Patents

Literature

153results about How to "Guaranteed punching quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

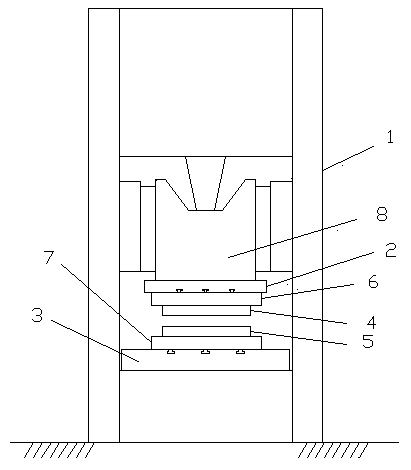

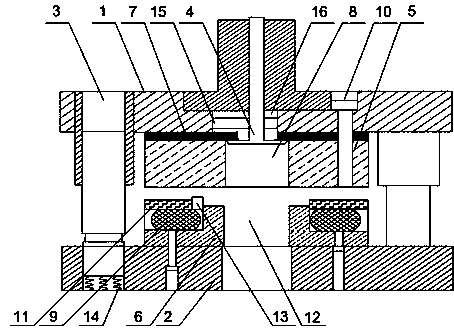

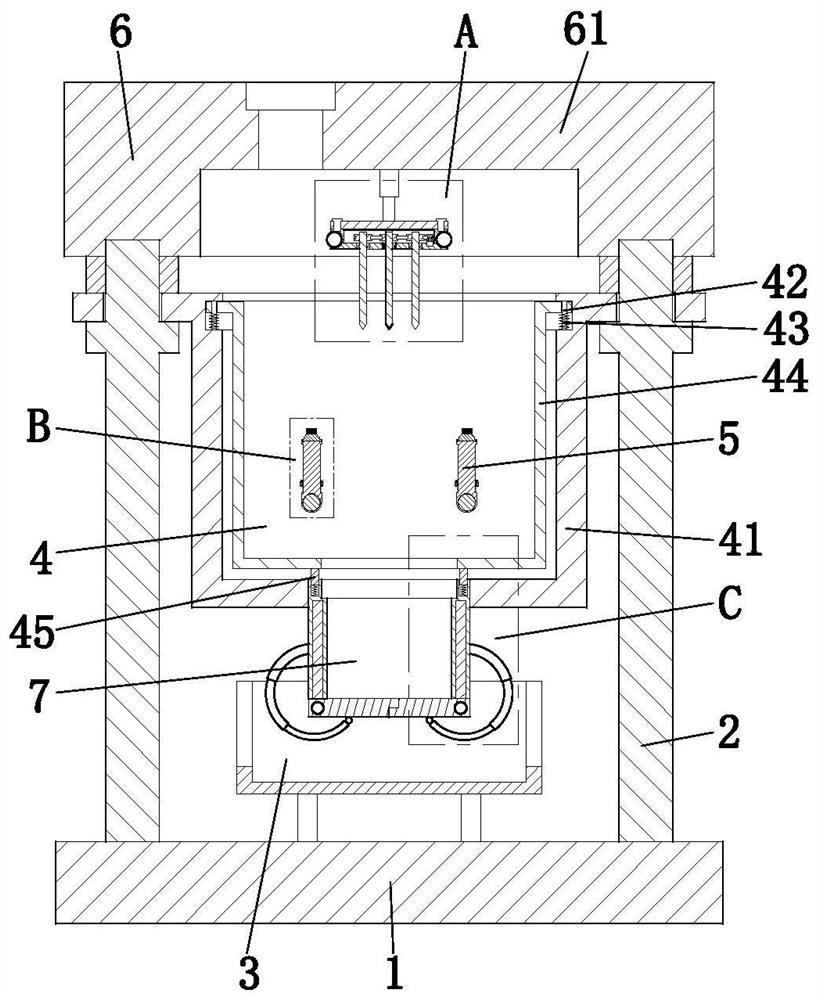

Swarf cleaning device applied to stamping die

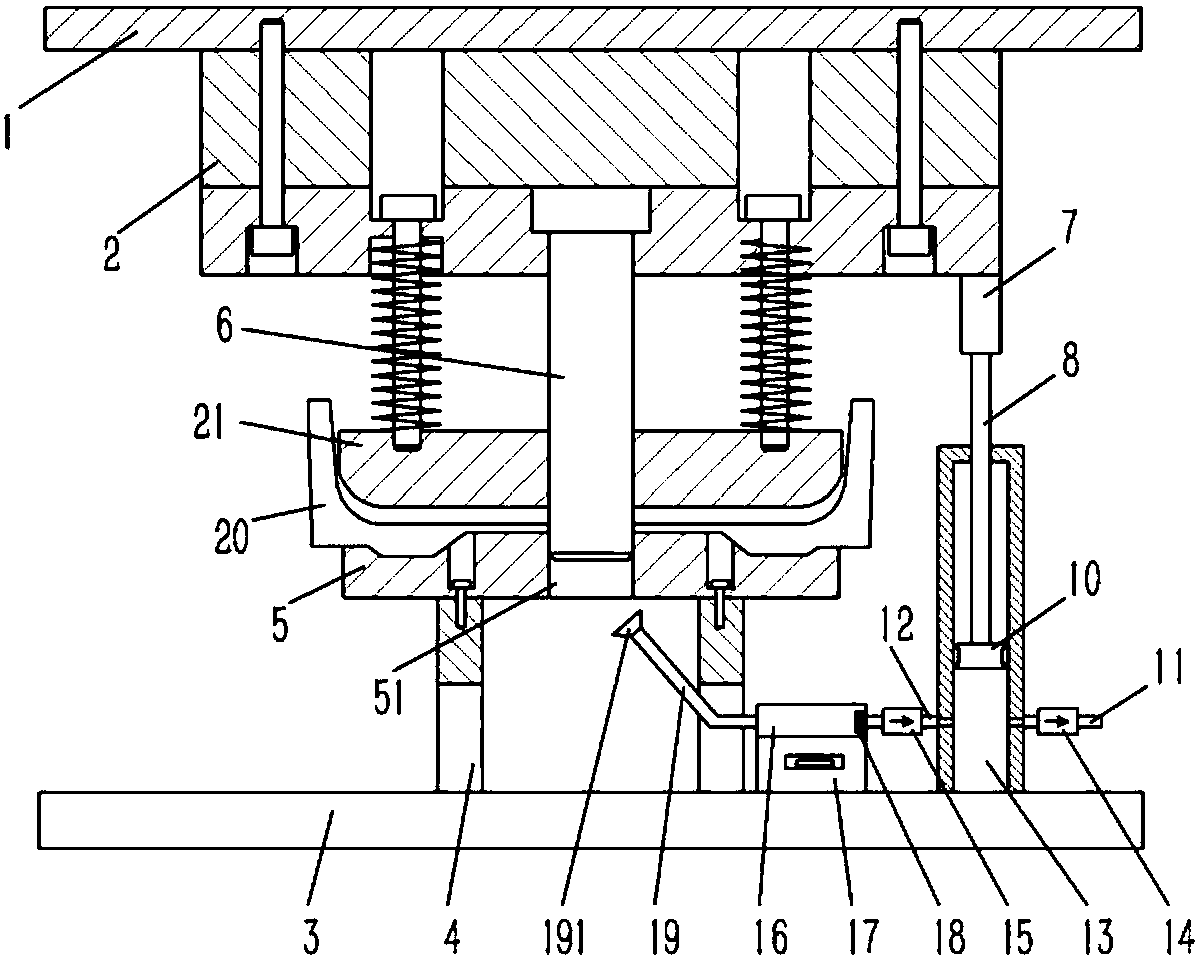

The invention discloses a swarf cleaning device applied to a stamping die. The swarf cleaning device comprises an upper die mounting plate and an upper die, the upper die is fixed on the lower end face of the upper die mounting plate, a lower die is arranged on the lower side of the upper die and fixed on stand columns, and the lower ends of the stand columns are fixed on a lower die mounting plate. A lower pressing die is arranged on the upper die and is in inserted connection with a punch, the upper end of the punch is fixed on the upper die, and a punched hole opposite to the punch is formed in the lower die. A fixed block is fixed at one side edge of the upper die, a vertical piston rod is fixed on the fixed block, a piston is fixed at the lower end of the piston rod and inserted intoan air cylinder, the lower end of the air cylinder is fixed on the lower die mounting plate, an exhaust pipe and an air suction pipe are fixed at the lower end of the air cylinder, and the air suctionpipe is fixedly connected with a swarf collection box. A dust absorption pipe is fixed on the side, back on to the air suction pipe, of the swarf collection box. The front end of the dust absorptionpipe is bent to form an inclined pipe. The swarf cleaning device can absorb swarf produced by cutting on the die, thereby reducing die abrasion and guaranteeing the blanking quality of subsequent workpieces.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

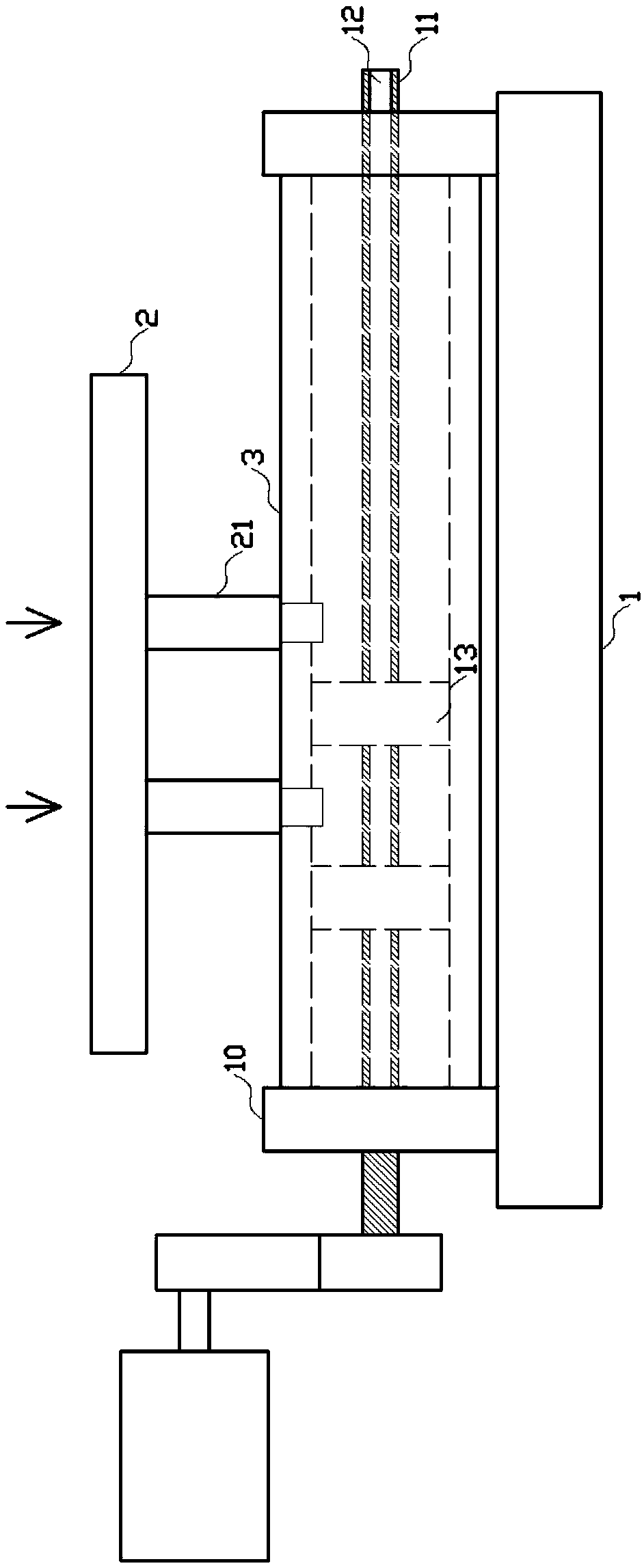

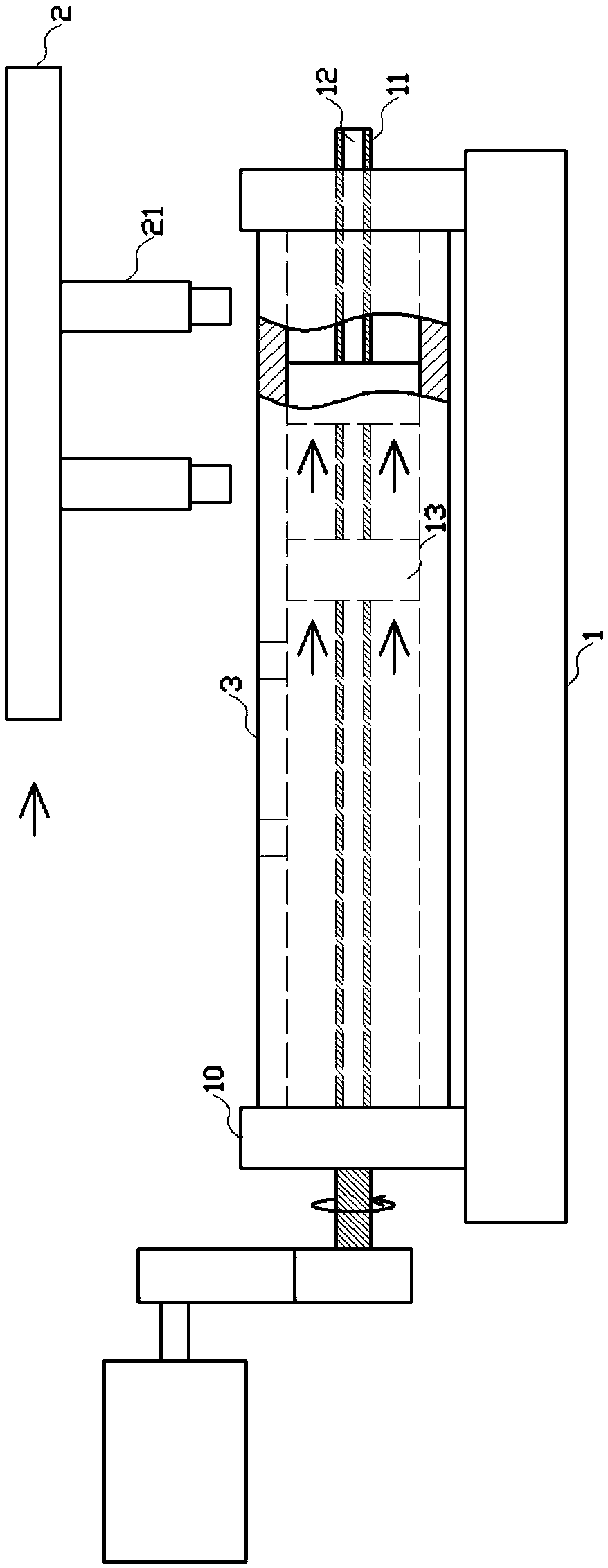

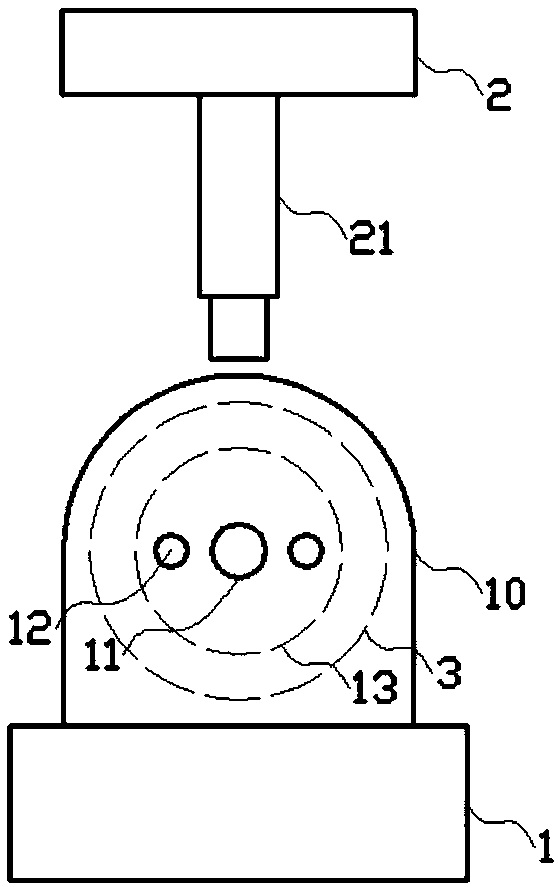

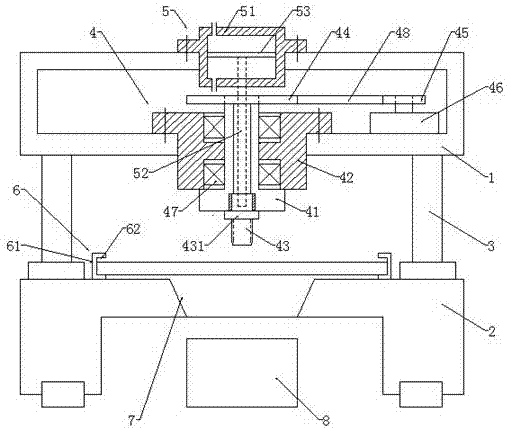

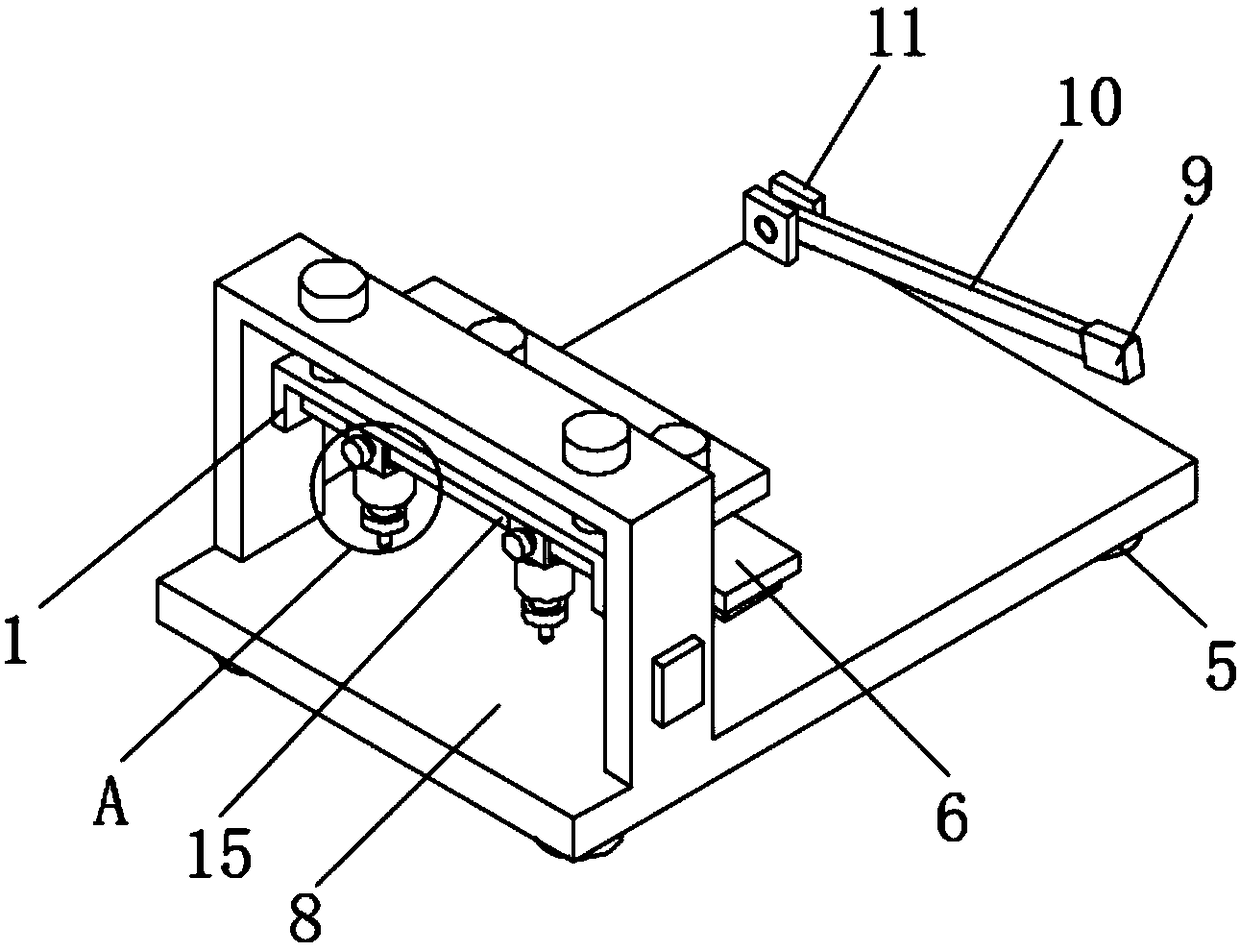

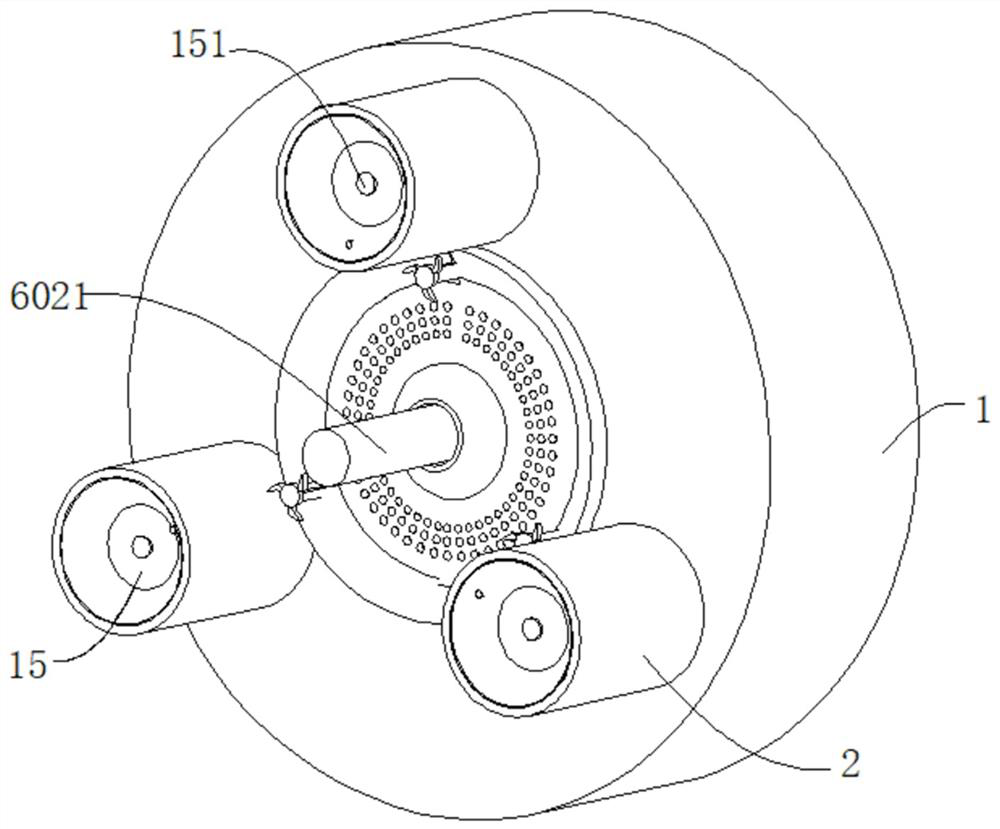

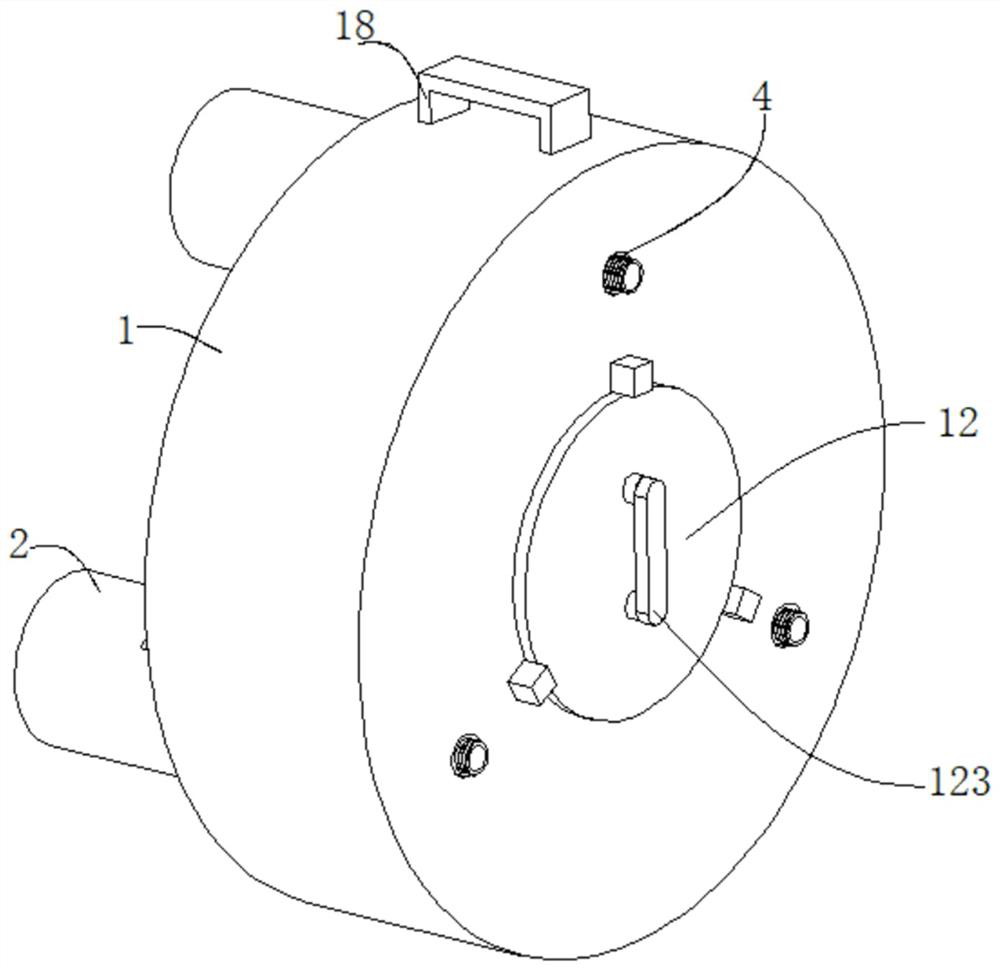

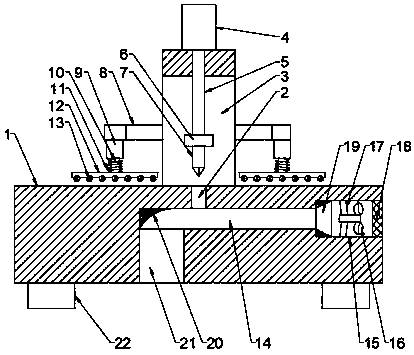

Anti-deformation tubular product punching and stamping mold

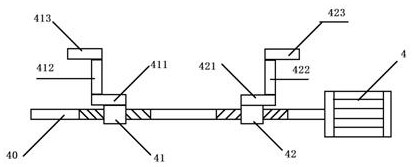

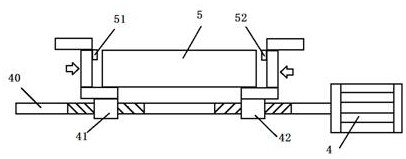

ActiveCN108620478ANo deformation or bendingGuaranteed punching qualityPerforating toolsPunchingEngineering

