Method and production line for rapidly preparing aerogel through radio frequency radiation

A radio frequency radiation, aerogel technology, applied in aerogel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of security threats to the life safety of on-site personnel, unfavorable product quality labor costs, and many on-site operators. , to achieve the effect of improving the level of automation and safety control, shortening the process reaction time, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The radio frequency radiation rapid preparation airgel production line and preparation method of the present invention will be described in more detail below in conjunction with the accompanying drawings and through specific implementation methods.

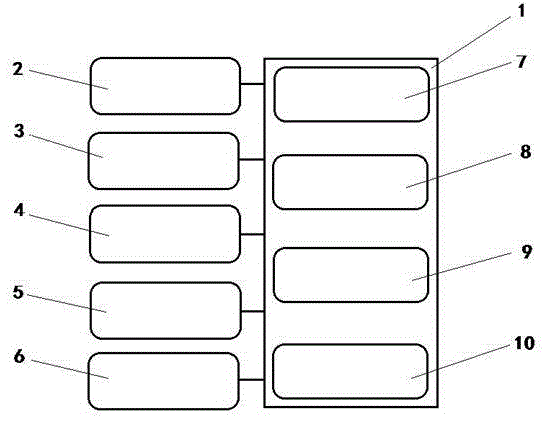

[0057] Such as figure 1 As shown, the radio frequency radiation rapid preparation airgel production line of the present invention includes a radio frequency radiation rapid preparation airgel host 1, a raw material system 2, an inert gas system 3, a heating system 4, a recovery system 5, and a waste treatment system 6; The airgel host 1 is rapidly prepared by radio frequency radiation, including a sol-gel section 7 , an aging section 8 , a replacement modification section 9 , and a drying section 10 .

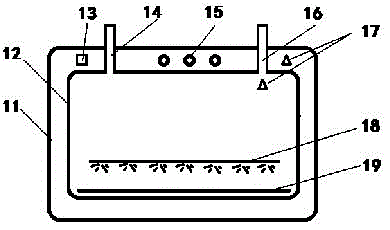

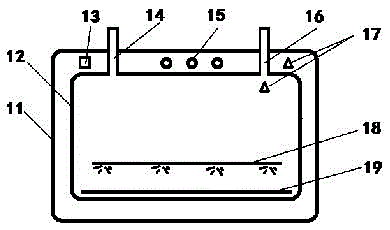

[0058] Such as figure 2 As shown, the sol-gel section 7 of the radio frequency radiation rapid preparation airgel host includes the outer box 11 of the host, the inner tank 12 of the host, the automatic control device 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com