Patents

Literature

376results about How to "Realize fully automatic production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unmanned kitchen

ActiveCN106516229ARealize fully automatic productionImprove production efficiencyCooking vesselsPackagingEngineeringMechanical engineering

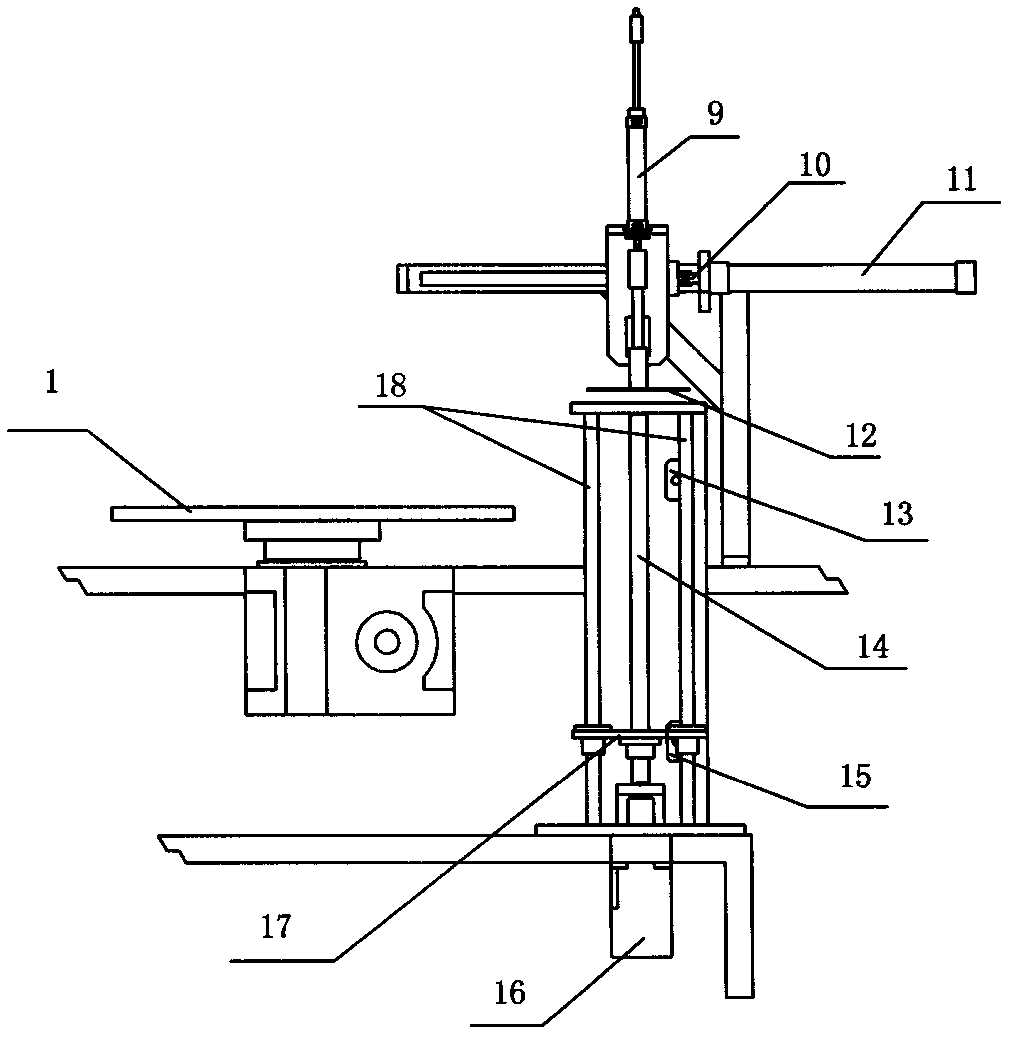

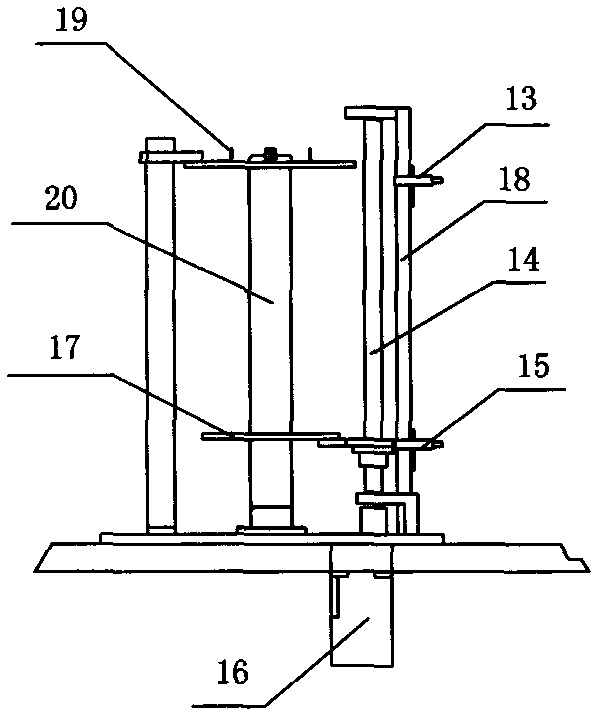

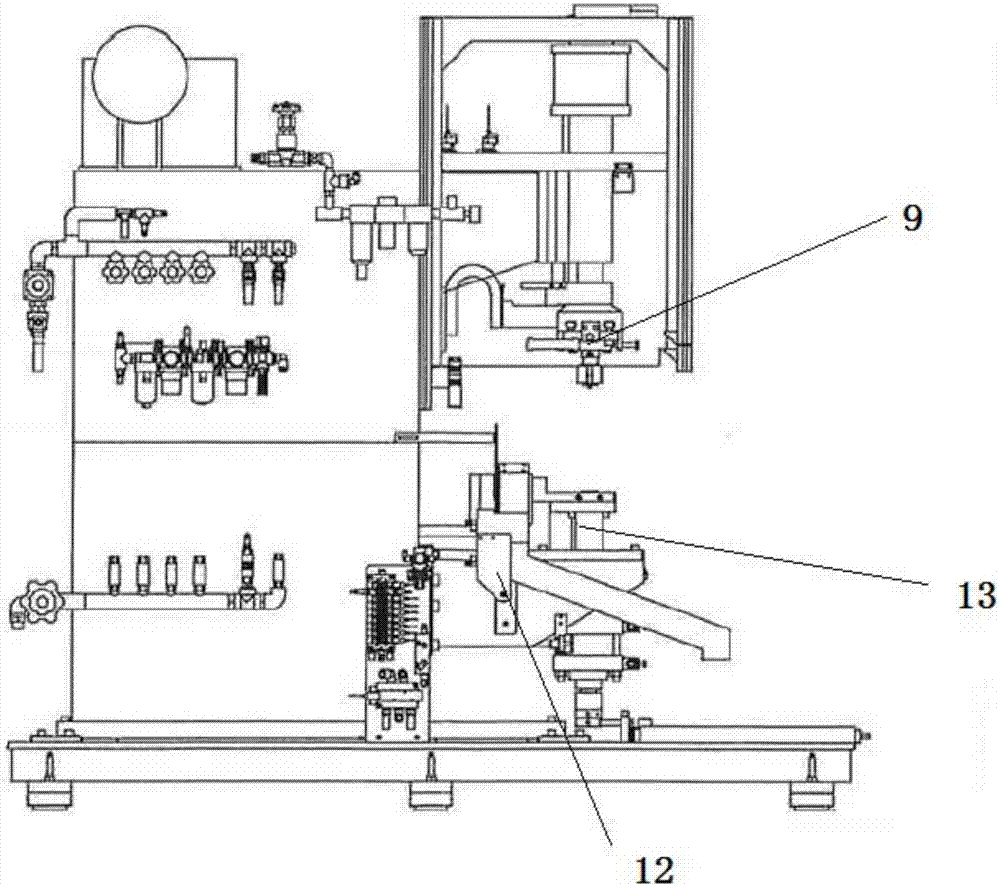

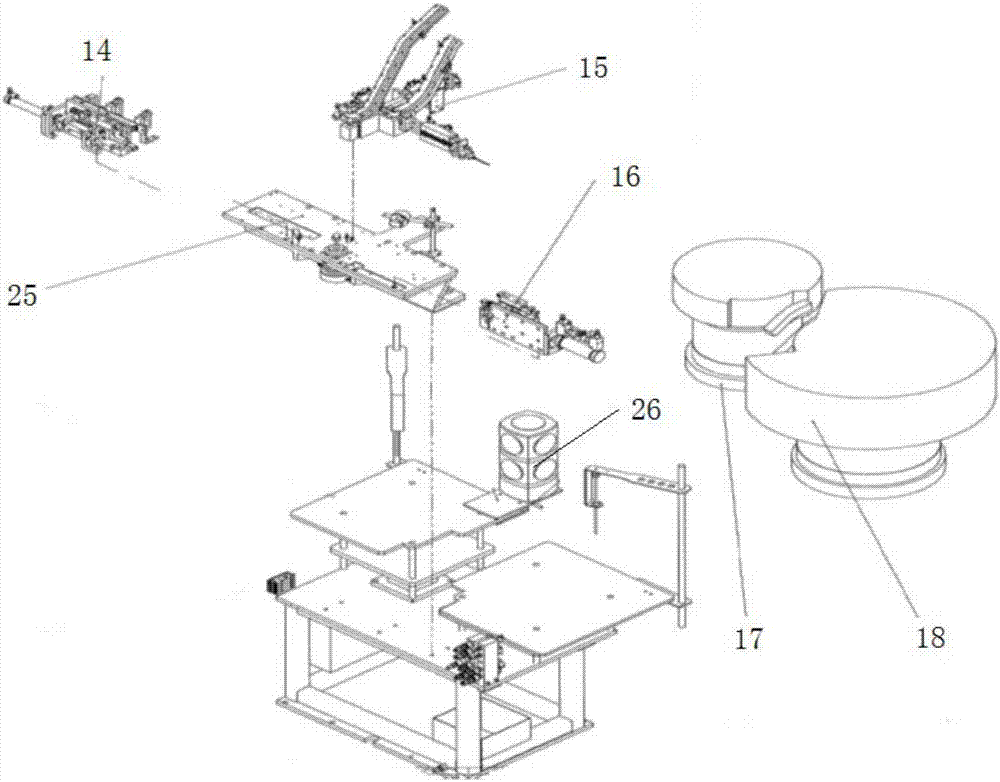

The invention discloses an unmanned kitchen. The unmanned kitchen comprises a clean vegetable cabinet, a clean vegetable box conveying device, placing racks, seasoning adding devices, a first conveying table, stir-frying machines, a second conveying table and a meal box sorting device, wherein the clean vegetable cabinet is formed through integrally connecting a main cabinet with an auxiliary cabinet with a sliding door; the clean vegetable box conveying device is formed through connecting a bracket, a disc sucker with a fixed rack; feeding devices are mounted on the placing racks; the seasoning adding devices are arranged on one sides of the placing racks; the stir-frying machines are positioned below the right sides of the seasoning adding devices; a plurality of box output control consoles and meal loading devices are mounted on the first conveying table; main bodies of the meal loading devices are formed through connecting pushing cylinders, lifting cylinders, clamping jaw cylinders, a plurality of linear bearings, guide rods with fixed plates; a meal box sealing device is arranged below the tail end of the first conveying table; the second conveying table is positioned at the back part of the meal box sealing device; and the meal box sorting device is formed through connecting a Y-direction moving seat, a clamping device with a meal box sucking device.

Owner:严福英

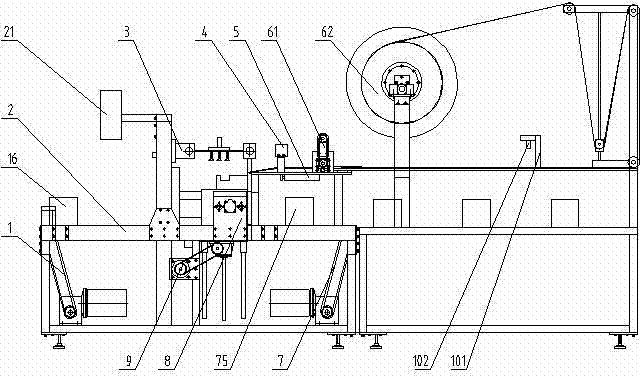

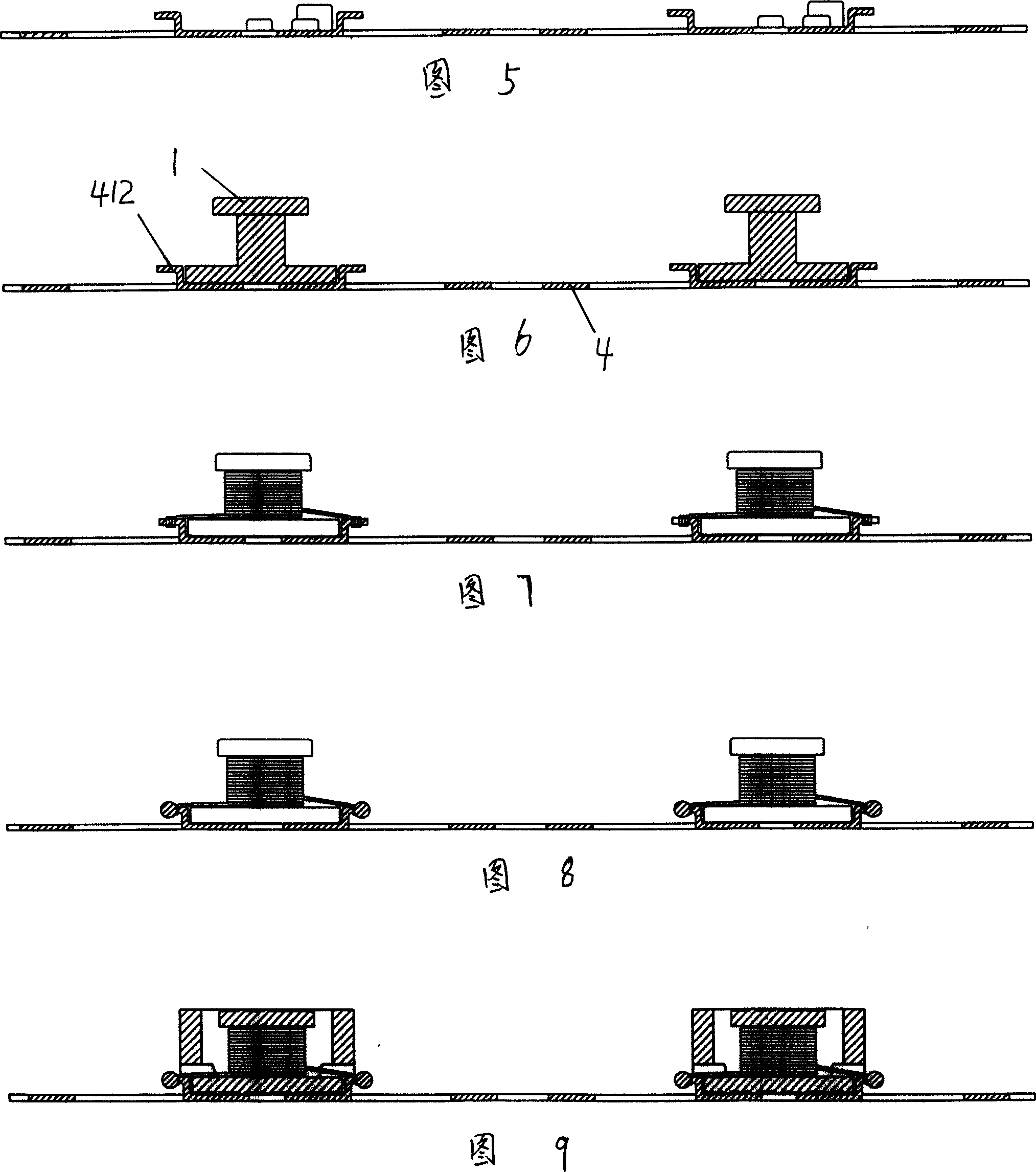

Automatic paper scrap-pressing device for combined fireworks

The invention discloses an automatic paper scrap-pressing device for combined fireworks, which comprises a fireworks external cylinder positioning mechanism and a circular paper scrap-pressing mechanism arranged on a rack. The automatic paper scrap-pressing device can automatically, quickly, conveniently and synchronously finish the processing and filling for the circular paper scrap of one product and can finish the processing for at least eight products per minute, so that the production efficiency is greatly increased. Since human factors are removed, the phenomenon of missing packaging or uneven circular paper scrap is avoided, and the product quality is ensured.

Owner:LIUYANG YIHELONG FIREWORKS GRP

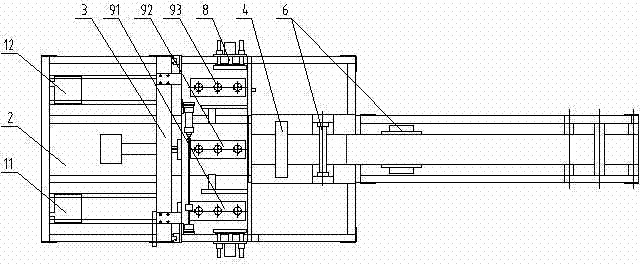

Medical glove lining paper packaging machine

ActiveCN104859881ARealize fully automatic productionEasy to useWrapper folding/bending apparatusWrappingPulp and paper industryMoving parts

The invention discloses a medical glove lining paper packaging machine which is sequentially provided with an unwinding part, a folding part, a cutter part, a transverse paper moving part, a left and right glove conveying part, a glove clamping part, a left and right folding part, a longitudinal paper moving part, a forward and backward folding part, a middle folding part, a finished product conveying part, and a long packet material receiving part or a short packet material receiving part or a long and short packet material receiving part. The machine is specially used for full-automatic production of medical glove lining paper packages, is simple and reasonable in structure, and is high in production efficiency. In the production process, left hand gloves and right hand gloves are conveyed separately, so that it is guaranteed that the phenomenon that two left hand gloves or two right hand gloves are arranged in the same package does not occur; meanwhile, empty packaging and half packaging are prevented, and packaging quality is guaranteed; an air blowing device is arranged so that the gloves can be sleeved more easily, and speed is increased; the produced medical glove lining paper packages are provided with folded parts, and it is guaranteed that the gloves are convenient to use, hygienic and absolutely safe; after medical glove lining paper is packaged, the lining paper is automatically collected and sorted in long packets or short packets according to free choices, and the lining paper can be used conveniently by users.

Owner:ZHEJIANG HONGCHANG MACHINERY

Full-automatic vertical mold-transferring hose injection head machine

InactiveCN101767402AIncrease productivityRealize fully automatic productionHollow articlesInjection molding machineInjection moulding

The utility model relates to a full-automatic vertical mold-transferring hose injection head machine. The machine comprises a stander, a vertical mold-transferring device, an injection molding device, a feeding device, a demoulding device and a power mechanism for driving the stander, the vertical mold-transferring device, the injection molding device, the feeding device, and the demoulding device, wherein a plurality of mold mandrels for fixing a hose are vertically arranged on four sides of the mold-transferring device respectively; the power mechanism drives the mold-transferring device to perform an periodic one-way 90 DEG rotation; the hose is correspondingly arranged on a plurality of mandrels on one side of the mold-transferring device by the feeding device; the hose top arranged on the mandrels is correspondingly molded into a hose head through injection by the injection molding device; the molded hose is correspondingly drawn out of the mandrels by the demoulding device; the plurality of the mandrels on each side of the mold-transferring device are circularly rotated among the feeding device, the injection molding device and the demoulding device; and the feeding device, the injection molding device and the demoulding device perform corresponding to-and-fro motions so as to realize automatic hose delivery, hose head molding and finished product recovery. The full-automatic mold-transferring hose injection head machine realizes full-automatic production of PE plastic hose injection head process.

Owner:朱海宁

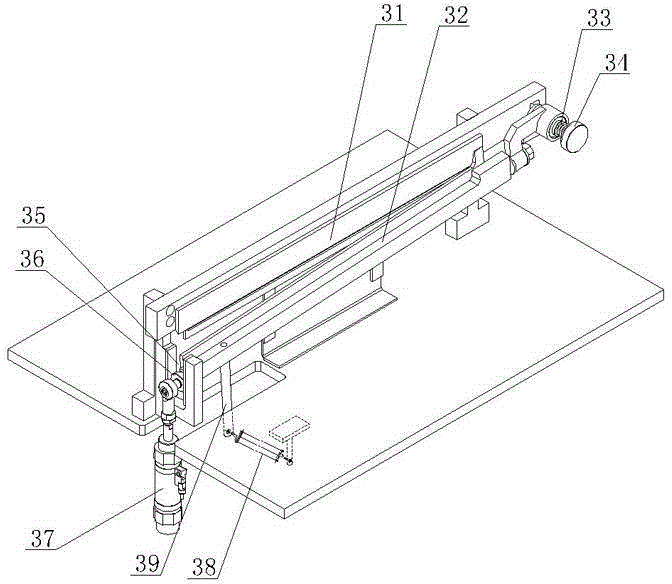

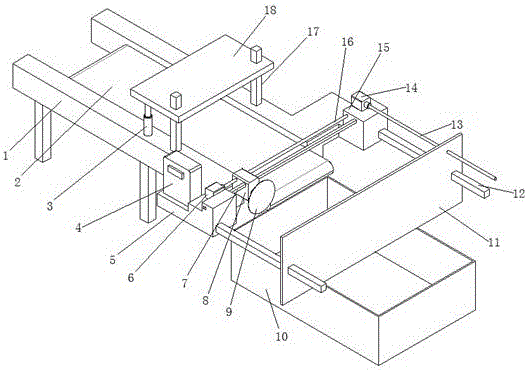

Plate cutting device

InactiveCN105834504ARealize fully automatic productionIncrease productivityShearing machinesMetal working apparatusCouplingElectric machinery

The invention discloses a plate cutting device. The plate cutting device comprises a main support, a conveying device is arranged in the middle of the main support, electric telescopic rods are arranged on the two sides of the conveying device, the upper ends of the electric telescopic rods are connected with a pressing plate, and third guide rods are mounted on the front sides of the electric telescopic rods; through holes in sliding connection with the third guide rods are formed in the pressing plate, and a pressing block is arranged on the lower side face of the pressing plate; one end of the main support is connected with a first auxiliary support and a second auxiliary support, a first guide rod is arranged between the first auxiliary support and the second auxiliary support, and a cutting motor is in sliding connection to the first guide rod; and a blade is fixed to an output shaft of the cutting motor, a first stepping motor is mounted on the first auxiliary support, and an output shaft of the first stepping motor is connected with one end of a first lead screw through a coupler. The plate cutting device can achieve full-automatic production, an automatic compressing mechanism is adopted, the machining precision is high, and high-precision large-batch production can be achieved.