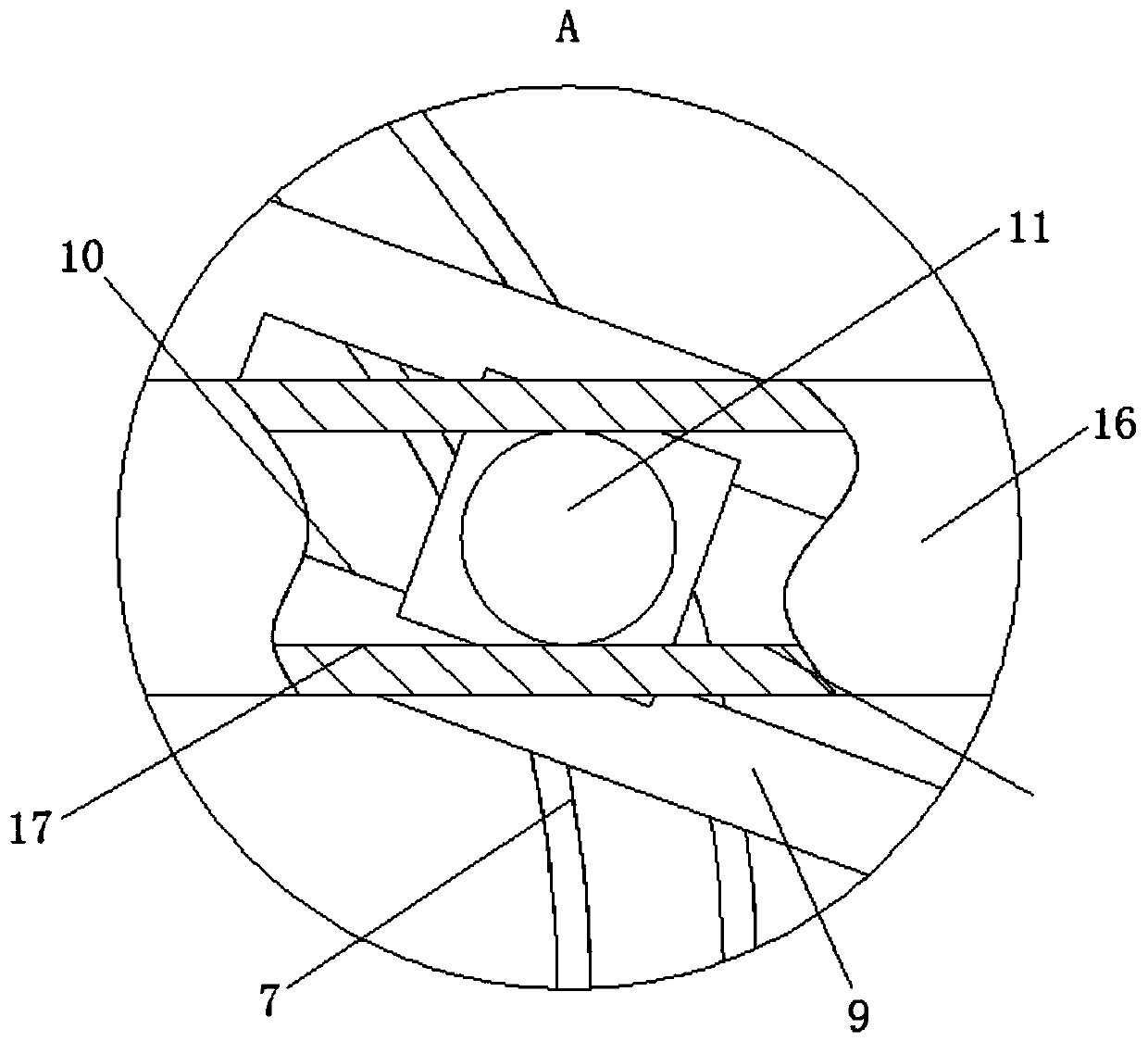

The invention provides an anti-deformation tubular product punching and stamping mold which comprises a positioning and adjusting module and a punching module, wherein the positioning and adjusting module comprises a base, a positioning base is arranged at the upper end of the base, and a fixed slot is formed in the positioning plate; a through hole is formed in the center of circle of the fixed slot, and a threaded rod is assembled in the through hole; positioning holes are formed in two sides of the through hole, and positioning bars are slidably assembled in the positioning holes; the positioning and adjusting module comprises a round supporting plate, a threaded hole is formed in the center of the supporting plate, and positioning hobbles are formed in two sides of the threaded hole. The anti-deformation tubular product punching and stamping mold is structured such that a tubular product in punching process has an enough supporting force to prevent deformation by mounting a supporting structure in the tubular product; in addition, the position of the supporting structure can be adjusted corresponding to the punching position through a threaded transmission structure inside, sothat a supporting effect during porous processing is achieved.

Owner:佛山市帆睿五金有限公司

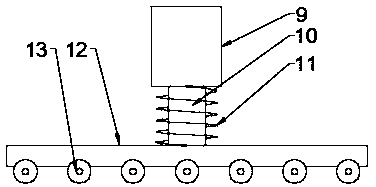

Novel, full-automatic and efficient punching machine

InactiveCN107186799AEasy to recycleRealize fully automatic punchingMetal working apparatusPunchingPiston

The invention provides a new type of fully automatic high-efficiency punching machine, which includes a frame and a workbench. It is arranged under the hole cleaning device; the hole punching device includes a rotary sleeve, a support seat, a punching head, a driven gear, a driving gear and a motor arranged on a frame; the hole cleaning device includes a cylinder and a vertical hole cleaning rod, A piston that moves up and down is arranged in the cylinder. The advantages are: the hole punching device and the hole cleaning device that cooperate with each other are adopted. When the hole punching device completes the hole punching work, the hole cleaning device can immediately and automatically push the remaining material in the hole diameter of the punching head downwards, realizing fully automatic punching. The hole is cleared, which improves the drilling efficiency and drilling quality; the drilling head is detachable and replaceable, and the drilling head of different diameters can be replaced according to the hole diameter of the drilling, which is convenient and quick; the collection box is adopted, which is convenient for cleaning Recycling of residual materials is beneficial to the recycling of residual materials and reduces costs.

Owner:盐城市天驰汽配有限公司

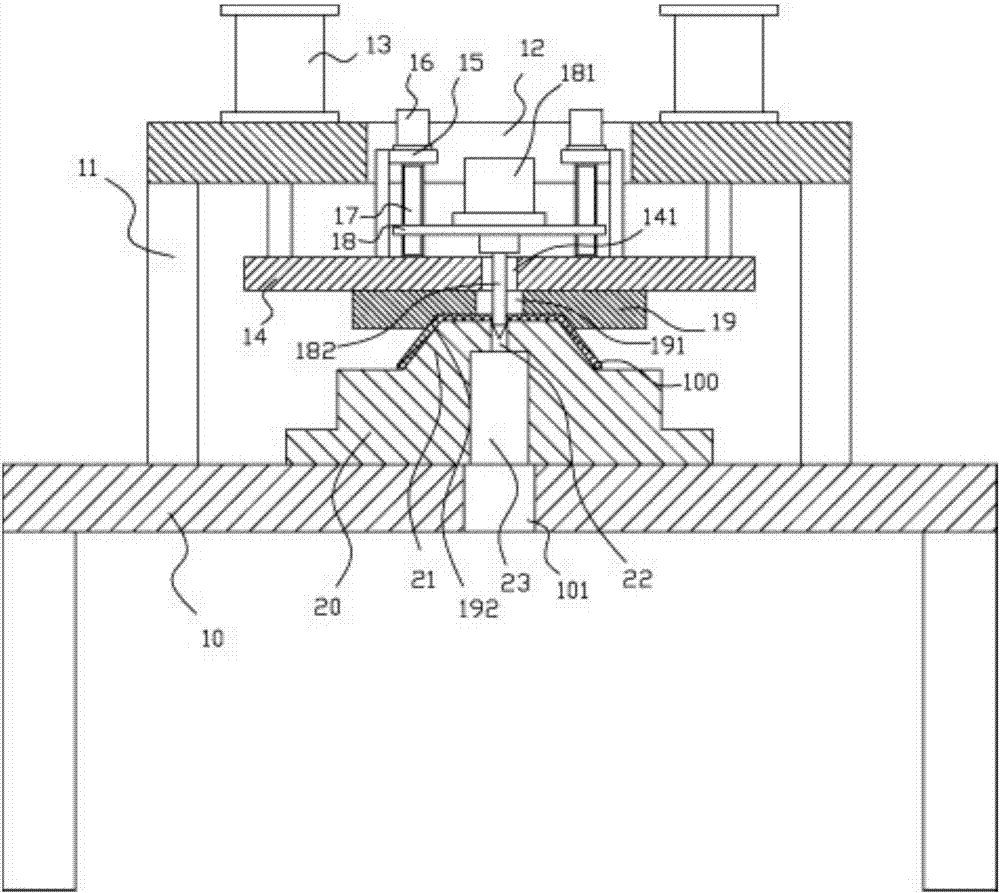

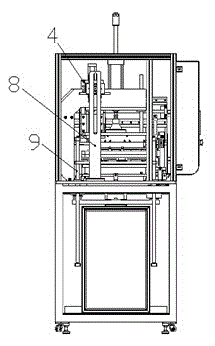

Drilling mechanism for upper shell of wire connecting box

InactiveCN107498093AGuaranteed punching qualityRealize automatic punchingBoring/drilling componentsBoring/drilling machinesEngineeringComputer engineering

The invention discloses a drilling mechanism for an upper shell of a junction box, which includes a frame, a main support frame is fixed on the top surface of the middle part of the top plate of the frame, the middle part of the top plate of the main support frame has a main through groove, and the main support frame Lifting cylinders are fixed on both sides of the top plate, the push rod of the lifting cylinder passes through the top plate of the main support frame and the upper connecting plate is fixed, the two sides of the middle top surface of the upper connecting plate are fixed with lifting support frames, and the lifting support frame The lifting motor is fixed on the top plate, the bottom end of the vertical screw is hinged on the upper connecting plate, the top end of the vertical screw is hinged on the top plate of the lifting support frame, the output shaft of the lifting motor is a spline shaft, and the spline shaft is inserted into the sleeve In the spline hole that the top of the vertical screw rod has, the lifting plate is screwed in the two vertical screw rods, and the middle top surface of the lifting plate is fixed with a drilling motor. It can fix the workpiece and ensure that its bottom and top surfaces are supported, and realize automatic drilling to ensure the quality of drilling.

Owner:FOSHAN XUNAOJIE AUTOMATION TECH CO LTD

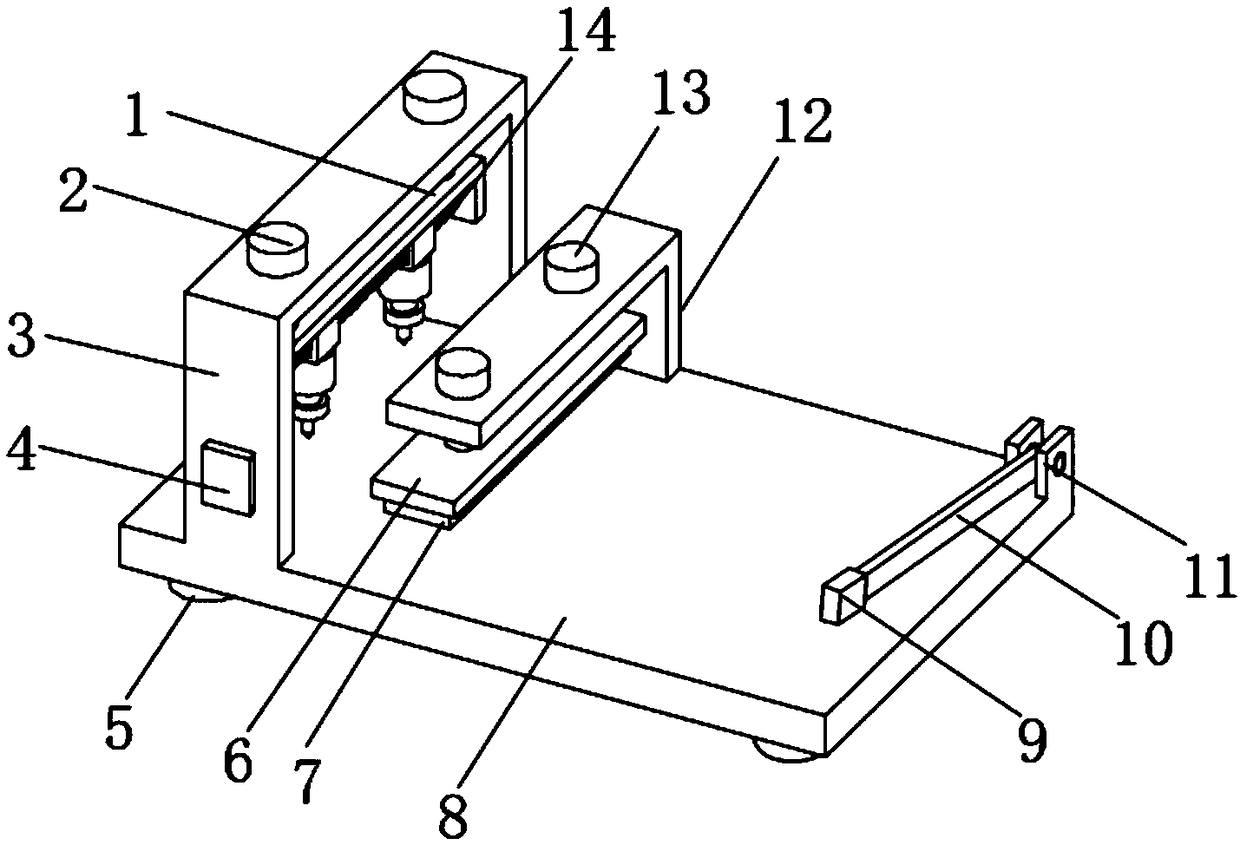

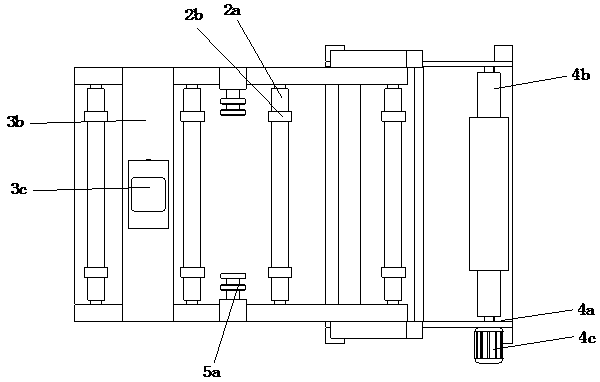

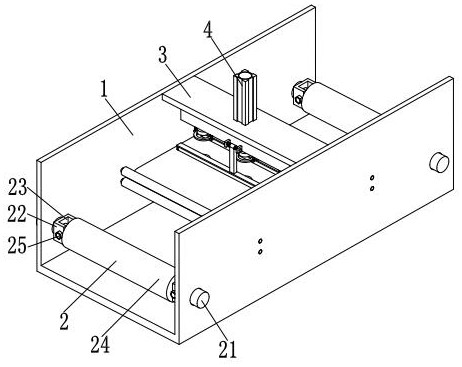

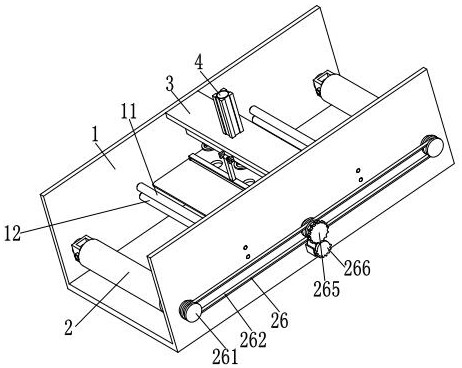

Punching device of decoration strip products

ActiveCN102649283AImprove work efficiencyReduce labor intensityMetal working apparatusAutomationPunching

The invention discloses a punching device of decoration strip products. A strip positioning base which is formed by a plurality of positioning blocks sequentially arranged at intervals and used for laying a work piece to be machined during punching is arranged on a frame; a plurality of punching components are sequentially fixed on the frame at intervals along the length direction of the positioning base; a plurality of grooves for female die seats of the punching components to be inserted into are formed on the positioning base; the height of the plane of the positioning base used for laying the work piece to be machined is level with the height of the female die seats; and simultaneously a discharging component which can discharge a machined work piece from one side of the positioning base and a guiding component which is positioned on the other side of the positioning base and used for laying the work piece to be machined before being punched are also arranged on the frame. The punching device can clamp the strip work piece and punch different positions on the work piece in sequence, is not required to perform multiple position adjustment on the strip work piece, also has the automation and manual combined discharging component, not only improves the operating efficiency and reduces the labor intensity, but also guarantees the safety in production and improves the machining accuracy.

