Patents

Literature

707results about How to "Improve stamping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

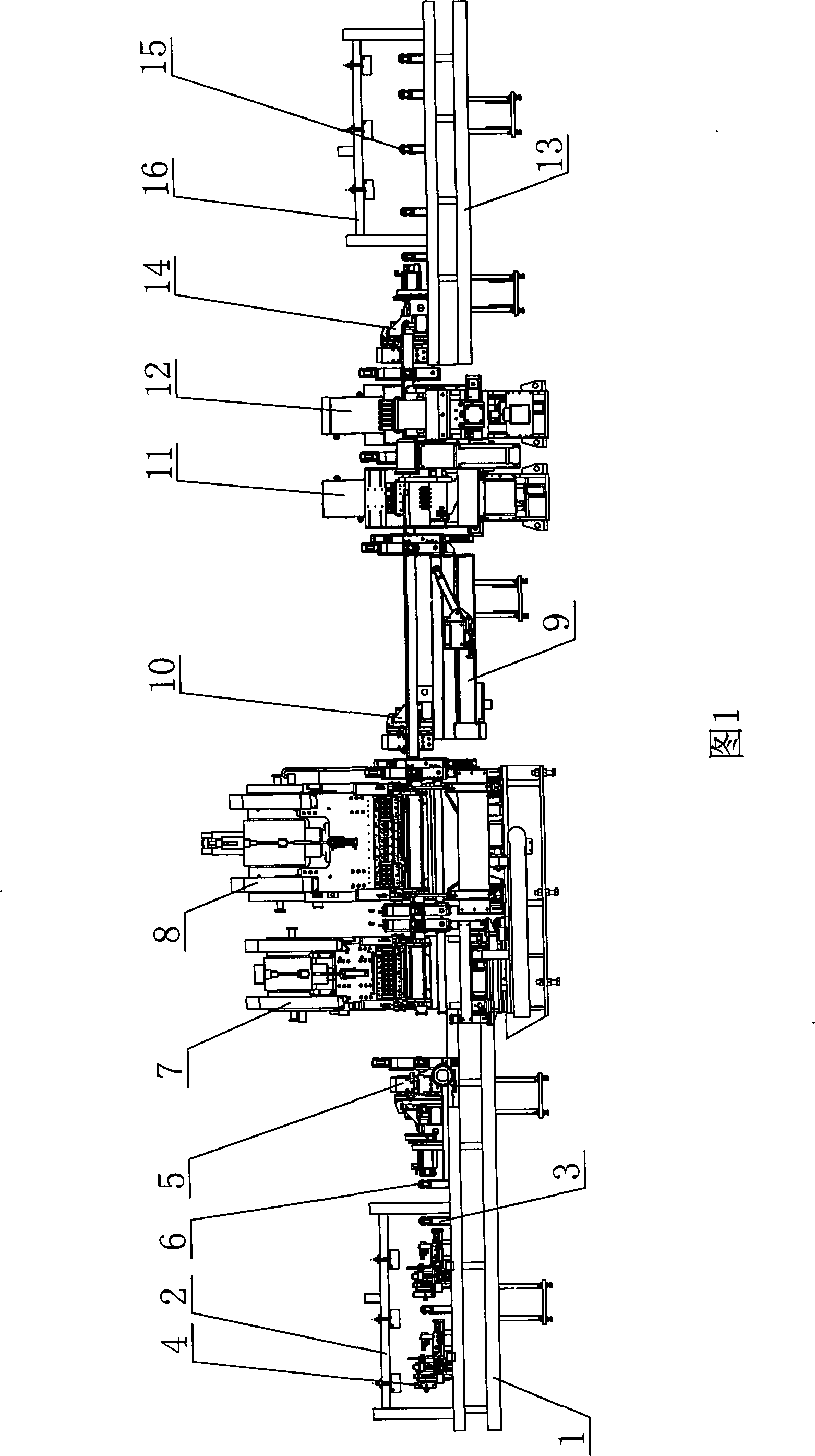

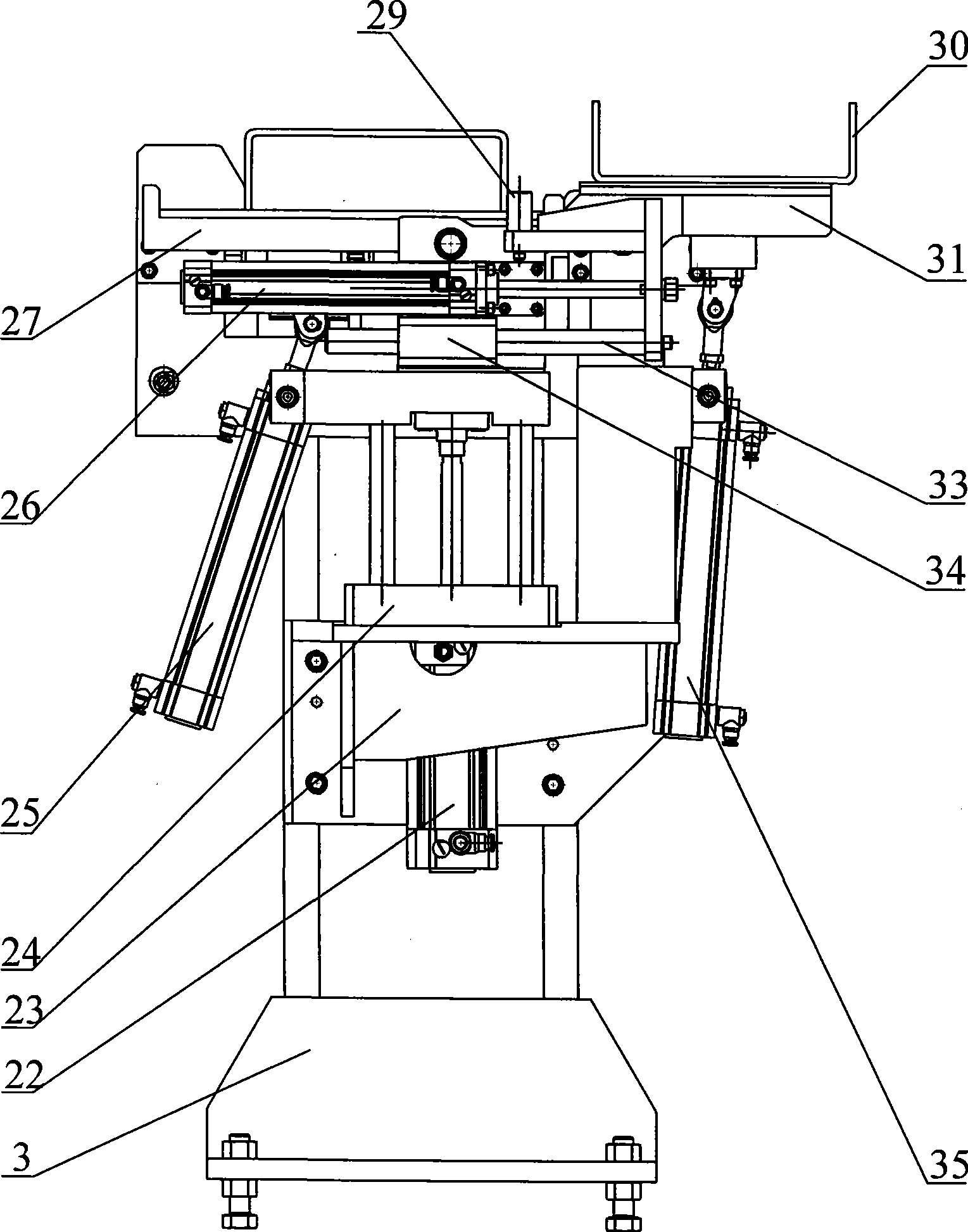

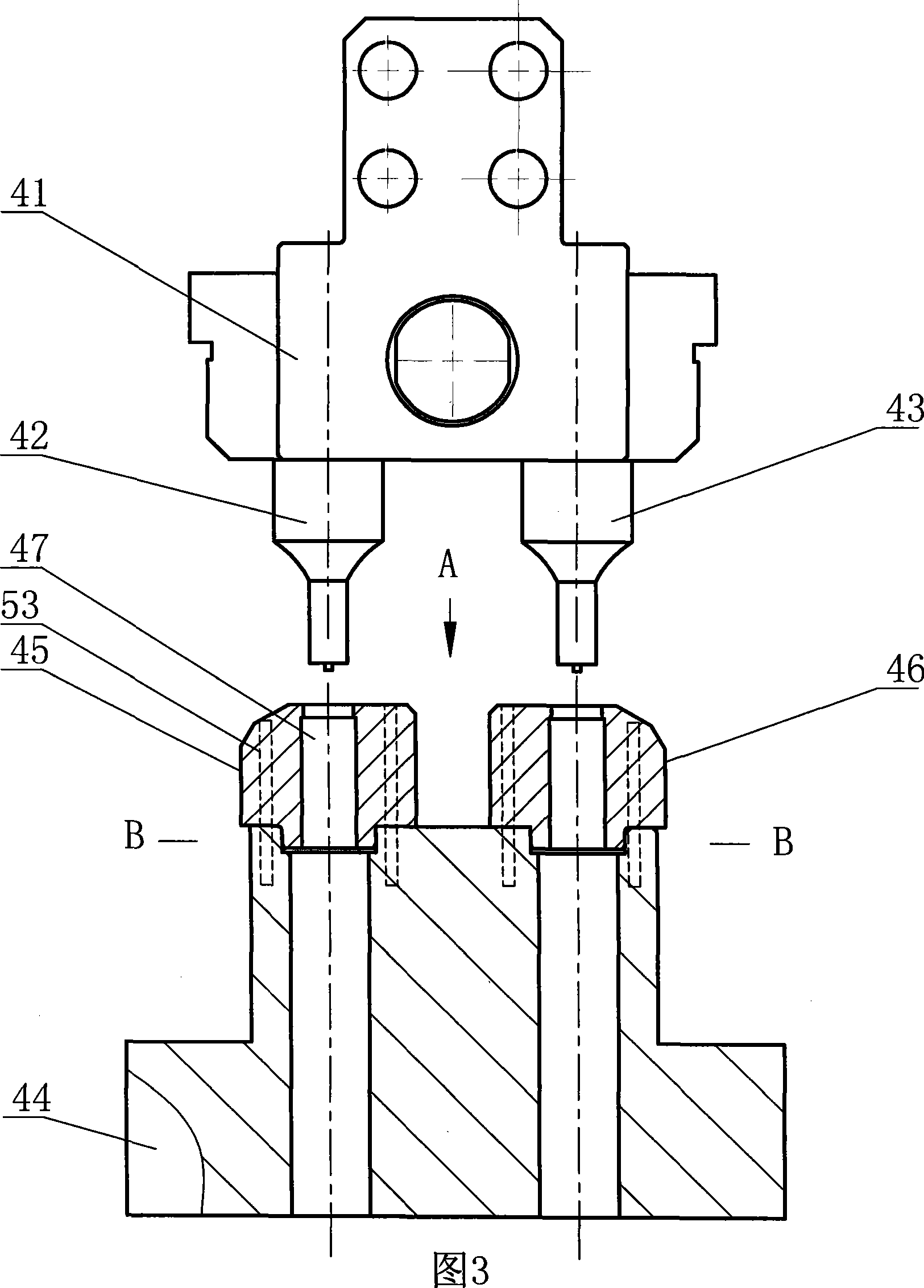

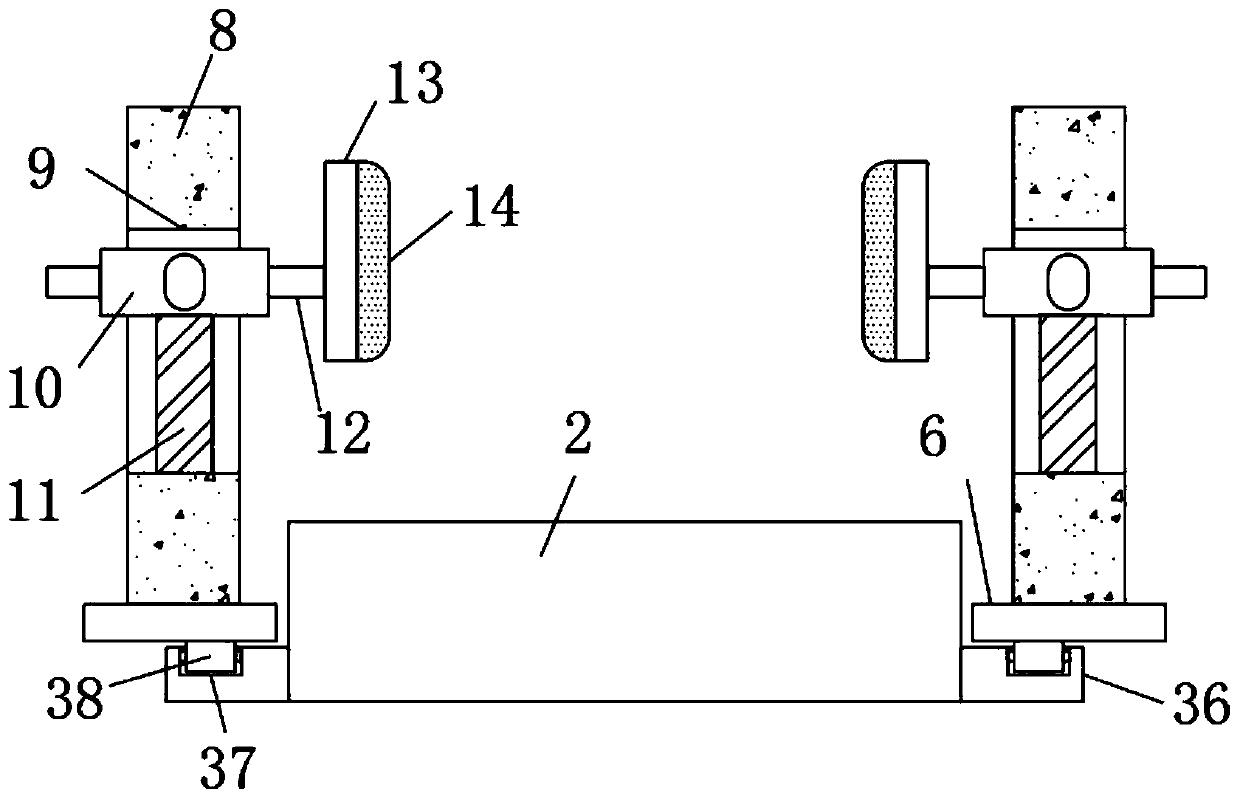

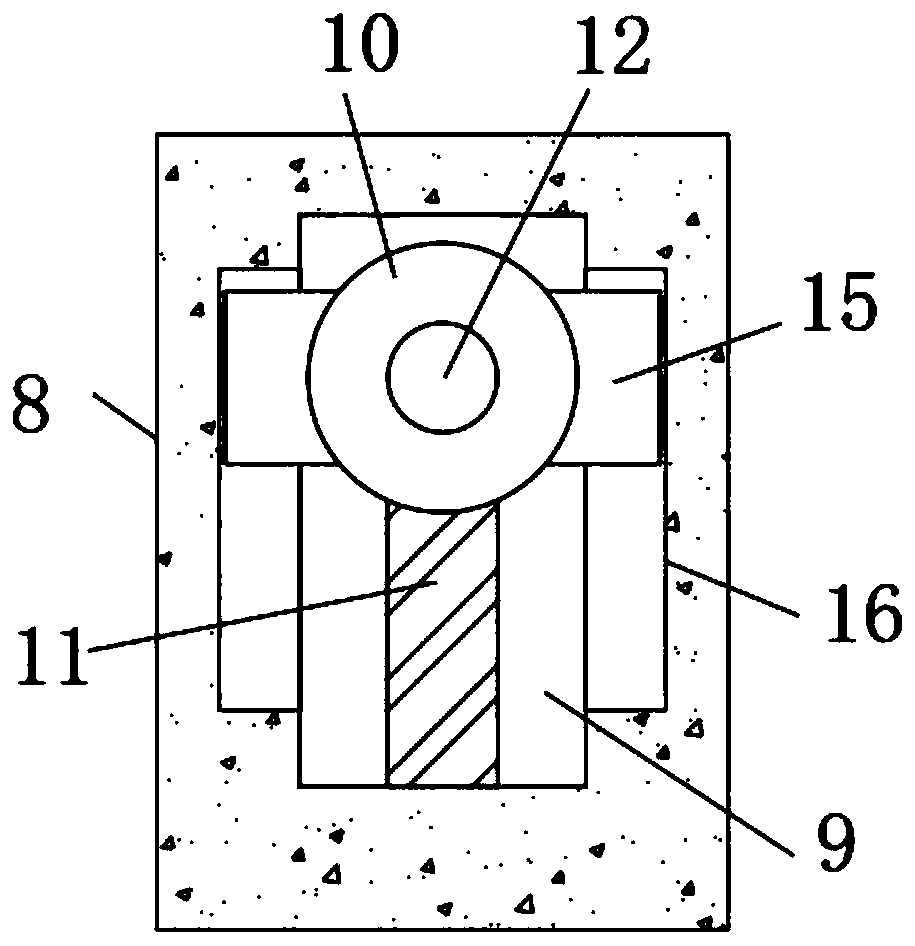

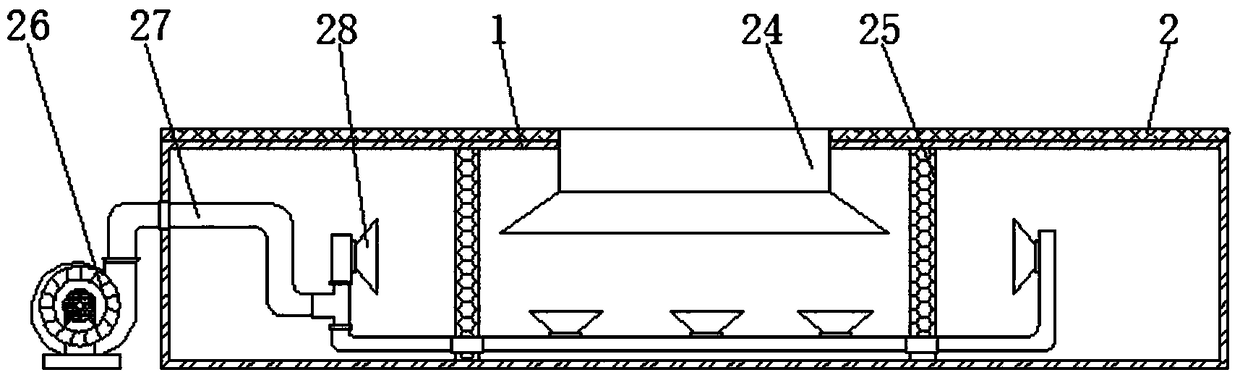

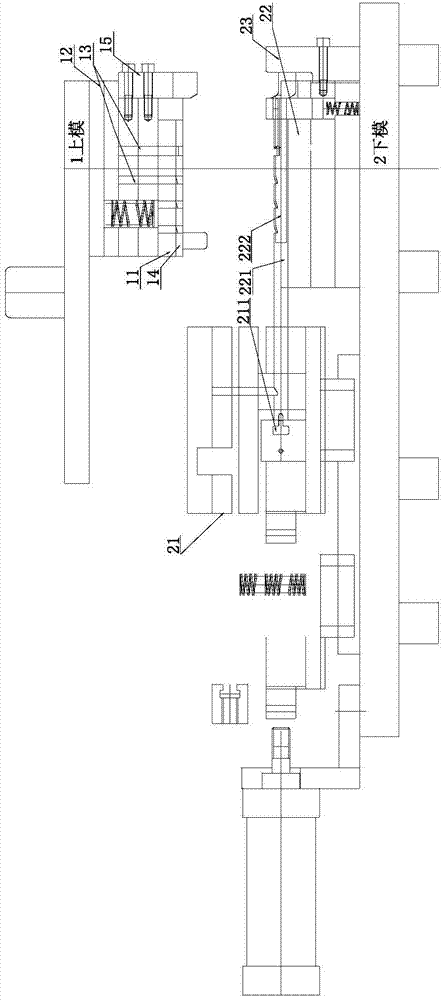

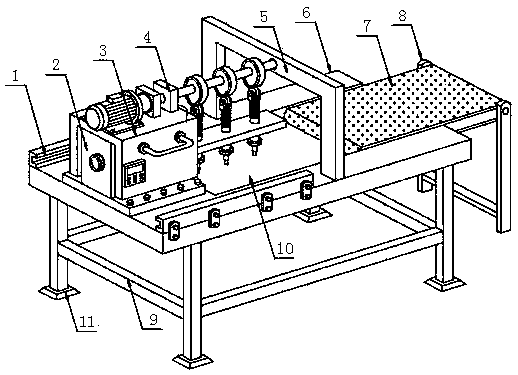

U shaped beam three-face punching technique and production device using the technique

InactiveCN101386046AThe punching position is accurateReduce manufacturing costShaping toolsPerforating toolsShaped beamPunching

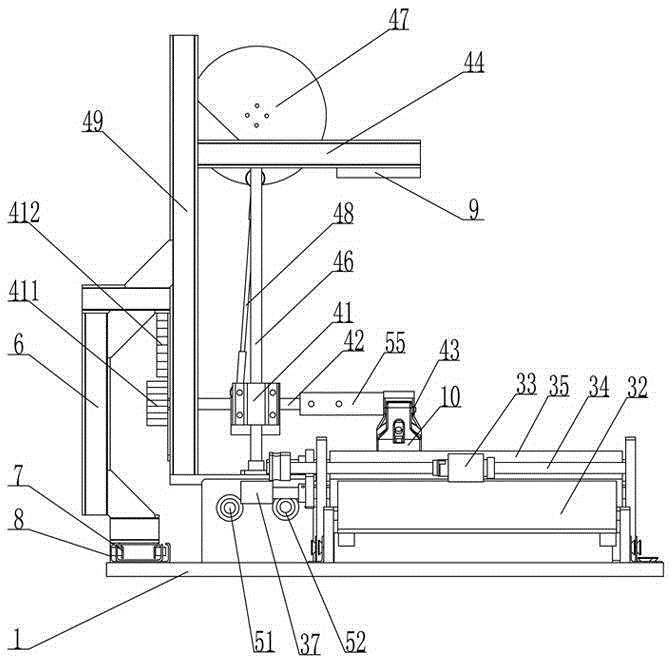

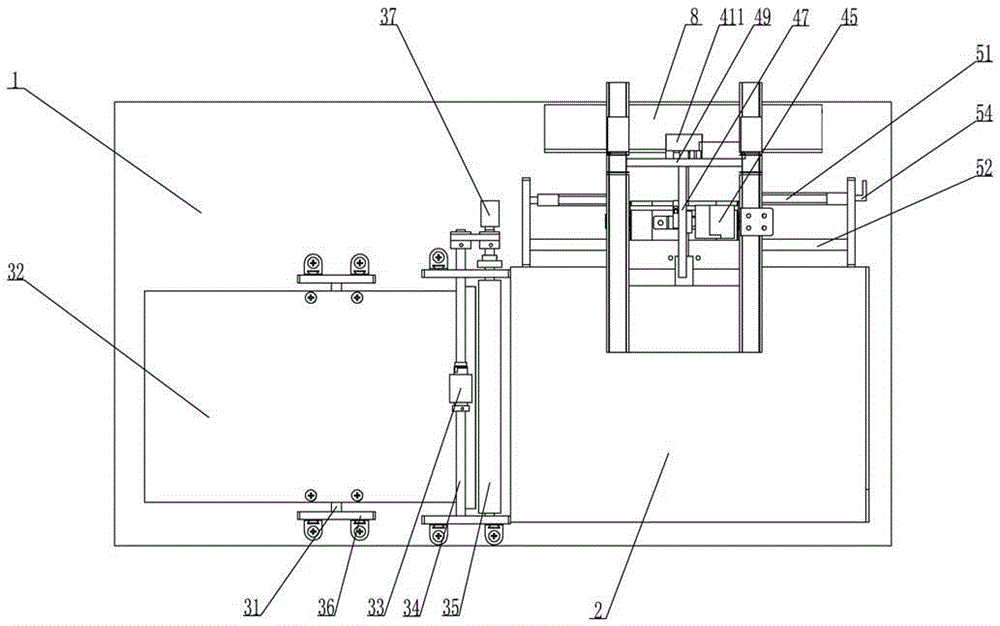

The invention discloses a three-side-punch process of a U-shaped beam and a production device used in the process. The process comprises the following steps: the U-shaped beams are placed on a feeding platform, a feed picking device is adopted to successively pick up the spare U-shaped beams and hoist the beams to a support roller of the feeding end; a first feeding clamping device is adopted to clamp the U-shaped webs and feed the webs to working platforms of a ventral small punching machine which can move along the X / Y axis and a ventral large punching machine which can move along the Y axis; the ventral small punching machine which can move along the X / Y axis and the ventral large punching machine which can move along the Y axis punch the beams; a second feeding clamping device clamps the U-shaped beams and continuously feed the beams to the working platform of a left wing punching machine and a right wing punching machine; the left wing punching machine and the right wing punching machine punch the beams; the U-shaped beams are hoisted to a discharging platform after being fully punched. The invention has the advantages of simple process, high production efficiency, low cost and reasonable process arrangement; and the produced U-shaped beams have precise punching location.

