Patents

Literature

217results about How to "Improve punching accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

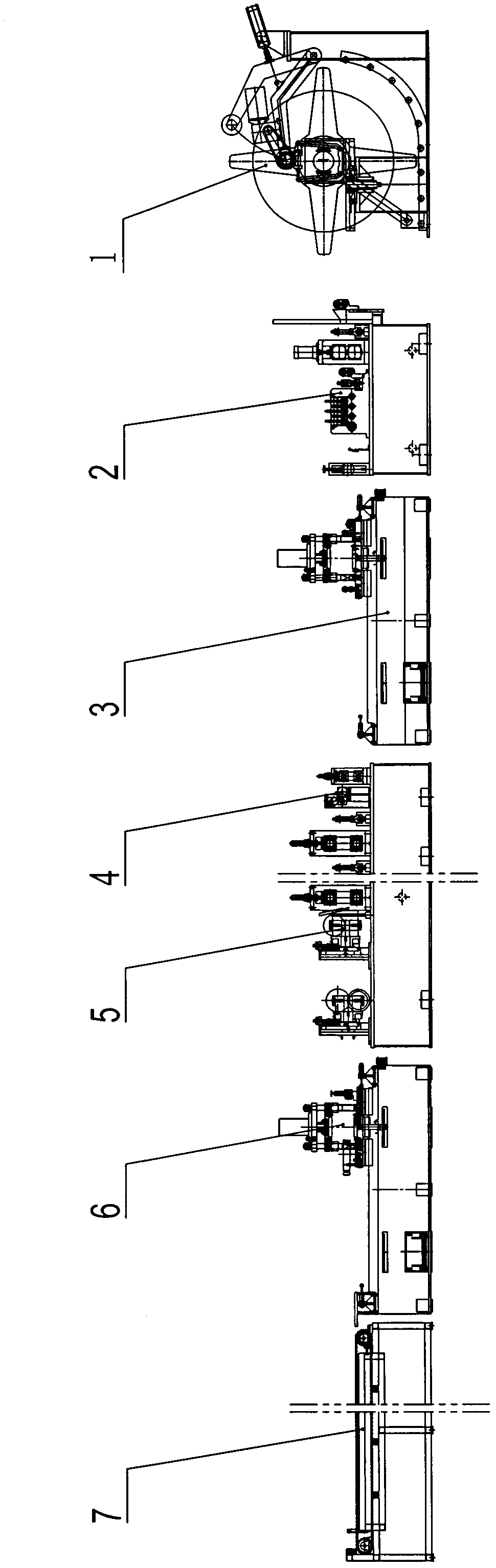

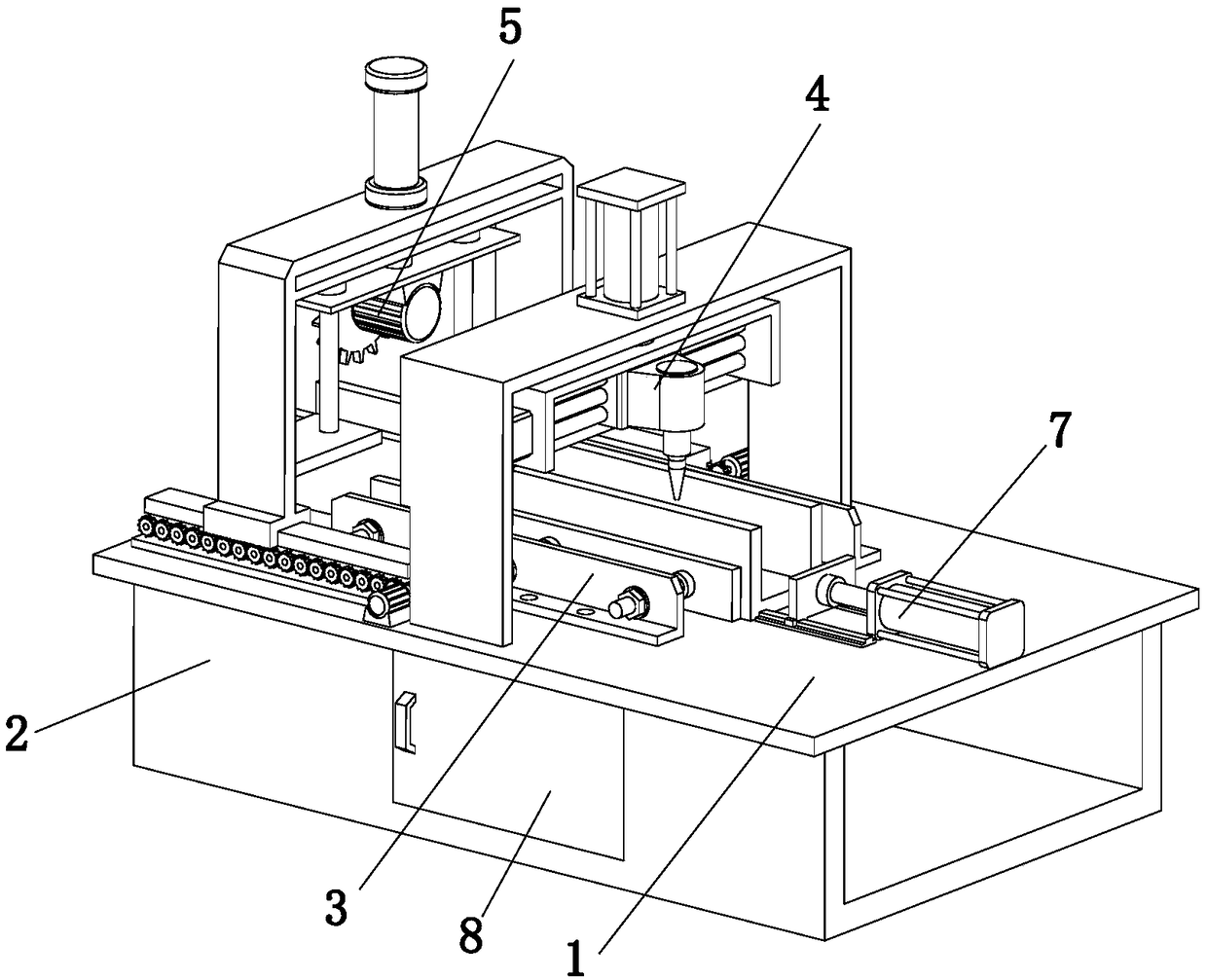

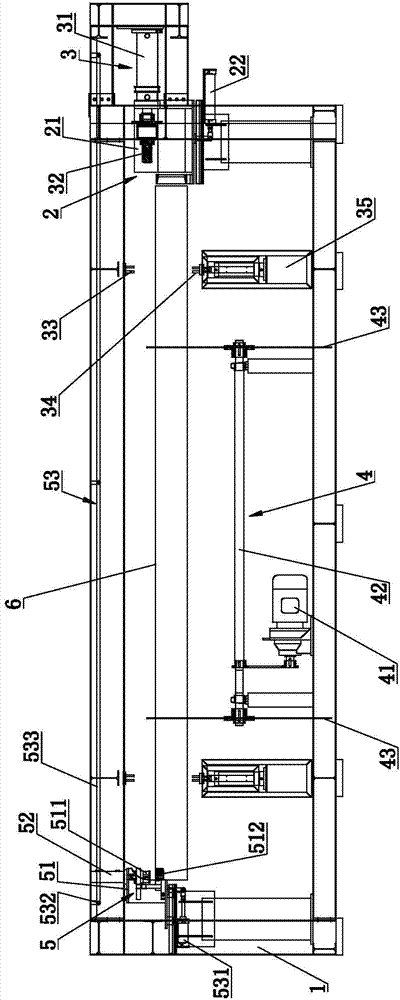

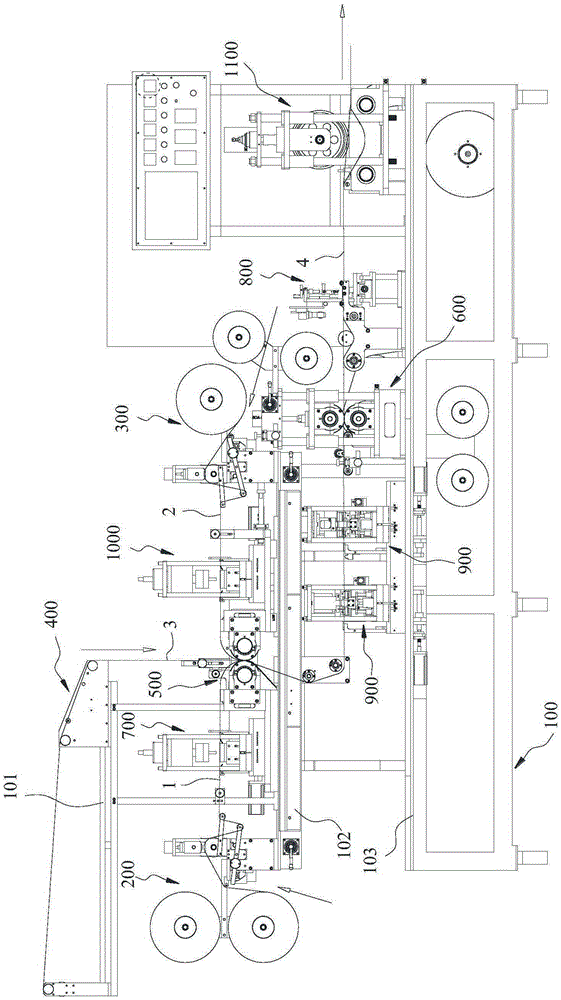

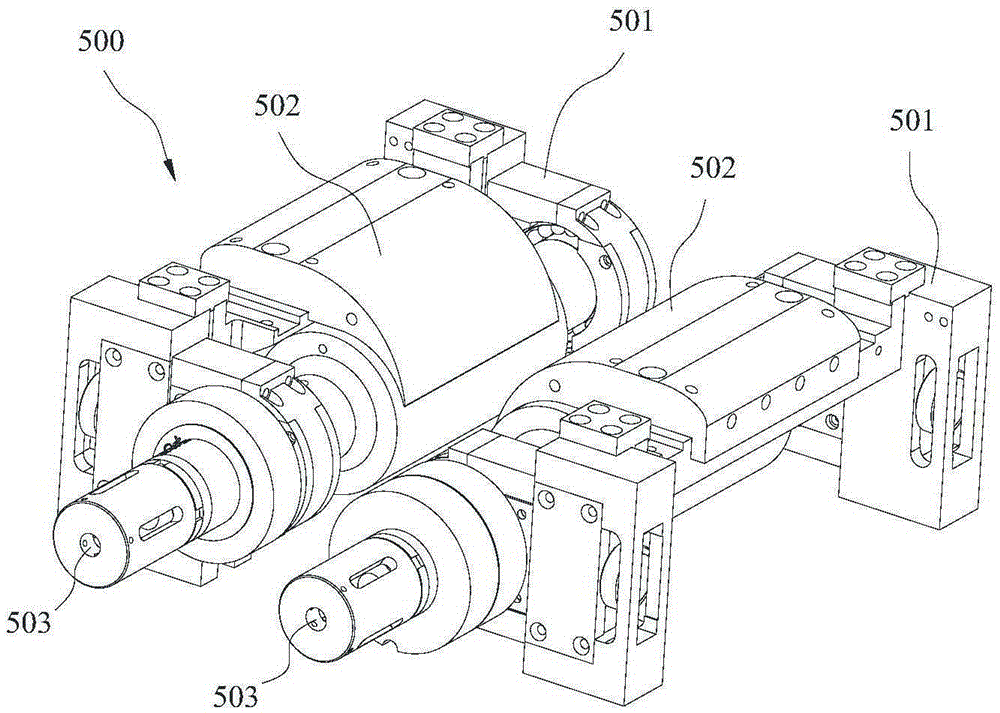

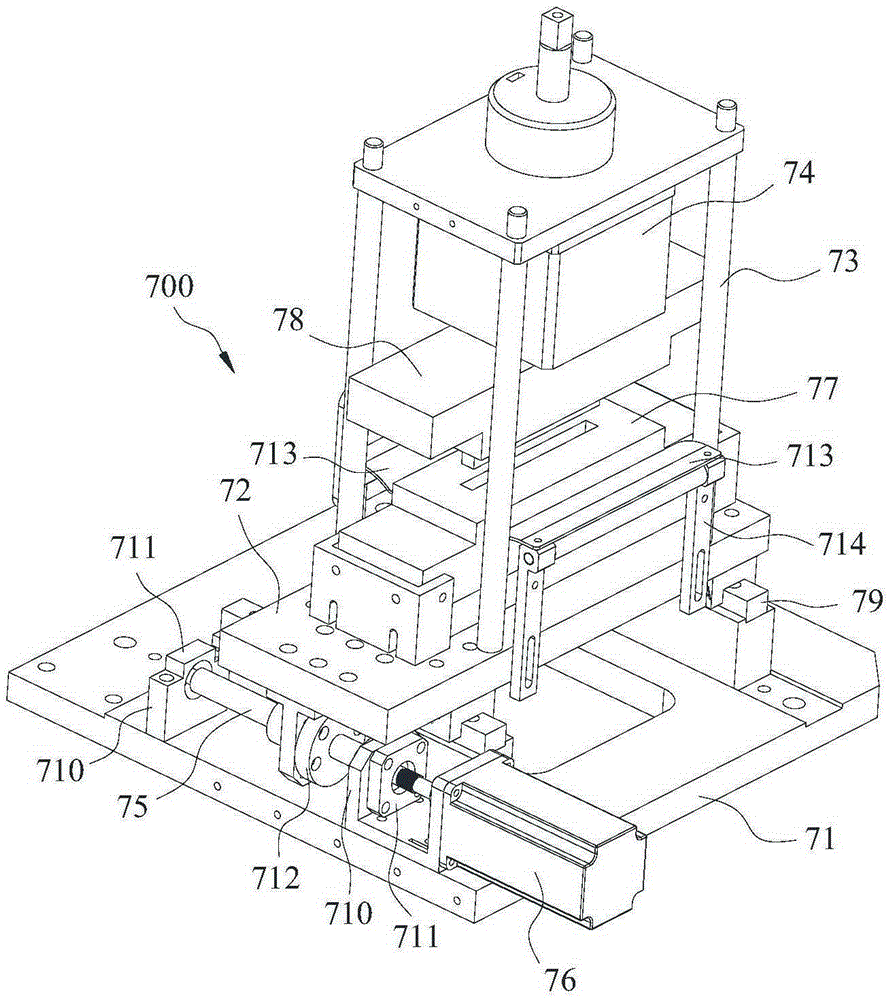

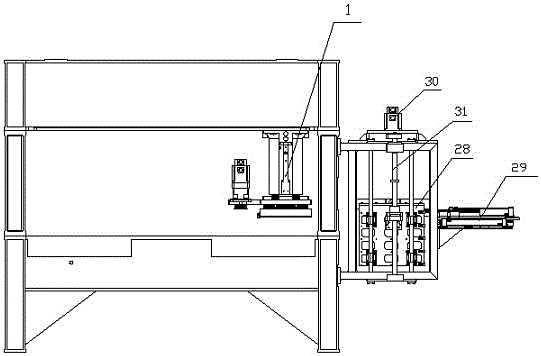

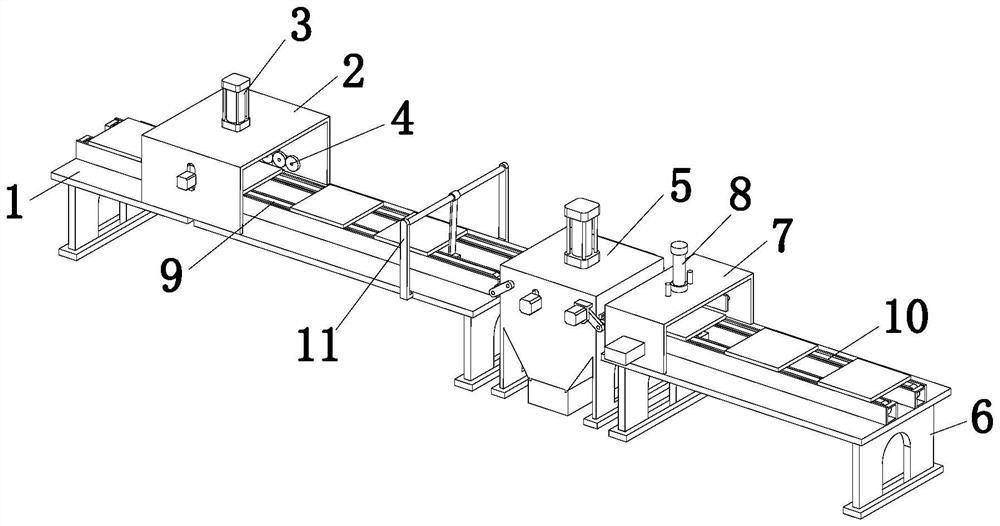

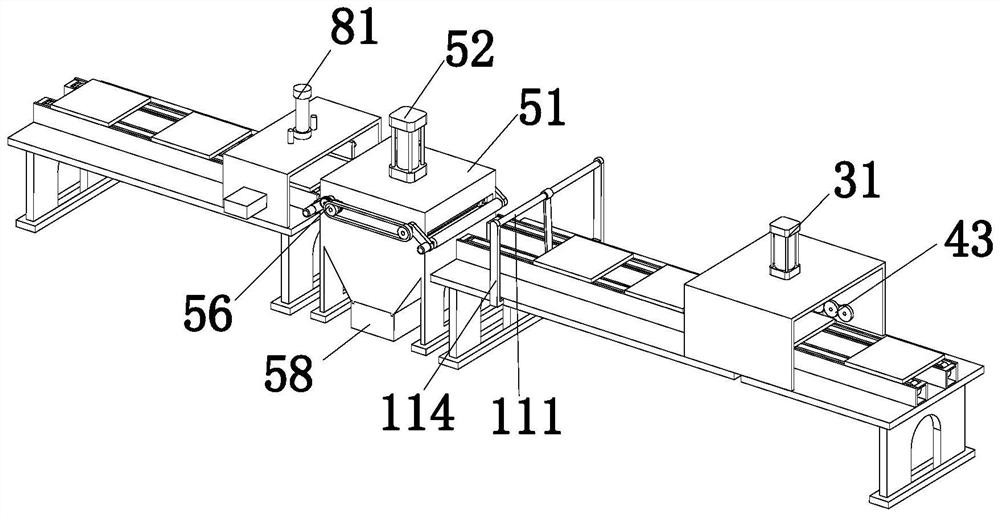

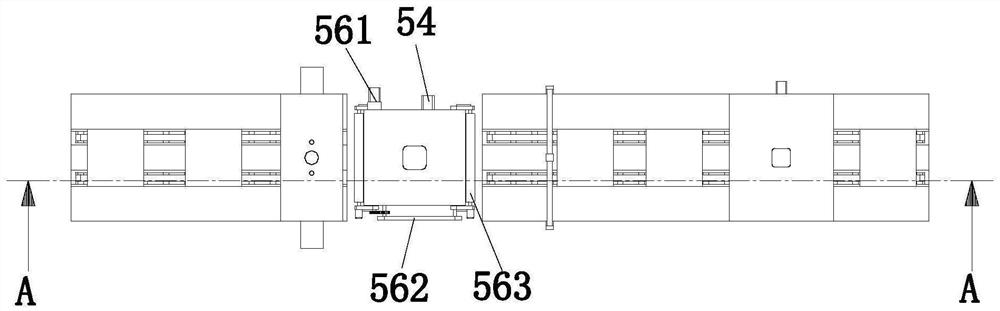

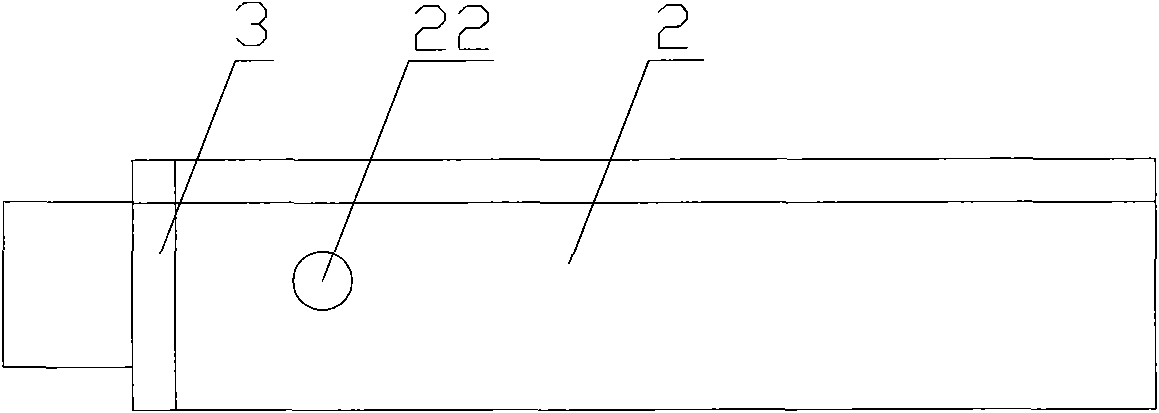

Roll forming processing method for online punching and production line

The invention relates to a roll forming processing method for online punching and a production line in the technical field of sheet roll forming. The method comprises the following steps of: emptying, leveling, punching, roll forming, cutting and blanking. The punching step comprises the following specific steps of: detecting a real-time displacement signal of the linear motion of a sheet; driving a punching mechanism to move at an accelerated speed according to the displacement signal and drive the sheet to a set punching position along the movement direction of the sheet; driving the punching mechanism to track the linear motion of a coiled sheet and keep moving synchronously with the sheet; in a process of keeping synchronous movement with the sheet, allowing the punching mechanism to punch a hole at the set position on the sheet; and returning the punching mechanism to an initial position. The invention also provides the production line for implementing the method. Punching is performed after a servo motor controlled by a programmable logic controller (PLC) drives a workbench to track the sheet. The processing method and the production line can improve sheet processing accuracy and increase sheet processing speed and can be used for molding, punching and processing sheets with fixedly shaped cross sections.