Owner:NINGBO XINTAI MACHINERY

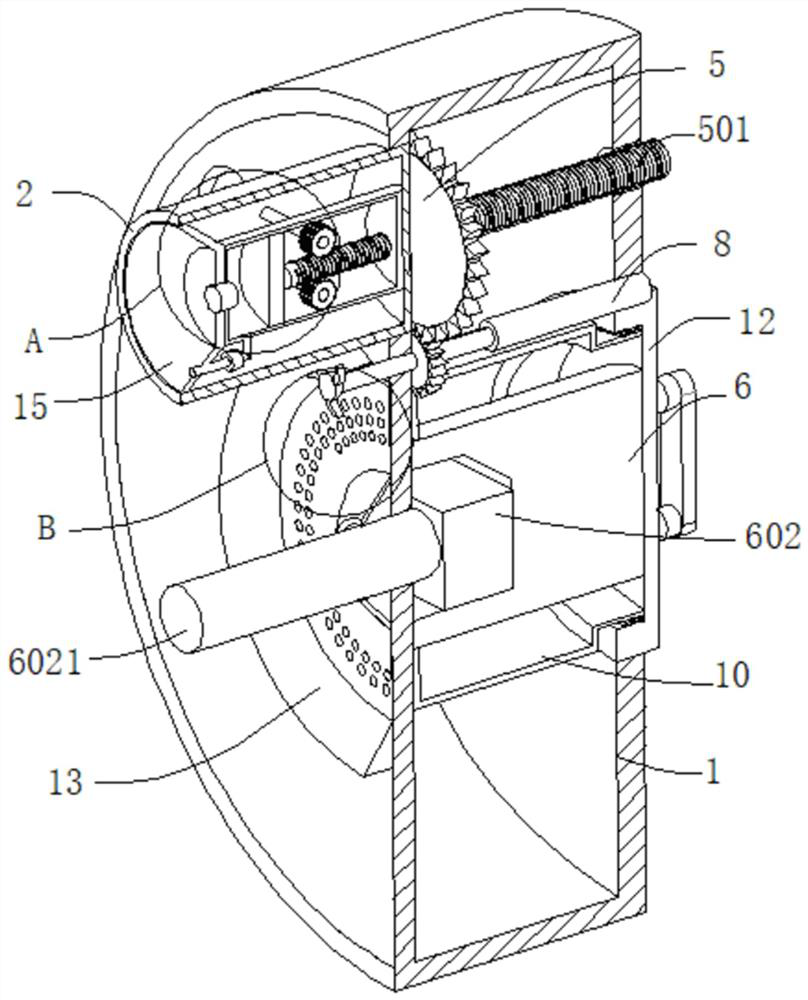

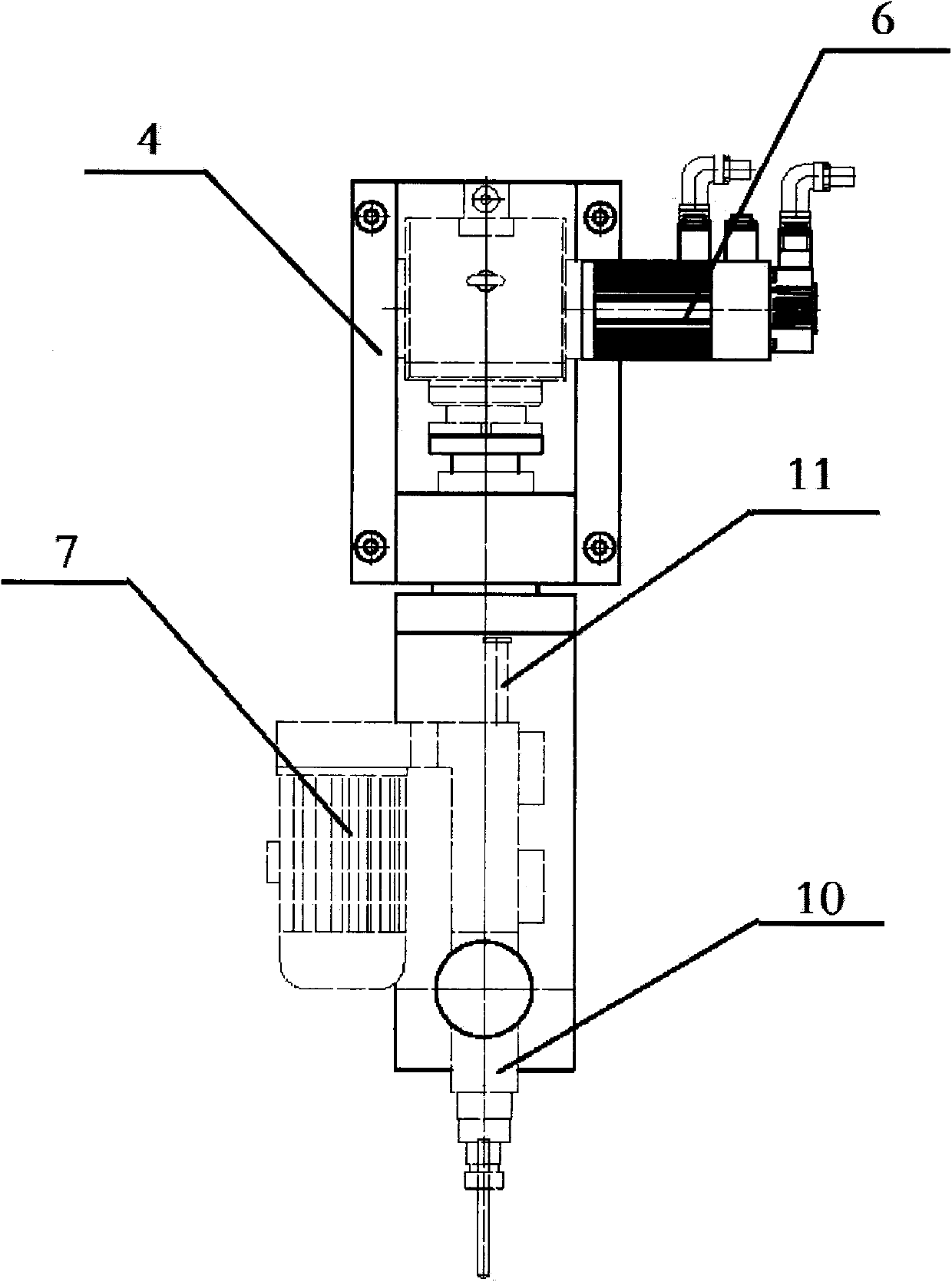

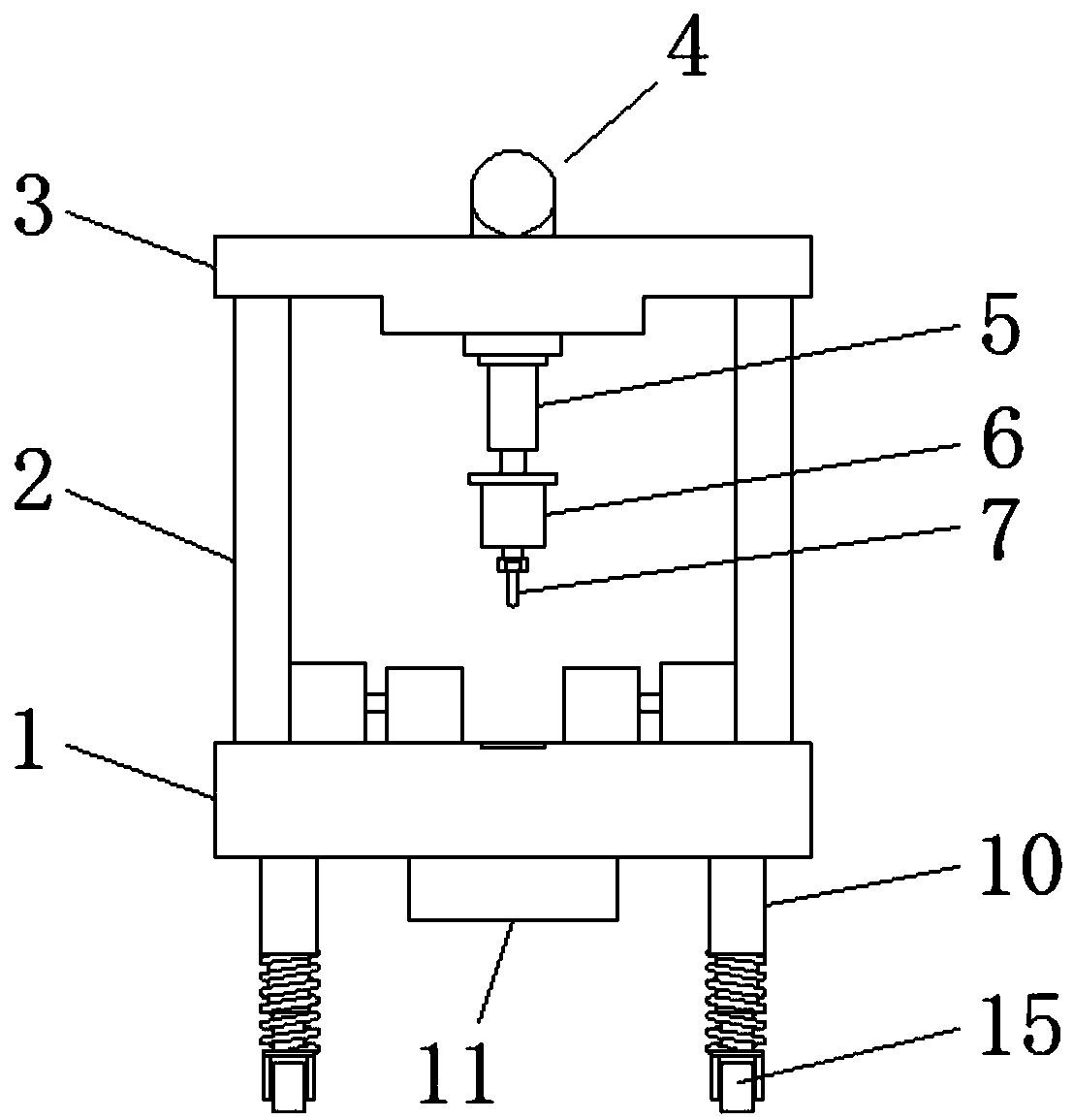

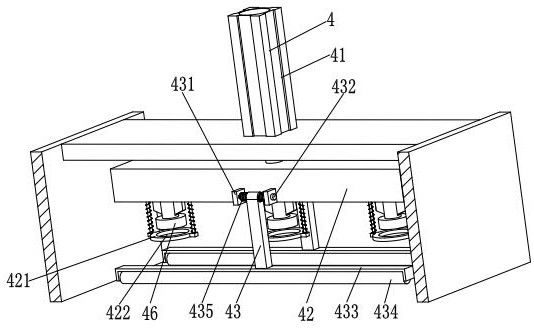

Self-pressing type hole punching device and punching method

InactiveCN108672547AIngenious and reasonable structureGuaranteed punching qualityPerforating toolsMetal-working feeding devicesPunchingEngineering

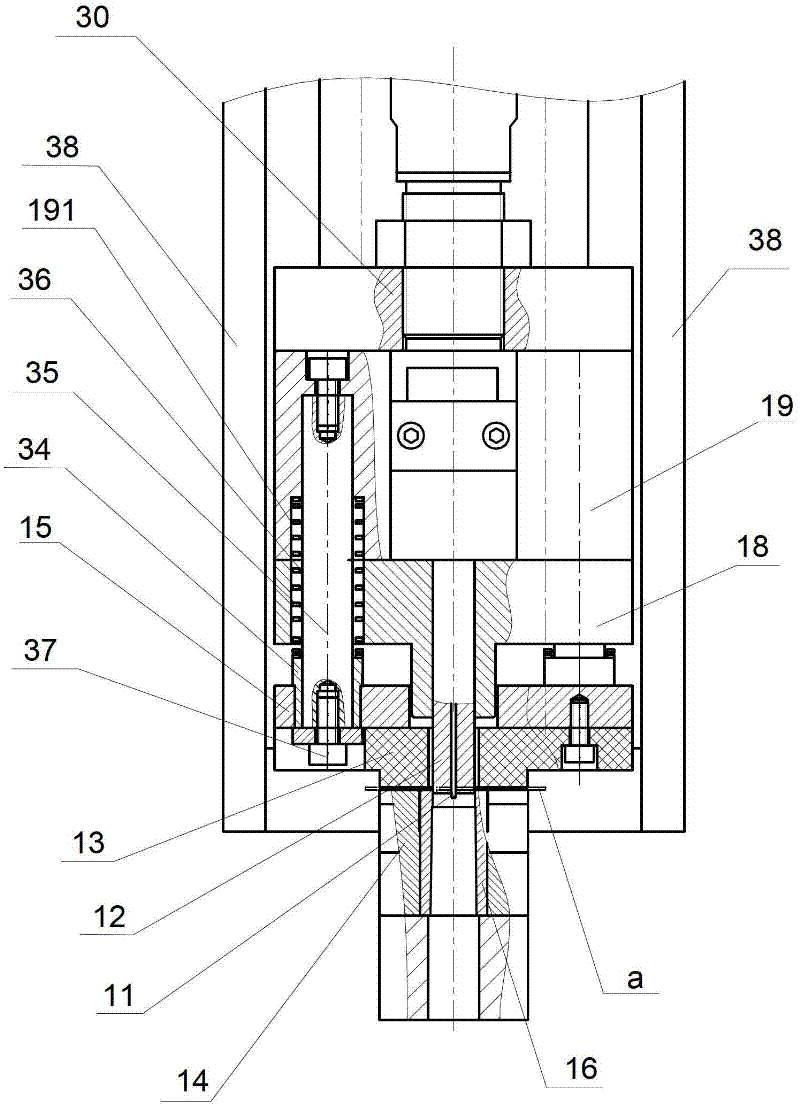

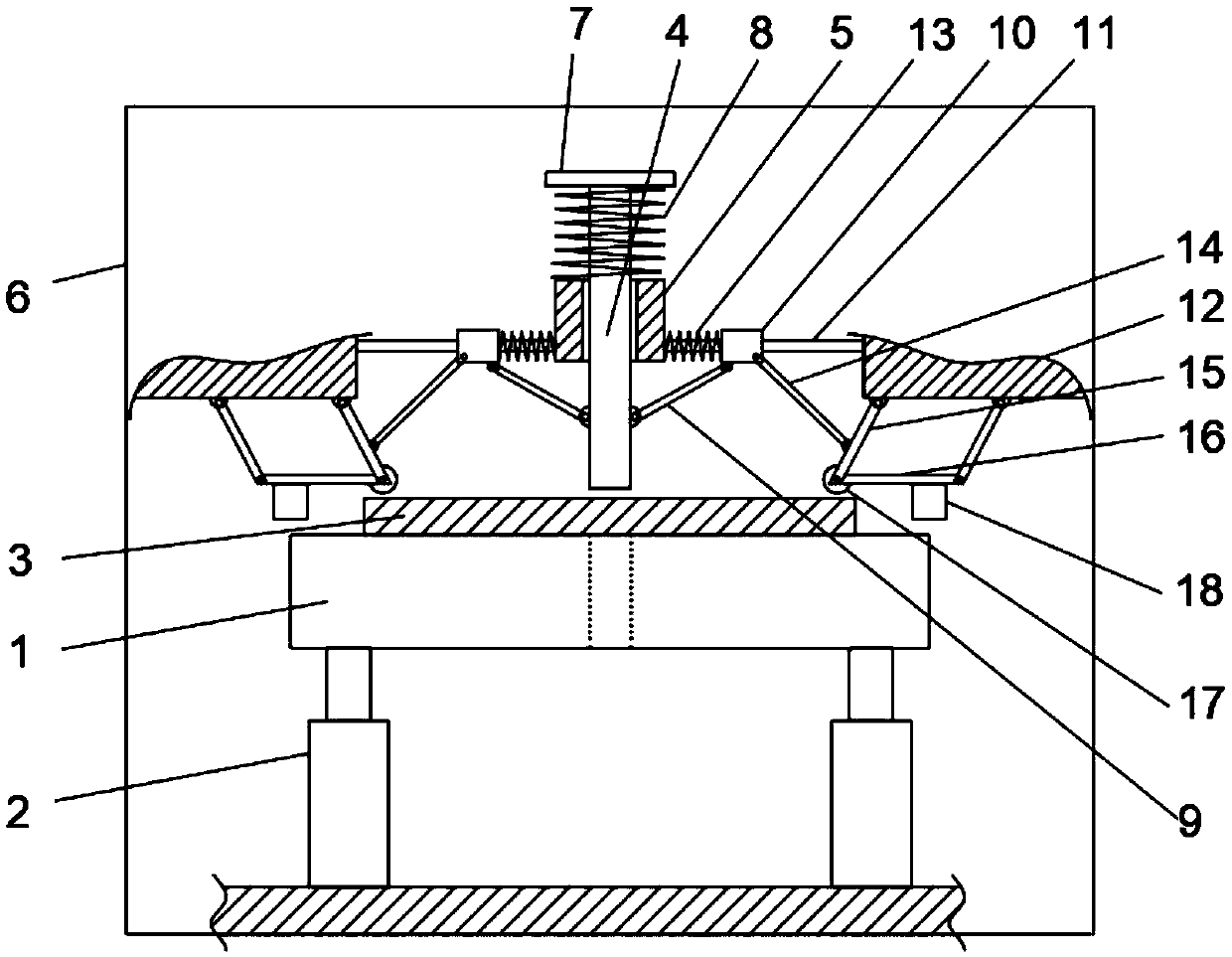

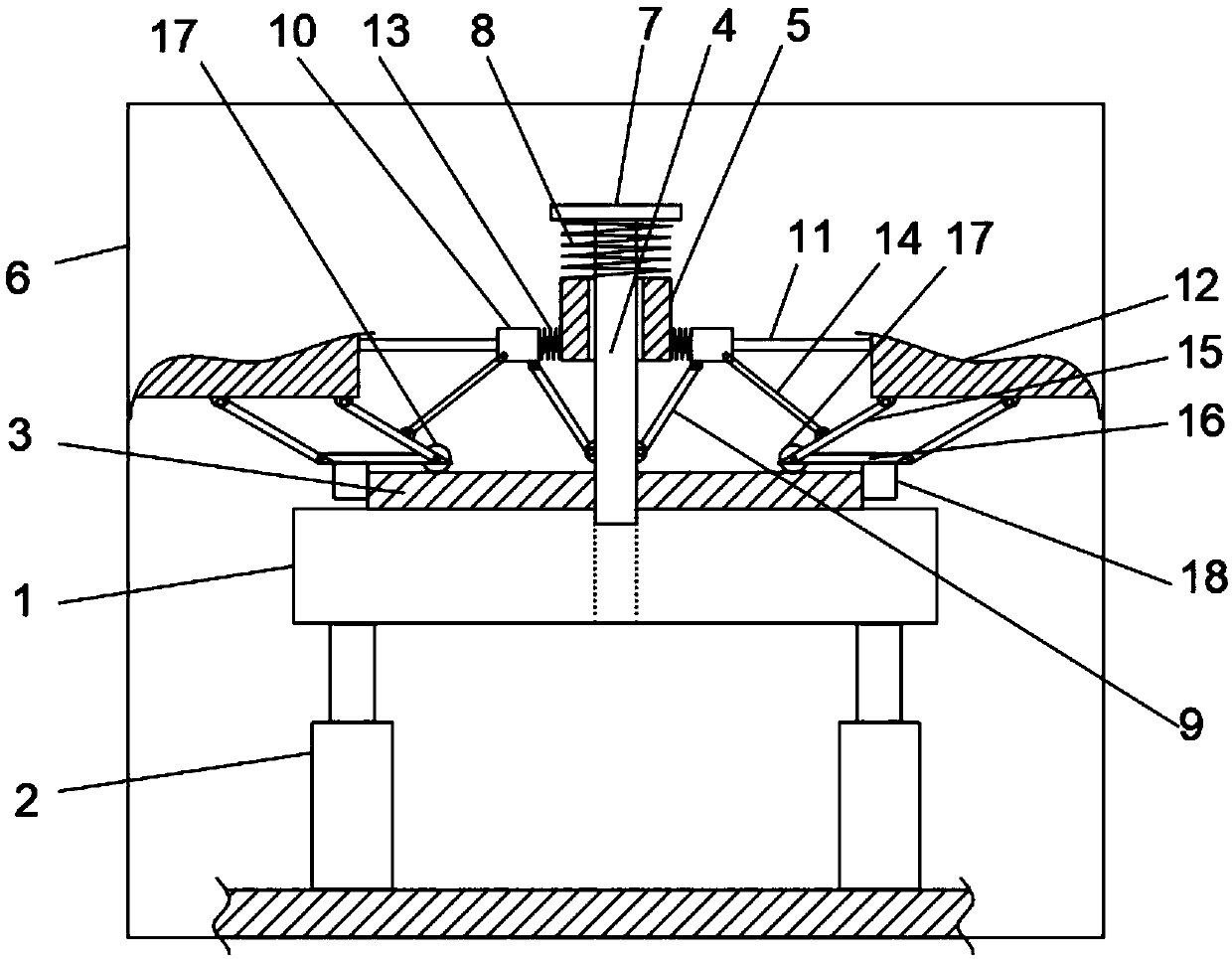

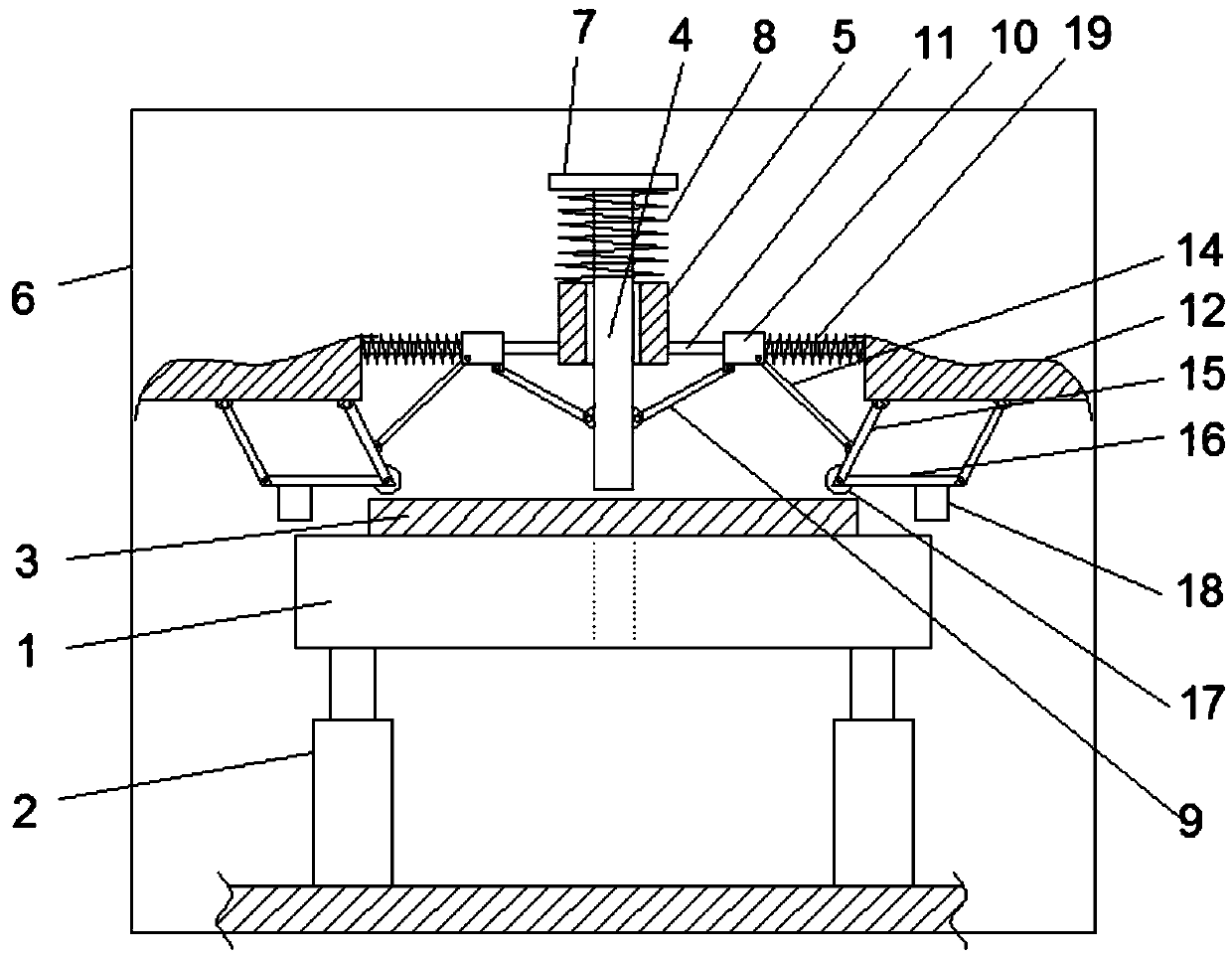

The invention discloses a self-pressing type hole punching device and a punching method. The self-pressing type hole punching device comprises a lifting workbench for bearing a punched part, a hole punching rod for punching the punched part, a locating device for clamping and locating the punched part, and a linkage device for linking the punched part and the locating device. The hole punching rod, the locating device and the linkage device are all located above the workbench, the locating device is located at the circumferential position of the hole punching rod, and the linkage device is connected with the hole punching rod and the locating device. According to the self-pressing type hole punching device and the punching method, the hole punching rod and the locating device can achieve linkage, and hole punching efficiency is improved.

Owner:陈嘉亮

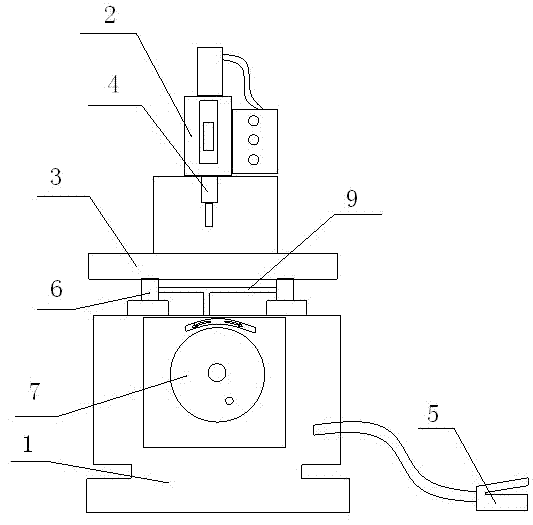

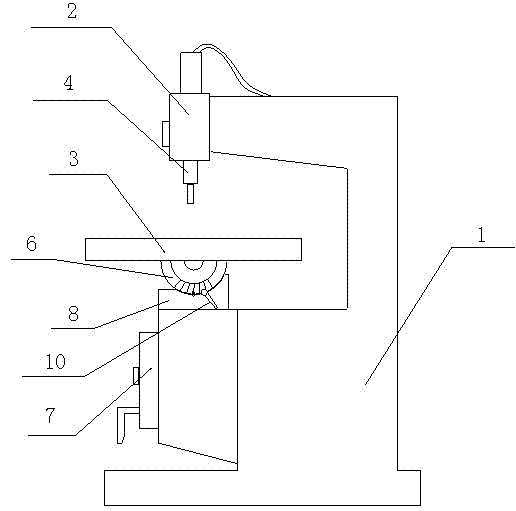

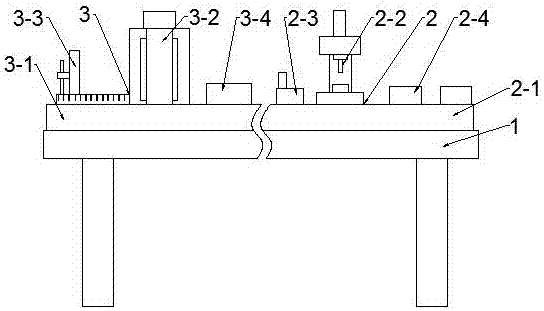

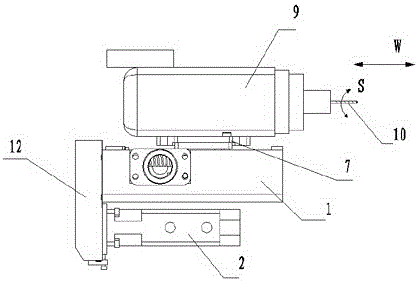

Punching machine with accurately angle-adjustable platform for materials

The invention discloses a punching machine with accurately angle-adjustable platform for materials. The punching machine comprises a frame (1) and a punching component (2), a working platform (3) and a motor. The punching component is arranged in the frame (1), the working platform is located on the upper portion of the frame, and the motor is located inside the frame. A drill bit (4) arranged inside the punching component (2) can slide up and down, two semi-circle wheels (6) are arranged between the working platform (3) and the frame (1), planes of the two semi-circle wheels (6) support the working platform (3), cambered surfaces of the semi-circle wheels (6) are located in arc-shaped grooves (7) of the frame (1). The punching machine with the accurately angle-adjustable platform for the materials has the advantages that angles of the working platform can be accurately adjusted, so that holes with various angles can be drilled. A foot controller is designed to liberate both hands of a controller, and therefore, the controller can stabilize the materials with both hands and ensure the quality of punching.

