Patents

Literature

512results about How to "Realize unmanned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

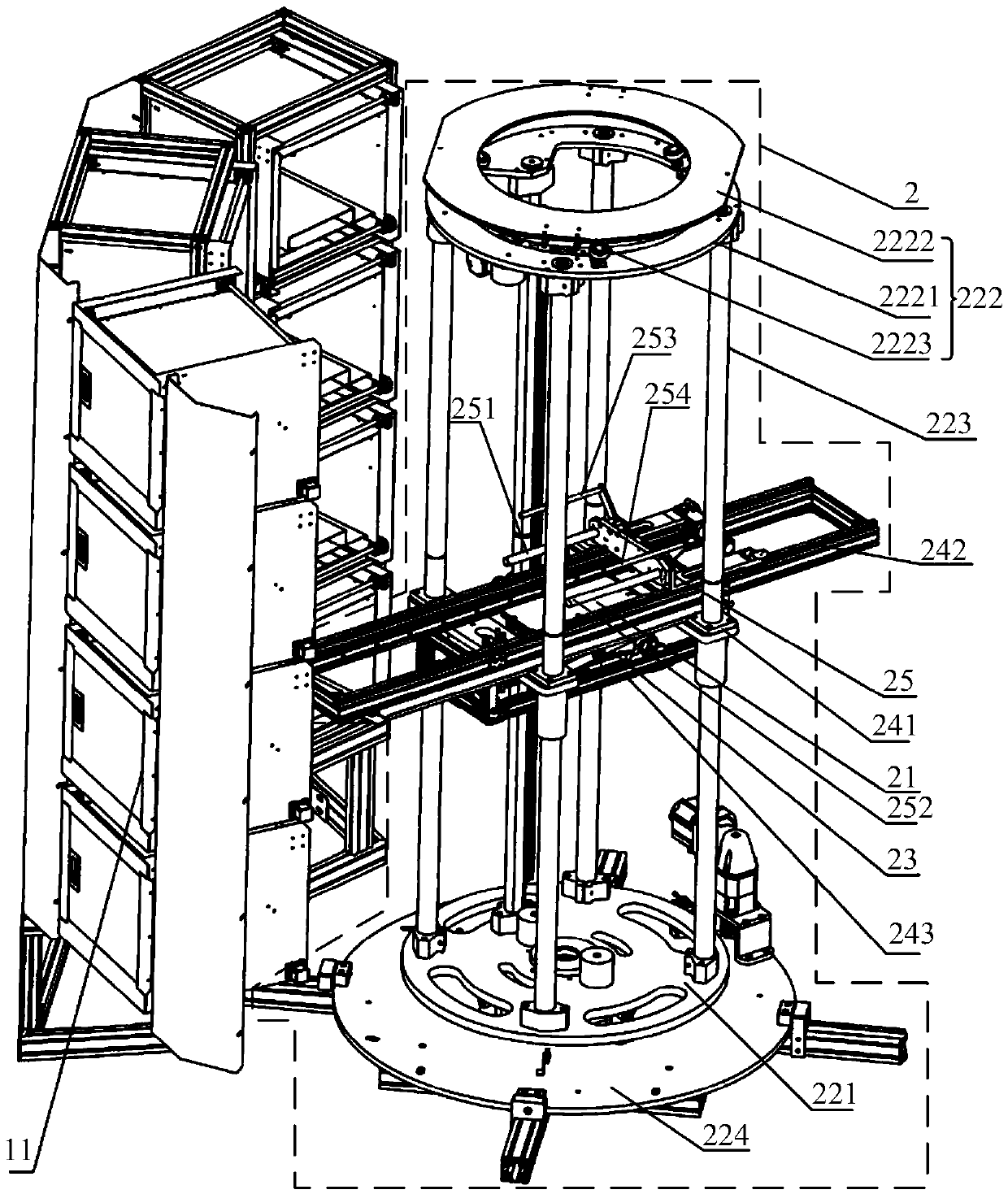

AGV (Automatic Guided Vehicle) and method

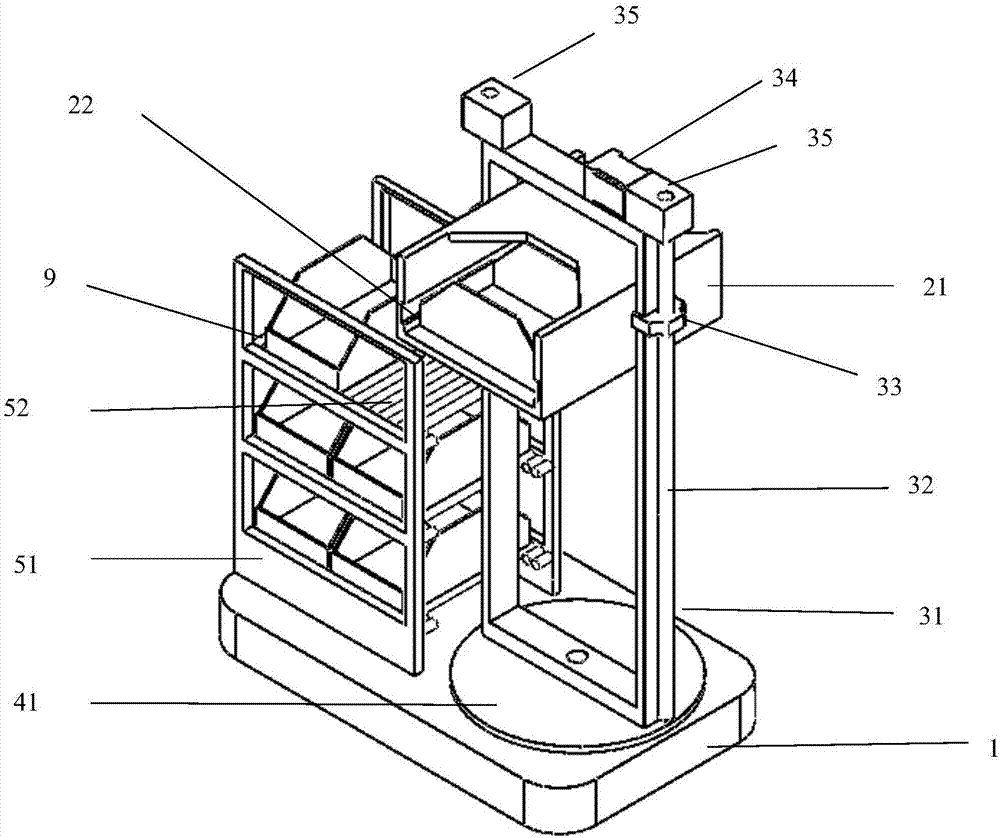

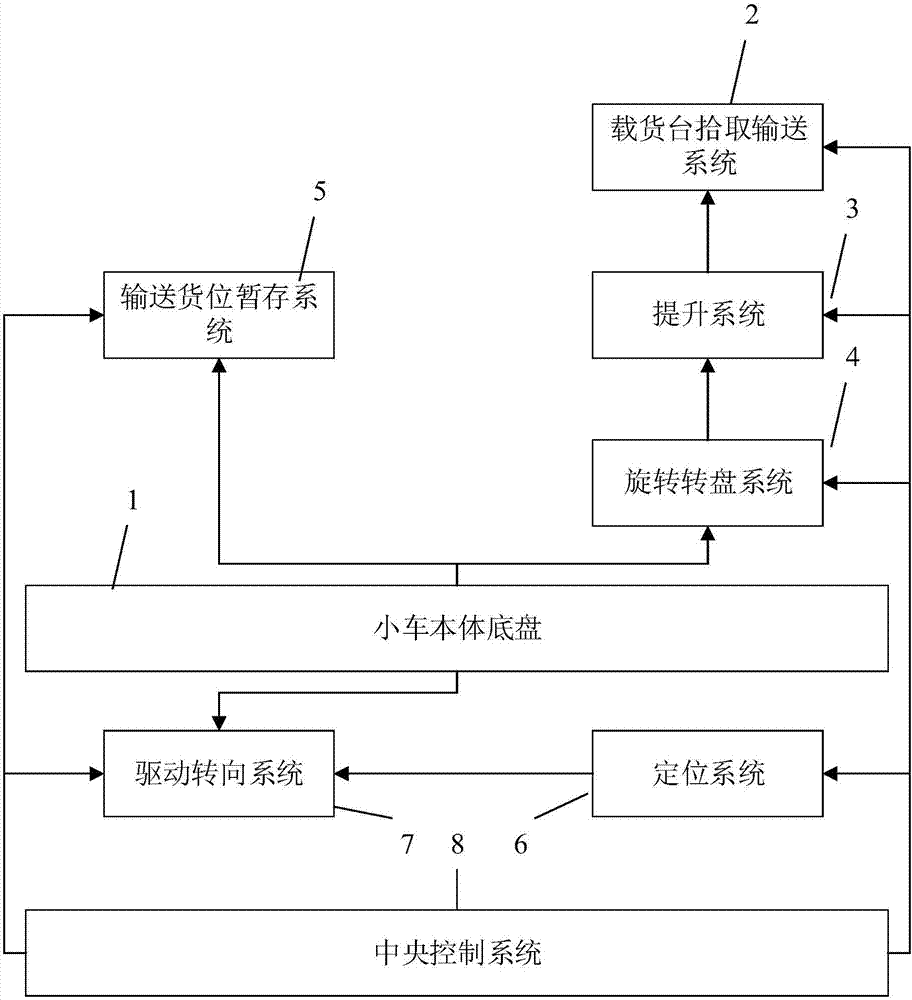

PendingCN107226310AImprove picking efficiencyImprove accuracyControl devices for conveyorsStorage devicesEngineeringTemporary storage

The invention discloses an AGV (Automatic Guided Vehicle) and a method. The AGV (Automatic Guided Vehicle) comprises a vehicle body chassis, a cargo bearing platform picking-up and conveying system, a lifting system, a rotary rotary-table system and a delivered cargo temporary storage system; the rotary rotary-table system and the delivered cargo temporary storage system are fixed to the two sides of the upper portion of the vehicle body chassis correspondingly; the lifting system is fixed to the upper portion of the rotary rotary-table system, and the control end of the lifting system is connected with the cargo bearing platform picking-up and conveying system; the delivered cargo temporary storage system comprises a plurality of layers of temporary storage racks, and each layer of the temporary storage racks is provided with a plurality of temporary storage cargo positions; and the lifting system is used for controlling the sliding height of the cargo bearing platform picking-up and conveying system, and the rotary rotary-table system is used for controlling the rotation angle of the lifting system. By means of the AGV (Automatic Guided Vehicle) and the method, operation of manual picking-up of workbins is omitted, manpower and time are saved, and meanwhile workbin picking-up efficiency and accuracy are also improved.

Owner:湖北九州云仓科技发展有限公司

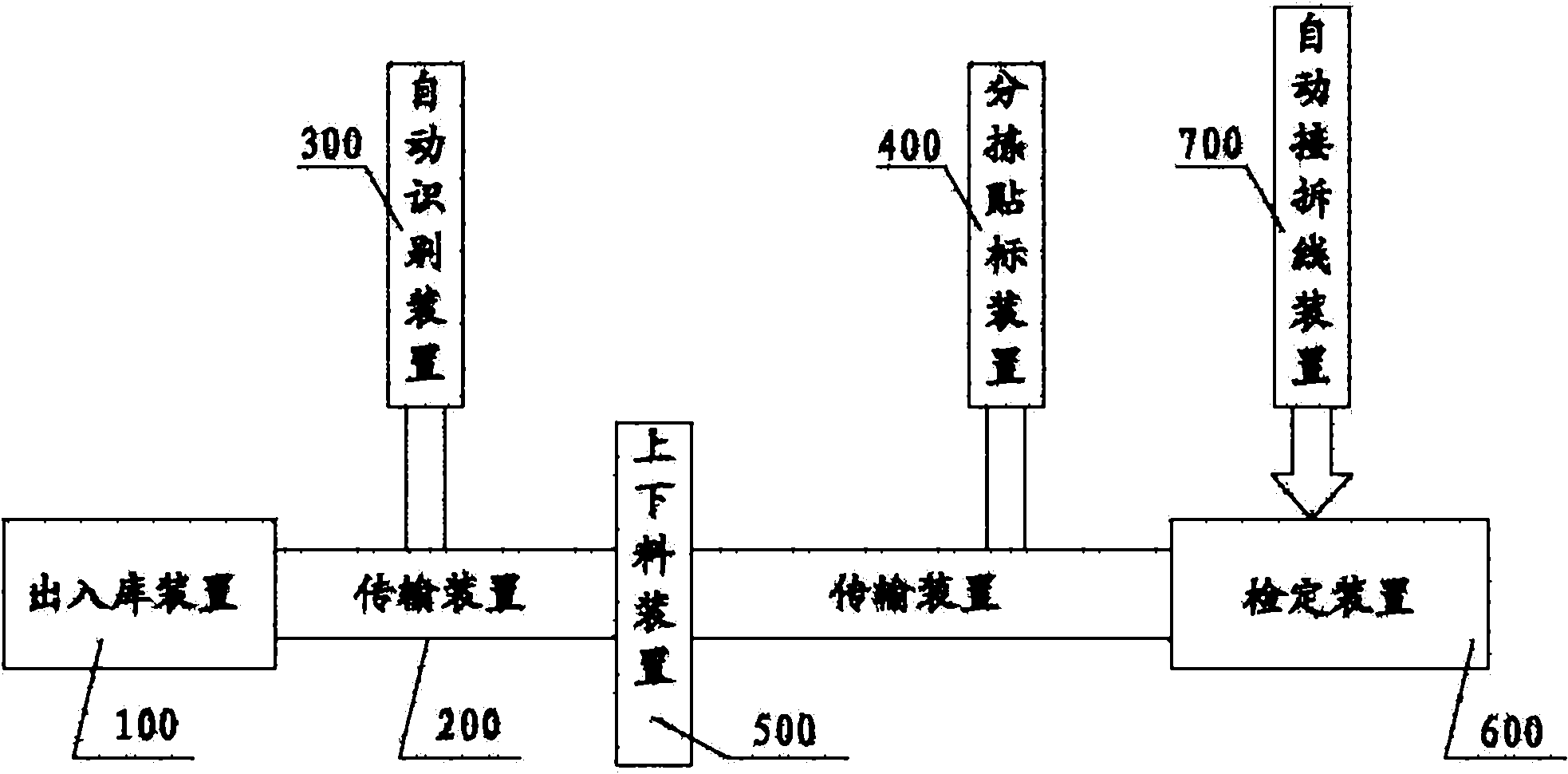

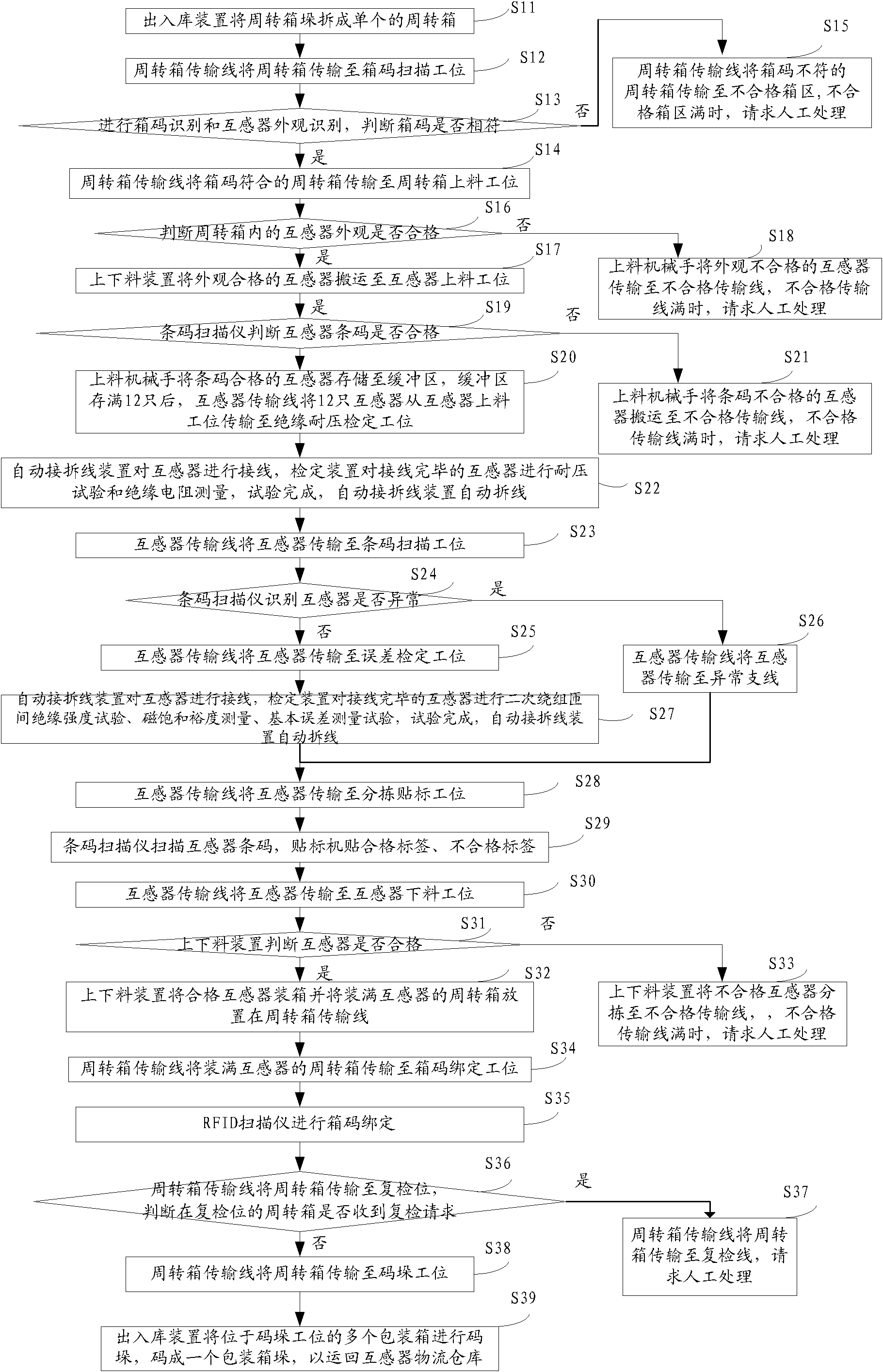

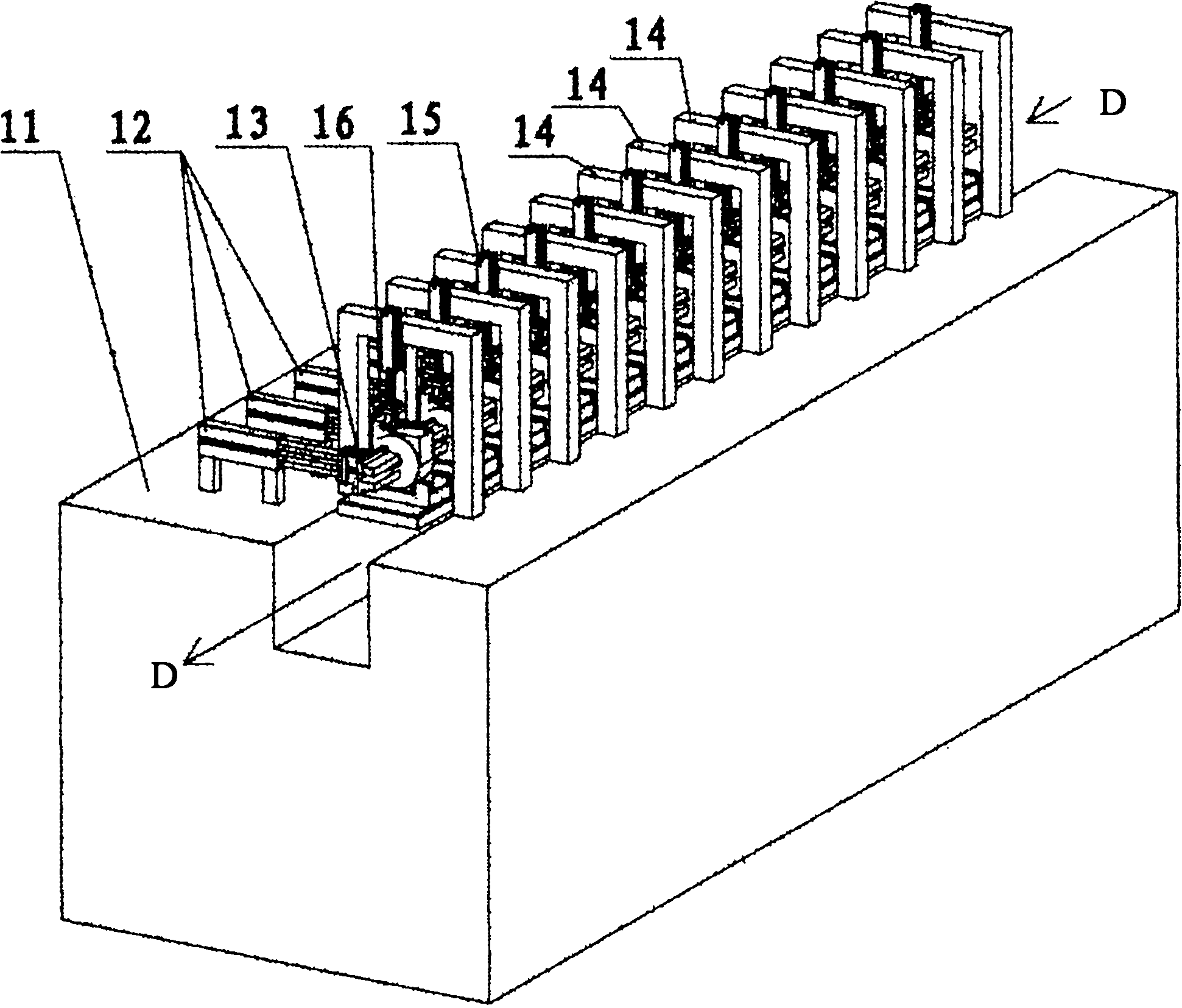

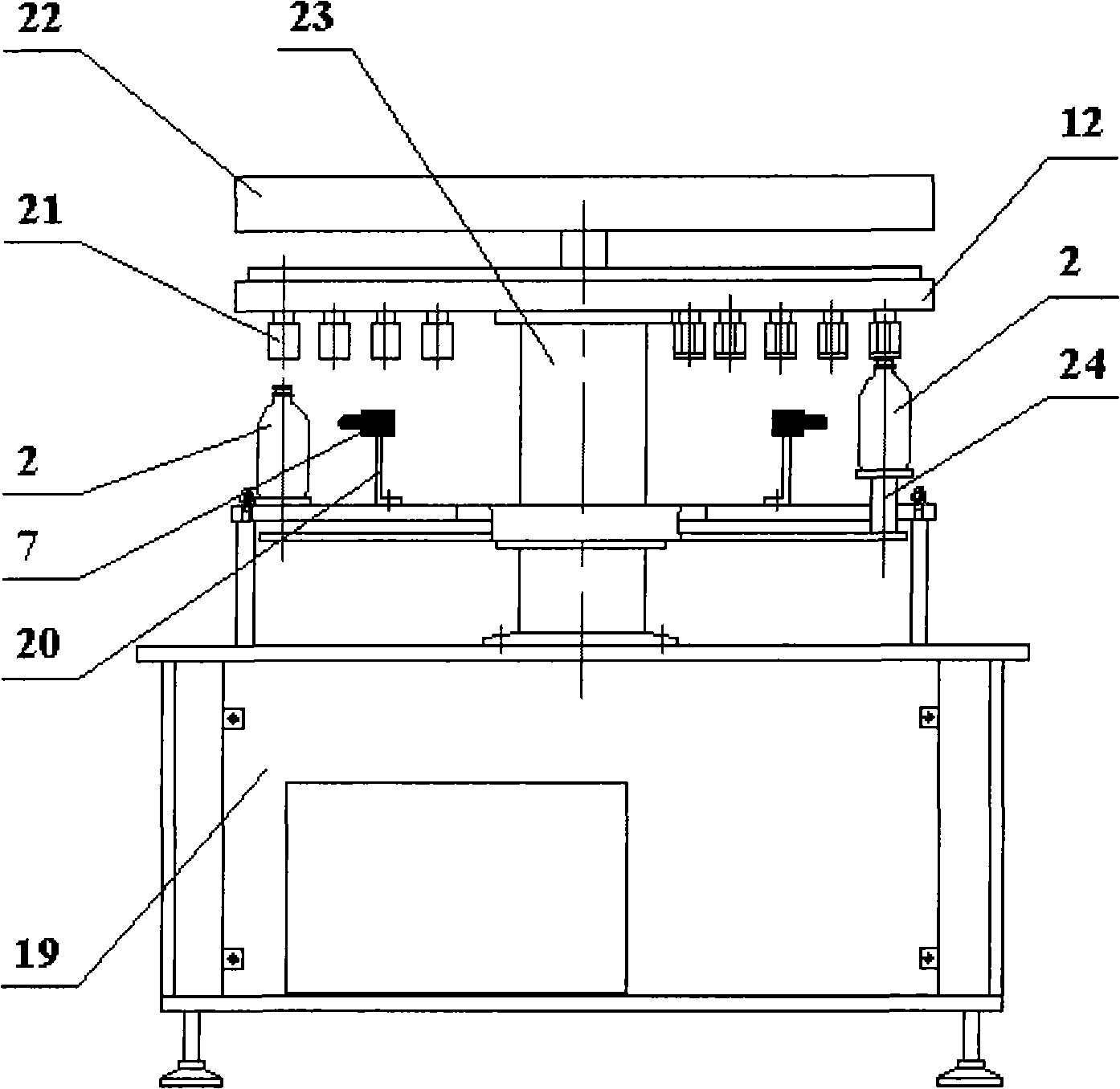

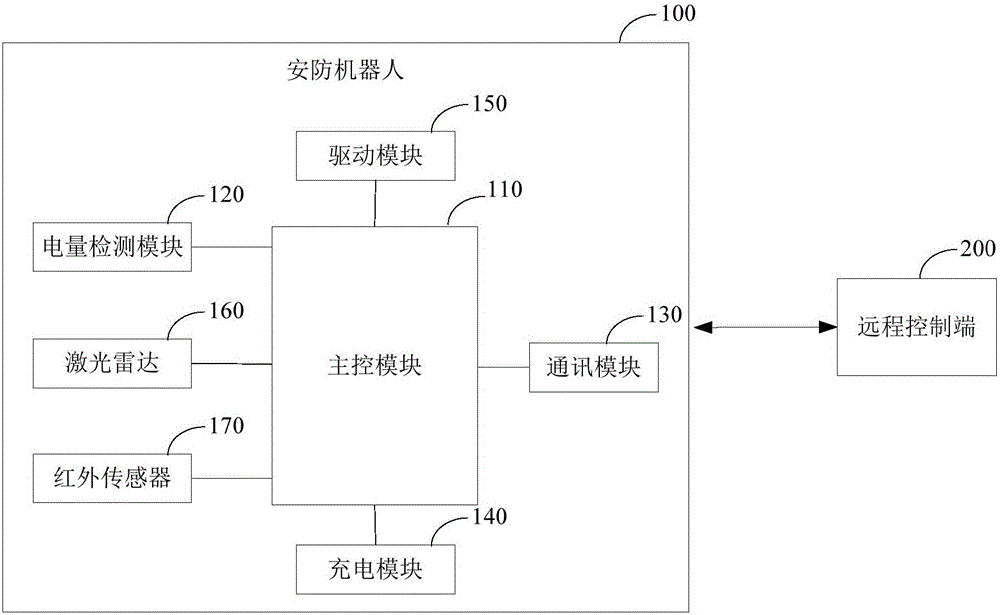

Automatic calibration line and method for intelligent type low-tension current transformers

ActiveCN102135607AImprove test efficiencyReduce human errorElectrical measurementsEngineeringIdentification device

The invention discloses an automatic calibration line for intelligent type low-tension current transformers, comprising a warehouse in-out device, a loading and unloading device, an automatic identification device, a transmission device, an automatic line connecting and disconnecting device, a calibration device and a sorting and labeling device, wherein the warehouse in-out device realizes the automatic warehouse in-out of the intelligent type low-tension current transformers; the material loading and unloading device realizes the automatic loading and unloading of the intelligent type low-tension current transformers; the automatic identification device realizes the automatic identification of the intelligent type low-tension current transformers; the transmission device realizes the automatic transmission of the intelligent type low-tension current transformers; the automatic line connecting and disconnecting device realizes the automatic line connection of the intelligent type low-tension current transformers for the calibration by the calibration device and also realizes the automatic line disconnection of the intelligent type low-tension current transformers; and the sortingand labeling device realizes the automatic sorting of the intelligent type low-tension current transformers. The automatic calibration line is free from manually carrying out the warehouse in-out, the transmission, the identification, the sorting, the loading and unloading and the line connection and disconnection on the intelligent type low-tension current transformer when calibrating the intelligent type low-tension current transformer, and has the advantages of no personal error, high calibration efficiency, good automation degree and capability of automatically measuring multiple transformers. The invention also discloses an automatic calibration method of the intelligent type low-tension current transformer.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +2

