Patents

Literature

144results about How to "Realize fully automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

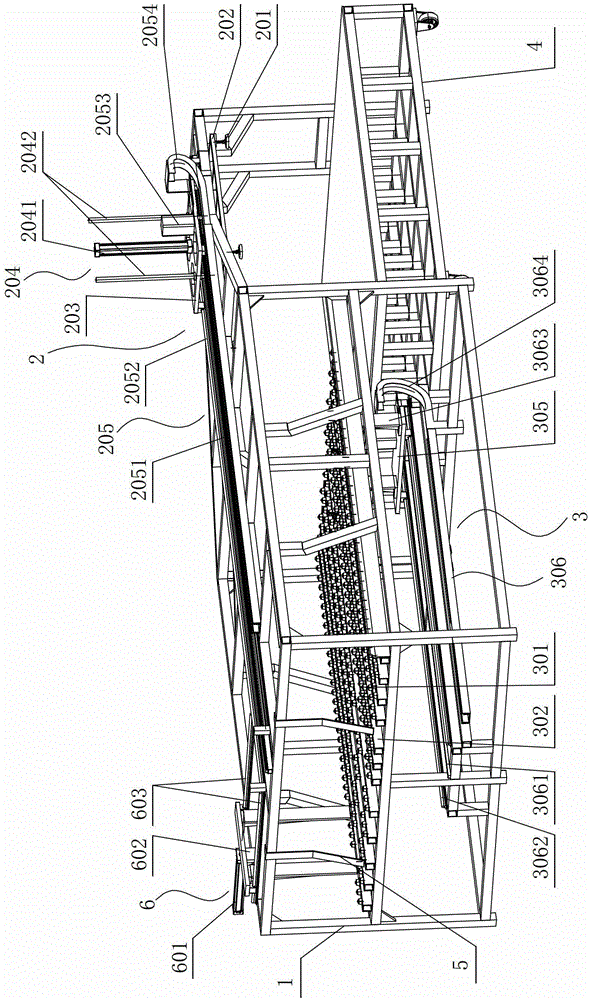

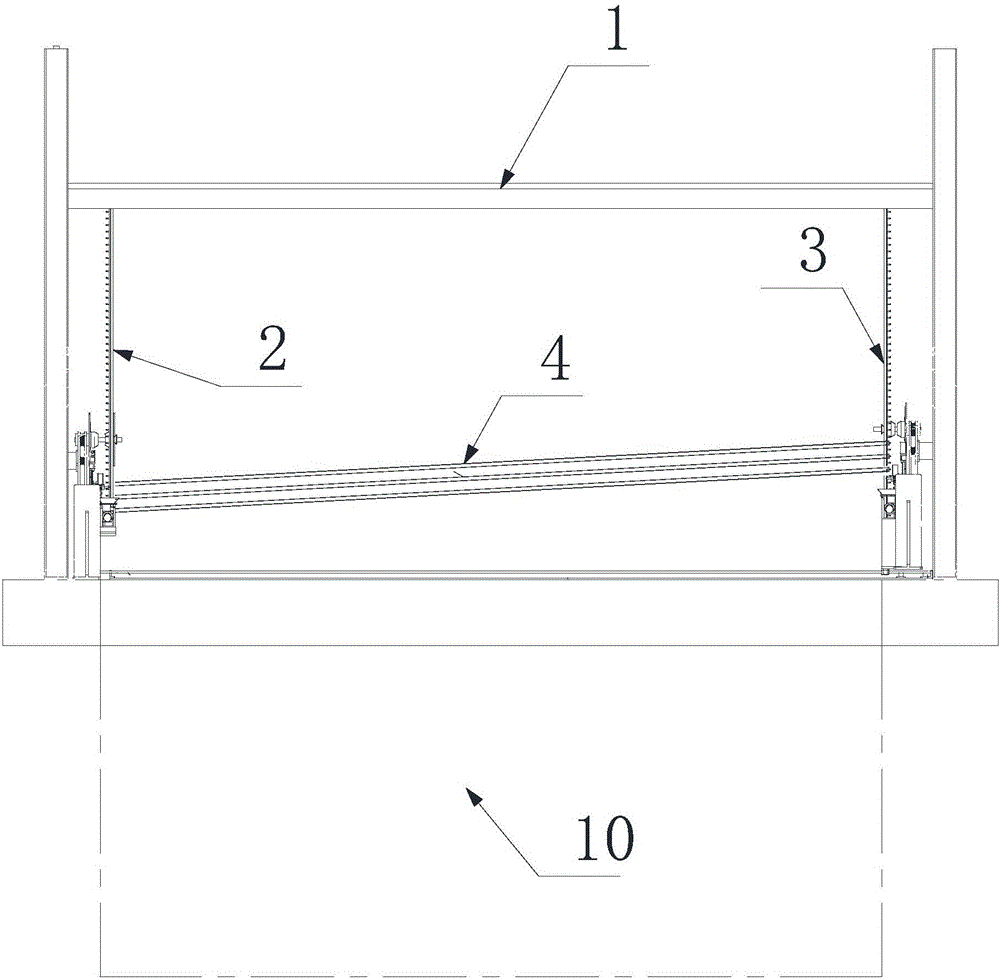

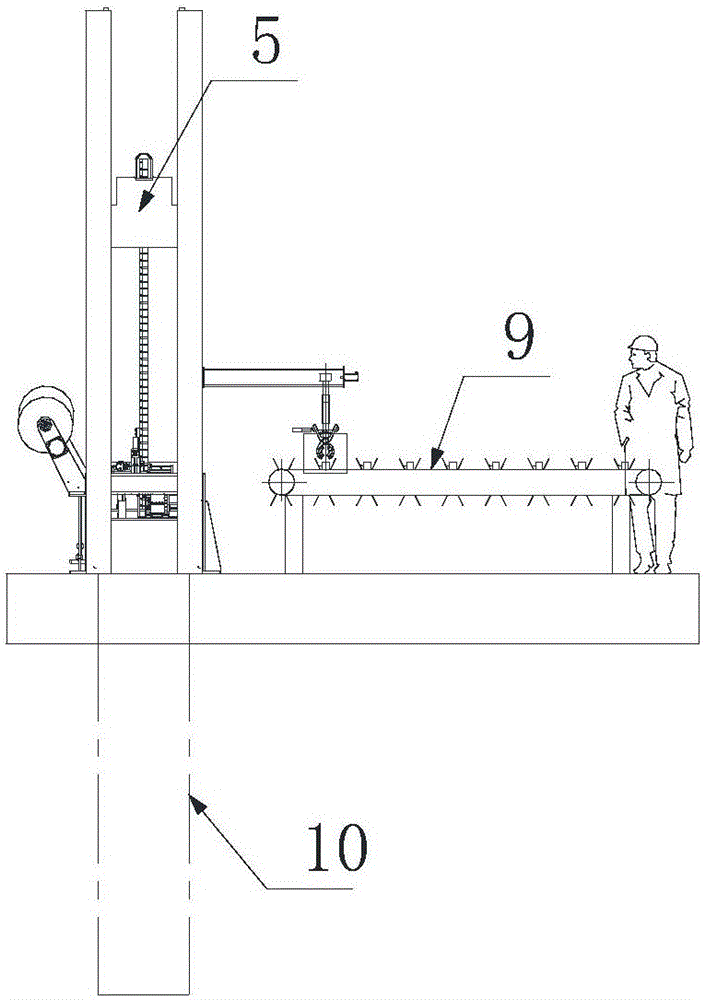

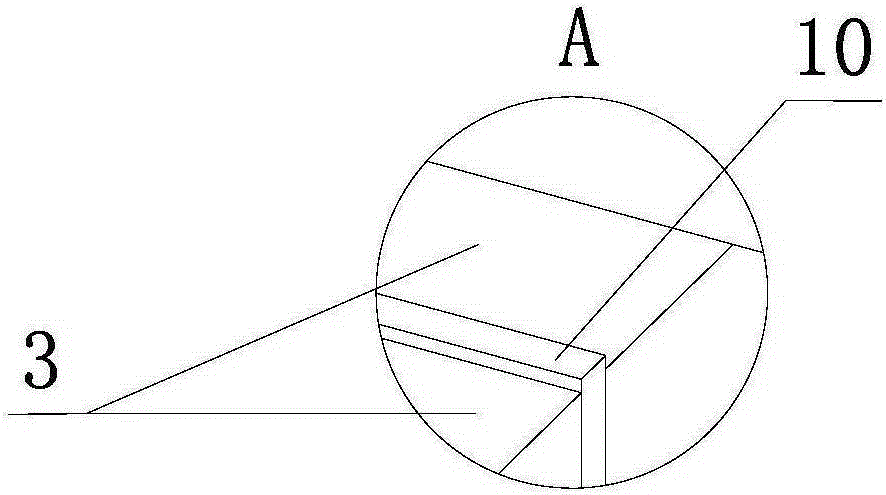

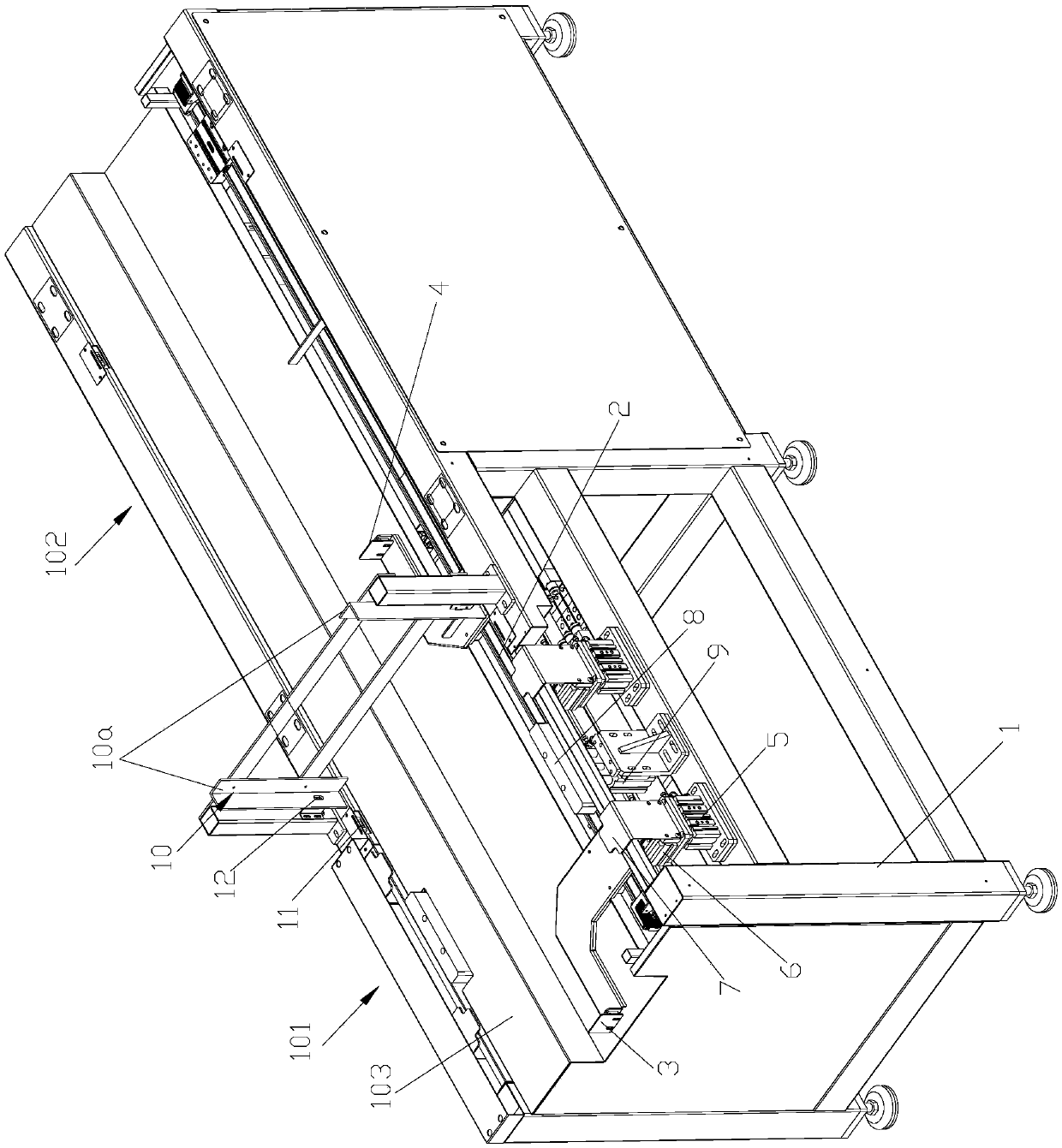

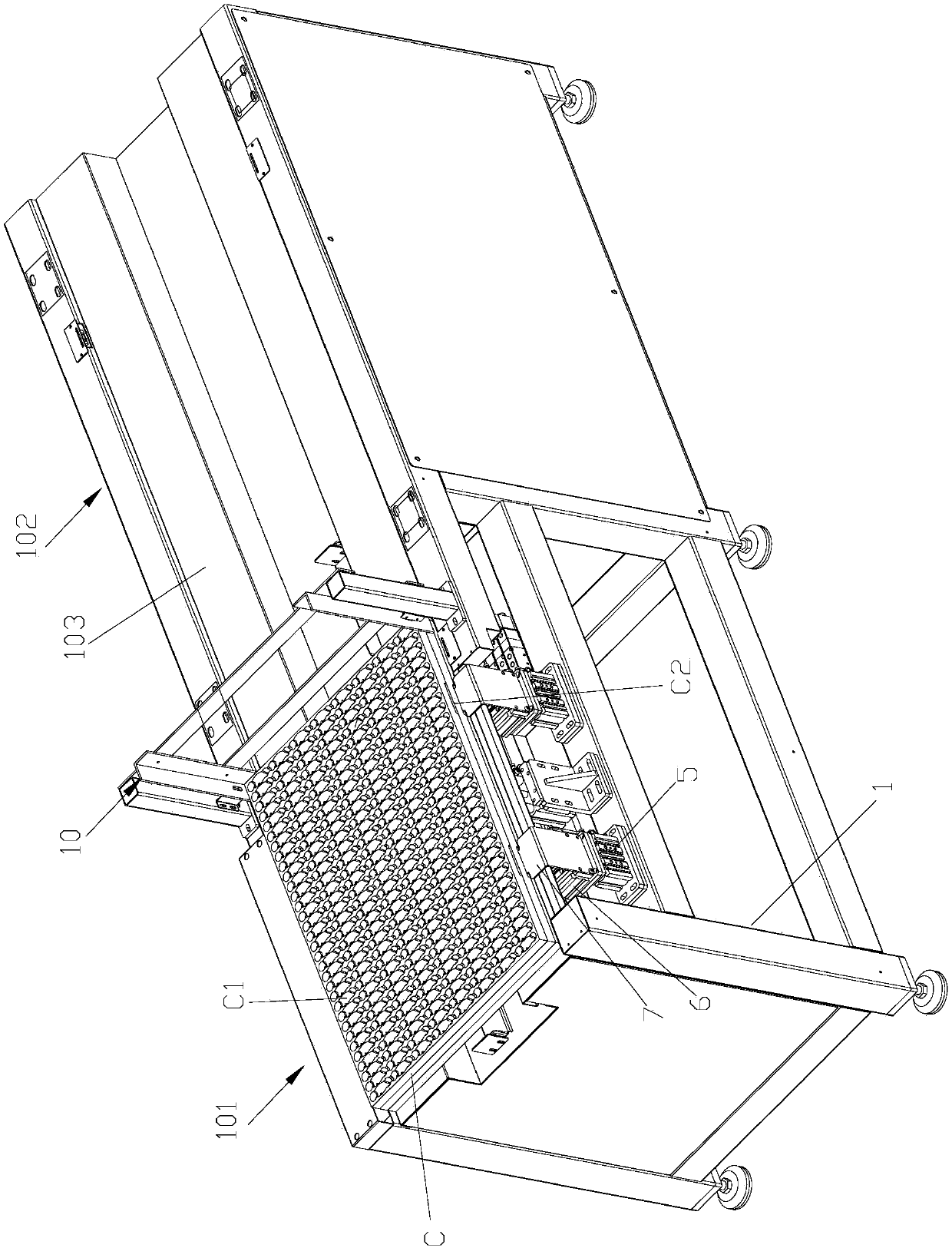

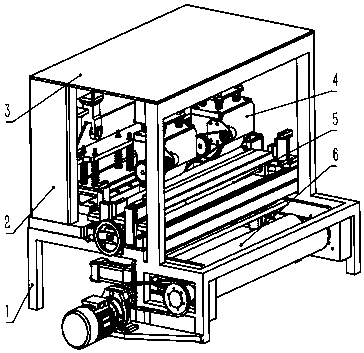

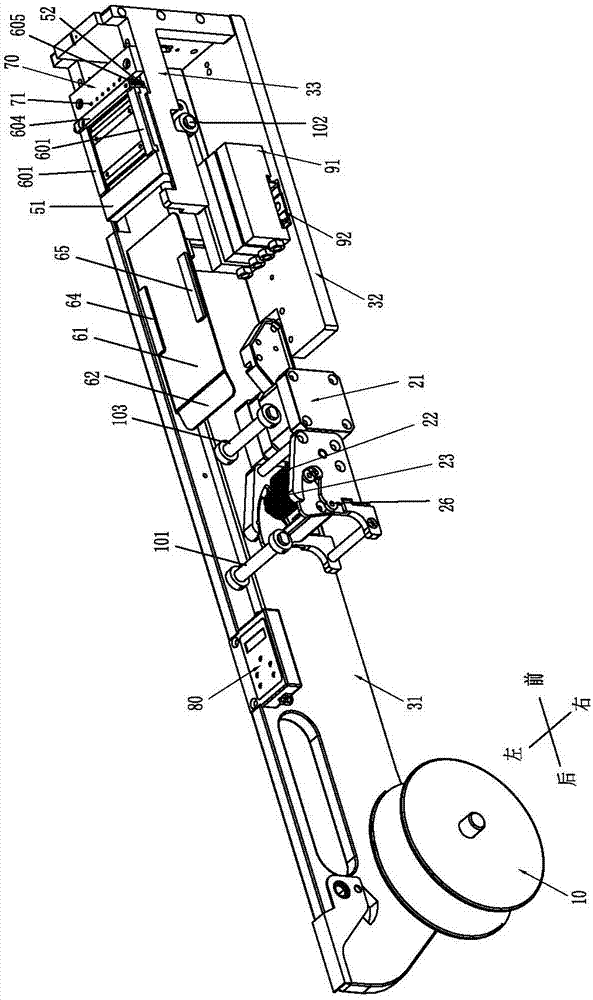

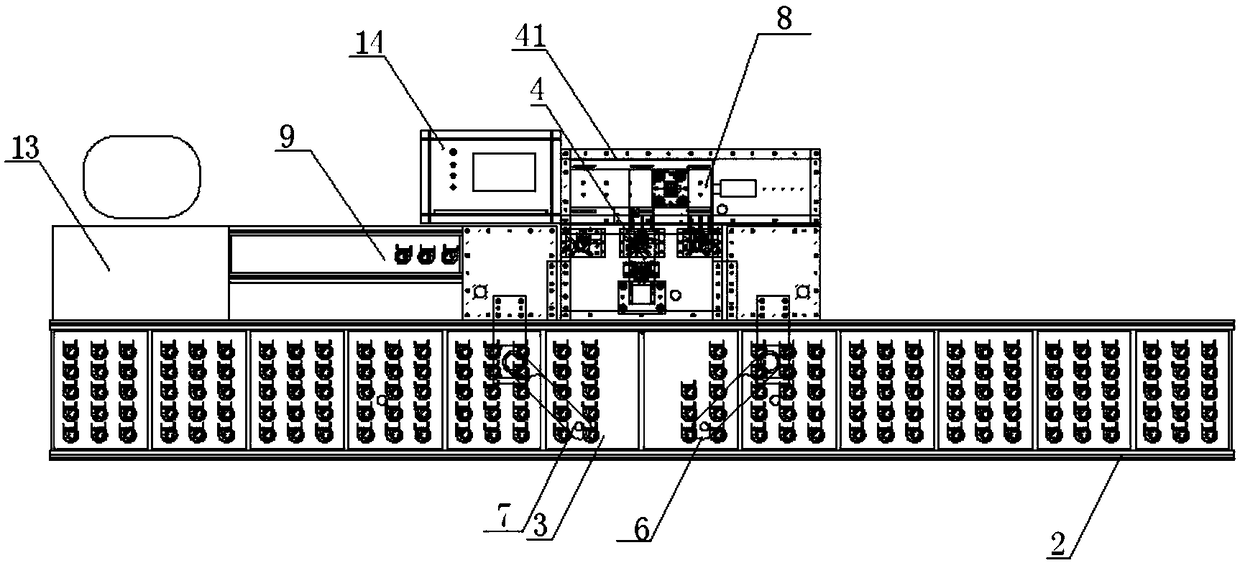

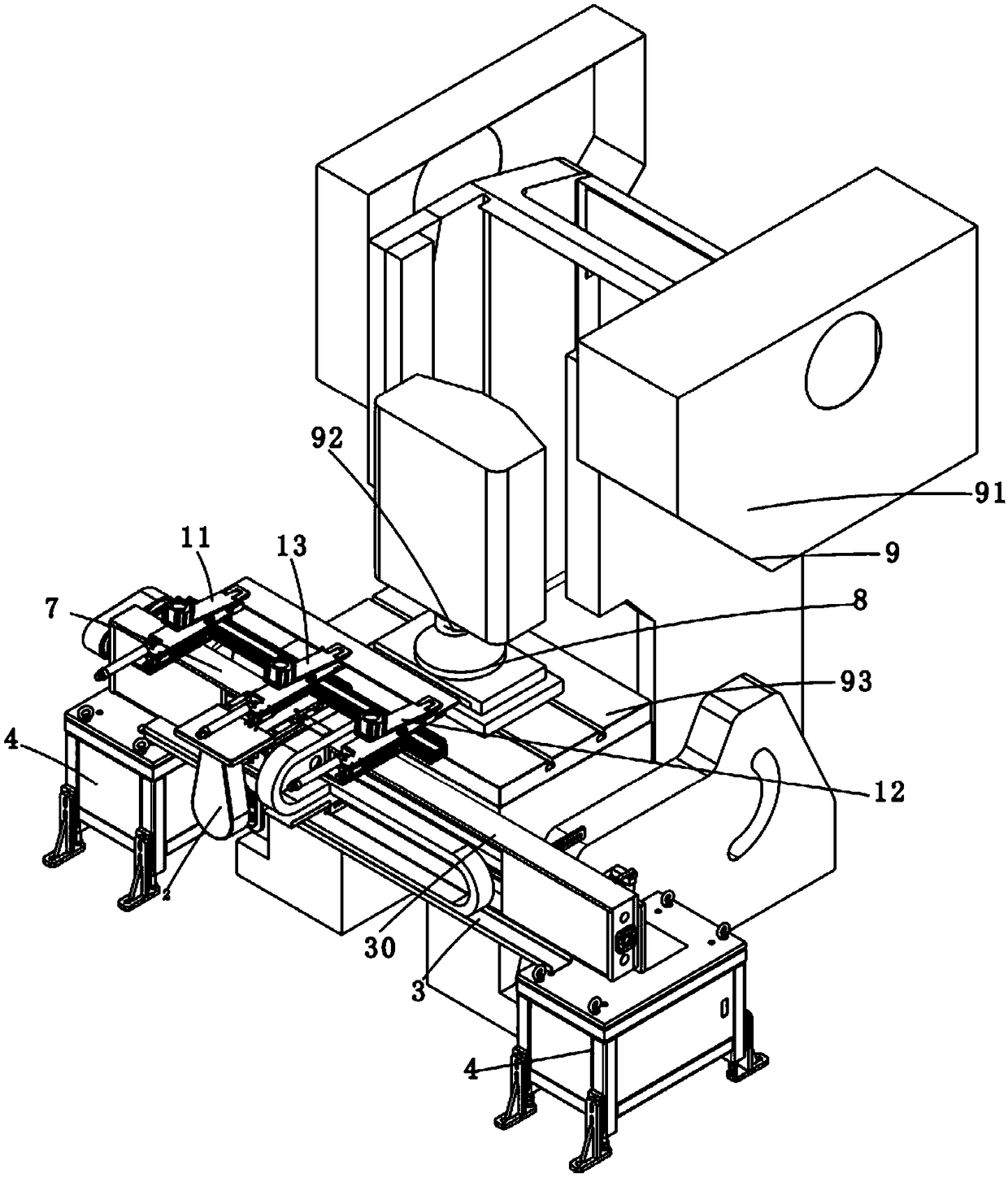

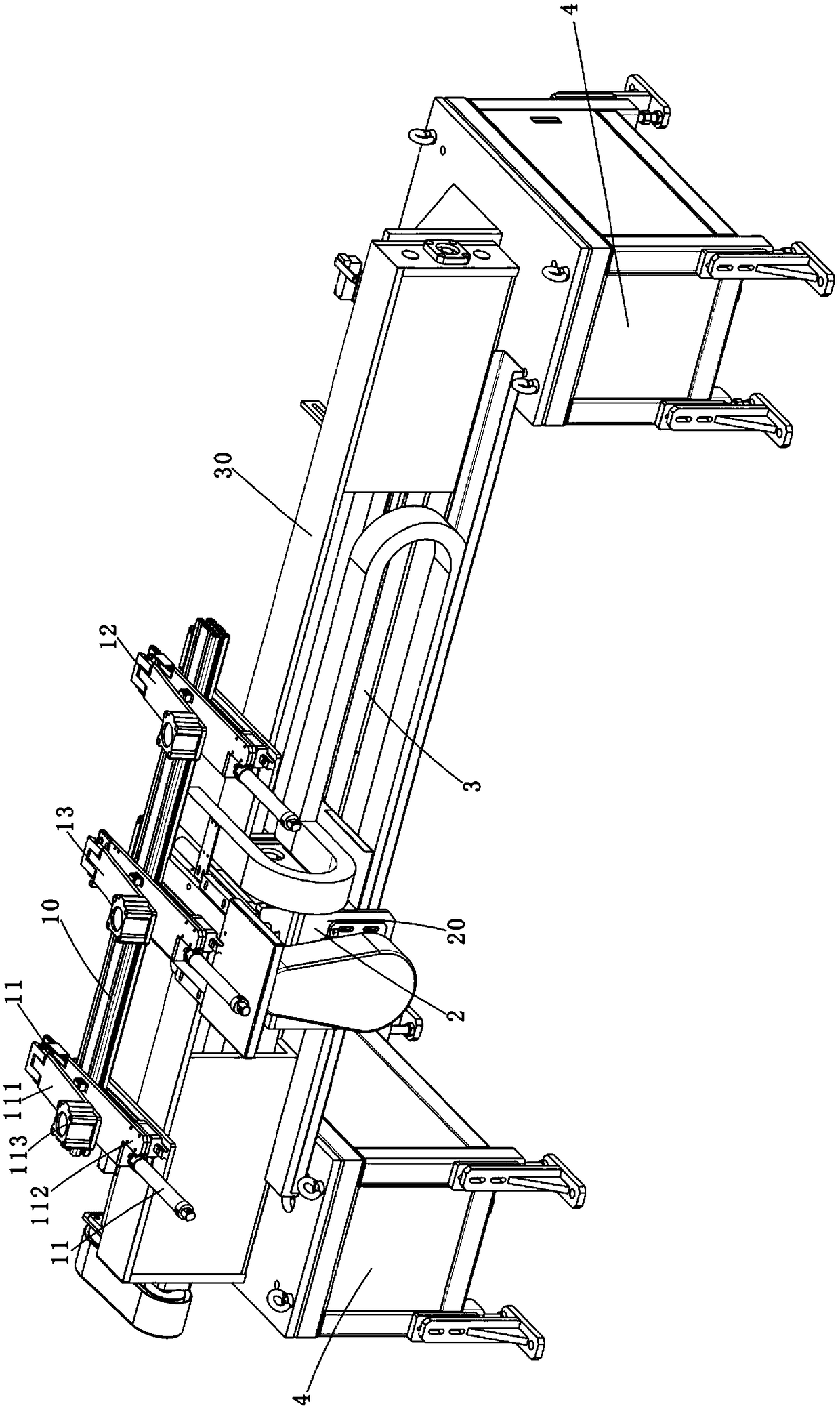

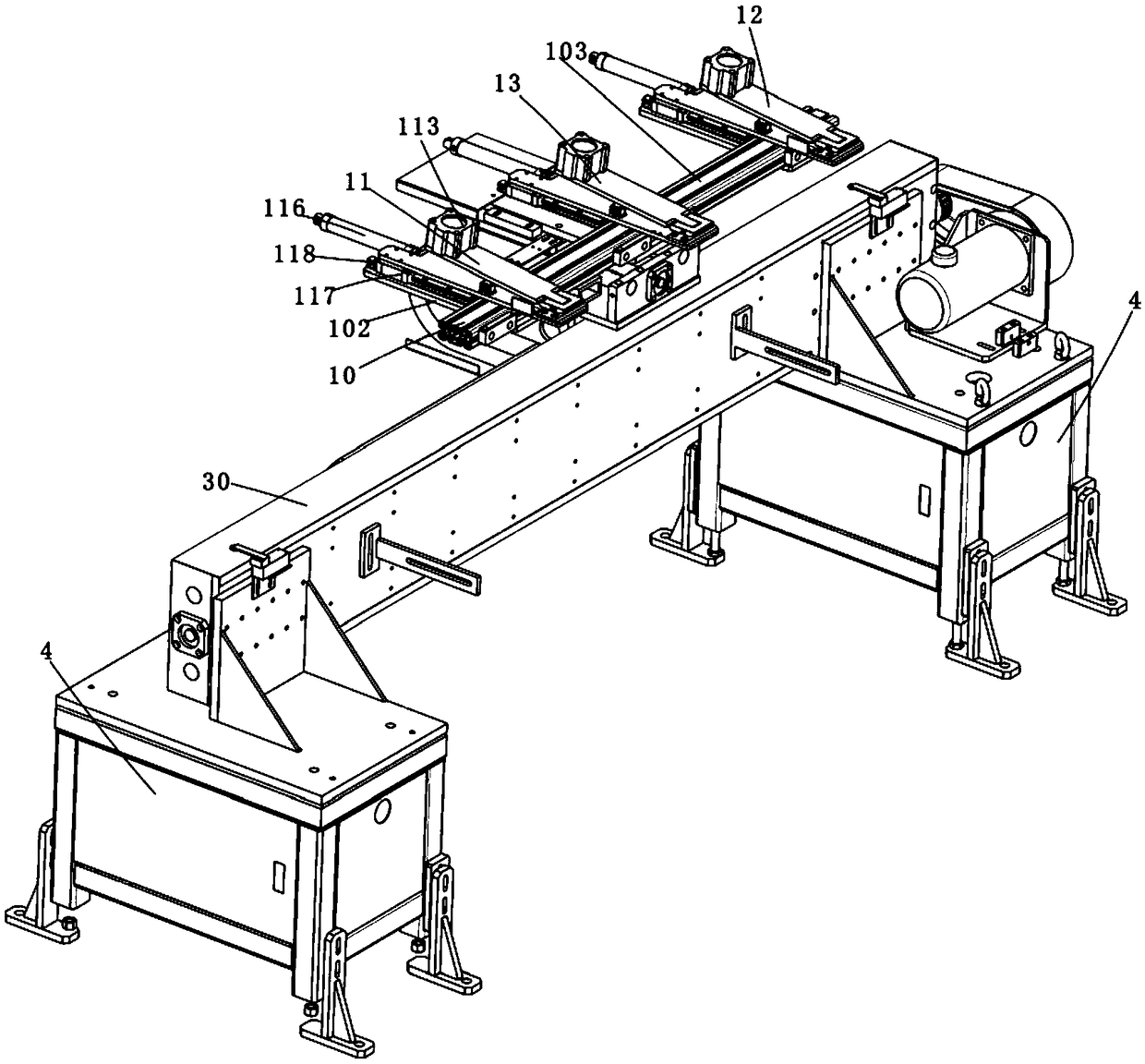

Automatic tread feeding device

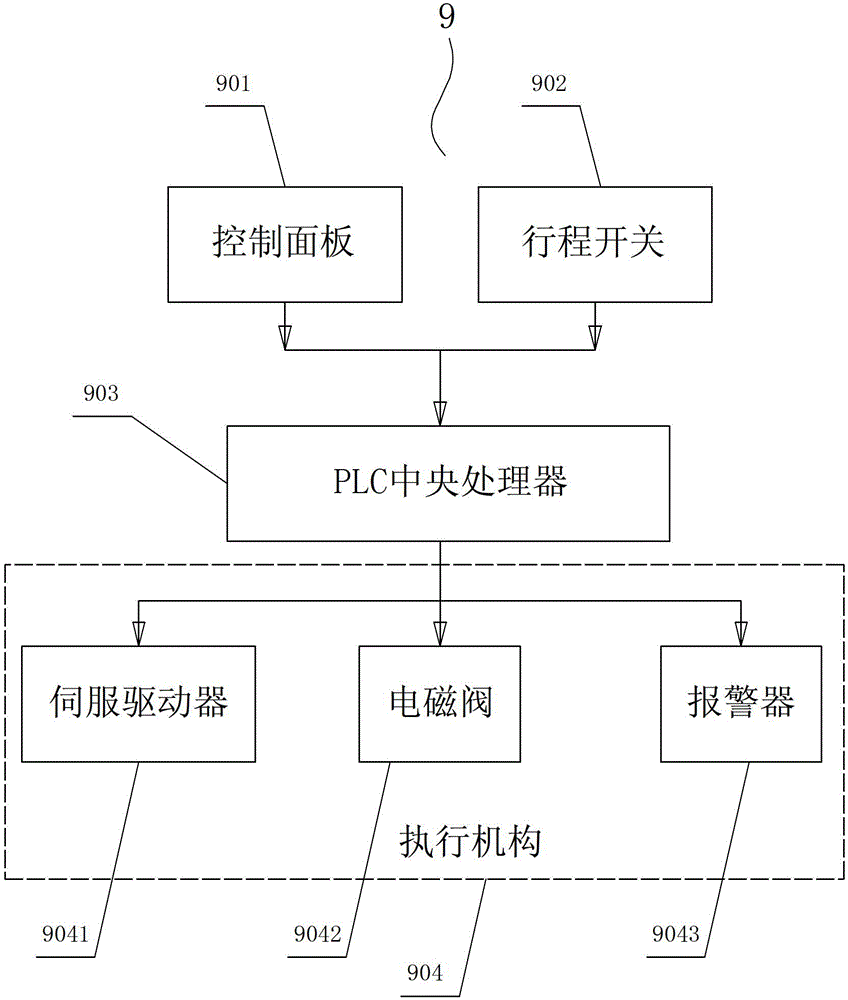

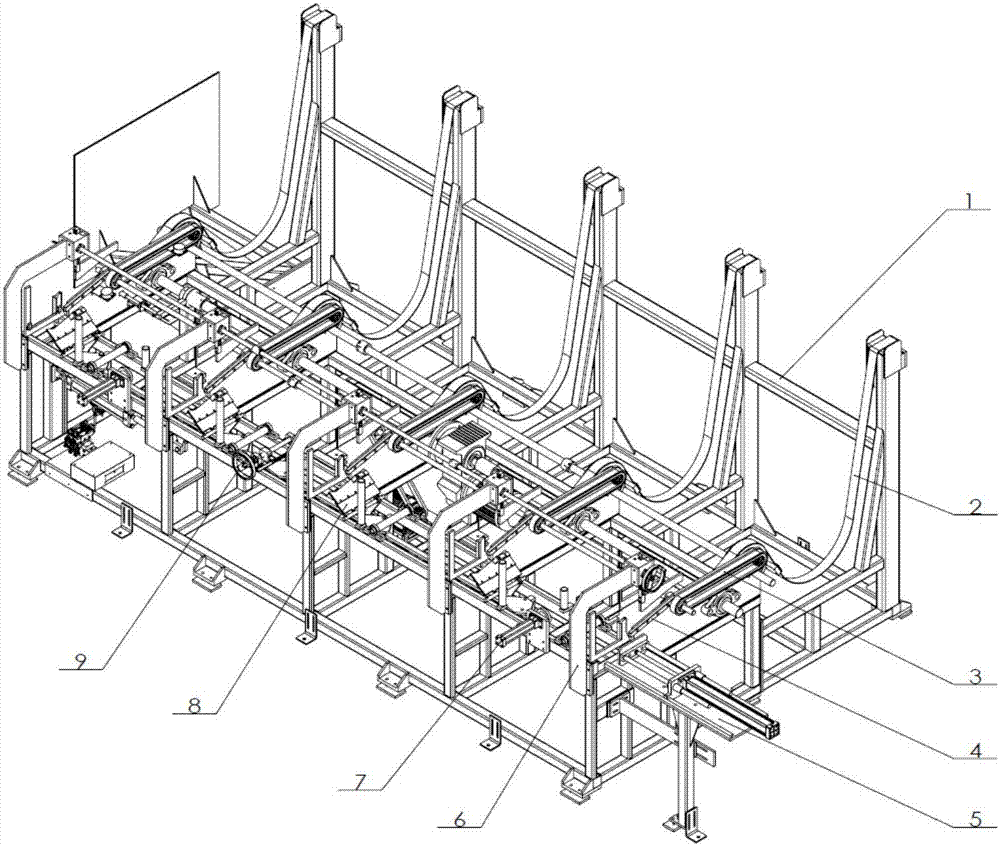

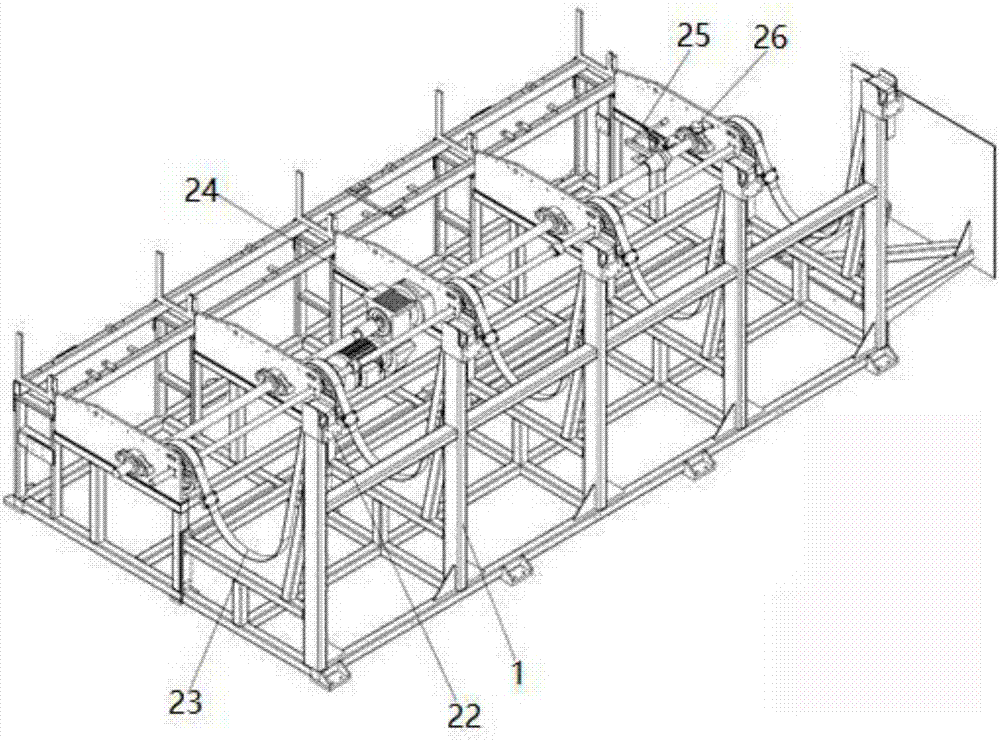

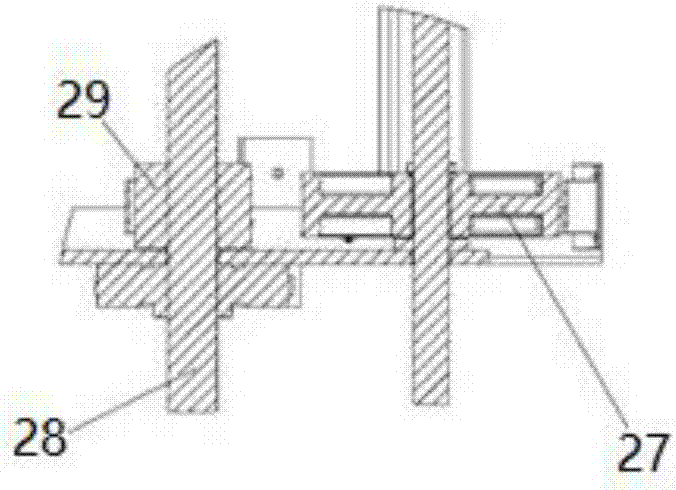

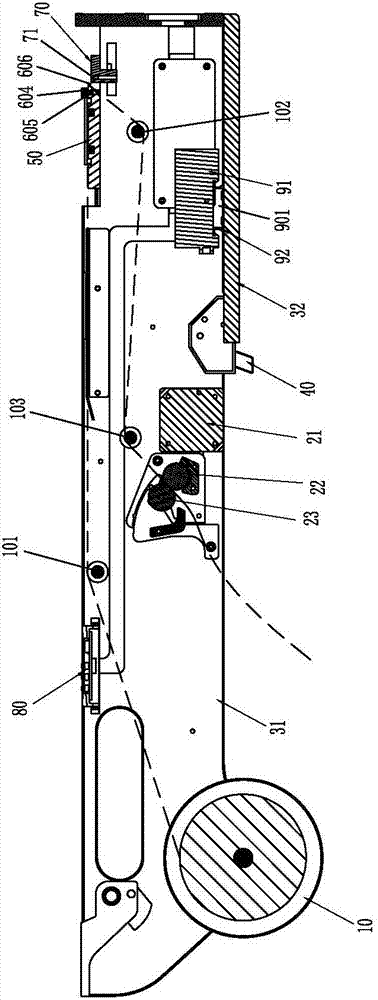

ActiveCN105690822ARealize fully automatic feedingImprove processing qualityTyresControl systemEngineering

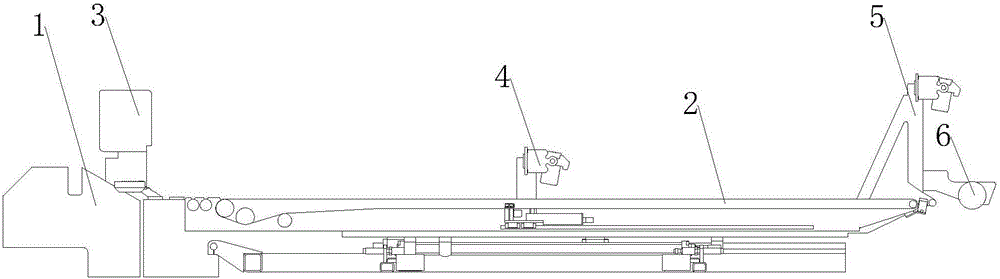

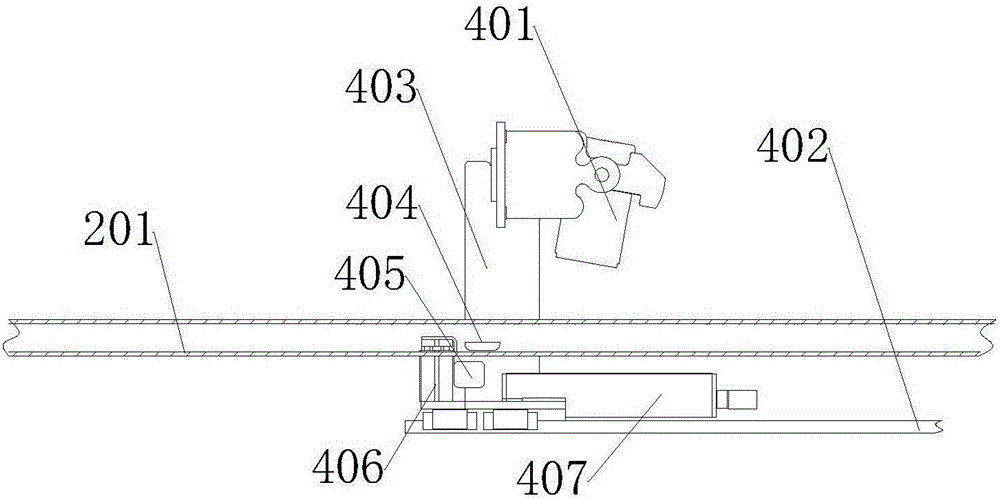

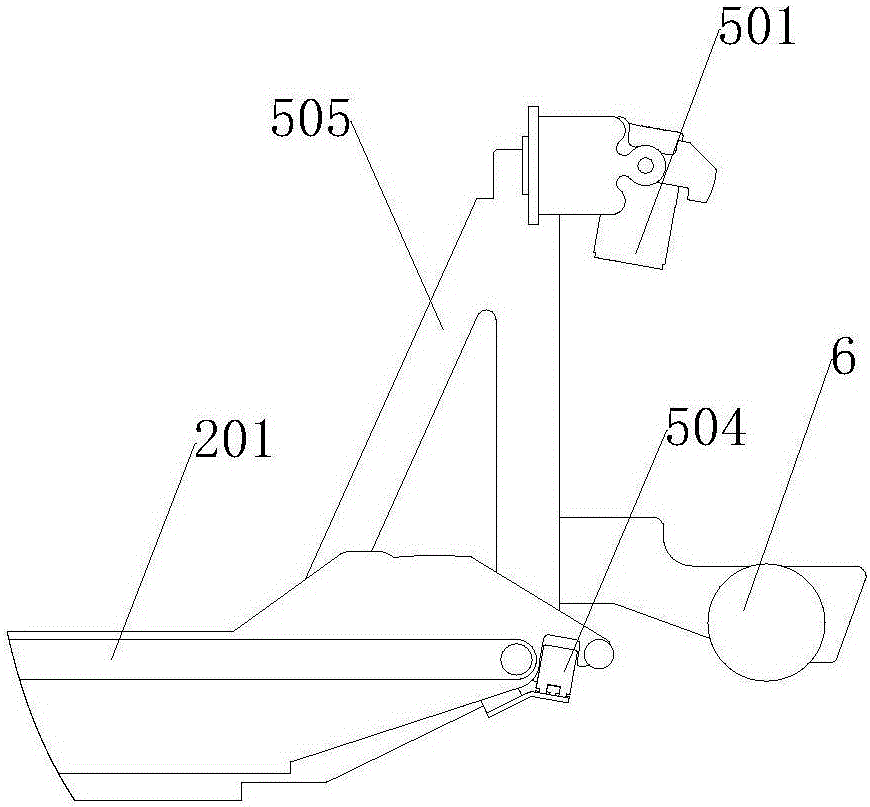

An automatic tread feeding device comprises a tread conveying mechanism, a tread cutting device, a press roll and a control system. According to the tread conveying direction, the tread conveying mechanism is divided into a rear conveying mechanism and a front conveying mechanism with the tread cutting device as a benchmark. The front conveying mechanism comprises a conveying belt, a tread length control device and a tread offset compensator, wherein the tread length control device and the tread offset compensator are both installed on the front conveying mechanism and located between the tread cutting device and the press roll. By means of the automatic tread feeding device, the purposes of tread automatic convey, visual length control, ultrasonic cutting, visual deviation correction and automatic joint attaching on a drum in the tire molding process are mainly achieved, full-automatic feeding of tread materials in the tire molding process is achieved, and the production quality of tires can be improved.

Owner:QINGDAO WANLONG INTELLIGENT CONTROL TECH CO LTD

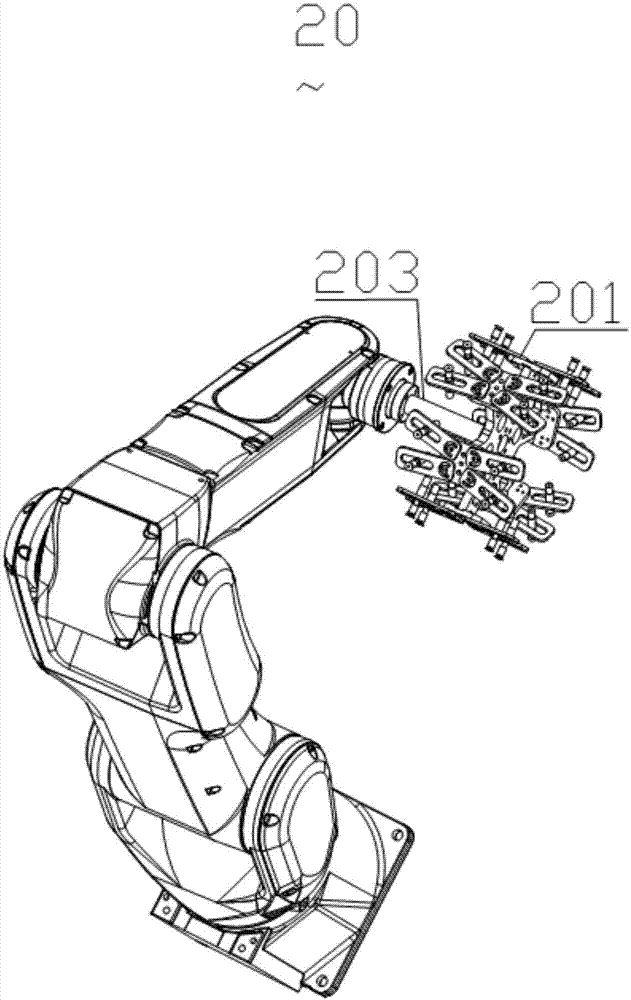

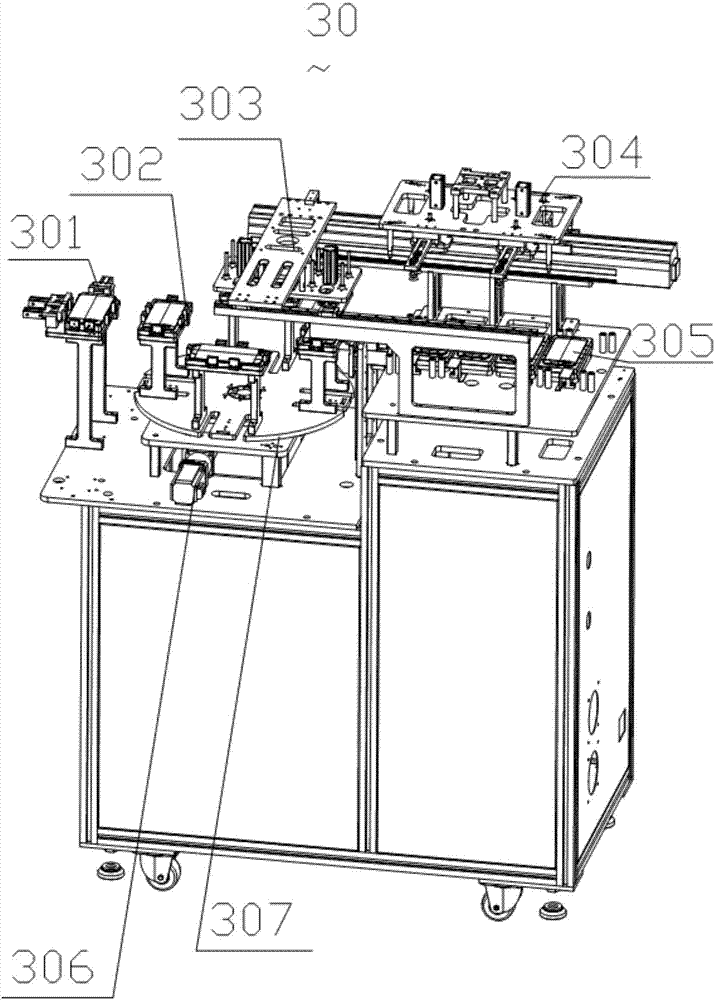

Automatic feeding system of injection molding machine

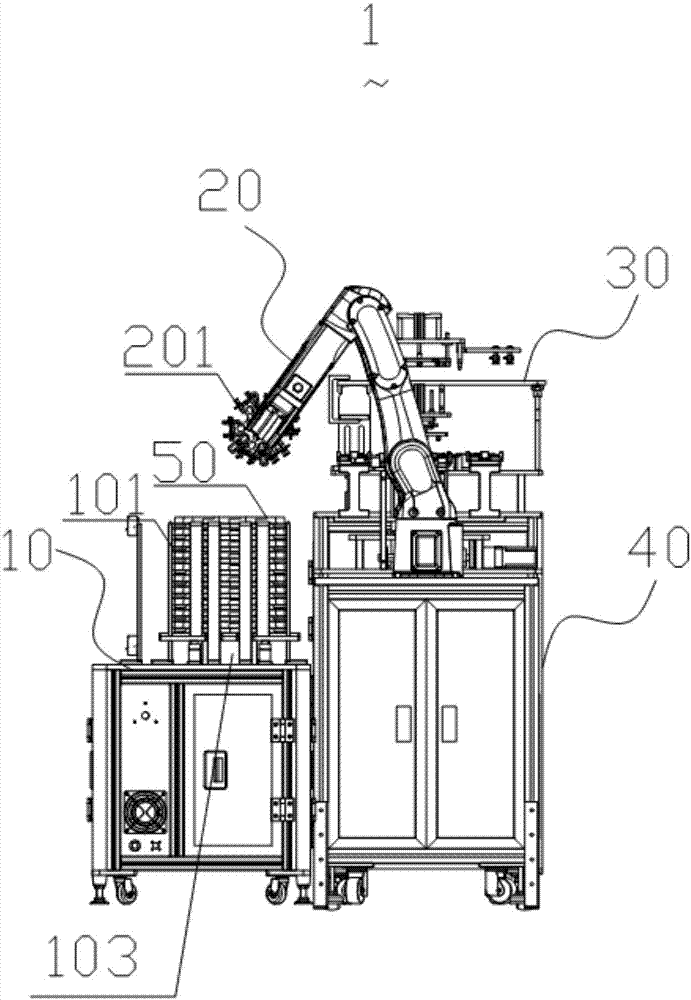