Owner:周玉翔

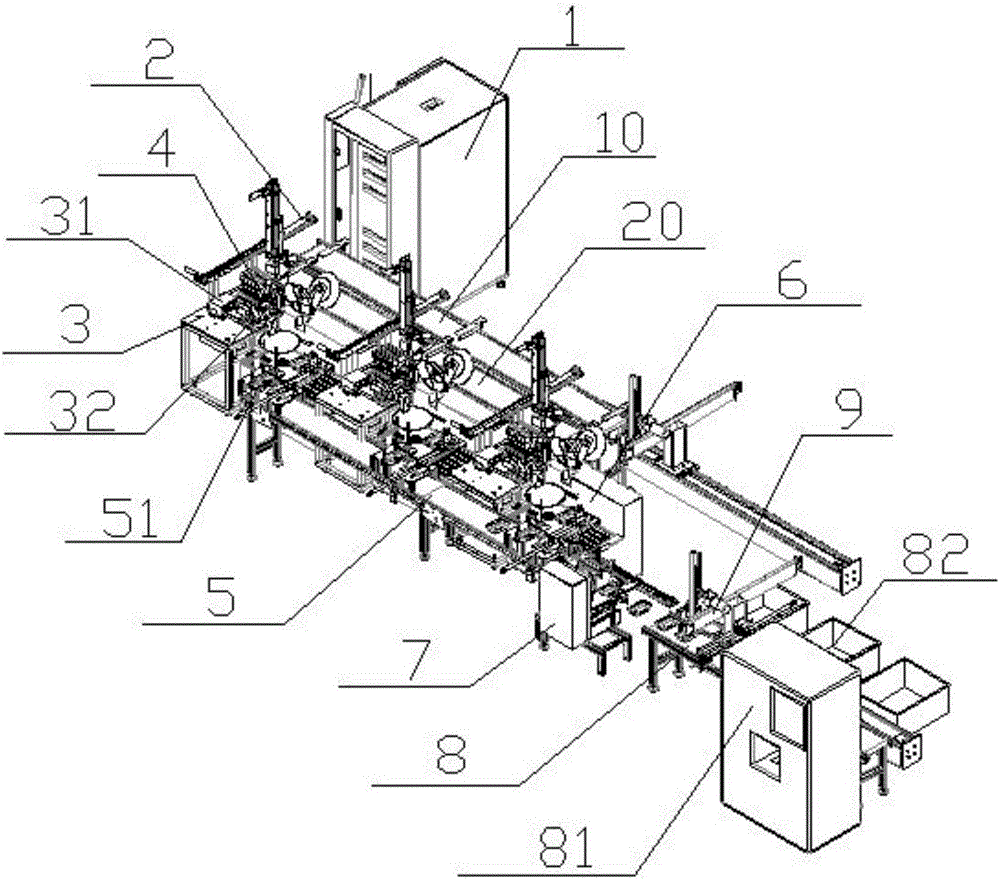

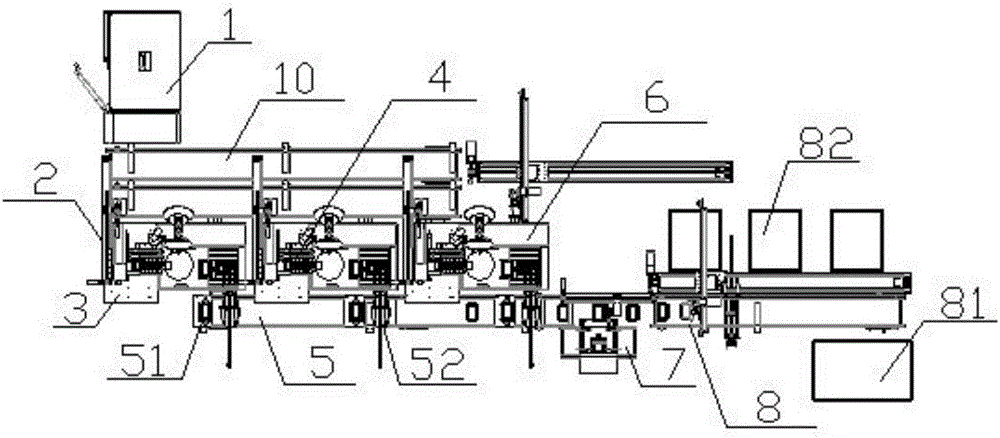

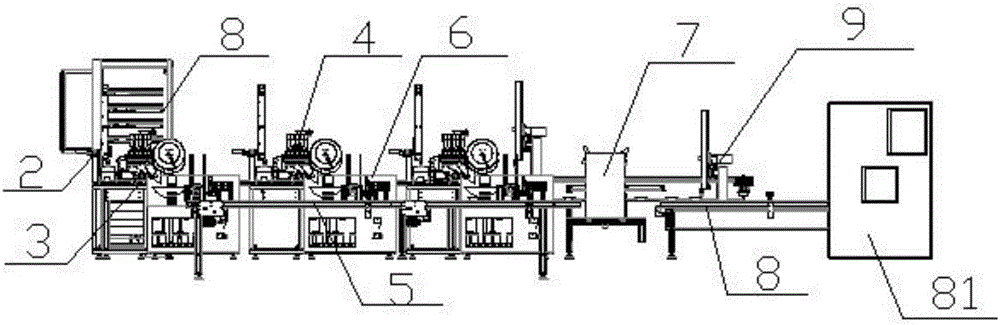

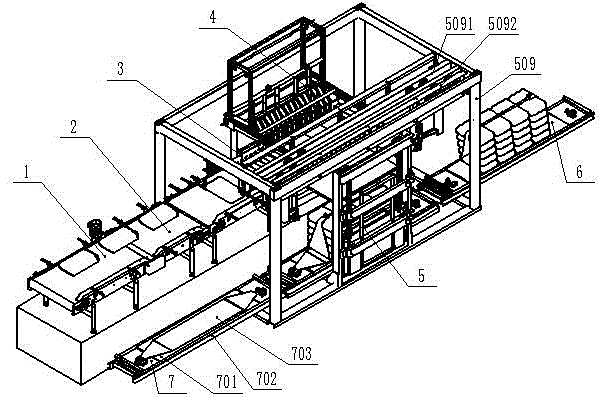

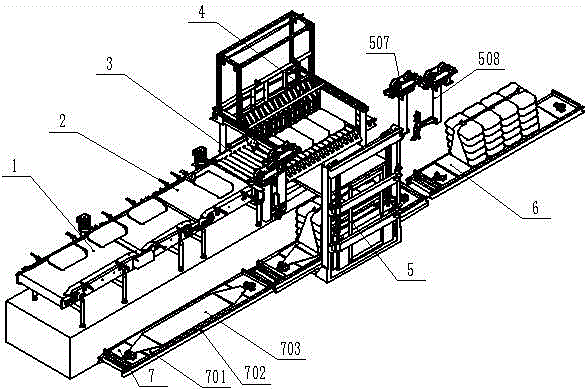

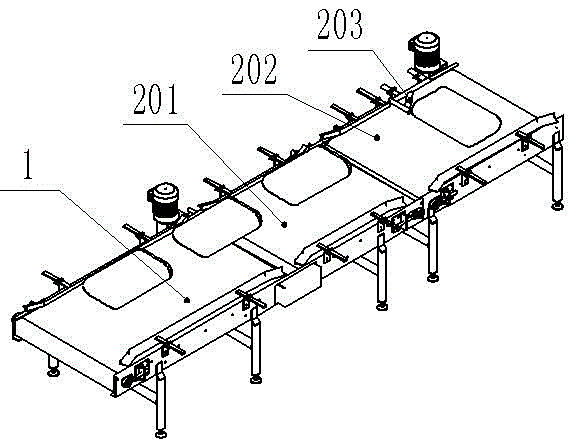

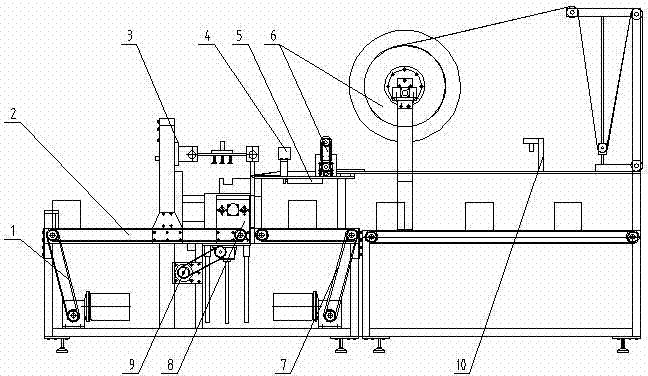

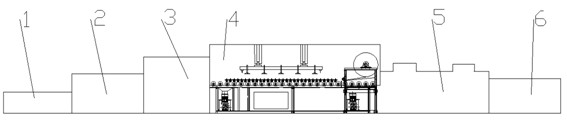

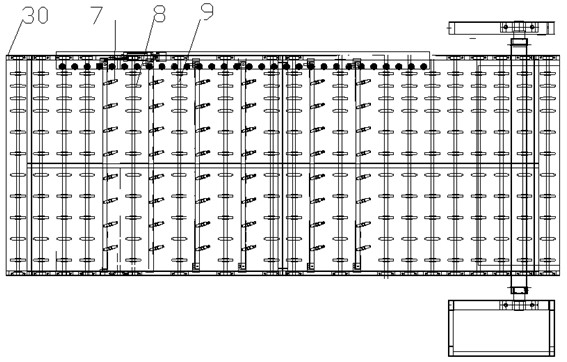

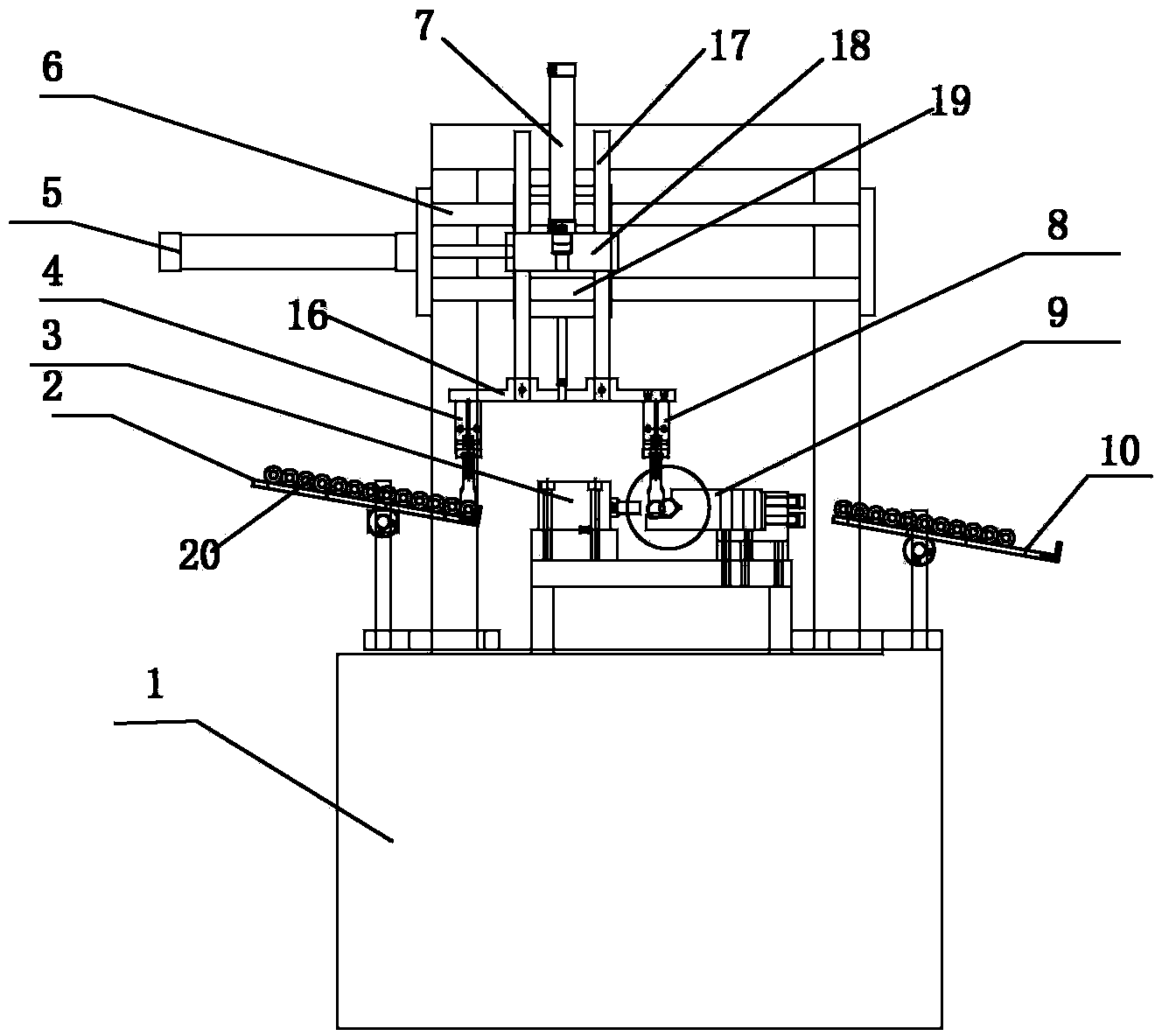

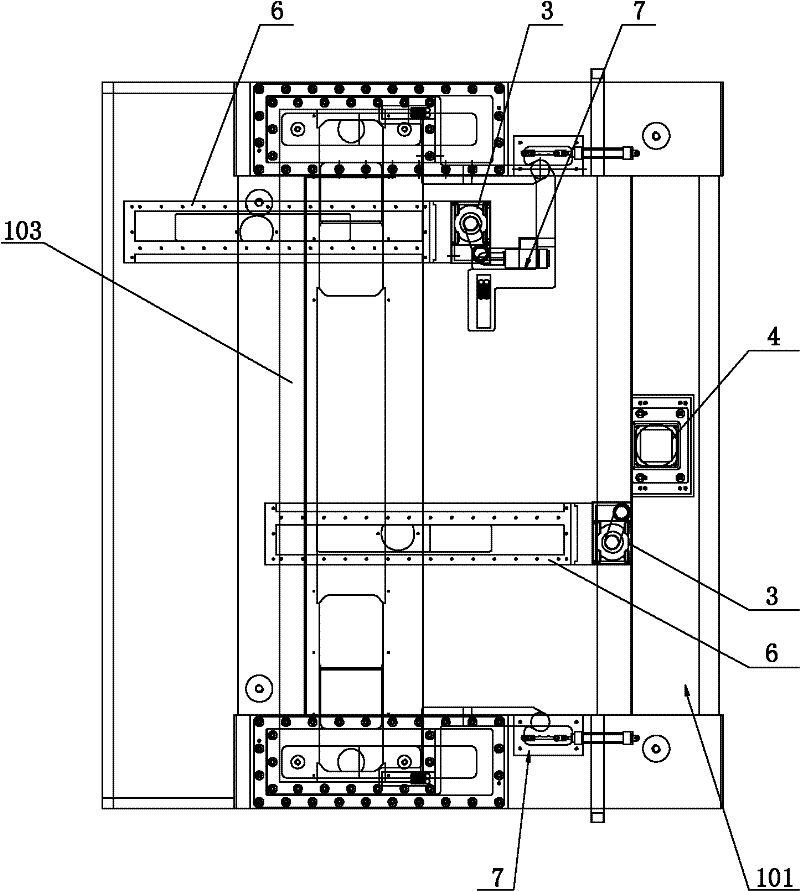

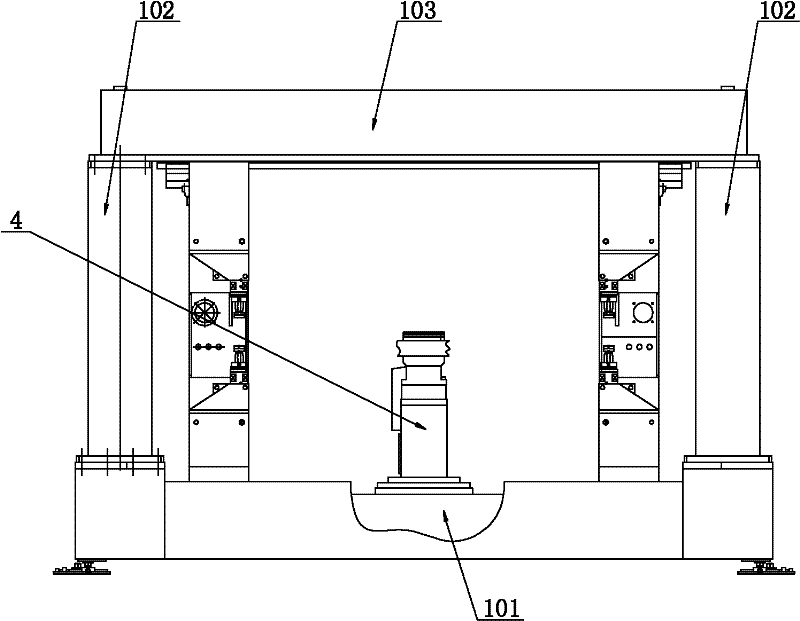

Automatic production line for goods stacking and packaging

InactiveCN105540218AReduce wasteRealize fully automatic productionConveyorsBinding material applicationProduction lineEngineering

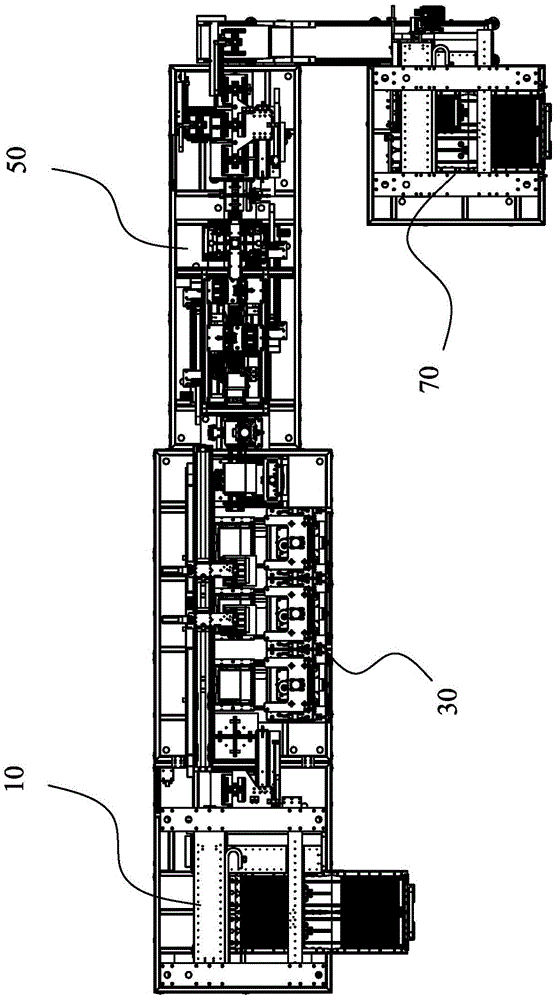

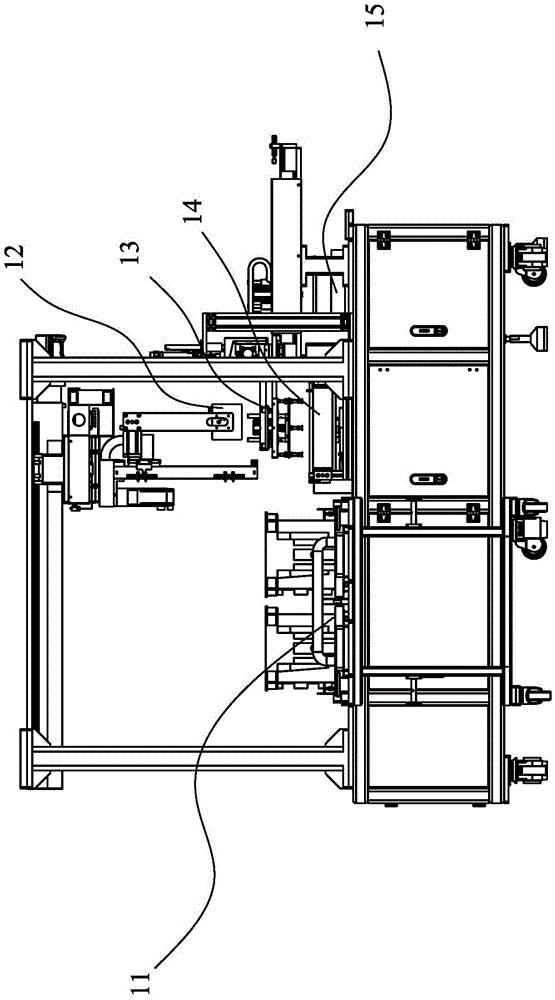

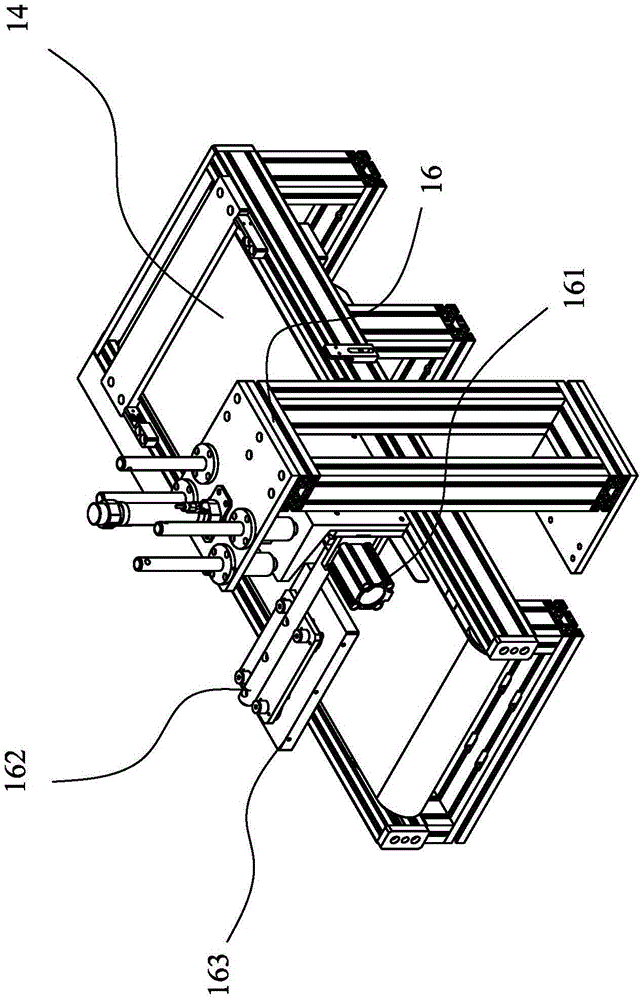

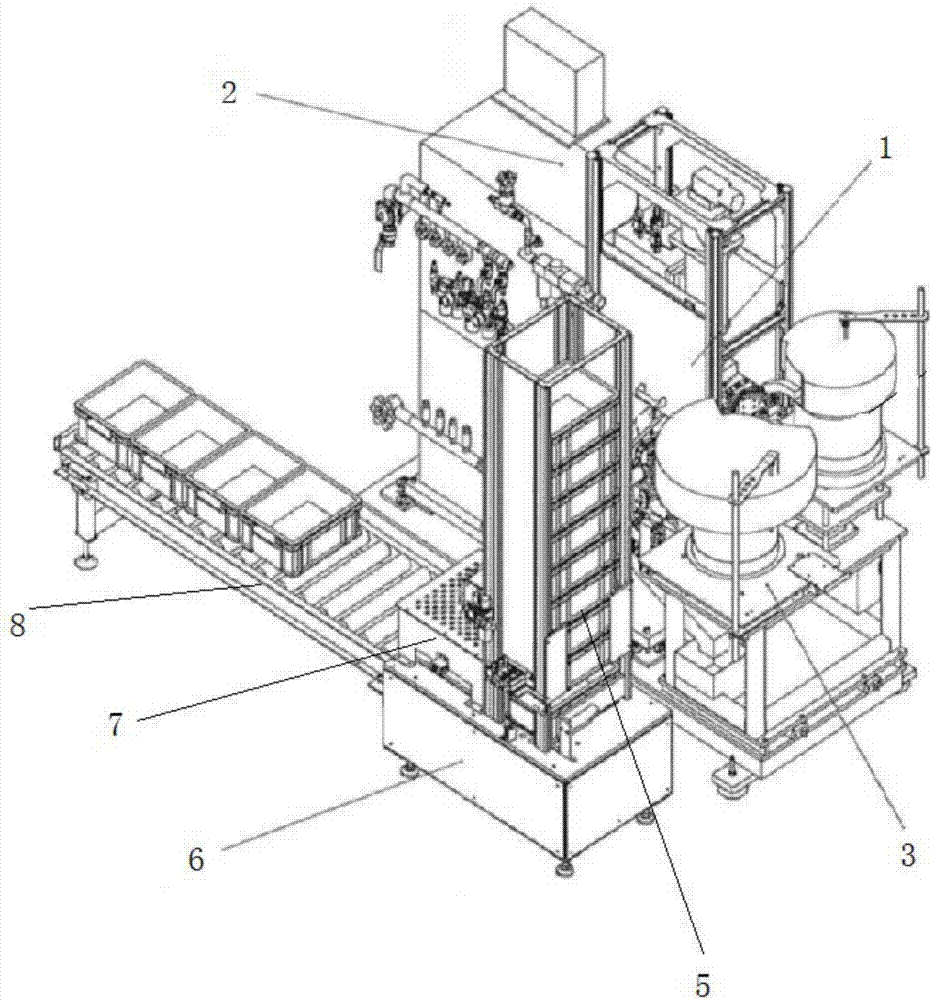

The invention provides an automatic production line for goods stacking and packaging, comprising an input mechanism (1), a posture adjusting mechanism (2), an arranging mechanism (3), a push mechanism (4), a stacking and packaging mechanism (5), an output mechanism (6) and a tray input mechanism (7), wherein the posture adjusting mechanism (2) is used for drawing a material away for a certain distance for posture adjustment, the arranging mechanism (3) completes the ordered arrangement of the material, the push mechanism (4) pushes the material to the next procedure, the stacking and packaging mechanism (5) is used for stacking and packaging the material, and the output mechanism (6) is used for conveying the packaged material out of the production line to a designated place. According to the invention, full automation of material input, arrangement, stacking, packaging and output are realized, production efficiency is improved, and labor force is liberated; during stacking and packaging, no impact is caused and bag breaking is uneasy to cause, so that resource waste is reduced; and human participation is not needed, and the whole production line can be sealed, thus being environment-friendly and having no pollution.

Owner:CHINA JILIANG UNIV

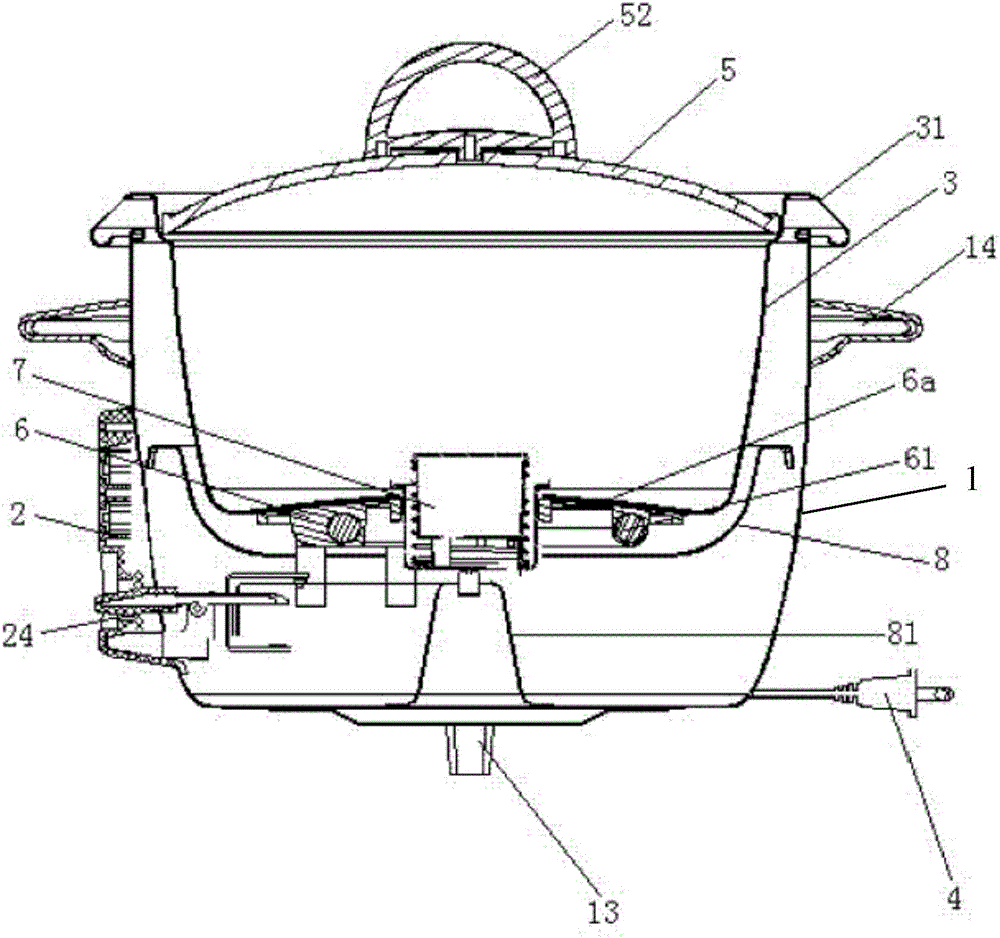

Electric cooker with post-fermentation function and making method of fermented foods

ActiveCN104095518AReduce operational complexityRealize fully automatic productionWarming devicesFood scienceBacillus nattoAutomotive engineering

Disclosed are an electric cooker with a post-fermentation function and a making method of fermented foods. The electric cooker includes an electric rice cooker, an electric soup pot, an electric hot pot, an electric stewpot, an electric steamer, a normal-pressure electric wok including an electric frying wok, a high-pressure electric pot, an electric kettle, a bread maker and a steamed bun maker. A control device of the electric cooker is provided with a fermented food making control program. The making method of the fermented foods includes a pre-treatment phase A, a cooking phase B, a cooling phase B1 and a fermenting phase C. The electric cooker and the making method of the fermented foods have the advantages that the soaking, steaming, bacteria mixing and fermenting steps required by the making of homemade natto are combined in a whole, and the whole course of soaking, cooking, cooling and fermenting can be automatically completed just after a user put food materials, water and edible fermentation bacteria into an inner pot or inner bucket of the electric cooker at one time and presses a button to start the electric cooker, the process is very simple and easy, complexity in making of the homemade natto is greatly reduced, and accordingly, full-automatic making of the natto is achieved and the development trend of the modern society is met.