Owner:CHENGDU HI TECH ZONE NIMA ELECTRONICS PROD DESIGN STUDIO

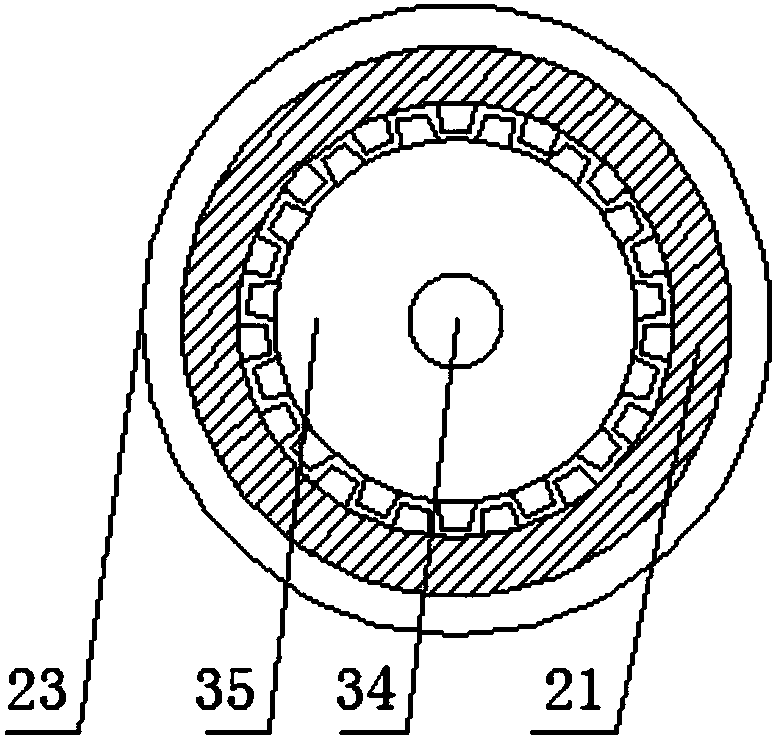

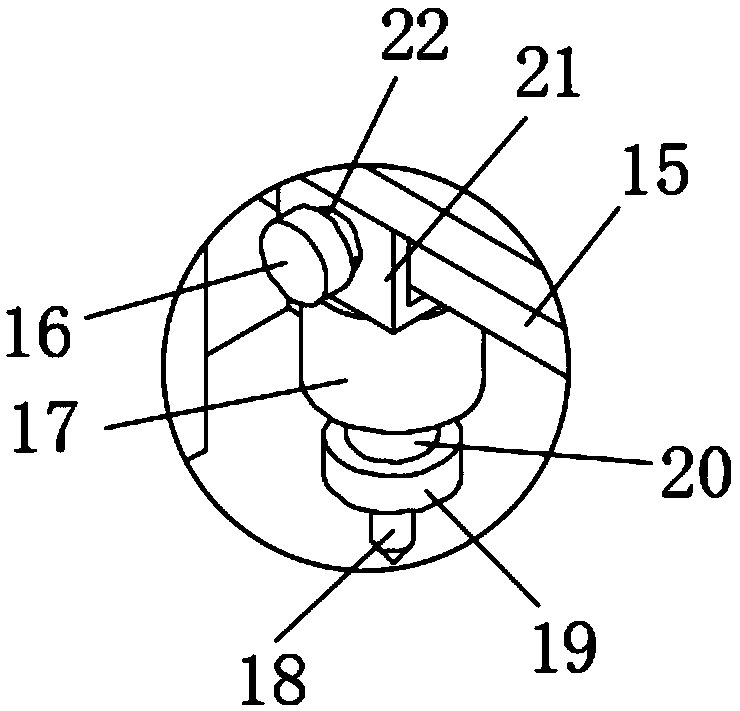

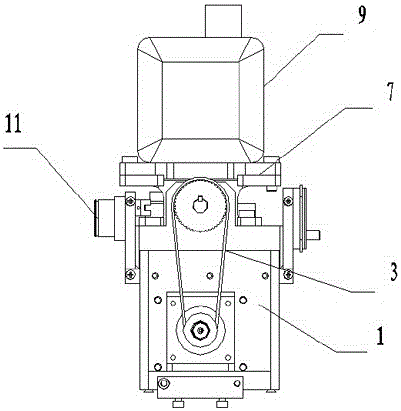

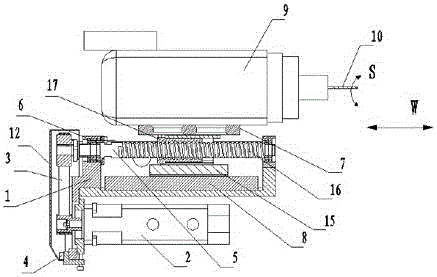

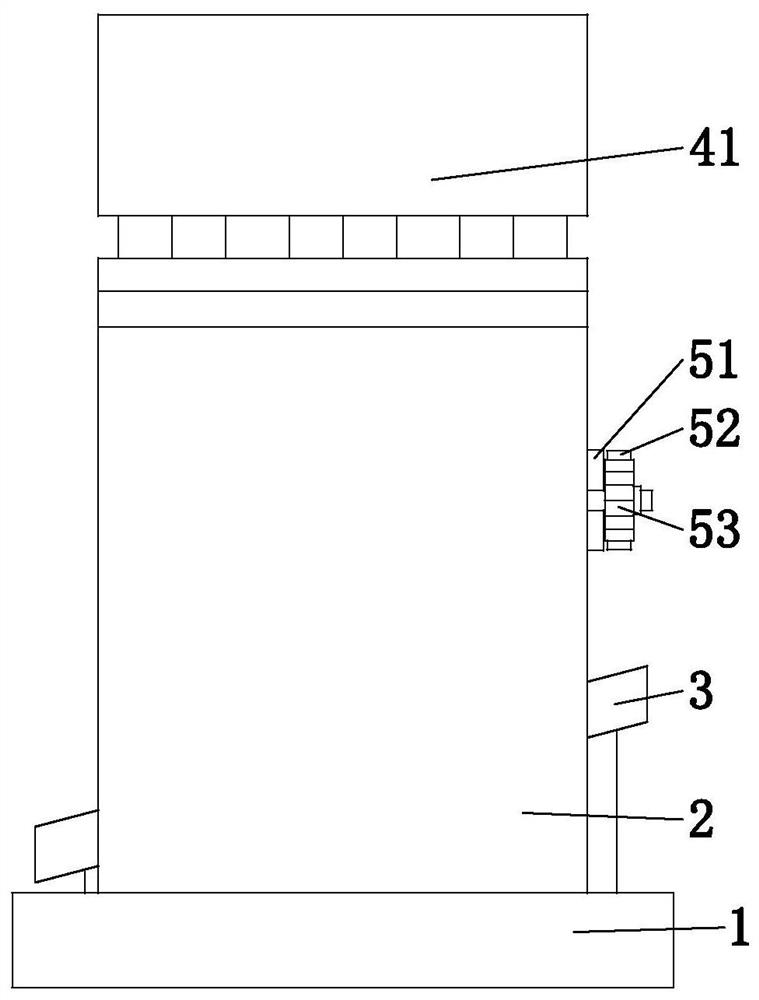

Sewing machine punching device for producing shoes

ActiveCN108372551AGuaranteed accuracyGuaranteed punching qualityMetal working apparatusPunchingEngineering

The invention discloses a sewing machine punching device for producing shoes. The sewing machine punching device comprises a bottom plate, first installation plates are fixedly connected to two sidesof the upper surfaces of the bottom plate through first supporting rods, locating seats are fixedly connected to two ends of the inner sides of the upper surfaces of the first installation plates through supporting frames, and annular holes are formed in the locating seats. A spline tube is rotatably connected into the annular holes through annular blocks, an avoidance hole is formed in the centerof the upper surface of the spline tube, a driven belt wheel is fixedly connected to the upper end of the outer surface of the spline tube, a second installation plate is fixedly connected to the outer side of the upper surface of the first installation plate through a second supporting rod, a motor is fixedly arranged on the rear side of the lower surface of the second installation plate throughbolts, and a driving belt wheel is fixedly connected to the lower surface of the motor through a shaft. The sewing machine punching device for producing the shoes can greatly improve the convenienceand accuracy of punching, guarantees the drilling quality and reduces the production cost.

Owner:江西源轮纺织有限公司

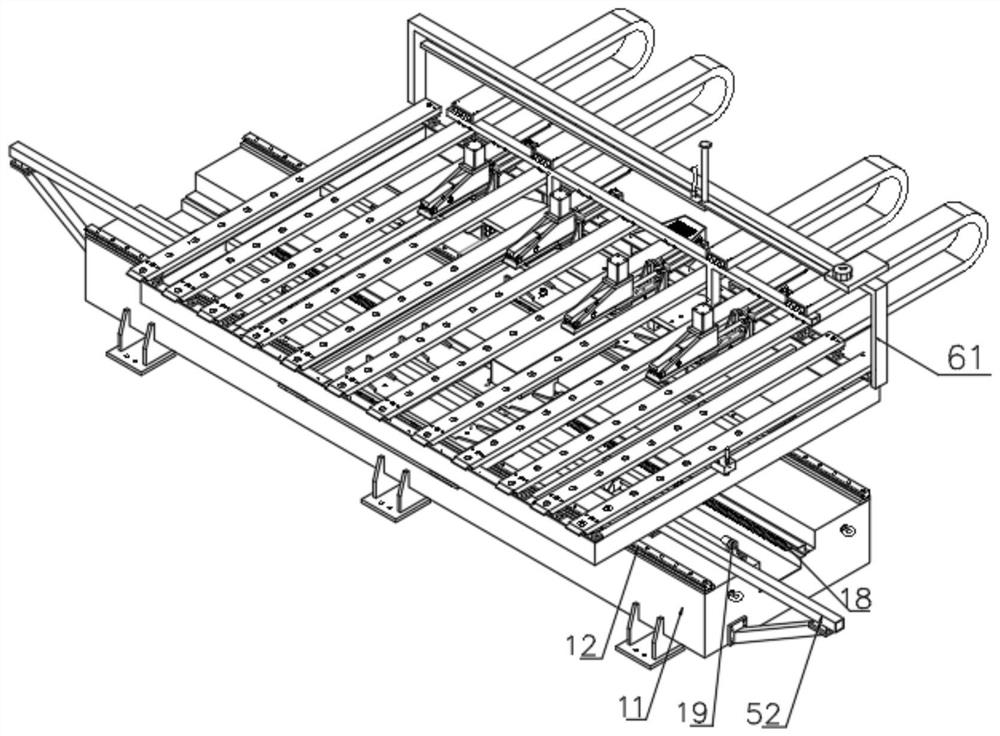

Avoiding dead-space-free processing and feeding machine for special clamp for thick plate

InactiveCN111644527AImprove stabilityFloating up and downShaping toolsMetal-working feeding devicesSteel platesProcess engineering

The invention discloses an avoiding dead-space-free processing and feeding machine for a special clamp for a thick plate. The avoiding dead-space-free processing and feeding machine for the special clamp for the thick plate comprises an X direction mechanism, a Y direction mechanism, a floating clamp with an avoiding function, a feeding platform, a platform support component and a lubricating mechanism, wherein the platform support component is arranged under the feeding platform; the X direction mechanism is arranged at the lower part of the feeding platform; the Y direction mechanism is arranged at the upper part of the feeding platform; the floating clamp with the avoiding function is arranged on the Y direction mechanism; and the lubricating mechanism is arranged on the feeding platform. A mechanical structure is changed by aiming at the thick plate, so that the damage to each component of the feeding machine due to reasons of plate materials is avoided; dead-space-free processingcan also be realized; the efficiency is high; the service life is high; in addition, the buffer supporting and floating effects are achieved; the applicability is higher; damage cannot easily occur; the manual work is replaced for lubricating the steel plate surface before hole punching; the hole punching quality is ensured; and the efficiency is high.

Owner:青岛大东智能装备科技有限公司

Punching device for archives management

The invention discloses a punching device for archives management. The punching device comprises a base, wherein a support frame is arranged on the left side of the upper surface of the base, a control switch group is arranged on the side surface of the support frame, two first electric telescopic rods penetrate through the upper surface of the support frame, a frame is connected to the telescopicends of the two first electric telescopic rods, a sliding plate is arranged in the frame, scale values are arranged on the right side surface of the sliding plate, two sliding blocks movably sleeve the outer surface of the sliding plate, threaded holes are formed in the side surfaces of the sliding blocks, bolts are in threaded connection to the interiors of the threaded holes, punching mechanisms are arranged on the lower surfaces of the sliding blocks, and pressing mechanisms are arranged on the upper surface of the base near the punching mechanisms. The punching device for archives management has the advantage of convenience in use, archives can be quickly punched, the punching efficiency is improved, the punching spacing can be changed, and the archives can be tightly pressed, so thatthe archives can be prevented from slipping during punching so as not to cause punching deflection, and the punching quality is guaranteed.

Owner:牟丽娟

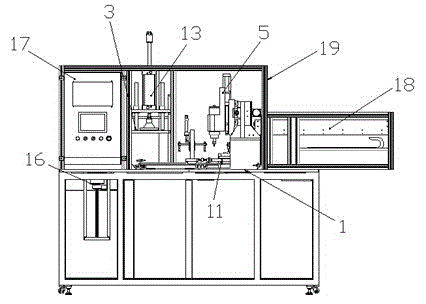

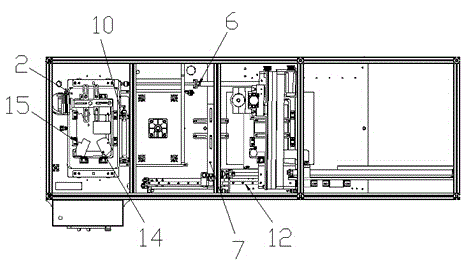

Automatic punching and carving-milling all-in-one machine

ActiveCN106695335AImprove general performanceLabor savingOther manufacturing equipments/toolsAutomatic controlPunching

The invention discloses an automatic punching and carving-milling all-in-one machine which saves manpower and labor hours and is high in efficiency. The automatic punching and carving-milling all-in-one machine comprises an automatic control device and an operation platform. A carrier, a punching mechanism, a material transfer mechanism and a carving-milling mechanism are arranged on the operation platform. The carrier is connected with a front-back movement mechanism through a connecting plate. The automatic punching and carving-milling all-in-one machine is high in universality and suitable for different materials; a material is automatically fed to the station of the punching mechanism through the carrier, and a material head of the material is shorn; after shearing is finished, the material is automatically fed to the carving-milling station through the material transfer mechanism to be carved and milled; after carving and milling are completed, the finished material is automatically put into a finished product bin through a collection mechanism; and according to the machine, a large amount of manpower is reduced, the work efficiency is improved, and quality is stable.

Owner:九仕恒自动化科技(昆山)有限公司

Grounded flat iron processing and manufacturing platform

ActiveCN107123914APrevent overshootPrevent problems such as slantingContact member manufacturingConnection contact member materialState of artEngineering

The invention discloses a grounded flat iron processing and manufacturing platform, which is used for solving the technical problems of low flat iron manufacturing mechanization degree, poor manufacturing quality, low work efficiency and the like in the prior art. The grounded flat iron processing and manufacturing platform comprises an operation platform and a spraying brushing mechanism, wherein a hole punching mechanism and a bending mechanism are arranged on the operation platform; the hole punching mechanism comprises a base, a hole punching machine, a support block and a positioning block are arranged at the upper part of the base; the support block is positioned at one side of the hole punching machine; the positioning block is positioned at the other side of the hole punching machine; the bending mechanism comprises a support seat; a bending machine, a positioning plate and a fixing plate are arranged on the support seat; the positioning plate is positioned at one side of the bending machine; the fixing plate is positioned at the other side of the bending machine; the spraying brushing mechanism comprises a spraying and brushing support frame; a fixing seat and a support plate are arranged on the spraying and brushing support frame; paint blocking plates are arranged on the fixing seat at intervals; a cover plate is arranged on the support plate. The fast and precise hole punching bending can be realized; the phase color mark can be formed in one step; the manufacturing time can be reduced from the original 50 minutes to 5 minutes; the work efficiency is improved by 10 times and the quality of the workpiece is ensured.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +2

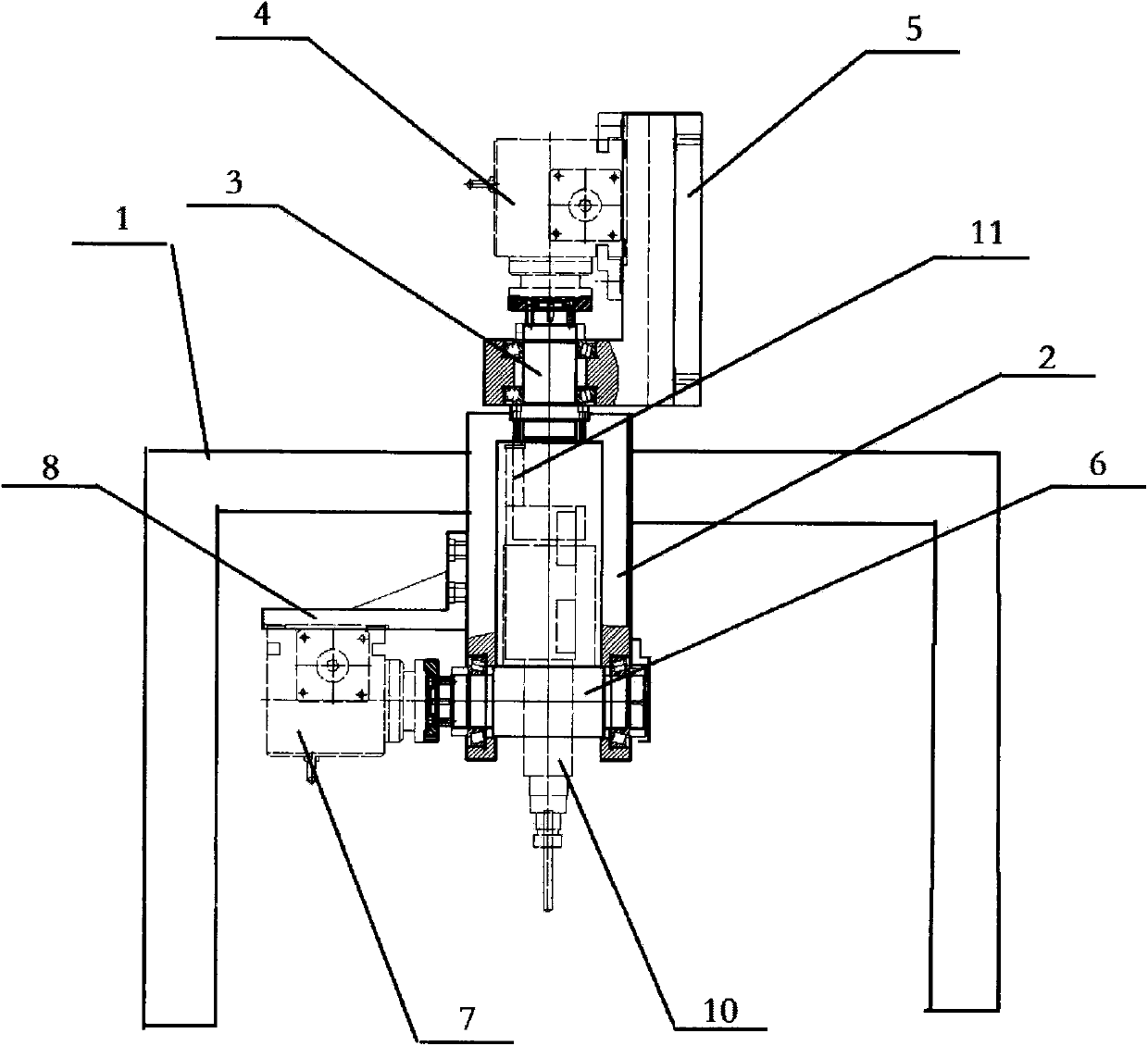

Punching device for fuselage frame

InactiveCN106312123AReduce machining accuracyControl manufacturing precisionAircraft componentsFeeding apparatusPunchingEngineering

The invention discloses a punching device for a fuselage frame. The punching device comprises a drill bit, an electric spindle, an installation plate assembly, a connection base, a supporting assembly and a drive assembly. The drill bit is installed on the electric spindle. The electric spindle is installed on the connection base. The connection base is installed on the supporting assembly. The drive assembly drives the connection base to slide on the installation plate assembly. The supporting assembly and the drive assembly are both installed on the installation plate assembly. By means of the punching device, automatic punching is conducted on large-curvature, double-curved-surface and poor-openness parts of small fuselage frames, the product quality and the work efficiency are improved, and the labor intensity of workers is lowered.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Method for replacing dies of high-speed punching machine

The invention discloses a method for replacing dies of a high-speed punching machine. The method for replacing the dies of the high-speed punching machine comprises the following steps that A, pressing plates used for fixing the dies are dismounted; B, a scram button is pressed; C, the dies to be dismounted are made to retreat from a workbench slowly; D, the dies to be dismounted are hoisted out through a crane; E, the dies to be dismounted are ground and polished by means of a grinding machine and coated with anti-rust oil; F, die mounting positions are aligned; G, the scram button is pressed; H, the dies to be mounted are gently placed on a die mounting sliding plate through hoisting by means of the crane; I, the dies to be mounted are slowly pushed into guide rail grooves of the workbench; J, the dies to be mounted are adjusted to be aligned to a feeding machine; and K, the die mounting height of a punching main unit is adjusted till a qualified product is punched. Compared with the prior art, the method for replacing the dies of the high-speed punching machine has the beneficial effects that the service life of the dies is prolonged, the punching quality of the product is guaranteed, and requirements of high-end customers are met.

Owner:JIANGSU TONGDA POWER TECH

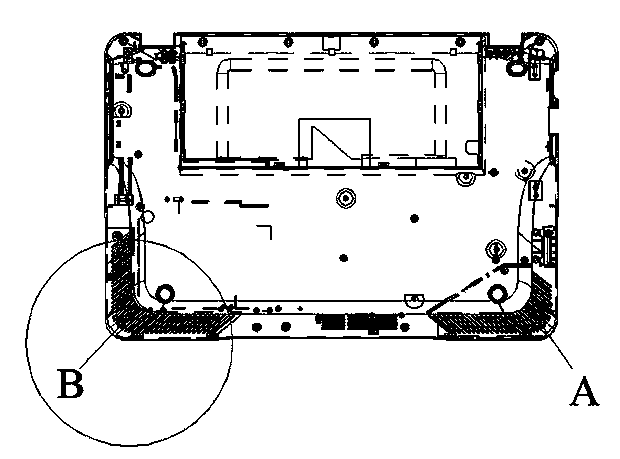

Punching die suitable for cambered holes

InactiveCN103950064AGuarantee punching qualityExtended service lifeMetal working apparatusEngineeringWaste material

Owner:KUSN CHANGYUN ELECTRONICS IND

Building wall punching device and using method thereof

ActiveCN111673917ASmooth feedingAvoid offsetWorking accessoriesStone-like material working toolsGear wheelArchitectural engineering

The invention discloses a building wall punching device and a using method thereof, and belongs to the technical field of building machinery. A building wall punching device comprises a machine base,three fixing pipes are movably connected to the outer wall of the machine base, a sleeve is fixedly connected to the inner wall of each fixing pipe, a fixing mechanism is connected to the inner wall of each sleeve, a second motor is connected to the outer wall of the machine base, a rotating rod is connected to the output end of each second motor, and a second gear is connected to the outer wall of each rotating rod. The second gear is rotationally connected to the inner wall of the machine base, the outer wall of the second gear is engaged with a first gear, the first gear is rotationally connected to the outer wall of the fixed pipe, and the outer wall of the first gear is connected with a threaded rod. According to the drilling machine, manual auxiliary drilling can be carried out on awall body with a small outer side space, so that the three fixing pipes are fixed to the wall body and relatively retract into the machine base, stable feeding of a drill bit in the drilling process is guaranteed, drill bit deviation of the drill bit in the drilling process is avoided, and then the drilling quality is guaranteed.

Owner:萧县威辰机电工程设备有限公司

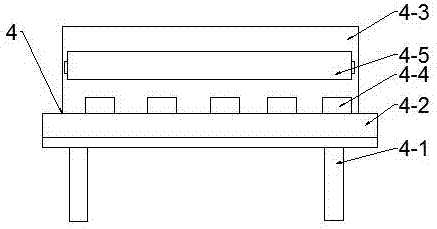

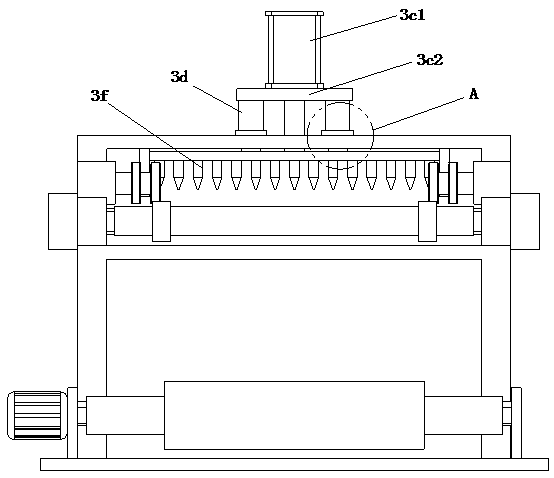

Perforating machine for inflatable film

PendingCN109866279APrevents wrinklingGuaranteed punching qualityMetal working apparatusDrive motorEngineering

The invention relates to the field of film machining equipment, in particular to a perforating machine for an inflatable film. The perforating machine comprises a supporting frame, a traction device and a perforating device are arranged on the supporting frame, a feeding device is arranged at the front end of the supporting frame, a pressing mechanism is arranged close to the front end of the perforating device, wherein the perforating device comprises a bottom plate and a mounting plate, a driving assembly is arranged at the top of the mounting plate, a guide assembly is arranged between thedriving assembly and the mounting plate, two side plates are arranged at the bottom of the mounting plate, and a perforating assembly is arranged between the two side plates. According to the perforating machine, a feeding roller is driven to rotate through driving of a driving motor, so that the inflatable film moves towards the perforating device on a plurality of roller shafts, a pressing platedoes reciprocating motion in the vertical direction of the two side plates through driving of an air cylinder so as to drive an ejector pin set at the bottom of the pressing plate to do reciprocatingmotion to complete the perforating operation of the inflatable film, the whole process adopts automation, so that the perforating quality of the inflatable film is ensured.