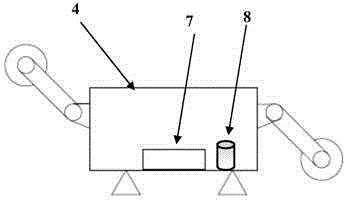

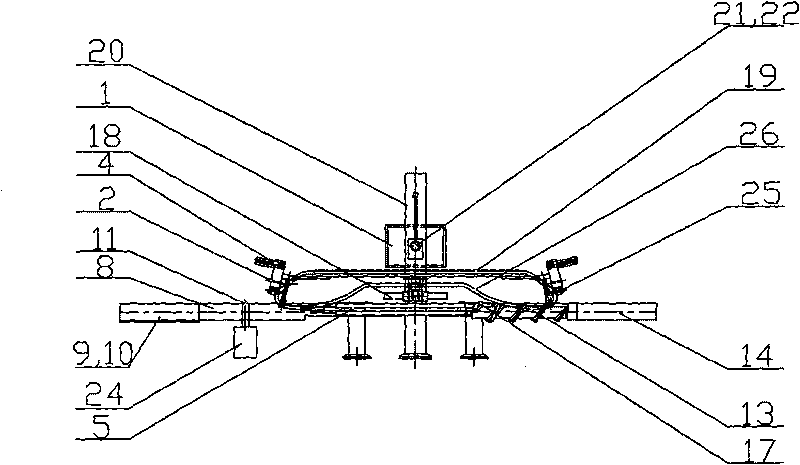

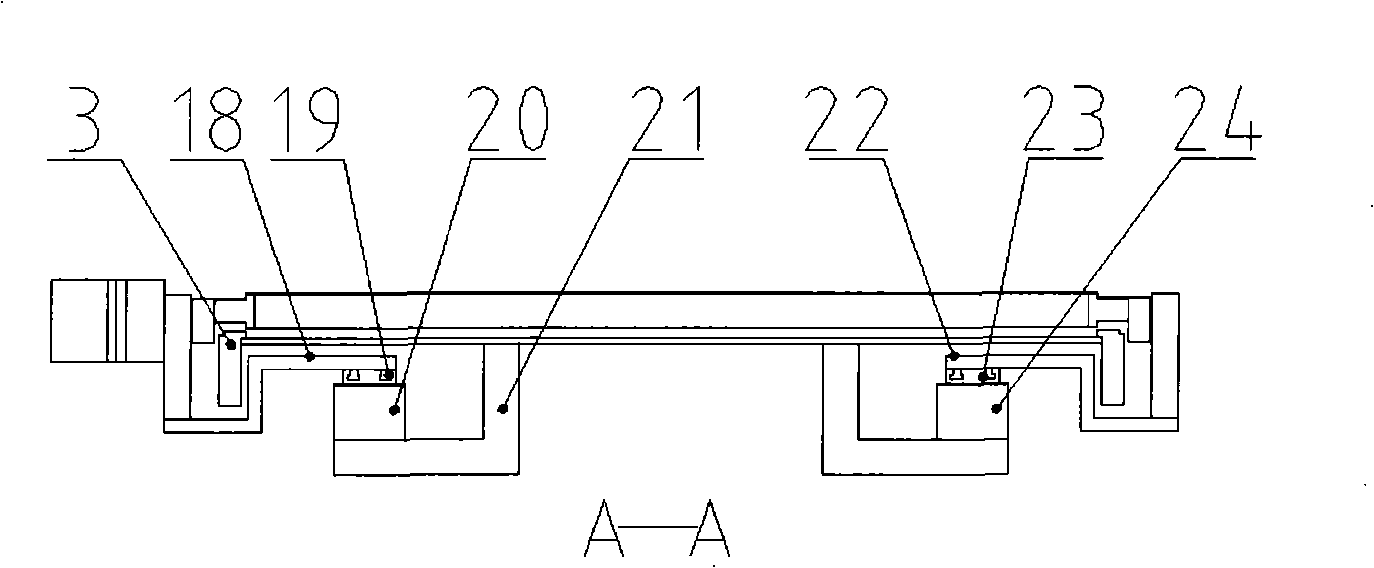

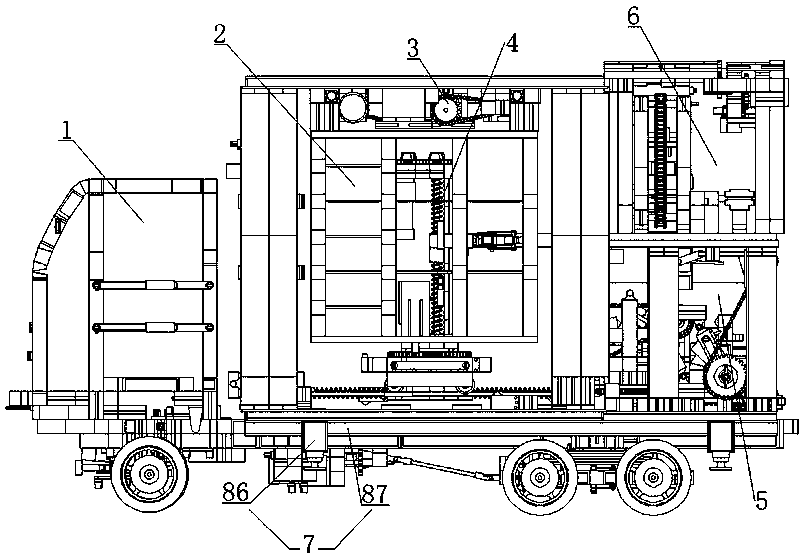

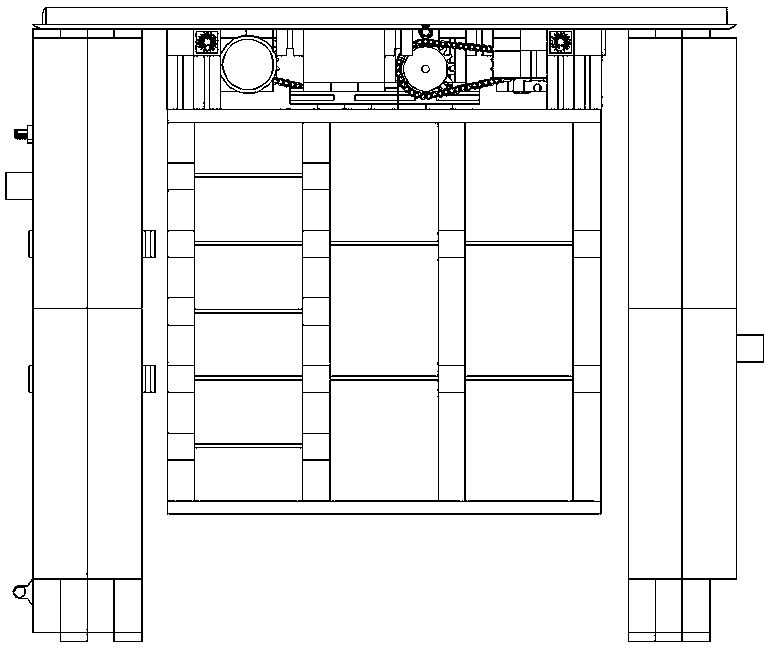

Loading robot

ActiveCN103964224ARealize unmannedFully automaticLoading/unloadingConveyor partsManipulatorPosition sensor

The invention discloses a loading robot. The loading robot is characterized by comprising a main framework, a manipulator, a vertical moving mechanism, a horizontal moving mechanism, a power unit and a sensing control device, the main framework is used for fixing all the mechanisms and other parts; the manipulator is used for rotating and grabbing goods; the vertical moving mechanism is connected with the upper end of the manipulator and used for driving the manipulator to vertically move; the horizontal moving mechanism is installed at the upper end of the main framework, is connected to the vertical moving mechanism through a sliding block and is used for driving the manipulator to horizontally move; the power unit comprises a rotary servo motor for controlling the manipulator to rotate, a vertical moving servo motor for controlling the vertical moving mechanism to move, and a horizontal servo motor for controlling the horizontal moving mechanism to move; the sensing control device comprises a goods position sensor, a goods falling sensor and a vehicle position sensor all of which are installed at different positions of the main framework and used for controlling the manipulator to operate. The loading robot achieves unmanned loading, thereby saving labor, improving the loading efficiency greatly and enabling loading to be standard and orderly.

Owner:青岛德和丰科贸有限公司

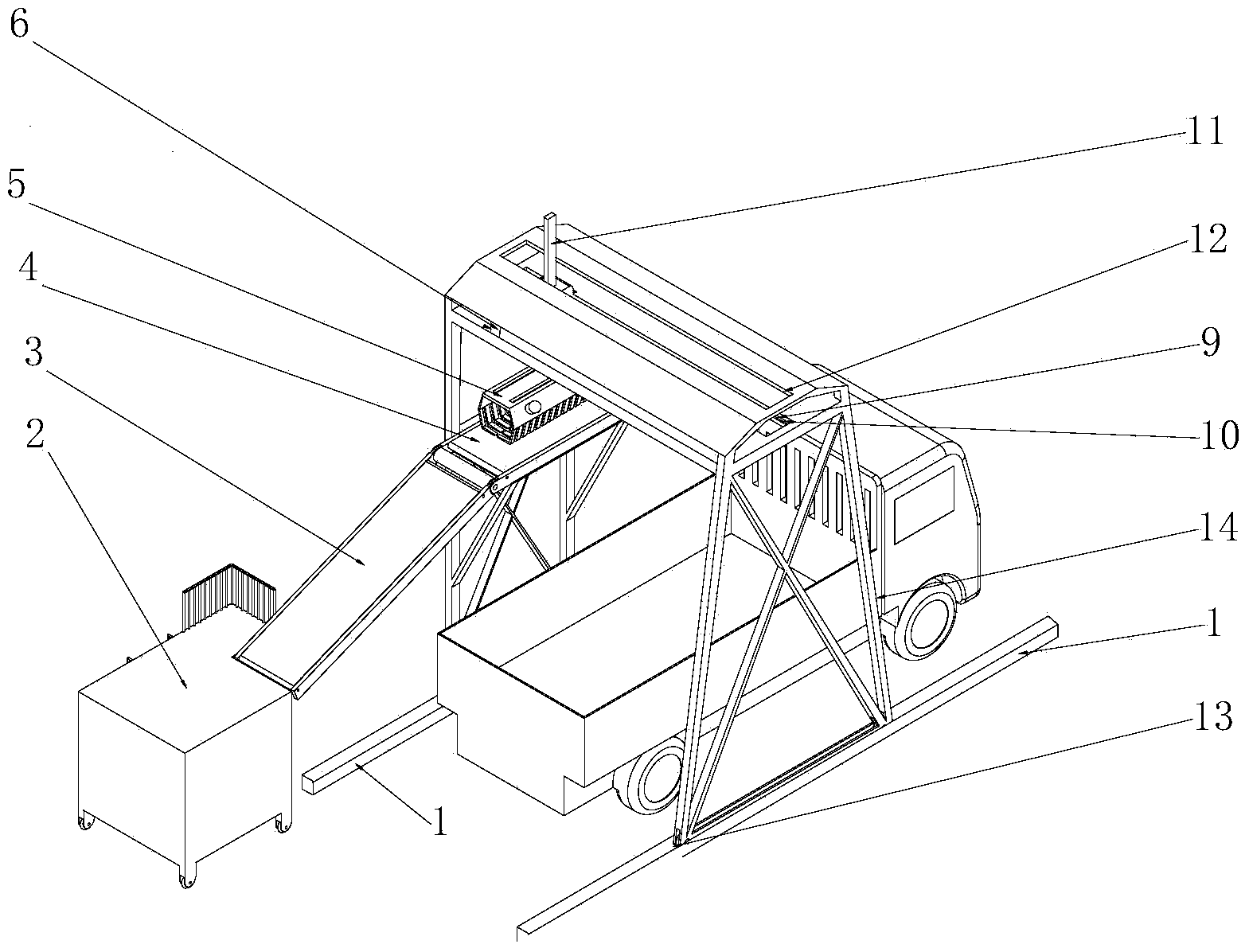

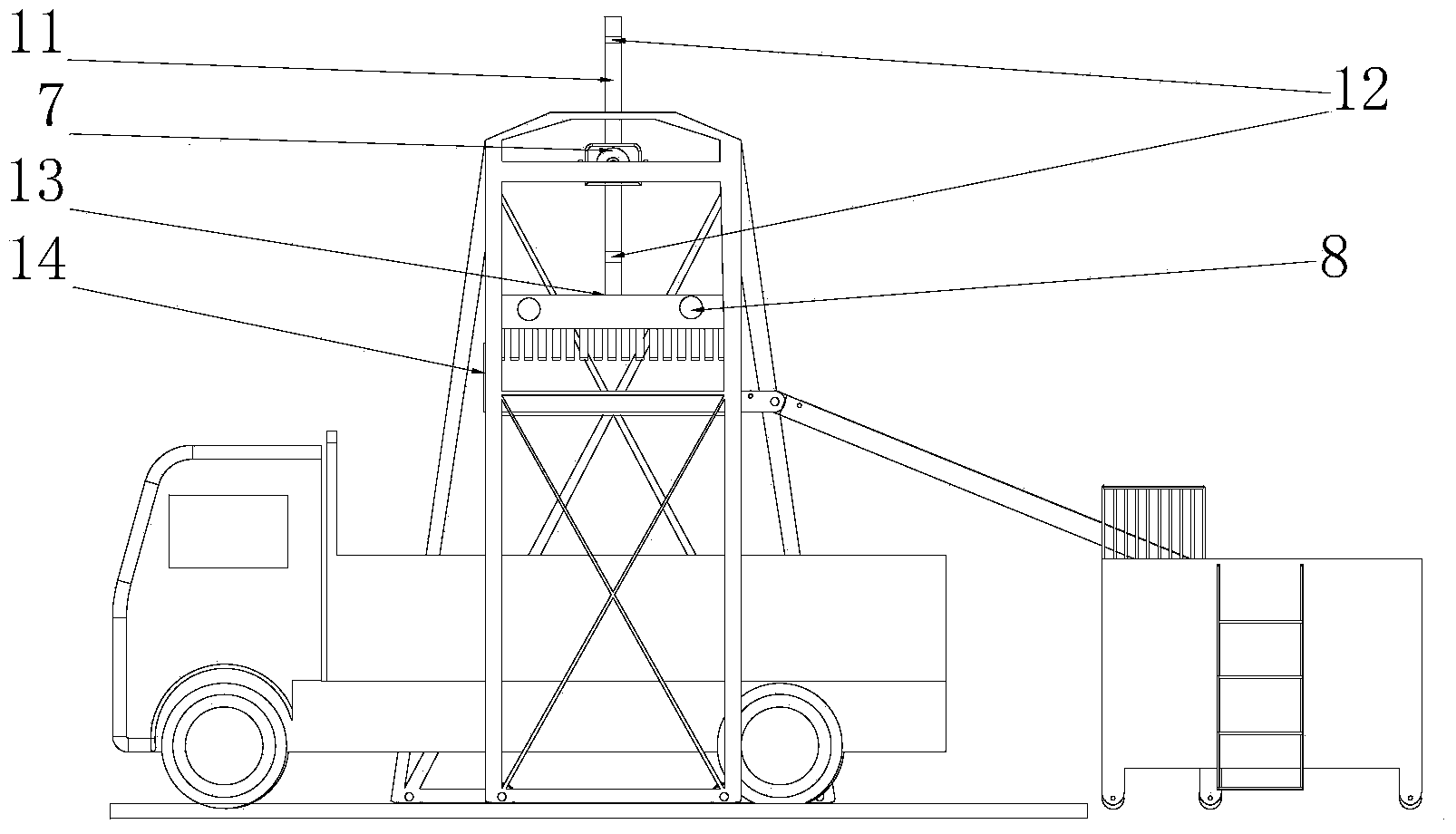

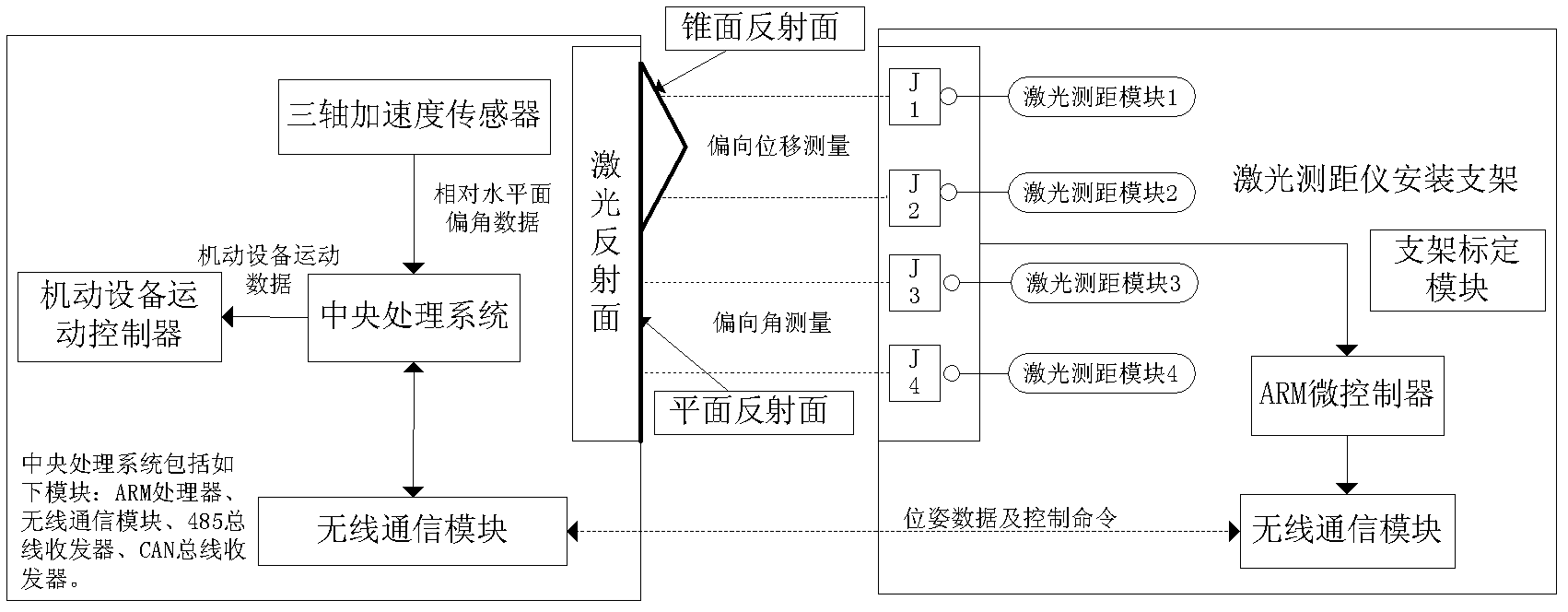

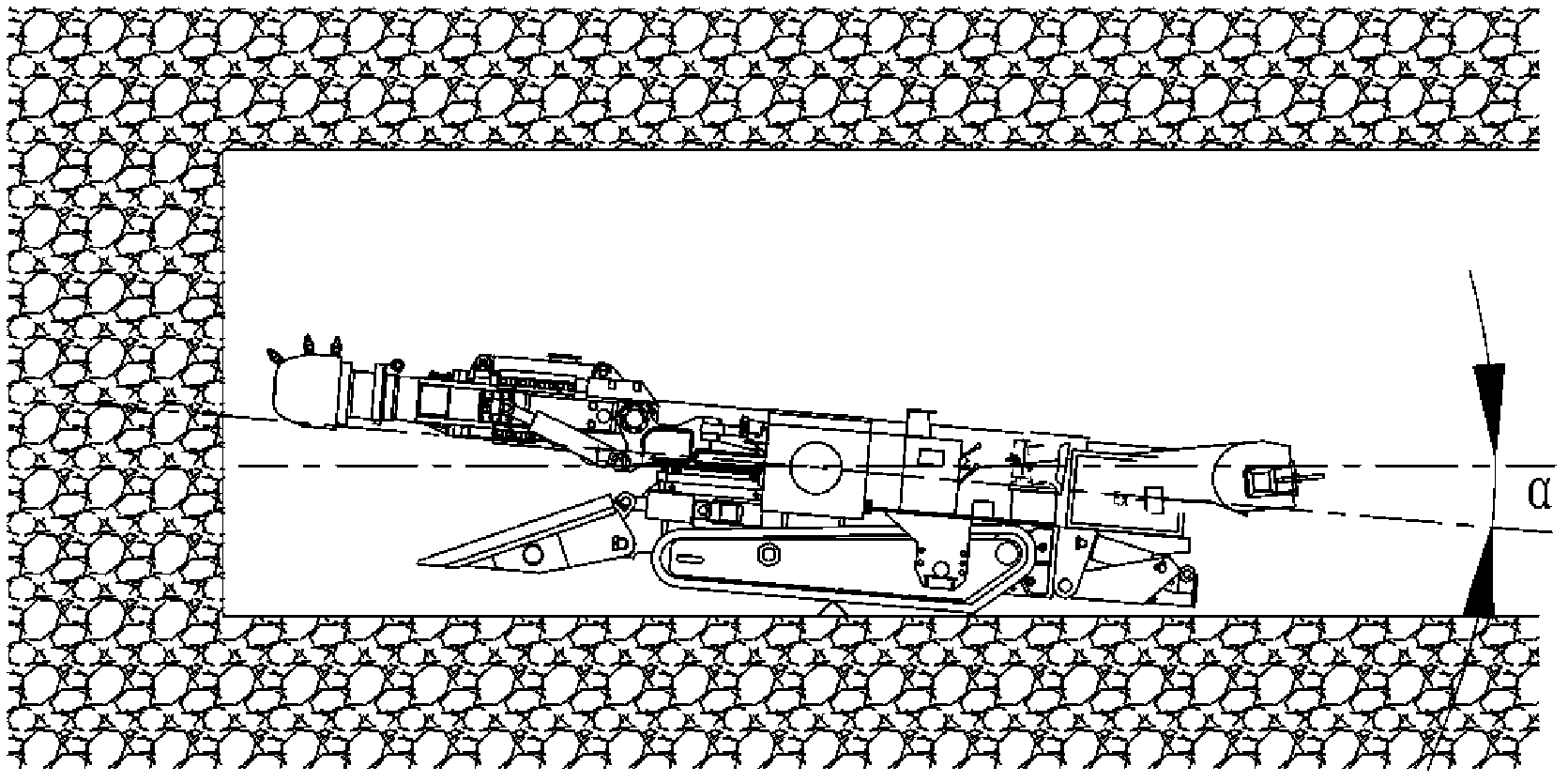

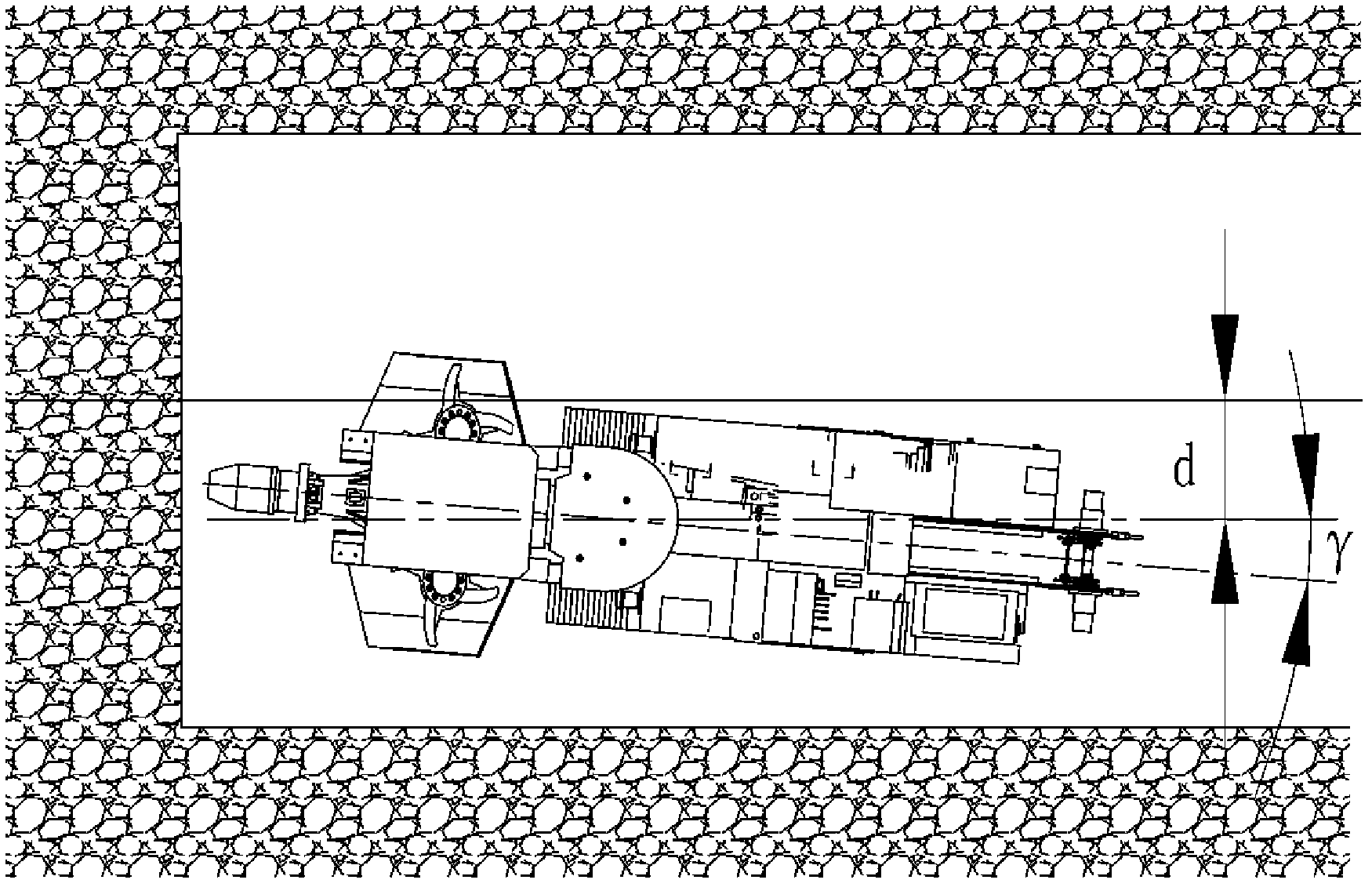

Position and posture measuring system and method for mechanical equipment

InactiveCN102322857AThere is no error accumulation processRealize automatic controlAngle measurementOptical rangefindersLaser rangingComputer module

The invention relates to a position and posture measuring system and method for mechanical equipment. The position and posture measuring system is characterized in that: four laser distance-measuring modules are arranged at the top of an alley at the back of the mechanical equipment to measure points of special positions on the mechanical equipment so as to obtain four different distances; position offset of the mechanical equipment relative to a predetermined track and angular offset of the mechanical equipment on a vertical surface are calculated based on the four distances; offset data is transmitted to a central processing system on the mechanical equipment through a wireless communication module; position and posture parameters of the mechanical equipment and positioning navigation data can be obtained in combination with a dip angle of the mechanical equipment relative to a horizontal plane, wherein the dip angle is measured by a triaxial acceleration sensor which is arranged onthe mechanical equipment; and the central processing system is used for transmitting the positioning navigation data to a control box of the mechanical equipment. The position and posture measuring system has the advantages of high measuring speed, good real-time performance, high measurement accuracy and no accumulated error, and is suitable for the position and posture measurement as well as the positioning navigation of underground mechanical equipment.

Owner:WUHAN UNIV OF TECH

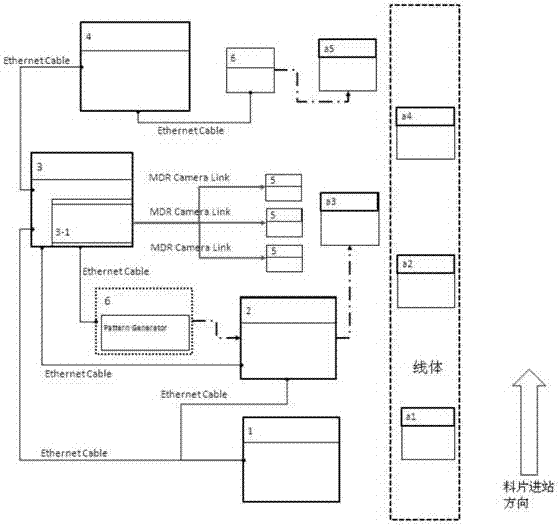

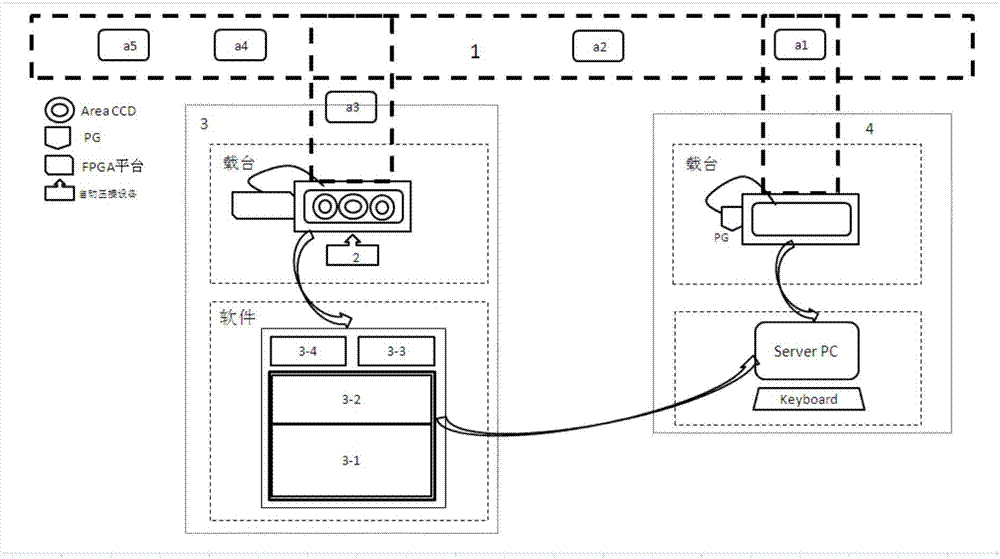

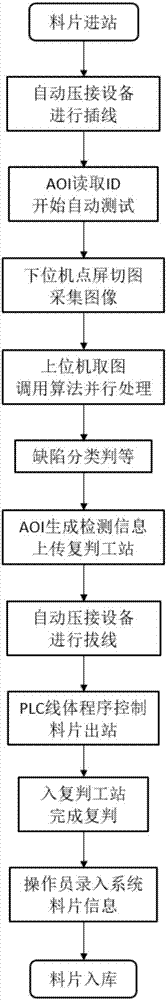

Full-automatic LCD detecting control system and method based on AOI technology

ActiveCN107144992AIncrease productivityEasy to operateProgramme control in sequence/logic controllersNon-linear opticsLiquid-crystal displayControl system

The invention discloses a full-automatic LCD detecting control system and method based on an AOI technology. The system comprises an Inline line body PLC module and a detecting workstation, wherein automatic compression joint equipment and an AOI system are arranged in the detecting workstation; the Inline line body PLC module is used for controlling the position of an LCD panel on an assembly line; the automatic compression joint equipment is used for controlling a motor to carry out automatic plug wire compression joint on the LCD panel of the detecting workstation; after plug wire compression joint is finished, the AOI system is informed to begin to detect; after a detection finish signal transmitted from the AOI system is received, a wire is automatically unplugged from the LCD panel; and the AOI system is used for receiving a detection beginning signal and then automatically optically detecting the LCD panel, generating a detecting information file, and transmitting the detecting finish signal to the automatic compression joint equipment. Disadvantages of manual detection can be overcome, the defect detection speed is high, the precision is also high, the system is automatic and practical, a non-contact mode is carried out, and the development prospect in the industry of defect detection of liquid crystal displays is wide.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