Owner:王晓东

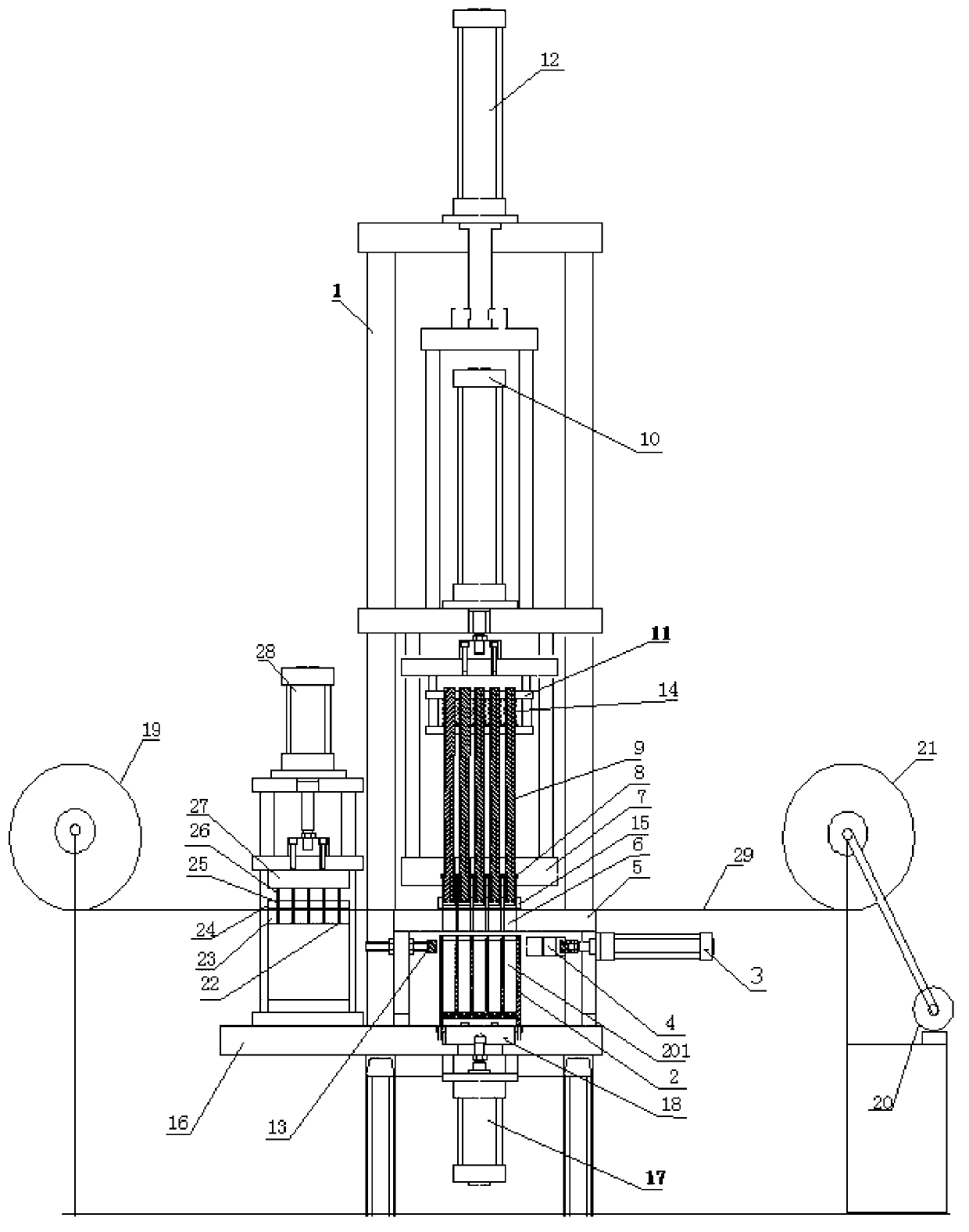

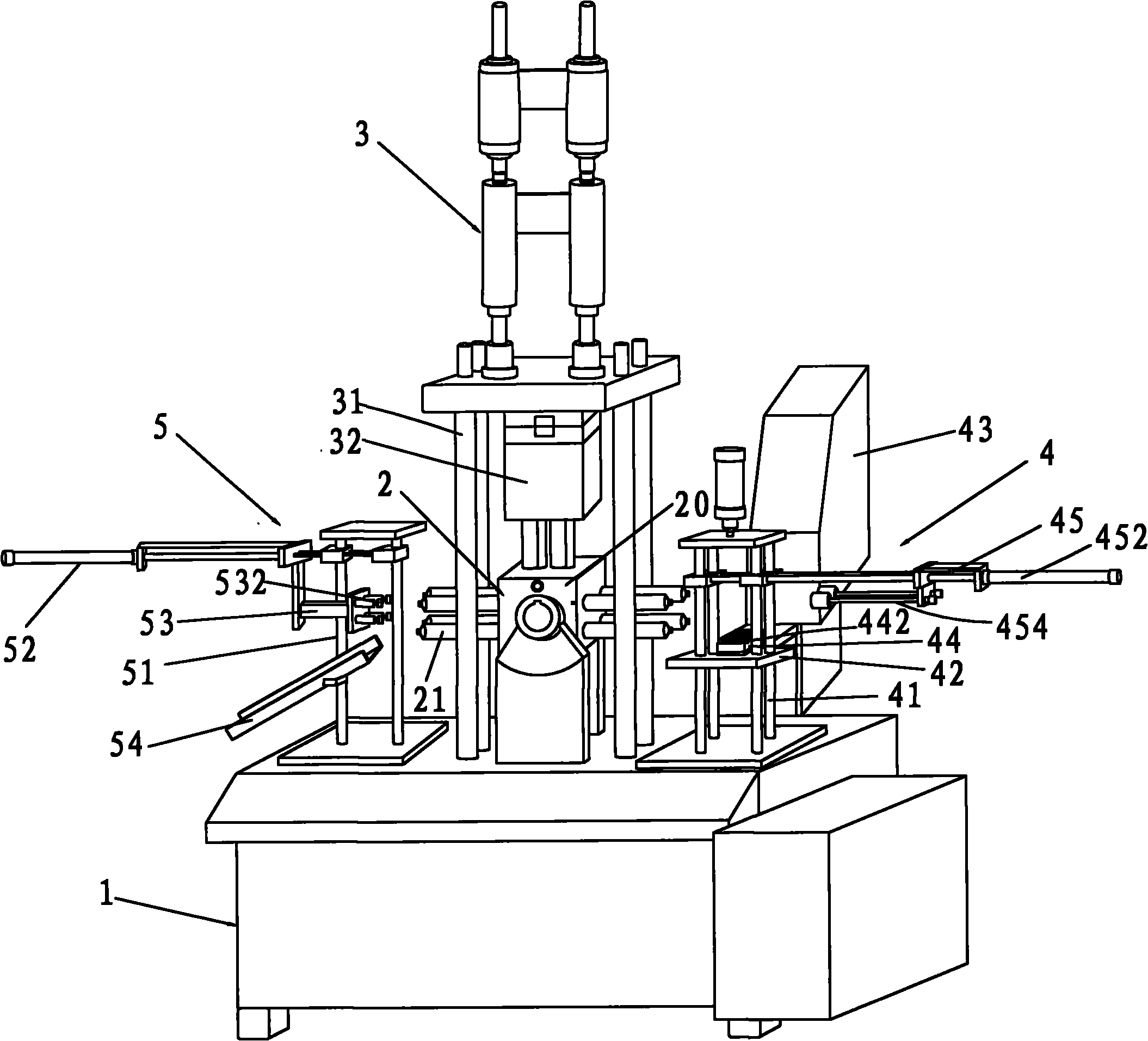

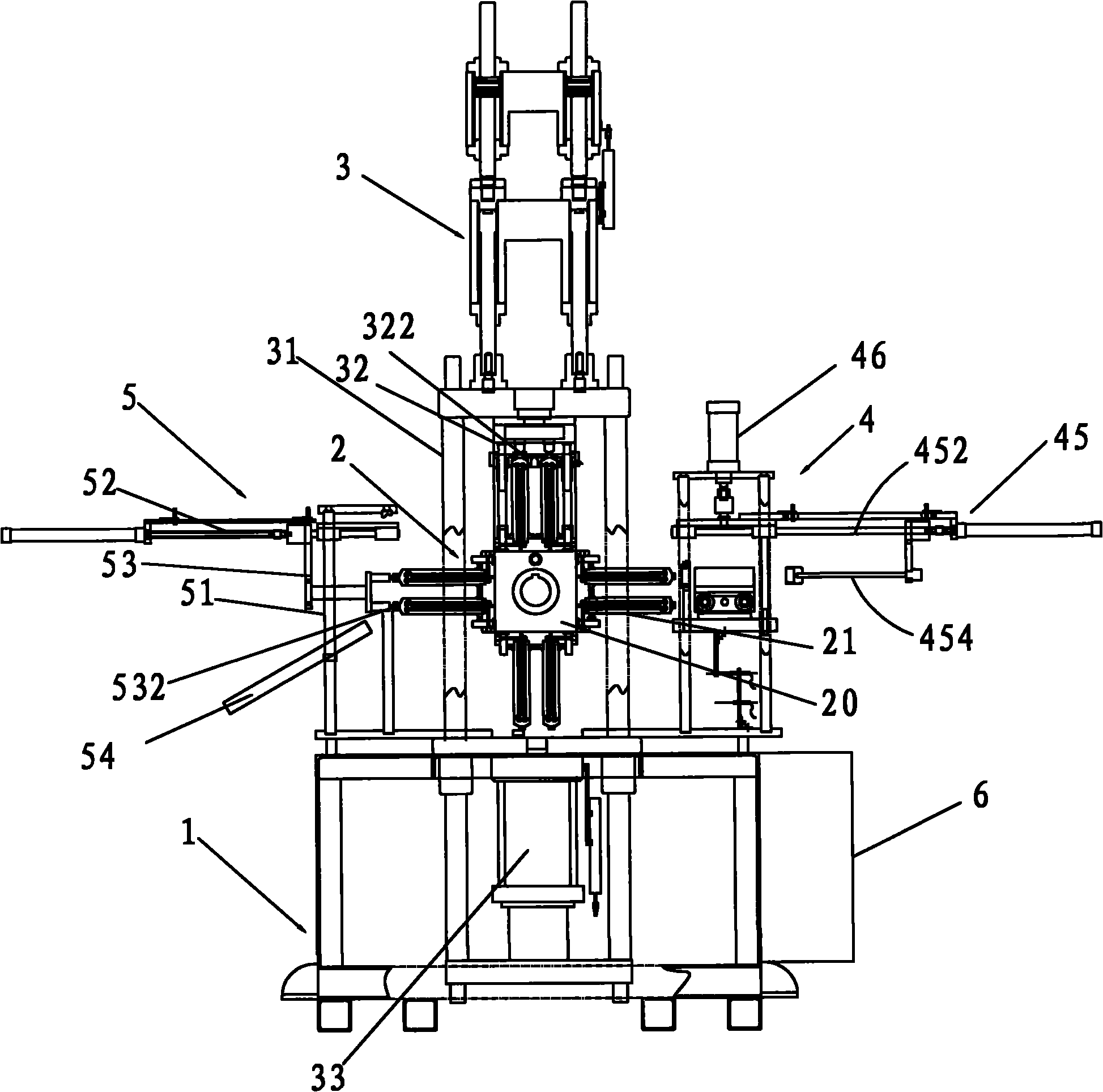

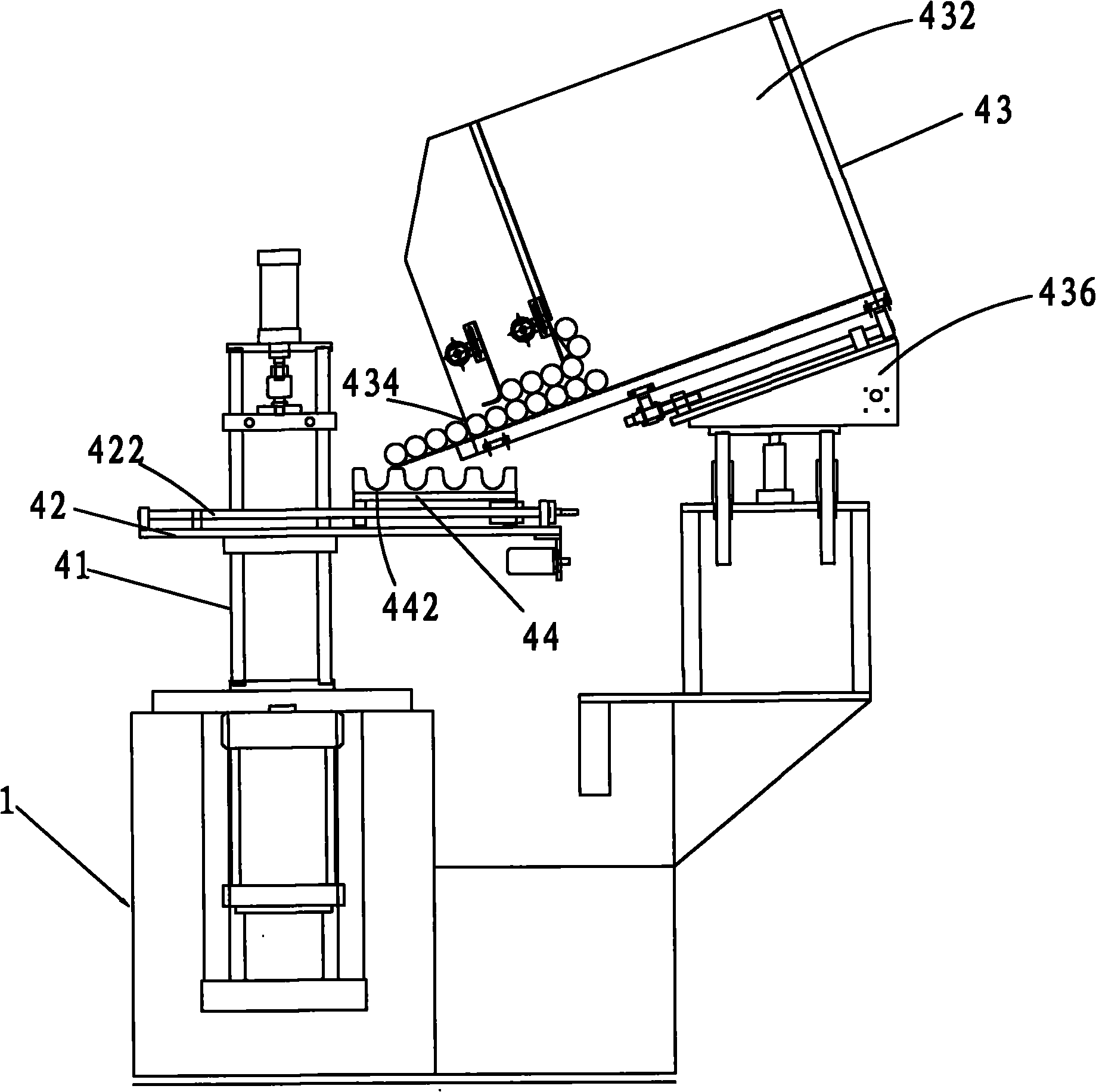

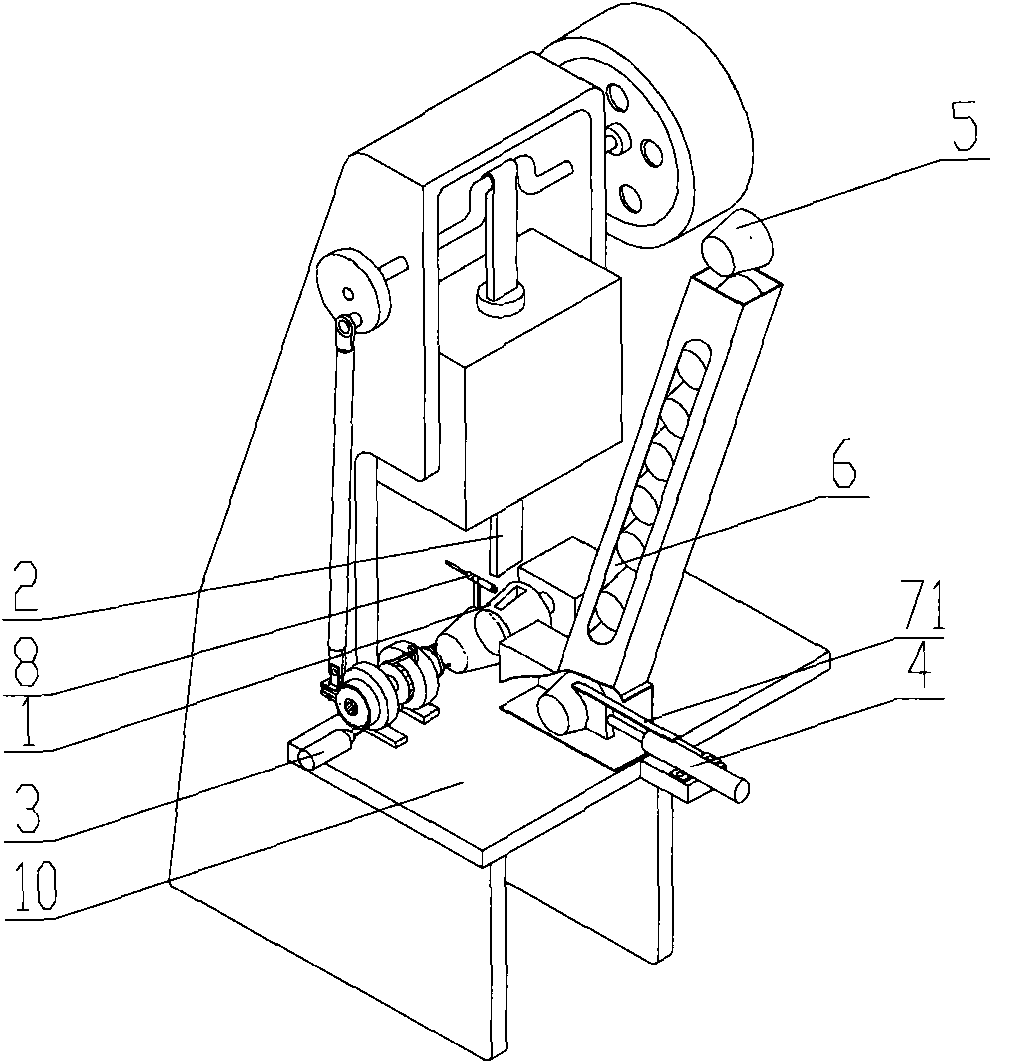

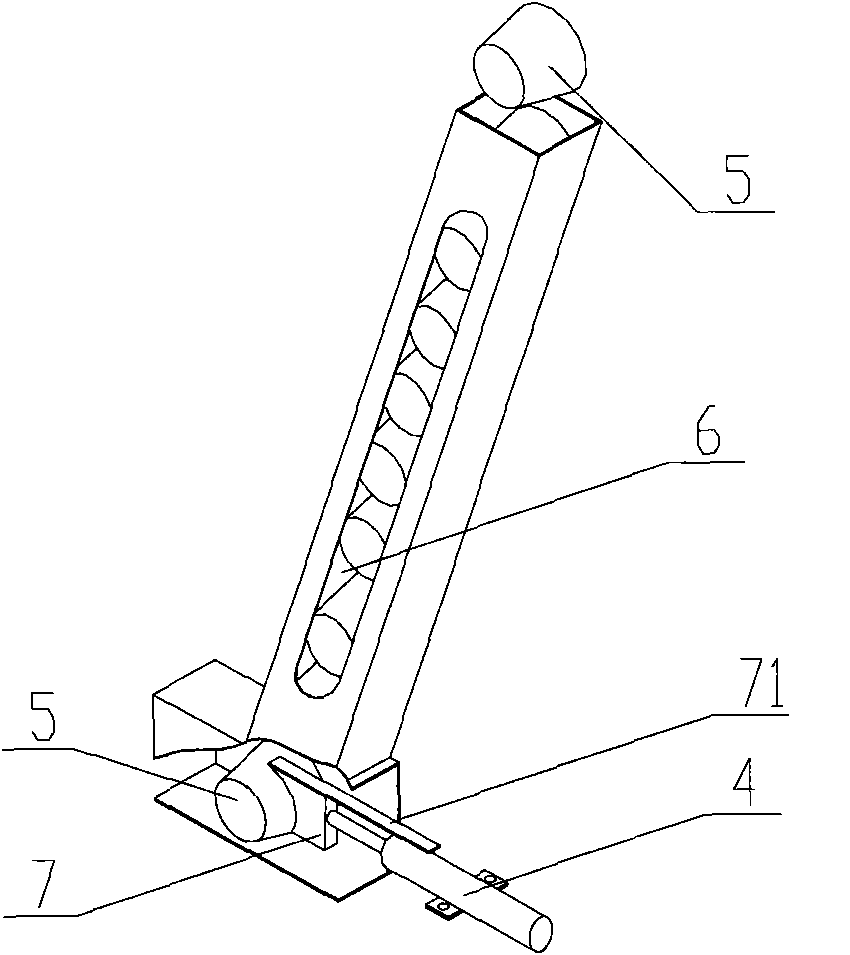

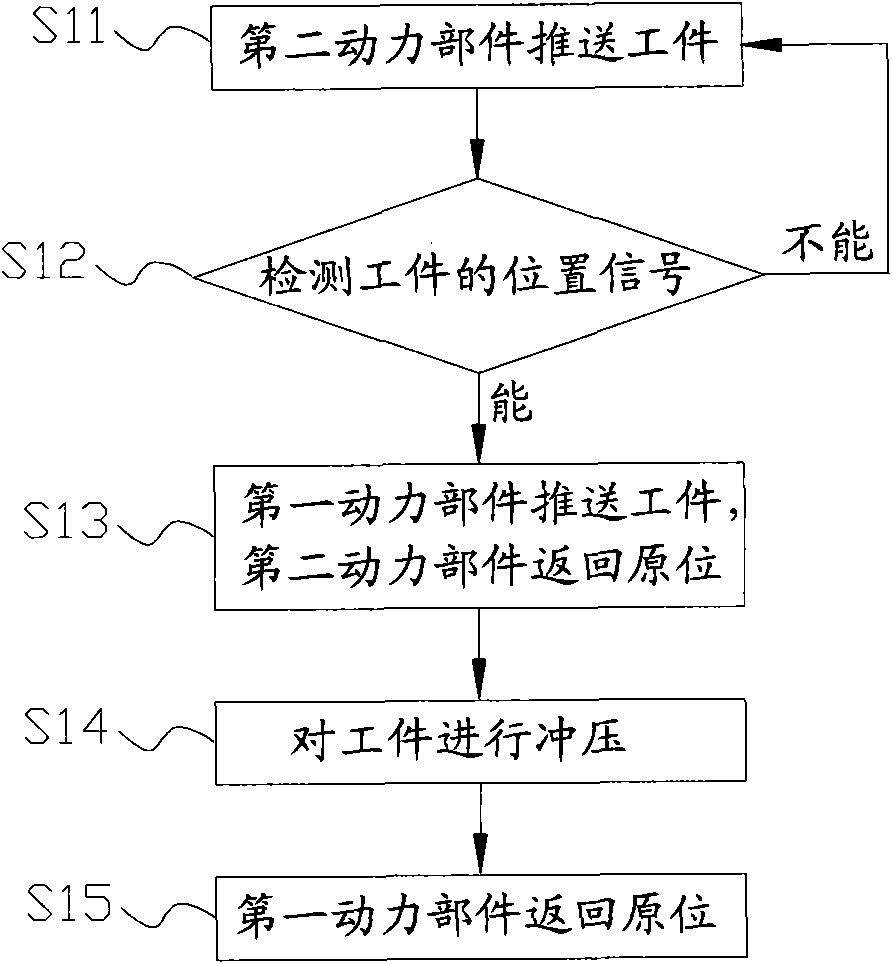

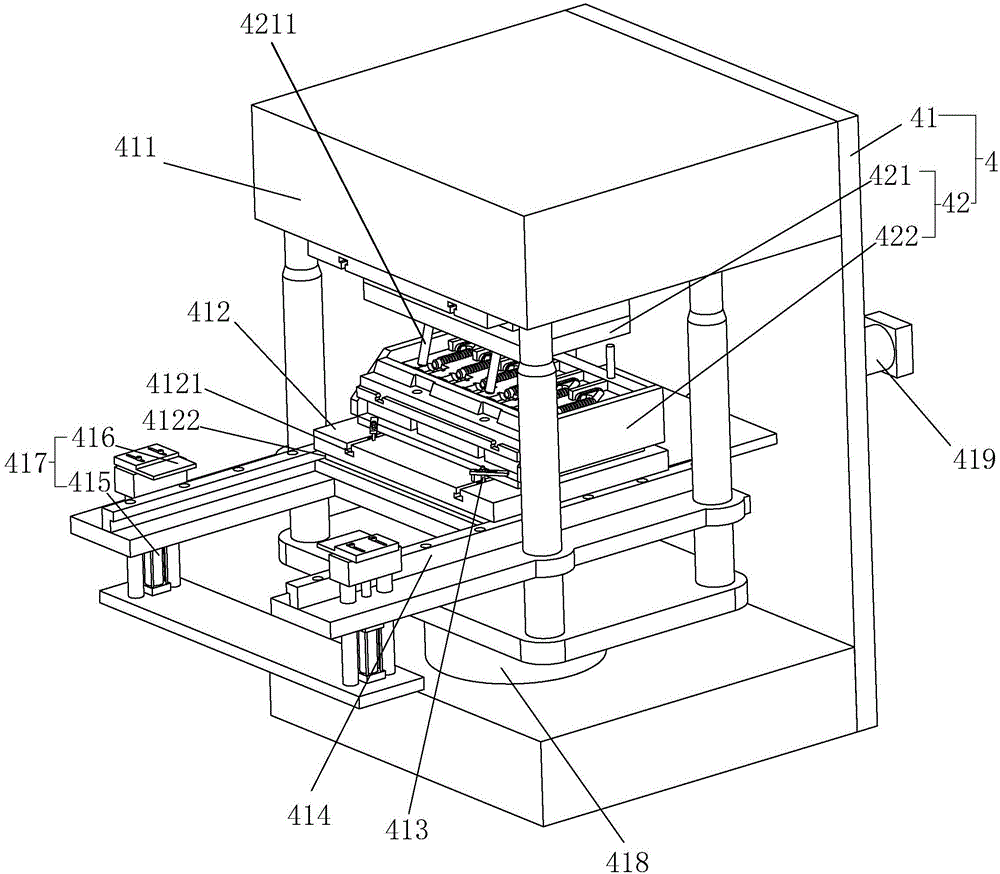

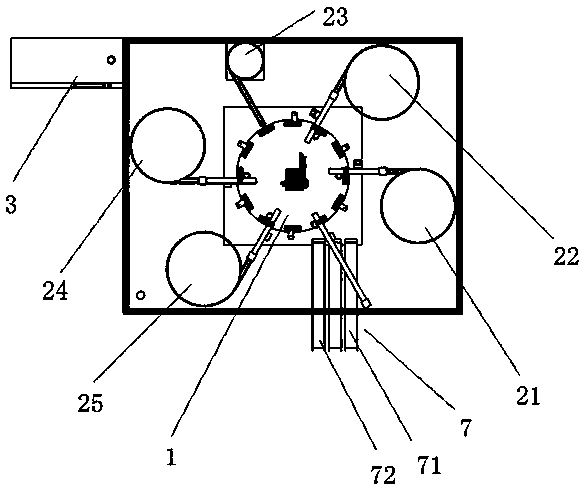

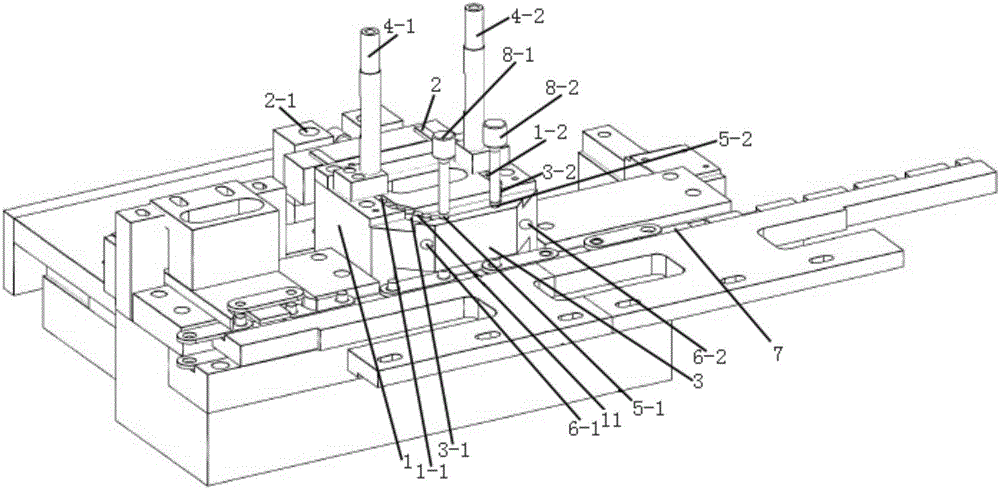

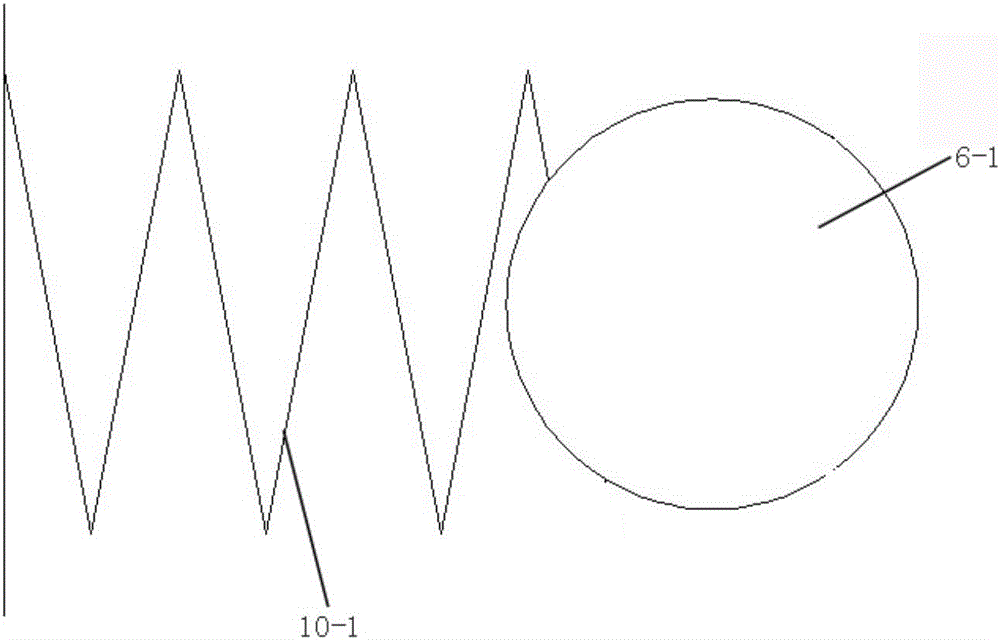

Processing equipment for bearing cage

ActiveCN101912918AImprove stabilityReduce insecurityMetal-working feeding devicesPositioning devicesPower componentProduction quality