Owner:六安市路安包装制品有限公司

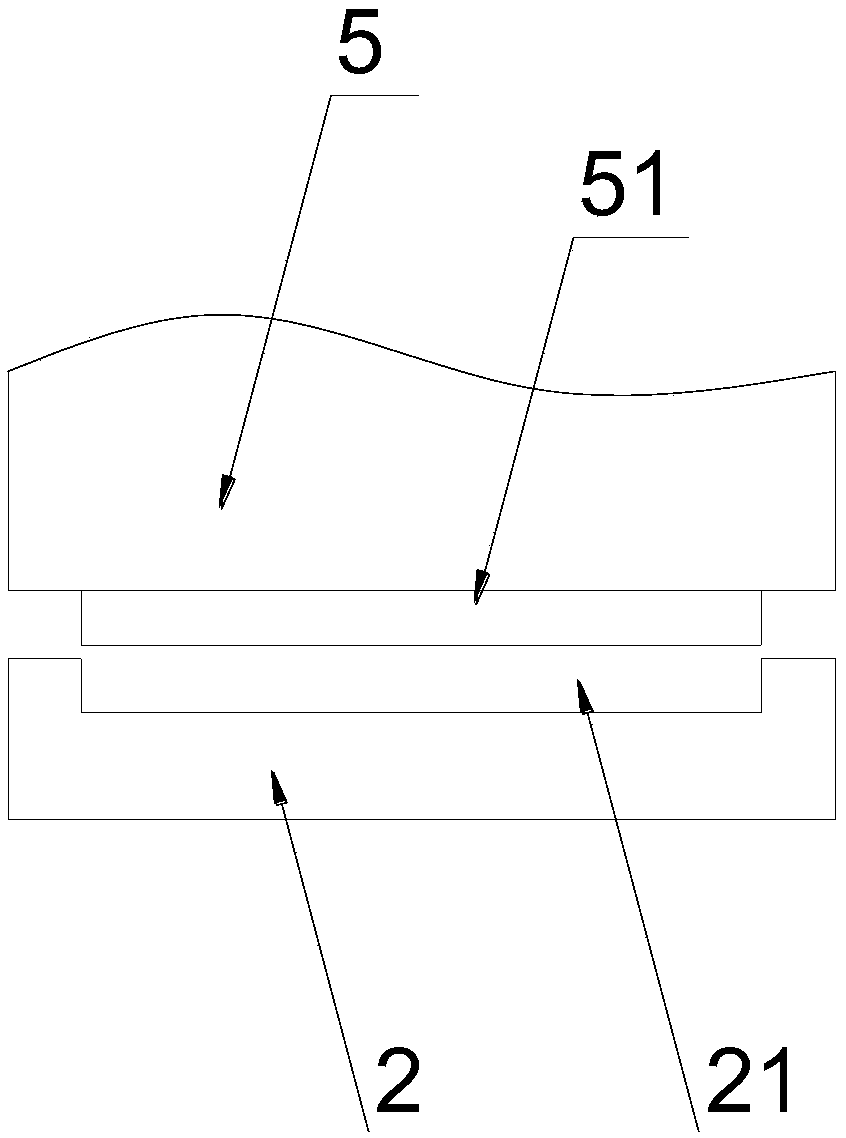

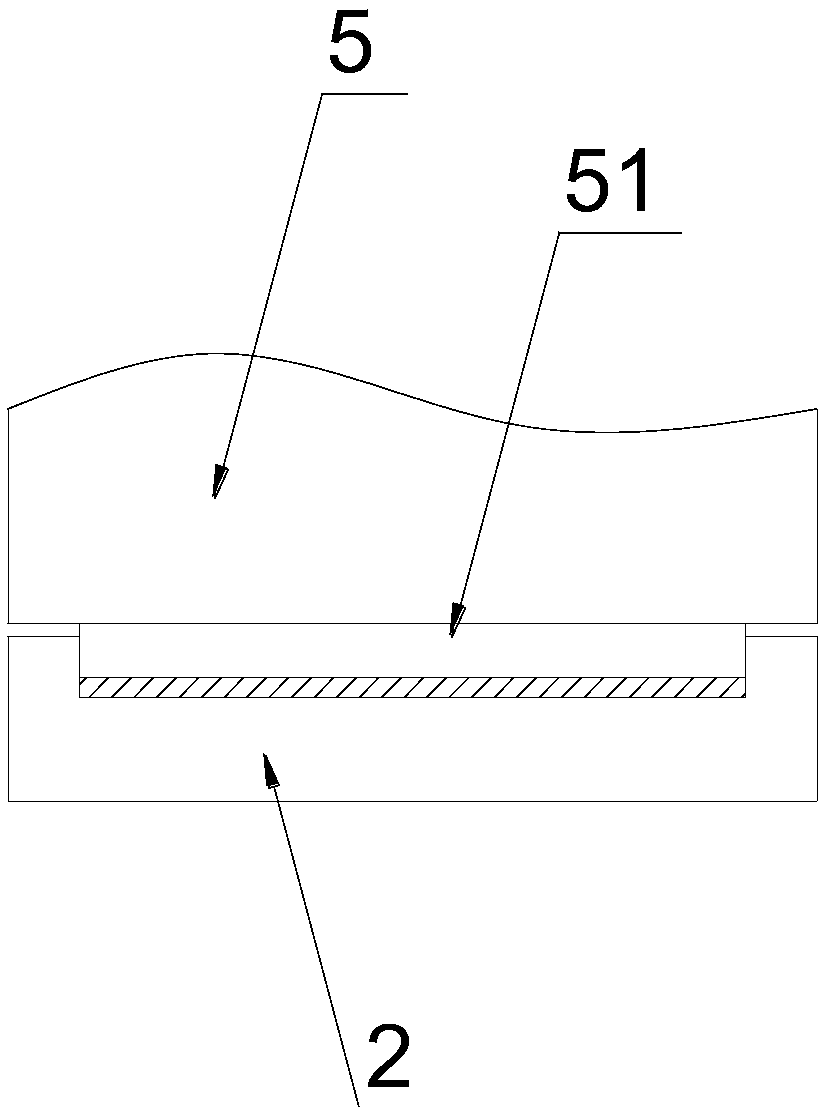

Lifting lug reinforcing board blanking mechanism

The invention discloses a lifting lug reinforcing board blanking mechanism. The lifting lug reinforcing board blanking mechanism comprises an upper die base and a lower die base which is connected with the upper die base through a locating column, wherein a punching die is arranged inside the upper die base, two rubber blocks are installed on a lower die fixing board, and each rubber block is provided with an annular leveling board. The lifting lug reinforcing board blanking mechanism further comprises a blanking hole penetrating through the lower die base and the lower die fixing board. When the lifting lug reinforcing board blanking mechanism works, the annular leveling boards are arranged on the rubber blocks, the horizontal height of each annular leveling board is greater than that of the lower die fixing board, the rubber blocks are compressed to deform when a material board moves downwards along with the punching die, and the annular leveling boards also move downwards along with the punching die. When the material board is blanked by the punching die, the annular leveling boards are matched with the lower die fixing board, roll rims or protrusions which are possibly generated on the edge of the residual material are removed, blanking quality for the next time of the material board is guaranteed, waste of the materials is reduced, and production cost is reduced.