The invention provides an automatic feeding system of an injection molding machine. The automatic feeding system comprises a control system, a tray feeding device, a transfer robot and an injection molding machine feeding device, wherein the tray feeding device, the transfer robot and the injection molding machine feeding device are connected with the control system, at least one feeding area which is used for storing a tray for bearing a workpiece is formed on the tray feeding device, and a first chuck fixture is at least installed on the tail end of the transfer robot. When the automatic feeding system is operated, the transfer robot is controlled to suck at least one workpiece from the tray by utilizing the first chuck fixture and convey the workpiece to the injection molding machine feeding device by the control system, and the workpiece is conveyed to the injection molding machine by the injection molding machine feeding device. Therefore, full-automatic feeding can be realized by the automatic feeding system of the injection molding machine, the damage to the surfaces of products due to manual feeding is avoided, additionally, the hazard index of manual operation can be reduced, the working efficiency is improved, and the production cost is reduced.

Owner:GUANGDONG EVERWIN PRECISION TECH

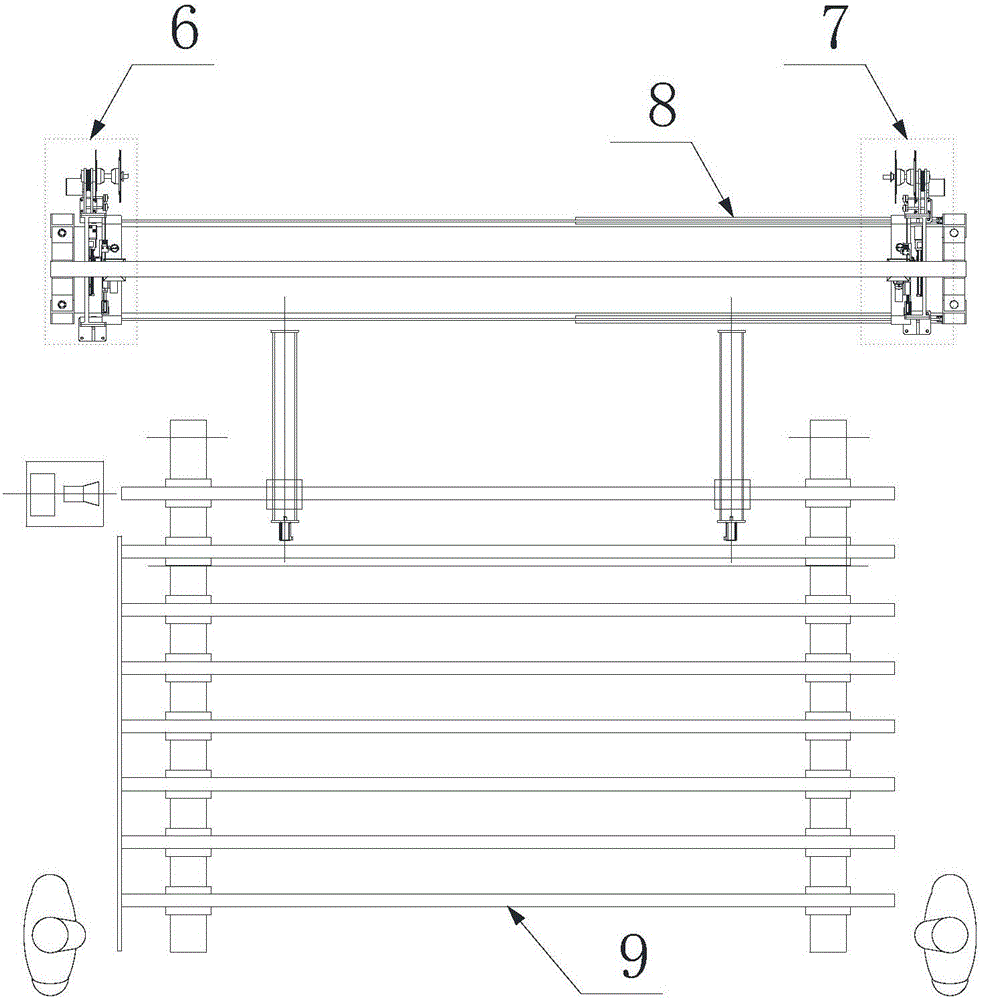

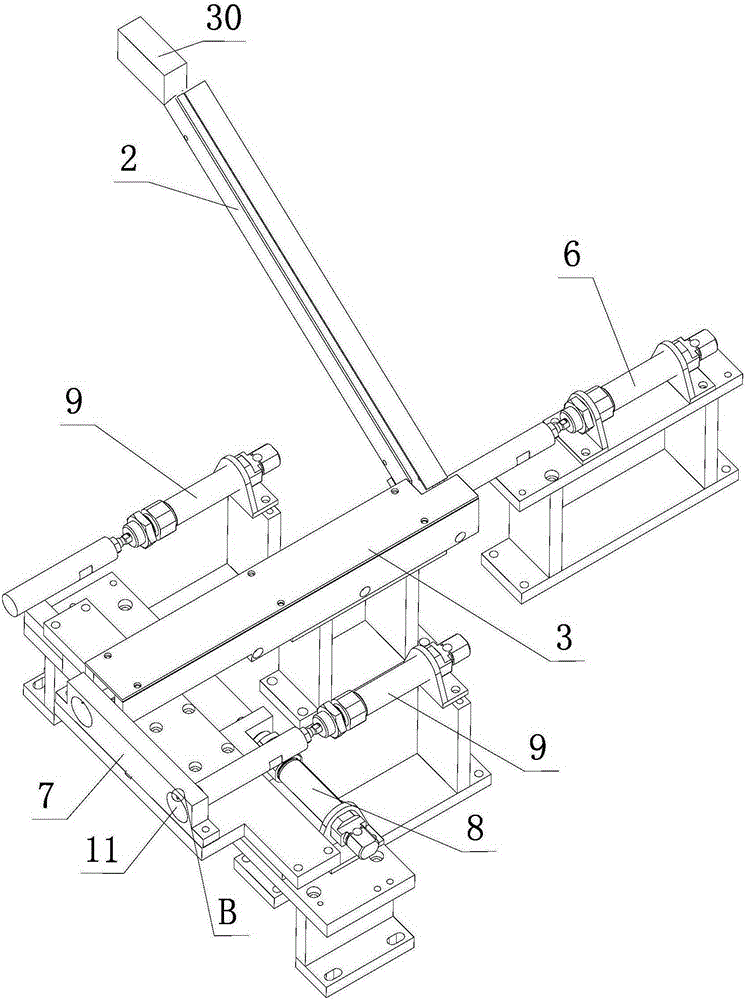

Automatic steel plate cropping material feeding mechanism

ActiveCN102909285ARealize fully automatic feedingAutomatic continuous pushMetal-working feeding devicesPositioning devicesControl setProgrammable logic controller

An automatic steel plate cropping material feeding mechanism is characterized by comprising a frame, a feeding device, a ramming device and a programmable logic controller (PLC) control integrated system used for controlling the feeding device and the ramming device. The feeding device is arranged at the top of the frame, the ramming device is arranged in the middle at one end of the frame, and the ramming device is connected with a material inlet of a shearing machine. A steel plate is arranged below the other end of the frame, and the feeding device and the ramming device are respectively connected with the PLC control integrated system through a control line. The whole process of the automatic steel plate cropping material feeding mechanism needs no manual operation, can achieve full-automatic feeding and improve qualified rate of slabs, greatly improves production efficiency, avoids potential safety hazards caused by manual operation, and is high in safety performance.