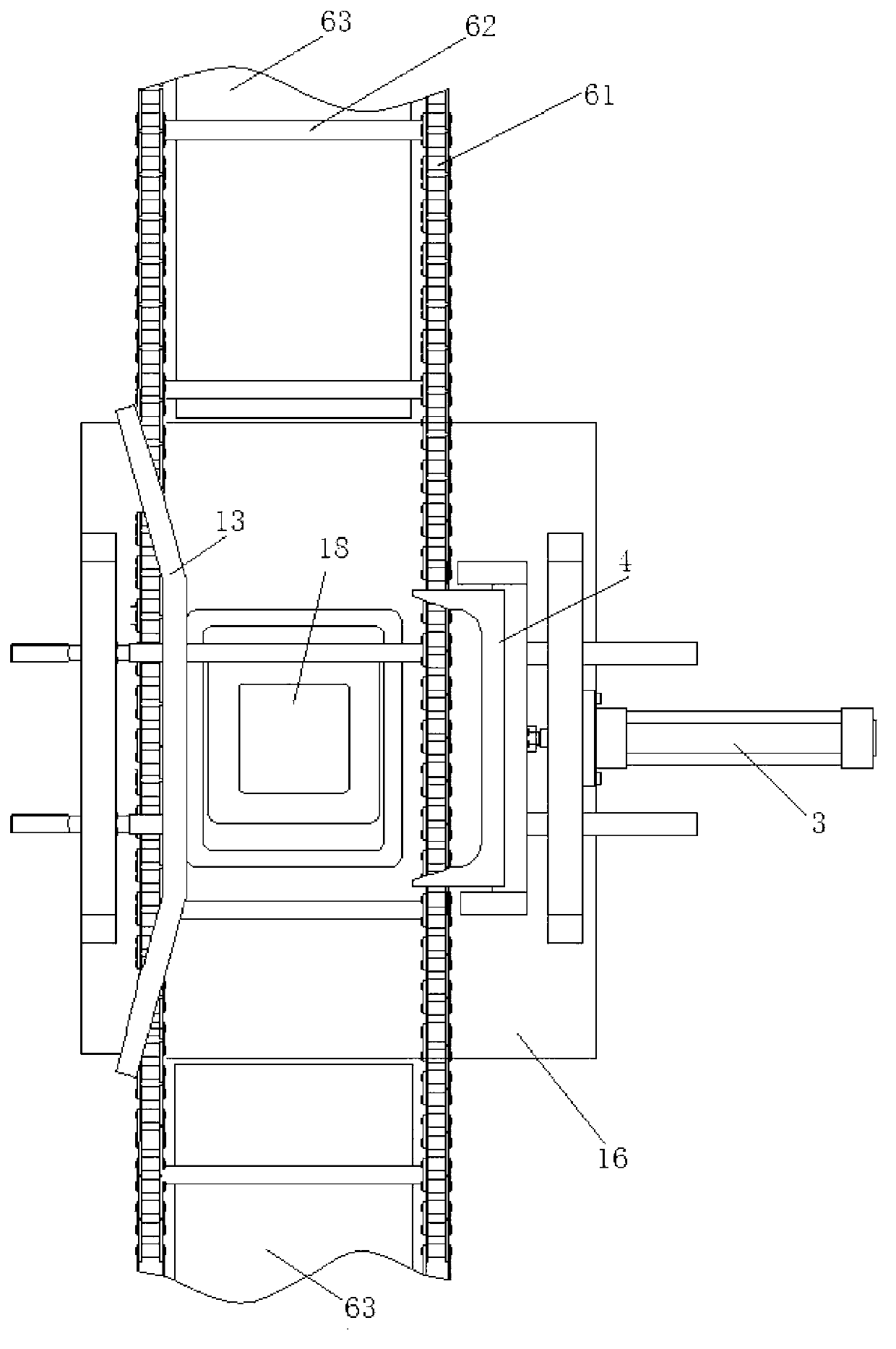

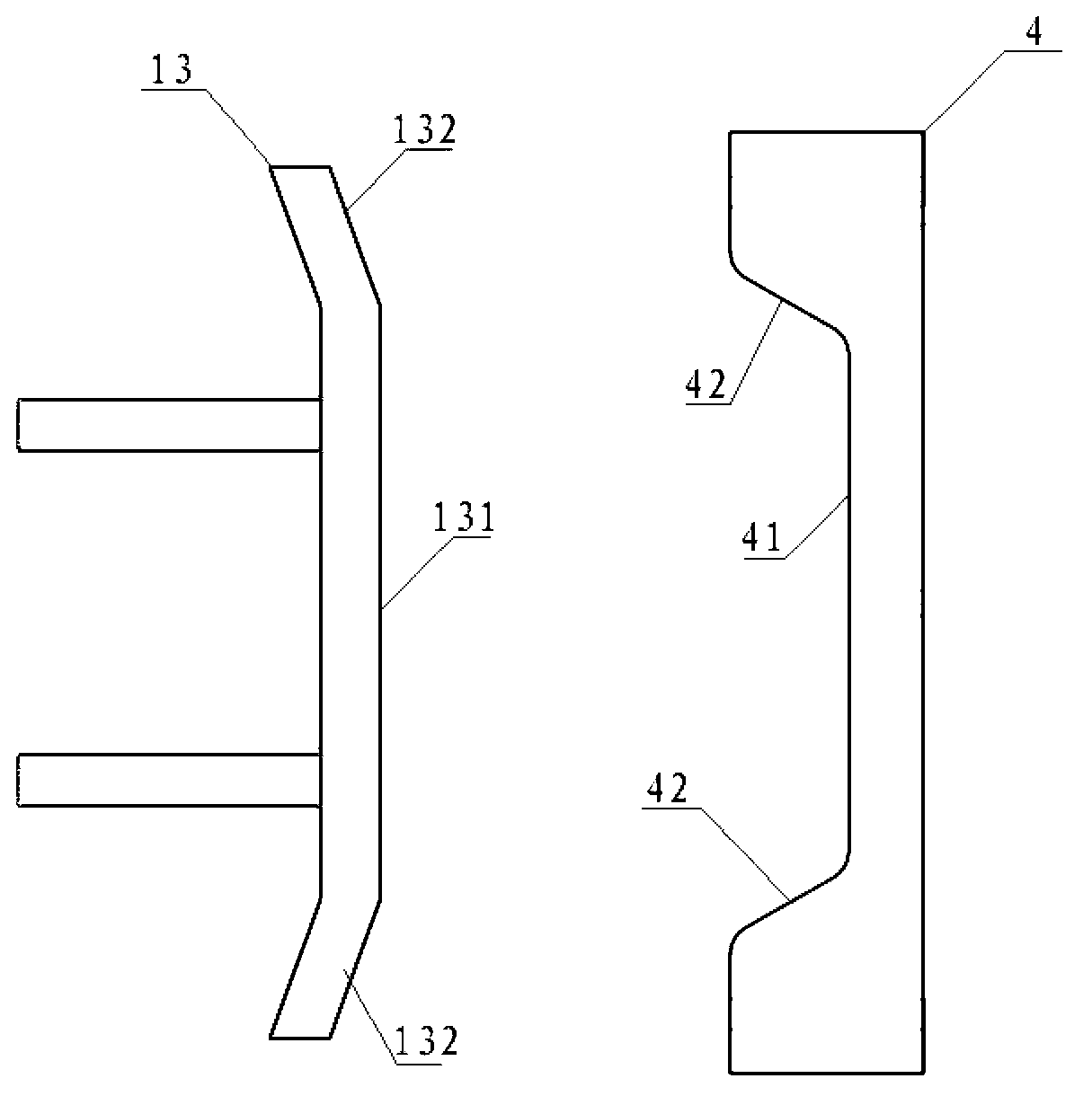

The invention discloses processing equipment for a bearing cage. The equipment comprises a female die (1), a male die (2), a first power component and an automatic feeding device, wherein the female die (1) and the male die (2) are used for punching a workpiece (5); the first power component (3) pushes the workpiece (5) until the workpiece (5) is sleeved outside the female die (1); the automatic feeding device is provided with a second power component (4); the power direction of the second power component (4) and the power direction of the first power component (3) form a preset angle; and the workpiece (5) is pushed to a preset position through the second power component (4), and then pushed to the female die (1) through the first power component (3). The processing equipment has the advantages of effectively improving the production efficiency of the bearing cage, reducing the effects of personal factors on the bearing cage and enhancing the production quality of the bearing cage.

Owner:SHANDONG GOLDEN EMPIRE PRECISION MACHINERY TECH CO LTD

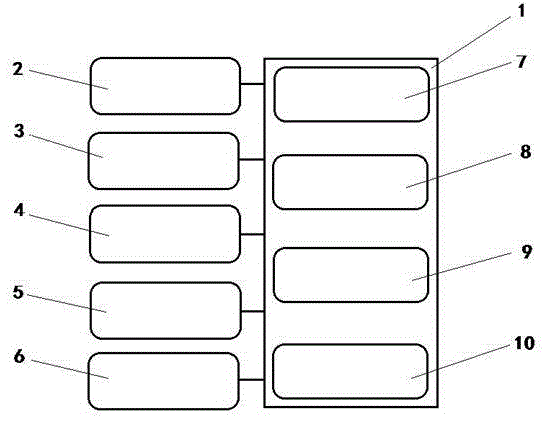

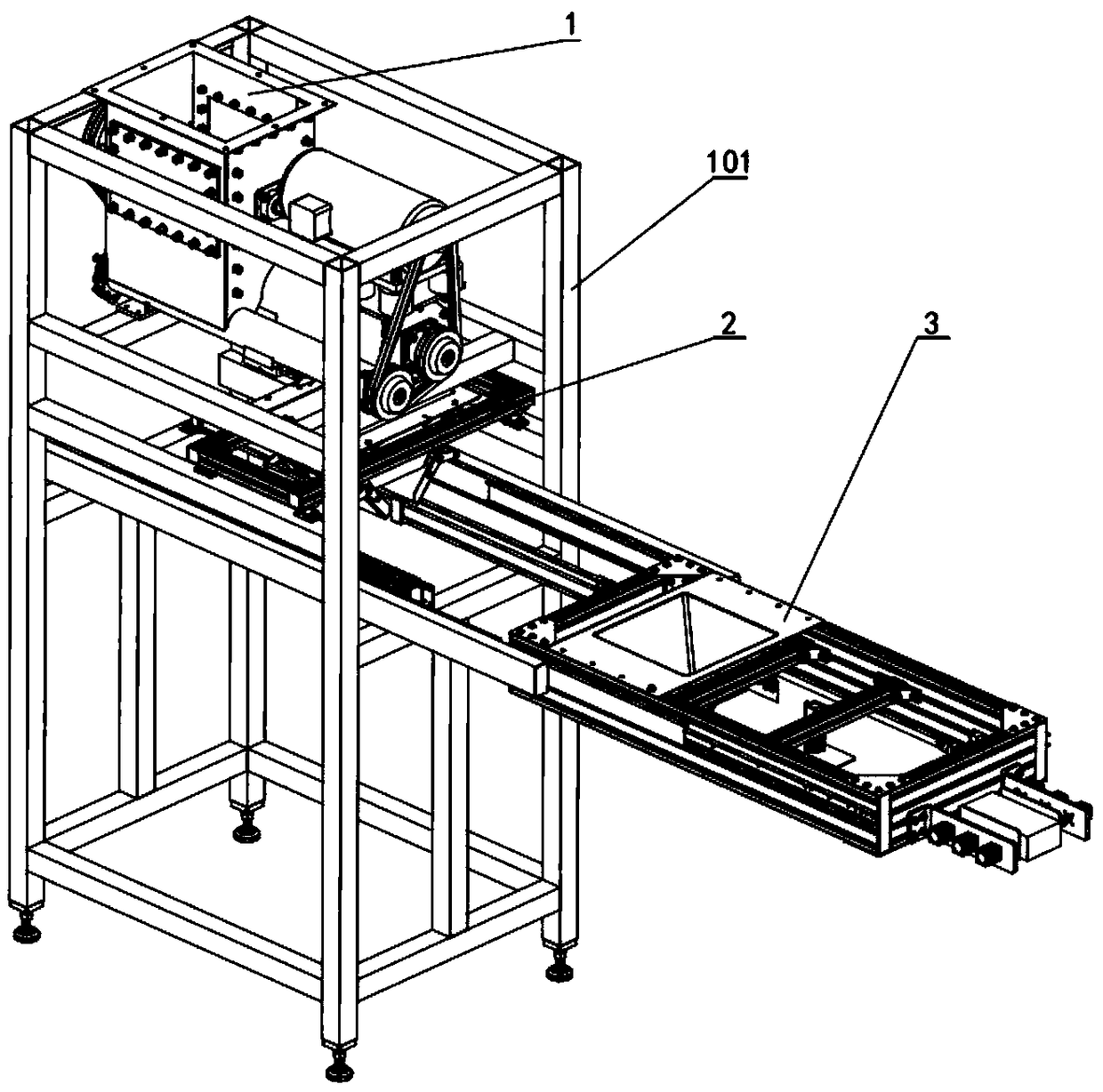

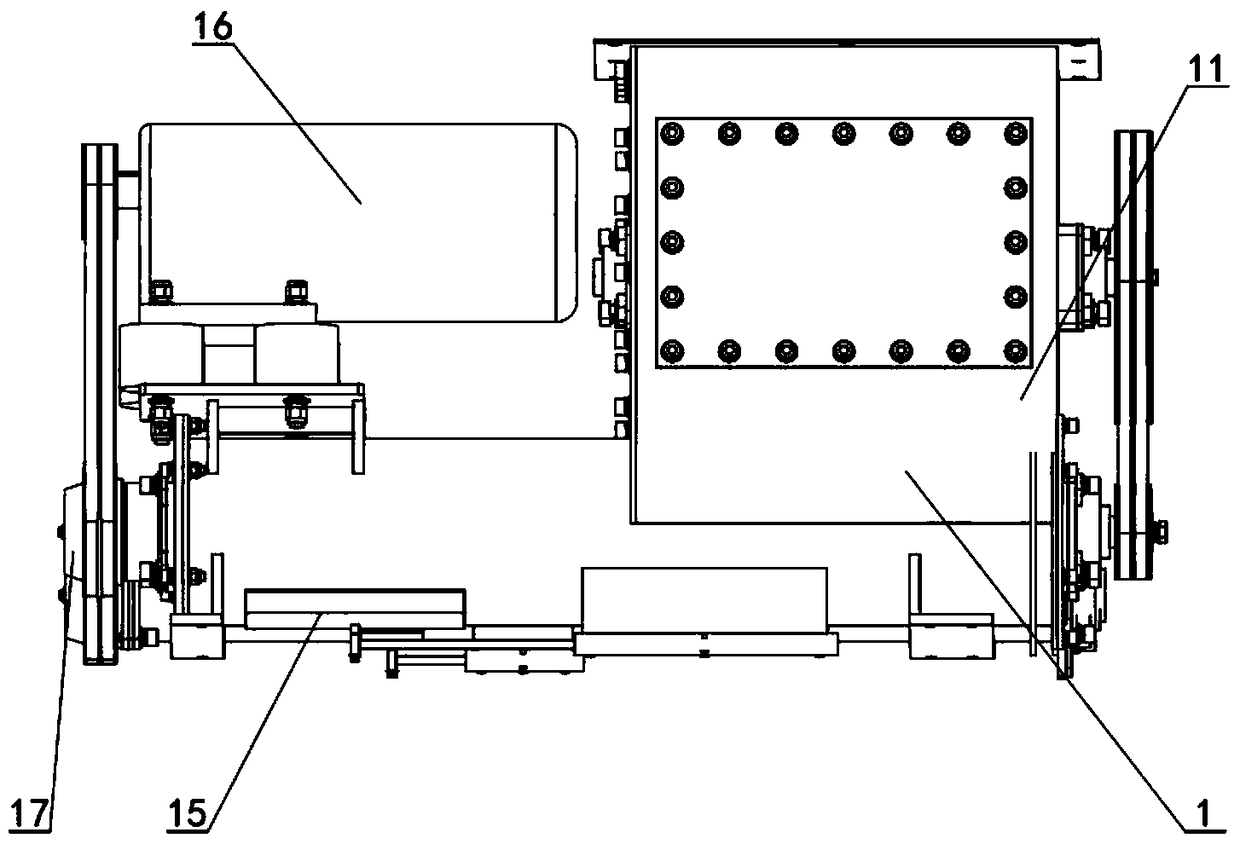

Novel full-automatic numerical control board packaging machine

InactiveCN103794823ASimple structureOverall small sizeFinal product manufactureLead-acid accumulators constructionNumerical controlSmall footprint

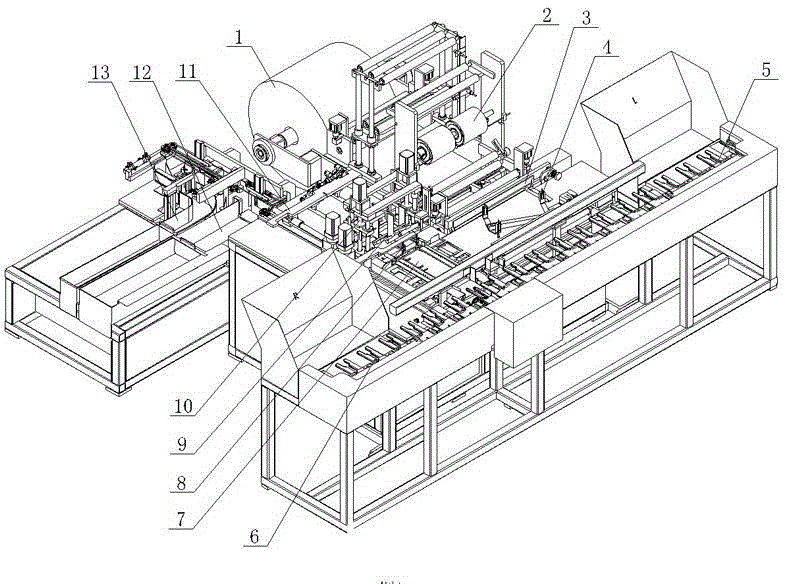

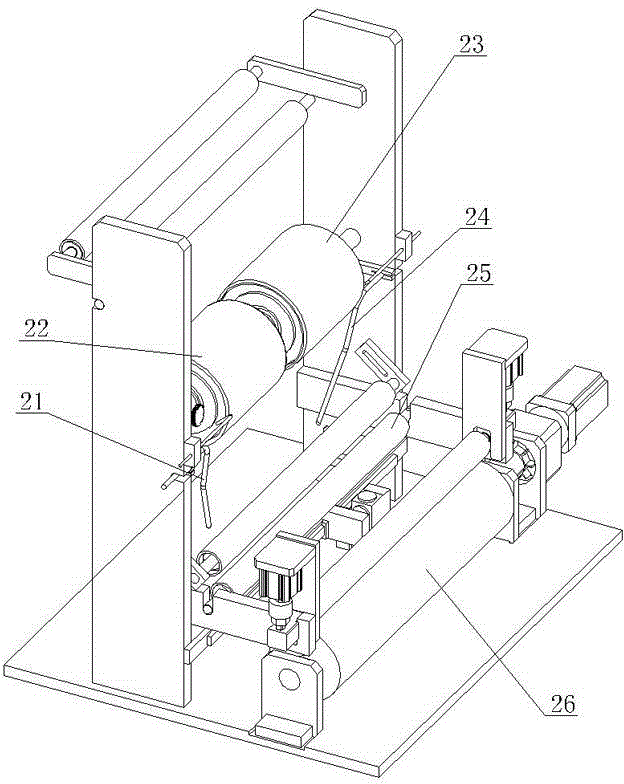

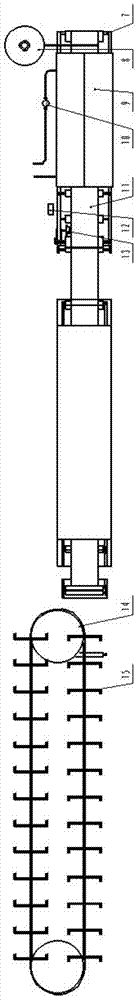

The invention relates to a novel full-automatic numerical control board packaging machine which comprises a pole plate conveying device, a pole plate finishing device, a pole plate lifting device, a pole plate absorbing device, a clapboard paper conveying device, a clapboard paper cutting device, a board packaging device, a pole plate group conveying device and a stand, wherein the pole plate conveying device is arranged at the left lower part of the stand; the tail end of the pole plate conveying device is provided with the pole plate finishing device; the pole plate lifting device is arranged under the stand; the pole plate absorbing device is arranged above the pole plate lifting device; the clapboard paper conveying device is arranged at the right upper part of the stand; the tail end of the clapboard paper conveying device is provided with the clapboard paper cutting device and the board packaging device; the pole plate group conveying device is arranged just under the clapboard paper conveying device. The novel full-automatic numerical control board packaging machine not only is simple in structure, compact in volume and small in occupied land area and improves the environment of a workplace, but also greatly improves the board packaging efficiency and the board packaging quality.

Owner:浏阳市联创机械设备制造厂

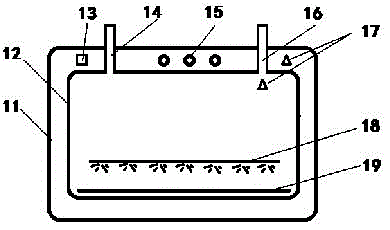

Full-automatic laminated glass production system and process thereof

ActiveCN102659325AImprove safety performance and production efficiencySmall footprintFilm frameAgricultural engineering

The invention discloses a full-automatic laminated glass production system and a process thereof. According to the full-automatic laminated glass production system, a sheet assembly table, a cleaning machine, an air drying machine, a positioning film paving sheet closing table, a rolling machine and a sheet disassembly table are connected sequentially; an integrated air purification device, a glue film frame, a first motor and a second motor are arranged on a base; the base is connected with a positioning platform by a support; a transmission shaft, a positioning plate, a glue film clamp, a third motor and a third guide rail are arranged on the positioning platform; an inclined transmission wheel and a horizontal transmission wheel are arranged on the transmission shaft; a positioning pulley is arranged on the positioning plate; a sucker frame is arranged on the positioning platform; two air cylinders are hung on the sucker frame; a sucker plate is arranged at the lower ends of the two air cylinders; vacuum suckers, a transverse film cutting mechanism, a longitudinal film cutting mechanism, a first guide rail and a second guide rail are arranged on the sucker plate; and a glue film spreading machine and a glue outlet are formed on the glue film frame. The full-automatic laminated glass production system is high in automated degree, and manual operation is replaced, so that the production efficiency, product quality and safety are improved greatly, and the field cost and labor cost are saved greatly.

Owner:广西远大玻璃节能科技股份有限公司

Method and production line for rapidly preparing aerogel through radio frequency radiation

ActiveCN105582866AIncrease productivityRealize high-end manufacturingAerogel preparationColloidal chemistry detailsAutomatic controlEngineering

The invention relates to method and production line for rapidly preparing aerogel through radio frequency radiation. The aerogel production line comprises a main machine for rapidly preparing the aerogel through radio frequency radiation, an original auxiliary material system, an inert gas system, a heat supply system, a recovery system and a three-waste treatment system. The main machine for rapidly preparing the aerogel through radio frequency radiation comprises a sol-gel station, an ageing station, a replacement modification station and a drying station. The main machine is provided with a radio frequency generator, a monitoring device and an automatic control device. The main machine is provided with an inner container which is through front and back, a crawler is arranged in the inner container and used for material conveying, a channel is formed in the inner container and can be communicated with or disconnected from other systems outside the main machine. Multiple forms of products such as aerogel powder, aerogel particles, aerogel felt, aerogel plates, aerogel cloth and aerogel films can be continuously produced, the extremely high production efficiency and automation degree are achieved, the aerogel industry is powerfully promoted to achieve production automation, large scale and intelligence.