Owner:JINAN CASTING FORGING MACHINERY INST

Adjustable automatic stamping machine

InactiveCN105252920AImprove stamping efficiencyImprove stamping qualityStampingEngineeringMechanical engineering

The invention relates to an adjustable automatic stamping machine. The adjustable automatic stamping machine comprises a stamping machine base. A stamping platform is arranged on the stamping machine base. A paper conveying mechanism is arranged on one side of the stamping platform. The paper outlet of the paper conveying mechanism is right opposite to the stamping platform. An automatic stamping mechanism is arranged on the rear side of the stamping platform. The automatic stamping mechanism comprises a movable block. A rotating shaft is transversely arranged on the movable block. One end of the rotating shaft extends to the portion above the stamping platform and is provided with a gripper used for clamping a stamp. An inkpad box fixing plate is arranged above the gripper. The automatic stamping mechanism further comprises a lifting mechanism used for driving the movable bock to vertically rise and fall, and a stamp turning mechanism which can drive the stamp to be turned upwards to be dipped with inkpad when the movable block rises, and can drive the stamp to be turned downwards to conduct stamping when the movable block falls. The adjustable automatic stamping machine has the beneficial effects of being high in stamping efficiency, high in universality, and the like, and therefore the labor intensity of office staff can be effectively lowered, and the work efficiency can be effectively improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

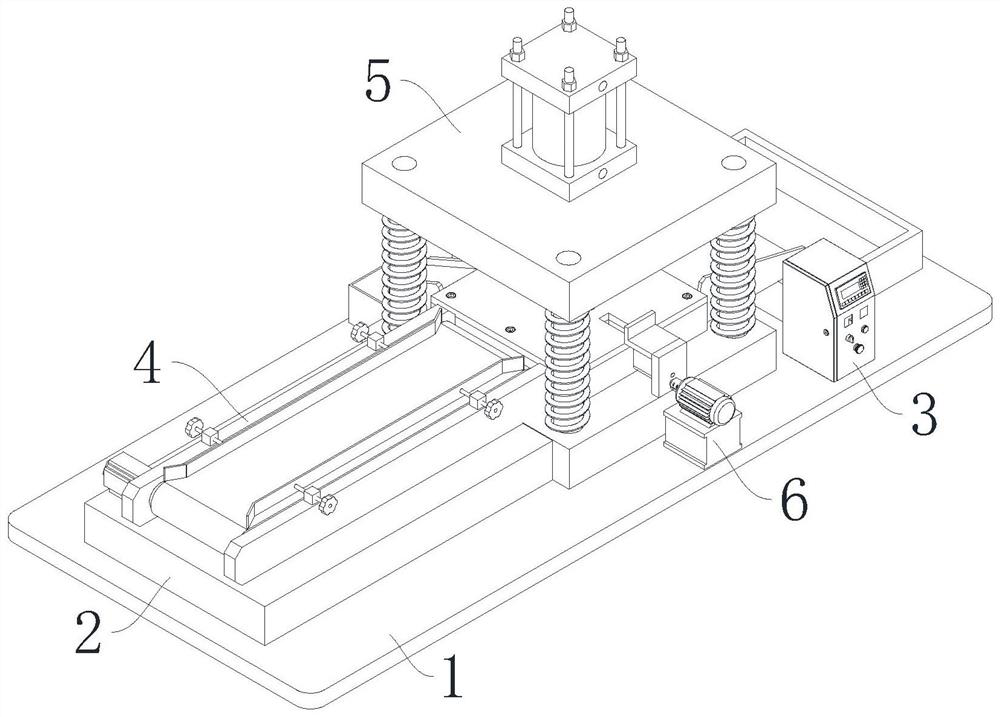

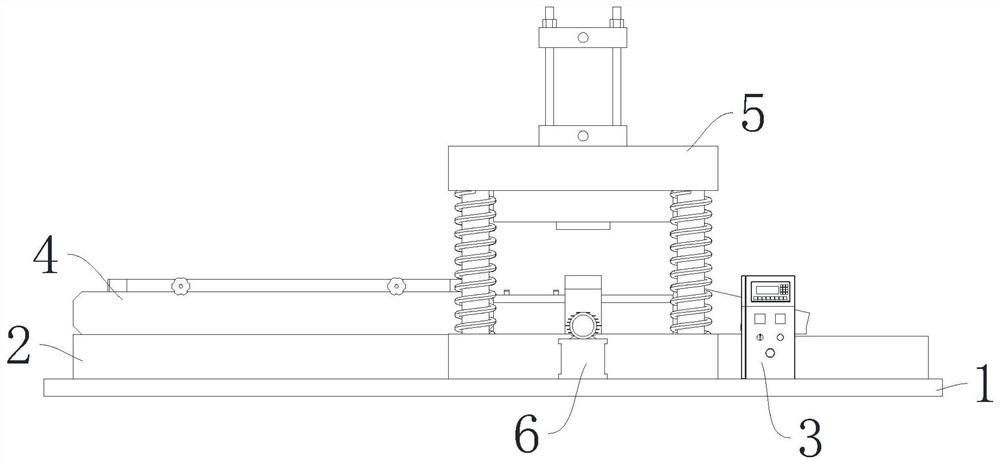

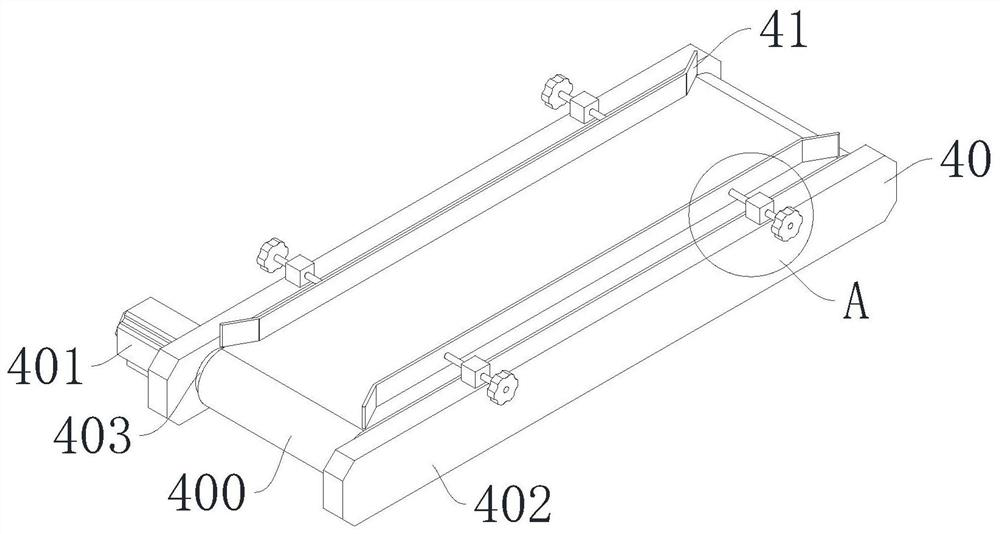

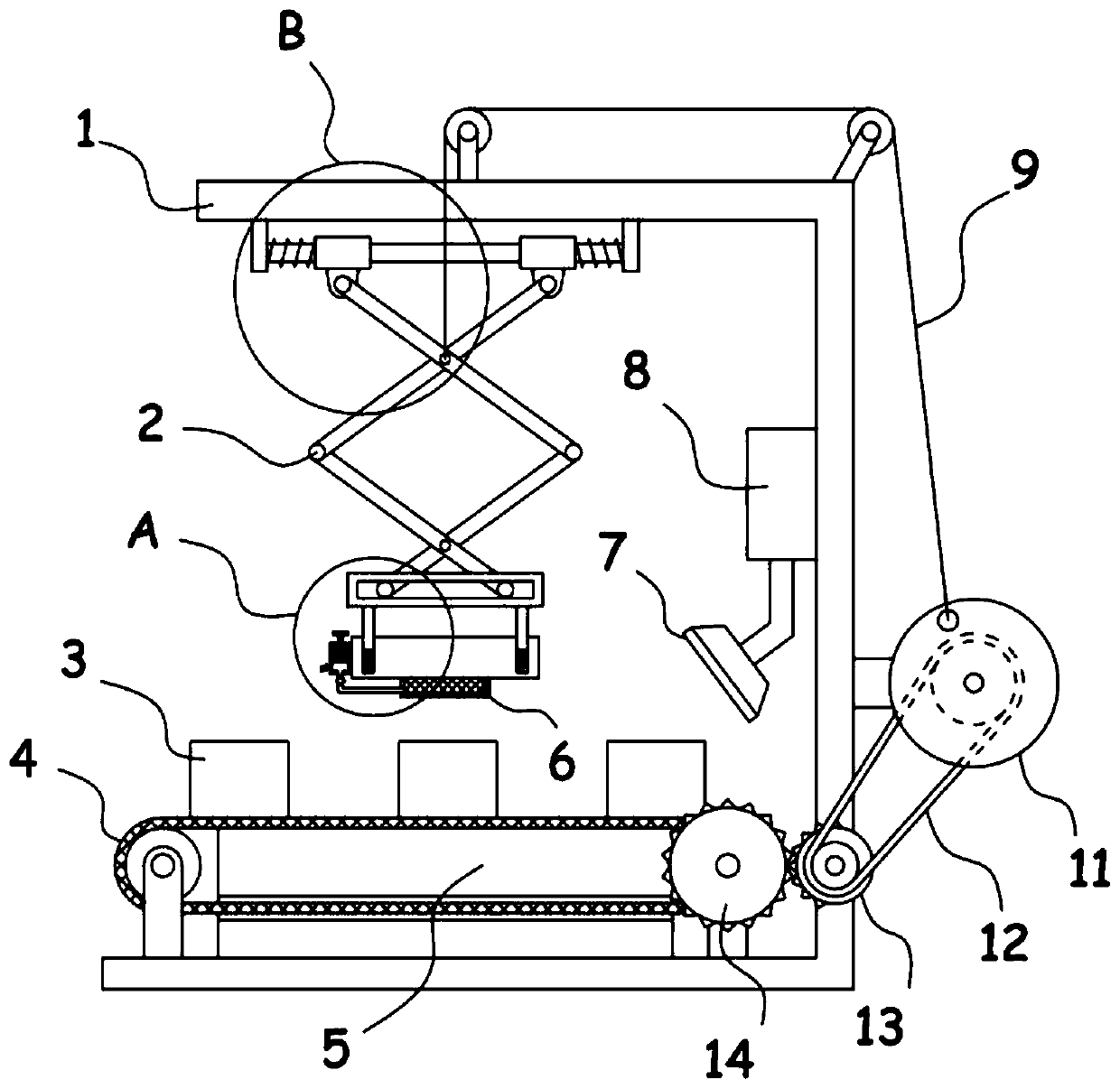

Punching device for automatic loading and unloading

The invention discloses a punching device for automatic loading and unloading. The punching device comprises an automatic loading mechanism and an automatic unloading and punching mechanism; the automatic loading mechanism is used for conveying metal sheets to the automatic unloading and punching mechanism, and comprises a mounting base, a pushing structure and a feeding structure; the pushing structure is mounted at the front end of the top surface of a mounting plate, and comprises a pushing cylinder, a push plate, a storage box and a pushing guide rail; the pushing cylinder, the push plate,the storage box and the pushing guide rail are arranged on the same straight line; the pushing cylinder and the push plate push the metal sheets, positioned at the bottommost part in the storage box,into the pushing guide rail to convey from the end near the pushing cylinder to the other end; the feeding structure is arranged at the back end of the top surface of the mounting plate, and is usedfor conveying the metal sheets, conveyed to the end far from the pushing cylinder of the pushing guide rail, from the pushing structure to the automatic unloading and punching mechanism; and the automatic unloading and punching mechanism is used for punching and automatically unloading the metal sheets. The punching device realizes automatic loading and unloading.

Owner:HONORFAITH FURNITURE

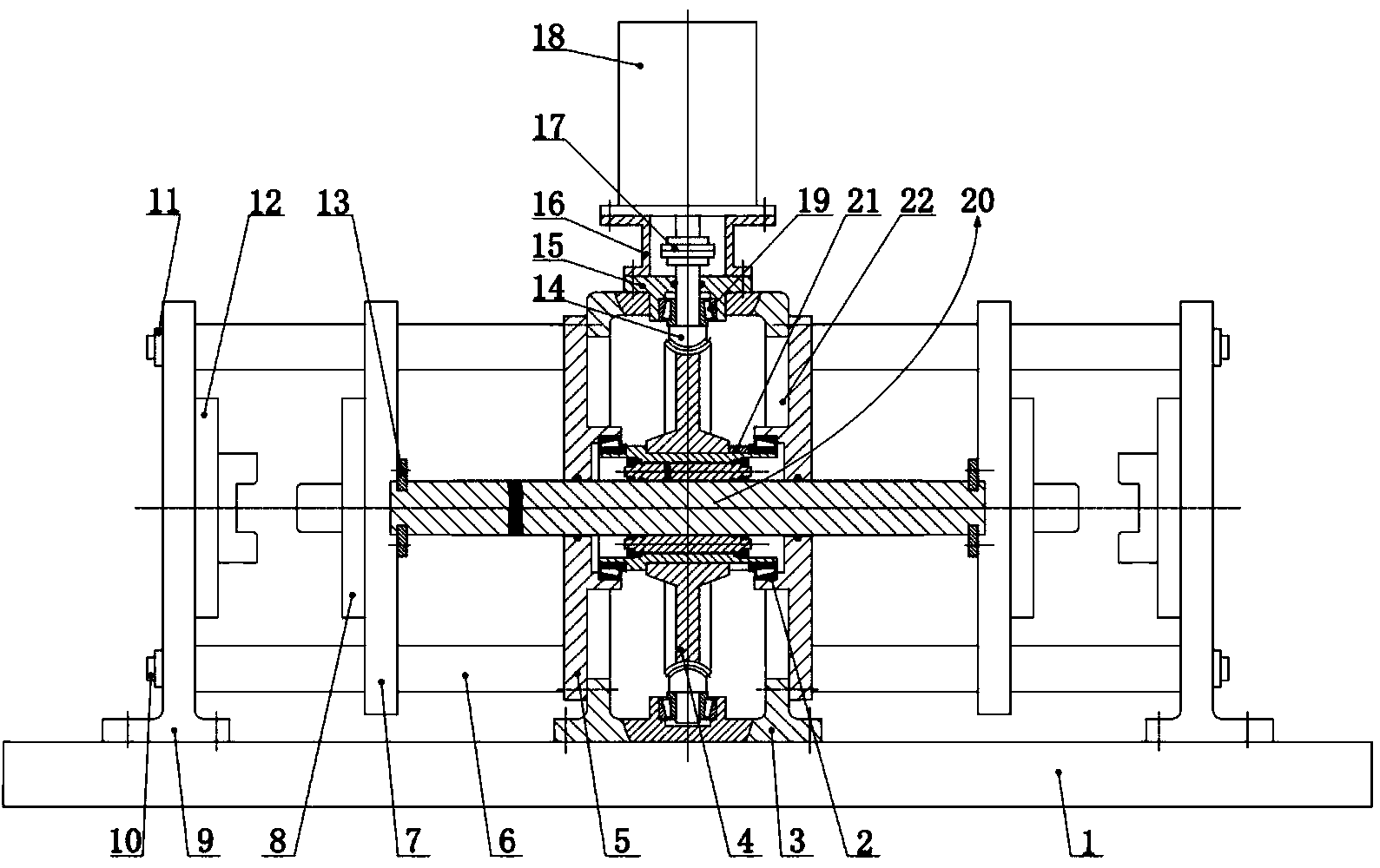

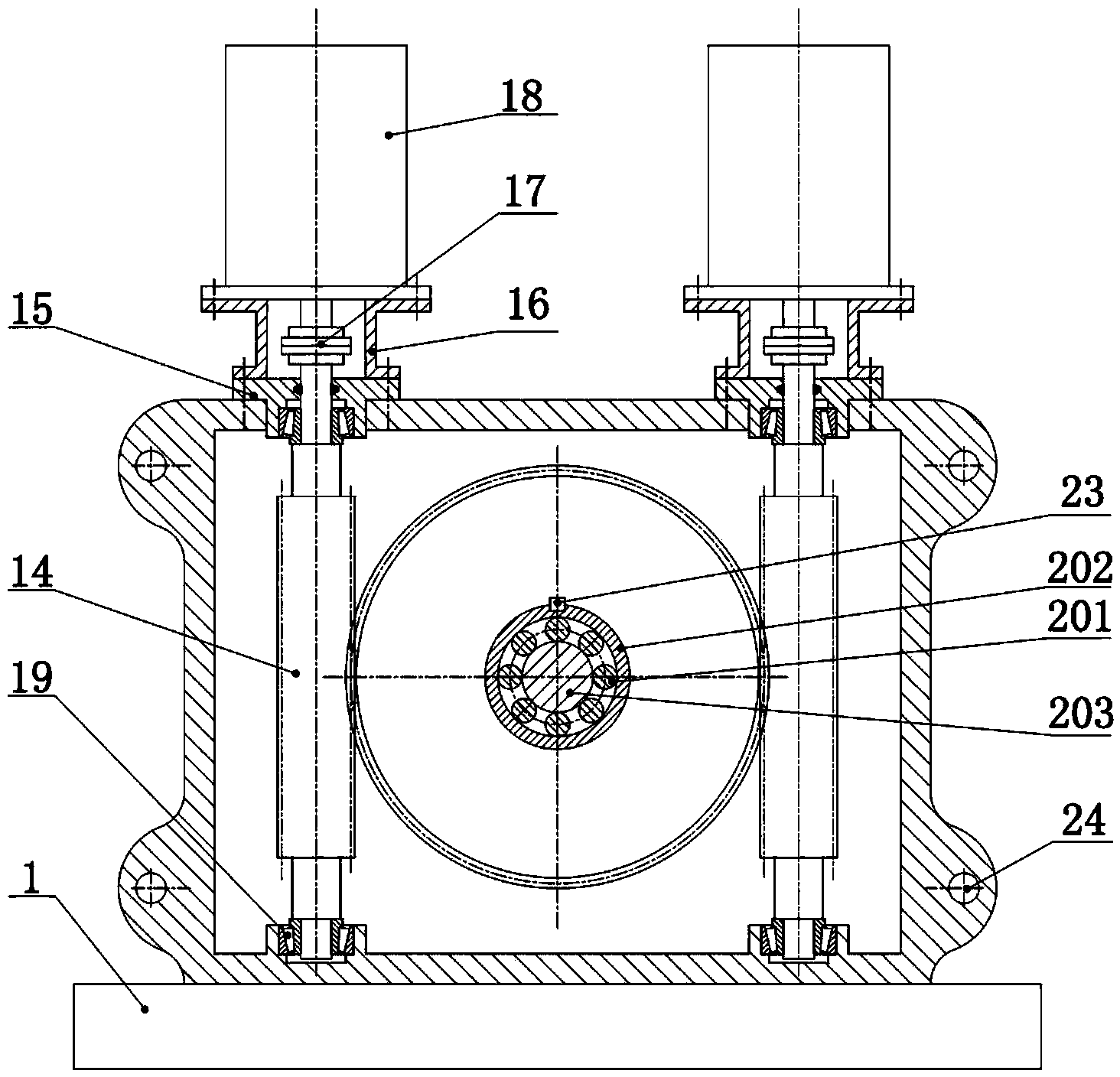

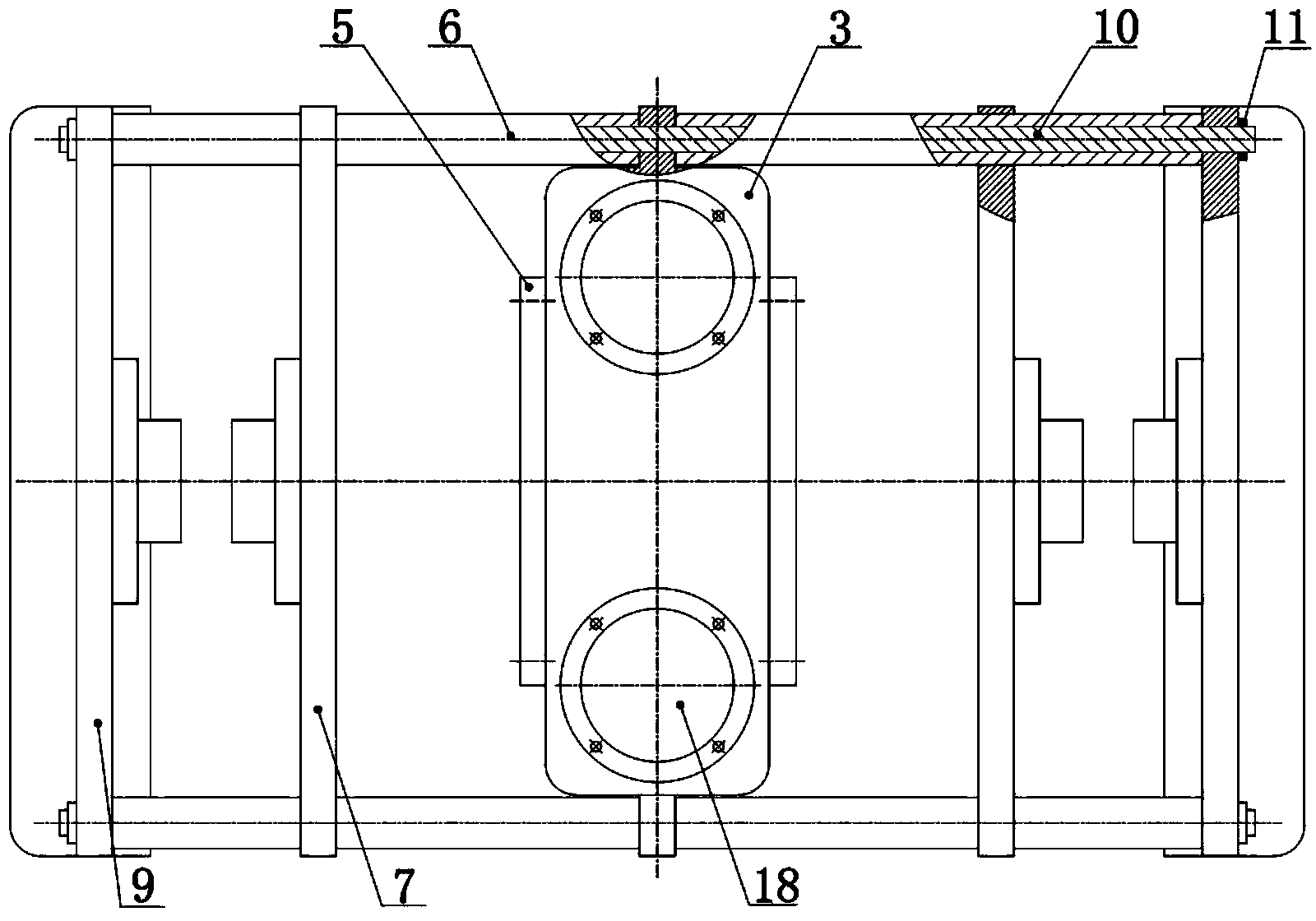

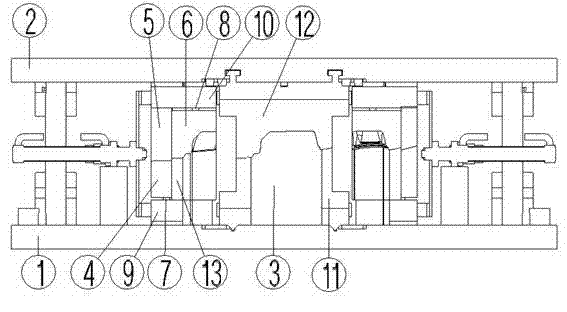

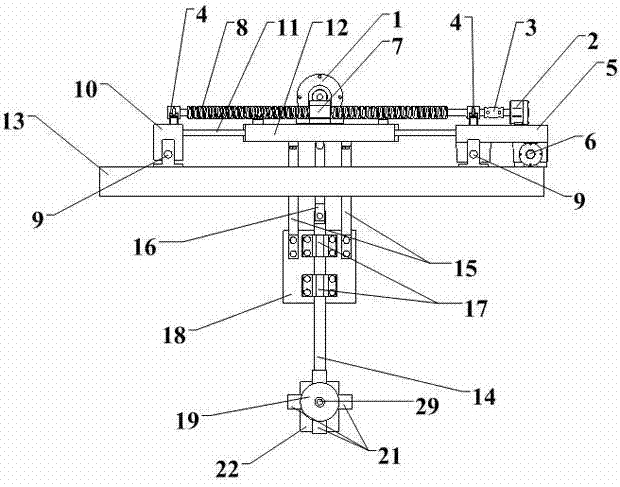

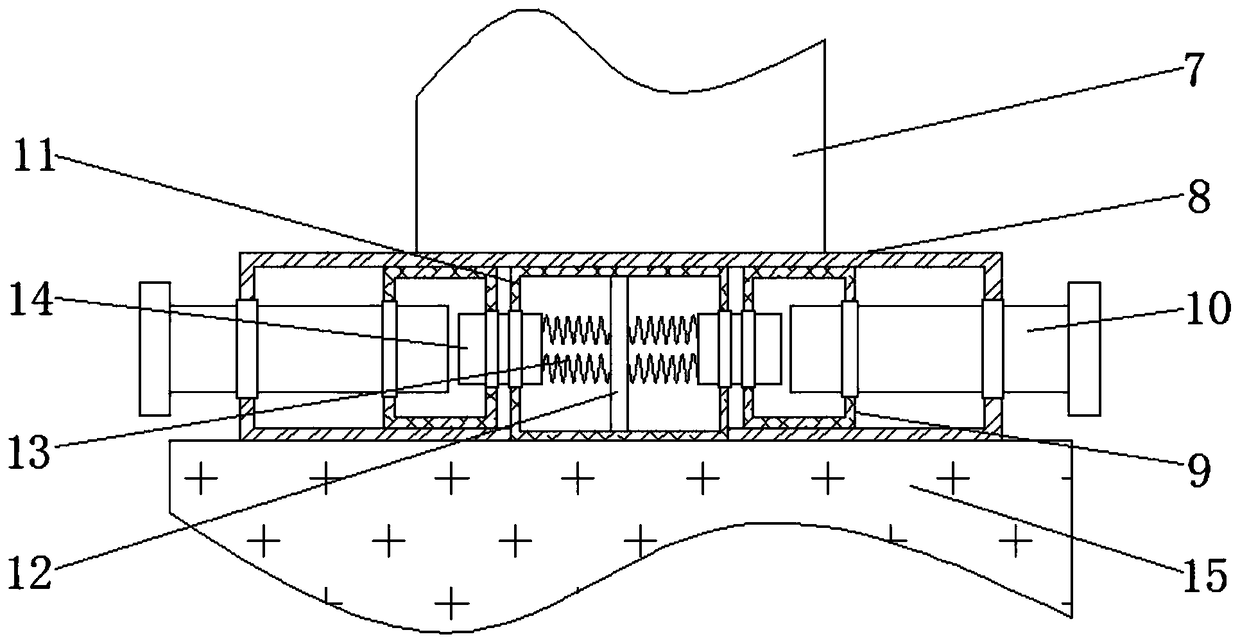

Two-way horizontal servo pressure machine for transmission of planet roller lead screw

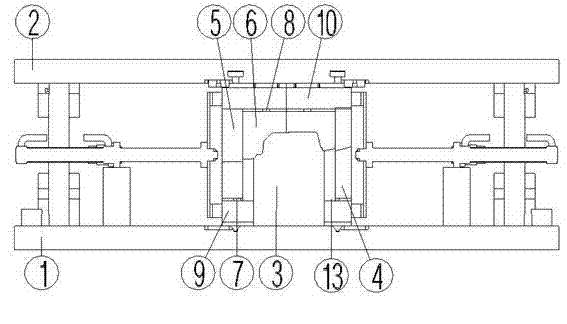

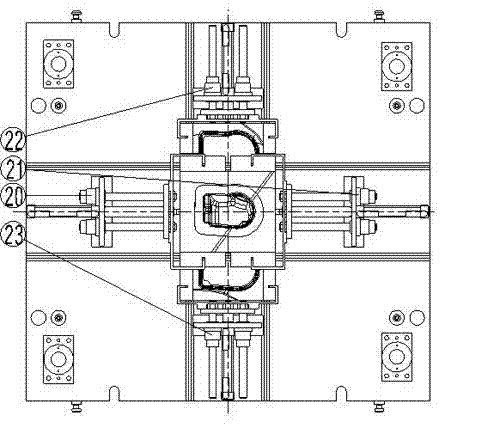

ActiveCN103802343AReduced commutation frequencyExtend your lifeGearingPortable liftingLinear motionGear drive

The invention discloses a two-way horizontal servo pressure machine for transmission of a planet roller lead screw. Two servo motors simultaneously drive one worm gear through two worms, a planet roller lead screw device is embedded into the worm gear, the worm gear drives a planet roller lead screw nut to rotate, the nut converts rotation into linear motion of the lead screw through a roller, dies at the two ends are driven to perform two-way stamping, the horizontal type arrangement form is adopted, a driving device is installed in a machine body, the machine body is installed in the middle of the pressure machine, the dies are symmetrically arranged on the two sides of the machine body, the structure is greatly simplified, and the structure of the whole machine is compact; the stamping efficiency is improved, energy consumption is reduced, and the service life of the motors is prolonged; loads of each worm are reduced, power of each motor is reduced, and cost is reduced.