Owner:YANGZHOU NANYANG WELDING PIPE MOLD CO LTD

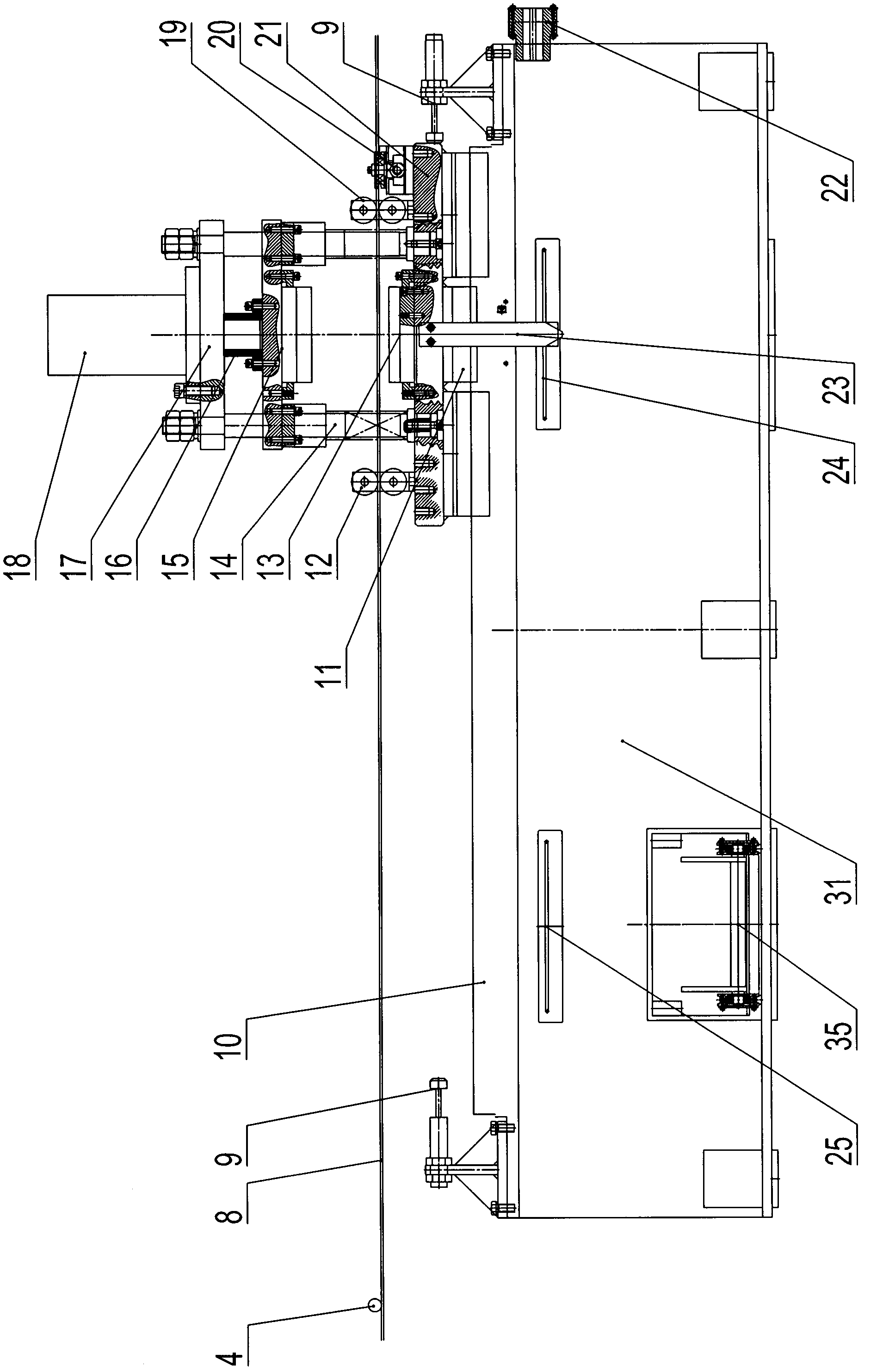

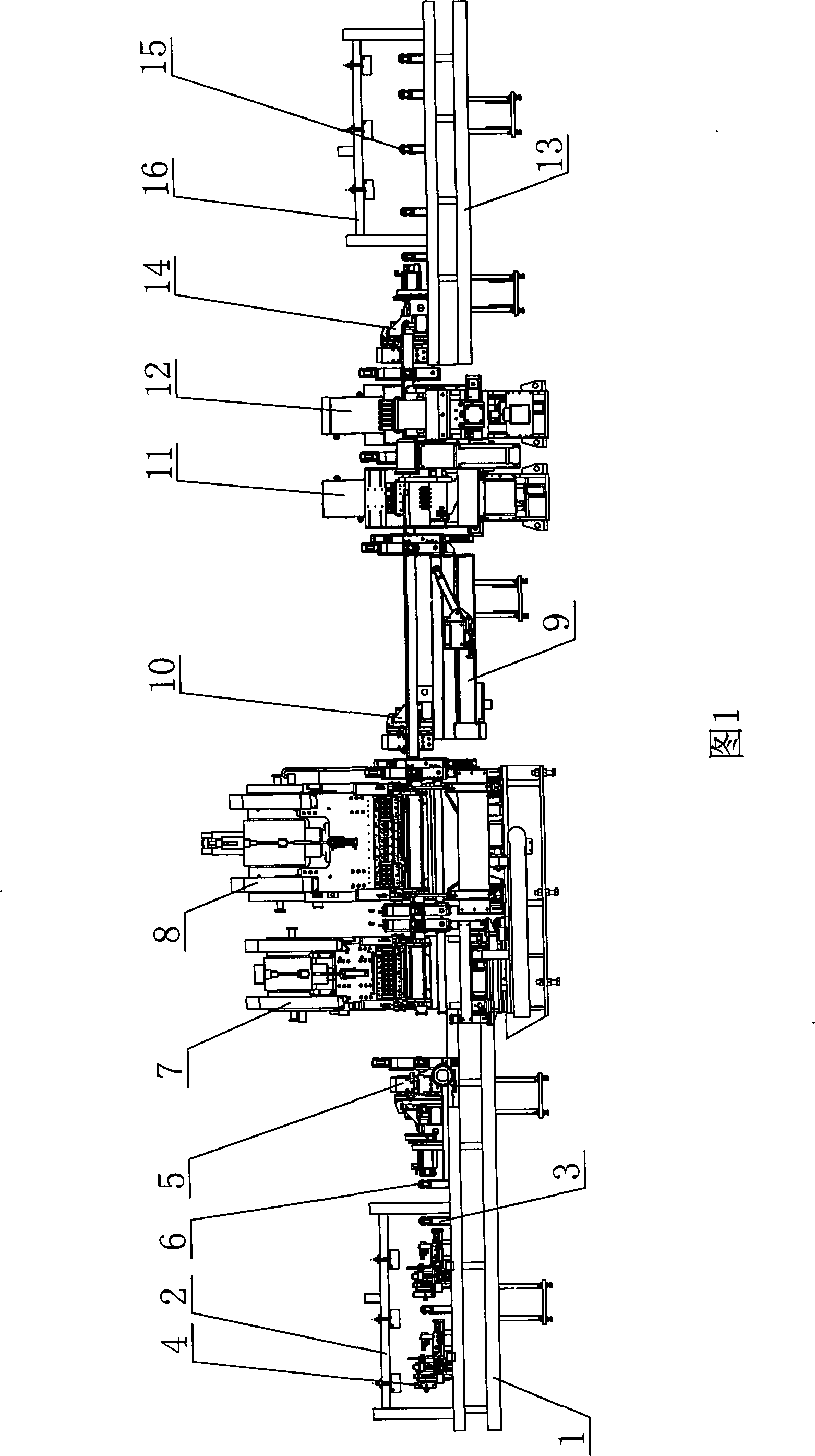

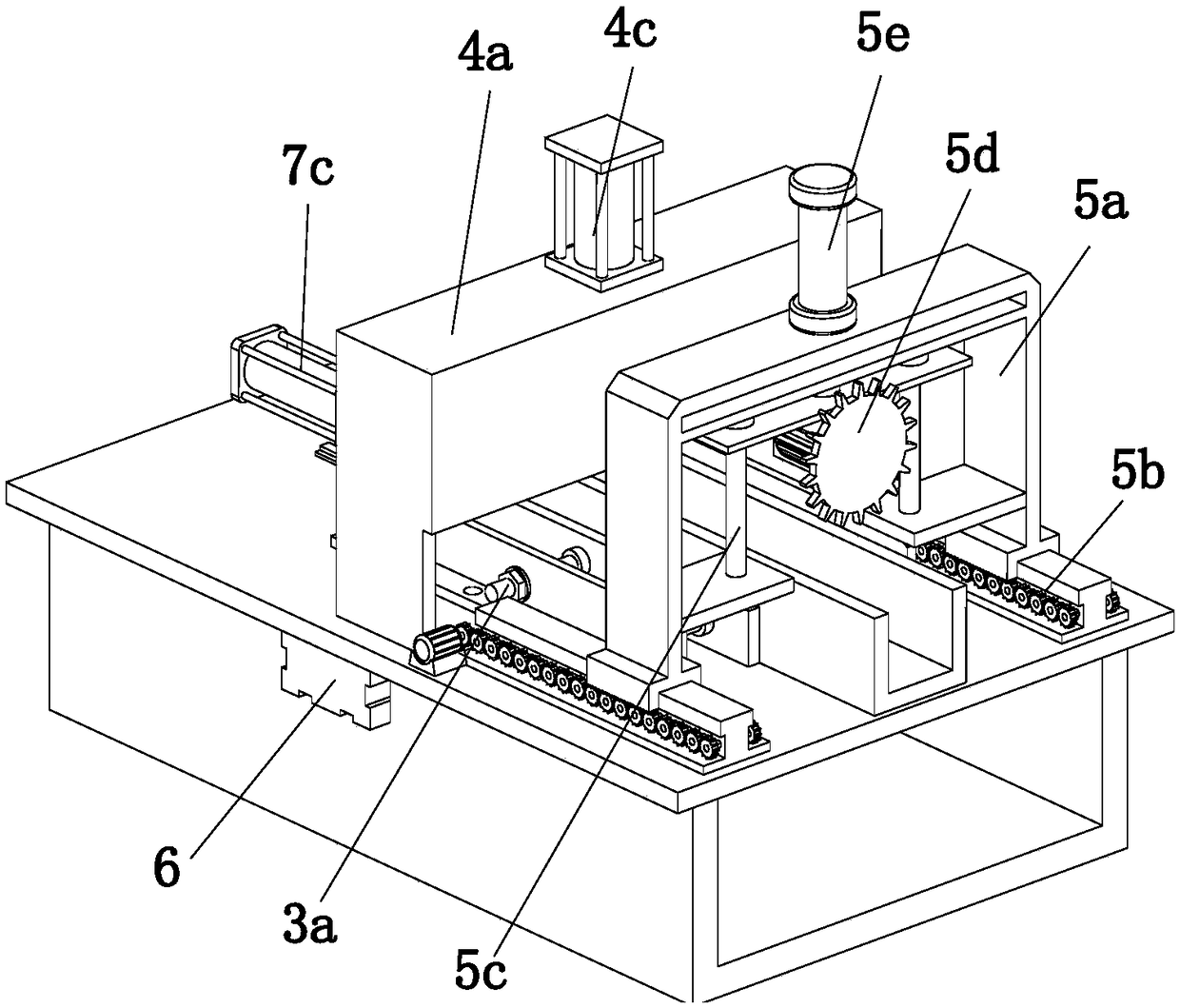

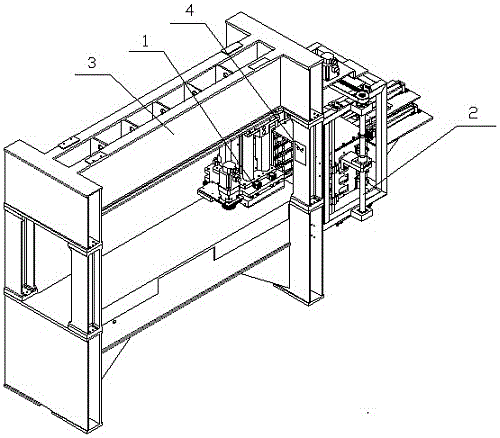

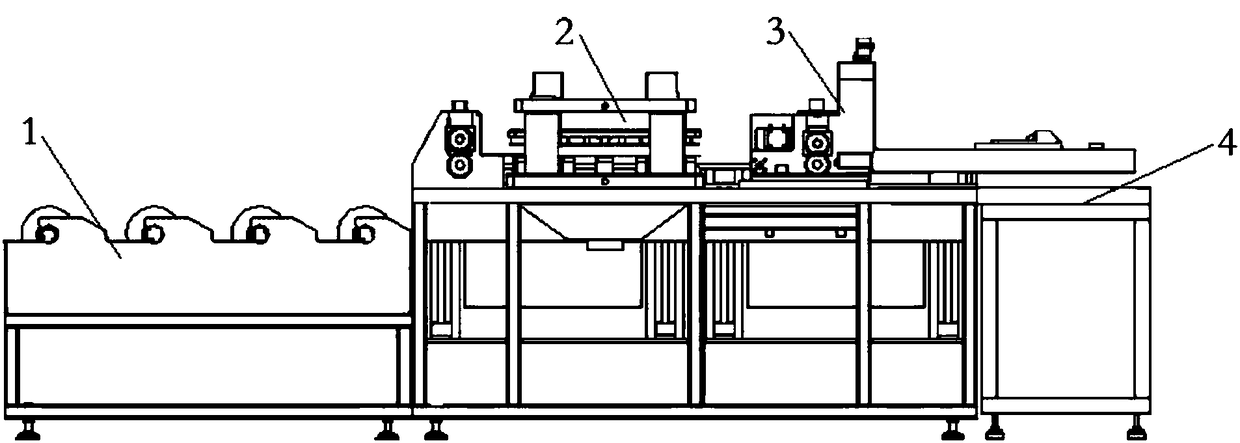

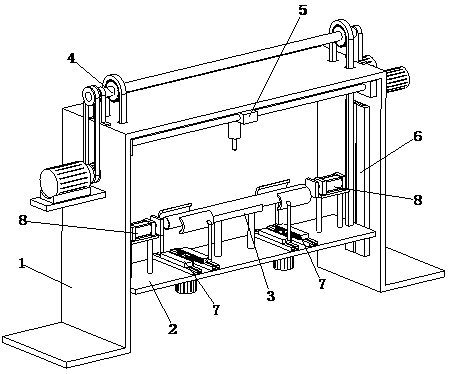

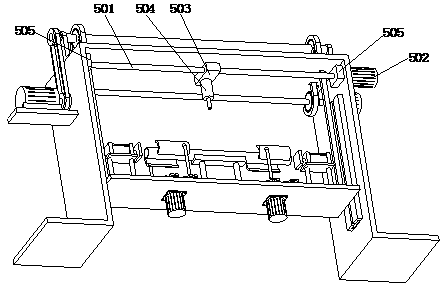

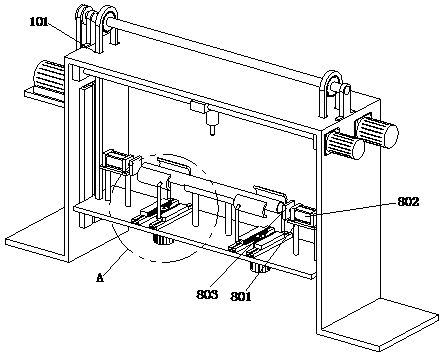

U shaped beam three-face punching technique and production device using the technique

InactiveCN101386046AThe punching position is accurateReduce manufacturing costShaping toolsPerforating toolsShaped beamPunching

The invention discloses a three-side-punch process of a U-shaped beam and a production device used in the process. The process comprises the following steps: the U-shaped beams are placed on a feeding platform, a feed picking device is adopted to successively pick up the spare U-shaped beams and hoist the beams to a support roller of the feeding end; a first feeding clamping device is adopted to clamp the U-shaped webs and feed the webs to working platforms of a ventral small punching machine which can move along the X / Y axis and a ventral large punching machine which can move along the Y axis; the ventral small punching machine which can move along the X / Y axis and the ventral large punching machine which can move along the Y axis punch the beams; a second feeding clamping device clamps the U-shaped beams and continuously feed the beams to the working platform of a left wing punching machine and a right wing punching machine; the left wing punching machine and the right wing punching machine punch the beams; the U-shaped beams are hoisted to a discharging platform after being fully punched. The invention has the advantages of simple process, high production efficiency, low cost and reasonable process arrangement; and the produced U-shaped beams have precise punching location.

