Turret device for numerical control press

A technology for CNC punching machines and turrets, which is applied in the field of turret devices for CNC punching machines, can solve problems affecting actual use, low punching efficiency, and inconvenient disassembly and assembly, and achieve the effects of ensuring normal use, improving applicability, and improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

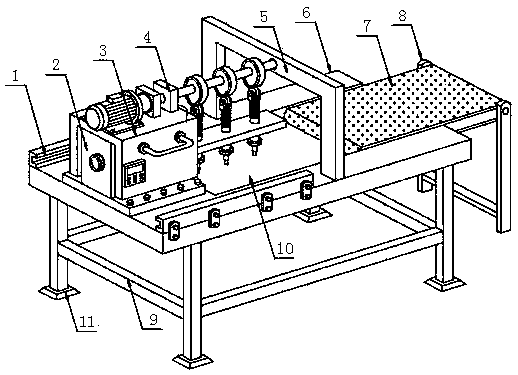

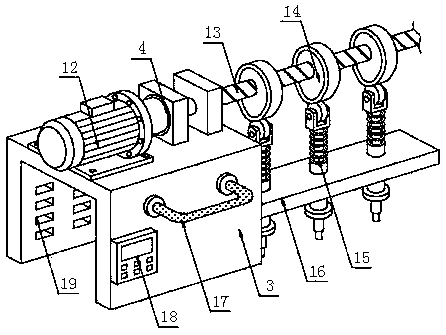

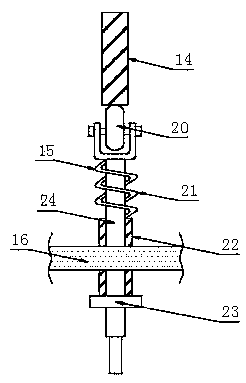

[0024] see Figure 1~5 , in an embodiment of the present invention, a turret device for a numerically controlled punching machine, comprising a workbench 6, the lower surface of the workbench 6 is fixed with a first mounting bracket 9, and the center of the upper surface of the workbench 6 along its length direction From left to right, a square mounting seat 2 and a placement groove 10 are fixed in sequence, and a protective plate 1 is fixed on the edge of the upper surface of the workbench 6 along its length direction, and one side of the workbench 6 is provided with a second installation Support 8, the second mounting bracket 8 is provided with a conveyor belt 7, the center of the upper surface edge of the workbench 6 is also affixed with a support frame 5, the bottom of the first mounting bracket 9 is affixed with anti-skid feet 11, the square mounting seat 2 The turret assembly 4 is clamped on the outside, and the turret assembly 4 includes a fixed seat 3, a motor 12, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com