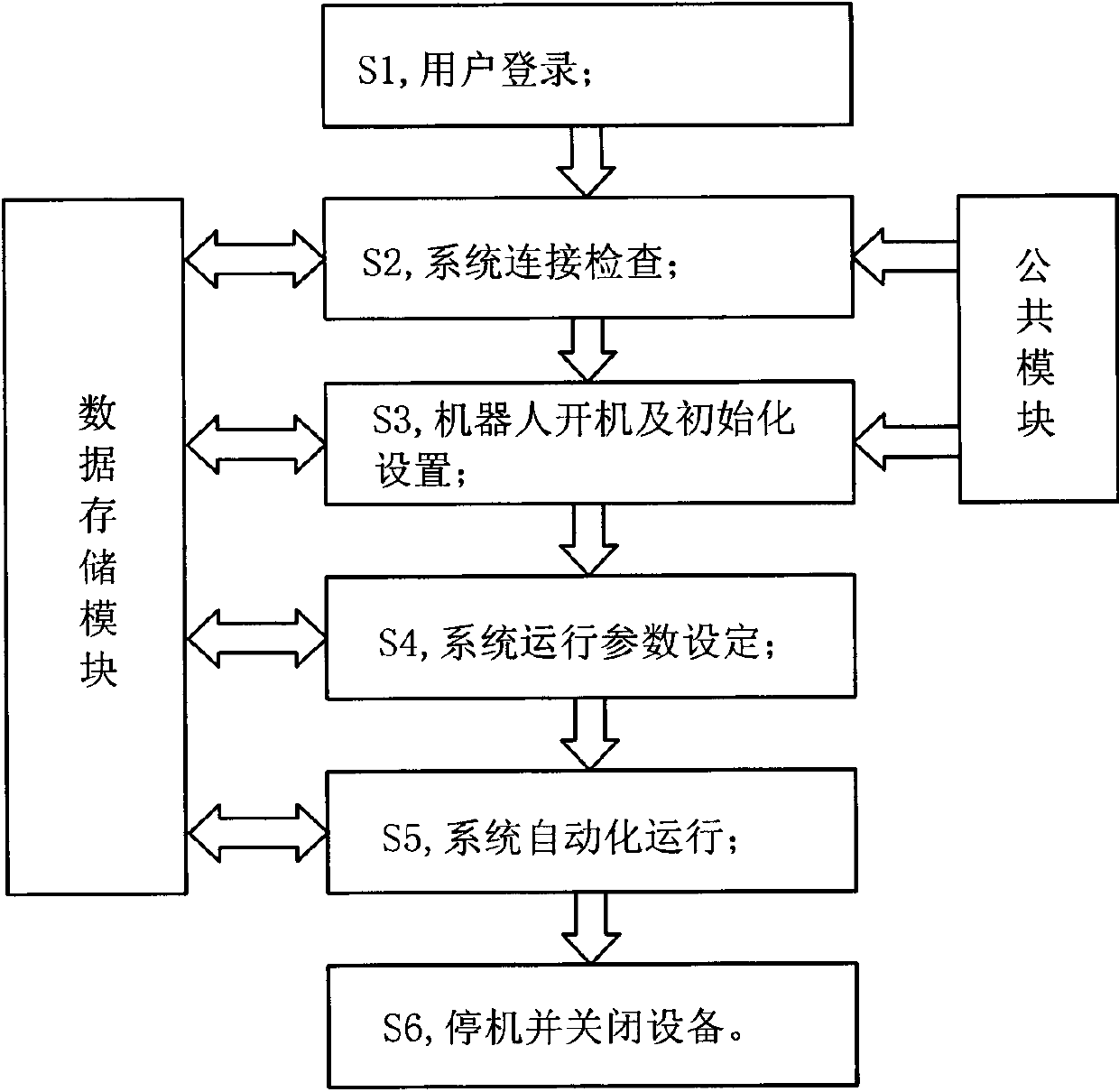

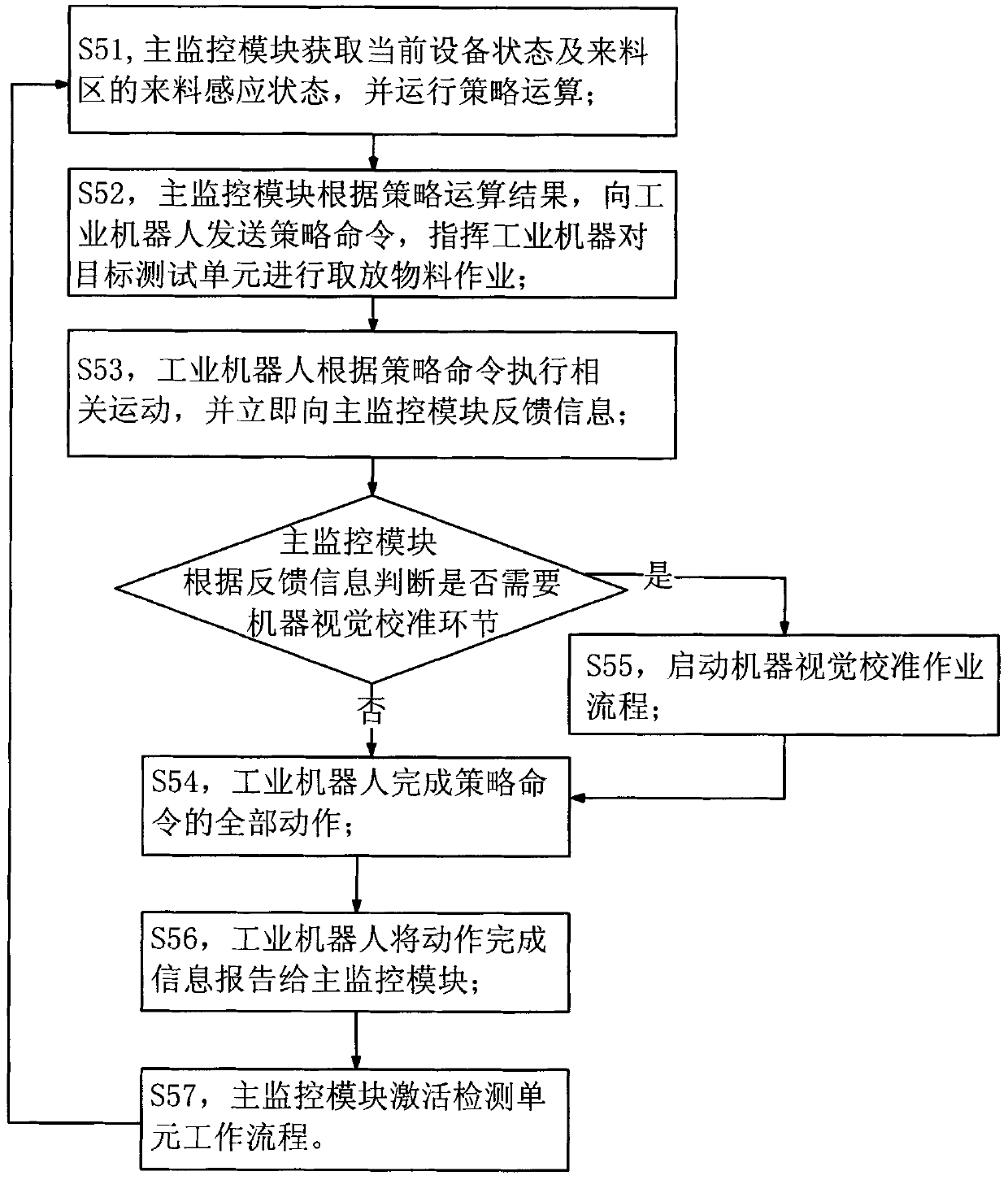

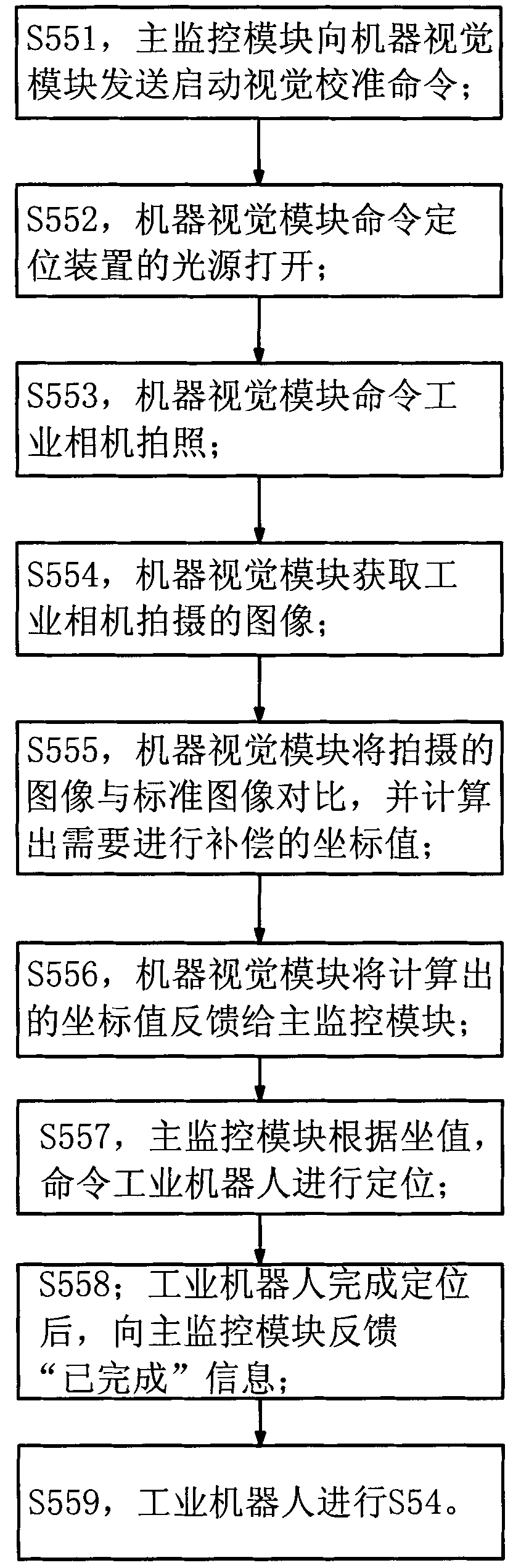

Automatic feeding, testing and sorting system and operation method thereof

ActiveCN103368795ARealize automatic feedingRealize unmannedData switching networksConveyor partsProgrammable logic controllerControl engineering

The invention discloses an automatic feeding, testing and sorting system and an operation method of the system. The operation method comprises the following steps of: S1, user login; S2, system connection checking; S3, robot starting and initialized setting; S4 system operation parameter setting; S5 system automatic operation; S6 stopping and equipment shutting. The operation method provided by the invention realizes organic combination in controlling test units, an industrial robot, a PLC (Programmable Logic Controller) electrical system, an image acquisition module and other peripheral equipment, automation in feeding, starting a test and sorting tested products to corresponding areas, as well as an unmanned testing process. In S2 and S3, required programs can be called from a public module in which global thread programs are stored; in S2, S3, S4 and S5, key variables required during system operation and stored in a data storage document can be called or rewritten so as to greatly improve the calculation efficiency.

Owner:SHENZHEN JIACHEN TECH

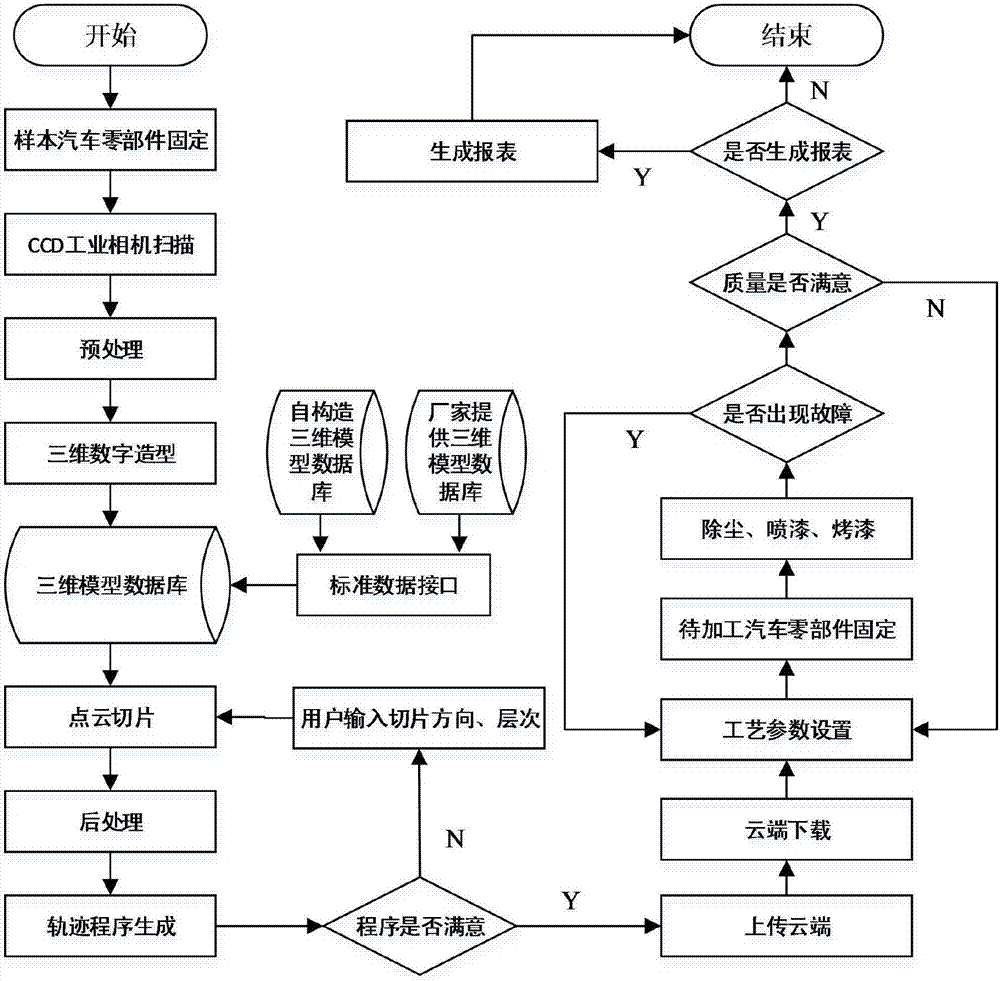

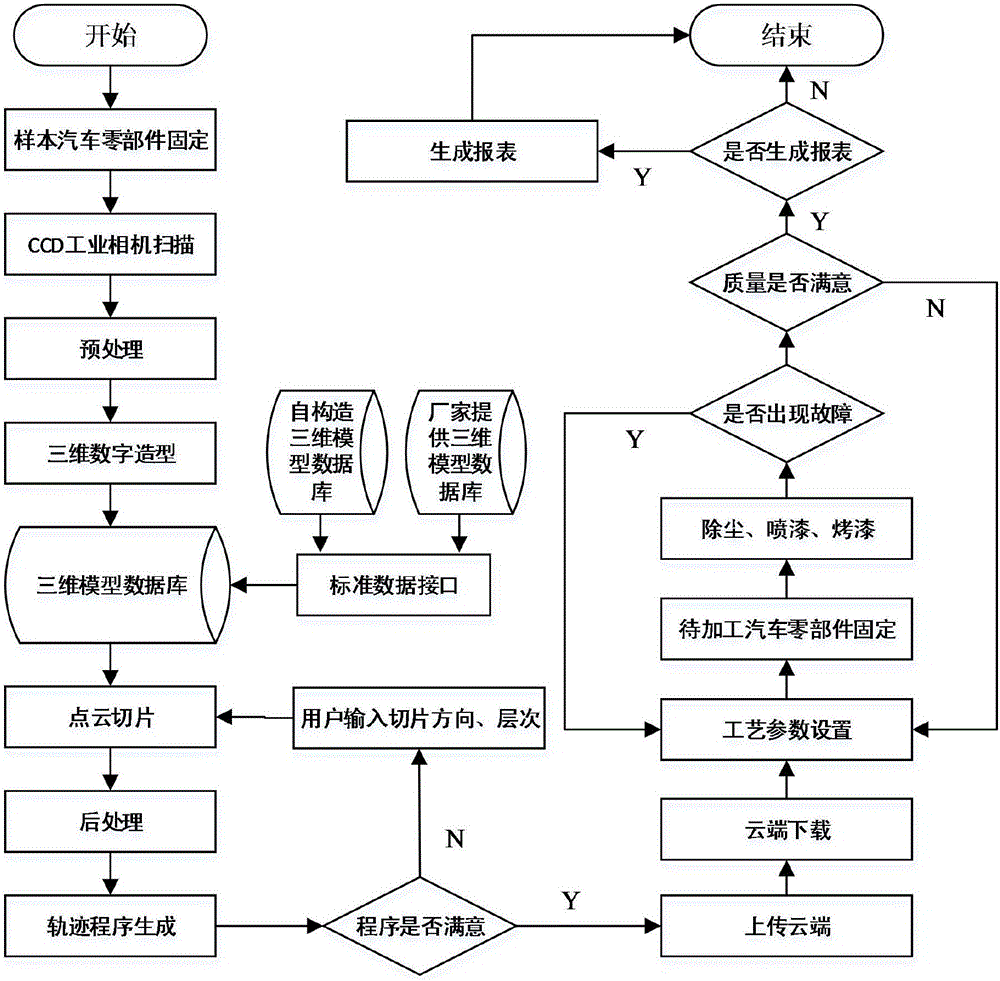

Intelligent automobile paint spraying method based on cloud computing

ActiveCN106853433AAvoid health damageAvoid inconsistenciesGeometric CADLiquid surface applicatorsPoint cloud3d scanning

The invention discloses an intelligent automobile paint spraying method based on cloud computing and relates to the field of paint spraying processes. The problems of high paint loss, poor quality consistency, influence on operator health, severe contamination, low efficiency and high cost of existing manual paint spraying are solved. The intelligent automobile paint spraying method based on cloud computing comprises the steps that firstly, a 3D scanning device scans automobile parts to generate point cloud data, the point cloud data are preprocessed to generate a three-dimensional digital model, and the model is stored in a three-dimensional model database; the three-dimensional digital model generates point cloud slices based on slicing directions and slicing levels input by a user; a spray gun pose is determined and a spray gun trajectory is optimized based on the point cloud slices to obtain a spray gun trajectory, and the spray gun trajectory is uploaded to a cloud platform; the cloud platform downloads programs corresponding to the parts and inputs processing parameters for spraying; after spraying is completed, the spraying quality is inspected, report forms for filing can be selected after quality conformance. The intelligent automobile paint spraying method is good in quality consistency, free of contamination, high in efficiency and low in cost.

Owner:吉林省天大精益智能制造技术有限公司

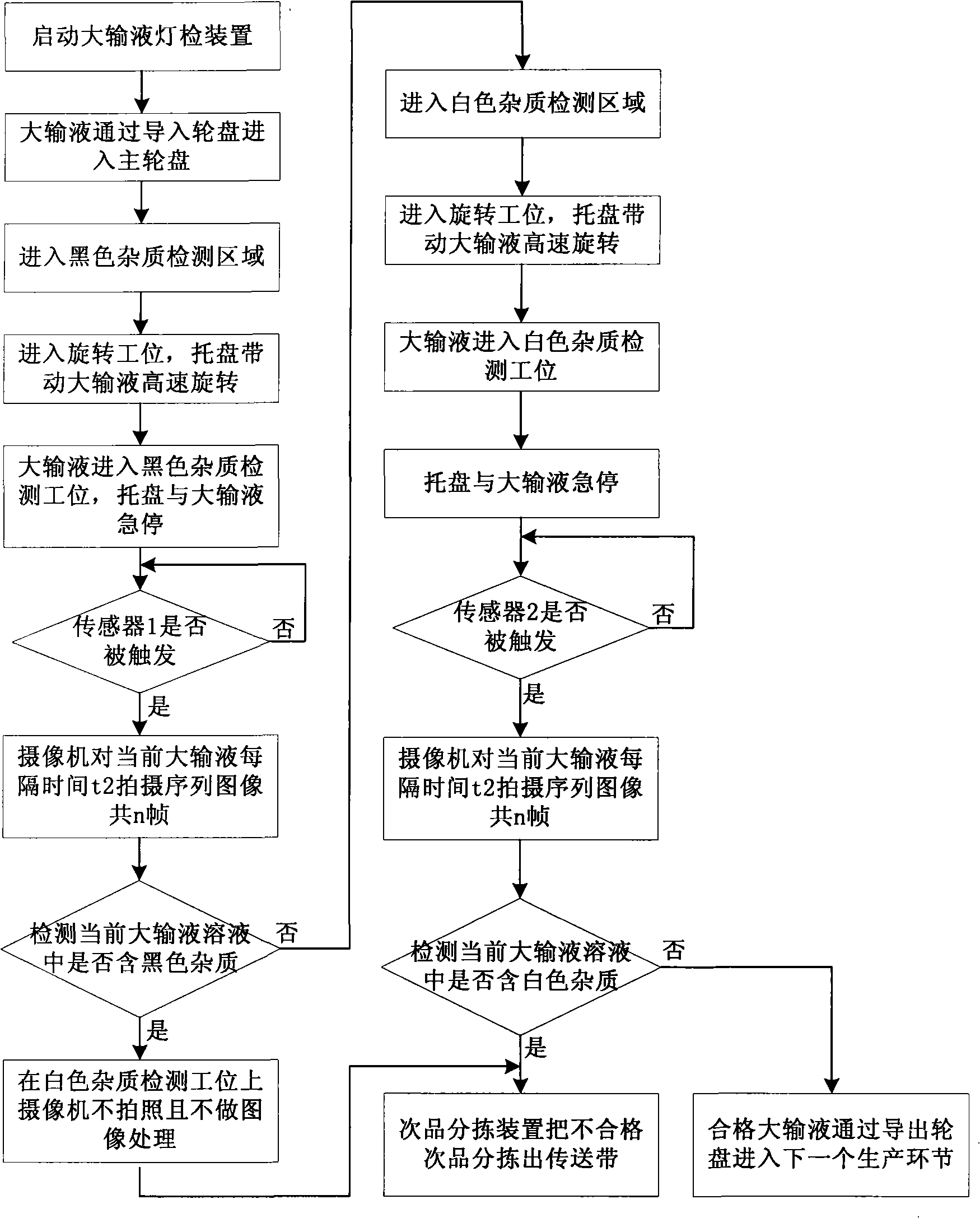

Method and apparatus for automatic detection on large infusion production line

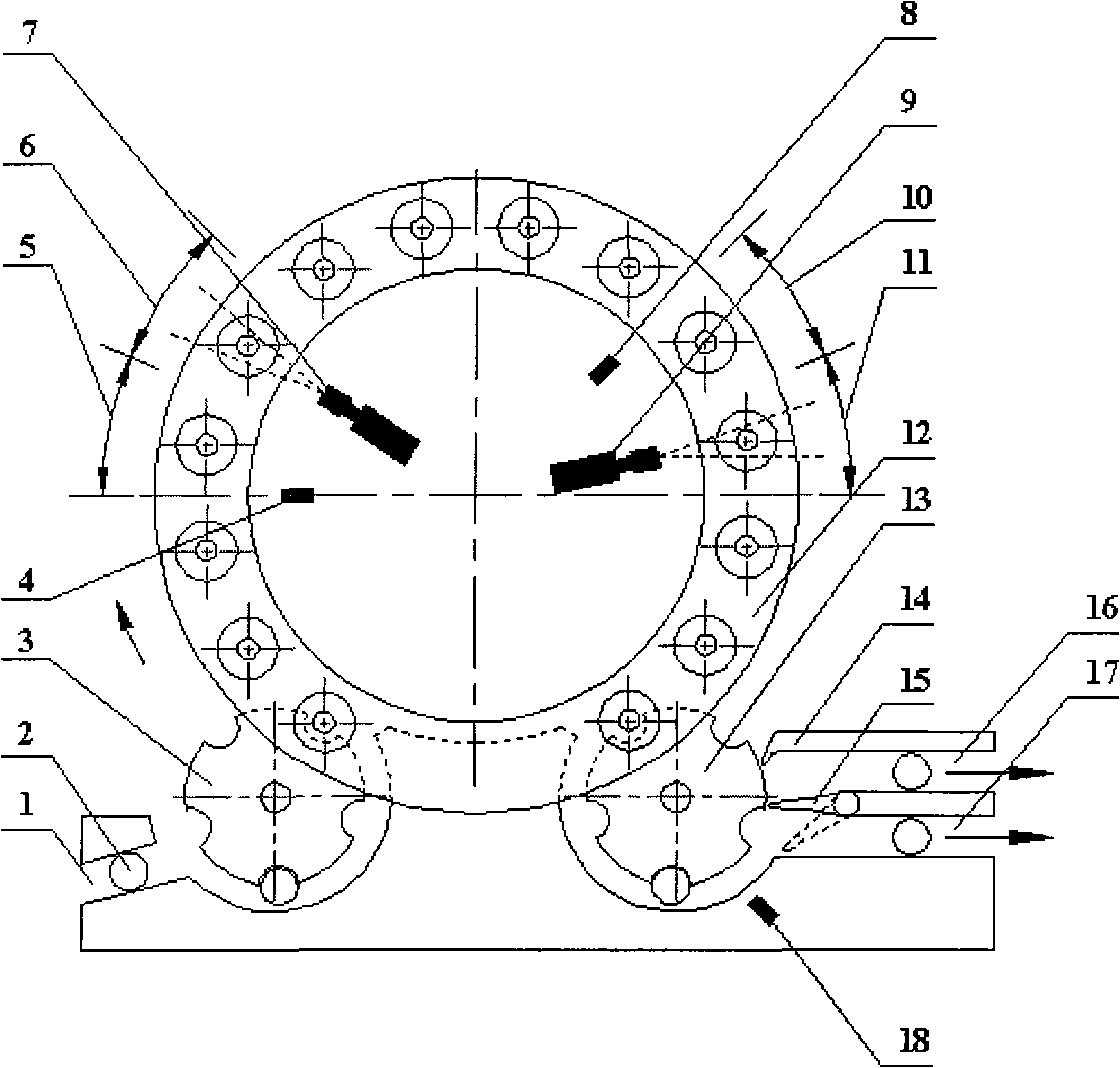

InactiveCN101303316AObjective reflectionReliable reflectionPharmaceutical containersMedical packagingProduction lineForeign matter

The invention discloses an automatic detection method for a large transfusion production line, including the following steps: 1, making a transfusion bottle filled with liquid medicine rotate in a high-speed, then rapidly stopping the transfusion bottle, so that the liquid medicine in the bottle has a self-rotating movement under the inertia; 2, picking-up a plurality of images of the transfusion bottle in which the liquid medicine is in a self-rotating state; 3, respectively digitally processing and mutually comparing to the plurality of images, distinguishing the exogenous impurity in the liquid medicine, in order to judge whether the bottle of liquid medicine is qualified. The invention also discloses an automatic detection apparatus for a large transfusion production line, which is characterized by including a rotation device, a controller, a video camera and an image processing apparatus, wherein, the output end of the controller is connected with the control terminal of the rotation device, a gripping device for fixing up the transfusion bottle, a rotating work station and a detecting work station are provided on the rotation device, and the video camera outputs data to the image processing apparatus. The invention can automatically detect whether impurity exists in the liquid medicine, with high testing accuracy and fast testing velocity.

Owner:HUNAN UNIV

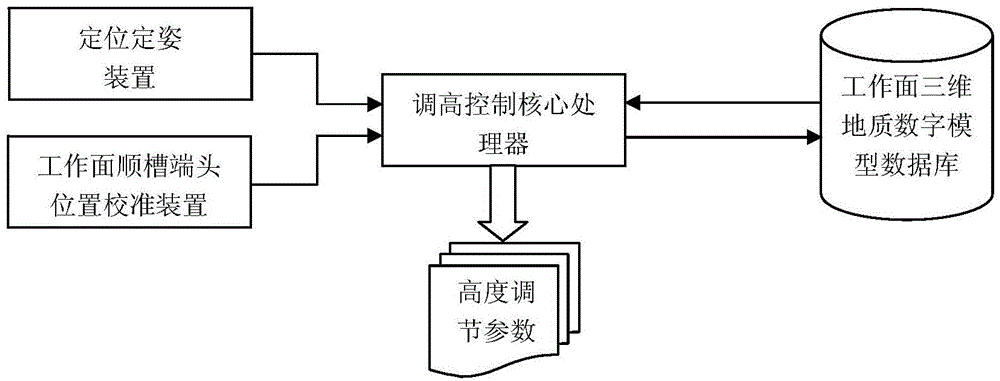

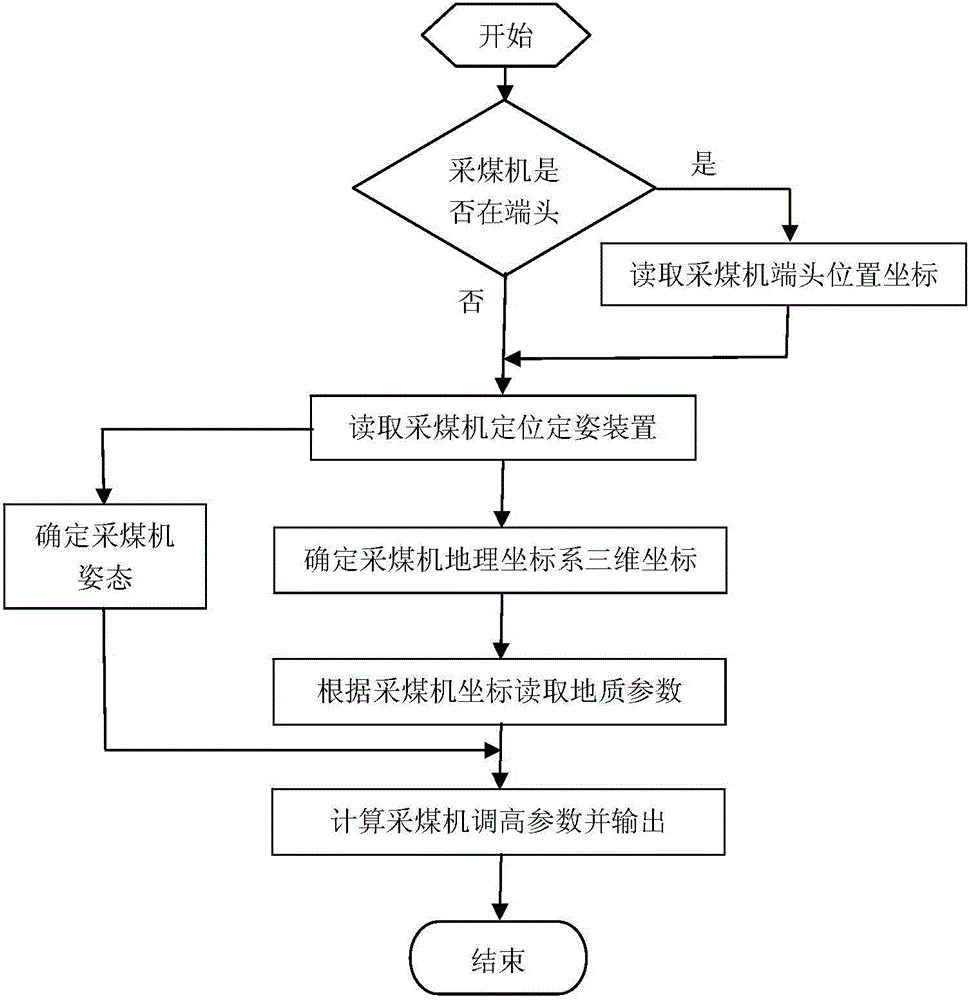

Coal-cutter roller automatic height-adjusting system

ActiveCN104481534ARealize automatic height adjustmentRealize intelligenceSlitting machinesCutting machinesThree-dimensional spaceEngineering

A disclosed coal-cutter roller automatic height-adjusting system determines the position and the attitude of a coal cutter under a working-face geographic coordinate system through a positioning attitude-determining device and a working-face crossheading end position calibrating device, and a height-adjusting control core processor fuses measure data into a working-face three-dimension geological digital model according to the coal-cutter coordinates, performs three-dimension space analysis in the working-face three-dimension geological digital model according to the position of the coal cutter, obtains the cut coal layer thickness and cut coal layer variation at the position of the coal cutter, and real-timely dynamically adjusts the cutting height of the coal cutter by combining address environment parameters including coal layer dirt band. The provided coal-cutter roller automatic height-adjusting system is capable of realizing automatic height adjusting of a coal-cutter roller.