Owner:LIUZHOU LIUHE FANGSHENG MACHINERY

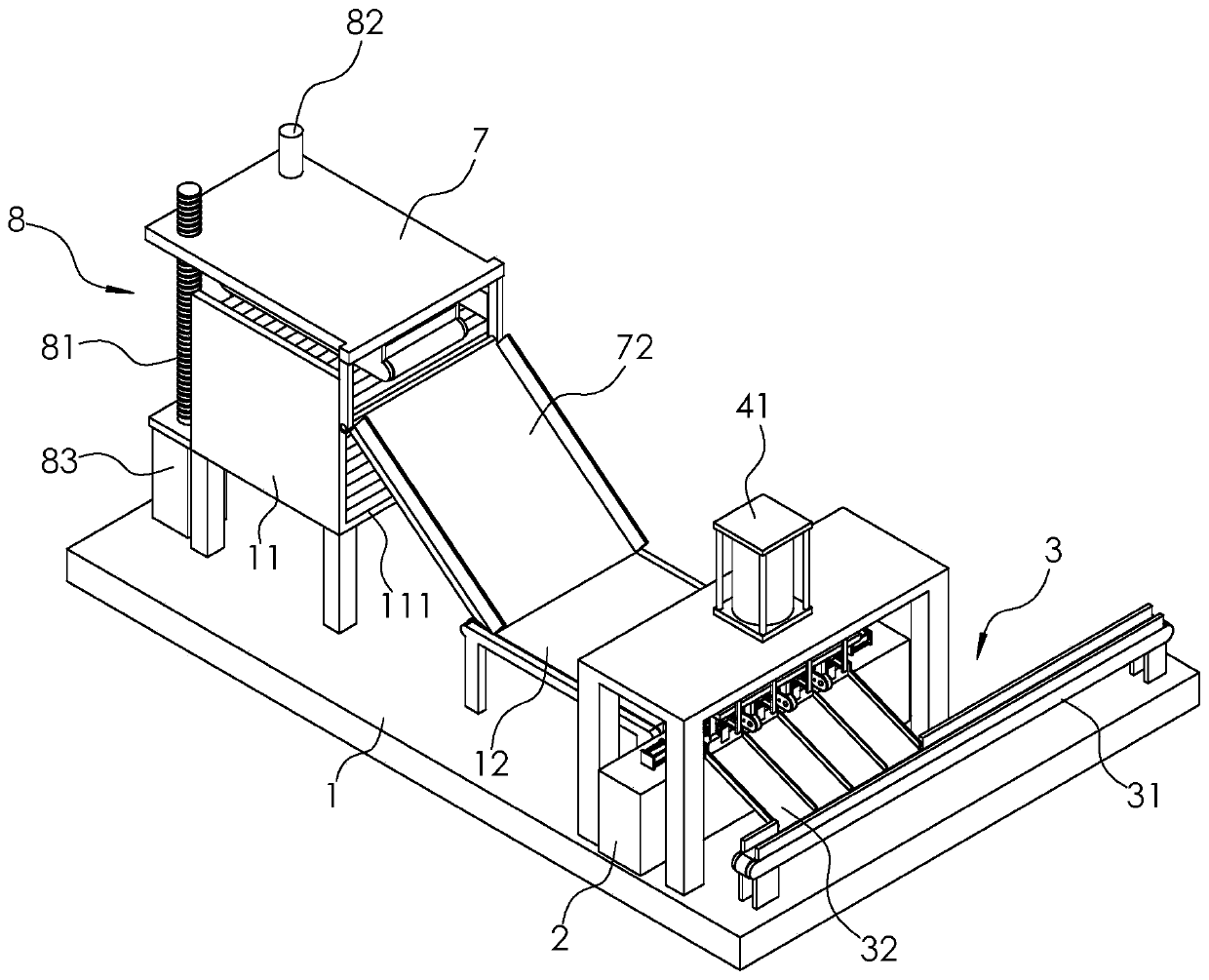

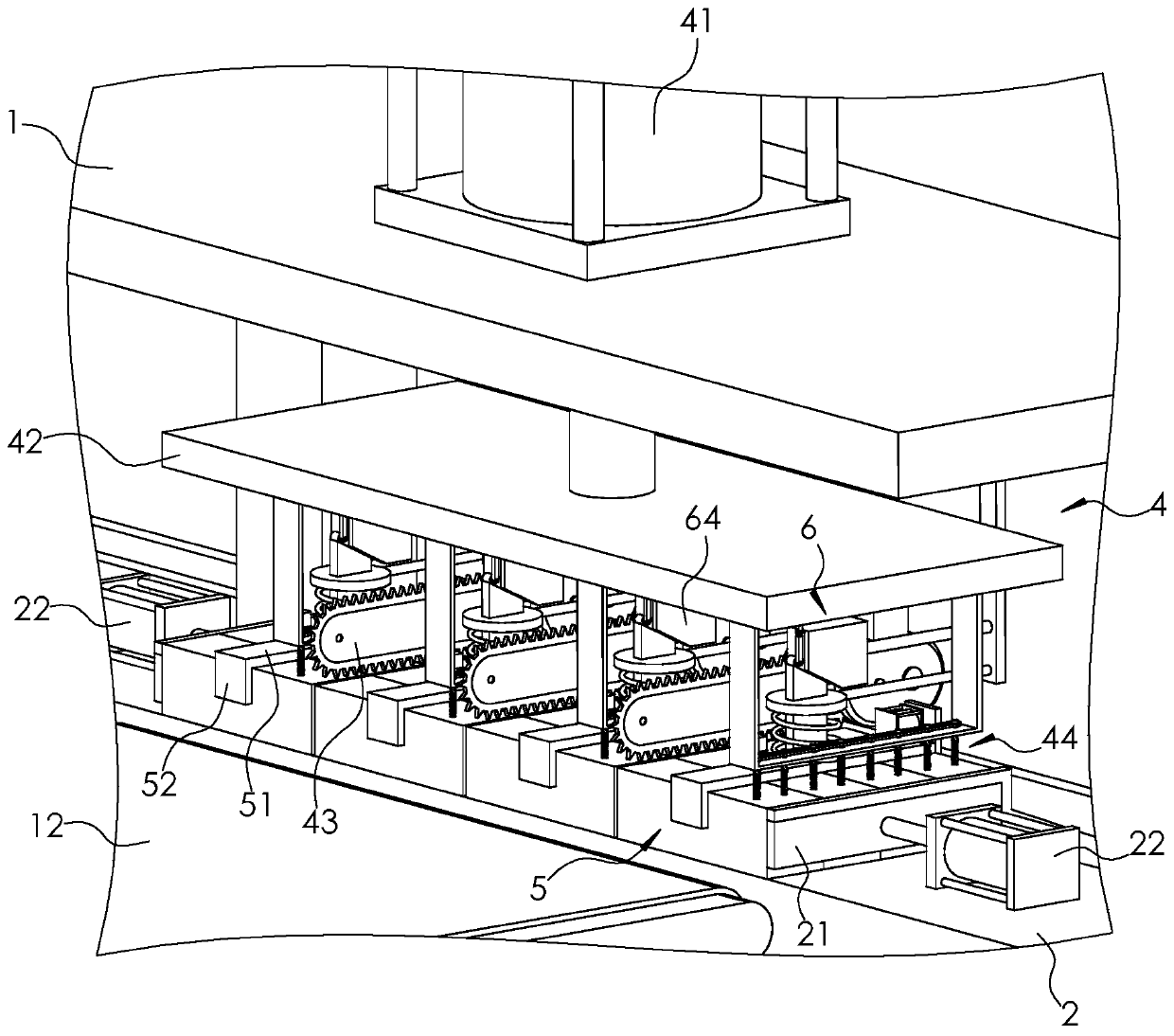

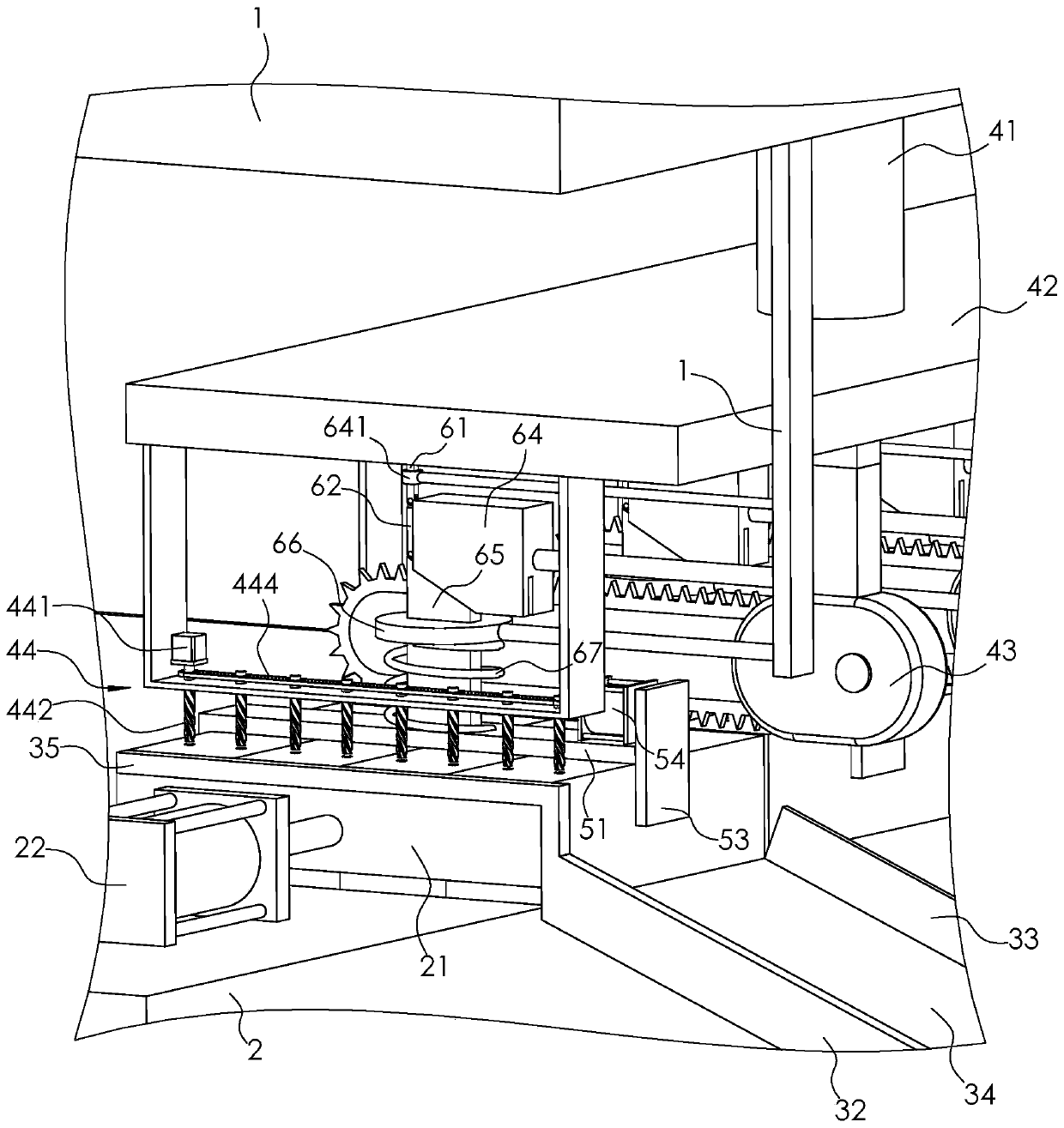

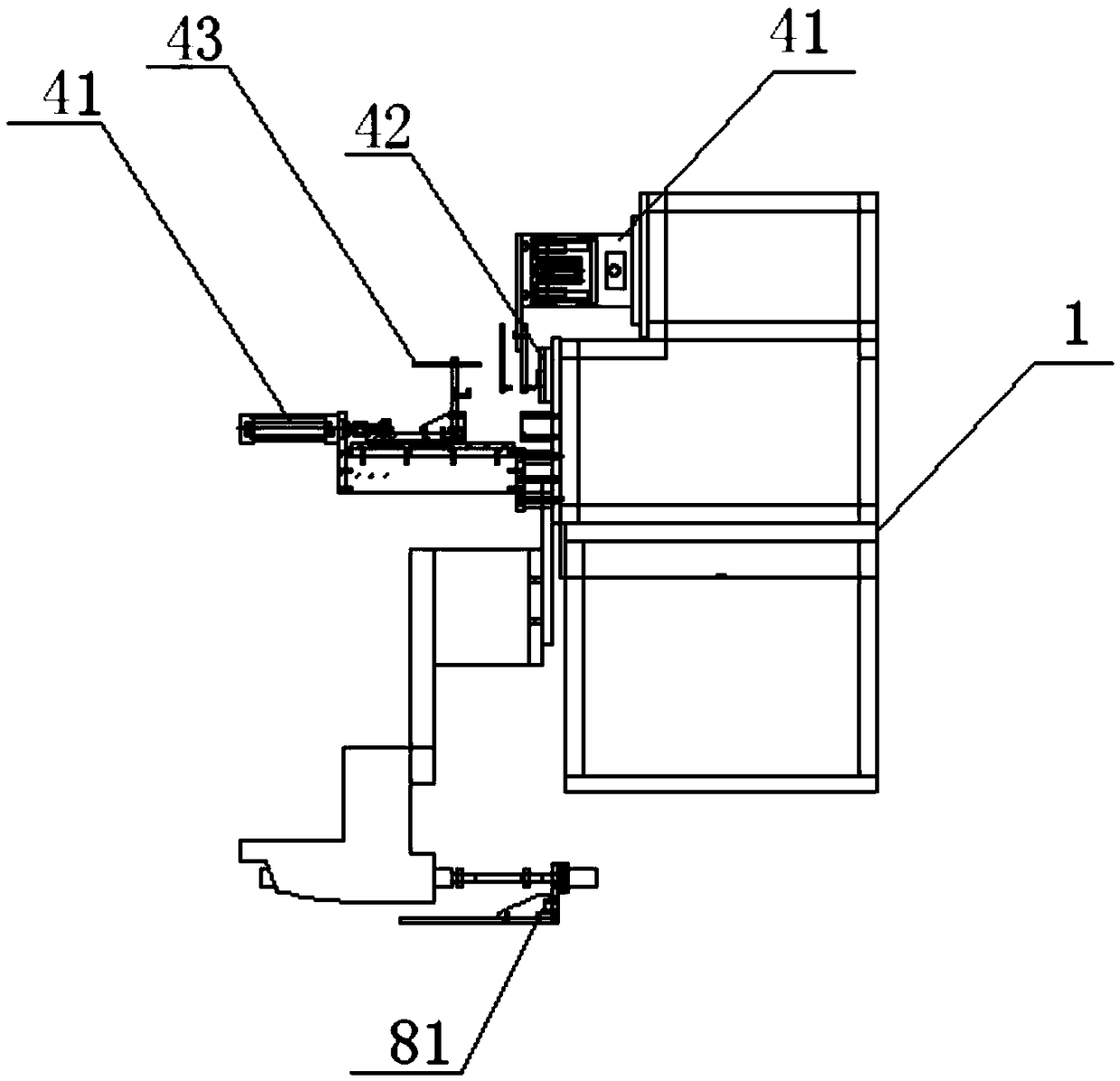

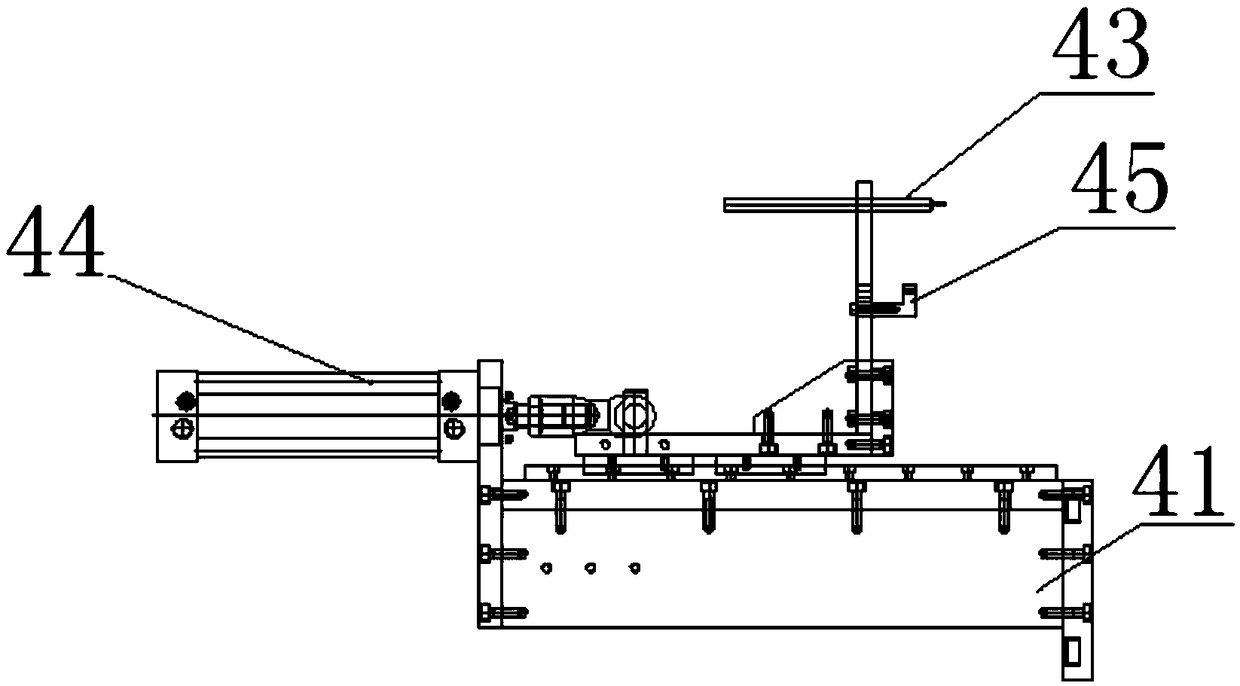

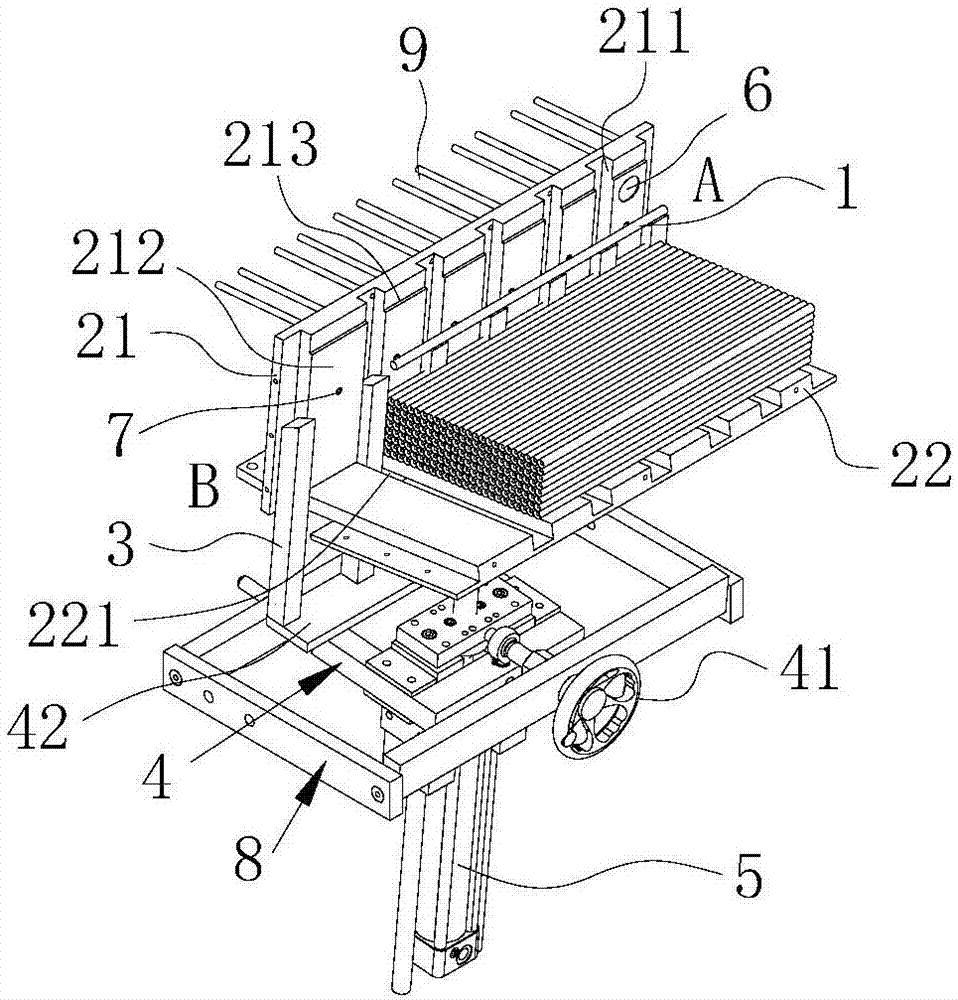

Belt type loading device applied to numerical-control circular sawing machine

ActiveCN107138800AIncrease stock capacityRealize fully automatic feedingMetal sawing devicesMetal working apparatusNumerical controlCircular saw

The invention provides a belt type loading device applied to a numerical-control circular sawing machine. The belt type loading device comprises a loading frame basal body, a belt wheel assembly, a chain conveying assembly, an inclined supporting plate, an air cylinder pushing assembly, a baffle regulating assembly, a clamping oil cylinder assembly, a turnover oil cylinder assembly and a rod diameter regulating assembly. A whole bundle of rods is lifted onto a belt of the belt wheel assembly, and the belt is tightened, so that the rods drop onto a chain of the chain conveying assembly; the chain conveying assembly drives the rods to move to the inclined supporting plate; the height position of a baffle block of the baffle regulating assembly is regulated according to the diameters of the rods, and the rods are controlled to pass through one by one, then, the rods are turned over to a U-shaped plate of the loading frame basal frame through a turnover oil cylinder of the turnover oil cylinder assembly, the air cylinder pushing assembly pushes materials forwards, the clamping oil cylinder assembly clamps rods, the workbench of a machine head part of a main machine retreats to the origin point to clamp the rods, the clamping oil cylinder assembly of the loading mechanism is loosened, and the workbench clamps the rods to forwards feed to complete cutting. The whole process is automatically controlled, and manual control is not needed.

Owner:SHANGHAI HANHONG PRECISION MACHINERY

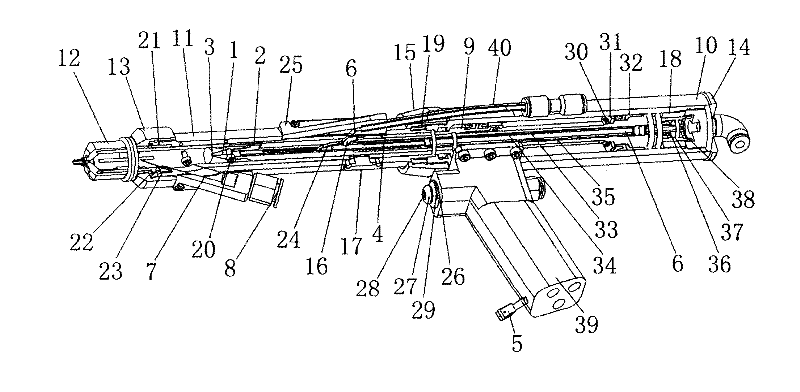

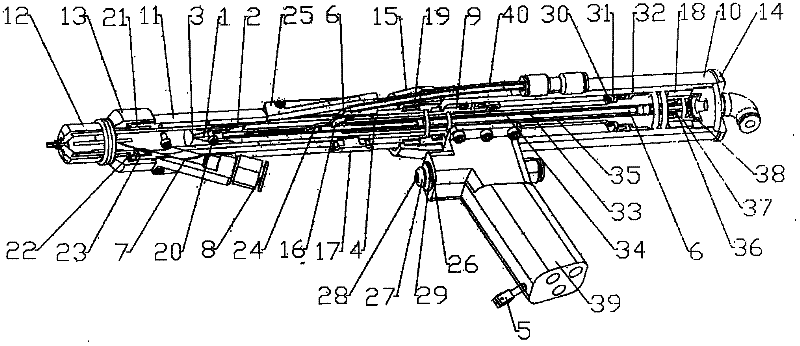

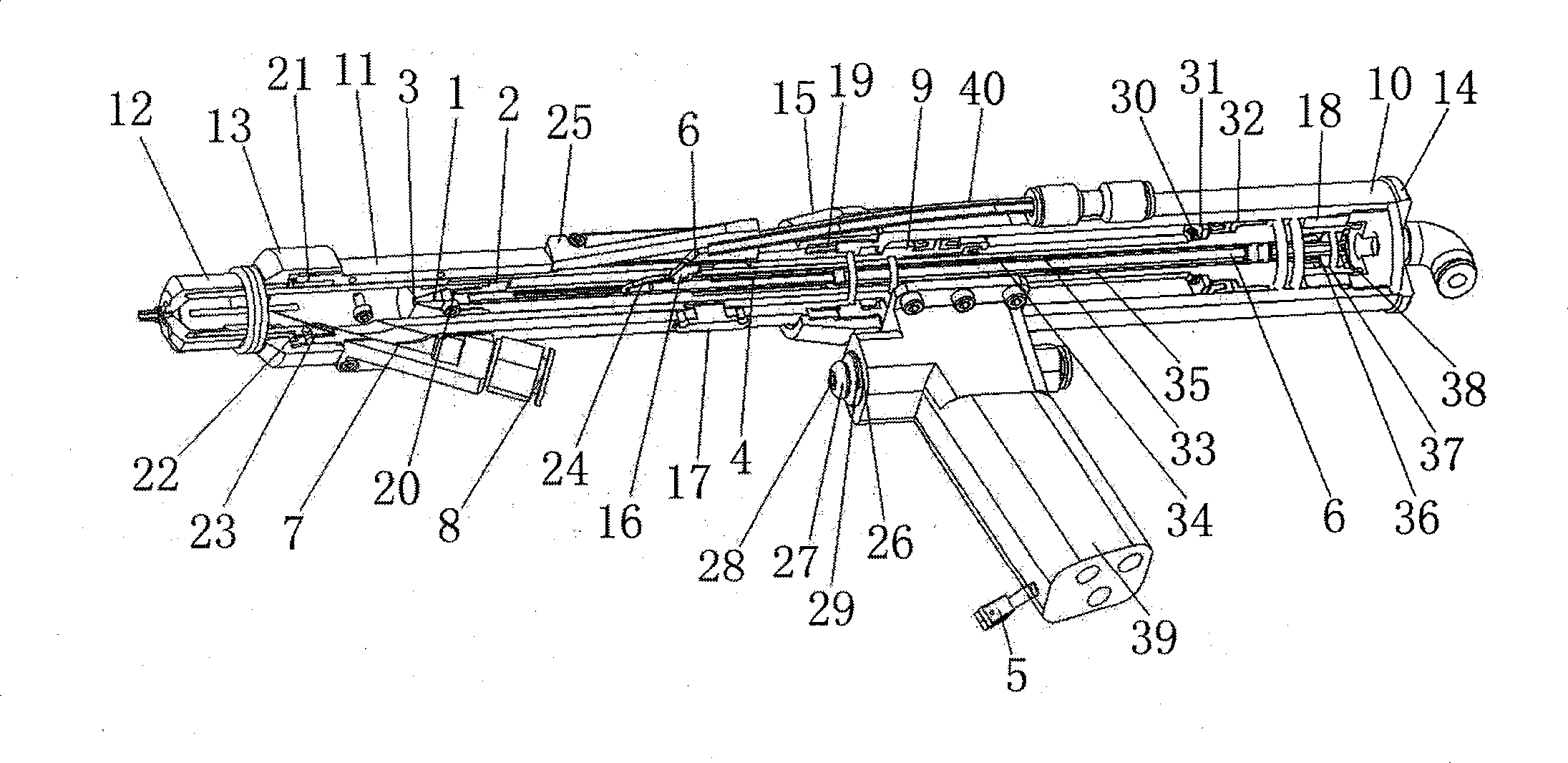

Automatic rivet pulling mechanism

ActiveCN102380571ASolve the problem of inefficiency and uneven standardsRealize fully automatic feedingNatural stateSemi automatic

The invention discloses an automatic rivet pulling mechanism comprising a rivet pulling gun. The rivet pulling gun comprises a gun body with a hollow cavity, and a rivet pulling piston, a sleeve, a sleeve piston, a thimble, a chuck and a seal end which are installed in the cavity. The automatic rivet pulling mechanism is characterized in that an automatic waste rivet discharging mechanism is arranged on the gun body, and comprises a spring piece, a rivet outlet channel, a rivet outlet pipe and compression air for driving the waste rivet to move, the rivet outlet channel is communicated with the rivet outlet pipe, a waste rivet discharging chute is arranged on the sleeve, one end of the spring piece is fixed, and the other end of the spring piece is free and extends into the sleeve by the waste rivet discharging chute, when the spring piece is in natural state, the spring tilts from front to back so as to form a return channel by which a waste rivet enters the rivet outlet channel. According to the automatic rivet pulling mechanism, full-automatic feeding, broken pulling and waste discharging are realized, the problem that manual and semi-automatic rivet pulling are low in efficiency is solved, and the automatic rivet pulling mechanism can be fixed on a mechanical hand so as to realize automatic production.