Owner:宁波圣润新材料有限公司

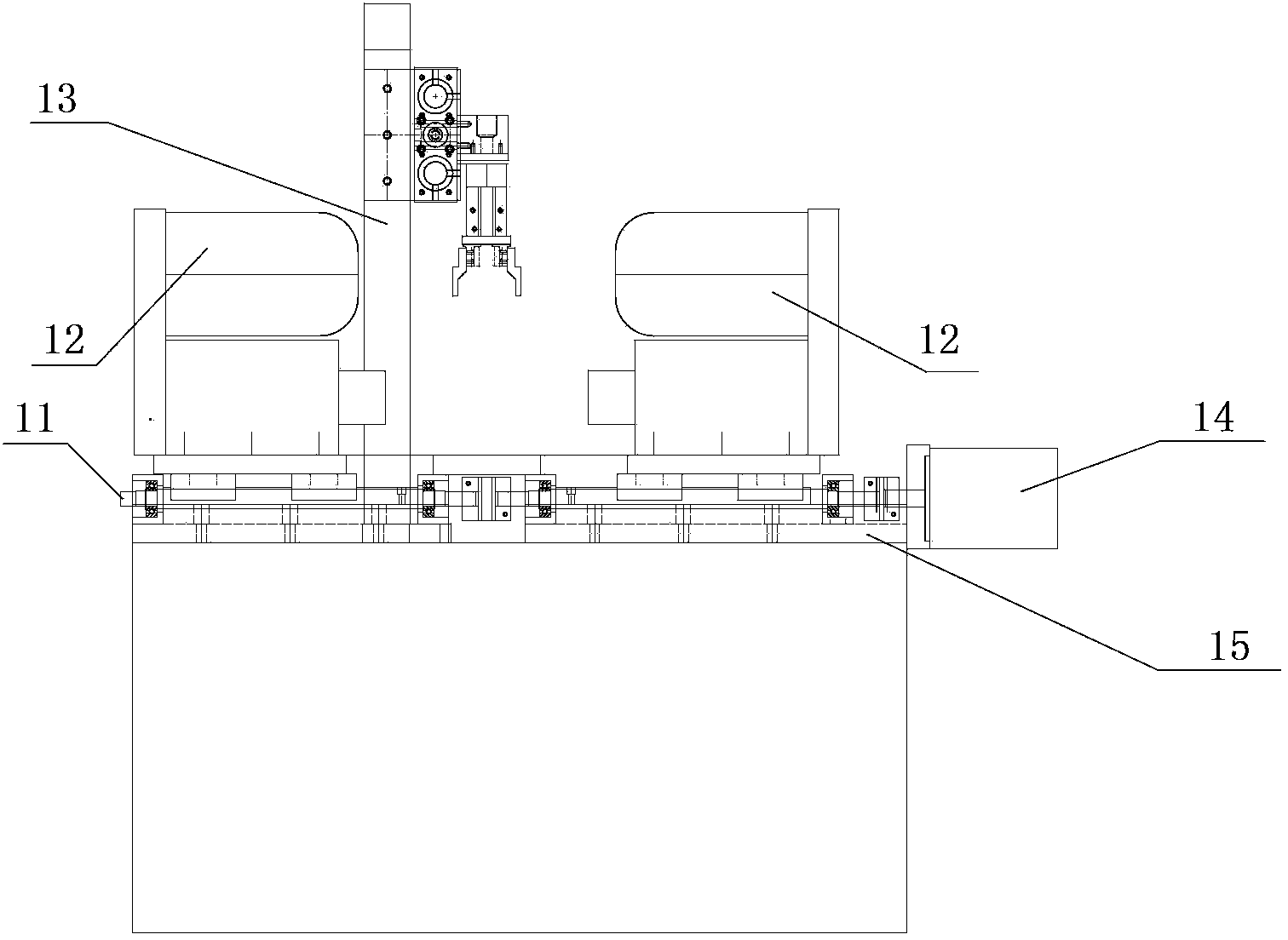

Pipe double end chamfering machine

InactiveCN104249268ARealize fully automatic feedingRealize fully automatic productionMachine tool componentsFeeding apparatusVertical cylinderMechanical engineering

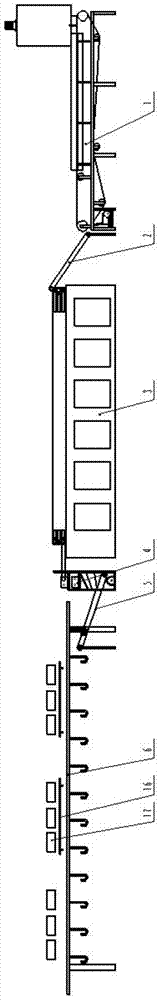

The invention relates to a pipe double end chamfering machine which comprises a lathe body, a charging and discharging mechanism, a chamfering mechanism, a clamping mechanism, a charging bin and a discharging bin, wherein the charging and discharging mechanism, the chamfering mechanism and the clamping mechanism are fixedly arranged on the lathe body; the charging and discharging mechanism comprises a vertical cylinder, a guide rail, a horizontal cylinder and a charging and discharging pneumatic finger; the charging and discharging pneumatic finger is connected with a guide post by virtue of a connecting bracket; the guide post is slidably connected with a vertical guide plate; the connecting bracket is connected with the vertical cylinder; the horizontal cylinder is connected with a horizontal guide plate; the horizontal guide plate is slidably connected with the guide rail; the horizontal guide plate is fixedly connected with the vertical guide plate; The clamping mechanism is arranged on the lathe body between the charging bin and the discharging bin. The pipe double end chamfering machine has the beneficial effects of realizing full-automatic operations such as charging, chucking, processing and discharging, processing four chamfer angles inside and outside two end surfaces by virtue of once chucking, conveniently regulating the processing frequency and the tool feeding depth by virtue of PLC (Programmable Logical Controller) control over equipment and realizing full-automatic production.

Owner:天津市中马骏腾精密机械制造有限公司

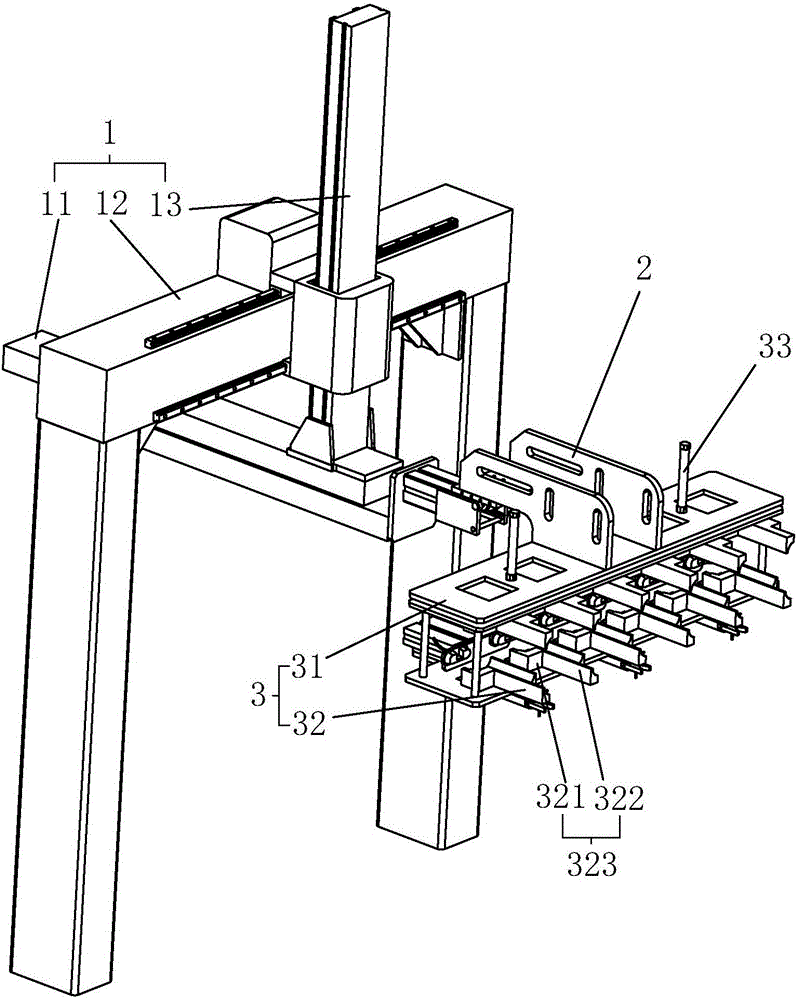

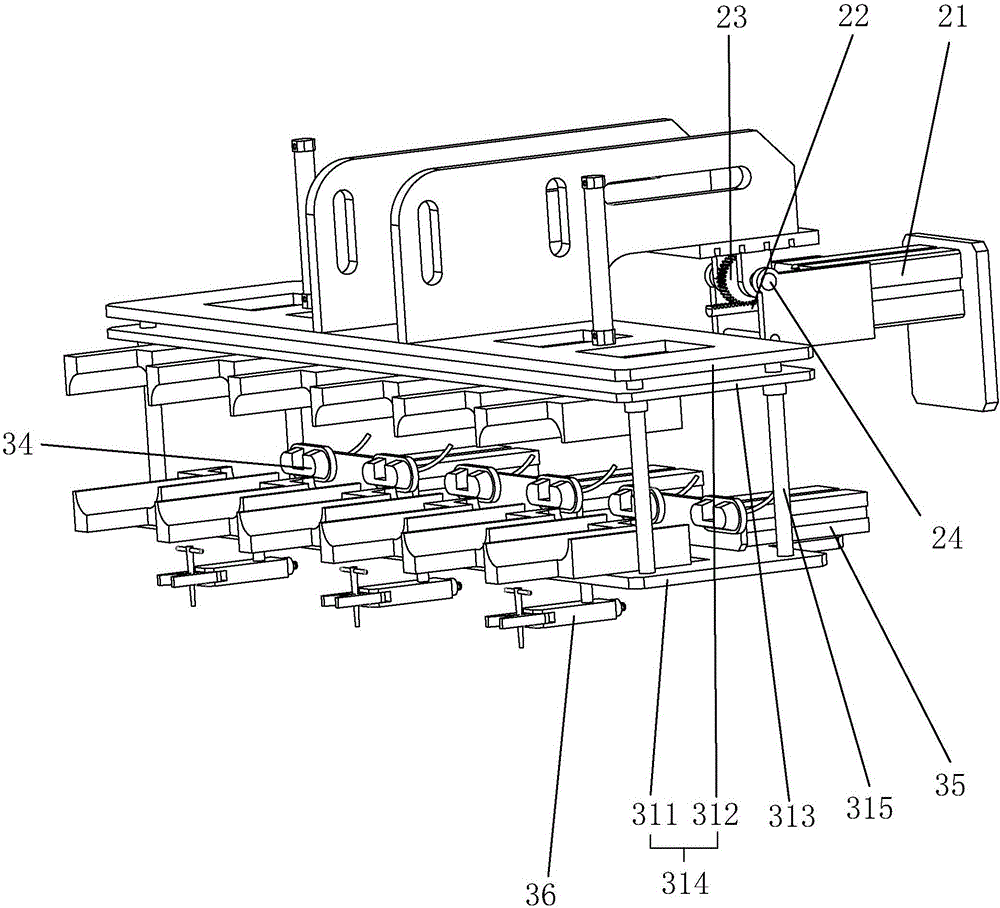

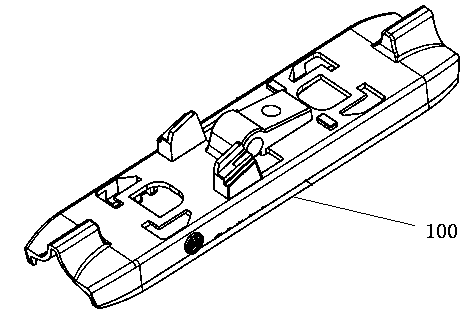

Wire harness seal sleeve demolding manipulator and production equipment with same

ActiveCN106827422ARealize fully automatic productionImprove demoulding efficiencyDomestic articlesSlide plateEngineering

The invention discloses a wire harness seal sleeve demolding manipulator. The wire harness seal sleeve demolding manipulator comprises a triaxial displacement table, a clamping assembly and connecting arms. The clamping assembly comprises a support and a demolding part. The demolding part comprises a demolding cavity. The demolding cavity comprises a clamping portion and a protection portion in sequence. The support comprises fixed plates and a sliding plate. The demolding part is divided into two portions which are fixed to one fixed plate and the sliding plate correspondingly. When the sliding plate moves towards one fixed plate to the limiting position, the two portions of the demolding part are combined and attached to each other to form the whole demolding cavity, a blowing portion communicating with an external air source is fixedly arranged on one fixed plate and located on the other side, opposite to the protection portion, of the clamping portion, and the connecting arms are fixedly connected with one fixed plate. Besides, the invention further discloses production equipment with the manipulator. By means of the wire harness seal sleeve demolding manipulator and the production equipment with the same, automatic production and automatic demolding of wire harness seal sleeves are achieved, the labor cost is reduced, and meanwhile, the production efficiency is improved.

Owner:浙江一番汽车配件科技有限公司

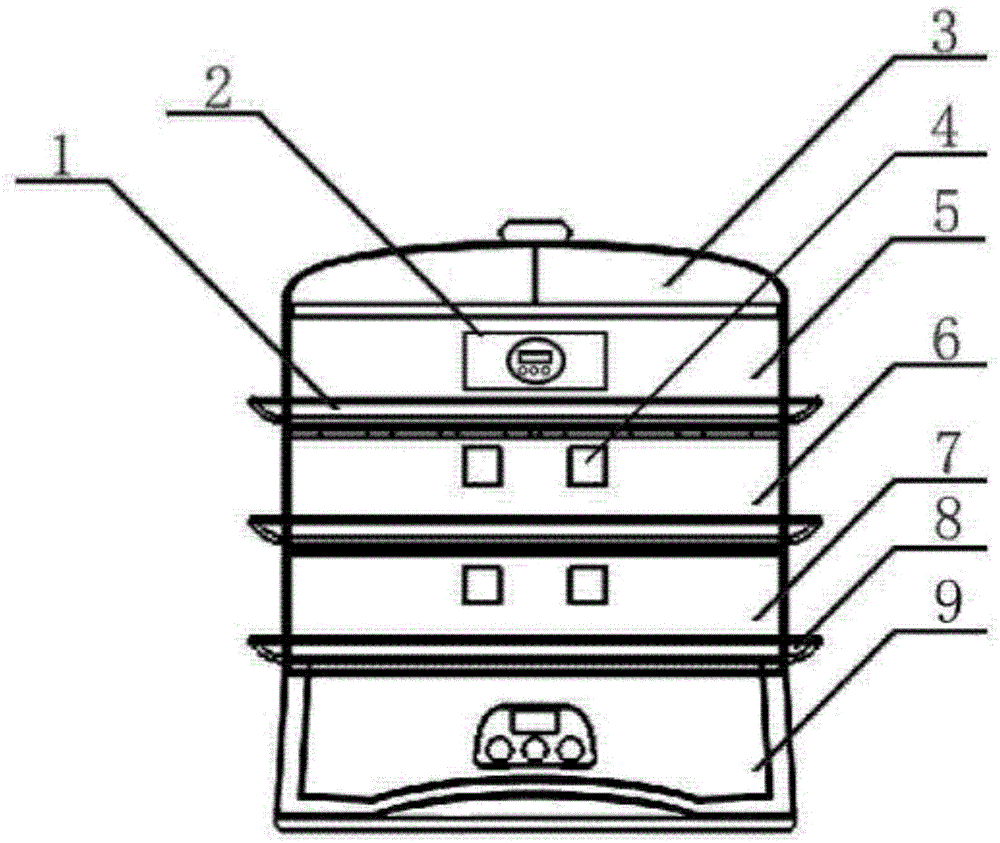

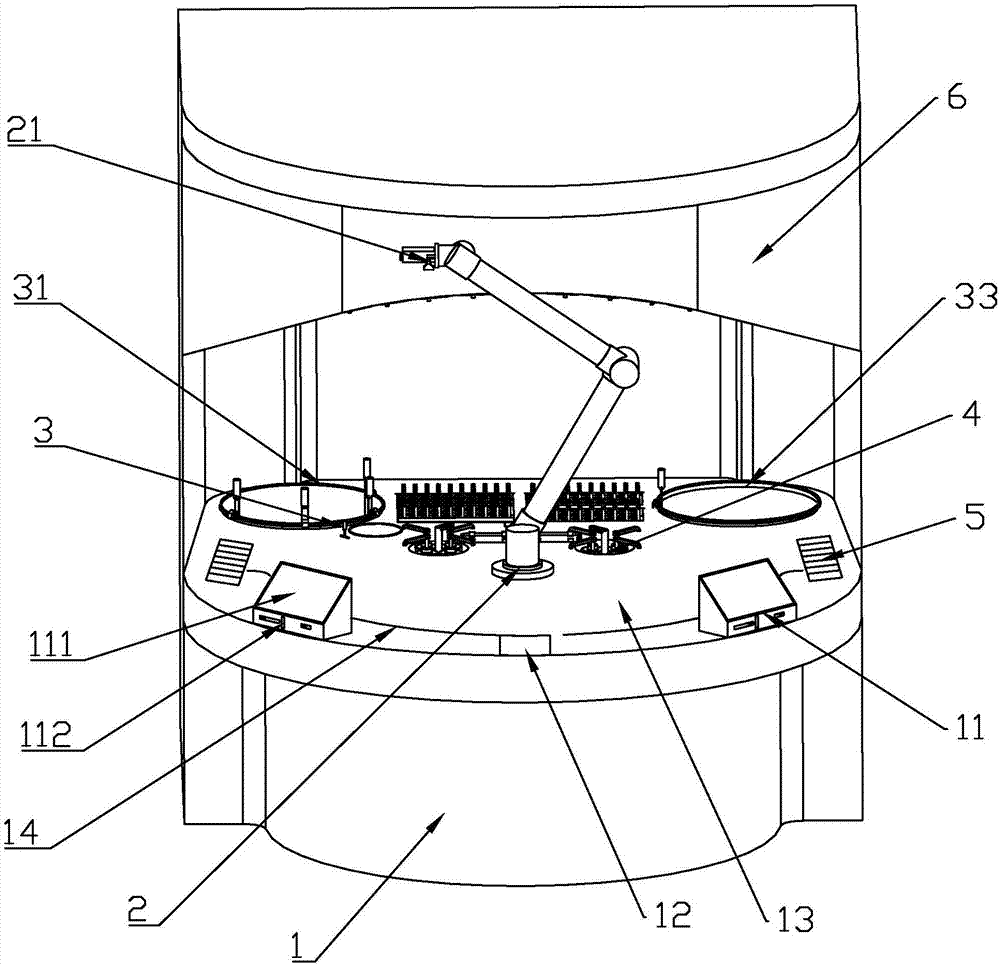

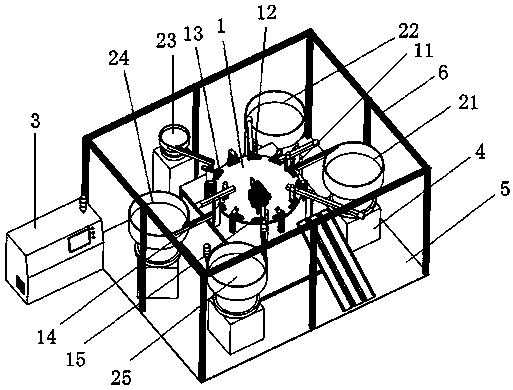

Automatic freshly-made wheaten food vending machine and working method thereof

ActiveCN107393176AReasonable structure layoutHigh degree of integrationApparatus for meter-controlled dispensingFood vending machinesAdditive ingredient

The invention discloses an automatic freshly-made wheaten food vending machine and a working method thereof, and relates to the technical field of automatic vending machines. The machine comprises a machine body, vending devices and a taking port are arranged on the exterior of the machine body, and the interior of the machine body comprises a mechanical arm, wheaten food cooking devices, sauce adding devices, conveying devices and an upper layer goods shelf which are arranged on an operation platform; wheaten food is obtained from the upper layer goods shelf by the mechanical arm, cooking of the wheaten food is completed by matching of the mechanical arm and the wheaten food cooking devices, saucer addition is conducted by the sauce adding devices, the wheaten food is seal-capped by a combined clamp and clamped to the conveying devices, and the finished products are conveyed to the taking port by the conveying devices. According to the automatic freshly-made wheaten food vending machine, structural configuration is rational, the integration degree is high, the working efficiency is high, fully automatic wheaten food product making and vending can be achieved, the freshness of the food is guaranteed, and health and sanitation are provided; meanwhile, the machine has various choices of flavors, food amounts and different ingredients, so that the requirements of customers are met.

Owner:罗志豪

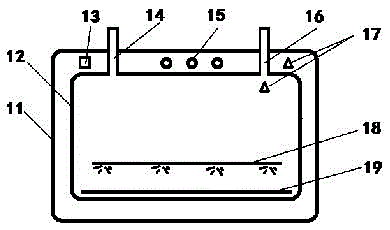

Automatic secondary-packaging molding production line

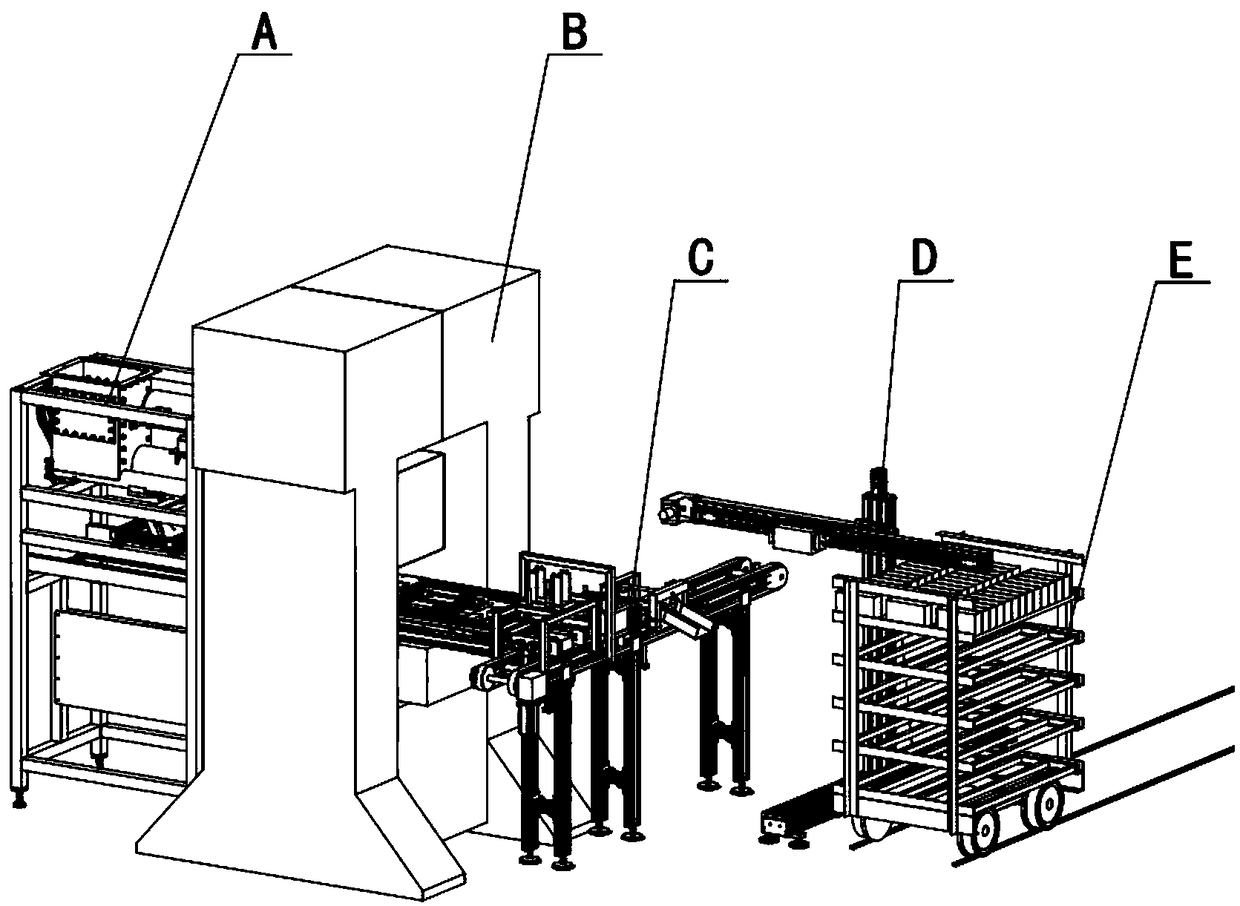

ActiveCN105633478ARealize fully automatic productionIncrease productivityAssembling battery machinesFinal product manufactureProduction lineEconomic benefits

The invention discloses an automatic secondary-packaging molding production line. The production line comprises a feeding unit, a packaging unit, a molding unit and a discharging unit, wherein the feeding unit comprises a feeding pull band; the packaging unit comprises a primary-packaging station and a primary-cutting station; the primary-packaging station is arranged close to the primary-packaging correction station; an upper packaging cavity, a low packaging cavity and a movable cavity are formed in the primary-packaging station; the primary-cutting station is provided with a primary-cutting mechanism for cutting sealing edges of cells; the molding unit comprises a cell transfer mechanism, and a fine packaging mechanism, a rolling wheel edge-folding mechanism, an adhesive dispensing mechanism, a thermoprint edge-folding mechanism, and a second weighing station arranged on the two sides of the cell transfer mechanism in sequence; and the discharging unit comprises a discharging pull band. According to the automatic secondary-packaging molding production line, the feeding unit, the packaging unit, the molding unit and the discharging unit are integrated on one equipment, so that the fully automatic production of a softly-packaged lithium battery from feeding to discharging can be realized; and therefore, the production efficiency of the lithium battery is improved, the productivity is improved, the production cost is lowered, and the economic benefit is increased.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

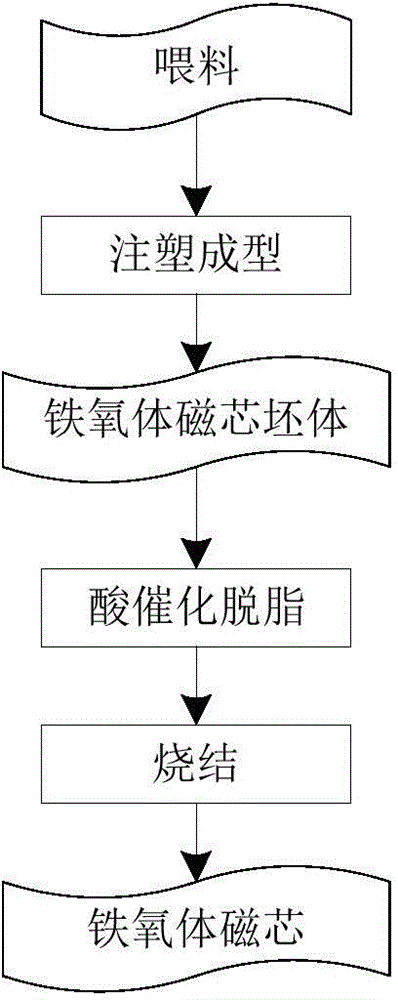

Ferrite magnetic core blank body and preparation method thereof, and ferrite magnetic core and preparation method of ferrite magnetic core

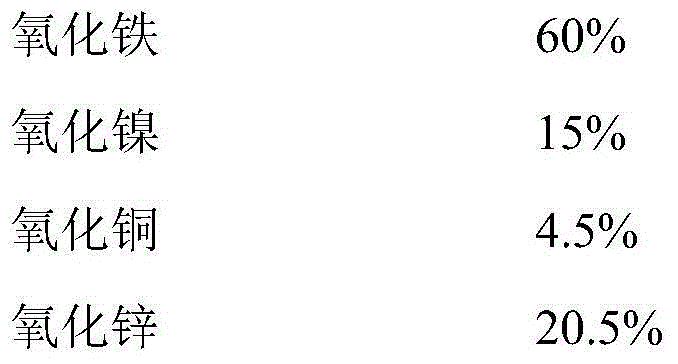

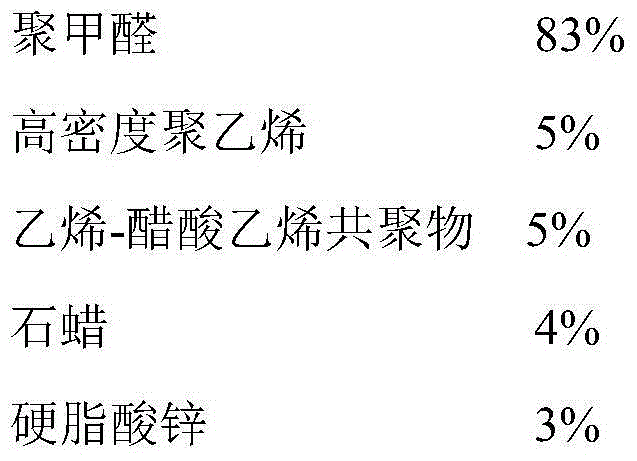

The invention discloses a ferrite magnetic core blank body and a preparation method thereof, a ferrite magnetic core and a preparation method of the ferrite magnetic core. The preparation method of the ferrite magnetic core blank body comprises the steps: (1) blending 70%-95% of a ferrite powder and 5%-30% of a binder, and thus obtaining a feedstock for injection molding, wherein the ferrite powder includes 60%-70% of iron oxide, 10%-20% of nickel oxide, 2%-10% of copper oxide and 15%-25% of zinc oxide, and the binder comprises 80%-90% of polyoxymethylene, 3%-6% of high-density polyethylene, 3%-6% of an ethylene-vinyl acetate copolymer, 2%-5% of paraffin, and 2%-5% of zinc stearate; and (2) carrying out injection molding with the feedstock, and thus forming the ferrite magnetic core blank body. The preparation method not only improves the consistency of the magnetic core, the feeding flexibility is good, during injection molding of the ferrite magnetic core blank body, the product and a back material are not broken, demoulding is easy, and a mold is not required to be often cleaned, so that full-automatic production can be realized, the labor cost is greatly reduced, and the production efficiency is improved.