Owner:CHENGDU HAILINGDA MACHINERY

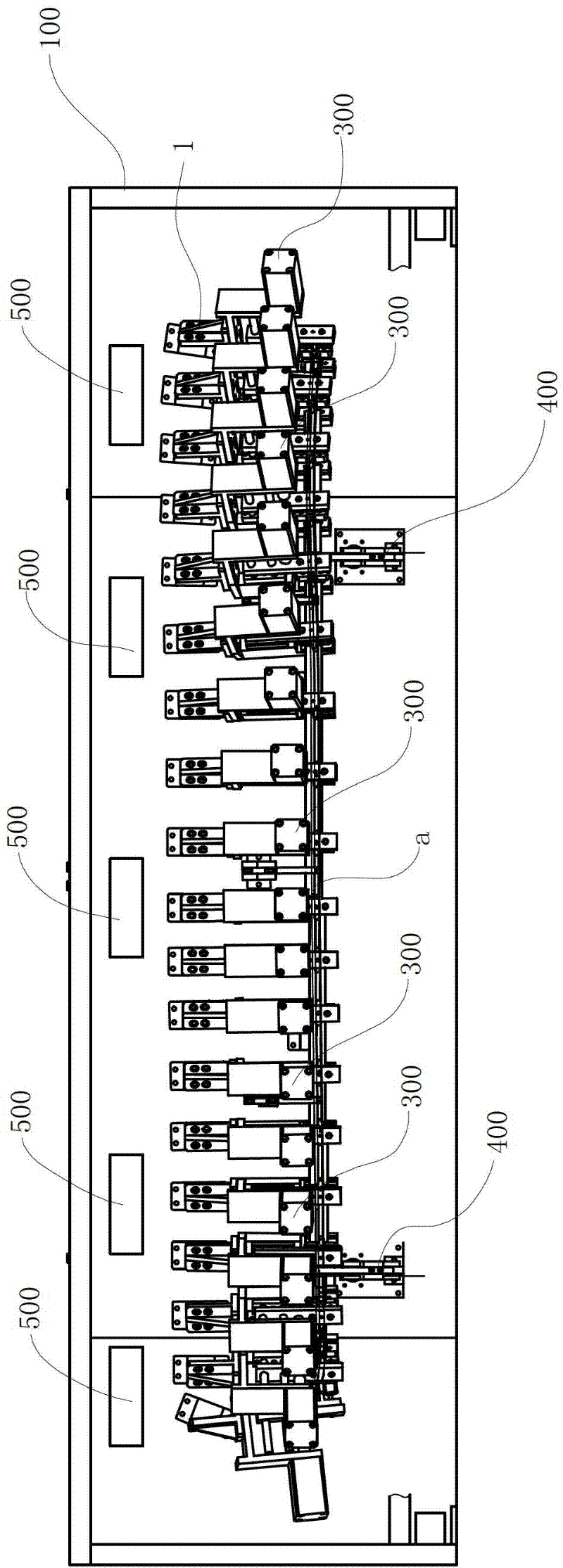

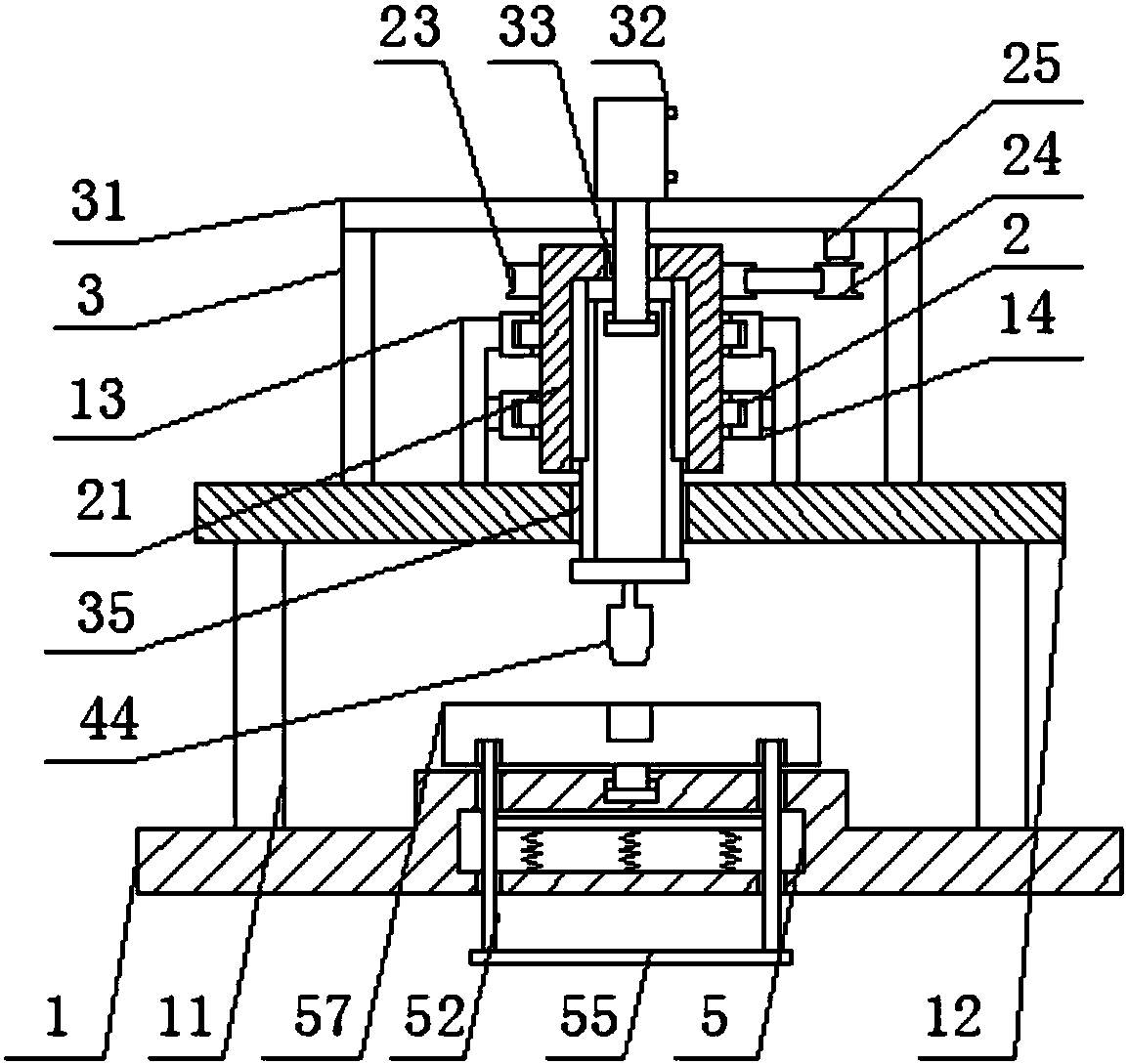

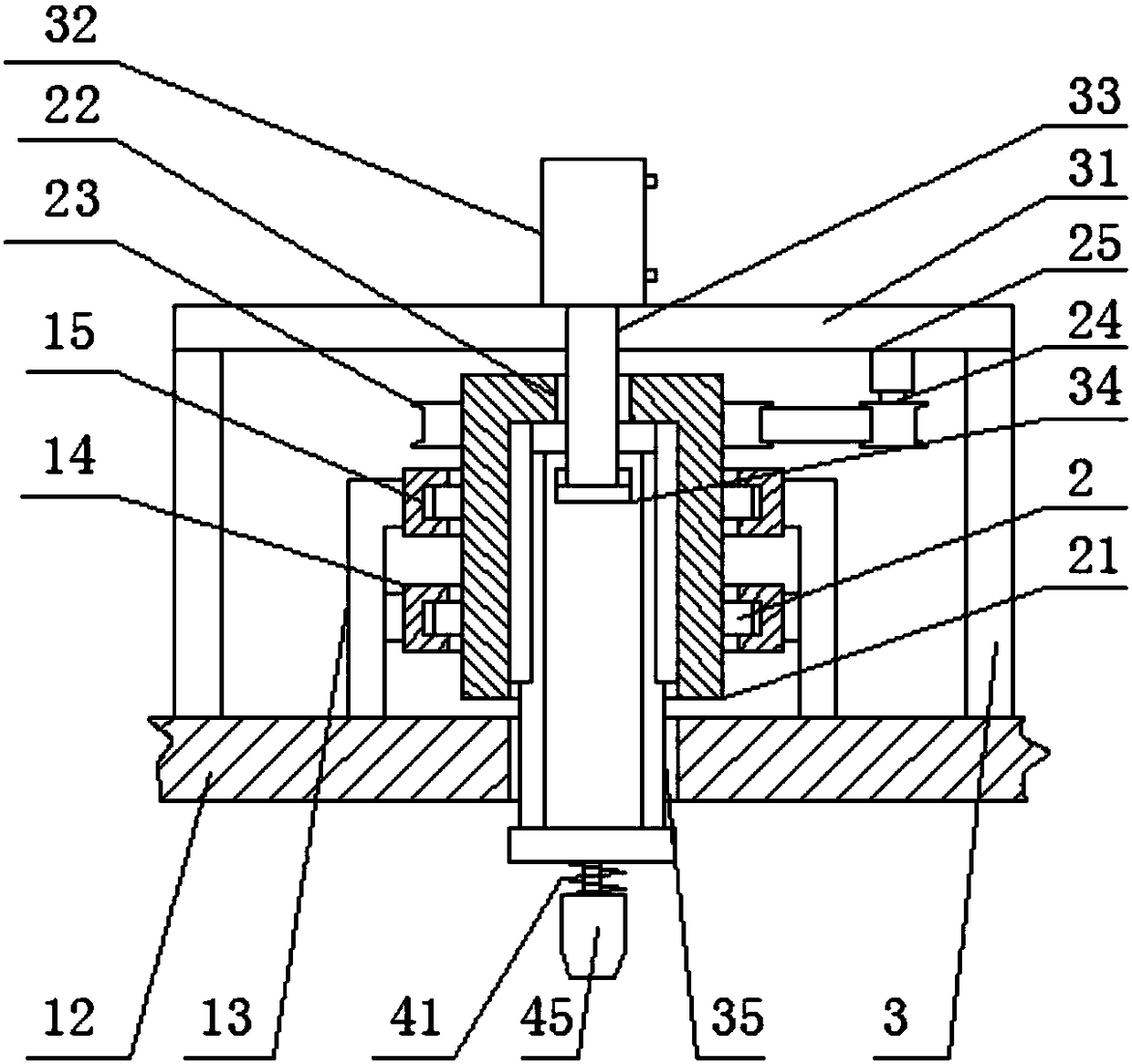

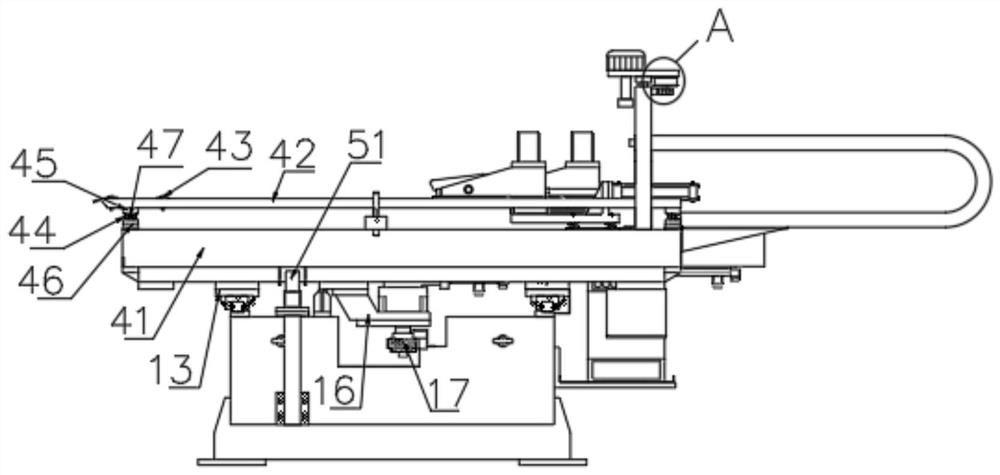

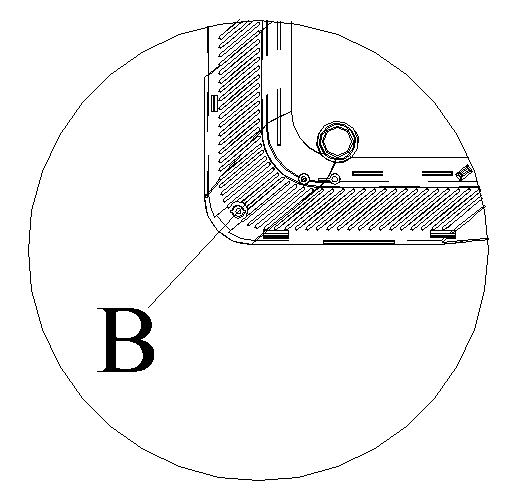

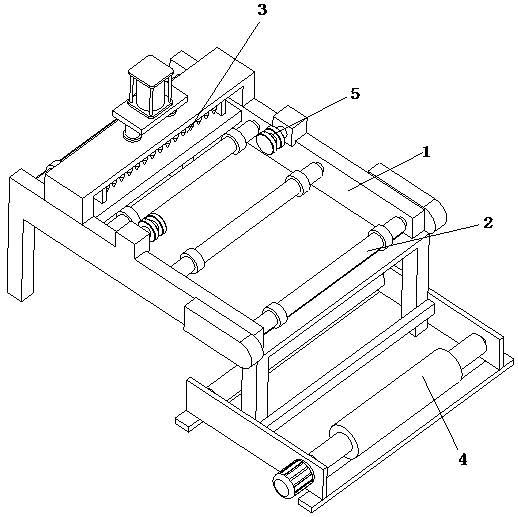

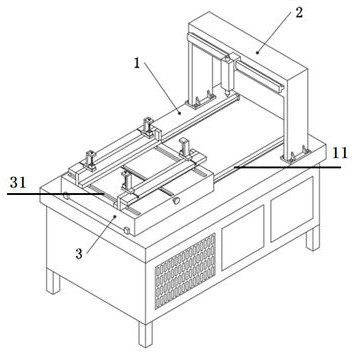

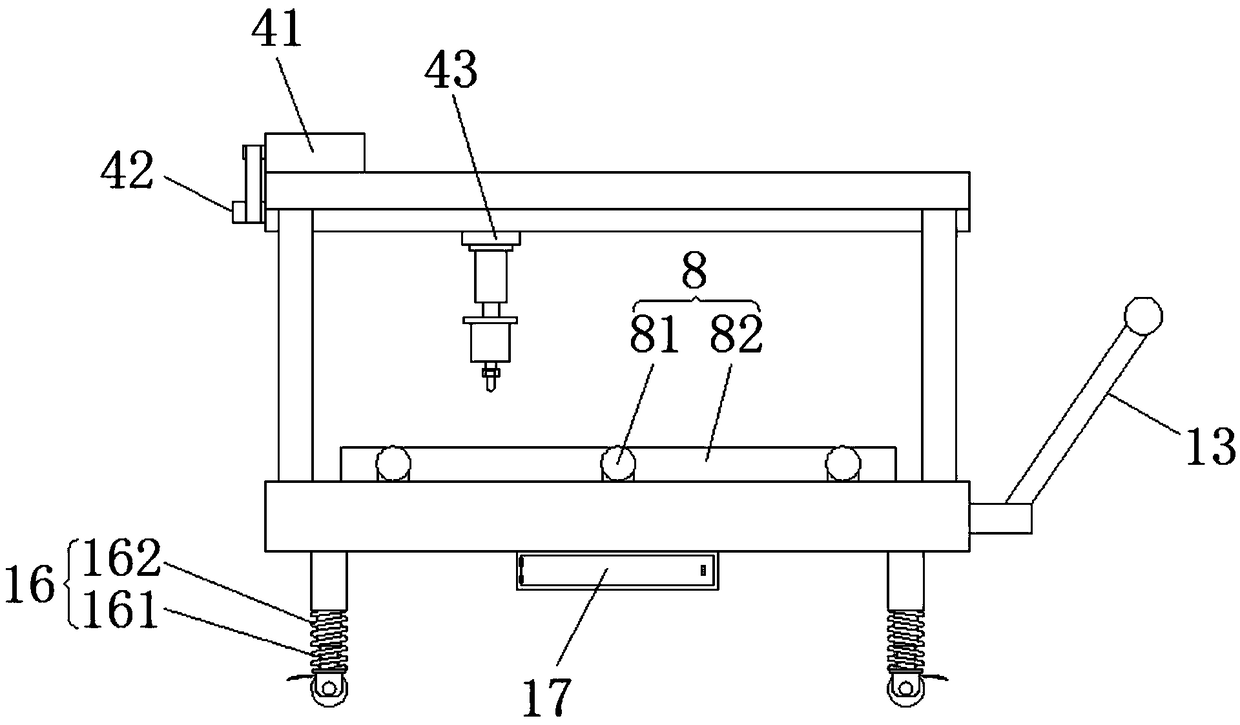

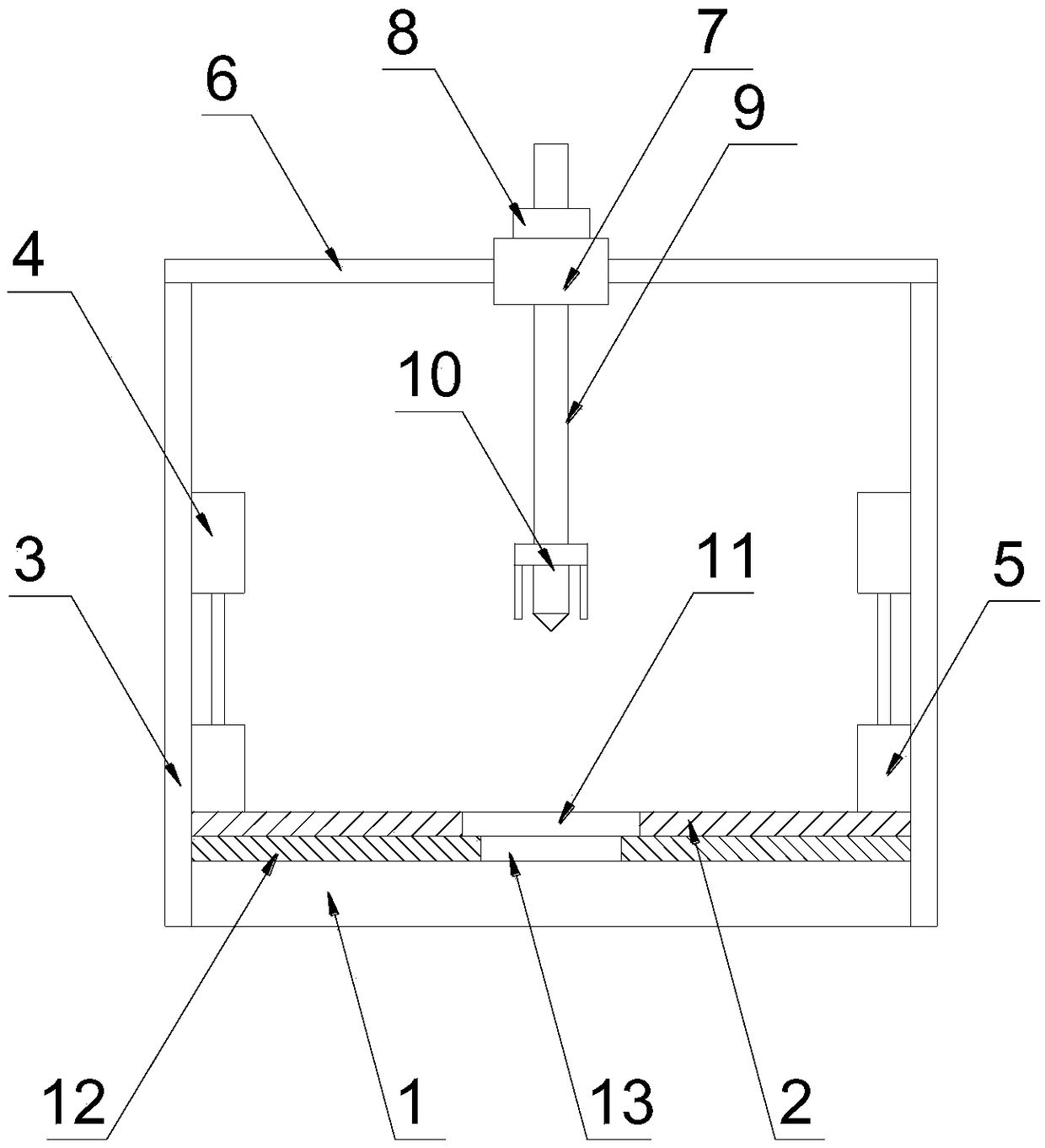

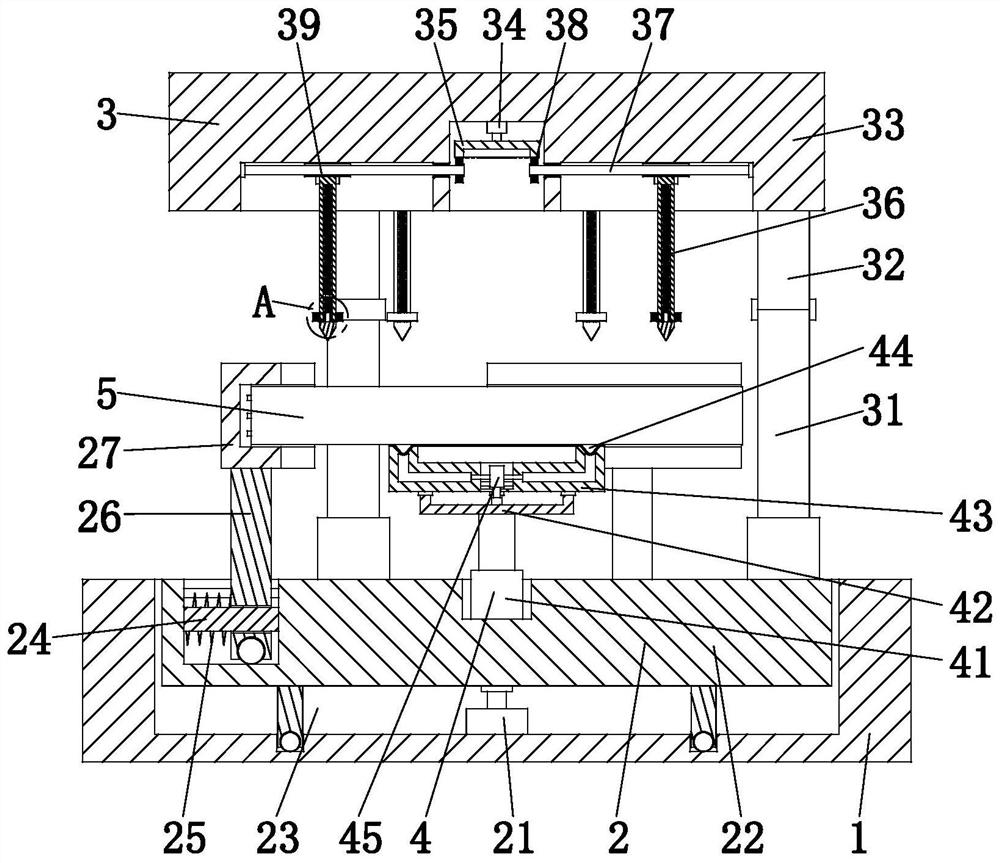

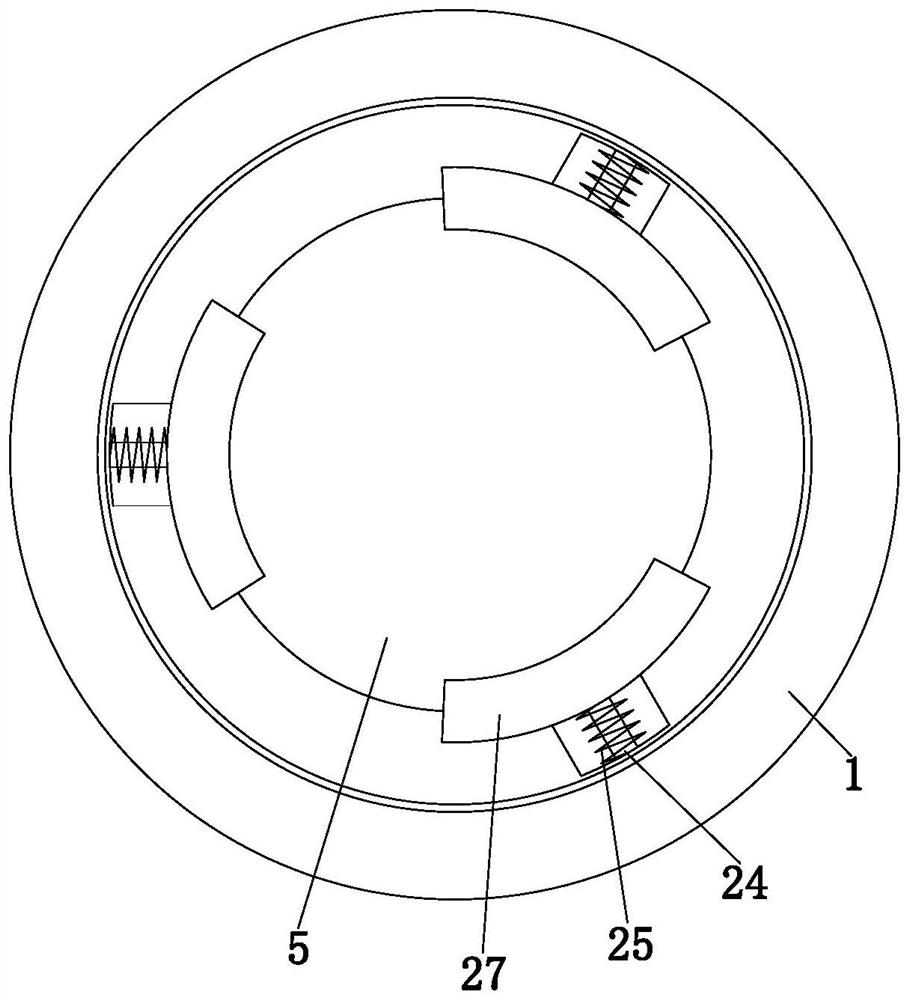

Full-automatic punching numerical control machine tool and control method thereof

InactiveCN114535648AChange the mode of traditional manual operationReduce human involvementFouling preventionShaping safety devicesNumerical controlPunching

The invention relates to a full-automatic punching numerical control machine tool and a control method thereof.The full-automatic punching numerical control machine tool comprises a rack (1) and an automatic punching drill bit, a movable positioning table (3) is arranged on the rack (1), the positioning table (3) fixes a punched workpiece (5) through a clamping and limiting device, and the full-automatic punching numerical control machine tool further comprises a control unit; the control unit controls the driving mechanism to enable the positioning table (3) to move towards the position below the automatic punching drill bit, and the clamping and limiting device sequentially clamps and limits the punched workpiece (5) in the moving process. Left-right clamping, up-down limiting and horizontal moving of a punching workpiece are synchronously carried out through one driving device, so that a traditional manual operation mode is changed, manpower participation is greatly saved, clamping, limiting and moving can be fully automatically achieved, and the punching device is suitable for machining of high-precision parts, and the machining efficiency is improved. And the requirement of intelligent manufacturing can also be met.

Owner:余院珠

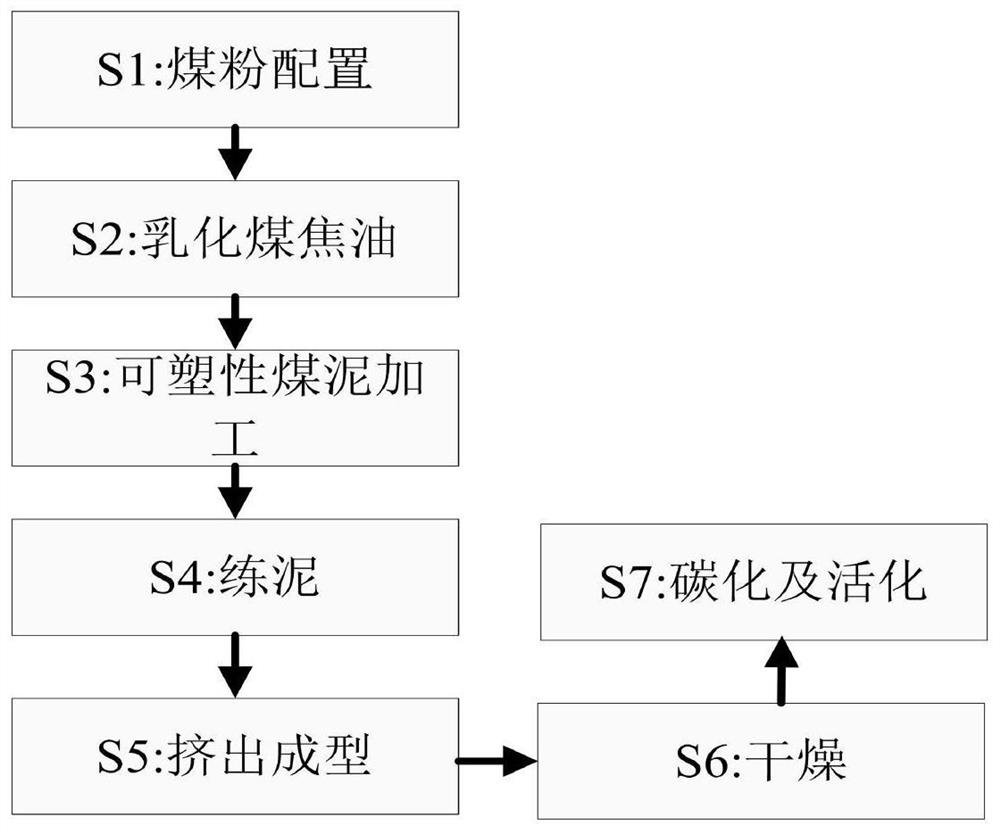

Honeycomb activated carbon production and processing method

InactiveCN112439386AImprove cleanlinessEasy to fall intoCarbon compoundsOther chemical processesActivated carbonPolymer science

The invention provides a honeycomb activated carbon production and processing method. A bottom plate, a limiting support plate, a material guide plate, a material collecting unit, an auxiliary unit, an execution unit and a drying unit are matched to complete production and processing of honeycomb activated carbon. The problems that in the existing honeycomb activated carbon production process, activated carbon is difficult to gather, press and form due to viscosity of coal slime in the honeycomb activated carbon production process, the production quality of the activated carbon is affected, the coal slime adheres to the outer wall of a stirring plate due to viscosity of the activated carbon, and the activated carbon cannot be recycled, the overturning effect of the stirring plate is influenced, in the honeycomb activated carbon punching process, the hole size is not uniform, and the activated carbon is difficult to separate from a conical needle are solved.

Owner:南京建当化工科技有限公司

Multi-way numerical control punching machine

InactiveCN103990827AReduce the burden onEnsure safetyPrecision positioning equipmentBoring/drilling machinesNumerical controlRotational axis

The invention discloses a multi-way numerical control punching machine. The multi-way numerical control punching machine comprises a main support, the main support is provided with a universal support, the upper portion of the universal support is provided with a first rotating shaft, and the first rotating shaft is movably connected with a first dividing head. The bottom of the universal support is provided with a second rotating shaft, and the second rotating shaft is provided with a second dividing head. The universal support is internally provided with a pneumoelectric type drilling power head penetrating through the universal support to be respectively and movably connected with the first rotating shaft and the second rotating shaft, and the pneumoelectric type drilling power head is further electrically connected with a hydraulic damper. Multi-way punching is achieved through the dividing heads and the universal support, punching precision and depth are controlled through a numerical control device and the hydraulic damper, punching automation and multi-way punching can be achieved, the burden of workers is reduced, the safety of the workers is guaranteed, punching efficiency is improved, and the punching quality is guaranteed.

Owner:NANTONG SHENQIU MACHINERY

Punching device for paper processing based on rolling wheel pre-pressing technology

InactiveCN109227723AGuarantee punching qualityPrevent clogged punchingMetal working apparatusScrapCardboard

The invention discloses a punching device for paper processing based on a rolling wheel pre-pressing technology. The device comprises a base, a punched hole and a vertical frame are arranged in the middle of the top end surface of the base, and the vertical frame is arranged on the back side of the punched hole; a hydraulic cylinder is arranged at the top end of the vertical frame, the bottom endof a telescopic rod on the hydraulic cylinder penetrates through the top wall of the vertical frame and is fixedly connected with a punching head cooperating with the punched hole, and the telescopicrod is slidably connected with the vertical frame; connecting rods are symmetrically arranged at the bottoms of the left and right side ends of the vertical frame, telescopic sleeves are arranged at the bottom ends of the connecting rods, and telescopic rods are sleeved with inner cavities of the telescopic sleeves; pressing plates cooperating with the base are fixedly connected to the bottom endsof the telescopic rods, and several pressing wheels are uniformly arranged at the bottom ends of the pressing plates; by arranging the pressing plates and the pressing wheels, pre-pressing can be conducted on paper boards, the punching head can cooperate with the punched hole, the paper boards can be punched, and the punching quality of products can be effectively ensured; by arranging a suctionfan, paper scraps in the punched hole can be timely discharged, and it is effectively avoided that due to the fact that the paper scraps block the punched hole, the processing work is influenced.

Owner:WENZHOU SHI AN PACKING CO LTD

Punching device for bearing production

InactiveCN109226817AImprove drilling efficiencyAvoid accumulationMaintainance and safety accessoriesBoring/drilling machinesHydraulic cylinderPunching

The invention discloses a punching device for bearing production. The device comprises a base, supporting rods are arranged on the upper surface of the base, and a horizontal plate is fixedly installed at the tops of the supporting rods; a sliding mechanism is arranged on the horizontal plate, a first hydraulic cylinder is arranged on the sliding mechanism, and a motor is fixedly installed on a piston rod of the first hydraulic cylinder through a fixing base; a drill bit is fixedly installed on an output shaft of the motor through a shaft sleeve, a clamping mechanism is arranged on the upper surface of the base, and a clamping groove is formed in a clamping block; supporting legs are fixedly installed on the lower surface of the base, a dust collection box is fixedly installed on the lowersurface of the base, and a chute is formed in the base and communicated with the dust collection box. According to the punching device for bearing production, multiple bearings to be punched can be simultaneously punched, the punching efficiency is improved, dust generated during punching can be collected, convenience is provided for cleaning, and meanwhile the dust can be prevented from accumulating on the upper surface of the base.

Owner:钟国强

Stainless steel strip punching and trimming integrated equipment

InactiveCN113617931AImprove processing efficiencyShorten processing timeMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing engineering

The invention relates to the technical field of strip machining, in particular to stainless steel strip punching and trimming integrated equipment which comprises a fixing frame, a driving device, a connecting plate and a punching device, the driving device is arranged in the fixing frame, the connecting plate is connected at the upper end of the fixing frame, and the punching device is installed on the connecting plate. The problems that when a stainless steel strip is punched, the position of a punched hole is often inaccurate, the shape of the hole is irregular, burrs are often generated on the inner wall of the hole, and the machining efficiency of the stainless steel strip is reduced through a traditional trimming method can be solved. According to the stainless steel strip machining equipment integrating punching and trimming, the stainless steel strip is always in a tensioned state during machining, the accuracy of the position of a punched hole and the regular shape of the hole are ensured, the inner wall of the hole can be directly trimmed after punching is completed, and the machining efficiency of the stainless steel strip is improved.