Owner:天津镕思铭科技股份有限公司

Pipe double end chamfering machine

InactiveCN104249268ARealize fully automatic feedingRealize fully automatic productionMachine tool componentsFeeding apparatusVertical cylinderMechanical engineering

The invention relates to a pipe double end chamfering machine which comprises a lathe body, a charging and discharging mechanism, a chamfering mechanism, a clamping mechanism, a charging bin and a discharging bin, wherein the charging and discharging mechanism, the chamfering mechanism and the clamping mechanism are fixedly arranged on the lathe body; the charging and discharging mechanism comprises a vertical cylinder, a guide rail, a horizontal cylinder and a charging and discharging pneumatic finger; the charging and discharging pneumatic finger is connected with a guide post by virtue of a connecting bracket; the guide post is slidably connected with a vertical guide plate; the connecting bracket is connected with the vertical cylinder; the horizontal cylinder is connected with a horizontal guide plate; the horizontal guide plate is slidably connected with the guide rail; the horizontal guide plate is fixedly connected with the vertical guide plate; The clamping mechanism is arranged on the lathe body between the charging bin and the discharging bin. The pipe double end chamfering machine has the beneficial effects of realizing full-automatic operations such as charging, chucking, processing and discharging, processing four chamfer angles inside and outside two end surfaces by virtue of once chucking, conveniently regulating the processing frequency and the tool feeding depth by virtue of PLC (Programmable Logical Controller) control over equipment and realizing full-automatic production.

Owner:天津市中马骏腾精密机械制造有限公司

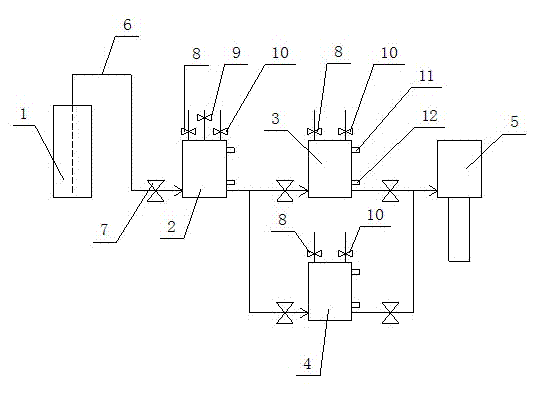

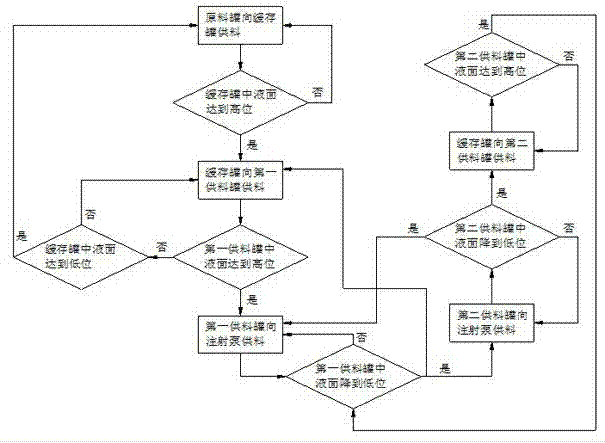

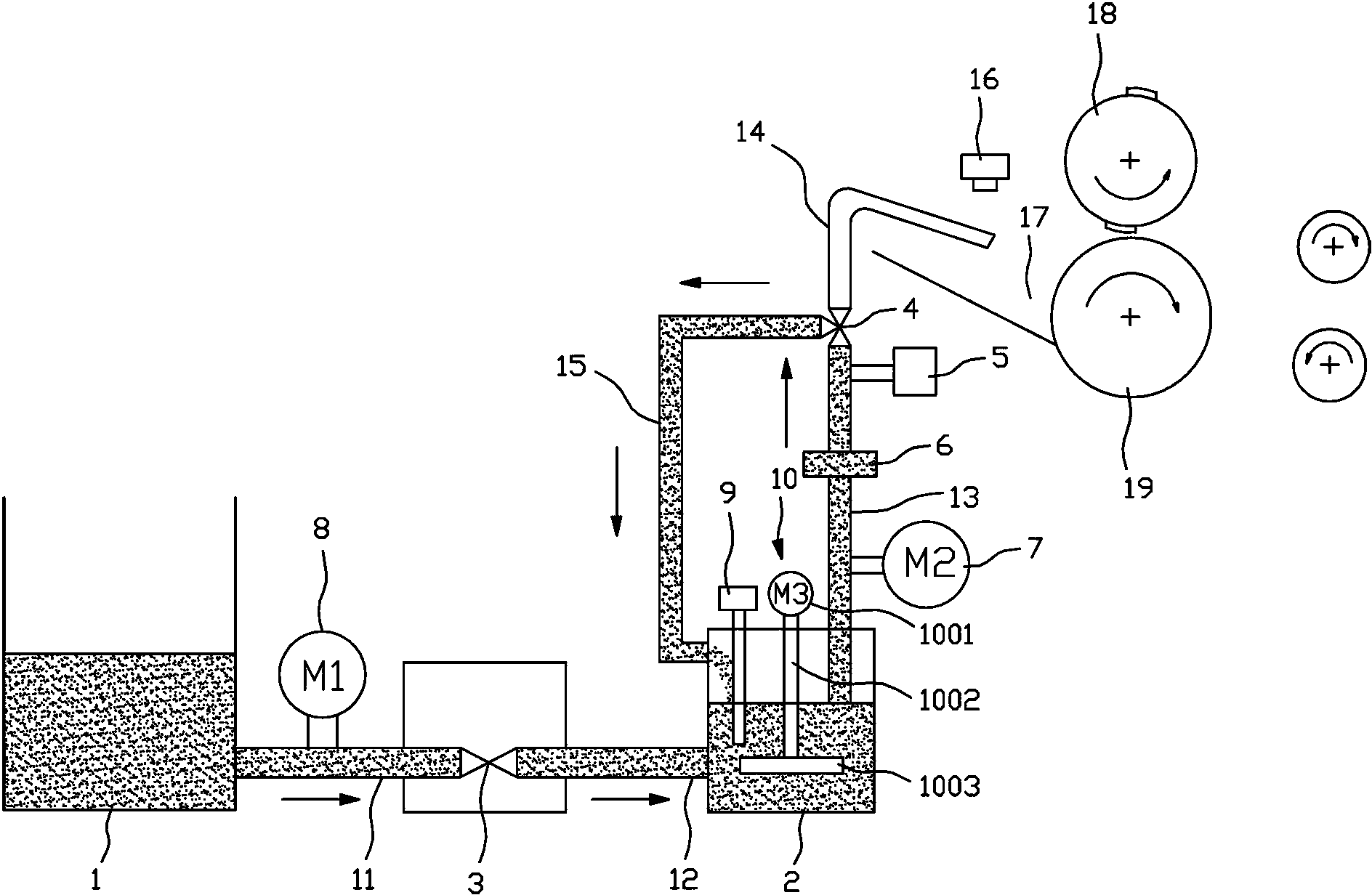

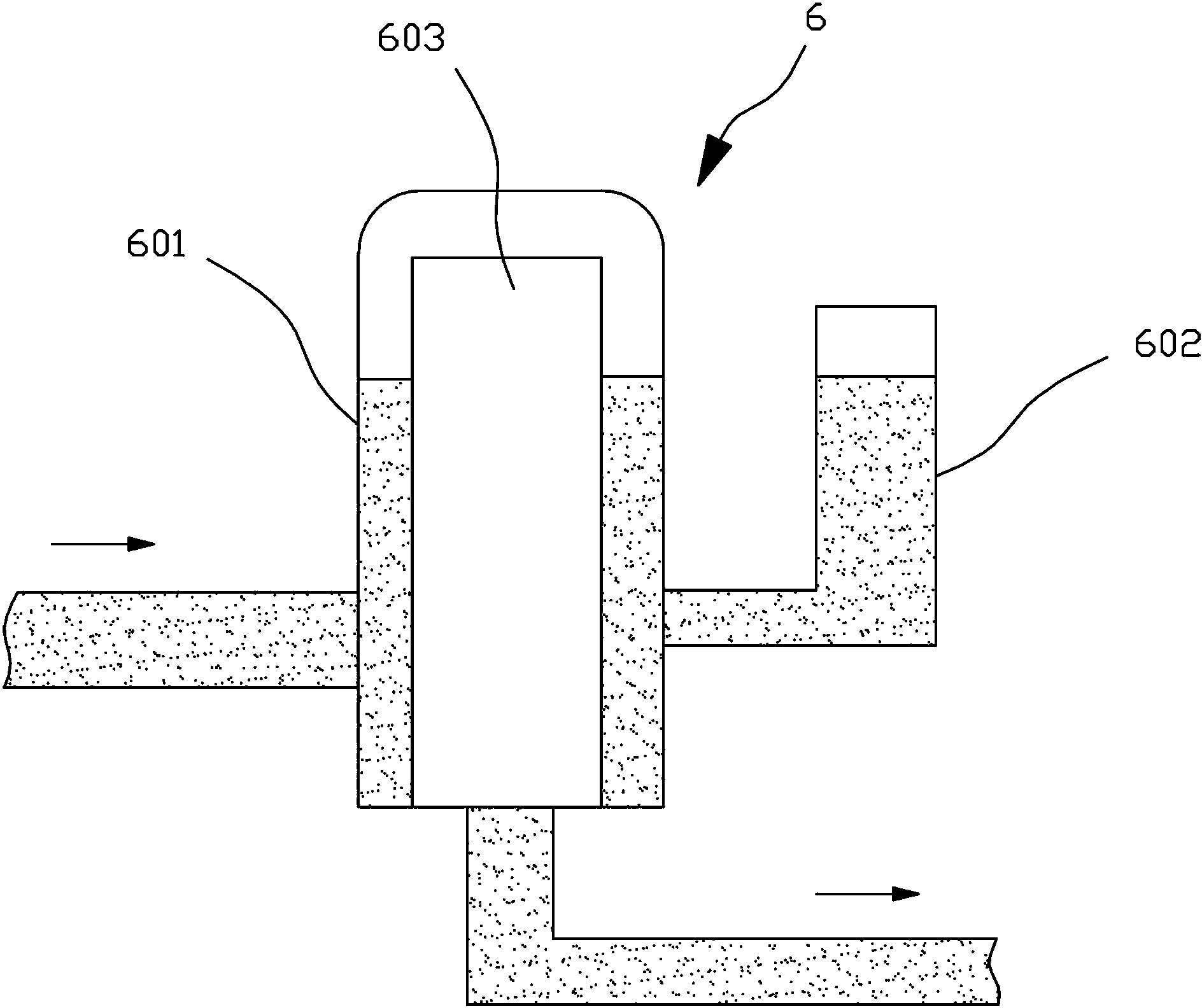

Feeding system for coating machine and control method

The invention discloses a feeding system for a coating machine and a control method. The feeding system comprises a stock tank, a buffer tank, a first feeding tank and an injection pump, which are sequentially connected through pipelines, wherein pneumatic valves are arranged between the stock tank and the buffer tank, between the buffer tank and the first feeding tank and between the first feeding tank and the injection pump; the feeding system is also provided a second feeding tank which is connected between the buffer tank and the injection pump through pipelines and is arranged in parallel connection with the first feeding tank, and pneumatic valves are provided between the second feeding tank and the buffer tank and between the second feeding tank and the injection pump. According to the invention, the technical problem that the injection pump needs to be shut down and wait when slurry is being supplemented to the feeding tanks in the prior art to be completely overcome, thereby improving production efficiency and the process utilization rate of the coating machine; when the buffer tank fills slurry to the feeding tanks and the feeding tanks fill the slurry into the injection pump, the manner of pressure feeding of the slurry by compressed gas is used, which enables the technical problem that conveying of slurry through pumping in traditional methods easily causes generation of bubbles in slurry and thus affects slurry quality to be overcome.

Owner:SICHUAN COC DISPLAY DEVICES

Automatic aluminum profile stacking device and control method thereof

ActiveCN106276171ARealize automatic feeding processIncrease labor intensityFilament handlingConveyor partsEngineeringConductor Coil

Owner:广州市祺兴自动化科技有限公司

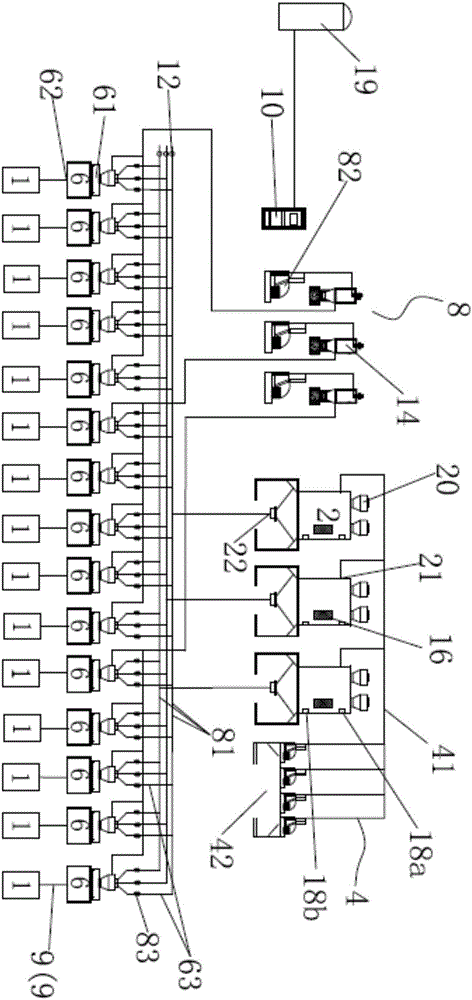

Automatic feeding system for producing optical cables

InactiveCN106113436AAvoid management chaosReduce irrelevant operationsFibre mechanical structuresProcess engineeringMaintenance Problem

The invention provides an automatic feeding system for producing optical cables. The automatic feeding system comprises a plurality of storage tanks and a plurality of storage buckets, wherein raw materials in a warehouse are sucked and conveyed to respective storage tanks by a first conveying mechanism by utilizing negative pressure; the raw materials in the storage tanks are sucked and conveyed to respective storage buckets by a second conveying mechanism by utilizing negative pressure; the raw materials in the storage buckets are extruded by virtue of screws and are conveyed to extrusion dies of optical cable production lines by a third conveying mechanism; one storage bucket is correspondingly arranged on one optical cable production line, one second feeding pipe is correspondingly arranged on one storage tank, all of the storage buckets communicate with all second feeding pipes by virtue of independent feeding branch pipes, regulating valves are respectively arranged on the feeding branch pipes, which storage tanks communicating with the storage buckets are respectively controlled by the regulating valves, and the feeding speed from the storage tanks to the storage buckets is regulated by virtue of the regulating valves. According to the automatic feeding system, full-automatic feeding for producing the optical cables is realized, the maintenance problem of production sites is solved, manpower and materials are saved, and the waste of the raw materials is avoided.

Owner:宏安集团有限公司

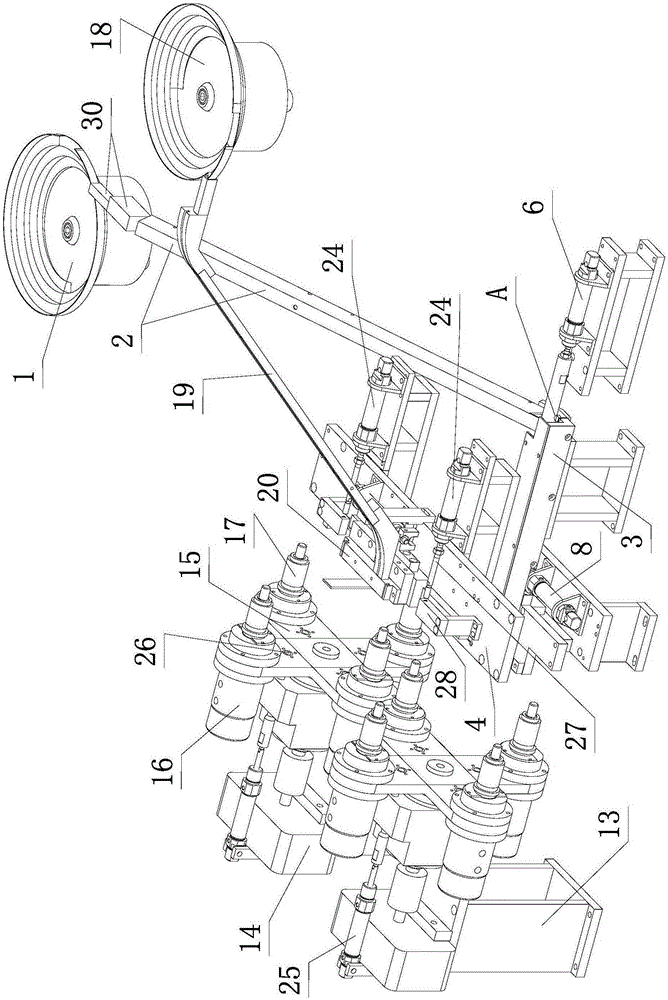

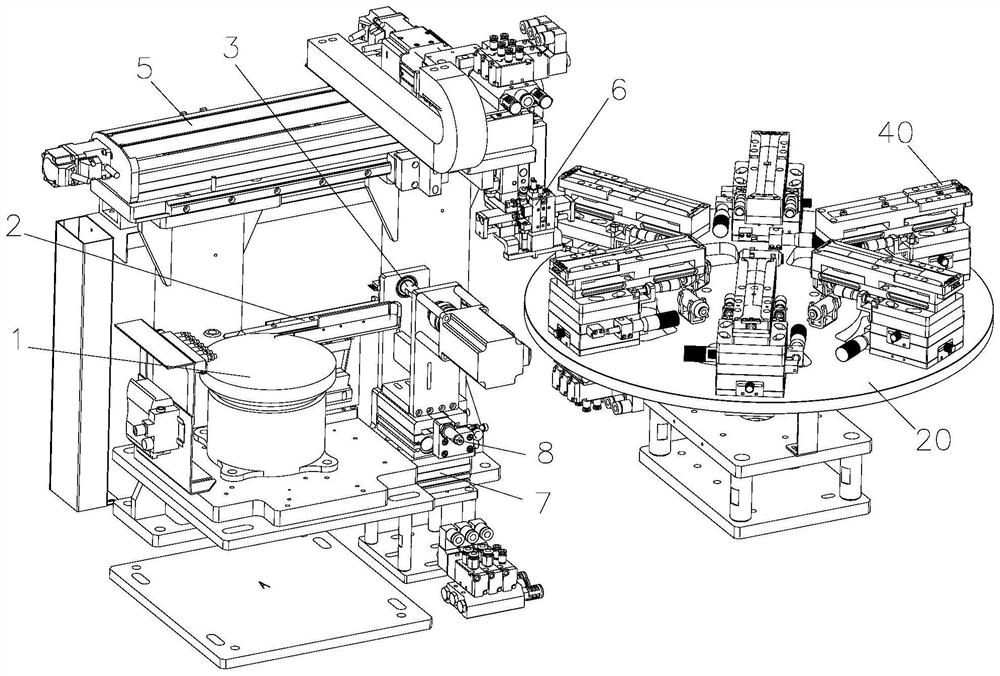

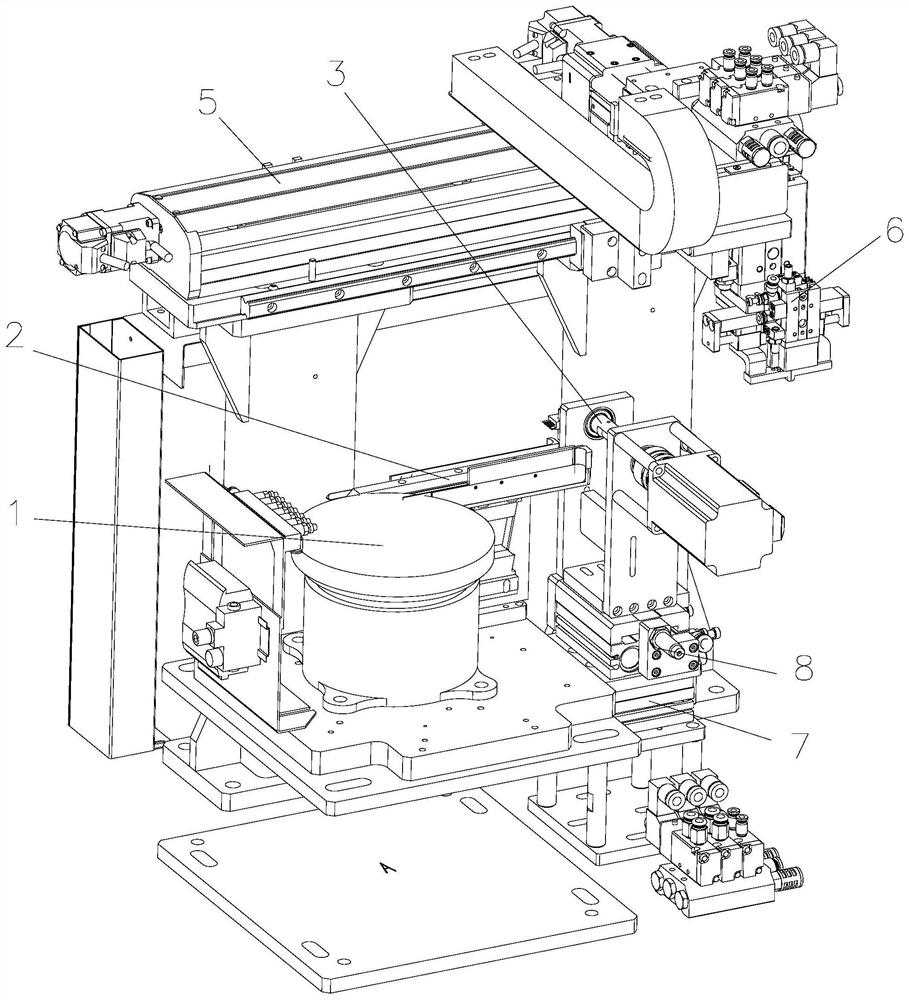

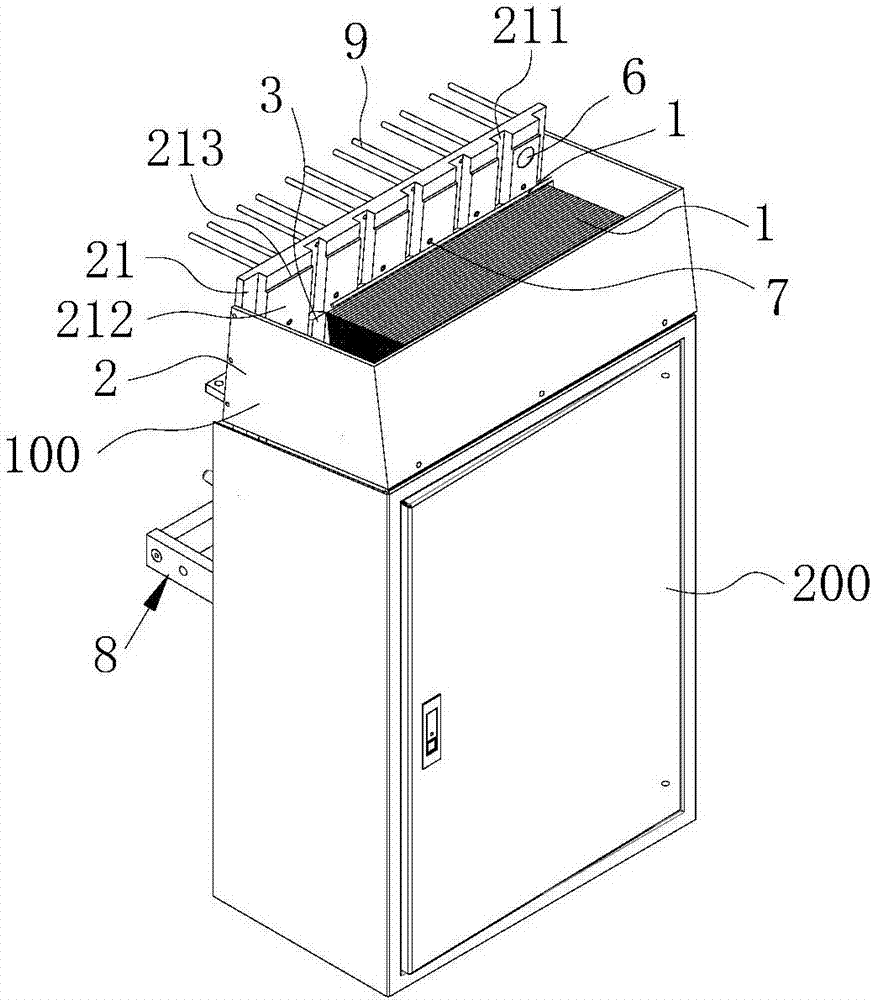

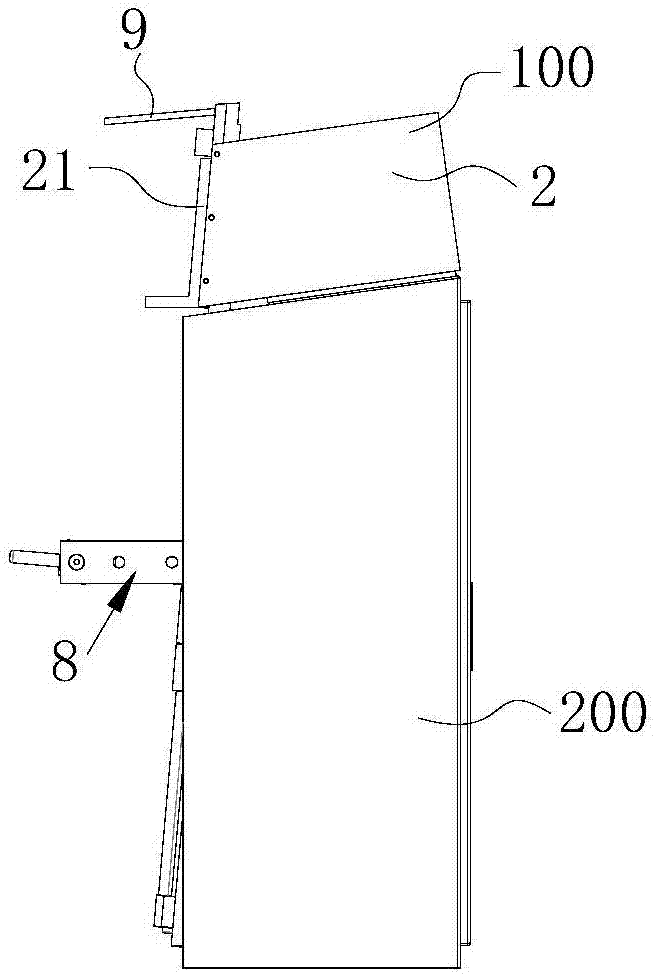

Sheet inserting machine

InactiveCN105217277AAngle Precise and StableMeet the precision requirementsJigging conveyorsConveyor partsAutomationRotor vibration