Owner:JINAN CASTING FORGING MACHINERY INST

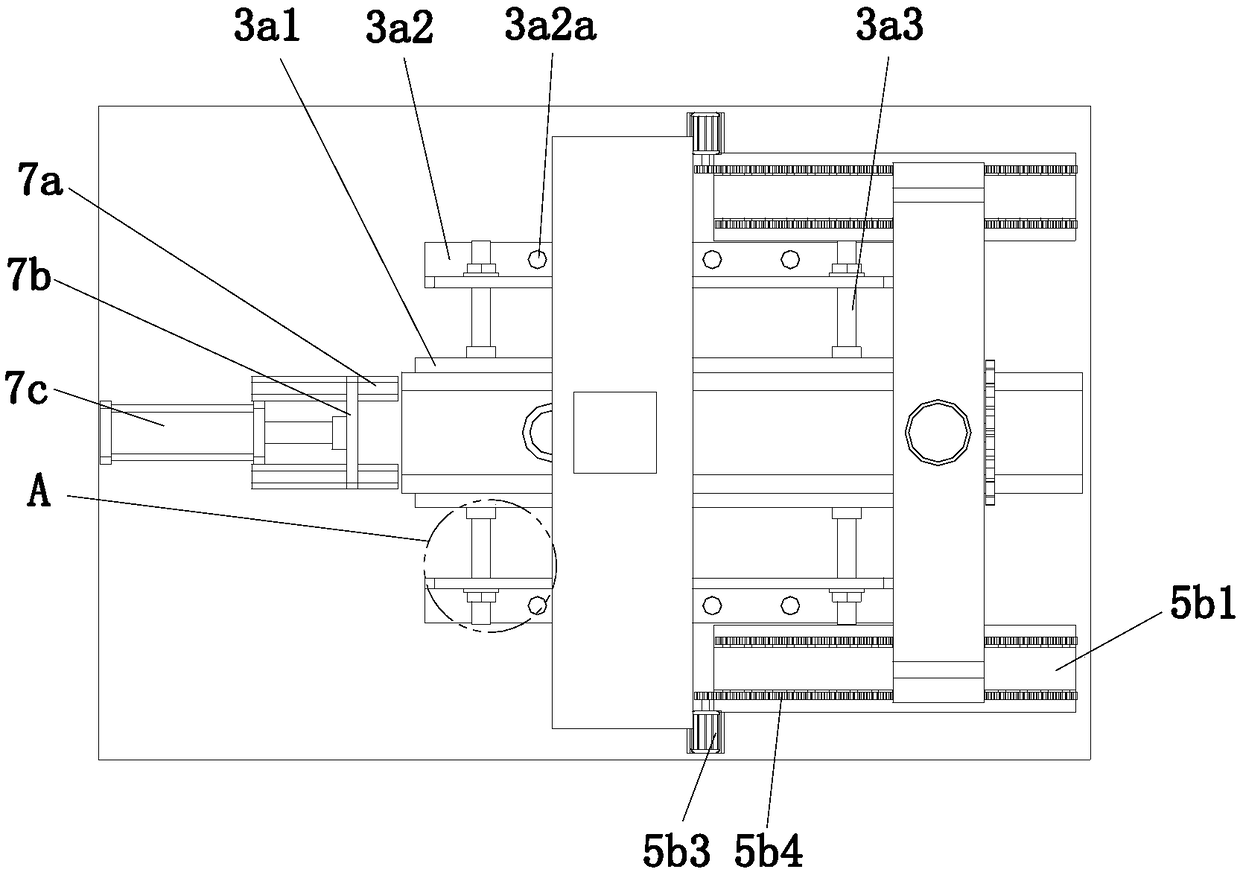

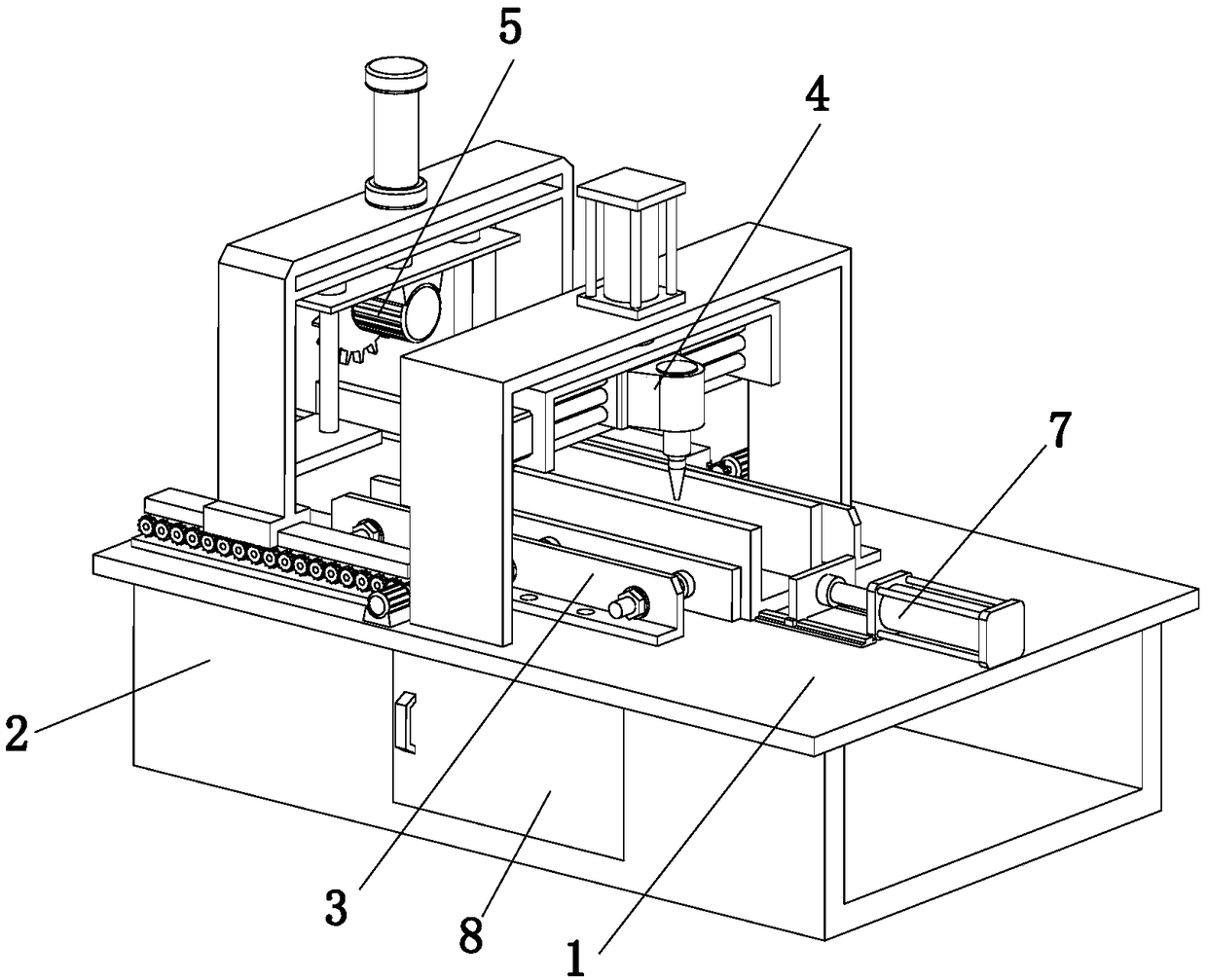

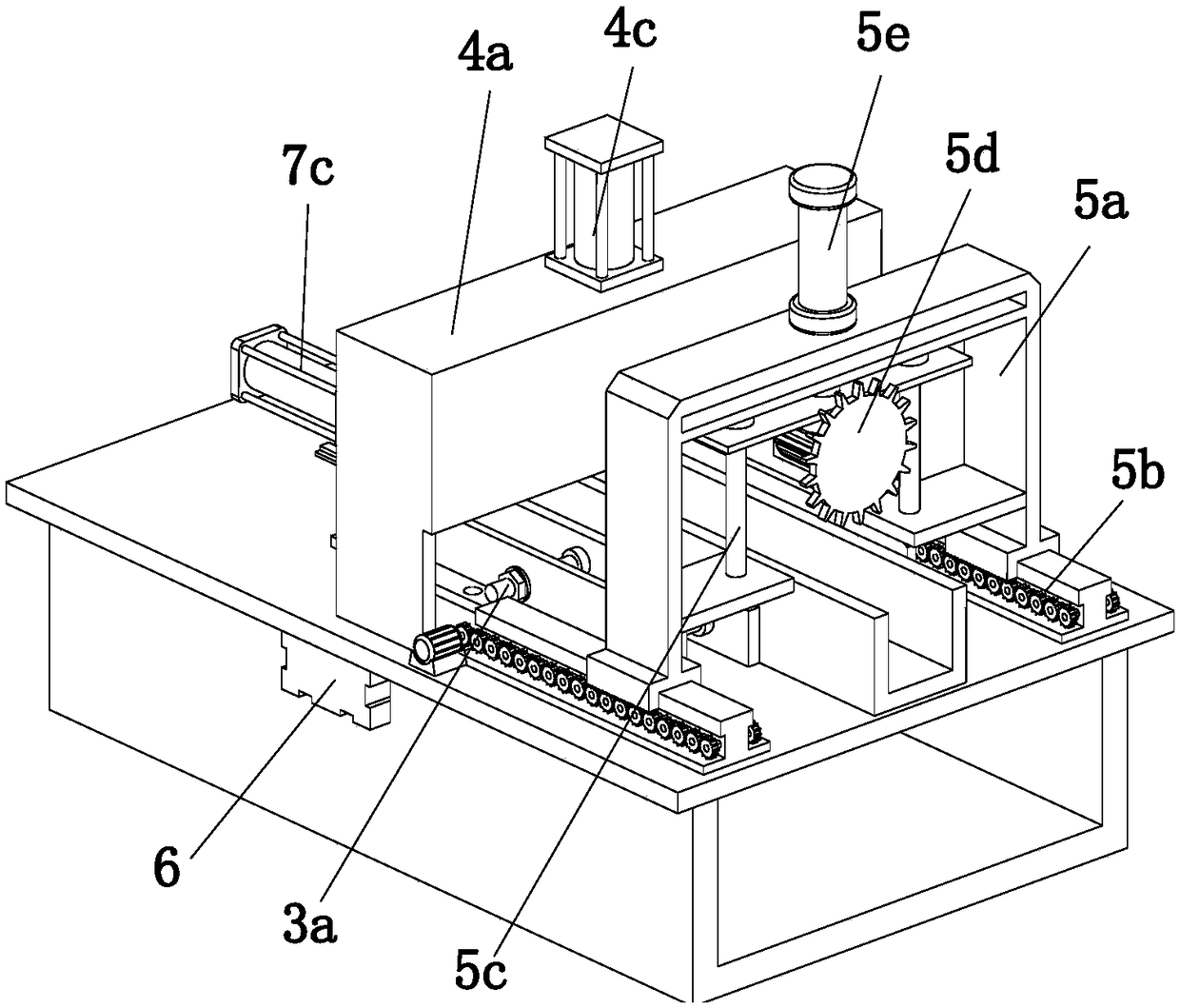

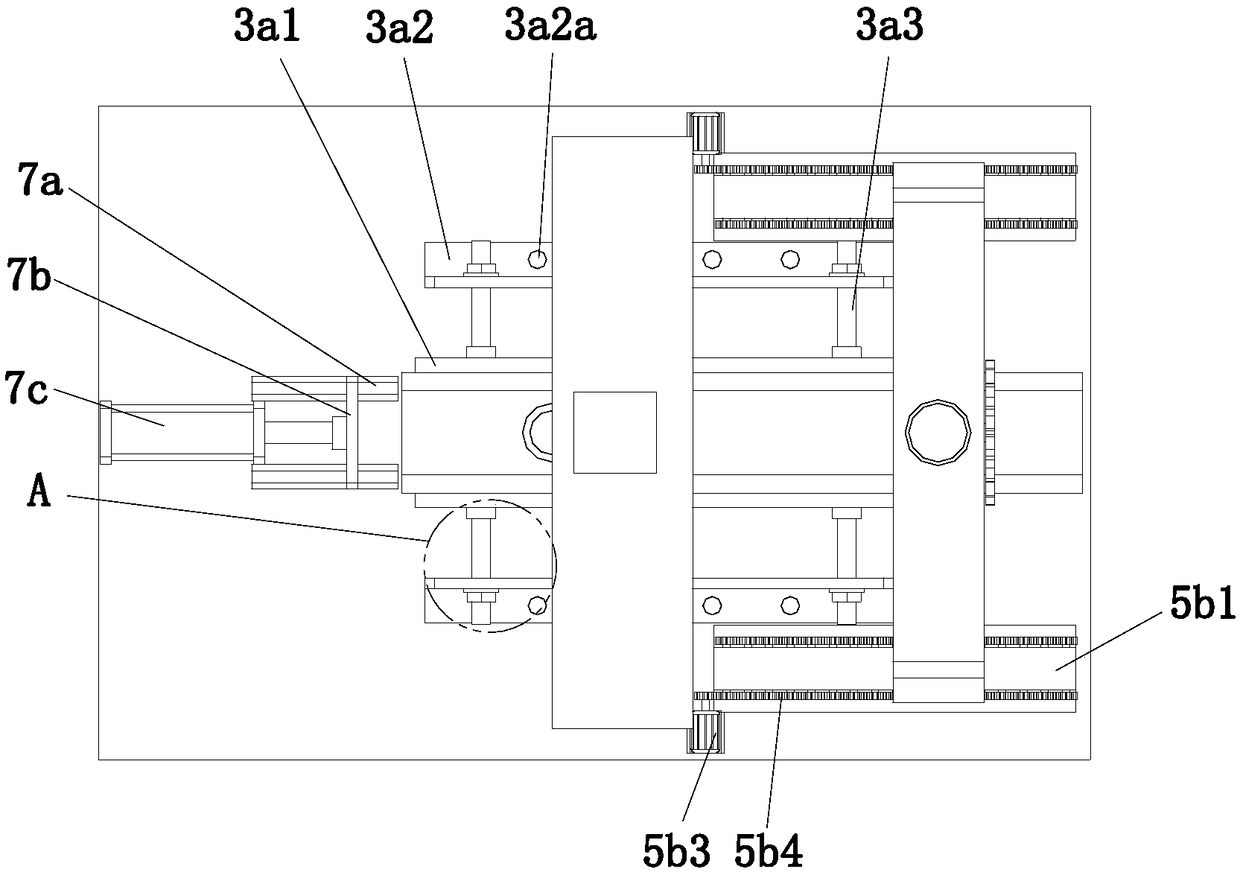

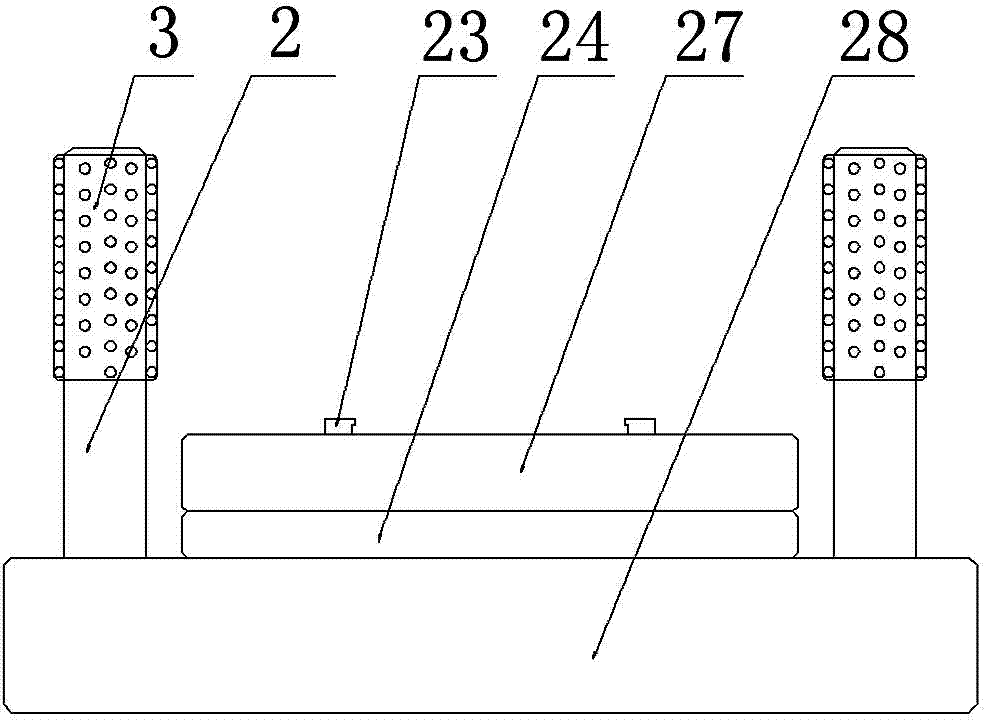

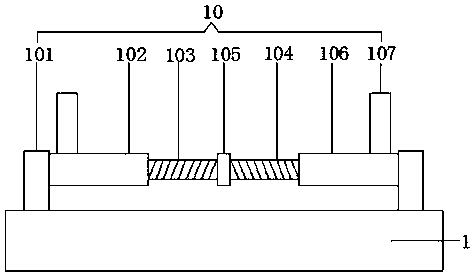

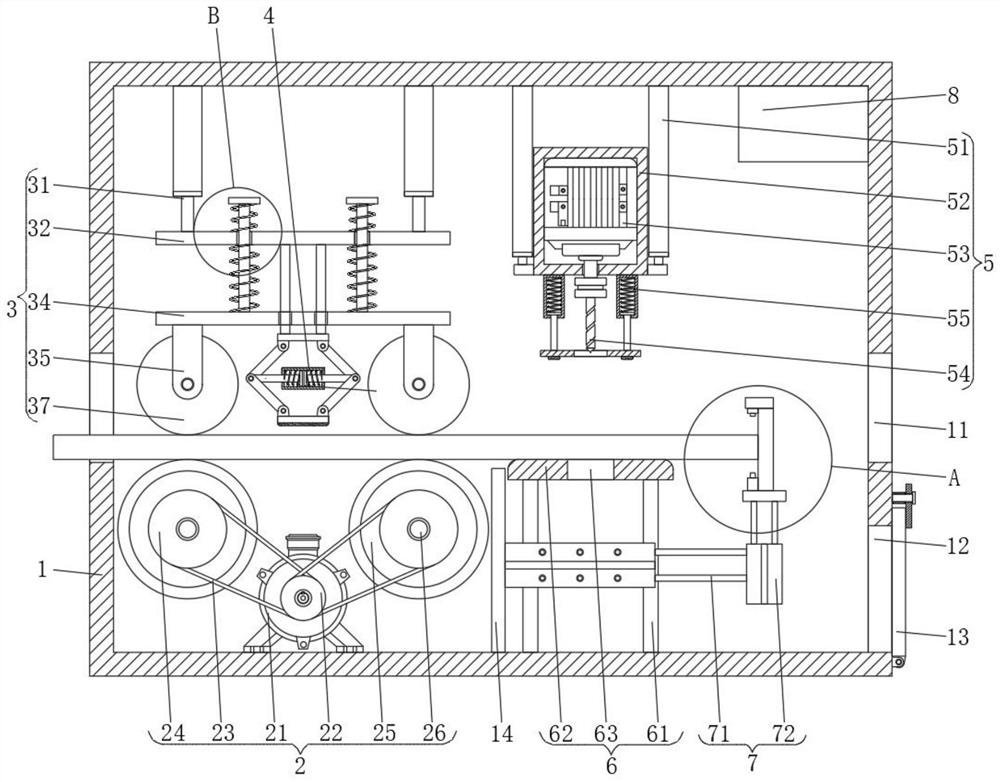

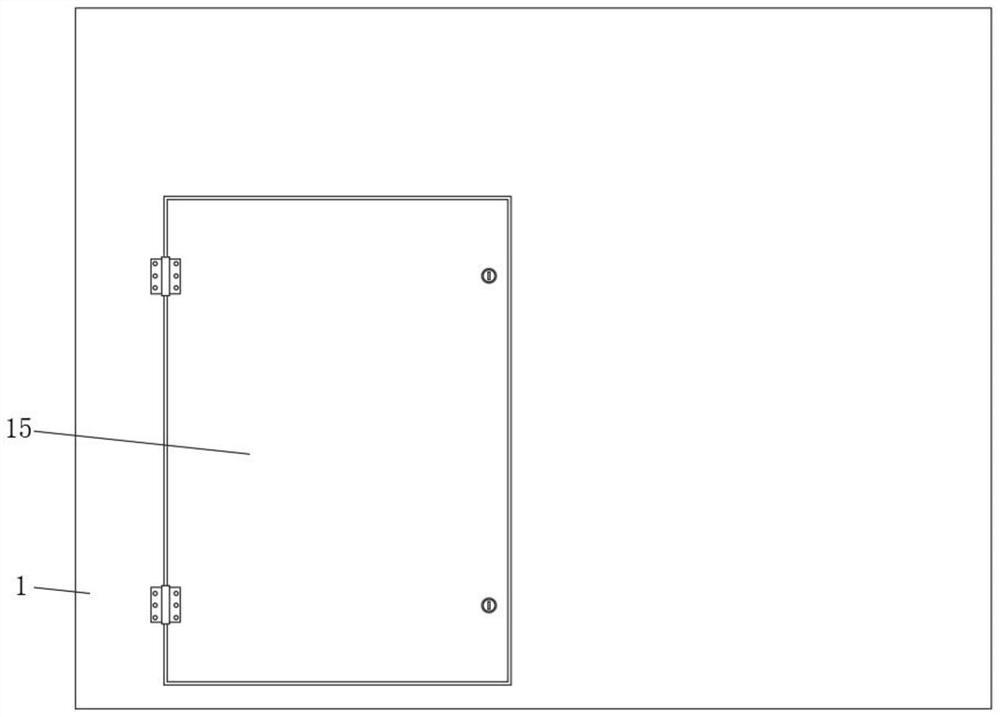

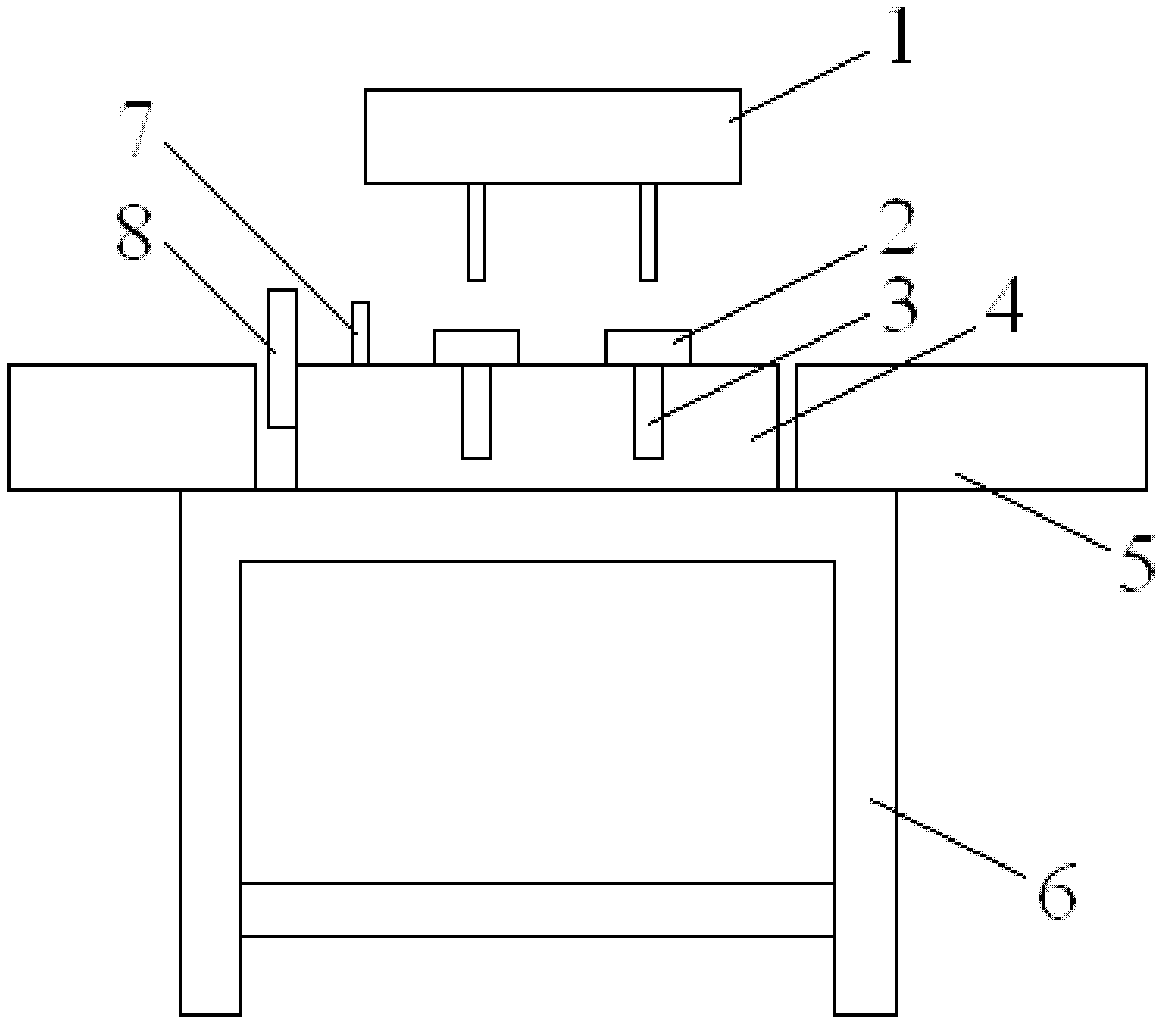

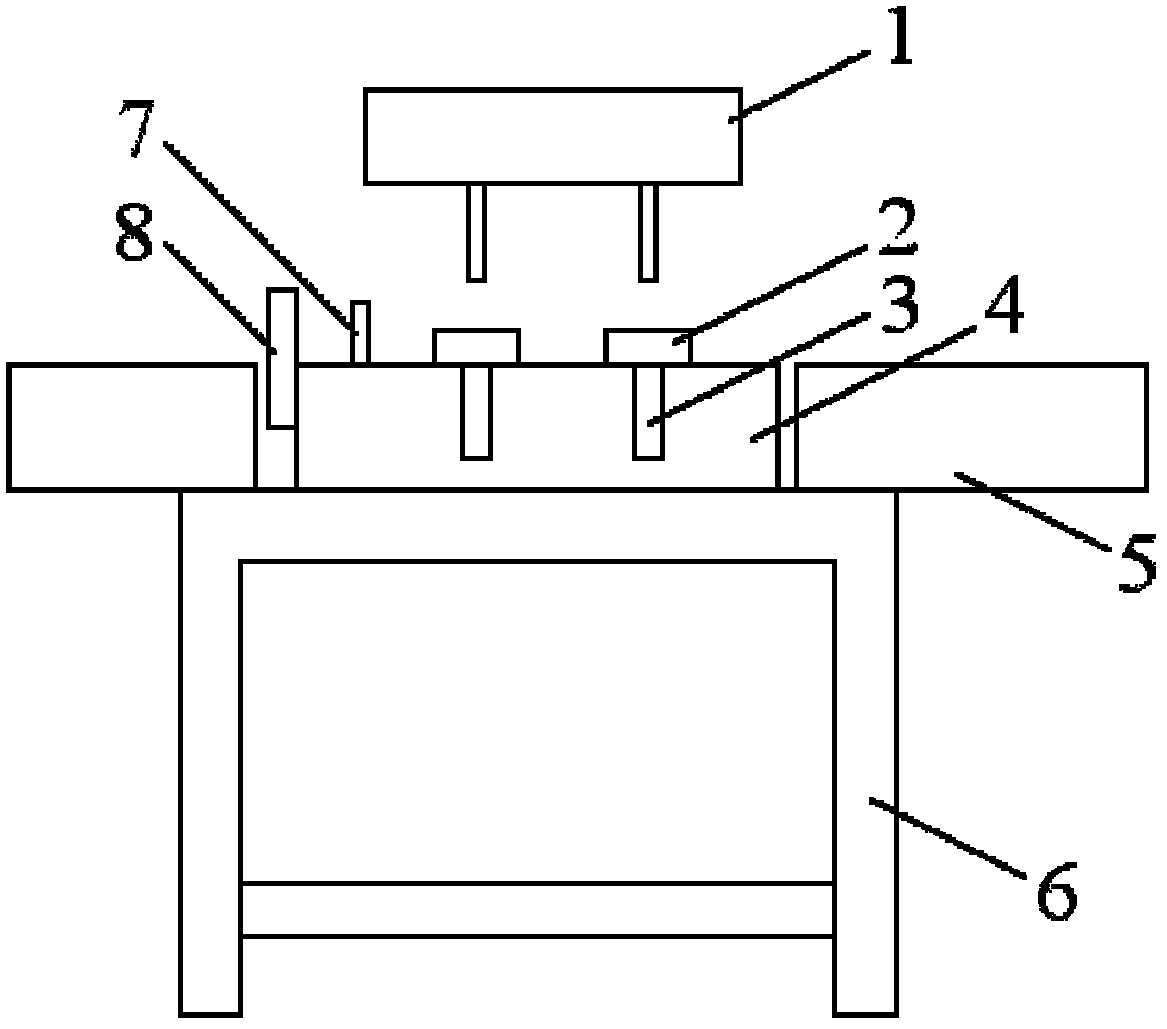

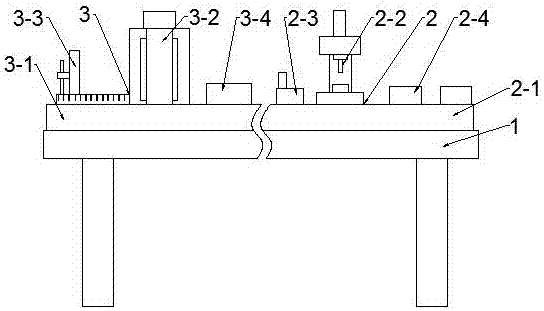

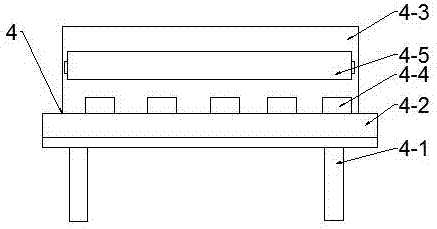

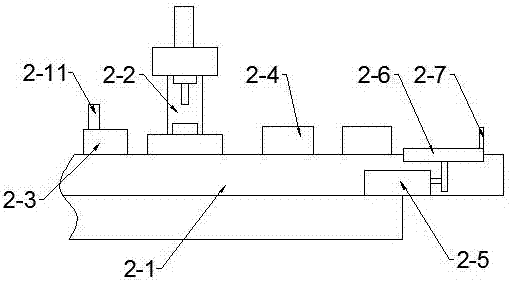

Working method of punching and cutting all-in-one machine for C-type steel of steel support

ActiveCN109014919ASimple structureSmall footprintPerforating toolsMetal-working feeding devicesPunchingEngineering

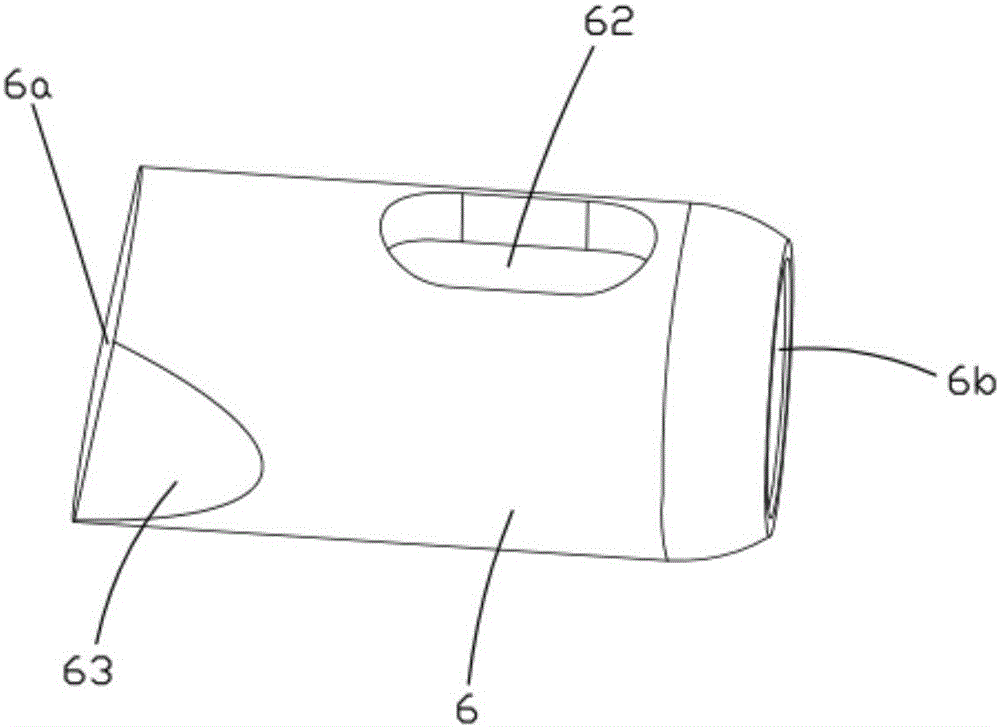

The invention relates to the field of steel structure machining, in particular to a working method of a punching and cutting all-in-one machine for C-type steel of a steel support. The punching and cutting all-in-one machine comprises a workbench and a U-shaped supporting plate. An adjustment positioning device, a punching device and a cutting device are arranged at the top of the workbench. An adjustment connecting device is arranged at the bottom of the workbench. A driving device is arranged at the top of the workbench. The adjustment positioning device comprises two limiting assemblies which are symmetrically arranged at the top of the workbench. The punching device comprises a first portal frame, a punching assembly and a first driving assembly. The two bottom ends of the first portalframe are separately located on one sides of the two limiting assemblies, and the first portal frame is vertically mounted at the top of the workbench. The punching assembly is mounted on the first driving assembly. The first driving assembly is mounted on the first portal frame. A door plate which can be opened is arranged on the side wall of the U-shaped supporting frame. The punching and cutting all-in-one machine is simple in structure; punching and cutting are integrated, so that the occupied area is reduced; and the automation degree is high, the production efficiency is improved, and the labor intensity of workers is relieved.

Owner:包头市正林钢构彩板有限公司

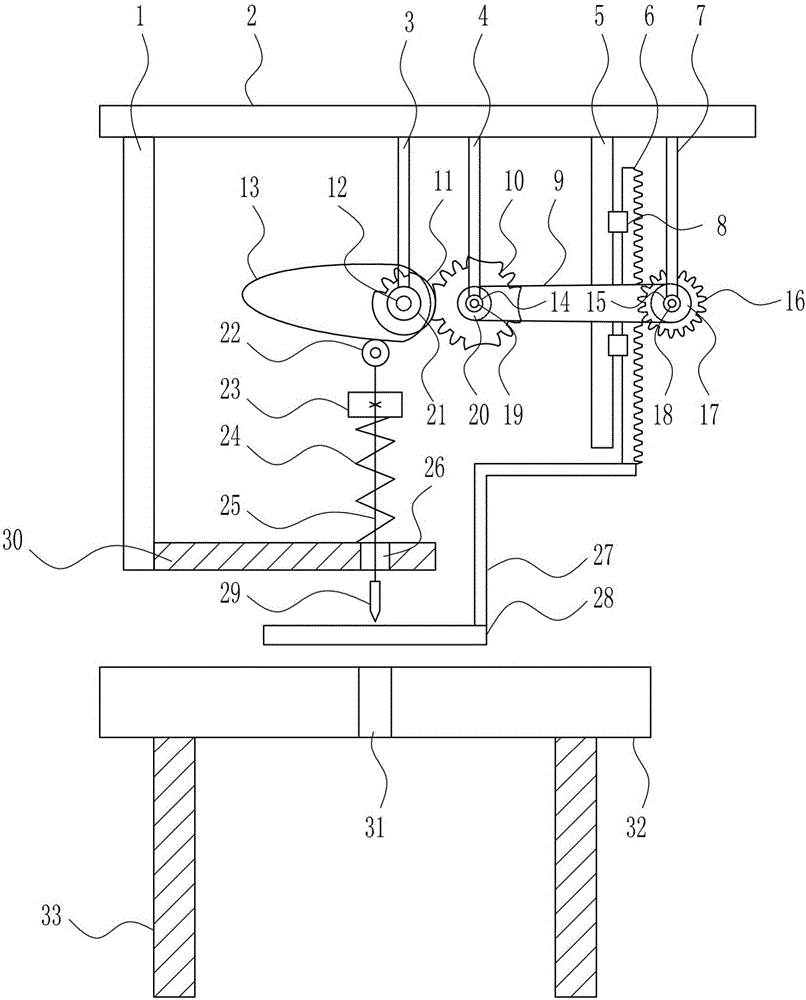

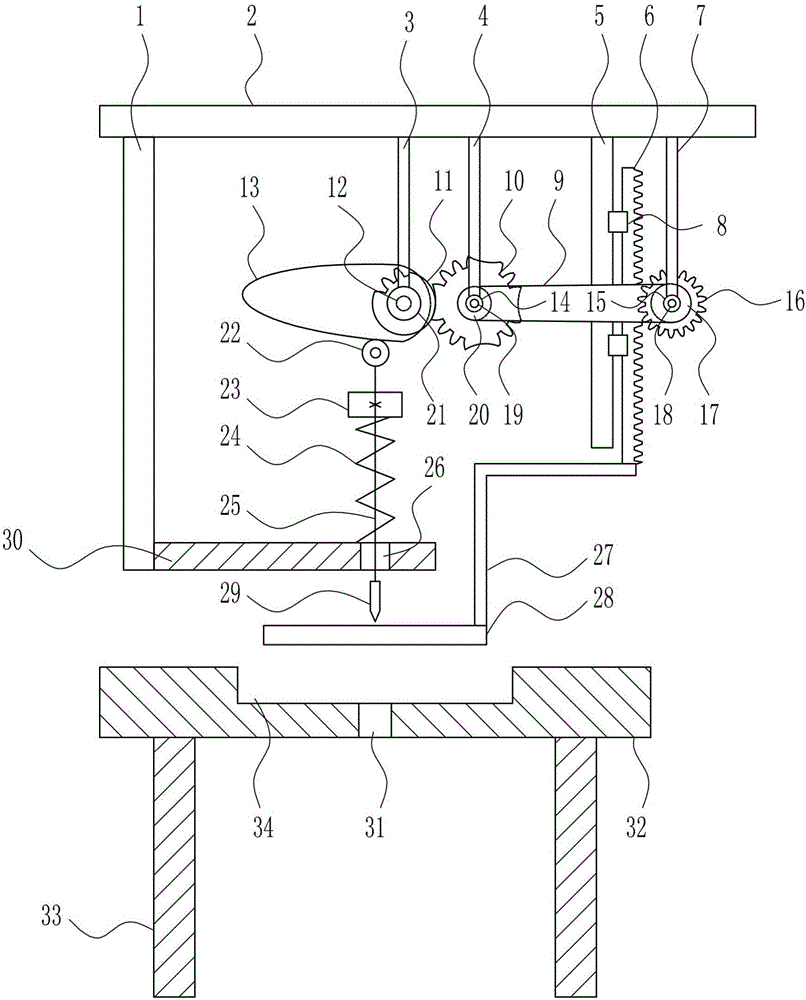

High precision punching device for hardware manufacturing

ActiveCN106180362AEasy to fixFast punching speedPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention relates to a punching device and particularly relates to a high precision punching device for hardware manufacturing. The invention solves the technical problem that the invention relates to the high precision punching device for hardware manufacturing, wherein the punching precision is relatively high. In order to solve the technical problem, the invention provides the high precision punching device for hardware manufacturing. The high precision punching device for hardware manufacturing comprises a first supporting rod, a top plate, a second supporting rod, a third supporting rod, a slide rail, a rack, a fourth supporting rod, a slide block, a flat belt, a first gear, a second gear, a first rotary shaft and the like; a through hole is formed in the middle of a shelf board, the top plate is arranged above the shelf board; the first supporting rod, the second supporting rod, the third supporting rod, the slide rail and the fourth supporting rod are successively arranged from left to right in the bottom of the top plate; a guide plate is arranged on the lower part of the right side of the first supporting rod, and a guide hole is formed in the guide plate. The punching device provided by the invention achieves relatively high punching precision.

Owner:盐城东方汽车广场投资发展有限公司

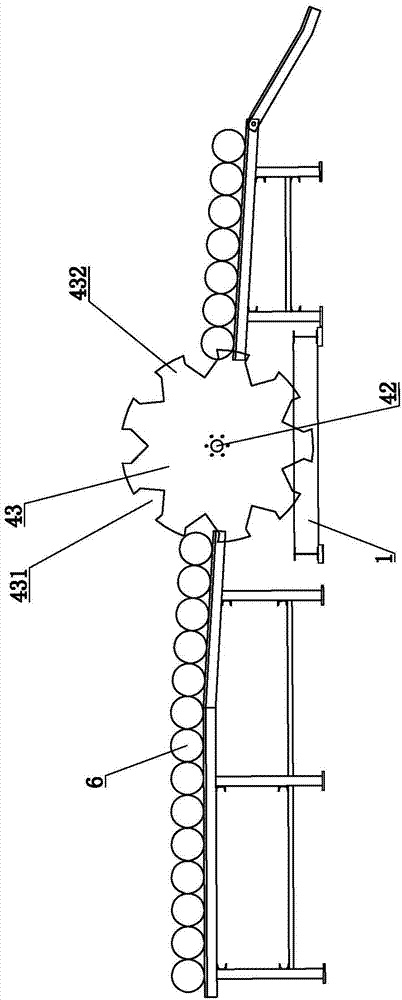

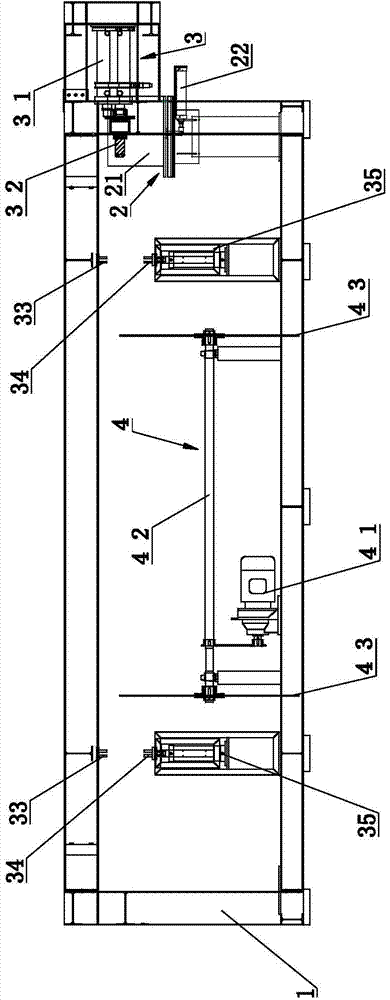

Punching and cutting all-in-one machine for C-type steel of steel support

ActiveCN109014920ASimple structureSmall footprintPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention relates to the field of steel structure machining, in particular to a working method of a punching and cutting all-in-one machine for C-type steel of a steel support. The punching and cutting all-in-one machine comprises a workbench and a U-shaped supporting plate. An adjustment positioning device, a punching device and a cutting device are arranged at the top of the workbench. An adjustment connecting device is arranged at the bottom of the workbench. A driving device is arranged at the top of the workbench. The adjustment positioning device comprises two limiting assemblies which are symmetrically arranged at the top of the workbench. The punching device comprises a first portal frame, a punching assembly and a first driving assembly. The two bottom ends of the first portalframe are separately located on one sides of the two limiting assemblies, and the first portal frame is vertically mounted at the top of the workbench. The punching assembly is mounted on the first driving assembly. The first driving assembly is mounted on the first portal frame. A door plate which can be opened is arranged on the side wall of the U-shaped supporting frame. The punching and cutting all-in-one machine is simple in structure; punching and cutting are integrated, so that the occupied area is reduced; and the automation degree is high, the production efficiency is improved, and the labor intensity of workers is relieved.