Owner:XI AN JIAOTONG UNIV

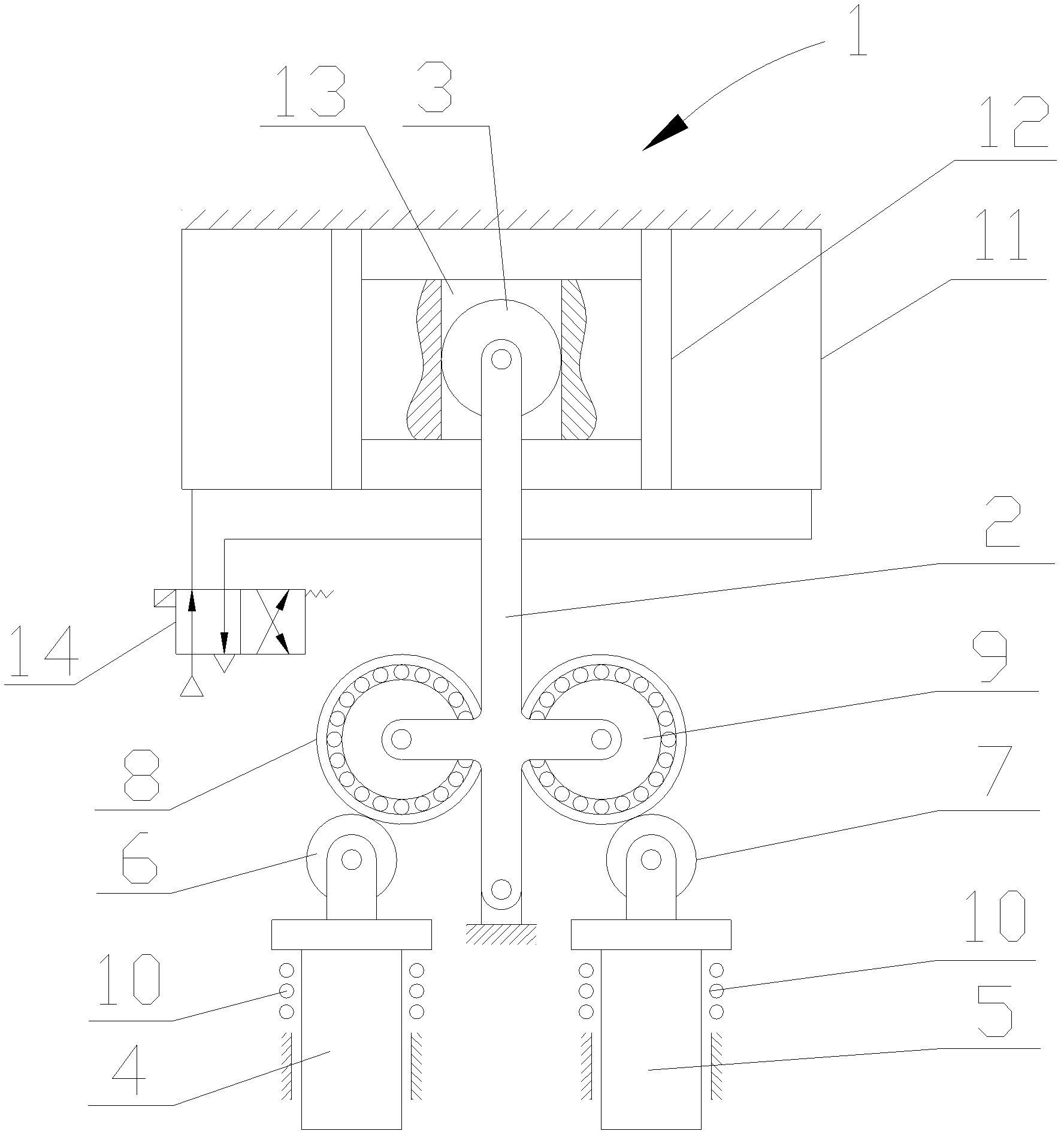

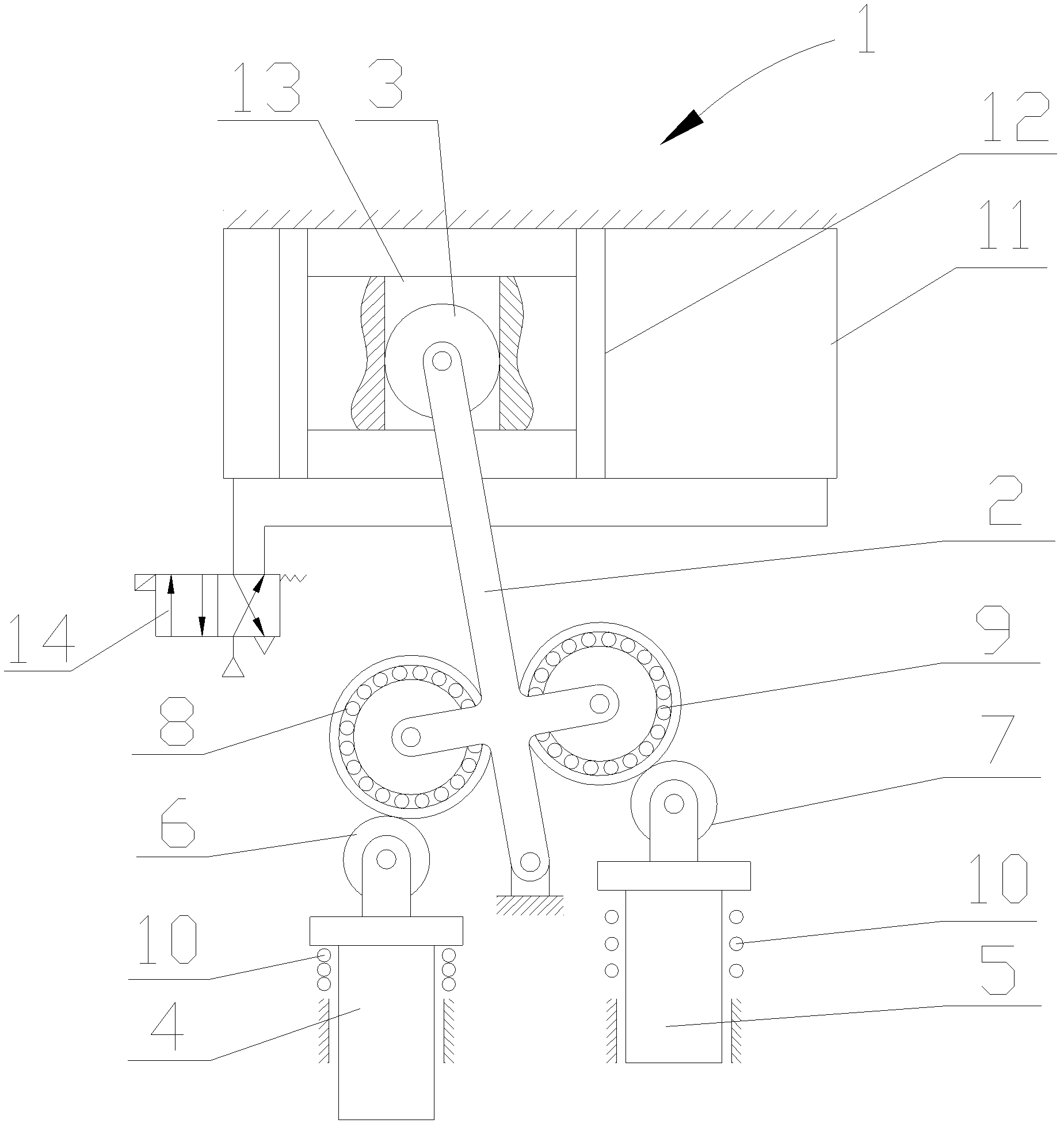

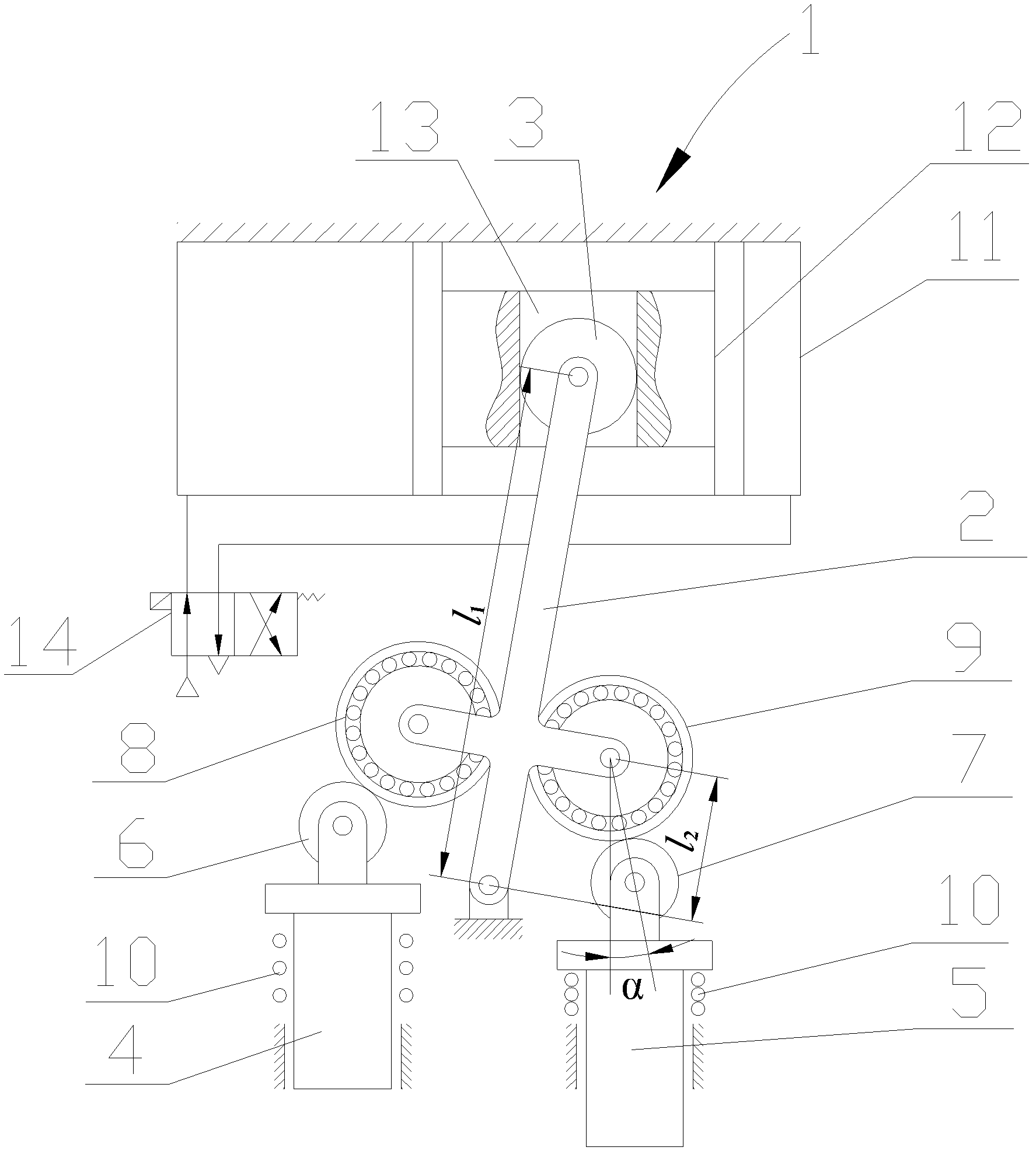

Dual-station pneumatic stamping machine

The invention discloses a dual-station pneumatic stamping machine, which is provided with a double-acting cylinder serving as a power source. A lever capable of swinging along with movement of a piston of the double-acting cylinder is disposed on a frame, and a roller which is capable of matching with upper rollers on stamping heads in transmission is disposed on the lever. When the double-acting cylinder is in operation, the piston continuously moves side by side inside a cylinder barrel, so that the first stamping head on the left of the lever and the second stamping head on the right of the lever are alternately operated in stamping. Idle stroke is absent in operation of the dual-station pneumatic stamping machine, stamping output force is approximately as large as acting force outputted by a piston rod of a medium-pressure hydraulic transmission system, the stamping efficiency is high, and the energy utilization rate is high. In addition, the dual-station pneumatic stamping machine is simple and compact in structure, convenient in operation and highly economical. Pneumatic transmission is used as the power source, so that operation of the machine is pollution-free, and the dual-station pneumatic stamping machine is widely applicable to stamping.

Owner:SUZHOU UNIV

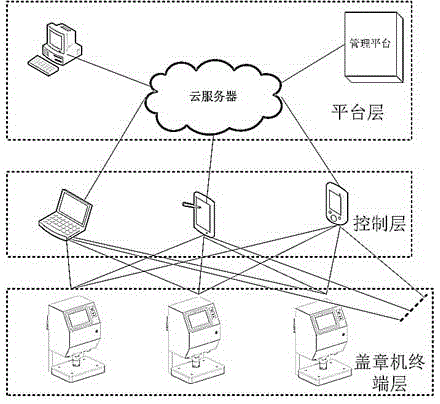

Stamping management system based on cloud platform

InactiveCN106626834AImprove stabilityImprove standardizationResourcesStampingControl layerComputer module

The invention provides a stamping management system based on a cloud platform. The stamping management system comprises a platform layer, a control layer and a stamping machine terminal layer. Connection between the platform layer and the control layer as well as between the control layer and the stamping machine terminal layer is built through a communication module. The platform layer comprises a cloud server and is provided with a management platform used for applying for approval before stamping, storing information of stamping machines, stamp using places, personnel and supervision departments and the like, storing an illegal stamping information record, intelligently unlocking / locking the stamping machines backstage, and generating a stamping record and an event statistics report. The control layer is provided with control modules and the communication module and connected with the platform layer and the stamping machine terminal layer through the communication module. The control modules are arranged in intelligent terminals and used for approving stamping and checking the stamping information, and the intelligent terminals are one or more of a mobile phone, a pad and a computer. The stamping machine terminal layer comprises the multiple rotary multi-head stamping machines used for stamping and transmitting the stamping information to the cloud server. By adoption of the stamping management system, switching stamping can be achieved through a plurality of stamps, and the stamping efficiency is greatly improved; and the normalization and intelligentization level of stamping management is greatly raised through the management system.

Owner:周相山

Automatic trimming and reshaping integrated automobile stamping die and stamping process thereof

The invention relates to an automatic trimming and reshaping integrated automobile stamping die and a stamping process thereof. The die comprises a lower die seat and an upper die seat, wherein a trimming male die is fixed on the lower die seat; a trimming work module consists of a second trimming male die, a trimming discharging plate, a trimming female die, a trimming pressing plate, a lower spring, an upper spring, a lower fixing plate and an upper fixing plate; a reshaping work module consists of a second reshaping male die and a reshaping female die; the first trimming male die is also used as a first reshaping male die; and left, right, front and rear driving devices are arranged at the front, rear, left and right positions of the lower die seat. A trimming die and a reshaping die are integrated, the functions of two sets of dies are realized on one set of die, the stroke frequency of a machine tool is reduced, time for assembling and replacing the die is shortened, and stampingcost is reduced.

Owner:FUZHEN TECH RES ANHUI

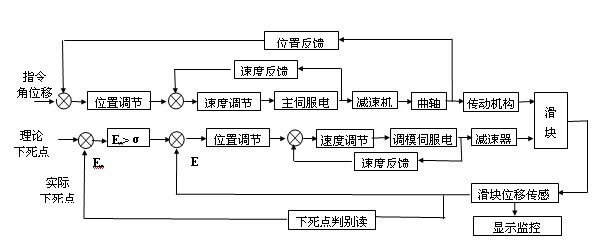

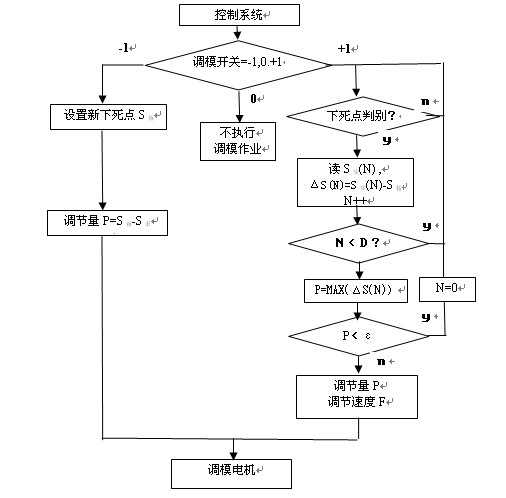

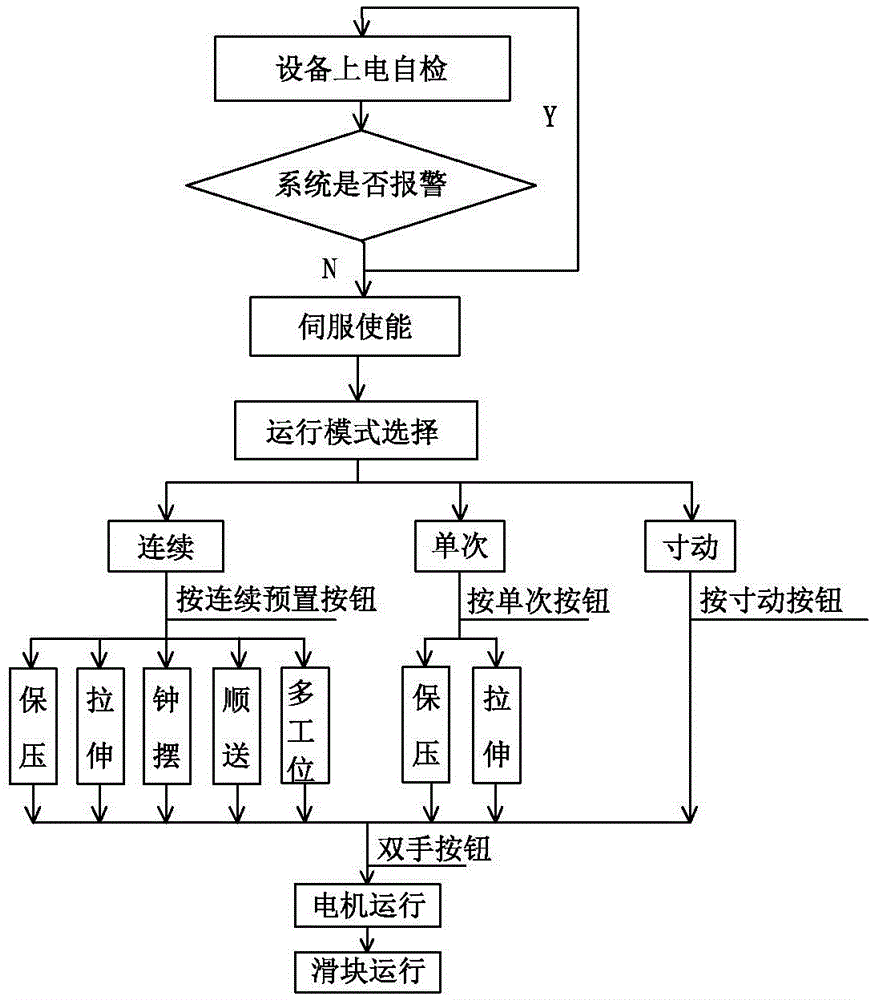

Control method of servo press

The invention relates to a control method of a servo press, and in particular to a bottom dead centre control method of the servo machine. The control method comprises a bottom dead centre reading and identification module, a comparison module and a threshold value module, wherein the bottom dead centre reading and identification module is used for identifying continuous signals in each work cycle period which are detected by a sliding block displacement sensor, and reading a bottom dead centre position value in the current cycle period; the comparison module is used for comparing a current bottom dead centre position value with a system setting value, and calculating an offset of the bottom dead centre; the threshold value module is used for comparing the current bottom dead centre offset of a sliding block with a given threshold value, if the bottom dead centre offset is greater than the given threshold value, the system starts a mould adjusting system to adjust the sliding block to a commanded bottom dead centre. The invention provides the control method of the servo press which can automatically adjust the bottom dead centre of the sliding block, and can satisfy work requirements for precision punching of the press.

Owner:扬州智科光机电技术开发中心有限公司

Stamping die capable of automatically correcting plate deviation

InactiveCN111687332APlay a limiting roleEasy to operateShaping toolsMetal-working feeding devicesControl engineeringStructural engineering

The invention relates to the technical field of stamping dies, in particular to a stamping die capable of automatically correcting plate deviation. The stamping die comprises a pedestal and a base, and further comprises a controller, a convey mechanism, a stamping mechanism and a pushing and closing mechanism. The base is fixedly arranged at one end of the top of the pedestal. The convey mechanismis fixedly arranged on the base. The convey mechanism comprises a transmission frame and two groups of limiting components, and the transmission frame is fixedly arranged on the top of the base. Thestamping mechanism is arranged on the pedestal and on a side of the convey mechanism. The stamping mechanism comprises an air cylinder, a supporting base, an upper die components and a lower die components. The pushing and closing mechanism is arranged on the top of the lower die component. The convey mechanism, the stamping mechanism and the pushing and closing mechanism are all electrically connected with the controller. By placing plates one by one on a conveyor belt, using a pair of limit components to limit the plates manually and manipulating the controller, the stamping die can automatically correct the deviation of plates before stamping, so that operation is convenient, safe and efficient, and stamping efficiency is improved.