The invention discloses a sheet inserting machine which comprises an automatic rotor feeding device, two station switching devices in left-right symmetry, an automatic inserting sheet feeding device, a left sheet inserting cylinder (24) and a right sheet inserting cylinder (24). The automatic rotor feeding device comprises a rotor vibration disc (1), a radial inclined feeding channel (2), an axial horizontal feeding channel (3), a pushing cylinder (6), a first swing plate, a first swing cylinder (8), a left feeding cylinder and a right feeding cylinder, wherein the pushing cylinder (6) is used for pushing rotors at the head end of the axial horizontal feeding channel (3) to the tail end of the axial horizontal feeding channel (3), and the first swing plate is perpendicular to the axial horizontal feeding channel (3). The automatic inserting sheet feeding device comprises an inserting sheet vibration disc (18), an inclined inserting sheet feeding channel (19), a second swing plate (20) perpendicular to the inclined inserting sheet feeding channel (19), and a second swing cylinder driving the second swing plate (20). The sheet inserting machine is high in automation degree, continuity and production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

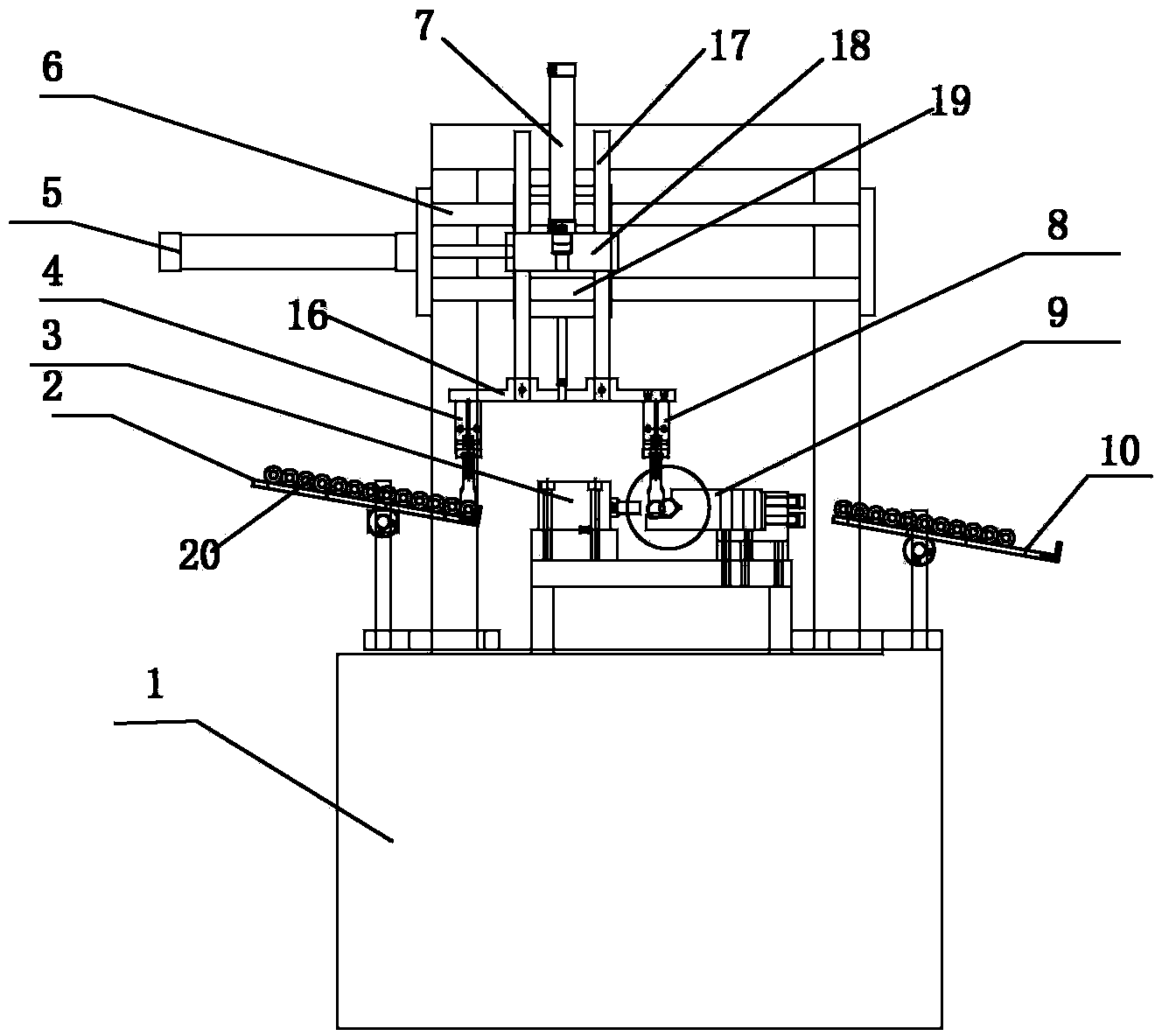

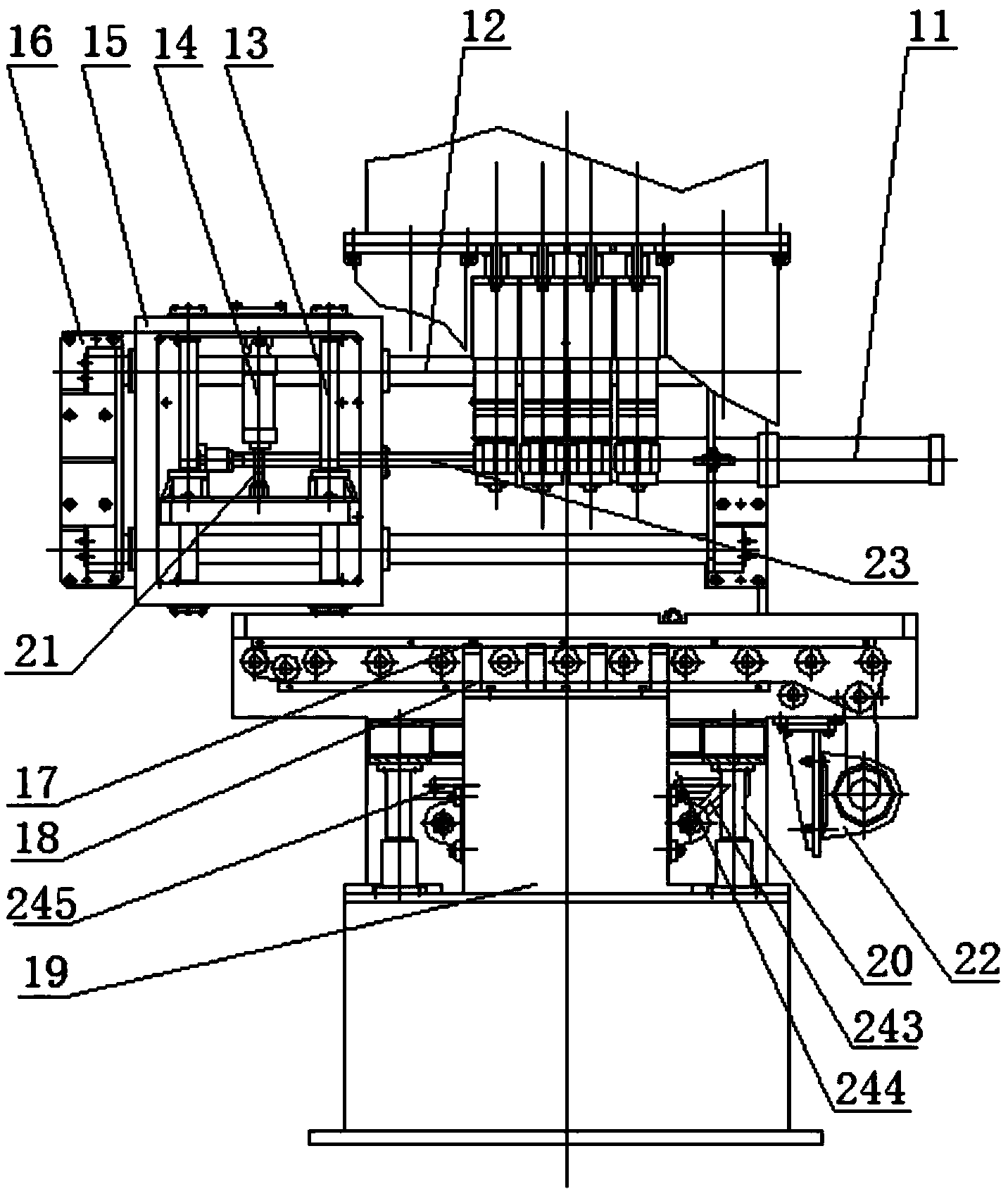

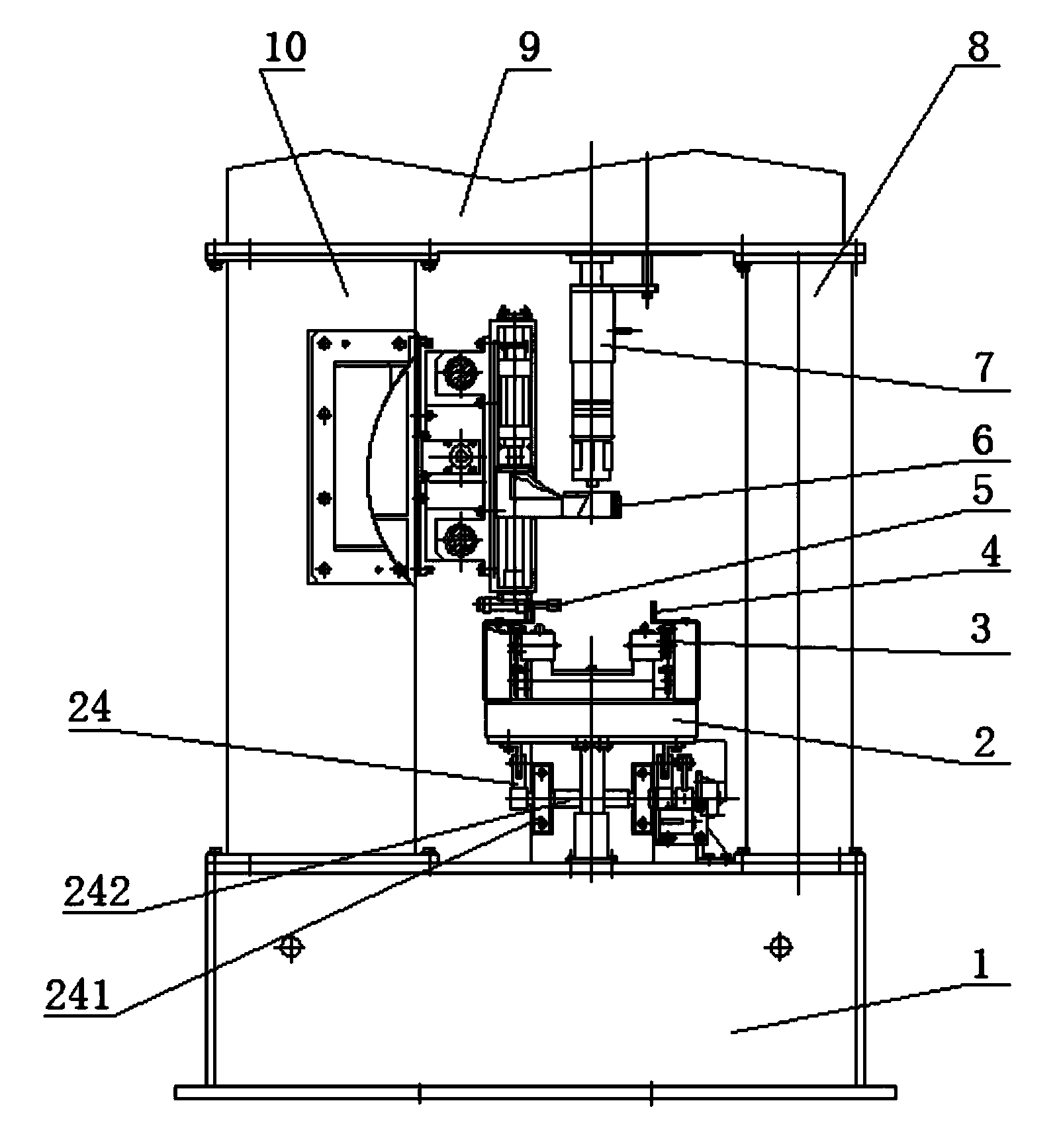

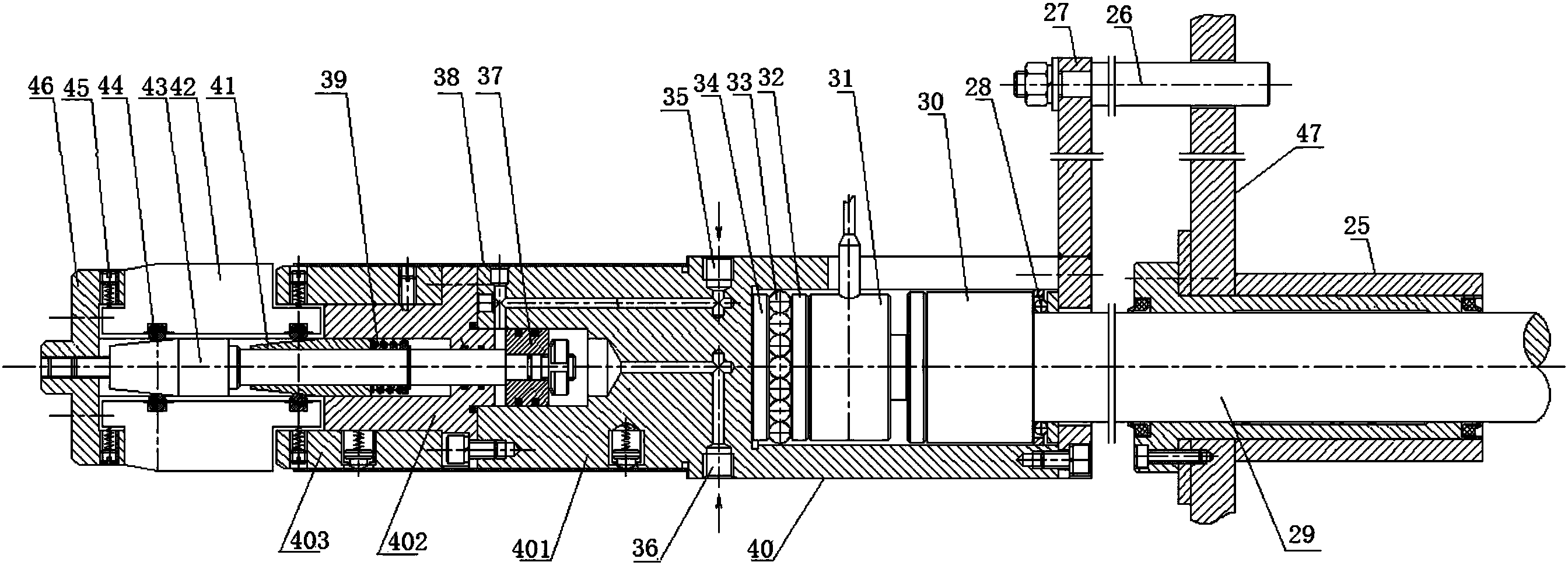

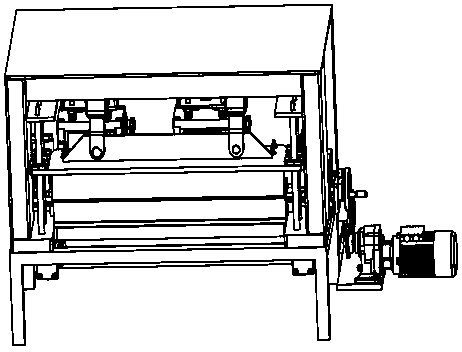

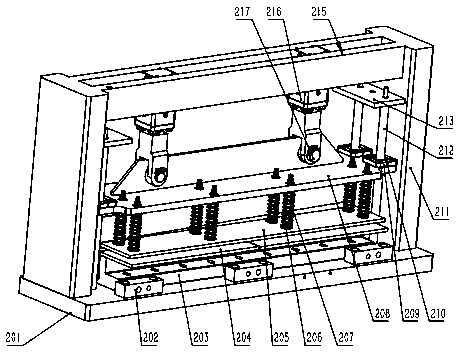

Engine cylinder liner press

ActiveCN103481053ARealize fully automatic feedingRealize high-precision automatic positioningMetal working apparatusCarrying capacityCylinder block

The invention discloses an engine cylinder liner press and belongs to the field of machinery. The engine cylinder liner press comprises a base, a top seat, a rear pillar, a front pillar, a cylinder liner feeding mechanism, a cylinder feeding mechanism, a cylinder liner head pressing device and a positioning and carrying device. The front of the base is connected with the front of the top seat through the front pillar. The rear portion of the base is connected with the rear portion of the top seat through the rear pillar, the cylinder liner head pressing device is arranged below the top seat and fixedly connected with the same. The cylinder liner feeding mechanism is mounted on the inner side of the rear pillar. The feeding portion of a cylinder liner feeder in the cylinder liner feeding mechanism is arranged right below the cylinder liner head pressing device. The cylinder feeding mechanism and the positioning and carrying device are arranged on the base. Full-automatic feeding of cylinder liners and cylinders is realized, and high-precision automatic positioning and high carrying capacity of the cylinders can be achieved.

Owner:金湖县项目服务中心

Machining device for mechanical arm

ActiveCN111230501ARealize automatic loading and unloadingAchieve positioningOther manufacturing equipments/toolsMetal working apparatusRobot handMachining process

The invention relates to a machining device for a mechanical arm. The machining device comprises a rack and a first transfer belt, a shelf is arranged at the input end of the first transfer belt, a worktable is arranged at the output end of the first transfer belt, and a discharging assembly is arranged on the side, away from the first transfer belt, of the worktable. The two ends of the worktableare both provided with a withstanding plate and a driving piece, and a plurality of insertion columns are fixed to the sides, facing steel pipes, of the two withstanding plates; a plurality of cutting assemblies, a plurality of drilling assemblies and a plurality of pressing assemblies are arranged on the upper side of the worktable, and the rack is provided with a lifting assembly and a drivingassembly. In the steel pipe machining process, the first transfer belt conveys the steel pipes onto the worktable, the driving pieces drive the withstanding plates to withstand the end portions of thesteel pipes, then the pressing assemblies tightly press the steel pipe, and all the cutting assemblies and drilling assemblies machine the steel pipes. After the steel pipes are cut and drilled, themachined steel pipes are pushed by new steel pipes onto the discharging assembly. By means of the machining device, the steel pipe machining efficiency is greatly improved.

Owner:杭州现代机械有限公司

Automatic rivet pulling mechanism

ActiveCN102380571BRealize fully automatic feedingRealize automated productionNatural stateSemi automatic

The invention discloses an automatic rivet pulling mechanism comprising a rivet pulling gun. The rivet pulling gun comprises a gun body with a hollow cavity, and a rivet pulling piston, a sleeve, a sleeve piston, a thimble, a chuck and a seal end which are installed in the cavity. The automatic rivet pulling mechanism is characterized in that an automatic waste rivet discharging mechanism is arranged on the gun body, and comprises a spring piece, a rivet outlet channel, a rivet outlet pipe and compression air for driving the waste rivet to move, the rivet outlet channel is communicated with the rivet outlet pipe, a waste rivet discharging chute is arranged on the sleeve, one end of the spring piece is fixed, and the other end of the spring piece is free and extends into the sleeve by the waste rivet discharging chute, when the spring piece is in natural state, the spring tilts from front to back so as to form a return channel by which a waste rivet enters the rivet outlet channel. According to the automatic rivet pulling mechanism, full-automatic feeding, broken pulling and waste discharging are realized, the problem that manual and semi-automatic rivet pulling are low in efficiency is solved, and the automatic rivet pulling mechanism can be fixed on a mechanical hand so as to realize automatic production.