Owner:SHENZHEN SUNLORD ELECTRONICS

A making method for fully automated small ultra-thin chip inductor

ActiveCN1996517AImprove reliabilityAvoid harmInductances/transformers/magnets manufactureInductance with magnetic coreInductorEngineering

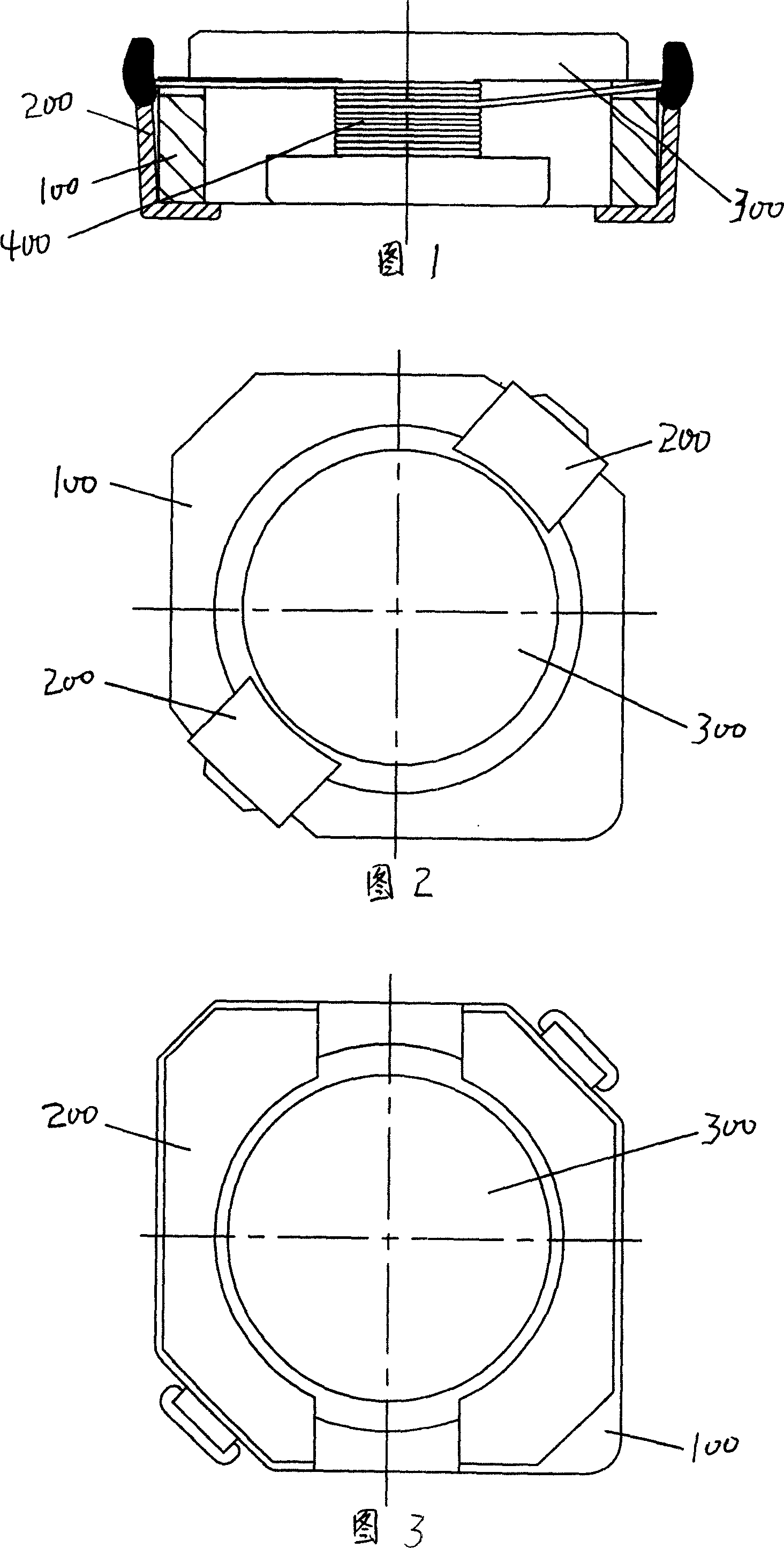

This invention relates to automatic small film slice induction process method, which comprises the following steps: a, arraying copper material band onto inductor bottom; setting folded wire end and small protruding bench on each weld board and impacting position hole on band part; b, sticking I-shaped iron core onto center of inductor; c, rolling coil with two ends of coil onto roller ends; d, welding by laser on rolling coil; e, spraying glue onto iron core; f, combing hollow iron chip; g, spraying glue; h, printing; I, cutting along isolation hole two ends; j, testing and packing.

Owner:中山市三礼电子有限公司

Automatic assembling device and implementation method thereof

PendingCN107825136ALow costRealize integrated assemblyAssembly machinesProcess engineeringMechanical engineering

The invention discloses an automatic assembling device and an implementation method thereof. The automatic assembling device comprises a rotary table. The rotary table is provided with a first station, a second station, a third station, a fourth station and a fifth station in the circumferential direction. One sides of the stations are provided with a first feeding mechanism, a second feeding mechanism, a third feeding mechanism, a fourth feeding mechanism and a fifth feeding mechanism correspondingly. One side of the rotary table is provided with a drive device. The rotary table is electrically connected with the drive device and is driven by the drive device. The rotary table rotates to drive workpieces to be assembled to sequentially pass through the first station, the second station, the third station, the fourth station and the fifth station, and assembling is completed. The device can achieve integrated assembling, and the self-checking working procedure is added in the automaticassembling process; and when the device is used, the feeding manners of all products, the assembling manner and the automatic detection and judgment are all achieved in a full-automatic manner, by means of the device, the production cost is greatly reduced, the production efficiency is improved, and the automatic assembling device is suitable for being used and popularized on the industry.

Owner:UNIVAC PRECISION PLASTICS SIP

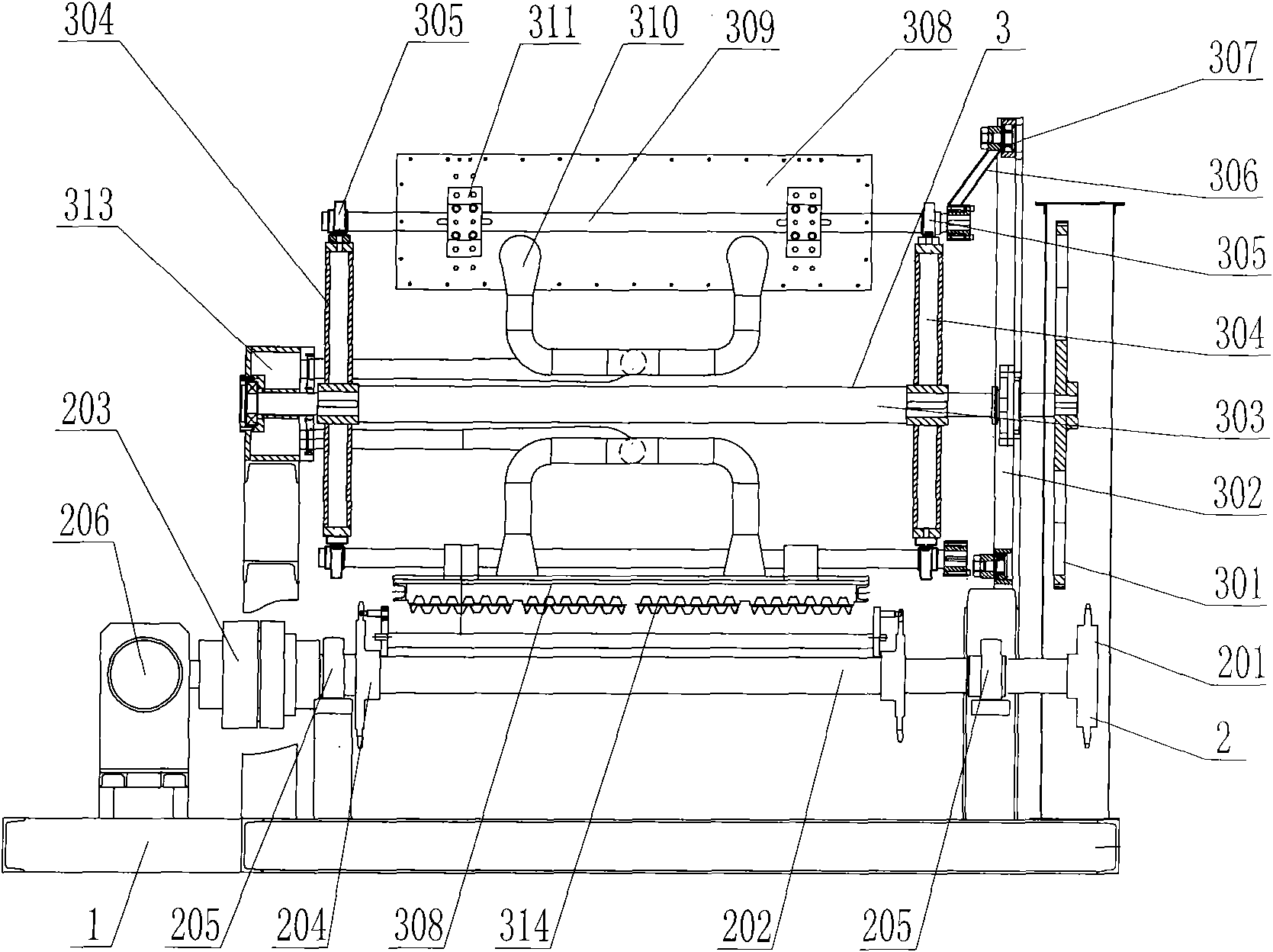

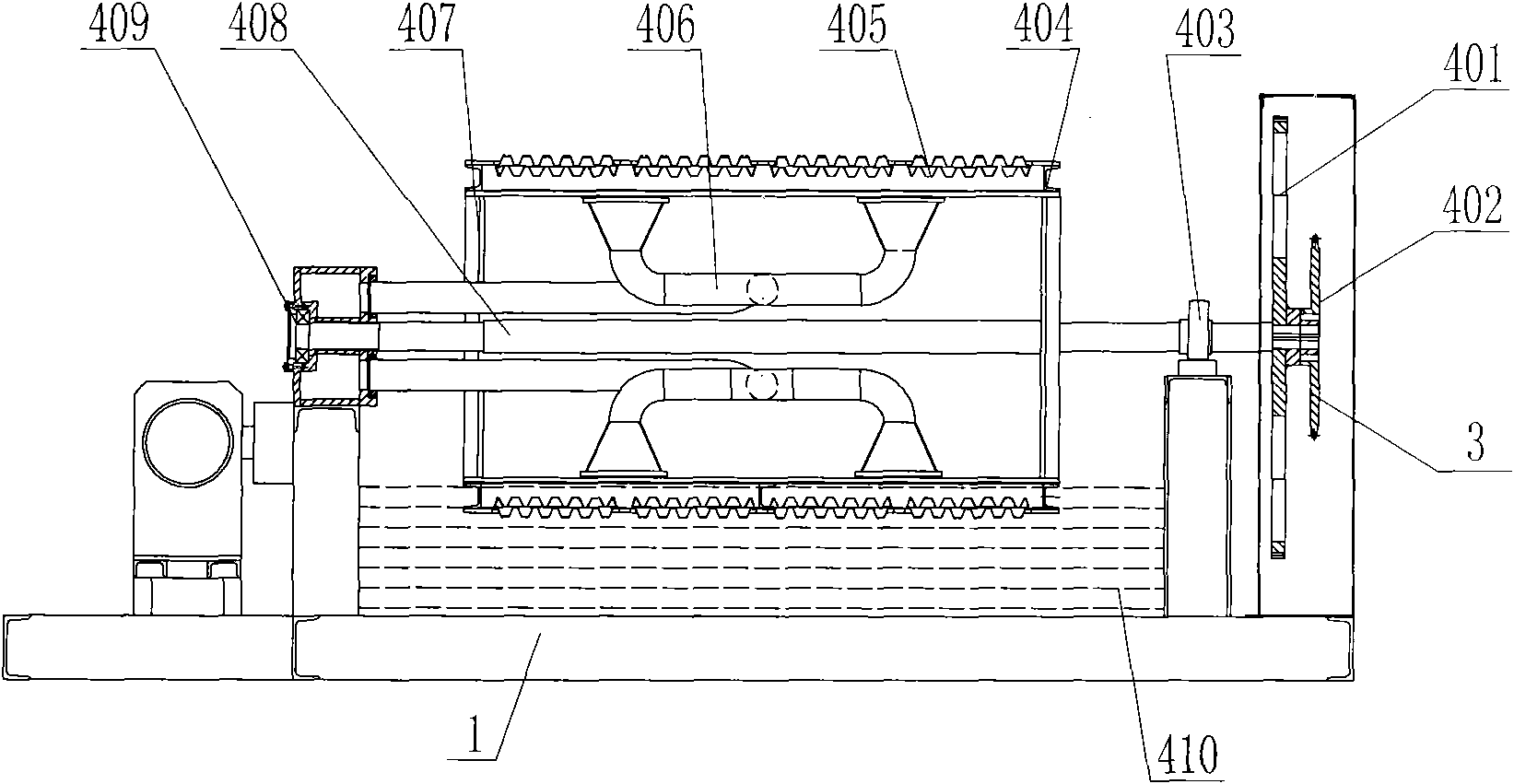

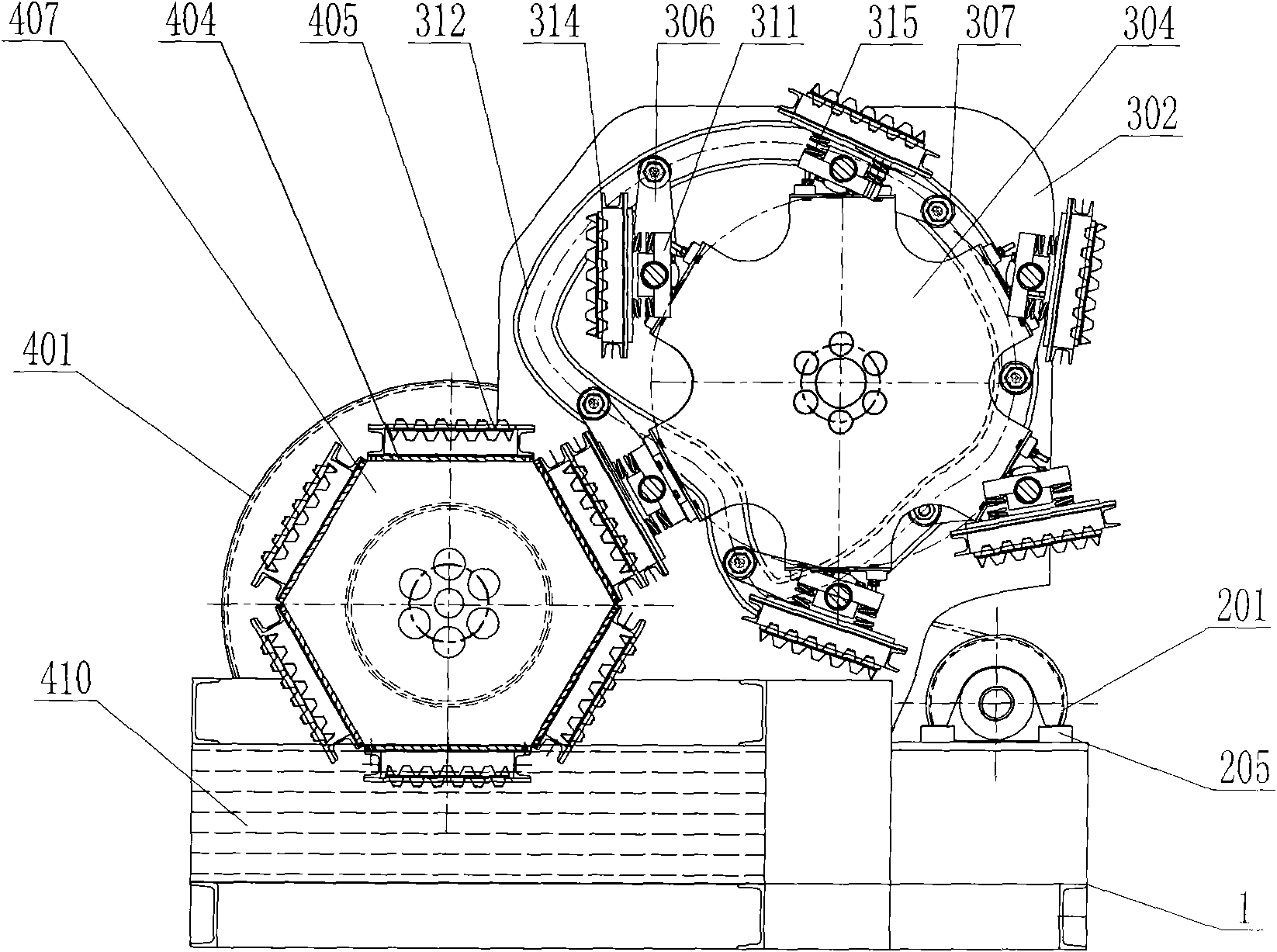

Full-automatic pulp-molding roller molding machine

ActiveCN101781871ASave resourcesMass productionTextiles and paperMolding machineAgricultural engineering

The invention discloses a full-automatic pulp-molding roller molding machine. A gear of a transfer rotary drum is fixed on one end of an upper main shaft. One side of the upper main shaft is movably arranged on a side frame, and the other side of the upper main shaft is movably arranged in a bearing of a pulp distribution box. Supporting brackets are fixedly arranged on two sides of the upper main shaft. Six rotating shafts are connected to the two supporting brackets, and each rotating shaft elastically fixes an upper mold mounting plate through a press plate and a spring. An upper pipeline is arranged on the bottom surface of the upper mold mounting plate, on which an upper mold is fixed. A crank arm is fixedly arranged at one end of each rotating shaft, and is connected with a roller. The roller and a track cam are in flexible connection. A driving gear and a chain wheel are fixedly arranged at one end of a lower main shaft of a pulp-absorption rotary drum, and the lower main shaft is supported by a left bearing block and a right bearing block. Six rotary drums are fixedly arranged on the lower main shaft, and six lower mold mounting plates are arranged on the six rotary drums. A lower mold is fixedly arranged on each lower mold mounting plate, and a lower pipeline is arranged on the bottom surface of each lower mold mounting plate. Due to the scheme of drying and transmitting products by a drying transmission device, the defect that the traditional pulp-molding molding machines have low working efficiency is overcome. The full-automatic pulp-molding roller molding machine is applied to manufacturing various paper-molded trays.

Owner:XIANGTAN SHUANGHUAN MACHINERY DEV

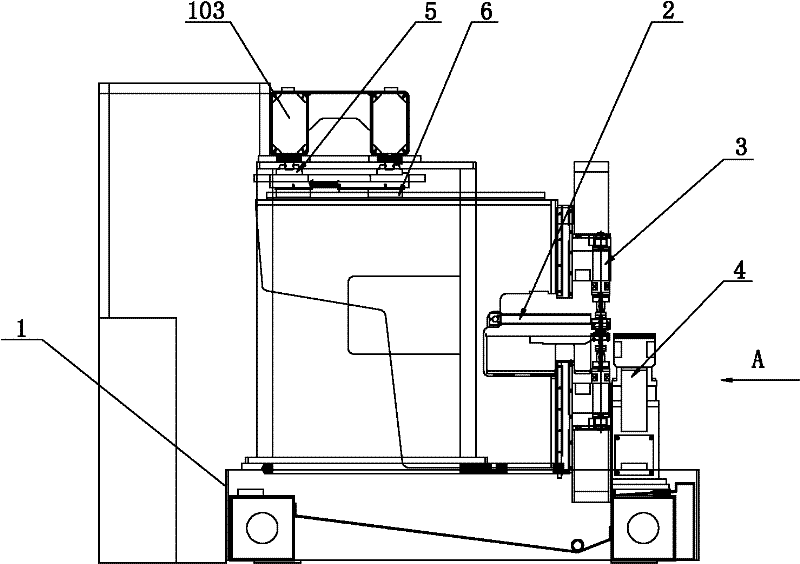

Door type drilling machine

InactiveCN102211859AMeet supporting needsRealize fully automatic productionGlass severing apparatusGlass productionEngineeringFully automatic

The invention relates to the technical field of drilling equipment, in particular to a door type drilling machine. The drilling machine comprises a host machine and a control module. The host machine comprises a machine frame, a locating device, a clamping mechanism and a drilling mechanism. The machine frame comprises a chassis, two lateral upright posts arranged on the chassis and transverse beams arranged on the two lateral upright posts. The locating device comprises a rotary mechanism, an X-directional driving mechanism and a Y-directional driving mechanism. The rotary mechanism is arranged at the lower part of the front end of the host machine and fixed on the chassis of the machine frame. The X-directional driving mechanism is arranged on the transverse beams. The Y-directional driving mechanism is arranged at the bottom of the X-directional driving mechanism. The clamping mechanism and the drilling mechanism are arranged on the Y-directional driving mechanism. The control module is connected with the rotary mechanism, the X-directional driving mechanism, the Y-directional driving mechanism, the clamping mechanism and the drilling mechanism. A drill in the door-type drilling machine disclosed by the invention is capable of freely moving in a glass plane. The fully automatic locating and drilling production is realized. The working efficiency is improved. Assorted requirements of production lines are satisfied.

Owner:武汉瑞林峰机器有限公司

UV-curable conductive adhesive

InactiveCN104152060AShorten the curing timeIncrease productivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistryPhotoinitiator

The invention discloses a UV-curable conductive adhesive. The UV-curable conductive adhesive comprises, by mass, 5-20% of a modified acrylate oligopolymer, 10-35% of an acrylic acid monomer, 2-5% of a photoinitiator, 0.5-2% of an assistant and 5-80% a conductive heat conduction filler. The UV-curable conductive adhesive can substantially reduce the conductive adhesive curing time, and is convenient for realizing the fully automatic production of a whole technology in order to improve the production efficiency; and the curing time is short, so electric energy reduction benefiting, environmental protection, energy saving and production cost reduction are realized, and the requirements of the modern development and the improvement of the market competitiveness are satisfied.

Owner:DONGGUAN MEISHENG ELECTRICAL PROD

Pin shaft feeder

ActiveCN106391987ARealize fully automatic productionEasy to operateMetal chainsReciprocating motionEngineering

The invention provides a pin shaft feeder. The pin shaft feeder comprises a pin shaft feeding body and a pin shaft discharging mold. Two grooves are formed in the two sides of the pin shaft feeding body correspondingly. A pin shaft push plate is arranged behind each groove, and each pin shaft push plate can be driven by an air cylinder to do reciprocating motion. The pin shaft discharging mold is in the shape of a trapezoid. Two rails which are each connected with the corresponding groove are arranged on the edges of the two oblique sides of the trapezoid correspondingly. A pin shaft discharging pipe is arranged at the end, adjacent to the corresponding pin shaft push plate, of each groove. A vertical through hole is formed in the other end of each rail. Full-automatic production can be achieved, operation is easy and convenient, a large amount of manpower is saved, and the production efficiency is also improved.

