Grounded flat iron processing and manufacturing platform

A technology for making platforms and grounding flat irons, which is applied in the direction of contact manufacturing, connection, and connection contact materials, etc., can solve the problems of poor quality of hue mark spraying, low degree of mechanization of flat irons, and non-uniform manufacturing processes, so as to improve work efficiency. The effect of environmental quality, reduction of physical damage, and uniform production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

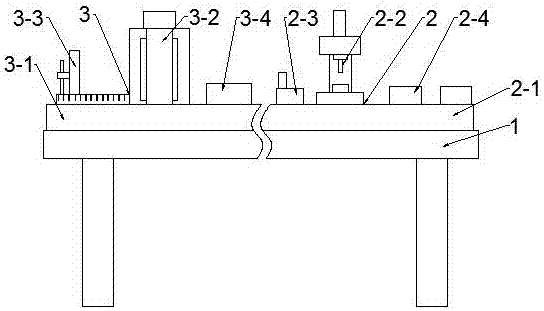

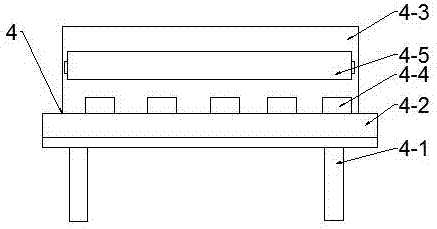

[0019] Embodiment 1: as Figure 1-2 As shown, a semi-automatic ground flat iron processing and manufacturing platform includes an operating platform 1 and a spraying mechanism 4, and the operating platform 1 is provided with a punching mechanism 2 and a bending mechanism 3; wherein, the punching mechanism 2 includes a base 2 -1, the top of the base 2-1 is provided with a punching machine 2-2, and the punching machine adopts a CH-60 type punching machine. Support block 2-3 and two positioning blocks 2-4, support block 2-3 is positioned at the side of punching machine 2-2, is used for supporting ground flat iron, and positioning block 2-4 is positioned at the side of punching machine 2-2 The other side is used to locate the ground flat iron so that it is in a horizontal straight line position; the bending mechanism 3 includes a support 3-1, and the support 3-1 is provided with a bending machine 3-2, a positioning plate 3-3 and Fixed plate 3-4, bending machine adopts CB-150D typ...

Embodiment 2

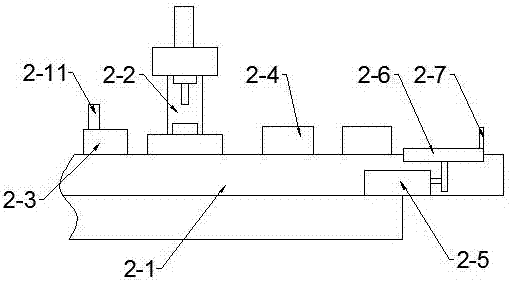

[0021] Embodiment 2: as Figure 3-6 As shown, a grounded flat iron processing and manufacturing platform with a higher degree of automation, the bottom of the base 2-1 is provided with a first motor 2-5, and the output end of the first motor 2-5 passes through a gear and a rack 2-6 connected, the upper end of the rack 2-6 is provided with a push plate 2-7, and the push plate 2-7 corresponds to the positioning block 2-4 and the support block 2-3; the first motor drives the push plate to move through the rack and pinion, Push the grounded flat iron on the positioning block to move forward. Both the first motor 2-5 and the punching machine 2-2 are connected with the controller, and are controlled by the controller to open and rotate. The positioning block 2-4 and the support block 2-3 are located on the same straight line to ensure the horizontal state of the grounding flat iron; the top of the positioning block 2-4 is provided with a positioning groove, and the grounding flat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com