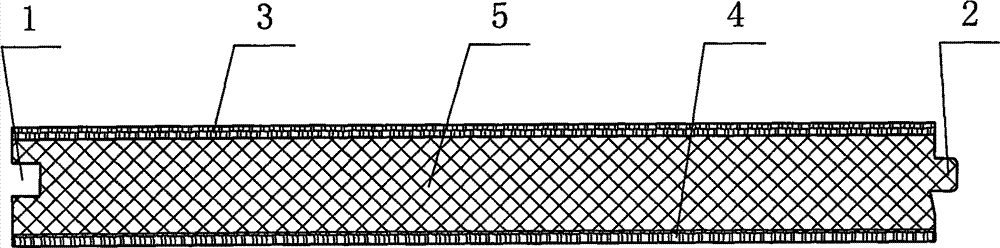

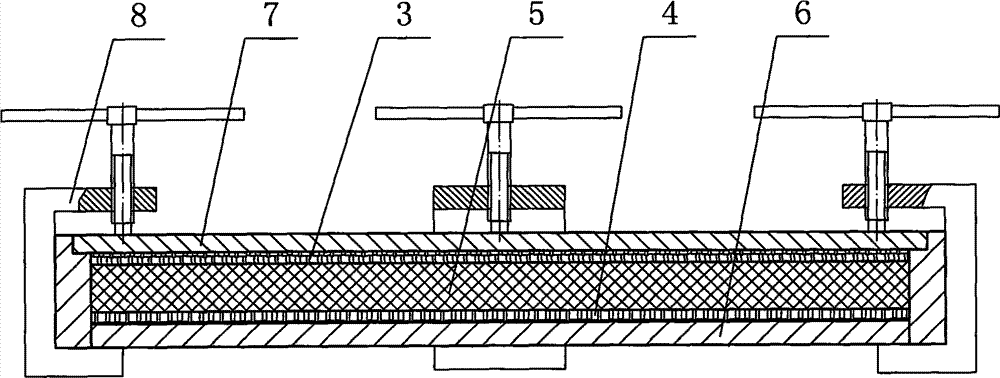

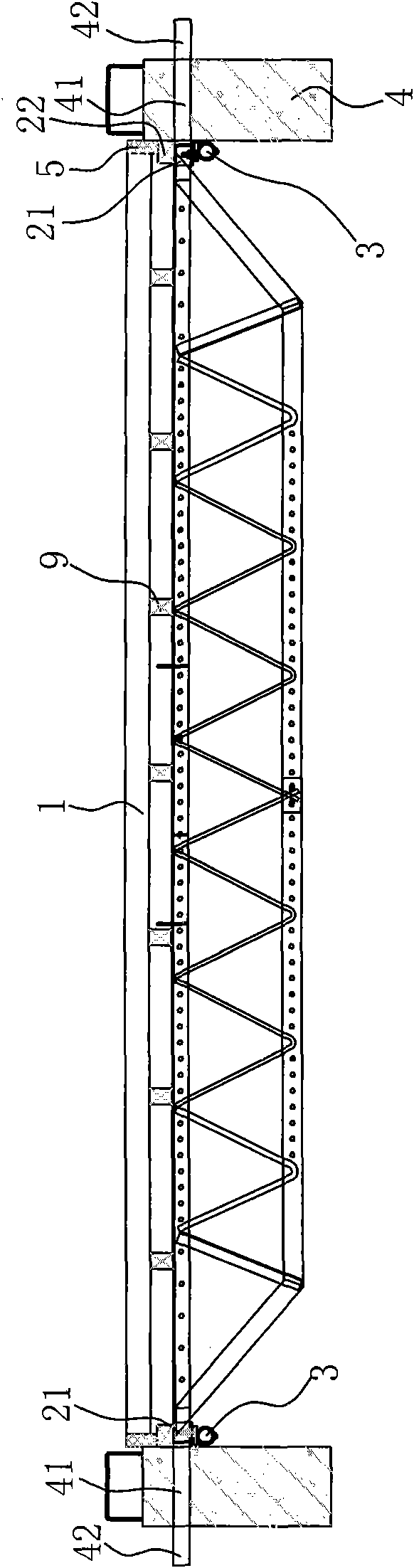

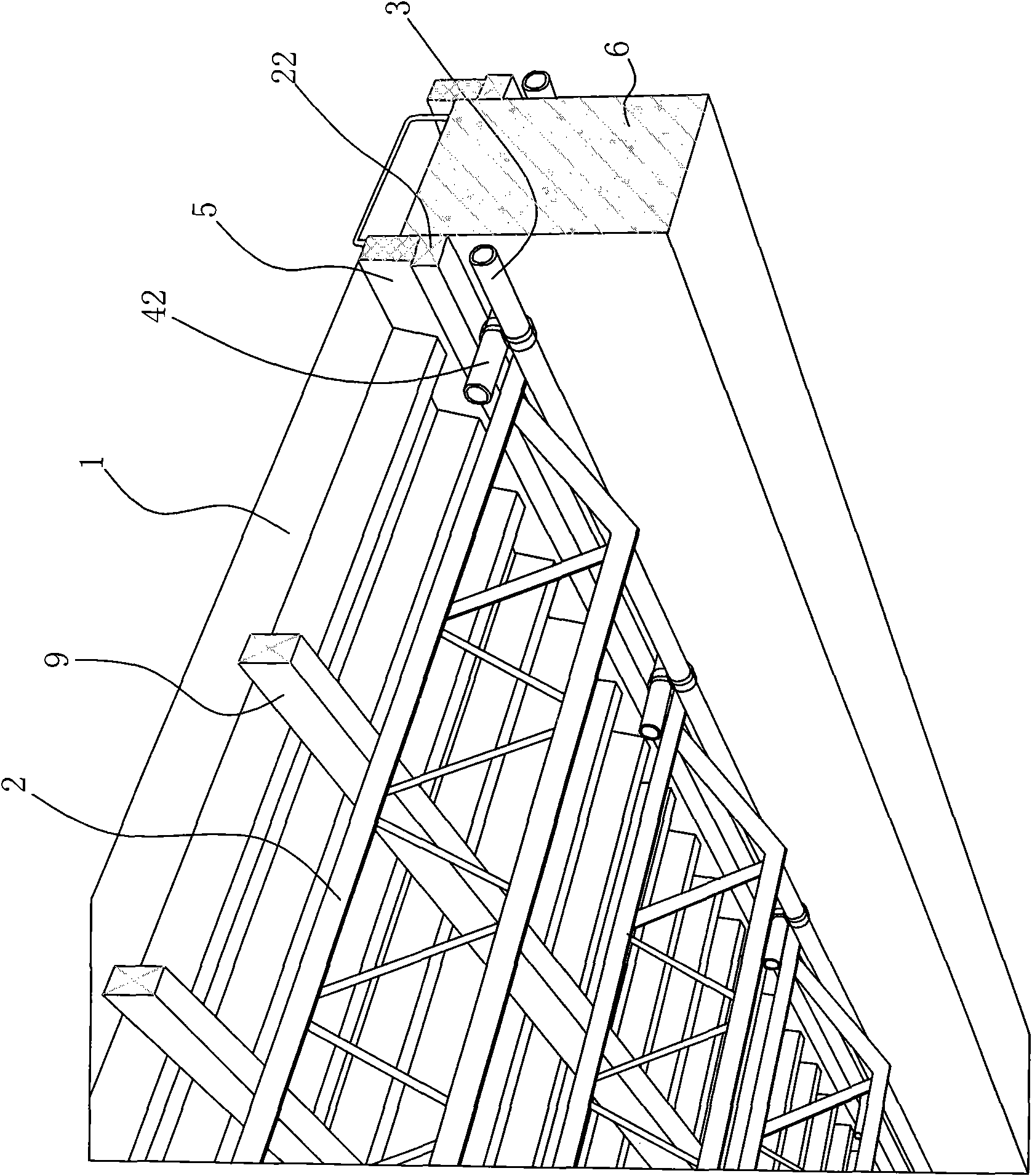

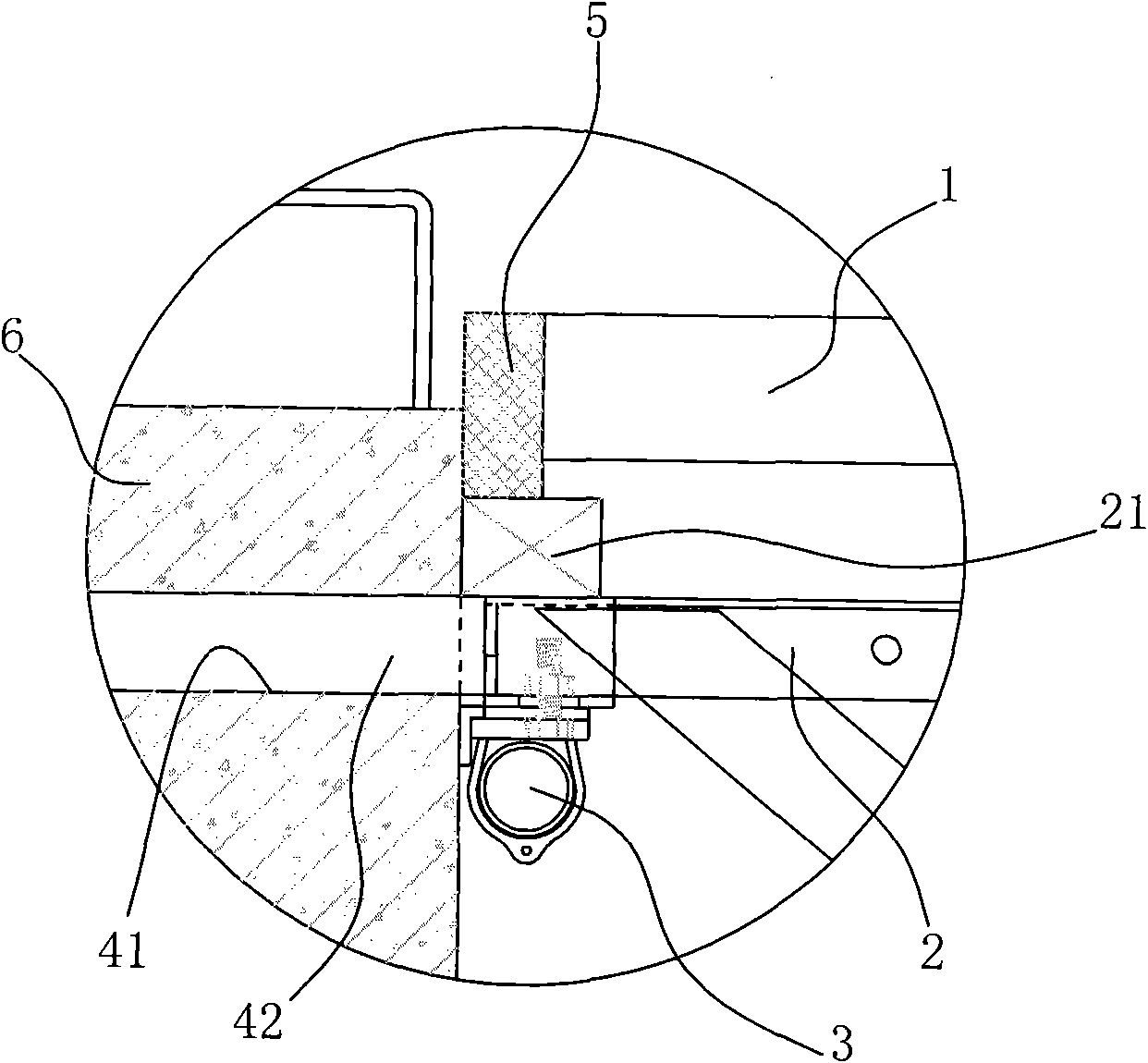

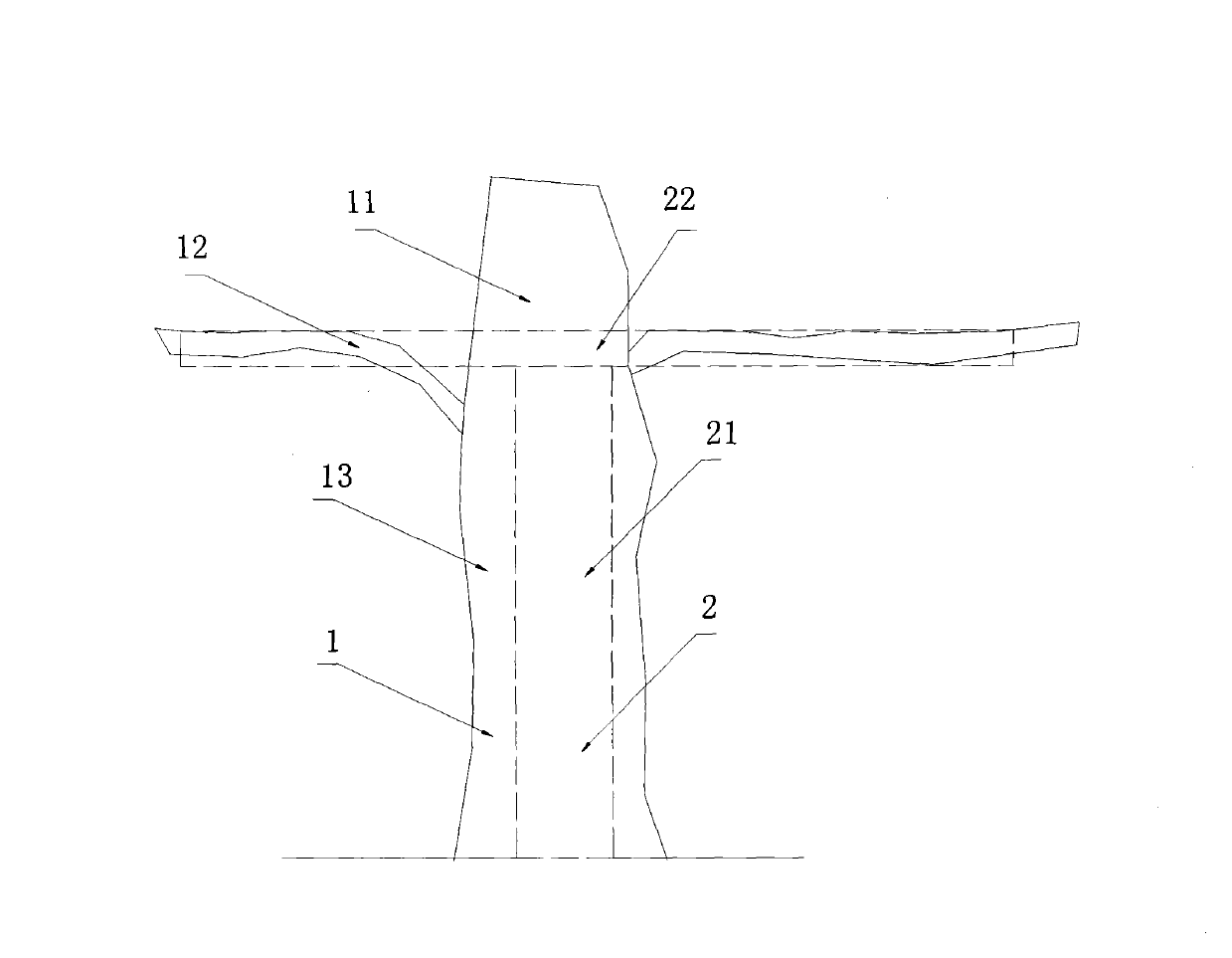

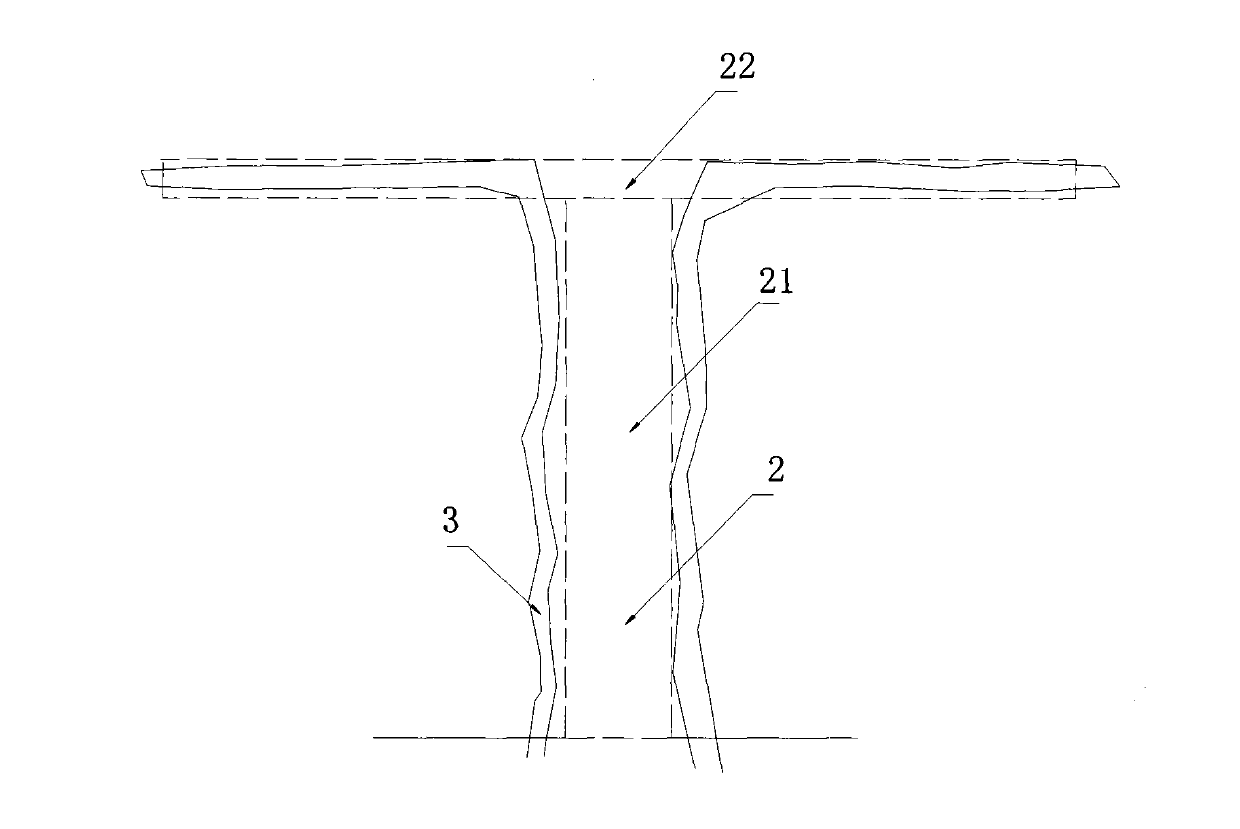