Owner:WUHU XINLONG MACHINERY

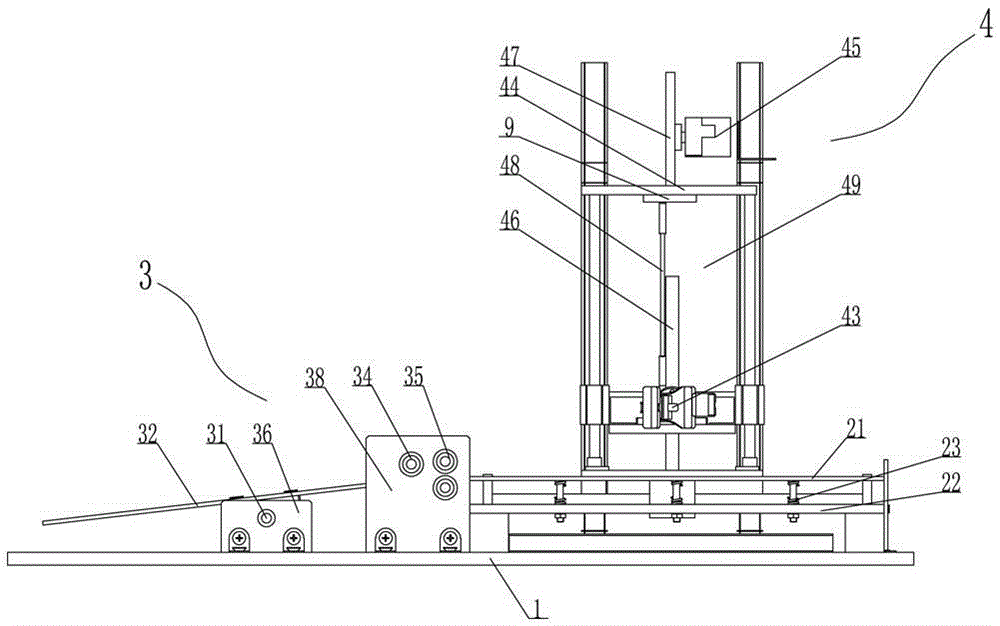

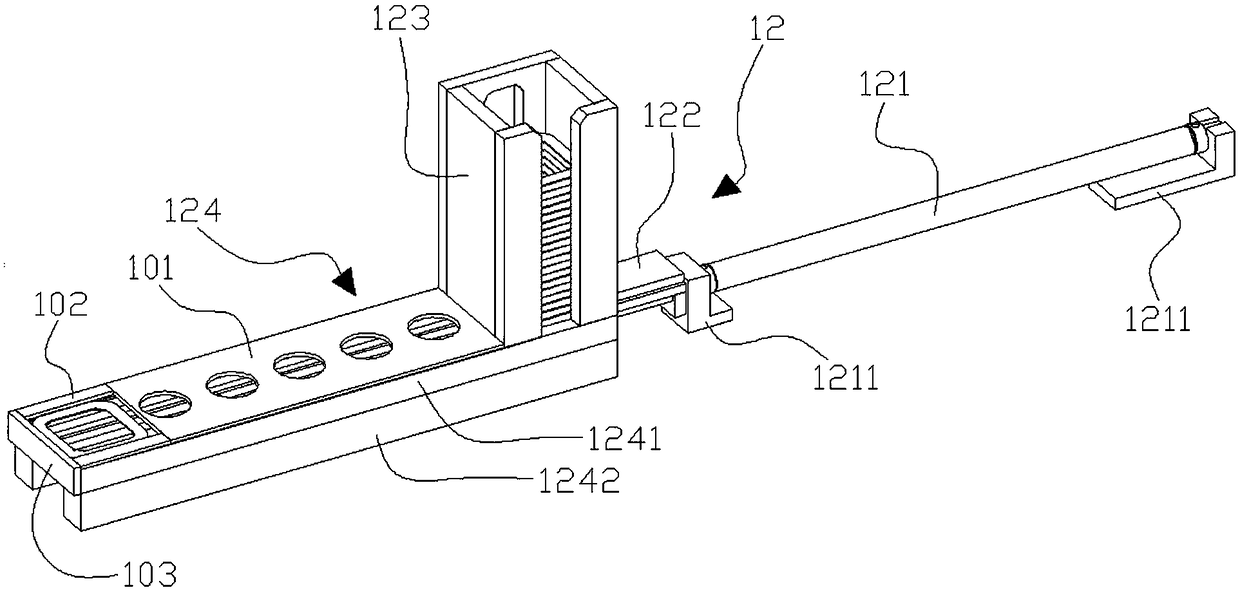

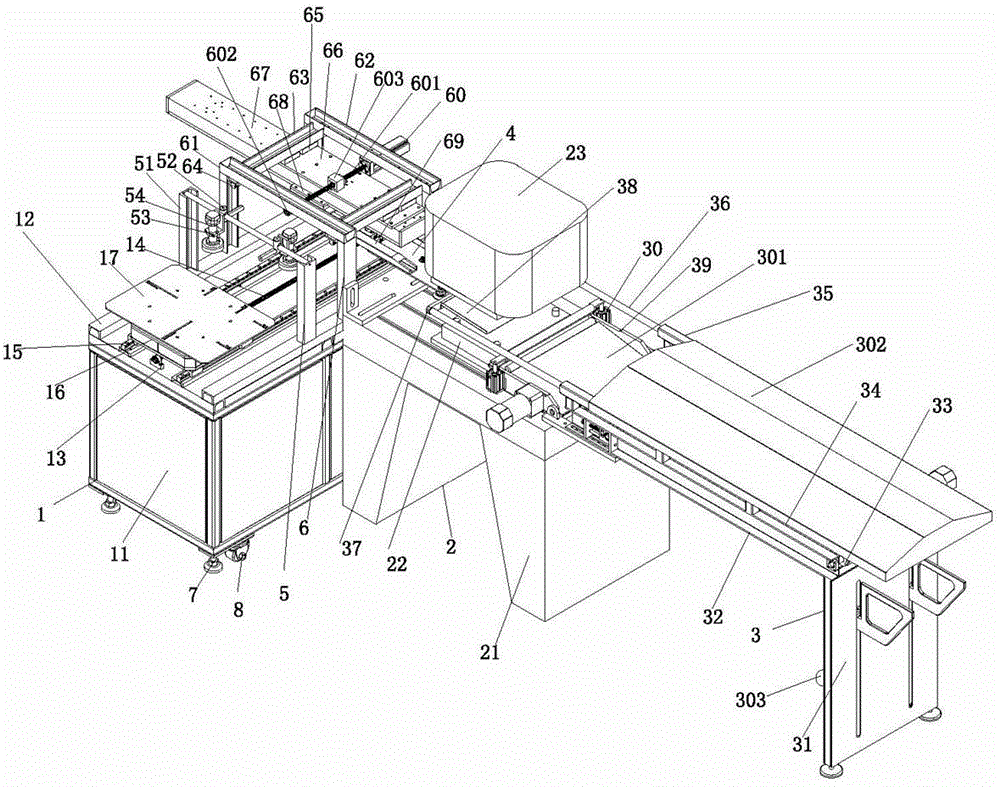

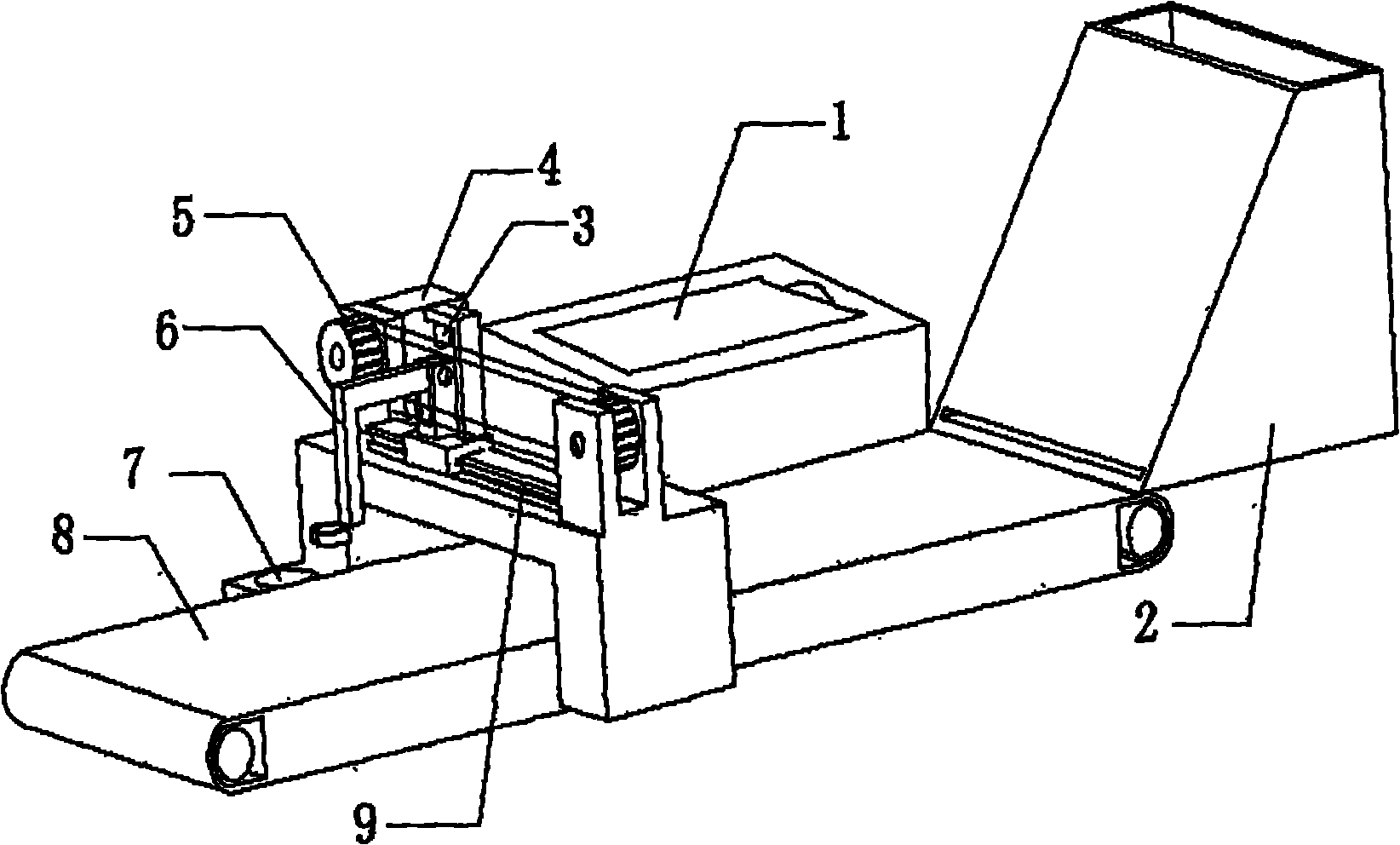

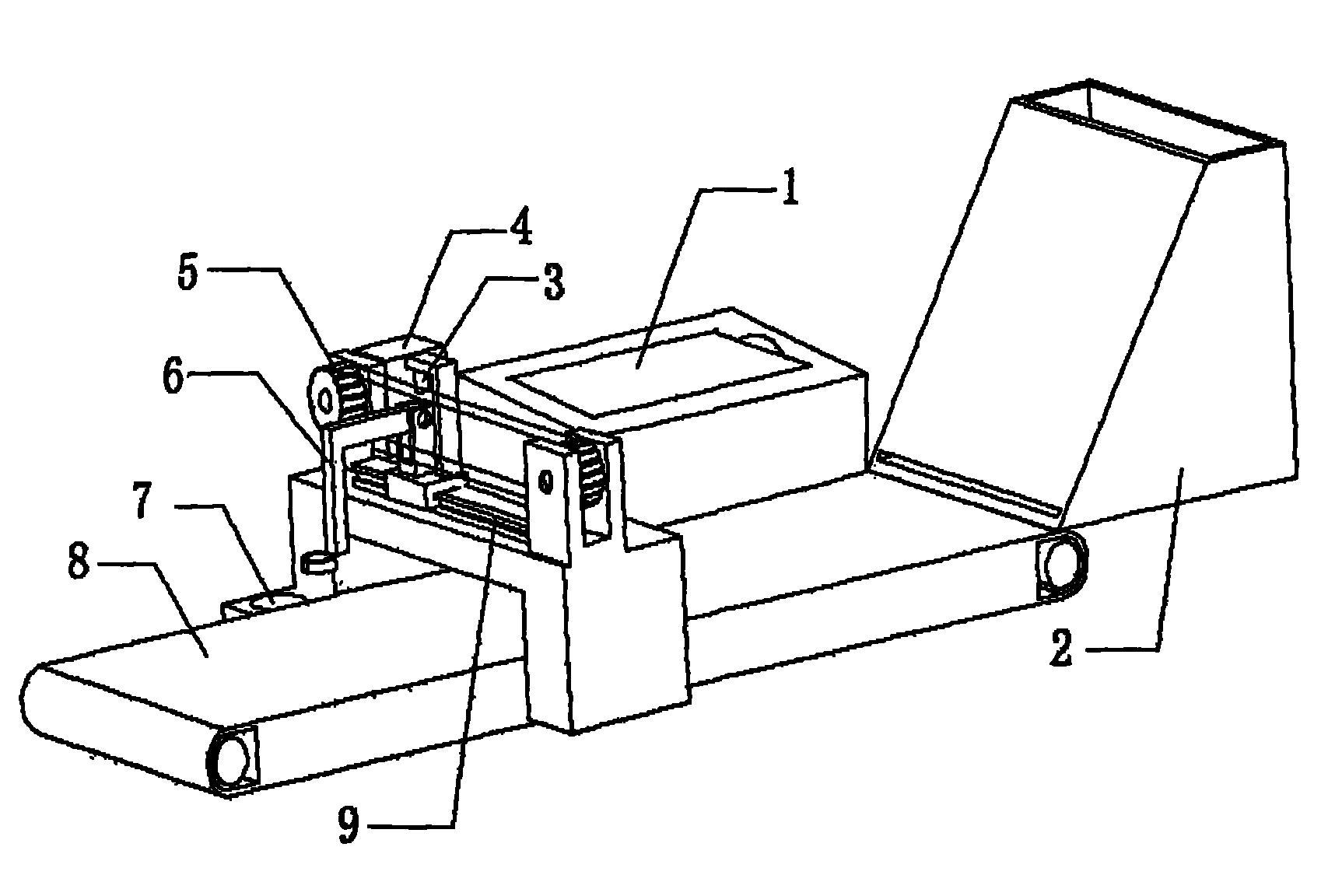

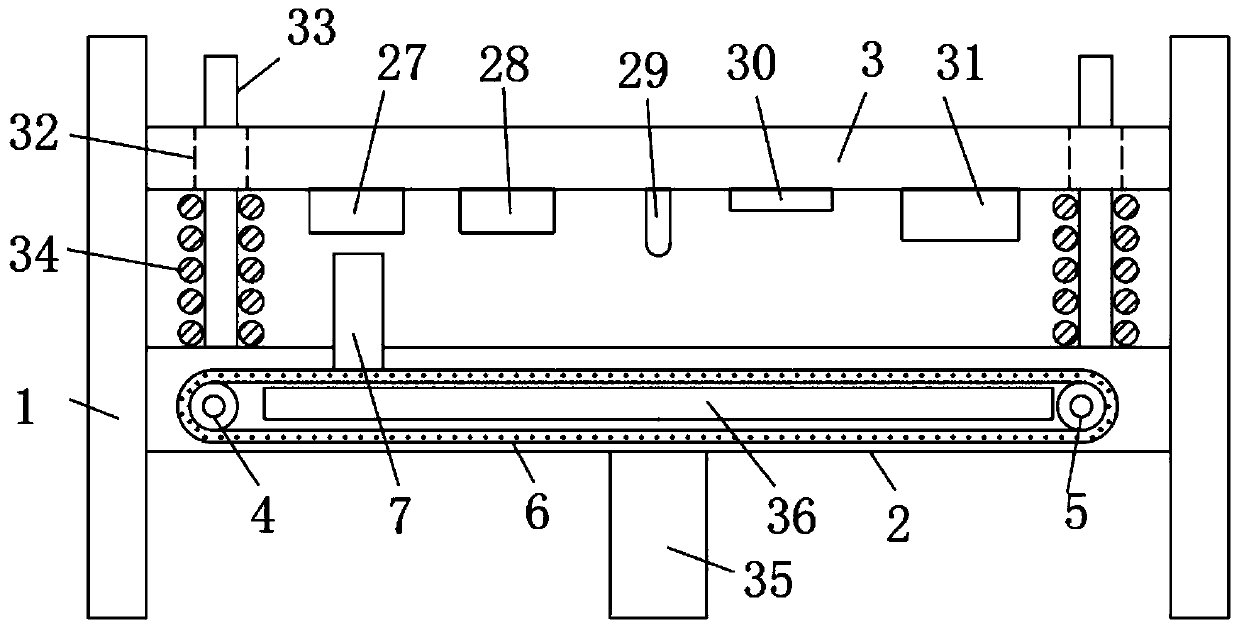

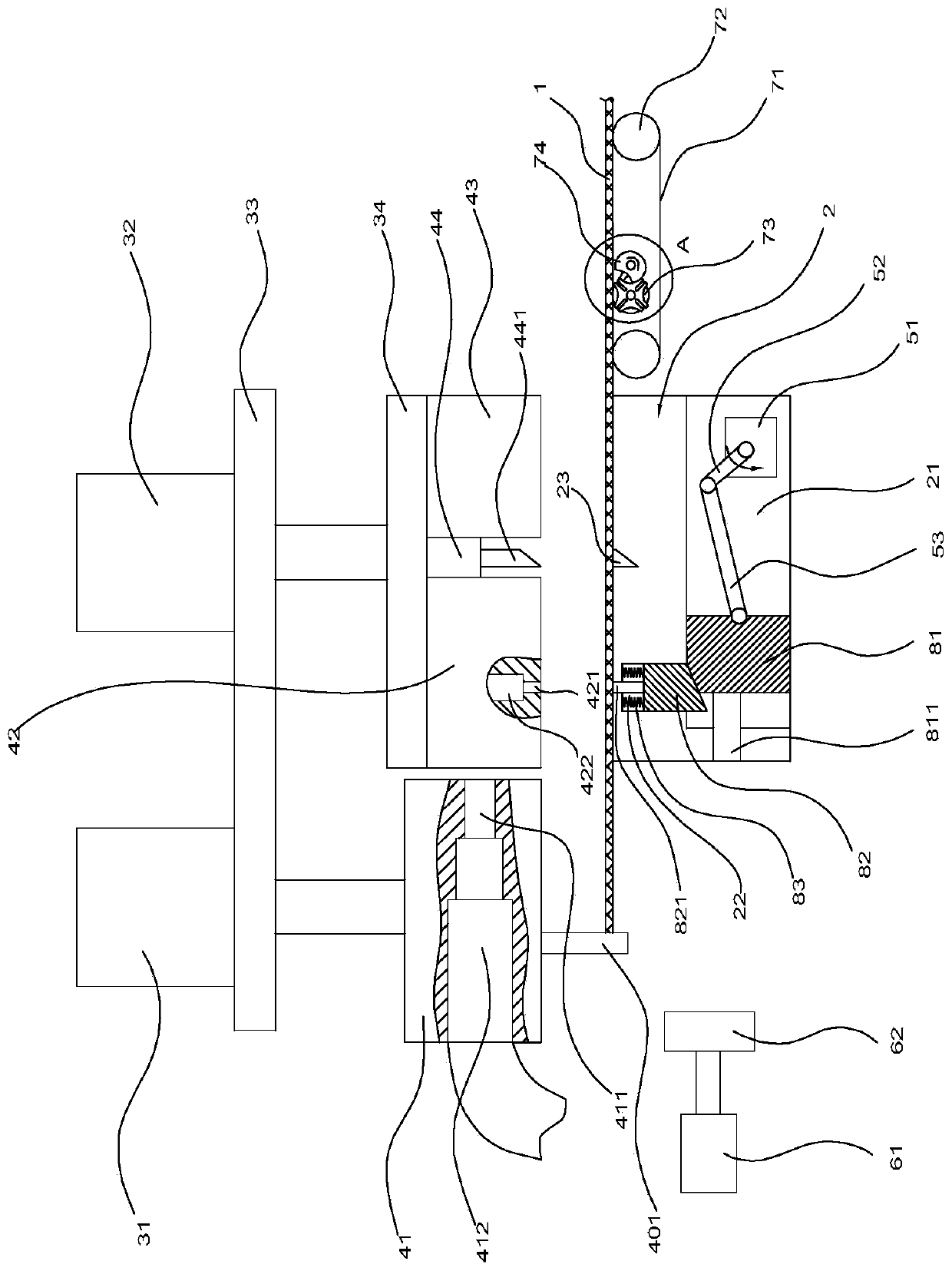

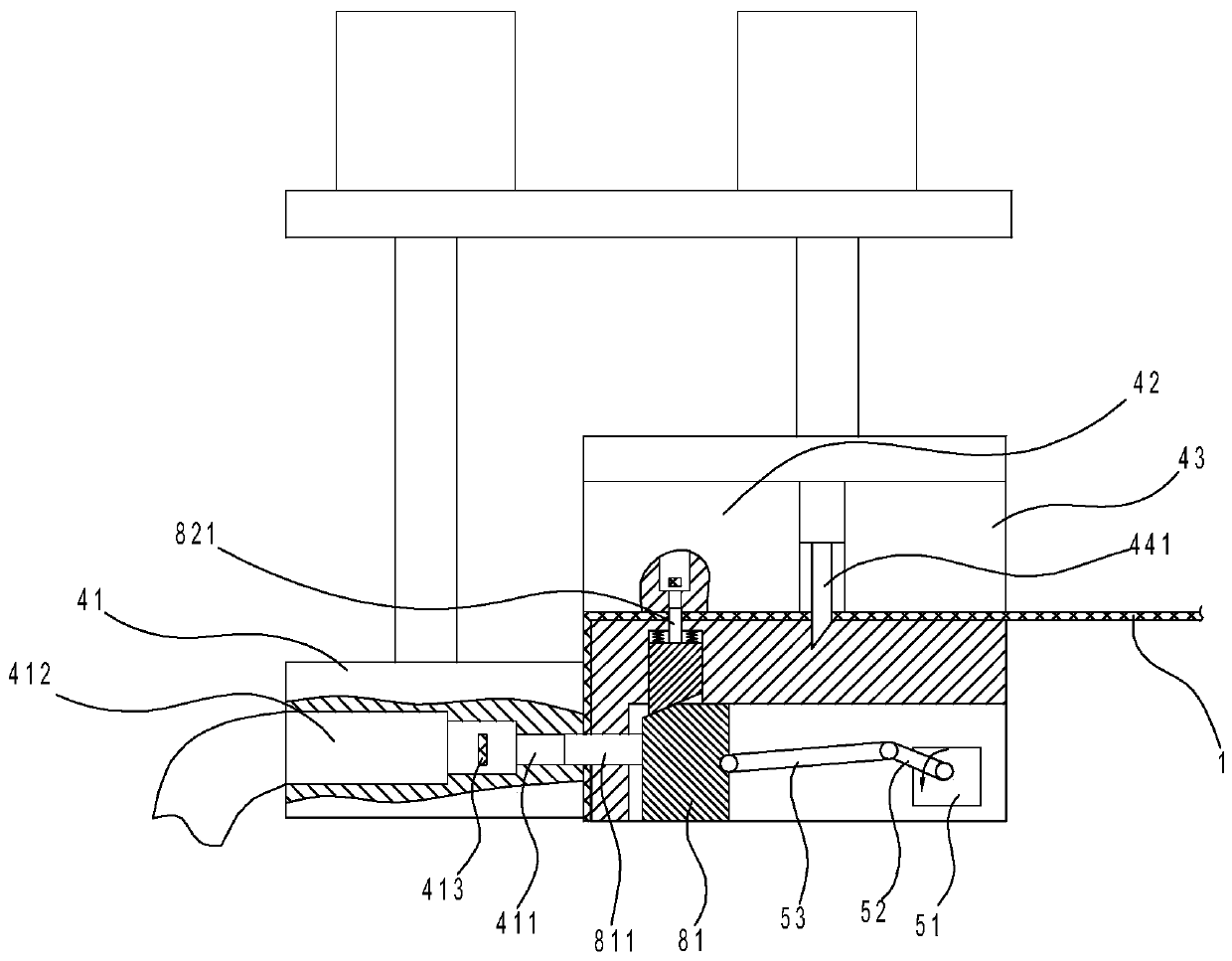

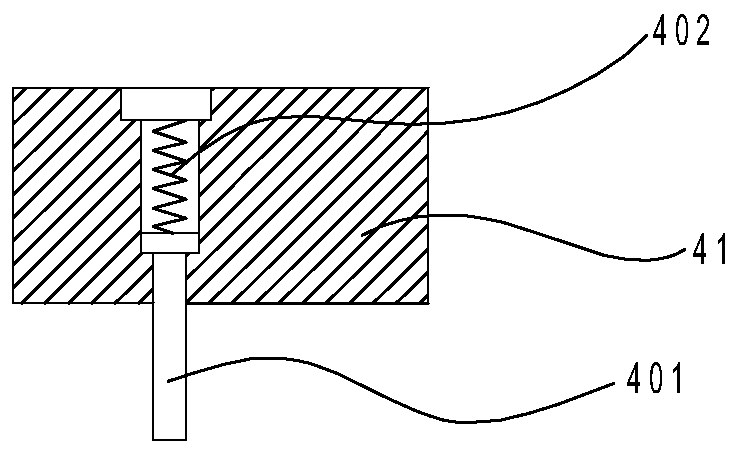

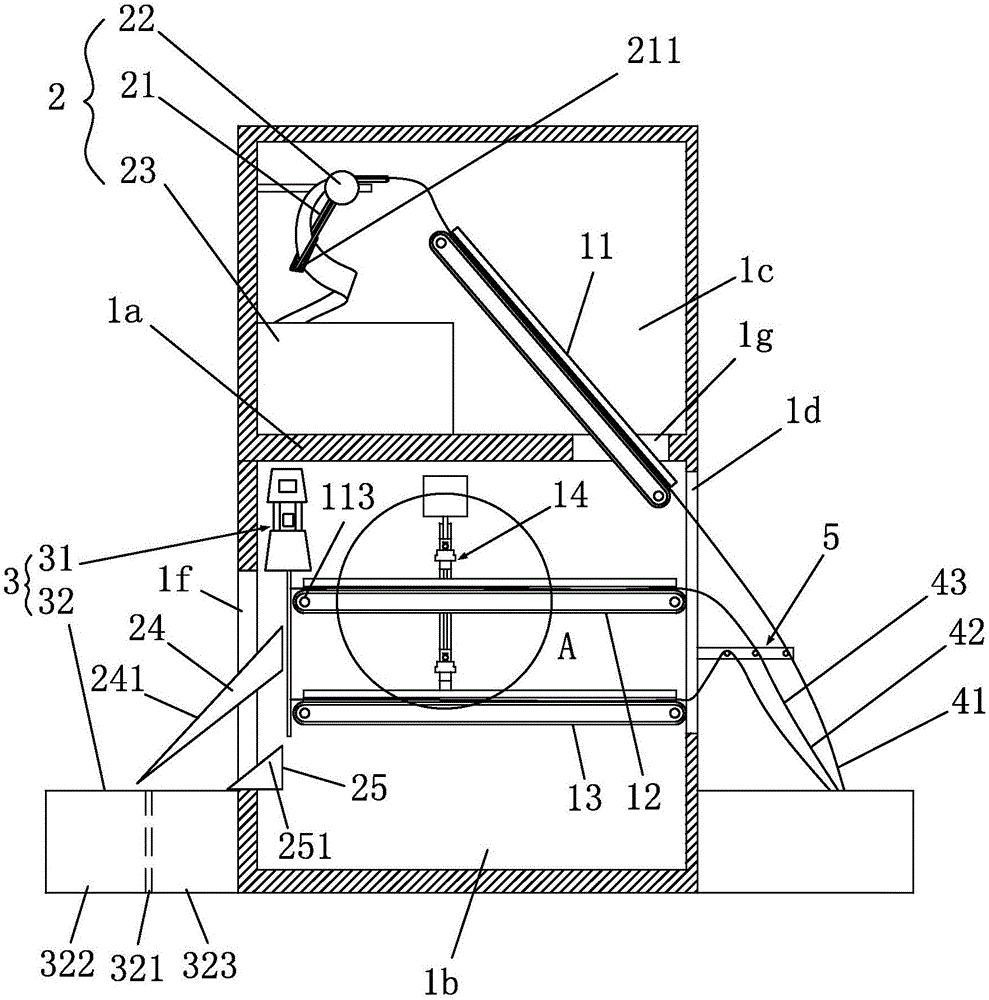

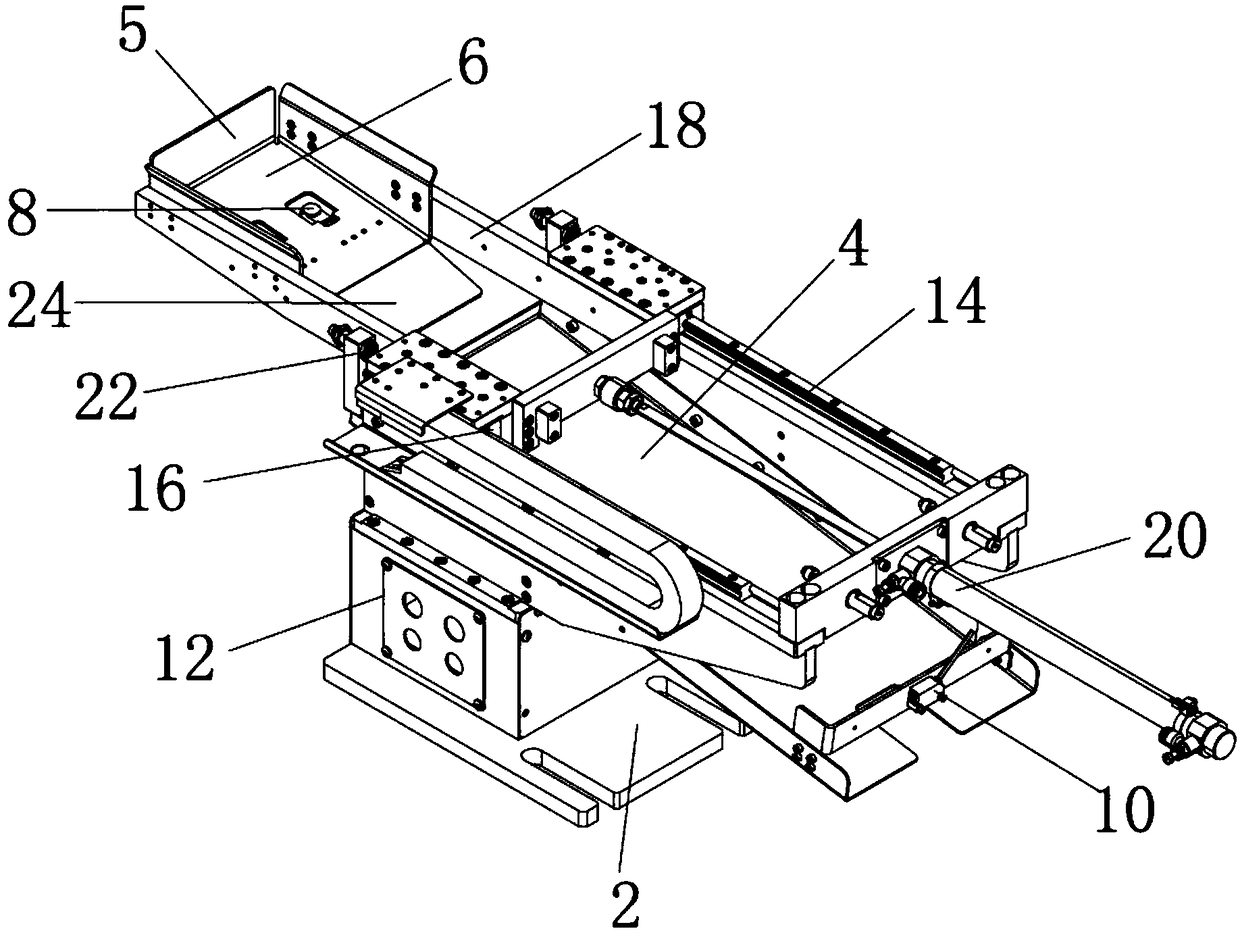

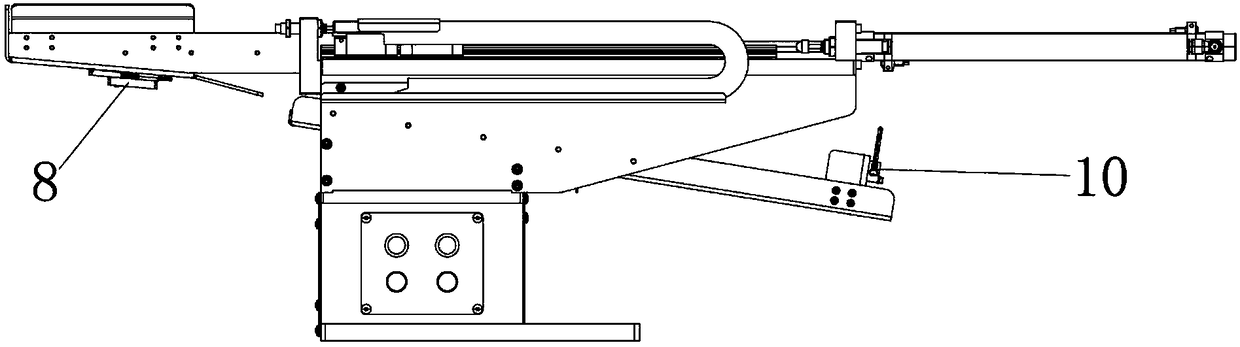

Full-automatic feeder of punch press

ActiveCN103817191AAdaptableImprove stamping efficiencyMetal-working feeding devicesMetal working apparatusCamera lensPunch press

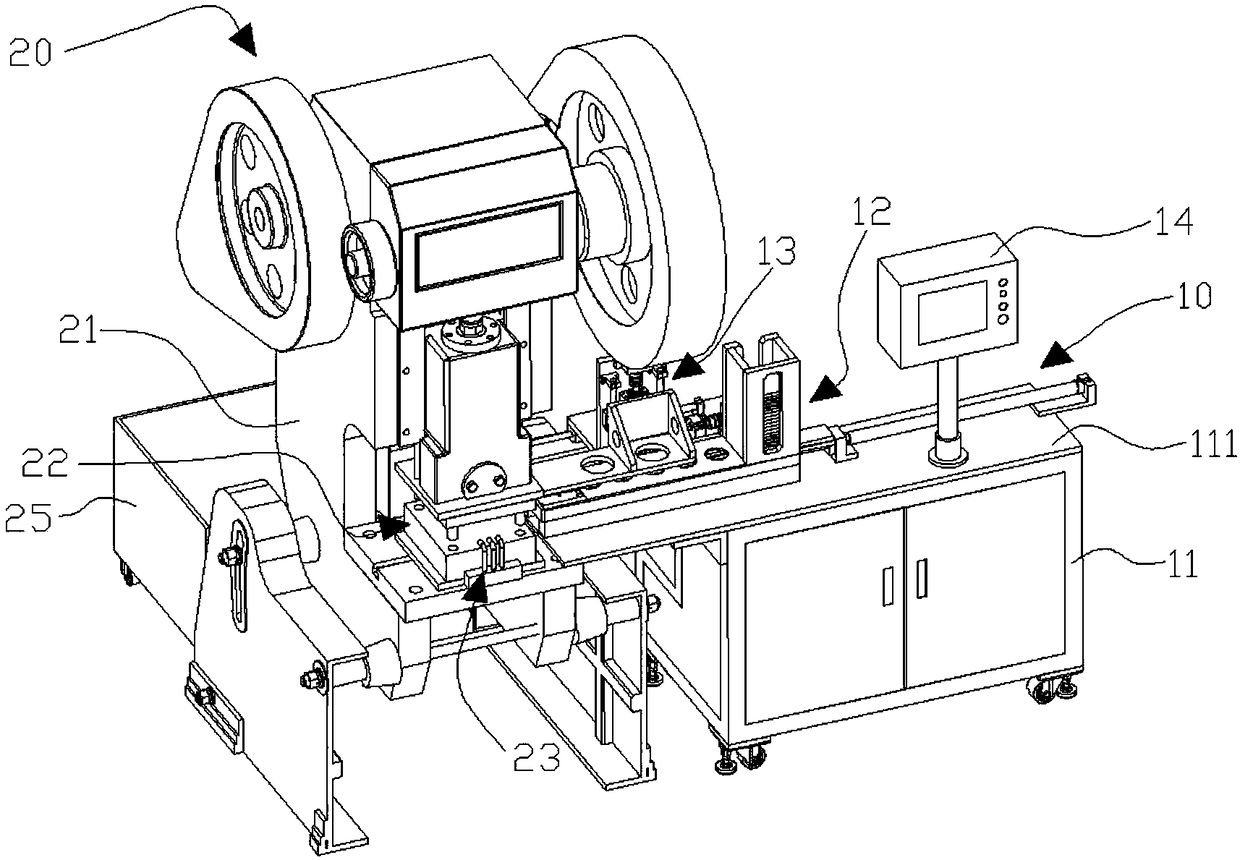

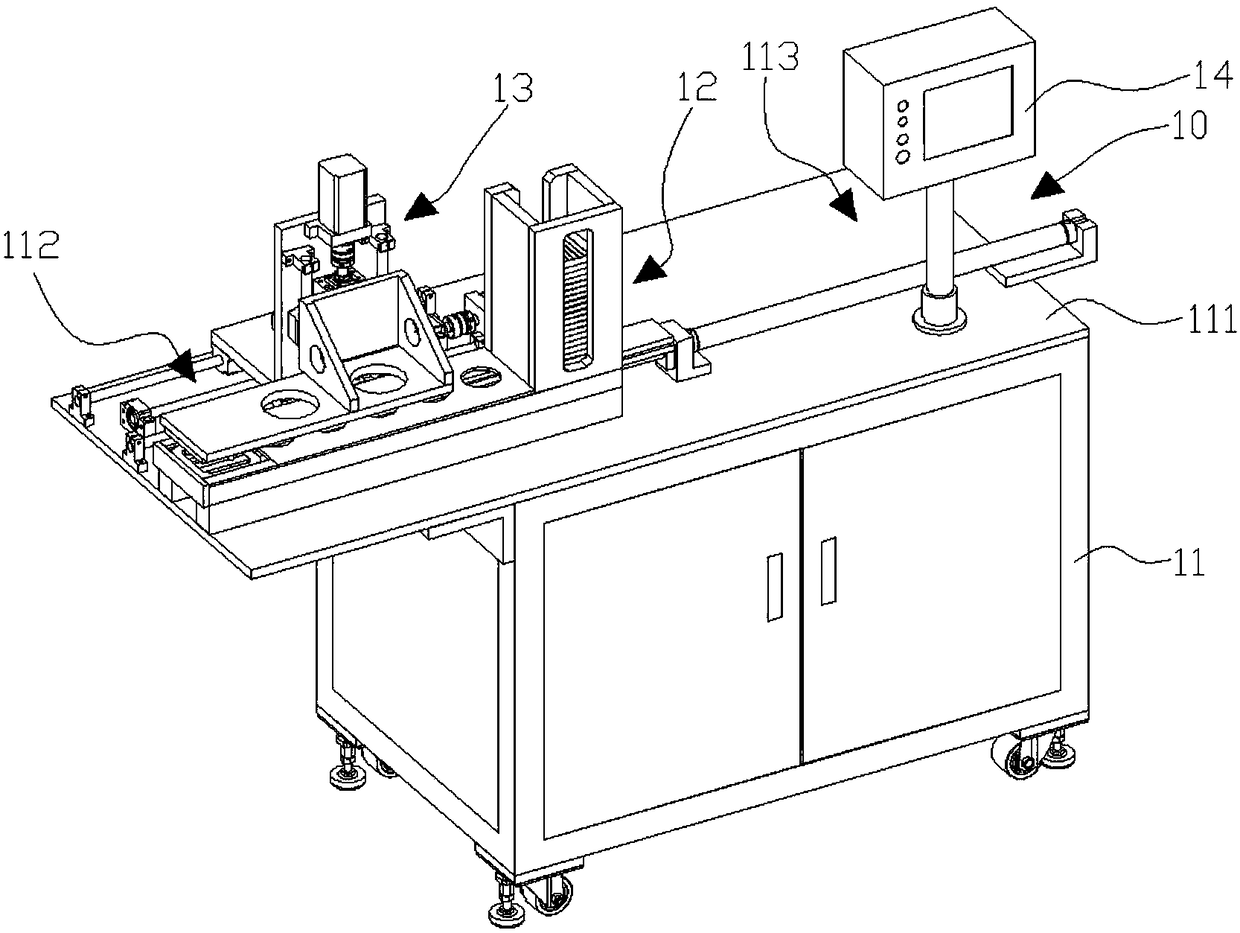

The invention discloses a full-automatic feeder of a punch press. The full-automatic feeder comprises a feeding device, a punching device and a collecting device. The feeding device comprises a feeding table, mounting base plates are respectively arranged on two sides of the upper end of the feeding table, an image positioning device and a multi-direction feeding unit are arranged on the mounting base plates, a screw positioning seat is arranged at each of two ends of the middle portion of the feeding table, the two screw positioning seats are connected via a first screw, two first guide rails are arranged on two sides of the first screw and connected via a positioning platform, and an initial positioning panel is arranged on the positioning platform. Poisoning marks on products are collected by a camera lens of the image positioning device, and after coordinate positions of the positioning marks are recorded by a computer and products to be punched is fed in, the coordinate positions of the positioning marks of the products to be punched are adjusted by the positioning platform to be identical with the coordinate positions of the positioning marks recorded by the computer, so that two positioning holes of each product to be punched can be ensured to be accurately suspended on two positioning pins of a punching die.