Owner:CHINA UNIV OF MINING & TECH

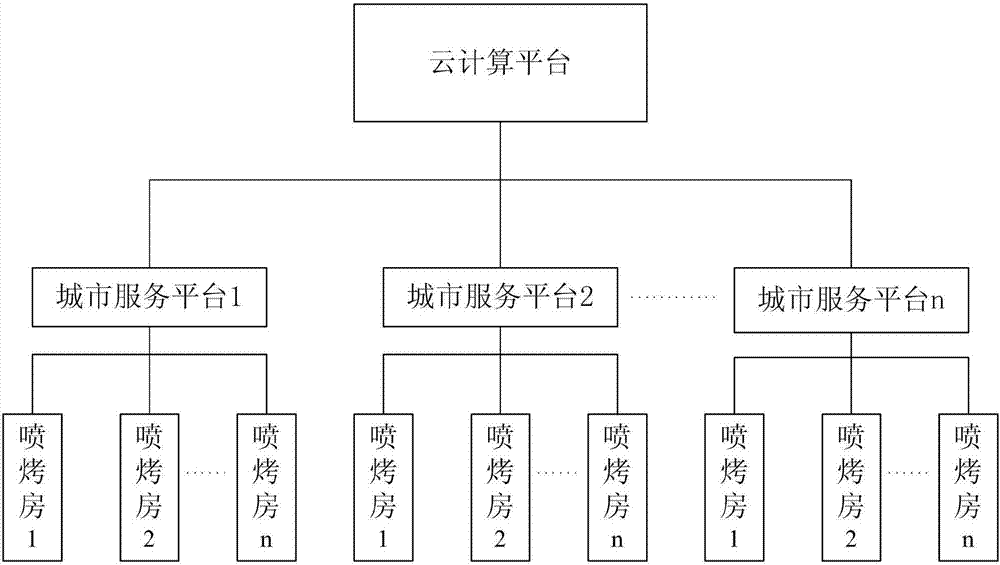

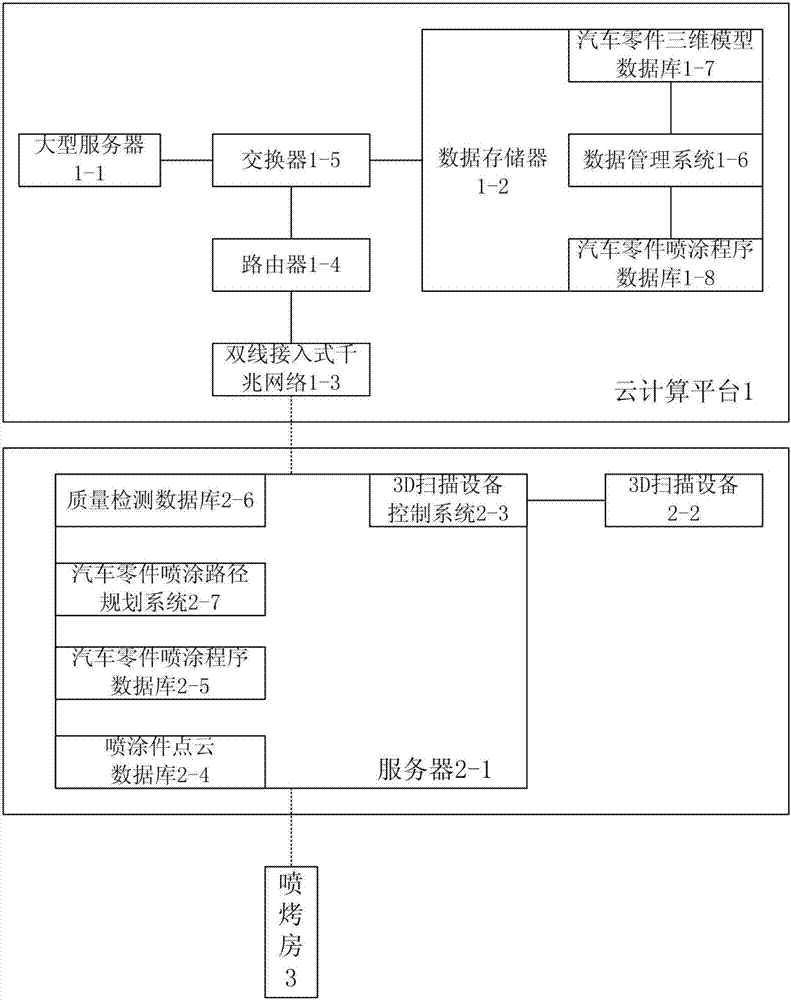

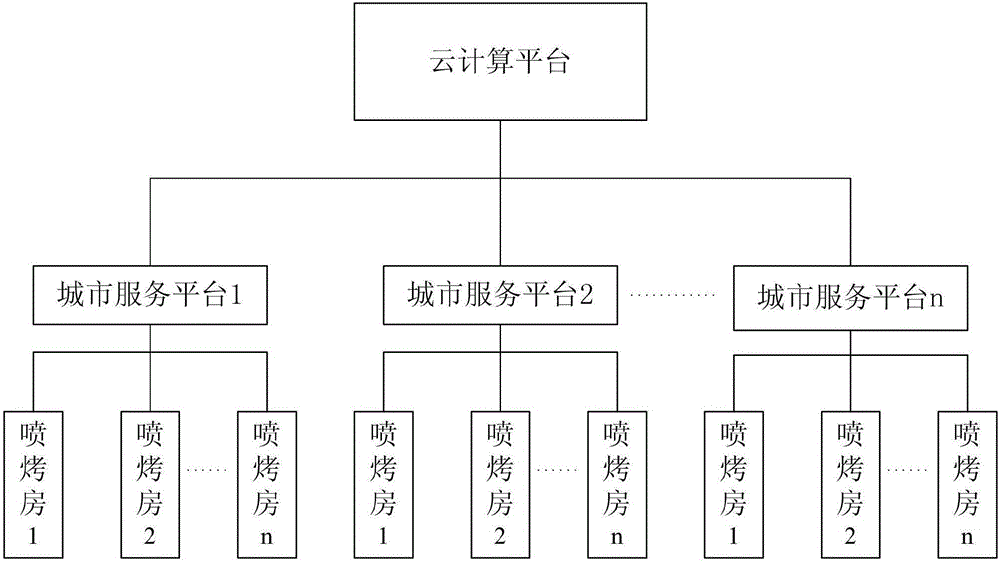

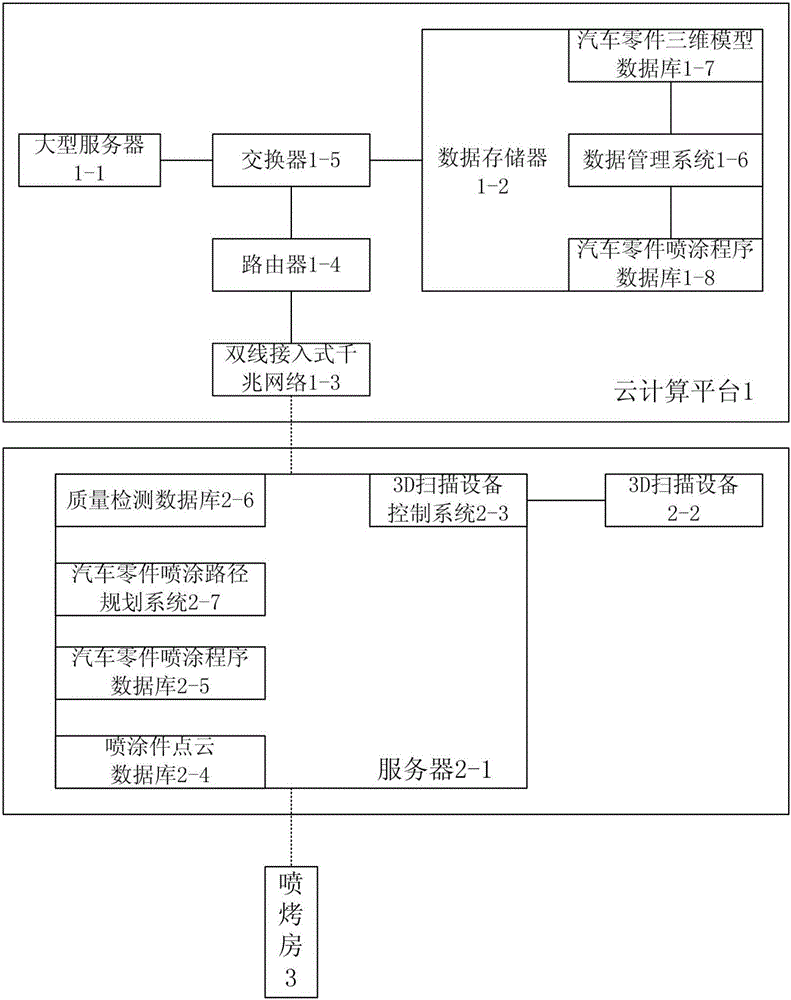

Automobile intelligent paint spraying system based on cloud computing

ActiveCN106527238AAvoid health damageAvoid inconsistenciesLiquid surface applicatorsCoatingsCooking & bakingData memory

The invention provides an automobile intelligent paint spraying system based on cloud computing, relating to the field of spray painting process. The problems of large paint loss, poor quality consistency, the affection of the health of operating personnel, serious pollution, low efficiency, and high cost in existing artificial painting are solved. The system comprises a cloud computing platform, multiple city service platforms, and a plurality of spraying and baking rooms. The cloud computing platform comprises a large server, a data memory, a double-wire-access type Gigabit network, a router, a switch, a data management system, an automobile spare part 3D model database, and an automobile spare part spraying program database. Each of the city service platforms comprises a high performance server, a 3D scanning device, a 3D scanning device control system, a spray piece point cloud database, an automobile spare part spraying program database, a quality inspection database, an automobile spare part spraying path planning system, and a double-wire-access type Gigabit network. Electric shutter doors are used to divide the spraying and baking rooms into spraying rooms and baking rooms. The system has the advantages of good quality consistency, no pollution, high efficiency and low cost.

Owner:吉林省天大精益智能制造技术有限公司

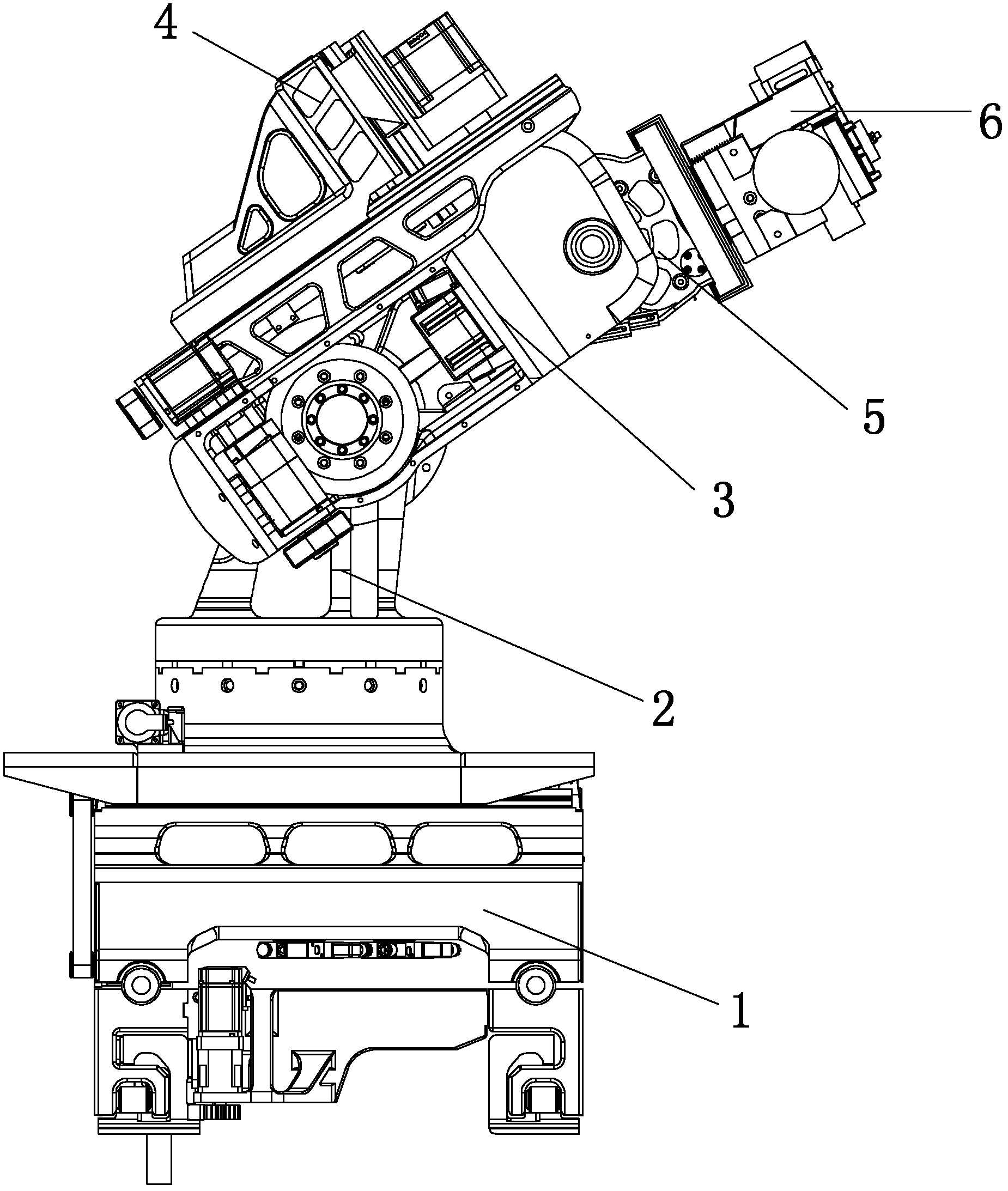

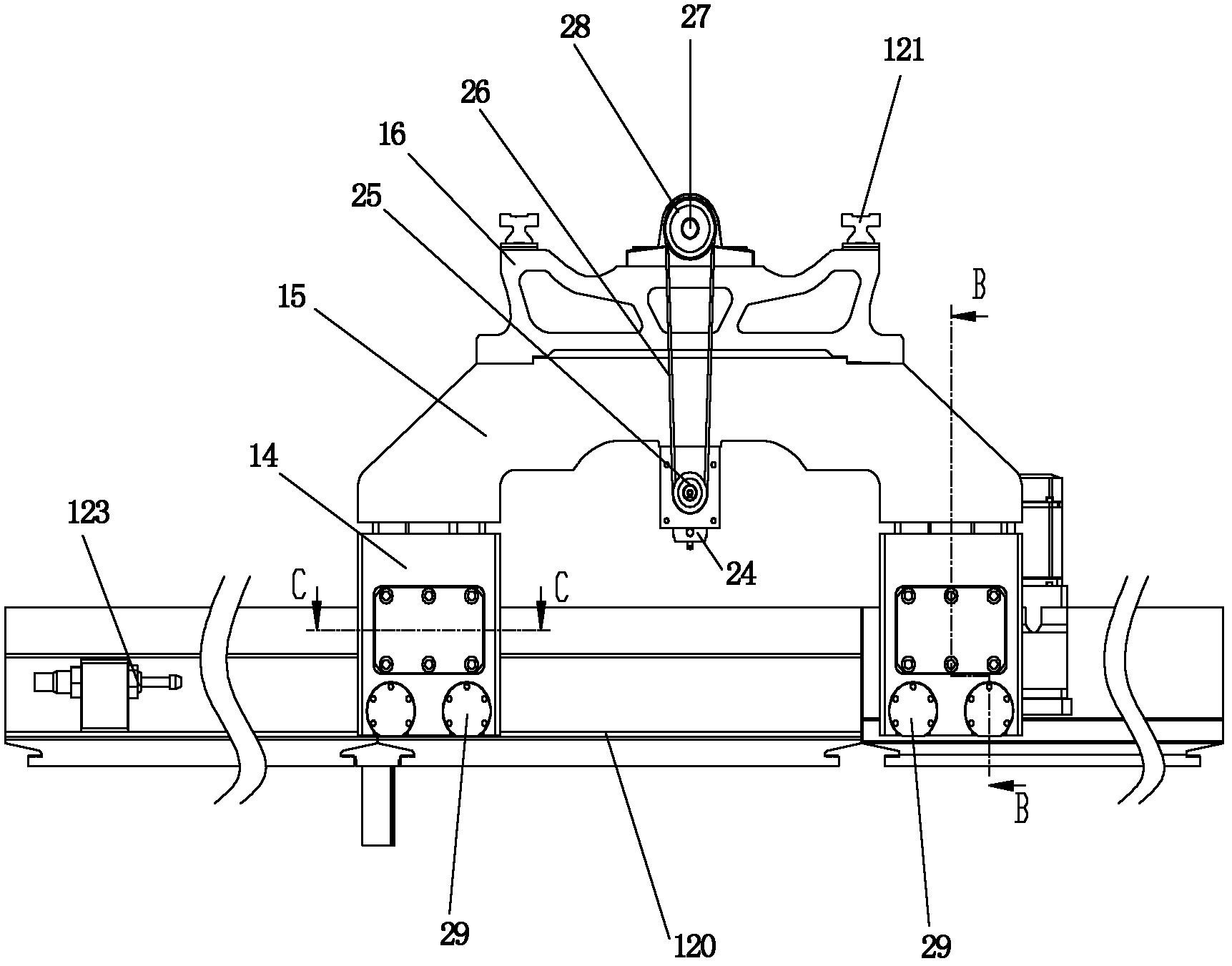

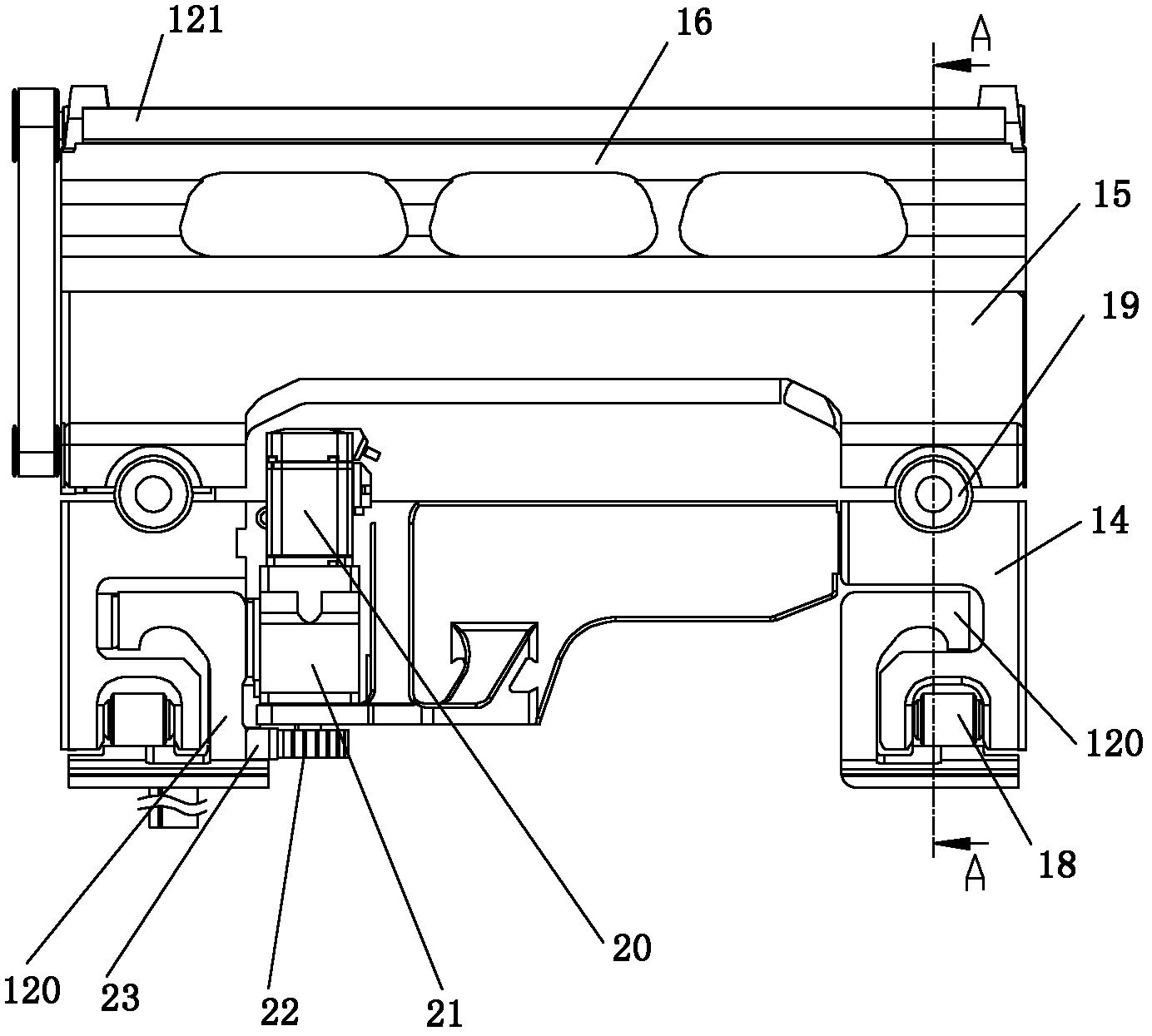

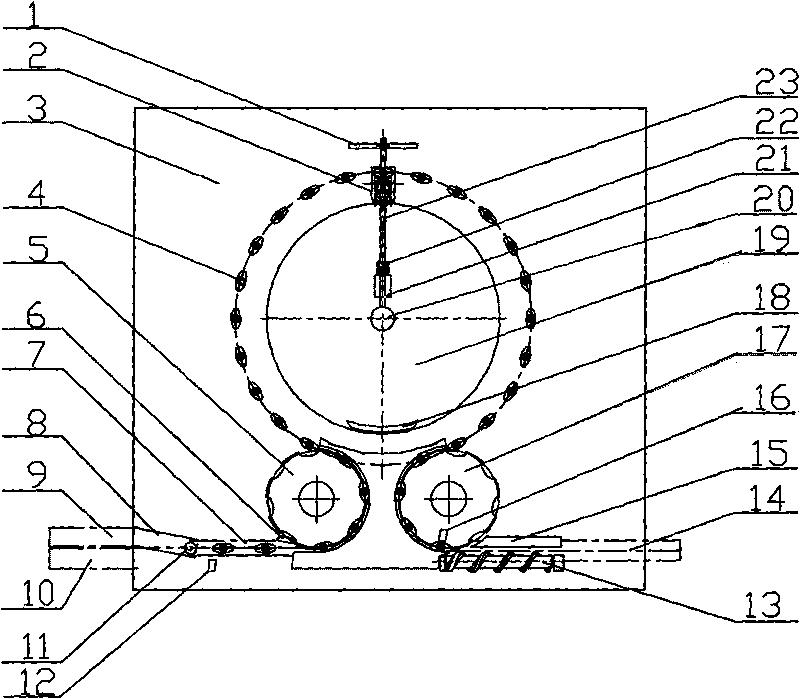

Industrial robot

ActiveCN102658546ACrawl smoothlyRealize unmannedProgramme-controlled manipulatorJointsIndustrial engineeringIndustrial robot

The invention provides an industrial robot, which comprises a base guide rail component, a base component, a large arm component, an engraving and milling component, a wrist component and a claw component, wherein the lower end of the base guide rail component is matched with a guide rail I and can roll along the guide rail I; the lower end of the base component is matched with a guide rail II which is arranged at the upper end of the base guide rail component and can slide along the guide rail II; the base component consists of an upper component and a lower component, wherein the upper component can rotate around the lower component; a shoulder shaft on the large arm component is in floating fit with a shoulder shaft hole formed on the upper part of the upper component, and the large arm component realizes the action of lifting or lowering the arm; the lower part of the engraving and milling component is matched with a guide rail III which is arranged on the side of the large arm component, can slide along the guide rail III and realizes a drilling action; the wrist component is arranged in a mounting hole of the large arm component through a loop bar and finishes the action of lifting and lowering the wrist; and the side of the claw component is matched with a guide rail IV which is arranged on the wrist component, slides along the guide rail IV and realizes the action of opening and closing the claws.

Owner:刘朝龙

Method and device for automatically detecting impurities in health wine

InactiveCN101692056ALow costSimple structureMaterial analysis by optical meansSortingEngineeringLight source

The invention discloses a method and a device for automatically detecting impurities in a health wine. The device comprises a detection wheel disc, a bottle feeding mechanism, a bottle discharging mechanism, a sorting mechanism for removing inferior health wine bottles, an mechanical arm for clamping and overturning health wine bottles, a detection bracket, a camera to shoot images for health wine bottles, a lens, a light source and a microprocessor. The method comprises the following steps: a health wine bottle is introduced into the detection wheel disc, is clamped and overturned by the mechanical arm; an sequence image of the health wine bottle is acquired when the health wine bottle is in an inverted state and keeps uniform motion; the acquired sequence image is located by a computer; whether impurities exist in the health bottle or not is judged; and the inferior health wine bottles are removed by a control sorting mechanism. The device and the method have the advantages of low cost, rapid detection speed, high reliability and high detection accuracy rate and the like.

Owner:HUNAN UNIV

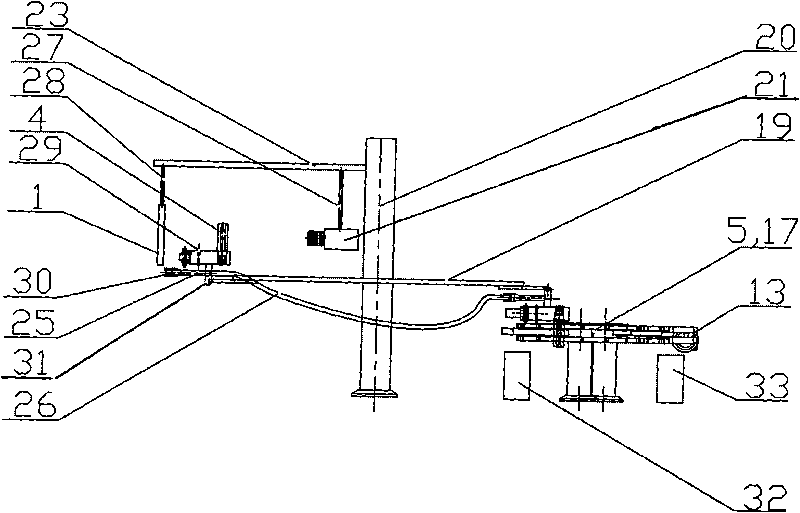

Automatic charging system for intelligent security and protection robot, and control method

ActiveCN107528370AImprove work efficiencyReduce labor costsProgramme-controlled manipulatorCircuit monitoring/indicationButt jointRemote control

The invention relates to an automatic charging system and method for an intelligent security and protection robot, and the system comprises remote control end and at least one security and protection robot. The security and protection robot comprises a main control module, an electric quantity detection module, a communication module, a drive module and a charging module, wherein the electric quantity detection module, the communication module, the drive module and the charging module are connected with the main control module. The main control module is used for obtaining the electric quantity of the battery of the security and protection robot through the electric quantity detection module, transmitting an electric quantity alarm signal to the remote control end through the communication module when the electric quantity of the battery is less than a preset threshold value, receiving a charging walking path fed back by the remote control end, controlling the drive module to drive the security and protection robot to move to a specific charging pile and controlling the charging module to be connected with the specific charging pile in a butt joint manner for charging. According to the invention, the system can enable the security and protection robot to automatically navigate to the charging pile for automatic charging when the electric quantity is not sufficient, improves the work efficiency of the security and protection robot, saves the manpower cost, and achieves the unmanned charging.

