Long-slab-span prefabricated beam floor formwork system

A prefabricated beam and floor formwork technology, which is applied in the fields of formwork/formwork members, formwork/formwork/work frame, and on-site preparation of building components, can solve problems such as limiting the turnover efficiency of formwork, and save formwork support members, The effect of saving wood and preventing pulp leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

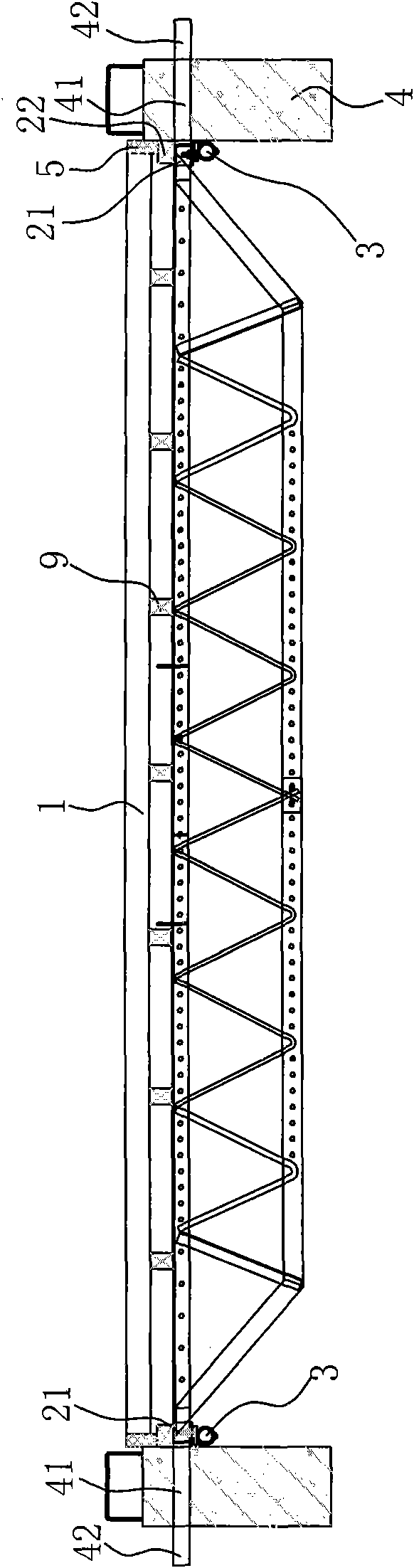

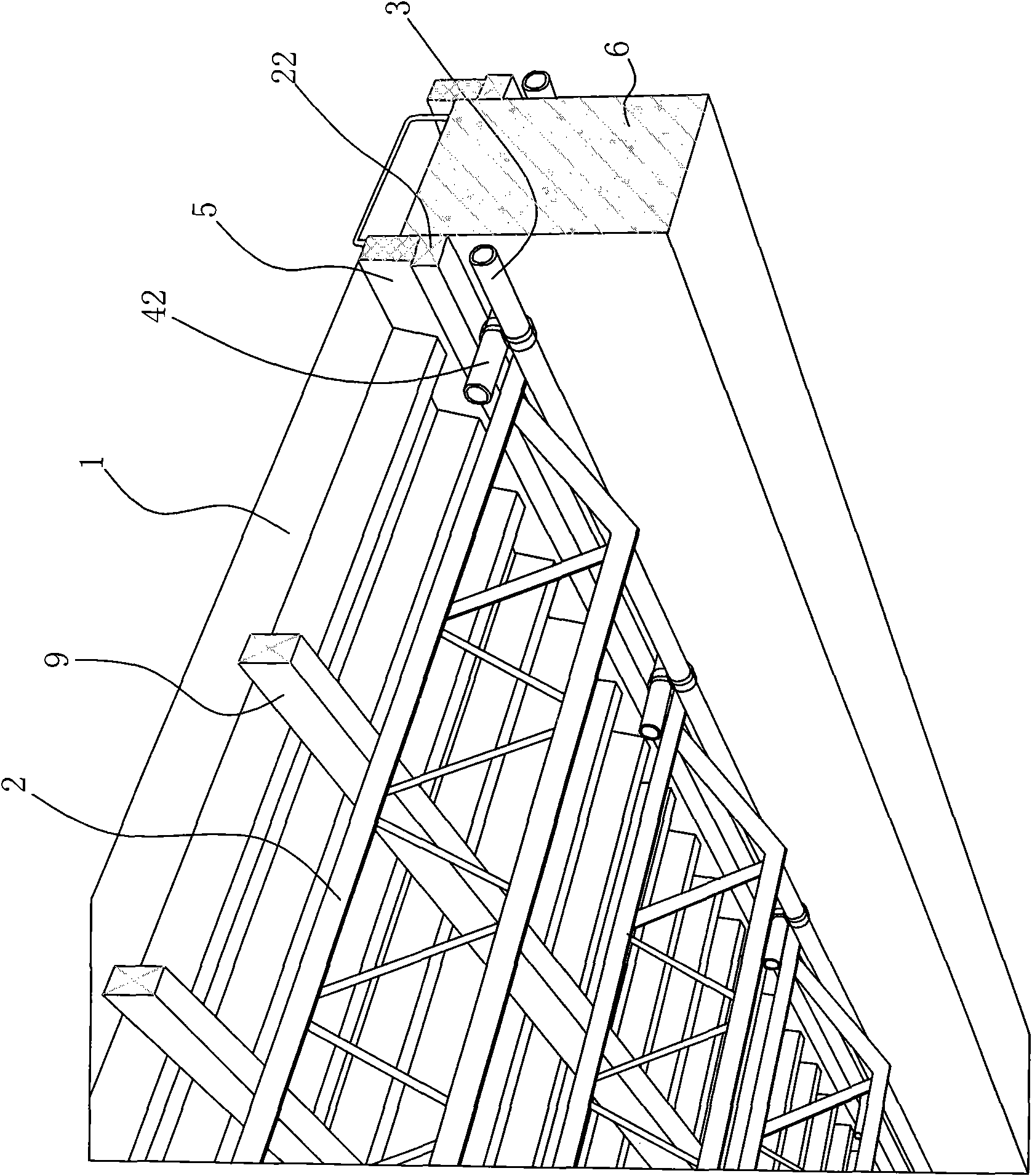

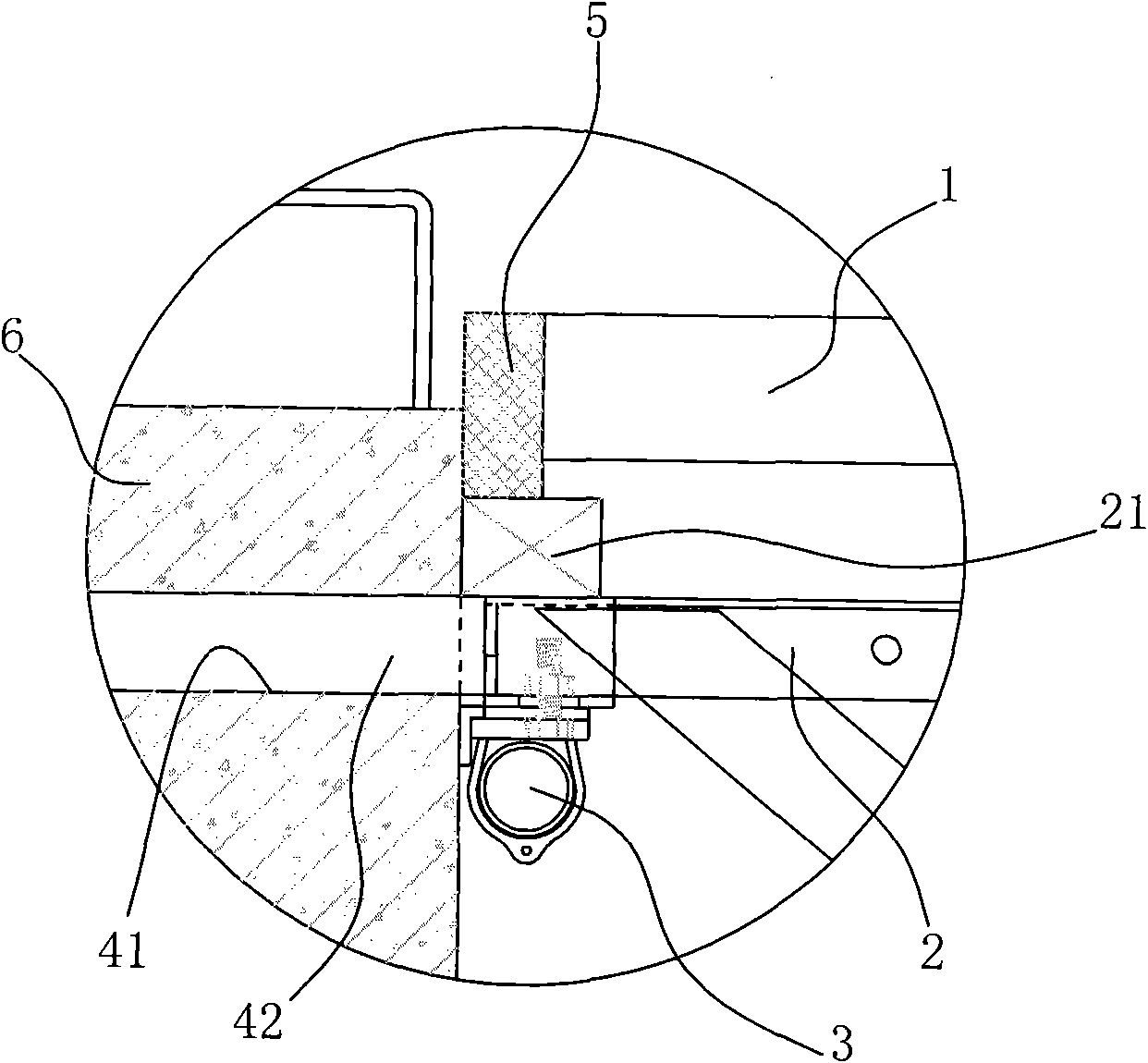

[0027] see figure 1 and figure 2 , the large-span prefabricated beam floor formwork system provided in the present invention includes a floor formwork 1, a truss 2 and a resting rod 3 supporting the truss 2, a grid 9 is laid on the truss 2, and the floor formwork 1 is laid on the grid 9, the prefabricated beam 4 is provided with a formwork hole 41, the formwork hole is provided with a connecting piece 42, and the resting rod 3 is installed on the prefabricated beam 4 through the connecting piece 42 . In the present invention, formwork holes 41 are provided on the prefabricated beam 4, through which the truss 2 and the floor formwork 1 are installed. Therefore, there is no need to set the ground support scaffolding at the bottom, which not only saves formwork support members, but also reduces the cost of the upper floor. The load will not be transferred to the lower floor, and the formwork of the lower floor can be removed earlier than the completion of the upper floor, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com