Owner:DONGGUAN ZHUNRUI AUTOMATION EQUIP

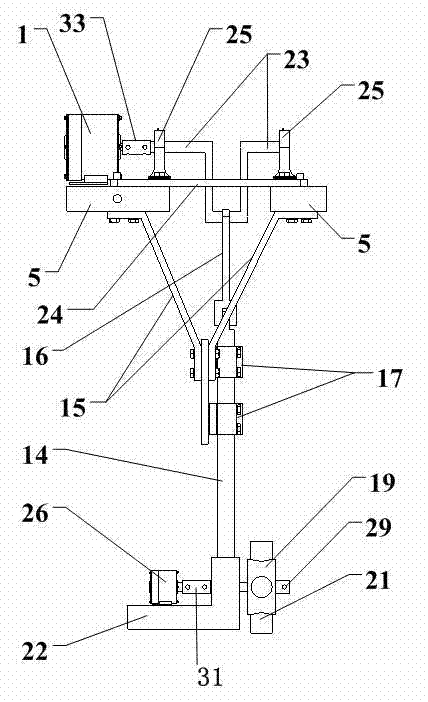

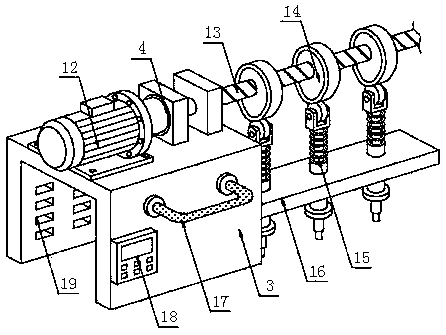

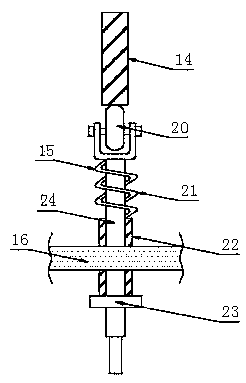

Stamping mechanism of automatic stamping machine

The invention discloses a stamping mechanism of an automatic stamping machine, and the stamping mechanism comprises a first motor, a second motor, a first support, a third motor, a first ball bearing lead screw pair, a first lead screw, a second support, a first slide rod, a third support, a fourth support, a second slide rod, a plate rib support, a connecting rod, a fixed plate, a turntable, a third slide rod, a second lead screw, a crankshaft, a connecting frame rod, a fourth motor, a second ball bearing lead screw pair, a stamp clamp and a connecting shaft. According to the stamping mechanism of the automatic stamping machine, because the lead screw is driven to rotate by a motor lead screw, so that the support with the ball bearing lead screw pair is driven to slide on the slide rod, the stamping mechanism which is arranged on the support realizes a structure which moves at any position on a plane and a stamping position is precisely selected. In addition, the motor drives the crankshaft to rotate, the crankshaft drives the connecting rod to move, so that the slide rod is driven to slide on a slide bearing which is fixedly arranged on the fixed plate, and the stamp is driven to move up and down. Moreover, the motor drives the turntable to move through the connecting shaft, so as to select different stamps which are arranged on the turntable.

Owner:GUANGDONG UNIV OF TECH

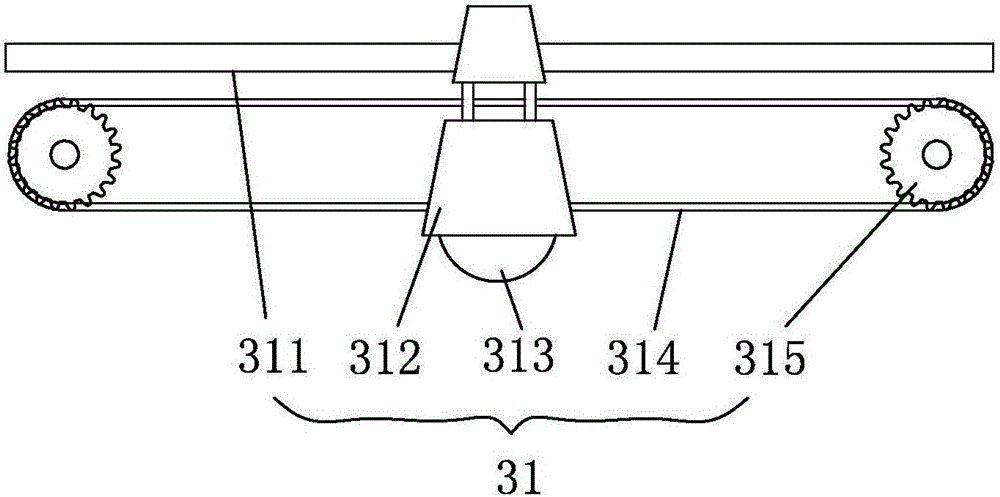

Automatic seal machine

InactiveCN102059862AImprove stamping efficiencyStamping problem simplifiedStampingPictoral communicationEngineeringConveyor belt

The invention provides an automatic seal machine which comprises a scanner, a paper feeding system and an automatic seal system, wherein the scanner is connected with the paper feeding system, the paper feeding system is connected to a conveyor belt of the automatic seal system, a manual sliding guide rail is arranged on the conveyor belt, an automatic seal arm is arranged on the manual sliding guide rail, the automatic seal arm is connected to a gear through a pulley with an electrical machine, and an inkpad groove is connected to one side of the conveyor belt. The scanner is connected with a computer, the sealed file is sent to a computer after scanned by the scanner, then the computer sends data, thus automatic seal is realized through setting the speed of the conveyor belt and the slipping manner of the seal arm along the guide rail. According to the invention, the problem of time and energy waste in a process of sealing a large number of same files is mainly solved, and a seal task can be rapidly and conveniently completed.

Owner:张正珣

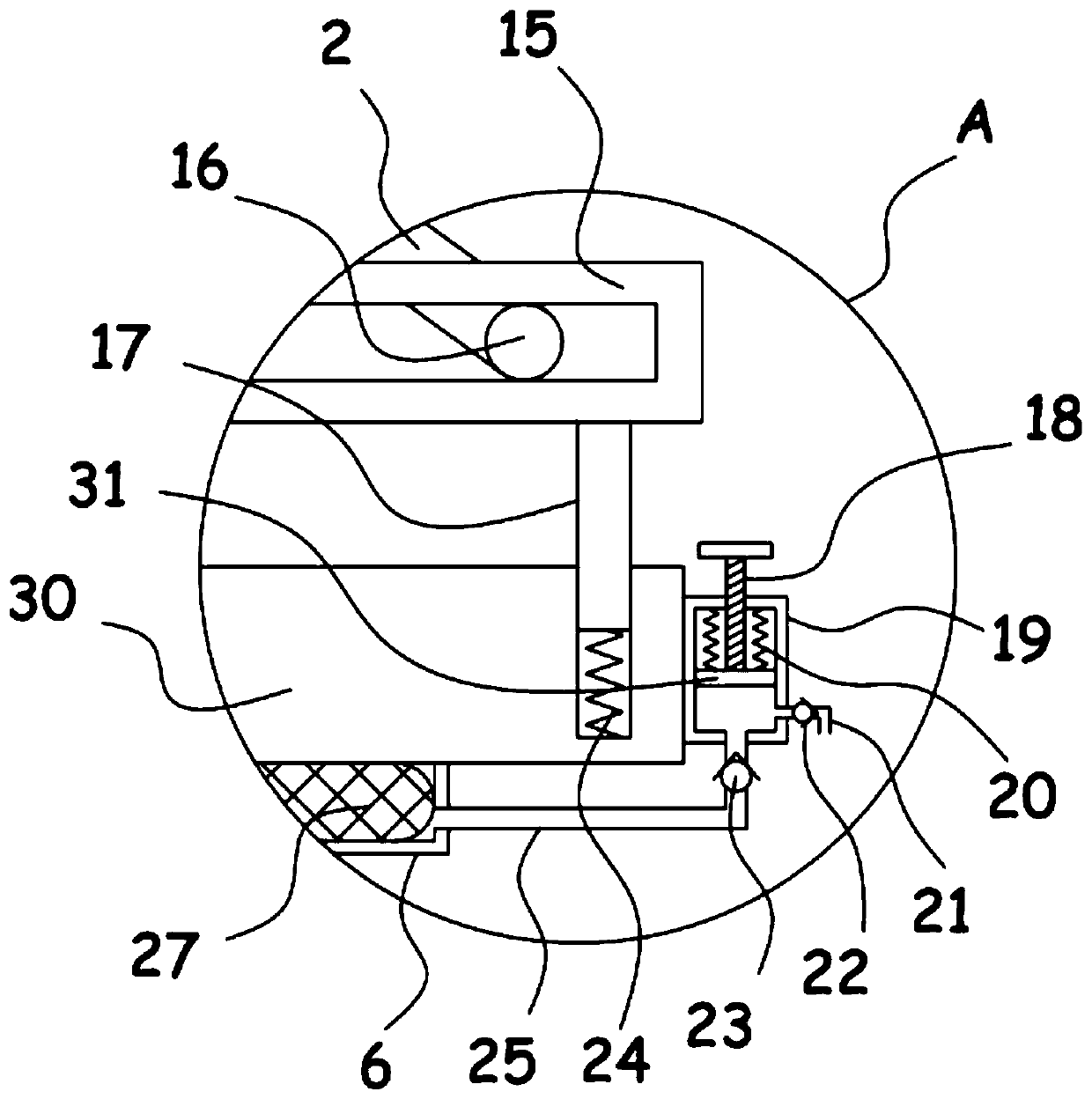

Automatic stamping device for product packaging box

ActiveCN110303781AImprove stamping efficiencyImprove the effect of the sealStampingContact timeEngineering

The invention discloses an automatic stamping device for a product packaging box, and relates to the technical field of product packaging. The automatic stamping device comprises a supporting frame and a supporting bottom block, a conveying belt used for conveying the packaging box is arranged on the supporting frame, the upper surface of the supporting bottom block is abutted against the inner side wall of the conveying belt, a rotating disc is connected with a telescopic frame in a driving mode through a driving mechanism, the lower end of the telescopic frame is connected with a stamping assembly comprising a stamp through a connecting assembly, and a driving end of the conveying belt is connected with a transmission gear. According to the automatic stamping device, the automation degree and the stamping efficiency are high, and the conveying belt can be driven in a stepping mode through a stepping mechanism, so that the packaging box on the conveying belt can move in a stepping mode, the packaging box can move below the stamp one by one to obtain a stamp, and the stamping efficiency of the packaging box is greatly improved; and in the stamping process of the stamp, a guide rodcan extend downwards relative to a connecting block, so that a certain contact time is kept between the stamp and the packaging box, and the effect of the stamp is obviously improved.

Owner:山东鲁润阿胶健康产业有限公司

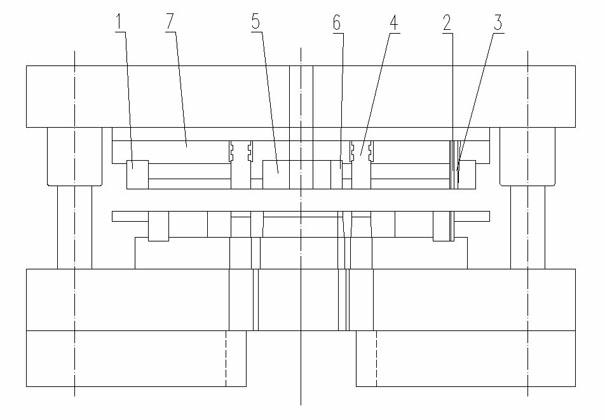

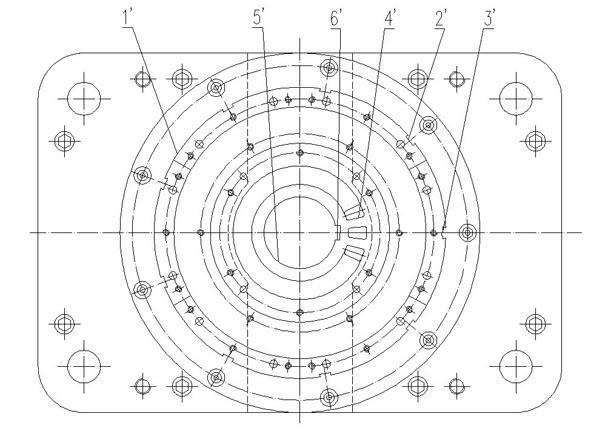

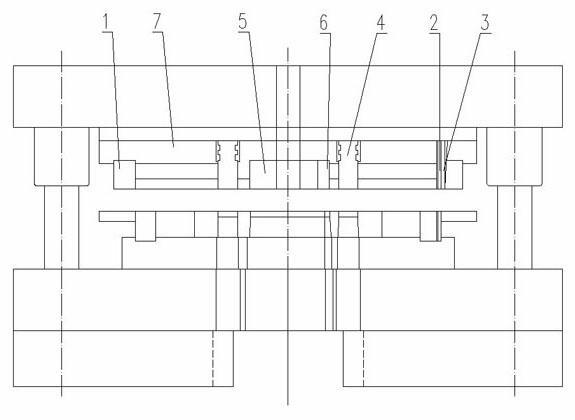

Process for blanking and stamping motor stator piece and rotor piece with air hole and key die thereof

ActiveCN102142743AAvoid uneven groovesAvoid wavinessManufacturing stator/rotor bodiesElectric machineStructural engineering

The invention provides a process for blanking and stamping a motor stator piece and a rotor piece with an air hole and a key die thereof. The process comprises the following technical stamping steps: (1) stamping a stator excircle, a rotor axle hole and an air hole again; (2) singly stamping a stator slot; and (3) singly stamping a rotor slot and separating the stator piece from the rotor piece. The key die comprises a top die part, a bottom die part and a guiding part, wherein the top die part comprises a stator excircle cavity die, a cramp slot punch, an external labeling slot punch, a rotor air hole punch, an axle hole terrace die and the upper cutting edge of a key slot punch; the upper cutting edge is fixed on an upper fixed plate; the position and the size of the upper cutting edge correspond to those of the stator excircle which needs to be stamped, the cramp slot, the external labeling edge, the rotor air hole, the axle hole and the key slot; and the bottom die part comprises a lower cutting edge corresponding to the upper cutting edge. In the process, two stamping steps are omitted, labor intensity is lowered, and stamping efficiency is improved. The phenomenon of the irregular shape of the stator sheet slot is avoided, the rotor sheet wave degree can be prevented, and stamping effect is good.

Owner:LANZHOU ELECTRIC CORP

Continuous automatic stamping die and stamping method thereof

ActiveCN110560562AWon't looseImprove stamping efficiencyShaping toolsMetal-working feeding devicesDrive shaftThrough transmission

The invention discloses a continuous automatic stamping die, and belongs to the technical field of stamping dies. The technical essential is as follows: the continuous automatic stamping die comprisessupport plates, wherein two support plates are arranged; the two support plates are fixedly connected through a lower die plate; an upper die plate is arranged above the lower die plate; a drive rollis arranged at one end of each of the two sides of the lower die plate; the drive rolls are connected with a drive device inlaid in the lower die plate through transmission shafts; a transmission roll is arranged at the other end of each of the two sides of the lower die plate; the transmission rolls are movably connected with the lower die plate through connection shafts; the drive roll and thetransmission roll which are located at the same side are connected through a conveying belt; and a clamping assembly is arranged at one end of the upper surface of each conveying belt. According to the continuous automatic stamping die, the drive rolls, the transmission rolls and the conveying belts are arranged at the two sides of the lower die plate, the clamping assemblies can be driven to move, a cylinder is arranged on each clamping assembly, and each clamping assembly is enabled to stably clamp a stamping material; and each cylinder is configured to be of a movable structure, so that thestamping material is capable of driving the cylinder to move during stamping working.