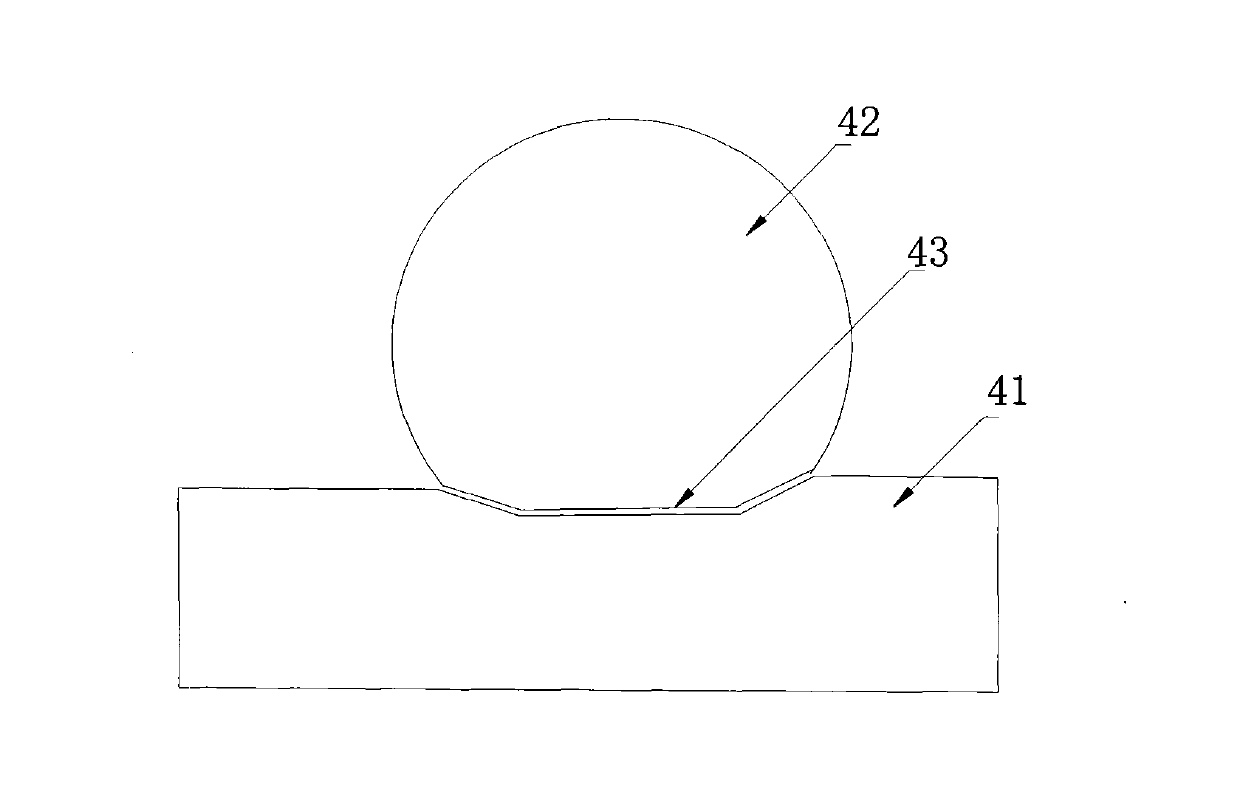

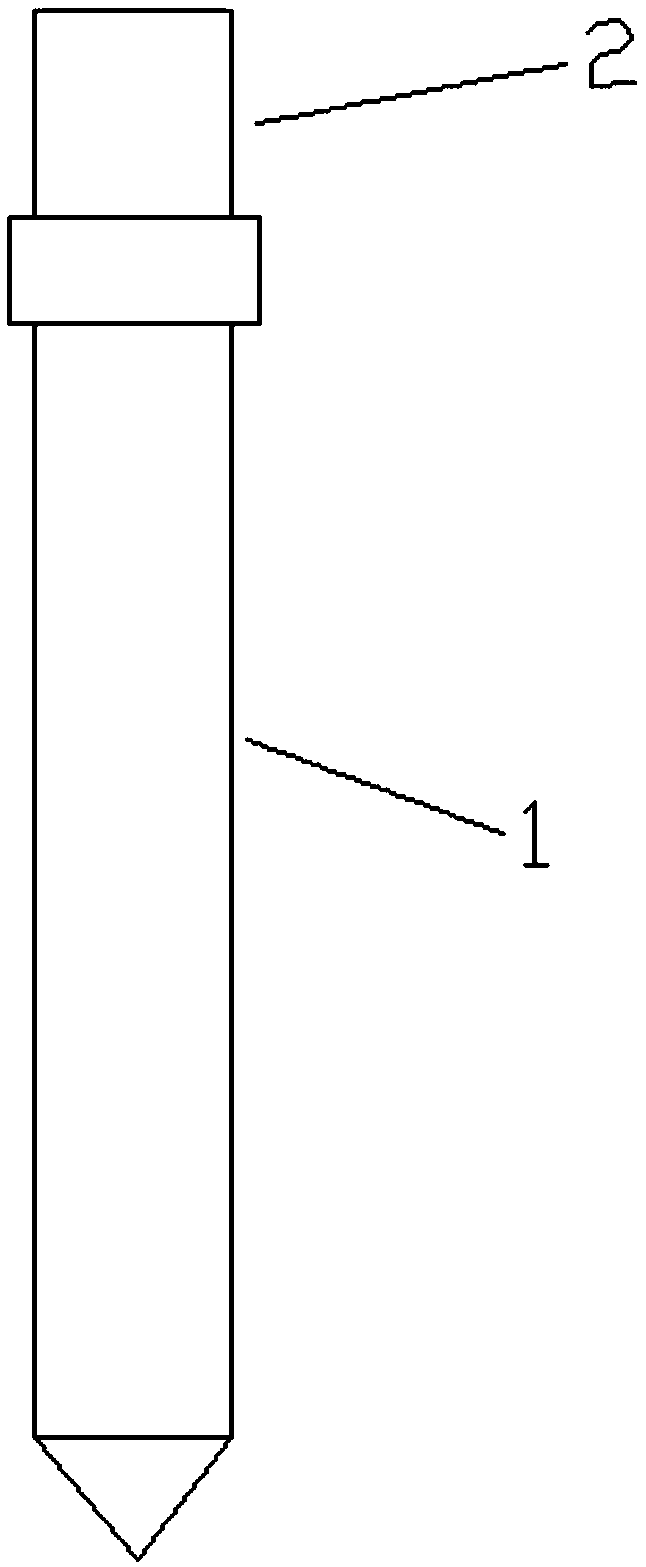

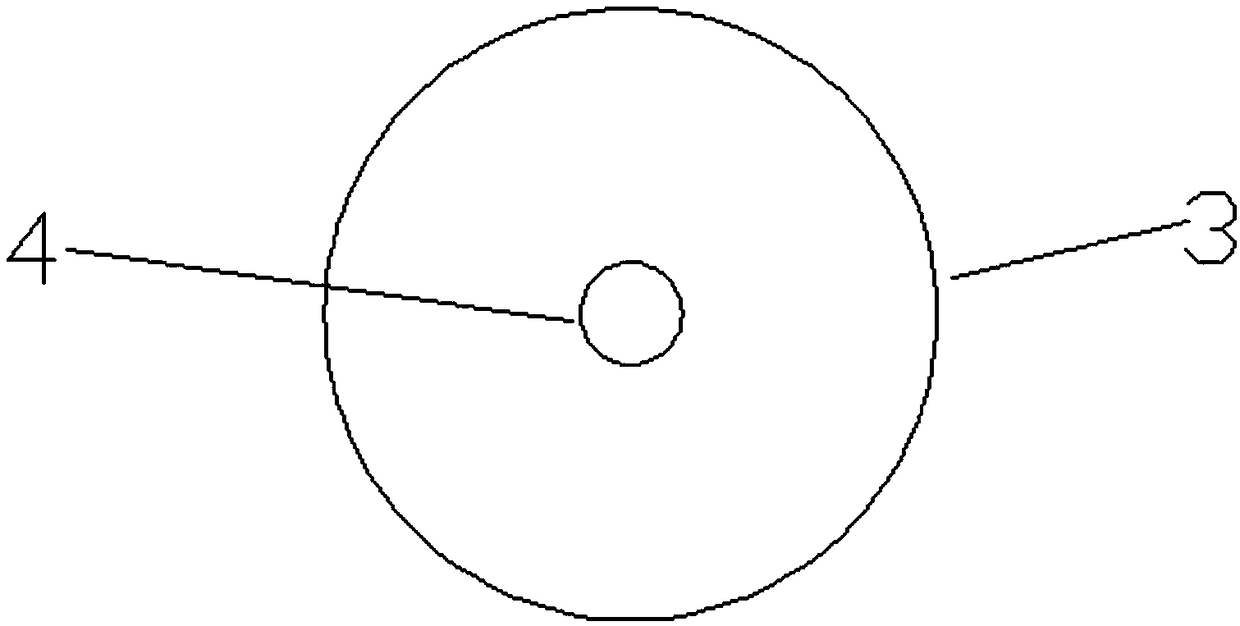

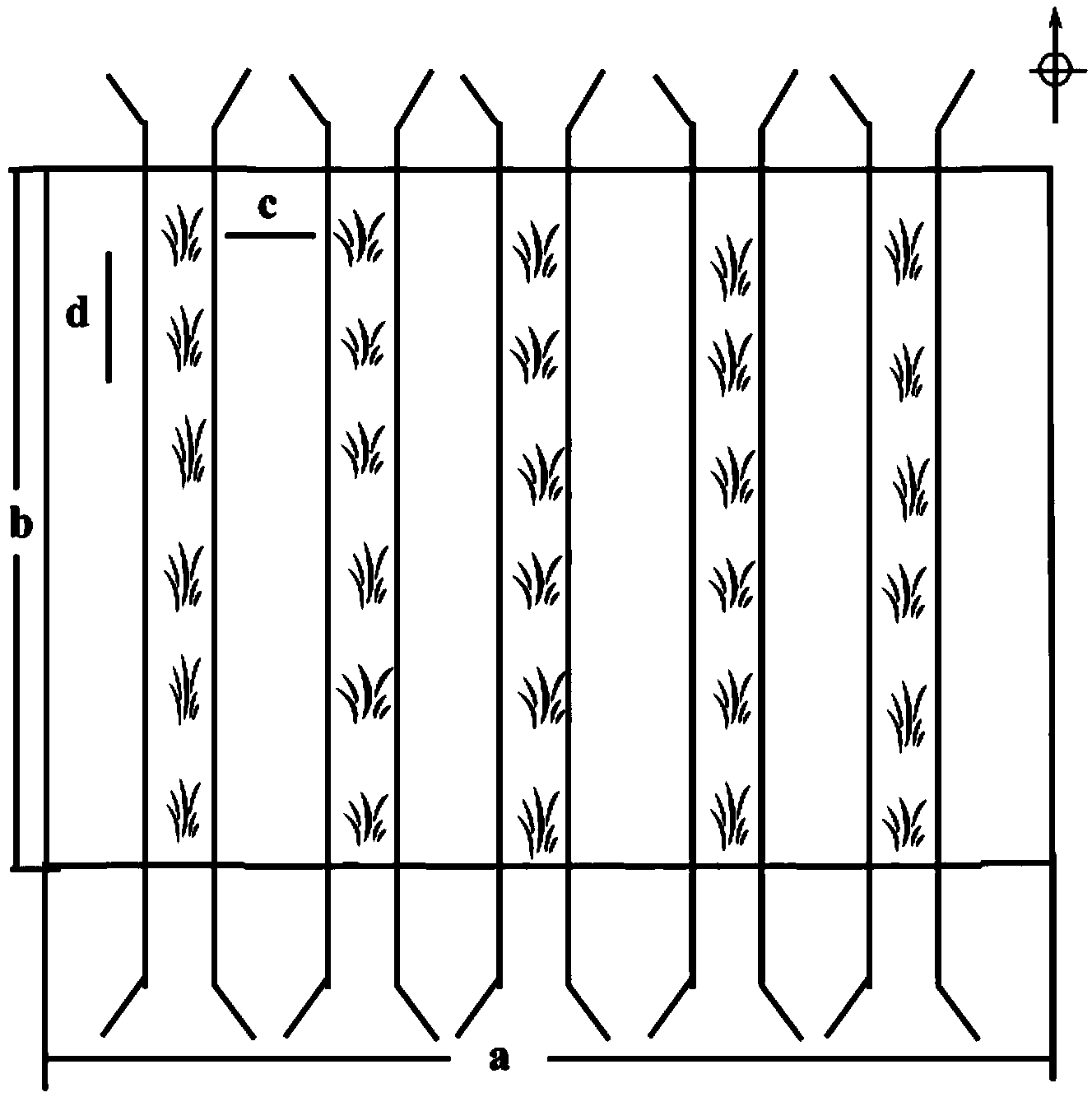

Long-slab-span prefabricated beam floor formwork system

InactiveCN102418414ASave support membersImprove turnover efficiencyForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFalseworkFloor slab

The invention discloses a long-slab-span prefabricated beam floor formwork system, which comprises a floor template, a truss and a placement rod for supporting the truss, wherein a grille is laid on the truss; the floor template is laid on the grille; a formwork hole is formed on a prefabricated beam; a connecting piece is arranged at the formwork hole; and the placement rod is arranged on the prefabricated beam through the connecting piece. In the system, the formwork hole is formed on the prefabricated beam; the placement rod is arranged through the formwork hole; the truss is arranged on the placement rod; the floor template is erected on the truss, and a landing supporting scaffold is not required to be arranged at the bottom of the floor template; and thus, a template supporting member is saved, load of an upper layer floor is not transferred to a lower layer floor, a lower layer floor template can be dismantled before completion of construction of the upper layer floor, and accordingly, the turnover efficiency of the template is increased.