Owner:HEBEI HANGXIAO STEEL STRUCTURE

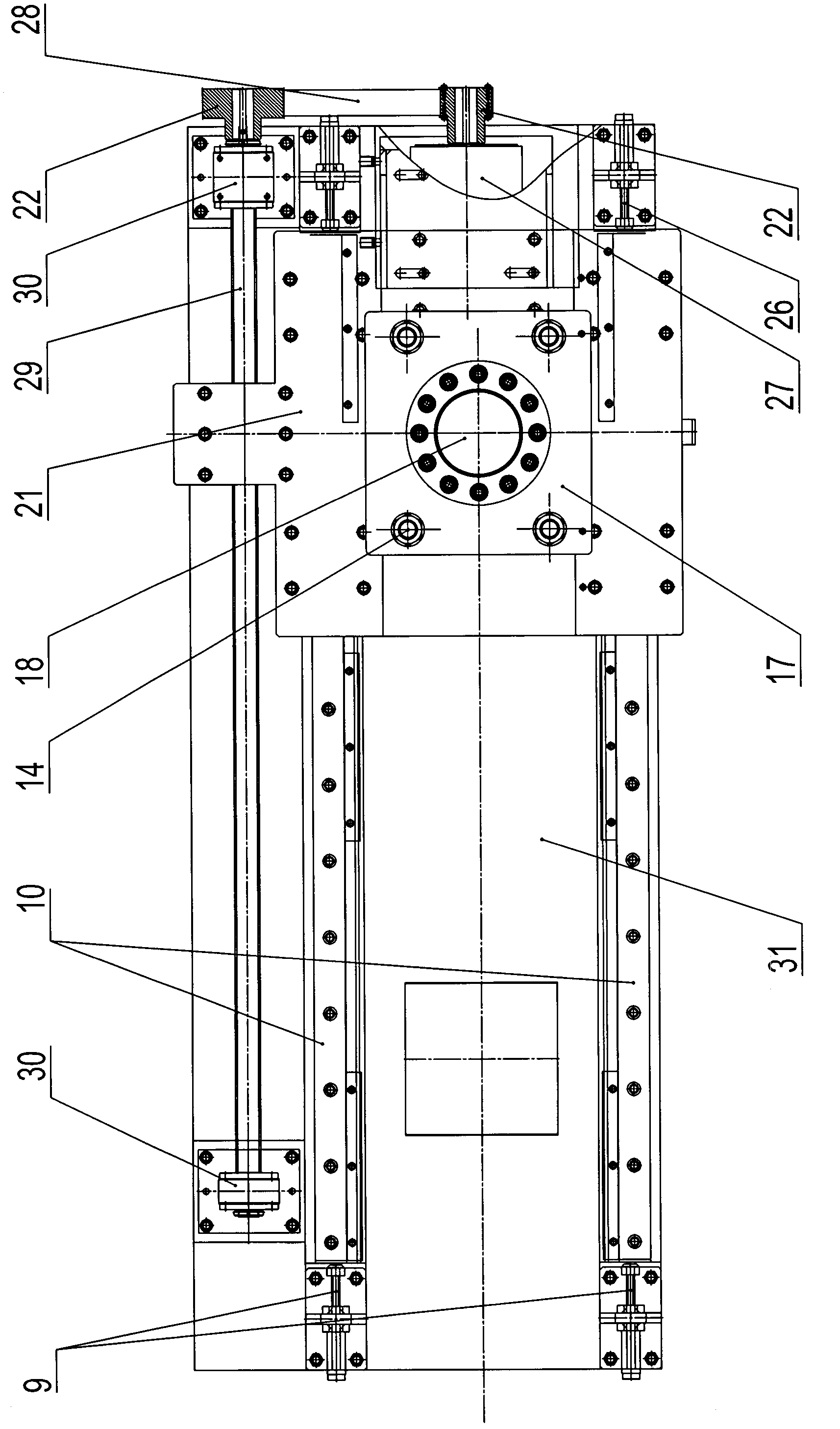

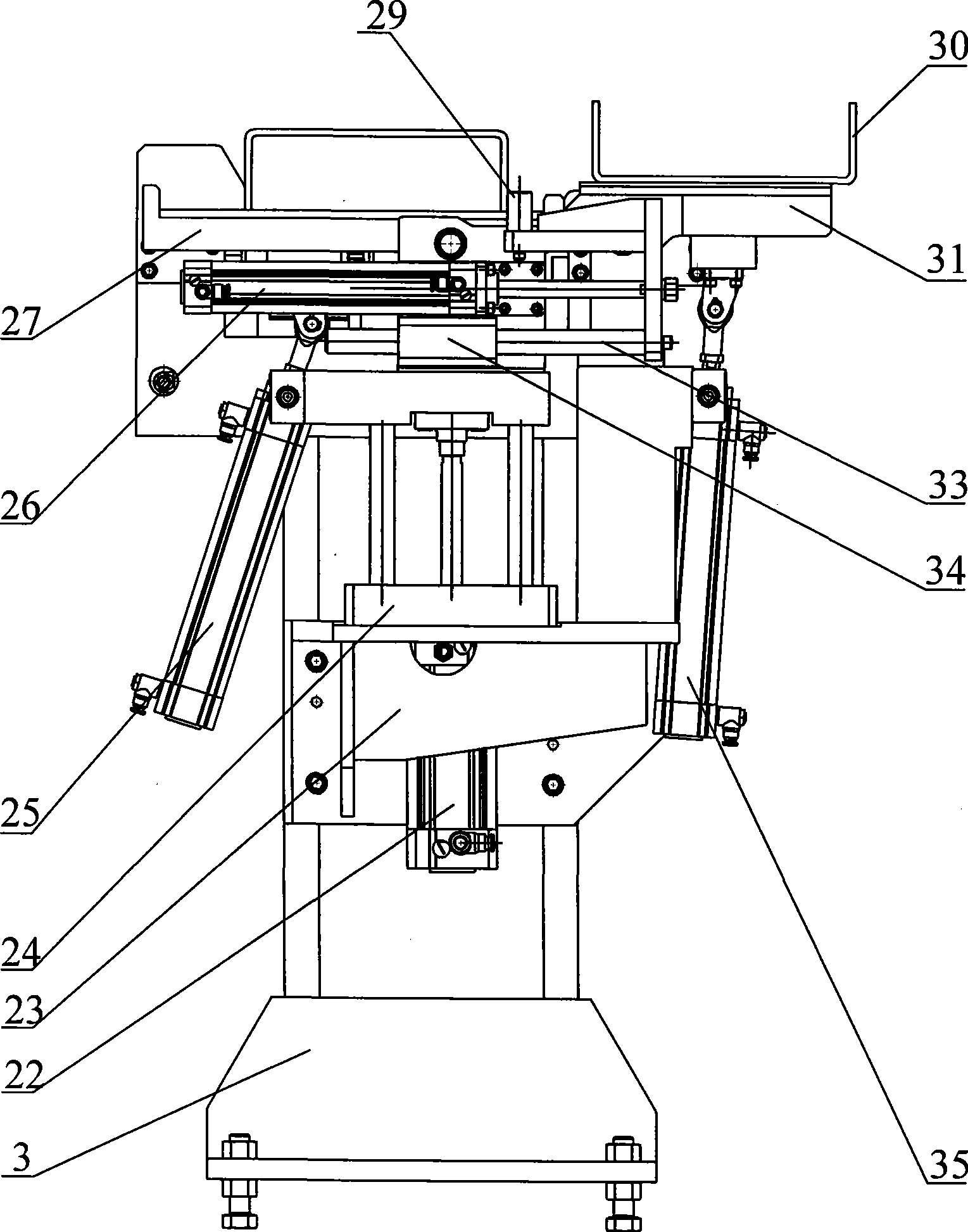

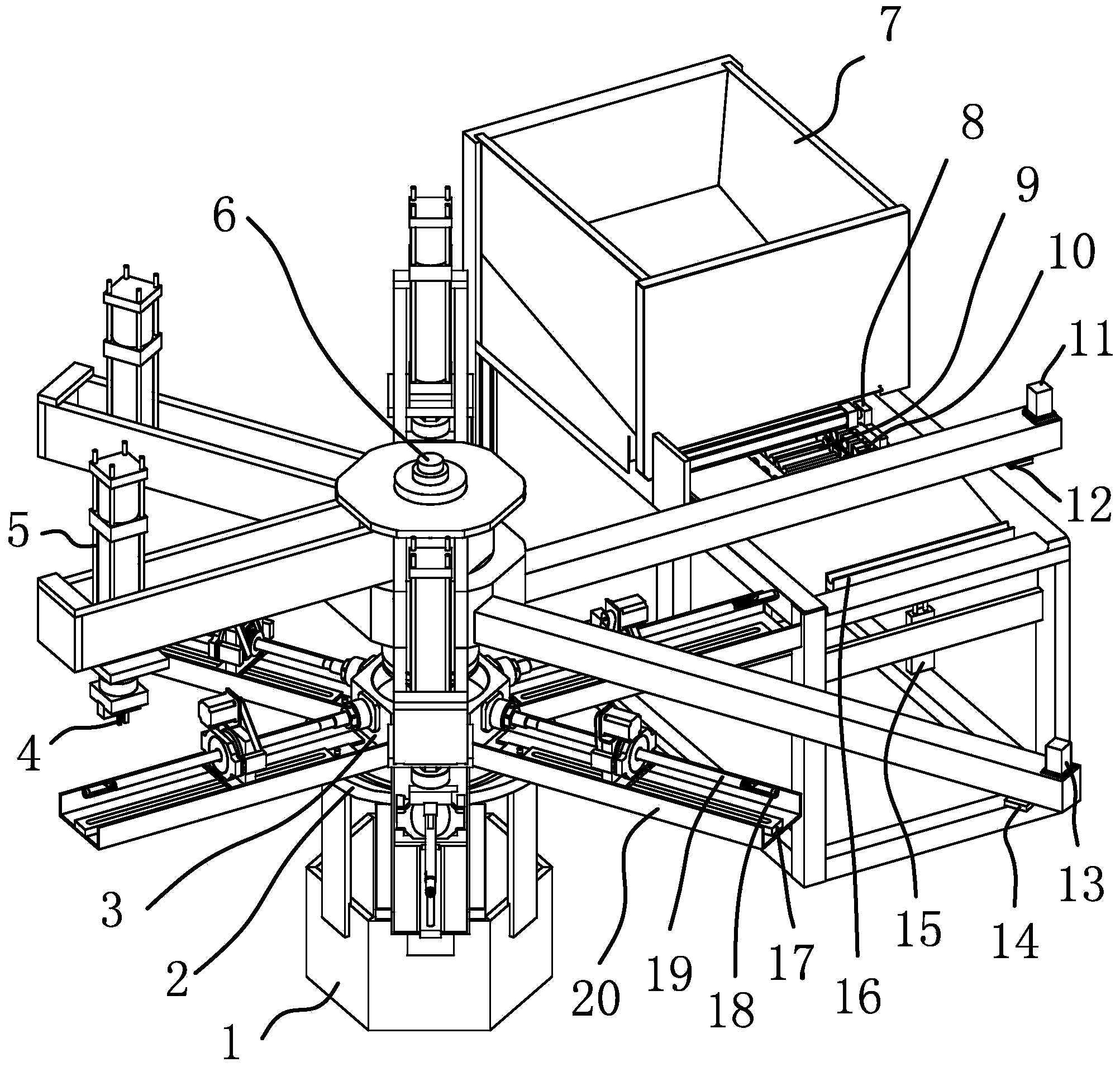

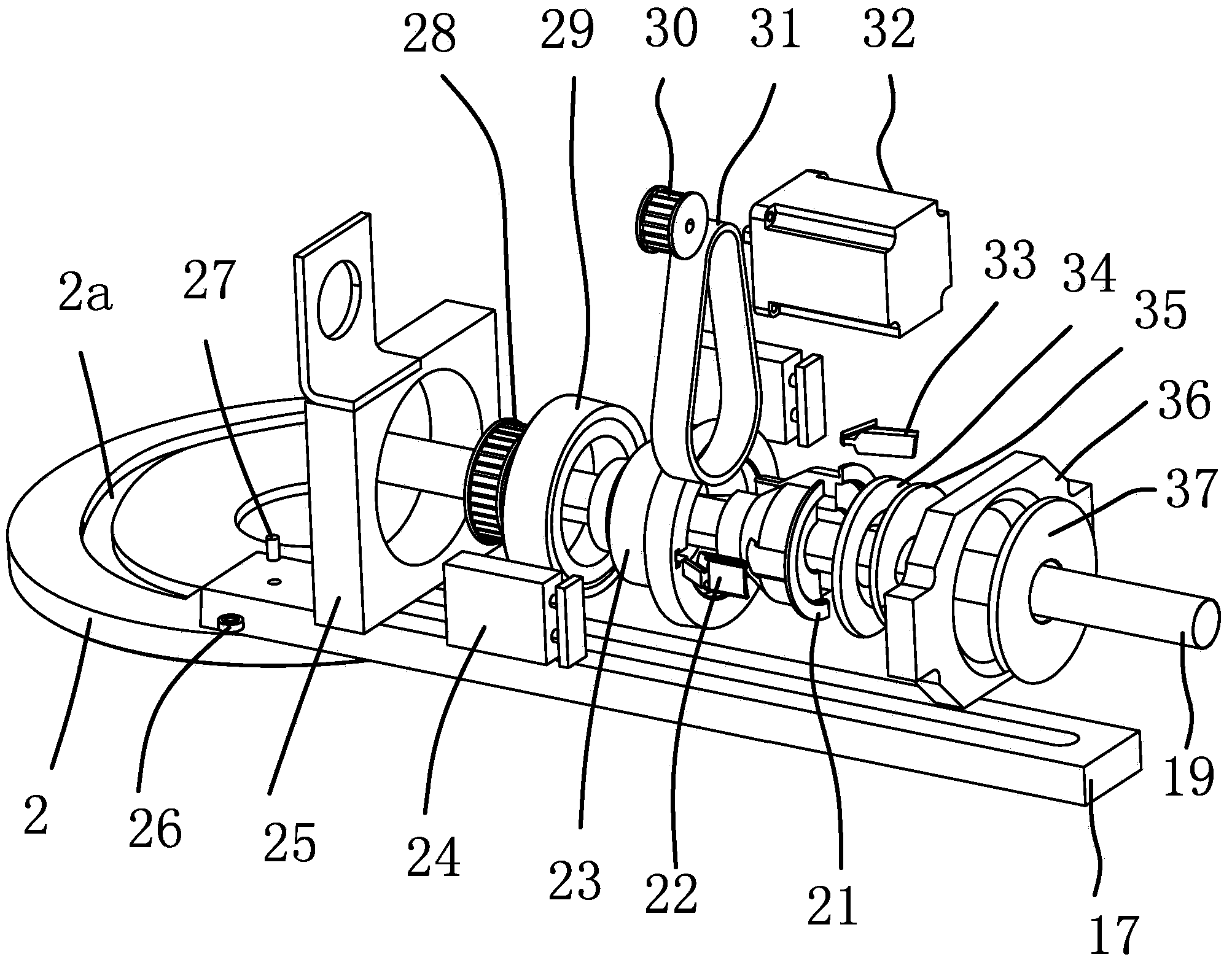

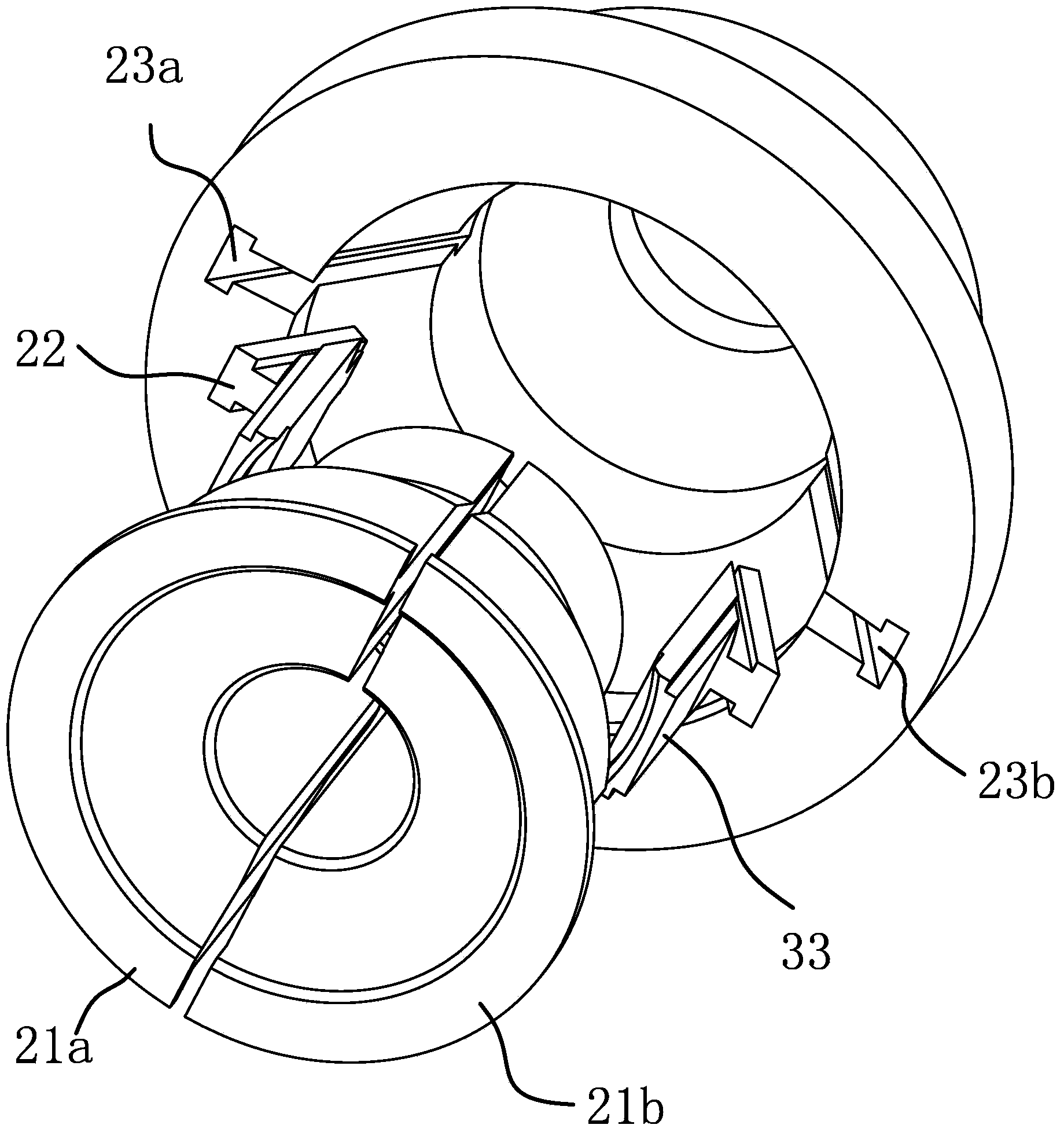

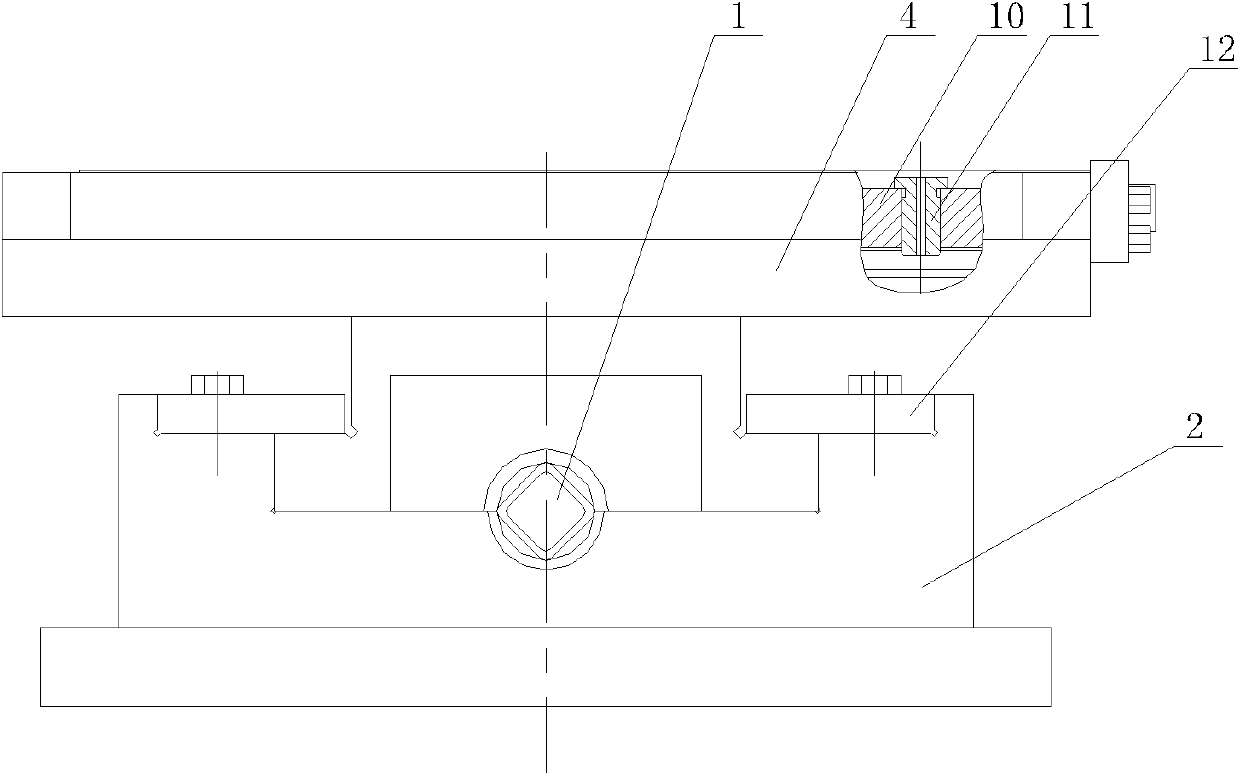

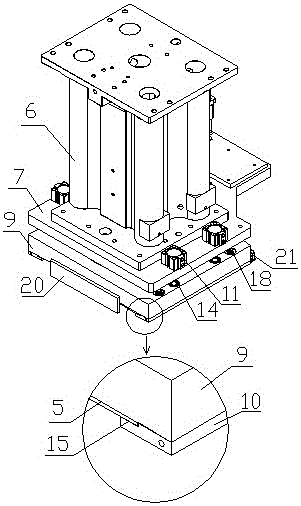

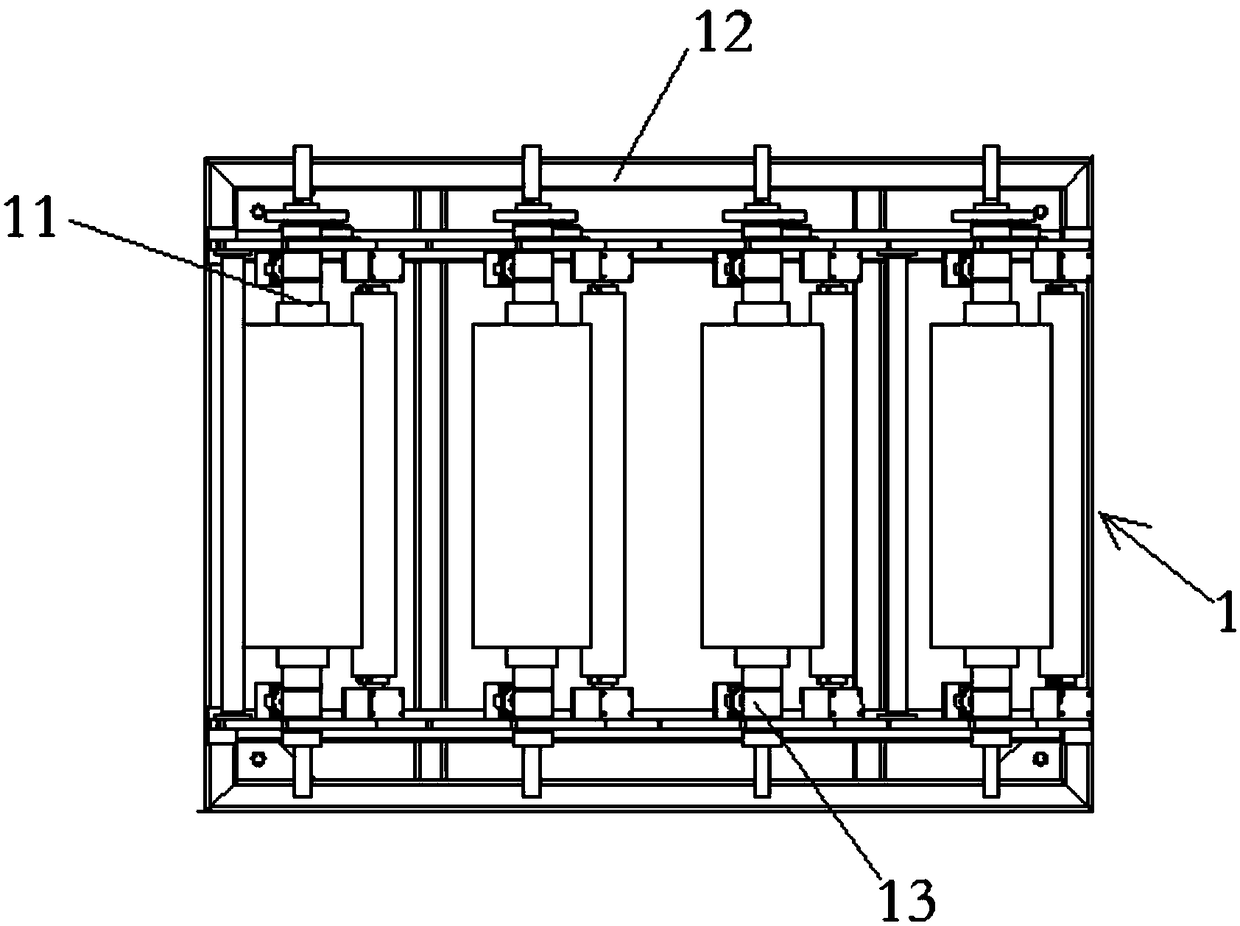

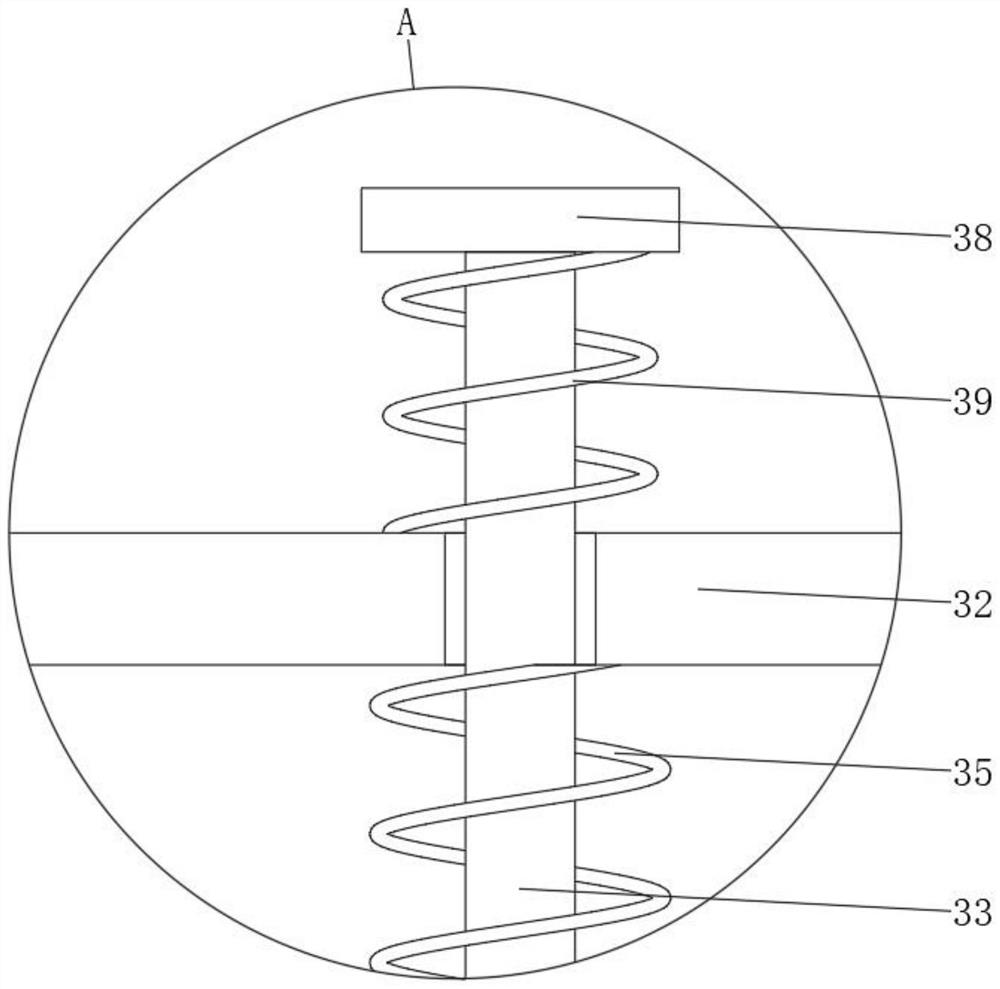

Full-automatic multi-station three-dimensional tube punching equipment

InactiveCN103963102AHigh positioning accuracyIncrease productivityMetal working apparatusPunchingEngineering

The invention provides full-automatic multi-station three-dimensional tube punching equipment and belongs to the technical field of machinery. The full-automatic multi-station three-dimensional tube punching equipment solves the technical problems that a punching machine in the prior art needs to assemble and disassemble tubes for many times when being used for punching holes on the tubes at different positions, and the punching accuracy cannot be guaranteed. The full-automatic multi-station three-dimensional tube punching equipment comprises a machine frame. A spindle is arranged on the machine frame, a rotating disk is fixed in the middle of the spindle, a plurality of core rods are evenly fixed on the rotating disk in the peripheral direction, a conveying device used for conveying the tubes to the core rods and sleeving the tubes on the core rods is arranged on the machine frame, locating devices which can axially locate the tubes sleeving the core rods are arranged on the core rods, and a punching device which can punch the tubes sleeving the core rods is arranged on the machine frame. The punching device comprises a punching head, wherein the punching head is arranged right above through holes of the core rods. A discharging structure which is used for enabling the punched tubes to be break away from the core rods is arranged on the machine frame. The full-automatic multi-station three-dimensional tube punching equipment has the advantages of being capable of automatically punching the tubes in a three-dimensional mode and high in punching efficiency.