Owner:严格防务科技集团有限公司

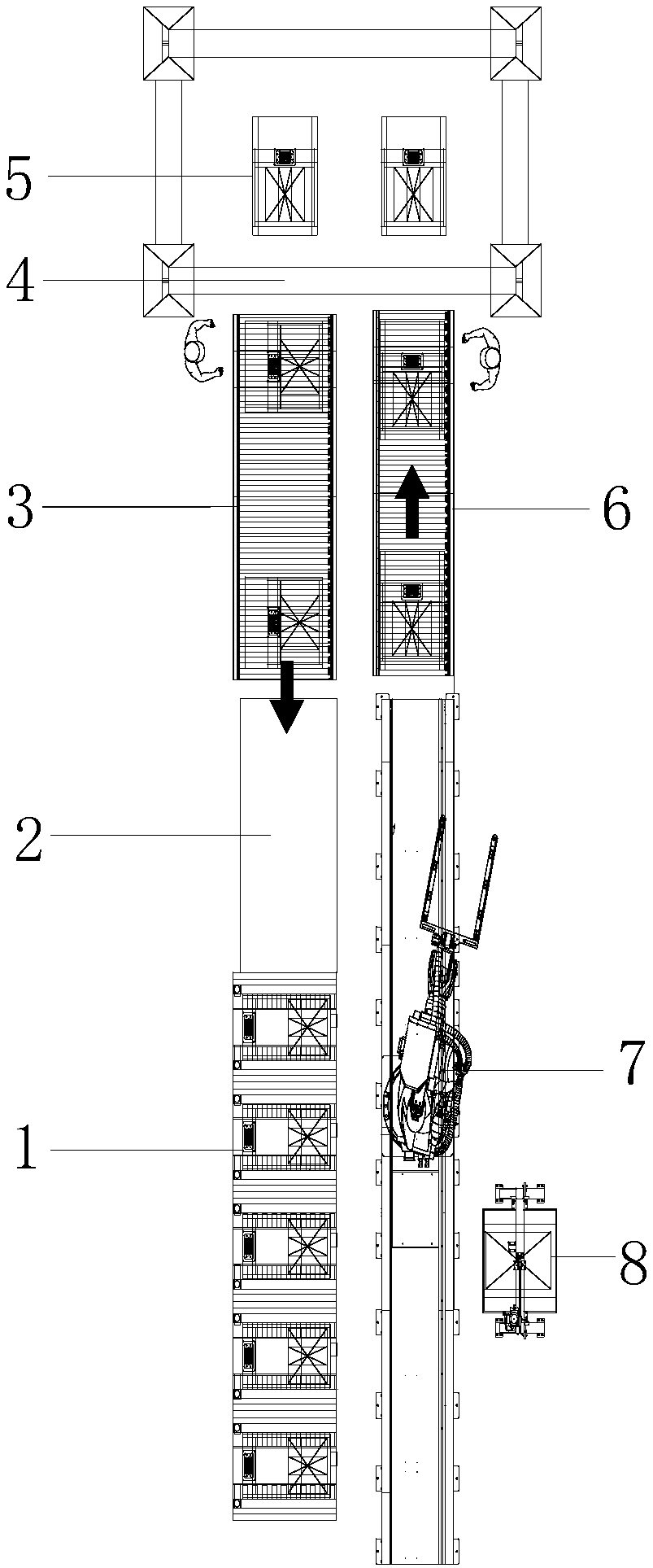

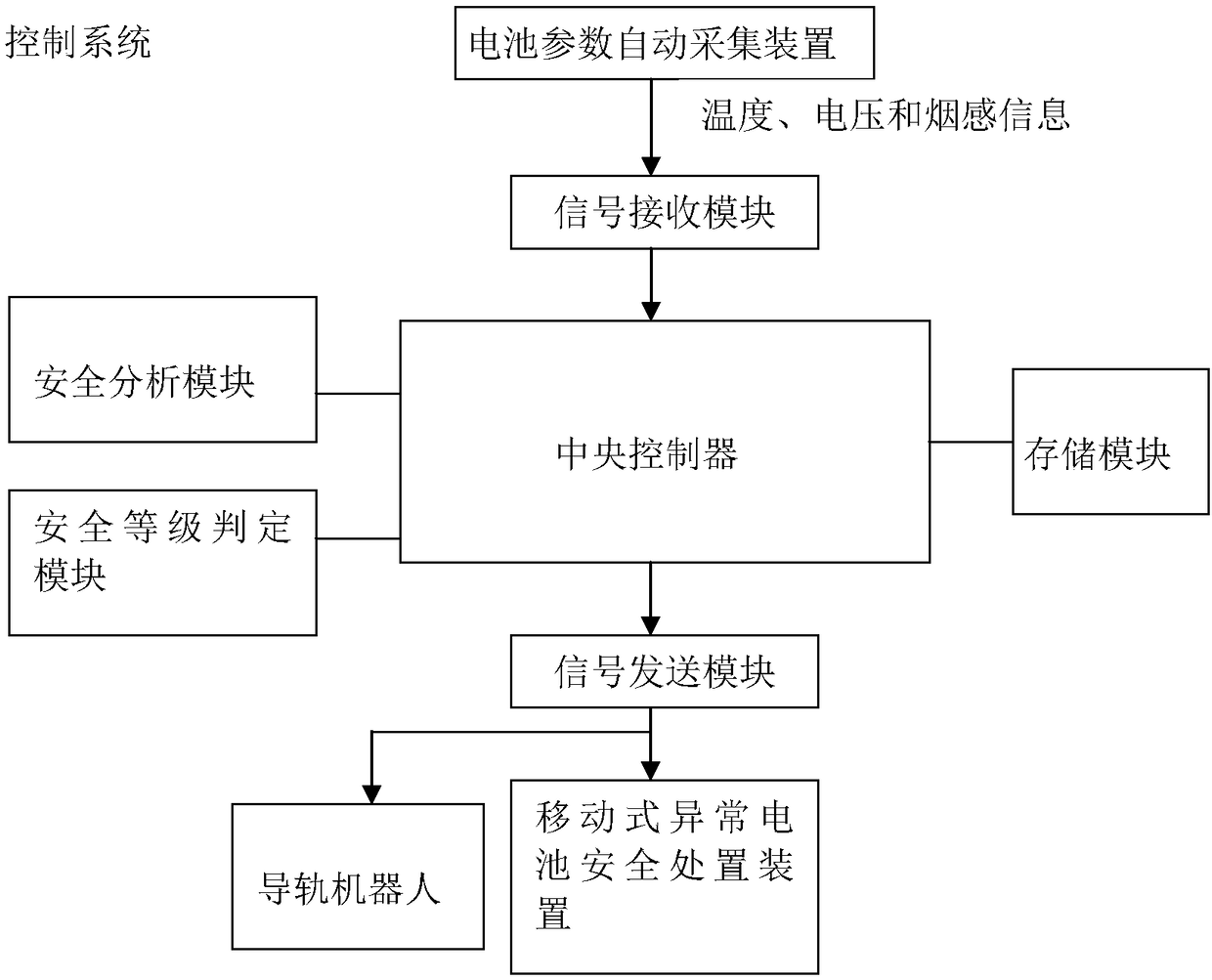

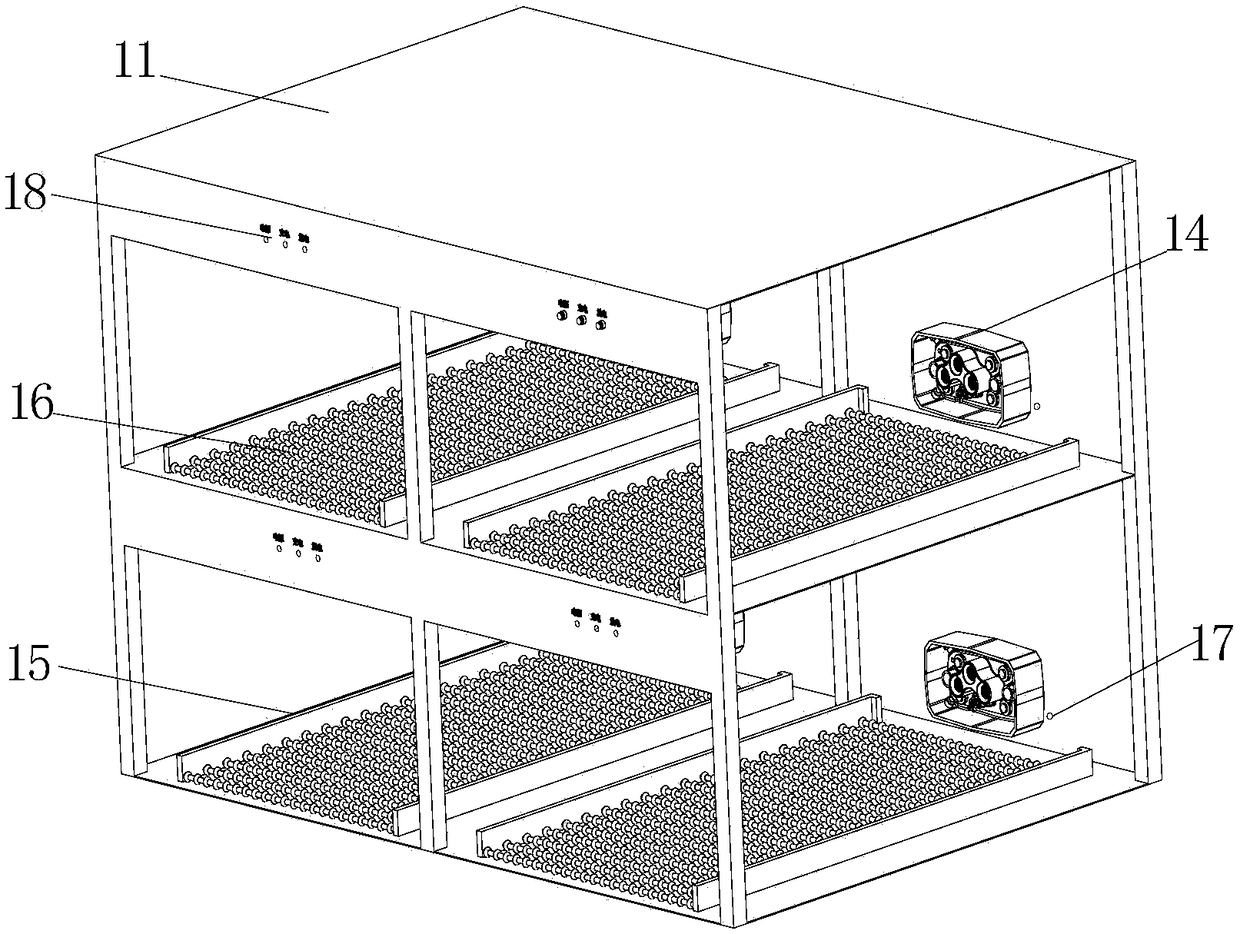

Automatic detection system and method for power battery and battery safety judgment and disposal method

ActiveCN108490367AFully automatedRealize unmannedElectrical measurement instrument detailsElectrical testingPower batteryElectricity

The invention discloses an automatic detection system and method for a power battery and a battery safety judgment and disposal method. The automatic detection system for the power battery comprises acontrol system as well as a KBK travelling crane, a feeding conveying line, a guide rail robot, a detection frame, detection equipment, a discharging conveying line, an automatic battery parameter acquisition device and an abnormal battery disposal system which are respectively and electrically connected with the control system. The automatic detection system realizes automatic and unmanned powerbattery detection, also realizes automatic acquisition and analysis of battery safety parameters, realizes intelligent and rapid abnormal handling by cooperating with the guide rail robot and is safeand reliable.

Owner:QINGDAO MEIKAILIN TECH

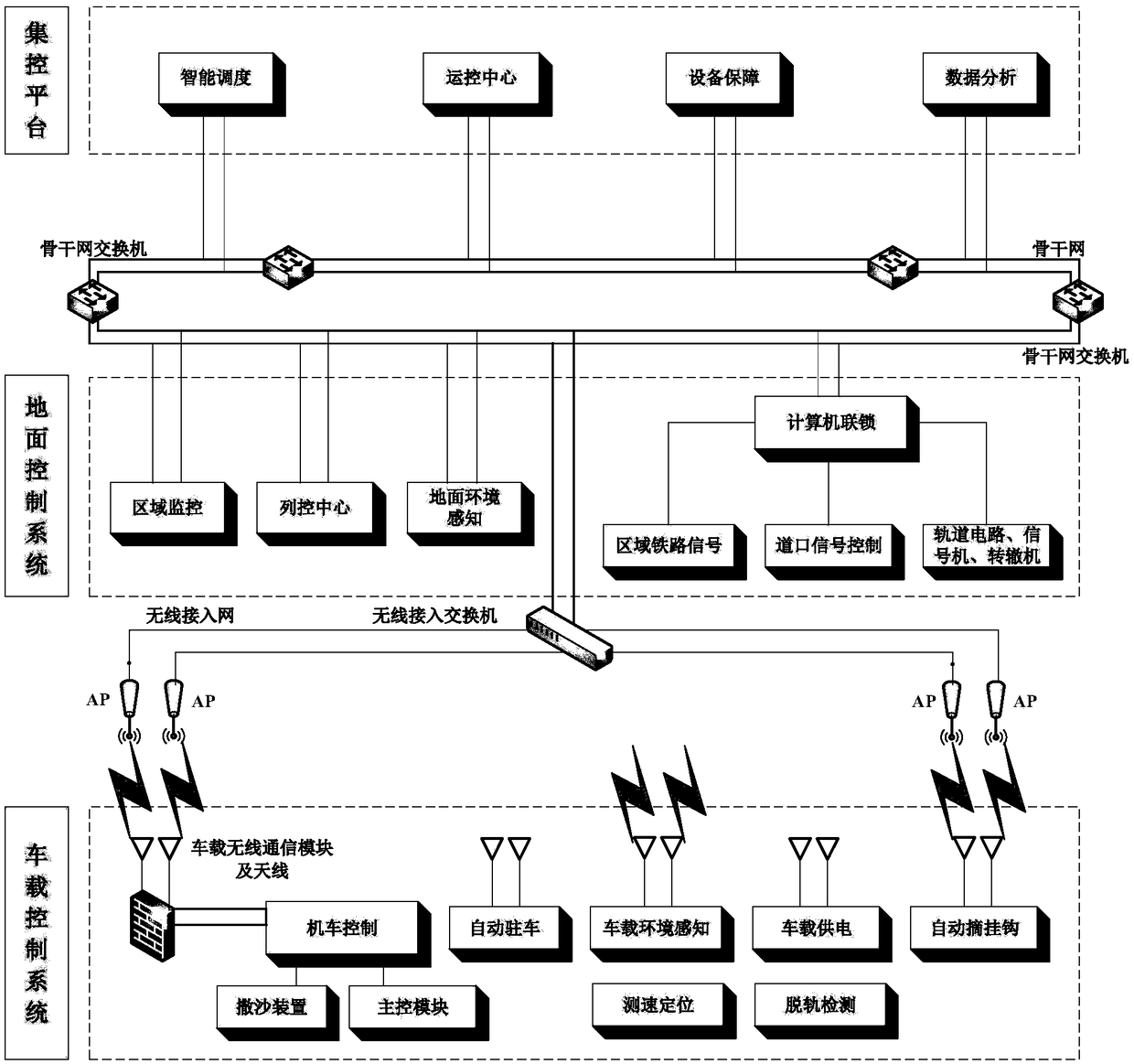

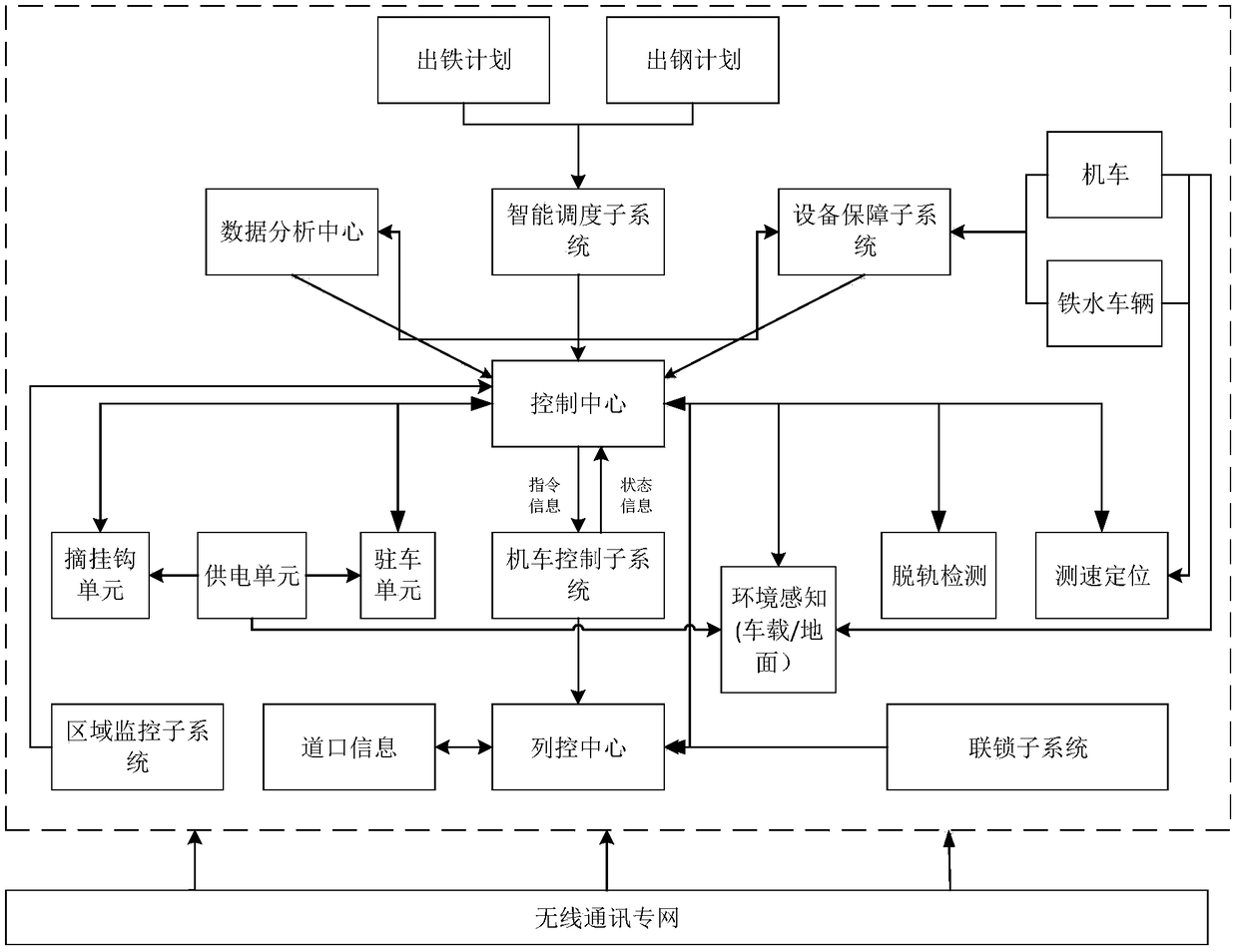

Intelligent molten iron conveying system

PendingCN109353359AReduce temperature dropAvoid temperature dropAutomatic systemsWagons/vansControl systemIron transport

The invention provides an intelligent molten iron conveying system. The system comprises a haulage motor body, a molten iron conveying vehicle body, a vehicle-mounted control system and a ground control system, wherein the vehicle-mounted control system is used for controlling motions of the haulage motor body and the molten iron conveying vehicle body according to a control instruction, the ground control system is used for collecting external environment information and controlling a ground advancing line of the haulage motor body and the molten iron conveying vehicle body according to the control instruction, and a centralized control platform is used for sending the control instruction to the vehicle-mounted control system and the ground control system. Automatic interaction of information and the control instruction is performed through the centralized control platform, a molten iron transporting vehicle achieves unmanned and organization scheduling intelligence in the whole molten iron transporting working process from a blast furnace casting field to a steel making transit station, the haulage motor operation efficiency is improved, the iron molten temperature drop is lowered, the road and haulage motor operation safety is improved, equipment damage and accidents caused by faults such as worker operation and judgment are completely eradicated, the operation risk is lowered, and personal safety of workers is ensured.

Owner:CISDI ENG CO LTD

AutomaticSteel bar on-line steel barautomatic counting and splitting system

InactiveCN102424156AIncrease production capacityRealize unmannedPackaging automatic controlSteel barMechanical engineering

The invention discloses an automatic on-line steel bar on-line automatic counting and splitting system, which comprises an automatic counting system and an automatic steel bar splitting system, wherein the automatic steel bar splitting system comprises an end part steel bar splitting machine, a subsequent complete steel bar splitting machine and a steel bar splitting visual feedback system. The automatic on-line steel bar on-line automatic counting and splitting system has the beneficial effects that the automatic on-line steel bar on-line automatic counting and splitting system can be used for realizing the automatic counting and fixed section separation on steel bars, the unmanned operation is realized, the labor is saved, the counting is almost continuous without intermission, once chain bed halt is only needed in the steel bar splitting process once, and the production and operation efficiency of enterprises is greatly improved, the steel bar splitting precision is high, the precise steel bar splitting can be completed under complicated work conditions, the application range is wide, and huge practical application values are realized.

Owner:JINAN HUOJU TECH DEV

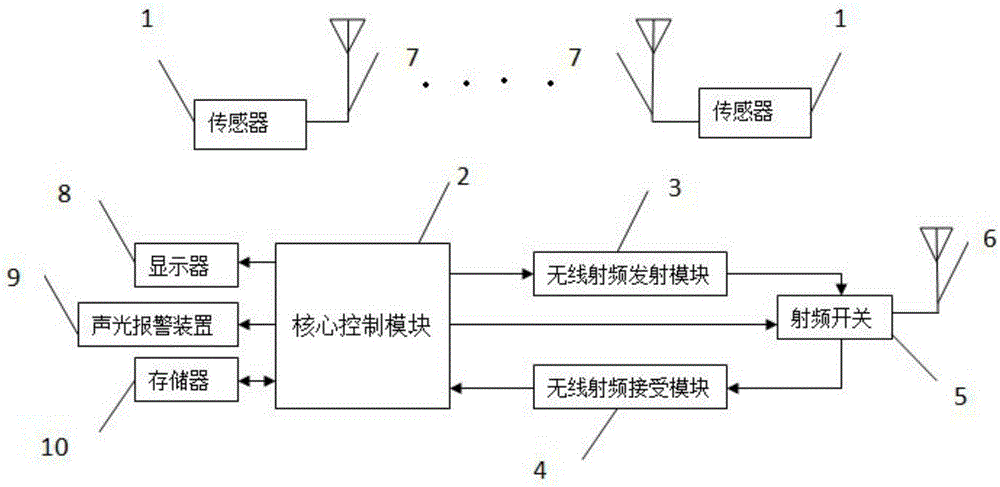

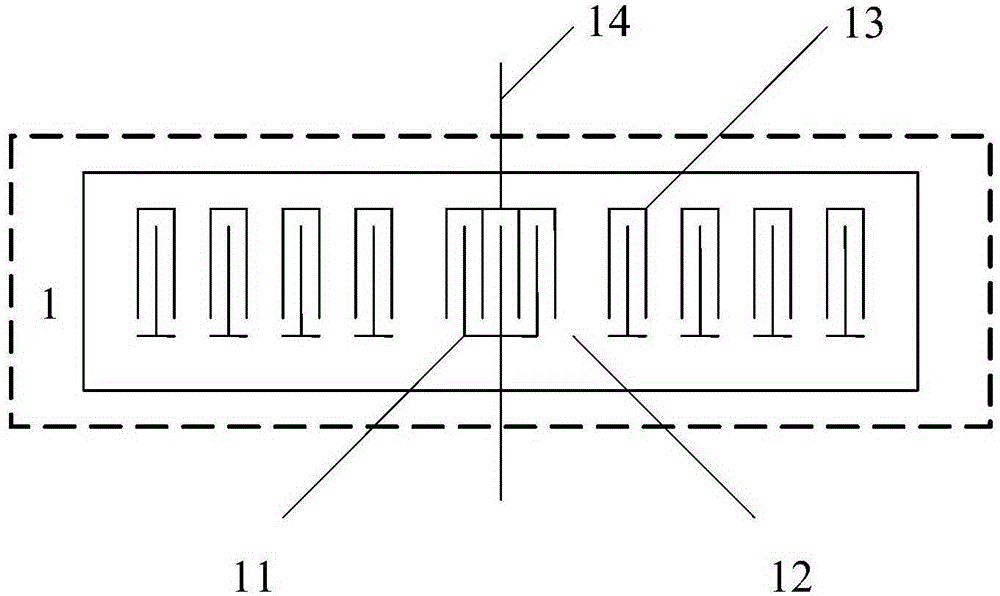

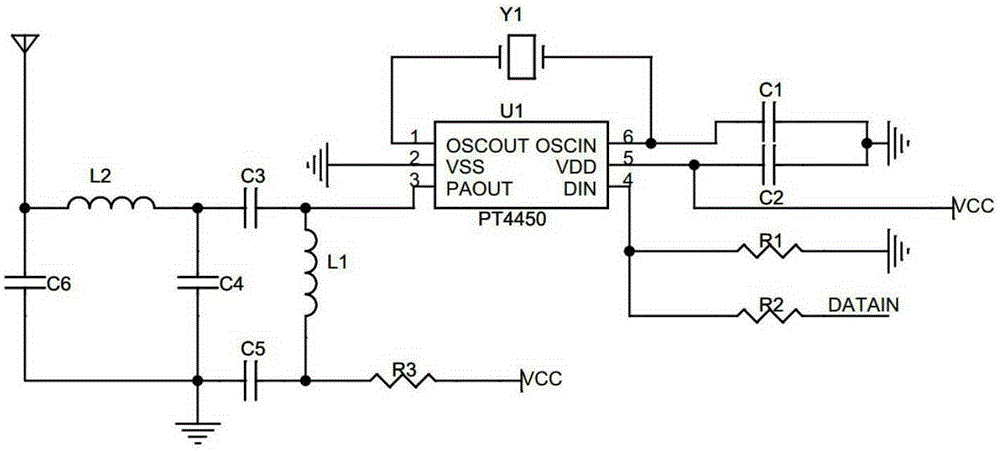

Online temperature measurement system based on passive wireless sound surface wave sensors

InactiveCN105157870AGood insulation and anti-electromagnetic interferenceImprove construction efficiencyThermometers using physical/chemical changesRadio frequencySurface wave

The invention discloses an online temperature measurement system based on passive wireless sound surface wave sensors. The system comprises a core control module, the passive sound surface wave sensors, a wireless radiofrequency emitting module, a wireless radiofrequency receiving module and a storage display module. The core control module controls the wireless radiofrequency emitting module to generate radiofrequency pulse signals, the signals are emitted through an apparatus antenna, and the passive sound surface wave sensors, after receiving the radiofrequency pulse signals, emit the radio frequency pulse signals comprising inside temperature information of power equipment through sensor antennas. The wireless radiofrequency receiving module receives and modulates the radiofrequency pulse signals to obtain temperature signals, the core control module processes the temperature signals by use of an adaptive filtering algorithm, a result is displayed through a display, and in case of temperature abnormities, an acousto-optic alarm apparatus generates an acousto-optic alarm. Compared to the prior art, the online temperature measurement system has good insulation and anti-electromagnetic interference performance and solves the problem of difficulty in monitoring a contact operation temperature inside such power equipment as a switch cabinet, a transformer and the like.

