Headrest rod stamping die

A technology for stamping die and headrest rod, which is applied in the field of molds for rolling adjustment grooves on headrest rods, can solve the problems of complex processing process and low precision of opening grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the headrest rod processing mold of the present invention, a specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings and actual working conditions.

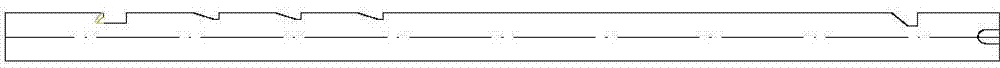

[0025] Figure 1a It is a schematic diagram of the structure of the headrest rod before molding, Figure 1b It is a schematic diagram of the structure of the headrest rod after forming. The headrest rod stamping die of the present invention is to realize the headrest rod workpiece by Figures 1a to 1b processing. The specific shape and number of the grooves on the headrest rod are determined by the actual requirements. It can be formed as the groove shown in the figure, or formed into grooves of other suitable shapes.

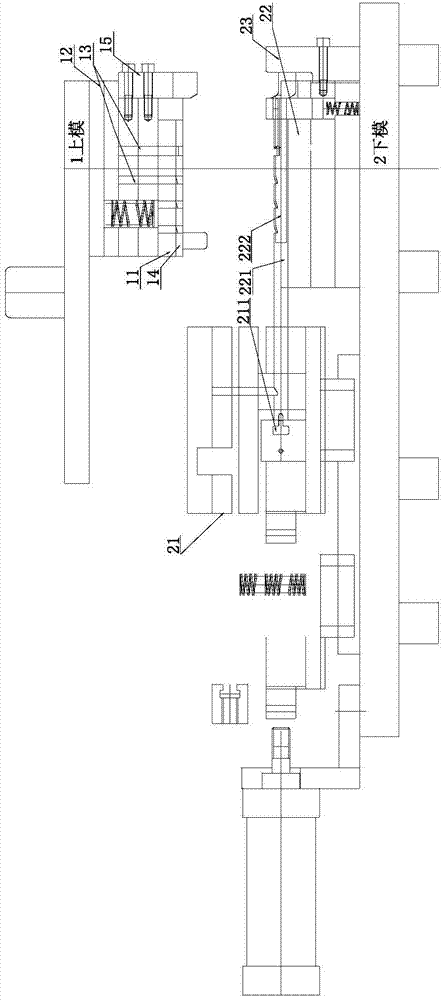

[0026] Such as Figure 2 to Figure 3 As shown, the headrest bar stamping die of the present invention includes an upper mold 1 and a lower mold 2, and the upper mold 1 includes a stripping plate 11, a stampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com