Owner:赵宝宏

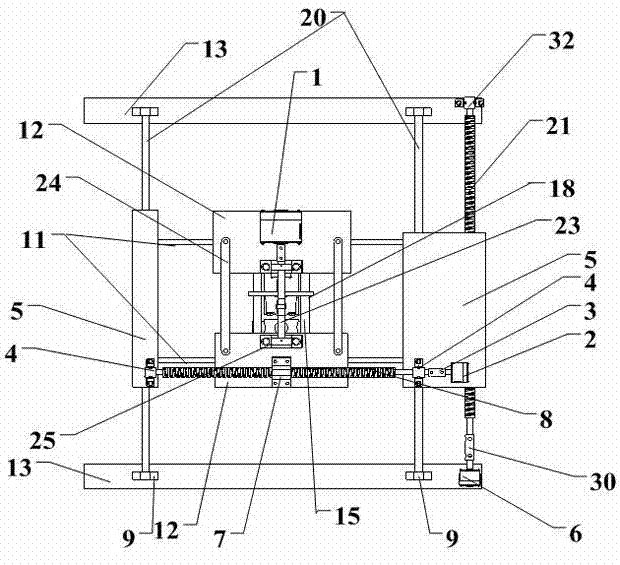

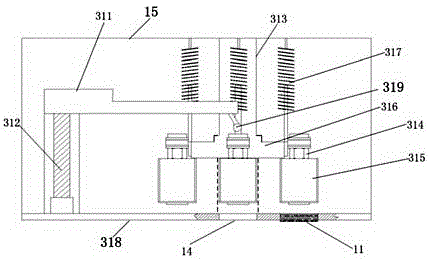

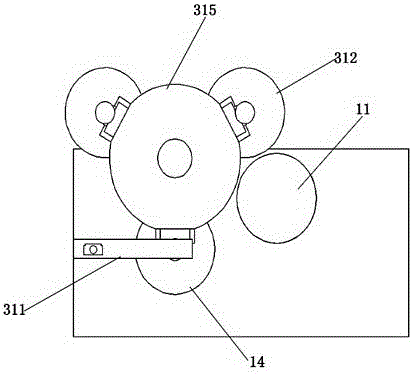

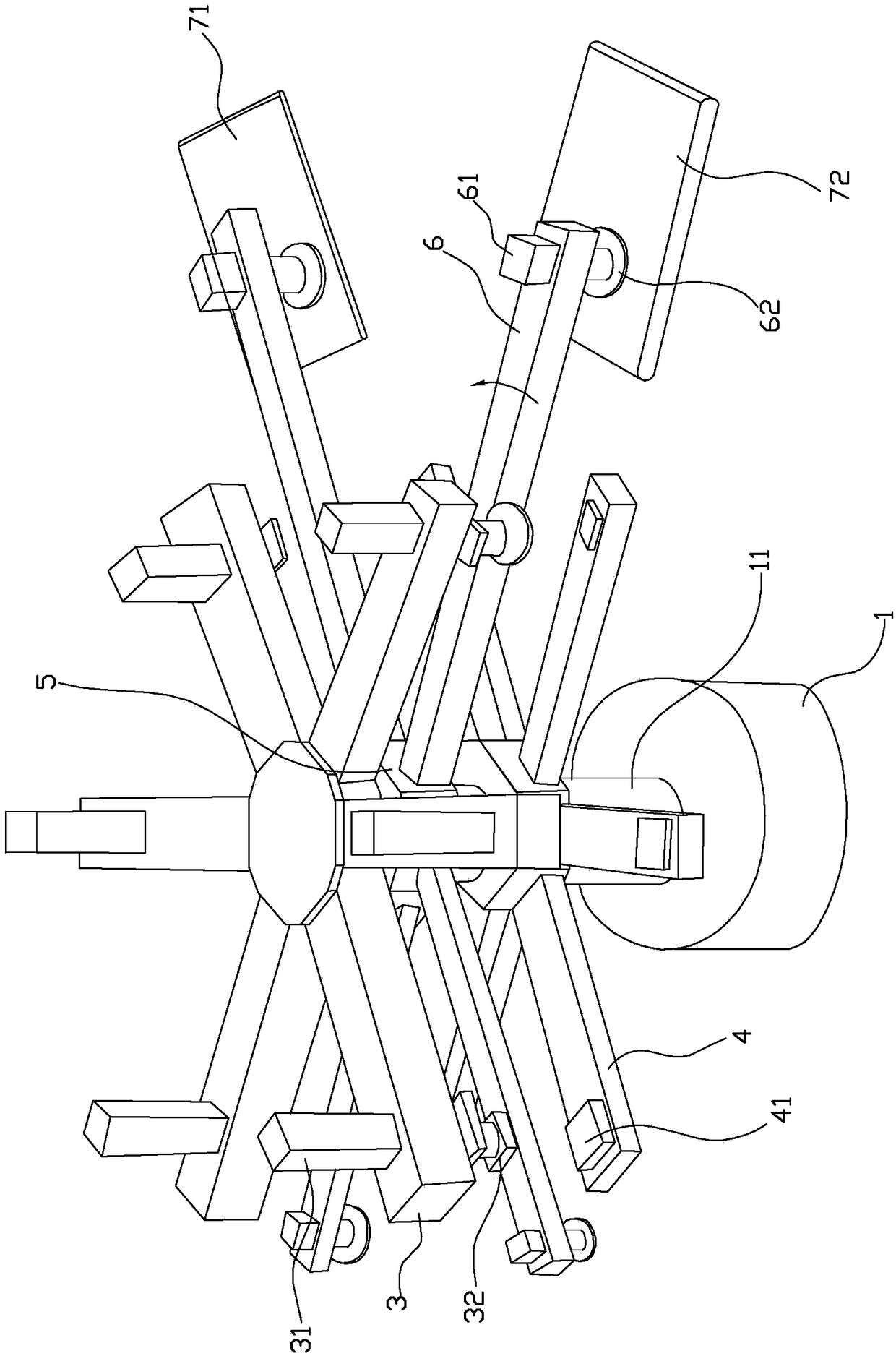

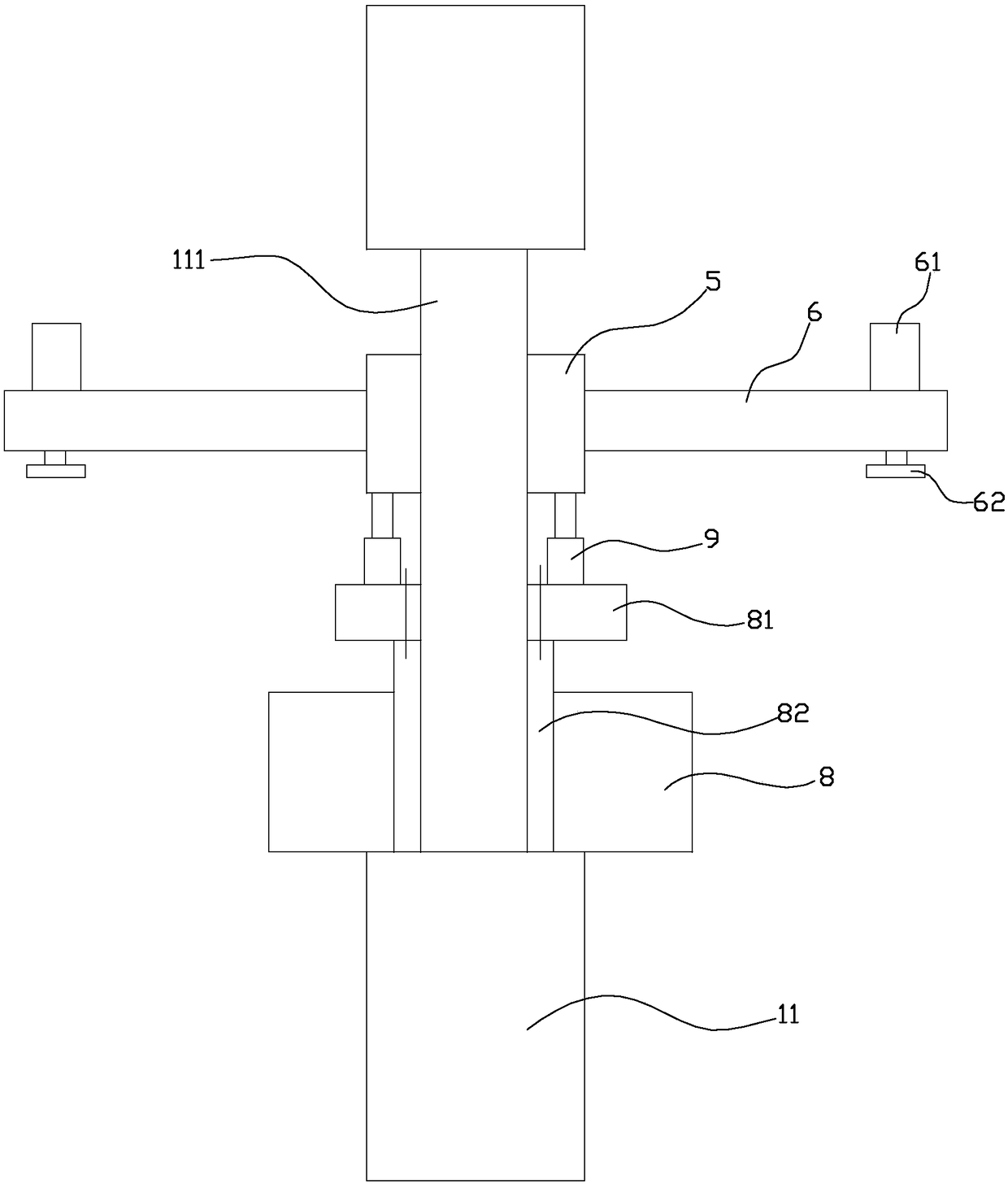

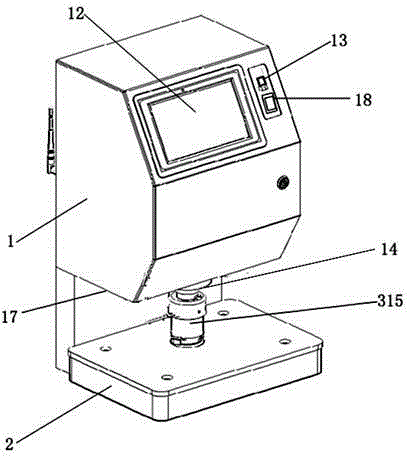

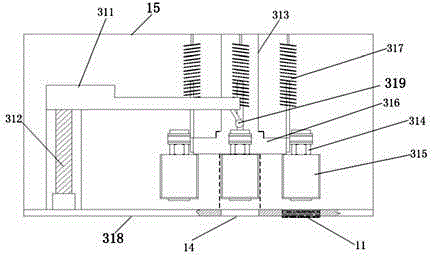

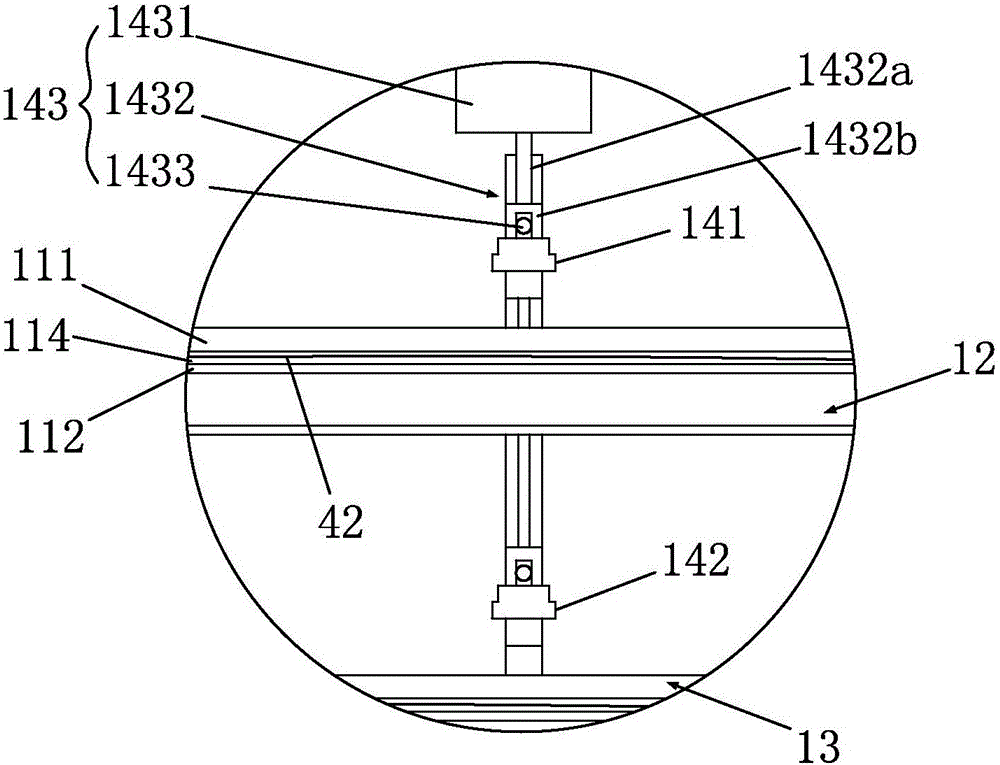

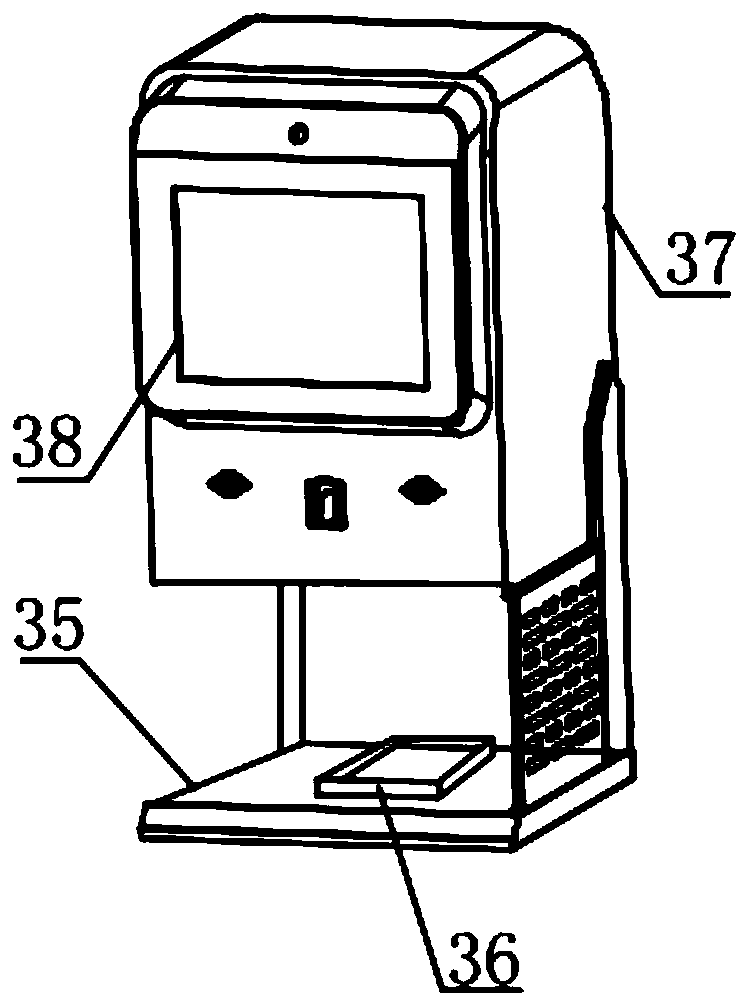

Rotary stamping machine head and stamping machine

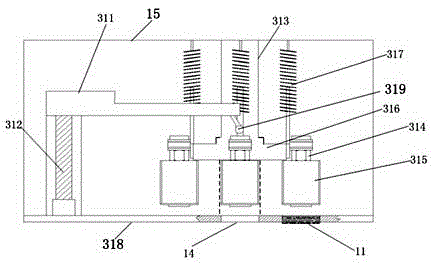

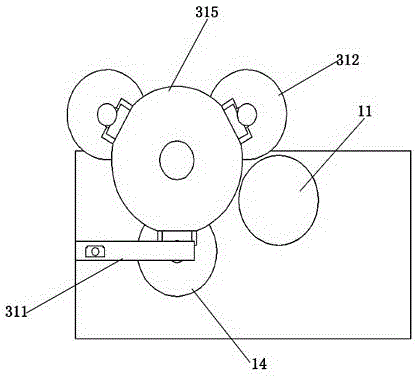

The invention provides a rotary stamping machine head and a stamping machine. A shell body 15 is disposed in the machine head 1, and a rotary mechanism, a stamping mechanism, a downward pressing mechanism and a fixation table 318 are disposed in the shell body 15, wherein the rotary mechanism comprises a supporting main shaft 313 and a rotary table 316, and the rotary table 316 is connected to the supporting main shaft 313 by a rotary bearing; the lower part of the supporting main shaft 313 is firmly connected to the fixation table 318; the stamping mechanism is disposed on the rotary table 316, and is in a slide connection with the rotation table by a slide rail; the stamping mechanism comprises a stamp loading mechanism 315; and a connecting rod with an elastic assembly 317 is firmly connected on the stamp loading mechanism 315, and the shell body 15 is connected on the elastic assembly 317. According to the invention, the rotary multi-head stamping mechanism is adopted; a rational translation mechanism and a rational lifting mechanism are designed for the stamping mechanism; a controller is adopted for concentrative control; and rapid switching of multiple stamps can be achieved, and stamping efficiency can be increased greatly.

Owner:周相山

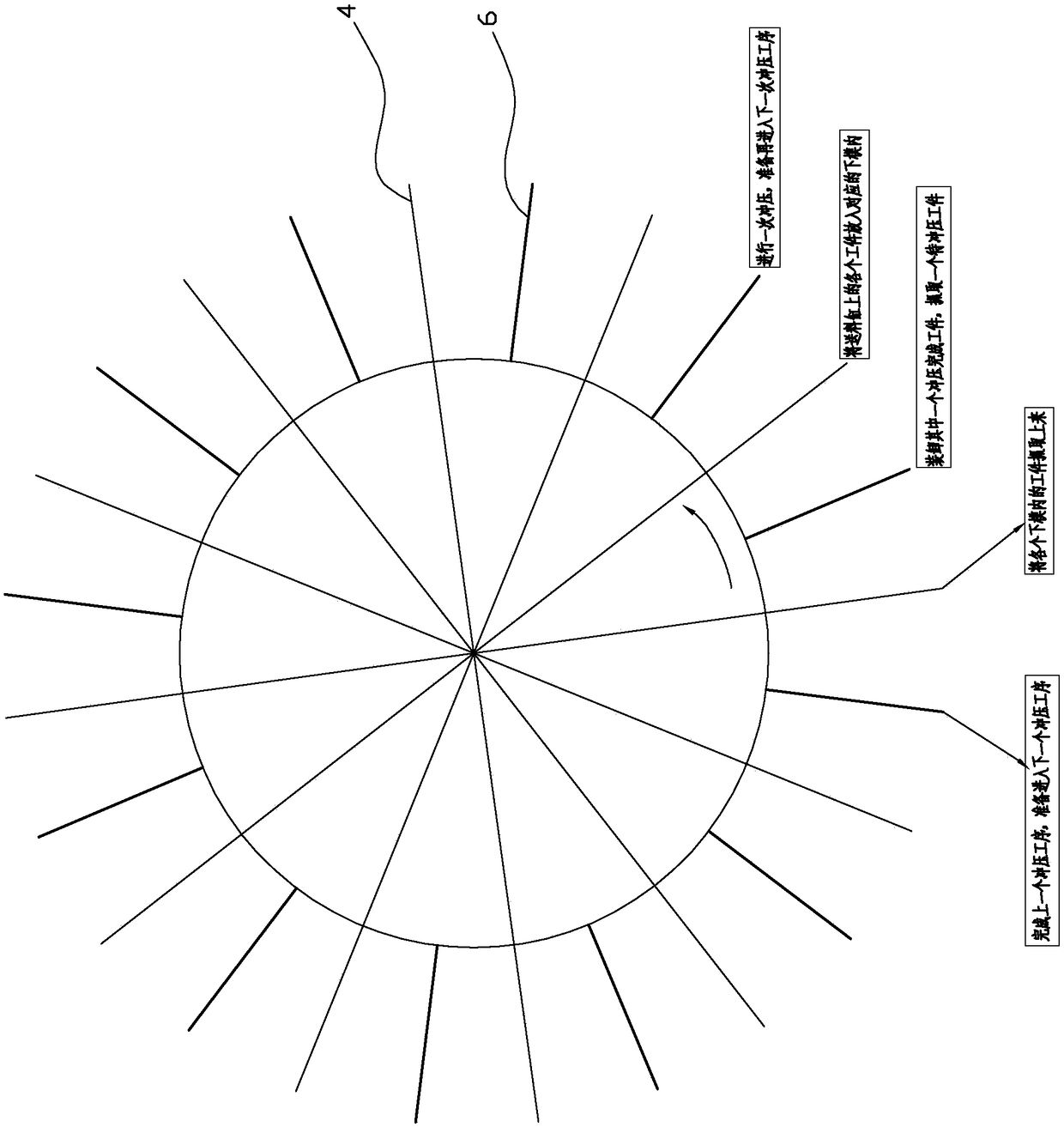

Automatic punching method capable of continuously multi-station punching workpieces

InactiveCN108526281ARealize multi-station automatic stampingGuaranteed continuous loopMetal-working feeding devicesStripping-off devicesPunchingStamping process

The invention discloses an automatic punching method capable of continuously multi-station punching workpieces. A feeding conveyor belt intermittently conveys each workpiece to be punched in place. The automatic punching method capable of continuously multi-station punching the workpieces is characterized in that during each punching process, each punching cylinder moves synchronously, and each punching process is continuously and circularly carried out; and each punching process comprises the following steps of rotating a rotary table at 360 / (2N) degrees, and grabbing a workpiece from a lowerdie; then rotating the rotary table at 360 / (2N) degrees, unloading a punched workpiece, and feeding a workpiece to be punched; rotating the rotary table at 360 / (2N) degrees, and placing the workpieces into the lower die; rotating the rotary table at 360 / (2N) degrees, and carrying out one-time punching on the workpieces; and repeating the punching process. The invention provides the automatic punching method capable of continuously multi-station punching the workpieces, the workpieces are automatically multi-station punched, the manual labor intensity is reduced, and the punching efficiency isimproved.

Owner:佛山市顺德区与进实业有限公司

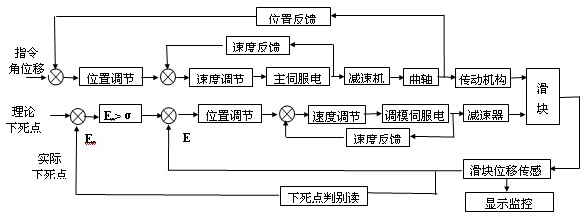

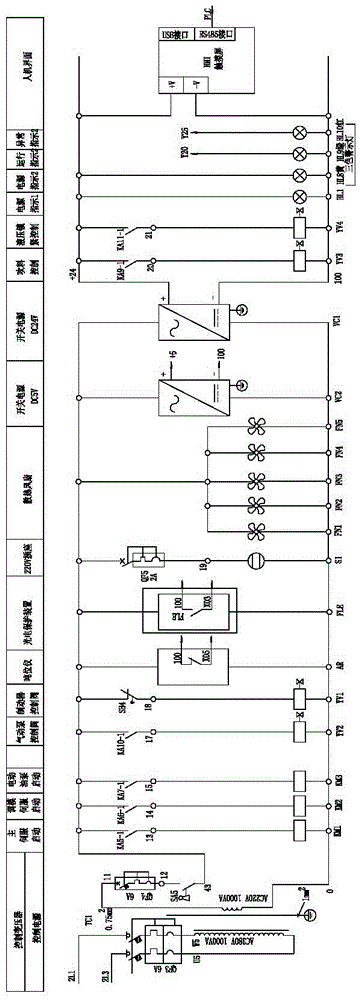

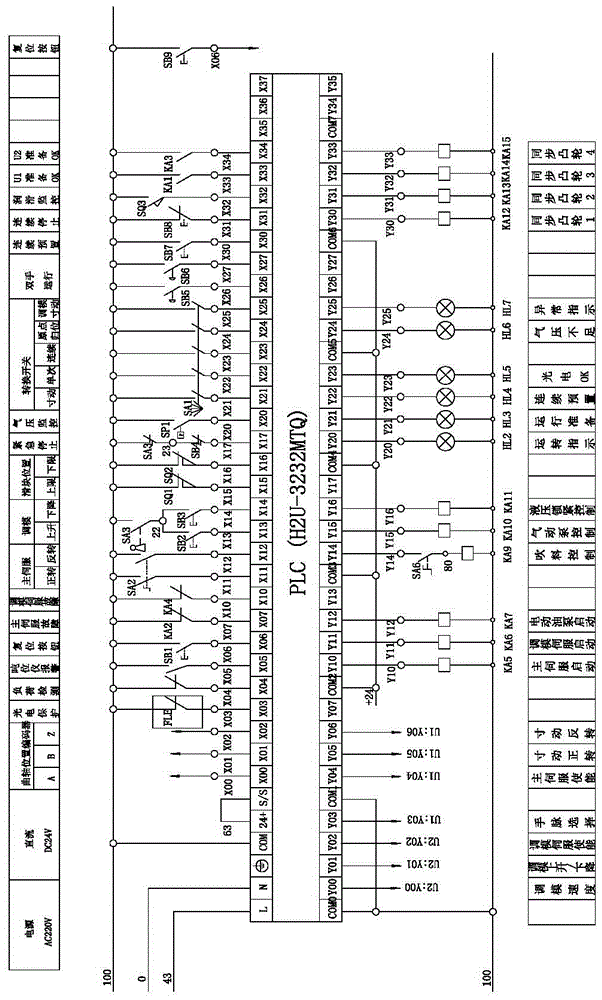

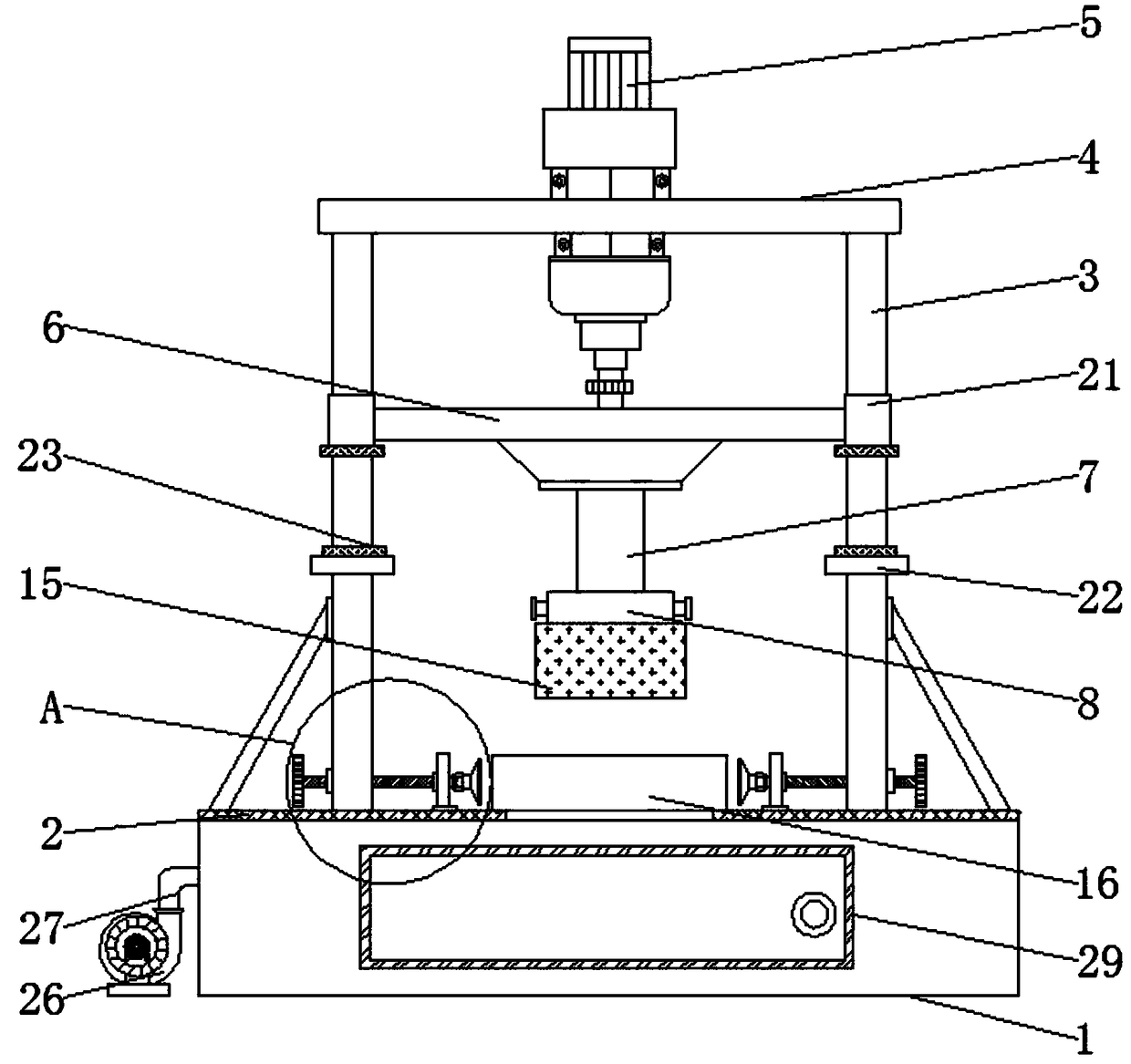

Control system and method for intelligent-type servo press

ActiveCN105700453AGuaranteed stamping accuracyGuarantee stamping qualityProgramme control in sequence/logic controllersPunchingControl power

The invention discloses a control system for an intelligent-type servo press, and the system comprises a servo drive unit, a PLC control unit, and a control power unit. The servo drive unit comprises a main drive servo controller, a mold adjustment servo controller, an electric pump motor, and a multifunction power meter, wherein the main drive servo controller, the mold adjustment servo controller, the electric pump motor and the multifunction power meter are connected to a three-phase power supply. The PLC control unit comprises a PLC, and a drive power end of the PLC is connected with an AC 220V power supply. A control power end of the PLC is connected with a DC 24V power supply, and the PLC collects the operation signals of all corresponding devices, and transmits the control signals for controlling the corresponding devices. The control power unit comprises a control transformer, wherein the front end of the control transformer is connected with an AC 380V power supply, and the rear end of the control transformer outputs an AC 220V voltage serving as the AC 220V power supply. The system guarantees the punching precision of the press and the quality of a punched part, improves the punching efficiency, and can be used in the control of the press.

Owner:YANGLI GRP CORP LTD

Stamping die easy to replace

InactiveCN108097773AEasy to replaceEasy to fixShaping toolsMetal-working feeding devicesEngineeringSlide plate

The invention discloses a stamping die easy to replace. The stamping die comprises a dust removal box of which the top is fixedly connected to a sliding plate, and the both sides of the top of the sliding plate are fixedly connected to sliding rods; a fixed plate is fixedly connected between the top ends of the two sliding rods, and the top of the fixed plate is fixedly connected to a cylinder; the output end of the cylinder penetrates the fixed plate, and extends to the bottom of the fixed plate; the end, extending to the bottom of the fixed plate, of the cylinder is fixedly connected to thesliding plate; and the invention relates to the technical field of stamping dies. According to the stamping die easy to replace, the die can be replaced properly, and facilitate workers to operate; the stamping efficiency of the device is improved, and the device is convenient and efficient, so that the device is easy to replace, and the stamping effect of the device is ensured; the stamping errorof the device is reduced, and the device is easy to fix; and damage to stamping by chippings is avoided, so that the device has the function of chipping removal.

Owner:HEFEI DONGLU MACHINERY MFG

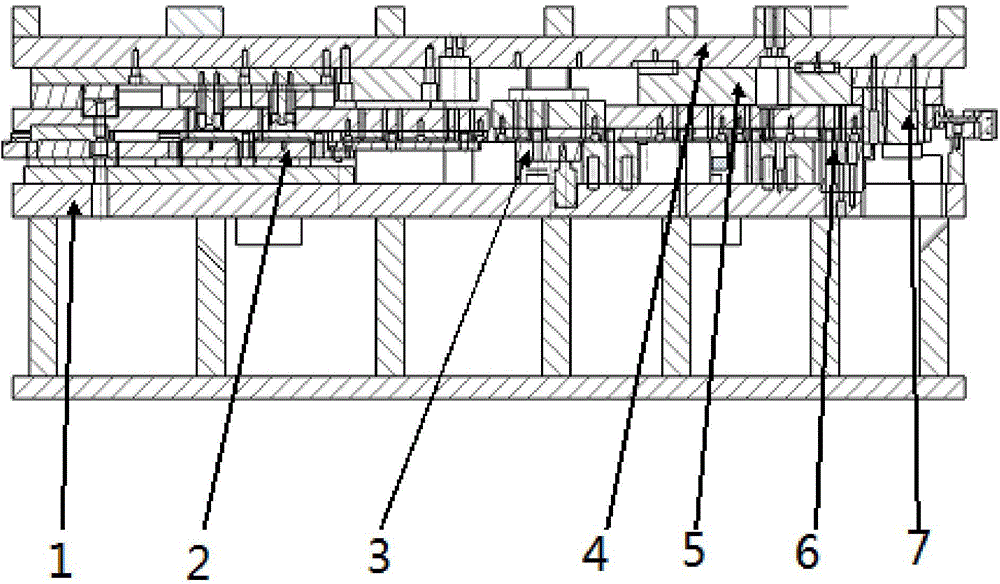

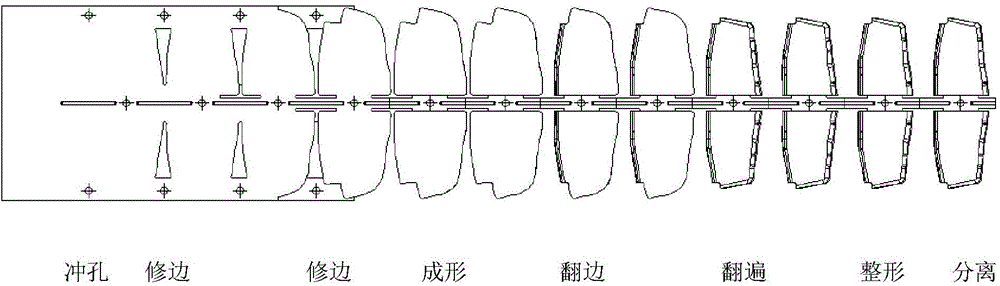

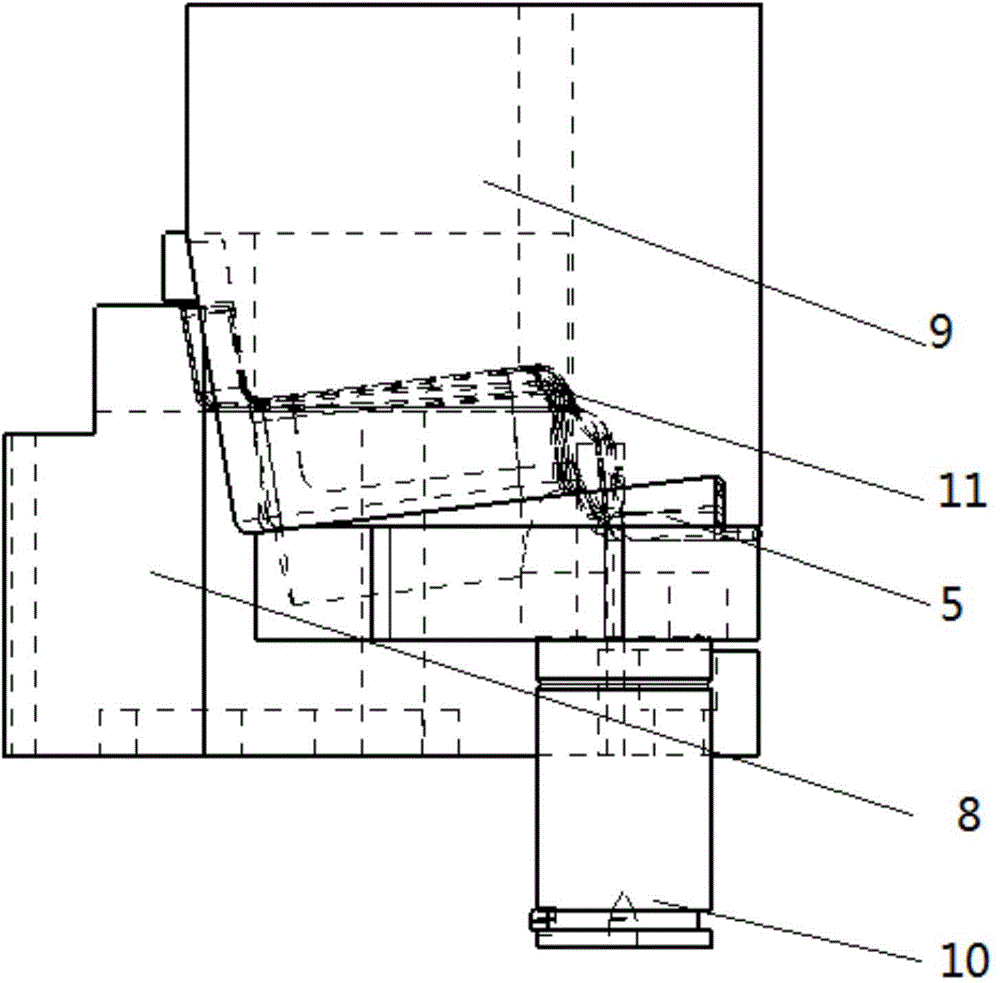

Continuous production die for rear portion blanking plate parts of automobile carling

InactiveCN104525741AExtended service lifeAvoid damageShaping toolsVehicle componentsEngineeringMechanical engineering

The invention relates to a continuous production die for rear portion blanking plate parts of an automobile carling. The continuous production die for the rear portion blanking plate parts of the automobile carling comprises a lower die portion and an upper die portion, the lower die portion comprises a lower die seat (1), a stamping female die cutter (2), a lower die trimming cutter block (3), a lower flanging male die (8), a shaping block, and a discharge opening,wherein the stamping female die cutter(2),the lower die trimming cutter block(3),the lower flanging male die(8),the shaping block and the discharge opening are arranged on the lower die seat(1) in sequence.The upper die portion comprises an upper die seat (4), a stamping male die cutter, an upper die trimming cutter block, a flanging cutter (9), a pressure plate (5) and a shaping punch (6), wherein the stamping male die cutter,the upper die trimming cutter block,the flanging cutter (9) ,the pressure plate (5) and the shaping punch (6) are arranged at the lower surface of the upper die seat (4) in sequence; the pressure plate (5) is arranged at the lower middle portion of the upper die trimming cutter block and is connected with the upper die trimming cutter block. Compared with the prior art, the continuous production die for the rear portion blanking plate parts of the automobile carling has the advantages of being high in quality, convenient to maintain low in cost and the like.