Owner:徐州卓越精密科技有限公司

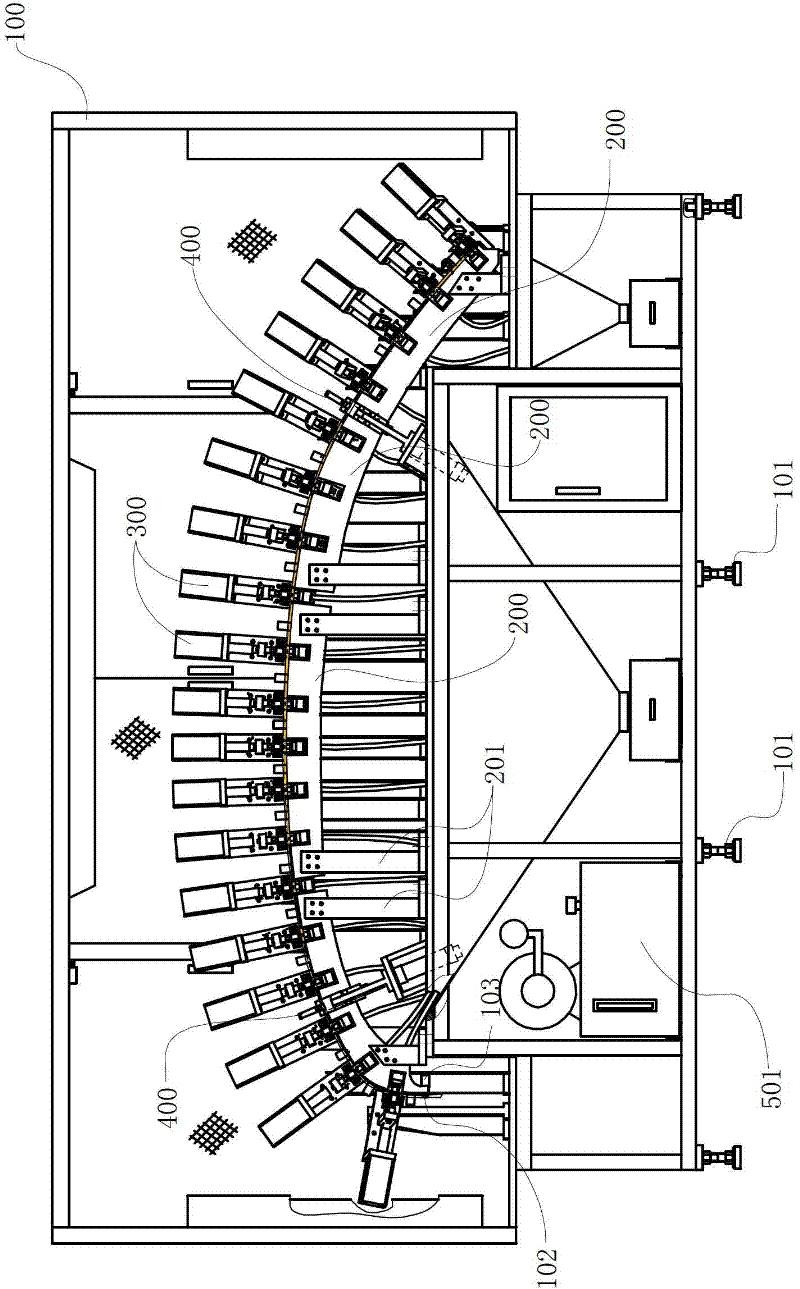

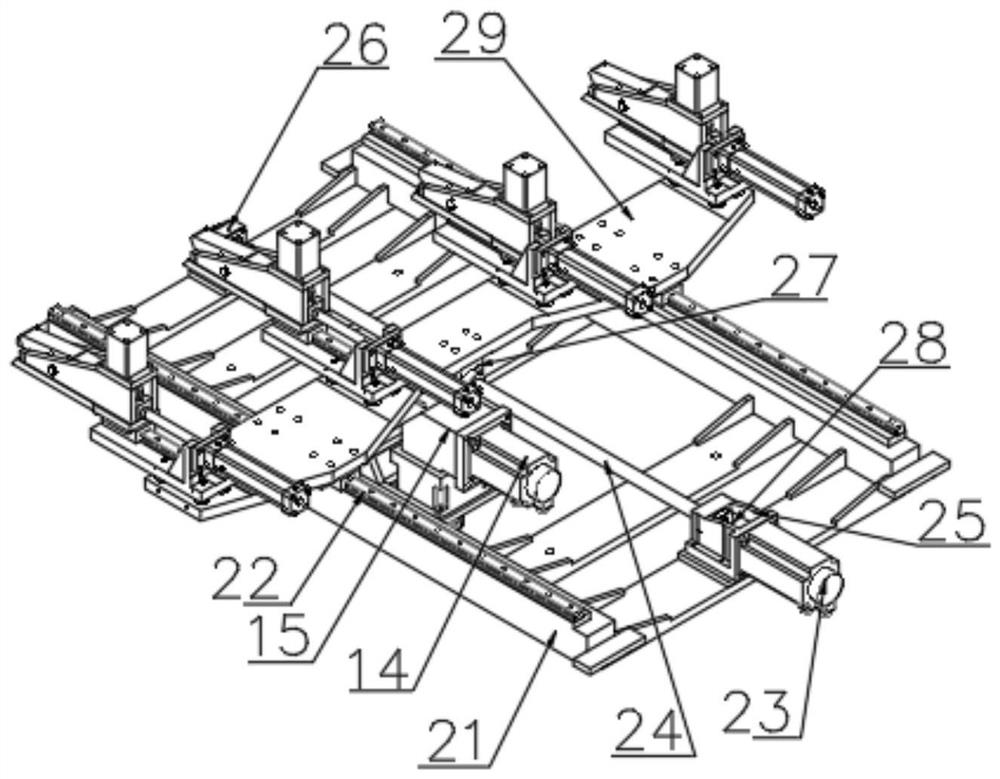

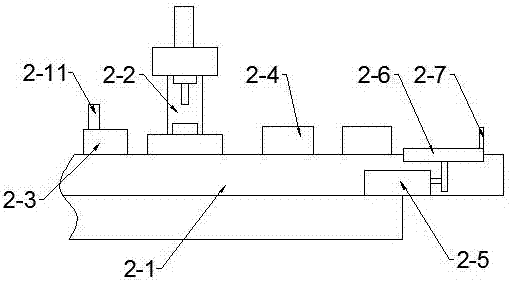

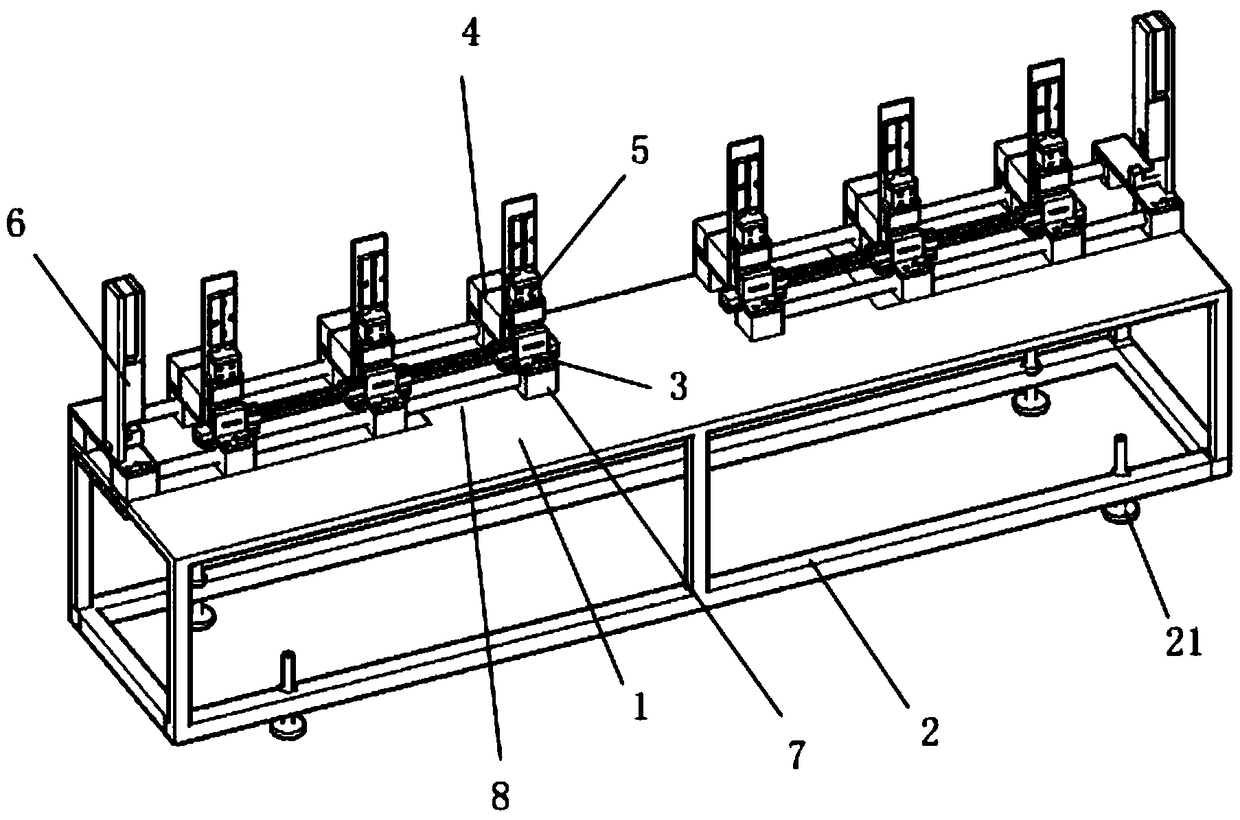

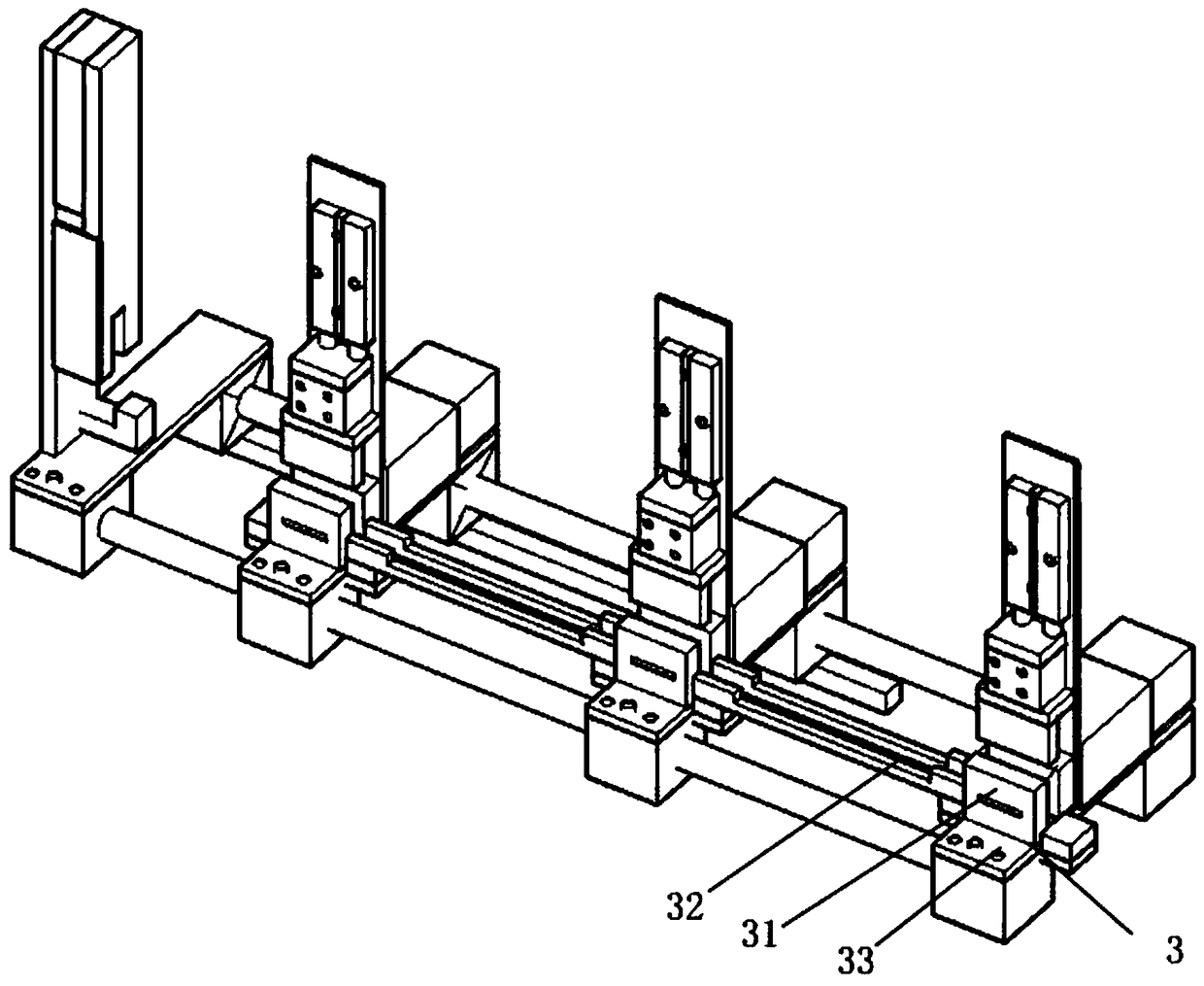

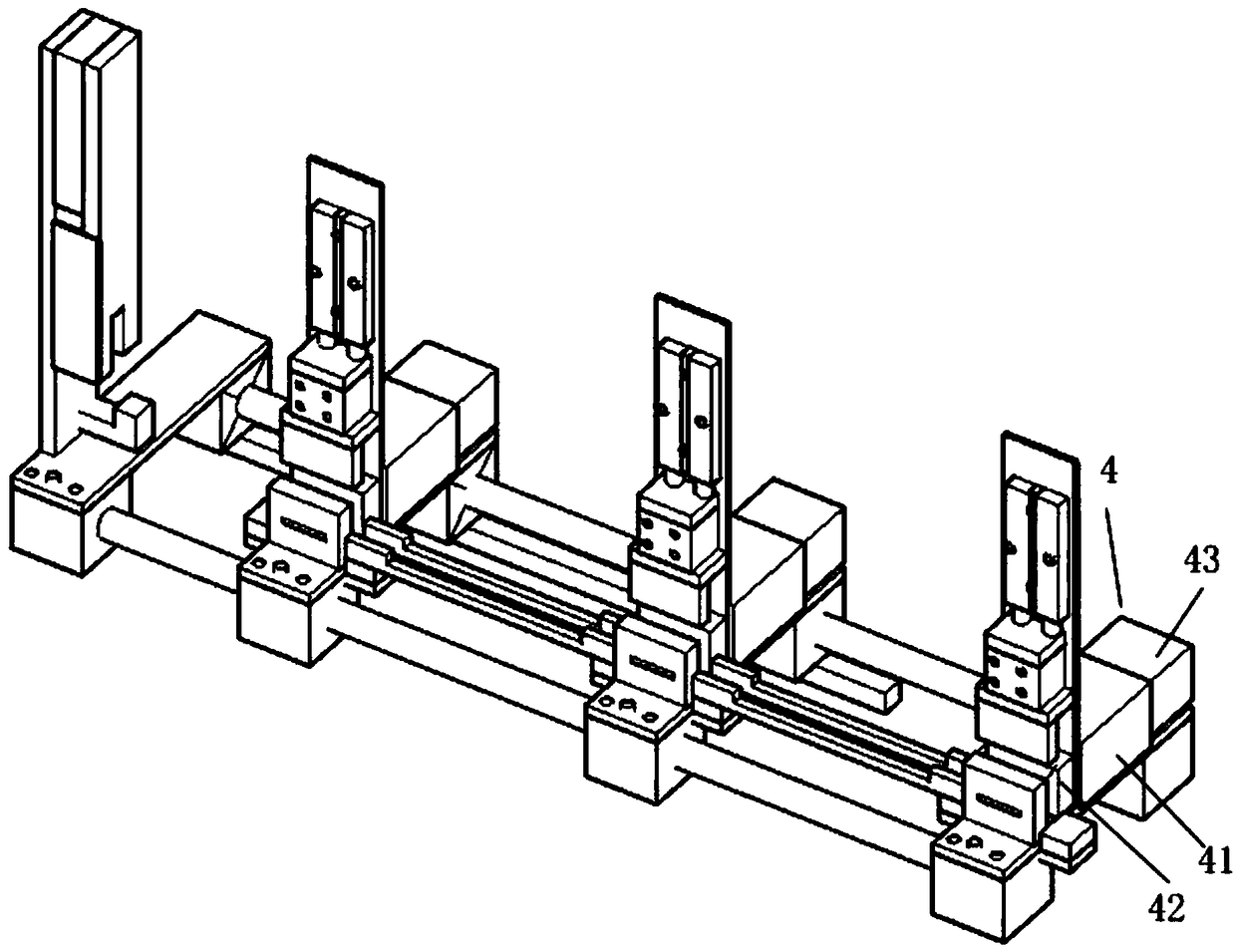

Multi-station automatic blanking machine mechanical device and blanking method

PendingCN108247728AFlexible adjustmentIncrease productivityMetal working apparatusEngineeringLocation Equipment

The invention relates to a multi-station automatic blanking machine mechanical device and a blanking method. The mechanical device comprises an operation platform, a machine frame, positioning appliances, pressing appliances, blanking appliances and end socket cutting appliances. The operation platform is installed on the machine frame. The positioning appliances, the pressing appliances, the blanking appliances and the end socket cutting appliances are all installed on the machine frame. One positioning appliance, one pressing appliance and one blanking appliance form a blanking station, three blanking stations are in one set, two sets of blanking stations are formed, and each set of blanking stations are provided with one end socket cutting appliance. The multi-station automatic blankingmachine mechanical device has the advantages that the multiple stations are formed, multi-station blanking and accurate cutting tasks can be completed at the same time, production efficiency is high,the blanking position can be flexibly adjusted, and blanking tasks for different sealing strips can be completed.

Owner:SHANGHAI RONGNAN TECH CO LTD +2

Efficient mobile phone accessory machining device

InactiveCN108637301AWon't moveQuick changePositioning apparatusMetal-working holdersPower equipmentEngineering

The invention discloses an efficient mobile phone accessory machining device comprising a base, a workbench, a supporting beam, a cross beam, a clamping device, moving equipment, power equipment, a drill stem and a drill bit. The workbench is arranged on the base. The workbench is provided with a through hole allowing the drill bit to penetrate. The supporting frame is vertically arranged at the edge of the base. The cross beam is fixedly connected with the top of the supporting frame and horizontally arranged. The clamping device comprises air cylinders and tightly pressing blocks. The air cylinders are fixed to the supporting frame. A piston rod of each air cylinder is vertically arranged. The tightly pressing blocks are arranged at the lowest ends of the piston rods. A tightly pressingboss is arranged at the bottom of each tightly pressing block. Holding grooves are formed in the upper surface of the workbench. The tightly pressing bosses are inserted into the holding grooves in amatched manner. The moving equipment is arranged on the cross beam in a sliding manner. The power equipment is arranged on the moving equipment. According to the efficient mobile phone accessory machining device, the clamping device can rapidly complete clamping action of a workpiece to be machined, rapid replacement of the workpiece to be machined is achieved, the drilling efficiency can be improve beneficially, the drilling accuracy is improved, and the drilling quality is guaranteed.

Owner:ANHUI FUYUEDA ELECTRONICS CO LTD

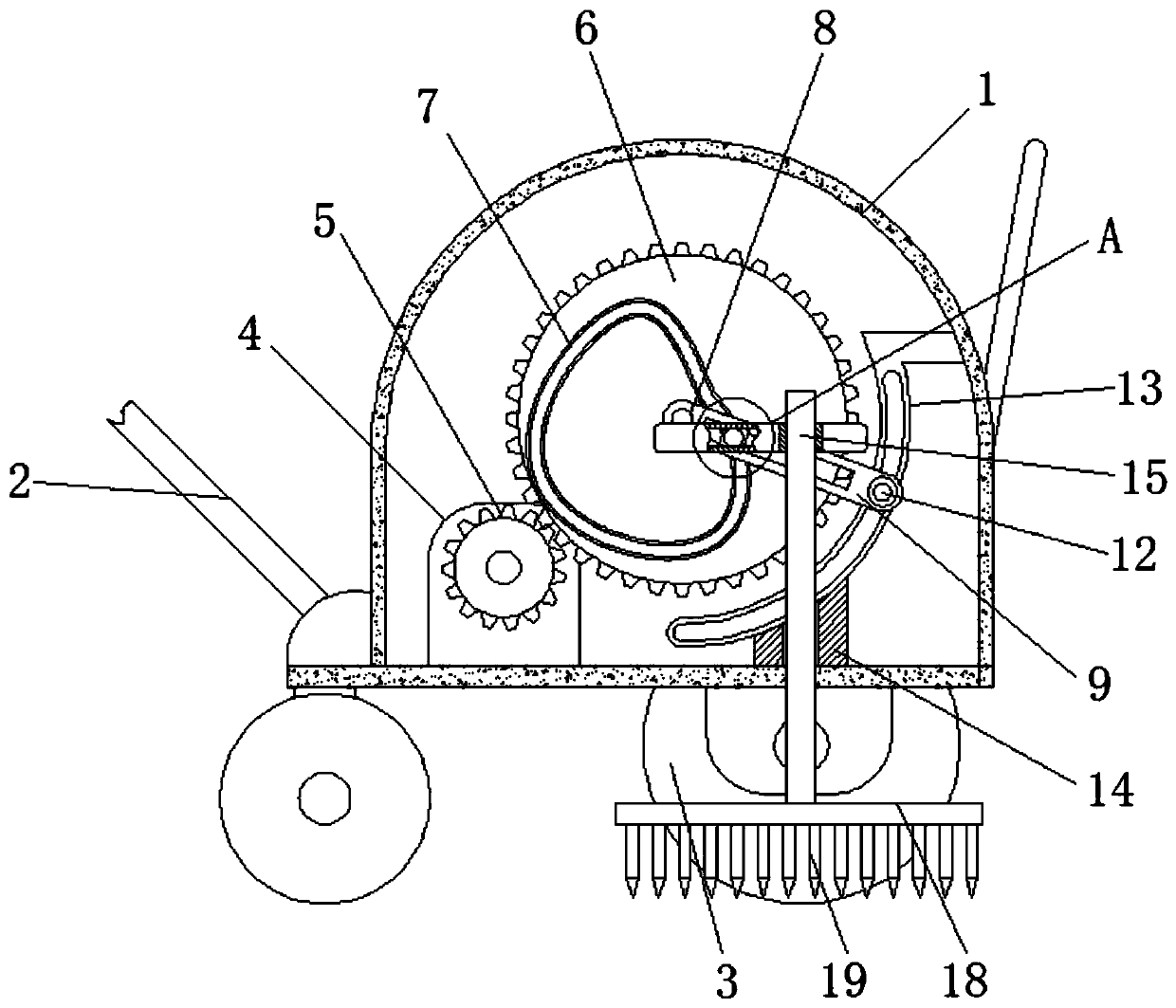

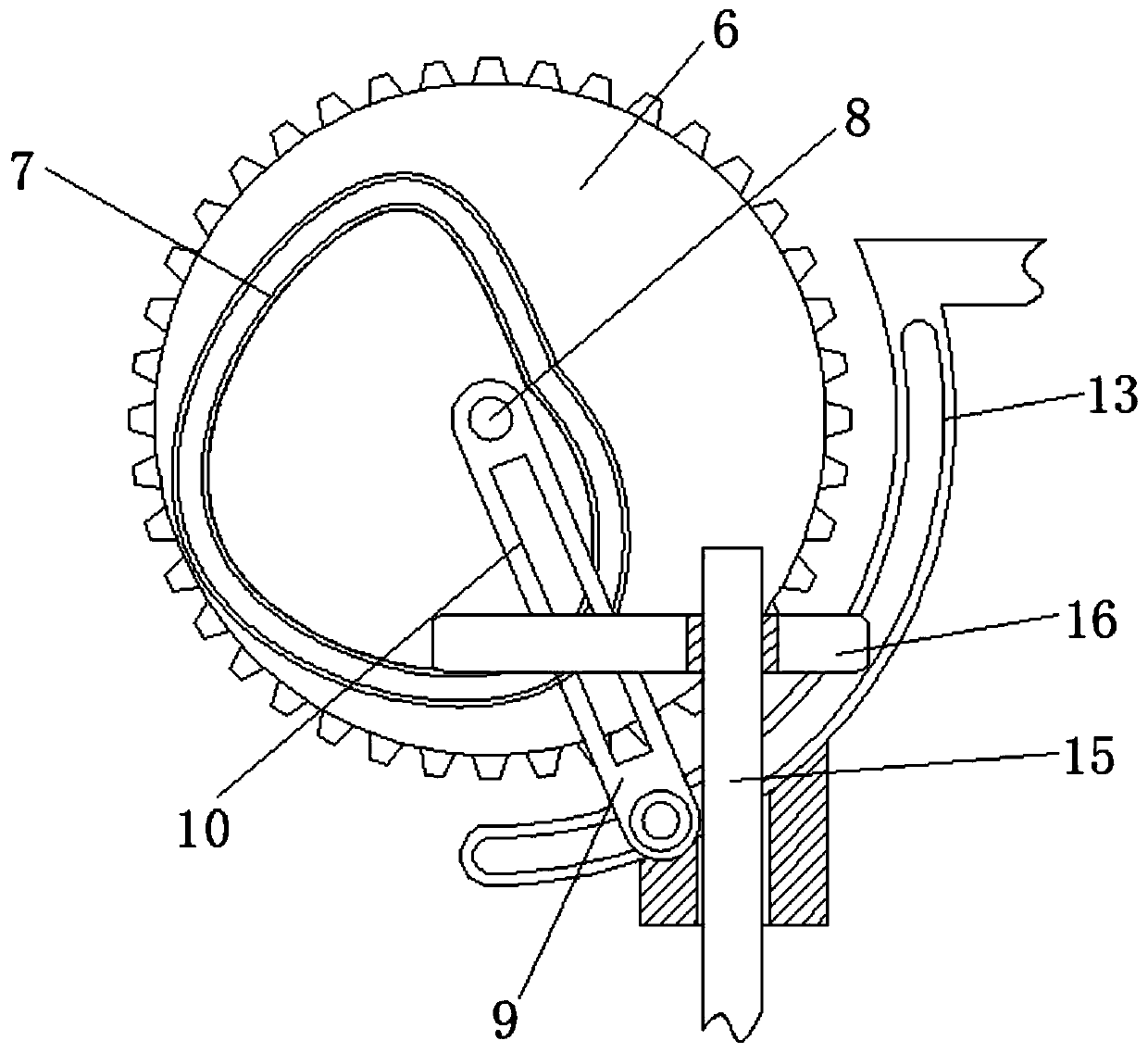

Adjustable lawn aerator based on convex guide rail transmission principle

InactiveCN111201848AGuaranteed punching qualityProtect environmentLawn machinesAgricultural scienceGear wheel

The invention relates to the technical field of environmental protection, and discloses an adjustable lawn aerator based on a convex guide rail transmission principle. The adjustable lawn aerator based on the convex guide rail transmission principle comprises a vehicle body, wherein a handle is fixedly connected outside the vehicle body; wheels are movably connected to the bottom of the vehicle body; a motor is fixedly connected inside the vehicle body; a main gear is fixedly connected outside the motor; a fluted disc is engaged and connected outside the main gear; a guide rail is fixedly connected outside the fluted disc; a connecting shaft is fixedly connected inside the fluted disc; an adjusting rod is movably connected outside the connecting shaft; and a first slide groove is formed inside the adjusting rod. Through the cooperative use of the adjusting rod, a slide block and a transverse rod, the effect of automatically regulating the aeration depth according to different lawns anddifferent soil conditions can be achieved, so that the use range of the device is expanded; the aeration quality of the lawn is ensured, so that the ecological environment of the lawn is protected; and the lawn is enabled to healthily grow.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