Owner:NANJING UNIV OF SCI & TECH

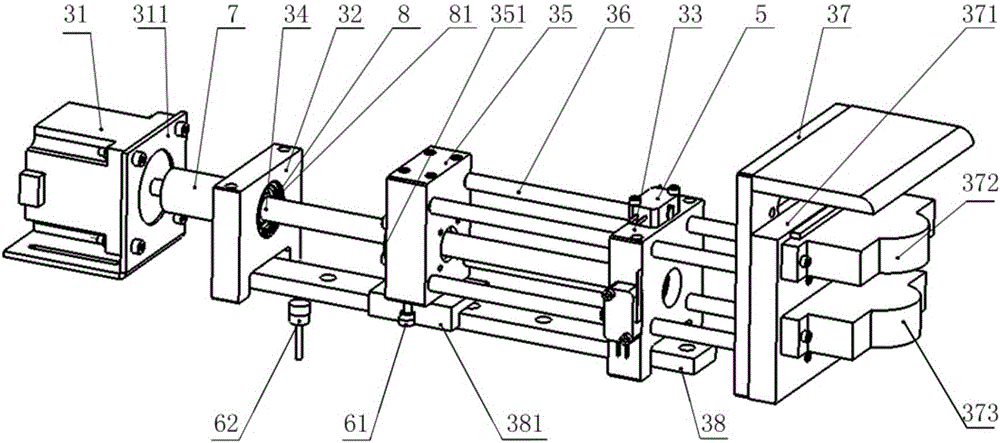

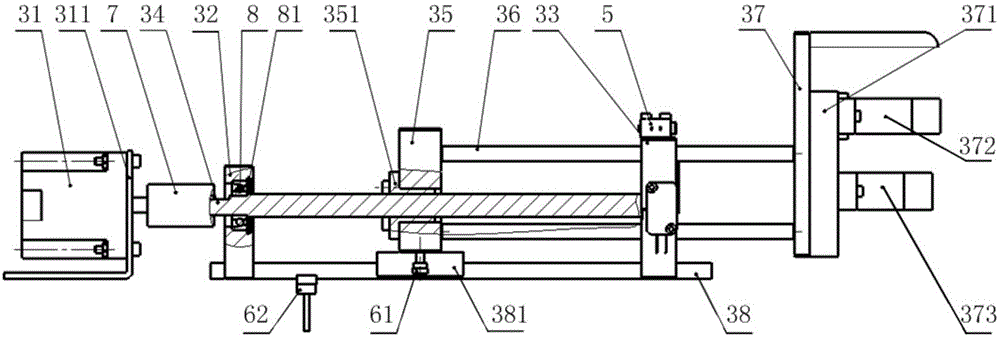

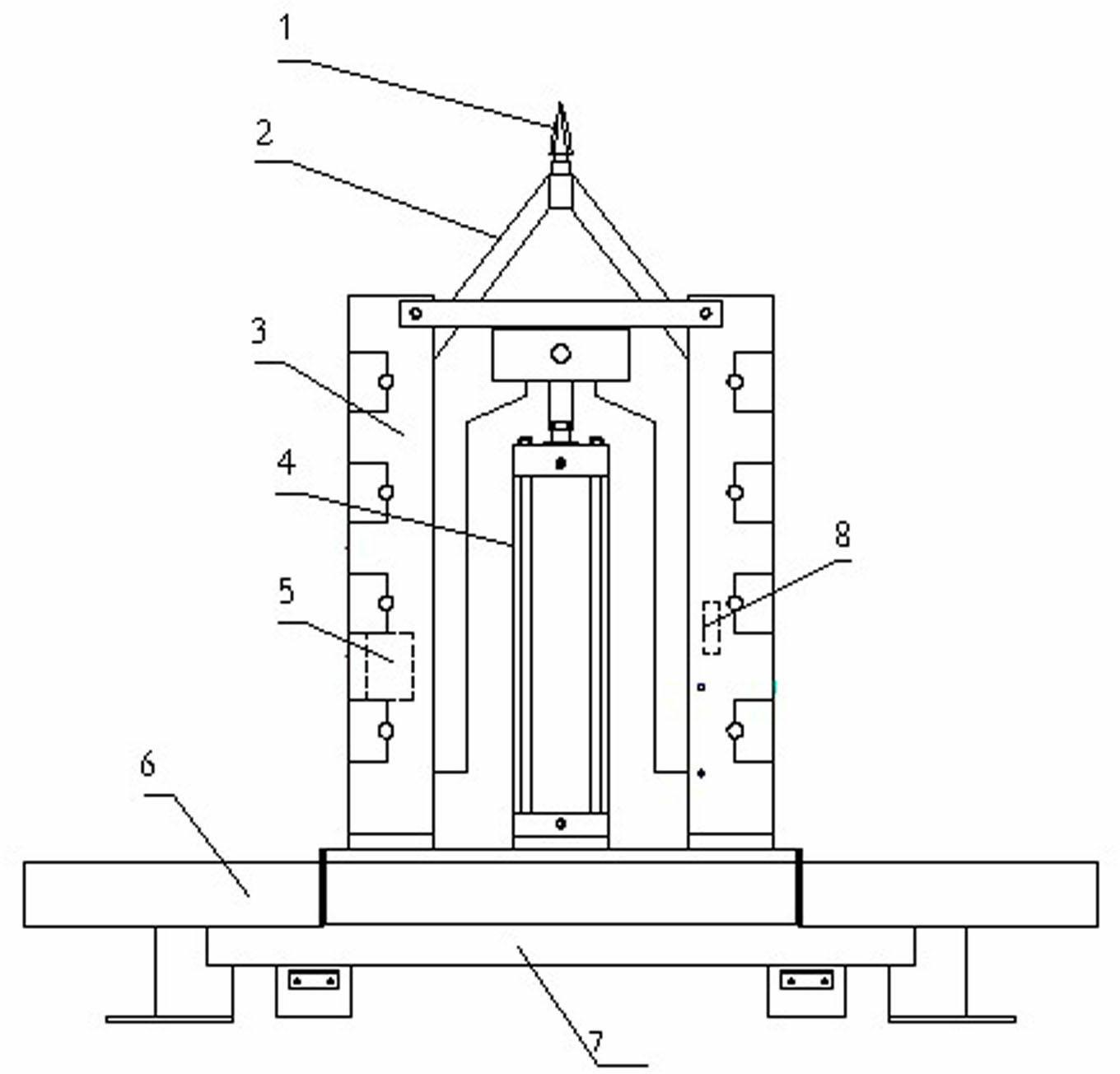

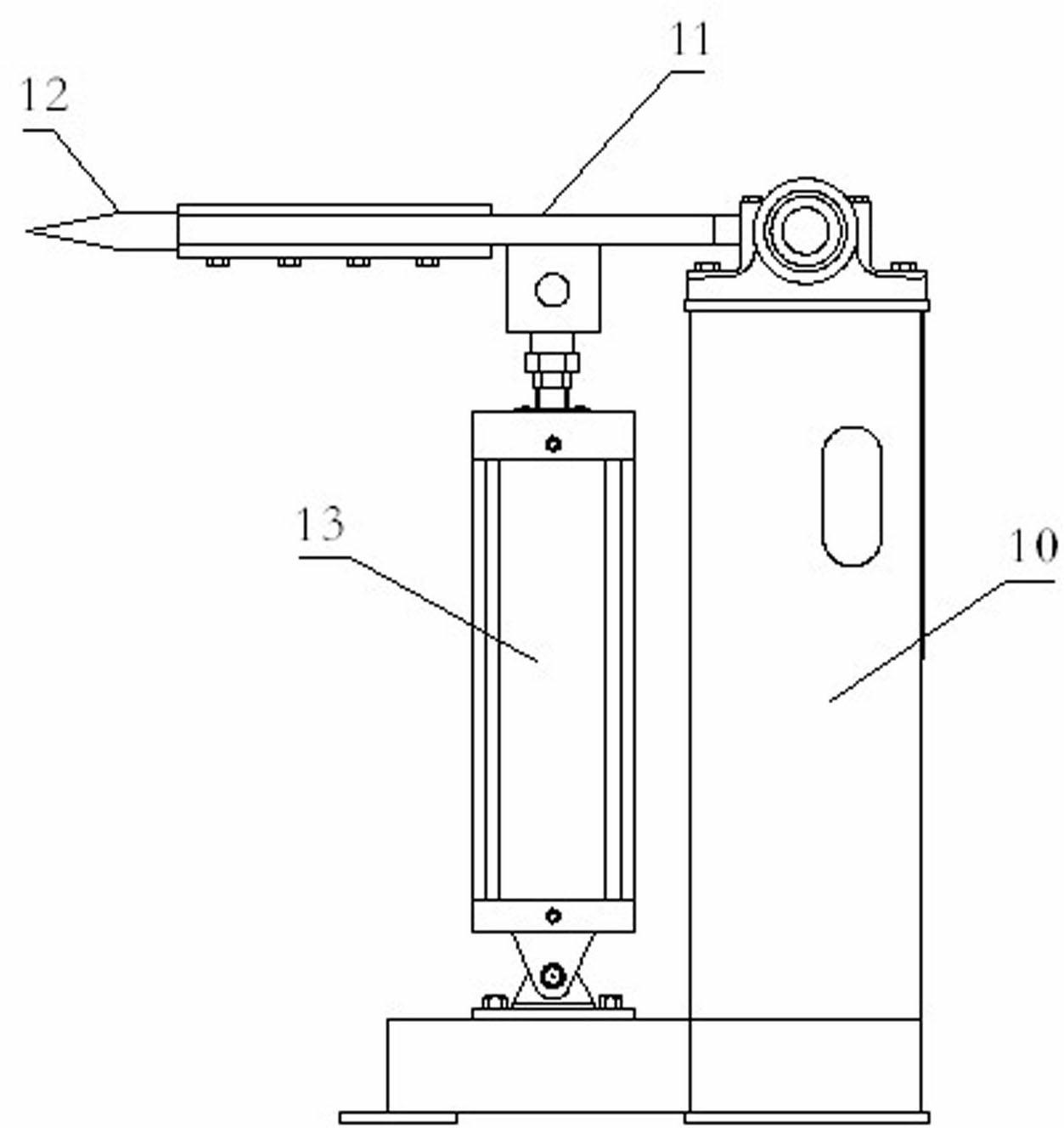

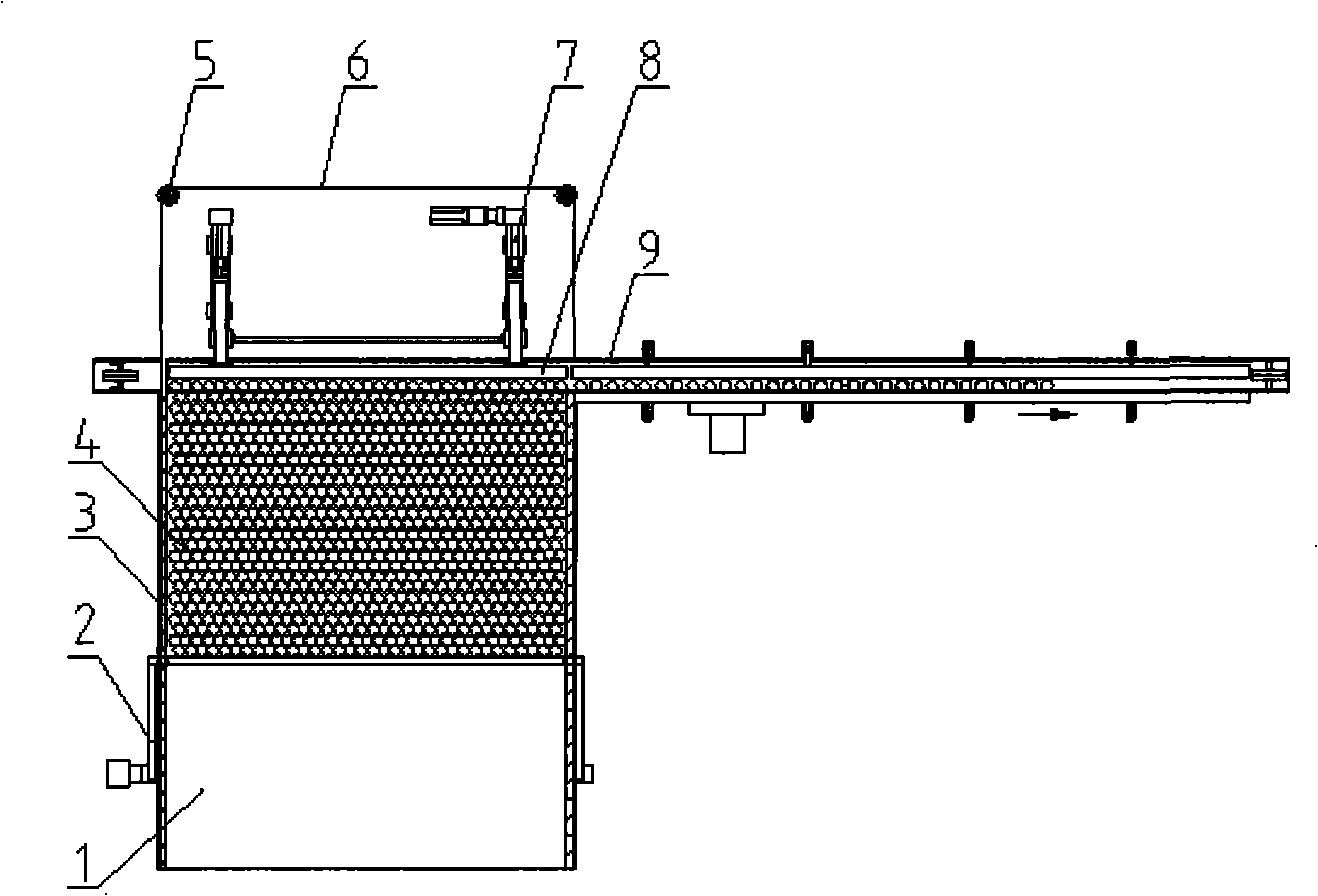

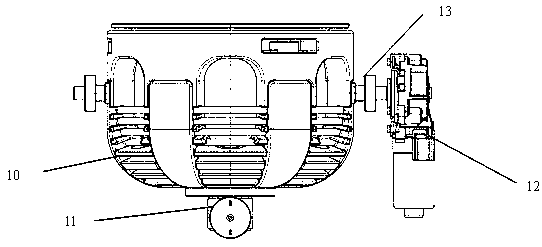

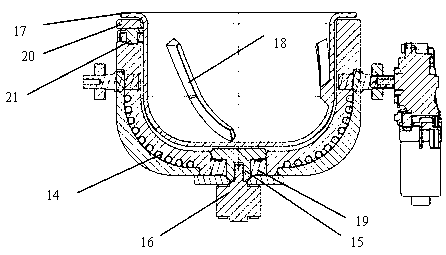

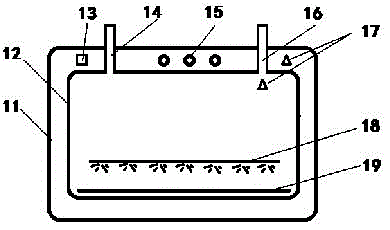

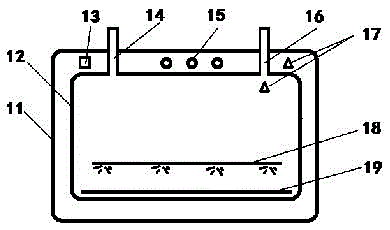

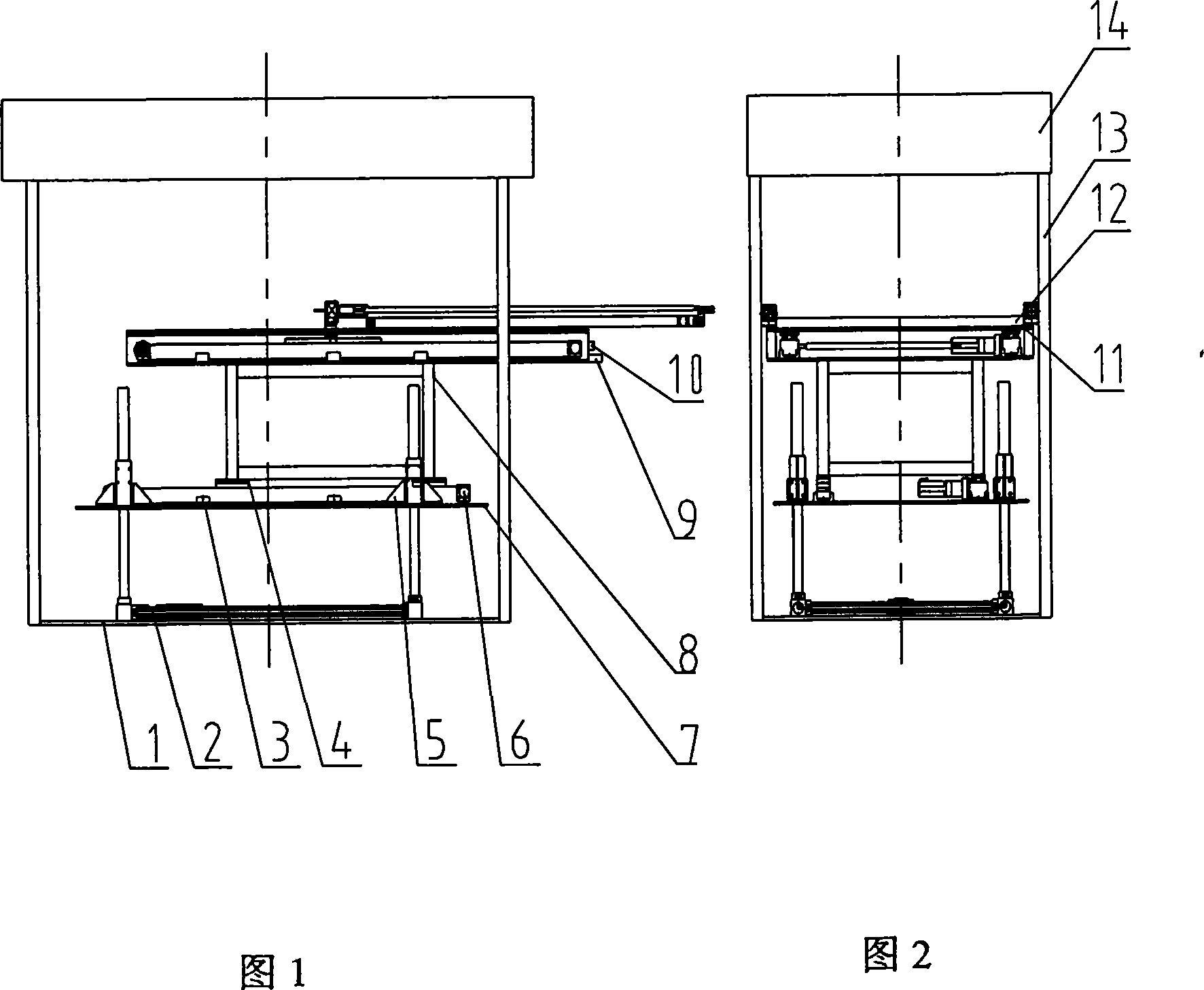

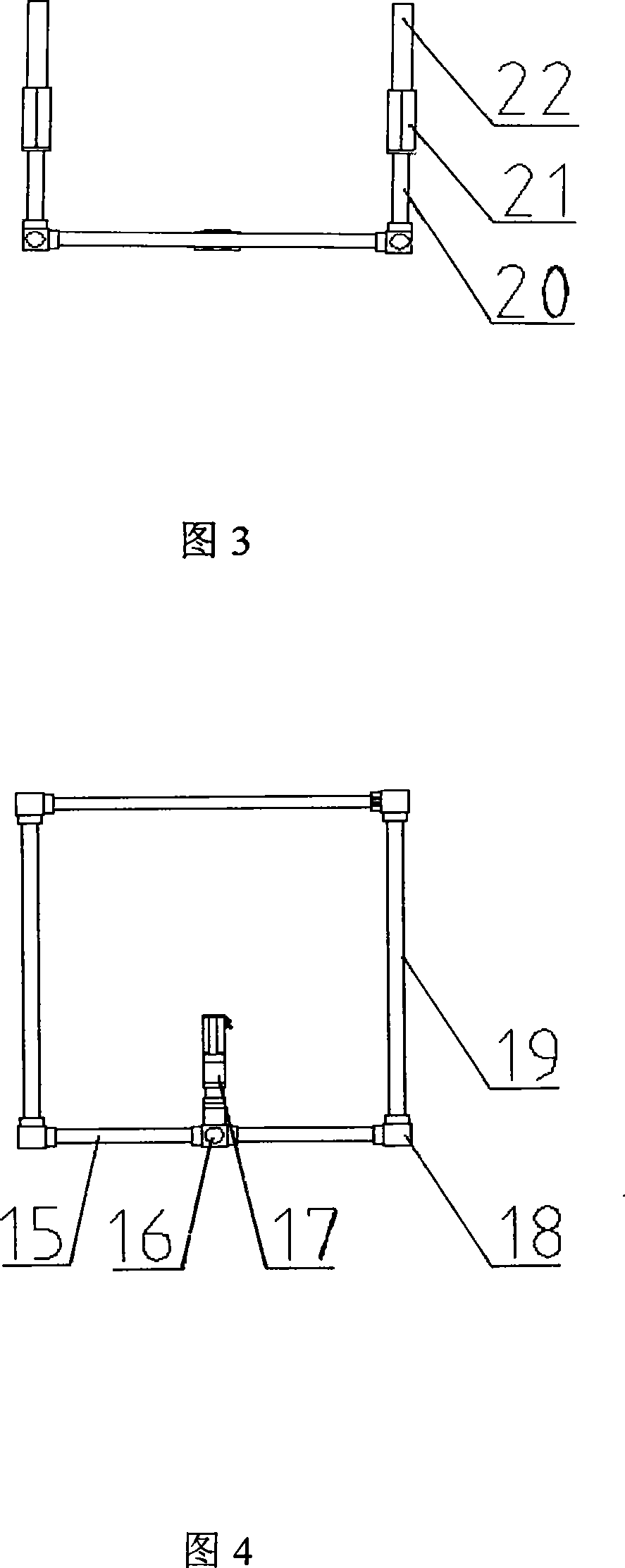

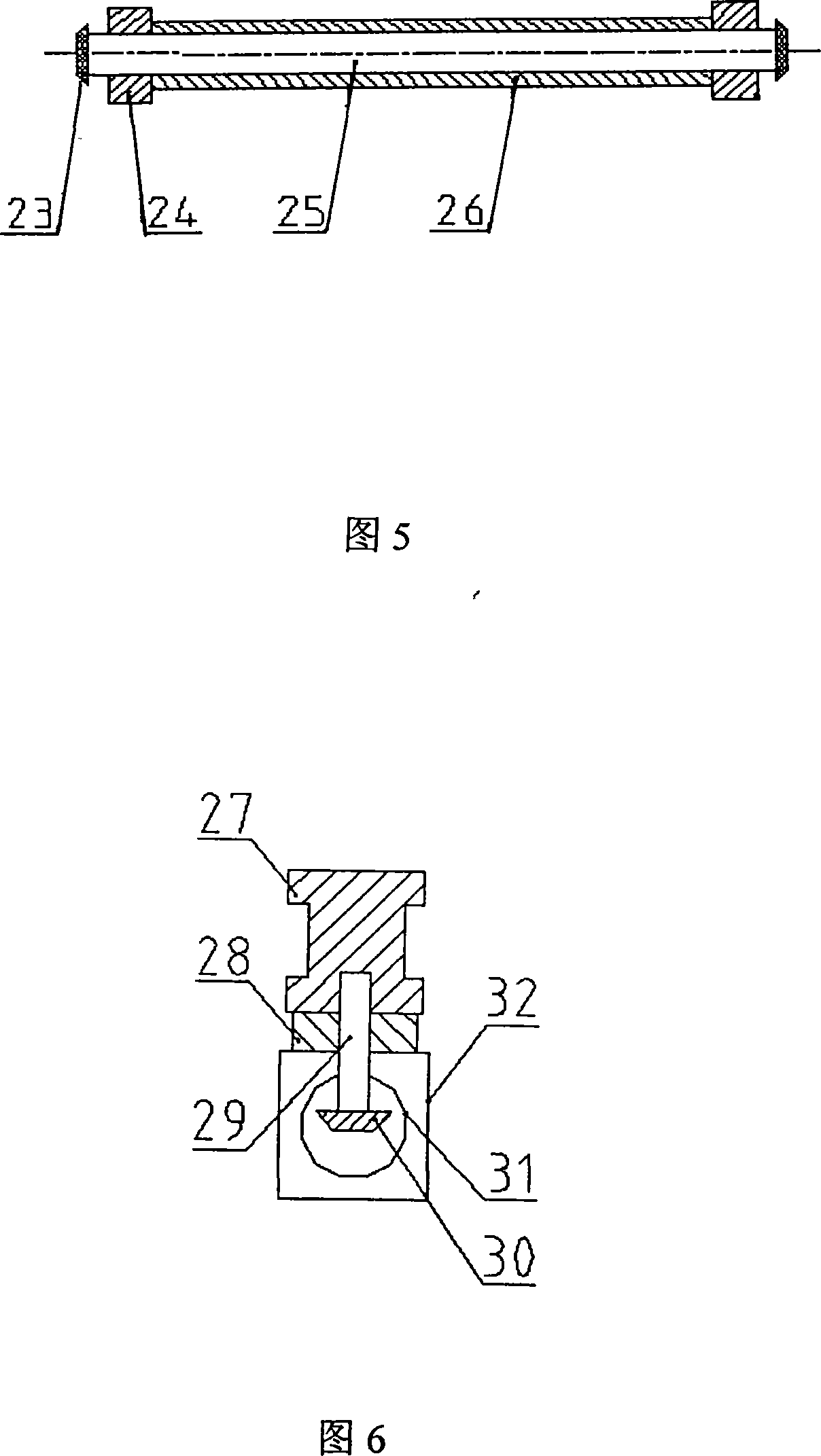

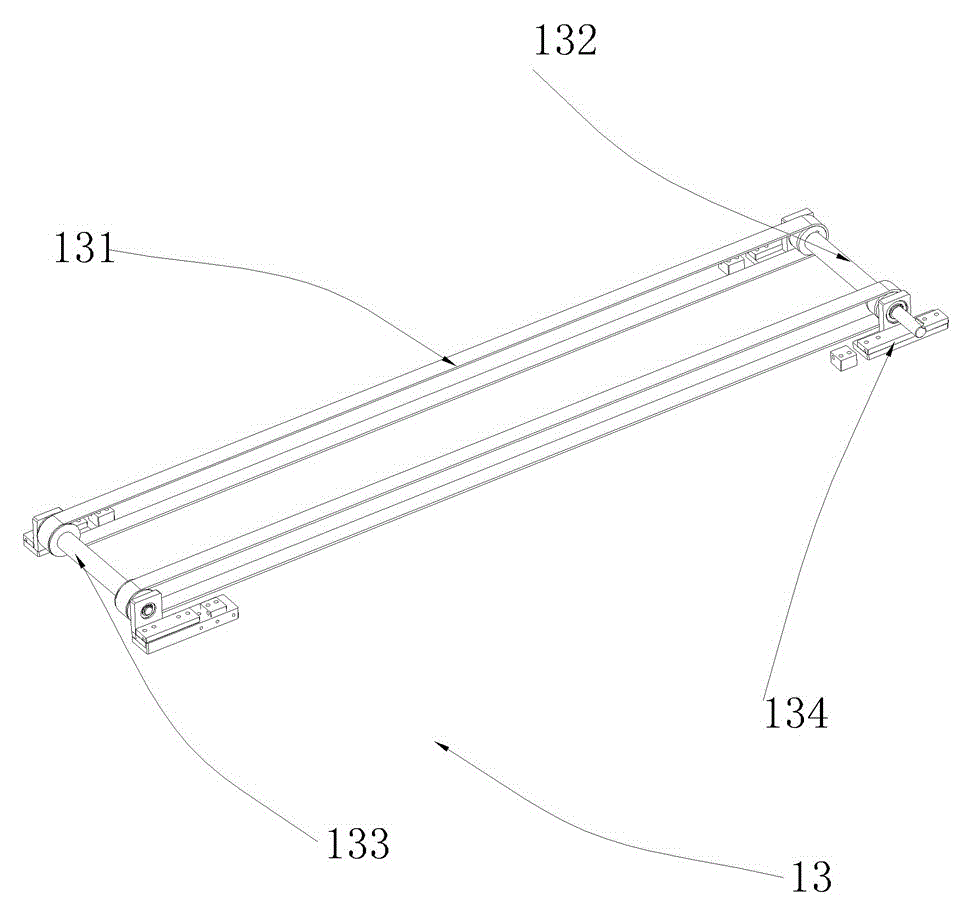

Silin bottle automatic drawing mechanism used for freeze-drying machine

ActiveCN101403563ARealize automatic dischargeRealize unmannedDrying solid materials without heatFreeze-dryingEngineering

The invention relates to a vial automatic discharging device used for a freeze dryer. The device is characterized by consisting of a material containing desk, a discharging system subassembly, guide tracks, a bracket, a decorative board, a thruster system subassembly, a handspike subassembly and a transmitter system subassembly, wherein, the material containing desk, the decorative board and the thruster subassembly are arranged on the bracket which can be slightly adjusted, the transmitter system subassembly is connected with the end of the material containing desk, the thruster system subassembly is arranged on the decorative board which is arranged at the side end of the transmitter system subassembly, the handspike subassembly is connected with a slider in the thruster system subassembly, and the discharging system subassembly is arranged on the guide tracks which are arranged at two sides of the material containing desk. The device has the advantages of providing the possibility of unmanned operation in a clean room, and and reducing pollution sources, thus providing higher guarantee for the sterility of products and effectively improving the labor productivity.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

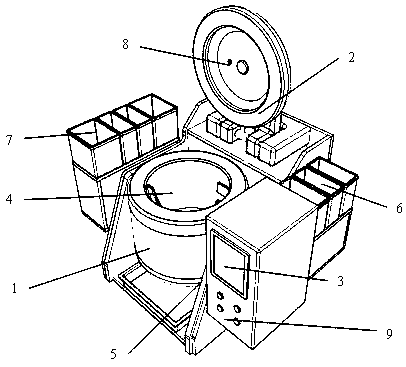

Intelligent stir-fry machine

InactiveCN109497820ARealize modular expansionRealize customizationWarming devicesVessels with intergral heatingTemperature controlMicrocomputer

The invention provides an intelligent stir-fry machine. The intelligent stir-fry machine is mainly characterized in that a temperature control unit controlled by a microcomputer compares the pot bodyinner container temperature detected by a temperature sensor with the heating temperature for dish frying and a heating speed preset value, after calculation, the temperature control unit converts a compensate value into the power for controlling electromagnetic heating, and accordingly the heating temperature and the heating speed of a pot body are controlled. The pot body is connected with a turnover motor, the pot body can be controlled by the microcomputer to turn over, and thus requirements for different positions of dish serving, pot washing and seasoning feeding are met. A microcomputercontroller controls a main foodstuff feeding device and an auxiliary seasoning feeding device through calculation. The intelligent stir-fry machine has the advantages that aiming at different tastes,the requirements are input, the control commands are automatically calculated and given out, accordingly, the rotating and turnover pot body with a heating function, the main foodstuff feeding mechanism and the auxiliary seasoning feeding mechanism cooperate with one another to conduct different motions, and the stir-fry function with modularization development, customization, unmanned performance and intelligentization is achieved.

Owner:SHENYANG YINGRUI MACHINERY

Intelligent express delivery device

ActiveCN107599938AThe process of sending and receiving express delivery is convenientGet rid of time constraintsProgramme-controlled manipulatorItem transportation vehiclesLogistics managementDelivery vehicle

The invention relates to an intelligent express delivery device and belongs to the technical field of logistics transport devices. The intelligent express delivery device solves the technical problemof low efficiency of package delivery and pick-up in the prior art. The technical solution comprises a storage area arranged in the front part of a carriage, wherein a storage area unfolding device isarranged on the top of the carriage; an automatic compartment door is also arranged on the top of the carriage; a package pick-up device is mounted at the middle of the bottom of the carriage; the rear part of the carriage is provided with an upper layer and a lower layer; the lower layer is a package sending and pick-up platform; the upper layer of the carriage is an unmanned aerial vehicle package delivery device; and a hydraulic lifting device is mounted between the bottom of the carriage and a carrying vehicle. The intelligent express delivery device applies the technical improvement of the automated storage and retrieval system to an express delivery vehicle so as to achieve a high intensive degree, free the package sending and pick-up from the time limitation, realize the intelligence and unmanned operation of the package sending and pick-up process, save human resources and solve the problem of "the last kilometer" of packages to a greater extent. The intelligent express delivery device conforms to the development trend of "Internet plus express delivery" and is worth popularizing and applying widely.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method and production line for rapidly preparing aerogel through radio frequency radiation

ActiveCN105582866AIncrease productivityRealize high-end manufacturingAerogel preparationColloidal chemistry detailsAutomatic controlEngineering

The invention relates to method and production line for rapidly preparing aerogel through radio frequency radiation. The aerogel production line comprises a main machine for rapidly preparing the aerogel through radio frequency radiation, an original auxiliary material system, an inert gas system, a heat supply system, a recovery system and a three-waste treatment system. The main machine for rapidly preparing the aerogel through radio frequency radiation comprises a sol-gel station, an ageing station, a replacement modification station and a drying station. The main machine is provided with a radio frequency generator, a monitoring device and an automatic control device. The main machine is provided with an inner container which is through front and back, a crawler is arranged in the inner container and used for material conveying, a channel is formed in the inner container and can be communicated with or disconnected from other systems outside the main machine. Multiple forms of products such as aerogel powder, aerogel particles, aerogel felt, aerogel plates, aerogel cloth and aerogel films can be continuously produced, the extremely high production efficiency and automation degree are achieved, the aerogel industry is powerfully promoted to achieve production automation, large scale and intelligence.