Owner:SHANGHAI ZHONGDA AUTO PARTS

Metal plate stamping die

ActiveCN110883211AAchieve positioningImprove stamping efficiencyShaping toolsPerforating toolsStamping processStructural engineering

The invention discloses a metal plate stamping die which comprises a supporting plate, a movable template, a lower die and an upper die unit. The metal plate stamping die is characterized in that a first punching cylinder and a second punching cylinder are arranged on the supporting plate, the upper die unit comprises a first upper die, a second upper die and a third upper die, the first upper dieis arranged at an output end of the first stamping cylinder, the movable template is arranged above an output end of the second punching cylinder, the second upper die and the third upper die are arranged below the movable template in parallel, a first stamping groove is formed in the first upper die, a second stamping groove is formed in a side wall of the second upper die, a transversely-arranged installation groove and a vertically-arranged sliding groove are formed in the lower die, a transverse sliding block is arranged in the installation groove in a sliding mode, a transverse punch isarranged on the transverse sliding block, a vertical sliding block is arranged in the sliding groove in a sliding mode, a vertical punch is arranged on the vertical sliding block, and the vertical sliding block makes contact with the transverse sliding block through a slope. According to the metal plate stamping die, in the one-time stamping process, the bending of a metal plate and the multi-direction punching machining can be achieved at the same time.

Owner:太仓市华茂金属制品有限公司

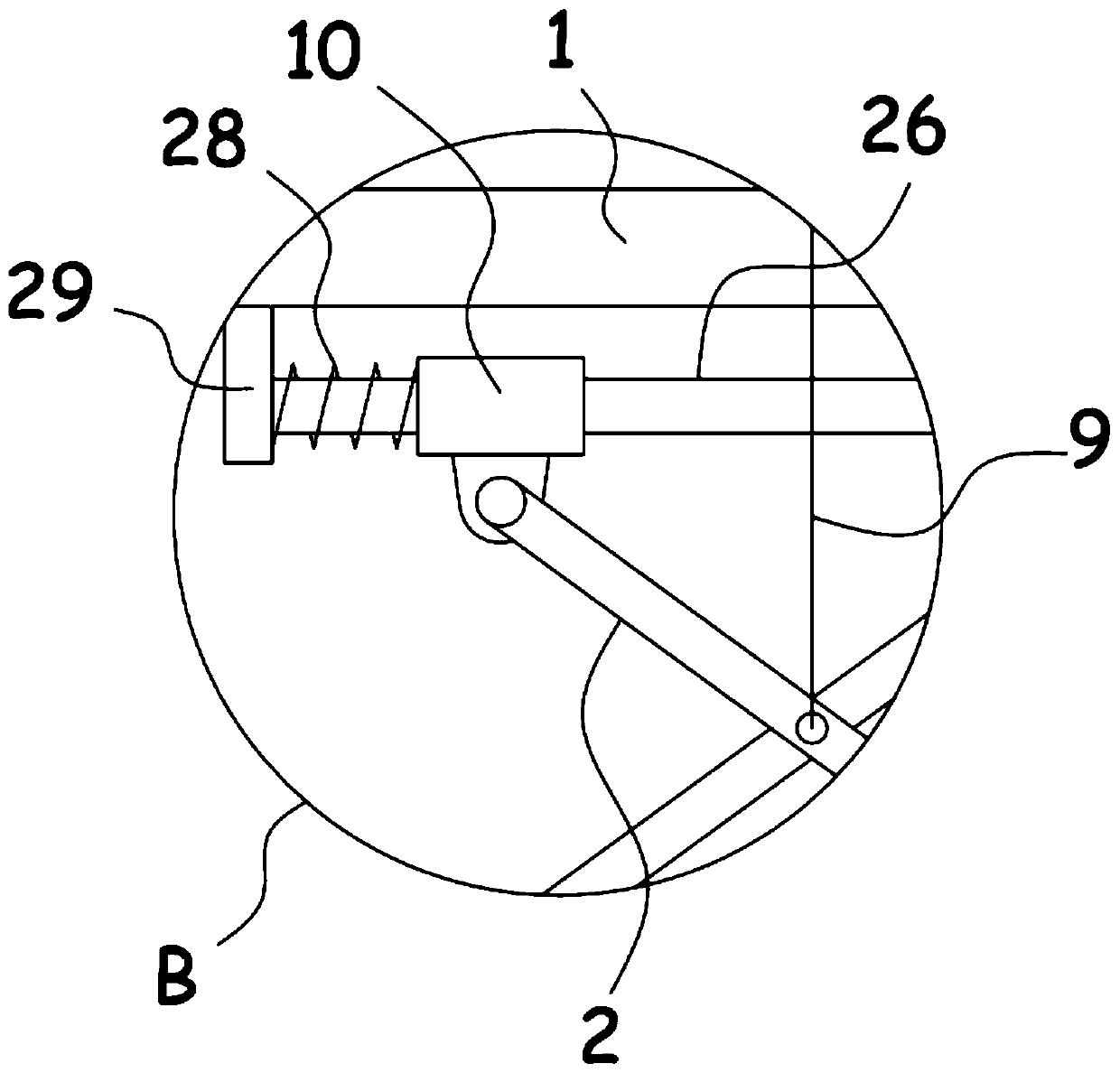

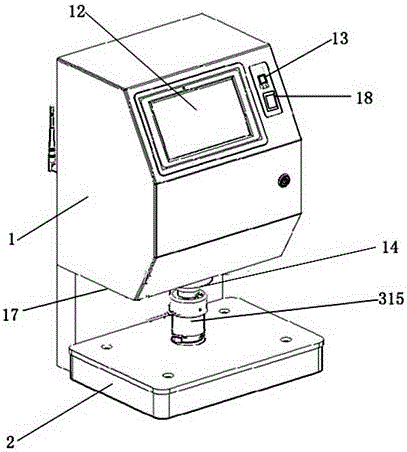

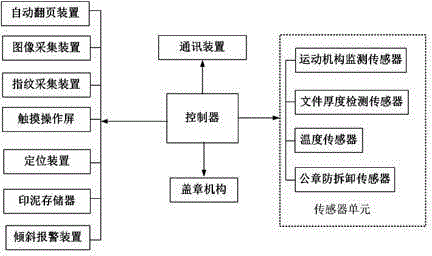

Rotary type multihead sealing machine capable of automatically identifying file thickness

InactiveCN106696490AKeep clearThickness real-time detectionStampingImaging processingPulp and paper industry

The invention provides a rotary type multihead sealing machine capable of automatically identifying file thickness. The rotary type multihead sealing machine comprises a machine head 1 and a base 2, wherein a shell 15 is arranged in the machine head 1; a rotary mechanism, a sealing mechanism, a down-pressing mechanism and a fixed station 318 are arranged in the shell 15; an image acquisition device is further arranged on the machine head and comprises a face image acquisition device 18; the face image acquisition device is used for identifying the face image of a person who needs sealing and does not seal the file not meeting the sealing requirements; a file thickness detecting sensor is connected with a controller and is mounted at a seal outlet (14); and the file thickness detecting sensor is used for detecting thickness of a to-be-sealed file in real time, so that the controller adjusts the sealing intensity. According to the invention, the file thickness detecting sensor is arranged in the sealing machine to detect thickness of the to-be-sealed file in real time, so that on the basis, the sealing intensity is automatically adjusted to ensure clear sealing and stable equipment; a plurality of seals can simultaneously seal files, so that the sealing efficiency is greatly improved; and the face image acquisition device intelligently identifies the sealed file and keeps the evidence through the image processing techniques, so that the using safety of seals is improved.

Owner:山东睿星艺佰教育发展有限公司

Small invoice sealing machine

ActiveCN106064536ARealize automatic continuous stampingImprove stamping efficiencyStampingInvoiceEngineering

The invention discloses a small invoice sealing machine and belongs to the technical field of automatic office equipment. The technical problems that an existing automatic sealing machine is large in occupied area and assembly and installation are troublesome are solved. The small invoice sealing machine comprises a first conveying mechanism used for conveying first page invoices, a second conveying mechanism used for conveying second page invoices, a third conveying mechanism used for conveying third page invoices, a first diving mechanism used for driving the first conveying mechanism, the second conveying mechanism and the third conveying mechanism, a first control device used for controlling the first diving mechanism to operate intermittently, a sealing mechanism used for sealing the second page invoices and the third page invoices, a first gathering mechanism used for gathering the first page invoices, and a second gathering mechanism used for gathering the second page invoices and the third page invoices. The first gathering mechanism is located above the second conveying mechanism and the third conveying mechanism. The first conveying mechanism is arranged obliquely, and the tail end of the first conveying mechanism is higher than the head end of the first conveying mechanism.

Owner:STATE GRID ZHEJIANG JIASHAN POWER SUPPLY CO LTD +2

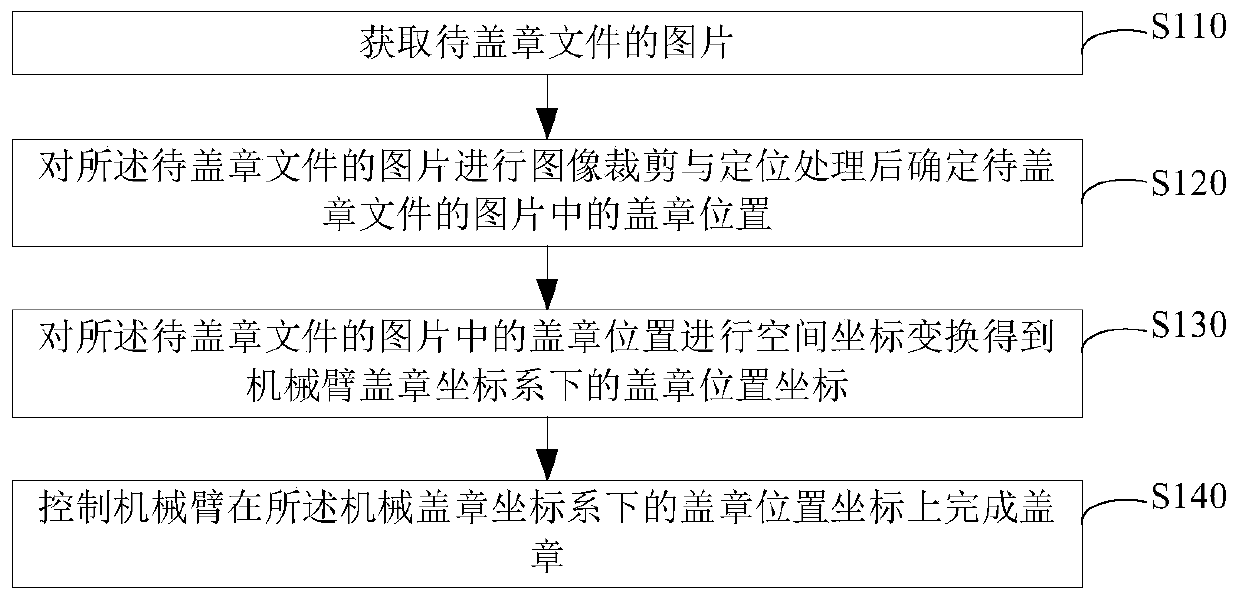

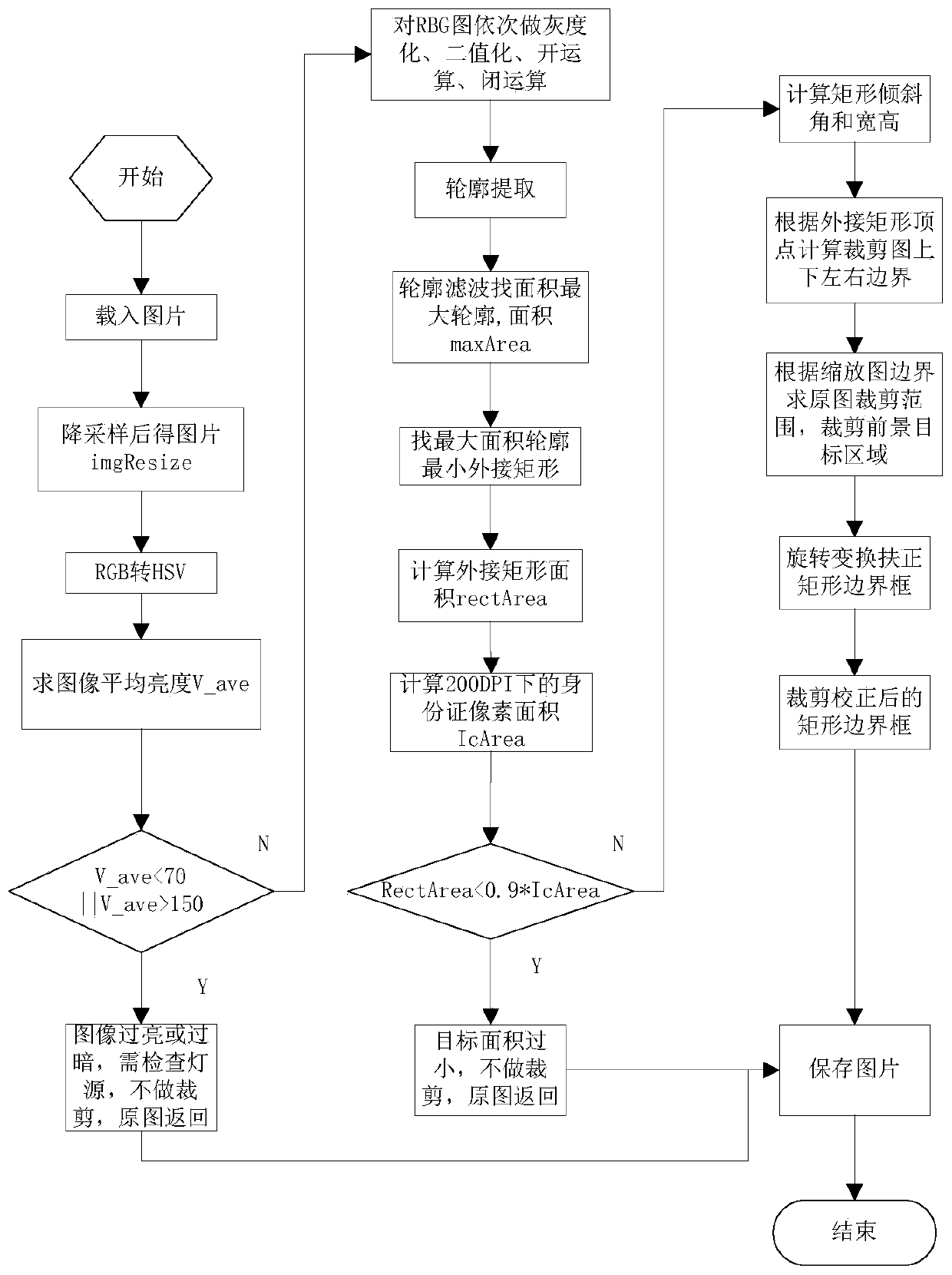

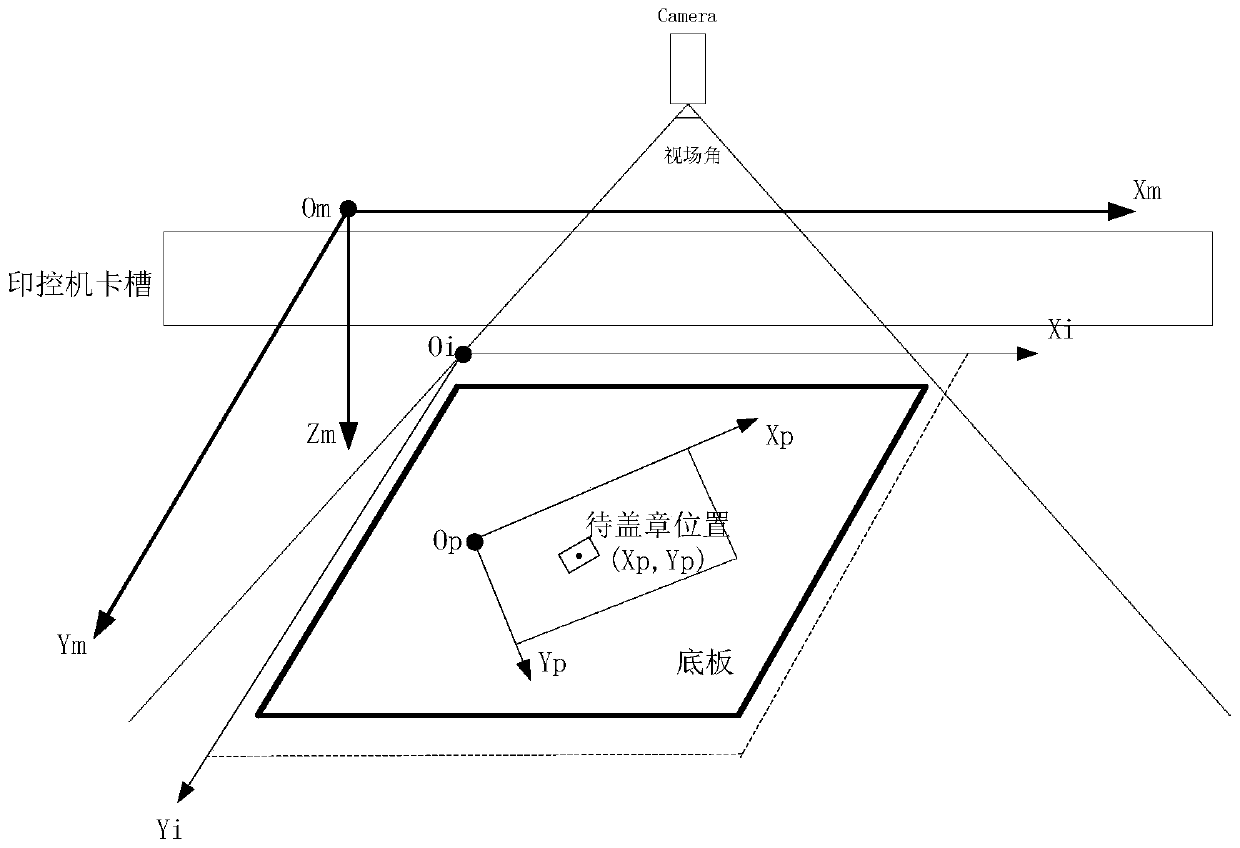

Stamping control method, device and system for stamping control machine based on image recognition

ActiveCN111284154AImprove stamping efficiencyImprove stamping accuracyImage enhancementImage analysisStampingEngineering

The invention relates to the technical field of intelligent stamping control machines, and particularly discloses a stamping control method for a stamping control machine based on image recognition. The stamping control machine comprises the following steps of acquiring a picture of a document to be stamped; cutting and positioning the picture of the document to be stamped, and determining a stamping position in the picture of the document to be stamped; performing spatial coordinate transformation on the stamping position in the picture of the document to be stamped to obtain stamping position coordinates under a mechanical arm stamping coordinate system; and controlling the mechanical arm to complete the stamping on the stamping position coordinates under the mechanical arm stamping coordinate system. The invention further discloses a stamping control device and system for the stamping control machine based on image recognition. Through the adoption of the stamping control method forthe stamping control machine based on image recognition provided by the invention, the stamping efficiency is improved, and the stamping precision is improved.

Owner:JIANGSU SUNBOON INFORMATION TECH

Material receiving device for stamping discharging

PendingCN108311607AImprove stamping efficiencyReduce manual labor intensityMetal-working feeding devicesPositioning devicesElectricityShovel

The invention discloses a material receiving device for stamping discharging. The material receiving device for stamping discharging comprises a rack. The rack is provided with a material receiving box and a material receiving driving mechanism. A material receiving shovel is connected with the power output end of the material receiving driving mechanism. The material receiving shovel is driven bythe material receiving driving mechanism to carry out forward stroke or backward stroke. The material receiving shovel extends into a press to receive materials when carrying out forward stroke, andtransfers the materials into the material receiving box when carrying out backward stroke. A first touch sensor is arranged in the center of the material receiving shovel. A second touch sensor is arranged on the material receiving box. Both the first touch sensor and the second touch sensor are electrically connected to a material receiving controller. The material receiving controller is in control connection with the material receiving driving mechanism. According to the material receiving device for stamping discharging, the material receiving shovel is driven by the material receiving driving mechanism to extend into the press to receive the formed stamping parts and transfer the stamping parts into the material receiving box, the material taking of the stamping parts of the press iscompleted in a full automatic manner, and after the material receiving device of stamping discharging is adopted for use, the stamping efficiency of the press can be improved, the manual labor intensity is reduced, and the potential safety hazards are eliminated.

Owner:SUZHOU MENGCHUAN AUTOMATION TECH

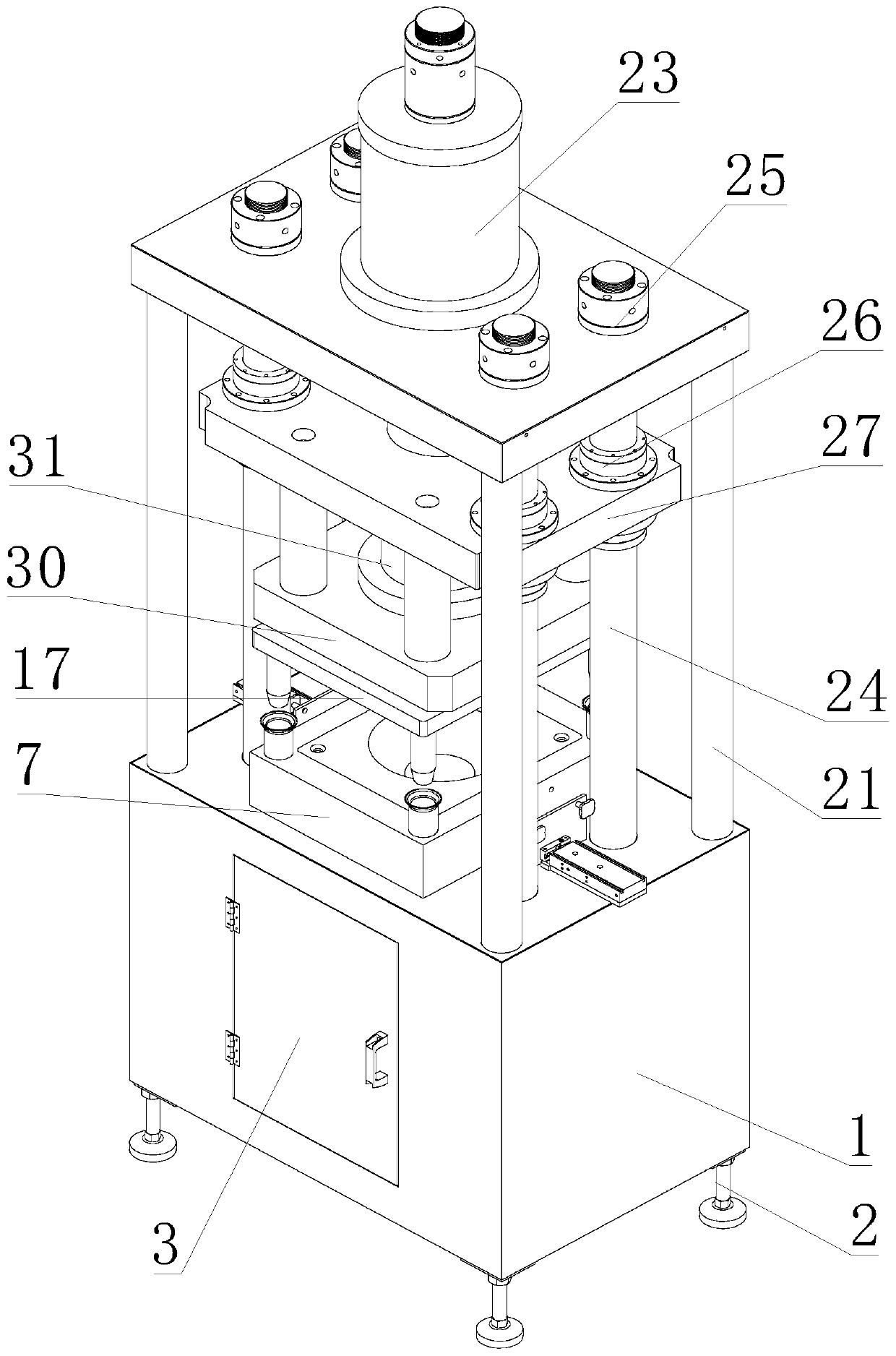

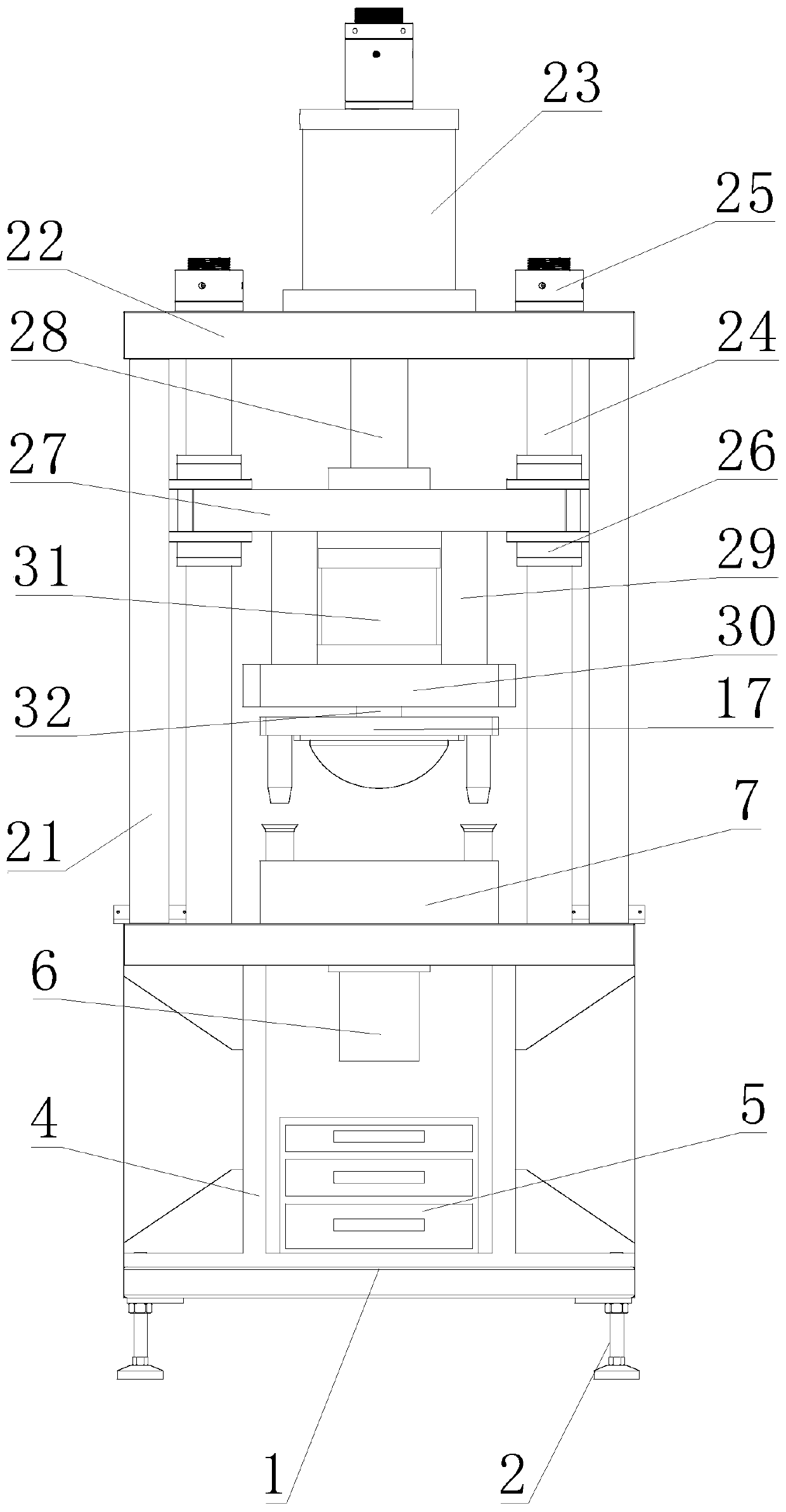

Headrest rod stamping die

ActiveCN104759531AImprove stamping efficiencyReduce manufacturing costShaping toolsStripping-off devicesSmall footprintEngineering

The invention provides a headrest rod stamping die. The headrest rod stamping die comprises an upper die (1) and a bottom die (2), wherein the lower die (2) comprises a left movable module (21) and a right movable module (22); a positioning hole (211) conforming to the shape of a headrest rod workpiece is formed in the left movable module (21); a lower half groove (221) coaxial with the positioning hole (211) of the left movable module (21) and conforming to the shape of the headrest rod workpiece is formed in the right movable module (22) of the bottom die (2); a core rod assembly is further arranged on the right movable module (22). Compared with the stamping die with both the left movable module and the right movable module in the prior art, the headrest rod stamping die is simple in structure and small in floor area, and furthermore, the manufacturing cost of the die is also reduced and the headrest rod stamping efficiency is improved.