Owner:浙江飞戎机器人科技有限公司

Reamer

ActiveCN104492988AIncrease productivitySave energyShaping toolsMetal-working feeding devicesReamerSmall footprint

The invention discloses a reamer. The reamer comprises a rack, wherein the rack is provided with an electromagnetic heating device and a reaming device which are arranged from front to back in sequence; the electromagnetic heating device comprises an electromagnetic heating coil; the reaming device comprises a reaming hole driven by a first power device; the rack is provided with a poking plate feeding device; the poking plate feeding device comprises a rotating shaft connected with a second power device; the rotating shaft is transversely arranged on the rack; the two ends of the rotating shaft are fixedly provided with circular poking plates; the peripheral parts of the poking plates are provided with at least three feeding fork entries for conveying metal pipes; poking plates are formed between adjacent feeding fork entries and can rotate to the positions, corresponding to the electromagnetic heating coil and a reaming head, on every two adjacent feeding fork entries respectively. The reamer has the advantages of high production efficiency, small floor area and low power consumption.

Owner:高密天一机械科技有限公司

Appliance for accounting document puncher

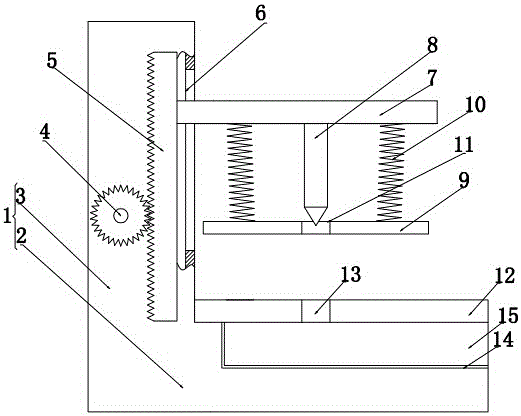

InactiveCN106272690AImprove drilling efficiencyImprove punching accuracyMetal working apparatusPunchingEngineering

The invention discloses an appliance for an accounting document puncher, and relates to an office device. The appliance comprises an L-shaped support. The L-shaped support comprises a horizontal portion and a perpendicular portion, and a gear and a rack meshed with the gear are installed inside the perpendicular portion; the gear is connected with a driving device; a fixing hole is formed in the perpendicular portion, an installation frame is fixedly installed on the rack, and the installation frame penetrates out of the fixing hole; a punching pin is formed in the installation frame; a pressing plate is arranged below the installation frame, the pressing plate and the installation frame are connected through a compression spring, and a guiding hole matched with the punching pin is formed in the pressing plate; a base plate is installed on the horizontal portion, and a drain hole matched with the punching pin is formed in the base plate. According to the appliance, the punching efficiency is high, the punching accuracy is improved, the punching work can be completed without large physical power needs provided by operators in the overall punching process, the structure is simple, and operation is convenient.

Owner:陈思奇

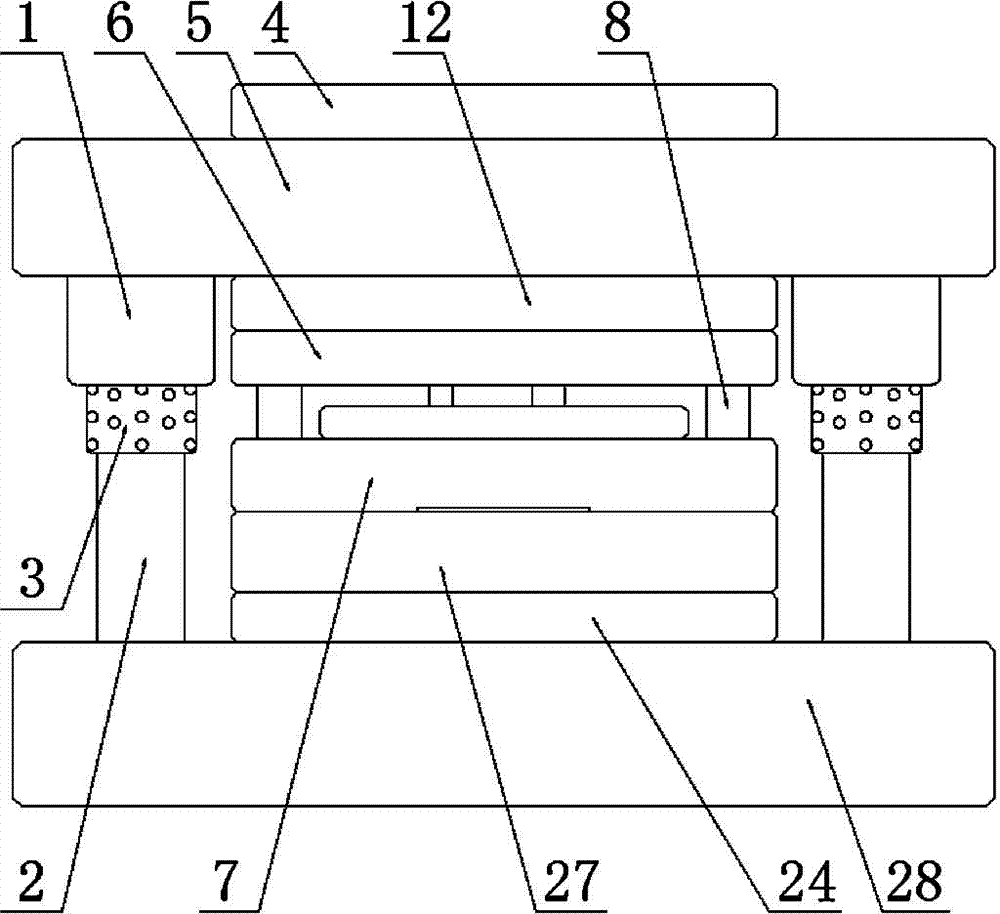

Progressive stamping die of motor rotor

The invention discloses a progressive stamping die of a motor rotor. The progressive stamping die of the motor rotor comprises an upper die body and a lower die body. An upper mounting plate of the upper die body is provided with a first punch column and a second punch column which are arranged in parallel in the feeding direction. Punches in the first punch column and punches in the second punch column are staggered, and the center-to-center distance between the first punch column and the second punch column is smaller than the diameter of the motor rotor. A lower die plate of the lower die body is provided with a first die cavity column and a second die cavity column in the feeding direction. The first die cavity column and the second die cavity column correspond to the first punch column and the second punch column respectively. The progressive stamping die of the motor rotor is high in production efficiency and low in manufacturing cost.

Owner:广安旗力机电有限公司

Automatic FFC pressure connecting forming machine

The invention discloses an automatic FFC pressure connecting forming machine. The automatic FFC pressure connecting forming machine comprises a machine frame, a first film feeding mechanism, a second film feeding mechanism, a conductor feeding mechanism, a first hot press device, a second hot press device, a first punching device, a second punching device, a reinforcing plate attaching device and a striping device. The machine frame comprises a top layer frame, a middle layer frame and a bottom layer frame. The conductor feeding mechanism is installed on the top layer frame. The first film feeding mechanism and the second film feeding mechanism are arranged at the two ends of the middle layer frame respectively. The first hot press device is installed on the middle layer frame and located between the first film feeding mechanism and the second film feeding mechanism. The reinforcing plate attaching device, the second hot press device and the striping device are sequentially installed on the bottom layer frame in the conveying direction of semi-finished FFC products. An outlet of the first film feeding mechanism and an outlet of the second film feeding mechanism are right opposite to the first hot press device horizontally. An outlet of the conductor feeding mechanism is right opposite to the first hot press device vertically. By means of the automatic FFC pressure connecting forming machine, the semi-finished FFC products can be attached firmly, reinforcing plates are attached precisely and firmly, the product quality is improved, and the rate of finished products is increased.

Owner:佛山市顺德区禾惠电子有限公司

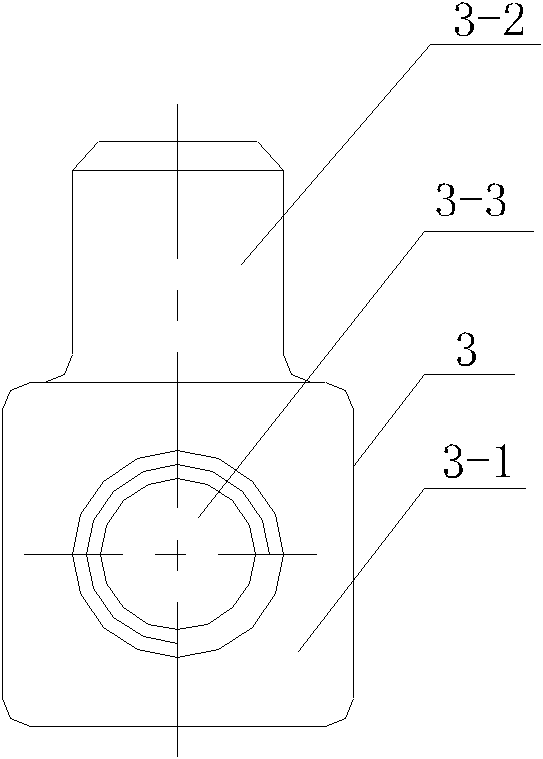

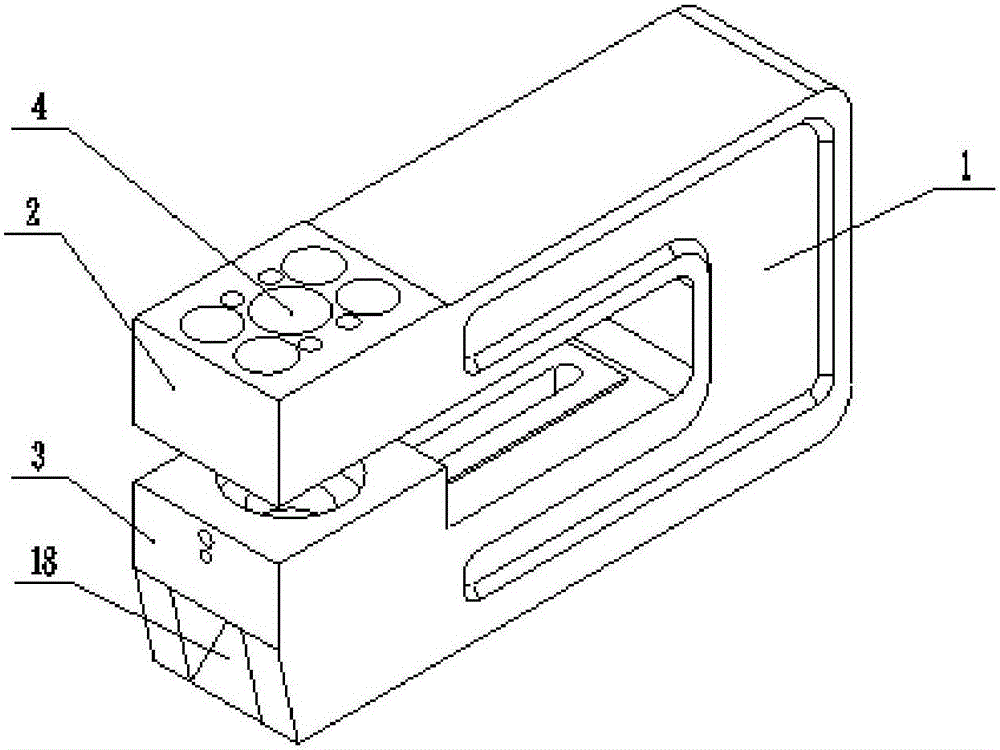

Porous clamping device capable of automatically centering and drilling long-thin steel-sheet type parts

ActiveCN102950312ANot easy to deflectLess prone to deflectionPositioning apparatusMetal-working holdersIsosceles trapezoidPunching

A porous clamp device capable of automatically centering and drilling long-thin steel-sheet type parts relates to a porous centering and drilling clamp device for long-thin steel sheets, and solves the problem that a porous processing mold for the long-thin steel sheets is complex in structure, long in processing period, high in cost, low in punching accuracy and the like. A claw and a sliding top block are slidingly matched with two first sliding chutes on a base, two nuts are arranged in two second sliding chutes on the base and slidingly matched with the second sliding chutes and fixed with the claw and the sliding top block, a stop plate is arranged on the claw which is detachably connected with a slide plate, an inverted isosceles trapezoid groove and a long groove for storing drilling parts are formed between the claw and the sliding top block, a mold is inverted in the isosceles trapezoid groove, a fastening screw leans on the mold, a drill bushing is inlaid in a drilling bushing hole of the mold, a positioning block of a screw rod is arranged in a screw rod support seat on the base, and two ends of the screw rod are connected with the two nuts in a threaded manner. The porous clamp device is used for clamping and fixing in drilling of the long-thin steel-sheet type parts.

Owner:HARBIN JIANCHENG GRP

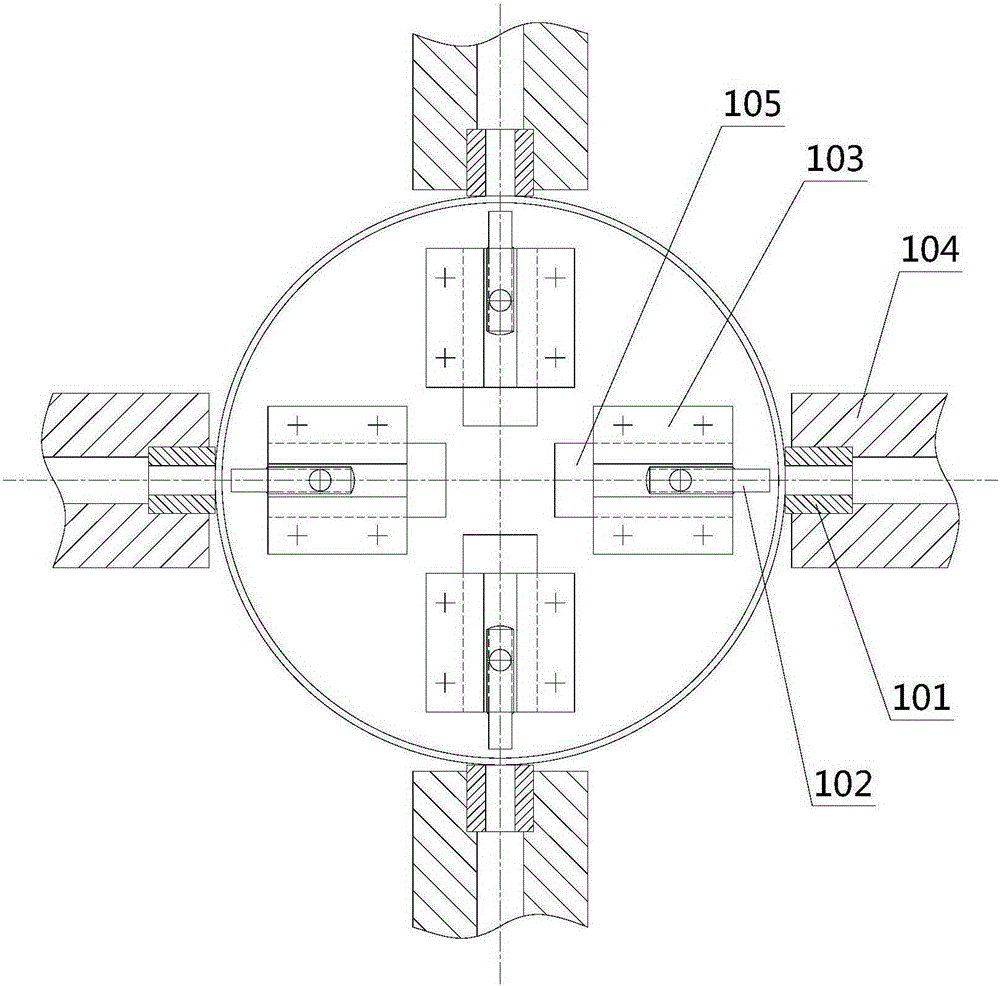

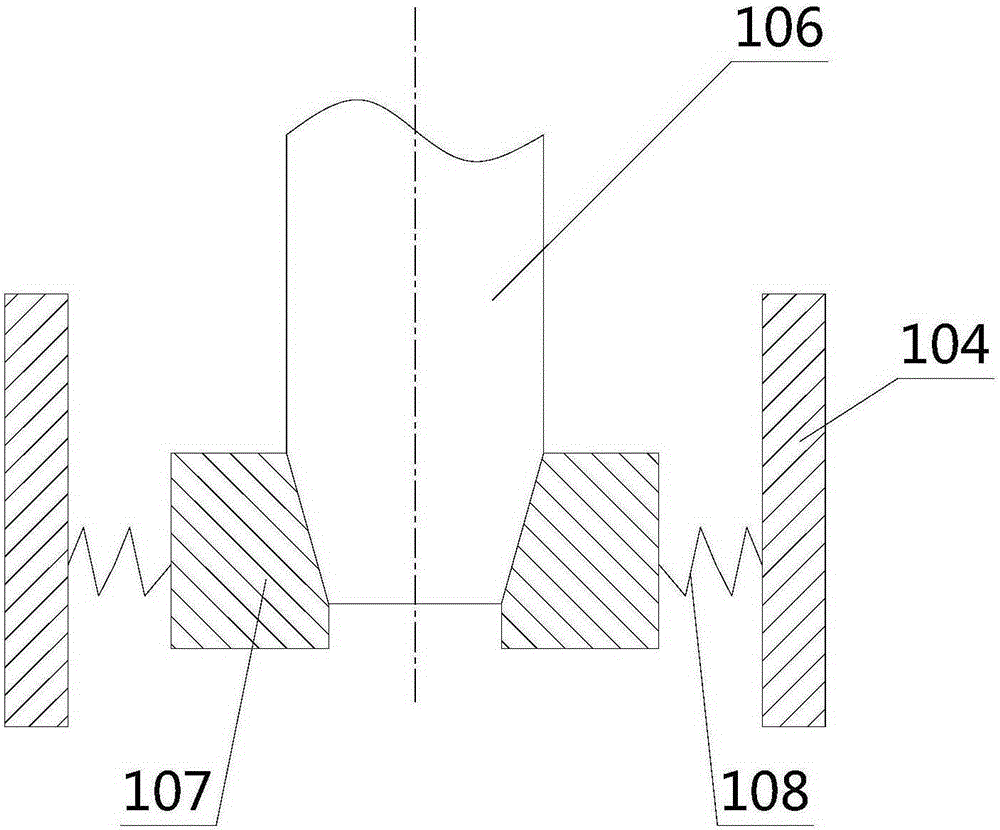

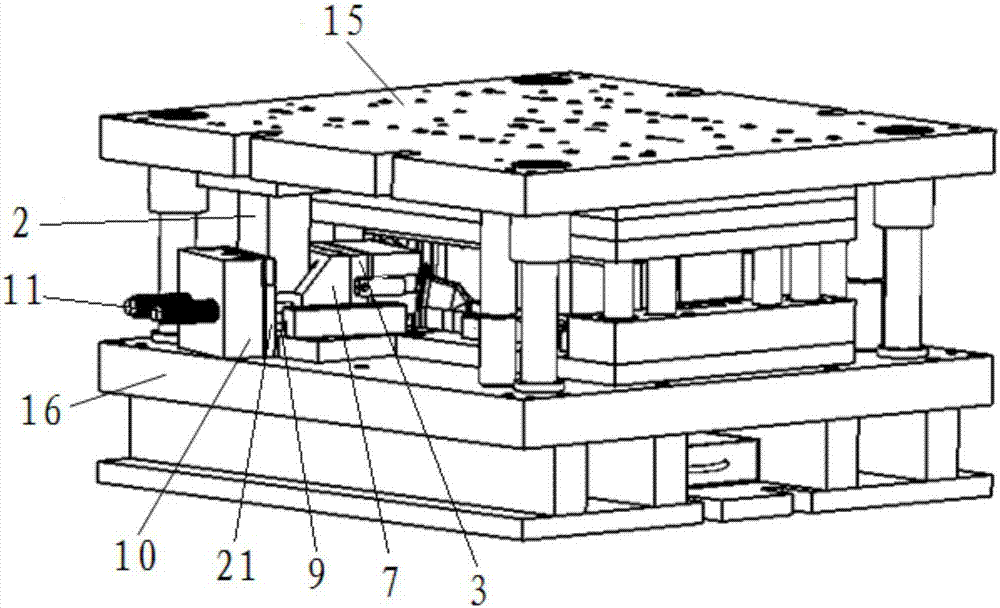

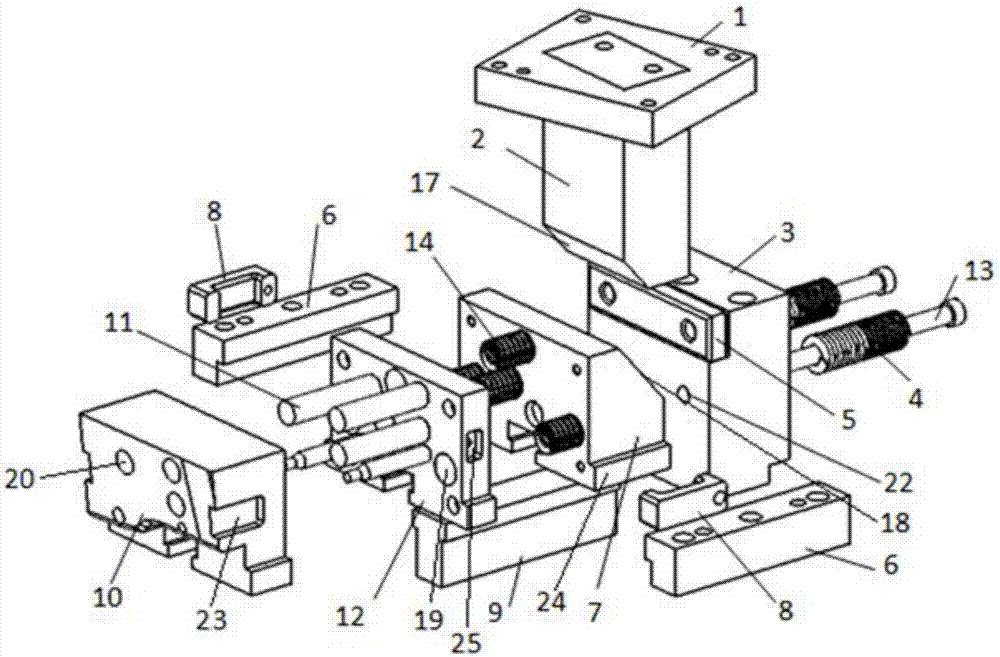

Lateral punching die for cylindrical parts

The invention provides a lateral punching die for cylindrical parts, and belongs to the field of punching dies. The lateral punching die comprises a plurality of punching units. Each punching unit comprises a female die and a male die, wherein the female die and the male die are matched, the male die is fixed to a sliding block, the female die is fixed to a base, and the sliding block is connected with a slide rail in a sliding mode. According to the lateral punching die for the cylindrical parts, the sliding blocks slide on the sliding rails so that the lateral punching die realizes punching, the multiple punching units carry out punching simultaneously, multiple holes can be machined through clamping at one time, the punching accuracy is improved, repeated clamping is not needed, and therefore the labor hour is saved. The lateral punching die is especially suitable for punching the large-diameter cylindrical parts. The manufacture cost, the use cost and the maintenance cost of the die are lowered.

Owner:CHONGQING CHIHENG MOLD

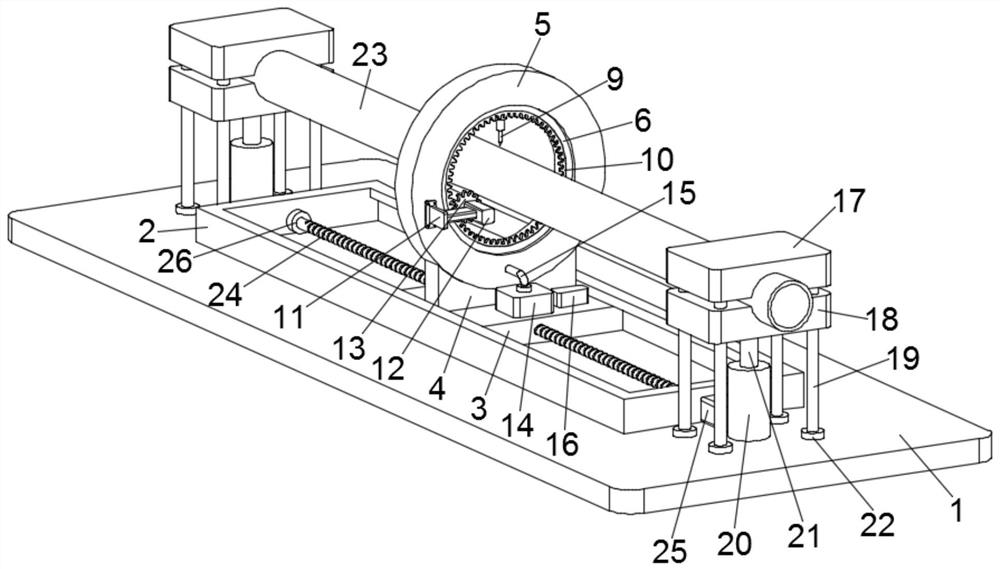

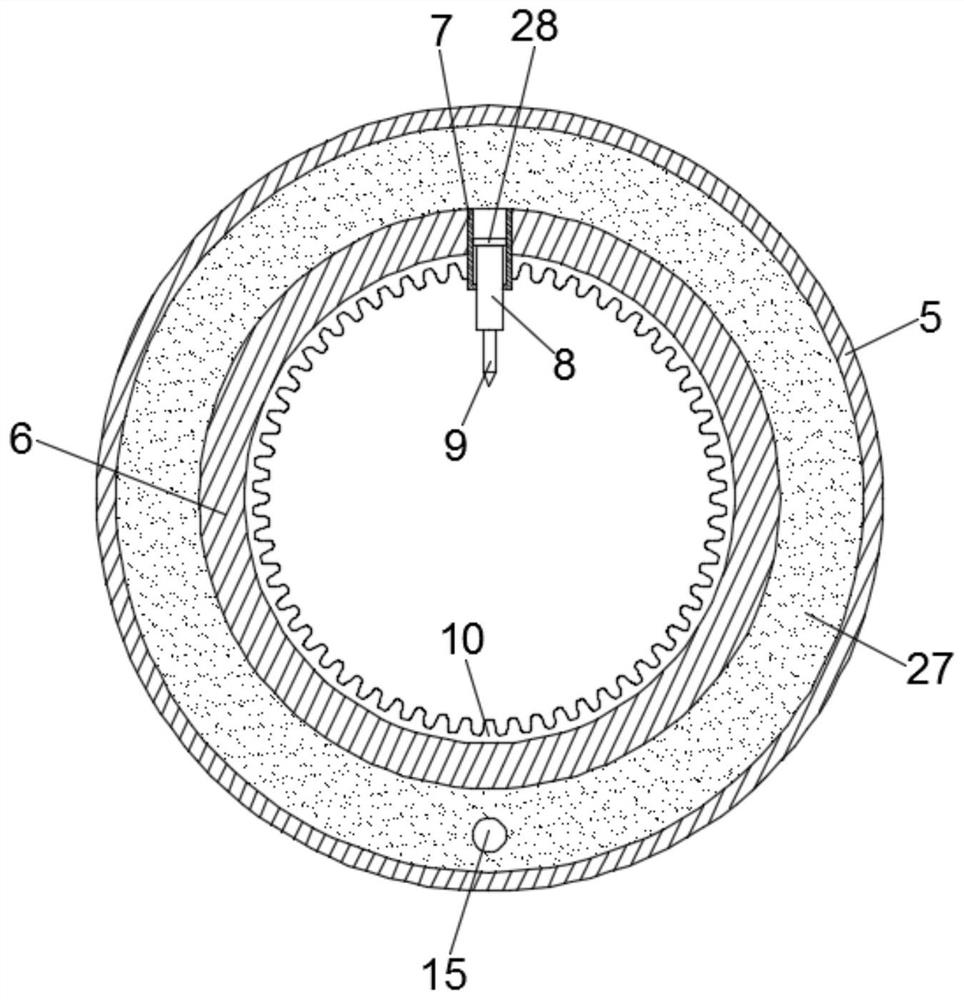

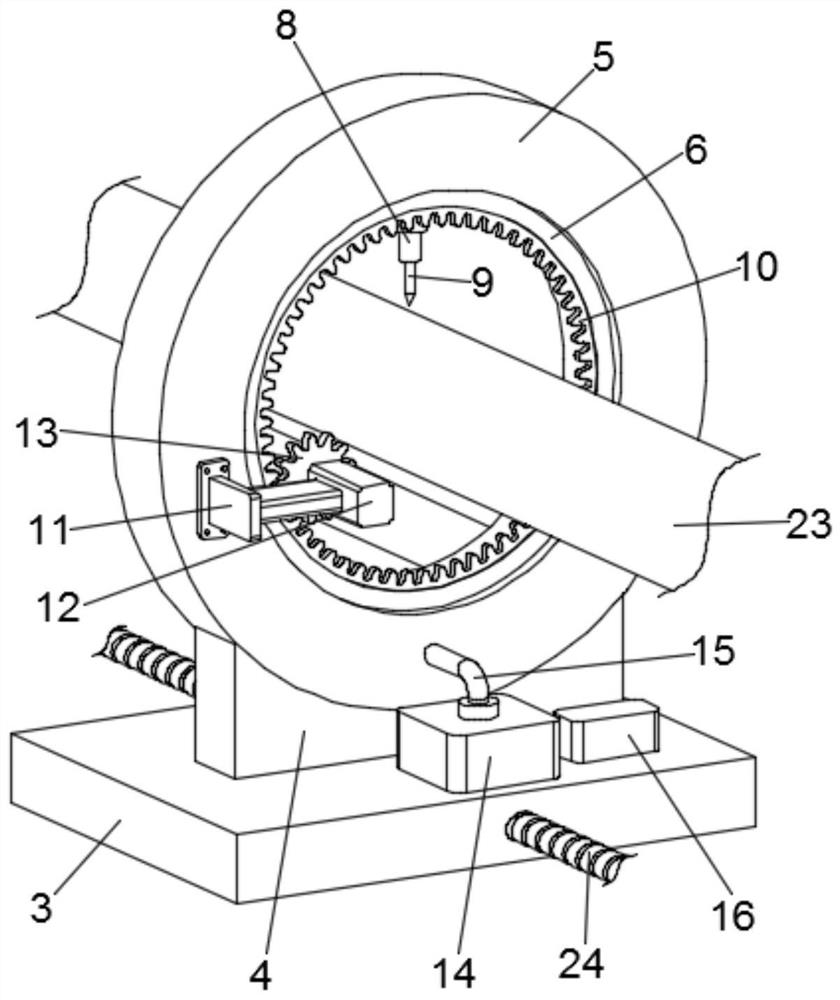

Steel pipe punching device for building construction

The invention discloses a steel pipe punching device for building construction. The steel pipe punching device comprises a base, a sliding rail is installed on the base, a ring sleeve is installed inthe sliding rail in a sliding mode, an annular cavity is formed in the ring sleeve, a rotating ring is rotationally clamped on the inner side of the ring sleeve, a sleeve is fixedly installed on the rotating ring, a telescopic ejector rod is movably sleeved with the sleeve, a punch is installed at the extending tail end of the telescopic ejector rod, and a hydraulic device communicating with the annular cavity is installed on a sliding block; a rotating motor is installed on the outer wall of the ring sleeve, a gear is rotationally installed at the output end of the rotating motor, a gear ringis arranged on the inner wall of the rotating ring, and a controller is installed on the sliding block; and a transverse moving mechanism is arranged on the sliding rail, and clamping assemblies arearranged at the two ends of the sliding rail. According to the steel pipe punching device for building construction, a steel pipe is clamped and fixed through the clamping assemblies, the ring sleeveis driven by the transverse moving mechanism to move transversely along the steel pipe, and meanwhile, the punch can rotate around the circumferential direction of the steel pipe to any angle, and therefore punching operation of the steel pipe at different positions and angles is achieved, adjustment is convenient and flexible, the punching precision is high, and the punching efficiency is improved.