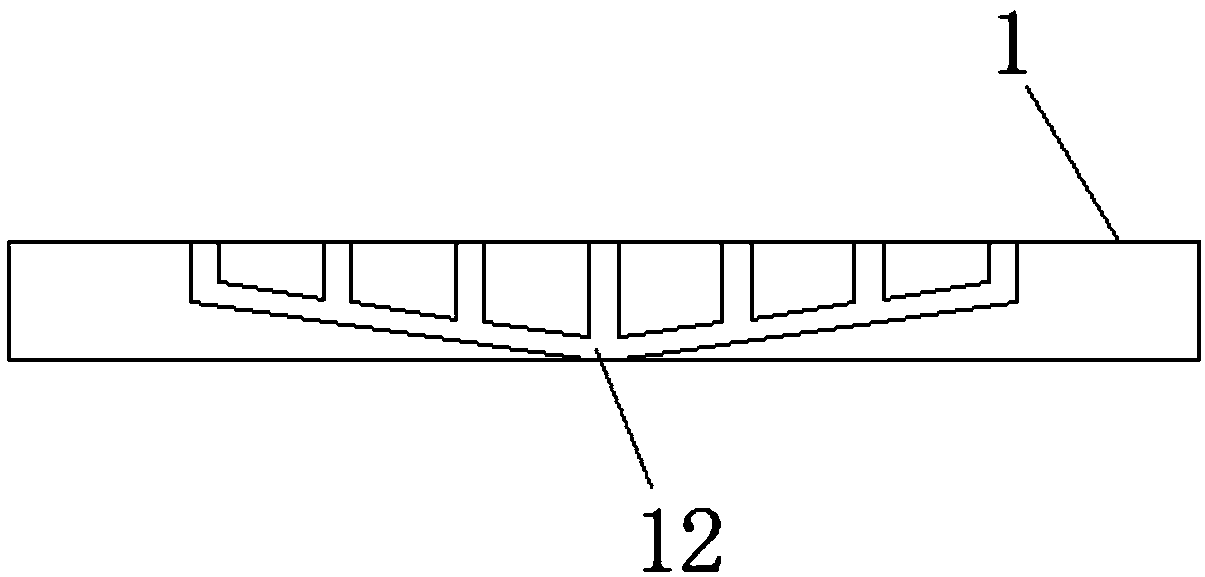

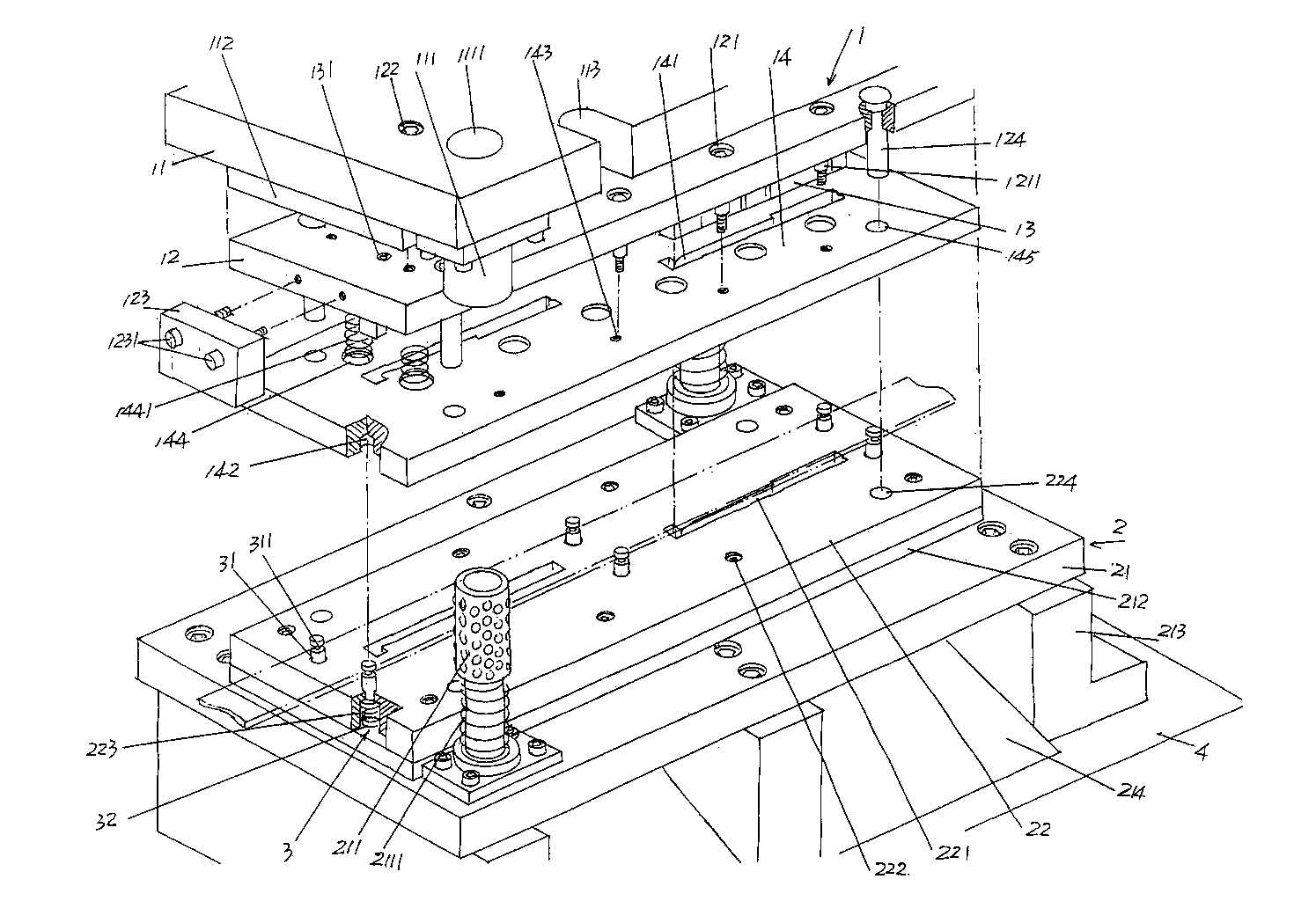

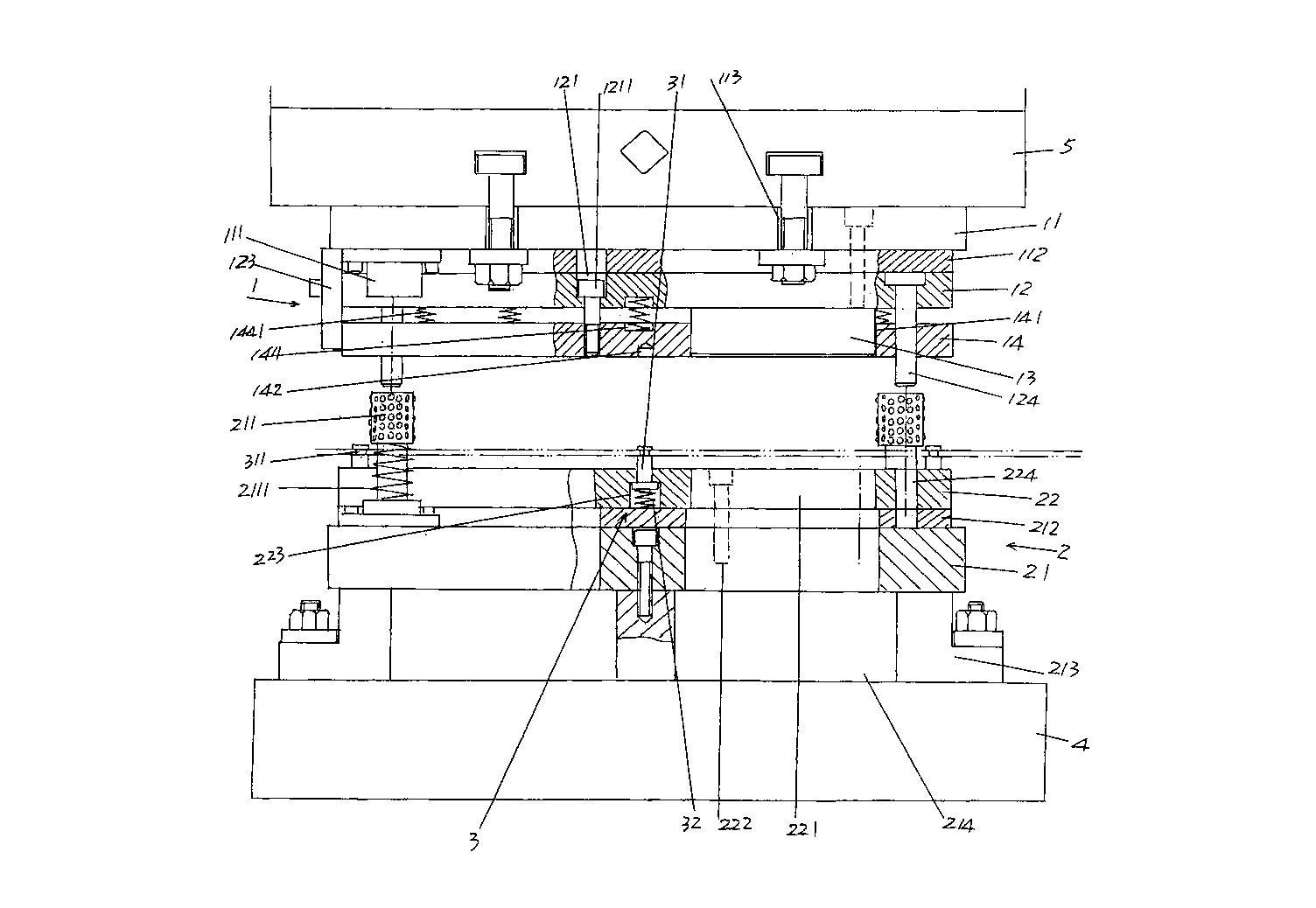

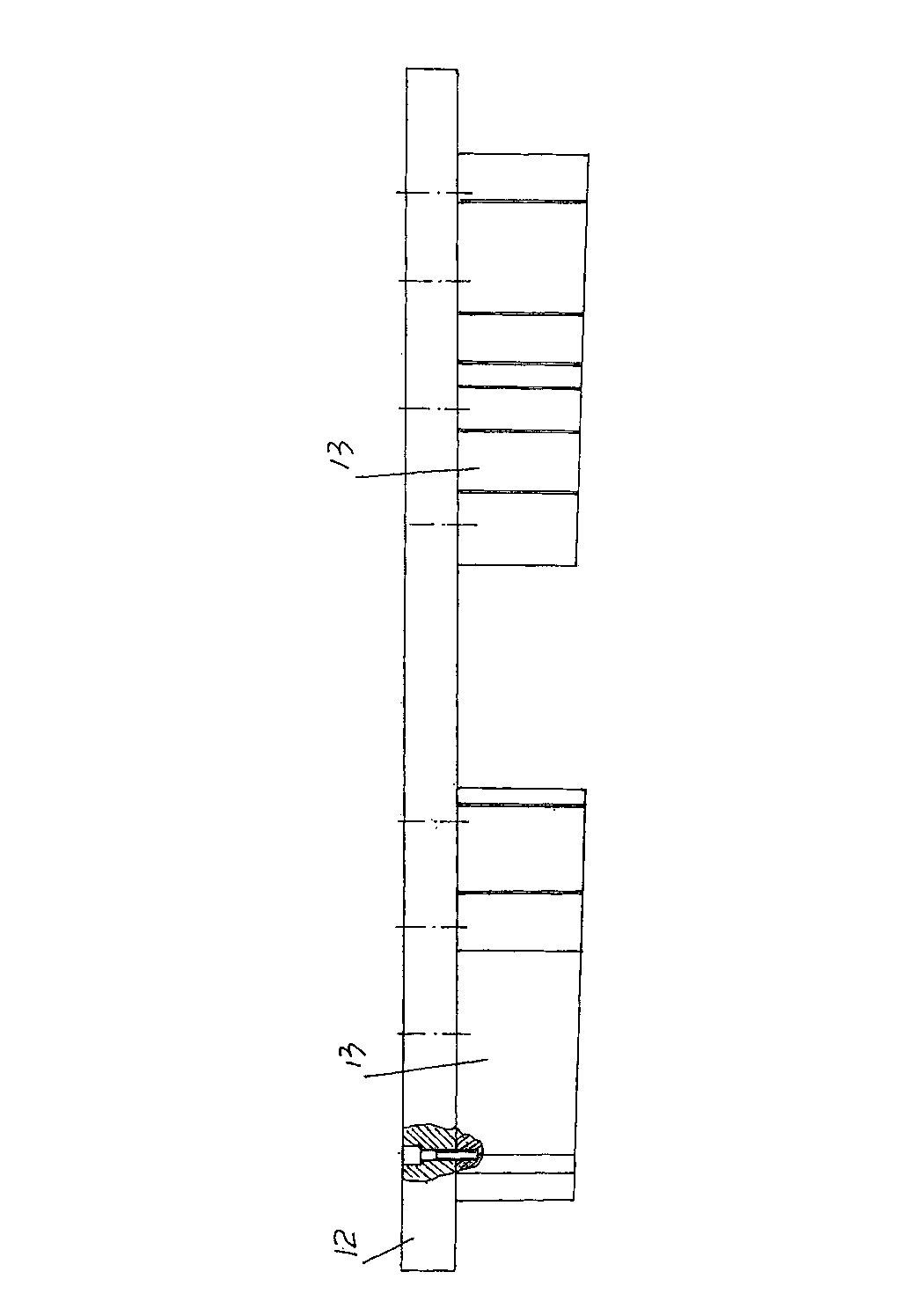

Needle bed insert blank forming die for computer knitting flat knitting machine

InactiveCN102699198AQuality assurancePrevent flutteringShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

The invention discloses a needle bed insert blank forming die for a computer knitting flat knitting machine and belongs to the field of dies. An upper die mechanism comprises an upper die plate frame, an upper die plate and insert male stamping dies, and a lower die mechanism comprises a lower die plate frame and a lower die plate. The needle bed die insert blank forming die is characterized in that one side, which faces the lower die, of each insert male stamping die has a relatively higher end and a relatively lower end; the height difference between the relatively higher end and the relatively lower end is equal to the thickness of a needle bed insert blank to be subjected to stamp forming; the upper die mechanism comprises a pressing plate; the pressing plate is connected with one side of the upper die plate; guiding die holes are formed in the pressing plate, two sides of the pressing plate are provided with a group of first guiding screw holes respectively; second guiding screw holes are formed in two sides of the upper die plate; thin steel strip guiding and limiting mechanisms are arranged on one side of the lower die plate; each thin steel strip guiding and limiting mechanism comprises a guide rod and a spring; and charging grooves are formed on the lower part of the lower die plate frame. The needle bed insert blank forming die has the advantages that the quality of the blank is guaranteed, and the equipment investment is reduced; the stamping quality is guaranteed; unqualified blanks cannot be generated; and the needle bed insert blank forming die can be applied to needle bed insert blank collection.

Owner:常熟市尚湖镇冶塘伟东模具厂

Perforating device for electric power fitting

InactiveCN111299649APrecise punchingGuaranteed punching qualityMeasurement/indication equipmentsLarge fixed membersControl theoryScrew thread

The invention discloses a perforating device for an electric power fitting. The perforating device for the electric power fitting comprises a base, wherein one side of the upper end of the base is fixedly connected with a first sliding rail; a first chute is formed in the upper end of the first sliding rail; the interior of the first chute is connected, in a sliding manner, with a first sliding block which is matched with the first chute; a screw hole is formed in the first sliding block; a first motor is arranged at an end part of the first sliding rail; a power output end of the first motoris connected with a screw rod; the screw rod is in threaded connection with the screw hole in the first sliding block; the upper end of the first sliding block extends to the upper side of the first chute and is fixedly connected with a first fixed seat; the upper end of the first fixed seat is fixedly connected with a first electric telescopic rod; the upper end of the first electric telescopic rod is fixedly connected with a second sliding rail; scale marks are respectively marked at the side ends of the first sliding rail and the second sliding rail; and the side ends of the first fixed seat and a second fixed seat are respectively and fixedly connected with a transverse pointer and a longitudinal pointer. The perforating device for the electric power fitting is simple in structure andconvenient to operate, and can realize accurate perforating of fitting so as to ensure perforating quality.

Owner:青岛正为能源科技有限公司

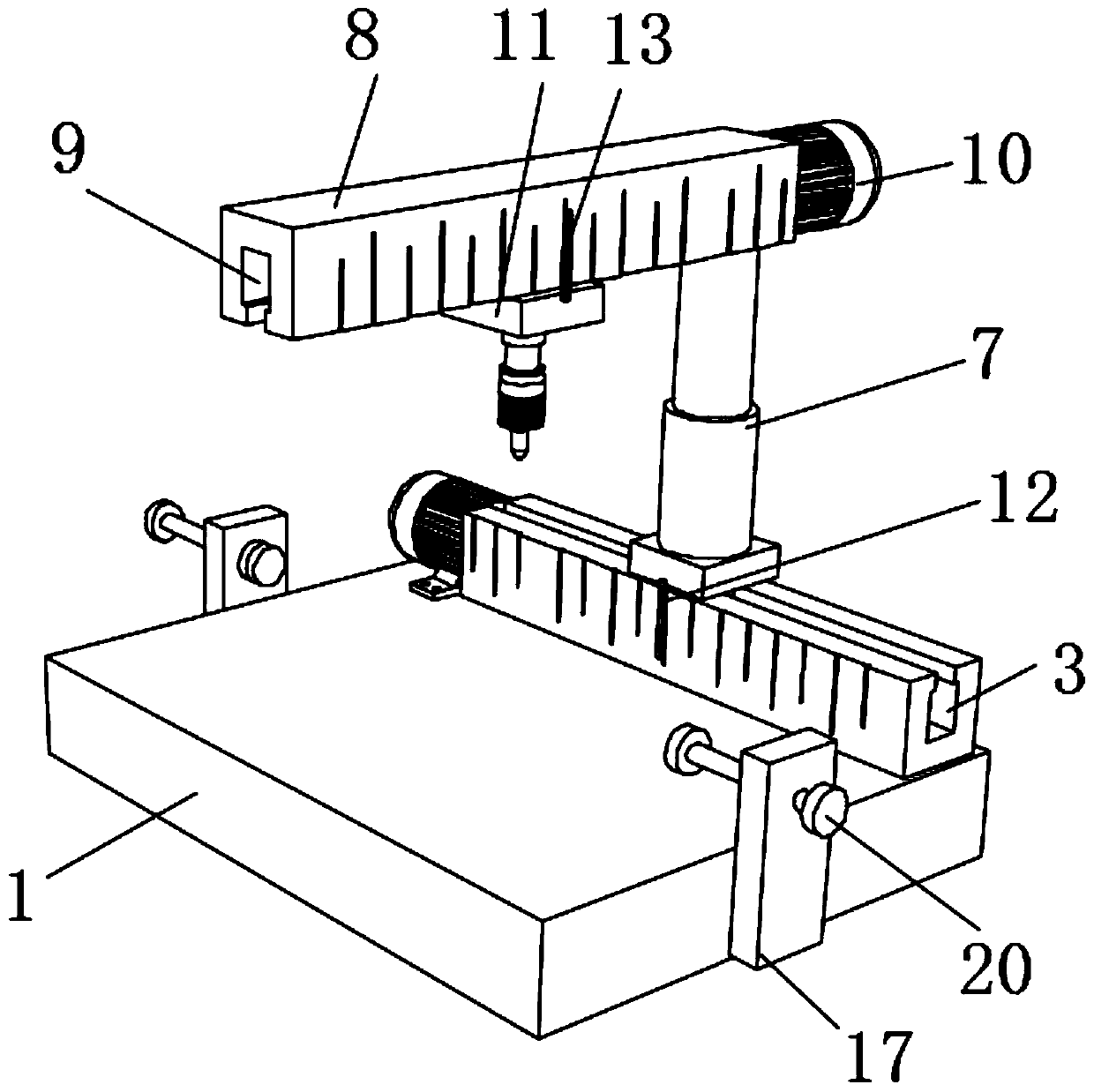

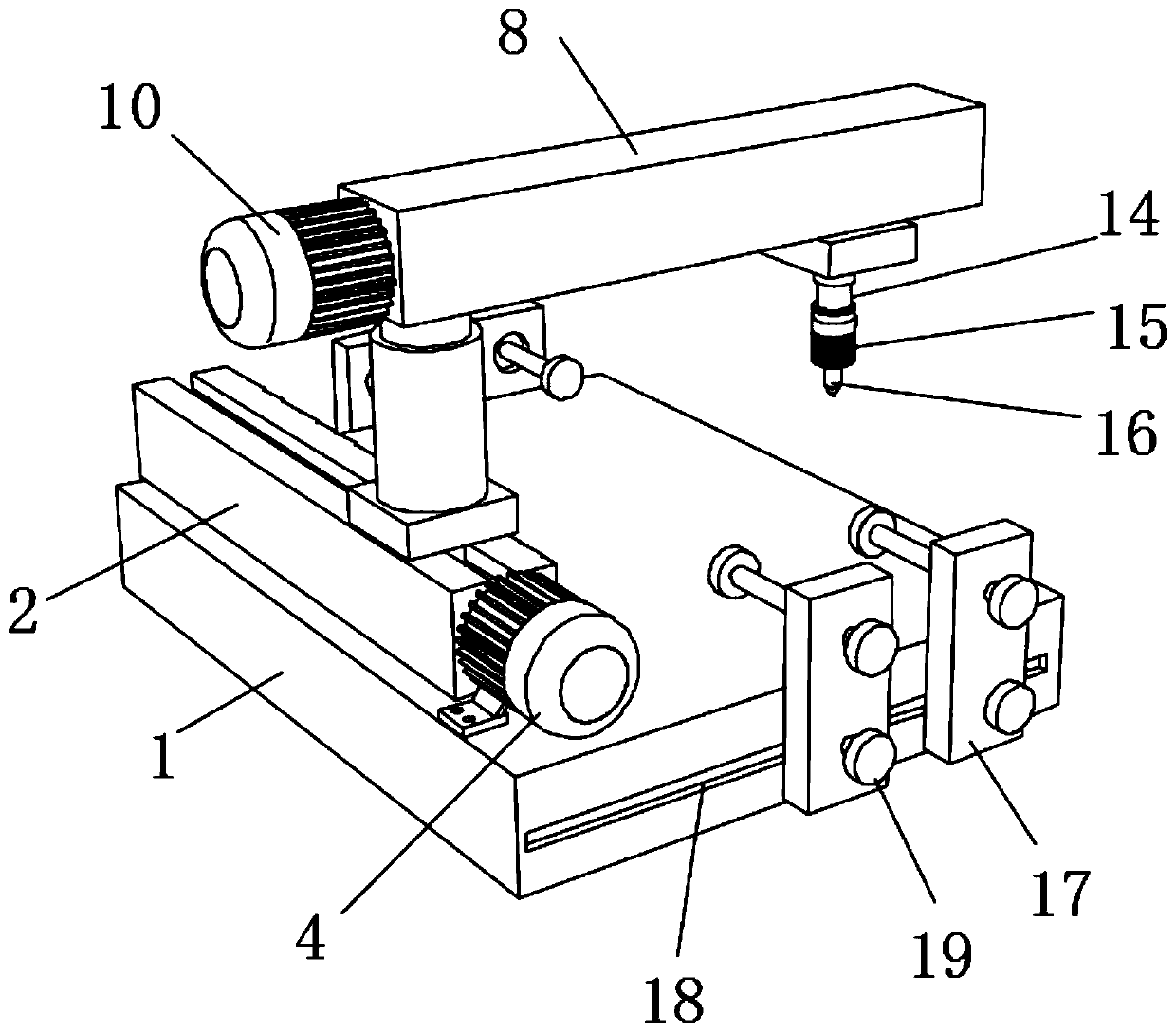

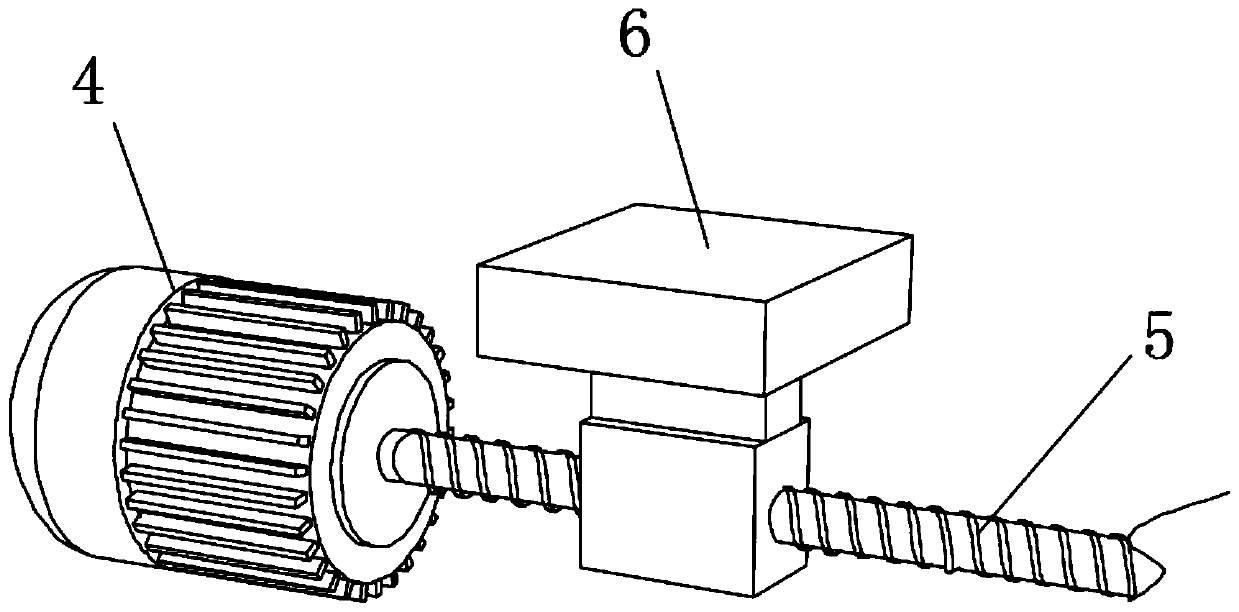

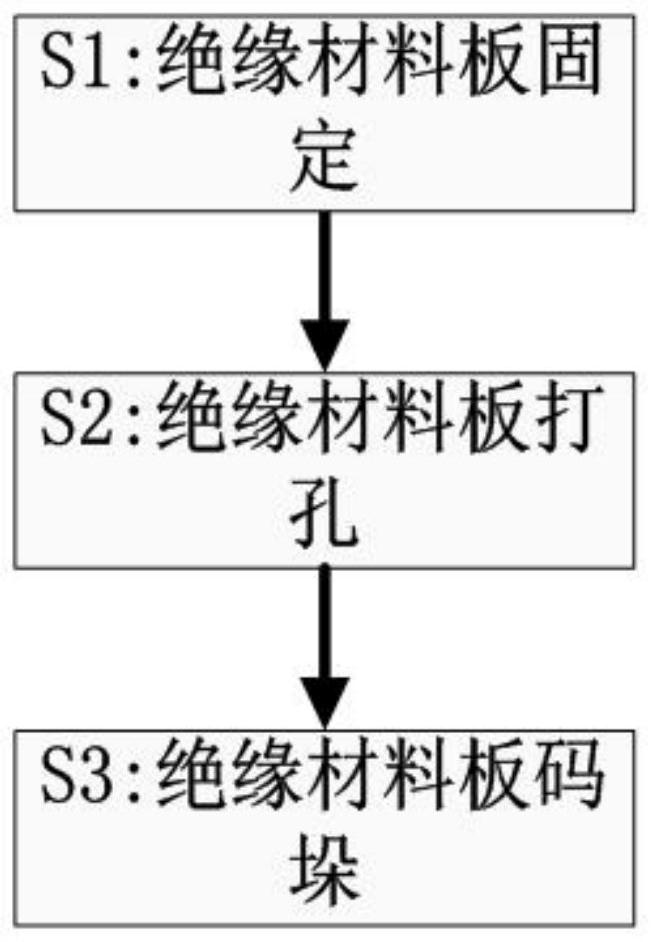

Manufacturing and processing process of electrical insulating material

InactiveCN111958680AAvoid shakingGuaranteed stabilityCleaning using toolsMetal working apparatusPunchingMachining process

The invention provides a manufacturing and processing process of an electrical insulating material. The manufacturing and processing of the electrical insulating material is completed by the cooperation of an annular sleeve, a fixing unit, a drilling unit, an adsorption unit and an insulating material plate to be processed. According to the manufacturing and processing process of the electrical insulating material provided by the invention, the problems that most of punching holes of a circular insulating material plate are radial, the current radial punching mode is difficult to maintain thestability of the circular insulating material plate, the circular insulating material plate shakes to affect the punching quality, an existing punching mode is easy to block with the insulating material plate, the penetration capability of a needle to the insulating material plate is further influenced, and the like can be solved.

Owner:尤之浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com