Side-punching system for short strip materials

A side stamping and short strip technology, which is applied in the field of short strip side stamping system, can solve the problems of large demand for manual operation, decreased production efficiency, and slow stamping efficiency, so as to improve utilization rate, reduce waste, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

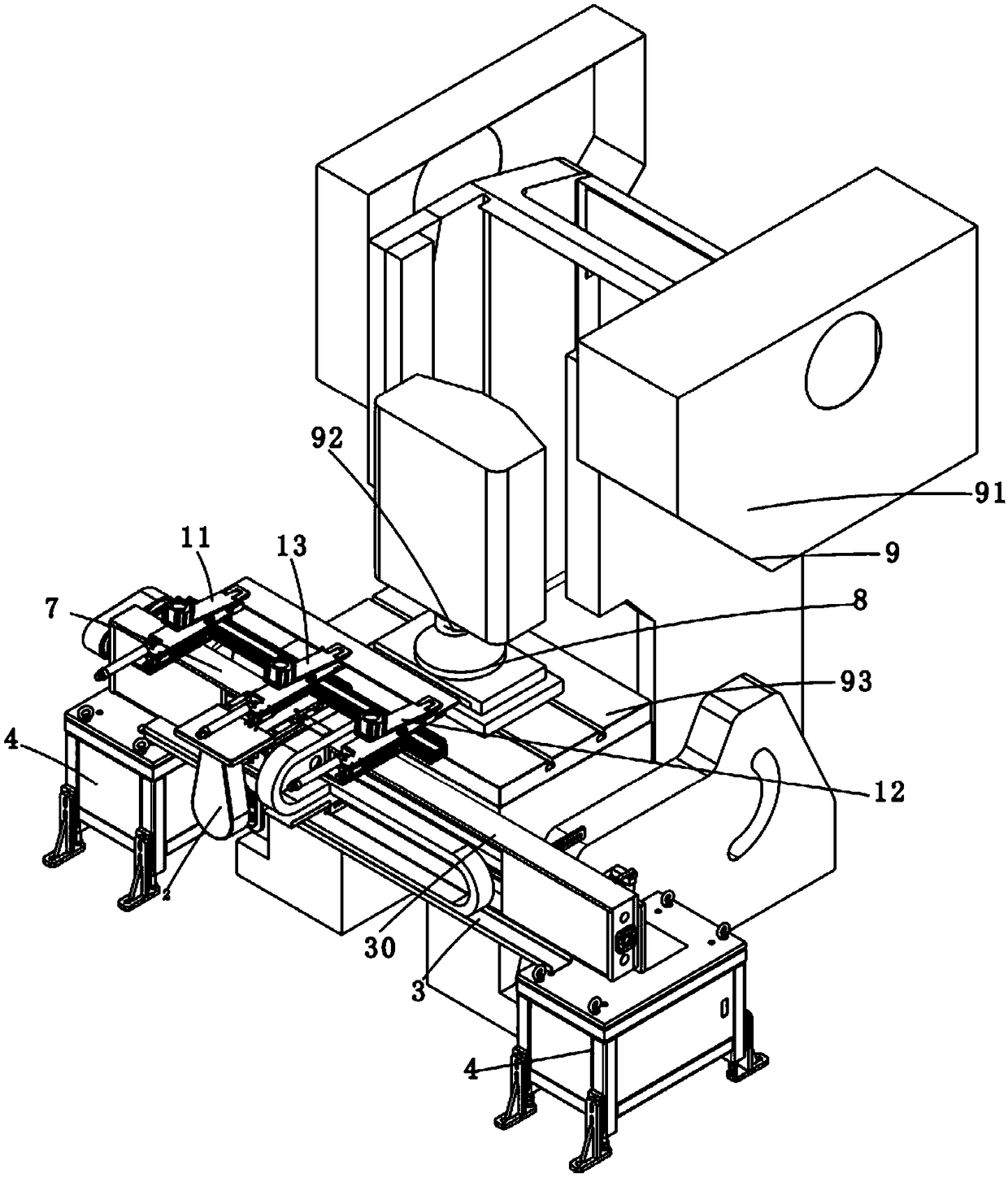

