CNC punch array die installation structure

A technology of CNC punching machine and installation structure, which is applied to forming tools, manufacturing tools, safety equipment, etc., can solve the problems affecting the working efficiency of punching machines, the service life of punching energy consumption and die changing structure, the damage of telescopic drive components, and the large energy consumption of CNC punching machines, etc. problem, to achieve the effect of simple structure, increased weight and high stamping frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

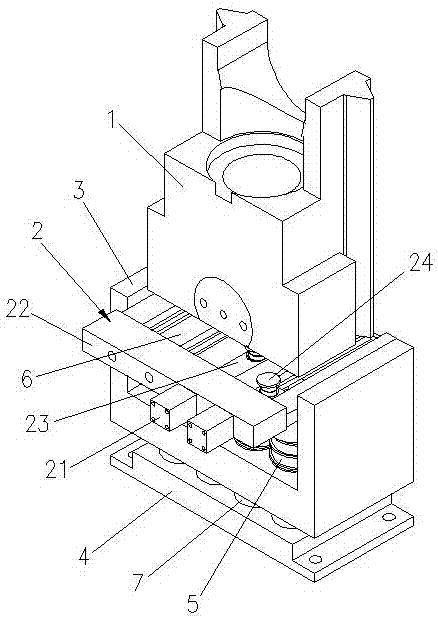

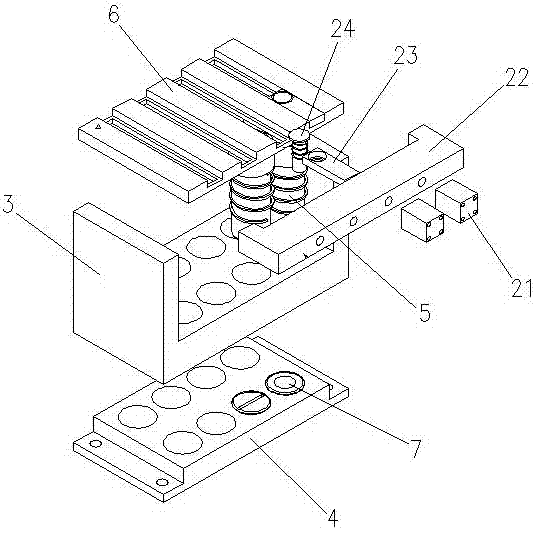

[0035] In practical application, the die changing structure 2 is installed on the upper template 3, and the piston 24 on the die changing structure 2 is arranged in the area between the punch 1 and the upper die assembly 5, and is connected with the punch 1 and the upper die assembly respectively. 5 corresponds. The telescopic drive assembly 21 is installed and fixed on the mounting base 22. One end of the telescopic drive assembly 21 is connected with the connecting piece 23, and the other end of the connecting piece 23 is sleeved with a piston 24, and the elastic assembly on the piston 24 keeps the piston 24 in position. lift up.

[0036] like Image 6 As shown, in the standby state, the punch 1 is at the highest point, and the push rod of the telescopic drive assembly 21 is in a retracted state, and the piston is outside the upper die assembly 5 and the punch 1 at this time. Assuming that the punch 1 is pressed down at this time, since the piston 24 is outside the upper d...

Embodiment 2

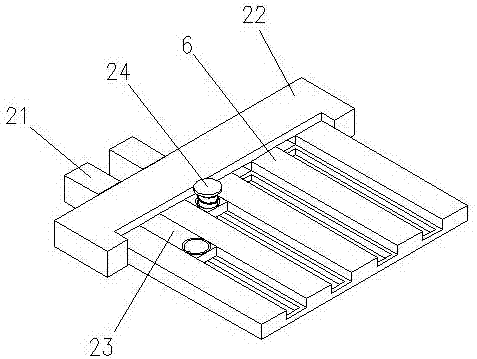

[0040] like figure 1 , figure 2 , image 3 As shown, in practical applications, the end of the piston 24 is slidably sleeved on the piston guide plate 6, and when the telescopic drive assembly 21 pushes the piston 24 to move, the piston 24 is displaced along the chute on the piston guide plate 6, thereby ensuring Accurate displacement positioning of the piston 24. At the same time, the problem of displacement of the piston 24 during the working process is prevented.

Embodiment 3

[0042] like Figure 4 , Figure 5 As shown, in practical applications, the mounting base 22 is provided with a guide hole, the guide hole runs through the mounting base 22, the shape and size of the guide hole correspond to the connector 23, and the connector 23 guides and slides in the guide hole, Thereby, the accurate displacement positioning of the piston 24 is ensured. At the same time, the problem of displacement of the piston 24 during the working process is prevented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com