Owner:SUZHOU SHUNGE INTELLIGENT TECH

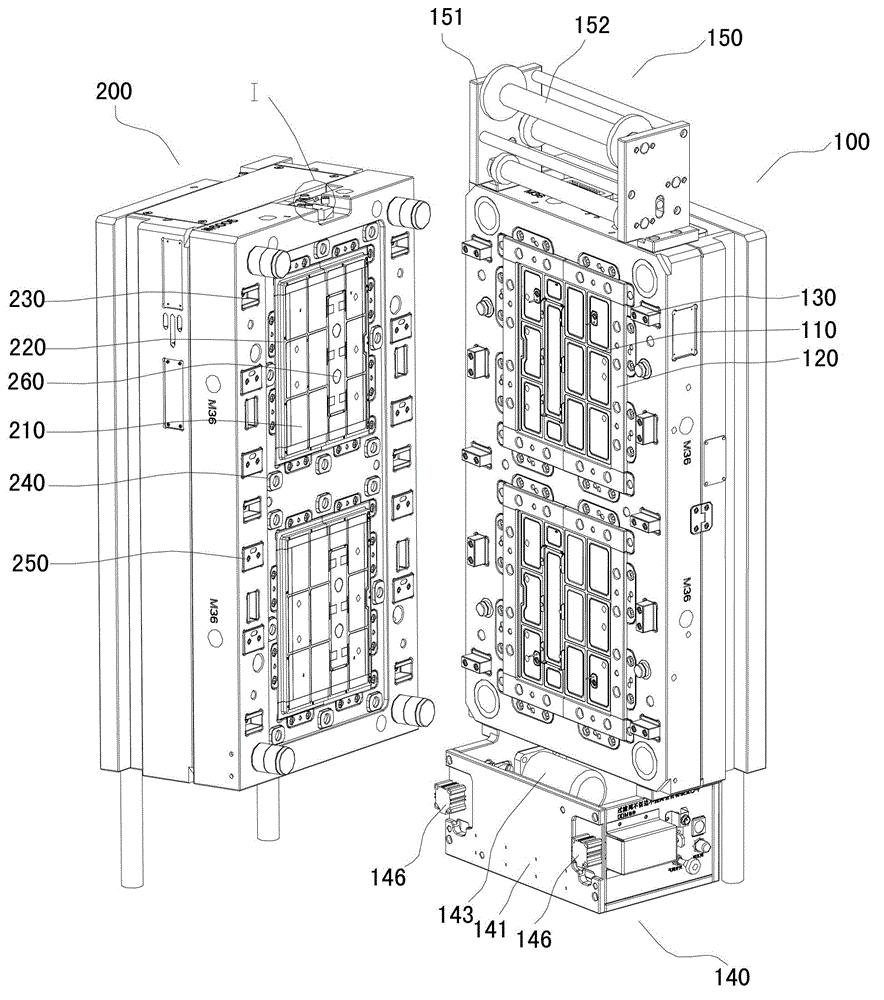

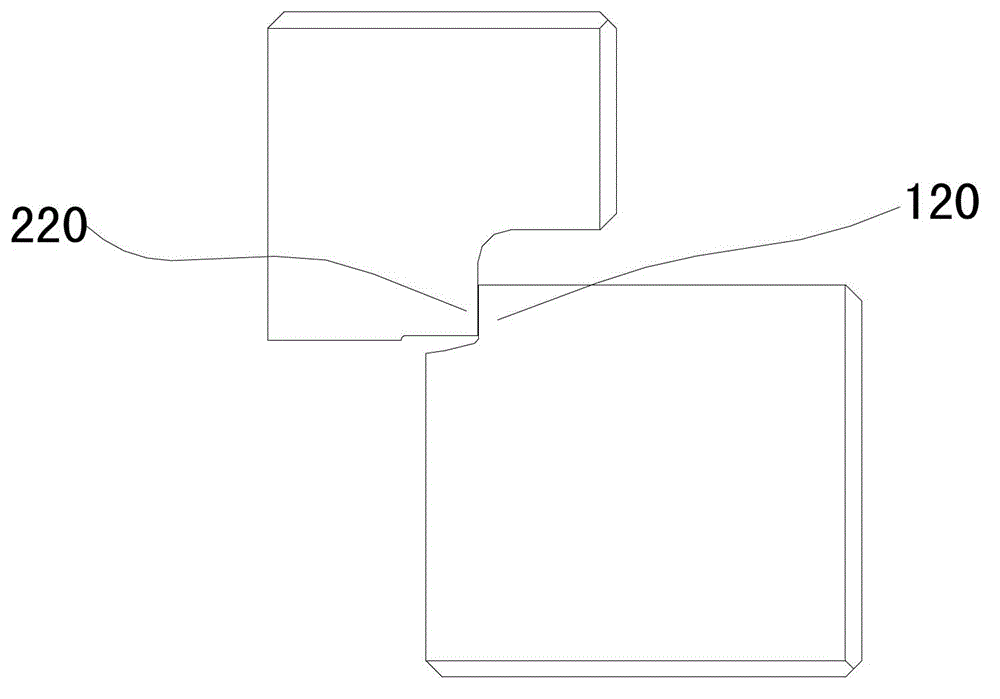

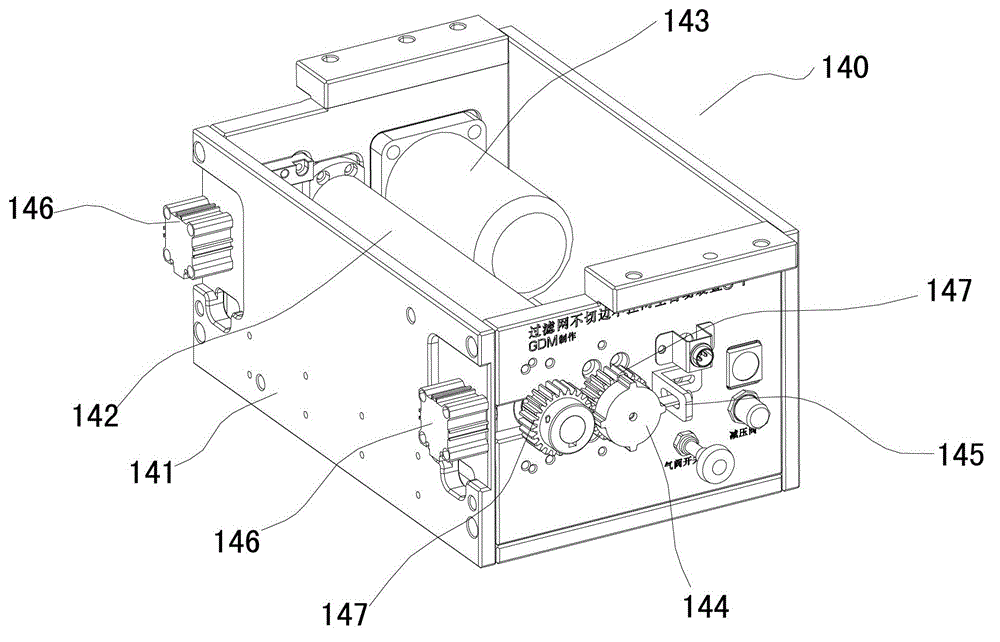

Device for producing components of filter screen

ActiveCN102909824ARealize fully automatic productionIncrease productivityDomestic articlesEngineeringInjection moulding

The invention discloses a device for producing components of a filter screen. The device comprises a first die and a second die, wherein the first die is provided with a first parting surface and a first net cutting blade; the first net cutting blade has a closed ring structure; the second die is provided with a second parting surface and a second net cutting blade; the second net cutting blade has a closed ring structure; a net material conveying device for pulling a net material into a framework die cavity is arranged on the first die, and comprises one or more pairs of driving rollers, one or more pairs of driven rollers and a driving device which is used for driving the driving roller; and the driving roller and the driven roller are arranged along the net material conveying direction and are respectively fixed at two ends of the first die. The net material is automatically conveyed into the framework die cavity through the net material conveying device and then is molded through integrative injection molding to realize the full-automatic production of the filter screen, so that the conventional production mode through which the net material is manually placed into a mould for injection molding piece by piece is changed, the production efficiency of the components of the filter screen is greatly improved, and the product quality is improved.

Owner:ZHUHAI GREE DAIKIN PRECISION MOLD

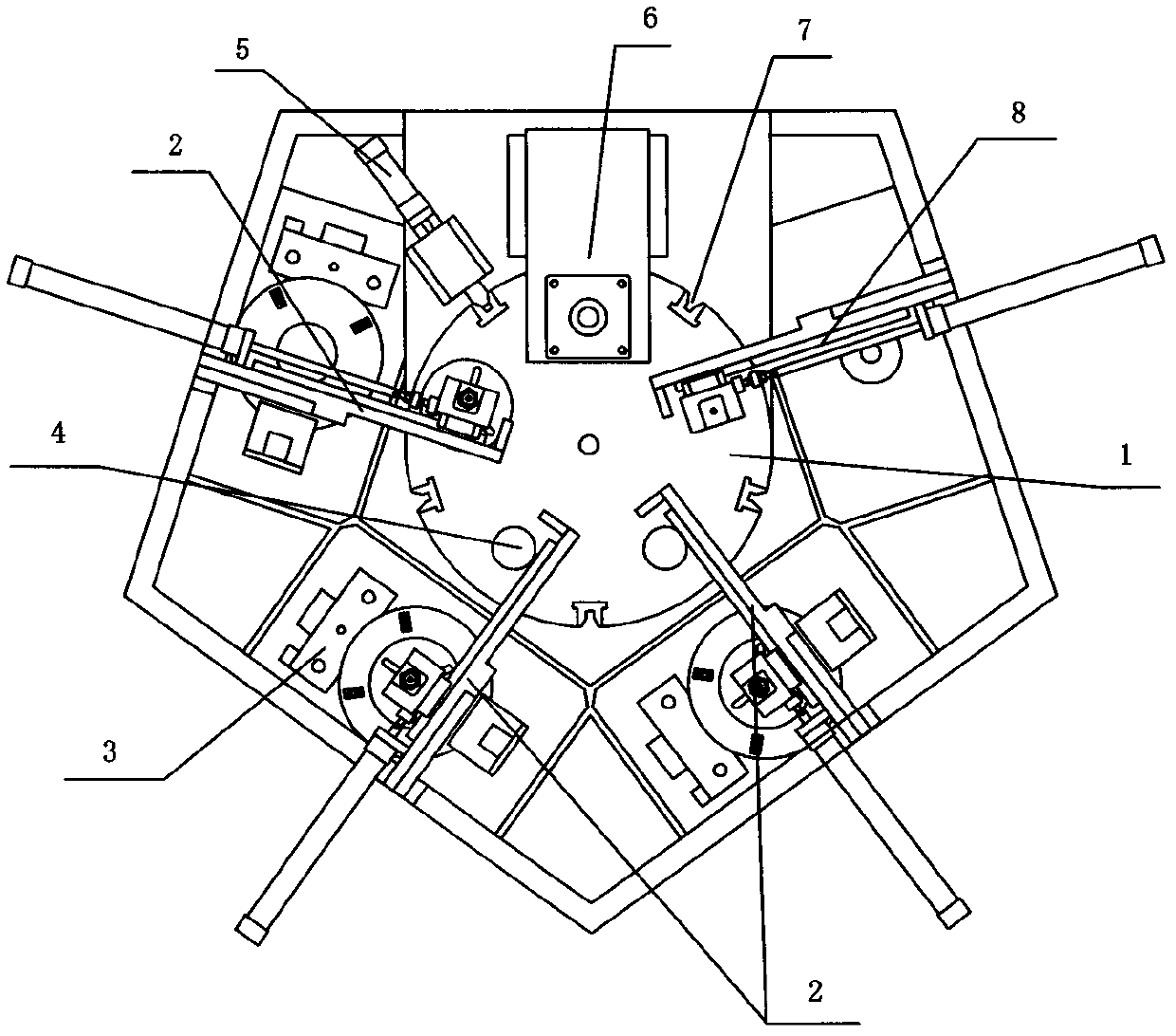

Fully automatic loudspeaker cone pasting machine

InactiveCN103313181ARealize fully automatic productionIncrease productivityElectrical transducersLaminationEngineeringCam

The invention provides a fully automatic loudspeaker cone pasting machine, which belongs to the field of machinery for manufacturing loudspeaker parts. The artificial pasting mode has the defects of low efficiency and potential safety hazard existence. The fully automatic loudspeaker cone pasting machine comprises a round turntable, wherein five stations (which are sequentially the paper cone placing station, the press strip placing station, the edge placing station, the pasting station and the finished product taking station) in symmetrical arrangement are arranged on the round turntable, lower molds are arranged on each station, the lower side of the turntable is connected with a turntable cam divider which is connected with a turntable speed reducing motor, the paper cone placing station, the press strip placing station and the edge placing station are correspondingly provided with a picking mechanical hand and a material bracket, the picking mechanical hand picks materials on the material bracket and places the materials onto the corresponding stations, the finished product taking station is correspondingly provided with a material taking mechanical hand, the material taking mechanical hand picks finished product materials on the lower molds and places the materials onto the material bracket, the pasting station is correspondingly provided with a pasting mechanical hand, and the pasting mechanical hand carries out hot pressing forming on the materials. The fully automatic loudspeaker cone pasting machine realizes the fully automatic manufacturing of loudspeaker cones.

Owner:SHENGZHOU KEDI ELECTRONICS

Automatic nut cap welding machine

ActiveCN106964887AReasonable structureRealize automated detectionWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringFully automated

The invention relates to an automatic nut cap welding machine. The automatic nut cap welding machine comprises a welding machine body and an automatic part conveying assembly, wherein a welding assembly is mounted on one side of the welding machine body, and comprises a welding upper electrode which vertically ascends and descends, and a lower electrode mounted below the welding upper electrode; and a product collecting box automatic conveying assembly is mounted on one side of the welding machine body. The automatic nut cap welding machine disclosed by the invention has the advantages that the structure is reasonable; automatic feeding and automatic combination and welding are adopted, so that full-automatic production is realized; and multiple devices can be simultaneously operated by one person, so that the production efficiency is improved, the labor strength of staff is lowered, and the labor cost is reduced.

Owner:宁波长华布施螺子有限公司

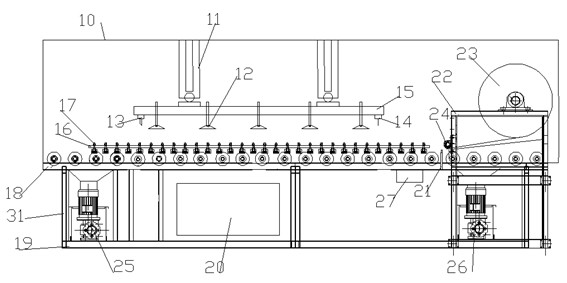

Full-automatic dryland lotus bean vermicelli production line

InactiveCN103584018AIncrease the level of automationIncrease productivityFood preparationCircular discReduction drive

The invention discloses a full-automatic dryland lotus bean vermicelli production line, and aims to provide full-automatic dryland lotus bean vermicelli production equipment which has the advantages of high automation level, good product quality and low worker labour intensity. The full-automatic dryland lotus bean vermicelli production line comprises a sheet jelly machine, wherein the rear part of the sheet jelly machine is sequentially provided with a conveyor belt, a refrigerating machine, a bean vermicelli cutting machine, a hanging frame transmission machine and a dryer; the dryer comprises a disc circulating rack, the disc circulating rack is provided with a hanging frame, and a heating pipe and a fan are arranged above the hanging frame; the dryer also comprises a temperature measuring device and a humidity measuring device, the sheet jelly machine comprises a rack and a sheet jelly conveyor belt, the rack is provided with a steam box and an electromotor, and the sheet jelly conveyor belt is connected with the electromotor through a belt and a reducer; a powder bucket and an electronic control system are arranged on the side of the rack, the electronic control system is connected with the electromotor, the steam box is connected with a steam system through a pipeline, the steam box is internally provided with the temperature measuring device, and the electronic control system is connected with the temperature measuring device of the steam system. The full-automatic dryland lotus bean vermicelli production line provided by the invention is suitable for producing different kinds of bean vermicelli.

Owner:杨舒翔

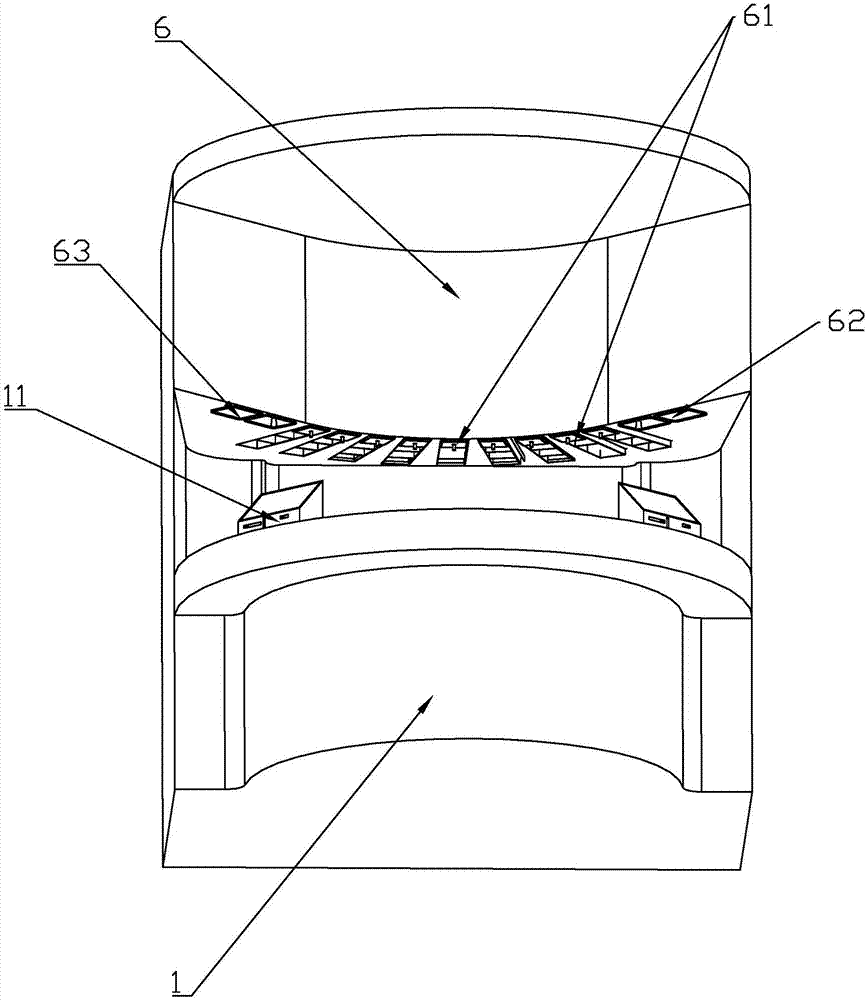

Refractory material full-automatic production line

PendingCN109278177AQuality improvementImprove weighing accuracyDischarging arrangementCeramic shaping plantsProduction lineBrick

A refractory material full-automatic production line comprises a weighing-distributing device, a press, a detecting-conveying line, a stacking robot and a transporting trolley, and is characterized inthat the weighing-distributing device comprises a fixing frame as well as a discharging mechanism, a weighing mechanism and a distributing mechanism which are mounted on the fixing frame; the discharging mechanism is equipped with a storage bin; a feeding port is arranged at the top of the storage bin; the weighing mechanism is positioned below the discharging mechanism and comprises a weighing hopper; a frame body is arranged on the outer side of the weighing hopper; the distributing mechanism is positioned below the weighing mechanism and comprises a distributing framework; the distributingframework is horizontally arranged at the middle of the fixing frame; two sides of the distributing framework and the middle of the fixing frame are matched through a transversely-arranged guiding rail; and a distributing gate is arranged at a discharging port at the bottom of the distributing hopper. The refractory material full-automatic production line provided by the invention has the advantages that the weighing precision is improved; the refractory brick quality is improved; the problems about manual sampling errors, brick body damage and the like are solved; and the production efficiency is improved.

Owner:沈阳罗泰智能系统有限公司

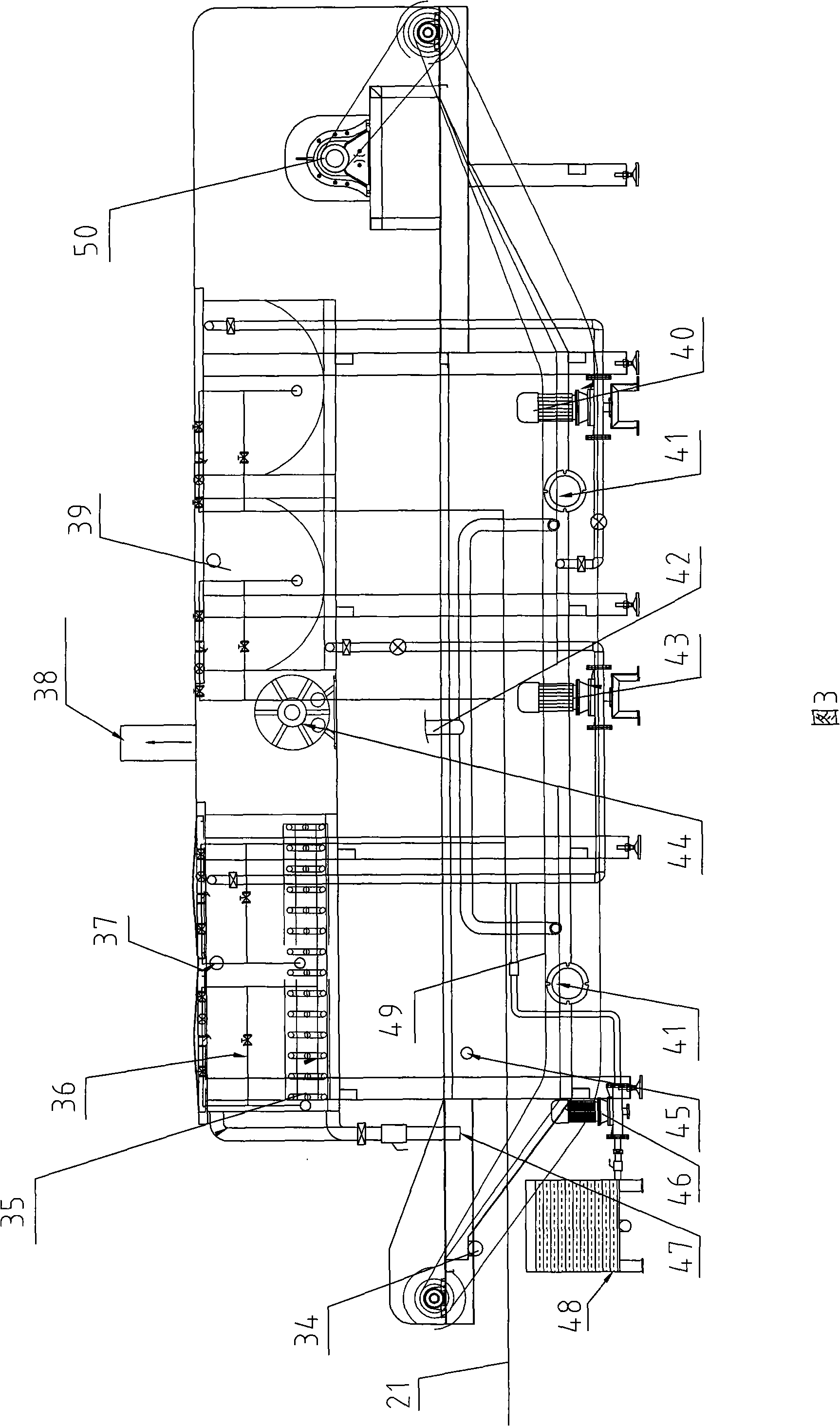

Full-automatic alkali-dipping, rinsing and marinating production line

The invention relates to a production line for fully-automatic alkali parboiling, bleaching and marinating, which belongs to foodstuff processing mechanical equipment and aims to solve the problems that the prior marinated food processing equipment has large labor coefficient, unstable product quality caused by human factors, and low production efficiency. The production line comprises an alkali-parboiling machine, a bleaching machine, a marinating machine and an automatic control device, wherein the three machines are provided with a stirring mechanism and a dewatering mechanism respectively, and the alkali-parboiling machine and the marinating machine are also provided with a technological parameter sensor and an overflow liquid reclaiming mechanism which are electrically connected with the automatic control device. The production line is applicable to processing marinated foods.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