Owner:宁波圣润新材料有限公司

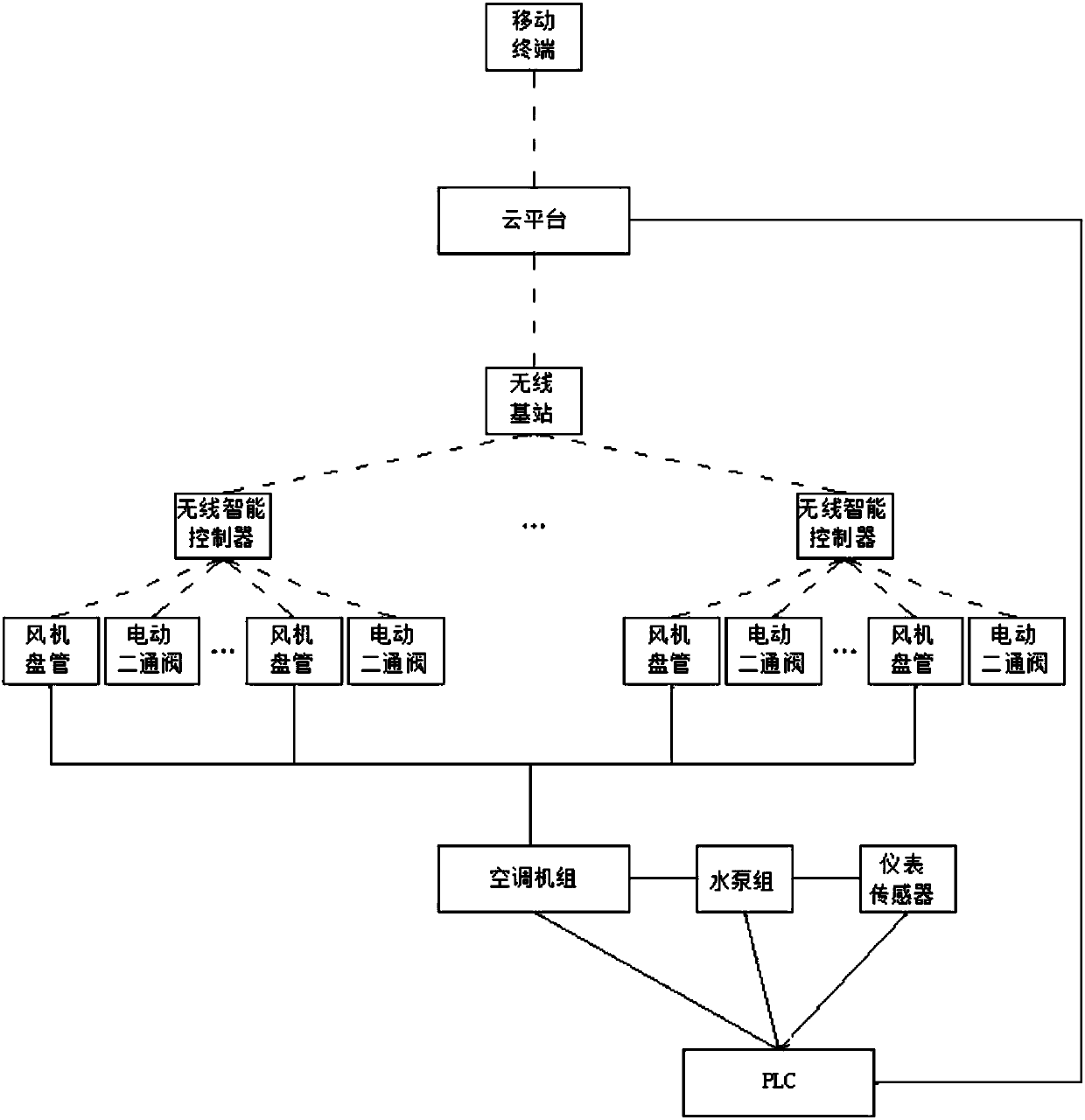

Unmanned-operation central air conditioner intelligent system and control method thereof

ActiveCN107726546AFast data responseEasy constructionMechanical apparatusControl systemComputer module

The invention discloses an unmanned-operation central air conditioner intelligent system and a control method thereof. The unmanned-operation central air conditioner intelligent system comprises a terminal billing system, a cloud platform and a machine room control system. The terminal billing system comprises a wireless receiving and transmitting module, a wireless intelligent controller and a wireless base station. A control box of a fan coiled tube is connected with the wireless receiving and transmitting module, the wireless receiving and transmitting module is in wireless connection withthe wireless intelligent controller, and the wireless intelligent controller is in wireless connection with the wireless base station. The wireless intelligent controller comprises an electric two-wayvalve opening-closing module for controlling an electric two-way valve to be opened and closed, a fan starting-closing module for controlling the fan to be started and stopped and an air speed control module for adjusting the air outlet speed of the fan. The cloud platform is in wireless connection with the wireless base station. The machine room control system comprises a water pump set, an airconditioner unit, an instrument sensor and a PLC, and the fan coiled tube is connected with the air conditioner unit through a pipeline. According to the unmanned-operation central air conditioner intelligent system and the control method thereof, a machine room control system is automatically adjusted according to the terminal load rate, so that closed-loop adjustment is achieved, energy consumption is greatly saved, and the user using comfort is improved.

Owner:WUHAN HONGTU ENERGY SAVING TECH

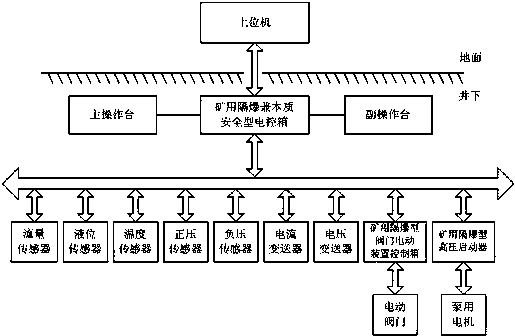

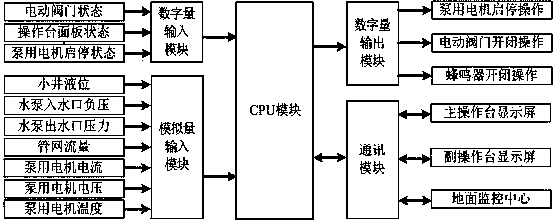

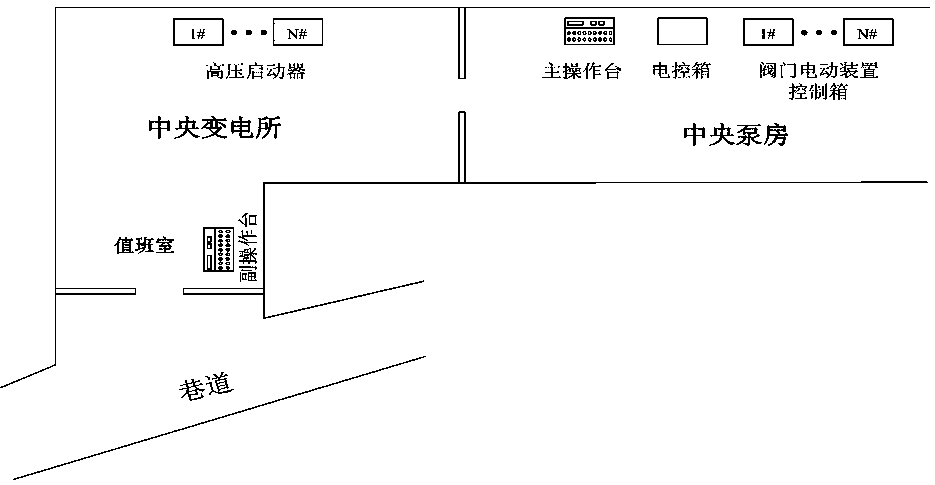

Mine main drainage automatic control and remote monitoring system

InactiveCN104076789ARealize unmannedRealize operation with fewer peopleDrainageProgramme total factory controlAutomatic controlAutomatic train control

The invention discloses a mine main drainage automatic control and remote monitoring system. A network type control structure with an upper computer combined with a lower computer is adopted, the upper computer comprises an industrial personal computer, and the lower computer comprises a main operating table, a sub operating table, a mining explosive-proof and intrinsic safety type electric cabinet, an executing mechanism and a sensor. Data between the upper computer and the lower computer are exchanged in real time through the Ethernet, and then the executing mechanism is used for controlling underground drainage equipment. The mine main drainage system real-time monitoring management system has the functions of information collection and storage, automatic control, data processing and network transmission, and can effectively improve a management mode of a mine main drainage system, improve productivity and achieve unmanned and flexible-manpower-line operation of an underground central pump house.

Owner:TAIYUAN UNIV OF TECH

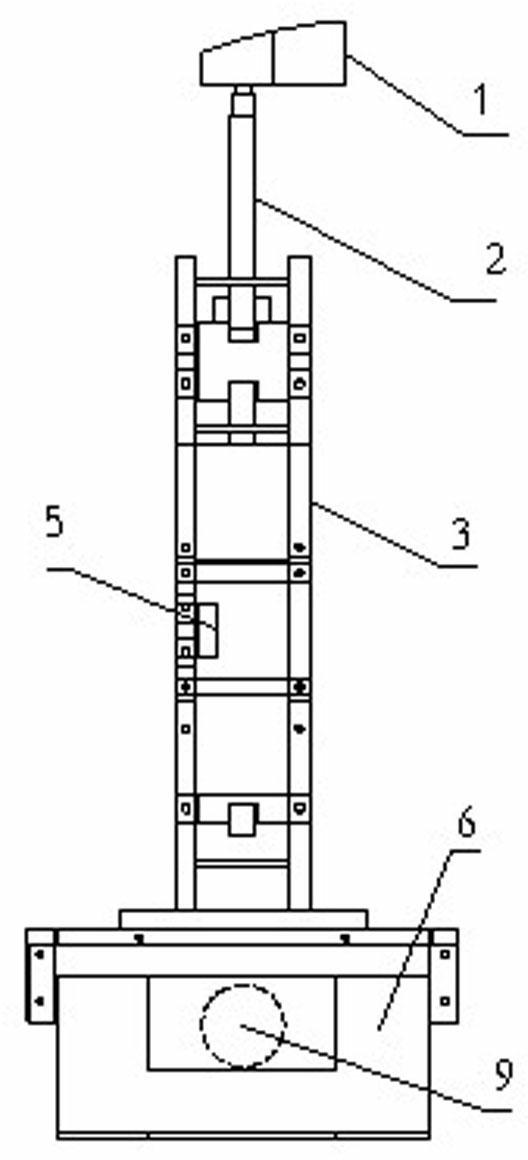

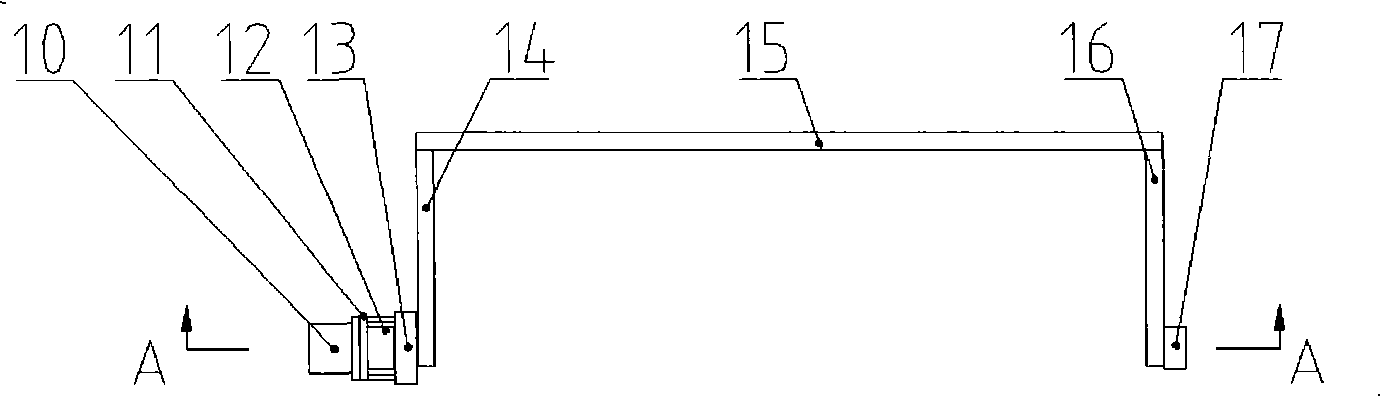

Automatic guiding carriage device

ActiveCN101231134AReduce artificial pollutionImprove productivityDrying solid materials without heatProduction rateButt joint

The invention relates to an automatically guiding trolley device, which is characterized in that a trolley device case consists of a slide block connection board and a rack; the slide block connection board is connected on the an X-rail straight line location system slide block; an elevator platform straight line location system component is positioned on the slide block connection board through a mounting base; an adjustment mounting block is positioned on the elevator platform straight line location system component; a butt-joint platform straight line location system component is positioned on the elevator platform straight line location system component through a fixing component, the slide block connection board and a carriage; a loading platform is positioned on the butt-joint platform straight line location system component; a vertical alignment sensor and a horizontal alignment sensor are positioned at the front end of the loading platform; a catching platform component is positioned on the butt-joint platform straight line location system component; and a fan filter device is arranged at the upper end of the carriage. The invention has the advantages of providing the possibility of unmanned operation in a clean house, and reducing artificial pollutant source, thereby providing more guarantee for the product aseptic and effectively increasing productivity.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

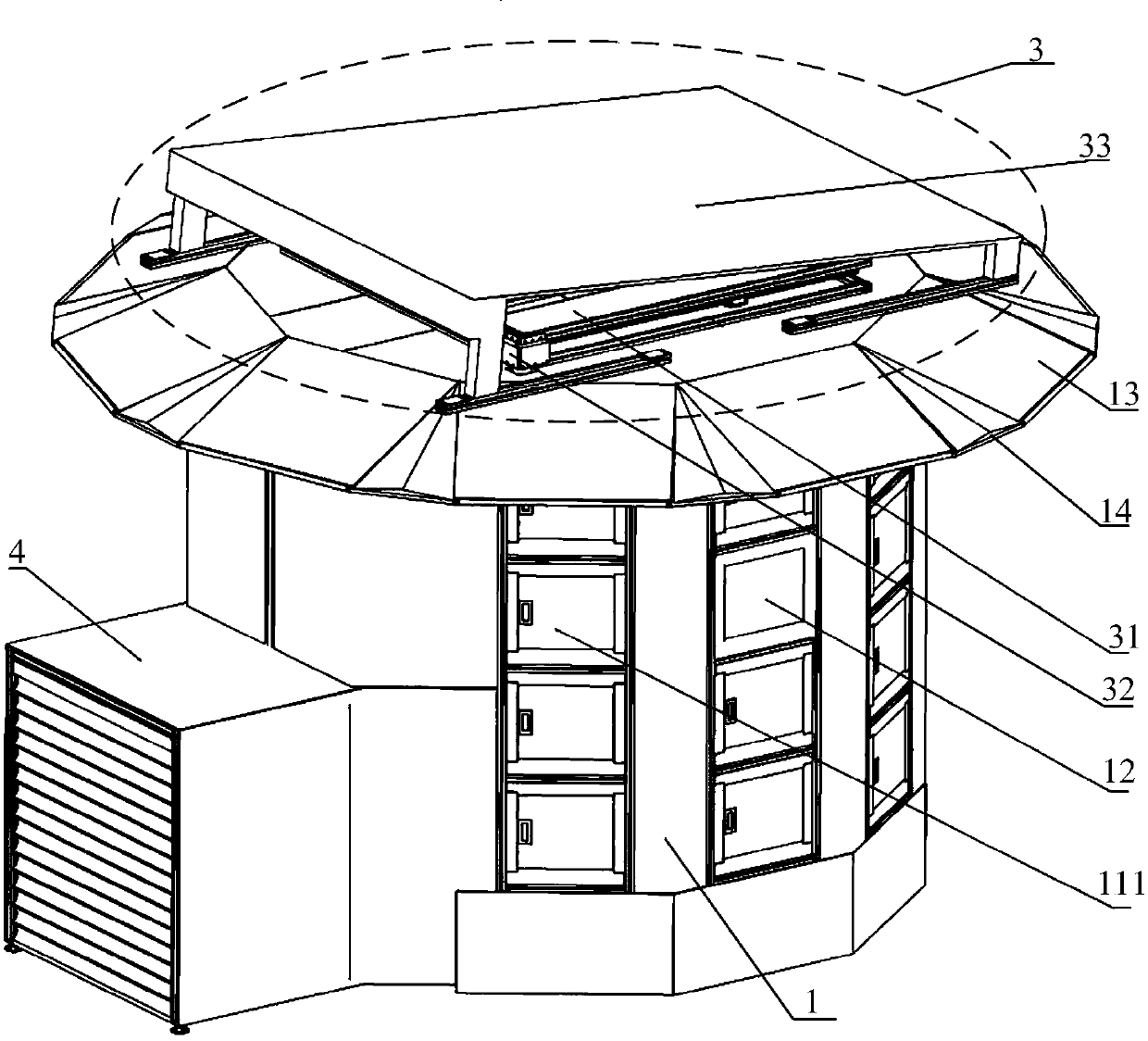

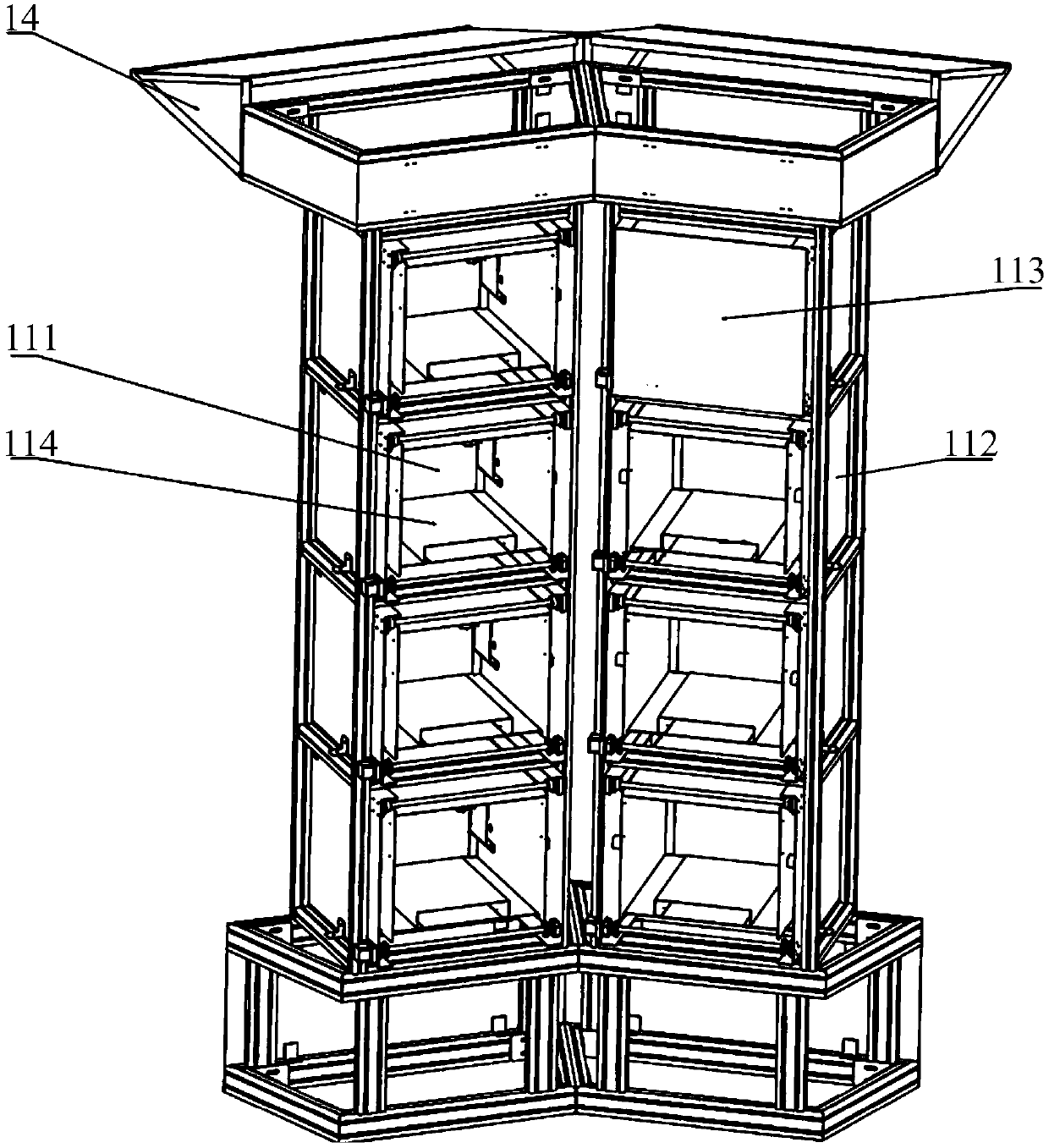

Self-pickup cabinet

ActiveCN110371562AEasy dockingRealize unmannedCoin-freed apparatus detailsApparatus for meter-controlled dispensingEngineering

The embodiment of the invention discloses a self-pickup cabinet. According to the specific implementing manner of the self-pickup cabinet, a body part, a sorting device, an arrester and a master control device are included. The body part is of a hollow structure with the top opened, and at least part of the hollow structure is formed through surrounding of a plurality of self-pickup boxes. The arrester is arranged on the top of the body part and comprises a parking apron, and the parking apron is provided with a channel through which goods dispatched by an unmanned aerial vehicle can pass, andthe channel is right opposite to the top opening. The sorting device is arranged in the hollow structure, is in communication connection with the master control device and can receive the goods dispatched by the unmanned aerial vehicle according to a goods receiving instruction after the goods receiving instruction sent by the master control device is received, and the received goods are conveyedinto the self-pickup boxes of the self-pickup cabinet according to a first sorting instruction after the first sorting instruction sent by the master control device is received. According to the self-pickup cabinet, the goods dispatched by the unmanned aerial vehicle are conveyed to the corresponding self-pickup boxes through the sorting device, and unmanned goods delivery is better achieved.

Owner:XIAN JINGDONG TIANHONG TECH CO LTD

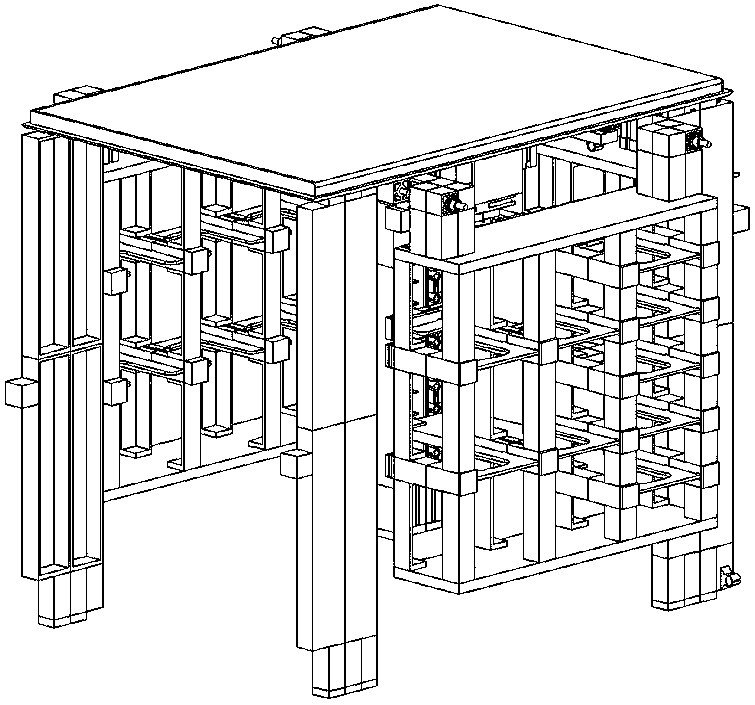

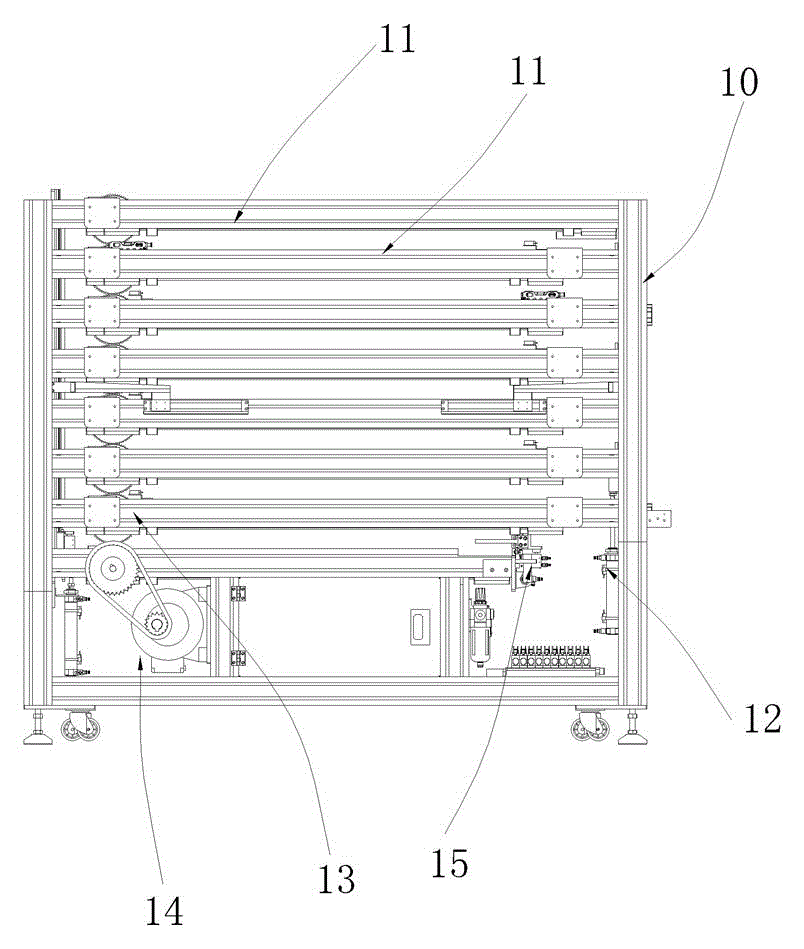

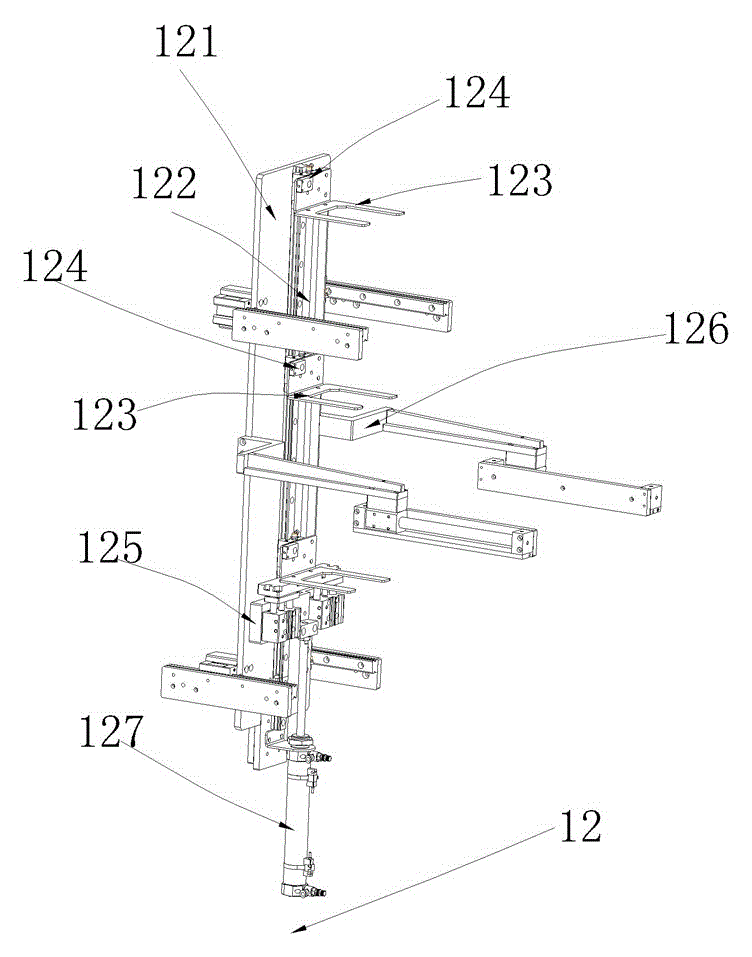

Full-automatic flowing storage platform equipment and flowing storage method for clamping jigs

ActiveCN105083892ASolve problems such as strict requirements on storage timeDisrupt the storage status quoStorage devicesMechanical conveyorsEngineeringElectrical and Electronics engineering

The invention discloses a full-automatic flowing storage platform equipment and a flowing storage method for clamping jigs. The equipment comprises a rack and multiple material layers which are sequentially distributed in the rack from top to bottom; two sides of each material layer are provided with lifting mechanisms; a conveying mechanism is arranged on each material layer; the rack is also provided with a driving mechanism; the driving mechanism is in drive connection with the conveying mechanisms; after being driven by the driving mechanism, the singular layers of material layers and the even layers of material layers move toward the same direction, and the upper and lower layers of material layers move toward different directions; and the equipment further comprises a transporting mechanism used for transporting the clamping jigs on the bottommost layer. According to the full-automatic flowing storage platform equipment, the flowing of the clamping jigs on the upper and lower layers is realized; and final carrying is performed by the carrying mechanism; the traditional clamping jig storage status is broken through; the equipment with a flowing storage structure, high product compatibility and stable flowing is provided; besides, unmanned operation is realized, and manual intervention is avoided; and the product quality is improved.

