Automatic tool die changing type special-shaped material blanking machine

A technology of automatic tool changing and blanking machine, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unstable product quality, inaccurate processing stations, waste of too much time, etc., to achieve reasonable structure, Time-saving and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

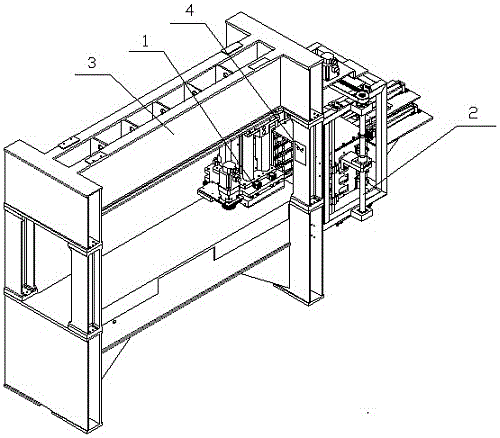

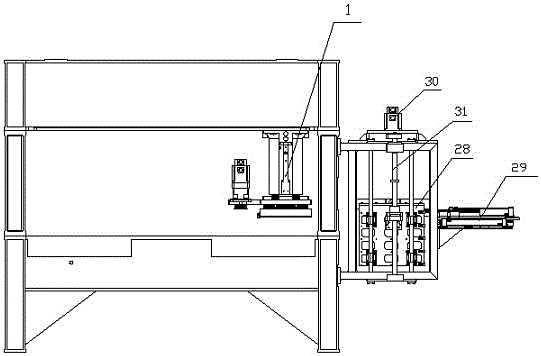

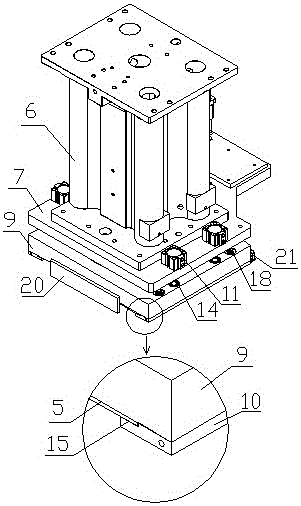

[0026] As shown in the figure, the special-shaped material punching machine with automatic tool change mode according to the present invention includes a punching head 1, a tool changing die mechanism 2, a frame 3, and a control box 4, and the punching head 1 is arranged on the frame 3 , A knife mold 5 is arranged under the stamping head 1, the tool changing mechanism 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com