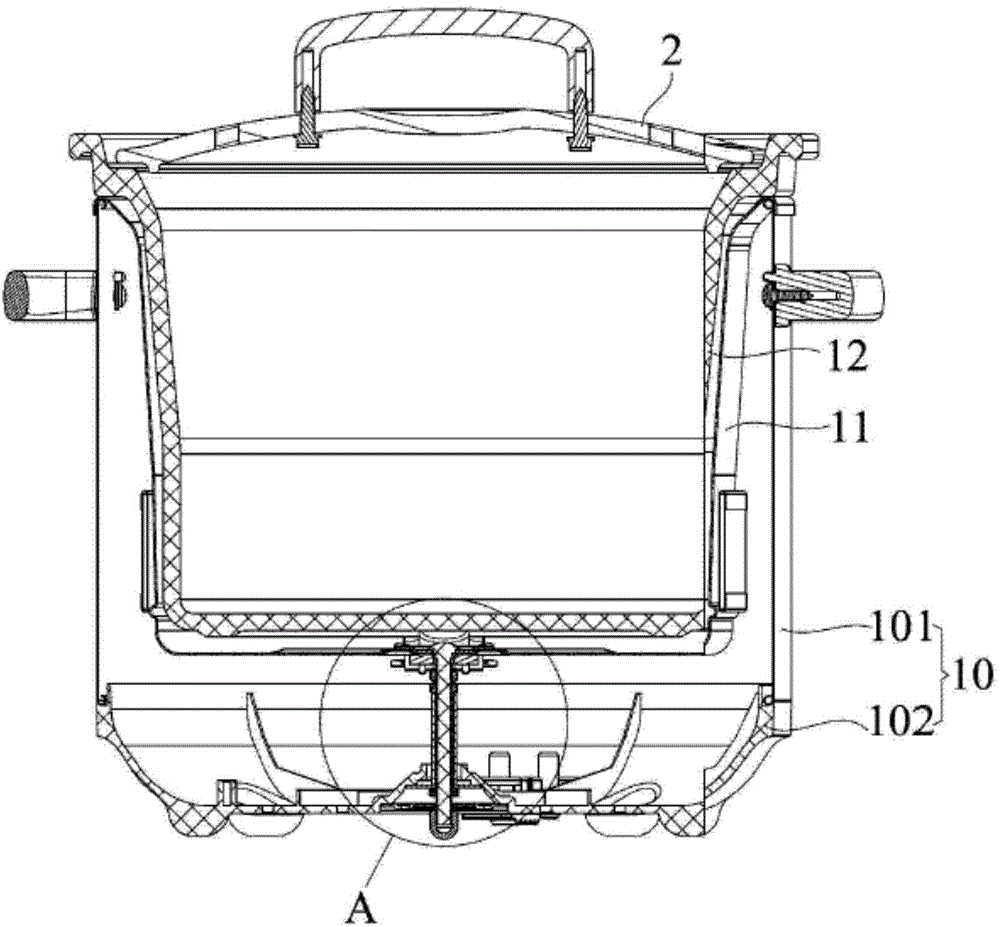

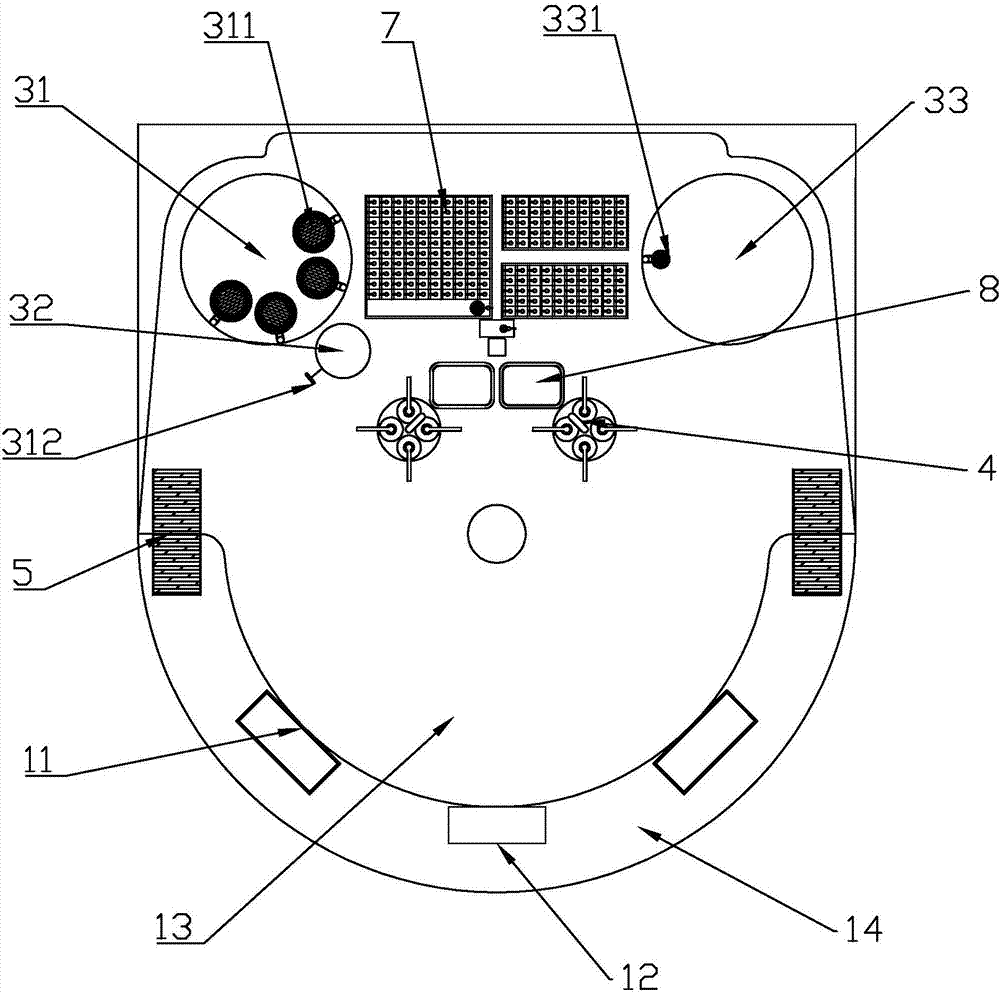

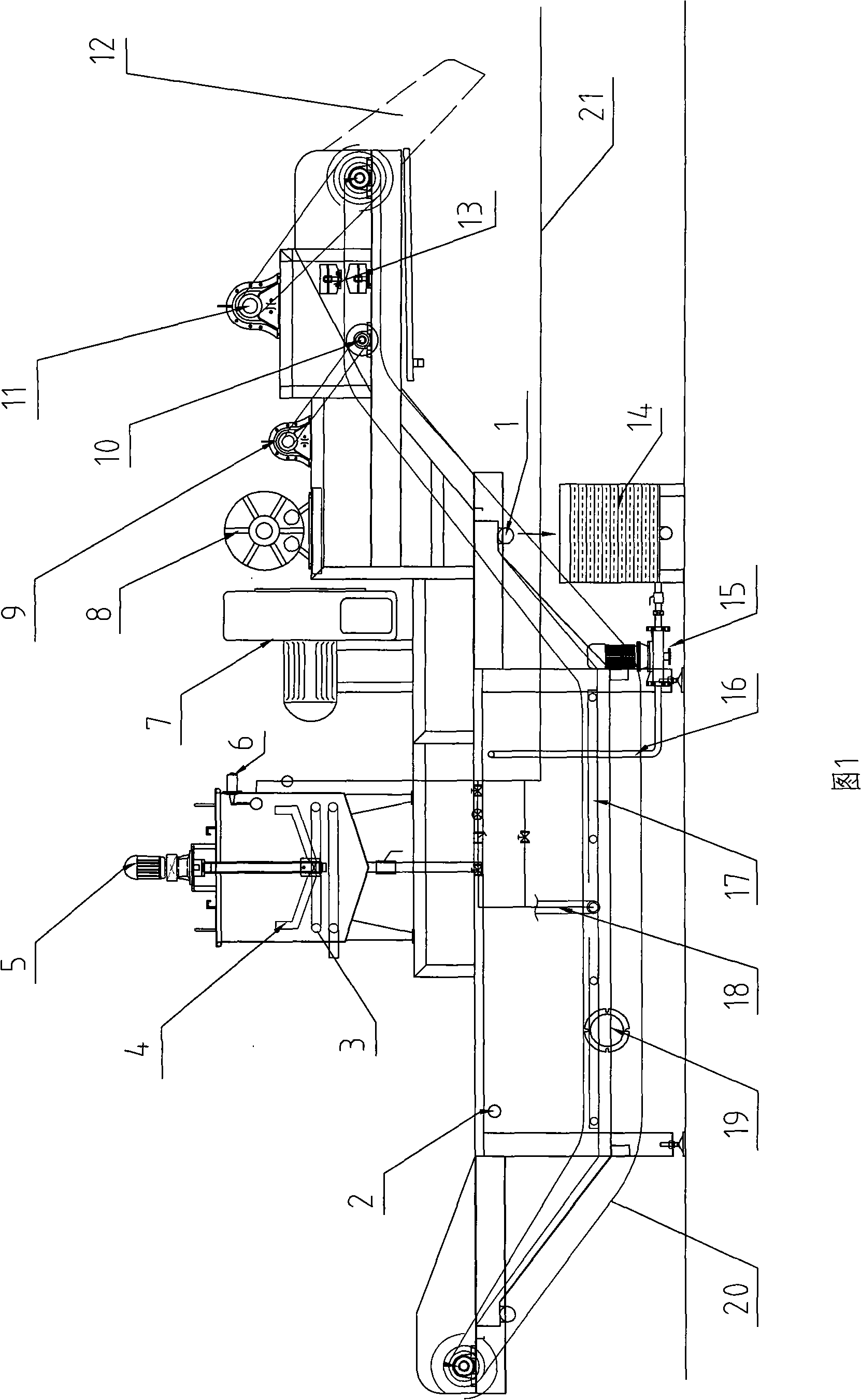

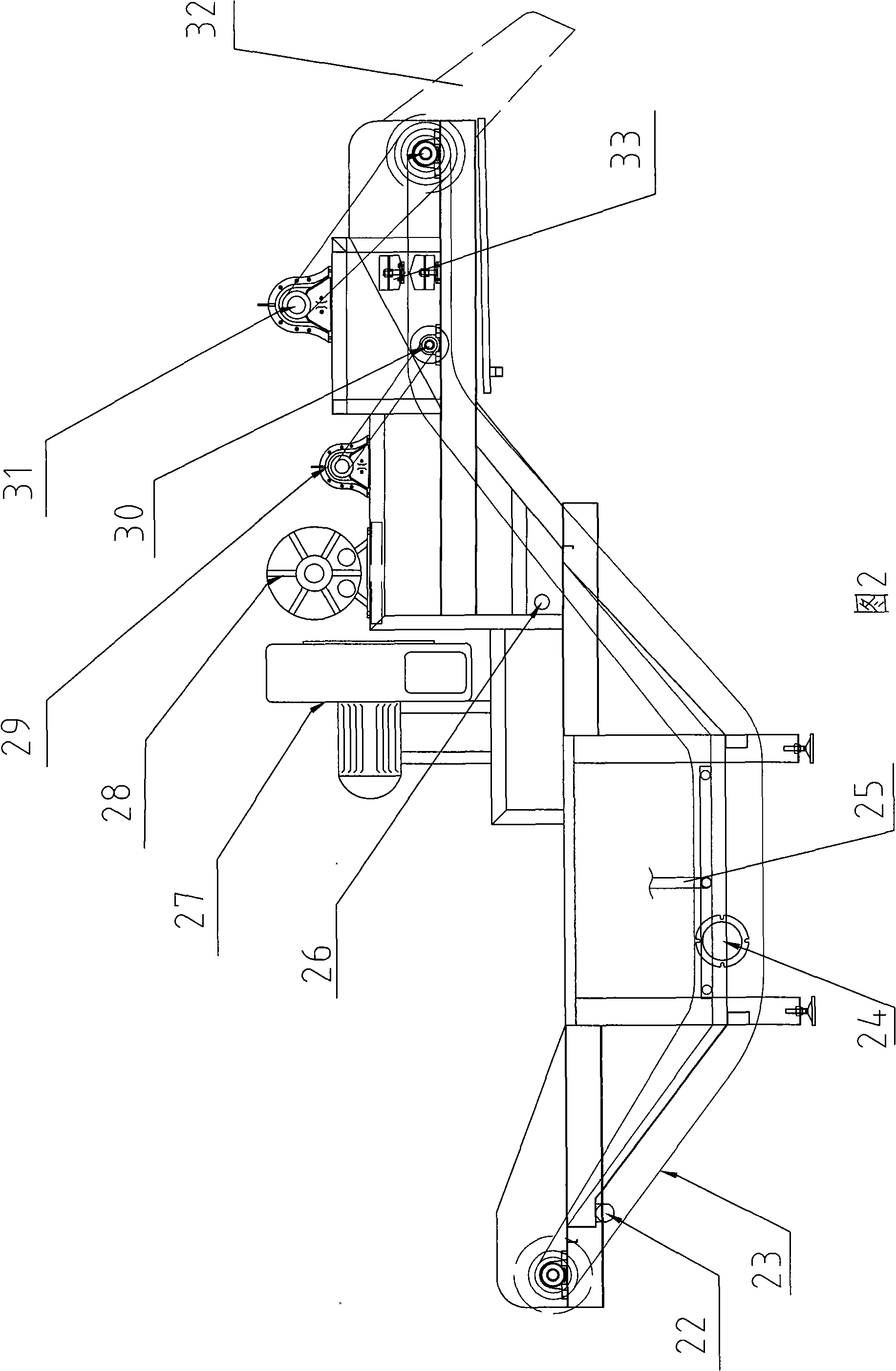

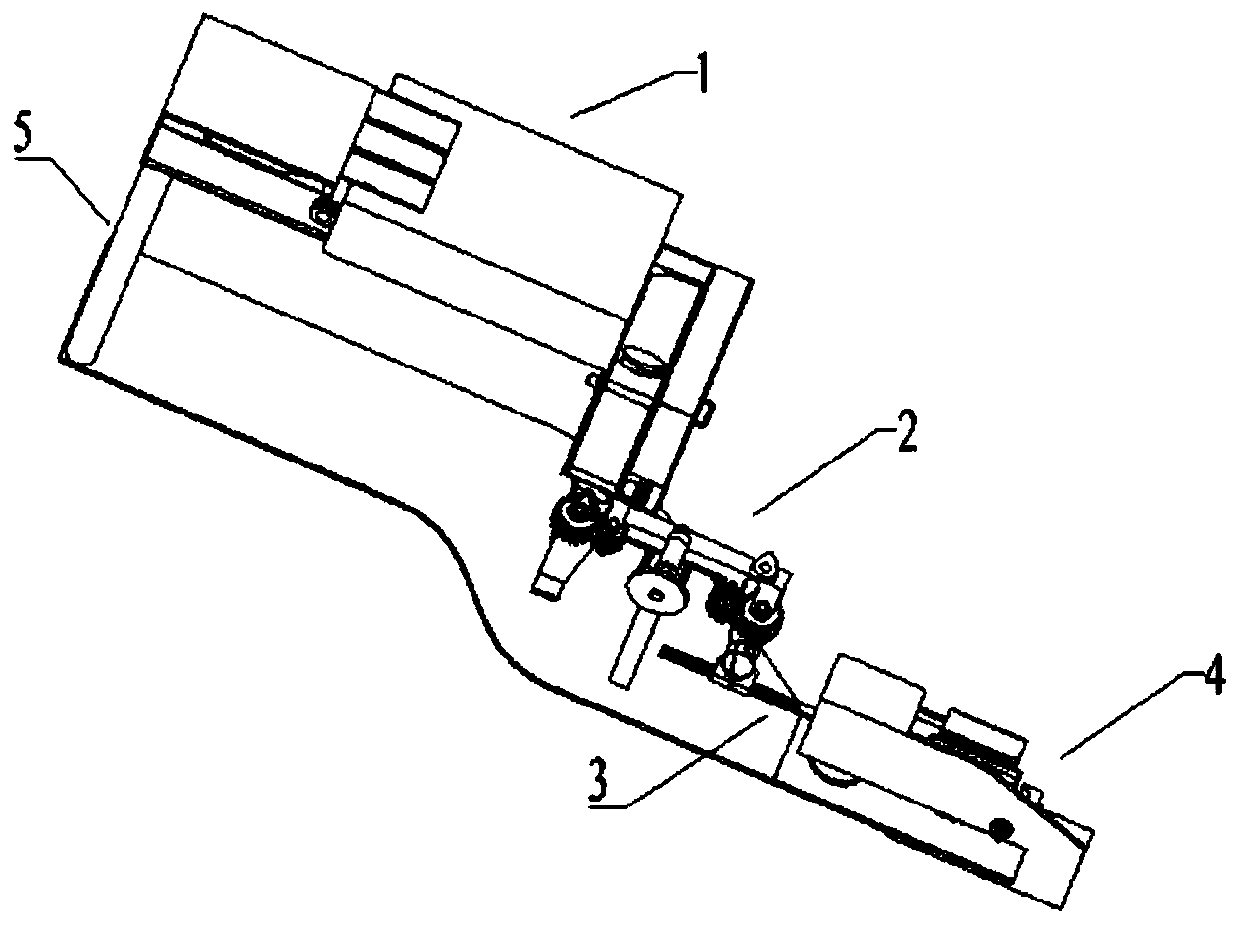

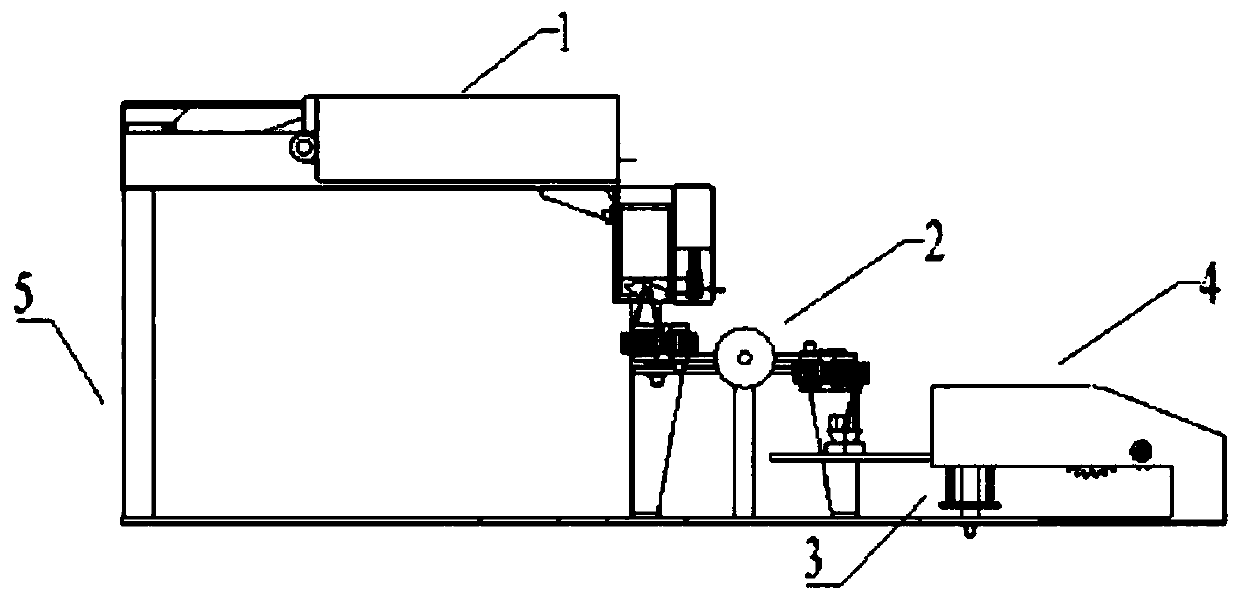

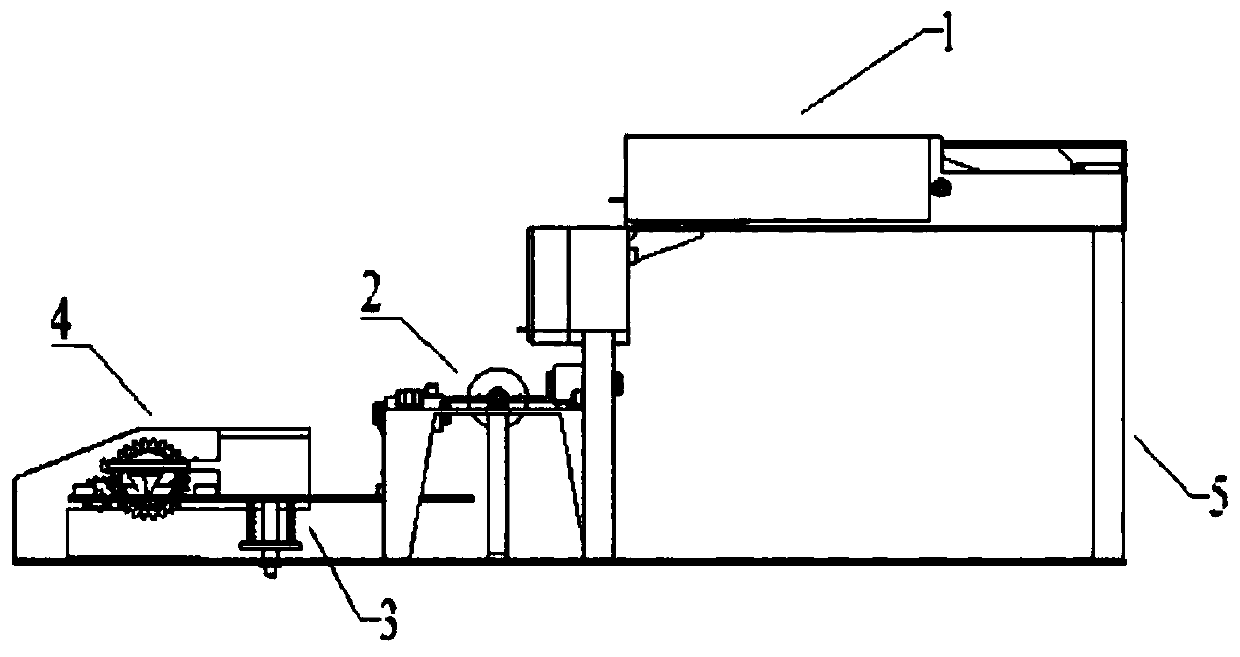

Full-automatic glutinous rice dumpling making device and full-automatic glutinous rice dumpling making method

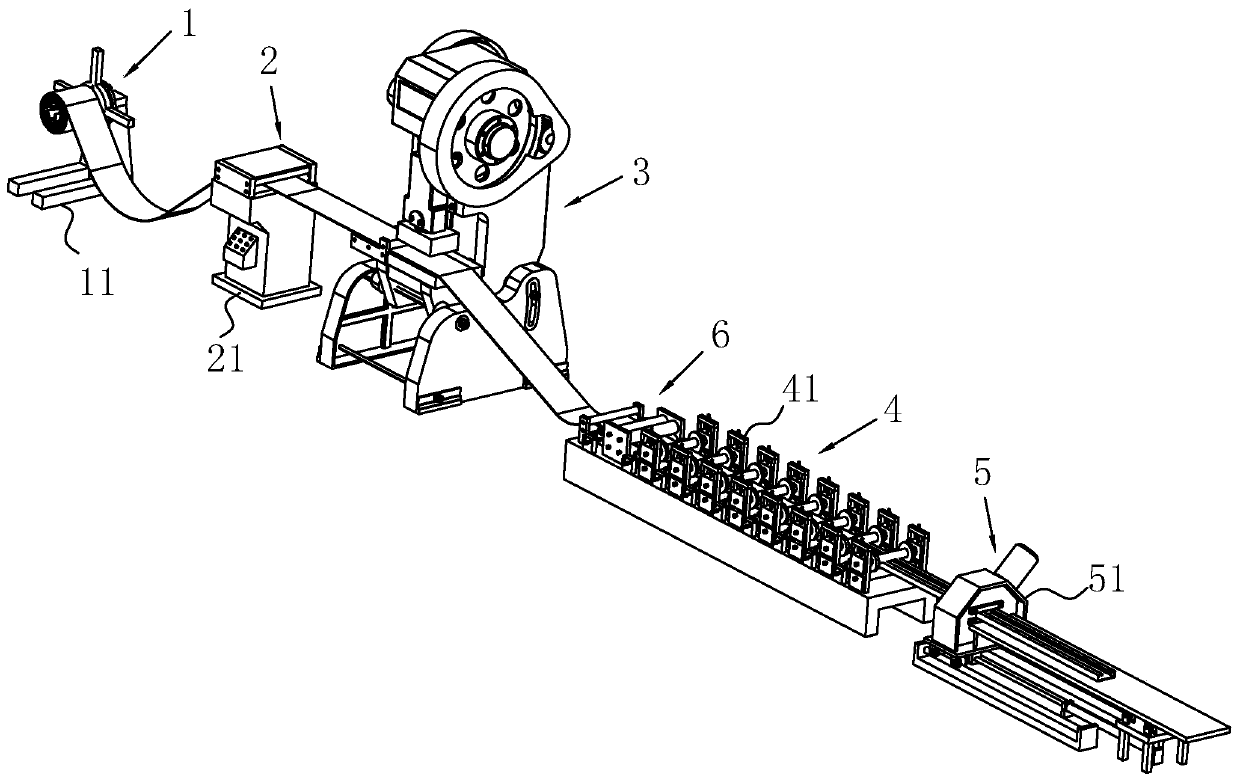

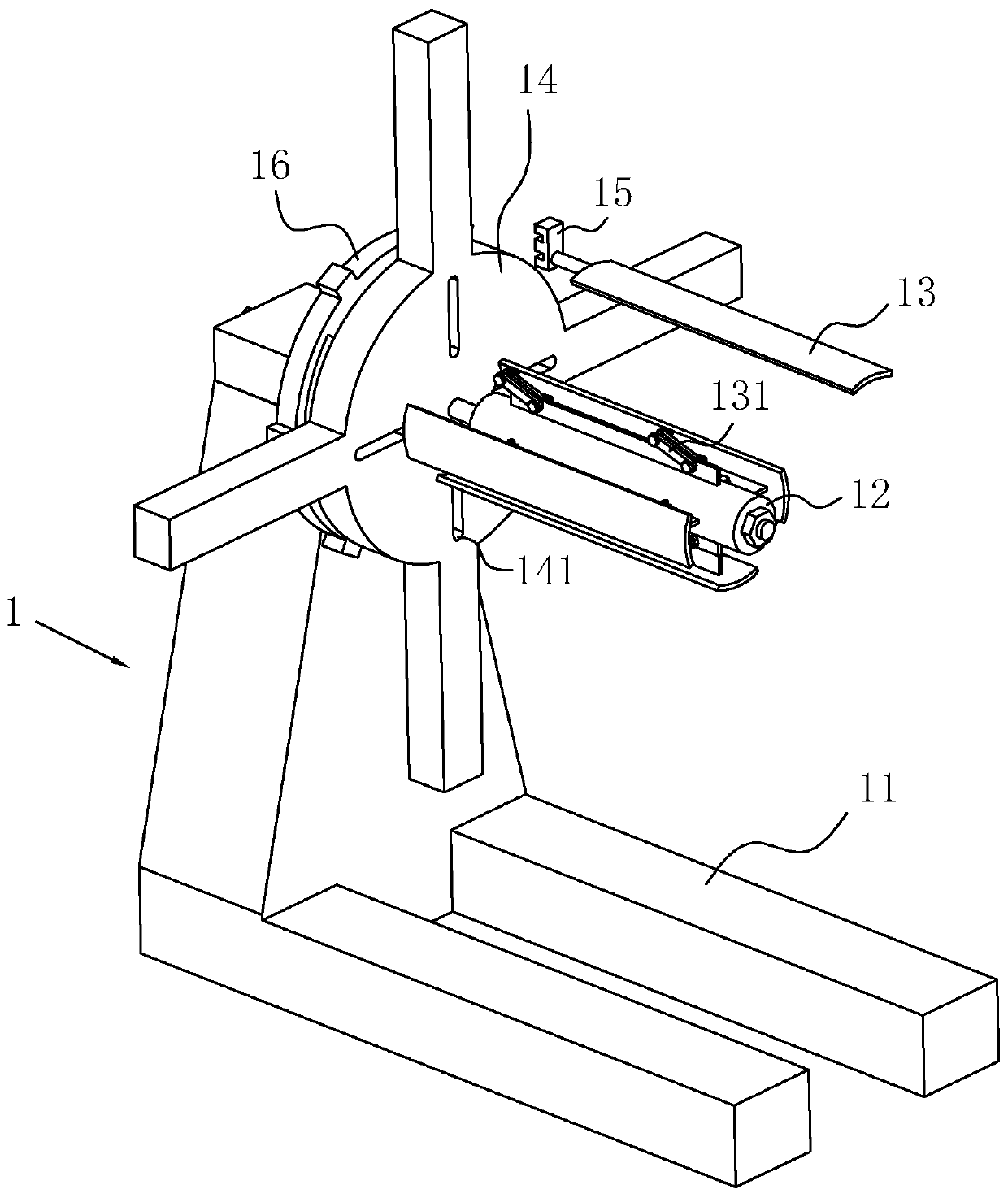

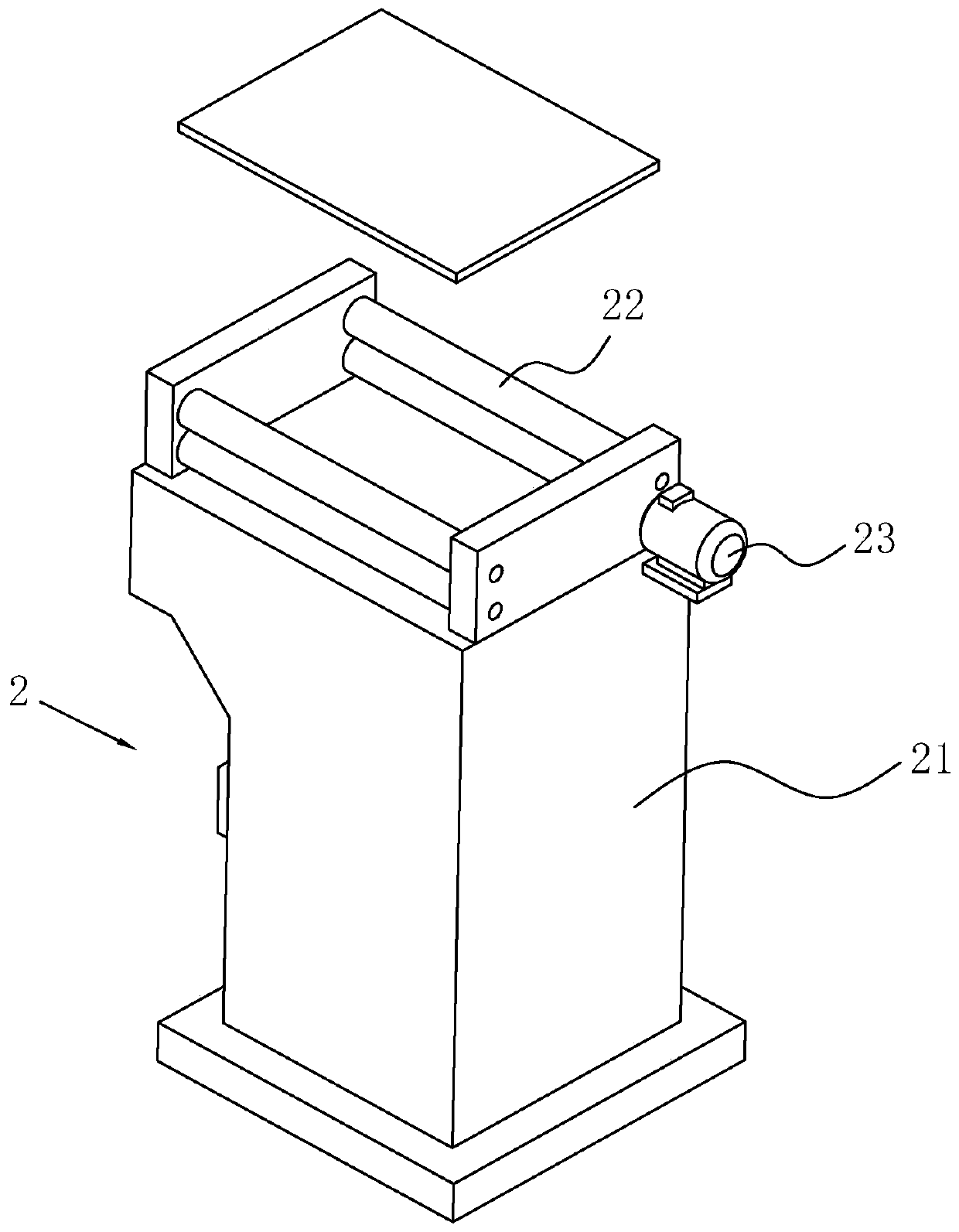

The invention discloses a full-automatic glutinous rice dumpling making device which comprises a rice dumpling leaf separator (1), a rice dumpling leaf circulating supply device (2), a rice dumpling conveyer (3), an automatic bundling device (4) and a rack (5). The rice dumpling leaf separator (1), the rice dumpling leaf circulating supply device (2), the rice dumpling conveyer (3) and the automatic bundling device (4) are fixedly arranged on the rack (5), the rice dumpling leaf circulating supply device (2) is arranged at a discharge port of the rice dumpling leaf separator (1), and one sideof the rice dumpling conveyer (3) corresponds to the rice dumpling leaf circulating supply device (2), and the other side of the rice dumpling conveyer (3)corresponds to the automatic bundling device(4). The invention also discloses a full-automatic glutinous rice dumpling making method. The full-automatic glutinous rice dumpling making device achieves full-automatic production of glutinous ricedumplings, improves production efficiency, saves labor cost and is complete in function, reasonable in design, convenient to maintain later and good in stability, and the cost is reduced while the efficiency is improved.

Owner:王建芬

Automatic production line for steel springboard

InactiveCN109759501ARealize fully automatic productionIncrease productivityMetal-working feeding devicesMetal working apparatusProduction linePunching

The invention relates to an automatic production line for steel springboards. A leveling machine for leveling the sheet metal, a punching machine for punching the sheet metal, a forming machine for bending the punched sheet metal, and a hydraulic shear for slitting the formed sheet metal are sequentially arranged on the downstream of a sheet metal feeding machine. During operation, the sheet metalis output from the sheet metal feeding machine, the sheet metal is conveyed to the punching machine for punching after being leveled by the leveling machine, then the sheet metal is output from the punching machine and enters the forming machine to be bent, the formed sheet metal enters the shearing machine to be cut into the required length until the processing is finished, and the full-automatic processing of the steel springboards is realized.

Owner:南京安骄金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com