Owner:潘帅

Plate punching die and punching method thereof

The invention discloses a plate punching die and a punching method thereof, and belongs to the field of punching dies. The die comprises a die rack, a punch, a female die body, screws with the same height and a female die body fixing plate. The die rack is of a C-shaped structure, and the two ends of an opening of the die rack are provided with a punch supporting part and a female die body supporting part correspondingly. The punch supporting part is provided with a punch accommodating hole, the punch is arranged in the punch accommodating hole, and the upper end of the punch is connected with a blowing head. A supporting plate is arranged between the blowing head and the punch supporting part. A discharging spring is arranged between the supporting plate and the blowing head, and a support spring is arranged between the supporting plate and the punch supporting part. One ends of the screws with the same height are connected with the supporting plate, and the other ends of the screws with the same height penetrate through the punch supporting part to be connected with a discharging plate. The female die body is mounted on the female die body supporting part through the female die body fixing plate. The punching die is high in punching efficiency and precision and convenient to replace, has the advantages of being simple in structure, easy to operate, flexible in machining, low in cost and long in service life, and is capable of punching products in various specifications.

Owner:JINSHEN NUMERICALLY Y CONTROLLED MOLDS

Punching method for internal high pressure forming pipe fitting

The invention discloses a punching method for an internal high pressure forming pipe fitting. After internal high pressure forming, further setting of a punching tool is not required, a forming die is used for supporting, liquid pressure is utilized for applying a force on a punching portion, and therefore the punch portion is evenly stressed, and the punching precision is improved; the punching direction is from inside to outside, so that the product internal dent problem due to internal punching is completely solved; and at the same time, burrs generated during punching are located on the outer side of a workpiece and can be eliminated by subsequent simple polishing, and the overall finish degree of the product is good. The invention further discloses a device used for achieving the punching method for the internal high pressure forming pipe fitting, the punching method can be achieved through the optimal setting of the device, and therefore the applicability of the punching method is high assuringly, and the machining cost is lower.

Owner:BAOLONG ANHUI AUTO PARTS

Automatic tool die changing type special-shaped material blanking machine

The invention discloses an automatic tool die changing type special-shaped material blanking machine which comprises a punching head, a tool die changing mechanism, a rack and a control box. The punching head is arranged on the rack, and a tool die is arranged below the punching head. The tool die changing mechanism is arranged on one side of the punching head, the control box is arranged on the rack, and the tool die changing mechanism can be used for driving the tool die to move between the punching head and a tool die warehouse and be positioned. The clamping effect of a tool die arranged after changing is good, the structure is reasonable, operation is convenient, tool die positioning is accurate, time is saved, the work efficiency is improved, and in addition, the blanking precision is improved.

Owner:YANCHENG HUASEN MACHINERY

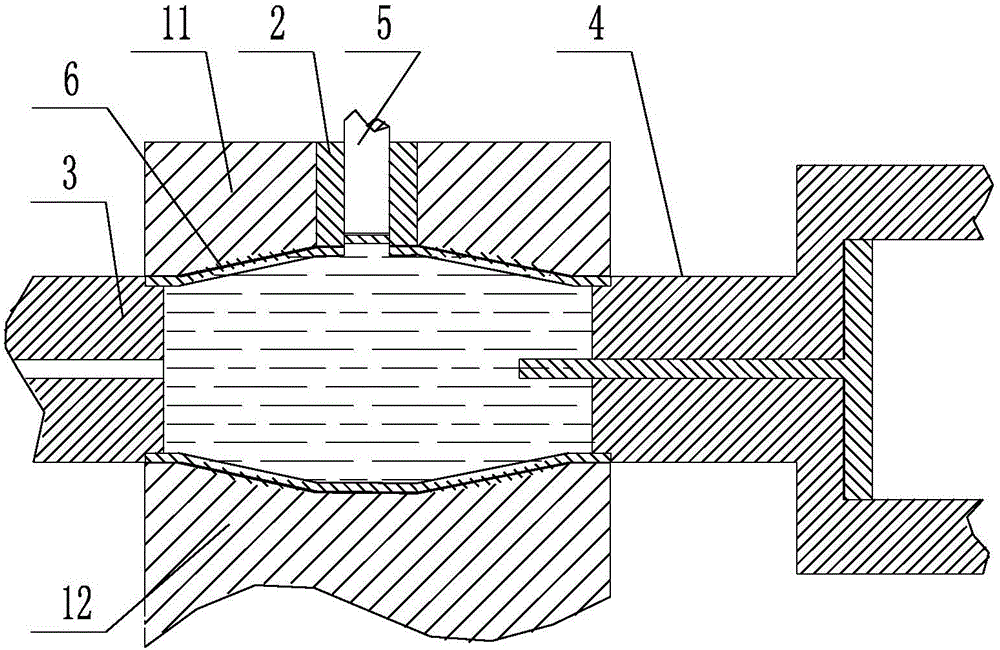

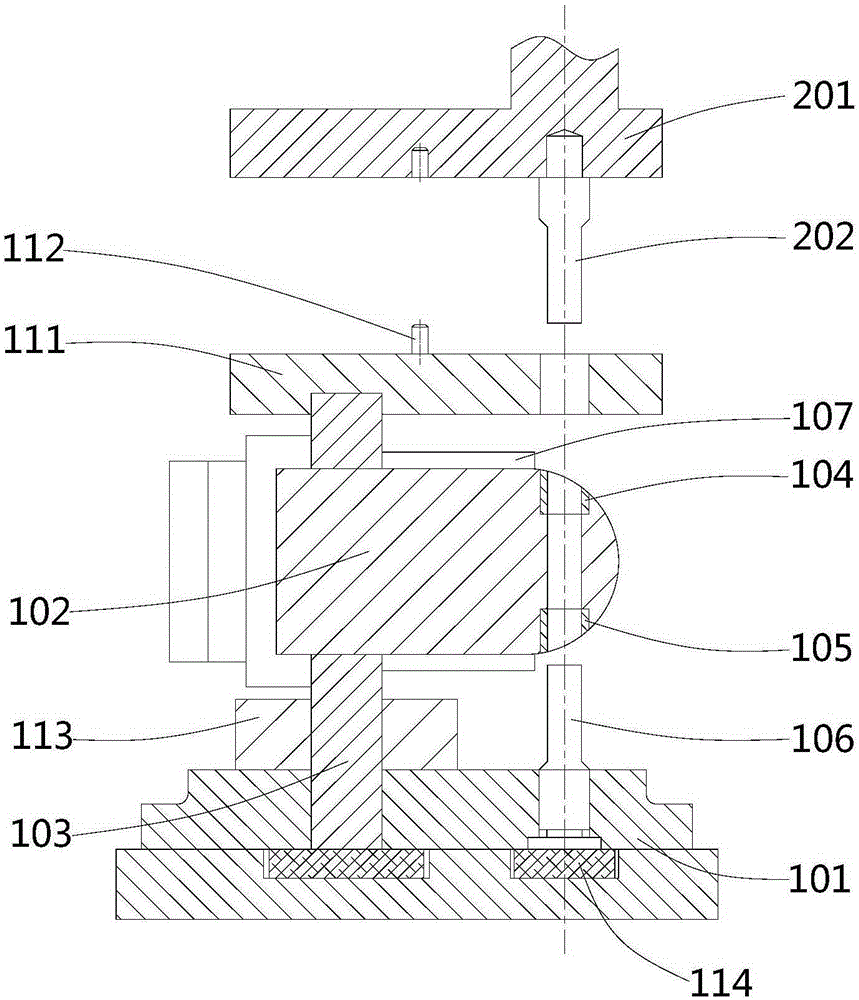

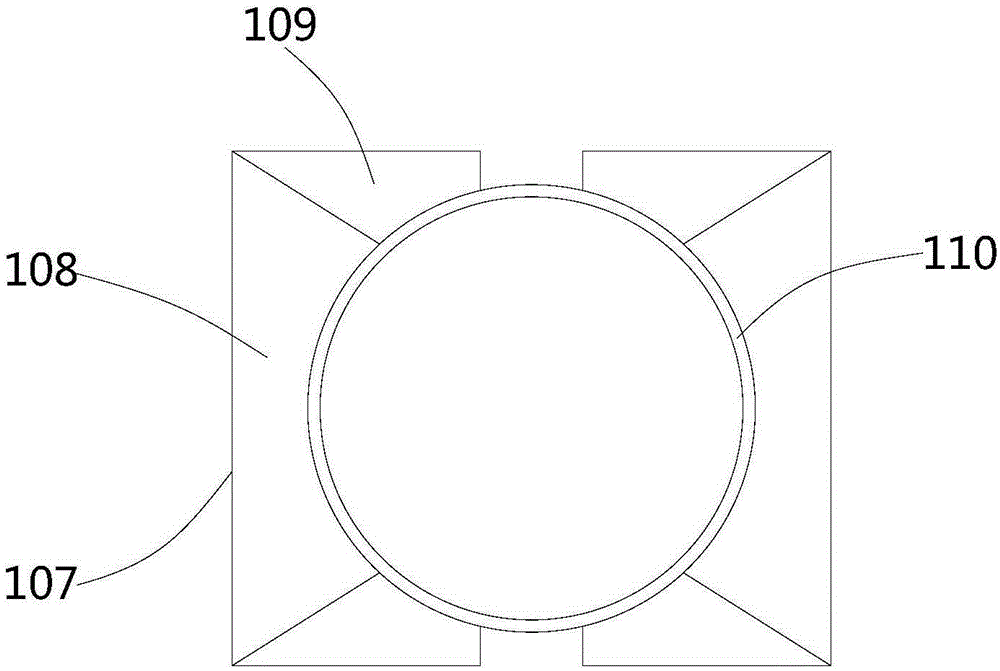

Spherical surface cantilever type bi-directional punching die

ActiveCN105215149AEasy to fixGuaranteed to proceed normallyPerforating toolsMetal-working feeding devicesPunchingSpherical shaped

The invention provides a spherical surface cantilever type bi-directional punching die and belongs to the field of punching dies. The punching die comprises a lower die base and an upper die base. The lower die base is provided with a cantilever part. One end of the cantilever part is connected with the lower die base through a female die fixing base. The other end of the cantilever part serves as a working end. The working end is provided with a spherical surface. The spherical surface is provided with an upper female die body and a lower female die body in a vertically opposite mode. The upper die base is provided with an upper male die body. The lower die base is provided with a lower male die body. The upper male die body corresponds to the upper female die body. The lower male die body corresponds to the lower female die body. Clamping blocks are arranged at the positions, close to the left side and the right side of the working end, of the lower die base respectively. The clamping blocks are detachably connected with the lower die base. The spherical surface cantilever type bi-directional punching die can punch spherical surface work-pieces synchronously in two directions, the work-pieces do not need to be punched one by one, machining efficiency is improved, punching precision is greatly improved, deformation of the spherical surface work-pieces in the punching process is reduced, and the machining quality of the manufactured work-pieces is ensured.

Owner:启东市鸿洋润滑产品有限公司

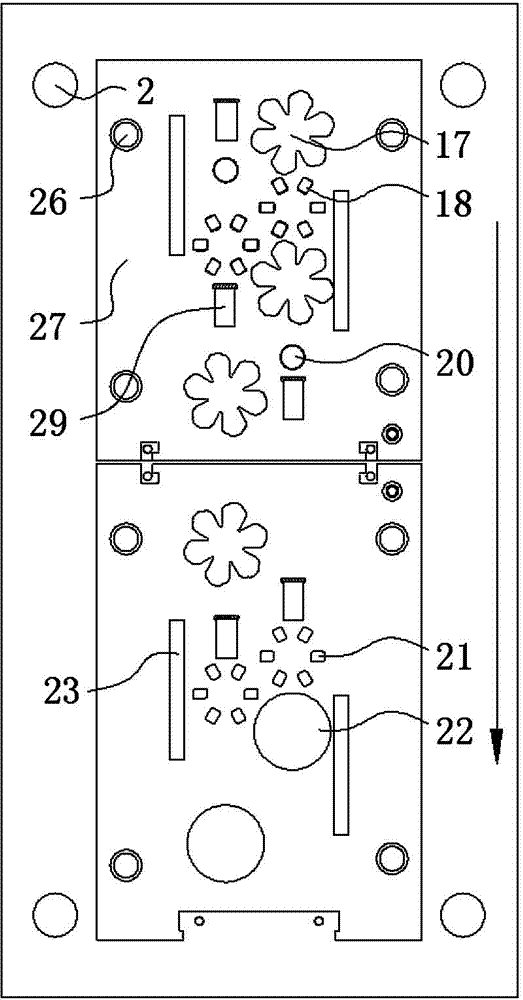

Prepreg cutting and drilling integrated device and machining process

InactiveCN108274529AImprove punching accuracyNot easy to deviateInsulating layers/substrates workingMetal working apparatusPunchingLocking mechanism

The invention discloses a prepreg cutting and drilling integrated device. The prepreg cutting and drilling integrated device comprises a prepreg coiling and locking mechanism, a punching mechanism, acutting mechanism and a collection mechanism. The punching mechanism and the cutting mechanism are progressive die mechanisms. The cutting mechanism and the collection mechanism are connected througha conveying mechanism. According to the prepreg cutting and drilling integrated device, the punching mechanism is additionally arranged in front of a cutting position and can complete the punching procedure before cutting. The prepreg cutting and drilling integrated device is high in punching precision, not prone to deviation and low in product rejection rate. The punching procedure is conducted before the cutting procedure. Time consumed for manually collecting and stacking plates is saved. The number of equipment purchasing types is reduced. The connection time between a slicing machine anda punching machine and the preparation time are saved. The production efficiency is improved. The production cost is lowered. The requirements for automatic production are met. The invention further discloses a machining process. The machining process is high in machining precision, efficiency and automation degree and low in production cost.

Owner:江西景旺精密电路有限公司

Punching machining die device based on special-shaped seamless steel pipe arc section blanking and pressing

ActiveCN110355263AImprove punching accuracyAvoid stuffingPerforating toolsGrinding machinesRolling resistancePunching

The invention discloses a punching machining die device based on special-shaped seamless steel pipe arc section blanking and pressing. The punching machining die device is characterized by structurally comprising a T-shaped pressure pin block, sliding pin column jackets, sleeves, an upper parting panel, a bending die cover plate, counterpoint bow frame shaft pillars and a base block. By means of the punching machining die device, the bending die cover plate is matched with the counterpoint bow frame shaft pillars, an aluminum slag plate is removed in a rolling friction manner, and padding of an insulation pad is avoided; then light ray correlation shaft frames are used for conducting auxiliary operation on a punching pile, a deep-correction left-right cooperation clamping rolling output effect is formed, and a slag discharging and discharging punching auxiliary matching effect is achieved; then rotation lasers are corrected to be emitted to a middle position point in a correlation manner so that the punching pile can have a lower position end crosshair, and the punching precision and the depth limitation are improved; the blanking progress of a special-shaped pipe can be rapid andefficient, a single-pipe multi-punch-hole homeopathic sliding and pushing slag discharging effect is also enhanced, when a bending die is subjected to die pressing, impact locking can be conducted onan arc top face of the pipe, hydraulic force of insertion pin pillars at the two ends rises again, the stress mark and garland probability of a steel pipe face is lowered, and punching completeness isensured.

Owner:西安美汉电气工程有限公司

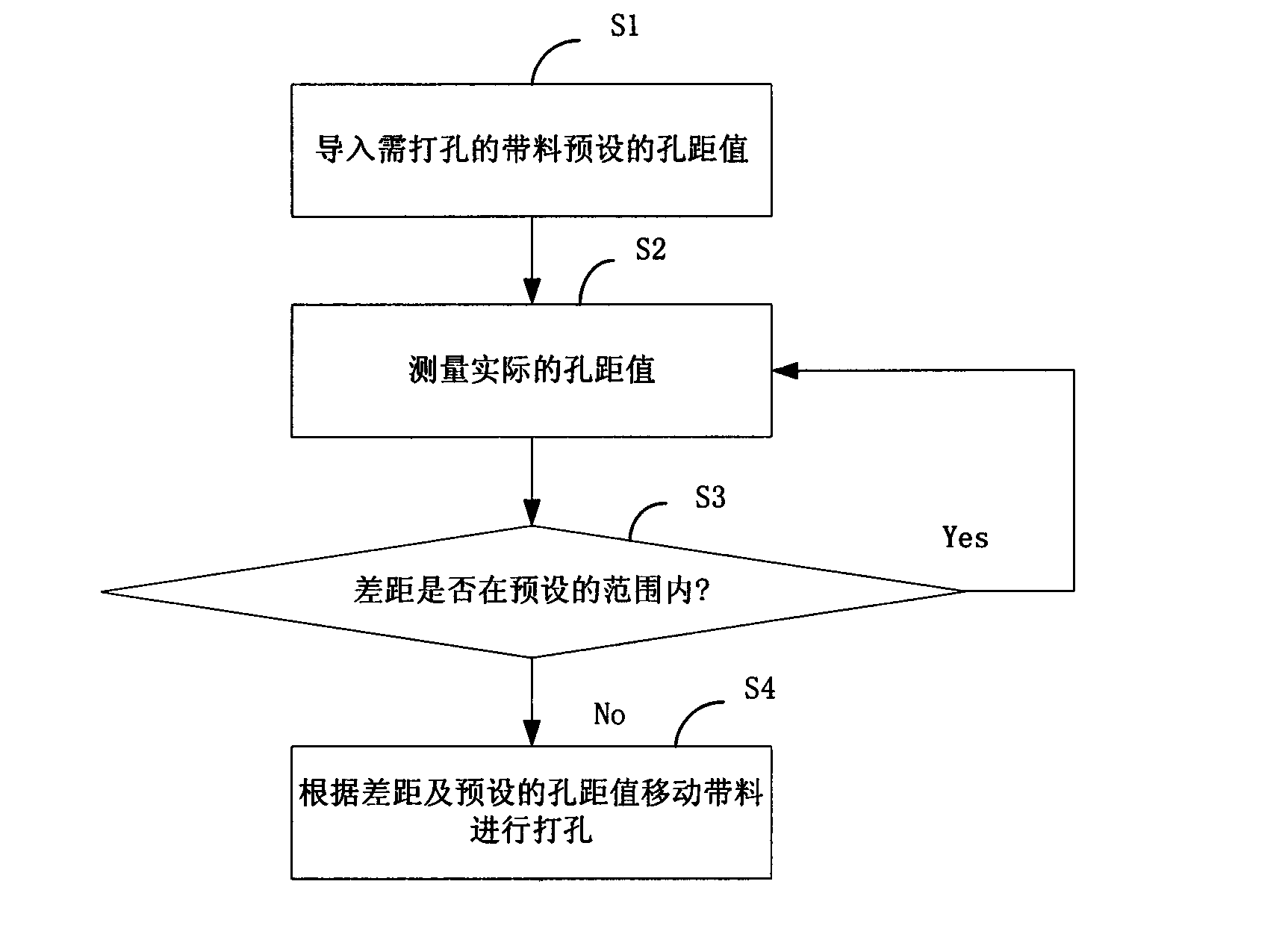

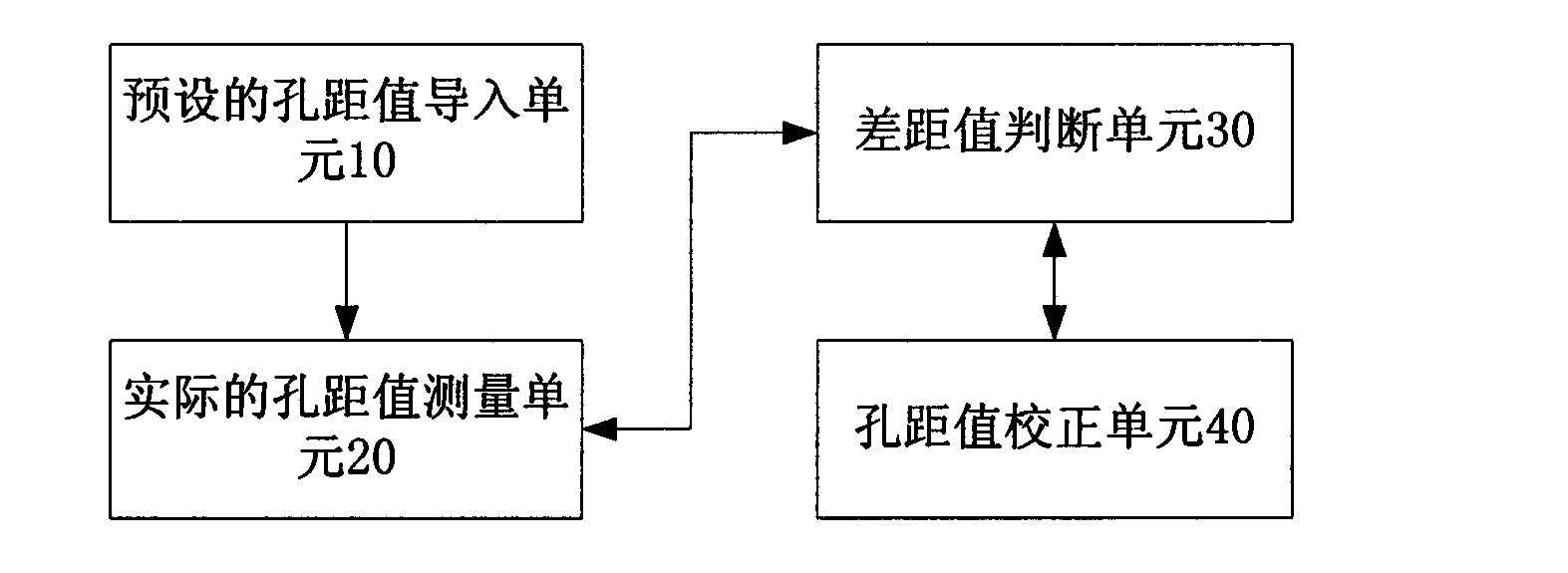

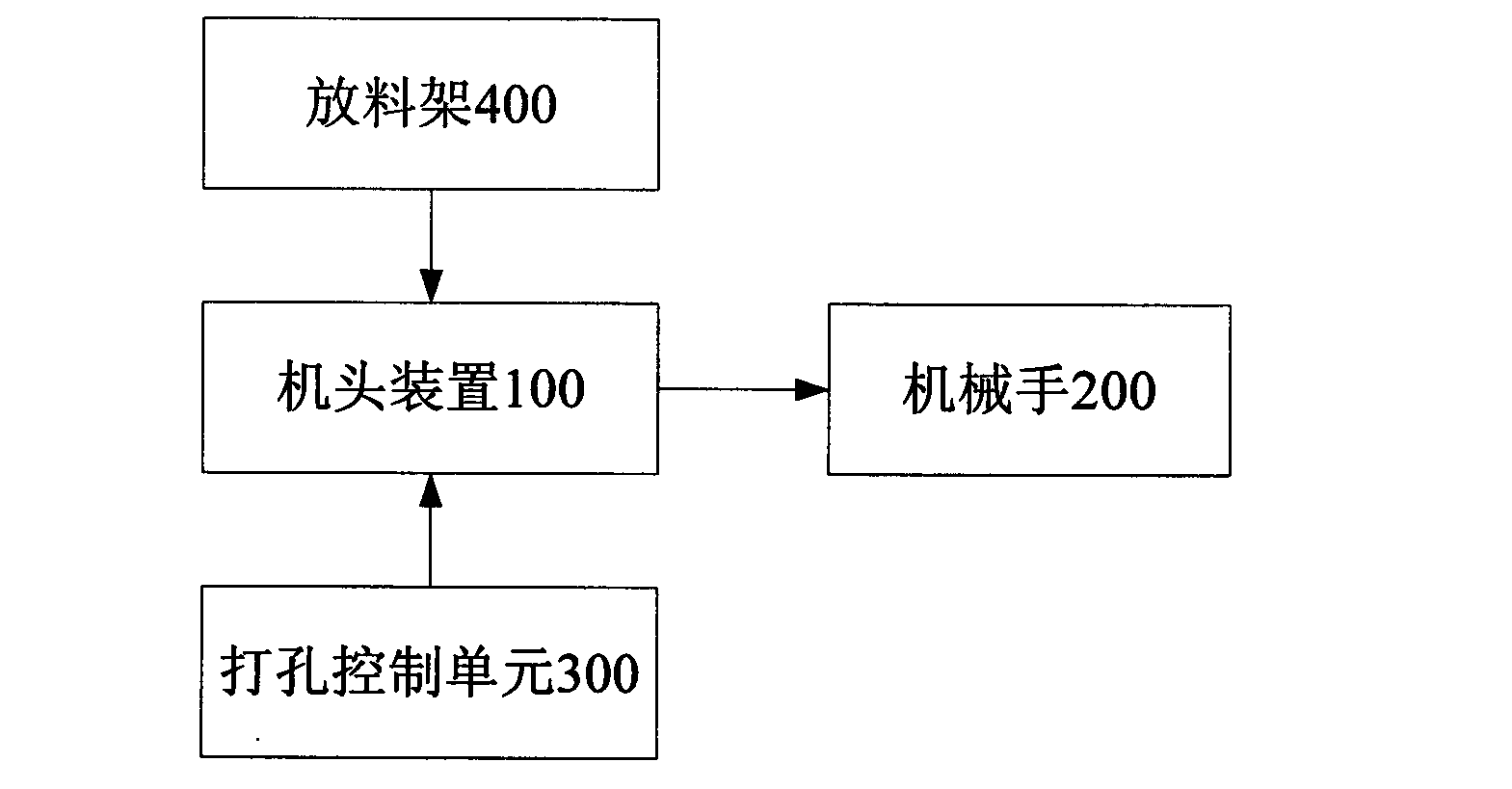

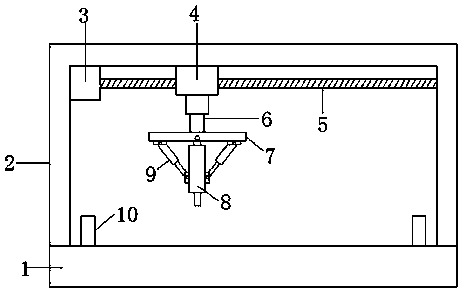

Punching method, device and equipment

InactiveCN102699952AReduce mistakesImprove punching efficiencyMetal working apparatusPunchingEngineering

The invention provides a punching method which comprises the following steps of: (S1) automatically importing the preset hole pitch value of a belt to be punched; (S2) constantly moving the belt, punching the belt according to the preset hole pitch value, and measuring the actual hole pitch value; (S3) judging whether the difference between the actual hole pitch value and the preset hole pitch value is within the preset range; and (S4) moving the belt to punch according to the difference and the preset hole pitch value. The invention also discloses punching device and equipment. According to the punching method, device and equipment provided by the invention, the position of a punch can be adjusted, the punching hole pitch can be automatically corrected, the error is reduced, manual detection is completely unneeded, and the punching efficiency and accuracy are increased.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

Car bumper punching device

InactiveCN108927850APrevent looseningImprove punching accuracyPerforating toolsMetal working apparatusPunchingEngineering

The invention belongs to the technical field of car bumper production equipment and particularly discloses a car bumper punching device. The car bumper punching device comprises a working table; a U-shaped framework with an opening facing downwards is mounted at the top of the working table; a servo motor is mounted on the left side of the top of an inner cavity of the U-shaped framework; a screwrod is mounted at the power output end of the right side of the servo motor; a lifting apparatus is mounted at the bottom of a mounting block; a mounting plate is mounted at the power output end of the bottom of the lifting apparatus; a punching device body is hinged to the center of the bottom of the mounting plate; and electric telescopic rods are symmetrically hinged to the left side and the right side of the bottom of the mounting plate. By means of the car bumper punching device provided by the invention, the two ends of a car bumper are clamped correspondingly through a clamping apparatus, thus the car bumper is prevented from loosening, then the punching accuracy is improved, furthermore the punching angle of the punching device body can be adjusted, the labor intensity is relieved,and the punching efficiency is improved.