Owner:杨峰 +1

Earth-cultured plant cultivation and shaping method and product

InactiveCN104221641AHarm reductionRealize ecologyHorticulture methodsPlant cultivationForest resource

The invention aims to provide an earth-cultured plant cultivation and shaping method and a product. The method enables plants to have practical structures during growth without secondary artistic creation and complex and cumbersome processing and sculpturing. The earth-cultured plant cultivation and shaping method includes the steps: (1) designing and making a cultivation scheme and making a support suitable for the cultivation scheme; (2) selecting a tree variety for planting and fixing a seedling onto the support according to the shape of the support; (3) pruning and maintaining to keep the seedling growth shape fitting the shape of the support so as to meet requirements of the cultivation scheme; (4) demounting the support, chopping down the plant and treating the plant as a formed product. According to the earth-cultured plant cultivation and shaping method, articles for daily life, production and living facilities and artworks which are originally ecologic, cheap and excellent can be provided for people, and a great amount of timbers are saved to greatly protect the extremely insufficient forest resources of the earth.

Owner:宋志远

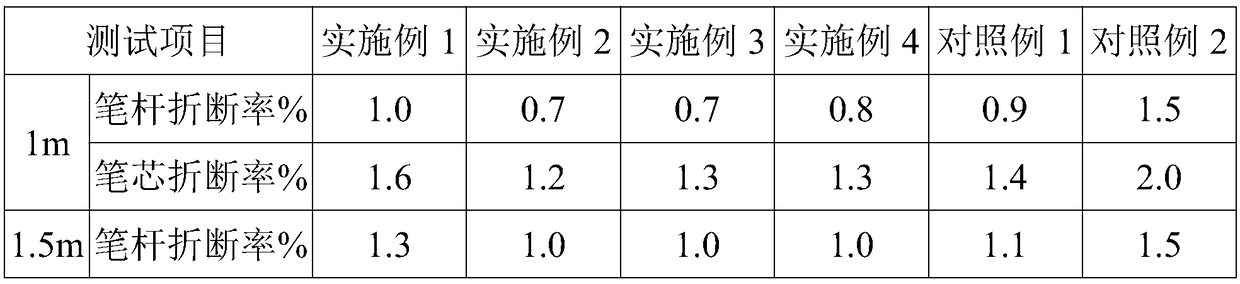

Environment-friendly wood-like plastic pencil

ActiveCN109050080AAppropriate material selectionReasonable formulaNon-propelling pencilsEcological environmentPolystyrene

The invention discloses an environment-friendly wood-like plastic pencil and relates to the technical field of pencil manufacturing processing. The pencil comprises a pencil rod, a pencil lead, a pencil cover and an eraser head. The pencil rod is prepared from 40-60 parts of polystyrene, 40-60 parts of talcum powder, 1-5 parts of titanium dioxide, 0.1-1 part of zinc stearate, 0.5-3 parts of calcium stearate and 1-5 parts of pigment. The pencil lead is prepared from 70-90 parts of polystyrene, 5-25 parts of talcum powder, 5-25 parts of thermoplastic elastomer SBS, 70-90 parts of graphite, 0.1-1part of zinc stearate and 0.5-3 parts of calcium stearate. The pencil cover is prepared from 80-100 parts of polystyrene, 20-40 parts of thermoplastic elastomer SBS and 10-30 parts of pigment. According to the plastic pencil, material selection is appropriate, the formula is reasonable, the produced pencil is attractive in appearance, free of lead shifting and breakage, moderate in roll cutting hardness, smooth in writing and high in colorability, wood is replaced with plastic, a large amount of wood is saved, and national forest resources and ecological environment are reasonably and effectively protected.

