Material receiving device for stamping discharging

The technology of a material receiving device and a material receiving box, which is applied to the feeding device, positioning device, storage device and other directions, can solve the problems of the equipment not running continuously, the stamping efficiency, the hidden danger of safety, and the high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

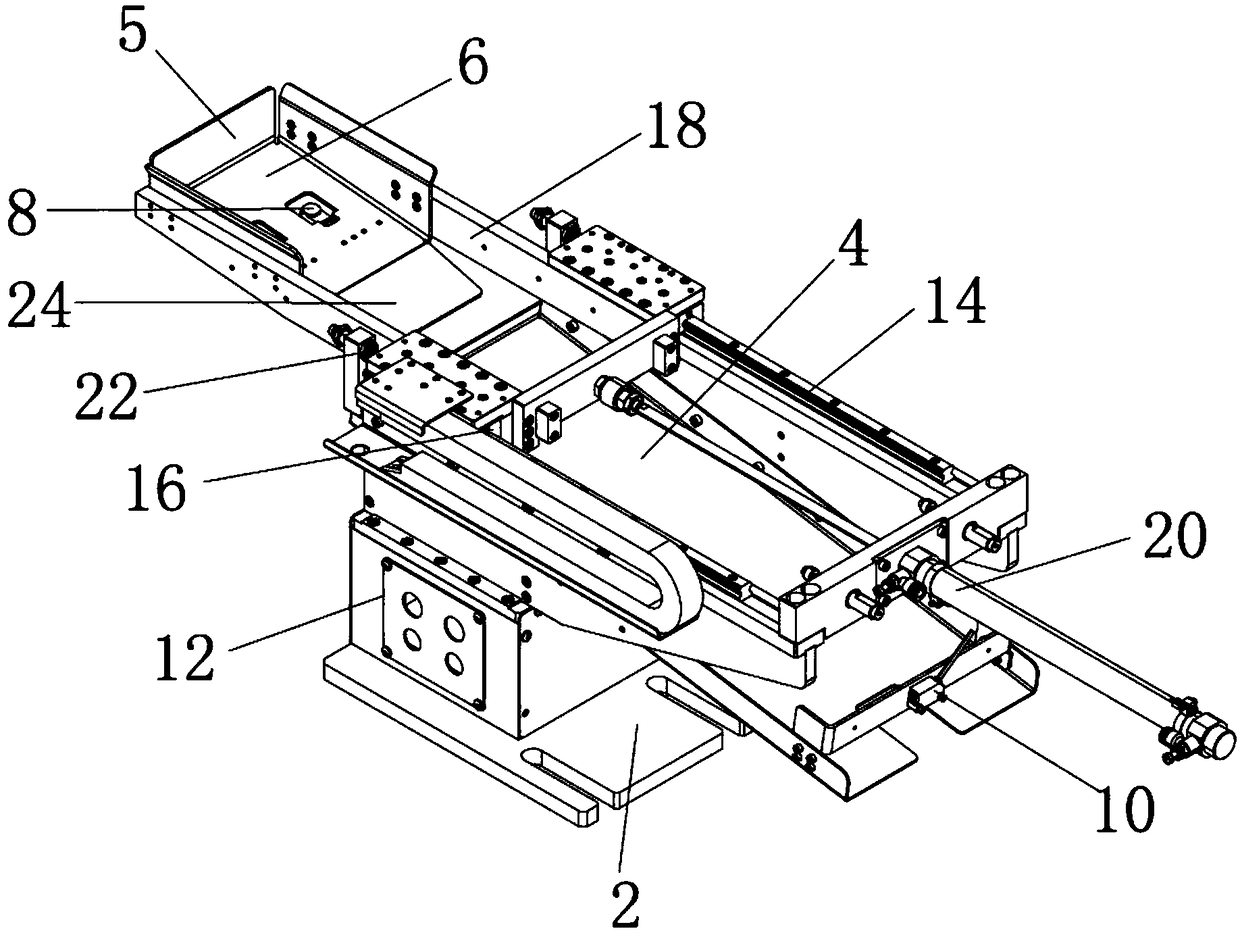

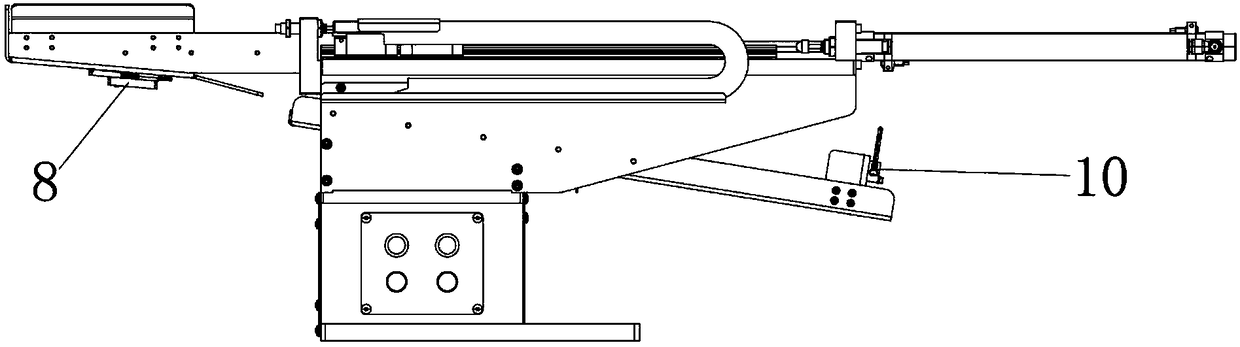

[0016] Such as Figure 1-2 As mentioned above, this embodiment discloses a material receiving device for stamping and discharging, including a frame 2, on which a material receiving box 4 and a material receiving drive mechanism are arranged, and the power output end of the above material receiving drive mechanism is connected to There is a material receiving shovel 6, and the above-mentioned material receiving driving mechanism drives the material receiving shovel 6 to progress or retreat, and the above-mentioned material receiving shovel 6 is inserted into the press to receive materials during the process, and the material is transferred to the above-mentioned material receiving box 4 when it is retracted . Surroundings 5 are provided around the above-mentioned material receiving shovel 6, and the surrounding plate 5 on one side of the material receiving box 4 is inclined downward relative to the horizontal plane to form a material guide plate 24. The downwardly inclined e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com