Owner:合肥江淮毅昌汽车饰件有限公司

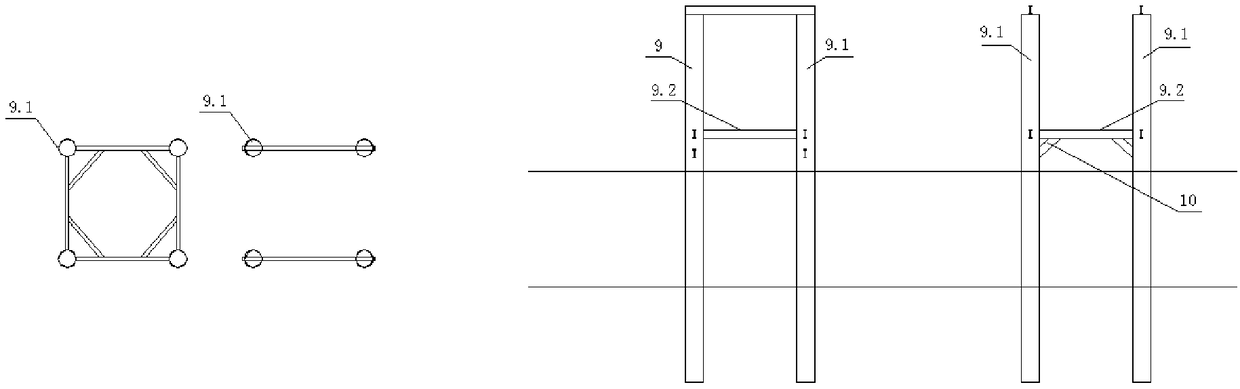

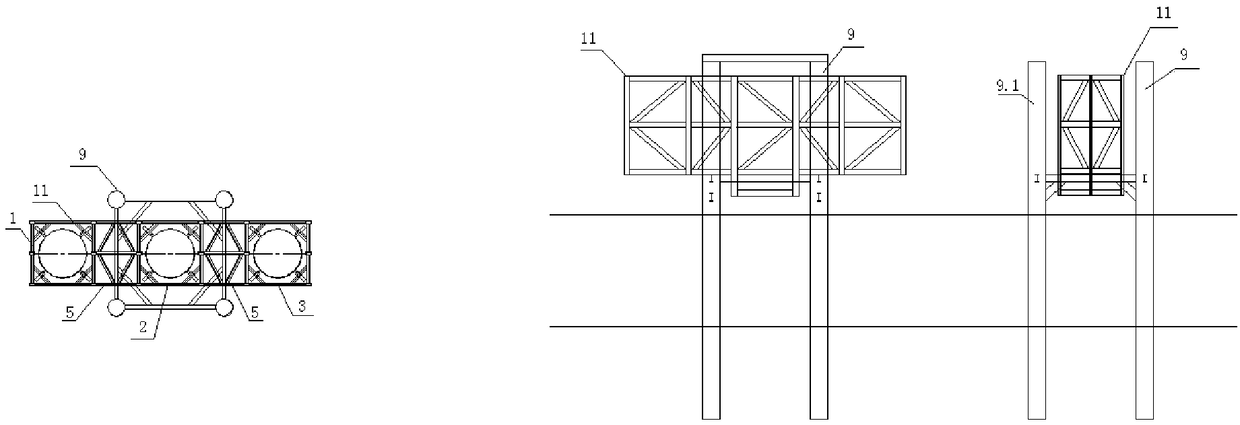

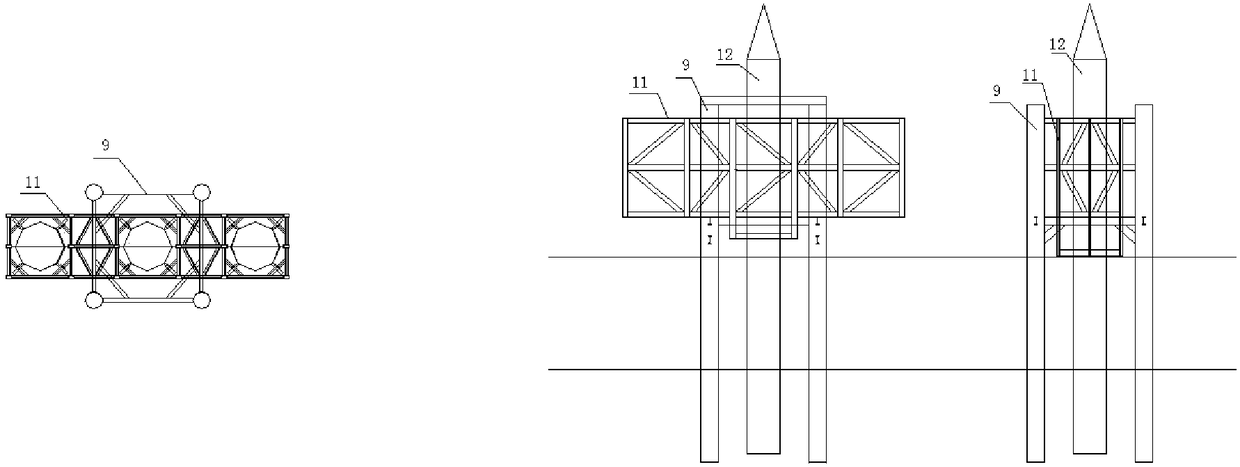

Large-diameter steel pile casing and three-frame type guide frame driving construction method

ActiveCN108193680AHigh positioning accuracyImprove vertical accuracyBulkheads/pilesCastingSelf weight

The invention discloses a large-diameter steel pile casing and three-frame type guide frame driving construction method. The method comprises the following steps that four auxiliary piles are driven in for placing a three-frame type guide frame, and connected through I-shaped steel; the three-frame type guide frame is placed to an auxiliary positioning steel pipe pile platform, and coordinates andperpendicularity are adjusted; steel pile castings sink due to the self weight; the steel pile castings on the two sides of the guide frame continue to be driven and are positioned, inserted and driven in the same ways as the first steel pile casting; locking connection between the guide frame and the auxiliary steel pipe piles and parallel connection of upper ports between the steel pipe piles are cut away, the guide frame is lifted up and rotated by 90 degrees and then placed down, and steel pile castings on the two sides in the longitudinal direction are driven in the same way; the guide frame is lifted and opened, and the auxiliary steel pipe piles are dismantled; two pieces of I45b type steel are welded to the top port of a middle guide port of the guide frame to be used as a bearingbeam, the middle guide port is placed down to the driven steel pile casting, the driven steel pile casting is used as a positioning base pile, and other steel pile castings are driven. The large-diameter steel pile casing and three-frame type guide frame driving construction method has the advantage of improving steel pile casting driving precision.

Owner:CCCC SHEC FIRST HIGHWAY ENG +2

Surface treatment device and treatment method for household solid wood board production

ActiveCN114800093ASatisfy double-sided automatic grinding operationImprove processing efficiencyEdge grinding machinesStationary drilling machinesSolid woodPunching

The invention relates to the technical field of furniture board production equipment, in particular to a surface treatment device for household solid board production, which comprises a left support frame, a first portal frame, a limiting mechanism, a side edge grinding mechanism, a treatment mechanism, a right support frame, a second portal frame and a punching mechanism, two discharging conveying belts are installed at the top of the right supporting frame, and a turn-over mechanism is arranged at the end, close to the processing mechanism, of the left supporting frame. Through mutual cooperation of all the mechanisms, automatic feeding operation, two-side-edge grinding operation, front-back-side grinding operation, automatic punching operation and automatic discharging operation on solid wood boards can be achieved; the full-automatic double-sided solid wood board grinding machine is high in automation degree, the production cycle is shortened, solid wood boards can be turned over in the conveying process, double-sided automatic grinding operation of the solid wood boards is met, the machining efficiency and effect of the solid wood boards are improved, and the overall equipment is high in practicability.

Owner:山东鲁班世家门业有限公司

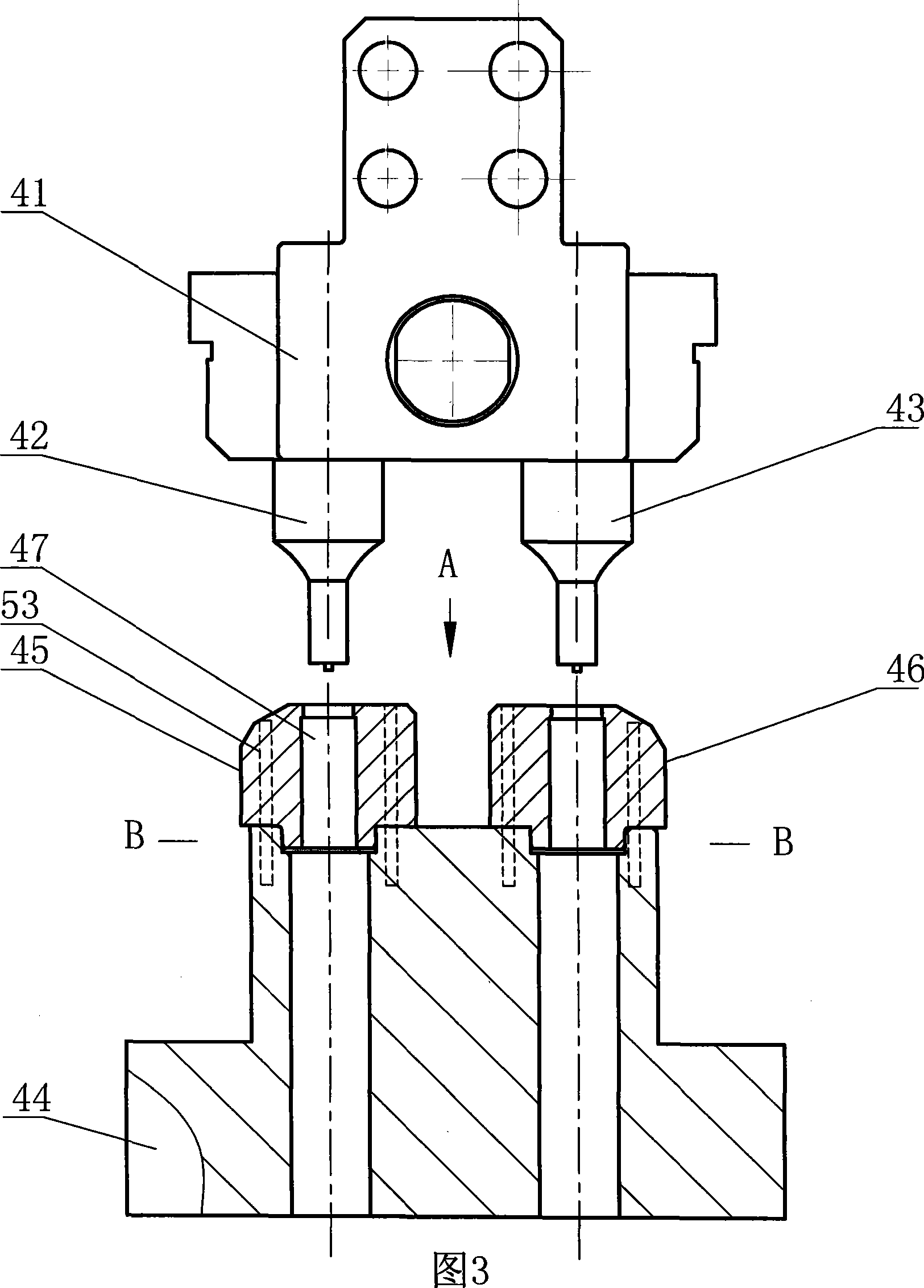

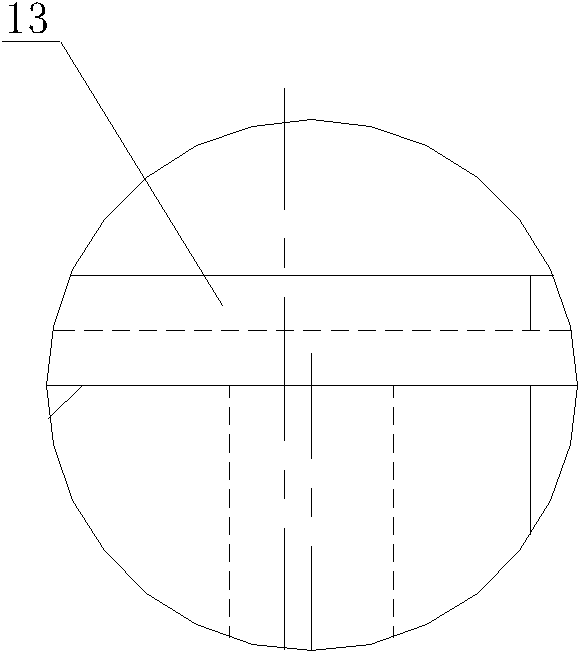

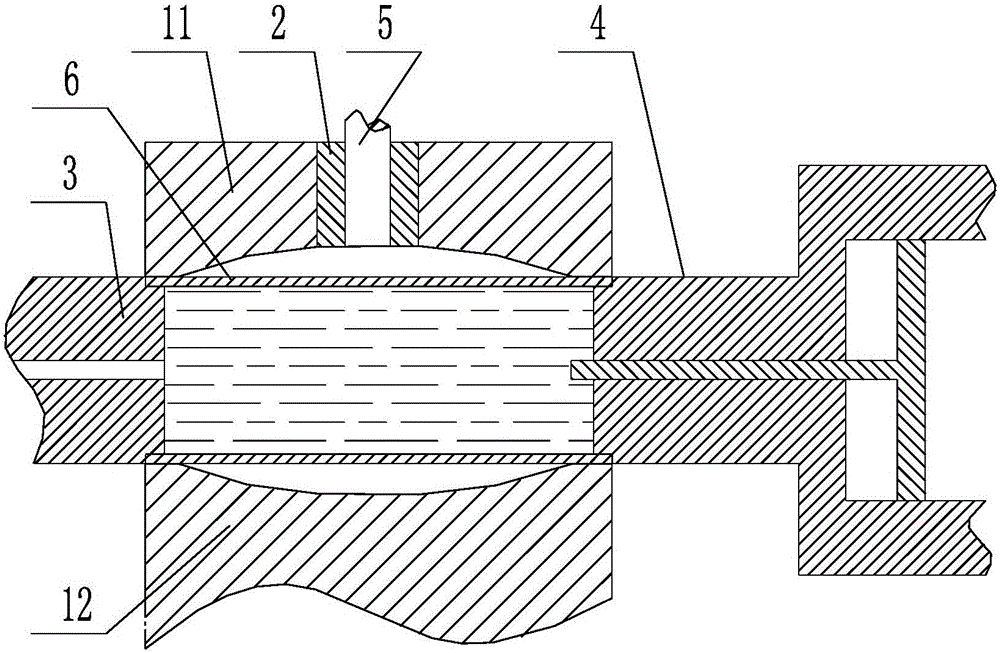

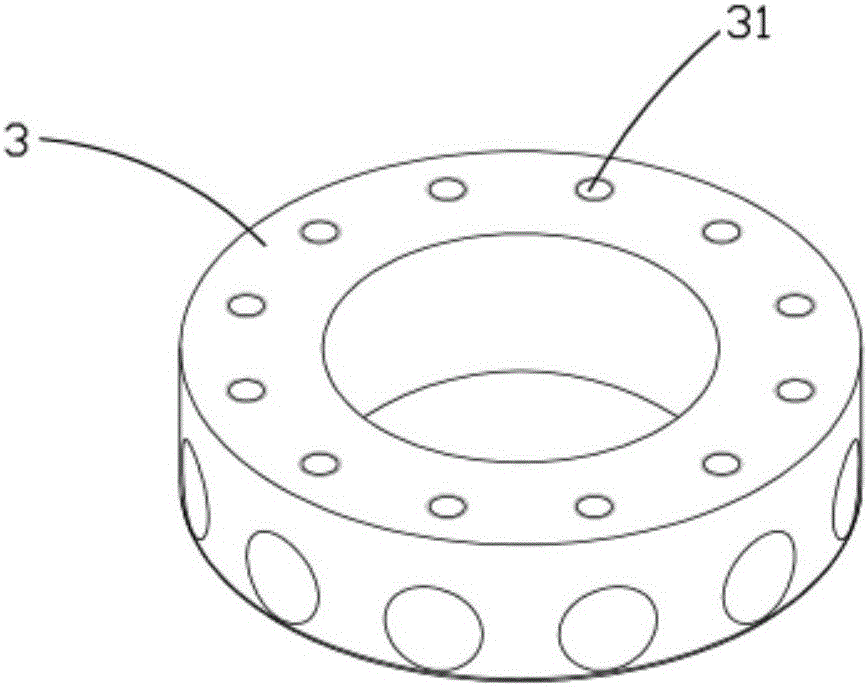

One-time stamping forming mold for ball pocket of holder

ActiveCN105689591AEven by forceNot easy to damagePerforating toolsBearing componentsPunchingEngineering

The invention relates to a one-time stamping forming mold for a ball pocket of a holder. The one-time stamping forming mold comprises a base, a main sliding body, an inner mold, outer molds and a shrink sleeve. The main sliding body is arranged inside the base vertically; the main sliding body is sleeved with the inner mold, and a plurality of outer molds are evenly arranged on the base in the circumferential direction; the outer molds are all arranged outside the inner mold; the shrink sleeve is arranged on the upper portions of the outer molds in a sleeving mode; a plurality of punches are evenly arranged on the side wall of the inner mold in the circumferential direction; and limiting grooves are formed in the inner walls of the outer molds. A first spring is placed horizontally inside each punch; a kidney-shaped hole is formed in the upper portion of each punch; a plurality of pin holes are evenly formed in the upper end face of the inner mold; and a plug pin is arranged inside each pin hole. According to the one-time stamping forming mold for the ball pocket of the holder, the diameter variation of the main sliding body is utilized to push the punches to move radially in a divergent way along the main sliding body, so that multiple holes are punched in the ball pocket of the holder at a time; through the elastic effect of the first springs arranged inside the punches, automatic resetting of the punches after the completion of the punching is achieved. The mold is simple, punching is stable and highly precise, and automation and flow line operation can be easily achieved.

Owner:ZHEJIANG GUNAI RUBBER & PLASTIC SCI & TECH

Automatic punching machine with positioning function

ActiveCN113547365AEasy to collectWith collection functionMeasurement/indication equipmentsFeeding apparatusPunchingEngineering

The invention discloses an automatic punching machine with a positioning function, and relates to the technical field of machining. The automatic punching machine comprises a punching box, wherein a conveying assembly is arranged at the left side of the bottom of the inner wall of the punching box; a material pressing assembly is arranged at the left side of the top of the inner wall of the punching box; the material pressing assembly is provided with a positioning and pressing assembly; a punching assembly is arranged at the top of the inner wall of the punching box; a supporting assembly is arranged at the bottom of the inner wall of the punching box and positioned below the punching assembly; the supporting assembly is provided with a positioning assembly; and a controller is arranged at the right side of the top of the inner wall of the punching box. According to the automatic punching device with the positioning function, the position is adjusted and controlled through the positioning assembly, and the right side of a material is limited, so that the effect of precise positioning is achieved. The effects of precise positioning and automatic punching are achieved through the arrangement of the punching box, the conveying assembly, the material pressing assembly, the positioning and pressing assembly, the punching assembly, the positioning assembly and the controller. Automatic positioning and punching are achieved, and the punching work efficiency is improved.

Owner:徐州市晶鑫新材料有限公司

Panel punching device

The invention discloses a panel punching device. The panel punching device comprises a base on which a worktable is arranged, a positioning column is fixedly mounted at one side of an upper surface of the worktable, and a plurality of cavities are respectively arranged on the worktable at an inner side of the positioning column, the space between the positioning column and each of the plurality of cavities is the same as the space between two adjacent cavities; the worktable at the rear side of the plurality of cavities is respectively correspondingly provided with a plurality of positioning blocks, and a baffle is arranged at the outer side of the positioning column; and a punch is arranged above the worktable and respectively over against the plurality of cavities on the worktable. The panel punching device is simple in structure; by using a three-point positioning theory, the positioning column and the positioning blocks are arranged around the cavities on the worktable to accurately position the panel, thereby greatly improving the punching precision; the operation is simple, and the panel punching device has good practical value.

Owner:MINGGUANG JIAYI ELECTRIC CONTROL TECH

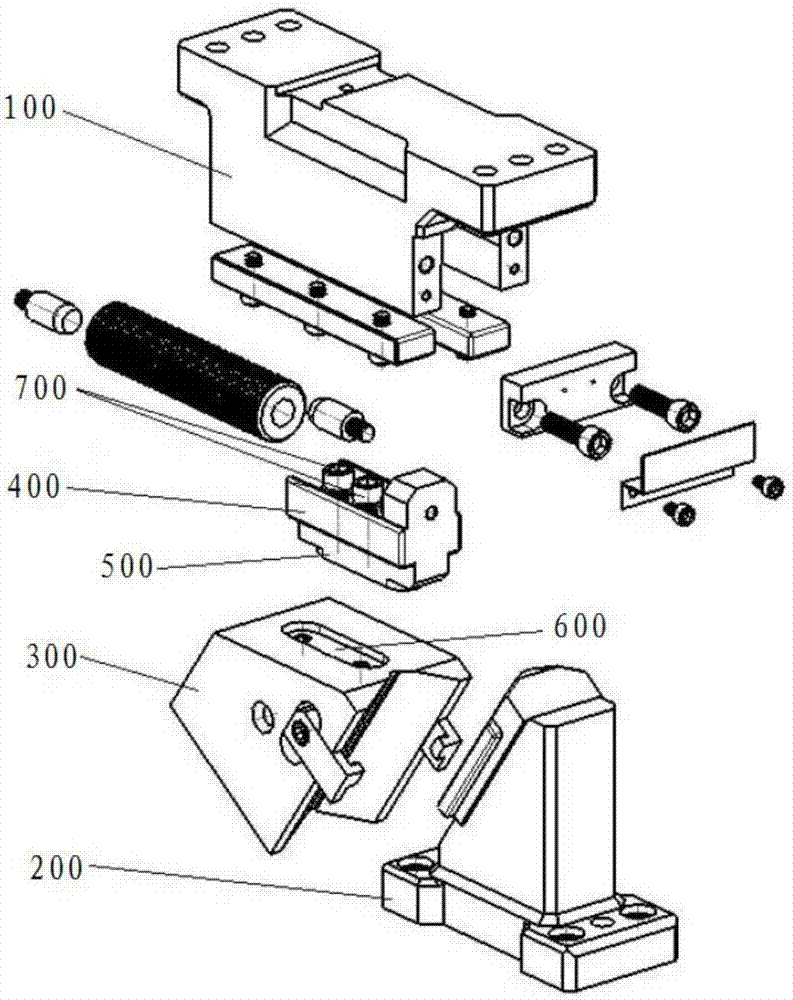

Side piercing tapered wedge mechanism with material pressing function

InactiveCN107335711AImprove yield rateGuaranteed accuracyMetal-working feeding devicesPositioning devicesEngineeringProduct Part

The invention discloses a side piercing tapered wedge mechanism with a material pressing function. The side piercing tapered wedge mechanism comprises an upper sliding block, a side guide block, a lower sliding block, a bottom guide block and a piercing head assembly, wherein the upper sliding block is fixedly mounted at the bottom of an upper template; the side guide block and the bottom guide block are fixedly mounted at the top of a lower template; the lower sliding block and the piercing head assembly are mounted on the bottom guide block in a sliding manner; the side piercing tapered wedge mechanism further comprises a material pressing plate and a return assembly; a material pressing plate spring is mounted on the lower sliding block; a through hole is formed in the piercing head assembly; a piercing head avoiding hole is formed in a material pressing plate; the material pressing plate is connected with the bottom guide block in a sliding manner; the material pressing plate spring penetrates through the through hole and presses against the material pressing plate; a piercing head on the piercing head assembly penetrates through the piercing head avoiding hole; and the return assembly is mounted on the side guide block and is connected with the lower sliding block. The side piercing tapered wedge mechanism disclosed by the invention can complete the work of material pressing first and then piercing for a hole in the side surface of a product part, and is simple in structure and small in installation space; the piercing head is convenient to remove; and the development cost of a die is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