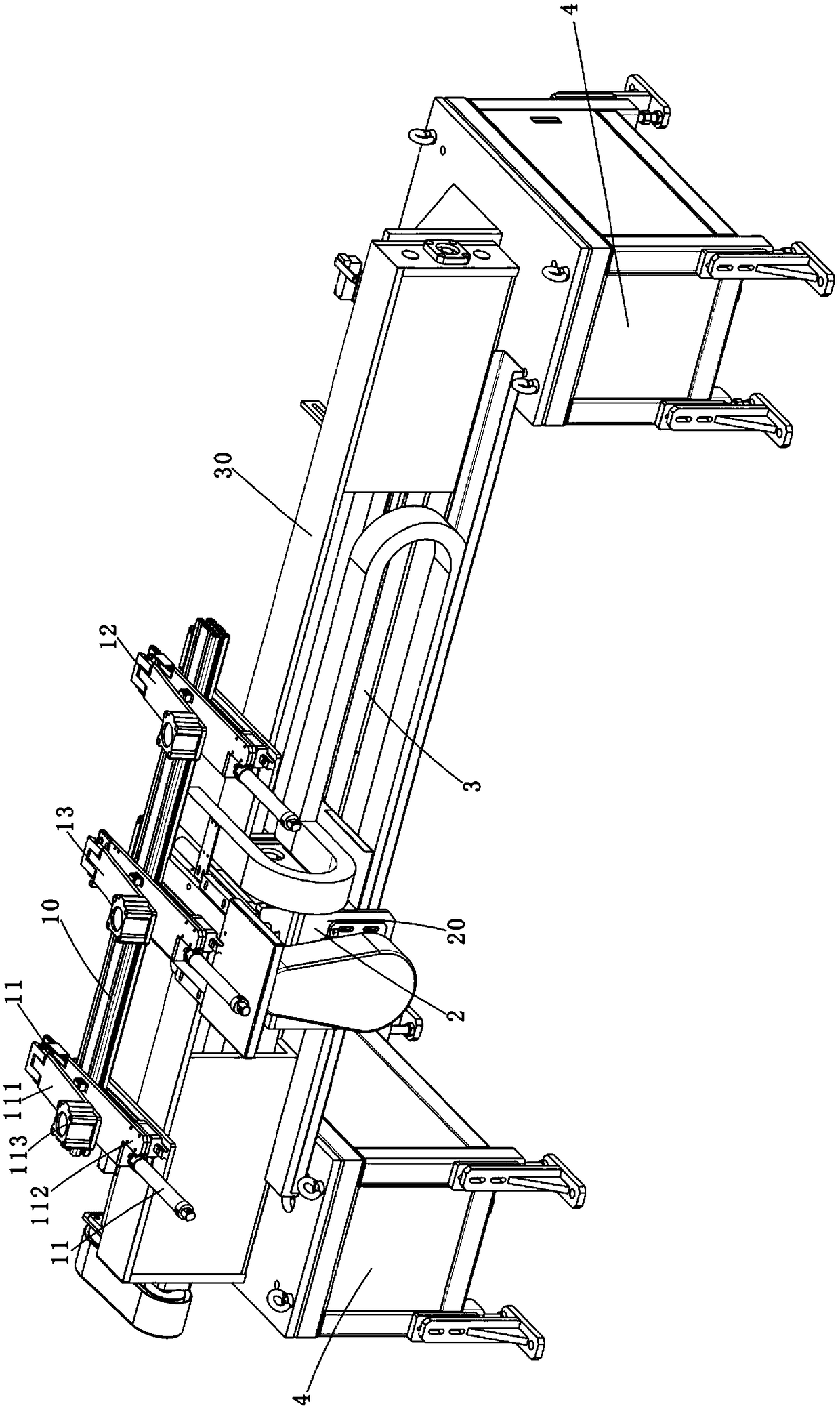

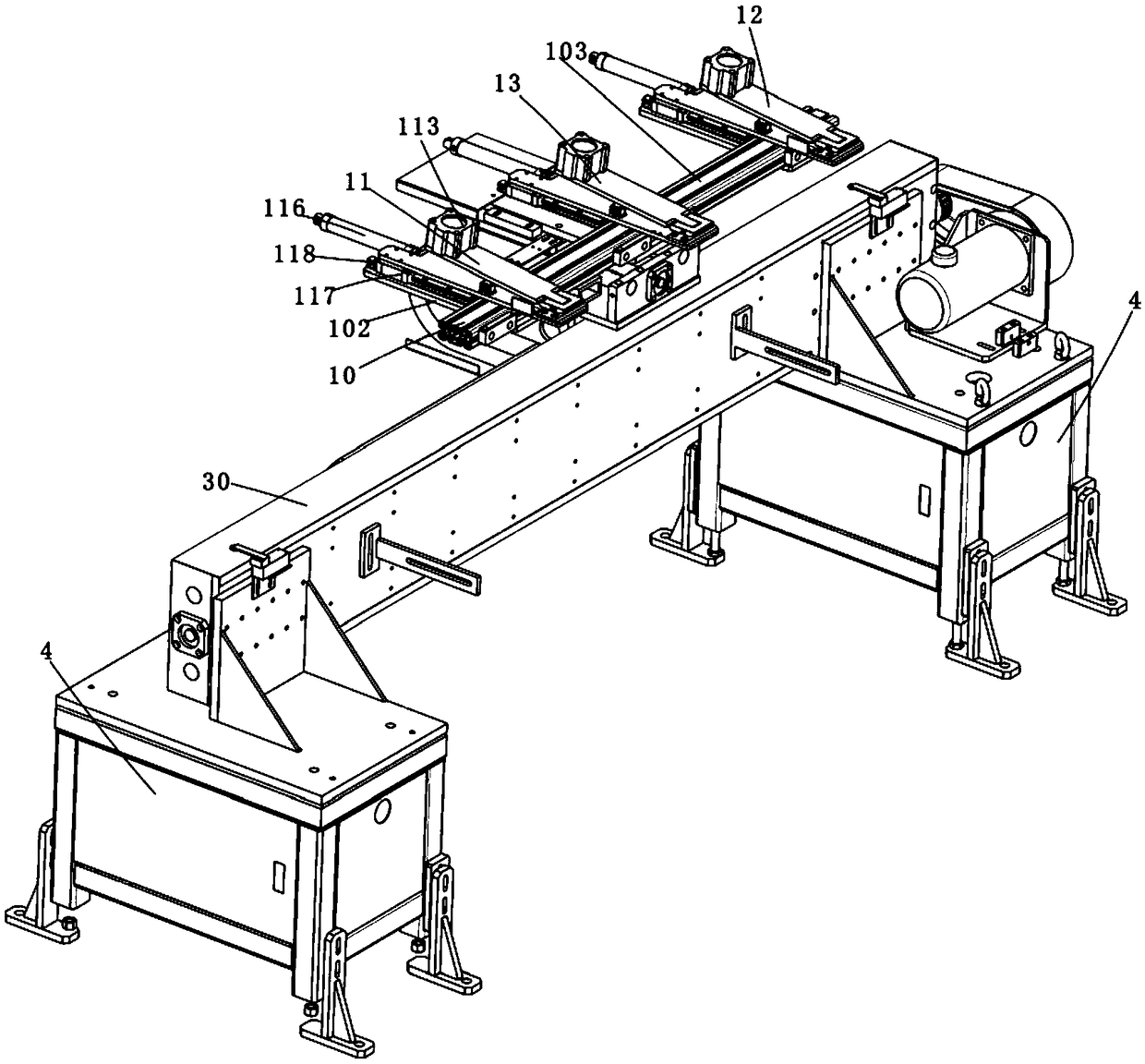

[0037] like Figure 1-14As shown, a stamping system for the side of short strips includes stamping equipment 9, a mold 8 and a feeding device 7, wherein the stamping equipment 9 includes a placement frame 91, a stamping head 92 and a stamping platform 93, and the placement frame 91 It is a metal frame, and the stamping head 92 is a metal head driven by a cylinder. The stamping head 92 can move up and down during work to stamp the mold 8. The stamping platform 93 is a metal plate with a smooth end surface. Composition, the stamping platform 93 is arranged on the said placement frame 91; the mold 8 is a mold made of metal, its specific shape is set according to the shape requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com