Owner:安徽得亿文教用品有限公司

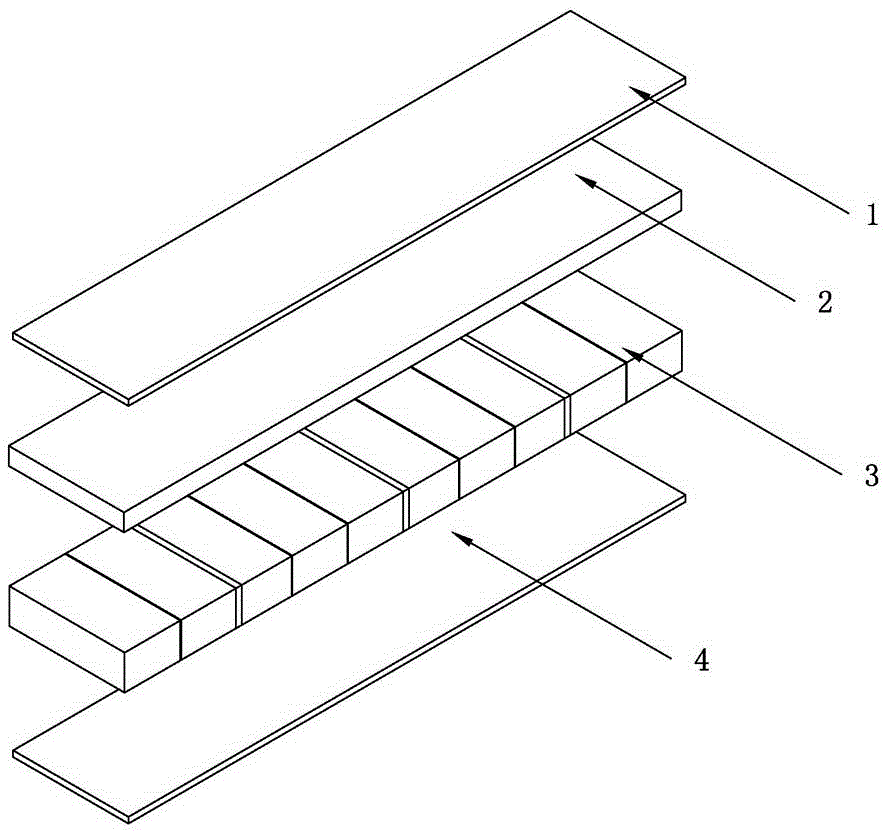

PVC composite floor and manufacturing method thereof

InactiveCN106183132AImprove waterproofProtect forest resourcesLamination ancillary operationsLaminationPolyurethane adhesiveLacquer

The invention discloses a PVC composite floor and a manufacturing method of the PVC composite floor, and belongs to the field of floor manufacturing. The PVC composite floor comprises a PVC surface layer and a composite base material which are glued and compounded through adhesive, the PVC surface layer is prepared from hard or soft PVC, and the base material is composed of a lining plate, a core layer and a bottom plate in a glued mode. The manufacturing method comprises the steps of preparation of the composite base material and preparation of the PVC composite floor. The preparation of the composite base material comprises the steps that 1, materials in different layers needed by the base material are dried to obtain the corresponding moisture content; 2, the lining plate, the core plate and the bottom plate are pressed; 3, maintenance is carried out; 4, the base material is repaired; 5, the two faces of the base material are sanded; 6, the base material is placed in a conditioning room for use. The preparation of the PVC composite floor comprises the steps that 11, the PVC surface plate and the composite base material are glued through the two-component polyurethane adhesive; 12, the bottom plate of a plain plate is sanded; 13, tenoning is carried out; 14, chamfering and paint sealing are carried out; 15, packaging is carried out. The advantages of a reinforced floor and a PVC floor are integrated, the PVC composite floor has the elastic foot feeling of solid wood, and waterproof and fireproof properties, friction resistance and acid and alkali resistance are improved.

Owner:DAYA JIANGSU FLOOR

Cultivation method for schisandra chinensis

InactiveCN104106363AImprove germination rateTo satisfy the market's needsHorticultureEcological environmentSeed treatment

The invention discloses a cultivation method for schisandra chinensis. The cultivation method includes the steps of seed treatment, seedling growing, transplantation, field management and harvest. Wild schisandra chinensis resources are protected through the cultivation pattern of seedling growing and transplantation, and technical support is provided for protecting forest resources and ecological environment and increasing the yield of the schisandra chinensis.

Owner:DIAOYUTAI MEDICAL GRP JILIN TIANQIANG PHARMA

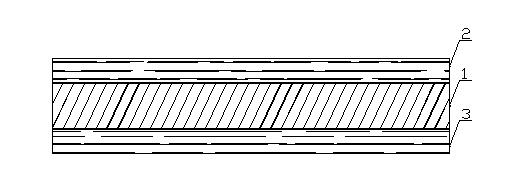

Sub-rail bamboo and wood composite heightening railroad tie plate for concrete sleeper and manufacture method thereof

ActiveCN101818468AHard woodReduce distortionRail fastenersPlant material mechanical workingSurface layerEngineering

The invention relates to a sub-rail bamboo and wood composite heightening railroad tie plate for a concrete sleeper and a manufacture method thereof, in particular to a sub-rail heightening railroad tie plate for a concrete sleeper and a manufacture method thereof, which solves the problems that the traditional heightening railroad tie plate can not simultaneously meet the requirements of planeness, rigidity, pressure resistance and wear resistance and the labor efficiency is low and the gluing amount is large in the manufacture process of the heightening railroad tie plate. The sub-rail bamboo and wood composite heightening railroad tie plate for a concrete sleeper comprises a core layer, an upper bamboo curtain surface layer and a lower bamboo curtain surface layer, wherein two sides of the core layer are respectively glued with the upper bamboo curtain surface layer and the lower bamboo curtain surface layer. The manufacture method of the heightening railroad tie plate comprises the following steps of: braiding bamboo woods on a braiding machine to form a bamboo curtain; gluing wooden materials, then assembling the wooden materials with the bamboo curtain, closing and ageing; and then hot forming a composite plate. The invention provides the heightening railroad tie plate with high planeness and rigidity as well as favorable pressure resistance and wear resistance. The adopted manufacture method improves the labor efficiency and saves the cost. The invention is used for regulating the horizontal height of the rail surface of a railroad, thereby ensuring the stable running of a train.

Owner:哈尔滨新星铁路垫板制造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com