Owner:天津镕思铭科技股份有限公司

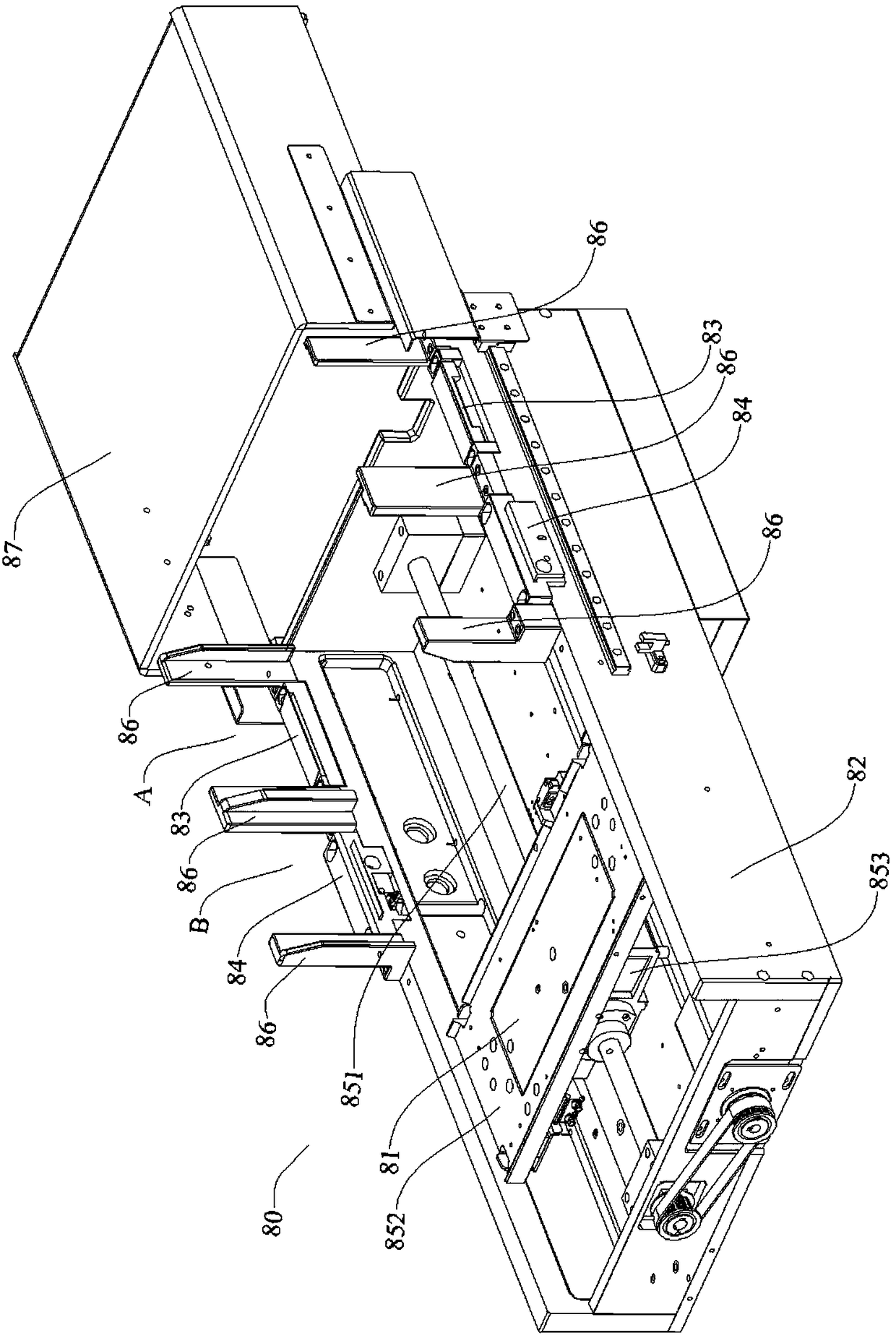

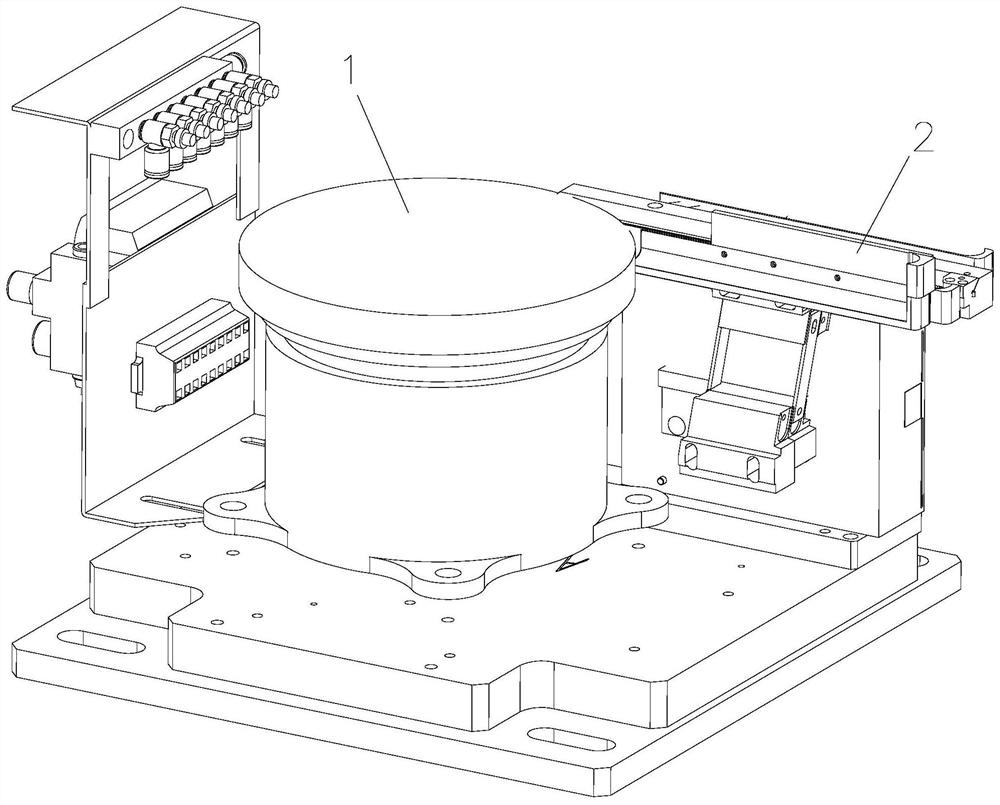

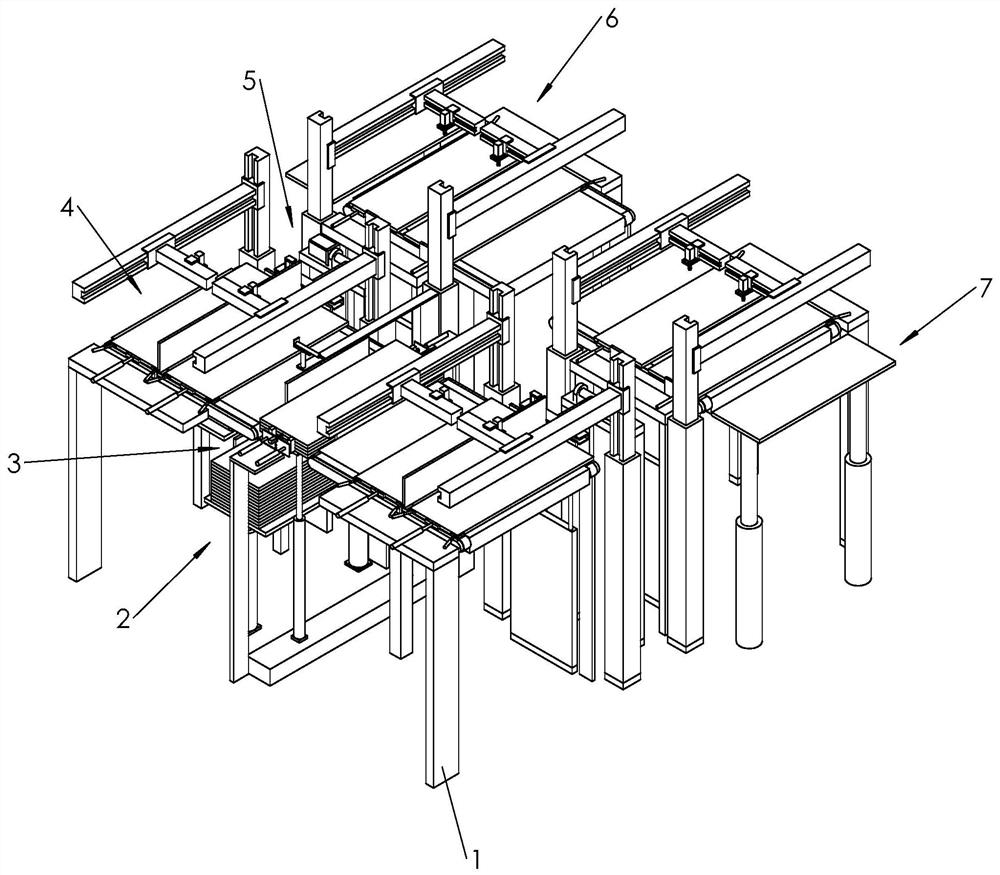

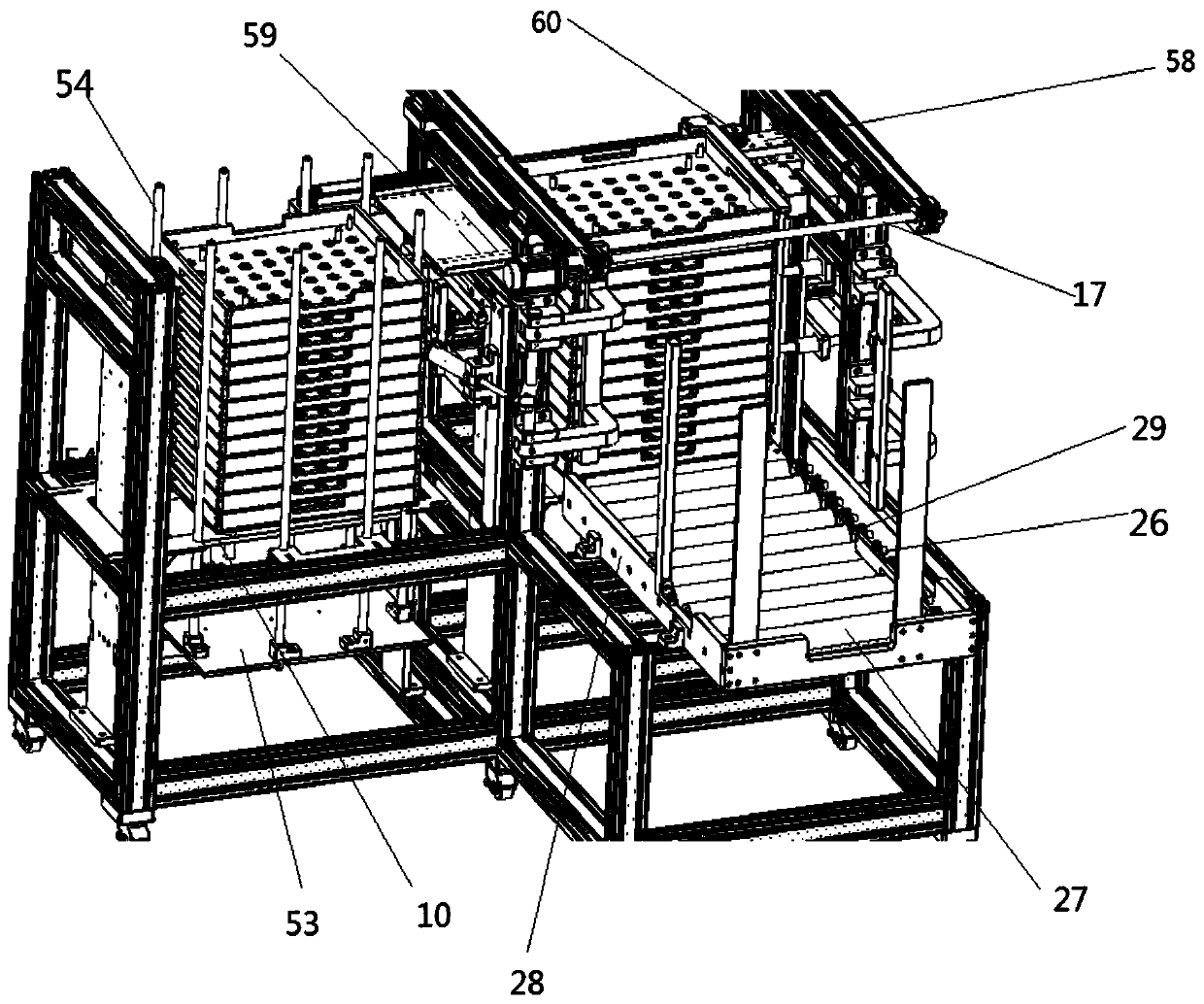

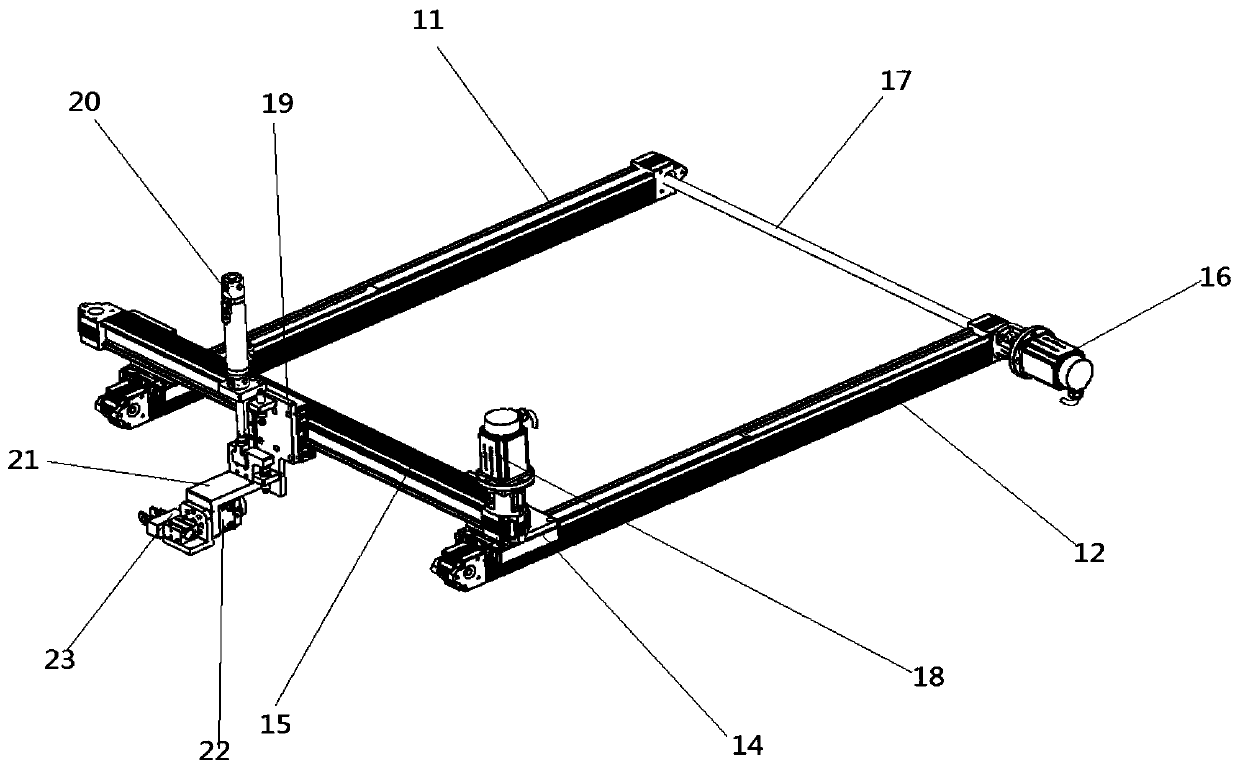

Automatic feeding device of material tray

PendingCN109607158ARealize fully automatic feedingStable deliveryConveyorsConveyor partsEngineeringMechanical engineering

The invention provides an automatic feeding device of a material tray. The device comprises a machine frame, wherein the top of the machine frame comprises a material tray placing station and a material tray receiving station; the left side and the right side of the top of the machine frame are both provided with slide ways, a first pushing piece and a second pushing piece are further arranged onthe machine frame, the first pushing piece is located in the material tray placing station, the second pushing piece is located at the material tray receiving station, the first pushing piece and thesecond pushing piece are both located in a hollow groove between the two slide ways; the first pushing piece and the second pushing piece are pushed through a common conveying mechanism or independentconveying mechanisms, when the upper part of the second pushing piece is pushed from the back to the front, the second pushing piece can be pushed over forwards, each of the left slide way outer sideand the right slide way outer side of the machine frame is provided with at least one first jacking component, a transverse telescopic component is arranged on each first jacking component, the transverse telescopic components are connected with inserting plates and used for driving the inserting plates, and the inserting plates face the middle of the machine frame. According to the device, the full-automatic feeding of the material tray is realized, the material tray is smooth in conveying, and the cost is low.

Owner:无锡汉塔科技有限公司

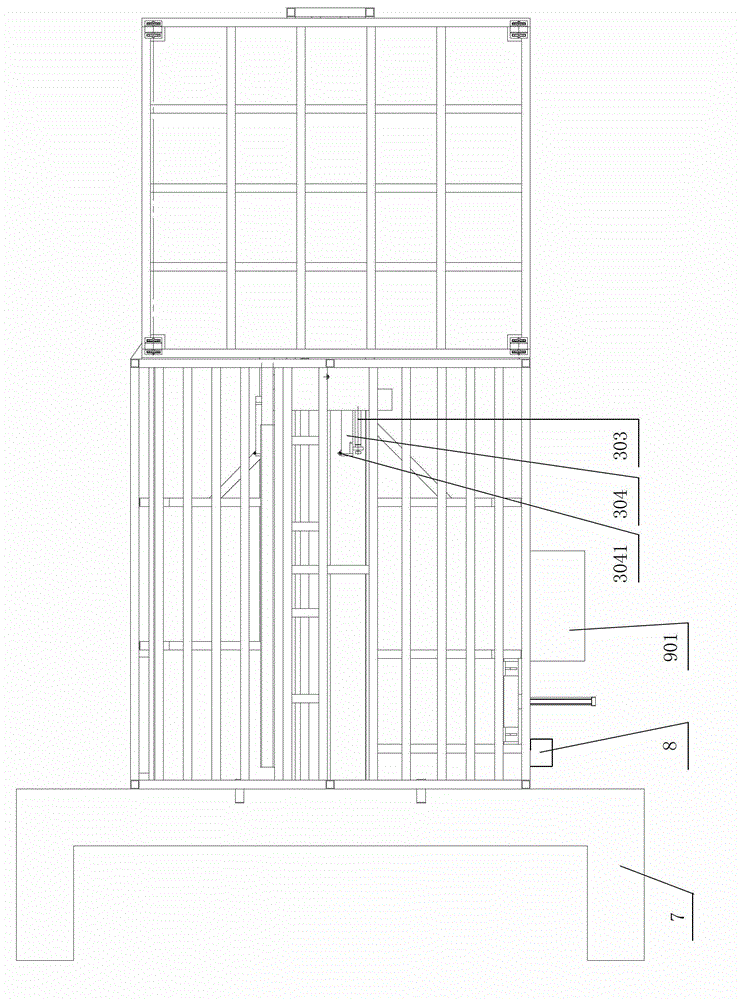

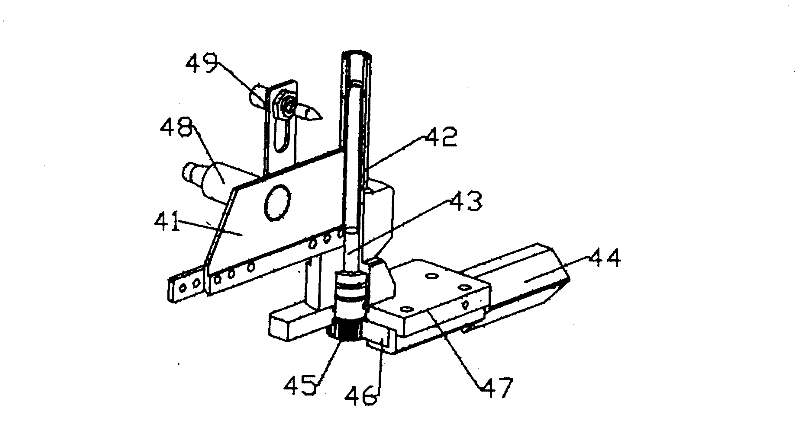

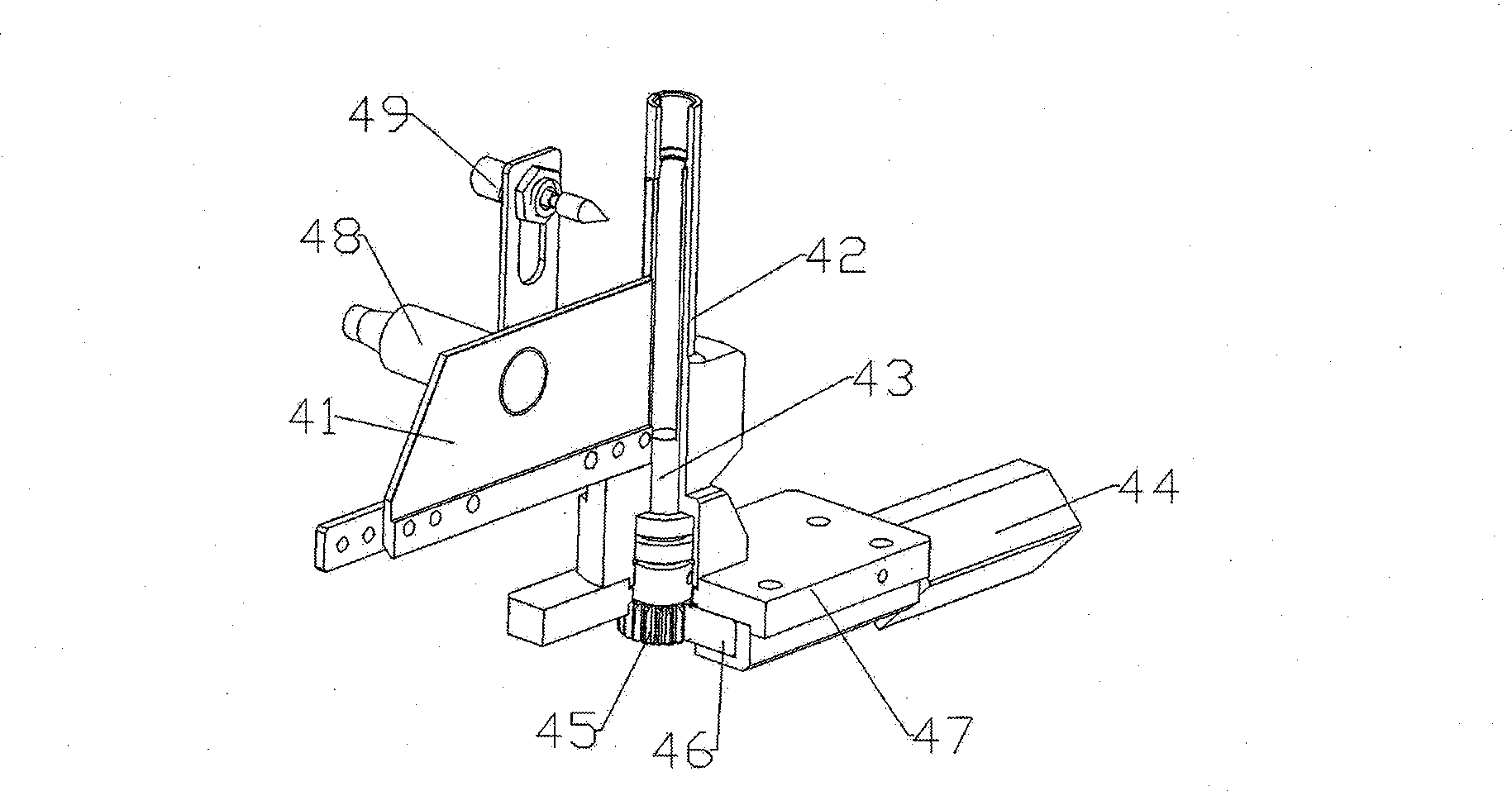

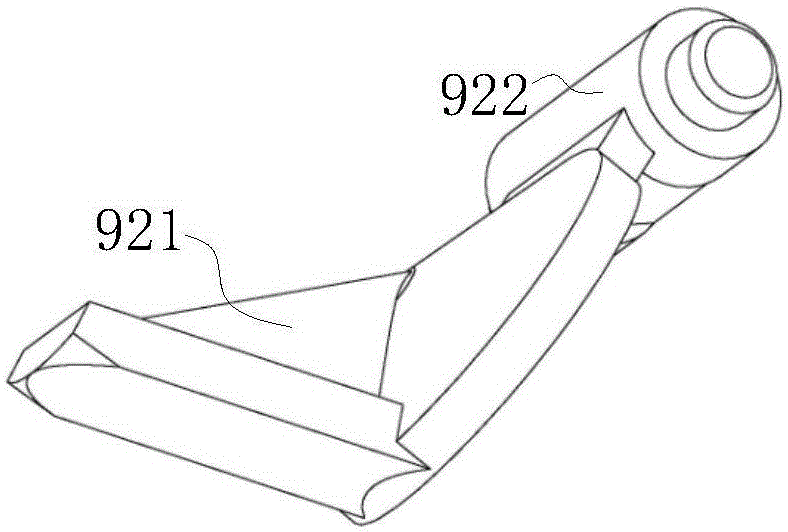

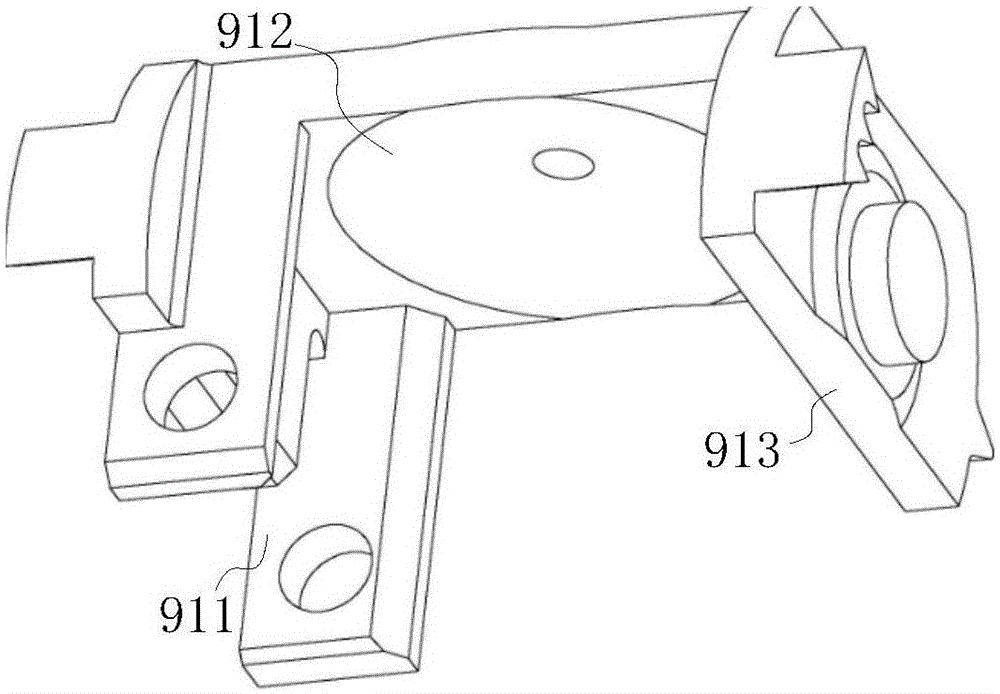

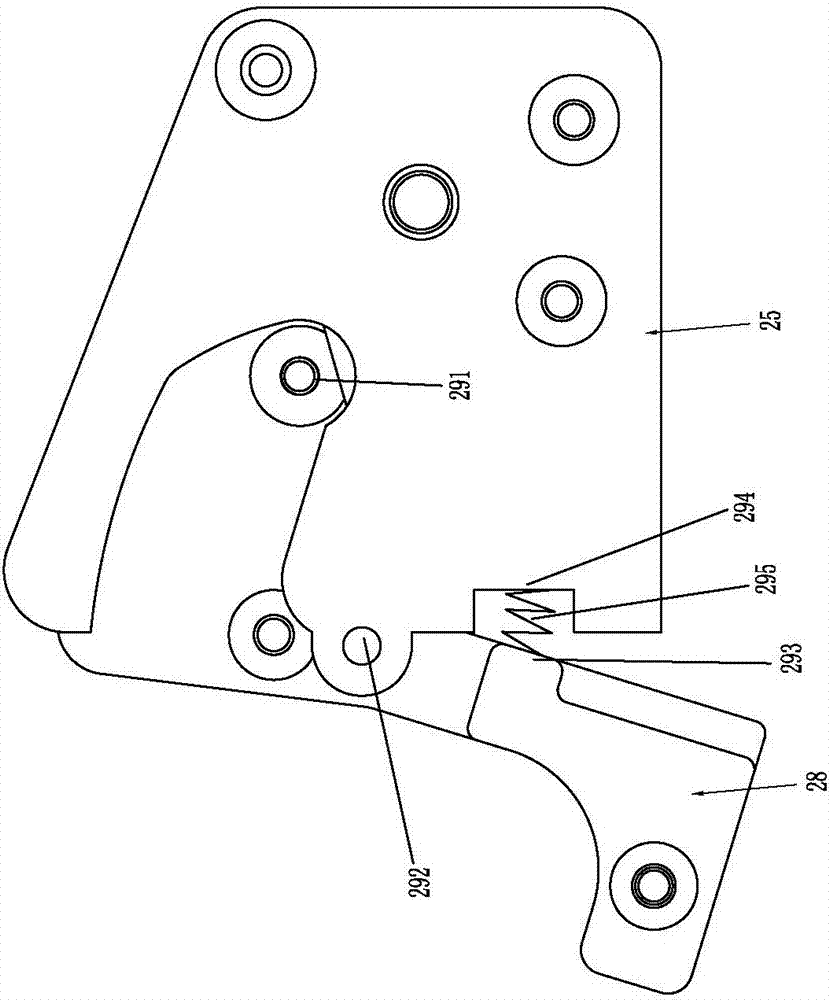

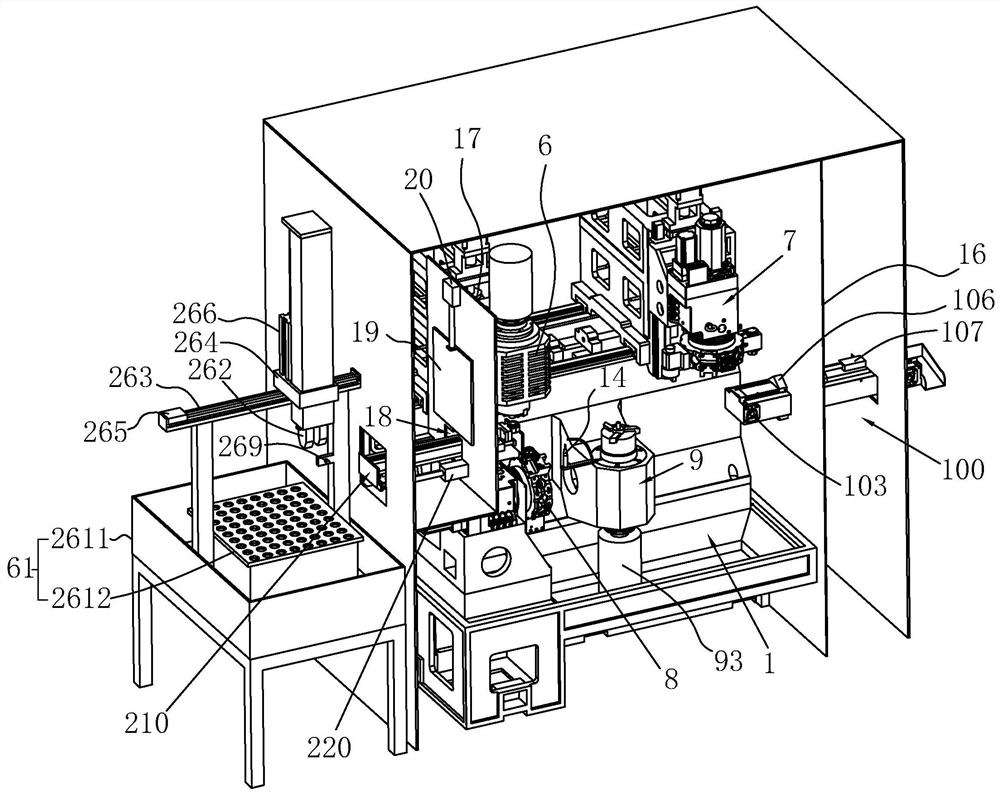

Automatic assembly mechanism for sensitive elements of automobile safety belts

ActiveCN105798566ARealize fully automatic feedingAvoid breakingMetal working apparatusAutomobile safetyProduction automation

The invention belongs to the field of automatic assembly of automobile parts, and particularly relates to an automatic assembly mechanism for sensitive elements of automobile safety belts. The automatic assembly mechanism for the sensitive elements of the automobile safety belts is high in assembly accuracy, accurate in locating, high in qualification rate of products and capable of realizing production automation. The automatic assembly mechanism for the sensitive elements of the automobile safety belts comprises an assembly mechanism body, the assembly mechanism body comprises a locating mechanism, the locating mechanism comprises a fixing plate, the two sides of the upper surface of the fixing plate are connected to the lower ends of guide columns respectively, the upper parts of the guide columns penetrate through through-holes formed in the corresponding positions of a locating block, and a groove is formed in the center of the locating block; an expanding mechanism is arranged below the locating block. Through the expanding mechanism, a sensitive claw and a sensitive base can be automatically assembled, the production efficiency can be improved, and the risk of damaging the parts in the assembly process can be lowered.