Owner:SHENZHEN QIANGRUI ELECTRONICS

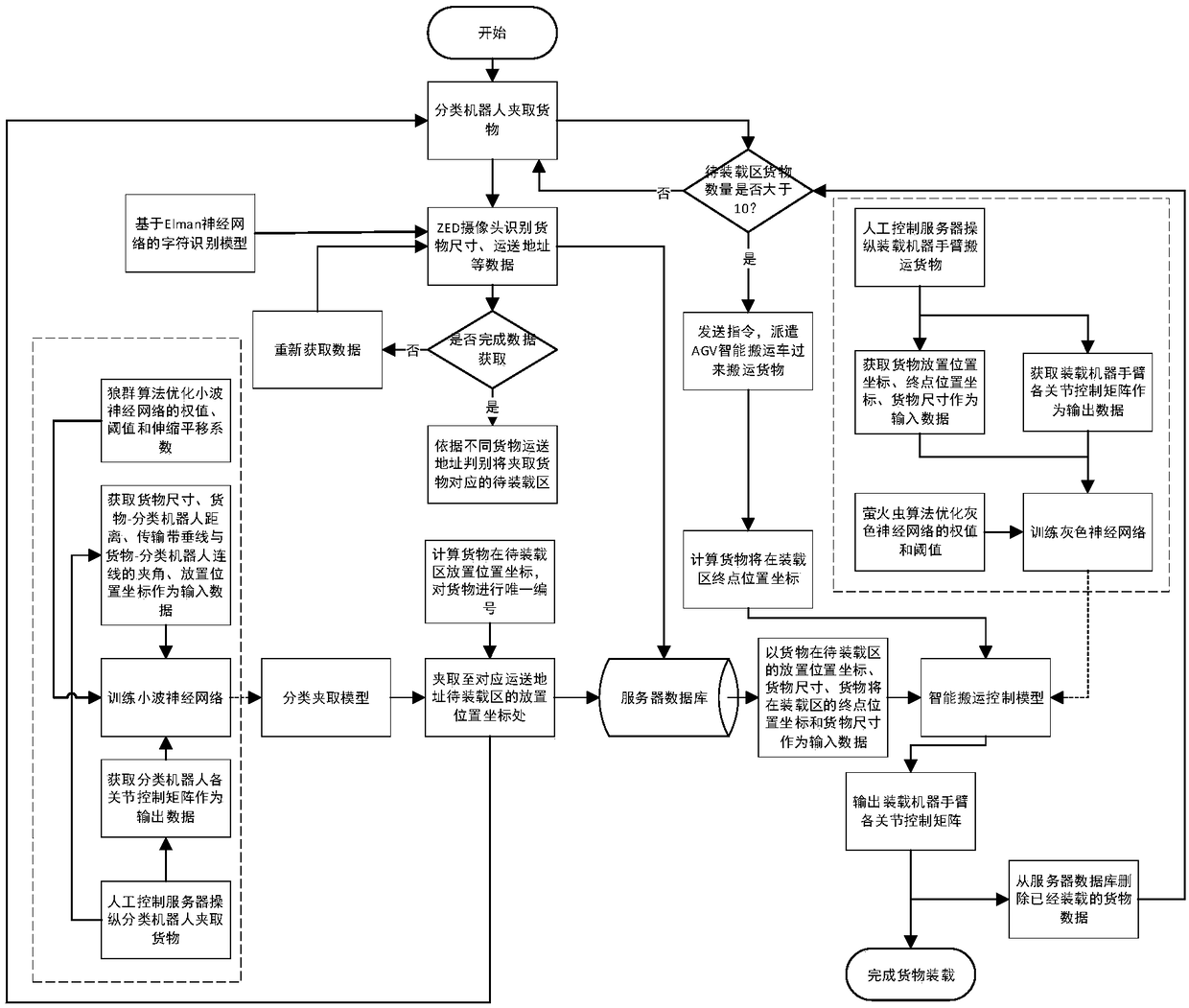

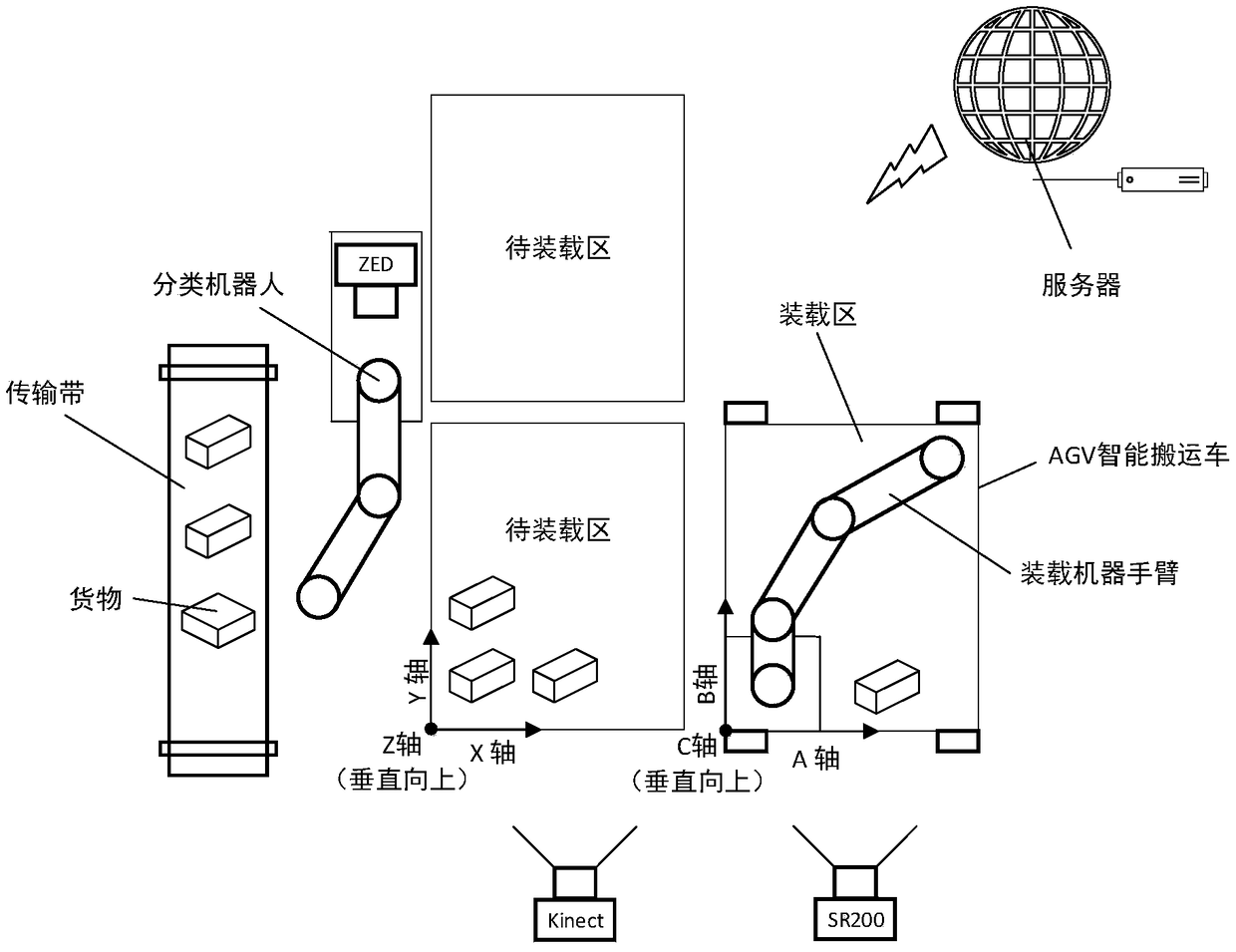

Loading method and device of intelligent logistics environment robot

ActiveCN108942946ASimple structureEasy to operateProgramme-controlled manipulatorMachine visionLogistics management

The invention discloses a loading method and device of an intelligent logistics environment robot. The method comprises the following steps that firstly, cargo information is acquired in real time; secondly, the coordinates of the placement positions of cargoes in to-be-loaded areas corresponding to conveying addresses are calculated; thirdly, a classification robot is utilized for clamping the cargoes to the corresponding to-be-loaded areas used for temporary storage from a conveying belt; fourthly, the coordinates of the final positions of the cargoes in loading areas of an AGV intelligent carrier; and fifthly, the cargoes are carried to the loading areas of the AGV intelligent carrier according to a control matrix obtained by an intelligent carrying control model. The cargo sizes, the cargo conveying addresses, the cargo position coordinates and other information are automatically acquired by combining machine vision, the classification robot and the intelligent carrier are utilizedfor automatically and intelligently classifying and loading the cargoes by setting up a neural network model, the loading error rate is greatly reduced, and the loading efficiency is improved.

Owner:CENT SOUTH UNIV

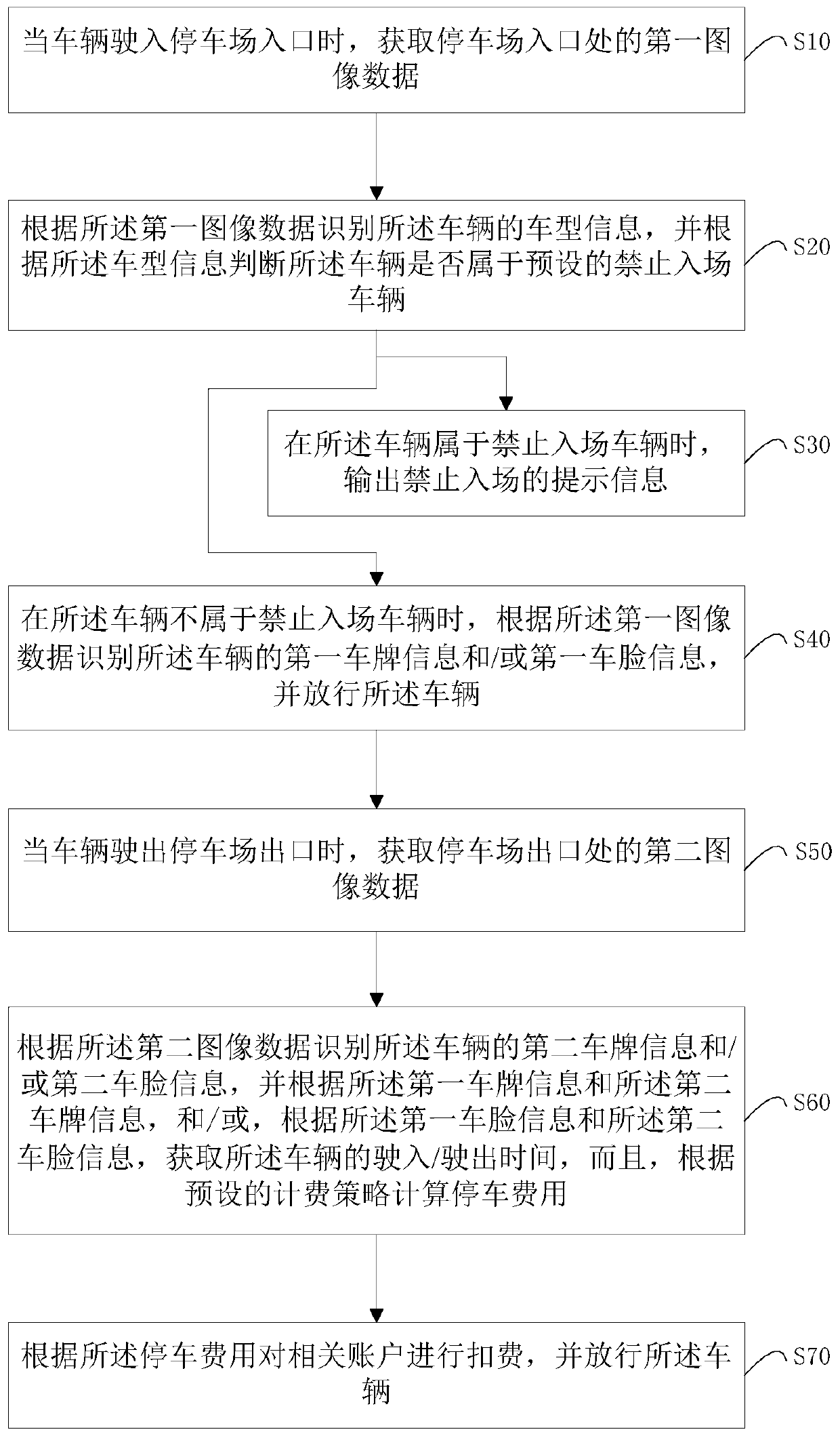

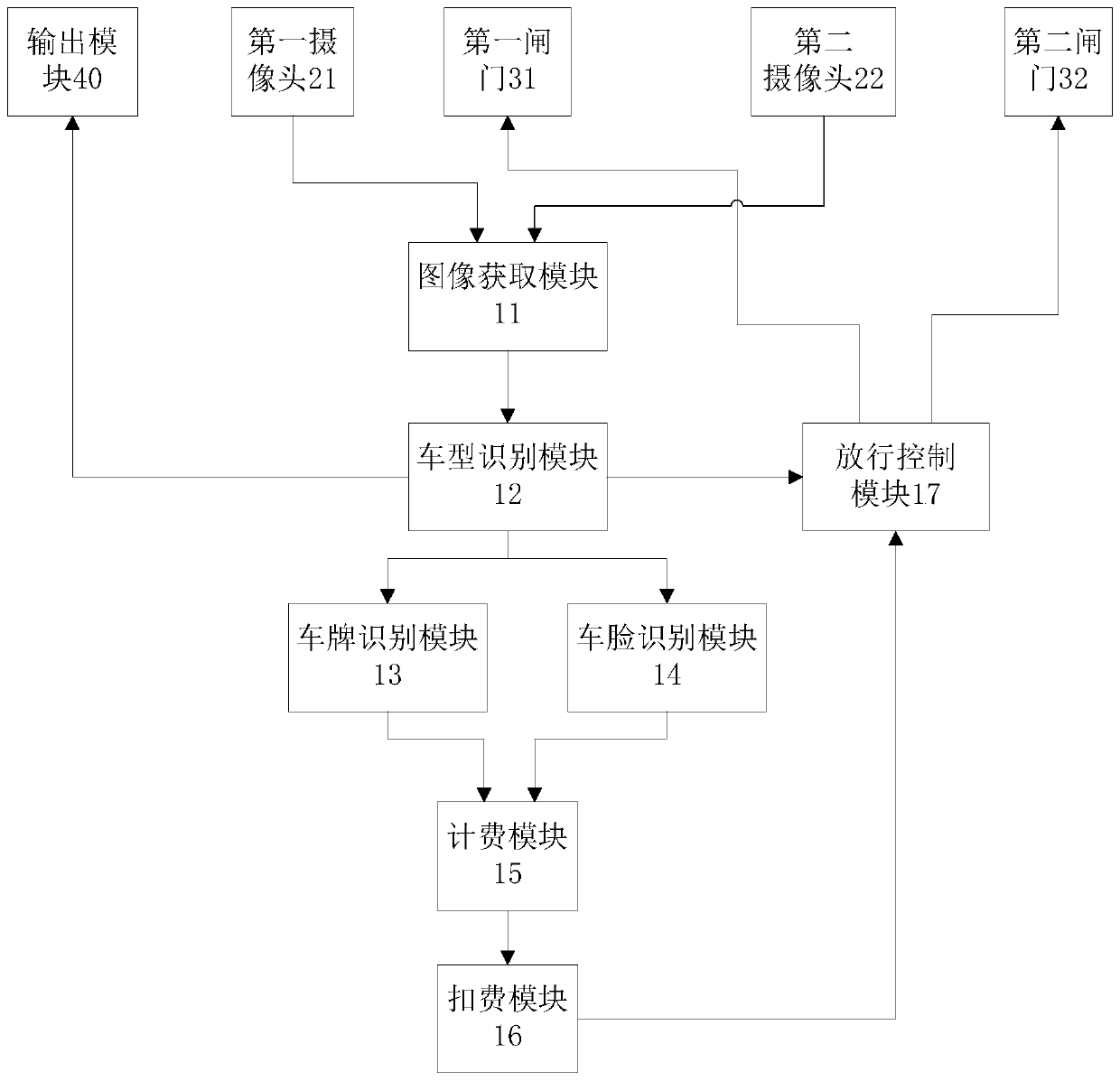

Unattended parking lot charge management method and system

InactiveCN110298928AMaximize turnoverImprove the parking experienceTicket-issuing apparatusCharacter and pattern recognitionApproaches of managementImaging data

The invention relates to an unattended parking lot charge management method and system. The parking lot charge management method comprises the following steps: acquiring first image data at an entrance of a parking lot; identifying vehicle model information of a vehicle, and judging whether the vehicle belongs to a preset no-entrance vehicle or not; if belonging to outputting prompt information ofno entrance; when not belonging to, identifying first license plate information or first vehicle face information of the vehicle and releasing the vehicle; acquiring second image data at an exit of the parking lot; identifying second license plate information and / or second vehicle face information of the vehicle, obtaining driving-in / driving-out time of the vehicle according to the first licenseplate information and the second license plate information and / or according to the first vehicle face information and the second vehicle face information, and calculating parking fee according to a preset billing strategy; and carrying out fee deduction on the related account according to the parking fee, and releasing the vehicle. According to the technical scheme of the invention, the closed type parking lot is intelligent and unmanned.

Owner:SHENZHEN GENVICT TECH

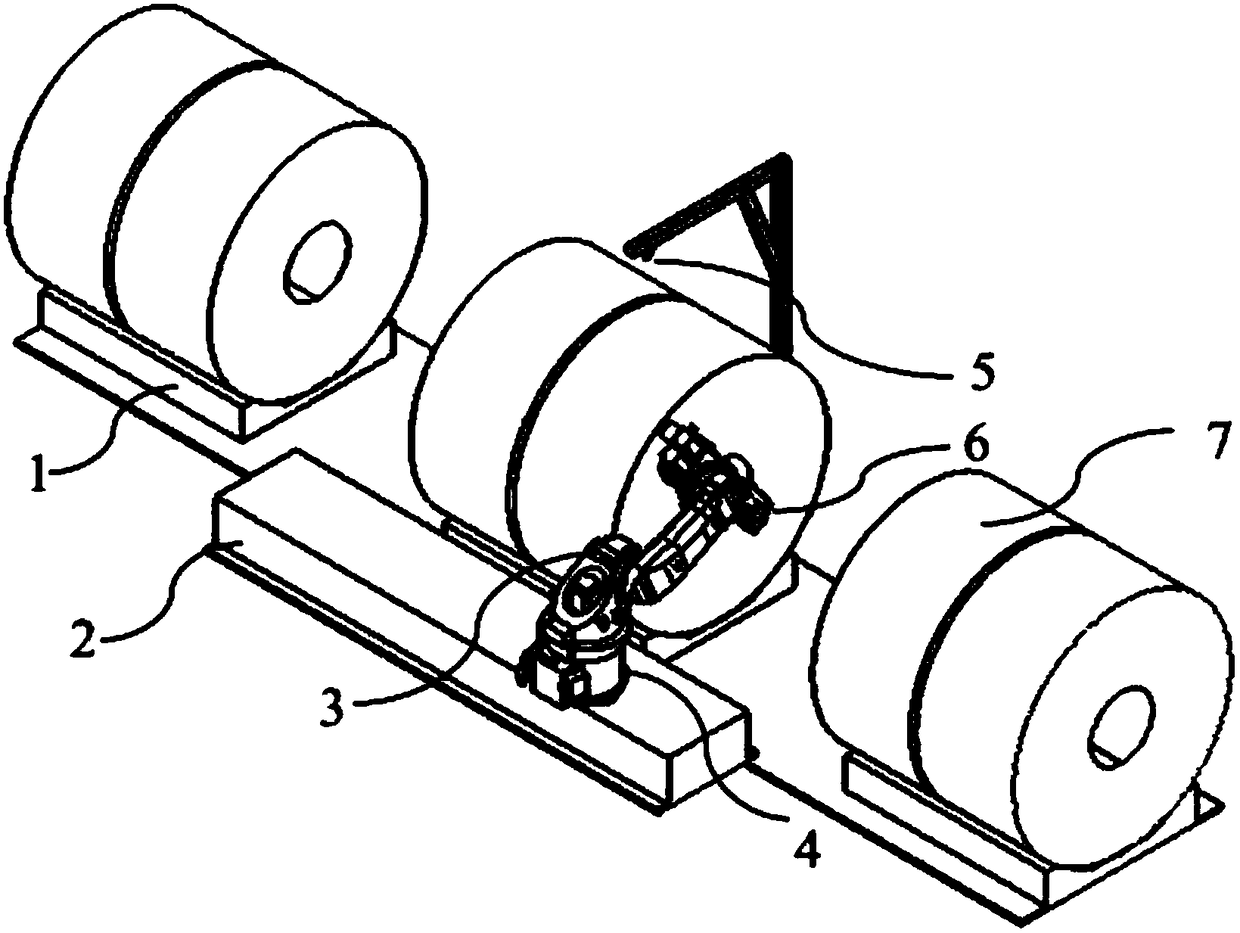

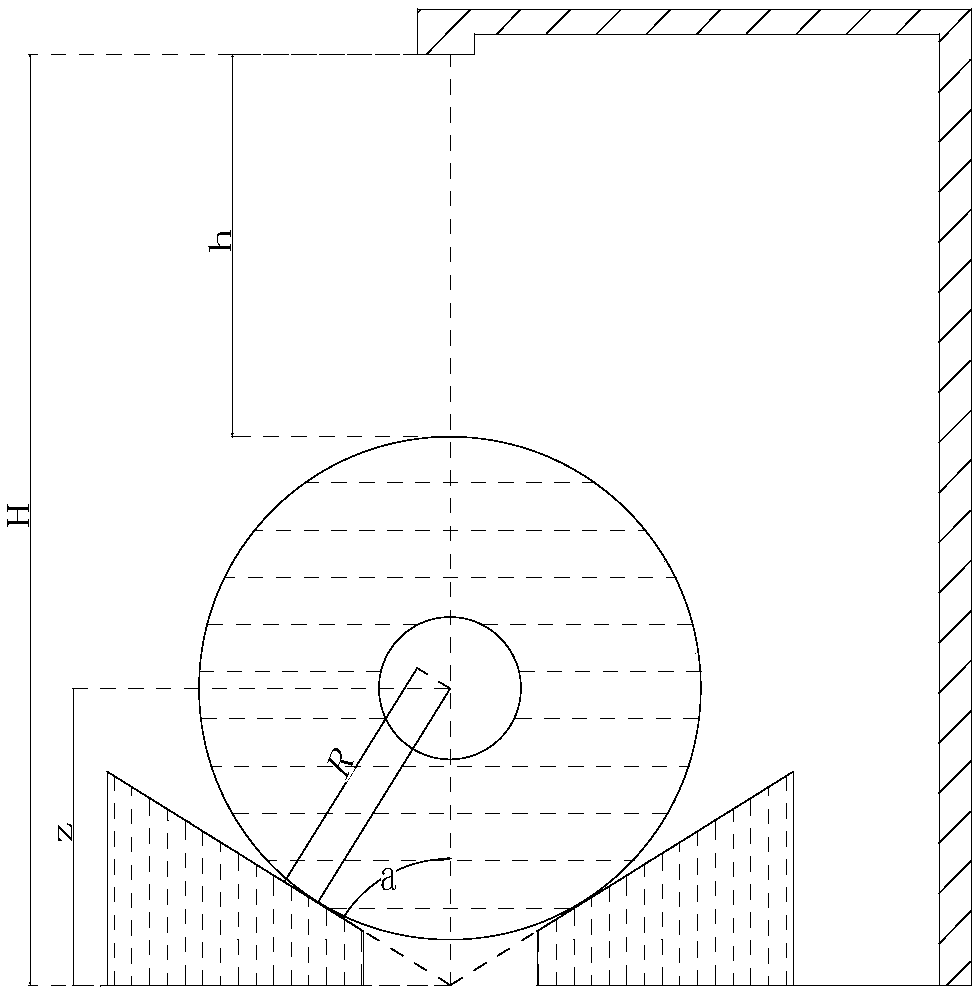

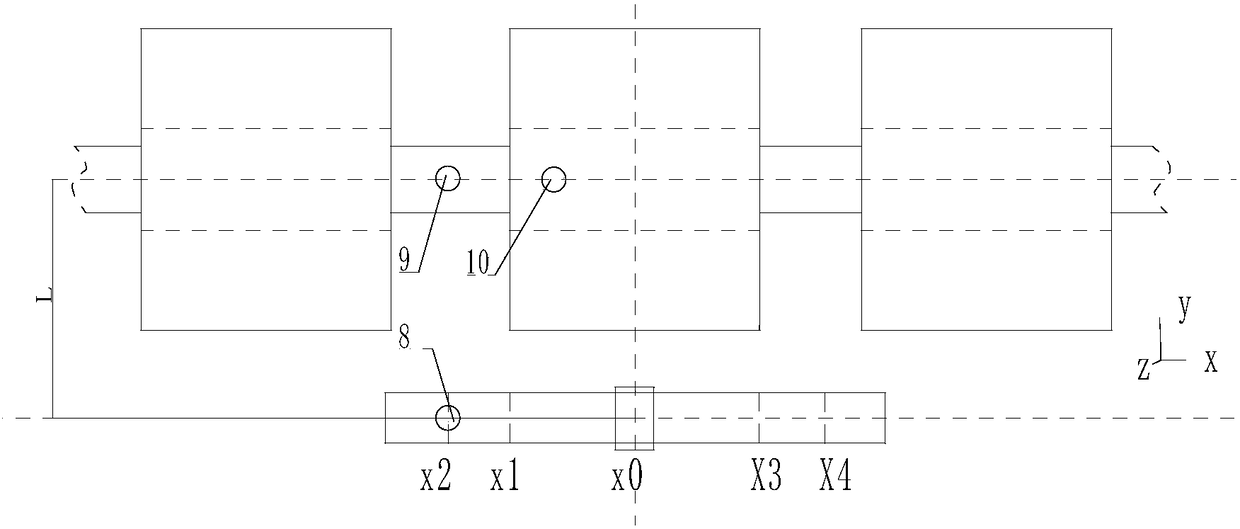

Cold-rolled steel coil core welding method based on joint robot

ActiveCN108480881AFully automatedRealize unmannedWelding/cutting auxillary devicesAuxillary welding devicesMaximum diameterArthrobotrys

The invention provides a cold-rolled steel coil core welding method based on a joint robot. The cold-rolled steel coil core welding method comprises the following steps that firstly, a steel coil coreautomatic-welding device is mounted in a stepping beam area at an outlet for the procedure before batch annealing, wherein the steel coil core automatic-welding device mainly comprises the joint robot, a linear sliding table, a detection unit and a welding machine; secondly, motion interlocking is established between a stepping beam and the joint robot; thirdly, the height of a steel coil is detected; fourthly, the end face position of the steel coil is detected; and fifthly, welding motion teaching programming is conducted, specifically, at each coil welding position, a steel coil with the maximum width and the minimum diameter is used as a reference work condition for teaching programming for the joint robot, and in every two adjacent coil positions, the steel coil with the maximum width and the maximum diameter is used as a reference work condition for teaching programming for the joint robot. According to the cold-rolled steel coil core welding method based on the joint robot, manual welding work is replaced by the robot, so that automatic and unmanned welding of steel coil cores is achieved.

Owner:ANSTEEL BEIJING RES INST

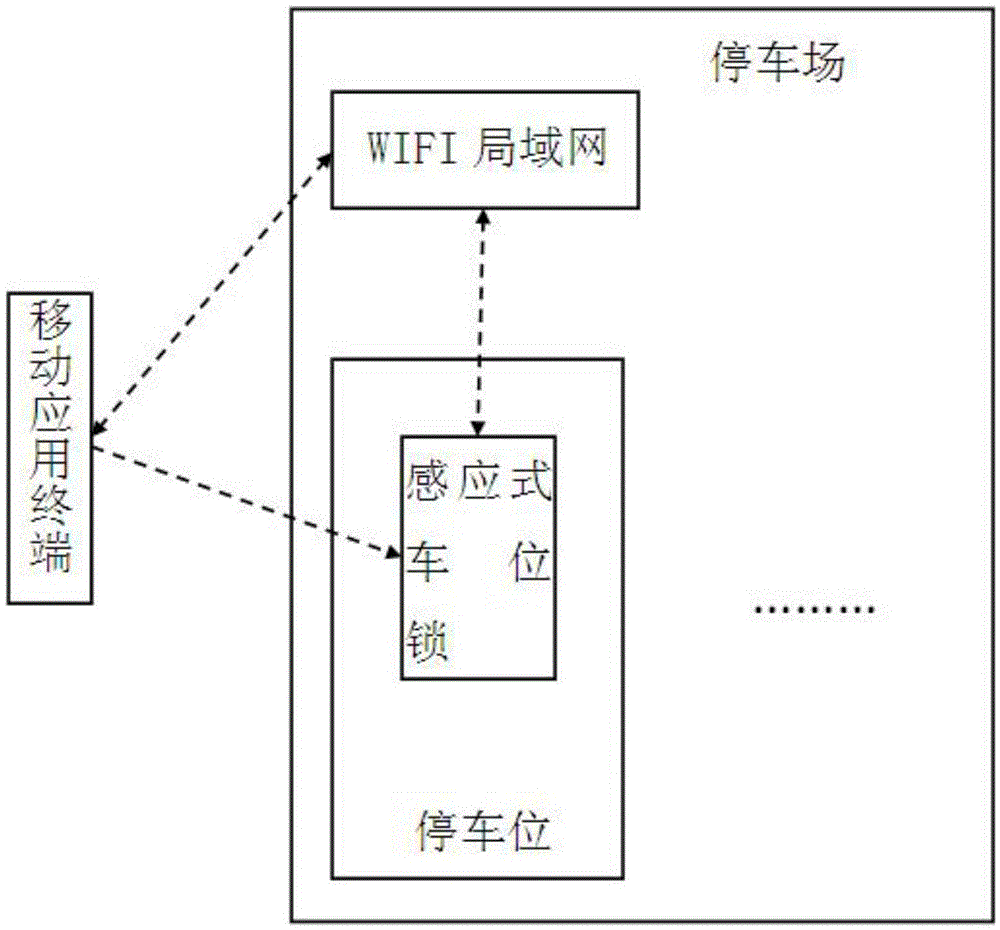

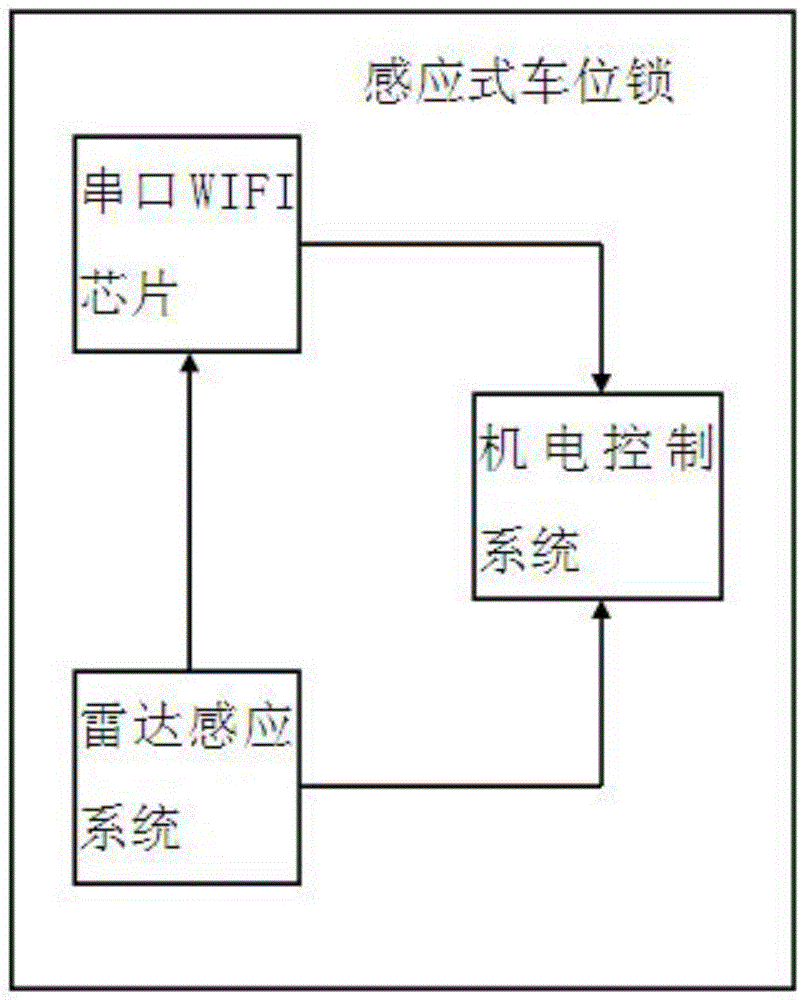

Parking spot integrated management system

InactiveCN105427659AImprove use valueImprove convenienceTicket-issuing apparatusReservationsPaymentRadar

The invention discloses a parking spot integrated management system. The system is composed of a WIFI local area network arranged in a parking lot, inductive parking spot locks mounted in parking spots, and a carry-on mobile application terminal. Each inductive parking spot lock comprises a parking spot lock holder, a serial WIFI chip arranged inside the parking spot lock holder, a radar induction system and an electromechanical control system. The mobile application terminal is internally equipped with a wireless communication module and an APP client. The inductive parking spot locks and the mobile application terminal are in two-way communication connection with the WIFI local area network via a wireless network. The mobile application terminal and the inductive parking spot locks are in two-way communication connection with each other. By using the parking spot management system of the invention, informationized parking spot management, convenient parking fee payment, unmanned parking lot management and full-automatic parking lock control are realized, diversified modes of parking spot development are provided, the use value of parking spots is promoted, the system is simple and easy to operate, and a lot of time is saved for car owners.

Owner:BEIJING WANDING TENGDA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com