Owner:上海兴韬五金有限公司 +2

Automobile rear axle mold

ActiveCN110695217AReduce in quantityReduce production and processing costsShaping toolsEjection devicesStampingPiston rod

The invention discloses an automobile rear axle mold which includes a lower machine case, a lower die seat, a concave die body, an upper die seat, a first support column and a guide plate. A stampingsupport table is fixedly installed in the lower machine case, a plurality of sets of guide column installing holes are formed in the stamping support table, the stamping support table is fixedly provided with a first hydraulic oil cylinder, a first oil cylinder piston rod is arranged on the first hydraulic oil cylinder, and the upper end of the first oil cylinder piston rod slides to extend out ofthe upper surface of the stamping support table; the lower die seat is installed on the stamping support table, a demolding hole is formed in the center of the lower die seat, guide holes are formedin the four corner positions of the lower die seat, and guide sleeves are arranged on the guide holes; and the problems that an existing automobile rear axle mold is not universal, one die seat can only punch one kinds of parts, multiple different stamping dies are needed for processing of automobile rear axle parts, and consequently waste of cost is caused are solved.

Owner:柳州市锐思机械设计有限公司

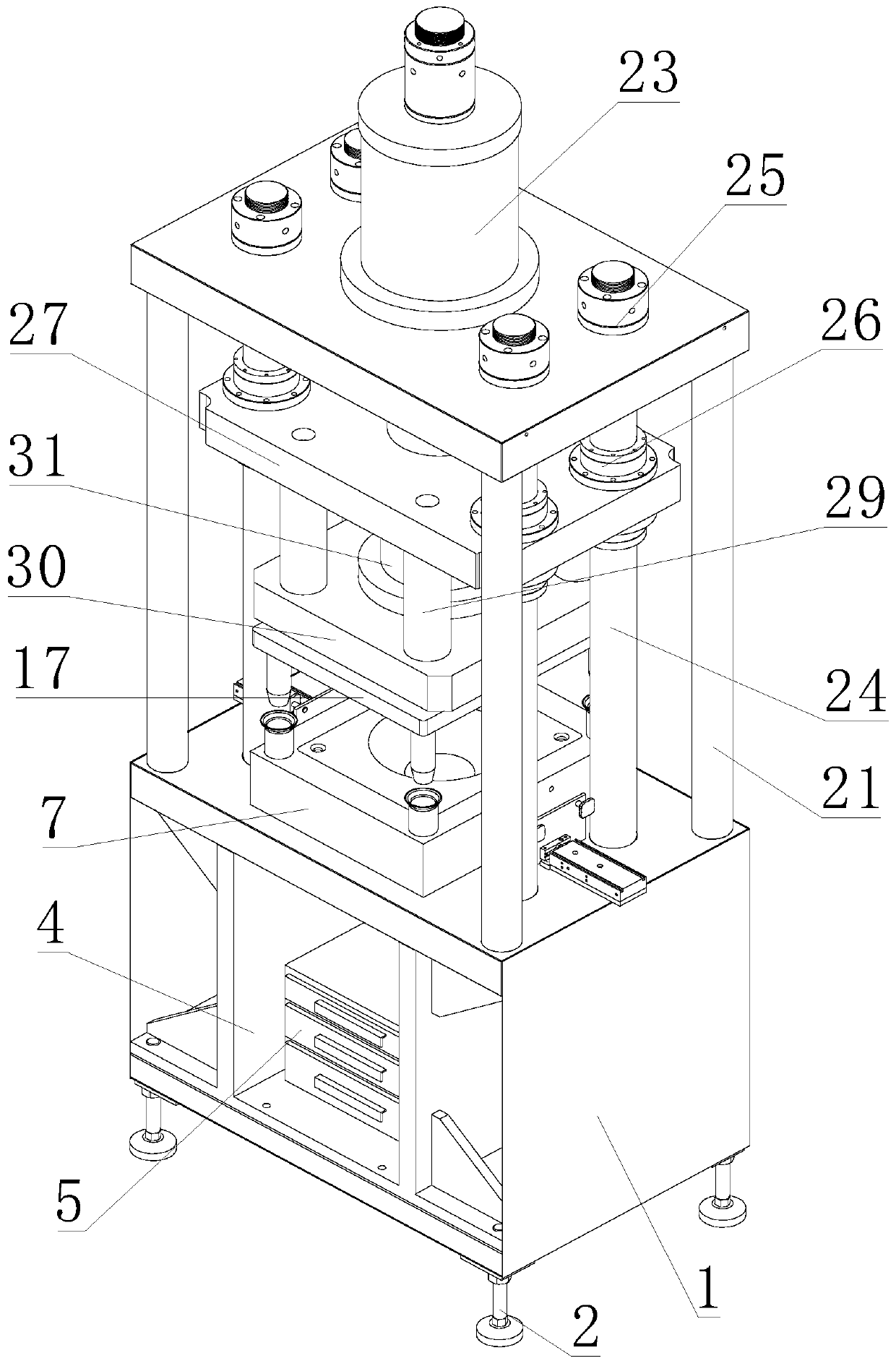

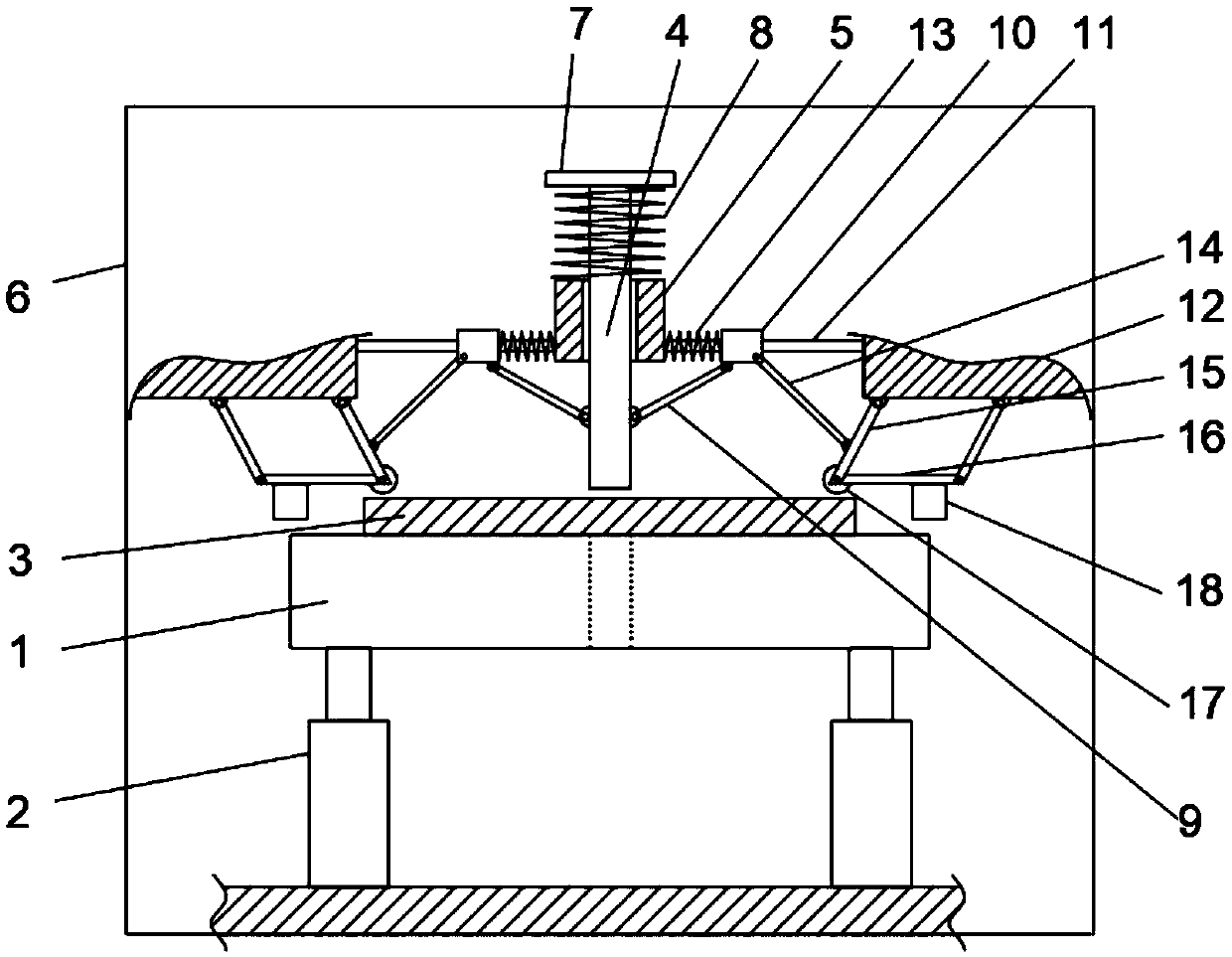

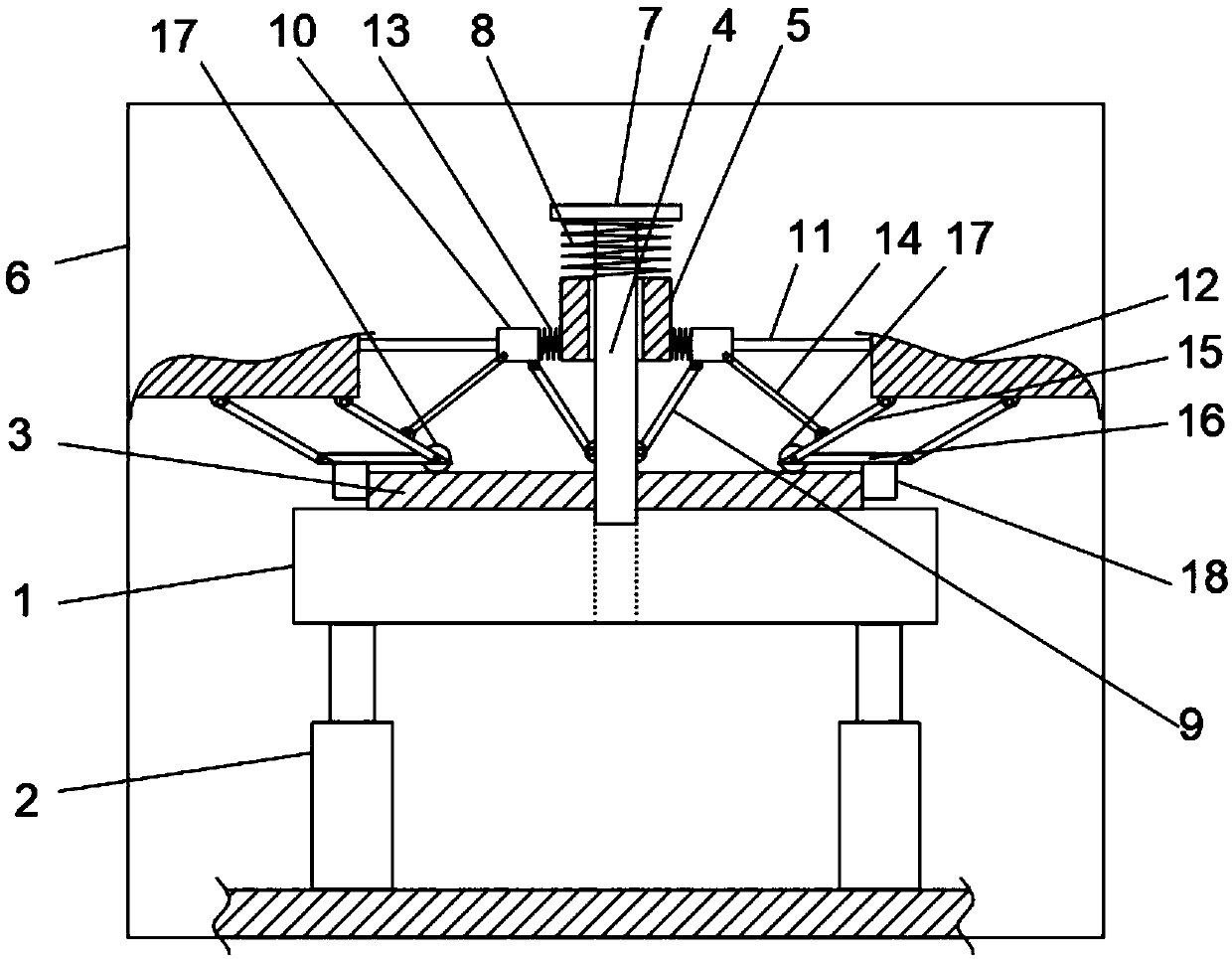

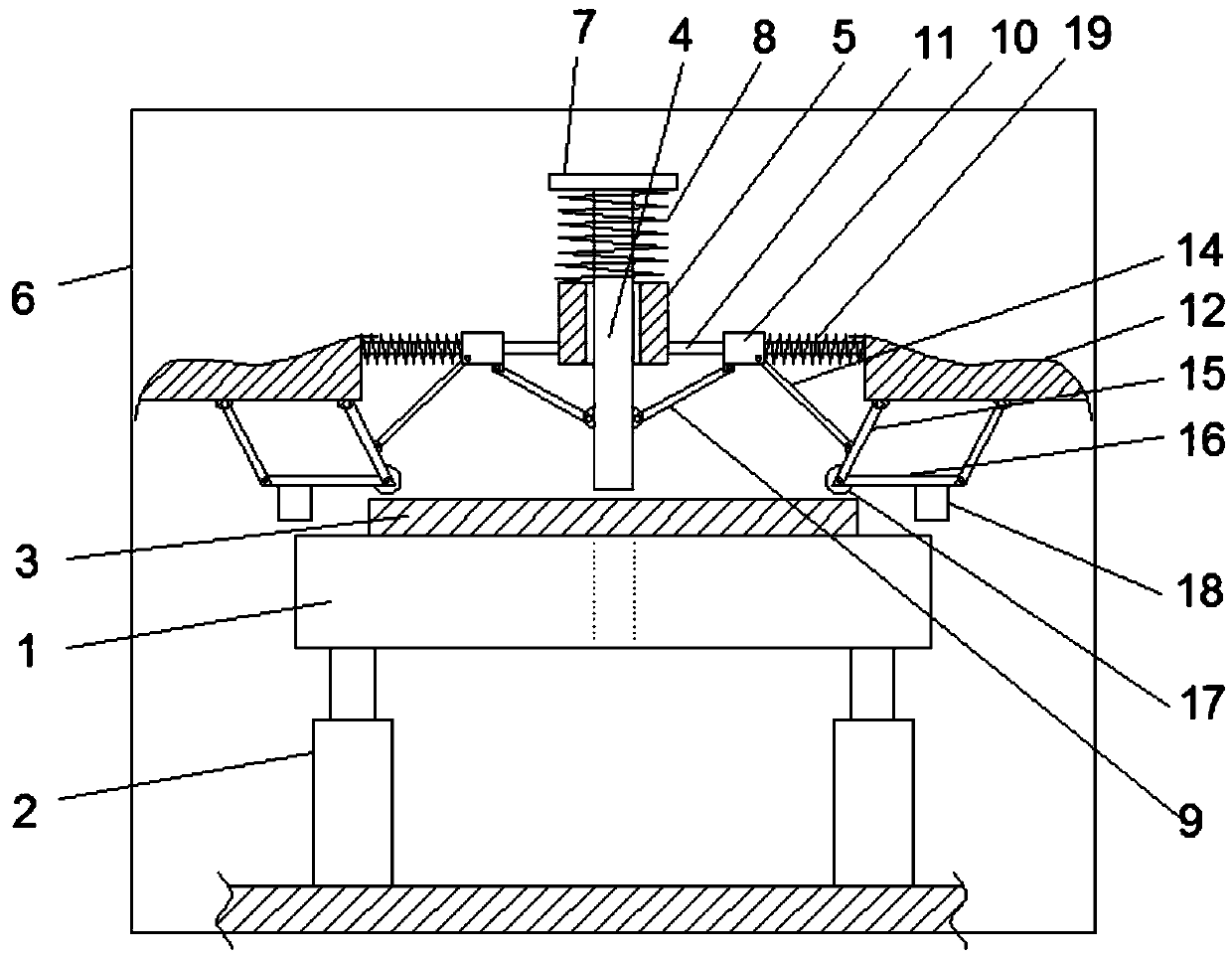

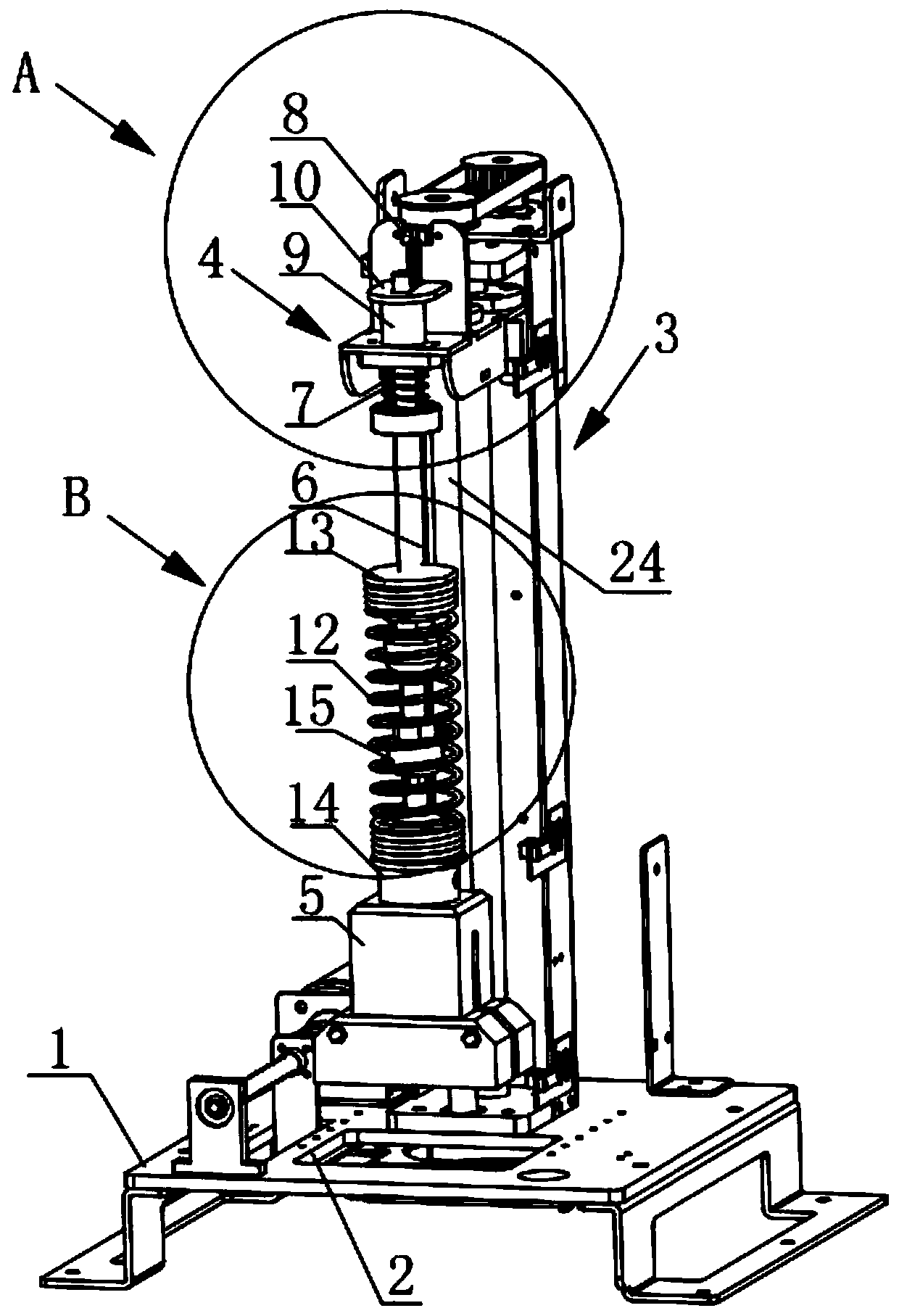

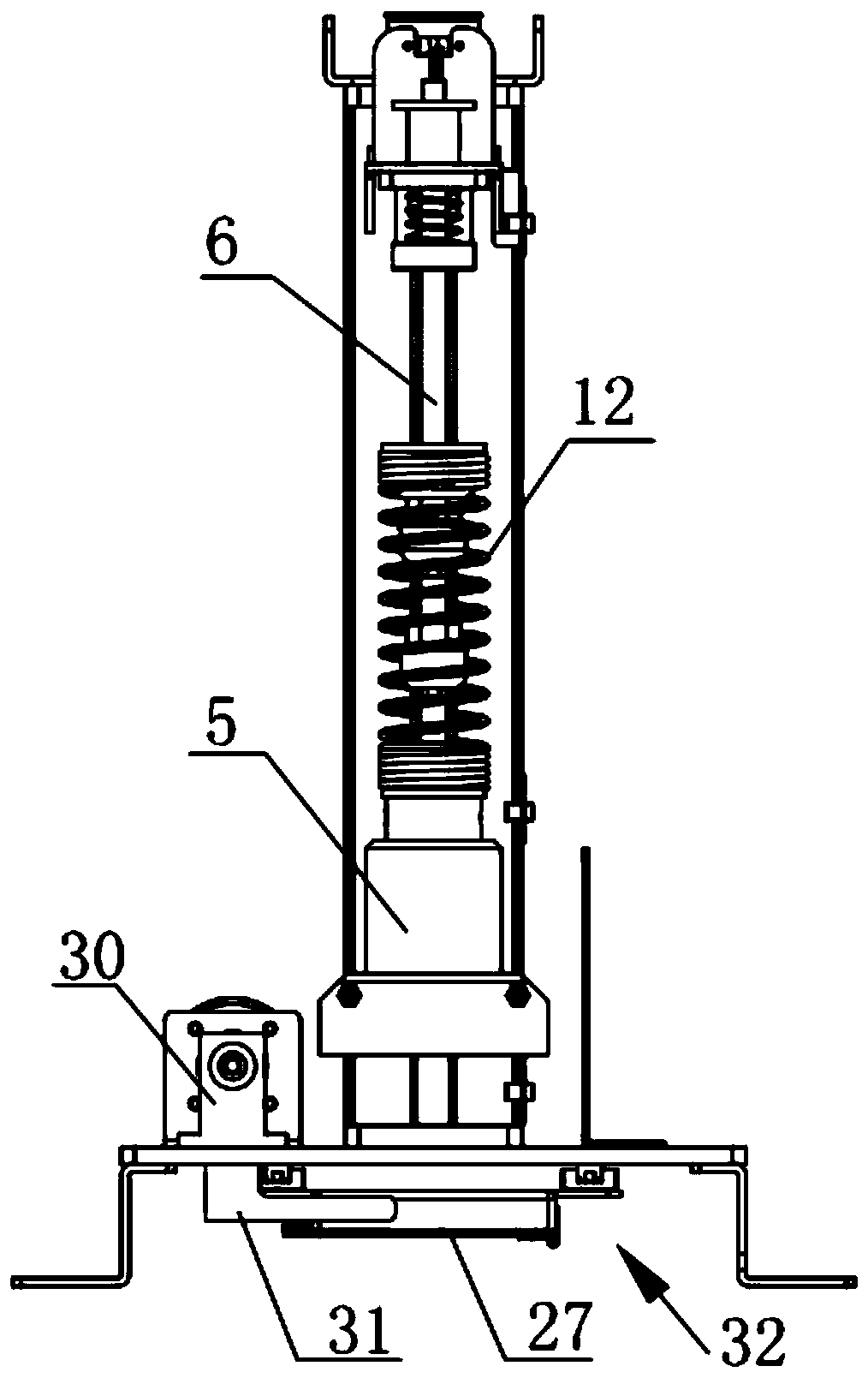

Self-pressing type hole punching device and punching method

InactiveCN108672547AIngenious and reasonable structureGuaranteed punching qualityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a self-pressing type hole punching device and a punching method. The self-pressing type hole punching device comprises a lifting workbench for bearing a punched part, a hole punching rod for punching the punched part, a locating device for clamping and locating the punched part, and a linkage device for linking the punched part and the locating device. The hole punching rod, the locating device and the linkage device are all located above the workbench, the locating device is located at the circumferential position of the hole punching rod, and the linkage device is connected with the hole punching rod and the locating device. According to the self-pressing type hole punching device and the punching method, the hole punching rod and the locating device can achieve linkage, and hole punching efficiency is improved.

Owner:陈嘉亮

Turret device for numerical control press

The invention relates to the technical field of numerical control press machining, and discloses a turret device for a numerical control press. The edge of the upper surface of a workbench is fixedlyconnected with a protection plate in the length direction, and a conveying belt is arranged on a second mounting support. The center of the edge of the upper surface of the workbench is further fixedly connected with a supporting frame. The bottom of a first mounting support is fixedly connected with anti-sliding legs. A turret assembly is clamped outside a square mounting base, and a driving assembly is arranged in the square mounting base. The turret assembly can reach higher punching frequency within identical time; meanwhile, a multi-station design manner is adopted, punching of three sections can be completed at the same time, and the punching efficiency is greatly improved; a traditional punching process is optimized, and the applicability is improved remarkably; and a worker can fast demount and mount the turret assembly through the driving assembly conveniently, the demounting and mounting time of the turret assembly is shortened, the worker can easily maintain the turret assembly and replace corresponding parts, and normal use is guaranteed.

Owner:烟台晟煊制冷设备有限公司

Full-automatic intelligent invoice seal machine

PendingCN110303782AFull Clarity GuaranteedAutomatically realize automatic oil supplyStampingMechanical pressure/force controlMechanical engineering

The invention relates to the technical field of invoice seal machines, in particular to a full-automatic intelligent invoice seal machine which comprises a working table, a displayer, a clamping component, a seal control mechanism, a first detecting element and a controller, wherein the working table is used for carrying a to-be-sealed invoice; the displayer is used for setting and selecting working procedure; the clamping component is used for clamping a seal; the seal control mechanism is used for driving the seal to move downward to finish sealing and to move upwards after sealing so as toreset the seal; the first detecting element is used for detecting the to-be-sealed invoice information; after detecting the invoice information, the first detecting element sends a signal to the controller; and the controller receives the signal of the detecting element and sends the signal to the seal control mechanism to finish sealing operation. The full-automatic intelligent invoice seal machine can automatically identify whether the invoice belongs to the allowable sealing range and automatically seal the invoice allowing to be sealed to greatly lower the manual labor intensity, effectively ensures the completeness and definition of each sealing, automatically supplies ink to a seal, and effectively improves the sealing efficiency and sealing quality.

Owner:青岛方天科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com