Automatic detection system and method for power battery and battery safety judgment and disposal method

A power battery and automatic detection technology, applied in measuring devices, parts of electrical measuring instruments, measuring electricity, etc., can solve problems such as safety threats to personnel and plant areas, failure to detect and deal with them in time, abnormal heating of outgoing lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

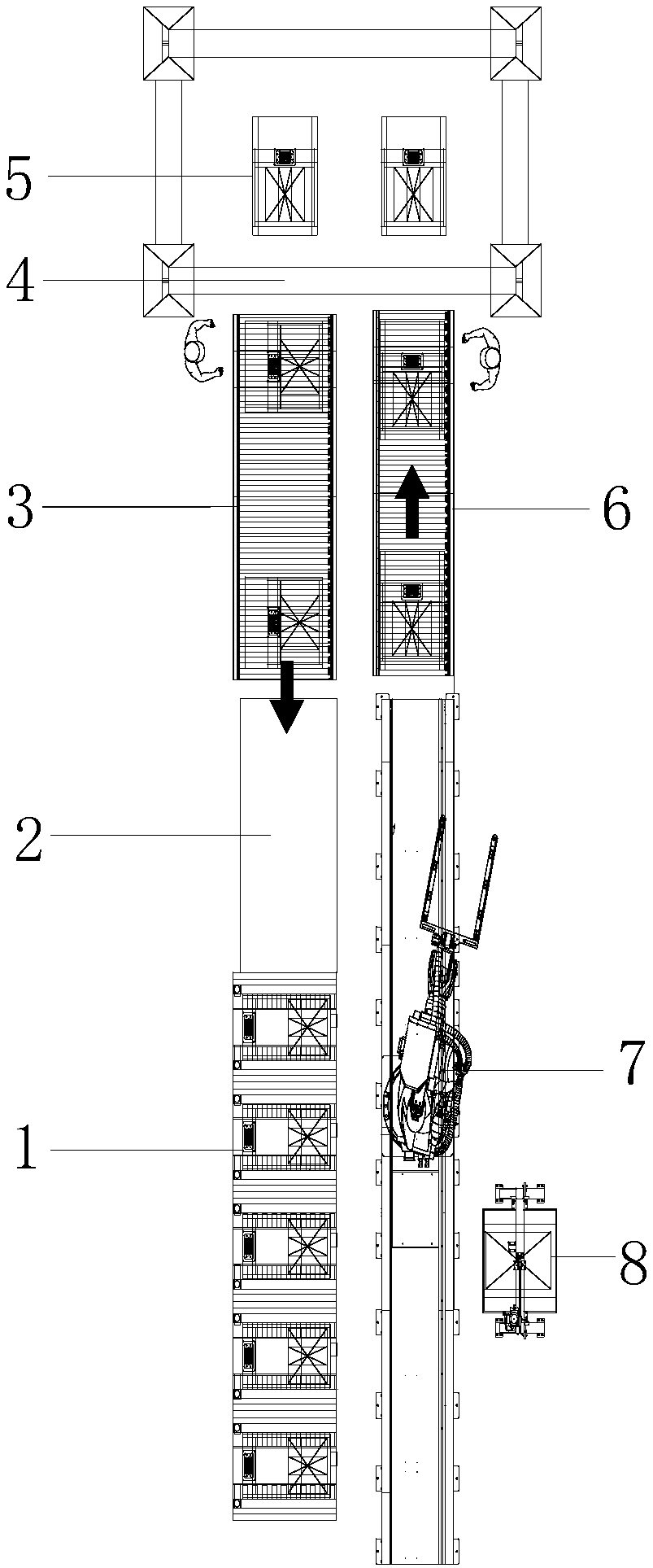