Owner:上海科工机电设备成套有限公司

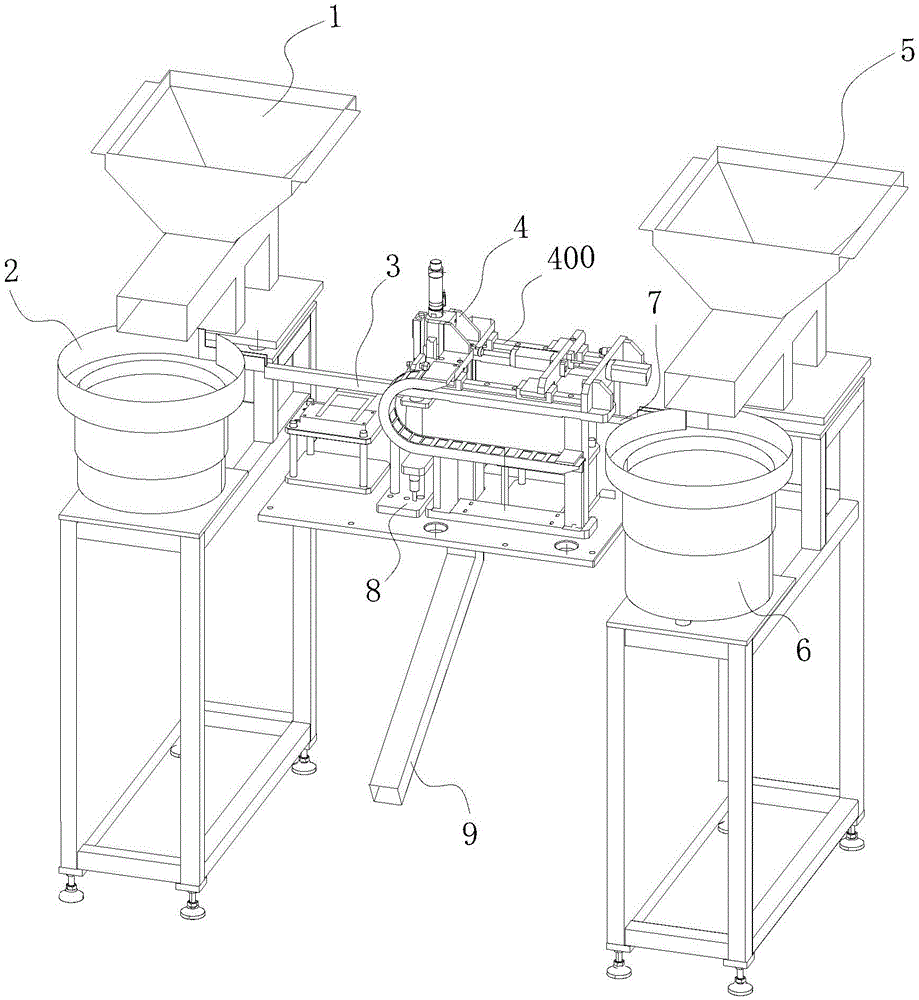

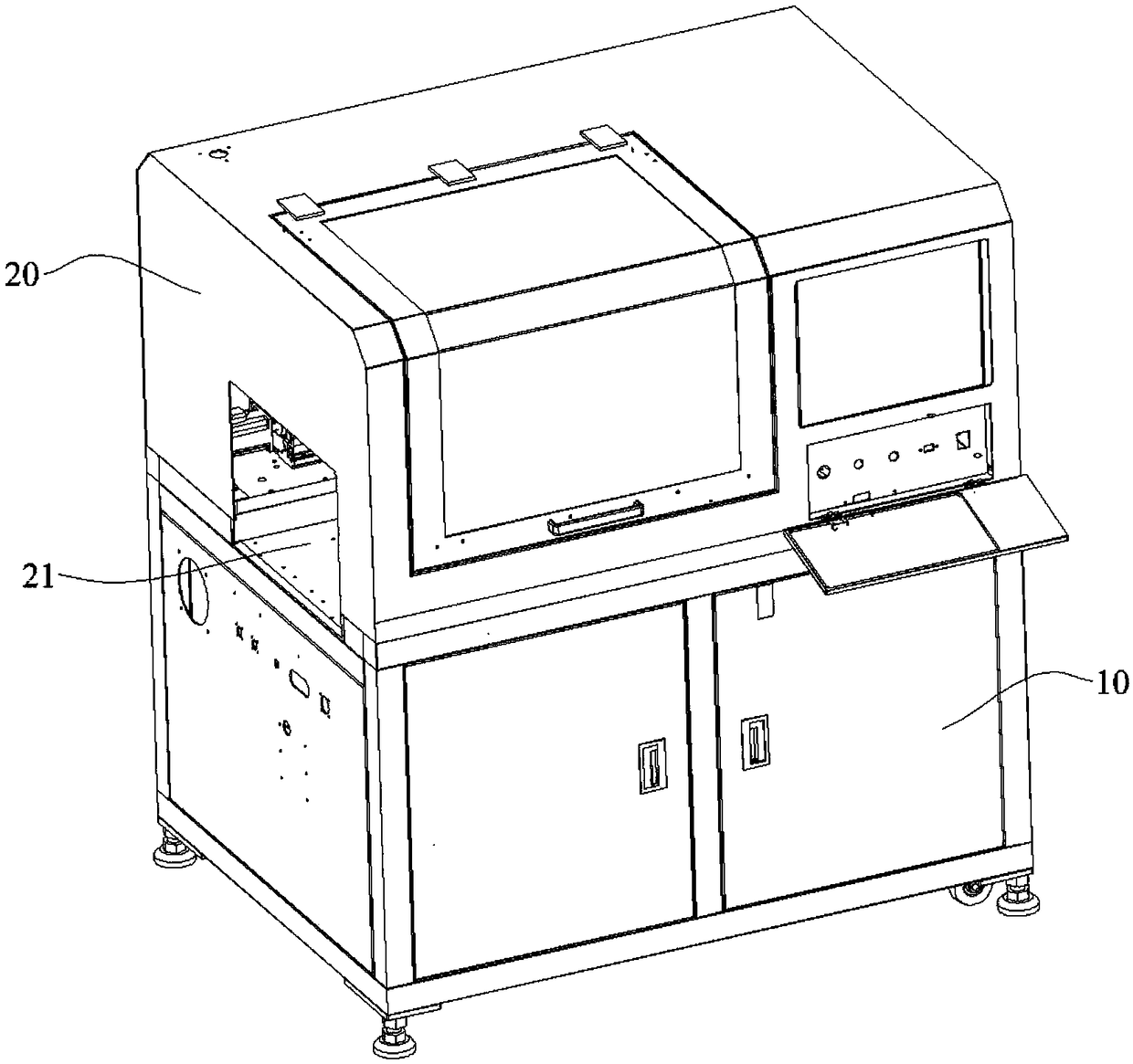

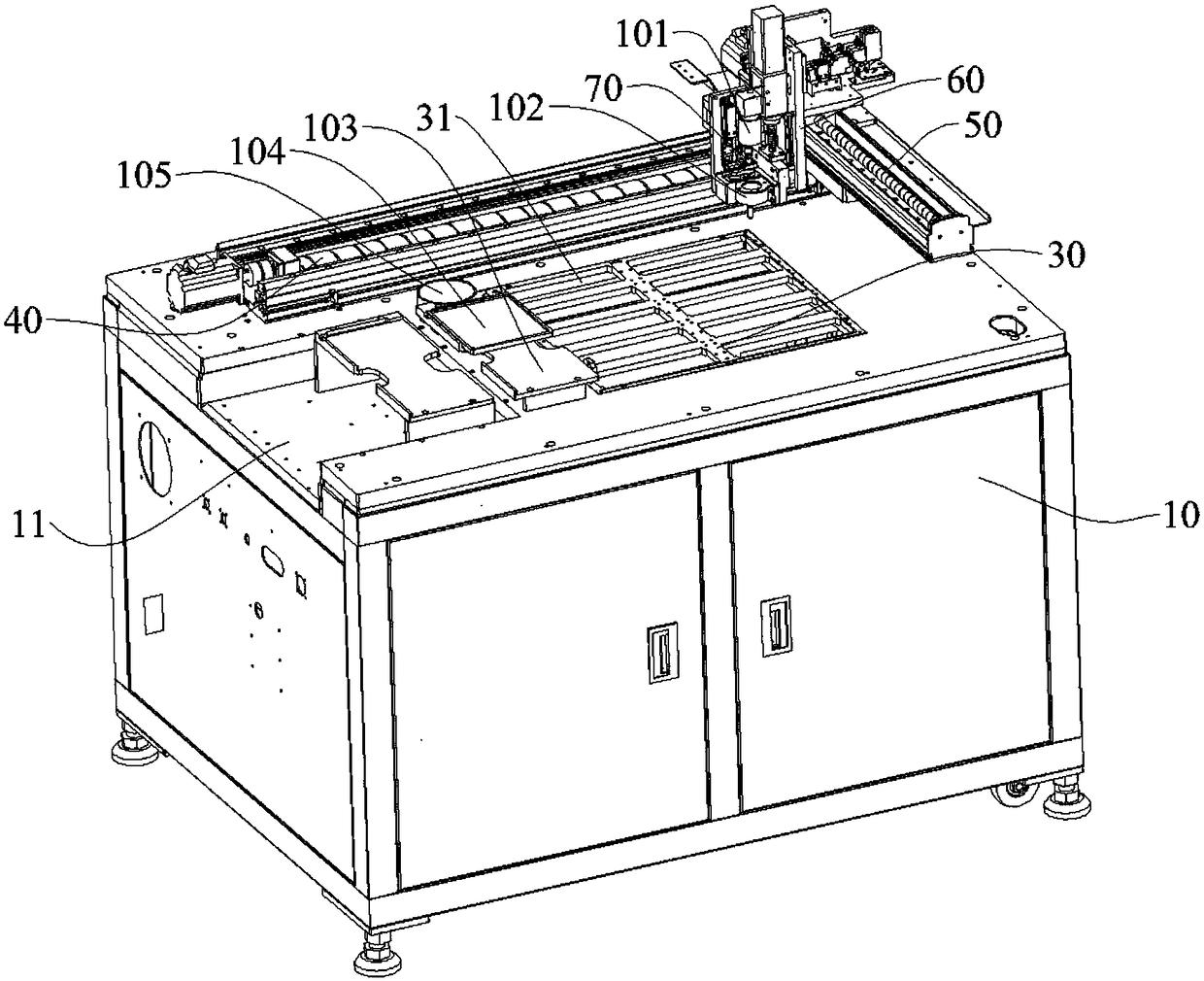

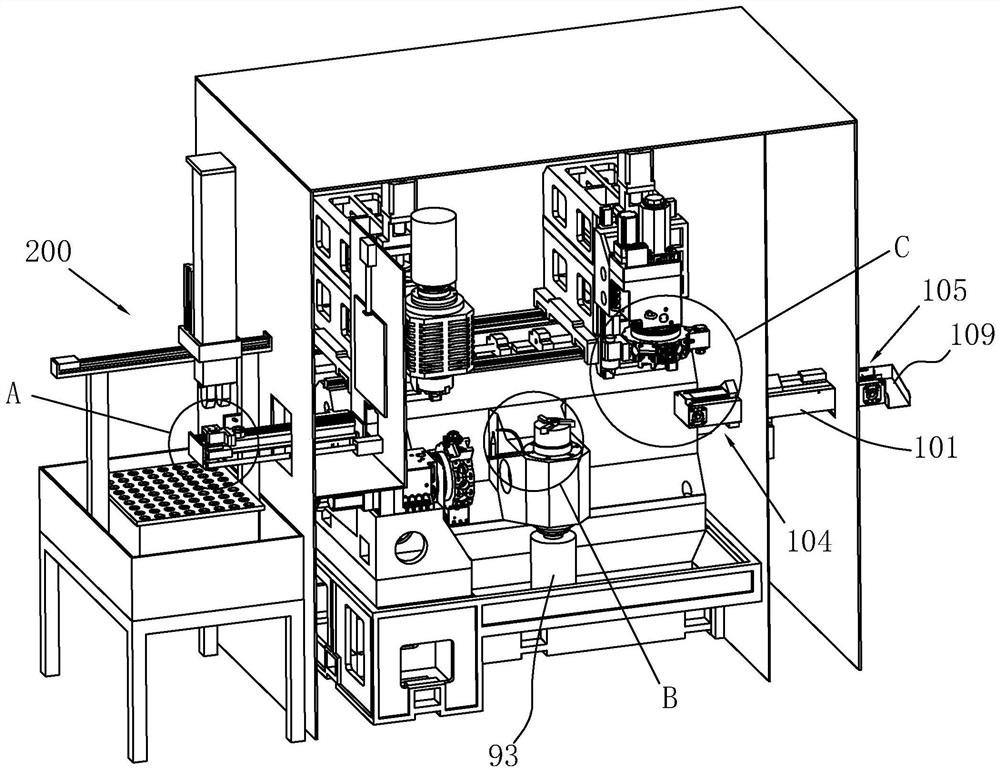

Chip programming device

ActiveCN108483038ASmall footprintImprove programming efficiencyPackagingConveyor partsSingle chipEmbedded system

The invention provides a chip programming device. The chip programming device can solve the problems that the universality is poor, and the equipment cost is high due to the fact that an existing chiprecorder can only be suitable for a single chip feeding mode. The chip programming device comprises a machine table and a chip sucking device, and further comprises a disc-mounted chip feeding deviceand / or a braided chip feeding device; a chip programming area is arranged on the machine table; programmers are arranged on the chip programming area through a programmer fixing base; a box-shaped cover cap is arranged on the machine table; a feed port is formed in the bottom of the left side wall of the box-shaped cover cap; a sunken platform is arranged at the position, right opposite to the feed port, of the machine table; the discharging end of the disc-mounted chip feeding device and / or the braided chip feeding device extends into the box-shaped cover cap through the feed port and is detachably arranged on the sunken platform; and ten programmer mounting ports are formed in the programmer fixing base.

Owner:SUZHOU XINHUARUI ELECTRONICS

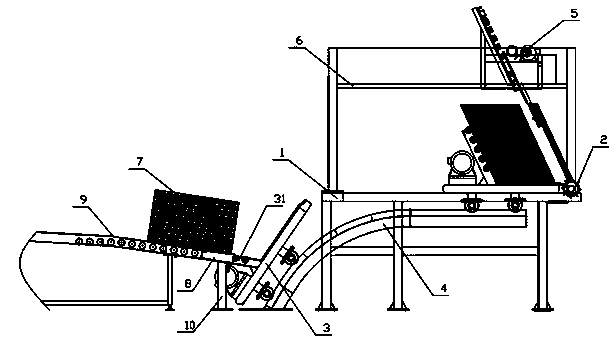

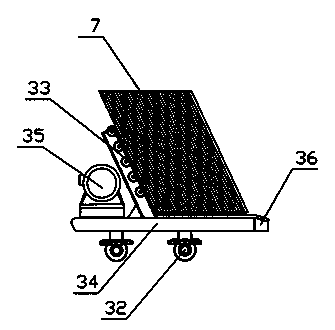

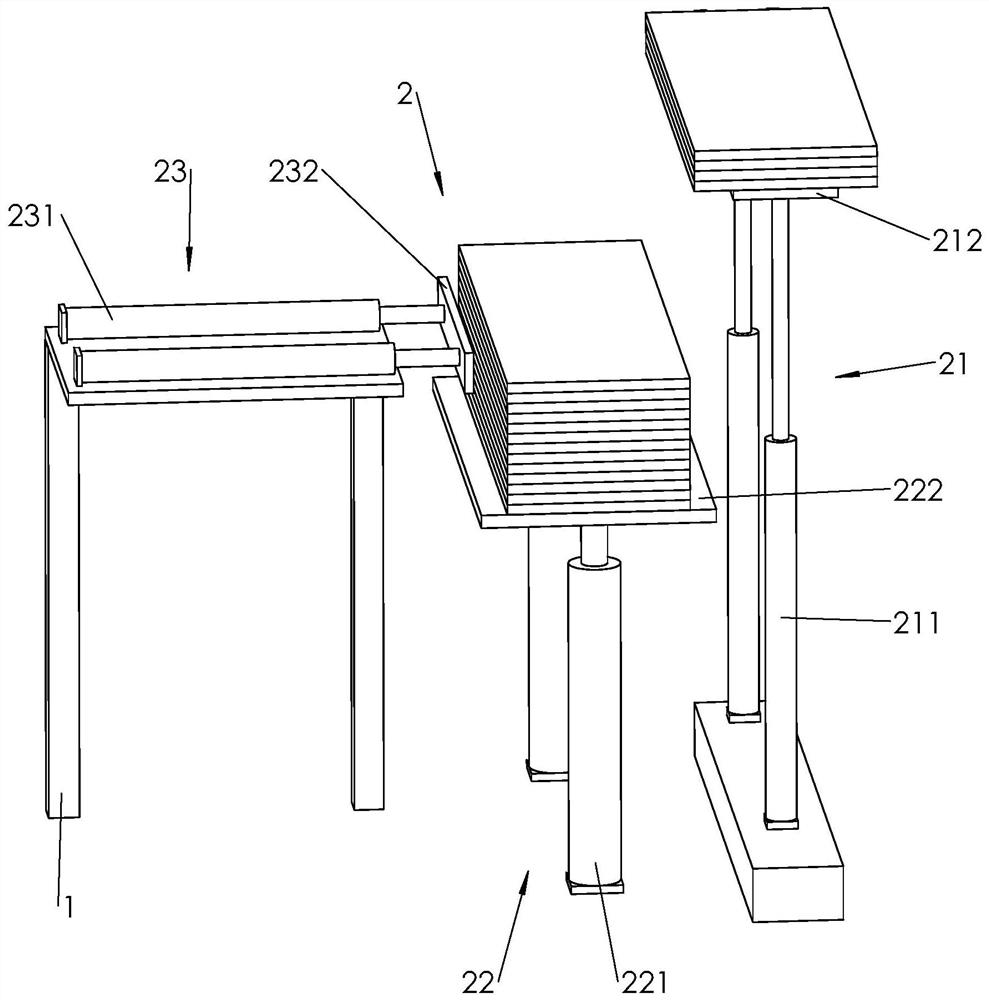

Automatic pulp feeding machine suitable for feeding pulp

ActiveCN103395609ARealize fully automatic feedingEliminate security risksMechanical conveyorsEngineeringAutomation

The invention discloses an automatic pulp feeding machine suitable for feeding pulp. The automatic pulp feeding machine suitable for feeding pulp comprises a rack. A feeding opening formed by a paper stripping mechanism is formed in the rack. A material receiving and conveying mechanism and a material pushing mechanism are further arranged on the rack. The material receiving and conveying mechanism comprises a material conveying trolley and a material conveying rail on which the material conveying trolley walks. The material conveying trolley is arranged on the material conveying rail. A material receiving plate is arranged on the material conveying trolley in an inclined mode. The material conveying rail comprises an ascending segment and a horizontal segment. One end of the ascending segment is a pulp receiving end and the other end of the ascending segment is connected with one end of the horizontal segment. The other end of the horizontal segment is a pulp pouring end. A material pushing mechanism is arranged above the horizontal segment. The feeding opening is formed in the pulp pouring end of the horizontal segment. The material conveying trolley moves between the pulp receiving end and the pulp pouring end through the material conveying rail. According to the automatic pulp feeding machine suitable for feeding the pulp, full-automation feeding of the pulp is achieved, manual operation is removed, full automation of a production process is achieved and manual cost and manual safety risks are reduced.

Owner:YIBIN HIEST FIBER

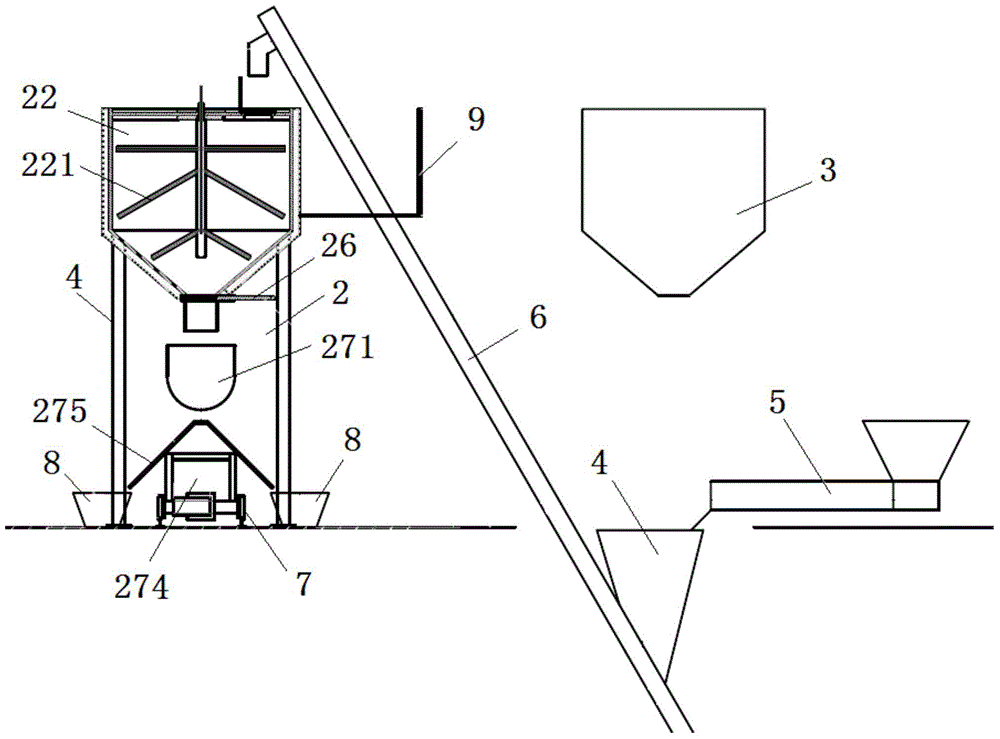

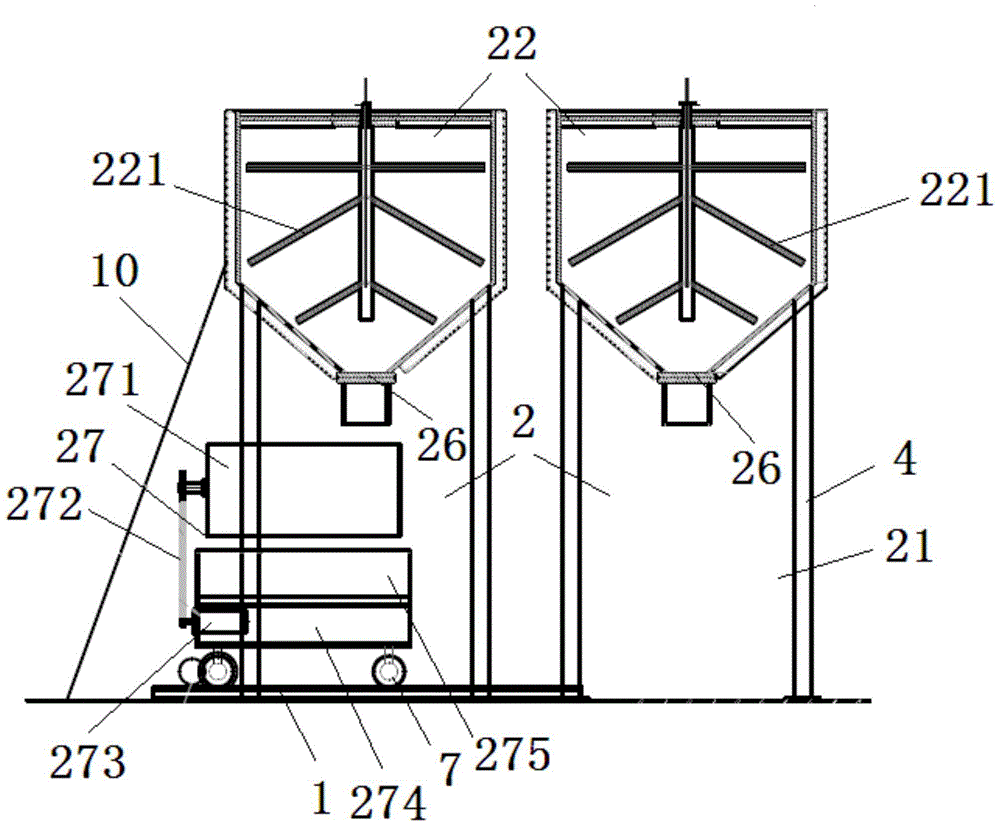

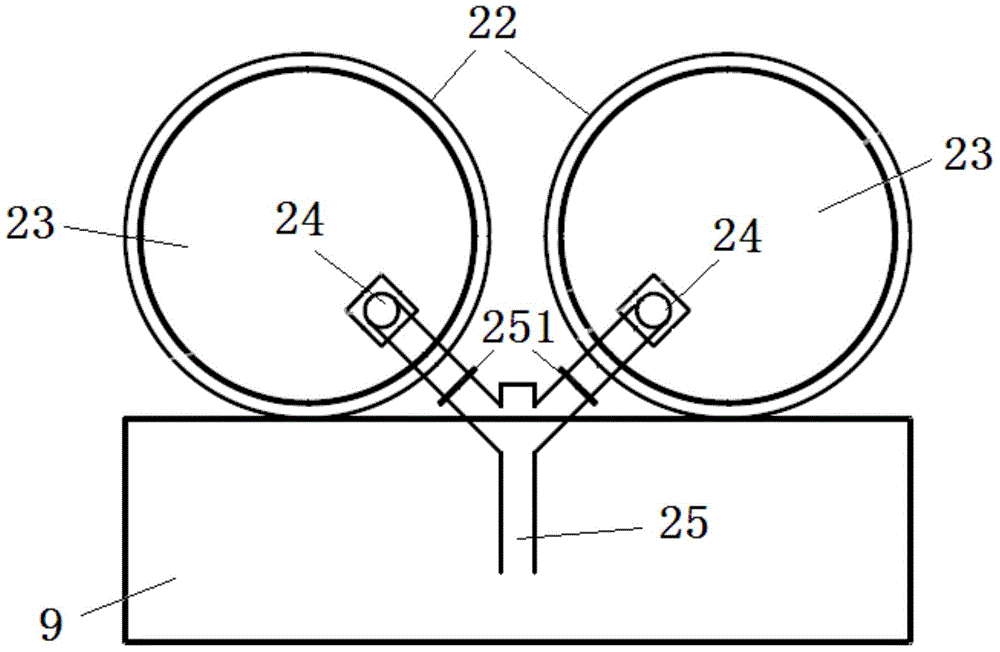

Automatic feeding device for pig house

The invention relates to an automatic feeding device for a pig house. The automatic feeding device is characterized by comprising a rail, a feeding car, a water inlet / feeding tank, a feed mixing tank, a horizontal mixing packing auger and a lifting packing auger, wherein four wheels matched with the rail are arranged on the bottom of the feeding car; a water inlet and a feeding opening of the water inlet / feeding tank are electrically connected with current control equipment; the water inlet / feeding tank is positioned on the top of the feed mixing tank; the feed mixing tank is connected with the horizontal mixing packing auger; a drive motor of the horizontal mixing packing auger is electrically connected with the current control equipment; a discharge hole in the bottom of the feed mixing tank is connected with the lifting packing auger; a drive motor of the lifting packing auger is electrically connected to the current control equipment. The automatic feeding device is simple in structure, is capable of effectively increasing the yield of pigs, reducing the labor power and improving the efficiency, and can be widely applied to the breeding field of various animals.

Owner:TAIAN BEST FARM BEST FOOD AGRI SCI &TECH +1

Automatic cloth cutter

ActiveCN110409163AImprove work efficiencyImprove efficiencySevering textilesEngineeringMechanical engineering

The invention provides an automatic cloth cutter. The automatic cloth cutter comprises a main support, a cutter device, a machine top cover, a floating pressing roller and a pulling device, wherein the cutter device is arranged on the main support, the machine top cover is arranged on the cutter device, the floating pressing roller is installed on the lower end face of the machine top cover, an adjuster is arranged on the main support and located on the lower portion of the floating pressing roller, the pulling device is arranged on the main support, and the cutter device includes a bottom plate, vertical frames, cross beams, upper cutting devices and a lower cutting device. The bottom plate is fixedly installed on the main support. The two ends of the bottom plate are provided with the vertical frames. The vertical frames are provided with the cross beams. The upper cutting devices are installed on the cross beams, the lower cutting device is installed on the bottom plate, the upper cutting devices cooperate with the lower cutting device, the floating press roller presses cloth on the upper surface of the cutter device through relatively suitable pressure, the pressure is ensuredto be uniform, and the working efficiency is improved.

Owner:浙江庄臣新材料有限公司

Intelligent and accurate automatic label feeding device

PendingCN107300929ARealize fully automatic feedingImprove work efficiencyOptical detectionControl using feedbackProcess equipmentGear wheel

The invention provides an intelligent and accurate automatic label feeding device which comprises a frame, a tray placing mechanism, a traction driving mechanism, a label peeling mechanism and a PLC. The tray placing mechanism is provided with a tray mounting shaft installed on the frame. The traction driving mechanism comprises a motor, a driving gear and a driven pressing gear. The label peeling mechanism comprises a label peeling knife, a pressing mechanism arranged above the label peeling knife correspondingly, and a label adsorbing platform which is arranged corresponding to the front side of the label peeling knife. The label adsorbing platform is provided with a label sensing hole, correspondingly, the frame is equipped with an infrared sensor for sensing whether a label reaches the label sensing hole. The PLC is connected to the motor and the infrared sensor. The fully automatic feeding is realized, the working efficiency is improved, especially, combined with the infrared sensor, the a label sending position is more precise, a label lost condition can be fed to the PLC in real time, and the device is cooperatively applied to subsequent labeling and labeling process equipment well.

Owner:东莞市南部佳永电子有限公司

Automatic micro-spring feeding device

PendingCN111761336ARealize fully automatic feedingReduce labor intensityMetal working apparatusRotational axisRobot hand

The invention relates to an automatic micro-spring feeding device. The automatic micro-spring feeding device comprises a vibrating disk, a material track, a spring rotating mechanism, a spring jackingmechanism, a spring carrying manipulator and a spring clamping fixture. The spring rotating mechanism comprises a motor mounting plate, a rotating motor and a rotary shaft. The automatic micro-springfeeding device conducts feeding through the vibrating disk. Due to feeding limitation of the vibrating disk, the automatic micro-spring feeding device can only implement horizontal feeding. Therefore, the automatic micro-spring feeding device needs to receive horizontal springs through the spring rotating mechanism first, changes the springs from horizontal to vertical, jacks out the springs fromspring fixing holes through the spring jacking mechanism, can clamp the springs through the clamping fixture and finally transports the springs and the spring clamping fixture to a preset position through the spring carrying manipulator to realize full-automatic feeding of the springs. The automatic micro-spring feeding device is high in efficiency, capable of reducing the labor intensity of operators, capable of effectively ensuring the position accuracy of the springs in a vertical clamping mode and upright of the springs and especially suitable for micro-springs.

Owner:深圳市精联精密科技有限公司

Full-automatic medical bottle cap assembling machine

PendingCN112959061ARealize fully automatic feedingStable structureAssembly machinesMetal working apparatusControl systemEngineering

The invention discloses a full-automatic medical bottle cap assembling machine. The full-automatic medical bottle cap assembling machine comprises an inner cap feeding mechanism, a bottom film feeding mechanism, a rubber plug feeding mechanism, an outer cap feeding mechanism, an inner cap conveying mechanism, an assembling conveying mechanism, a laser cutting mechanism used for thermal cutting of the bottom films, an inner cap film covering mechanism used for covering the surfaces of openings of the inner caps with cut bottom film material pieces and conducting spot welding connection, a hot-pressing attaching mechanism used for fixing the bottom film material pieces to the inner caps in a hot-pressing mode, an inner cap carrying mechanism used for carrying the inner caps subjected to film covering into the outer caps on the assembling and conveying mechanism, an inner cap pressing mechanism used for pressing and fixedly connecting the inner caps, the rubber plugs and the outer caps, a finished product collecting mechanism used for collecting assembled finished products, and a control system used for controlling all the mechanisms to operate, wherein the inner cap feeding mechanism, the bottom film feeding mechanism, the rubber plug feeding mechanism and the outer cap feeding mechanism are used for feeding inner caps, bottom films, rubber plugs and outer caps; and the inner cap conveying mechanism is used for conveying the inner caps, the outer cups and assemblies in the inner caps and the outer caps. According to the full-automatic medical bottle cap assembling machine, full-automatic assembling of medical bottle caps is achieved, manual operation is avoided, the assembling efficiency is improved, and the bottle caps are free of chippings and dust pollution.