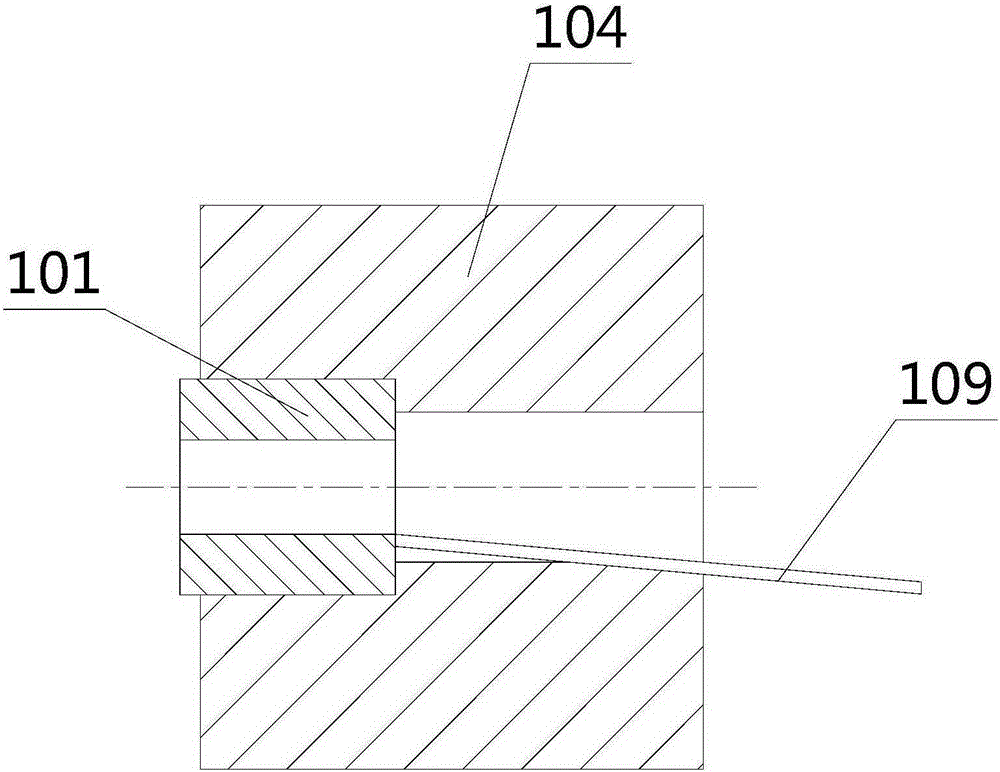

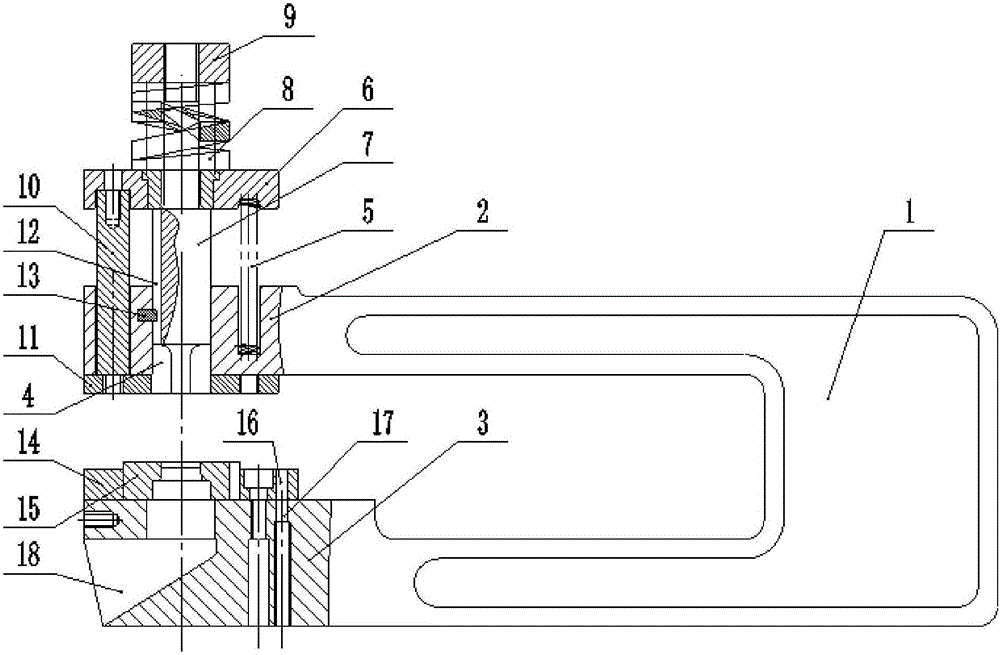

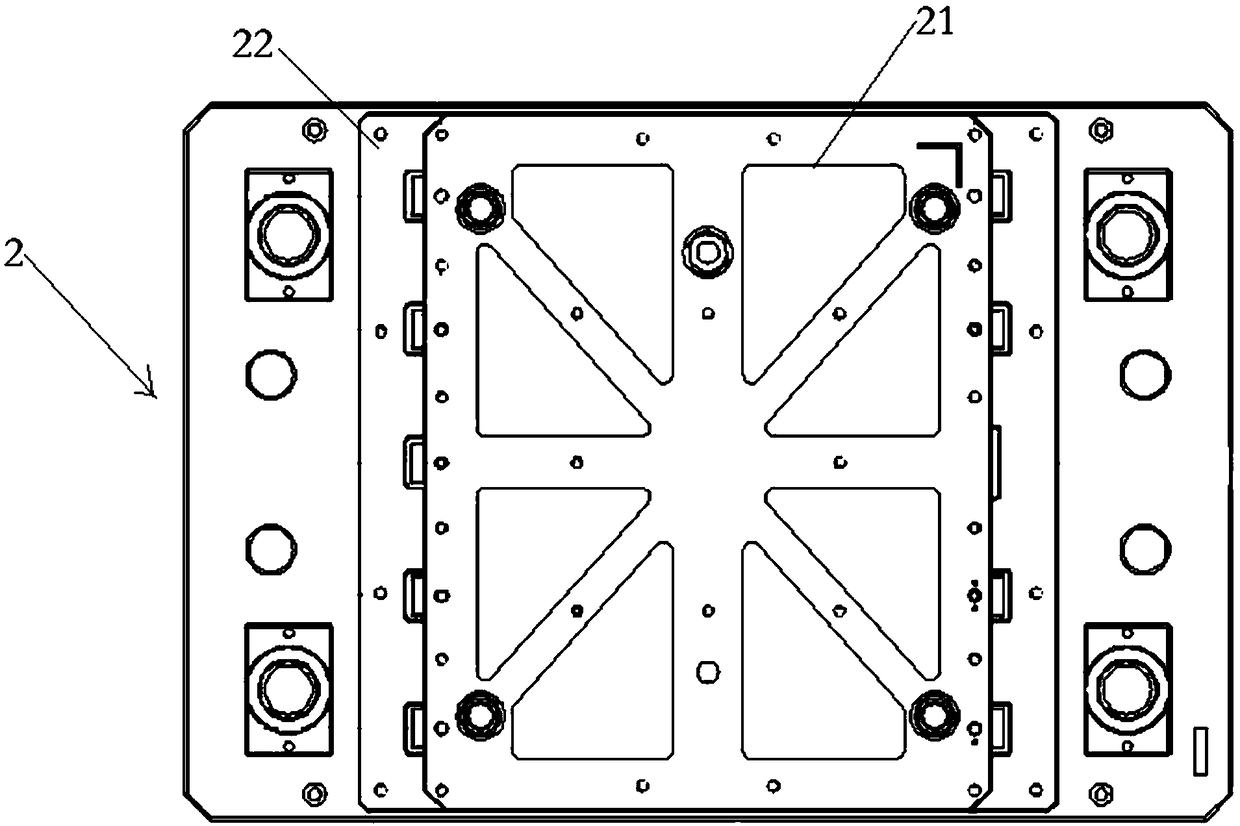

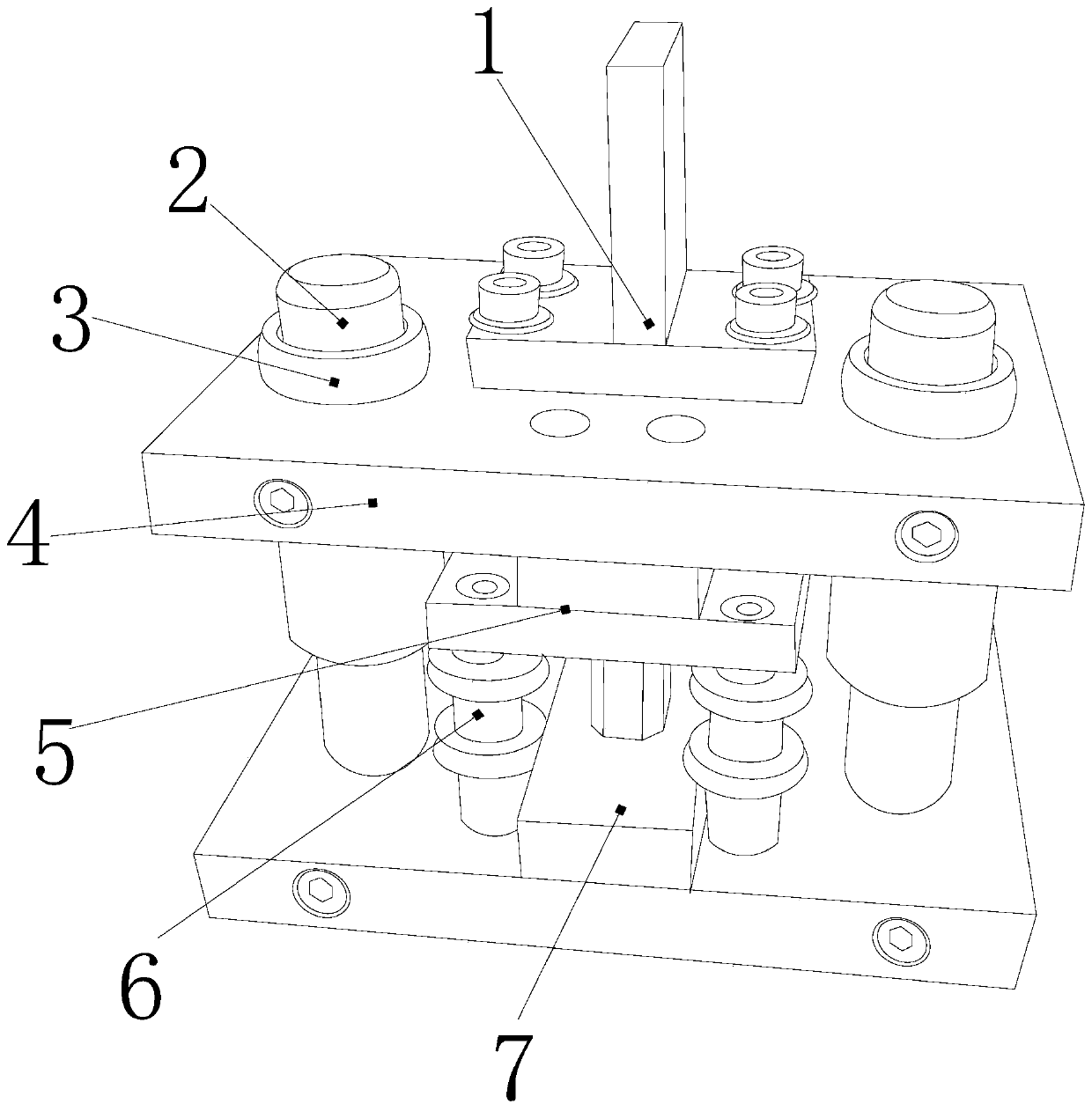

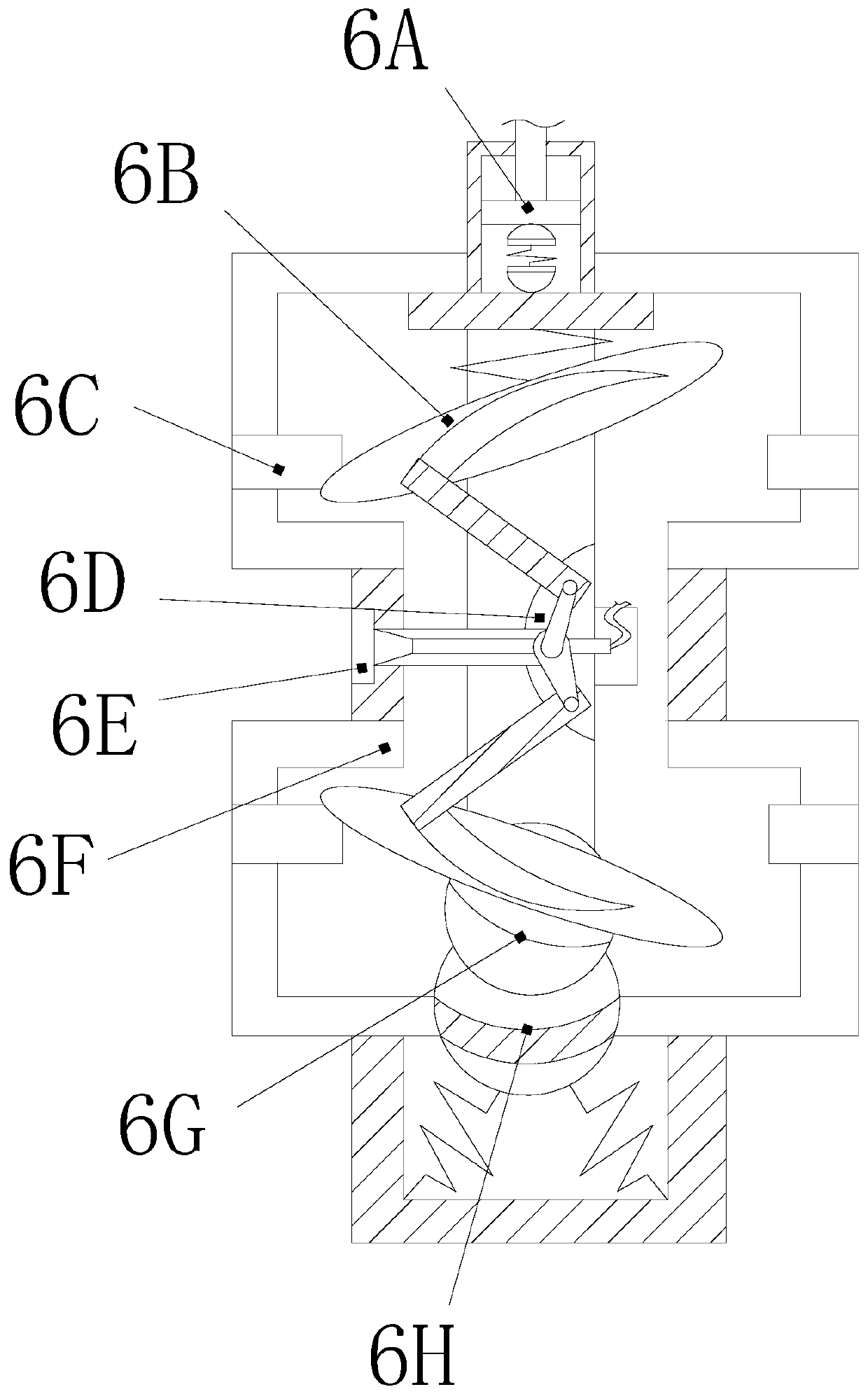

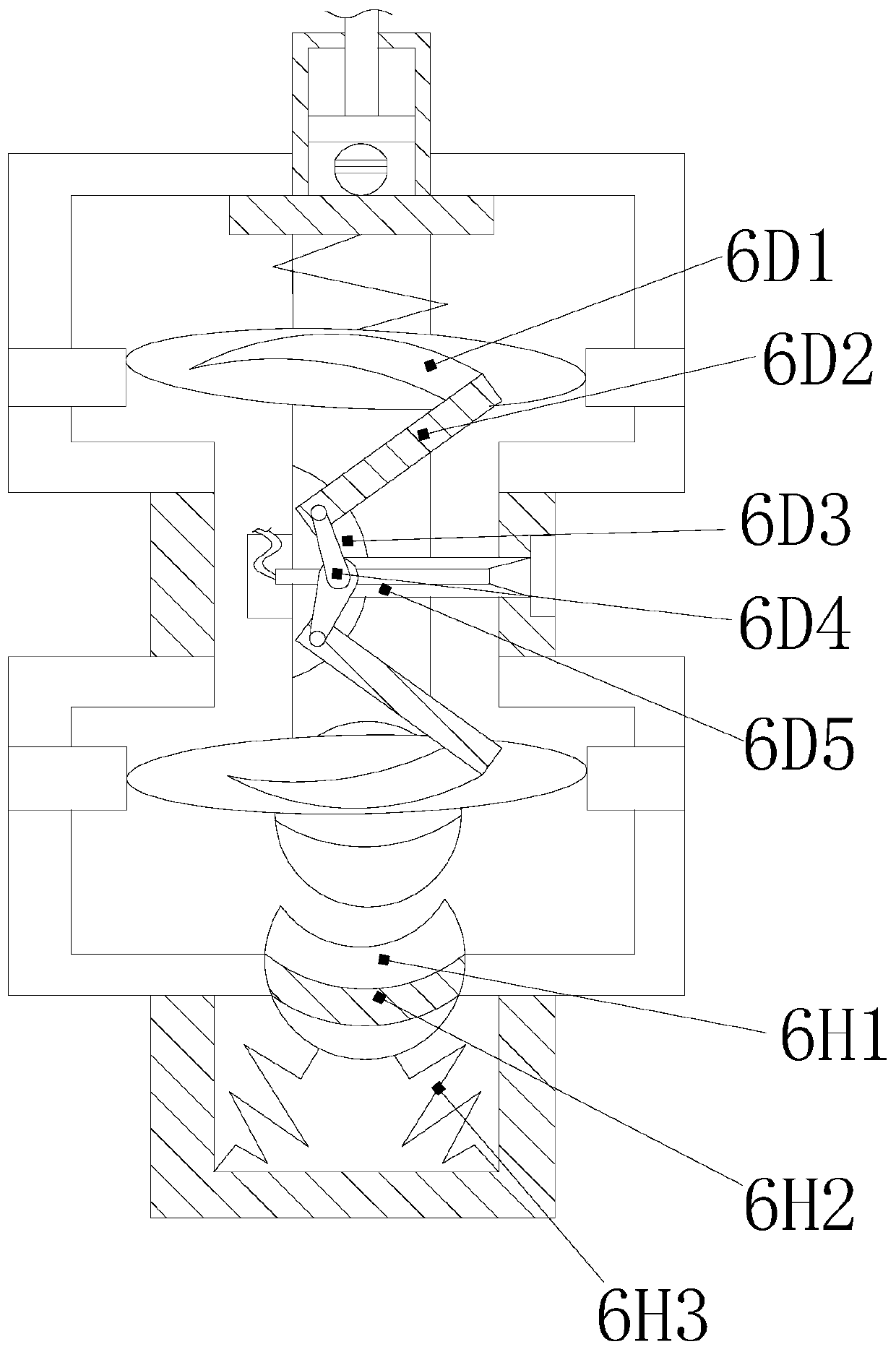

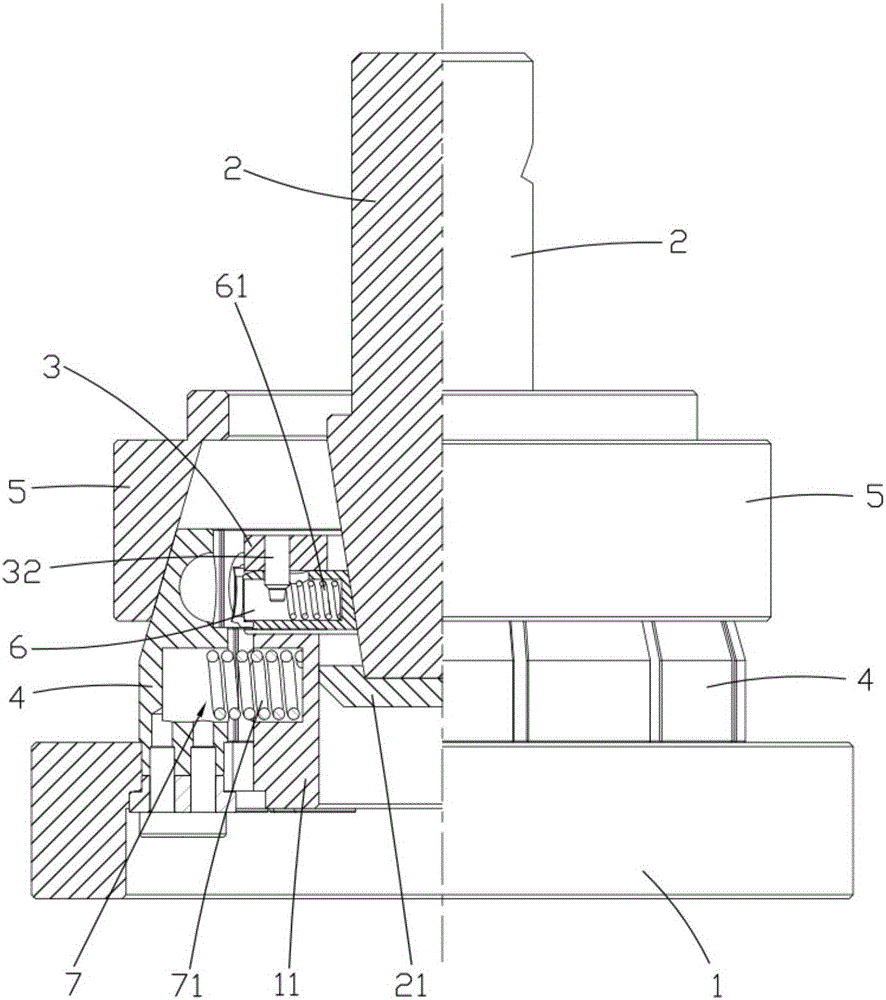

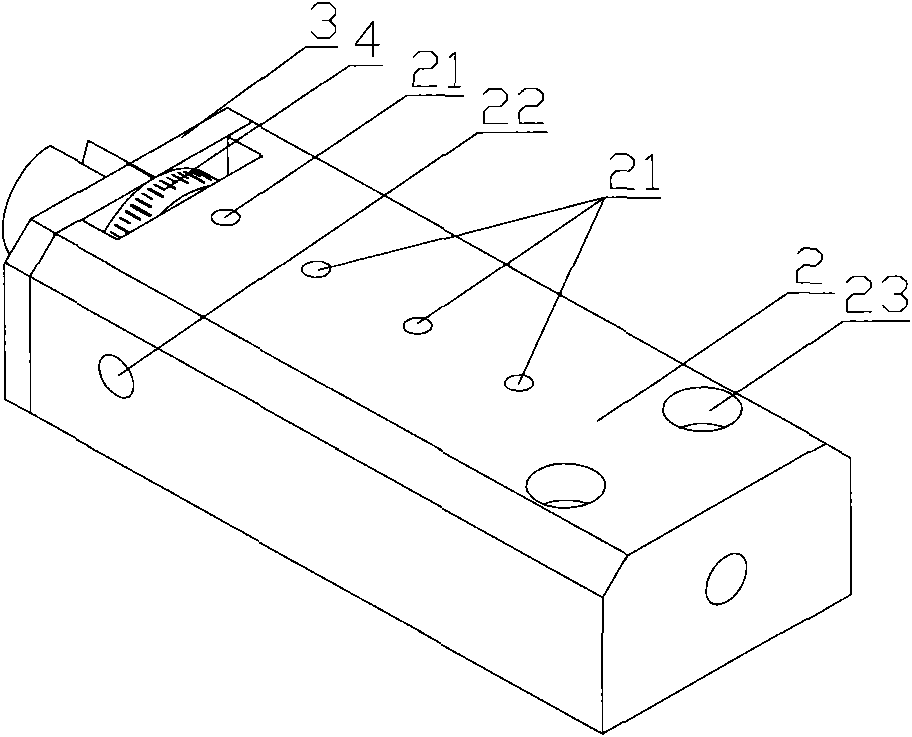

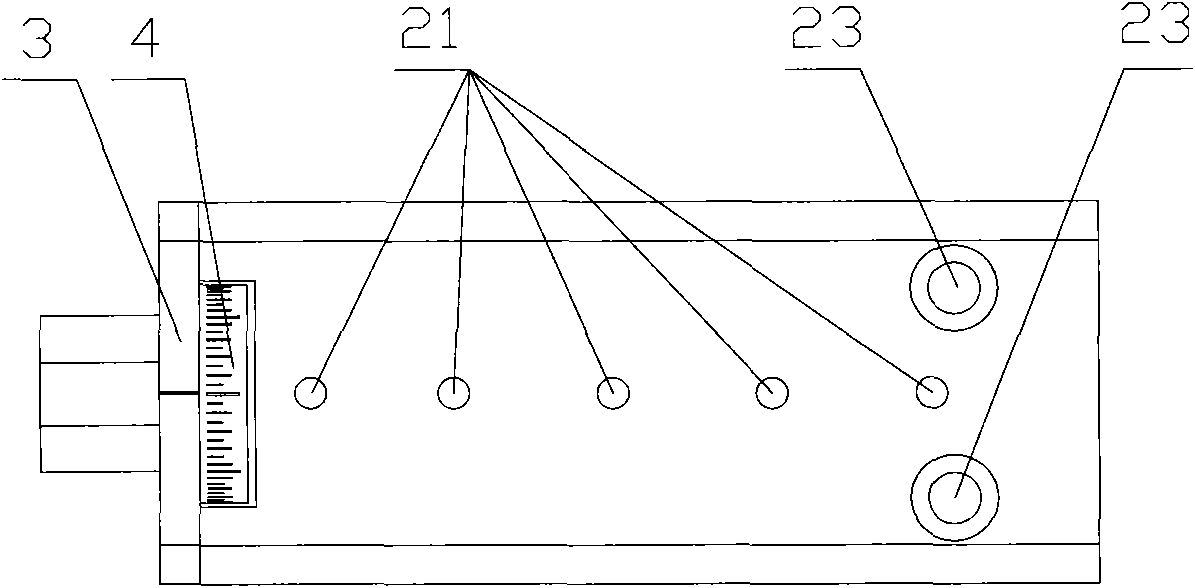

Punching device and punching and positioning apparatus thereof

ActiveCN101856736AImprove punching accuracyHigh working reliabilityDrill jigsPunchingControllability

The invention discloses a punching and positioning apparatus, which is applied to a punching device for perforating oil hole on oil tubes, and comprises a shell (2) which is at least provided with two first positioning holes (21), wherein the oil tubes can move along the arrangement direction of the first positioning holes (21), and the relative position between the oil tubes and the shell (2) can be selectively fixed through a fixed part. Therefore, when perforating the oil hole, the position of the oil tube relative to the shell (2) is selected according to the requirement and is fixed on the position through the fixed part, a drill bit of a drilling machine punches on a pre-determined position of the oil tube through the first positioning hole (21), so during the processing process of the oil hole perforation, the punching position is free from being judged by the worker, the punching accuracy can be remarkably improved, the rejection rate can be remarkably reduced, the production cost can be saved, the position controllability of the oil tube during the drilling operation and the working reliability during the operation process can be improved. The invention also discloses a punching device comprising the punching and positioning apparatus.

Owner:WORLD TRANSMISSION TECH TIANJIN SHARE LTD

Automobile air conditioning condenser collecting pipe punching machining device

ActiveCN110340214APrevent from being firmly fixedAvoid shakingPerforating toolsPunchingAutomobile air conditioning

The invention discloses an automobile air conditioning condenser collecting pipe punching machining device, and belongs to the technical field of vehicle accessory machining. The device includes a portal frame, a moving plate, a pipe placing frame, a lifting assembly, a punching assembly, two sliding rails, two first clamping assemblies and two second clamping assemblies, the two sliding rails aresymmetrically arranged on the inner side wall of the portal frame, the moving plate is horizontally arranged on the two sliding rails, the pipe placing frame is arranged at the center of the top endof the moving plate, the two first clamping assemblies are symmetrically arranged on the two sides of the pipe placing frame, the two second clamping assemblies are symmetrically arranged beside the two first clamping assemblies, the lifting assembly is arranged on the portal frame, the bottom end of the lifting assembly is fixedly connected with the moving plate, and the punching assembly is arranged at the inner top end of the portal frame. According to the device, the problem that a collecting pipe cannot be firmly fixed, and the collecting pipe can shake during being punched, so that the position of an actual punching hole is inconsistent with the position of an original punching hole and the punching precision is influenced is solved.

Owner:LIAOCHENG DETONG AUTO PARTS MFG CO LTD

Grounded flat iron processing and manufacturing platform

ActiveCN107123914APrevent overshootPrevent problems such as slantingContact member manufacturingConnection contact member materialState of artEngineering

The invention discloses a grounded flat iron processing and manufacturing platform, which is used for solving the technical problems of low flat iron manufacturing mechanization degree, poor manufacturing quality, low work efficiency and the like in the prior art. The grounded flat iron processing and manufacturing platform comprises an operation platform and a spraying brushing mechanism, wherein a hole punching mechanism and a bending mechanism are arranged on the operation platform; the hole punching mechanism comprises a base, a hole punching machine, a support block and a positioning block are arranged at the upper part of the base; the support block is positioned at one side of the hole punching machine; the positioning block is positioned at the other side of the hole punching machine; the bending mechanism comprises a support seat; a bending machine, a positioning plate and a fixing plate are arranged on the support seat; the positioning plate is positioned at one side of the bending machine; the fixing plate is positioned at the other side of the bending machine; the spraying brushing mechanism comprises a spraying and brushing support frame; a fixing seat and a support plate are arranged on the spraying and brushing support frame; paint blocking plates are arranged on the fixing seat at intervals; a cover plate is arranged on the support plate. The fast and precise hole punching bending can be realized; the phase color mark can be formed in one step; the manufacturing time can be reduced from the original 50 minutes to 5 minutes; the work efficiency is improved by 10 times and the quality of the workpiece is ensured.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com