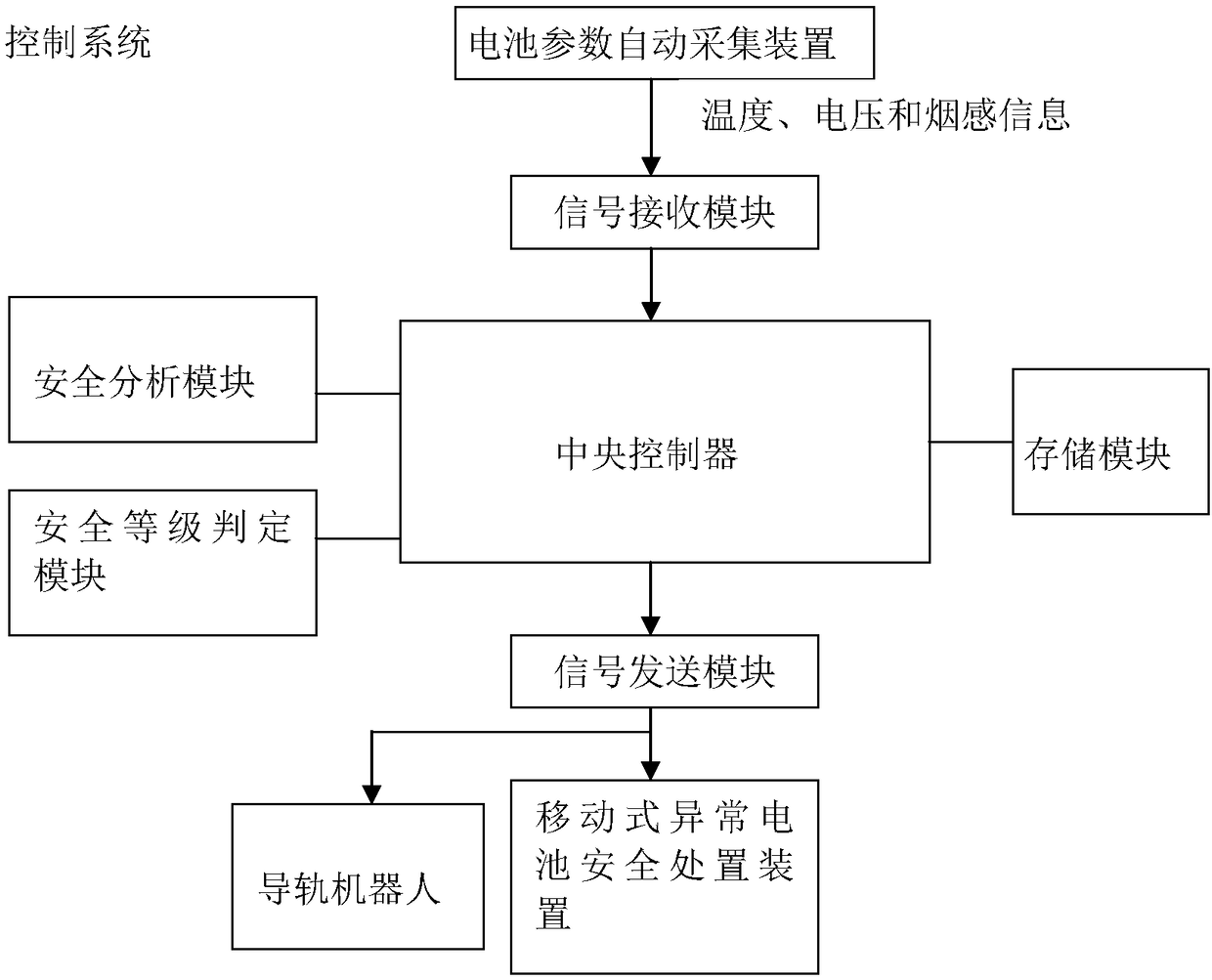

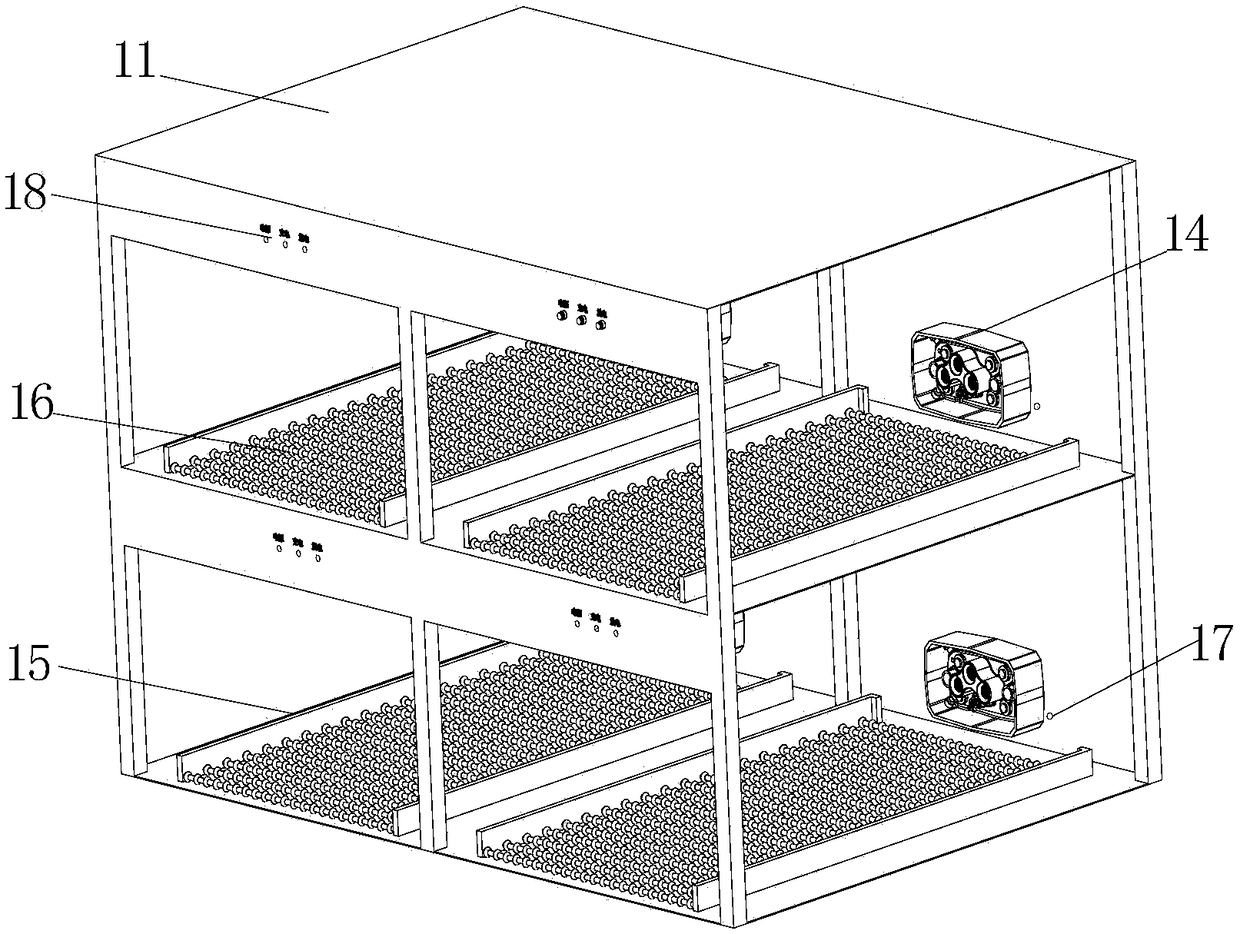

[0050] Such as Figure 1-2 As shown, the power battery automatic detection system includes the control system and the KBK crane 4 electrically connected to the control system, the feeding conveyor line 3, the guide rail robot 7, the testing frame 1, the testing equipment 2, the discharging conveyor line 6, and the battery parameters Automatic collection device, abnormal battery processing system. The battery parameter automatic collection device is used to collect battery safety parameters and transmit them to the control system. The abnormal battery processing system is a mobile abnormal battery safety disposal device 8. The abnormal battery processing system receives the signal sent by the control system and is used to process the abnormal power battery. Dispose of safely and move to a safe area. The devices of the detection system are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com