Owner:苏州艾欧科机器人科技有限公司

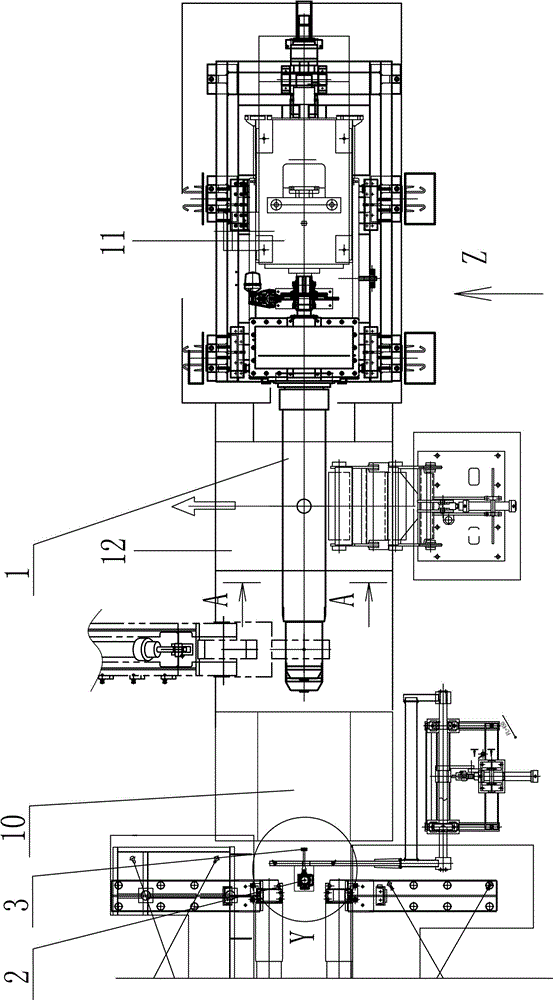

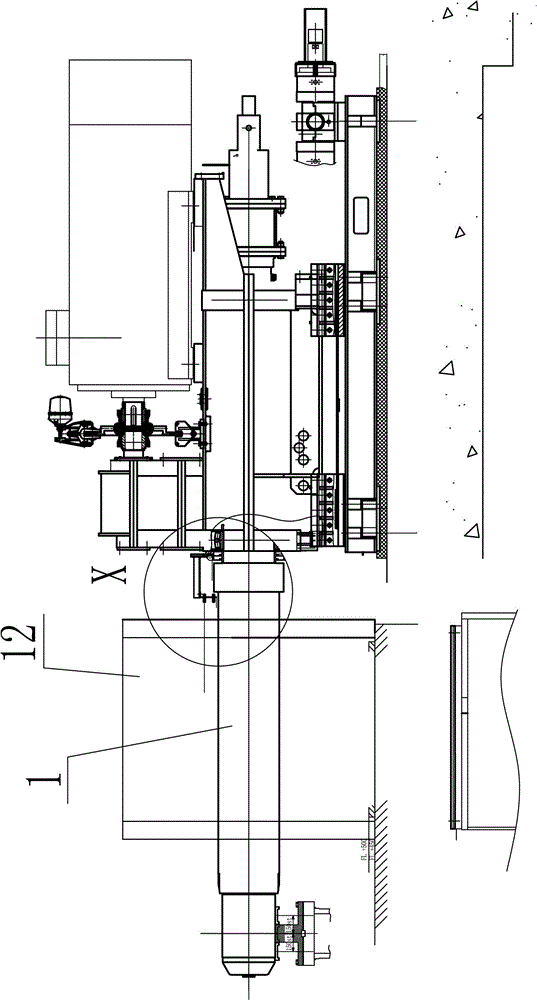

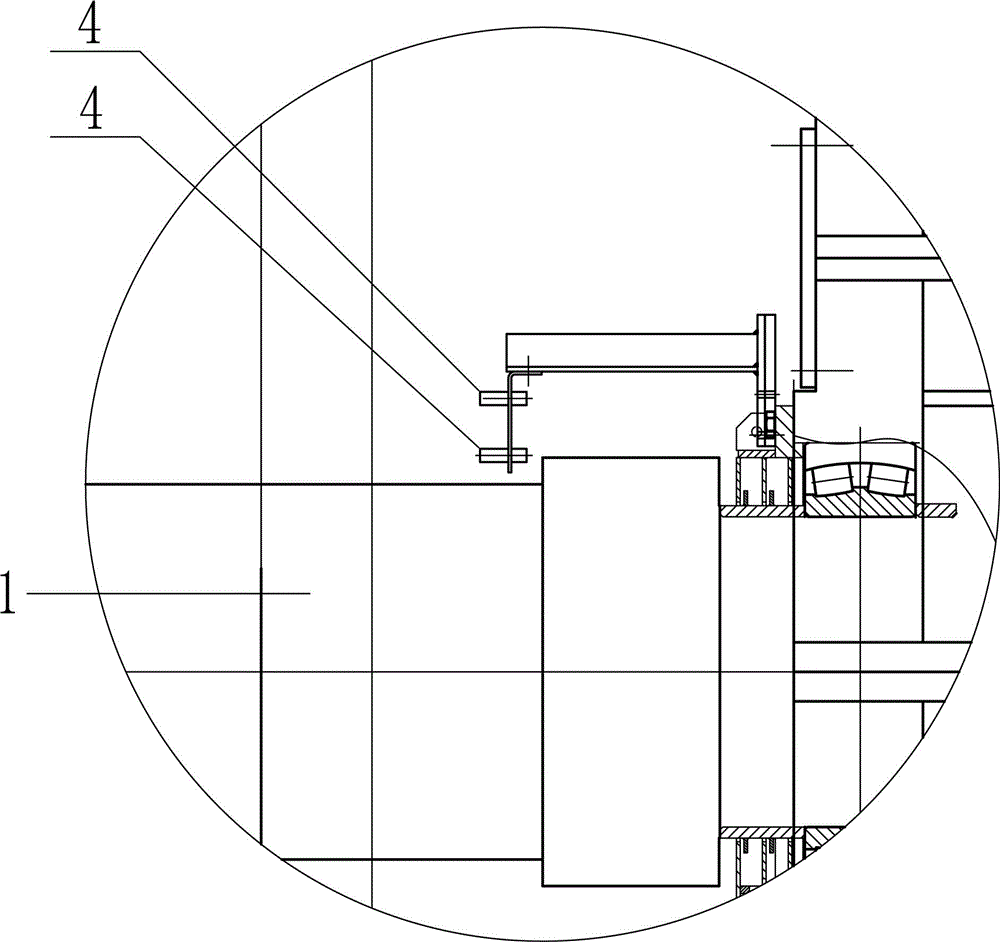

Automatic coiling device for steel strip coil with inner ring provided with folding head and use method thereof

InactiveCN105772534AHigh degree of automationImprove productivityMetal working apparatusLaser rangingLaser rangefinder

The invention relates to the field of tight coiling or coiling or uncoiling of metal strip materials, in particular to an automatic coiling device for a steel strip coil with the inner ring provided with a folding head and a use method thereof. The automatic coiling device for the steel strip coil with the inner ring provided with the folding head comprises an uncoiling machine (1), and is characterized by further comprising a gear motor (2), a laser range finder (3), laser probes (4) and sleeves (5), wherein a groove is formed in the lateral wall of one end surface of each sleeve (5); the sleeves (5) are arranged outside a coiling drum (12) in a sleeving mode; a stepping motor (11), the gear motor (2), the laser range finder (3) and the laser probes (4) are connected with a controller (6) through signal lines. The use method of the automatic coiling device for the steel strip coil with the inner circle provided with the folding head is characterized by including the following steps of a, axis alignment; b, measurement of the folding head; c, alignment of the folding head; and d, uncoiling. The automatic coiling device for the steel strip coil with the inner ring provided with the folding head and the use method thereof are high in automation degree, high in production efficiency and wide in application range.

Owner:BAOSTEEL ENG & TECH GRP

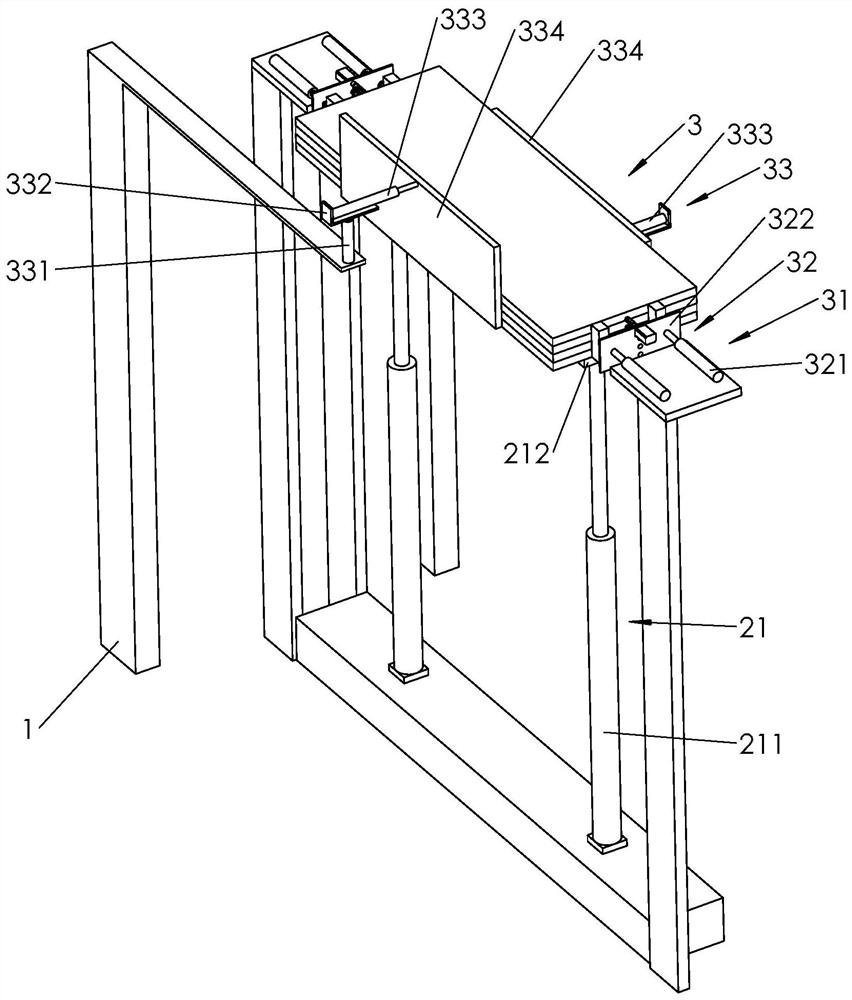

Plate material hole punching device

ActiveCN111842985AImprove drilling efficiencyRealize fully automatic feedingMetal working apparatusBoring/drilling componentsStructural engineeringAutomatic processing

The invention relates to a plate material hole punching device. The plate material hole punching device comprises a support, a material loading mechanism, an end face processing mechanism, a front face processing mechanism, an overturning mechanism, a reverse face processing mechanism and a material unloading mechanism, wherein the material loading mechanism comprises a material placing component;the end face processing mechanism comprises a first clamping component, two sets of end face hole punching components and two sets of first material pushing components; the front face processing mechanism comprises two sets of first conveying components, two sets of material segregation components, a plurality of second clamping components, a plurality of front face hole punching components and aplurality of second material pushing components; the overturning mechanism comprises two sets of third clamping components and two sets of overturning components; the reverse face processing mechanism comprises two sets of third material pushing components, two sets of second conveying components, a plurality of fourth clamping components and a plurality of reverse face hole punching components;and the material unloading mechanism comprises two sets of material receiving components. By means of the plate material hole punching device, full-automatic processing of plate materials is finished,furthermore, the end face hole punching components, the front face hole punching components and the reverse face hole punching components can work simultaneously, and the hole punching efficiency ofthe plate materials is improved.

Owner:佛山市杰明顿装饰材料有限公司

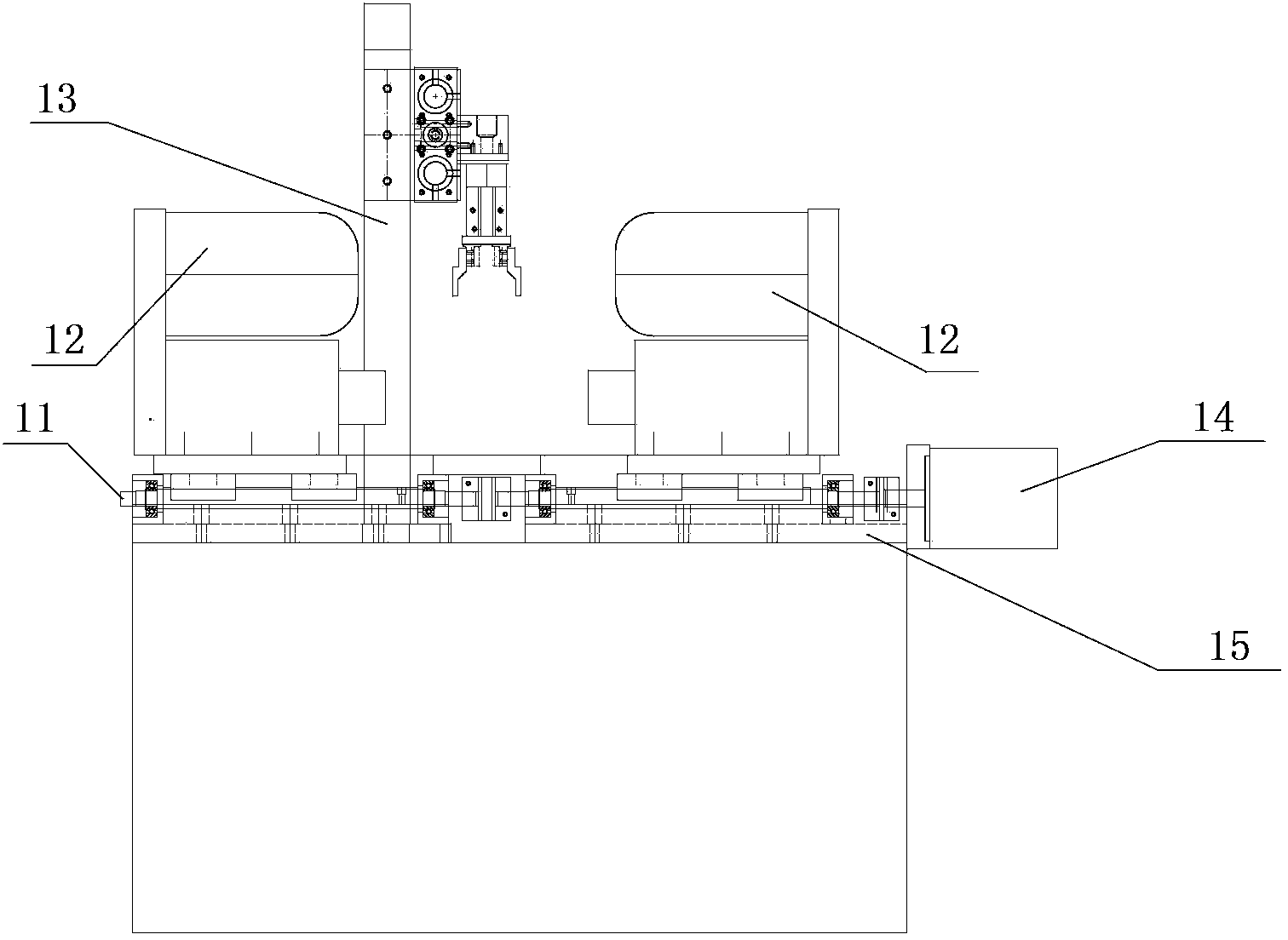

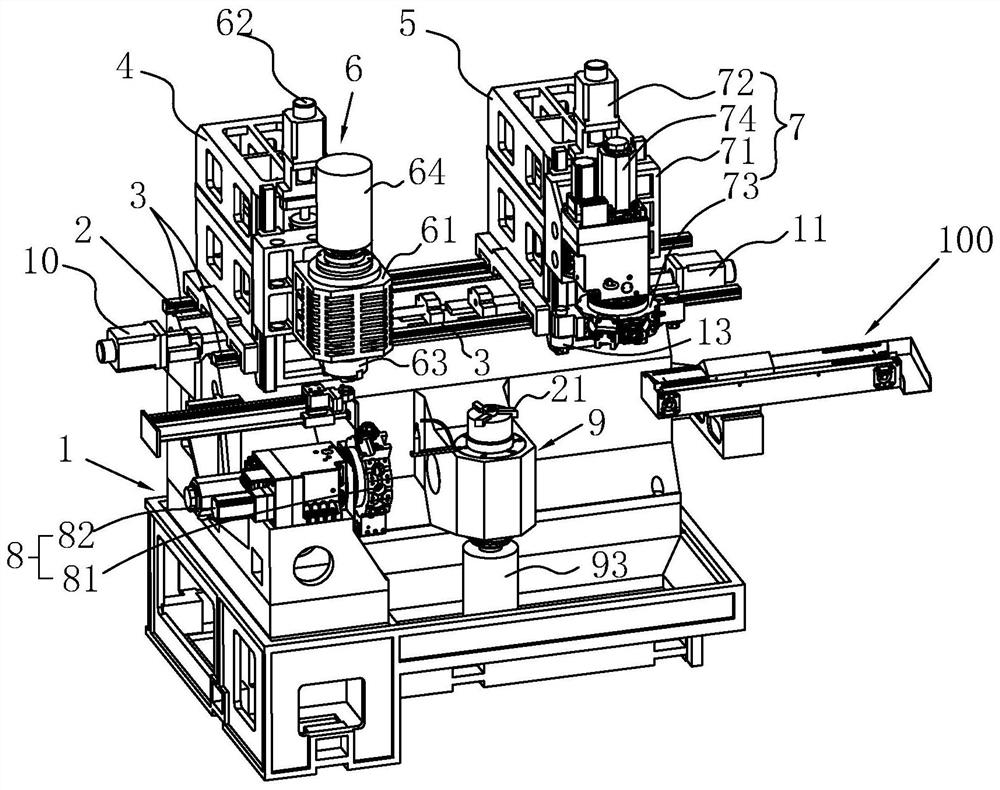

Erected-inverted machine tool with double spindles and double knife towers

PendingCN111761079AImprove machining accuracy and machining efficiencyHigh degree of automationLarge fixed membersMetal working apparatusProcessing accuracyContinuous production

The invention provides an erected-inverted machine tool with double spindles and double knife towers, and belongs to the field of numerically-controlled machine tools. The erected-inverted machine tool with the double spindles and the double knife towers comprises a machine body, wherein an installation platform is horizontally arranged on the machine body along the X axis; an X-axis guide rail ishorizontally arranged on the installation platform; a first vertical column and a second vertical column are sequentially vertically arranged above the installation platform; a first drive part driving the first vertical column to move along the X-axis guide rail, and a second drive part driving the second vertical column to move along the X-axis guide rail are further arranged on the machine body; a first spindle part is arranged on the first vertical column; a second knife tower part is arranged on the second vertical column; a first knife tower part is arranged on a part located at one side of the first spindle part, of the machine body; and a second spindle part is arranged on a part located between the first vertical column and the second vertical column, of the machine body. The erected-inverted machine tool with the double spindles and the double knife towers has the functions of automatically loading, automatically machining and automatically unloading, and is high in automation degree; the erection and the inversion of the machine tool are combined, and overturning is not needed during workpiece machining, so that continuous production can be carried out; the X-axis guiderail is horizontally arranged, so that more stable movement and high machining accuracy are achieved; and moreover; the mechanisms of the machine tool are compact in structure, and the machine tool is compact in overall layout.

Owner:湖北山铁智能装备有限公司

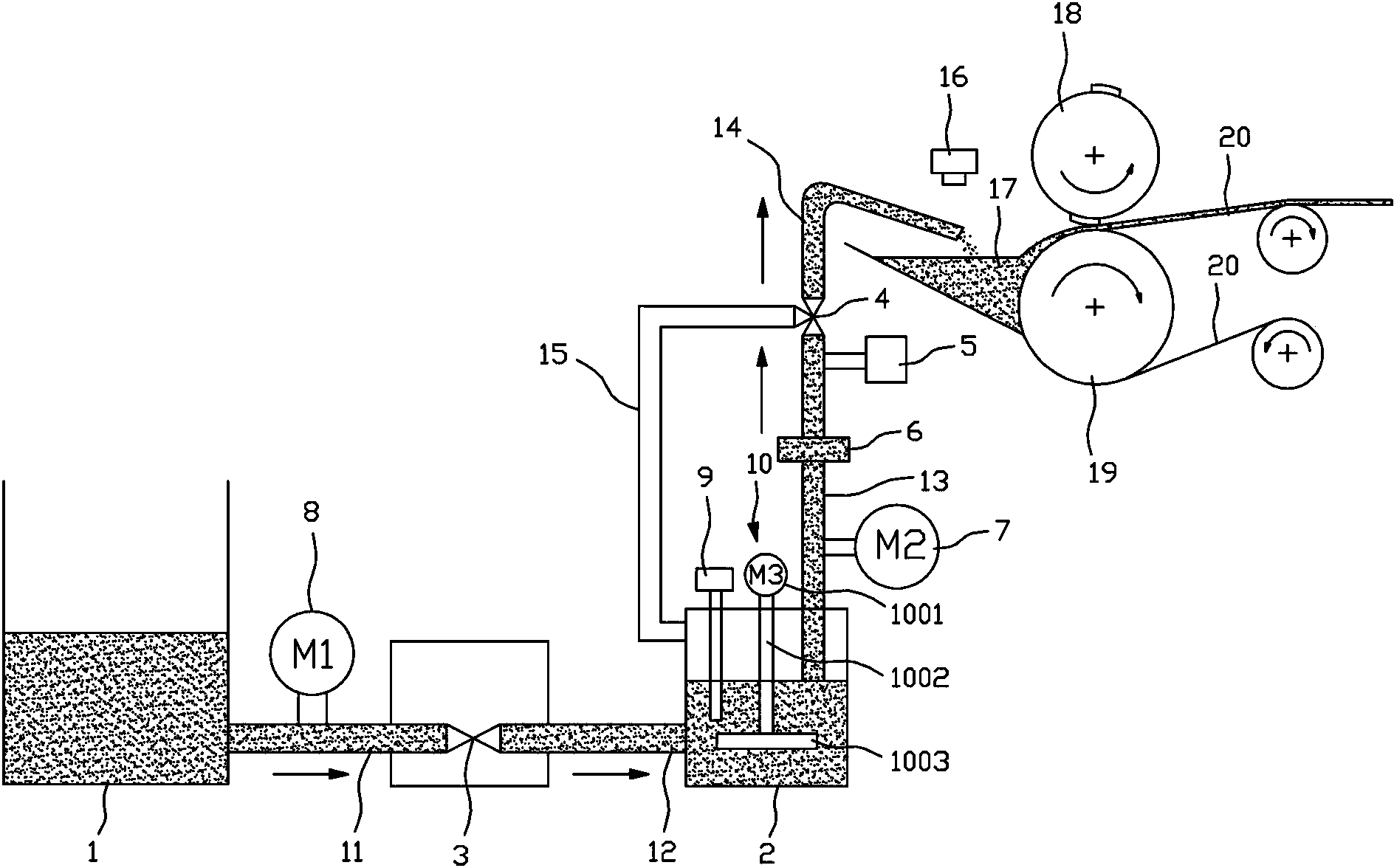

Coating machine feeding system

ActiveCN103752469ARealize fully automatic feedingPrevent solidificationLiquid surface applicatorsCoatingsSlurryLiquid level sensor

The invention discloses a coating machine feeding system. The coating machine feeding system comprises a slurry barrel used for containing slurry for coating, a feeding bucket, a valve with an inlet and an outlet, a three-way valve with an inlet and two outlets, a first liquid level sensor used for detecting the liquid level of the feeding bucket, and a second liquid level sensor used for detecting the liquid level of a slurry tank, wherein the slurry barrel is connected with the inlet of the valve through a first pipeline; the outlet of the valve is connected with the feeding bucket through a second pipeline; the feeding bucket is connected with the inlet of the three-way valve a third pipeline; one outlet of the three-way valve extends to the slurry tank or the upper part of the slurry tank through a fourth pipeline; the other outlet of the three-way valve is connected with the feeding bucket through a fifth pipeline; a first motor is arranged on the first pipeline or the second pipeline; a second motor and a pressure sensor are arranged on the third pipeline. According to the system, the full-automatic feeding can be realized, so that the feeding efficiency is high, and coating machines can be processed in batch.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

Automatic height detecting device

PendingCN108759754ARealize fully automatic feedingImprove detection accuracyProgramme-controlled manipulatorMeasurement devicesMechanical engineeringTesting equipment

Owner:KUSN GUANGHE ELECTRONICS TECH

Side-punching system for short strip materials

InactiveCN109261827AAvoid wastingIncrease profitMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses a side-punching system for short strip materials. The side-punching system comprises punching equipment, a die arranged on the punching equipment and a feeding device arrangedon a front side of the punching device. The feeding device comprises a first frame, a first clamping device, a second clamping device and a third clamping device, the first clamping device is used forclamping one end of a material, the second clamping device is used for clamping the other end of the material so as to cooperate with the first clamping device, the third clamping device is arrangedbetween the first clamping device and the second clamping device and used for clamping a middle portion of the material, and when the third clamping device clamps the middle portion of the material, the first clamping device or the second clamping device unclamps the material and move backwards. The side-punching system for the short strip materials has the advantages that a use ratio of the integral material is increased, the amount of waste is decreased, production cost for same yield is reduced, comprehensive automatic feeding is realized, manual moving or overturning during material punching is omitted, labor intensity and labor cost of workers are reduced, punching efficiency of a punching machine is improved, and production efficiency is improved.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

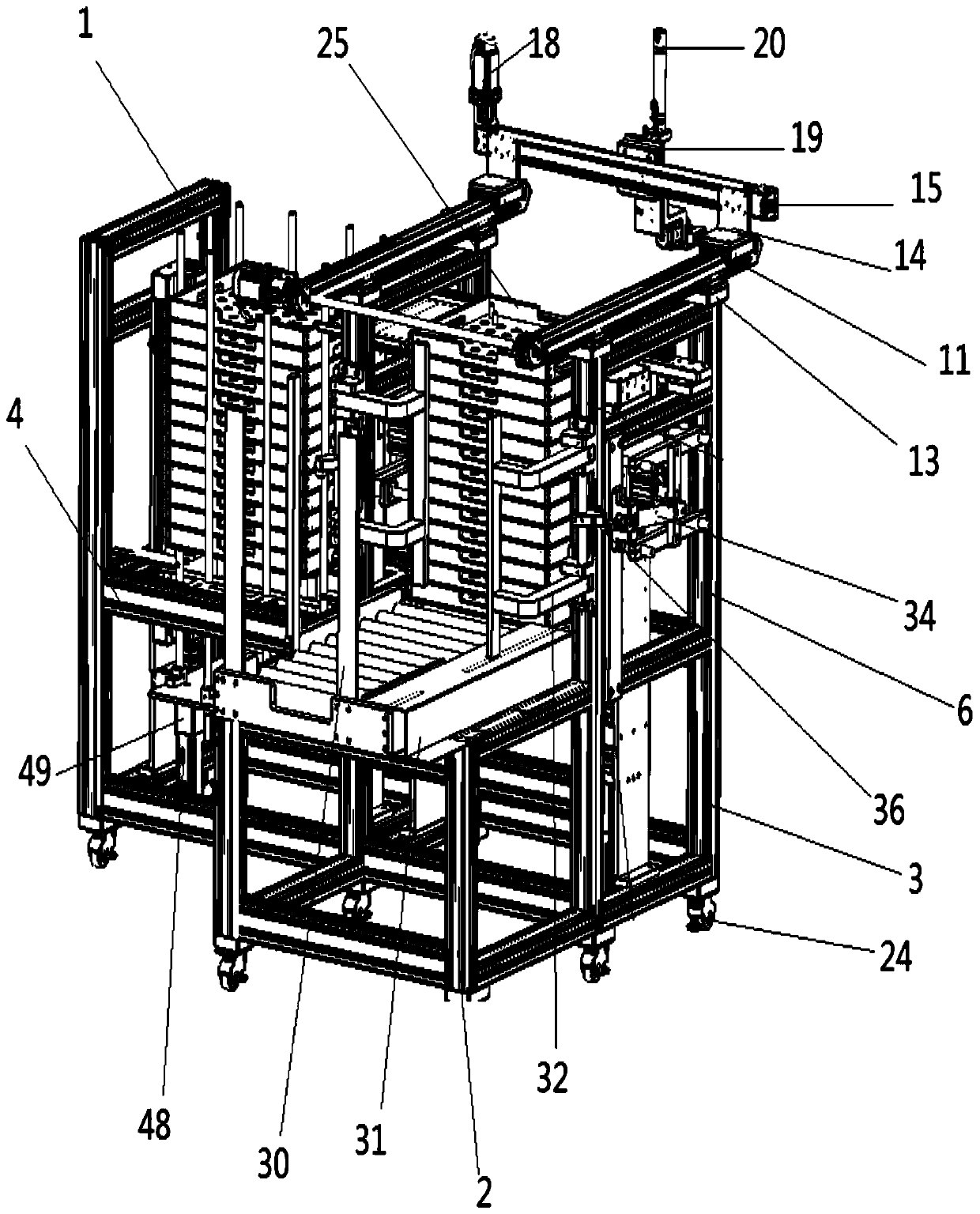

Tray type feeding and discharging device

PendingCN110510419AUnlimited shapeUnlimited sizeStacking articlesDe-stacking articlesProduction lineBiochemical engineering

The invention provides a tray type feeding and discharging device. The tray type feeding and discharging device comprises a frame, wherein a cuboid-shaped first frame body, a second frame body and a third frame body are arranged on the machine frame, and the first frame body, the second frame body and the third frame body are arranged in an L-shape; a first stand column, a second stand column, a third stand column and a fourth stand column are respectively arranged at four corners of the top surface of the second frame body; and the second frame body is provided with a first tray platform, andthe third frame body is provided with a second tray platform. The tray type feeding and discharging device is simple in structure and low in manufacturing cost, can meet the feeding and discharging operations of most of tray materials or products, replaces manual low-efficiency operation, improves the production efficiency, and can realize full-automatic feeding, discharging and transportation.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

Round bar machining device and feeding device thereof

PendingCN107160226AAvoid stuck problemsAdjust the placement spaceGrinding feedersMetal working apparatusEngineeringRound bar

The invention provides a round bar machining device and a feeding device thereof. The feeding device comprises a loading box, multiple pushing rods, an adjusting mechanism and a power mechanism; the loading box is of a box structure with an opening in the upper and is used for bearing round bars, multiple vertically through grooves are formed in the inner surface of one side wall of the loading box, multiple pushing stop faces are formed by the non-groove position of the inner surface of the side wall of the loading box, the multiple pushing rods stretch into the loading box from the lower portion of the loading box, and the pushing rods are opposite and close to the grooves; the adjusting mechanism is connected with the pushing rods and can drive the pushing rods to move in the direction facing or away from the grooves, the pushing rods are partly embedded in or moved out of the grooves, the top faces of the pushing rods partly or completely exceed the pushing stop faces, and the exceeding faces form pushing faces suitable for a single round bar; and the power mechanism is connected with the pushing rods so as to drive the pushing rods to vertically move.

Owner:深圳市引领工业装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com